Page 1

Motor Contactor

J7KN

Main contactor

• AC & DC operated

• Integrated auxiliary contacts

• Screw fixing and snap fitting (35 mm DIN rail) up to 37 kW

• Range from 4 to 110 kW (AC 3, 380/415V)

• Finger proof (BGV A2)

• System contactors for Fuseless Load Feeders with integrated

link module

Accessories

• front mounted single pole additional auxiliary contacts

(1 NO or 1 NC)

• Side mounted additional auxiliary contacts (1 NO/1 NC)

• Mechanical interlock

• Suppressors (RC and varistor)

• Pneumatic timer modules

• Link modules MPCB - Motor contactor

Approved Standards

Standard Guide No (US,C)

UL NLDX, NLDX7

IEC 947-4-1 see page 95

VDE 0660

EN 60947-4-1

Motor Contactor J7KN 25

Page 2

Ordering Information

■ Model Number Legend

1. Motor Contactors

J7KN#-###-##-####

1324

1) Motor Contactor

2) G: DC solenoid motor contactor

3) Rated Motor Current (AC3 400V)

10: 10A

14: 14A

18: 18A

22: 22A

24: 24A

32: 32A

40: 40A

50: 50A

62: 62A

74: 74A

85: 85A

110: 110A

151: 150A

176: 175A

200: 200A

4) Integrated auxiliary contact

10: 1NO 0NC

01: 0NO 1NC

21: 2NO 1NC

22: 2NO 2NC

5) Coil voltage (AC operated)

24: AC24V 50/60Hz

48: AC48V 50Hz

90: AC100V 50/60 Hz

110: AC110V 50Hz, AC110-120V 60Hz

180: AC180-210V 50Hz, AC200-240V 60Hz

230: AC220-240V 50Hz, AC240V 60Hz

400: AC380-415V 50Hz, AC415-440V 60Hz

500: AC500-550V 50Hz, AC550-600V 60Hz

Coil voltage(DC operated)

24D: DC24V

48D: DC48V

110D: DC110V

125D: DC125V

Coil voltage(DC solenoid operated - G-type)

24D: DC24V

48D: DC48V

60D: DC60V

110D: DC110V

125D: DC125V

220D: DC220V

Coil voltage(AC & DC operated) for J7KN 151 & J7KN 176 only

24: 24V 50/60Hz, 24VDC

48: 48V 50/60Hz, 48VDC

110: 110-120V 50/60Hz, 110VDC

230: 220-240V 50/60Hz, 220VDC

400: 380-415V 50/60Hz

5

: 0NO 0NC

4: 4 main poles

2. Sytem Contactors for Fuseless Load Feeders with integrated

Link Module

J7KN-###-##-###-VK3

123

1) Additional reference for LVSG

2) Rated Motor Current (AC 3 400 V)

3) Integrated Auxiliary Contact

4) Coil voltage (AC operated)

5) Attached link module VK 3

3. Aux. Contact Modules for Motor Contactors

J73KN-#-##-#

123

1) Auxiliary Contact Modules

2) B: for motor contactor (4-37kW)

3) Combination of NO/NC contacts

4) S: side mounting for motor contactor (11-37kW and

4. Accessories for Motor Contactors

(Pneumatic Timers)

J74KN-#-## ### ##

123

1) Accessories for Motor Contactors

2) B: Motor Contactor (4-18.5kW)

3) TP: Pneumatic Timer

4) 40: 40 sec

5) DA: ON-delayed

5. Accessories for Motor Contactors (Mechanical Interlock)

J74KN-#-##

123

1) Accessories for Motor Contactors

2) B: Motor Contactor (4-18.5kW)

3) ML: Mechanical Interlock

45

10: 10 A

14: 14 A

18: 18 A

22: 22 A

10: 1NO 0NC

01: 0NO 1NC

24: AC24V 50/60Hz

48: AC48V 50Hz

110: AC110V 50Hz, AC110-120V 60Hz

180: AC180-210V 50Hz, AC200-240V 60Hz

230: AC220-240V 50Hz, AC240V 60Hz

400: AC380-415V 50Hz, AC415-440V 60Hz

500: AC500-550V 50Hz, AC550-600V 60Hz

4

C: for motor contactor (11-37kW)

D: for motor contactor (75-90kW)

E: for motor contactor (110kW)

10: 1NO 0NC

01: 0NO 1NC

11: 1NO 1NC

22: 2NO 2NC

75-90 kW)

: front mounting for motor contactor (4-37kW)

A: 6A version

F: front mounting for motor contactor (75-90kW)

U: EM and LB version

45

180: 180 sec

IA: OFF-delayed

C: Motor Contactor (11-37kW)

D: Motor Contactor (45-55kW)

E: Motor Contactor (75-90kW)

26 Motor Contactor J7KN

Page 3

6. Accessories for Motor Contactors (RC Suppressor units)

J74KN-#-## ###

123

1) Accessories for Motor Contactors

2) A: for Mini Motor Contactor and Motor Contactor

3) RC: RC-surge suppressors

4) 48: 24 - 48 VAC/DC (A+B type)

7. Accessories for Motor Contactors (4-37 kW) (Varistor units)

J74KN-#-## ###

123

1) Accessories for Motor Contactors

2) A: for Motor Contactor (4-11kW) to snap on

3) VG: Varistor Suppressors

4) 230: 110-230VAC/DC

8. Accessories for Motor Contactors

(Additional Terminals and Terminal Covers)

J7KN-#######

12

1) Accessories for Motor Contactors

2) LG-9030: for Motor Contactors (22-37 kW)

LG-11224: for Motor Contactors (75-90 kW)

LG-10404: for Motor Contactors (75-90 kW)

Marking Systems for contactors J7KNA - J7KN 74 and aux.

contact blocks J73KN-B

9. Insulated wiring systems for motor contactors

Parallel or reverse contactors

Star-Delta contactors

J75-WK-##

1 2 3

1) Additional reference for LVSG

2) Wiring system

3) Combination of 2 contactors, type:

21 = J7KN 10 - ..22

41 = J7KN 24 - ..40

4

(4-18.5kW)

(between DIN-rail and Contactor)

B: for Mini Motor Contactor and Motor Contactor

(4-55kW)

C: for Motor Contactor (4-37kW) to snap on the contactor

D: for Mini Motor Contactor (4-5.5kW)

230: 110 - 230 VAC/DC (A+B type)

400: 250 - 415 VAC/DC (A+B type)

24: 12 - 48 VAC/DC (C+D type)

110: 48 - 127 VAC/DC (C+D type)

230: 110 - 250 VAC/DC (C+D type)

4

to coil terminals

B: for Motor Contactor (4-37kW) to snap on to contactor

400: 250-415VAC/DC

Additional Terminal for Single Pole

Additional Terminal for Single Pole

Terminal Cover for 3 terminals

P487-1: Marking plate, 2-section without marking, divisible

P245-1: Marking plate, 4-section without marking, divisible

Star - delta combination of 3 contactors, type:

22 = J7KN 10 - ..22

Motor Contactor J7KN 27

Page 4

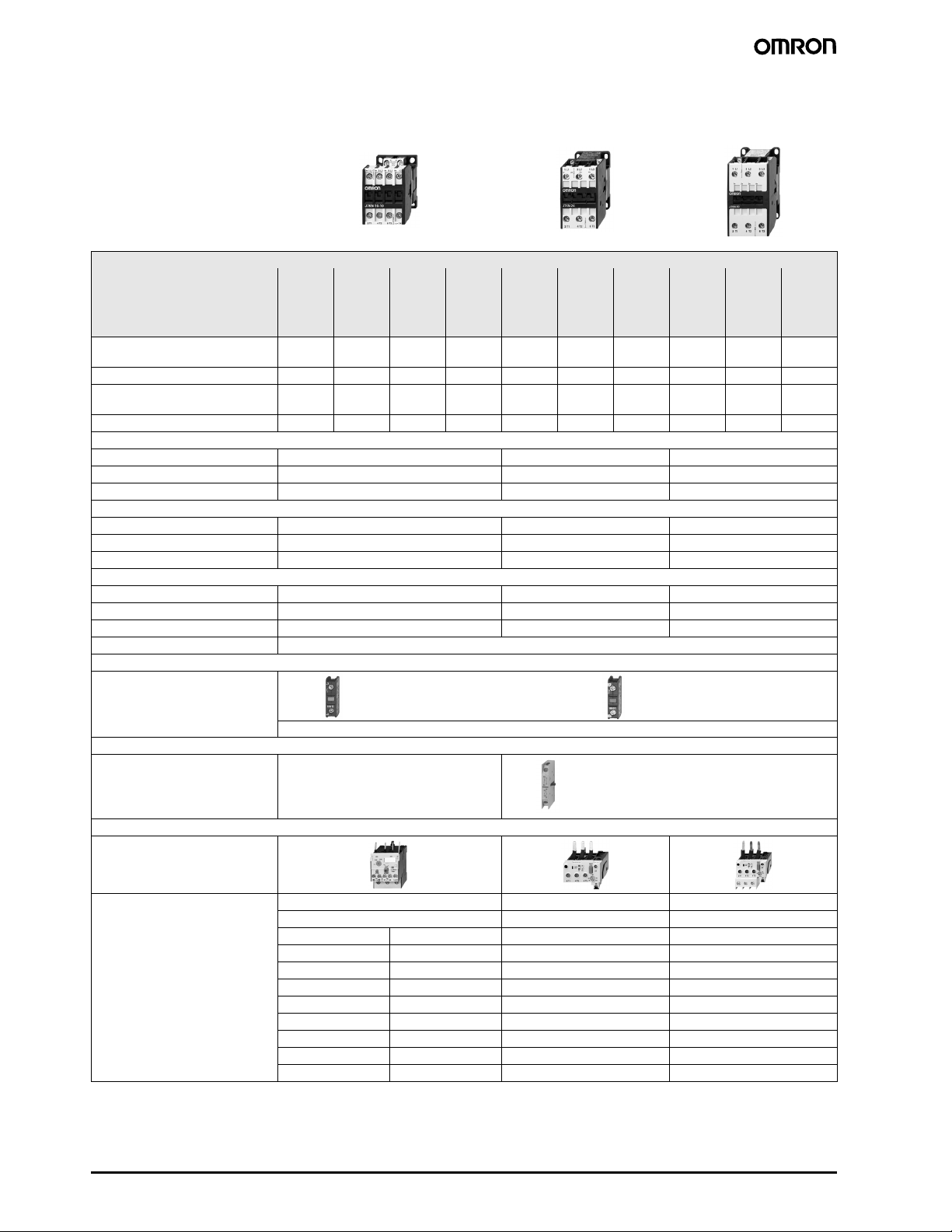

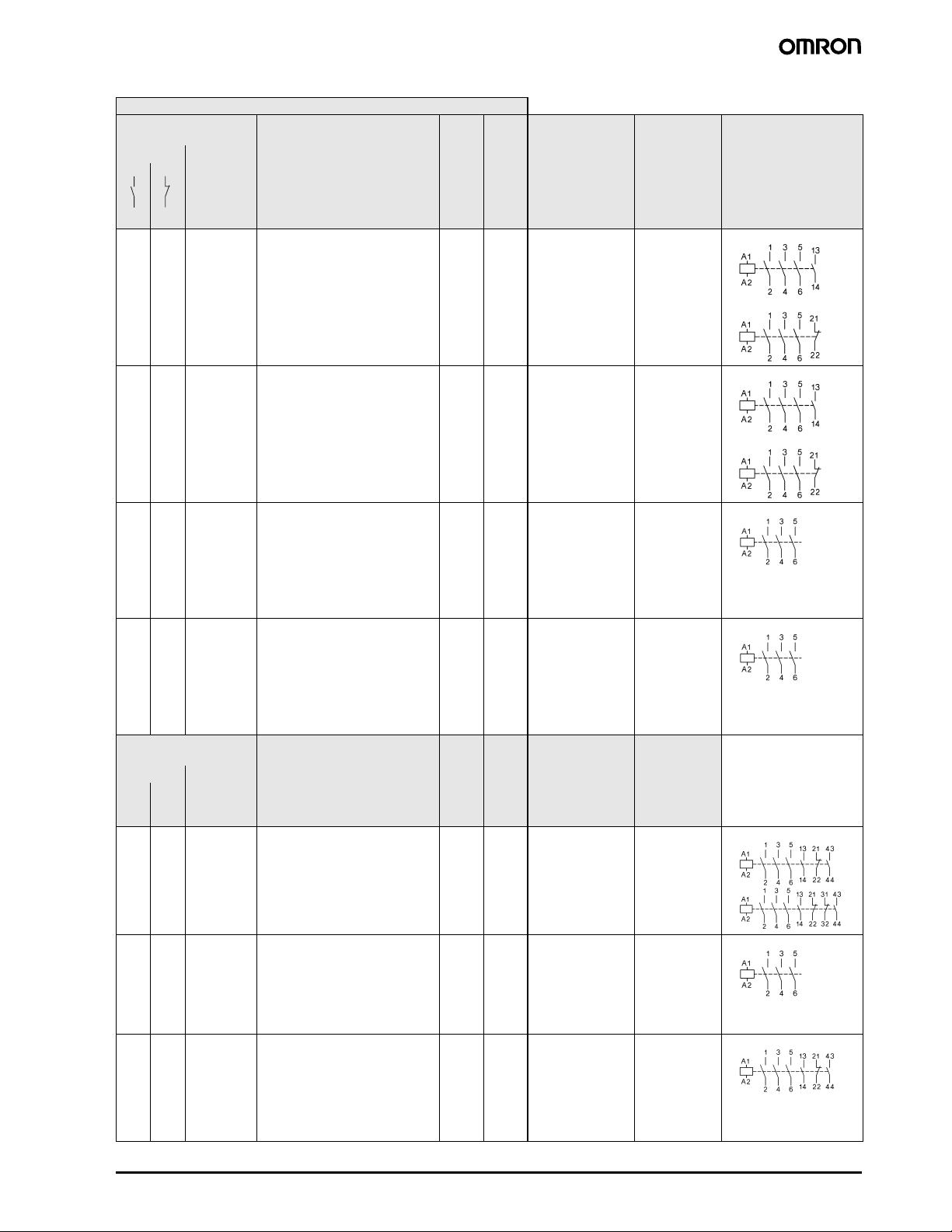

■ List of Models

Contactors 3-pole

• Up to 210A AC3

• Up to 350A AC1

• DIN-rail mounting up to AC3 74A

• International Approvals

• Data according to IEC 947 /

EN 60947

Ratings

AC3 400V Motor 10A 14A 18A 22A 24A 32A 40A 50A 62A 74A

380-400V 4kW 5,5kW 7,5kW 11kW 11kW 15kW 18,5kW 22kW 30kW 37kW

660-690V 5,5kW 7,5kW 10kW 10kW 15kW 18,5kW 18,5kW 30kW 37kW 45kW

AC1 690V at 40°C 25A 25A 32A 32A 50A 65A 80A 110A 120A 130A

Type J7KN-

Auxiliary contacts 1NO 1NO 1NO 1NO - - - - - -

Type J7KN-

Auxiliary contacts 1NC 1NC 1NC 1NC - - - - - -

Cable cross-section

Solid mm

Flexible mm

Cables per clamp 2 1 + 1 1 + 1

Auxiliary contact

I

th

AC15 230V A 12 - -

Power consumption of coils

Mounting 35mm DIN-rail or base

Additional aux. contact blocks

Front mounting

contact configuration 1NO 1NC

40°C A 16 - -

400V A 4 - -

Inrush VA 33 - 45 90 - 115 140 - 165

Hold VA 7 - 10 9 - 13 13 - 18

Operation range of coils 0,85 - 1,1 0,85 - 1,1 0,85 - 1,1

10-10

10-01

2

0,75 - 6 1,5 - 25 4 - 50

2

1 - 4 2,5 - 16 10 - 35

J7KN14-10

J7KN14-01

J7KN18-10

J7KN18-01

J7KN22-10

J7KN22-01

J7KN-24 J7KN-32 J7KN-40 J7KN-50 J7KN-62 J7KN-74

------

maximal 4 J73KN-B..

Additional aux. contact blocks

Side mounting contact configuration 1NO+1NC

Overload Relay (thermal)

Single phase protection

Temperature compensation

Trip and alarm contacts

Type J7TKN-B J7TKN-C J7TKN-D

Setting Ranges Setting Ranges Setting Ranges

0,12 - 0,18A 4 - 6A 28 - 42A 40 - 52A

0,18 - 0,27A 6 - 9A 52 - 65A

0,27 - 0,4A 8 - 11A 60 - 74A

0,4 - 0,6A 10 - 14A

0,6 - 0,9A 13 - 18A

0,8 - 1,2A 17 - 24A

1,2 - 1,8A 23 - 32A

1,8 - 2,7A

2,7 - 4A

28 Motor Contactor J7KN

Page 5

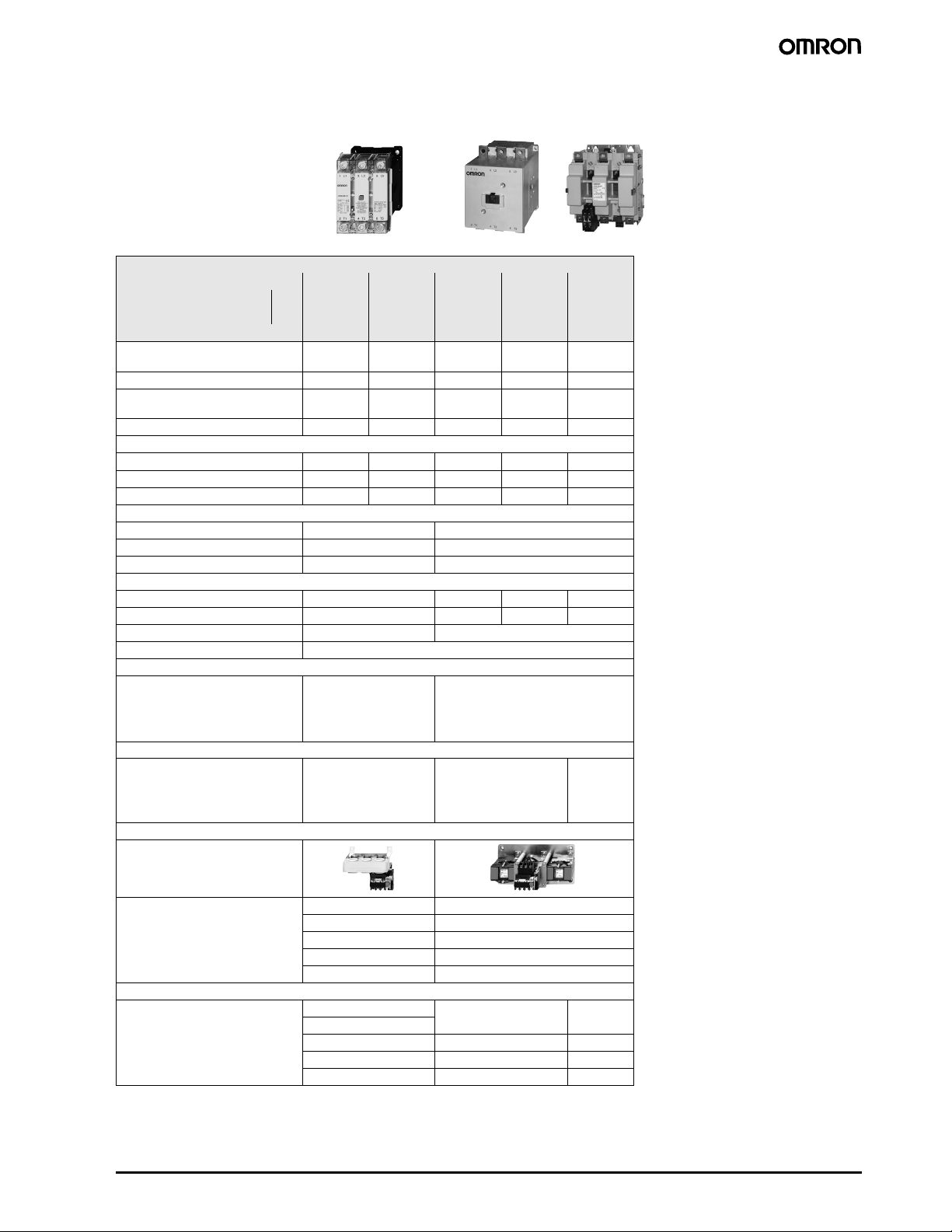

Ratings

AC3 400V Motor 85A 110A 150A 175A 210A

380-400V 45kW 55kW 75kW 90kW 110kW

660-690V 55kW 55kW 75kW 110kW 132kW

AC1 690V at 40°C 150A 170A 230A 250A 350A

Type J7KN-

Auxiliary contacts 2NO+2NC 2NO+2NC - - 2NO+1NC

Type -----

Auxiliary contacts -----

Cable cross-section

Solid mm

Flexible mm

Cables per clamp 11111

Auxiliary contact

I

th

AC15 230V A 12 3

Power consumption of coils

Mounting base

Additional aux. contact blocks

Front mounting - 2NO + 2NC

contact configuration

40°C A 16 10

400V A 6 2

Inrush VA 350 - 420 350 350 700

Operation range of coils 0,85 - 1,1 0,85 - 1,1

85-22

2

10 - 70 10 - 70 busbar busbar busbar

2

16 - 50 16 - 50 18x4 18x4 22x4

hold VA 23 - 29 5 5 20

J7KN110-22

J7KN-151 J7KN-176 J7KN-200-

21

Additional aux. contact blocks

Side mounting - 1NO + 1NC contact configuration

Overload Relay (thermal)

Single phase protection

Temperature compensation

Trip and alarm contacts

Type J7TKN-E J7TKN-F

Setting Ranges Setting Ranges

60 - 90A 100 - 150A

80 - 120A 140 - 220A

Busbar Sets

J74TK-SU-176 J74TK-SU-

200

Motor Contactor J7KN 29

Page 6

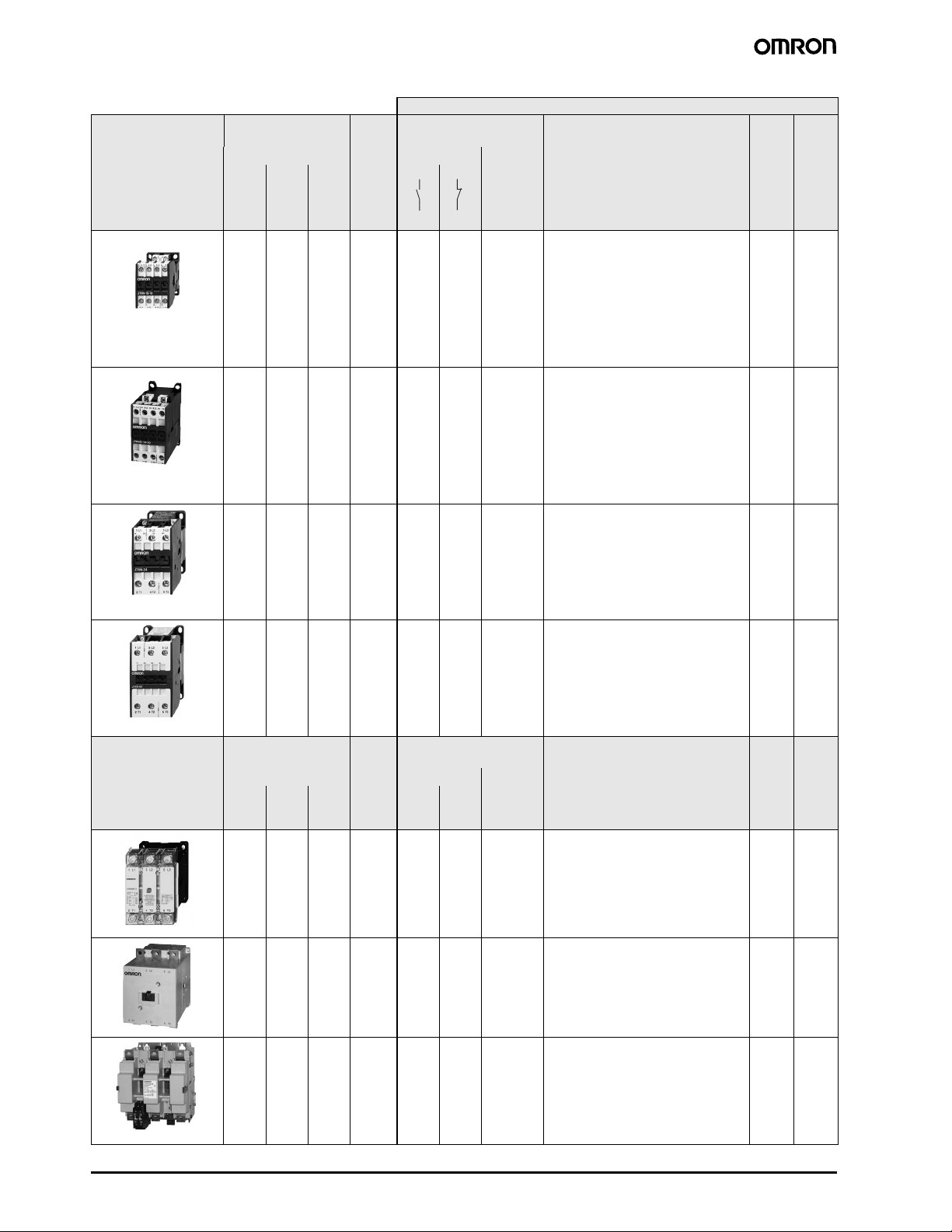

Contactors 3-pole

AC Operated

Ratings Rated

Aux. Contacts Type Pack Weight

Current

AC2, AC3 AC1 Built-in Additional

380V

500VkW660V

400V

690V

690V

see

page 33

415V

kW

4

4

5.5

5.5

7.5

7.5

11

11

4

4

5.5

5.5

7.5

7.5

11

11

11

15

18.5

5.5

5.5

7.5

7.5

10

10

10

10

5.5

5.5

7.5

7.5

10

10

10

10

15

18.5

18.5

kW

5.5

5.5

7.5

7.5

10

10

10

10

5.5

5.5

7.5

7.5

10

10

10

10

15

18

18.5

A

25

25

25

25

32

32

32

32

25

25

25

25

32

32

32

32

50

.5

65

80

NO NC

1

1

1

1

-

Ty p e

max. 4

J73KN-B

1

-

1

-

1

-

1

--- - --

-

-

max. 4

-

-

J73KN-B +

2 J73KNC-11S

.

Coil Voltage

*1

24 24V 50/60Hz

110 110V 50Hz

230 220-240V 50Hz

J7KN-10-10###

J7KN-10-01###

J7KN-14-10###

J7KN-14-01###

J7KN-18-10###

J7KN-18-01###

J7KN-22-10###

J7KN-22-01###

J7KN-24###

J7KN-32###

J7KN-40###

pcs.

1

1

1

1

1

1

1

1

1

1

1

kg/pc.

0.23

0.23

0.23

0.23

0.23

0.23

0.23

0.23

0.48

0.48

0.48

22

30

30

110

30

37

37

120

37

45

45

130

Ratings Rated

-

-

max. 4

-

-

J73KN-B +

2 J73KNC11S

-

-

J7KN-50###

J7KN-62###

J7KN-74###

Aux. Contacts Type Pack Weight

Current

AC2, AC3 AC1 Built-in

380V

500VkW660V

415V

kW

455555755555150

759075907590230

690V

kW

690V

A

17022

250--

NO NC

2

2

-

-

max. 3

1 x J73KND22F or

230 220-230V 50Hz

Coil Voltage

400 380-400V 50Hz

J7KN-85-22###

J7KN-110-22###

J7KN-151###

J7KN-176###

*2

*2

1 x J73KND11F and

2 x J73KND11S

110 132 132 350 2 1 J73KN-E-22J7KN-200-21###

1

0.85

1

0.85

1

0.85

*1

pcs. kg/pc.

1

1.8

1

1.9

1

4

1

4

*2

17.3

*1

Coil voltage range and other coil voltages see page 36

*2

AC and DC in one coil

30 Motor Contactor J7KN

Page 7

DC Operated

Aux. Contacts

see page 33

Built-in Additional 24

NO NC Ty p e pcs kg/pc. Ty pe Ty p e

max. 3

-

1

1

1

1

-

1

1

1

1

-

-

-

-

-

-

-

1

1

1

1

1

1

1

1

-

-

-

-

-

-

J73KN-B

max. 4

J73KN-B

max

. 3

J73KN-B

+

2 J73KNC-11S

Typ e Coil voltage Pack Weight Accept Overload

Relay

J7KN-10-10###D

*1

J7KN-10-01###D

J7KN-14-10###D

J7KN-14-01###D

J7KN-18-10###D

J7KN-18-01###D

J7KN-22-10###D

J7KN-22-01###D

J7KNG-10-10###D

J7KNG-10-01###D

J7KNG-14-10###D

J7KNG-14-01###D

J7KNG-18-10###D

J7KNG-18-01###D

J7KNG-22-10###D

J7KNG-22-01###D

J7KN-24###D

*1

J7KNG-24###D

J7KN-32###D

J7KNG-32###D

J7KN-40###D

J7KNG-40###D

48

60

110

125

220

24V DC

48V DC

60V DC

110V DC

125V DC

220V DC

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

page 56 page 57

J7TKN-B -

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

J7TKN-B -

0.53

0.53

0.53

0.53

0.53

0.53

0.53

0.53

0.55

J7TKN-B

J7TKN-C

0.57

0.55

0.57

0.55

0.57

Busbar Set for

Overload Relay

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Wiring Diagram

Coil Circuits see page 35

Terminal Markings

-10

-01

-10

-01

-

-

max. 3

-

-

J73KN-B

+

2 J73KN-

-

-

J7KN-50###D

*1

J7KN-62###D

J7KN-74###D

1

0.9

J7TKN-D

1

0.9

1

0.9

C-11S

Aux. Contacts Typ e Coil voltage Weight Accept Overload

Relay

Busbar Set for

Overload Relay

Built-in page 56 page 57

110

NO NC

2211-

-

--max. 3

1 x J73KND22 or

J7KN-85-21###D

J7KN-110-21###D

J7KN-151-###

J7KN-176-###

*2

*2

220

110V DC

220V DC

kg/pc. Ty p e Ty pe

1

1.8

J7TKN-E -21/-22

1

1.9

1

4

J7TKN-F

1

4

J7TKN-F

J73TK-SU-176

1 x J73KND11 and

2 x J73KND11S

21 J7KN-200-21###

*2

1 7.3 J7TKN-F J73TK-SU-200 -21

*1

Only 3 additional Aux. Contacts are possible! (See also the wiring diagrammms coil circuit DC operated page 35)

*2

AC and DC in one coil

Motor Contactor J7KN 31

Page 8

System Contactors for Fuseless Load Feeders with integrated Link Module (see page 72)

AC Operated

Ratings Rated

AC2, AC3 AC1 Built-in Additional

380V

500VkW660V

400V

415V

kW

4

5.5

7.5

11

*1

Coil voltage range and other coil voltages see page 36

5.5

7.5

10

10

690V

kW

5.5

7.5

10

10

Contactors 4-pole

AC Operated

Ratings Rated

AC2,

AC3

380V

400V

415V

kW

4

5.5

7.5

11

AC1 AC1

400VkW690V

17.5

17.5

22

22

Current

A

25

25

32

32

Current

690V

A

25

25

32

32

Aux. Contacts Type Pack Weight

*1

pcs. kg/pc.

1

1

1

1

*1

pcs. kg/pc.

1

1

1

1

NO NC

1

-

1

-

1

-

1

-

Aux. Contacts

see page 33

Built-in

NO NC

-

-

-

-

-

-

-

-

see

page 33

Ty p e

max. 4

J73KN-B

Additional

see

below

Ty p e

max. 4

J73KN-B

24 24V 50/60Hz

Coil Voltage

110 110V 50Hz

230 220-240V 50Hz

J7KN-10-10 ###-VK3

J7KN-14-10 ###-VK3

J7KN-18-10 ###-VK3

J7KN-22-10 ###-VK3

Typ e Pack Weight

Coil Voltage

24 24V 50/60Hz

110 110V 50Hz

230 220-240V 50Hz

J7KN-10-4 ###

J7KN-14-4 ###

J7KN-18-4 ###

J7KN-22-4 ###

0.25

0.25

0.25

0.25

0.22

0.22

0.22

0.22

75

90

*1

Coil voltage range and other coil voltages see page 36

159

173

230

250

DC Operated

Ratings Rated

AC2,

AC3

380V

400V

415V

kW

4

5.5

7.5

11

*1

Coil voltage range and other coil voltages see page 36

AC1 AC1

400VkW690V

17.5

17.5

22

22

Current

A

25

25

32

32

-

-

-

-

Aux. Contacts

see page 33

Built-in

NO NC

-

-

-

-

-

-

-

-

max. 3

J73KN-D-11F

J73KN-D-22F

J73KN-D-11S

Additional

see

below

Ty p e

max. 4

J73KN-B

J7KN-151-4 ###

J7KN-176-4 ###

Typ e Pack Weight

Coil Voltage

24 24V 50/60Hz

110 110V 50Hz

230 220-240V 50Hz

J7KNG-10-4 ###D

J7KNG-14-4 ###D

J7KNG-18-4 ###D

J7KNG-22-4 ###D

*1

1

4.7

1

4.7

pcs. kg/pc.

1

0.53

1

0.53

1

0.53

1

0.53

32 Motor Contactor J7KN

Page 9

10

10

10

10

10

10

*1

0.02

0.02

0.02

0.02

0.02

0.02

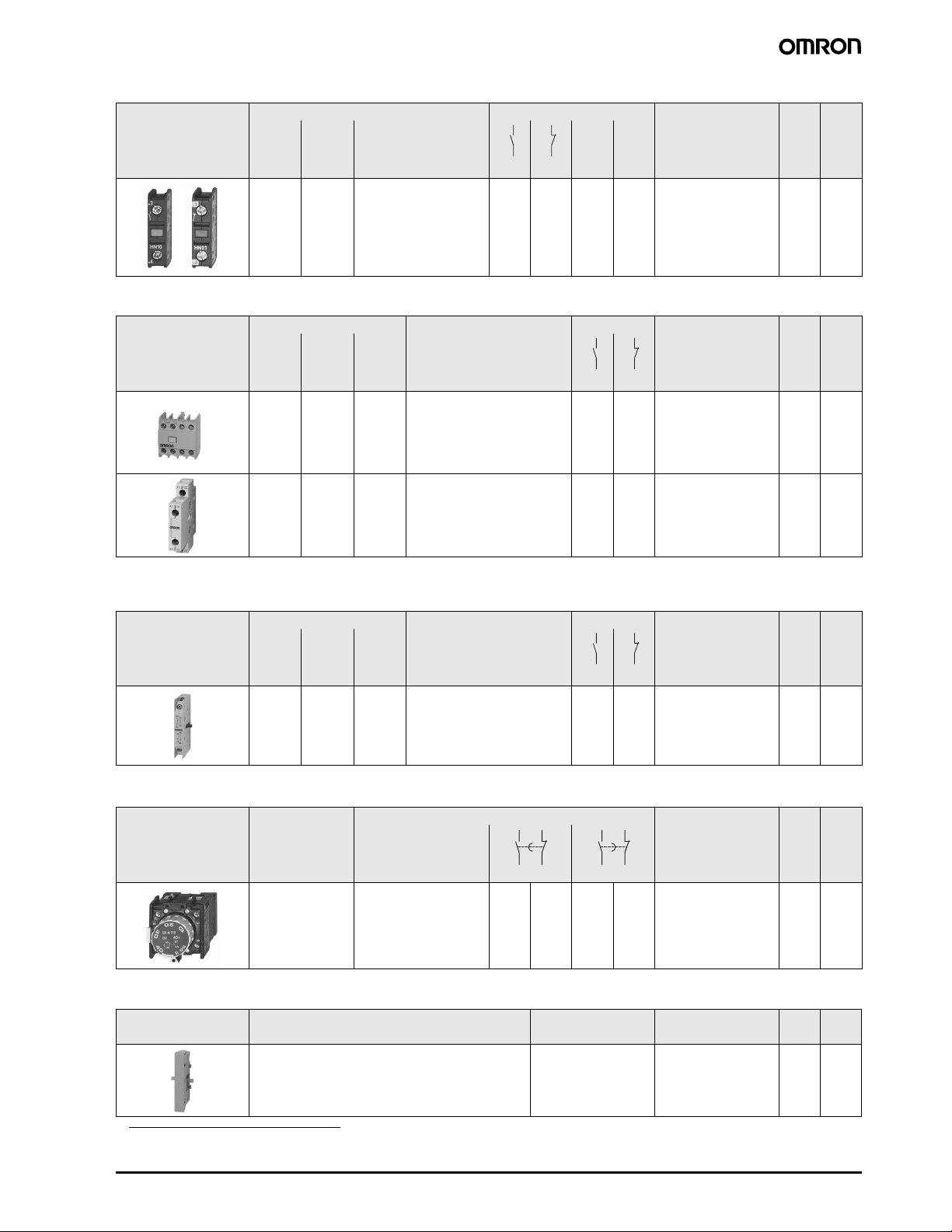

Auxiliary Contact Blocks for contactors J7KN-10... to -74... type J73KN for low level switching

Front mounting Rated Operational Current Contacts Ty p e Pack Weig ht

AC15

230V

A A A NO NC pcs. kg/pc.

3

3

3

3

6

6

AC15

400V

2

2

2

2

4

4

AC1

690V

10

10

10

10

25

25

EM LB

J73KN-B-10

-

-

-

1

J73KN-B-01

-

-

1

-

J73KN-B-10U

-

1

-

-

J73KN-B-01U

1

-

-

-

J73KN-B-10A

-

-

-

1

J73KN-B-01A

-

-

1

-

Auxiliary Contact Blocks for contactors J7KN-151... to 176... type J73KN for low level switching

Rated Operational Current Contacts Ty p e Pack Weight

AC15

230V

A A A Mounting NO NC pcs. kg/pc.

3

3

3 2 10 side 1 1 J73KN-D-11S 10.12

AC15

400V

2

2

AC1

690V

10

10

front 1

1

J73KN-D-11F

2

2

J73KN-D-22F

1

0.08

1

0.08

Auxiliary Contact Blocks

for contactors J7KN-24... to KN-74 and J7KN-200... type J73KN for low level switching

Rated Operational Current Contacts Ty p e Pack Weight

AC15

230V

A A A Mounting NO NC pcs. kg/pc.

3

3

AC15

400V

2

2

AC1

690V

10

10

max. 2 side mounting

(J7KN-24-74)

max. 2 front mounting

(J7KN-200)

1

1

J73KN-C-11S

2

2

J73KN-E-22

Pneumatic Timer for contactors J7KN-10... to -40...

Function Time range Contacts Ty pe Pack Weight

s pcs. kg/pc.

NO NC NO NC

On-delay 0.1 - 40 1 1 - - J74KN-B-TP40DA 10.09

On-delay 10 - 180 1 1 - - J74KN-B-TP180DA 10.09

Off-delay 0.1 - 40 - - 1 1 J74KN-B-TP40IA 10.09

Off-delay 10 - 180 - - 1 1 J74KN-B-TP180IA 10.09

Mechanical Interlocks

Interlocks contactor with contactor Mounting Ty pe Pack Weight

Ty p e + Ty p e pcs. kg/pc.

J7KN10 - J7KN40 + J7KN10 - J7KN40 horizontal J74KN-B-ML 1 0.006

J7KN24 - J7KN74 + J7KN24 - J7KN74 horizontal J74KN-C-ML 1 0.010

J7KN85 - J7KN110 + J7KN85 - J7KN110 horizontal J74KN-D-ML 1 0.076

J7KN151 - J7KN176 + J7KN151 - J7KN176 horizontal J74KN-E-ML 1 0.076

1010.02

0.12

1. suitable according to DIN 19240 (test ratings 17V DC, 5mA) Technical data see page 49

Motor Contactor J7KN 33

Page 10

Suppressor Units

Var isto r

snap on coil

terminals

Var isto r

snap on top of

contactor

RC-Unit

snap on

contactor

RC-Unit

snap on

contactor

RC-Unit

to fix via

fixing band or

adhesive strip

with contactor

Suitable for Contactors Suitable for Coil Voltages Ty p e Pack

J7KNA

J7KN10-J7KN22

J7KN10-J7KN74 110 - 230 V AC/DC

J7KNA 12 - 48 V AC/DC

J7KN10-J7KN74 12 - 48 V AC/DC

J7KN85-J7KN110 24 - 48 V AC/DC

110 - 230 V AC/DC

250 - 415 V AC/DC

250 - 415 V AC/DC

48 - 127 V AC/DC

110 - 230 V AC/DC

48 - 127 V AC/DC

110 - 230 V AC/DC

110- 250 V AC/DC

250 - 415 V AC/DC

J74KN-A-VG230

J74KN-A-VG400

J74KN-B-VG230

J74KN-B-VG400

J74KN-D-RC24

J74KN-D-RC110

J74KN-D-RC230

J74KN-C-RC24

J74KN-C-RC110

J74KN-C-RC230

J74KN-B-RC48

J74KN-B-RC230

J74KN-B-RC400

pcs.

10100.01

10100.02

10

10

10

10

10

10

5

5

5

Weight

kg/pc.

0.01

0.02

0.02

0.036

0.036

0.02

0.036

0.036

0.04

0.04

0.04

Additional Terminals Single Pole

For Contactors Cable Cross-sections to clamp mm² Ty pe Pack Weight

solid or

stranded

J7KN50 - KN74 4 - 35 6 - 25 4 - 25 J74KN-LG-9030 1 0.052

J7KN151 - KN176 16 - 120 --- 16 - 95 J74KN-LG-11224

flexible flex. with multi-

core cable end

Terminal Covers for terminal protection according DIN 57106, BVG-A2

For Contactors Specification Ty p e Pack Weight

J7KN151 - KN176 one unit J74KN-LG-10404 10.12

Marking Systems for contactors J7KNA to J7KN74 and aux. contact blocks J73KN-B

Description Specification Ty pe Pack Weight

Marking Plate 2-section without marking, divisible J74KN-P487-1 100 0.025

Marking Plate 4-section without marking, divisible J74KN-P245-1 100 0.050

pcs. kg/pc.

pcs. kg/pc.

pcs. kg/pc.

34 Motor Contactor J7KN

Page 11

Insulated wiring systems for motor contactors

Description Versio n

For reversing or parallel

contactors ( 2 parts )

(A)

25 J7KN 10 - 22 J75-WK-21 1

40 J7KN 24 - 40 J75-WK-41 1

For contactors Type Pack

pcs

For star-delta combination

(3 parts)

25 J7KN 10 - 22 J75-WK-22 1

■ Wiring Diagrams Coil Circuit

AC operated DC operated

J7KN-10...

to

J7KN-110...

with double winding coil*

J7KN-10...D

to

J7KN-22...D

J7KN-24...D

to

J7KN-74...D

J7KN-110...D

J7KNG

A1+

1

AC and DC operated

J7KN-151...

to

J7KN-176...

J7KN-200-21

~/

A1

A2~/

~

-

+

~

L1 L2

31

32

A2-

*1) 3 Additional Aux. Contacts are possible with the J7KN-.....D

types! (See also page 31)

Motor Contactor J7KN 35

Page 12

Specifications

■ Coil Voltages

Type-suffix for contactor types J7KN-10... to J7KN-74...

Suffix

to contactor

type e.g.

J7KN-10-10-24 for 50HzVfor 60 HzVmin Vmax Vmin Vmax

24 24 24 22 24 24 27

48 48 48 44 48 48 52

110 110 110-120 100 110 110 122

180 180-210 200-240 180 210 200 240

230 220-240 240 220 240 240 264

400 380-415 415-440 380 415 415 460

500 500-550 550-600 500 550 550 600

Standard voltages in bold type letter

Type-suffix for contactor types J7KN-85... to J7KN-110...

Suffix

to contactor

type e.g.

J7KN-85-22-24 for 50HzVfor 60 HzVmin Vmax Vmin Vmax

20 20 24 20 22 24 26

24 24 24 27 29 32

48 48 60 47 52 56 62

90 90 110-120 90 100 108 120

110 110-120 110 122 132 146

180 180-200 208-240 180 200 208 240

230 220-240 277 220 240 264 288

400 380-415 460-480 380 415 455 498

500 500-550 600-660 500 550 600 660

Standard voltages in bold type letter

Voltage Marking Rated Control Voltage U

at the coil range for

50Hz

Voltage Marking Rated Control Voltage U

at the coil range for

50Hz

60Hz

60Hz

s

V

s

V

Type-suffix for contactor types J7KN-151... to J7KN-200...

Suffix Voltage Marking Rated Control Voltage U

to contactor

type e.g.

J7KN-151-230 for 50 HzVfor 60 HzVmin Vmax Vmin Vmax Vmax

24 24 24 24 24 24 24 24

48 48 48 48 48 48 48 48

110 110 120 110 120 110 120 110

230 220-240 220-240 220 240 220 240 220

400 380-415 380-415 380 415 380 415 -

Standard voltages in bold type letter

at the coil range for

50Hz

60Hz DC

s

V

36 Motor Contactor J7KN

Page 13

■ Engineering data and characteristics

Approximate Values for three-phase Motors

Motor Full Load Currents

Approximate values of motor F.L.C. and minimum „slow blow“ respectively „gL“ short-circuit fuse

Motor rating 220-230V Motor 240V Motor 380-400V Motor 415V Motor 500V Motor 660-690V Motor

Range according to BS for 415V Value of fusing at

kW PS~hp hp cos %

0.06 0.08 - 0.7 59 0.38 1 1 0.35 1 1 0. 22 11- - -0.1611- - -

0.09 0.12 - 0.7 60 0.55 2 2 0.5 2 2 0.33 11- - -0.2411- - -

0.12 0.16 - 0.7 61 0.76 2 2 0.68 2 2 0. 42 22- - -0.3311- - -

0.18 0.24 - 0.7 61 1.1 2 2 1 2 2 0.64 22- - -0.4611- - -

0.25 0.34 - 0.7 62 1.4 4 2 1.38 4 2 0. 88 22- - -0.5922- - -

0.37 0.5 - 0.72 64 2.1 4 4 1.93 4 4 1.22 4 2 - - - 0.85 2 2 0.7 2 2

0.55 0.75 - 0.75 69 2.7 4 4 2.3 4 4 1.5 42- - -1.24 20.922

0.75 1 1 0.8 74 3.3 6 4 3.1 6 4 2 4 4 2 4 4 1.48 4 2 1.1 2 2

1.1 1.5 1.5 0.83 77 4.9 10 6 4.1 6 6 2. 6 442.5442.1441.542

1.5 2 2 0.83 78 6.2 10 10 5.6 10 10 3.5 643.5642.64 42 44

2.2 3 3 0.83 81 8.7 16 10 7.9 16 10 5 10 6 5 10 6 3.8 6 6 2.9 6 4

2.5 3.4 - 0.83 81 9.8 16 16 8.9 16 10 5.7 10 10 - - - 4.3 6 6 - - -

3 4 4 0.848111.620 1610.620 16 6.6 16 10 6.5 16 10 5.1 10 10 3.5 6 4

3.75 5 0.848214.225 2013 25 16 8.2 16 10 7.5 16 10 6.2 16 10 - - -

4 5.5 - 0.84 82 15.3 25 20 14 25 20 8.5 16 10 - - - 6.5 16 10 4.9 10 6

5.5 7.5 7.5 0.85 83 20.6 35 25 18.9 35 25 11.5 20 16 11 20 16 8.9 16 10 6.7 16 10

7.51010 0.868527.4353524.8353515.5 25 20 14 25 16 11.9 20 16 9 16 10

8 11 - 0.86 85 28.8 50 35 26.4 35 35 16.7 25 20 - - - 12.7 20 16 - - -

11 15 15 0.86 87 39.2 63 50 35.3 50 50 22 35 25 21 35 25 16.7 25 20 13 25 16

12.5 17 - 0.86 87 43.8 63 50 40.2 63 50 25 35 35 - - - 19 35 25 - - -

15 20 20 0.86 87 52.6 80 63 48.2 80 63 30 50 35 28 35 35 22.5 35 25 17.5 25 20

18.5 25 25 0. 86 88 64.9 100 80 58.7 80 63 37 63 50 35 50 50 28.5 50 35 21 35 25

20 27 - 0.86 88 69.3 100 80 63.4 80 80 40 63 50 - - - 30.6 50 35 - - -

22 30 30 0.87 89 75.2 100 80 68 100 80 44 63 50 40 63 50 33 50 50 25 35 35

25 34 - 0.87 89 84.4 125 100 77.2 100 100 50 80 63 - - - 38 63 50 - - -

30 40 40 0.87 90 101 125 125 92.7 125 100 60 80 63 55 80 63 44 63 50 33 50 35

37 50 50 0.87 90 124 160 160 114 160 125 72 100 80 66 100 80 54 80 63 42 63 50

40 54 - 0.87 90 134 160 160 123 160 160 79 100 100 - - - 60 80 63 - - -

45 60 60 0.88 91 150 200 160 136 200 160 85 125 100 80 100 100 64.5 1 00 80 49 63 63

51 70 - 0.88 91 168 200 200 154 200 200 97 125 100 - - - 73.7 100 80 - - -

55 75 - 0.88 91 181 250 200 166 200 200 10 5 160 125 - - - 79 125 100 60 80 63

59 80 80 0.88 91 194 250 250 178 250 200 112 160 125 105 160 125 85.3 125 100 - - -

75 100 100 0.88 91 245 315 250 226 315 250 140 200 160 135 200 160 106 160 125 82 125 100

90 125 125 0.88 92 292 400 315 268 315 315 170 250 200 165 200 200 128 160 160 98 125 125

110 150 150 0.88 92 358 500 400 327 400 400 205 250 250 200 250 250 156 200 200 118 160 125

129 175 175 0.88 92 420 500 500 384 500 400 242 315 250 230 315 250 184 250 200 - - -

132 180 - 0.88 92 425 500 500 393 500 500 245 315 250 - - - 186 250 200 140 200 160

147 200 200 0.88 93 472 630 630 432 630 500 273 315 315 260 315 315 207 250 250 - - -

160 220 - 0.88 93 502 630 630 471 630 630 295 400 315 - - - 220 315 250 170 200 200

184 250 250 0.88 93 590 800 630 541 630 630 340 400 400 325 400 400 259 315 315 - - -

200 270 - 0.88 93 626 800 800 589 800 630 370 500 400 - - - 278 315 315 215 250 250

220 300 300 0.88 93 700 1000 800 647 800 800 408 500 500 385 500 400 310 400 400 - - -

250 340 - 0.88 93 803 1000 1000 736 1000 800 460 630 500 - - - 353 500 400 268 315 315

257 350 350 0.88 93 826 1000 1000 756 1000 800 475 630 630 450 630 500 363 500 400 - - -

295 400 400 0.88 93 948 1250 1000 868 1000 1000 546 800 630 500 630 630 416 500 500 - - -

315 430 - 0.88 93 990 1250 1250 927 1250 1000 580 800 630 - - - 445 630 500 337 400 400

355 483 - 0.89 95 - - - - - - 636 800 800 - - - 483 630 630 366 500 400

400 545 - 0.89 96 - - - - - - 710 1000 800 - - - 538 630 630 410 500 500

The motor F.L.C. be valid for standard internal and surface cooled three-pole

motors with 1500 min

the table and D.O.L.-start: starting current max. 6x motor F.L.C., starting time

max. 5s; star-delta-start: starting current max. 2x motor F.L.C., starting time

max. 15s. For motors with higher F.L.C., higher starting current and / or longer

starting time, larger short-circuit fuses are required.

-1

. The fuses values be valid for the motor F.L.C. shown in

motor start

F. L . C .AD.O. L.AYDAF. L . C .AD.O. L.AYDAF. L . C .AD.O. L.AYDAF. L . C .AD.O.L .AYDAF. L . C .AD.O. L.AYDAF. L . C .AD.O. L.AYD

The maximum admissible value is dependent on the switchgear

respectively thermal overload relay.

Value of fusing at

motor start

Value of fusing at

motor start

Value of fusing at

motor start

Value of fusing at

motor start

Value of fusing at

motor start

A

Motor Contactor J7KN 37

Page 14

Approximate values of motor F.L.C. according to CSA and UL

Motor

rating

hp A A A A A A A A A A A A

*1

Motor F.L.C. at 110-120V Motor F.L.C. at 220-240V

1-phase 2-phase 3-phase 1-phase 2-phase 3-phase 1-phase 2-phase 3-phase 1-phase 2-phase 3-phase

½ 9.8 4.0 4.4 4.9 2.0 2.2 2.5 1.0 1.1 2.0 0.8 0.9

¾ 13.8 4.8 6.4 6.9 2.4 3.2 3.5 1.2 1.6 2.8 1.0 1.3

1 16.0 6.4 8.4 8.0 3.2 4.2 4.0 1.6 2.1 3.2 1.3 1.7

1½ 20.0 9.0 12.0 10.0 4.5 6.0 5.0 2.3 3.0 4.0 1.8 2.4

2 24.0 11.8 13.6 12.0 5.9 6.8 6.0 3.0 3.4 4.8 2.4 2.7

3 34.0 16.6 19.2 17.0 8.3 9.6 8.5 4.2 4.8 6.8 3.3 3.9

5 56.0 26.4 30.4 28.0 13.2 15.2 14.0 6.6 7.6 11.2 5.3 6.1

7½ 80.0 38.0 44.0 40.0 19.0 22.0 21.0 9.0 11.0 16.0 8.0 9.0

10 100.0 48.0 56.0 50.0 24.0 28.0 26.0 12.0 14.0 20.0 10.0 11.0

15 135.0 72.0 84.0 68.0 36.0 42.0 34.0 18.0 21.0 27.0 14.0 17.0

20 - 94.0 108.0 88.0 47.0 54.0 44.0 23.0 27.0 35.0 19.0 22.0

25 - 118.0 136.0 110.0 59.0 68.0 55.0 29.0 34.0 44.0 24.0 27.0

30 - 138.0 160.0 136.0 69.0 80.0 68.0 35.0 40.0 54.0 28.0 32.0

40 - 180.0 208.0 176.0 90.0 104.0 88.0 45.0 52.0 70.0 36.0 41.0

50 - 226.0 260.0 216.0 113.0 130.0 108.0 56.0 65.0 86.0 45.0 52.0

60 - - - - 133.0 145.0 - 67.0 77.0 - 53.0 62.0

75 - - - - 166.0 192.0 - 83.0 96.0 - 66.0 77.0

100 - - - - 218.0 248.0 - 109.0 124.0 - 87.0 99.0

125-----312.0-135.0 156.0 - 108.0 125.0

150-----360.0-156.0 180.0 - 125.0 144.0

200-----480.0-208.0 240.0 - 167.0 192.0

250-----602.0--302.0 - - 242.0

300--------361.0 - - 289.0

350--------414.0 - - 336.0

400--------477.0 - - 382.0

500--------590.0 - - 472.0

Determine the motor current for 200V and 208V by increasing the values for 220-240V at 200V about 15% and for 208V about 10%.

*1

Motor F.L.C. at 440-480V Motor F.L.C. at 550-600V

38 Motor Contactor J7KN

Page 15

Contactors

Data according to IEC 947-4-1, EN 60947-4-1, VDE 0660

Main Contacts Type J7KN-10 J7KN-14 J7KN-18 J7KN-22 J7KN-24 J7KN-3 2 J7KN-40 J7 KN-50 J7KN-62 J7 KN-74

Rated insulation voltage U

Making capacity I

Breaking capacity I

J7KN-10 to J7KN-22 cosϕ = 0,65 500V AC A 150 150 180 180 300 370 370 500 700 700

J7KN-24 to J7KN-72 cosϕ = 0,35 690V AC A 100 100 150 150 260 340 340 400 500 500

Utilization category AC1

Switching of resistive load

Rated operational current I

Rated operational power

of three-phase resistive loads

50-60Hz, cosϕ = 1

Rated operational current Ie (=I

Rated operational power

of three-phase resistive loads

50-60Hz, cosϕ = 1

Minimum cross-section of conductor

at load with I

Utilization category AC2 and AC3

Switching of three-phase motors

Rated operational current I

open and enclosed

Rated operational power

of three-phase motors

50-60Hz

Utilization category AC4

Switching of squirrel cage motors, inching

Rated operational current Ie (=Ith)

open and enclosed

(=Ith)

e

*1

V AC 690 690 690 690 690 690 690 690 690 690

i

eff

eff

at Ue = 690V AC A 200 200 200 200 400 500 500 700 900 900

400V AC A 180 180 200 200 380 400 400 600 800 800

1000V ACA---------

(=Ith) at 40°C, open A25253232506580110120130

e

220V kW 9,5 9,5 12,2 12,2 19,0 24,7 30,4 41,9 45,7 49,5

230V kW 9,9 9,9 12,7 12,7 19,9 25,9 31,8 43,8 47,7 51,7

240V kW 10,4 10,4 13,3 13,3 20,8 27,0 33,2 45,7 49,8 54,0

380V kW 16,4 16,4 21,0 21,0 32,9 42,7 52,6 72,3 78,9 85,5

400V kW 17,3 17,3 22,1 22,1 34,6 45,0 55,4 76,1 83,0 90,0

415V kW 17,9 17,9 23,0 23,0 35,9 46,7 57,4 79,0 86,2 93,3

440V kW 19,0 19,0 24,4 24,4 38,1 49,5 60,9 83,7 91,3 99,0

500V kW 21,6 21,6 27,7 27,7 43,3 56,2 69,2 95,2 103,8 112,5

660V kW 28,5 28,5 36,5 36,5 57,1 74,2 91,3 125,6 137,0 148,4

690V kW 29,8 29,8 38,2 38,2 59,7 77,6 95,5 131,3 143,2 155,2

1000VkW----------

) at 60°C, enclosedA2525323240556590100110

the

220V kW 9,5 9,5 12,2 12,2 15,2 20,9 24,7 34,3 38,1 41,9

230V kW 9,9 9,9 12,7 12,7 15,9 21,9 25,9 35,8 39,8 43,8

240V kW 10,4 10,4 13,3 13,3 16,6 22,8 27,0 37,4 41,5 45,7

380V kW 16,4 16,4 21,0 21,0 26,3 36,2 42,7 59,2 65,7 72,3

400V kW 17,3 17,3 22,1 22,1 27,7 38,1 45,0 62,3 69,2 76,1

415V kW 17,9 17,9 23,0 23,0 28,7 39,5 46,7 64,6 71,8 79,0

440V kW 19,0 19,0 24,4 24,4 30,4 41,9 49,5 68,5 76,1 83,7

500V kW 21,6 21,6 27,7 27,7 34,6 47,6 56,2 77,9 86,5 95,2

660V kW 28,5 28,5 36,5 36,5 45,7 62,8 74,2 102,8 114,2 125,6

690V kW 29,8 29,8 38,2 38,2 47,7 65,7 77,6 107,4 119,4 131,3

1000VkW----------

mm²4 4 6 6 101625355050

e

220VA121518222430405063 74

230VA11,514,518222430405062 74

240VA11141822243240506274

380-400VA10141822243240506274

415V A 9 14 18 22 23 30 40 50 62 74

440V A 9 14 18 22 23 30 40 50 62 74

500VA7 9 9 9 17,52121334242

660-690V A 6,5 8,5 8,5 8,5 17 20 20 31 40 40

1000VA--- ------

220-230V kW 3 4 5 6 6 8,5 11 12,5 18,5 22

240V kW 3 4 5 7 7 9 11,5 13,5 19 23

380-400V kW 4 5,5 7,5 11 11 15 18,5 22 30 37

415VkW4,56 8,512121620243340

440VkW4,56 8,512121620243340

500V kW 5,5 7,5 10 10 15 18,5 18,5 30 37 45

660-690V kW 5,5 7,5 10 10 15 18,5 18,5 30 37 45

1000VkW--- ------

220V A121518182430405063 63

230V A11,514,518182430405062 62

240V A11141818243240506262

380-400VA10141818243240506262

415V A 9 14 18 18 23 30 37 45 60 60

440V A 9 14 18 18 23 30 37 45 55 55

500V A 9 12 16 16 17,5 21 21 33 42 42

660V A7 9 9 9 172020314040

690V A 6,5 8,5 8,5 8,5 17 20 20 31 40 40

1000VA--- ------

Motor Contactor J7KN 39

Page 16

Utilization category AC4

Switching of squirrel cage motors, inching

Rated operational power

of three-phase motors

50-60Hz

220-230V kW 3 4 5 5 6 8,5 11 12,5 18,5 18,5

240VkW34557911,513,51919

380-400V kW 4 5,5 7,5 7,5 11 15 18,5 22 30 30

415V kW 4,5 6 8,5 8,5 12 16 20 24 33 33

440V kW 4,5 6 8,5 8,5 12 16 20 24 33 33

500V kW 5,5 7,5 10 10 15 18,5 18,5 30 37 37

660-690V kW 5,5 7,5 10 10 15 18,5 18,5 30 37 37

1000VkW--- ------

Main Contacts Type J7KN-10 J7KN-14 J7KN-18 J7KN-22 J7KN-24 J7KN-32 J7KN-40 J7KN-50 J7KN-62 J7KN-74

Utilization category AC 5a

Switching of gas discharge lamps

Rated operational current I

per pole at 220/230V

e

Fluorescent lamps,

uncompensated and serial c ompensated A 20 20 25 25 40 52 64 88 96 104

parallel compensated A 7 9 9 9 18 22 22 30 40 45

dual-connection A 22,5 22,5 28 28 45 58 72 98 108 117

Metal halide lamps*2,

uncompensated A1215191930 3948667278

parallel compensated A 7 9 9 9 18 22 22 30 40 45

Mercury-vapour lamps*3,

uncompensated A22,525282845587299108117

parallel compensated A 7 9 9 9 18 22 22 30 40 45

Mixed light lamps

Utilization category AC 5b

Switching of incandescent lamps

*4

*5

A202025254052648896104

Rated operational current Ie per pole at 220/230V A 12,5 12,5 12,5 12,5 25 31 31 43 56 56

Utilization category AC 6a

Transformer primary switching

at inrush n30303030303030303030

Rated operational current I

Rated operational power

dependent on inrush n

400V A 4,5 5,5 7,5 7,5 10,5 13,5 13,5 20 27 33

e

220-230V kVA 1,8 2,2 3 3 4,2 5,4 5,4 8 10,7 13

240V kVA 1,9 2,3 3,1 3,1 4,3 5,6 5,6 8,3 11,2 13,5

380-400V kVA 3,1 3,8 5,2 5,2 7,3 9,3 9,3 13,5 18,5 22,5

For different inrush-factors x

use the following formula:

Px=Pn*(n/x)

Utilization category AC 6b

Switching of three-phase capacitor banks

Maximum inrush current (peak value) as multiple k of the capacitor

rated current

Rated operational current I

Rated operational power

(sin 1)

415-440V kVA 3,4 4,2 5,7 5,7 8 10,2 10,2 15 20,5 25

500V kVA 3,9 4,8 6,5 6,5 9 11,5 11,5 17 23 28

660-690V kVA 5,4 6,5 9 9 12,5 16 16 24 32 39

k35252020252525252520

500V A8 1215,515,52332324560 70

e

220-230V kVAr 3 4,5 6 6 8,5 12 12 17 24 28

240V kVAr 3,5 5 6,5 6,5 9,5 13 13 18,5 25 29

380-400V kVAr 5 7,5 10 10 15 20 20 29 39 46

For different multiples x

use the following formula:

Px=Pk*(k/x)

Switching of detuned capacitors

Rated operational current I

Rated operational power 220-230V kVAr 2,9 5 7 7,5 11 14 16 20 28 33

415-440V kVAr 5,5 8 11 11 16 22 22 32 43 50

500V kVAr7 10131320262639 5058

660-690VkVAr7 101313202626405058

690V A 8 13 18 20 28 36 42 48 72 105

e

240V kVAr 3,1 5,4 7 8 11 14 17 20 28 36

380-400V kVAr 5 9 12,5 13 20 25 27,5 33,3 50 75

415-440V kVAr 5,5 9,5 13 14 22 27 30 36 53 75

1)

1)

1)

500V kVAr6 111517253036406075

660-690VkVAr8 1520223341485582100

Utilization category DC1

Switching of resistive load

Time constant L/R 1ms

Rated operational current I

e

1 pole24V A 20 25 32 32 50 65 80 110 120 130

60V A 20 25 32 32 50 65 80 110 120 130

110VA6 6 6 6 101010121212

220V A 0,8 0,8 0,8 0,8 1,4 1,4 1,4 1,4 1,4 1,4

3 poles in series 24V A 20 25 32 32 50 65 80 110 120 130

60V A 20 25 32 32 50 65 80 110 120 130

110VA20253232506580110120130

220VA16202020303535638080

40 Motor Contactor J7KN

Page 17

Utilization category DC3 and DC5

Switching of shunt motors and series motors

Time constant L/R 15ms

Rated operational current I

Maximum ambient temperature

Operation open °C -40 to +60 (+90)

with thermal overload relay open °C -25 to +60

enclosed °C -25 to +40

Storage °C -50 to +90

Short circuit protection

for contactors without thermal overload relay

Coordination-type "1" according to IEC 947-4-1

Contact welding without

hazard of persons

max. fuse size gL (gG)A63636363808080160160160

Coordination-type “2” according to IEC 947-4-1

Light contact welding accepted

max. fuse size gL (gG)A25353535505050100125125

Contact welding not accepted

max. fuse size gL (gG)A16161616253535506363

For contactors with thermal overload relay the device with

the smaller admissible backup fuse (contact or or thermal

overload relay) determines the fuse size.

Cable cross-sections

for contactors without thermal overload relay

main connector solid or stranded mm² 0,75 - 6 1,5 - 25 4 - 50

Cables per clamp 2 1 1

Cables per clamp 2 2 2

main connector solid AWG 18 - 10 16 - 10 12 - 10

Cables per clamp 2 1 1

Cables per clamp 2 2 2

Frequency of operations z

Contactors without thermal overload relay

Mechanical life

AC operated S x 10610 10 10 10 10 10 10 10 10 10

DC operated S x 10610 10 10 10 10 10 10 10 10 10

DC solenoid operated S x 10650 50 50 50 50 50 50 - - -

Short time current 10s-current A 96 120 144 176 184 240 296 360 504 592

Power loss per pole at Ie/AC3 400V W 0,21 0,35 0,5 0,75 0,7 1,3 2 2,2 3,9 5,5

Resistance to shock acc. to IEC 68-2-27

Shock time 20ms sine-wave NO g 10 10 10 10 8 8 8 8 8 8

*1

Suitable at 690V for: earthed-neutral systems, overvoltage I to IV, pollution degree 3 (standard-industry): U

Data for other conditions on request.

*2

Metal halide lamps and sodium-vapour lamps (high- and low-pressure lamps)

*3

High-pressure lamps

*4

Blended lamps, containing a mercury high-pressure unit and a tungsten helix in a flourescent glass bulb (daylight lamps)

*5

Current inrush approx. 16 x I

*6

With reduced control voltage range 0,9 up to 1,0 x Us and with reduced rated current Ie/AC1 according to Ie/AC3

Main Contacts Type J7KN-10 J7KN-14 J7KN-18 J7KN-22 J7KN-24 J7KN-3 2 J7KN-40 J7 KN-50 J7KN-62 J7 KN-74

e

flexible with multicore cable end mm² 0,75 - 4 1,5 - 16 6 - 35

1 pole24V A 20 25 32 32 50 65 80 110 120 130

60V A 6 6 6 6 30 30 30 60 60 60

110V A 1,2 1,2 1,2 1,2 1,8 1,8 1,8 1,8 1,8 1,8

3 poles in series 24V A 20 25 32 32 50 65 80 110 120 130

220V A 0,2 0,2 0,2 0,2 0,2 0,2 0,2 0,25 0,25 0,25

60V A 20 25 32 32 40 40 40 80 8 0 80

110VA20202020404040808080

220V A 2,5 2,5 2,5 2,5 4 4 4 5 5 5

*6

enclosed °C -40 to +40

flexible mm ² 1 - 4 2,5 - 16 10 - 35

solid or stranded mm² 6+(1-6) / 4+(0,75-4) 16+(2,5-6) / 10+(4-10) 50+4 / 35+6 / 25+(6-16)

flexible mm² 6+(1,5-6) / 4+(1-4) 16+(2,5-6) / 10+(4-10) 50+(4-10) / 35+(4-16)

flexible AWG 18 - 10 14 - 4 10 - 0

flexible AWG 10+( 14-10) / 12+(18-12) 4+(18-12) / 6+( 18-8) 1+(12-10) / 2+(8-12)

without load 1/h 10000 10000 10000 10000 7000 7000 7000 7000 7000 7000

AC3, Ie1/h 600 600 600 600 600 600 600 400 400 400

AC4, Ie1/h 120 120 120 120 120 120 120 120 120 120

DC3, Ie1/h 600 600 600 600 600 600 600 400 400 400

e

2,5+(0,75-2,5) / 1,5+(0,75-1,5) 6+(4-6) / 4+(2,5-4) 16+(6-16) / 10+(6-16)

2,5+(0,75-2,5) / 1,5+(0,75-1,5) 6+(4-6) / 4+(2,5-4) 25+(4-25) / 16+(4-16)

solid AWG 10+(16-10) / 12+(18-12) 10+(16 -10) / 12+(18-12) 10+(12-10) / 12+12

14+(18-14) / 16+(18-16) 1 4+(18-14) / 16+(18-16)

14+(18-14) / 16+(18-16) 8 +(18-8) / 10+(18-12) 3+(12-8) / 4+(10 -6)

NCg6666------

= 8kV.

imp

Motor Contactor J7KN 41

Page 18

Main Contacts Type J7KN-85 J7KN-110 J7KN-151 J7KN-176 J7KN-200

Rated insulation voltage U

Making capacity I

Breaking capacity I

*1

i

eff

eff

at Ue = 690V AC A 1100 1200 1500 1800 1700

V AC 750 750 690 690 690

400V AC A 950 1100 1200 1400 1600

J7KN-10 to J7KN-22 cosϕ = 0,65 500V AC A 850 1000 1200 1400 1600

J7KN-24 to J7KN-72 cosϕ = 0,35 690V AC A 600 600 700 800 1200

1000V AC A - - - - -

Utilization category AC1

Switching of resistive load

Rated operational current I

Rated operational power

of three-phase resistive loads

50-60Hz, cosϕ = 1

(=Ith) at 40°C, open A 150 170 230 250 350

e

220V kW 57 64 87 95 133

230V kW 59 67 91 99 139

240V kW 62 70 95 103 145

380V kW 98 111 151 164 230

400V kW 103 117 159 173 242

415V kW 107 122 165 179 251

440V kW 114 129 175 190 266

500V kW 130 147 199 216 303

660V kW 171 194 262 285 400

690V kW 179 203 274 298 418

1000V kW - - 398 433 -

Rated operational current Ie (=I

Rated operational power

of three-phase resistive loads

50-60Hz, cosϕ = 1

) at 60°C, enclosed A 100 125 180 200 280

the

220V kW 38 47 68 76 106

230V kW 40 49 71 79 111

240V kW 41 52 74 83 116

380V kW 65 82 118 131 184

400V kW 69 86 124 138 193

415V kW 71 89 129 143 201

440V kW 71 95 137 152 213

500V kW 86 108 155 173 242

660V kW 114 142 205 228 320

690V kW 119 149 215 239 334

1000V kW - - - - -

Minimum cross-section of conductor

at load with I

Utilization category AC2 and AC3

Switching of three-phase motors

Rated operational current I

open and enclosed

(=Ith)

e

e

mm² 50 70 95 120 185

220V A 85 110 150 175 210

230V A 85 110 150 175 210

240V A 85 110 150 175 210

380-400V A 85 110 150 175 210

415V A 85 110 150 175 210

440V A 85 110 150 175 210

500V A 60 60 150 175 210

660-690V A 57, 5 57,5 120 140 150

1000V A - - 60 70 -

Rated operational power

of three-phase motors

50-60Hz

220-230V kW 2 5 33 40 50 60

240V kW 27 35 45 55 65

380-400V kW 4 5 55 75 90 110

415V kW 49 63 80 95 115

440V kW 49 63 85 100 125

500V kW 55 75 90 100 132

660-690V kW 5 5 55 110 132 132

1000V kW - - 75 90 -

Utilization category AC4

Switching of squirrel cage motors, inching

Rated operational current Ie (=Ith)

open and enclosed

220V A8598556385

230V A8598556385

240V A8598556385

380-400V A 85 85 55 63 85

415V A8585556385

440V A8585556385

500V A8585- - -

660V A6060- - -

690V A 57,5 57,5 - - -

1000VA-----

42 Motor Contactor J7KN

Page 19

Main Contacts Typ e J7KN-85 J7KN-110 J7KN-151 J7KN-176 J7KN-200

Rated operational power

of three-phase motors

50-60Hz

220-230V kW 25 30 15 18,5 25

240V kW 27 32 15,5 19 26

380-400V kW 45 45 25 30 45

415V kW 49 49 25 33 45

440V kW 49 49 30 34 48

500V kW 55 55 25 30 55

660-690V kW 55 55 25 30 55

1000V kW - - - - -

Utilization category AC 5a

Switching of gas discharge lamps

Rated operational current I

per pole at 220/230V

e

Fluorescent lamps,

uncompensated and serial compensated A 100 120 120 140 180

parallel compensated A 55 70 85 100 120

dual-connection A 112 144 120 140 180

Metal halide lamps*2,

uncompensated A 85 90 95 110 140

parallel compensated A55707585110

Mercury-vapour lamps*3,

uncompensated A 112 144 120 140 180

parallel compensated A55707585110

Mixed light lamps

Utilization category AC5b

Switching of incandescent lamps

*4

*5

A 100 120 100 120 160

Rated operational current Ie per pole at 220/230V A 69 75 100 120 160

Utilization category AC6a

Transformer primary switching

at inrush n3030303030

Rated operational current I

Rated operational power

dependent on inrush n

400V A3850658090

e

220-230V kVA 15 20 25 30 34

240V kVA 15,5 20,5 27 33 37

380-400V kVA 26 34 45 55 60

For different inrush-factors x

use the following formula:

Px=Pn*(n/x)

Utilization category AC6b

Switching of three-phase capacitor banks

Maximum inrush current (peak value) as multiple k of the capacitor

rated current

Rated operational current I

Rated operational power

(sin 1)

415-440V kVA 29 38 46 57 63

500V kVA3343556975

660-690V 45 60 56 69 100

k2020202015

500V A 87 100 120 155 195

e

220-230V kVAr 33 38 45 60 75

240V kVAr 36 42 52 62 78

380-400V kVAr 57 65 80 100 130

For different multiples x

use the following formula:

Px=Pk*(k/x)

415-440V kVAr 60 70 95 110 135

500V kVAr 70 80 100 130 170

660-690V kVAr 70 80 100 130 170

Switching of detuned capacitors

Rated operational current I

Rated operational power 220-230V kVAr 35 40 43 53 76

690V A 98 105 115 140 200

e

240V kVAr 39 43 45 55 80

380-400V kVAr 68 75 75 90 130

415-440V kVAr 71 77 80 100 140

500V kVAr 85 90 95 120 170

660-690V kVAr 110 120 125 150 200

Utilization category DC1

Switching of resistive load

Time constant L/R 1ms

Rated operational current I

e

1 pole24V A 150 170 - - -

60V A 150 170 - - -

110V A 20 25 - - -

220V A 2 2,5 - - -

3 poles in series 24V A 150 170 - - -

60V A 150 170 - - -

110V A 150 170 - - -

220V A 100 160 - - -

Motor Contactor J7KN 43

Page 20

Main Contacts Typ e J7KN-85 J7KN-11 0 J7KN-151 J7KN-176 J7KN-200

Utilization category DC3 and DC5

Switching of shunt motors and series motors

Time constant L/R 15ms

Rated operational current I

e

1 pole24V A 150 170 - - -

60V A 85 110 - - -

110V A 2 2,5 - - -

220V A 0,5 0,5 - - -

3 poles in series 24V A 150 170 - - -

60V A 100 110 - - -

110V A 100 110 - - -

220V A 7 8 - - -

Maximum ambient temperature

Operation open °C -40 to +60 (+90)

*6

-25 to +55 (+70)

*7

enclosed °C -40 to +40 -25 to +40

with thermal overload relay open °C -25 to +60 -25 to +55

enclosed °C -25 to +40 -25 to +40

Storage °C -50 to +90 -55 to +80

Short circuit protection

for contactors without thermal overload relay

Coordination-type "1" according to IEC 947-4-1

Contact welding without hazard of persons

max. fuse size gL (gG) A 250 250 250 315 400

Coordination-type “2” according to IEC 947-4-1

Light contact welding accepted

max. fuse size gL (gG) A 160 200 200 250 315

Contact welding not accepted

max. fuse size gL (gG) A 100 125 160 200 250

For contactors with thermal overload relay the device with

the smaller admissible backup fuse (contactor or thermal

overload relay) determines the fuse size.

Cable cross-sections

for contactors without thermal overload relay

main connector solid or stranded mm² 10 - 70

flexible mm² 6 - 50

*8

10 - 70*895 120 185

*8

16 - 50*8screw screw screw

flexible with multicore cable end mm² 10 - 35 10 - 35 M8 M8 M8

Cables per clamp

solid or stranded mm²

flexible mm²

Cables per clamp

main connector solid AWG 10 10

flexible AWG 6 - 0 6 - 0

Cables per clamp 1 1

solid AWG

flexible AWG

Cables per clamp

Frequency of operations z

Contactors without thermal overload relay

without load 1/h 3000 3000 1200 1200 1200

AC3, Ie1/h 300 300 - - -

AC4, Ie1/h 120 120 - - -

DC3, Ie1/h 300 300 - - -

Mechanical life

AC operated S x 1065 5 10 10 8

DC operated S x 1065 5 10 10 8

Short time current 10s-current A 680 880 1200 1400 1800

Power loss per pole

at Ie/AC3 400V

W4,3 6,0 8 11 8

Resistance to shock acc. to IEC 68-2-27

Shock time 20ms sine-wave NO g 7 7 - - -

NC g 5 5 - - -

*1

Suitable at 690V for: earthed-neutral systems, overvoltage I to IV, pollution degree 3 (standard-industry):

= 8kV. Data for other conditions on request.

U

imp

*2

Metal halide lamps and sodium-vapour lamps (high- and low-pressure lamps)

*3

High-pressure lamps

*4

Blended lamps, containing a mercury high-pressure unit and a tungsten helix in a flourescent glass bulb

(daylight lamps)

*5

Current inrush approx. 16 x I

*6

With reduced control voltage range 0,9 up to 1,0 x Us and with reduced rated current Ie/AC1 according to Ie/AC3

*7

With reduced control voltage range 1,0 x Us and with reduced rated current Ie/AC1 according to Ie/AC3

*8

Maximum cable cross-section with prepared conductor

e

44 Motor Contactor J7KN

Page 21

Contactors

Data according to IEC 947-4-1, EN 60947-4-1, VDE 0660

Auxiliary Contacts Ty pe J7KN-10 J7KN-14 J7KN-18 J7KN-22 J7KN-24 J7KN-32 J7KN-40 J7KN-50 J7KN-62 J7KN-74

Rated insulation voltage U

Thermal rated current Ith to 690V

Ambient temperature 40°CA16161616- - - - - -

Utilization category AC15

Rated operational current I

Utilization category DC13

Rated operational current I

Short circuit protection

short-circuit current 1kA,

contact welding not accepted

max. fuse size gL (gG)A25252525- - - - - -

For contactors with thermal overload relay the device with

the smaller admissible control fuse (contactor or thermal

overload relay) determines the fuse.

Control Circuit

Power consumption of coils

AC operated inrush VA 33-45 90-115 140-165

DC operated inrush W 75 140 200

DC solenoid operated inrush W 3 4 -

(J7KNG-types) sealed W 3 4 -

Operation range of coils

in multiples of control voltage UsAC operated 0,85-1,1 0,85-1,1 0,85-1,1

Switching time at control voltage U

AC operated make time ms 8-16 10-25 12-28

DC operated make time ms 8-12 10-20 12-23

DC solenoid operated make time ms 65-85 65-85 -

Cable cross-section

Auxiliary connector solid mm² 0,75-6 - -

flexible with multicore cable end mm² 0,75-4 - -

Magnet coil solid mm² 0,75-2,5 0,75-2,5 0,75-2,5

Clamps per pole 2 2 2

Auxiliary connector solid AWG 18 - 10 - -

Magnet coil solid AWG 14 - 12 14 - 12 14 - 12

Clamps per pole 2 2 2

*1

Suitable for: earthed-neutral systems, overvoltage category I to IV, pollution degree 3 (standard-industry): U

ditions on request

*2

Total breaking time = release time + arc duration

*3

Values for delay of the release time of the making contact and the make time of the break contact will be increased, if magnet coils are

protected against voltage peaks (varistor, RC-unit, diode-unit)

*4

with integrated suppressor

*1

i

e

e

DC operated 0,8-1,1 0,8-1,1 0,8-1,1

±10%*2,

s

release time ms 5- 13 8-15 8-15

arc duration ms 10-15 10-15 10-15

release time ms 8-13 10-15 10-18

arc duration ms 10-15 10-15 10-15

release time ms 20-30

arc duration ms 10-15 10-15 -

flexible with multicore cable end mm² 0,5-1,5 0,5-1,5 0,5-1,5

V~ 690 690 690 690 - - - - - -

60°CA12121212- - - - - -

220-240V A 12 12 12 12 - - - - - -

380-415V A 4 4 4 4 - - - - - -

440VA4444------

500VA3333------

660-690V A 1 1 1 1 - - - - - -

60VA8888------

110VA1111------

220V A 0,1 0,1 0,1 0,1 - - - - - -

sealed VA 7-10 9-13 13-18

W 2,6-3 2,7-4 5,4-7

sealed W 2 2 6

*3

*4

flexible mm² 1-4 - -

flexible mm² 0,5-2,5 0,5-2,5 0,5-2,5

flexible AWG 18 - 10 - -

flexible AWG 18 - 12 18 - 12 18 - 12

20-30

*4

-

= 8kV. Data for other con-

imp

Motor Contactor J7KN 45

Page 22

Auxiliary Contacts Ty pe J7KN-85 J7KN-110 J7KN-151 J7KN-176 J7KN-200

Rated insulation voltage U

Thermal rated current Ith to 690V

Ambient temperature 40°C A 16 16 10 10 10

Utilization category AC15

Rated operational current I

Utilization category DC13

Rated operational current I

Short circuit protection

short-circuit current 1kA,

contact welding not accepted

max. fuse size gL (gG) A 25 25 10 10 10

For contactors with thermal overload relay the device with

the smaller admissible control fuse (cont actor or thermal

overload relay) determines the fuse.

Control Circuit

Power consumption of coils

AC operated inrush VA 280-350 350-420 350 350 700

DC operated inrush W 170 320 350 350 700

Operation range of coils

in multiples of control voltage U

Switching time at control voltage U

AC operated make time ms 13-30 30-60 30-60 40-60

DC operated make time ms 20-30 - - -

Cable cross-section

Auxiliary connector solid mm² 0,75-2,5 - 0,75-2,5

flexible with multicore cable end mm² 0,5-1,5 -

Magnet coil solid mm² 0,75-2,5 1-2,5

Clamps per pole 14 - 12 16 - 12

Auxiliary connector solid AWG 18 - 12 - 16 - 12

Magnet coil solid AWG 18 - 12 16 - 12

Clamps per pole 0,75-2,5 0,75-2,5

*1

Suitable for: earthed-neutral systems, overvoltage category I to IV, pollution degree 3

(standard-industry): U

*2

Total breaking time = release time + arc duration

*3

Values for delay of the release time of the making contact and the make time of the

*1

i

e

e

AC operated 0,85-1,1 0,85-1,1 0,85-1,1 0,85-1,1

s

DC operated 0,8-1,1 0,85-1,1 0,85-1,1 0,85-1,1

±10%*2,

s

release time ms 8-15 30-80 30-80 15-45

arc duration ms 10-15 - -

release time ms 10-18 - - -

arc duration ms 10-15 - - -

flexible with multicore cable end mm² 0,5-1,5 -

= 8kV. Data for other conditions on request

imp

V~ 690 690 690 690 690

60°CA1212- - -

220-240V A 12 12 3 3 3

380-415V A 6 6 2 2 2

440V A 6 6 1 ,5 1,5 1,5

500V A 4 4 1 ,5 1,5 1,5

660-690V A 2 2 1 1 1

60V A 8 8 - - -

110V A 1 1 0 ,5 0,5 1

220V A 0,1 0,1 0,2 0 ,2 0,5

sealed VA 16 -23 23 -29 5 5 20

W 4-6 6-7,3 - - -

sealed W 2 4 5 5 20

*3

flexible mm² 0,75-2,5 - 0,75-2,5

flexible mm² 0,5-2,5 1-2,5

flexible AWG 14 - 12 - 16 - 12

flexible AWG 2 2

break contact will be increased, if magnet coils are protected against voltage peaks

(varistor, RC-unit, diode-unit)

46 Motor Contactor J7KN

Page 23

Contactors for North America

Data according to UL508

Main Contacts (cULus) Ty pe J7KN-10 J7KN-14 J7KN-18 J7KN-22 J7KN-24 J7KN-32 J7KN-40 J7KN-50 J7KN-62 J7KN-74

Rated operational current

"General Use"

Rated operational power 110-120V hp 1½ 2 2 3 5 5 7½ 10 10 10

of three-phase motors 200V hp 3 3 5 5 7½ 10 10 15 20 25

at 60Hz (3ph) 220-240V hp 3 3 7½ 7½ 10 10 15 20 25 30

Rated operational power 110-120 V h p ½ ¾ 1 1½ 1½ 2 3 3 5 7½

of AC motors 200V hp 1 1,5 2 3 3 5 7½ 7½ 10 15

at 60Hz (1ph) 220-240V hp 1½ 2 3 3 5 5 7½ 10 15 15

Rated operational power of 110-120V hp - - - - 2 3 - 3 5 -

three-phase motors at 60Hz (3ph) 200V hp - - - - 3 5 - 7½ 10 -

for elevators 220-240V hp - - - - 5 7½ - 7½ 10 -

Demands according to ANSI A17.5

(500.000 operations) 440-480V hp - - - - 10 15 - 20 25 -

Rated operationalcurrent 600V A - - - - 15 22 - 27 37 -

Fuses A 30 40 50 50 90 125 175 175 225 250

Suitable for use on a capability

of delivering not more than rms A 5000 5000 5000 5000 5000 5000 5000 5000 5000 5000

(SCCR) V 600 600 600 600 600 600 600 600 600 600

Auxiliary Contacts (cULus) A600 A600 A600 A600 - - - - - -

A25253030506580110120130

277V hp 3 5 7½ 7½ 7½ 10 15 20 25 30

380-415V hp 5 5 10 10 10 15 20 25 30 40

440-480V hp 5 7½ 10 15 15 20 25 30 40 50

550-600V hp 7½ 10 15 20 20 25 30 40 50 50

277V hp 2 3 3 5 5 7½ 10 10 15 15

380-415V hp 3 3 5 5 5 7½ 10 15 20 20

440-480V hp 3 5 5 7½ 7½ 10 15 20 25 25

550-600V hp 3 5 7½ 10 10 15 20 25 30 30

550-600V hp - - - - 10 20 - 25 30 -

Main Contacts (cULus) Ty pe J7KN-85 J7KN-110 J7KN-151 J7KN-176 J7KN-200

Rated operational current

"General Use"

Rated operational power 110-120V hp 15 - - - -

of three-phase motors 200V hp - 30 40 50 -

at 60Hz (3ph) 220-240V hp 35 40 50 60 -

Rated operational power 110-120 V h p 8 10 15 25 -

of AC motors 200V hp - 20 - - -

at 60Hz (1ph) 220-240Vhp20202530-

Rated operational power of 110-120V hp - - - - -

three-phase motors at 60Hz (3ph) 200V hp - - - - -

for elevators 220-240V hp - - - - -

Demands according to ANSI A17.5

(500.000 operations) 440-480V hp - - - - -

Rated operationalcurrent 600V A - 62 - - -

Fuses A - 300 300 500 -

Suitable for use on a capability

of delivering not more than rms A 10000 10000 10000 10000 -

(SCCR) V 600 600 600 600 -

Auxiliary Contacts (cULus) A600 A600 - - -

A 125 125 180 220 -

277V hp - - - - -

380-415V hp - - - - -

440-480V hp 65 75 100 125 -

550-600V hp 85 100 125 150 -

277V hp - - - - -

380-415V hp - - - - -

440-480V hp - 50 - - -

550-600V hp - 60 - - -

550-600V hp - - - - -

Motor Contactor J7KN 47

Page 24

Contactors

A

A

Data according to IEC 947-4-1, EN 60947-4-1, VDE 0660

Contact Life

For selection of the suitable contactor-type according to supply voltage, power rating and application (utilization category AC1, AC3 or

AC4) use contact life characteristic diagram.

For the most common supply voltages four scales of power ratings P

are provided for each utilization category.

Select contactor-type according to utilization category AC3 (breaking

current I

to utilization category AC4 (breaking current I

motor rating scales to the left.

Select contactor-type according to utilization category AC1 (breaking

current I

= Ie) using the motor rating scales to the right, according

a

*1

= Ie/AC1) using the breaking current scale.

a

= 6 x Ie) using the

a

*1

1. Pay attention to the approved rated values of the selected

contactor according to the national approvals

For contactors frequently used under AC3/AC4-mixed service conditions calculate contact life with the formula:

n

M = Contact life (switching cycles) for AC3/AC4-mixed operations

C3 = Contact life (switching cycles) for AC3 operations (normal switching

conditions). Breaking current I

C4 = Contact life (switching cycles) for AC4 operations (inching).

Breaking current Ia= multiples of rated motor current In.

%AC4 = Percents of AC4-operations related to the total cycles.

M

---------------------------------------------------------=

1

AC3

%AC4

-----------------x

+

= rated motor current In.

a

AC3

⎛⎞

----------- 1–

⎝⎠

100

AC4

Motor Rating

P

/AC4

n

Motor Rating

P

/AC4

n

Motor Rating

Pn/AC3

Motor Rating

Pn/AC3

Breaking Current

Ia (=Ie/AC1)

A

J7KN-74

J7KN-62

J7KN-50

J7KN-40

J7KN-32

J7KN-24

J7KN-22

J7KN-18

J7KN-14

J7KN-12

J7KN-10

J7KN-09

millions of operations

Breaking Current

Ia (=Ie/AC1)

A

J7KN-200

J7KN-175

J7KN-150

J7KN-110

J7KN-85

millions of operations

48 Motor Contactor J7KN

Page 25

Contactors

Utilization Categories

For easier choice of devices and in order to make the comparison of

different products simplier are utilization categories for contactors and

motor-starters according to IEC 947-4-1 and VDE 0660 Part 102 ,for

Ty pe of

Cate-

current

Alternating Current

Typical applications Rated operational

gory

AC1 Non-inductive or

slightly inductive loadsresistance furnaces

AC2 Slip-ring motors:

starting, switching off

AC3 Squirrel-cage motors:

starting, switching off motors during running

AC4 Squirrel-cage motors:

starting, plugging, inching

AC5a Switching of electric dis-

charge lamp controls

AC5b Switching of incandes-

cent lamps

AC6a Switching of transformers Ie 100A - - - - - - 4.5 1.05 0.45 3.6 1.05 0.45

AC6b Switching of capacitor

banks

AC7a Slightly inductive loads in

household appliances

and similar applications

AC7b Motor loadsfor household

applications

AC8a Hermetic refrigerant com-

pressor motor control with

manualresetting of overload releases

AC8b Hermetic refrigerant com-

pressor motor control with

automatic resetting of

overload releases

AC12 Control of resistive loads

and solid state loads with

isolation by opto couplers

AC13 Control of solid state

loads with transformer

isolation

AC14 Control of small electro-

magnetic loads (<=72VA)

AC15 Control of

electromagnetic load

(>72VA)

DC1 Non-inductive or

slightly inductive loads resistance furnaces

DC3 Shunt-motors: starting,

plugging, inching dynamic

braking of d.c. motors

Direct Current

DC5 Series-motors:

starting, plugging, inching

dynamic braking of d.c.

motors

DC6 Switching of incandes-

cent lamps

DC12 Control of resistive loads

and solid state loads with

isolation by opto couplers

DC13 Control of electromagnets all values 1 1 300 1 1 300 1.1 1.1 300 1.1 1.1 300

DC14 Control of electromagnet-

ic loads having economy

resistors in circuit

current

all values 1 1 0.95 1 1 0.95 1.5 1.05 0.8 1.5 1.05 0.8

all values 2.5 1 0.65 2.5 1 0.65 4 1.05 0.65 4 1.05 0.65

17A< Ie 17A 6 1 0.65 1 0.17 0.65 10 1.05 0. 45 8 1.05 0.45

Ie 100A 6 1 0.35 1 0.17 0.35 10 1.05 0.45 8 1.05 0.45

Ie> 100A 6 1 0.35 1 0.17 0.35 10 1.05 0.35 8 1.05 0.35

17A< Ie 17A 6 1 0.65 6 1 0.65 12 1.05 0.45 10 1.05 0.45

Ie 100A 6 1 0.35 6 1 0.35 12 1.05 0.45 10 1.05 0.45

Ie> 100A 6 1 0.35 6 1 0.35 12 1.05 0.35 10 1.05 0.35

all values ---- --31.050.4531.050.45

all values ---- --1.51.05 1)41.05 1)

Ie> 100A - - - - - - 4.5 1.05 0.35 3.6 1.05 0.35

- ------2) 2)

all values ---- --1.51.050.81.51.050.8

Ie 100A - - - - - - 8 1.05 0.45 6 1.05 0.45

Ie>100A------81.050.3561.050.35

Ie 100A - - - - - - 6 1.05 0.45 6 1.05 0.45

Ie>100A------61.050.3561.050.35

Ie 100A - - - - - - 6 1.05 0.45 6 1.05 0.45

Ie>100A------61.050.3561.050.35

all values ---- --110.9110.9

all values ---- --101.10.651.11.10.65

- ------61.10.761.10.7

- 10 1 0.7 1 1 0.4 10 1.1 0.3 10 1.1 0.3

all values 1111111.51.0511.51.051

all values 2.5122.51241.052.541.052.5

all values 2.5 1 7.5 2.5 1 7.5 4 1.05 15 4 1.05 15

all values ---- --1.51.05 1)41.05 1)

all values ---- --111111

all values ---- --101.115101.115

Test conditions for the number of

on-load operating cycles

Make Break Make Break

I/Ie U/Ue cos Ic/Ie Ur/Ue cos I/Ie U/Ue cos Ic/Ie Ur/Ue cos

Make L/R Break L/R Make L/R Break L/R

I/Ie U/Ue [ms] Ic/Ie Ur/Ue [ms] I/Ie U/Ue [ms] Ic/Ie Ur/Ue [ms]

Ue Rated operational voltage, U Voltage before make, Ur Recove ry vo ltage, Ie Rated operational current, I Current make, Ic Current broken

1) Test with incandescent lamps

2) Test conditions according to standard

control circuit devices and switching elements according to IEC 947-51 and VDE 0660 Part 200 determind. The table offers different utilization categories, typical applications and assorted test conditions.

Test conditions for

making and breaking capacit ies

Motor Contactor J7KN 49

Page 26

Accessories

Data according to IEC 947-5-1, EN 60947-5-1, VDE 0660

Auxiliary Contacts Ty pe J73KN-B J73KN-C J73KN-D J74KN- B-TP...

Rated insulation voltage U

Thermal rated current Ith to 690V

Ambient temperature 40°C A 10 10 10 10

Frequency of operations z 1/h 3000 3000 3000 1200

Mechanical life S x

Power loss per pole at I

Utilization category AC15

Rated operational current I

Utilization category DC13

Rated operational current I

Short circuit protection

short-circuit current 1kA, contact

welding not accepted max. fuse

size

For contactors with thermal overload relay or auxiliar y contacts the device with the smaller admissible control fuse

(contactor or thermal overload relay) determines the fuse

size.

Cable cross-sections

Cables per clamp 2 2 2 2

*1

Suitable for: earthed-neutral systems, overvoltage category I to IV, pollution degree

3 (standard-industry): U

*1

i

/AC1 W 0,5 0,5 - -

e

220-240V A 3 3 3 4

e

380-400V A 2 2 2 3

440V A 1,6 1,6 1,5 2

500V A 1,2 1,2 1,5 2

660-690V A 0,6 0,6 1 2

60VA22- 2,5

e

110V A 0,4 0,4 1 1,5

220V A 0,1 0,1 0,5 0,2

gL (gG) A 20 20 10 10

solid or stranded mm² 0,75-2,5 0,75-2,5 0,75-2,5 1-2,5

flexible with multicore cable end mm² 0,5-1,5 0,5-1,5 - 0,75-2,5

imp

V~ 690 690 690 690

60°C A 6 6 -

10 10 10 1

6

10

flexible mm² 0,75-2,5 0,75-2,5 0,75-2,5 0,75-2,5

= 8kV. Data for other conditions on request

Data according to CSA, UL and CUL

Auxiliary Contacts Ty pe J73KN-B J73KN-C J73KN-D J74KN- B-TP...

Rated operational current

„General Use“

Rated operational voltage max. V AC 600 600 600 600

Auxiliary Contacts A600 A600 A600 A600

A10101010

Contactors and Accessories

Wiring diagrams

Auxiliary contact blocks Pneumatic timer

J73KN-B-10 J73KN-B-01 J73KN-C-11S

(left side) (right side)

53 61

54 62

J73KN-D-11 J73KN-D-11S J73KN-D-22

*1

Correct terminal marking is given by mounting

*1

71 83

72 84

on-delayed off-delayed

J74KN-B-TP...DA J74KN-B-TP...IA

50 Motor Contactor J7KN

Page 27

■ Dimensions

AC operated DC operated

J7KN-10/14/18/22(-4)... J7KN-10/14/18/22...D

45

35-36

Ø5

59

49-50

M3.5

J7KN-24/32/40... J7KN-24/32/40...D

45

1010

35

82.5

78.5

6.5

50

J7KNG-10/14/18/22(-4)...D

45

35

89

80

104.5

100.5

111

107

Ø4.5

M3.5

6.5

79

Ø4,5

65

60

74

M5

6.5

63

J7KNG-24/32/40...D

80

89

J7KN-50/62/74... J7KN-50/62/74...D

10 10

95

100

110

60

50

Ø5.5

113

109

45 1010

35

›4.5

M5

6.5

125

121

86

Auxiliary contacts are optional

M6

7.5

68

Motor Contactor J7KN 51

Page 28

AC and DC operated

J7KN-85...

J7KN-110...

J7KN-151...

J7KN-176...

12 x 70

Auxiliary contacts are optional

J7KN-200...

Pneumatic timer

J74KN-B-TP...

52 Motor Contactor J7KN

Page 29

Auxiliary contact blocks

J74KN-A-VG J74KN-D

28

23

4

J74KN-B-VG J74KN-B-RC

150

65

11

J74KN-C

10010 19

10

24

7

Motor Contactor J7KN 53

Page 30

Position of Terminals

AC operated

J7KN-10-10

to

J7KN-22-10

DC operated with double winding coil

J7KN-10-10...D

J7KN-14-10...D

J7KN-18-10...D

J7KN-22-10...D

J7KN-10-01

to

J7KN-22-01

J7KN-10-01...D

J7KN-14-01...D

J7KN-18-01...D

J7KN-22-01...D

J7KN-24

J7KN-32

J7KN-40

J7KN-24...D

J7KN-32...D

J7KN-40...D

J7KN-50

J7KN-62

J7KN-74

J7KN-50...D

J7KN-62...D

J7KN-74...D

J7KN-85-22

J7KN-110-22

J7KN-85-21...D

J7KN-110-21...D

AC and DC operated DC operated

J7KN-151

J7KN-176

J7KN-200-21

J7KNG-10-10

J7KNG-14-10

J7KNG-18-10

J7KNG-22-10

J7KNG-10-01

J7KNG-14-01

J7KNG-18-01

J7KNG-22-01

J7KNG-24

J7KNG-32

J7KNG-40

3 L2 5 L3

1 L1

4 T22 T1

A1 A2

A2A1

6 T3

Do not use/install these products before having read the applicable precautions as listed in Cat. No. J09-EN-01

available from www.europe.omron.com or on request from OMRON local sales office.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

Cat. No. J06E-EN-01A

In the interest of product improvement, specifications are subject to change without notice.

54 Motor Contactor J7KN

Loading...

Loading...