Page 1

1/32 DIN Digital Panel Meter K3GN K-7

Panel

indicators

1/32 DIN Digital Panel Meter

K3GN

Compact and Intelligent Digital Panel Meter

• A single Panel Meter covering a wide range of applications.

3 main applicable functions:

• Process meter (DC voltage/current input).

• RPM processor/tachometer (frequency input).

• Digital data display for PC/PLC (RS-485 communications).

• Easy configuration

• Multi-range analog input: applicable for all standard analog

signals.

6 input ranges available: 4 to 20 mA/0 to 20 mA, 1 to 5 VDC/

0 to 5 VDC, ±5 VDC, ±10 VDC.

• 5 KHz max. input-pulse frequency range.

• Scaling in a wide range of engineering units.

• Programmable output operation action, decimal point

position setting, teaching function for input range, leading

zero suppression, average processing.

• Advanced and compact design

• Very compact 1/32 DIN housing: 48 (W) x 24 (H) x 83 (D).

• 5-digit display with programmable display color in red or

green.

• Good visibility: High contrast backlit LCD display.

• High protection against water and dust: NEMA4X/IP66 front

panel.

• Selectable outputs: 2 relay outputs, 3 transistor outputs,

RS-485, and combinations of these.

• High accuracy: ±0.1% full scale.

• Easy to configure through the front panel or via RS-485.

• EN/IEC conformity with CE marking and UL/CSA approval.

®

Model Number Structure

■ Model Number Legend

1. Input Type

ND: DC voltage/current, NPN

PD: DC voltage/current, PNP

2. Output Type

C: 2 relay contact outputs (SPST-NO)

T1: 3 transistor outputs (NPN open collector)

T2: 3 transistor outputs (PNP open collector)

3. Communications Output Type

None: Communications not supported

FLK: RS-485

24 VDC

12 3

K3GN - -

Page 2

K-8 1/32 DIN Digital Panel Meter K3GN

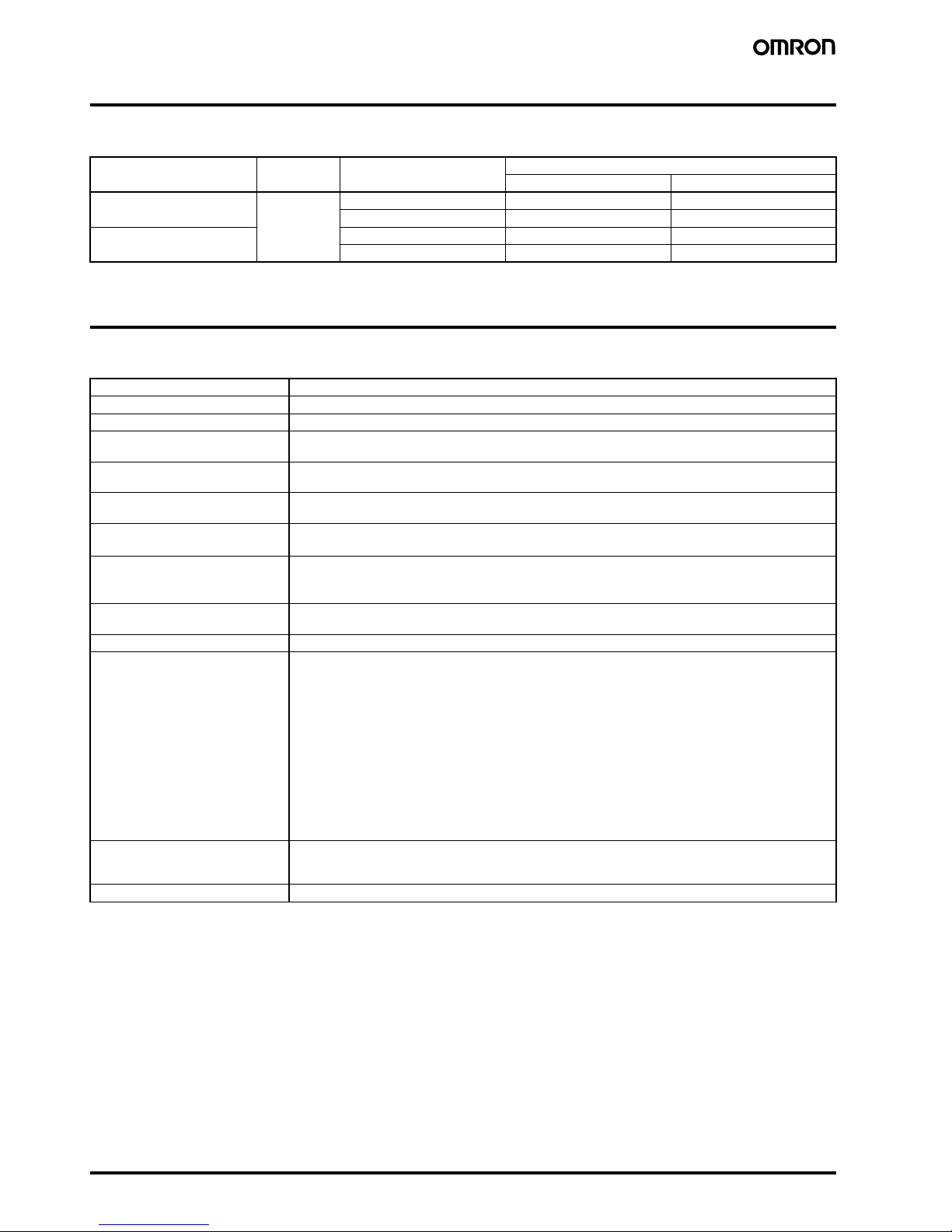

Ordering Information

■ List of Models

Specifications

■ Ratings

Note: A control power supply capacity greater than the rated capacity is required when the Digital Panel Meter is turned ON. Do not forget to take

this into consideration when using several Digital Panel Meters. When power is supplied, all indicators will light and outputs will be OFF.

When using startup compensation time operation, the display will read “00000” and all outputs will be OFF.

Input type Supply

voltage

Output Communications

No communications RS-485

DC voltage/current, NPN 24 VDC Dual relays (SPST-NO) K3GN-NDC 24 VDC K3GN-NDC-FLK 24 VDC

Three NPN open collector K3GN-NDT1 24 VDC K3GN-NDT1-FLK 24 VDC

DC voltage/current, PNP Dual relays (SPST-NO) K3GN-PDC 24 VDC K3GN-PDC-FLK 24 VDC

Three PNP open collector K3GN-PDT2 24 VDC K3GN-PDT2-FLK 24 VDC

Supply voltage 24 VDC

Operating voltage range 85% to 110% of the rated supply voltage

Power consumption (see note) 2.5 W max. (at max. DC load with all indicators lit)

Insulation resistance 20 MΩ min. (at 500 VDC) between external terminal and case.

Insulation provided between inputs, outputs, and power supply.

Dielectric strength 1,000 VAC for 1 min between external terminal and case.

Insulation provided between inputs, outputs, and power supply.

Noise immunity ±480 V on power supply terminals in normal mode, ±1,500 V in common mode, ±1 µs, or 100 ns for square-

wave noise with 1 ns

Vibration resistance

Malfunction: 10 to 55 Hz, 10 min each in X, Y, and Z directions; acceleration: 9.8 m/s

2

Destruction: 10 to 55 Hz, 30 min each in X, Y, and Z directions; acceleration: 19.6 m/s

2

Shock resistance

Malfunction: Models with transistor outputs: 196 m/s

2

for 3 times each in X, Y, and Z directions

Models with relay contact outputs: 98 m/s

2

for 3 times each in X, Y, and Z directions

Destruction: 294 m/s

2

for 3 times each in X, Y, and Z directions

Ambient temperature Operating: −10°C to 55°C (with no condensation or icing)

Storage: −25°C to 65°C (with no condensation or icing)

Ambient humidity Operating: 25% to 85% (with no condensation)

EMC (EMI) EN61326+A1 Industry

Emission Enclosure: CISPR 11 Group 1 class A: CISRP16-1/-2

Emission AC Mains: CISPR 11 Group 1 class A: CISRP16-1/-2

(EMS) EN61326+A1 Industry

Immunity ESD: EN61000-4-2: 4 kV contact discharge (level 2)

8 kV air discharge (level 3)

Immunity RF-interference: EN61000-4-3: 10 V/m (amplitude-modulated,

80 MHz to 1 GHz) (level 3)

Immunity Fast Transient Noise: EN61000-4-4: 2 kV (power line) (level 3)

Immunity Burst Noise: 1 kV line to line (I/O signal line)

Immunity Surge: EN61000-4-5: 1 kV line to line

2 kV line to ground (power line)

Immunity Conducted Disturbance EN61000-4-6: 3 V (0.15 to 80 MHz) (level 2)

Immunity Voltage Dip/Interrupting EN61000-4-11: 0.5 cycles, 0, 180°, 100% (rated voltage)

Approved standards UL508, CSA22.2;

Conforms to EN61326+A1, EN61010-1 (IEC61010-1)

Conforms to VDE0106/P100 (finger protection) when the terminal cover is mounted.

Weight Approx. 100 g

Page 3

1/32 DIN Digital Panel Meter K3GN K-9

Panel

indicators

■ Characteristics

Note 1. The minimum input time for control signals is 80 ms.

2. Refer to N102 Operation Manual for more details.

Input signal Process voltage

(1 to 5 V, 0 to 5 V, ±5V, ±10 V)

Process current

(4 to 20 mA, 0 to 20 mA)

No-voltage contact

(30 Hz max. with ON/OFF pulse width

of 16 ms min.)

Open collector

(5 kHz max. with ON/OFF pulse width

of 90 µs min.)

Digital data display (by RS-485

communication)

A/D conversion Double integral method

14 bit resolution

---

Sampling period 250 ms ---

Display refresh

period

Sampling period (sampling times multiplied by number of averaging times if average processing is selected.)

Pulse measurement

method

--- Periodic measurement ---

Connectable Sensors --- ON residual voltage: 2.5 V max.

OFF leakage current: 0.1 mA max.

Load current: Must have a switching capacity of 15 mA min.

Must be able to reliably switch load currents of 5 mA max.

Max. displayed digits 5 digits (−19999 to 99999)

Display 7-segment digital display, character height: 7.0 mm

Polarity display “−” is displayed automatically with a negative input signal.

Zero display Leading zeros are not displayed.

Scaling function Programmable with front-panel key inputs (range of display: −19999 to 99999). The decimal point position can be set as

desired.

External controls

(see note 1)

HOLD: (Measurement value held)

ZERO: (Forced-zero)

---

Hysteresis setting Programmable with front-panel key inputs (0001 to 9999).

Other functions Programmable Color Display

Selectable output operating action

Teaching set values

Average processing (simple average)

Lockout configuration

Communications writing control (communications output models only)

Forced-zero set with front panel keys

Control inputs (HOLD/ZERO) selection

via front panel keys

Field calibration

Startup compensation time (0.00 to 99.9 s)

Auto-zero time (0.0 to 19.9 s)

Output Relays: 2 SPST-NO

Transistors: 3 NPN open collector

3 PNP open collector

Combinations:

Communications output (RS-485) + relay outputs (2 SPST-NO);

Communications output (RS-485) + transistor outputs (3 NPN open collector);

Communications output (RS-485) + transistor outputs (3 PNP open collector)

Communications Communications function: RS-485

Delay in comparative

outputs

(transistor outputs)

750 ms max.

Degree of protection Front panel:NEMA4X for indoor use (equivalent to IP66)

Rear case: IEC standard IP20

Terminals: IEC standard IP20

Memory protection Non-volatile memory (EEPROM) (possible to rewrite 100,000 times)

Page 4

K-10 1/32 DIN Digital Panel Meter K3GN

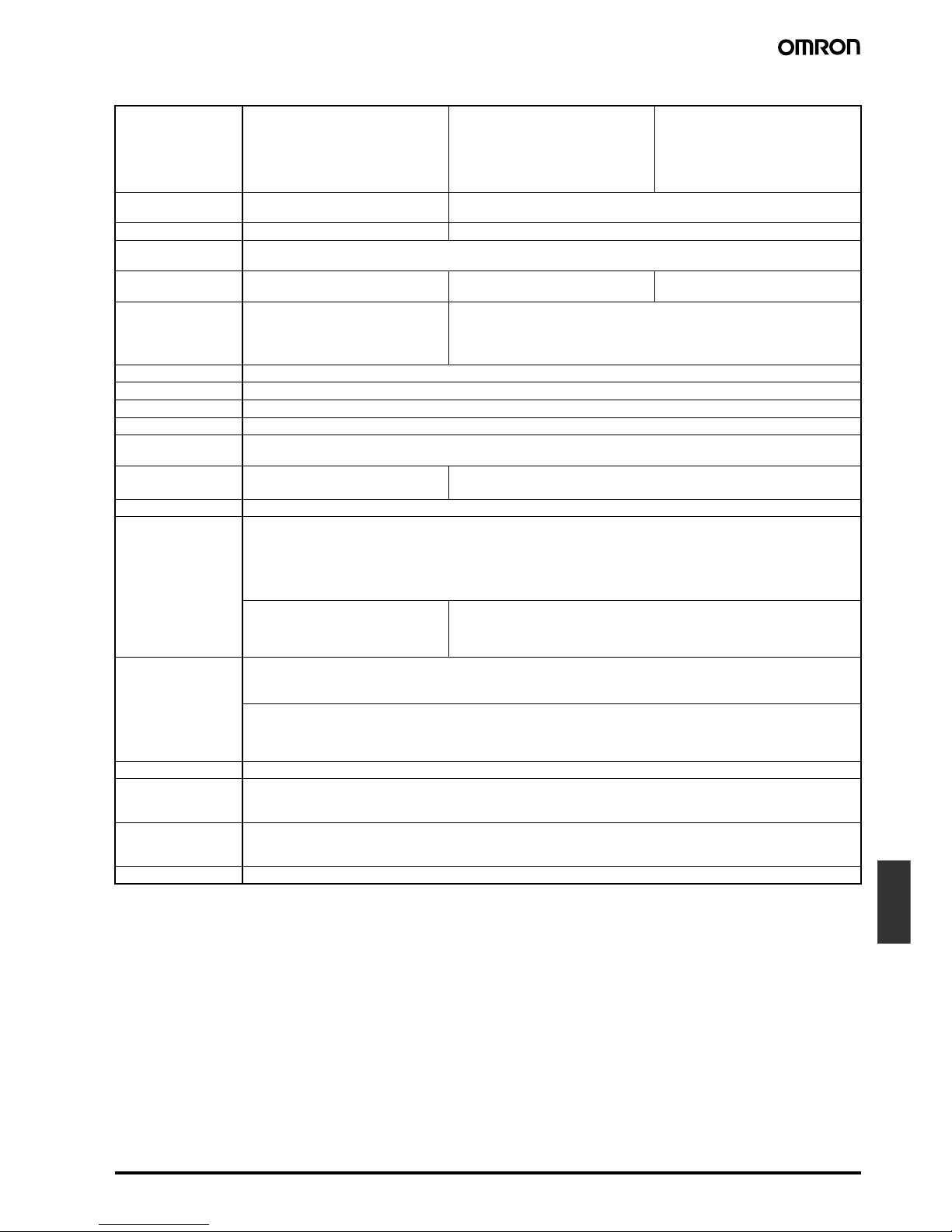

■ Measuring Ranges

Process Voltage/Current Inputs

No-voltage Contact/Open Collector Inputs

Digital Data Display (By RS-485 Communications)

■ Input/Output Ratings

Relay Contact Output

(Incorporating G6K Relays)

Transistor Output

■ Communications Specifications

Refer to N102 Operation Manual for more details.

Input Measuring range Measuring accuracy Input impedance Displayable range

DC voltage 1.000 to 5.000 V/

0.000 to 5.000 V

±0.1% FS ±1 digit max.

(at 23±3°C)

1 MΩ min. −19999 to 99999

(with scaling function)

−5.000 to 5.000 V ±0.1% FS ±1 digit max.

(at 23±5°C)

−10.00 to 10.00 V

DC current 4.00 to 20.00 mA/

0.00 to 20.00 mA

±0.1% FS ±1 digit max.

(at 23±3°C)

60 Ω

Input Measuring range Measuring accuracy

(at 23±5°C)

Displayable range

No-voltage contact (30 Hz max.) with ON/

OFF pulse width of 16 ms min.

0.05 to 30.00 HZ ±0.1% FS ±1 digit max. −19999 to 99999

(with scaling function)

Open collector (5 kHz max.) with ON/OFF

pulse width of 90µs min.

0 to 5000 HZ

Displayable range −19999 to 99999

Item Resistive load (cosφ = 1)

Rated load 1 A at 30 VDC

Rated carry current 1 A max. (at COM terminal)

Max. contact voltage 60 VDC

Max. contact current 1 A (at COM terminal)

Max. switching capacity 30 VA

Min. permissible load

(P level, reference value)

10 mV, 10 µA

Mechanical life 50,000,000 times min. (at a switching frequency of 36,000 times/hr)

Electrical life

(at an ambient temperature of 23°C)

100,000 times min. (at the rated load with a switching frequency of 1,800 times/hr)

Rated load voltage 24 VDC

Max. load current 50 mA

Leakage current 100 µA max.

Item RS-485

Transmission method 2-wire, half-duplex

Synchronization method Start-stop synchronization

Baud rate 1,200/2,400/4,800/9,600/19,200 bps

Transmission code ASCII

Communications Reading/Writing to

the K3GN

Read/write set values, read/write scaling values, enable/disable the writing of data through communications, forced-zero control, and other data.

Page 5

1/32 DIN Digital Panel Meter K3GN K-11

Panel

indicators

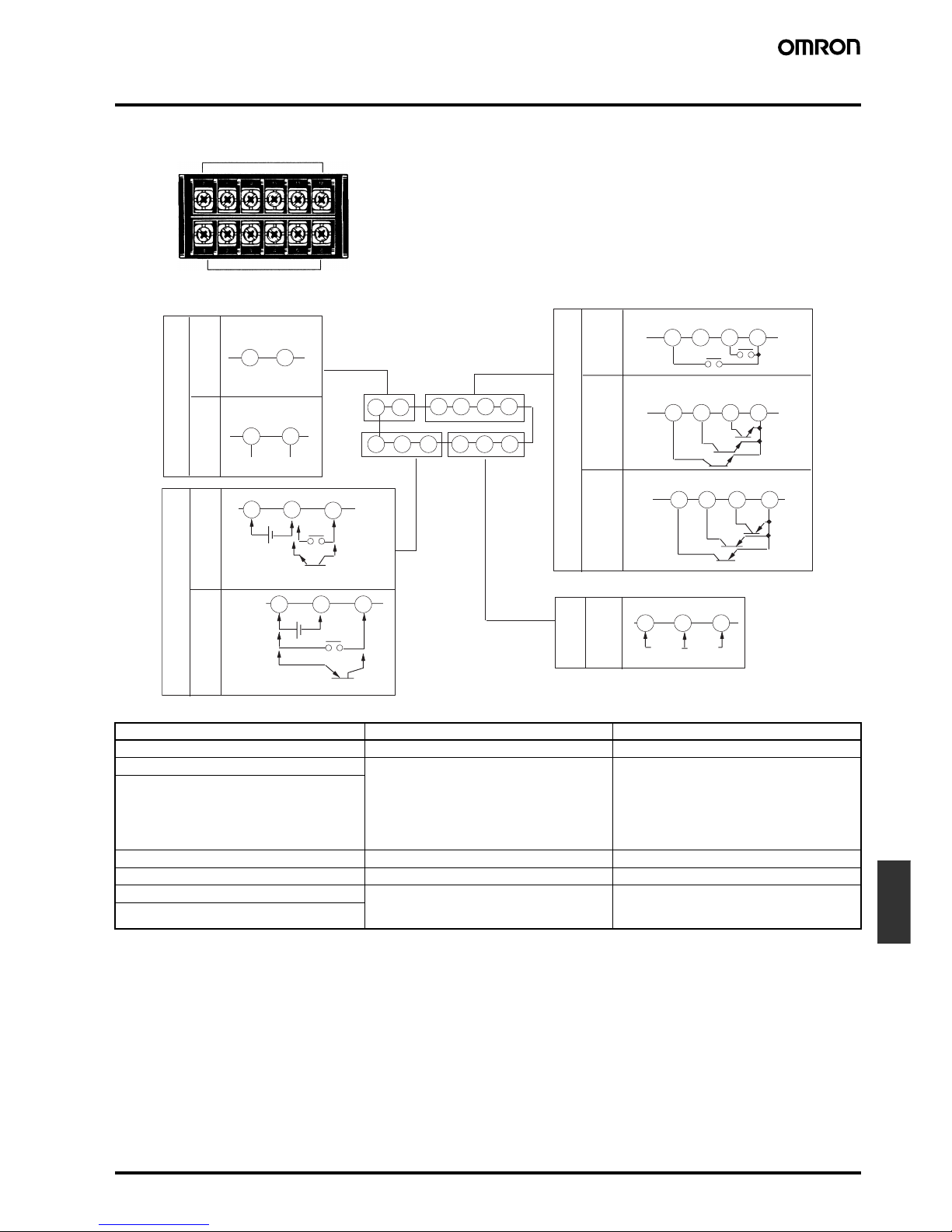

Connections

■ Terminal Arrangement

Note: *Operation power supply 24VDC: Recommended DC power supply: eg. OMRON s8VS

Terminal No. Name Description

A-B Operation power Connect the operation power supply.

C-B Event input or pulse/contact input Operates as follows depending on parameter

setting:

• Holds process value.

• Calibrate the process value to zero and clear

the forced-zero function.

• Pulse or contact input.

C-A

D,F-E Analog input Connect the voltage or current analog input.

G-H Communications RS-485 communications terminals.

I,K-L Outputs Outputs relay or transistor outputs. There is

also a PASS output for models with transistor

outputs.

I,J,K-L

B (+) A (−)

78

7

8

C

12

3

1

2

3

A

9101112

9101112

9101112

D

456

B

C

D

AB

78 9101112

123 456

Output terminals

Input terminals

NC NC

RS-485

Models with NPN inputsModels with PNP inputs

OUT1

PASSNCOUT2

COM

OUT1

OUT2

COM

OUT1 PASS OUT2 COM

Voltage Current

Analog input

COM

Event or pulse/contact input

Event or pulse/contact input

Analog input

Models without

communications

Models with

communications

Operation

power supply

24 VDC*

Operation

power supply

24 VDC*

Models with

PNP transistor outputs

Models with

NPN transistor outputs

Models with

relay outputs

Page 6

K-12 1/32 DIN Digital Panel Meter K3GN

■ Wiring

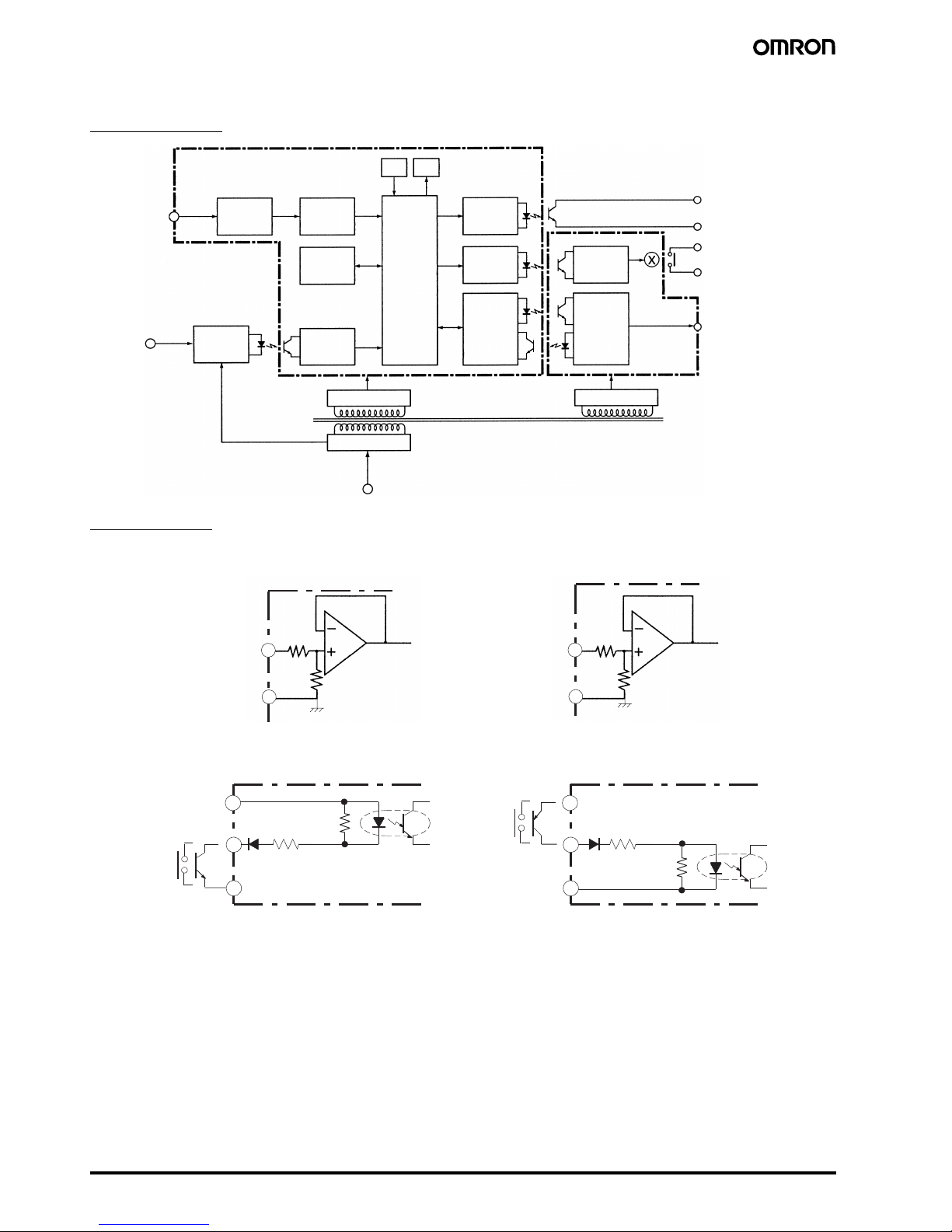

Block Diagram

Input Circuits

Analog Input (DC Voltage/Current)

Pulse Input/Control Event Input (HOLD/ZERO)

DisplayKey

Drive circuit

Drive circuit

Drive circuit

Constant voltage circuit 1

Power supply circuit

Input circuit

Operating power supply

Constant voltage circuit 2

EEPROM

Analog input

terminal

Pulse/

Control

input

terminal

Control input

circuit

A/D

conversion

circuit

Wavefo rm

rectification

circuit

Microcomputer

Note: 1. Transistor output models only.

2. Relay output models only.

3. Models with communications functions only.

Output

circuit

Communications driver

Transistor output

(See note 1.)

Contact output

(See note 2.)

Communications terminal

(See note 3.)

5

4

5

6

A

60 Ω

A+B=1 MΩ

B

Voltage input

COM

Current input

COM

To A / DTo A/D

2

3

24 VDC +

4.7 k

Ω

2.35 k

Ω

3

4.7 k

Ω

2.35 k

Ω

2

24 VDC

−

24 VDC +

24 VDC

−

1

1

PNP Input

NPN Input

Hold/Zero Pulse

Hold/Zero Pulse

Page 7

1/32 DIN Digital Panel Meter K3GN K-13

Panel

indicators

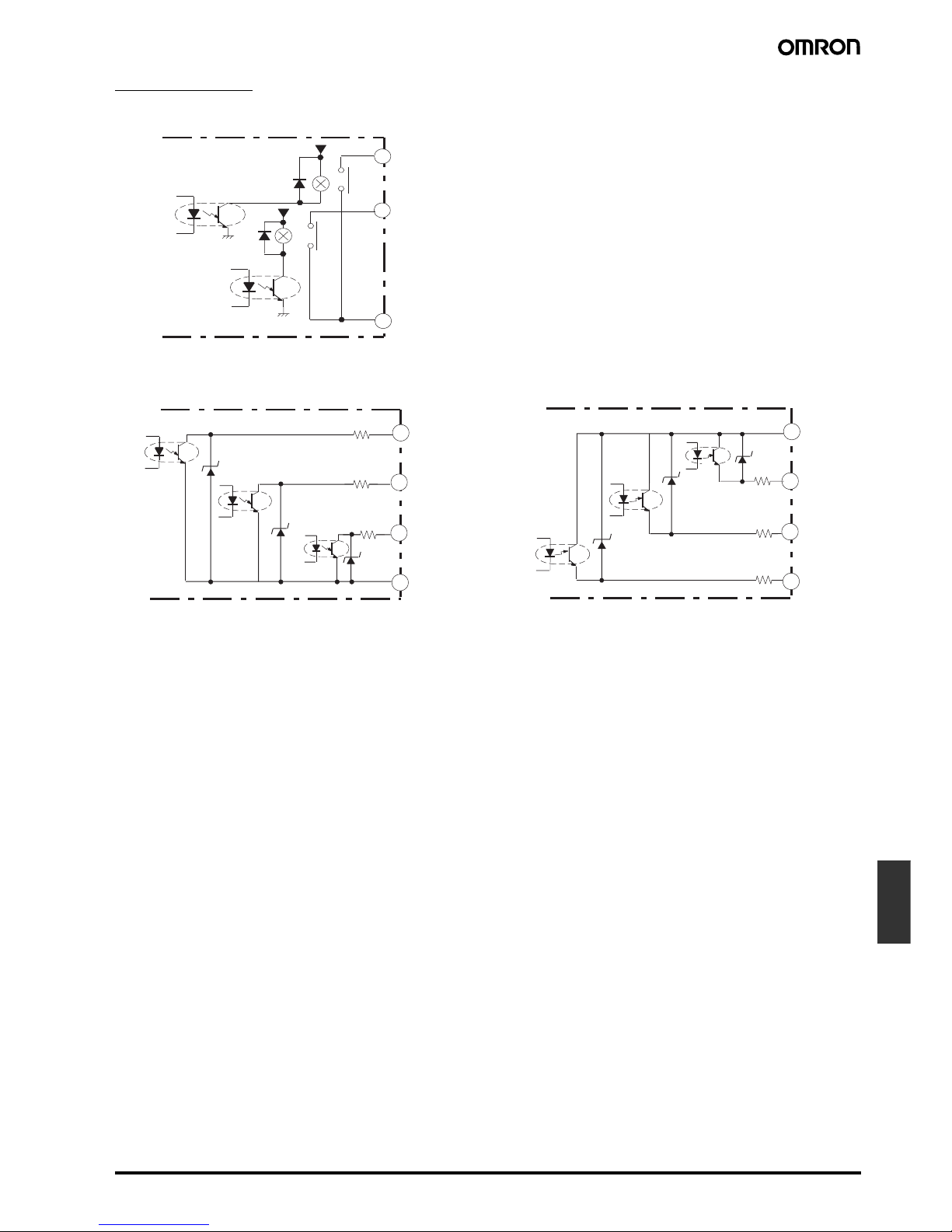

Output Circuits

Contact Output

Transistor Output

9

11

12

5 V

5 V

OUT1

OUT2

OUT3

9

10

11

12

8.2

Ω

8.2

Ω

8.2

Ω

OUT1

OUT2

PA SS

COM

NPN Output

9

10

11

12

8.2

Ω

8.2

Ω

8.2

Ω

OUT1

OUT2

PA SS

COM

PNP Output

Page 8

K-14 1/32 DIN Digital Panel Meter K3GN

Operation

■ Main Functions

Input Types and Ranges

Scaling

Analog (Process) Inputs

The K3GN converts input signals into desired physical values.

INPUT2: Any input value

DISPLAY2: Displayed value corresponding to INPUT2

INPUT1: Any input value

DISPLAY1: Displayed value corresponding to INPUT1

Pulse Frequency

The K3GN converts pulse signal inputs into desired units such as

revolutions or rotational speeds.

The slope of the linear relationship between the input value and display value is calculated automatically when an input value and its

corresponding display value are entered.

Input value: Any arbitrary input value

Display value: Desired display value corresponding to input value

If scaling for pulse signals is not performed, the input frequency will

be displayed.

The relationship between input, f, and display, D, is expressed in the

form D = f × a (multiplication factor). The value of a will vary accord-

ing to the display unit. For example, if the display unit is rpm, Y is

given by the following:

D = f × 1/N × 60 (i.e., a = 1/N × 60)

where N is the number of pulses per revolution and f is the input

pulse frequency (Hz).

If the display unit is m/min, Y is given by the following:

D = f × πd × 1/N × 60 (i.e., a = πd × 1/N × 60)

where πd = the wavelength (m) per revolution.

Example: When displaying the rotational speed (rpm) for a machine

that generates 5 pulse signals per revolution, D is given by the following:

D = f × 1/5 × 60,

so if f = 1, then D = 12. Therefore, input 1 for inp and 12 for dsp.

Average Processing

The average processing function stabilizes displayed values by averaging the corresponding input signals that fluctuate dynamically.

Hysteresis

The hysteresis of comparative outputs can be set to prevent the chattering of relay or transistor outputs.

Input type (setting parameter) Function Input range (setting parameters) Setting range

Analog input (analg) Selects DC voltage/current signal

input.

4 to 20 mA/0 to 20 mA (4-20) Displayable from −19999 to 99999

with scaling function. The position

of the decimal point can be set as

desired.

1 to 5 V/0 to 5 V (1-5)

±5 V (5)

±10 V (10)

Pulse input (pulse) Selects pulse input signal. 0.05 to 30 Hz (30)

0 to 5 kHz (sk)

Remote (rmt) Displays digital data from PLC or

PC.

---

Input value

INPUT1 INPUT2

Input value

Displayed value

Displayed value

DISPLAY1 DISPLAY2

DISPLAY1 DISPLAY2

INPUT2 INPUT1

inp

dsp

Input value

Displayed value

K3GN

Proximity Sensor

Upper limit (high acting)

Set value

Output

ON

OFF

Hysteresis

Measurement value

Page 9

1/32 DIN Digital Panel Meter K3GN K-15

Panel

indicators

Startup Compensation Time (Pulse

Input Only)

The startup compensation time parameter keeps the measurement

operation from sending an unnecessary output corresponding to

instantaneous, fluctuating input from the moment the K3GN is turned

ON until the end of the preset period.

The compensation time can be set in a range from 0.0 to 99.9 seconds as the waiting time until the devices subject to measurement

become stable after the startup of the power supply.

Changing the Display Color

The display can be programmed to change color when an output

turns ON. In an example, the K3GN can be programmed to display

Green for normal, and Red for errors. The color can be set to change

from either green to red or red to green when output turns ON.

K3GN can also be programmed to display only one unchanging

color: Red or Green.

Teaching

An actual measured value as a set value without any front panel key

input can be set with the teaching function. Teaching is useful for

making settings while checking the operation status of K3GN.

Forced-zero Function

It is possible to shift the zero point to a desired value (such as might

be required when adjusting reference values) with one touch of the

Up/Zero Key on the front panel.

Configurable Output Operating Action

Output 1 and output 2 can be set to operate in one of the 3 following modes:

• Upper limit (High Acting):

The output is turned ON when the measured value is greater than its set value.

• Lower limit (Low Acting):

The output is turned ON when the measured value is less than its set value.

• Upper and lower limits (Outside band Acting):

An upper limit (H set value) and lower limit (L set value) can be set independently.

The output is turned ON when the measured value is greater than upper-limit set value or less than the lower-limit set value.

Only transistor outputs have a PASS output which is output when both OUT1 and OUT2 are OFF.

The three types of output operations shown above can be combined as desired. The following are examples of possible combinations.

OUT1

OUT2

SV

ZERO

HOLD

CMW

Upper Limit (High Acting)

OUT1/2 set value

Measurement value

ON

OFF

Output

Hysteresis

Lower Limit (Low Acting)

OUT1/2 set value

ON

OFF

Output

Hysteresis Hysteresis

Measurement value

Hysteresis

ON

OFF

Output

Measurement value

Upper and Lower Limits

(Outside Band Acting)

Upper-limit set value

for OUT1/2

Lower-limit set value

for OUT1/2

Upper Limit 2-stage Output Threshold Output

ON

OFF

OUT2

ON

OFF

OUT1

OUT1 set value

ON

OFF

OUT2

ON

OFF

OUT1

ON

OFF

OUT2

ON

OFF

OUT1

OUT2

set value

OUT1

set value

Measurement

value

Upper-limit OUT2

set value

Upper-limit OUT1

set value

Lower-limit OUT1

set value

Lower-limit OUT2

set value

Measurement

value

Combination of Upper Limit and

Upper/Lower Limits

Upper-limit

OUT2 set value

Lower-limit

OUT2 set value

Measurement

value

Page 10

K-16 1/32 DIN Digital Panel Meter K3GN

Nomenclature

Name Functions

1. Main display Displays process values, parameters, and set values.

2. Status indicators OUT1 Lit when output 1 is ON.

OUT2 Lit when output 2 is ON.

SV Lit when a set value is being displayed or changed.

T Lit when the teaching function is enabled. Flashes when the K3GN is in teaching operation.

Lit when a calibration value is being displayed during user calibration. Flashes while reading a calibration value.

ZERO Lit while the forced-zero function is activated.

HOLD Lit when HOLD input is ON.

CMW Lit when communications writing is “enabled” and is out when it is “disabled.”

3. Level indicator Displays the current level that the K3GN is in. (See below for details.)

4. Level Key Used to change the level.

5. Mode Key Used to allow the Main display to indicate parameters sequentially.

6. Shift Key Used to enable that set value to be changed. When changing a set value, this key is used to move

along the digits.

7. Up/Zero Key Used to change a set value. Used to set or clear a forced-zero function when a measurement value is

being displayed.

1. Main display

2. Status indicators

3. Level indicator

4. Level key

2. Status indicators

7. Up/Zero key6. Shift key5. Mode key

Level indicator Level

p

Protect

Not lit Operation

a

Adjustment

s

Initial setting

c

Communications setting

f

Advanced function setting

u

User calibration

Page 11

1/32 DIN Digital Panel Meter K3GN K-17

Panel

indicators

Dimensions

Note: All units are in millimeters unless otherwise indicated.

Application Examples

Detection of Dust Exhaust

The change in the density of the dust is detected via the E3SA and

discriminated by the K3GN.

Monitoring of Tank Pressure

The output of the pressure sensor is processed and the pressure is

displayed. Remote monitoring of the operation is possible with the

communications function.

22.2

+0.3

0

22.2

+0.3

0

45

+0.6

0

3.6 mm

7 mm

Main Display Character Size

Panel Cutouts

Gang Mounting

(48 × No. of Panels − 2.5)

+1.0

0

40 min.

Separate

mounting

The products cannot be

made waterproof when

gang-mounted.

The K3GN uses M3 terminals. A terminal

cover is provided.

Exhaust

Grinder Dust collecting machine

E3SA

4 to 20 mA

K3GN

OUT2

(Upper upper-

limit alarm)

Device stops

OUT1

(Upper-limit

alarm) Output

reduction

instruction

Foam

Beer

Tank

Exhaust valve

Pump

K3GN

Host PC

RS-485

RS-232C

E8AA

Pressure

Sensor

Page 12

K-18 1/32 DIN Digital Panel Meter K3GN

Monitoring of Motor Load Current

If the startup time compensation of the K3GN is enabled, the K3GN

will not be influenced by the inrush current from starting the motor,

and no signal will be output from the K3GN.

Note: *Power Supply: Recommended DC power supply:

eg. OMRON S8VS.

Monitoring Difference between Two

Line Speeds

The difference between the two line speeds is calculated by the PLC

and the result is written via RS-485 to the K3GN where it is displayed.

Position Indication on X-Y Table

The position on the X-Y table is calculated by the PLC and the result

is written via RS-485 to the K3GN where it is displayed. The scaling

function can be used to display the result in millimeter units.

Monitoring the Remaining Quantity of

Soup

The distance to the surface of the soup is detected with an ultrasonic

sensor and, based on this distance, the K3GN displays the remaining

quantity. When the remaining quantity of soup decreases to less than

20%, the K3GN lights the “Replenish” indicator.

Monitoring Number of Motor

Revolutions

Note: *Power Supply: Recommended DC power supply:

eg. OMRON S8VS.

Power supply*

Signal input

K3GN

24-VDC power supply*

Electromagnetic relay

K3FK

CT Converter

OUT1

(Upper-limit

alarm)

OUT2

(Lower-limit

alarm)

RS-485 communications output

(calculation result)

K3GN

(Set the input type to

"Remote").

X

Y

PLC

mm

mm

00

135.4

PLC

X-Y Table

RS-485 Communication output

K3GN

(Set the input type to

"Remote".)

100 %

20 %

4 to 20 mA

K3GN

Volume of soup

OUT 1

Replenish

E4PA-LS50-M1

Ultrasonic Sensor

Large

cup

Medium

cup

Small

cup

Power supply*

Signal input

24-VDC power supply*

Electromagnetic relay

0 to 1 A

4 to 20 mA

K3FK CT Converter

K3GN-NDC

K3GN-NDC

OUT1 (Upper limit)

OUT1 (Upper limit)

OUT2 (Lower limit)

OUT2 (Lower limit)

E2E Proximity

Sensor

Page 13

1/32 DIN Digital Panel Meter K3GN K-19

Panel

indicators

Precautions

!WARNING

Do not touch any of the terminals while power is being supplied.

Doing so may result in electric shock. Also, do not touch the terminals with a screwdriver while power is being supplied. Electrical

shock may result via the screwdriver.

!Caution

Do not allow metal objects or conductive wire cuttings to enter the

product. Doing so may result in electric shock, fire, or malfunction.

!Caution

Do not attempt to disassemble, repair, or alter the product. Doing

so may result in electric shock, fire, or malfunction.

!Caution

Do not use the product where flammable or combustion gasses

are present.

!Caution

The lifetime of output relays varies greatly with the switching capacity and conditions. Consider the actual operating conditions,

and use the product within the rated load and electrical service life.

!Caution

Do not use loads exceeding the rated value. Doing so may result

in damage or burning.

!Caution

Use a power supply voltage within the specified ratings. Not doing

so may result in damage or burning.

!Caution

Be sure to tighten the terminal screws securely. The recommended tightening torque is 0.5 N·m. Loose screws may result in product failure or malfunction.

!Caution

Perform correct setting of the product according to the application.

Failure to do so may cause unexpected operation, resulting in

damage to the unit or injury.

!Caution

This product is not a safety device. Product failure may prevent operation of comparative outputs. Take safety measures, such as installing a separate monitoring system, to ensure safety and to

prevent serious accidents caused by such failure, thus ensuring

safety.

Observe the following precautions to ensure safety:

1. Do not connect anything to unused terminals.

2. Be sure to check each terminal for correct number and polarity

before connection. Incorrect or reverse connection may damage

or burn out internal components of the K3GN.

3. Do not use the product in locations subject to the following:

• Dust or explosive gasses (e.g., sulfide gas or ammonia gas).

• Condensation or icing as a result of high humidity.

• Outdoors or in direct sunlight.

• Splashing liquid or oil atmosphere.

• Direct radiant heat from heating equipment.

• Extreme changes in temperature.

4. Do not block heat dissipation around the product, i.e., provide suf-

ficient space for heat dissipation. Do not block the ventilation

holes on the back of the product.

5. Do not use paint thinner for cleaning. Use commercially available

alcohol.

6. Use a power supply meeting the power supply specifications of

the K3GN. Be sure that the rated voltage is achieved within 2 s

after turning ON the power.

7. Use the K3GN within the specified temperature and humidity

ranges. When installing the K3GN in a panel, be sure that the

temperature around the K3GN (not the temperature around the

panel) does not exceed 55°C. If the K3GN is subject to radiant

heat, be sure that the temperature of the surface of the K3GN

exposed to the radiant heat does not exceed 55°C by providing a

fan or other heat removal method.

8. Store the K3GN within the specified temperature and humidity

ranges.

9. Do not lay heavy objects on the product during use or storage.

Doing so may deform or deteriorate the K3GN.

10.Conduct aging for 15 minutes min. after power is ON for correct

measurement.

Mounting

Recommended panel thickness is 1 to 5 mm.

Insert the K3GN in the square cutout, insert the adapter from the

back, and push the K3GN into the cutout as far as possible. Use

screws to secure the K3GN. To make the K3GN waterproof, insert

watertight packing in the K3GN.

Install the watertight packing in the proper direction. Note that the

packing is direction-sensitive.

When gang-mounting two or more products in a cutout, be sure that

the ambient temperature does not exceed the specifications.

Mount the K3GN as horizontally as possible.

Separate the K3GN from machines generating high-frequency noise,

such as high-frequency welding machines and high-frequency sewing machines.

Operation

A K3GN model with a relay contact or transistor output may not output any alarm signal normally if the model has an error. It is recommended that an independent alarm device be connected to the

model.

The parameters are factory-set so that the K3GN will operate normally. The settings of the parameters may be changed according to

the application.

Wiring

Wire the power supply with the correct polarity. Wiring with incorrect

polarity may result in damage or burning.

Wire the terminals using crimp terminals.

Tighten terminal screws to a torque of approx. 0.5 N·m.

Wire signal lines and power lines separately to reduce the influence

of noise.

Use M3 crimp terminals of the type shown below.

5.8 mm max.

5.8 mm max.

Page 14

K-20 1/32 DIN Digital Panel Meter K3GN

Operating Procedures

■ Initial Settings

Specify set value of OUT 1 and 2.

Measurement starts.

Power ON

Press the Level Key @ for 3 s min. to move to the initial setting

level.

Select the input type and specify the analog input range or

pulse frequency input range.

Set the scaling values and specify output operating action as

required.

With communications output models, press the Level Key @ for

less than 1 s to move to the communications setting level.

After making communications settings, press the Level Key @

for less than 1 s to move to the initial setting level.

Move to the advanced function setting level and make settings

for average processing, HOLD/ZERO selection, hysteresis values, auto-zero time, startup compensation time, display color

programming, and other advanced function parameters as required.

Press the Level Key @ for less than 1 s min. to return to the

operation level.

Page 15

1/32 DIN Digital Panel Meter K3GN K-21

Panel

indicators

■ Levels

“Level” refers to a grouping of parameters. The following table lists the operations that are possible in each of the levels, and how to move between

levels. There are some parameters that are not displayed for certain models.

Note: The move to protection level time can be set in the advanced function setting level.

Level name Function Measurement

Protect Setting lockouts. Continue

Operation Displaying process values, setting/clearing forced-zero function, and

setting OUT 1/2 set values.

Continue

Adjustment Setting communications writing control. Continue

Initial setting Making initial settings of input type, scaling, output operating action,

and other parameters.

Stopped

Communications setting Setting baud rate, word length, and other communications data. Stopped

Advanced function setting Setting average processing, display color settings, and other ad-

vanced function parameters.

Stopped

Calibration Setting user calibration of the inputs. Stopped

+

+

-1234.5

Protection

Operation

Adjustment

Power ON

1 s min.

1 s min.

Initial setting

Password "−0169"

1 s min.

Calibration

Password "1201"

Continue to press the key for 2 s min.

Indicates change of level.

1 s min.

Less than 1 s

Less than 1 s

(see note)

Time set

by user

Flashing stops if key

is released.

Communications

setting

Advanced function

setting

Page 16

K-22 1/32 DIN Digital Panel Meter K3GN

■ Parameters

−

−

−

−

−

−

−

Adjustment level

Press Level Key for less than 1 s.

Power ON

Operation level

Set one

of these.

Set one

of these.

Process value

Note: 1. Some parameters are not displayed for certain models.

2. The K3GN will stop measurement if the level is changed to the initial setting level, the

advanced function setting level, the communications setting level, or the calibration

level.

3. If the input range is changed, some parameters are set to default values. Therefore,

set the input range first.

4. Settings displayed in reverse black/white are defaults.

Communications

writing

control

OUT1

set value

Upper-limit

OUT1 set

value

Lower-limit

OUT1 set

value

OUT2

set value

Upper-limit

OUT2 set

value

Lower-limit

OUT2 set

value

Monitor Status

Setting Status

Next parameter

The set value

flashes.

If there is no key operation for 5 seconds,

the setting is registered and the display

returns to monitor status.

Change the set

value using the

Up Key and

the Shift Key .

Changing Set Values

While parameters are being displayed, set values can be displayed

by pressing the Shift Key (monitor status).

Pressing the Shift Key again will make it possible for this set value

to be changed (setting status). The part that can be changed will

flash.

Change the set value as required, and press the Mode Key to register the setting and move to the next parameter.

Page 17

1/32 DIN Digital Panel Meter K3GN K-23

Panel

indicators

−

−

−

−

−

−

−

−

−

Press Level Key for less than 1 s.

For analog input

For pulse input

For pulse input

Press Level Key for more than 1 s.

Enter password "−0169"

Unit: times

Unit: s

Unit: s

Unit: s

Unit: ms

For pulse input

Input type

Analog

Pulse

Baud rate

Stop bits

Parity bits

None

Even

Odd

Initial setting level

Green (red)

Green

Red (green)

Red

Unit: Hz

Upper Limit

Lower Limit

Upper Limit

Lower Limit

Unit: s

For analog input

Enter password "1201"

Calibration level

Communications

setting level

Communications

unit no.

Word

length

Press Level Key

for more than 3 s.

Press Level

Key for

more than 1 s.

Remote

(digital

data display)

Analog

input

range

Input-pulse

frequency

range

For analog/

remote input

Input

value 1

for

scaling

Display

value 1

for

scaling

Input

value 2

for

scaling

Display

value 2 for

scaling

Input

value for

scaling

Display

value for

scaling

Decimal

point

position

Operating

Action for

OUT1 set

value

Operating

Action for

OUT2 set

value

Move to

advanced

function

setting level

Upper/Lower

Limits

Upper/Lower

Limits

Move to

calibration

level

Send

waiting

time

Move-toprotectlevel time

Display

Auto-return

time

Display

color

change

Startup

compensation

time

Auto-zero

time

OUT2

Hysteresis

OUT1

Hysteresis

For analog/

remote input

HOLD/

ZERO

selection

Average

processing

Parameter

initialization

Advanced function

setting level

−

−

−

−

−

−

−

−

−

− −

−

−

− −

Page 18

K-24 1/32 DIN Digital Panel Meter K3GN

Operation/Adjustment Lockouts

Prohibits key operations for operation level and adjustment level.

• Initial setting is 0.

• When the set value is 0 (the initial setting), protection is not set.

Setting Change Lockout

Prohibits setting changes.

• The initial setting is OFF.

Note: Changes to protection level parameters, moving to advanced

function setting level, and moving to calibration level are all allowed.

Initial Setting/Communications

Lockouts

Prohibits moving to the initial setting level, the communications setting level, and the advanced function setting level.

• The initial setting is 1.

Forced-zero shift Lockout

Prohibits the setting or clearing of a forced-zero using the front panel

key.

• The initial setting is OFF.

p

p

p

p

Protect level

Setting change lockout

• Prohibits setting changes using front panel keys.

Operation/adjustment

lockouts

Initial setting/communications lockouts

Forced-zero shift

lockout

• Prohibits menu display, writing, etc., for

operation level and adjustment level.

• Prohibits access to menu display, initial setting

level, communications setting level, and

advanced function setting level.

• Prohibits use of the forced-zero function using

front panel keys.

Setting Operation level Moving to

adjustment

level

Process value

display

Set value display

0 Allowed Allowed Allowed

1 Allowed Allowed Prohibited

2 Allowed Prohibited Prohibited

Setting Meaning

OFF Setting changes using front panel keys allowed (i.e., it is

possible to move to the state where changes to settings

can be made).

ON Setting changes using front panel keys prohibited (i.e., it

is not possible to move to the state where changes to

settings can be made).

Setting Moving to initial setting

level

Moving to

communications setting

level

0 Allowed (message for mov-

ing to advanced function

setting level displayed)

Allowed

1 Allowed (message for mov-

ing to advanced function

setting level not displayed)

Allowed

2 Prohibited Prohibited

Setting Meaning

OFF Executing and clearing of forced-zero allowed.

ON Executing and clearing of forced-zero prohibited.

Page 19

1/32 DIN Digital Panel Meter K3GN K-25

Panel

indicators

■ Troubleshooting

When an error occurs, error details will be displayed on the main display. Confirm the error from the main display and take the appropriate countermeasures.

Main display Level

display

Error contents Countermeasure

e111 (E111) Not lit RAM memory error Turn the power supply OFF and ON again. If the same error is displayed

even after the power is turned OFF and ON, it is necessary to replace

the memory. If normal operation is restored by turning the power supply

OFF and ON, it is possible that there is noise interference. Check that

there is nothing in the vicinity that may be the source of noise.

e111 (E111) 5 EEPROM memory

error

s.err (S.Err)

(Flashes at 0.5-s intervals)

Not lit Input error or input

range exceeded

All outputs turn OFF.

Check for incorrect input wiring, for disconnected power lines, for short-

circuiting, and the input type.

Bring the input value within range.

99999

(Flashes at 0.5-s intervals)

Not lit Greater than

displayable range

This is not an operational error. These messages are displayed when a

value to be displayed lies outside the displayable range, even if the input

value is within the input range and the range for which measurement is

possible.

Bring the input value and display value within range.

-19999

(Flashes at 0.5-s intervals)

Not lit Less than displayable

range

Page 20

K-26 1/32 DIN Digital Panel Meter K3GN

Additional Information

■ Application as a Process Meter

The initial settings required when using the K3GN a process meter are explained below using the following example.

Setting Example

Inputs in the range 1 to 5 V are scaled to the range 0 to 100.0 kg and

displayed. If the measurement value goes over 70.0 kg, output 1

turns ON. If the measurement value goes below 50.0 kg, output 2

turns ON.

Initial Setting Procedure

1. Check the wiring and turn ON the power.

2. Set analog input as the input type.

If a measurement value is displayed (operation level), move to the

initial setting level by holding down the Level Key for 3 s min.

Set parameter in-t to analg.

3. Set the analog range to 1 to 5 V.

Set parameter range to 1-5.

4. Set the scaling values.

Set parameter inp.1 to 1.000.

Set parameter dsp.1 to 0.

Set parameter inp.2 to 5.000.

Set parameter dsp.2 to 1000.

5. Set the position of the decimal point.

Set parameter dp to %%%%.%.

6. Operating action for OUT1 and OUT2 set values.

Set parameter out1.t to hi.

Set parameter out2.t to lo.

7. Set OUT1 set value to 70.0 and OUT2 set value to 50.0.

If an initial setting level parameter is displayed, press the Level

Key for 1 s min. to return to the operation level.

Set parameter out1 to 70.0.

Set parameter out2 to 50.0.

8.

Start actual operation.

■ Application as a Tachometer

The initial settings required when using the K3GN as a tachometer are explained below using the following example.

Setting Example

The speed of a conveyor belt is displayed in m/min units. For every

revolution of the shaft, 4 pulses are output. The diameter of the axis

of rotation is 12 cm. If the Rotational speed goes over 10.500 m/min,

output 1 turns ON. If the speed goes below 9.500 m/min, output 2

turns ON.

Deciding the Scaling Value

Rotational speed (m/min) = π × Diameter (m) × Revolutions per

minute (rpm)

Revolutions per minute (rpm) = Input frequency (Hz) ÷ Number of

pulses per revolution × 60

Applying the appropriate values to these 2 equations gives: Speed

(m/min) = 5.654866... × Input frequency (Hz)

Multiply by 1,000 to display the first 3 digits to the right of the decimal

point.

Speed (m/min) = 5654.866... × Input frequency (Hz)

100.0 kg

0.0 kg

1.000 V

5.000 V

50.0 kg

70.0 kg

Input value

Output 2 Output 1

Normal

Displayed

value

12 cm

Output

1

9.500

m/min

10.500

m/min

Normal

Output

2

56549

10 Hz Input value

Displayed

value

To limit inaccuracies due to scaling, select a round number

(e.g., 10) as the input value and select a display value of as

many digits as possible. In this example, scaling is performed

so that an input value of 10 gives a displayed value of 56549.

Page 21

1/32 DIN Digital Panel Meter K3GN K-27

Panel

indicators

Initial Setting Procedure

1. Check the wiring and turn ON the power.

2. Set pulse input as the input type.

If a measurement value is displayed (operation level), move to the

initial setting level by holding down the Level Key for 3 s min.

Set parameter in-t to pulse.

3. Set the pulse frequency to 30 Hz.

The input pulse frequency for the application is approximately

2 Hz and so can be assumed not to exceed 30 Hz. Set parameter

p-fre to 30.

4. Set the scaling values.

Set parameter inp to 10.

Set parameter dsp to 56549.

5. Set the decimal point.

Set parameter dp to %%.%%%.

6. Operating action for OUT1 and OUT2 set values.

Set parameter out1.t to hi.

Set parameter out2.t to lo.

7. Set OUT1 set value to 10.500 and OUT2 set value to 9.500.

If an initial setting level parameter is displayed, press the Level

Key for 1 s min. to return to the operation level.

Set parameter out1 to 10.500.

Set parameter out2 to 9.500.

8.

Start actual operation.

Page 22

K-28 1/32 DIN Digital Panel Meter K3GN

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. N101-E1-03

Loading...

Loading...