Page 1

Digital Indicators

K3HB

Compoway/F

Communications

CompoWay/F

Settings

List of

Overview

OMRON Corporation

Industrial Automation Company

Industrial Devices and Components Division H.Q.

Measuring Components Department

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7080/Fax: (81)75-344-7189

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel: (1)847-843-7900/Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

239920 Singapore

Tel: (65)6835-3011/Fax: (65)6835-2711

OMRON CHINA CO., LTD. BEIJING OFFICE

Room 1028, Office Building,

Beijing Capital Times Square,

No. 88 West Chang'an Road,

Beijing, 100031 China

Tel: (86)10-8391-3005/Fax: (86)10-8391-3688

K3HB Digital Indicators Communications User's Manual Cat. No. N129-E1-03

Communications User's Manual

P

Procedures

tion, and Wiring

munications

DeviceNet

Communications

Performance

and Maintenance

tion for DeviceNet

Operating

Parts, Installa-

Remote I/O Com-

Explicit Message

Communications

Troubleshooting

Additional Informa-

Authorized Distributor:

Communications

BCD Output

BCD

Note: Specifications subject to change without notice.Cat. No. N129-E1-03

Printed in Japan

0305

Cat. No. N129-E1-03

Page 2

K3HB Digital Indicators

Communications User’s Manual

Revised March 2005

Page 3

iv

Page 4

Preface

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

This manual describes the functions, performance, and application methods needed for optimum use

of the K3HB.

Please observe the following items when using the K3HB.

• This product is designed for use by qualified personnel with a knowledge of electrical systems.

• Read this manual carefully and make sure you understand it well to ensure that you are using the

K3HB correctly.

• Keep this manual in a safe location so that it is available for reference when required.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Trademarks

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

• DeviceNet is a registered trademark of the Open DeviceNet Vendors Association, Inc.

• Other product names and company names that appear in this manual are the trademarks or registered trademarks of the respective companies.

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Page 5

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS.

ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED

THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products.

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

vi

Page 6

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

vii

Page 7

Safety Precautions

■ Definition of Precautionary Information

The following notation is used in this manual to provide precautions required

to ensure safe usage of the product.

The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not

WARNING

CAUTION

■ Symbols

Symbol Meaning

avoided, will result in minor or moderate injury, or may

result in serious injury or death. Additionally there may

be significant property damage.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury or in

property damage.

Caution

Prohibition

Mandatory

Caution

General Caution

Indicates non-specific general cautions, warnings,

and dangers.

Electrical Shock Caution

Indicates possibility of electric shock under specific

conditions.

General Prohibition

Indicates non-specific general prohibitions.

General Caution

Indicates non-specific general cautions, warnings,

and dangers.

viii

Page 8

■ Precautions

WARNING

Do not touch the terminals while power is being supplied. Doing

so may possibly result in electric shock. Make sure that the

terminal cover is installed before using the product.

Always provide protective circuits in the network. Without

protective circuits, malfunctions may possibly result in accidents

that cause serious injury or significant property damage.

Provide double or triple safety measures in external control

circuits, such as emergency stop circuits, interlock circuits, or limit

circuits, to ensure safety in the system if an abnormality occurs

due to malfunction of the product or another external factor

affecting the product's operation.

CAUTION

Do not allow pieces of metal, wire clippings, or fine metallic

shavings or filings from installation to enter the product. Doing so

may occasionally result in electric shock, fire, or malfunction.

Do not use the product in locations where flammable or explosive

gases are present. Doing so may occasionally result in minor or

moderate explosion, causing minor or moderate injury, or property

damage.

Do not attempt to disassemble, repair, or modify the product.

Doing so may occasionally result in minor or moderate injury due

to electric shock.

Do not use the equipment for measurements within Measurement

Categories III and IV for K3HB-X and II, III, and IV for K3HB-S,

K3HB-V, K3HB-H, K3HB-R, K3HB-P, and K3HB-C (according to

IEC61010-1). Doing so may occasionally cause unexpected

operation, resulting in minor or moderate injury, or damage to the

equipment. Use the equipment for measurements only within the

Measurement Category for which the product is designed.

Perform correct setting of the product according to the application.

Failure to do so may occasionally cause unexpected operation,

resulting in minor or moderate injury, or damage to the equipment.

Ensure safety in the event of product failure by taking safety

measures, such as installing a separate monitoring system.

Product failure may occasionally prevent operation of comparative

outputs, resulting in damage to the connected facilities and

equipment.

Tighten the screws on the terminal block and the connector

locking screws securely using a tightening torque within the

following ranges. Loose screws may occasionally cause fire,

resulting in minor or moderate injury, or damage to the equipment.

Terminal block screws: 0.43 to 0.58 N·m

Connector locking screws: 0.18 to 0.22 N·m

ix

Page 9

CAUTION

Make sure that the product will not be adversely affected if the

DeviceNet cycle time is lengthened as a result of changing the

program with online editing. Extending the cycle time may cause

unexpected operation, occasionally resulting in minor or moderate

injury, or damage to the equipment.

Before transferring programs to other nodes or changing I/O

memory of other nodes, check the nodes to confirm safety.

Changing the program or I/O memory of other nodes may

occasionally cause unexpected operation, resulting in minor or

moderate injury, or damage to the equipment.

x

Page 10

Precautions for Safe Use

(1) Do not use the product in the following locations.

• Locations subject to direct radiant heat from heating equipment

• Locations where the product may come into contact with water or oil

• Locations subject to direct sunlight

• Locations where dust or corrosive gases (in particular, sulfuric or ammonia gas)

are present

• Locations subject to extreme temperature changes

• Locations where icing or condensation may occur

• Locations subject to excessive shocks or vibration

(2) Do not use the product in locations subject to temperatures or humidity levels

outside the specified ranges or in locations prone to condensation. If the product

is installed in a panel, ensure that the temperature around the product (not the

temperature around the panel) does not go outside the specified range.

(3) Provide sufficient space around the product for heat dissipation.

(4) Use and store the product within the specified temperature and humidity ranges.

If several products are mounted side-by-side or arranged in a vertical line, the

heat dissipation will cause the internal temperature of the products to rise,

shortening the service life. If necessary, cool the products using a fan or other

cooling method.

(5) The service life of the output relays depends on the switching capacity and

switching conditions. Consider the actual application conditions and use the

product within the rated load and electrical service life. Using the product beyond

its service life may result in contact welding or burning.

(6) Install the product horizontally.

(7) Mount to a panel between 1 and 8-mm thick.

(8) Use the specified size of crimp terminals (M3, width: 5.8 mm max.) for wiring. To

connect bare wires, use AWG22 (cross section: 0.326 mm

section: 2.081 mm2) to wire the power supply terminals and AWG28 (cross

section: 0.081 mm

(Length of exposed wire: 6 to 8 mm)

(9) In order to prevent inductive noise, wire the lines connected to the product

separately from power lines carrying high voltages or currents. Do not wire in

parallel with or in the same cable as power lines. Other measures for reducing

noise include running lines along separate ducts and using shield lines.

(10) Ensure that the rated voltage is achieved no longer than 2 s after turning the

power ON.

(11) Allow the product to operate without load for at least 15 minutes after the power is

turned ON.

(12) Do not install the product near devices generating strong high-frequency waves

or surges. When using a noise filter, check the voltage and current and install it

as close to the product as possible.

2

) to AWG16 (cross section: 1.309 mm2) for other terminals.

2

) to AWG14 (cross

(13) Do not use thinner to clean the product. Use commercially available alcohol.

(14) Be sure to confirm the name and polarity for each terminal before wiring the

xi

Page 11

terminal block and connectors.

(15) Use the product within the noted supply voltage and rated load.

(16) Do not connect anything to unused terminals.

(17) Output turns OFF when the mode is changed or settings are initialized. Take this

into consideration when setting up the control system.

(18) Install an external switch or circuit breaker that complies with applicable

IEC60947-1 and IEC60947-3 requirements and label them clearly so that the

operator can quickly turn OFF the power.

(19) Use the specified cables for the communications lines and stay within the

specified DeviceNet communications distances. Refer to the User’s Manual (Cat.

No. N129) for information on communications distances and cables.

(20) Do not pull the DeviceNet communications cables with excessive force or bend

them past their natural bending radius.

(21) Do not connect or remove connectors while the DeviceNet power is being

supplied. Doing so will cause product failure or malfunction.

(22) Use cables with a heat resistance specification of 70ºC min.

xii

Page 12

EC Directives

•EMC Directives

Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards. Whether the products conform to the standards in the system

used by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Conformance to EC Directives

The K3HB Digital Indicators comply with EC Directives. To ensure that the

machine or device in which the Unit is used complies with EC Directives, the

Unit must be installed as follows:

1,2,3... 1. You must use reinforced insulation or double insulation for the DC power

supplies used for the communications power supply, internal power supply,

and I/O power supplies.

2. Units complying with EC Directives also conform to the Common Emission

Standard (EN61326). Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the control panel used,

other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies

with EC Directives.

The following example shows one means of reducing noise.

1,2,3... 1. Noise from the communications cable can be reduced by installing a ferrite

core on the communications cable within 10 cm of the DeviceNet Master

Unit.

Ferrite Core (Data Line Filter): 0443-164151 (manufactured by Fair-Rite

Products Co., Ltd.)

Impedance specifications

25 MHz 105 Ω

100 MHz 190 Ω

2. Wire the control panel with as thick and short electric lines as possible and

ground to 100

Ω min.

3. Keep DeviceNet communications cables as short as possible and ground

to 100

Ω min.

xiii

Page 13

Complying with Safety Standards

For the DeviceNet power supply, always use a power supply with reinforced or

double insulation, that complies with EN/IEC standards.

Conformance to the standards is for indoor applications only.

xiv

Page 14

Related Manuals

The following manuals are also related to the K3HB Digital Indicator. Refer to these manuals when

using the K3HB.

K3HB Digital Indicators

Communications User's Manual

Describes the models, communications functions, specifications, and application methods of K3HB Digital Indicators with communications.

(This manual)

K3HB-S/-X/-V/-H Digital Indicators

User's Manual

Describes the models, functions, specifications, and application methods of K3HB-S/-X/-V/-H Digital Indicators.

Refer to this manual for information on specifications and functions other than DeviceNet.

K3HB-R/-P/-C Digital Indicators

User's Manual

Describes the models, functions, specifications, and application methods of K3HB-R/-P/-C Digital Indicators.

Refer to this manual for information on specifications and functions other than DeviceNet.

DeviceNet Operation Manual (W267)

Describes the configuration and connection forms for a DeviceNet network. Also describes connection methods

and specifications for devices used to connect to the network, such as cables and connectors, as well as methods for supplying communications power. When using DeviceNet, obtain this manual in advance and be sure you

understand its contents.

CVM1-DRM21-V1/C200HW-DRM21-V1

DeviceNet Master Units Operation Manual

Describes the specifications, functions, and application methods for the DeviceNet Master Units for CVM1/CVseries, C200HS, and C200HX/HG/HE PLCs.

SYSMAC CS/CJ Series

DeviceNet Units Operation Manual

Describes the specifications, functions, and application methods for the DeviceNet Units for CS/CJ-series PLCs.

(A CS/CJ-series DeviceNet Unit can function simultaneously as both a DeviceNet master and slave.)

(N128)

(N136)

(W379)

(W380)

DeviceNet Configurator Version 2

Operation Manual

Describes the application methods of the DeviceNet Configurator. The DeviceNet Configurator is used to build,

set, and manage DeviceNet networks on graphic displays. Refer to this manual as required.

(W382)

xv

Page 15

xvi

Page 16

TABLE OF CONTENTS

Part 1: CompoWay/F

SECTION 1

CompoWay/F Communications . . . . . . . . . . . . . . . . . . . . . . 1-1

1-1 Communications Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Frames (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 FINS-mini Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4 Variable Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-5 Reading the Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1-6 Writing to the Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1-7 Operation Commands (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-8 Setting Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1-9 Commands and Responses (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . . . . 1-13

1-10 Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

SECTION 2

List of Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Part 2: DeviceNet

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1-2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

SECTION 2

Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2-2 Functions Supported Only by the K3HB-DRT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

SECTION 3

Parts, Installation, and Wiring . . . . . . . . . . . . . . . . . . . . . . . 5-1

3-1 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

3-2 DeviceNet Communications Cables Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

SECTION 4

Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . 6-1

4-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

4-2 I/O Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

4-3 Ladder Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

xvii

Page 17

TABLE OF CONTENTS

SECTION 5

Explicit Message Communications . . . . . . . . . . . . . . . . . . . . 7-1

5-1 Overview of Explicit Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

5-2 Sending CompoWay/F Commands to the Digital Indicator . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

5-3 Explicit Messages Specific to DeviceNet-compatible Digital Indicators . . . . . . . . . . . . . . . 7-6

SECTION 6

Communications Performance . . . . . . . . . . . . . . . . . . . . . . . 8-1

6-1 Remote I/O Communications Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

6-2 Message Communications Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

SECTION 7

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 9-1

7-1 Indicators and Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

7-2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

SECTION 8

Additional Information for DeviceNet . . . . . . . . . . . . . . . . . 10-1

8-1 Detailed DeviceNet Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

8-2 Mounted Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

8-3 DeviceNet Connection Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

8-4 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Part 3: BCD Output

SECTION 1

BCD Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

1-2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

1-3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

1-4 Precautions for BCD Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

1-5 Programming Example 1: Connecting to a PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

1-6 Programming Example 2: Connecting to a PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R-1

xviii

Page 18

About this Manual:

This manual describes communications for the K3HB Digital Indicators and includes the sections

described below divided into two parts according to the type of communications.

Please read this manual carefully and be sure you understand the information provided before

attempting to setup or operate communications for a K3HB Digital Indicator.

Part 1: CompoWay/F

Section 1 describes CompoWay/F communications.

Section 2 provides a list of K3HB settings.

Part 2: DeviceNet

Section 1 introduces the features and specifications of K3HB-DRT Digital Indicators.

Section 2 outlines the basic operating procedures for the K3HB-DRT Digital Indicators.

Section 3 describes the methods used to install and wire K3HB-DRT Digital Indicators.

Section 4 describes the input (IN) areas and output (OUT) areas that K3HB-DRT Digital Indicators

can use for remote I/O communications. The methods to allocate data for master communications are

also described using sample programming.

Section 5 describes how to send explicit messages to the K3HB-DRT Digital Indicator, including how

to send CompoWay/F commands using explicit messages.

Section 6 provides information on the time required for a complete communications cycle, for an output response to be made to an input, to start the system, and to send messages.

Section 7 describes error processing, periodic maintenance operations, and troubleshooting procedures needed to keep the DeviceNet Network operating properly. Details on resetting replaced Digital

Indicators are also provided. Read through the error processing procedures in both this manual and

the operation manual for the DeviceNet master being used before operation so that operating errors

can be identified and corrected more quickly.

Section 8 provides DeviceNet specifications, tables of mounted objects, and tables of DeviceNet connection hardware.

Part 3: BCD Output

Section 1 describes BCD communications using K3HB Digital Indicators.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xix

Page 19

xx

Page 20

Part 1: CompoWay/F

SECTION 1 CompoWay/F Communications . . . . . . . . 1-1

1-1 Communications Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Frames (CompoWay/F Communications). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 FINS-mini Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4 Variable Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-5 Reading the Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-6 Writing to the Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-7 Operation Commands (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-8 Setting Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1-9 Commands and Responses (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . . 1-13

1-10 Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

SECTION 2 List of Settings. . . . . . . . . . . . . . . . . . . . . . . 2-1

Page 21

Part 1: CompoWay/F

Page 22

SECTION 1

CompoWay/F Communications

This section describes communications using CompoWay/F.

1-1 Communications Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 CompoWay/F Communications Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-2 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-3 Transfer Protocol (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-4 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2 Frames (CompoWay/F Communications). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-2-1 Command Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-2-2 Response Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 FINS-mini Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4 Variable Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-5 Reading the Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-6 Writing to the Variable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-7 Operation Commands (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-8 Setting Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1-9 Commands and Responses (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . . 1-13

1-9-1 Monitor Value Read (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . 1-13

1-9-2 Setting Data Read (CompoWay/F Communications). . . . . . . . . . . . . . . . . . . . . 1-13

1-9-3 Monitor Value/Setting Data Compound Read (CompoWay/F Communications) 1-14

1-9-4 Protect Level Setting Data Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1-9-5 Setting Data Write (CompoWay/F Communications) . . . . . . . . . . . . . . . . . . . . 1-15

1-9-6 Setting Data Compound Write (CompoWay/F Communications) . . . . . . . . . . . 1-16

1-9-7 Monitor Value/Setting Data Compound Read Store (Write) . . . . . . . . . . . . . . . 1-16

1-9-8 Monitor Value/Setting Data Compound Read Store Check (Read) . . . . . . . . . . 1-17

1-9-9 Monitor Value/Setting Data Compound Store Read. . . . . . . . . . . . . . . . . . . . . . 1-17

1-9-10 Write via Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1-9-11 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1-9-12 Bank Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1-9-13 Zero Execute/Cancel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1-9-14 Software Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1-9-15 Move to Setting Area 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1-9-16 Move to Protect Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1-9-17 Initialize Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1-9-18 Read Machine Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1-9-19 Controller Status Read (CompoWay/F Communications) . . . . . . . . . . . . . . . . . 1-21

1-9-20 Echo Back Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1-10 Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

Communications

CompoWay/F

1-1

Page 23

Communications Method Section 1-1

1-1 Communications Method

1-1-1 CompoWay/F Communications Protocol

CompoWay/F

Communications

nications. Featuring a unified frame format and commands that are compliant

with FINS, which has a record of successful use with OMRON programmable

controllers, CompoWay/F makes communications easy between multiple

components and a computer.

FINS (Factory Interface Network Service)

This is a protocol for message communications between controllers on an

OMRON factory automation network.

Supplement The communications function is used by creating a program on the host com-

puter. As such, the explanations in this chapter are from the perspective of the

host computer.

For example, “Read/Write” refers to the host computer reading or writing to

the K3HB.

1-1-2 Communications Specifications

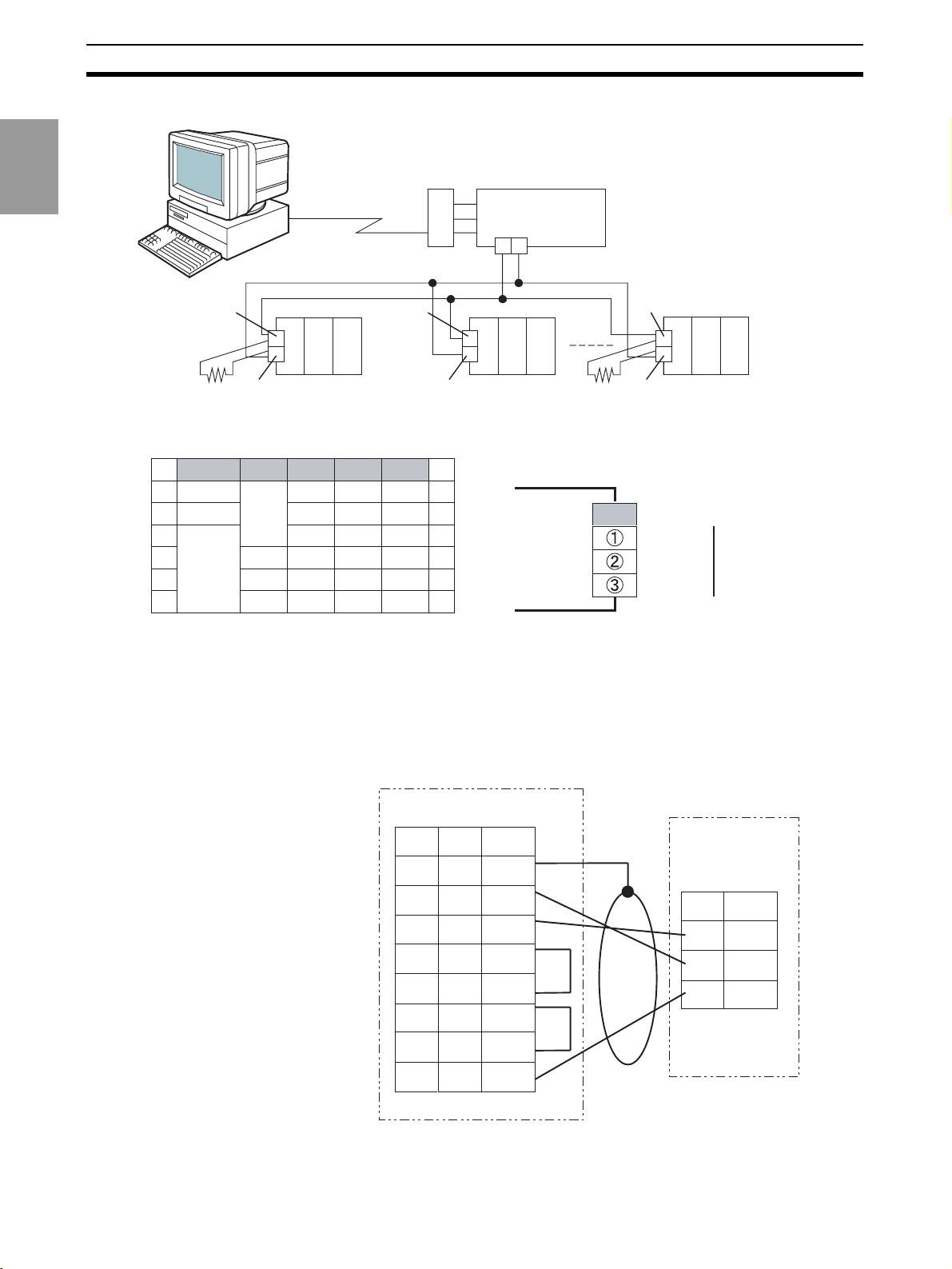

Transfer connection: Multi-point

Communications method: RS-485 or RS-232C (half duplex)

Synchronization method: Start-stop

Baud rate: 9.6k, 19.2k, 38.4k bit/s

Send code: ASCII

Data length: 7 or 8 bits

Stop bit length: 1 or 2 bits

Error detection: Vertical parity (none, even, or odd)

BCC (Block Check Character)

Start-stop synchronized data configuration

Flow control: None

Interface: RS-485 or RS-232C

Retry function: None

CompoWay/F is OMRON's unified protocol for general purpose serial commu-

Note Initial settings are shaded.

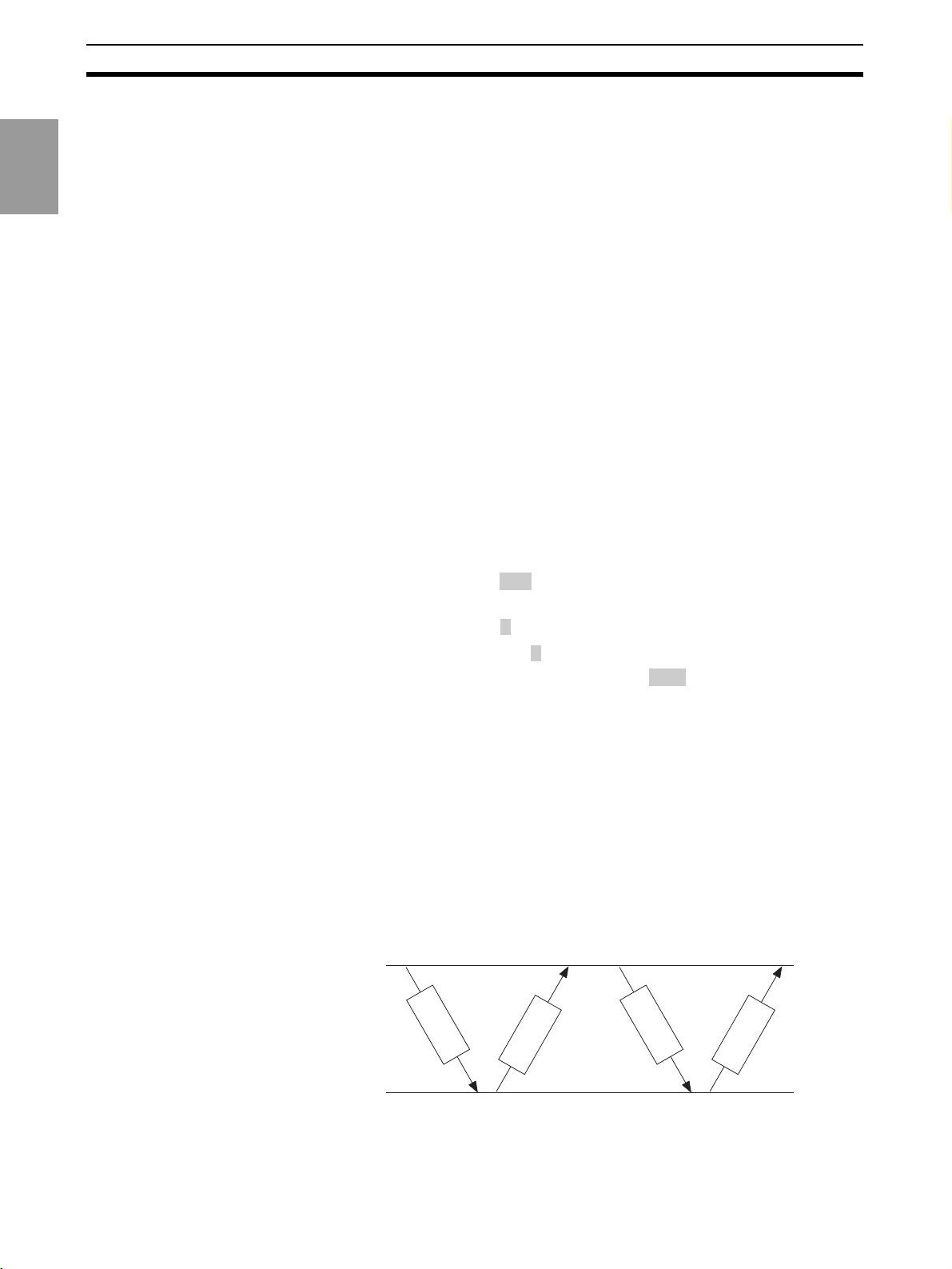

1-1-3 Transfer Protocol (CompoWay/F Communications)

The host computer sends a command frame, and the K3HB sends a response

frame based on the content of the command frame. One response frame is

sent in response to one command frame.

Host computer

1-2

K3HB

Command

frame

frame

Response

Command

frame

frame

Response

Page 24

Communications Method Section 1-1

The exchange between the command frame and response frame is explained

below.

After a receiving a response from the Digital Indicator, have the host computer

wait at least 50 ms before sending the next command.

When writing multiple sets of setting data in a row, such as when writing to the

variable area or performing a compound write, controllability may be affected.

Pay attention to the following points:

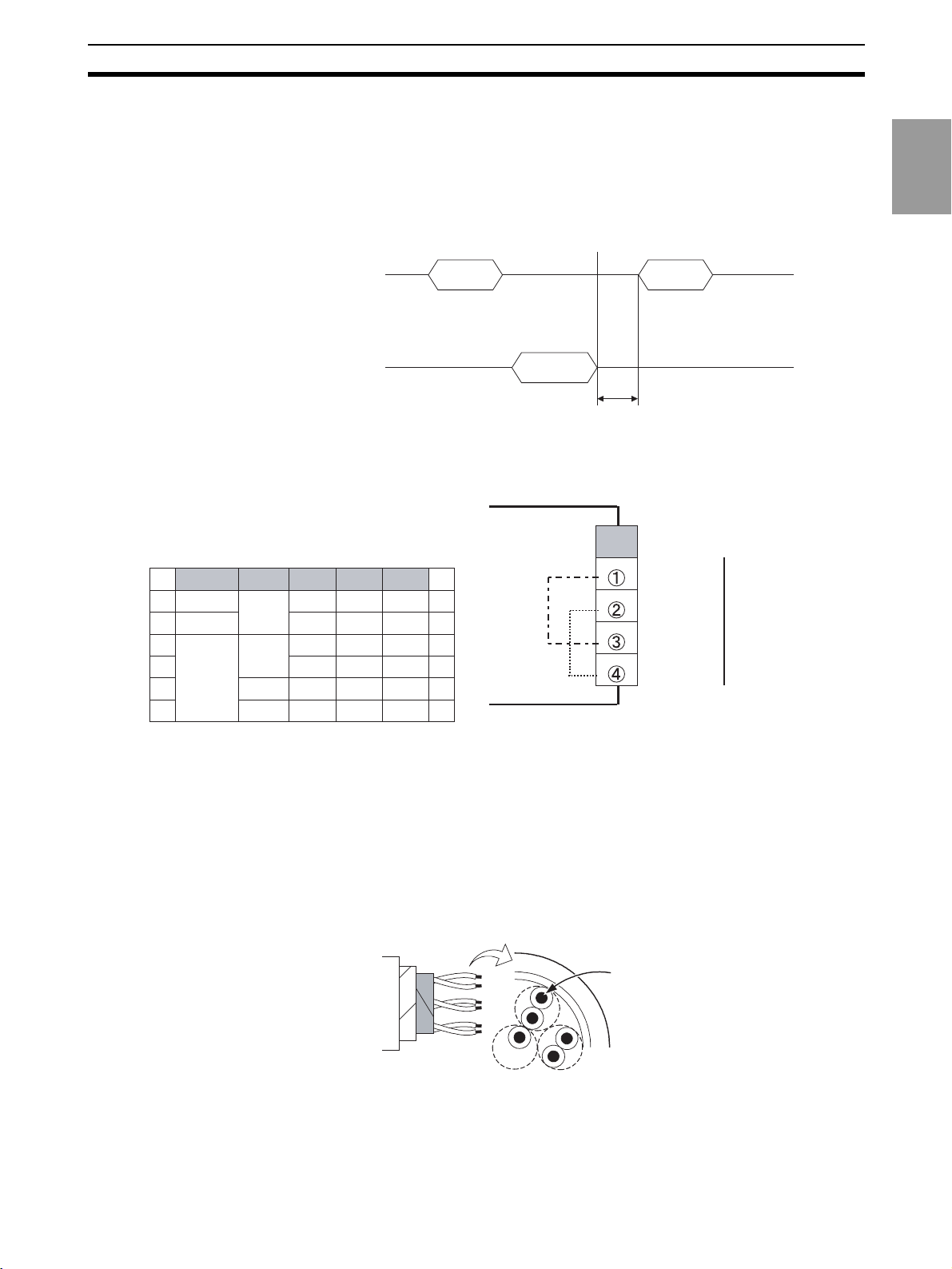

1-1-4 Cable Connections

RS-485

Command

Maximum of 3 sets of

setting data can be written

Response

Command

50 ms or higher

B

Communications

CompoWay/F

A B C D E

1 1

2

3

RS-485

RS-485

4

5

6

• Use terminals B1 through B4 to communicate with the host. The terminal

layout is designed for cross-over wiring and thus the B1-B3 and B2-B4

terminals are connected internally.

• Wiring is configured either 1:1 or 1:N. A maximum of 32 Units, including

the host computer can be connected with a 1:N configuration.

• The maximum total cable length is 500 m.

• Use shielded, twisted-pair wires of at least AWG28 to AWG16 for all

cables.

Cable Diagram (Reference)

B (+)

2

3

4

A (−)

B (+)

A (−)

RS-

485

5

6

At least AWG28

Conductor cross-sectional area:

0.081 mm

2

min.

• Attach a terminator to each end of the transmission path, including the

host computer. Use a 100- to 125-

Ω (1/2 W) resistor for the terminator.

• Use an RS-232C/RS-485 Converter to connect RS-232C devices, such

as personal computers.

1-3

Page 25

Communications Method Section 1-1

Converter Example: RS-232C/RS-485 Converter

K32-23209

Adapter

CompoWay/F

Communications

RS-232C

D-sub, 9-pin

(Straight)

K3SC-10

RS-232C/RS485

Converter

+

-

100- to 125-Ω

Terminator

(1/2 W)

RS-232C

B1 or B3

B2 or B4

(B)

(A)

K3HB

(No. 0)

B1 or B3

B2 or B4

(B)

(A)

K3HB

(No. 1)

B1 or B3

B2 or B4

(B)

(A)

K3-HB

(No. 31)

A B C D E

11

22

33

44

55

RS-232C

B

SD

RD RS-232C

SG

66

• Use terminals B1 through B3 to communicate with the host.

• Wiring is configured 1:1.

• The maximum cable length is 15 m. Use OMRON’s Z3RN RS-232C Optical Interface to extend the wiring path.

• Use shielded, twisted-pair wires of at least AWG28 to AWG16 for all

cables. (Same wire used for RS-485 cable.)

100- to 125-Ω

Terminator

(1/2 W)

1-4

Host computer

RS-232C

9-pin

25-pin

--- FG

1

3SD

2

2RD

3

7RS

4

8CS

5

6DR

6

4ER

20

5SG

7

K3HB

RS-232C

No.

1SD

2RD

3SG

Shield

Page 26

Frames (CompoWay/F Communications) Section 1-2

1-2 Frames (CompoWay/F Communications)

Based on CompoWay/F protocol, commands from the host computer and

responses from the K3HB take the form of frames.

The data comprising command frames and response frames are explained

below.

In the following explanation, an “H” following a numeric value (for example

02H) indicates that the value is a hexadecimal number. A number or letters

enclosed in quotation marks (for example “00”) is an ASCII character.

1-2-1 Command Frame

Sub-

Node

address

No.

02H "00" "0"

1

BCC calculation range

STX Code that indicates the beginning of the communications

Node No. This number specifies the destination.

Sub-address Not used on the K3HB. Be sure to set to “00”.

SID (Service ID) Not used on the K3HB. Be sure to set to “0”.

FINS-mini

Command text

ETX Code that indicates the end of the text (03H).

BCC Block Check Character.

FINS-mini

SIDSTX

command text

ETX1BCC

03H

1 byte221

frame (02H).

Be sure to set this code in the leading byte.

Specify the Unit No. of the K3HB.

When broadcasting to all units, specify “XX”. Responses are

not sent to a broadcast.

The text of the command.

This stores the result of the BCC calculation from Node No. to

EXT.

Communications

CompoWay/F

Sub-

Node

address

No.

02H 30H30H 30H30H 30H 30H 35H 30H 30H 03H 36H

BCC = 30H + 30H + 30H + 30H + 30H + 30H + 35H + 30H + 30H + 03H = 36H

+: XOR (exclusive OR) operation

FINS-mini

SIDSTX ETX BCC

command text

1-2-2 Response Frame

Node

Sub-

STX

No.

address

02H "00"

1

End

Code

Supplement A response is not sent to command frames that do not end with ETX.BCC

characters.

STX Code that indicates the beginning of the communications

Node No. The number that was specified in the command frame is

Sub-address Not used on the K3HB. Set to “00”.

FINS-mini

response text

ETX1BCC

03H

1 byte222

frame (02H).

Be sure to set this code in the leading byte.

repeated here.

This is the Unit No. of the responding K3HB.

1-5

Page 27

FINS-mini Text Section 1-3

End code Returns the result of the command executed as instructed by

the command frame.

FINS-mini

Text of the response

Response text

CompoWay/F

Communications

ETX Code that indicates the end of the text (03H)

BCC Block Check Character

Stores the result of the BCC calculation from Node No. to

EXT.

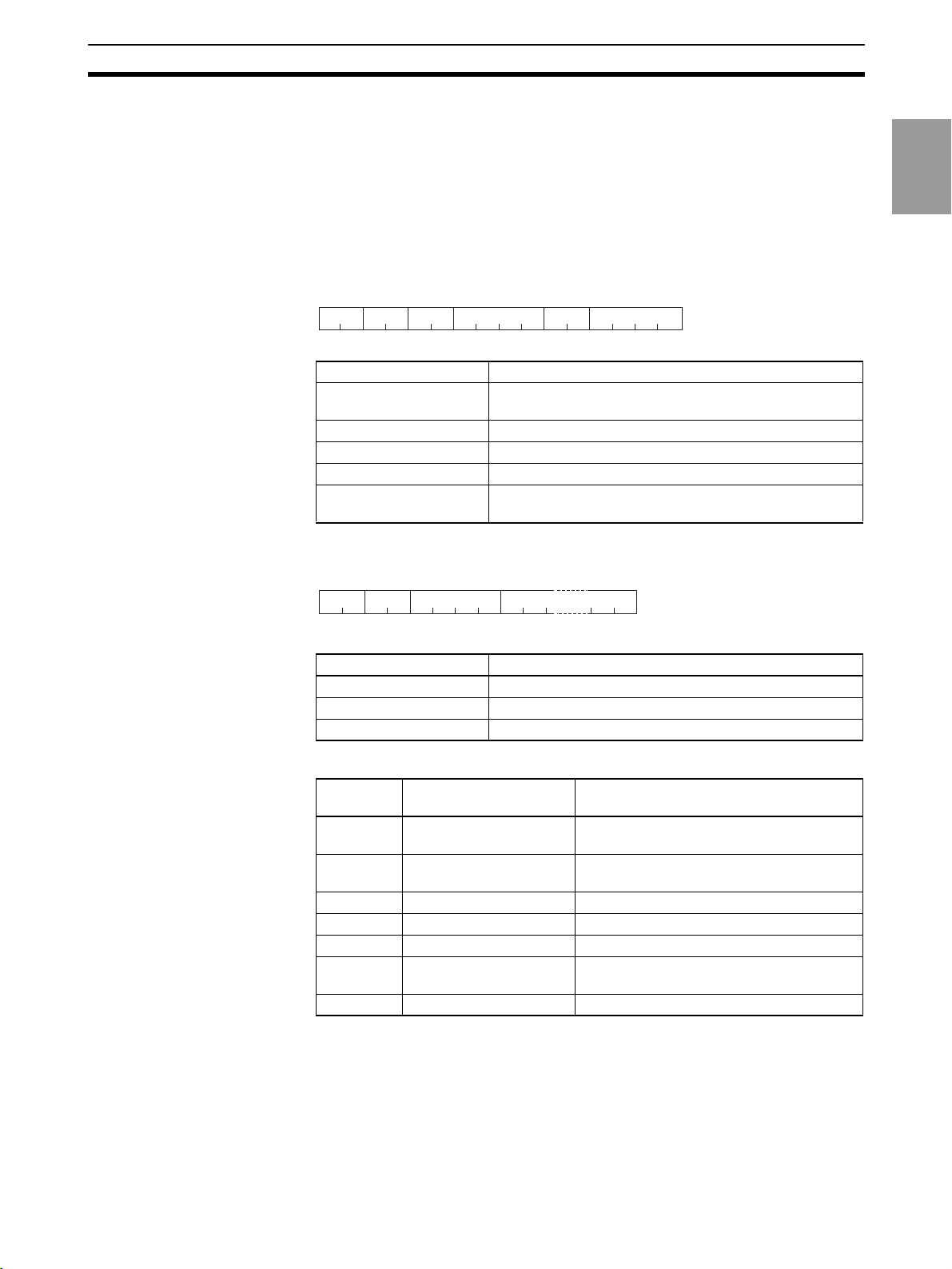

End Codes (CompoWay/F Communications)

End code Name Description Error detection

order of

priority

“0F” FINS command error Could not execute the specified FINS command 8

“10” Parity error Sum of bits that are “1” in received data does not agree with

the set communications parity value.

“11” Framing error Stop bit of command frame characters is “0”. 1

“12” Overrun error Attempted to transfer new data because received data buffer

is already full.

“13” BCC error Calculated BCC different from received BCC. 5

“14” Format error Characters other than “0” to “9” or “A” to “F” in FINS-mini com-

mand text. In the case of an echo-back test, when data other

than the test data is sent.

No SID and FINS-mini command text, or no FINS-mini com-

mand text.

“MRC/SRC” not correct in FINS-mini command text.

“16” Sub-address error No sub-address, SID, or FINS-mini command text; or sub-

address less than 2 characters and no SID and FINS-mini

command text.

“18” Frame length error The received frame exceeds the required number of bytes. 4

“00” Normal end Command was executed normally without error. None

2

3

7

6

1-3 FINS-mini Text

The FINS-mini command text and FINS-mini response text form the body of

command/response communications.

FINS-mini command text and FINS-mini response text are configured as follows.

Command Text FINS-mini command text consists of an MRC (main request code) and an

SRC (sub request code), followed by the required data.

Node

Sub-

No.

address

02H "00" "0" 03H

SRC

MRC

2 bytes

2

SIDSTX

command text

FINS-mini

Data

ETX BCC

1-6

Page 28

FINS-mini Text Section 1-3

Response text FINS-mini response text consists of the MRC and SRC, followed by an MRES

(main response code) and SRES (sub response code), and then the required

data.

Node

Sub-

No.

STX

02H "00" 03H

MRC2SRC2MRES

address

2

SRES

2 bytes

FINS-mini

Response textEnd code

ETX BCC

Data

If the specified FINS-mini command was not successfully executed, the

response will only contain the MRC, SRC, MRES and SRES.

List of FINS-mini Service Commands (CompoWay/F Communications)

MRC SRC Service name Description

“01” “01” Monitor value/setting data read Reads monitor values/setting

data.

“01” “02” Monitor value/setting data write Writes monitor values/setting

“01” “04” Monitor value/setting data com-

pound read

“01” “13” Monitor value/setting data com-

pound write

“01” “10” Monitor value/setting data com-

pound stored read

“01” “11” Monitor value/setting data com-

pound read store (write)

“01” “12” Monitor value/setting data com-

pound read store check (read)

“05” “03” Machine attribute read Reads the model and other

“06” “01” Controller status read Reads the operation status.

“08” “01” Echo-back test Performs an echo-back test.

“30” “05” Operation command Commands such as Run/Stop,

data.

Performs multiple reads of moni-

tor values/setting data.

Performs multiple writes of mon-

itor values/setting data.

Sequentially reads contents of

addresses specified in “monitor

value/setting data compound

read store.”

Specifies addresses to be read

using “monitor value/setting data

compound stored read.”

Reads the contents stored using

“variable area compound read

store.”

attributes.

AT Execute/Cancel, and “Move

to setting area 1".

Communications

CompoWay/F

1-7

Page 29

Variable Areas Section 1-4

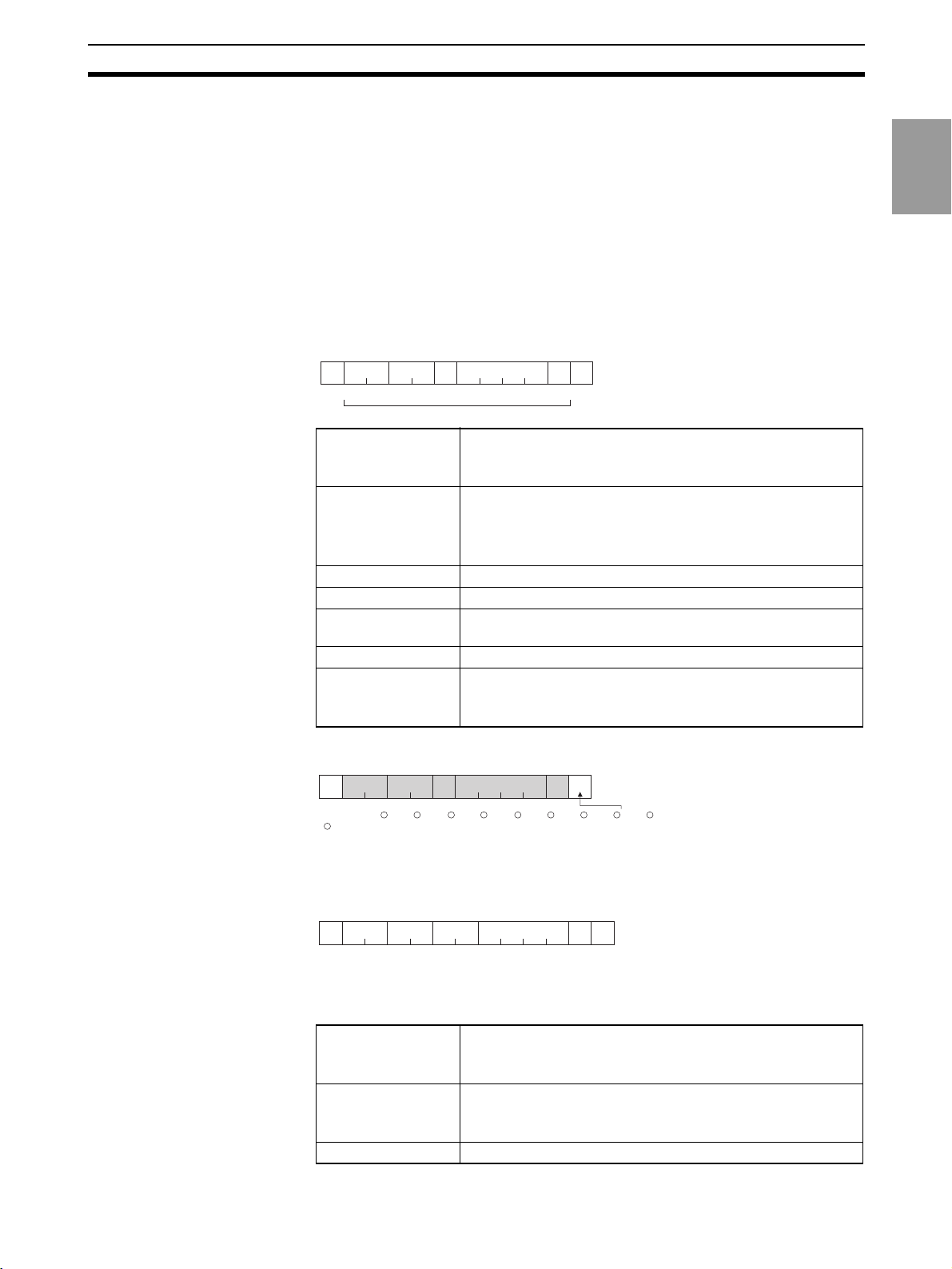

1-4 Variable Areas

The area used for data exchange when communicating with the K3HB is

called the “variable area.” The PV is read and various setting data are read

CompoWay/F

Communications

Variable Types Variable types in variable areas are as follows:

and written using the variable area of the K3HB.

Operation commands and reading of machine attributes do not use the vari-

able area.

K3HB

Operation

commands, etc.

Read/write

Microprocessor

Variable area

A variable area is accessed by specifying the position of a variable within the

variable area using the variable type and address.

Variable type Description Area

C0 Read-only parameters Setting area 0

C1 Protect level

C2 RUN level

C4 Initial setting level Setting area 1

C5 Input adjustment level

C6 Display adjustment level

C7 Scaling level

C8 Comparative set value level

C9 Linear output level

CA Communications setting level

CB Advanced function setting level

(during operation)

(during stop)

Addresses (CompoWay/F

Communications)

Each variable type has an address. Addresses are 2 bytes long and written in

hexadecimal. Addresses are assigned according to units of access size.

Address (2 bytes)

000000##0A6A5A4A3A2A1A

0

For more information on addresses, refer to List of Settings on page 2-1.

Number of Elements The number of elements is expressed as a 2-byte hexadecimal number. The

specification range for the number of elements varies depending on the command. See 1-9 Commands and Responses (CompoWay/F Communications)

(page 1-13) for more information.

For example, if the number of elements is 0010, the first 16 elements of data

(H'10) from the address are specified.

Set Values Values read and written to the variable area are expressed in hexadecimal

and disregard the decimal point position (negative values are expressed as a

two's complement).

Example: D'105.0

→ H'0000041A

The variable is an 8-digit number in hexadecimal. Negative values are expressed as a two's complement. The decimal is disregarded.

1-8

Page 30

Reading the Variable Area Section 1-5

For example, if the PV of the K3HB is 105.0, it will be read as H'0000041A

(105.0

→ 1050 → H'0000041A).

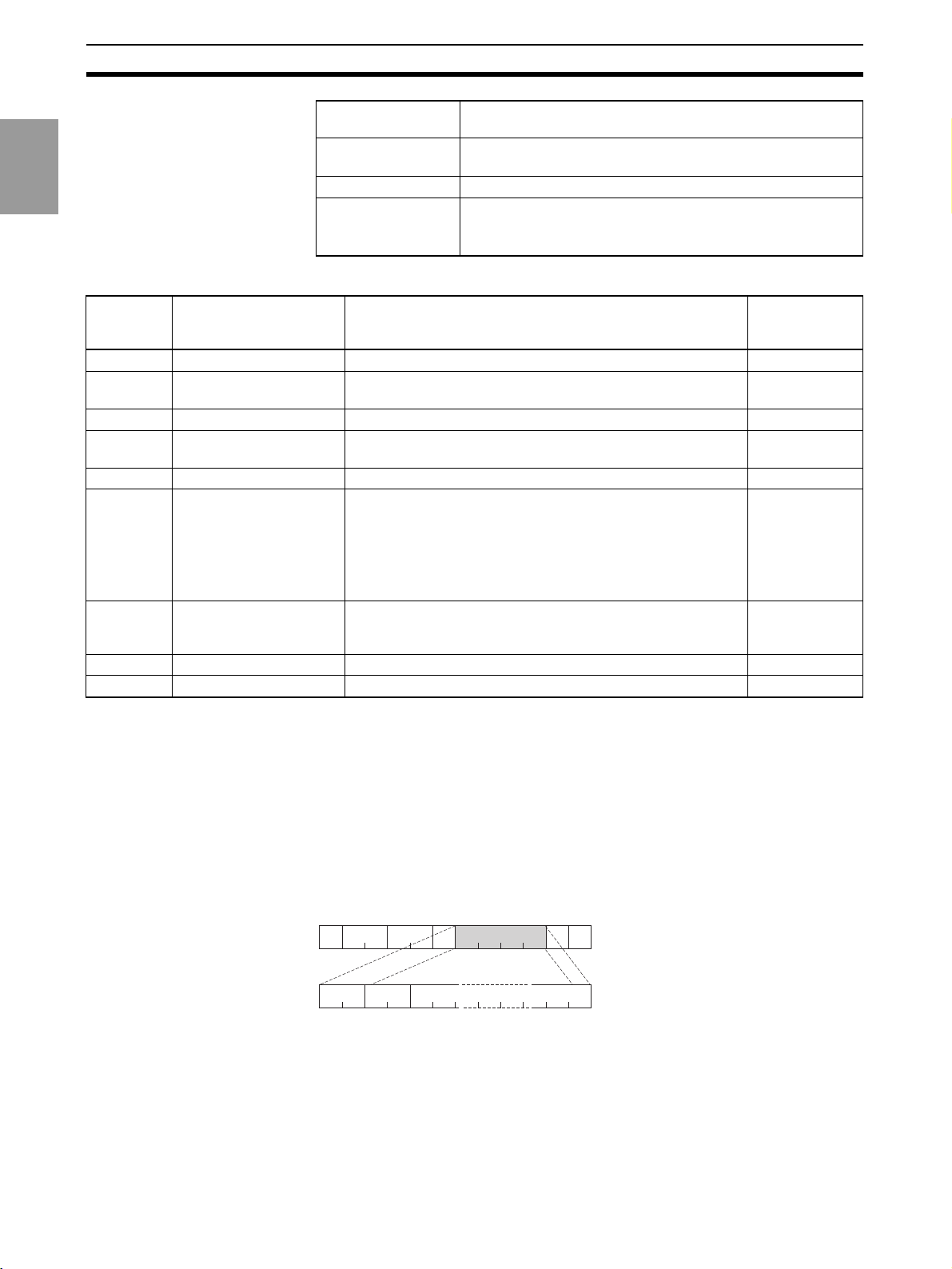

1-5 Reading the Variable Area

The data area is read by setting the required data in the following FINS-mini

command text format.

Command FINS-mini Command Text

MRC SRC

"01" "01" "00"

Variable

type

Data name Explanation

MRC/SRC Specifies the FINS-mini monitor value/setting data read

Variable type Specify a variable type.

First address of read Specify the address for the beginning of the read.

Bit position Not used on the K3HB. Specify “00”.

Number of elements Specifies the number of variables to read (max. of 25

Response FINS-mini Response Text

Response code

SRC

MRC

"01" "01"

2 2 4 Number of elements × 8 bytes

(MRES/SRES)

Read start

address

command.

(H'19)). Not needed for a compound read.

Bit

position

Number of elements

"0001" to "0019"

24222

Data to be read

(for compound read, number of elements × 10 bytes)

4

Communications

CompoWay/F

Data name Explanation

MRC/SRC The FINS-mini command text appears here.

Response code Result of execution of the command.

Read data Values for variables that were read.

Response Codes

Response

code

“1001” Command length too

“1002” Command length too

“1101” Area type error Incorrect variable type.

“110B” Response length too long Number of elements > 25 (H'0019).

“1100” Parameter error Specified bit position is other than “00”.

“2203” Operation error Unit error, unit change, display unit error,

“0000” Normal end

Error name Explanation

The command is too long.

long

The command is too short.

short

internal non-volatile memory error

1-9

Page 31

Writing to the Variable Area Section 1-6

1-6 Writing to the Variable Area

Write to the data area by setting the required data in the following FINS-mini

command text format.

CompoWay/F

Communications

Command FINS-mini Command Text

Variable

SRCMRC

type

"01" "02" "00"

Starting

address

of write

Bit

position

24222

Number of

elements

"0001" to "0018"

4

Write data

Data name Explanation

MRC/SRC Specifies the FINS-mini monitor value/setting data write

command.

Variable type Specify a variable type.

First address of write Specify the address for the beginning of the write.

Bit position Not used on the K3HB. Specify “00”.

Number of elements Specifies the number of variables to be written (max. of

24 (H'18)). Not needed for a compound write.

Write data Enter data to be written.

Response FINS-mini Response Text

Response code

SRCMRC

(MRES/SRES)

"01" "02"

22 4

Data name Explanation

MRC/SRC FINS-mini command text appears here.

Response code Result of execution of the command.

Response Codes

Response

code

“1002” Command length too

“1101” Area type error Incorrect variable type.

“1003” Number of elements/Data

“1100” Parameter error Bit position specification other than “00”.

“2203” Operation error Write via communications is disabled.

“0000” Normal end

Error name Explanation

The command is too short.

short

The specified number of elements does not

number do not agree

agree with the actual number of data elements.

Written data was outside of setting range.

Write to setting area 1 was attempted from

setting area 0.

Write to setting data of protect level was

attempted from other than protect level.

Calibration level in progress.

Unit error, unit change, display unit error,

internal non-volatile memory error.

1-10

Page 32

Operation Commands (CompoWay/F Communications) Section 1-7

1-7 Operation Commands (CompoWay/F Communications)

Operation commands are sent using the following FINS-mini command text

format.

Command FINS-mini Command Text

Instruction

SRCMRC

code

"30" "05"

2222

Data name Explanation

MRC/SRC Specify the FINS-mini operation command.

Operation code Specify an operation code.

Related information Specify information related to the command.

Operation commands for the K3HB are shown in the following table.

Operation code Description Related information

00 Write via communications 00: OFF (Disabled)

01 Reset 00

02 Bank selection 00 to 07: Bank 0 to 7

03 Zero execute/cancel 00: Zero cancel

06

07 Move to setting area 1 00

08 Move to protect level 00

0B Initialize settings 00

Related

information

Software reset

01: ON (Enabled)

01: Zero execute

00

Communications

CompoWay/F

Note A software reset will not respond (no service PDU response).

Response FINS-mini Response Text

Response code

SRCMRC

(MRES/SRES)

"30" "05"

22 4

Data name Explanation

MRC/SRC FINS-mini command text appears here.

Response code Result of execution of the command.

Response Codes

Response

code

“1001” Command length too

“1002” Command length too

“1100” Parameter error Operation code or related information is not

Error name Explanation

long

short

The command is too long.

The command is too short.

correct.

1-11

Page 33

Setting Areas Section 1-8

Response

code

“2203” Operation error Unable to execute because write via com-

CompoWay/F

Communications

“0000” Normal end

Error name Explanation

munications is disabled.

Unable to execute operation command. For

more information, see corresponding operation command explanation in 1-9 Com-

mands and Responses (CompoWay/F

Communications).

Unit error, unit change, display unit error,

internal non-volatile memory error

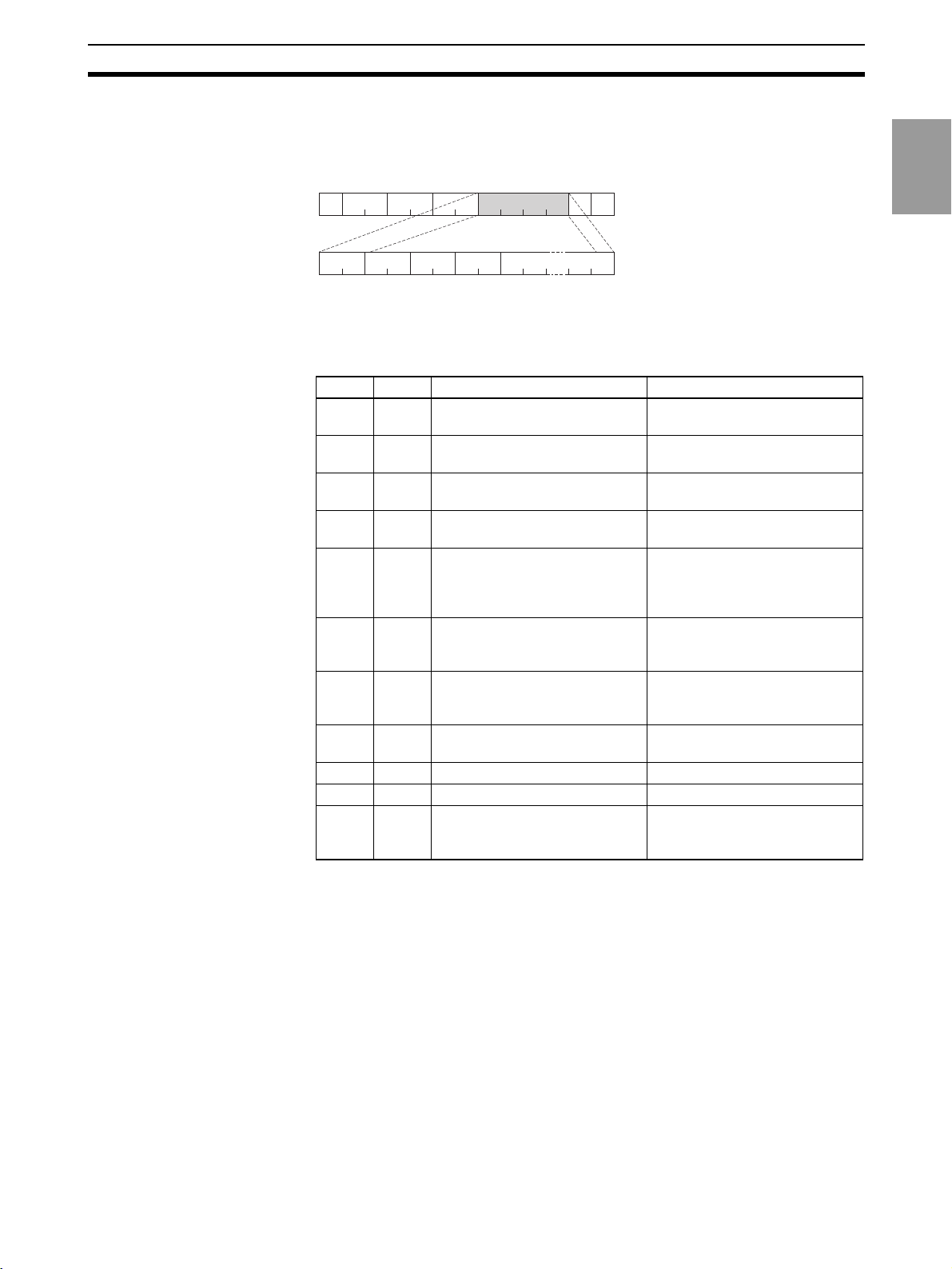

1-8 Setting Areas

The K3HB has two setting areas for communications: Setting area 0 and setting area 1.

In setting area 0, control continues.

As such, setting area 0 makes it possible to perform operations that require

control to be in progress, such as reading the PV, writing an SP, and run/stop,

as well as operations that do not interfere with control. On the other hand,

operations that may change control such as writing initial setting data cannot

be performed. (Note that setting data that cannot be written can still be read.)

In setting area 1, control is stopped.

This makes it possible to perform operations such as writing initial setting data

which are not possible in setting area 0.

When the power is turned on, setting area 0 is selected. To access setting

area 1, use the “Move to setting area 1” operation command. To return to setting area 0 from setting area 1, turn off the power or use the “Software reset”

operation command.

Power on

Setting area 0

Control in progress

Variable type Description Area

C0 Read-only parameters Setting area 0 (during control)

C1 Protect level

C2 RUN level

C4 Initial setting level Setting area 1 (during stop)

C5 Input adjustment level

C6 Display adjustment level

C7 Scaling level

C8 Comparative set value level

C9 Linear output level

CA Communications setting level

CB Advanced function setting

level

"Software reset" command

"Move to setting

area 1" command

Setting area 1

Control stop

1-12

Page 34

Commands and Responses (CompoWay/F Communications) Section 1-9

1-9 Commands and Responses (CompoWay/F

Communications)

The K3HB provides a set of applied commands that make use of variable area

read/write commands, operation commands, and other services provided by

the CompoWay/F communications protocol.

K3HB applied commands are explained below.

1-9-1 Monitor Value Read (CompoWay/F Communications)

Command

MRC SRC

"01" "01" "0001""00"

Variable

type

Address

Variable type Address Monitor value (data name)

“C0” “0000” Version

“0001” Status

“0002” Measurement value

“0003” Maximum value

“0004” Minimum value

This command is used to read the PV, status, and other monitor values. The

number of elements can be set from 0002 to 0019 to allow reading of monitor

values in contiguous addresses.

Bit

position

Number of

elements

Communications

CompoWay/F

Response

MRC SRC Response code

"01" "01" "0000" Monitor value

Data

Response codes: The above indicates a normal end. For the response codes,

see 1-5 Reading the Variable Area (page 1-9).

1-9-2 Setting Data Read (CompoWay/F Communications)

Command

MRC SRC

"01" "01" "00"

Variable

type

Address

Variable type Address Setting data (explanation)

“C1”

“0000” to “0004” Setting data of setting area 0

“C2”

“0000” to “0027” Setting data of setting area 1

“C4”

“C5”

“C6”

“C7”

“C8”

“C9”

“CA”

“CB”

Bit

position

Number of

elements

"0001"

Protect level

RUN level

Initial setting level

Input adjustment level

Display adjustment level

Scaling level

Comparison setting

Linear output setting level

Communications setting level

Advanced function setting level

This command is used to read setting data. The number of elements can be

set from 0002 to 0019 to allow successive reading of 2 to 25 items of setting

data in contiguous addresses.

1-13

Page 35

Commands and Responses (CompoWay/F Communications) Section 1-9

To specify the variable type or address, see SECTION 2 List of Settings

(page 2-1). The upper limit of an address will vary depending on the variable

type.

This command can be used in both setting area 0 and setting area 1.

CompoWay/F

Communications

Response

MRC SRC

"01" "01"

Response code

"0000"

Data

Setting data

Response codes: The above indicates a normal end. For the response codes,

see 1-5 Reading the Variable Area (page 1-9).

1-9-3 Monitor Value/Setting Data Compound Read (CompoWay/F

Communications)

Command

MRC SRC

"01" "04" "00"

Variable

type

Bit positionAddress

Variable type Address Setting data (explanation)

“C0” “0000” to “0004” Monitor values

“C1” to “C2” “0000” to “0004” Setting data of setting area 0

“C4” to “CB” “0000” to “0027” Setting data of setting area 1

Multiple monitor values or setting data can be read by sending a single command. Up to 20 items can be read even if the addresses are not contiguous.

To specify the variable type or address, see SECTION 2 List of Settings

(page 2-1). The upper limit of an address will vary depending on the variable

type.

This command can be used in both setting area 0 and setting area 1.

If an area type error or a setting data error occurs in any of the data being

read, no data will be read.

Variable

type

Address

AddressVariable type

Bit position

"00"

Bit position

"00"

Response

1-14

Variable

MRC SRC Response code Data

"01" "04" "0000"

type

Type

Monitor value / Setting data

Variable type Data

Type Monitor value / Setting data

Response codes: The above indicates a normal end. For the response codes,

see 1-5 Reading the Variable Area (page 1-9).

Page 36

Commands and Responses (CompoWay/F Communications) Section 1-9

1-9-4 Protect Level Setting Data Write

Command

Variable

type

SRCMRC

"01" "02" "C5" "00" "0001" Protect level setting data

Address Setting data

“0000” Operation adjustment protect

“0001” Setting level protect

“0002” Setting change protect

“0003” Forced zero protect

“0004” MAX/MIN protect

This command writes protect level setting data.

This command is used in setting area 0. An error will result if used in setting

area 1.

To use this command, use the “Write via communications” operation com-

mand to enable “Write via communications,” and then use the “Move to protect level” operation command to move to “Protect level.”

Response

SRCMRC

"01" "02" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-6 Writing to the Variable Area (page 1-10).

Address

Response code

Bit position

Number of

elements

Data

Communications

CompoWay/F

1-9-5 Setting Data Write (CompoWay/F Communications)

Command

Variable

type

SRCMRC

"01" "02" "00" "0001"

Address

Bit position

Variable type Address Setting data (explanation)

“C1”

“0000” to “0004” Setting data of setting area 0

“C2”

“C4”

“0000” to “0027” Setting data of setting area 1

“C5”

“C6”

“C7”

“C8”

“C9”

“CA”

“CB”

The above setting data is written. The number of elements can be set from 2

to 24 to write setting data of contiguous addresses.

To specify an address, see SECTION 2 List of Settings (page 2-1).

Setting data of setting area 1 can be written in setting area 1. An error will

result if written in setting area 0.

To use this command, “Write via communications” must be enabled using the

“Write via communications” operation command.

Number of

elements

Setting data

Protect level

RUN level

Initial setting level

Input adjustment level

Scaling level

Display adjustment level

Comparison setting

Linear output setting level

Communications setting level

Advanced function setting level

Data

1-15

Page 37

Commands and Responses (CompoWay/F Communications) Section 1-9

Response

SRCMRC

Response code

"01" "02" "0000"

Response codes: The above indicates a normal end. For the response codes,

CompoWay/F

Communications

see 1-6 Writing to the Variable Area (page 1-10).

1-9-6 Setting Data Compound Write (CompoWay/F Communications)

Command

Variable

type

"01" "13" "00"

AddressMRC SRC

Bit position

Data

Setting data

AddressVariable type

Bit position

"00"

Data

Setting data

Variable type Address Setting data (explanation)

“C1” to “C2” “0000” to “0004” Setting data of setting area 0

“C4” to “CB” “0000” to “0027” Setting data of setting area 1

Multiple setting data items can be written by sending a single command. Up to

12 items can be written even if the addresses are not contiguous.

To specify the variable type or address, see SECTION 2 List of Settings

(page 2-1).

Setting data of setting area 1 is written in setting area 1. An error will result if

written in setting area 0.

To use this command, “Write via communications” must be enabled using the

“Write via communications” operation command.

Response

SRCMRC

Response code

"01" "13" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-6 Writing to the Variable Area (page 1-10).

1-9-7 Monitor Value/Setting Data Compound Read Store (Write)

Command

1-16

Variable

"01" "11" "00"

type

Read address

Bit position

Variable

type

Variable

type

Read addressMRC SRC

Read address

Bit position

"00"

Bit position

"00"

Variable type Address Setting data (explanation)

“C0” “0000” to “0004” Monitor values

“C1” to “C2” “0000” to “0004” Setting data of setting area 0

“C4” to “CB” “0000” to “0027” Setting data of setting area 1

This command is used to store the addresses of multiple monitor values or

setting data that you wish to read.

The stored monitor values or setting data can be read by sending a single

“Monitor value/setting data compound store read” command. Up to 20 items

can be stored, even if the addresses are not continuous.

Page 38

Commands and Responses (CompoWay/F Communications) Section 1-9

To specify the variable type or address, see SECTION 2 List of Settings

(page 2-1). The upper limit of an address will vary depending on the variable

type.

This command can be used in both setting area 0 and setting area 1.

Response

SRCMRC

Response code

"01" "11" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-5 Reading the Variable Area (page 1-9).

1-9-8 Monitor Value/Setting Data Compound Read Store Check (Read)

Command

SRCMRC

"01" "12"

This is used to check the contents that were stored using “Monitor value/setting data compound read store.”

Response

Variable

Response code

"01" "12" "0000"

type

Type

Variable

type

Type

Read addressMRC SRC

Read address

Bit position

"00"

Communications

CompoWay/F

Response codes: The above indicates a normal end. For the response codes,

see 1-5 Reading the Variable Area (page 1-9).

1-9-9 Monitor Value/Setting Data Compound Store Read

Command

SRCMRC

"01" "10"

This is used to read by a single command the multiple monitor values or setting data items that were stored using “Monitor value/setting data compound

read store (write).”

This command can be used in both setting area 0 and setting area 1.

If an area type error or a setting data error occurs in any of the data being

read, no data will be read.

Response

Variable

MRC SRC

"01" "10" "0000"

Response code

Response codes: The above indicates a normal end. For the response codes,

see 1-5 Reading the Variable Area (page 1-9).

type

Type

Variable type

Type

Data

Monitor value / Setting data

Data

Monitor value / Setting data

1-17

Page 39

Commands and Responses (CompoWay/F Communications) Section 1-9

1-9-10 Write via Communications

Command

Command

SRC

MRC

CompoWay/F

Communications

"30" "05"

Related information Description

“00” Write via communications disabled

“01” Write via communications enabled

This command is used to enable or disable “Write via communications.” When

sent, it changes the set value of “Write via communications.”

When write via communications is disabled, communications cannot be used

to write setting data or send operation commands.

The initial setting is “disabled.”

This command can be used in both setting area 0 and setting area 1.

Response

SRCMRC

"30" "05" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-7 Operation Commands (CompoWay/F Communications) (page 1-11).

Related

information

code

"00"

Response code

1-9-11 Reset

Command

Response

1-9-12 Bank Selection

Command

code

"01"

Related

information

SRC

MRC

"30" "05"

Command

Related information Description

“00” Reset

This command resets the system to no-measurement status. It can only be

used in setting area 0.

SRCMRC

Response code

"30" "05" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-7 Operation Commands (CompoWay/F Communications) (page 1-11).

Command

SRC

MRC

"30" "05"

Related information Bank No. selected

“00” to “07” 0 to 7

code

"02"

Related

information

1-18

This command can be used only when “Bank Selection” is set to “Key.”

This command is used to change between comparative set values preset in

banks. There are 8 banks numbered 0 to 7.

This command can be used in both setting area 0 and setting area 1.

Page 40

Commands and Responses (CompoWay/F Communications) Section 1-9

Response

"30" "05" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-7 Operation Commands (CompoWay/F Communications) (page 1-11).

1-9-13 Zero Execute/Cancel

Command

MRC

"30" "05"

Related information Description

“00” Zero cancel

“01” Zero execute

This command is used to execute/cancel the forced zero and tare zero functions. The results of the command will depend on the status of the tare zero

setting, as shown below.

Tare

zero

OFF Forced zero ON Forced zero ON Forced zero OFF Forced zero OFF

ON Forced zero ON Tare zero ON Tare zero OFF Forced zero OFF

SRCMRC

Response code

SRC

Command

code

"03"

Related

information

Commands executed in order left to right.

Zero execute Zero execute Zero cancel Zero cancel

Communications

CompoWay/F

Response

1-9-14 Software Reset

Command

This command can be used only in setting area 0. An operation error will

occur in the following situations.

• When there is no-measurement status, there is an input error, or a measurement is outside the display range (but zero cancel is possible.)

• When a RESET or HOLD input is ON

• When the command is used in setting area 1

SRCMRC

Response code

"30" "05" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-7 Operation Commands (CompoWay/F Communications) (page 1-11).

SRC

MRC

"30" "05"

Command

code

information

"06" "00"

Related

A software reset causes the same operation as turning the power off and on.

This command can be used in both setting area 0 and setting area 1.

To use this command, “Write via communications” must be enabled using the

“Write via communications” operation command.

Response (No response)

A response is not returned to this operation command.

1-19

Page 41

Commands and Responses (CompoWay/F Communications) Section 1-9

1-9-15 Move to Setting Area 1

Command

Command

SRC

MRC

CompoWay/F

Communications

"30" "05"

code

information

"07" "00"

Related

Use this command to move to setting area 1.

The command is used in setting area 0. Nothing happens if the command is

used in setting area 1.

If the command is used when “Initial setting protect” is set to 2 (Disable move

to input initial setting level), an operation error will result.

To use this command, “Write via communications” must be enabled using the

“Write via communications” operation command.

Response

SRCMRC

Response code

"30" "05" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-7 Operation Commands (CompoWay/F Communications) (page 1-11).

1-9-16 Move to Protect Level

Command

MRC

"30" "05"

Use this command to move to protect level.

This command is used in setting area 0. If used in setting area 1, an operation

error will result.

To use this command, “Write via communications” must be enabled using the

“Write via communications” operation command.

Response

"30" "05" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-7 Operation Commands (CompoWay/F Communications) (page 1-11).

1-9-17 Initialize Settings

Command

MRC

"30" "05"

This returns all settings to the initial settings.

This command is used in setting area 1. If used in setting area 0, an operation

error will result.

To use this command, “Write via communications” must be enabled using the

“Write via communications” operation command.

SRC

SRCMRC

SRC

Command

code

information

"08" "00"

Response code

Command

code

information

"0B" "00"

Related

Related

1-20

Page 42

Commands and Responses (CompoWay/F Communications) Section 1-9

Response

SRCMRC

"30" "05" "0000"

Response codes: The above indicates a normal end. For the response codes,

see 1-7 Operation Commands (CompoWay/F Communications) (page 1-11).

1-9-18 Read Machine Attributes

Command

SRCMRC

"05" "03"

This command reads the K3HB model and communications buffer size.

The command can be used in any state of the K3HB.

Response

"05" "03" "0000" "00D9"

Response codes: The above indicates a normal end. For the response codes,

see 1-7 Operation Commands (CompoWay/F Communications) (page 1-11).

Model

3

H

∗Bytes 8 and 9 are blank

Response code

B-K

Communications

CompoWay/F

Buffer sizeFormatResponse codeSRCMRC

AB

Symbol Series Symbol Input

X Analog input VD DC voltage

AD AC voltage

VA DC current

AA AC current

V mV input LC mV

S Linear Sensor input SD Linear Sensor

H Temperature input TA Temperature

R Rotary pulse input NB NPN/voltage pulse input

PB PNP input

P Time interval input NB NPN/voltage pulse input

PB PNP input

C Up/Down counting pulse

input

NB NPN/voltage pulse input

PB PNP input

1-9-19 Controller Status Read (CompoWay/F Communications)

Command

SRCMRC

"06" "01"