Page 1

HD-1500 Platform

User's Manual

I645-E-02

Page 2

Copyright Notice

The information contained herein is the property of OMRON, and shall not be reproduced in whole or in

part without prior written approval of OMRON. The information herein is subject to change without

notice and should not be construed as a commitment by OMRON. The documentation is periodically

reviewed and revised.

OMRON, assumes no responsibility for any errors or omissions in the documentation.

Copyright 2020 by OMRON All rights reserved.

Any trademarks from other companies used in this publication are the property of those respective companies.

MPEG Layer-3 audio coding technology licensed from Fraunhofer IIS and Thomson.

Acapela© voice technology licensed from ACAPELA GROUP (https://www.acapela-group.com) Copyright

2003, all rights reserved.

Created in the United States of America

Page 3

Table of Contents

Chapter 1: Introduction 10

1.1 Definitions

1.2 Product Description

HD-1500 Autonomous Navigation 13

HD-1500 Localization 13

Custom Payload Structures 13

Body and Drive Train 14

What's Included - Basic Components 15

1.3 Software Overview

HD-1500 Software 20

SetNetGo 24

1.4 How Can I Get Help?

Related Manuals 24

Support 25

Download a Debuginfo File for Support 25

Network Setup 26

Obtain a DebugInfo File from SetNetGo 26

10

11

19

24

Chapter 2: Safety 28

2.1 General Hazards

2.2 Unprotected Areas

2.3 What to Do in an Emergency

Releasing the Brakes 33

Releasing an E-Stop 35

2.4 Dangers, Warnings, and Cautions

Alert Levels 35

Alert Icons 36

Special Information 37

2.5 User's Responsibilities

Electrical Hazards 38

Magnetic Field Hazards 39

Burn Hazard 40

Qualification of Personnel 40

Payload Movement and Transfer 40

Configurable Warning Buzzer 41

Speakers 42

Mechanical Brakes 42

Fleet Management 42

2.6 Environment

28

29

32

35

38

43

31500-000 Rev B HD-1500 Platform User's Manual 2

Page 4

Table of Contents

General Environmental Conditions 43

Public Access 44

Operating Clearances 44

Obstacles 46

2.7 Intended and Non-intended Use

Intended Use 47

Non-Intended Use 47

HD-1500 Platform Modifications 48

2.8 Protective Stops Initiated by AMR Safety Lasers

2.9 Safety System Overspeed Faults

2.10 Laser Safety

2.11 Interlock Switches

2.12 Battery Safety

Battery Safety Precautions 54

Battery Maintenance 56

2.13 Charging Station

Safety Precautions 57

2.14 Additional Safety Information

Mobile Robot HDSafety Manual (Cat. No. I647) 61

2.15 Disposal

47

50

51

51

52

53

56

61

61

Chapter 3: Setup 64

3.1 Overview of HD-1500 Setup

Tasks 64

3.2 Transport and Storage

HD-1500 Shipping and Storage 64

Battery Crate 65

Power Supply Box, and Docking Target Crates 66

3.3 Before Unpacking

3.4 Unpacking Considerations

Battery Unpacking 69

HD-1500 Unpacking 77

Docking Target Unpacking 93

Power Supply Box Unpacking 100

3.5 Installing the Battery

Installation 109

3.6 Attaching the Payload Structure and Options

Attach the Payload Structure 113

Attach the No Riding Warning Label 113

Attach HD-1500 Optional Devices 113

E-Stop Jumper on the User Access Panel 114

Warning Buzzer 114

64

64

67

67

109

113

3 HD-1500 Platform User's Manual 31500-000 Rev B

Page 5

Table of Contents

Warning Light 115

3.7 Installing the Charging Station

Required Tools and Fasteners 116

Charging Station Features and Parts 117

Charging Station Environmental Requirements 120

Power Supply Box Installation 121

Docking Target Installation 125

115

Chapter 4: Configuration 128

4.1 Settings and Configuration

Maintenance Ethernet Connection 128

Setting Up Wireless Ethernet 131

4.2 Create a Workspace Map

Map Creation Overview 134

Mapping Tasks 136

4.3 Acceleration, Deceleration, and Rotation Limits

4.4 Supplemental Information

Laser Setup 137

128

134

136

137

Chapter 5: Payload Structures 140

5.1 Safety

Warning Labels 140

Warning Lights 140

Warning Buzzer 141

5.2 Considerations

Performance 141

Weight Constraints 141

Power Consumption 142

Power Limits 142

Payload Attachment Location 143

Payload Dimensions and Design 143

Mounting Locations in the Platform 145

AMR Coordinate System 146

Center of Gravity (CG) 147

5.3 Payload-Related Tradeoffs

5.4 Connections Between the HD-1500 Platform and Payload Structure

Operator Panel on the Payload 151

Optional Connections 152

140

141

150

151

Chapter 6: Connectivity 154

6.1 Required Connections

Platform Required Connections 155

Charging Station Required Connections 158

31500-000 Rev B HD-1500 Platform User's Manual 4

155

Page 6

Table of Contents

6.2 User Access Panel Connections

USERPWR 163

REG PWR 163

SCPU 165

USER_PROTECTIVE_STOP input Behavior 166

LIGHTS 167

Drive Power Indicator 167

I/O 1 168

I/O 2 168

COMMS - RS-232, RS-422, CANBus 169

6.3 Electronics Bay Connections

AMR Controller 171

AMR Controller Connections 172

Ethernet Switches 176

159

170

Chapter 7: Operation 182

7.1 Operating Environment

Intended Use 182

Clearance 182

Obstacles 185

Environment and Floor 186

Getting Stuck (Immobilization Risk) 186

7.2 Typical Operation

7.3 Power and Charging

Battery Indicators and Controls 188

Charging Station 189

Safety Precautions 190

Manually Charging the AMR's Battery 195

Balancing the Battery 197

7.4 Operator Panel

Screen 199

E-Stop Buttons 201

Positioning an Optional Payload E-Stop 202

ON Button 202

OFF Button 202

Brake Release Button 203

Pendant Port 204

Maintenance Ethernet Connection 204

7.5 Other Controls and Indicators

Light Discs and Beacon 204

Front and Back Light Strips 208

7.6 Sensors

Lasers 213

Other Sensors 215

7.7 Start up

182

187

188

199

204

213

215

5 HD-1500 Platform User's Manual 31500-000 Rev B

Page 7

Table of Contents

Procedure 215

Pendant Controls and Operation Description 215

Chapter 8: Maintenance 220

8.1 Safety Considerations when Performing Maintenance

Electrical Hazards 221

Electrical Hazard Precautions 221

Burn Hazard 222

ESD Hazards 222

8.2 Safety Measures Prior and After Maintenance

Lock-Out, Tag-Out Procedure 222

8.3 Lifting the Platform Safely

8.4 Safety Inspection

Safety and Warning Devices 229

Warning Labels 230

8.5 Maintaining and Replacing Batteries

Maintaining Batteries 230

Replacing the Battery 231

8.6 Cleaning

Work Area Maintenance 240

Platform and Charging Station Cleaning 240

8.7 Replacing Non-Periodic Parts

Light Discs 245

Light Strips 249

Operator Panel 251

Side-Mount Lasers (Side Lasers) 252

Wifi Antennas 255

AMR Charging Contacts 256

E-Stop and Safety Laser Commissioning 258

Removing and Installing Skins 259

8.8 Field-Replaceable Periodic Parts

Caster and Drive Wheel Treads 272

Caster, Drive Wheel, and Drive Assembly 272

8.9 Restoring the Configuration

221

222

226

229

230

240

244

272

273

Chapter 9: Options 274

9.1 Fleet Manager, for Multi-AMR Coordination

9.2 Tools for Use in the Field

SetNetGo - Managing Software Packages 274

9.3 Pendant

9.4 Spare Battery

9.5 Side-Mount Lasers

31500-000 Rev B HD-1500 Platform User's Manual 6

274

274

275

276

276

Page 8

Table of Contents

Side Lasers Installation 276

Connections 277

Installation Procedure 277

Configuration 282

9.6 High-Accuracy Positioning System (HAPS)

HAPS Installation and Software Configuration 287

Components 288

HAPS Installation 288

HAPSSoftware Configuration 291

Specifications 293

Dimensions 294

9.7 Charging Station

287

295

Chapter 10: Technical Specifications 296

10.1 Dimension Drawings

HD-1500 Platform 296

HD-1500 Charging Station 299

10.2 HD-1500 Platform Specifications

Physical 300

Performance 301

Sensors 302

10.3 HD-1500 Charging Station Specifications

Power Supply Box Specifications 303

Docking Target Specifications 303

296

300

303

Chapter 11: HD-1500 Default Safety Zones 306

11.1 Default Safety Zones

306

Chapter 12: Glossary 328

7 HD-1500 Platform User's Manual 31500-000 Rev B

Page 9

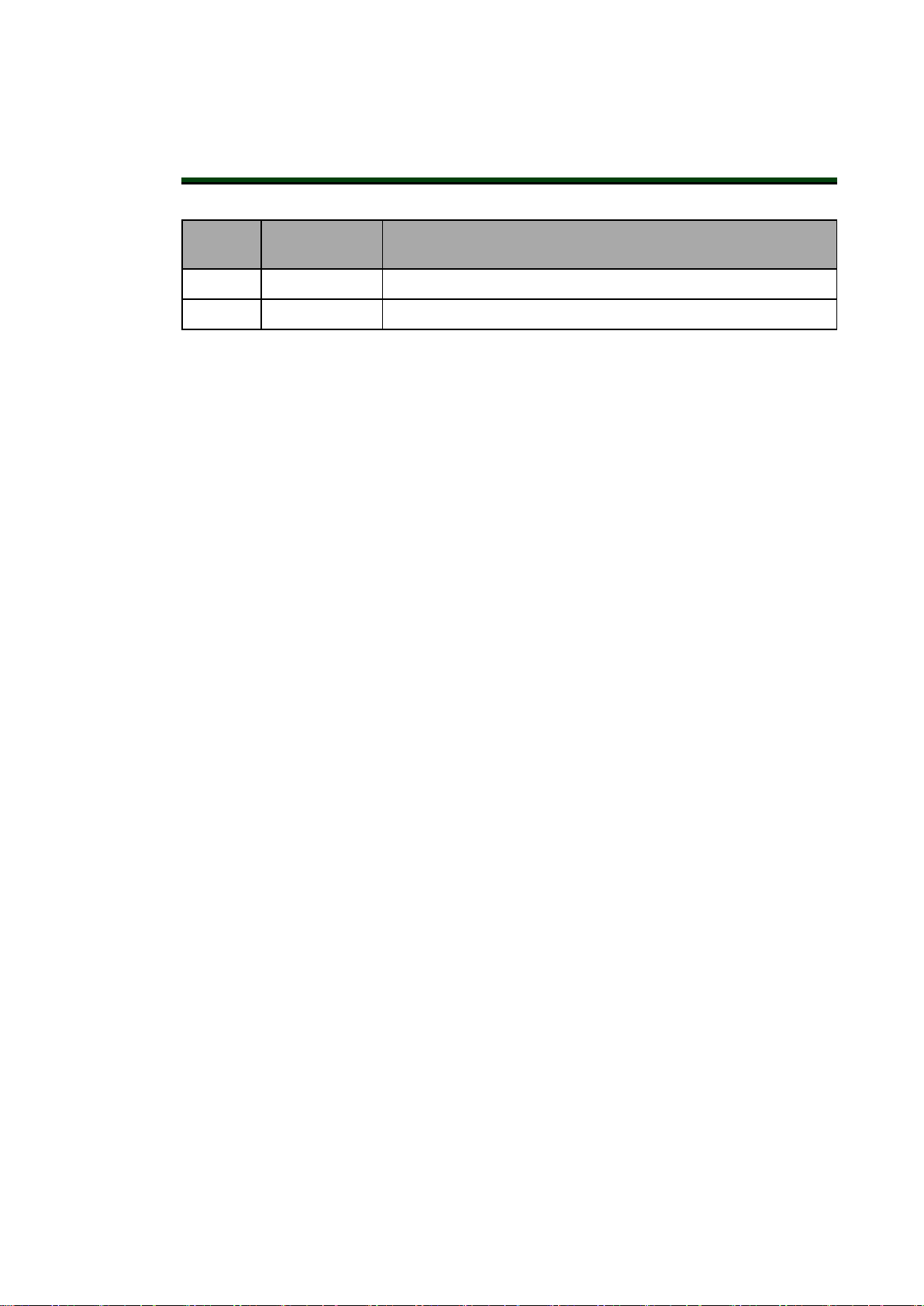

Revision History

Revision

Code

01 7/16/2020 Initial release of English version - Original Instructions

02 8/27/2020 Made changes to all chapters per updated engineering work.

Date Revised Content

31500-000 Rev B HD-1500 Platform User's Manual 8

Page 10

Page 11

This manual is OMRON's Original instructions describing the setup, operation, and user maintenance of an HD-1500 Autonomous Mobile Robot (AMR).

This manual does not describe all configuration steps that you perform using the software supplied with an HD-1500. The Fleet Operations Workspace Core User's Manual (Cat. No. I635)

describes configuration, and use of the HD-1500.

1.1 Definitions

This document uses the following terms to describe the HD-1500:

AMR (Autonomous Mobile Robot):This term describes the HD-1500 with an attached pay-

load structure, creating a complete Mobile Robot.

We use the term AMR when talking about controlling or monitoring the full mobile robot with

attached payload structure.

Fleet Manager: The operational mode of the computing appliance (EM2100 appliance) that

runs the FLOW Core software to control a fleet of AMRs.

Fleet Operations Workspace (FLOW): A computing system that consists of software and hardware packages, and is used to set up, integrate and manage a fleet of AMRs within a factory

environment. FLOW consists of two main elements: FLOW Core and FLOW iQ.

Chapter 1: Introduction

FLOW Core: All of the software used by Fleet Operations Workspace. The software runs on

the EM2100 appliance(s), the AMRs, and the user's PC.

FLOW iQ: A software package that captures, analyzes, and reports data to users in order to

measure, evaluate and constantly improve their AMR fleet performance in the factory.

Fleet: Two or more AMRs operating in the same workspace.

HD-1500: This is the model name of the AMR platform. This document uses the model name

HD-1500 when describing the setup, configuration, and connections.

Mobile Robot: An alternative industry term for AMR.

Payload Structure: Any passive or dynamic device attached to and possibly powered by the

HD-1500. This could be as simple as a crate for carrying objects such as factory parts or as

sophisticated as a robotic arm that picks up and manipulates factory parts.

Platform: The most basic part of the AMR. It includes:

o

The chassis, drive assemblies, light discs, light strips, suspension, casters, battery and

lasers.

o

An on-board AMR controller with built-in Inertial Measurement Units (IMU), navigation software, data and power connectors for a payload structure.

o

An Operator Panel.

o

The HD-1500 skins (external covers), and the chassis where you attach a payload structure.

31500-000 Rev B HD-1500 Platform User's Manual 10

Page 12

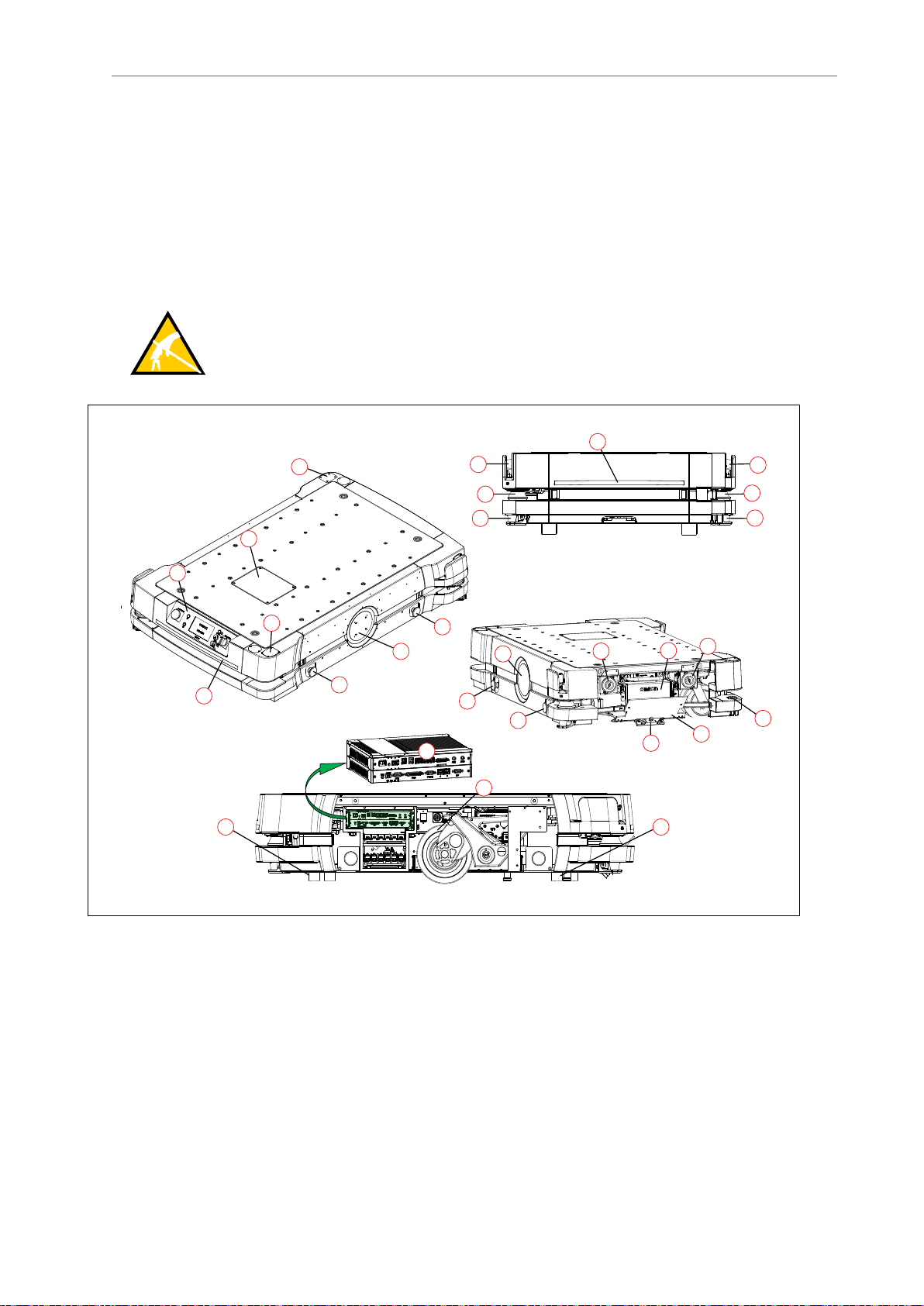

1.2 Product Description

D

F

E

D

E

K

M

J

H

H

I

N

O

O

F

G

Q

R

P

P

A

C

O

O

G

L

B

C

1.2 Product Description

The HD-1500 is a general-purpose mobile robot, designed to work in an indoor industrial

environment and around trained personnel. It is self-guided and self-charging, with an automated charging station. It has a maximum capacity of 1500 kg. Capacity includes the payload

structure and any load carried by that structure.

It’s Electrostatic Discharge (ESD) drive wheels discharge any accumulated electrical charge in

the AMR to ground which, if discharged into sensitive components of the AMR, could result

in serious damage of those components.

CAUTION: PROPERTYDAMAGE RISK

The AMR skins can accumulate electrical charge which, if discharged into ESD

sensitive devices, can cause damage to those devices.

11 HD-1500 Platform User's Manual 31500-000 Rev B

Figure 1-1. HD-1500 Platform Features

Page 13

Chapter 1: Introduction

B

C

A

E

D

F

Callout Description Callout Description

A Operator Panel with E-Stop But-

ton

B User Access Panel L Back Light Indication

C Wireless antenna x2 M High-Accuracy Positioning System

D Safety Scanning Laser x2 N

E Low Laser x2 O E-stop Button x4 (two on each side)

F Side Laser x2 - option P Front Caster x2, Rear Caster x2

G Light Disc x2 - one on each side

of the HD-1500

H Speaker x2 R AMR Controller

I Battery

J Battery Door

K Front Light Indication

(HAPS) x2 - option

Charging Contact x2 - top and bottom

Q Drive Wheel x2 - one on each side of

the HD-1500

Figure 1-2. Charging Station Features

31500-000 Rev B HD-1500 Platform User's Manual 12

Page 14

1.2 Product Description

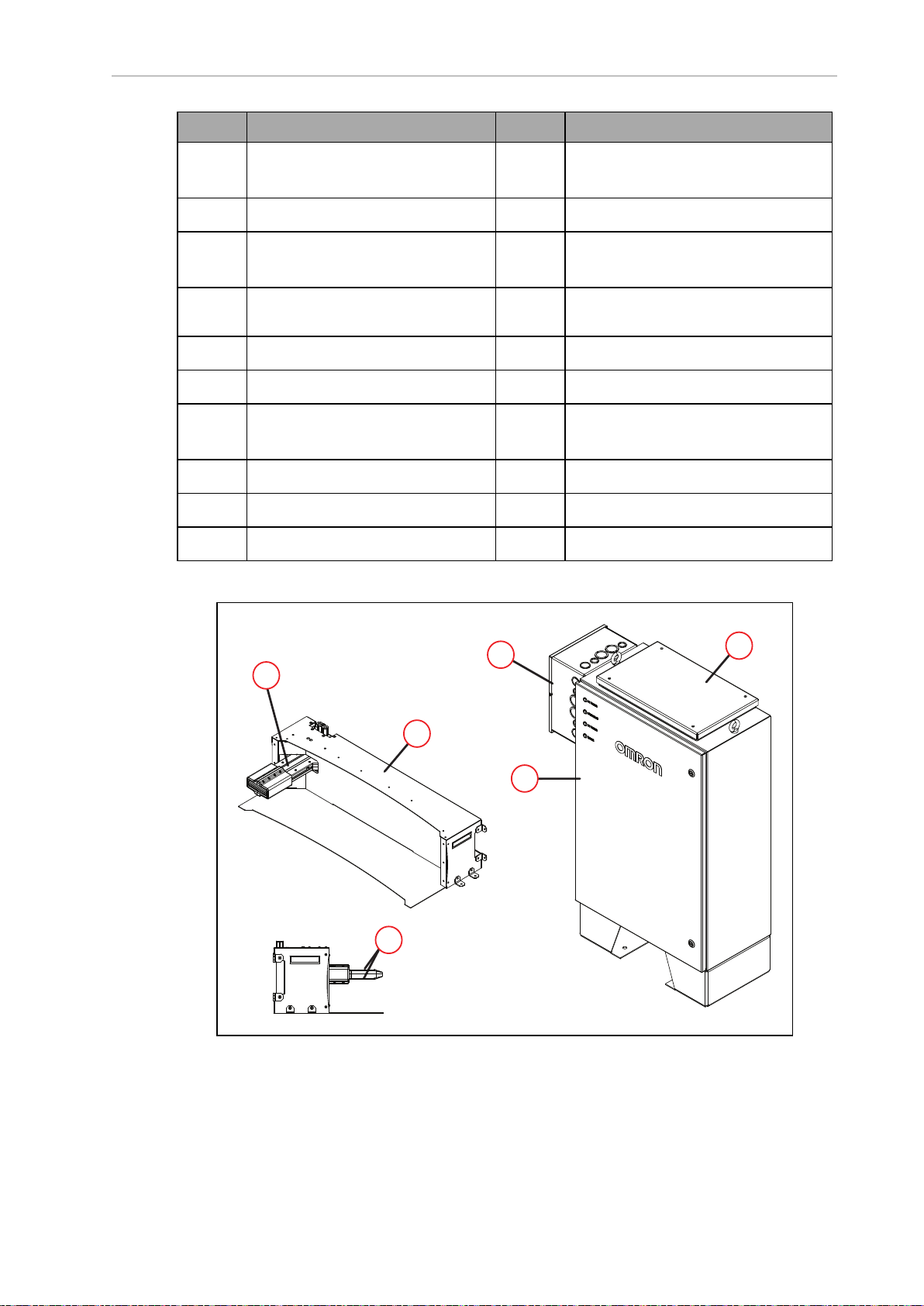

Callout Description Callout Description

A Power Supply Box D Docking Target

B Cooling Duct Cover E Charging Paddle

C Electrician Access Box F Charging Pads x2 - top and bottom

HD-1500 Autonomous Navigation

The HD-1500 combines hardware and mobile-robotics software to provide an adaptive, mobileplatform to transport your payload. The HD-1500 is equipped with Natural Feature Navigation system which enables the AMR to navigate, and perform its basic functions

independently and without the need for facility modification. After it scans physical features in

its environment, the HD-1500 navigates safely and autonomously to any accessible destination. It can move continuously and without human intervention, autonomously recharging

itself as necessary.

The HD-1500 uses range data from a Safety Scanning Laser as its primary means of detecting

obstacles and of maintaining an accurate understanding of its location in the environment.

Additionally, it uses data from the following sensors:

l

Two low lasers at the opposing corners of the AMR platform to detect objects below the

plane of the Safety Scanning Lasers.

l

Gyroscopes that detect and report HD-1500 rotational velocity.

l

Two encoders on each drive motor provide information on the distance traveled by

each drive wheel.

HD-1500 Localization

The encoders provide the navigation system with information on how far each wheel has

traveled, and in which direction. In addition, the Gyroscopes track the AMR's rotational velocity. The encoder information, combined with gyroscope data, is used to deduce the odometry.

The AMR analyzes this odometry data together with the data received from the safety scanning lasers, low lasers, and the side lasers to calculate its position within the map. This process is called localization.

Custom Payload Structures

For most applications, you will want to customize the platform with a payload structure,

attached to the top of the platform, for some combination of picking up, transporting, and dropping off your payload or material. The HD-1500 provides threaded mounting holes for payload attachment. The mounting holes provide a strong and adaptable method of attaching

payload structures to the chassis. A payload structure can be as simple as a crate that contains

manufacturing parts or a more sophisticated device such as a conveyor or robot arm. For more

information on designing a payload structure, see: Payload Structures on page 140.

The platform also provides a variety of interfaces and power connections to support your

application-specific sensors and accessories. For more information on available user connectors, see: Connectivity on page 154.

13 HD-1500 Platform User's Manual 31500-000 Rev B

Page 15

Chapter 1: Introduction

22

B

B

A

A

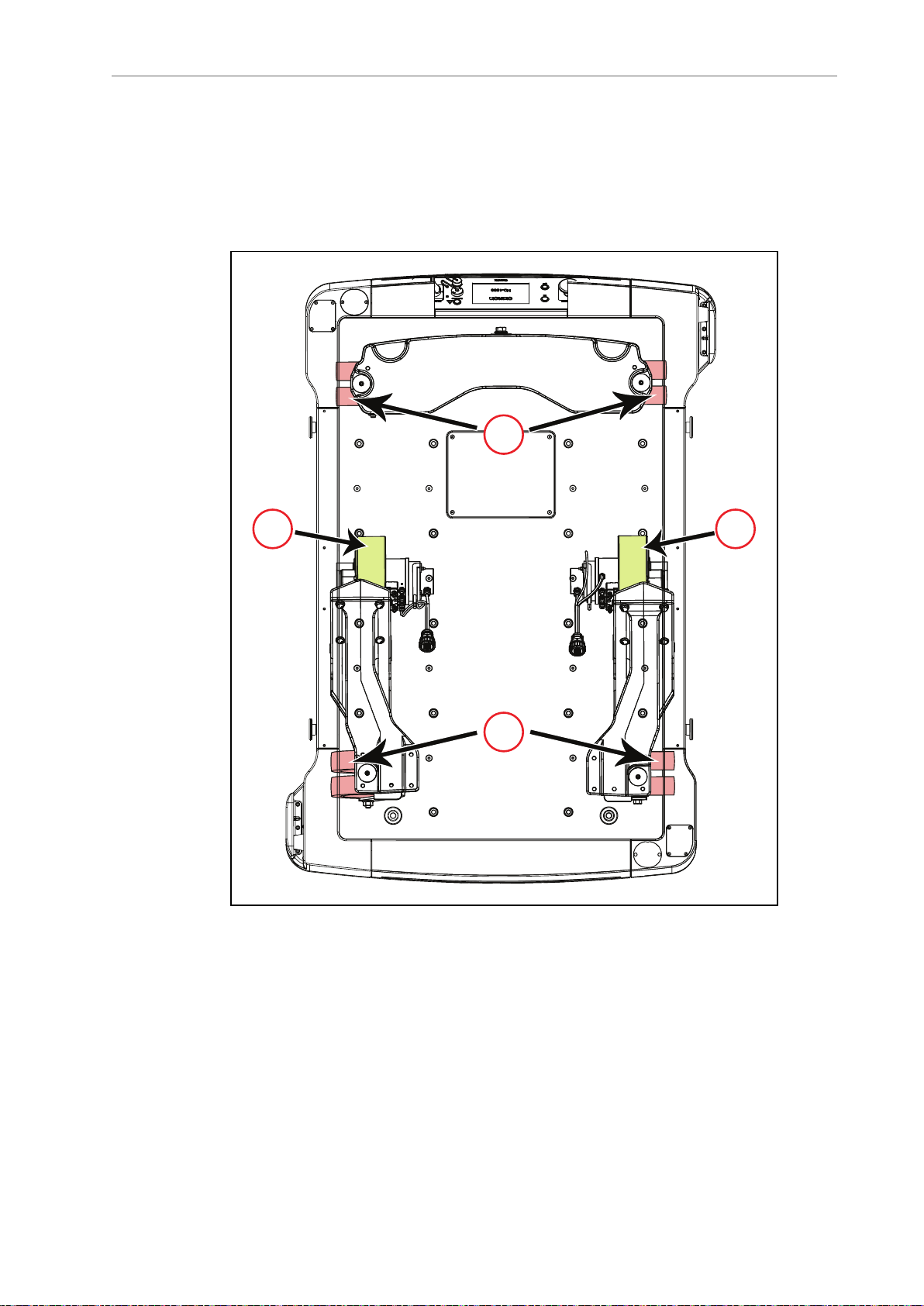

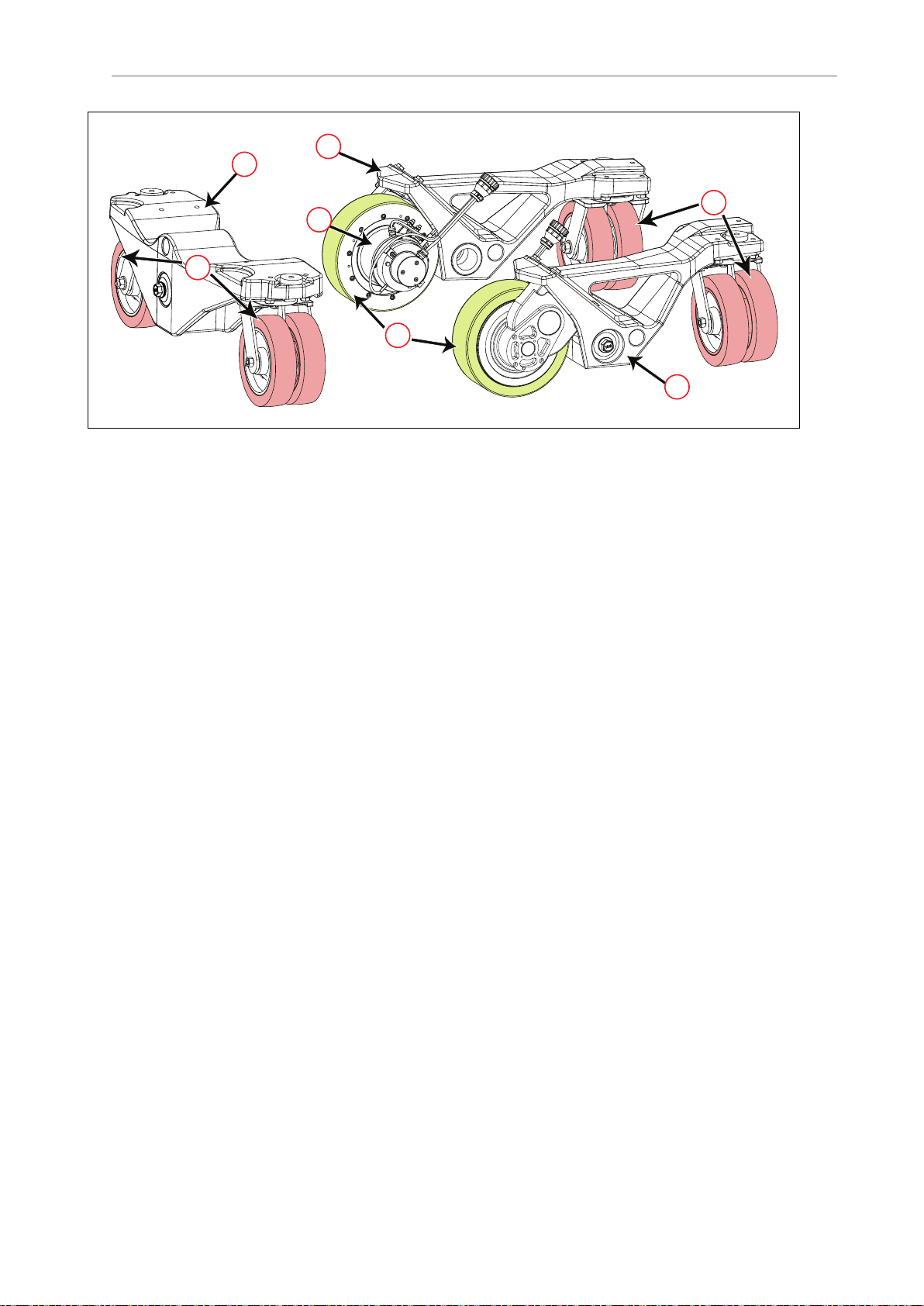

Body and Drive Train

The HD-1500 is a differential-drive AMR. It has two drive-wheels, and passive swivel-casters

at its front and rear for balance. The drive-wheels are mounted on the rocker arms, and have

solid polyurethane tread. Refer to the following figure for more information.

This drive style makes the HD-1500 highly maneuverable and allows it to rotate in place.

Figure 1-3. HD-1500Drive Train - Top View, (A)Casters, and (B) Drive Wheels

Each front caster is mounted to the same rocker arm as one of the drive-wheels. The two rear

casters are connected by another rocker that pivots about the AMR's longitudinal center-line.

This arrangement allows the AMR to maintain contact with the floor over uneven areas or

bumps, which benefits both traction and stability. Refer to the following figure for more information.

31500-000 Rev B HD-1500 Platform User's Manual 14

Page 16

1.2 Product Description

A

A

B

C

C

D

C

Figure 1-4. HD-1500Drive Train (A) Casters, (B) Drive Wheels, (C) Rocker Arms, and (D) Drive

Motor (one on each drive wheel)

What's Included - Basic Components

One fully-assembled HD-1500Platform which includes:

l

Two OMRON OS32C Safety Scanning Lasers (main lasers).

l

Two low lasers.

l

Differential drive train.

l

Skins.

l

AMR Controller which includes:

o

A computing appliance that runs the SetNetGo operating system and the

Advanced Robotics Automation Management (ARAM) software.

o

A system that runs a variant of the Mobile Autonomous Robot Controller

(MARC), called Polo.

The AMR Controller comes pre-loaded with ARAM and Polo firmware, and the

SetNetGo OS. The AMR Controller is housed inside the platform as displayed in

the following figure.

15 HD-1500 Platform User's Manual 31500-000 Rev B

Page 17

Chapter 1: Introduction

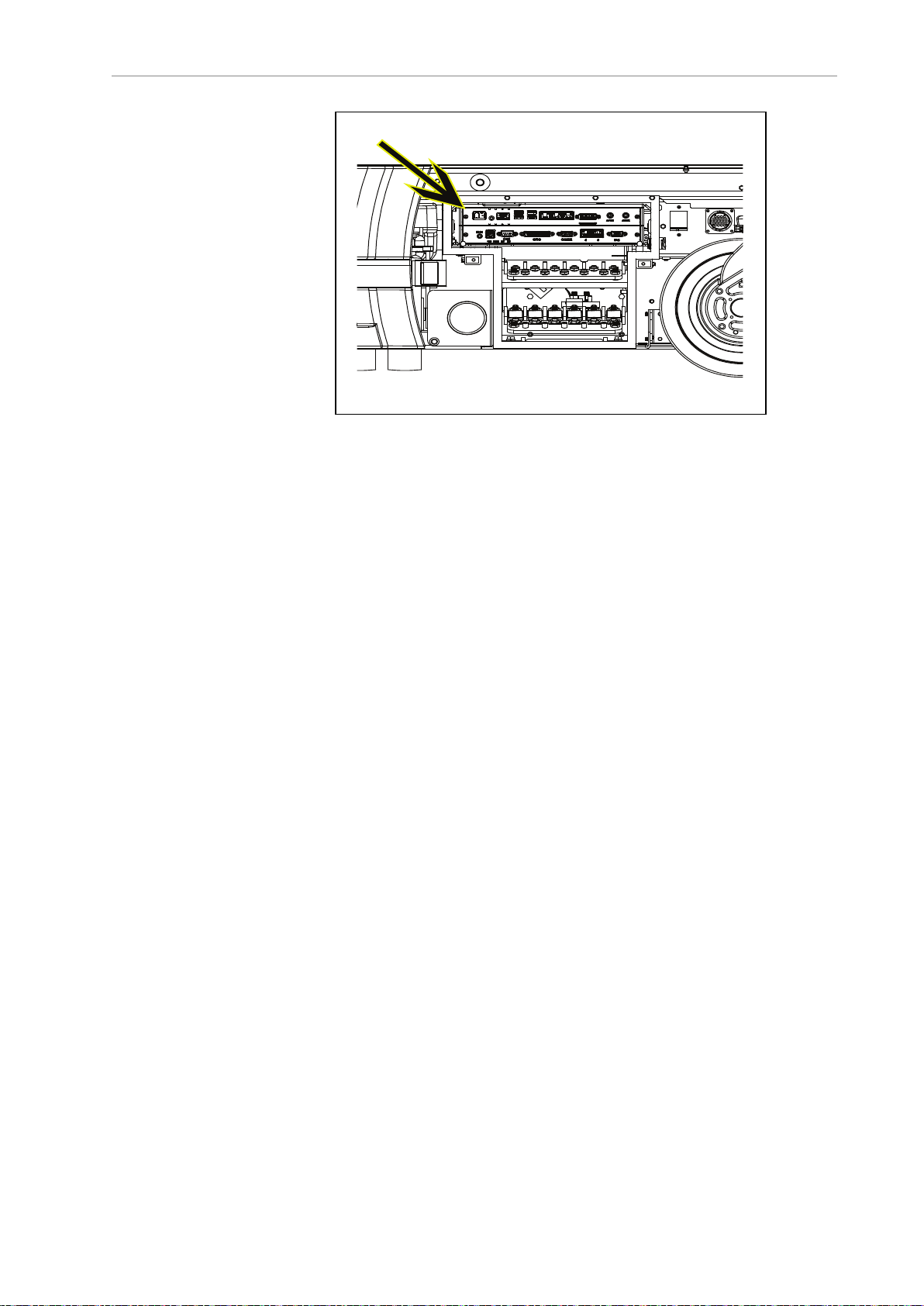

Figure 1-5. AMR Controller in the Platform

o

Other sensors including inertial sensing for use with AMR controls.

l

One battery

Shipped separately from the platform to comply with dangerous goods shipping regulations.

l Five emergency stop (E-Stop) buttons:

o

One on the Operator Panel

o

Two on each side of the platform

l Operator Panel

The Operator Panel includes a screen, an E-Stop button, ON and OFF buttons, a brake

release button, pendant port, Maintenance Ethernet connection, and a main disconnect

switch (which can be locked if needed). When the main disconnect switch is in OFF position (horizontal position), the power does not run through the AMR and therefore, the

AMR can not operate. To allow the power to run back through the AMR,you must turn

the main disconnect switch to ON position (vertical position), as displayed in the following figure.

You can move the operator panel to any preferred position on your payload structure.

However, because the operator panel contains one of the five E-Stop buttons, there are

important safety considerations when relocating or removing this panel. See: Positioning an Optional Payload E-Stop on page 202.

For information on the dimensions of the Operator Panel, see: Operator Panel on the

Payload on page 151.

31500-000 Rev B HD-1500 Platform User's Manual 16

Page 18

1.2 Product Description

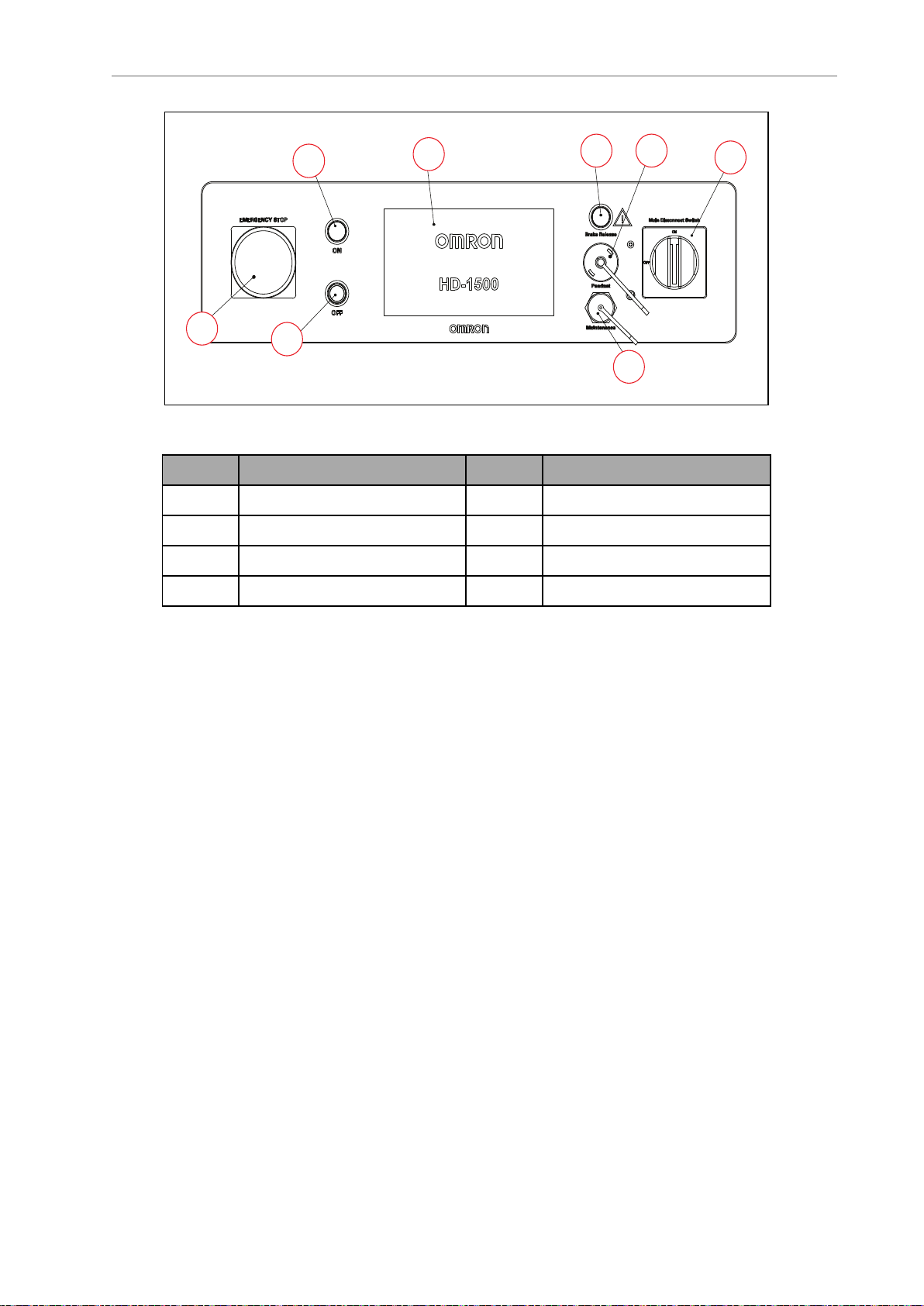

B G

F

H

D

C

A

E

Callout Description Callout Description

A Emergency Stop (E-Stop) E Main Disconnect Switch

Figure 1-6. Operator Panel

H

F

Ethernet Connection

Display Screen

B Brake Release Button

C On Button G Pendant Connection

D Off Button

l

Automated charging station

The automated charging station enables the HD-1500 to charge itself, without user intervention. It includes wall and floor mount brackets, for a choice of installation methods.

See: Installing the Charging Station on page 115.

The charging cord that connects the Power Supply box to the Docking Target which can

also be used for charging a battery outside of the platform. See: Manually Charging the

AMR's Battery on page 195.

l

A USB flash drive containing software and documentation.

In addition to the items included with every HD-1500, you need at least one pendant per AMR

fleet. Use this pendant to manually drive the HD-1500 and to create a digitized map of the

work environment.

For a fleet of AMRs, the Fleet Operations Workspace Core (FLOW Core) software (running on

an EM2100 appliance) shares the map between all AMRs in the fleet. This provides a common

frame of reference for navigation and localization, preventing contention between AMRs.

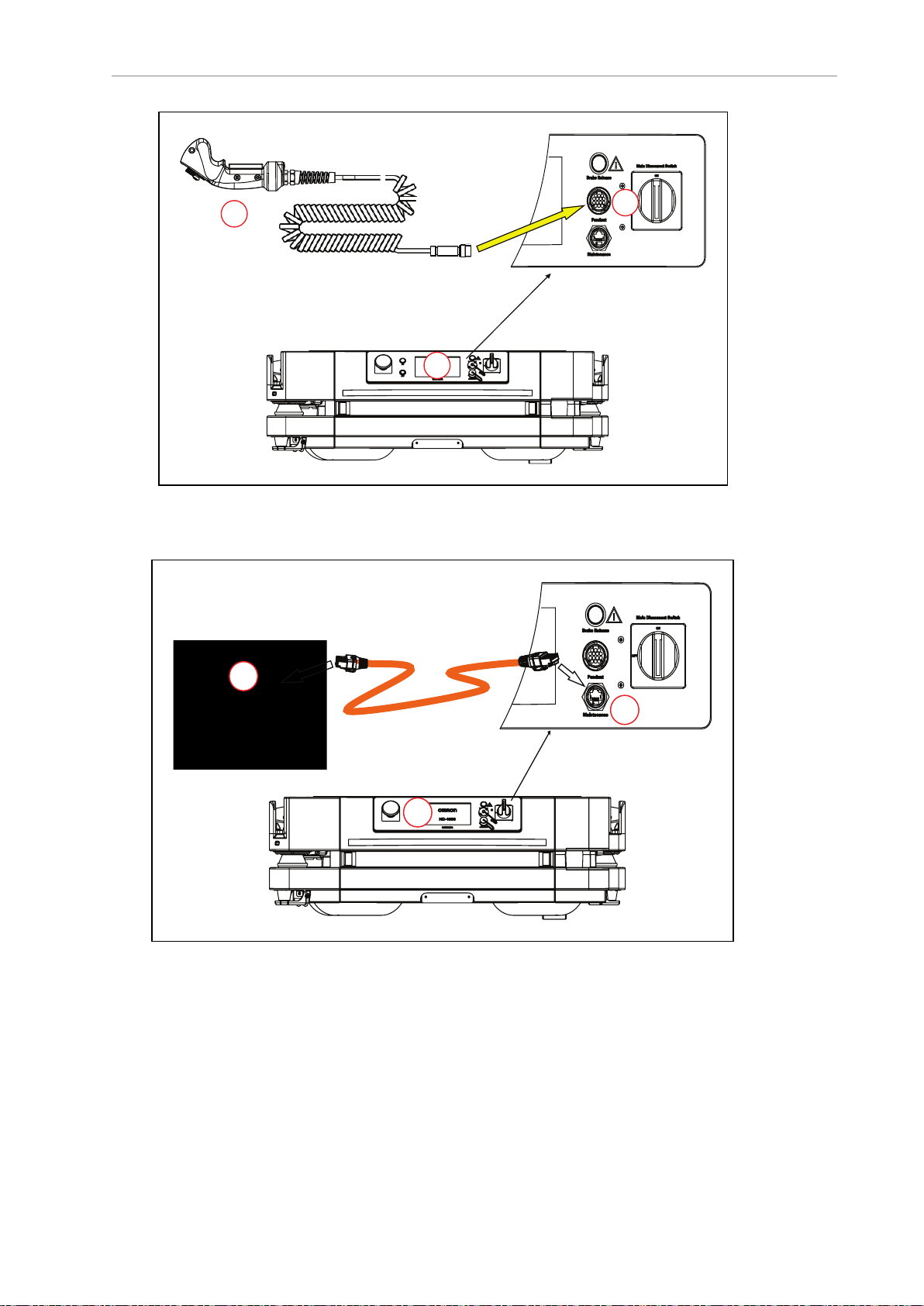

Figure 1-8. and Figure 1-9. display the location of the pendant, and the Ethernet ports on the

Operator Panel, installed on the rear of the HD-1500.

17 HD-1500 Platform User's Manual 31500-000 Rev B

Page 19

Chapter 1: Introduction

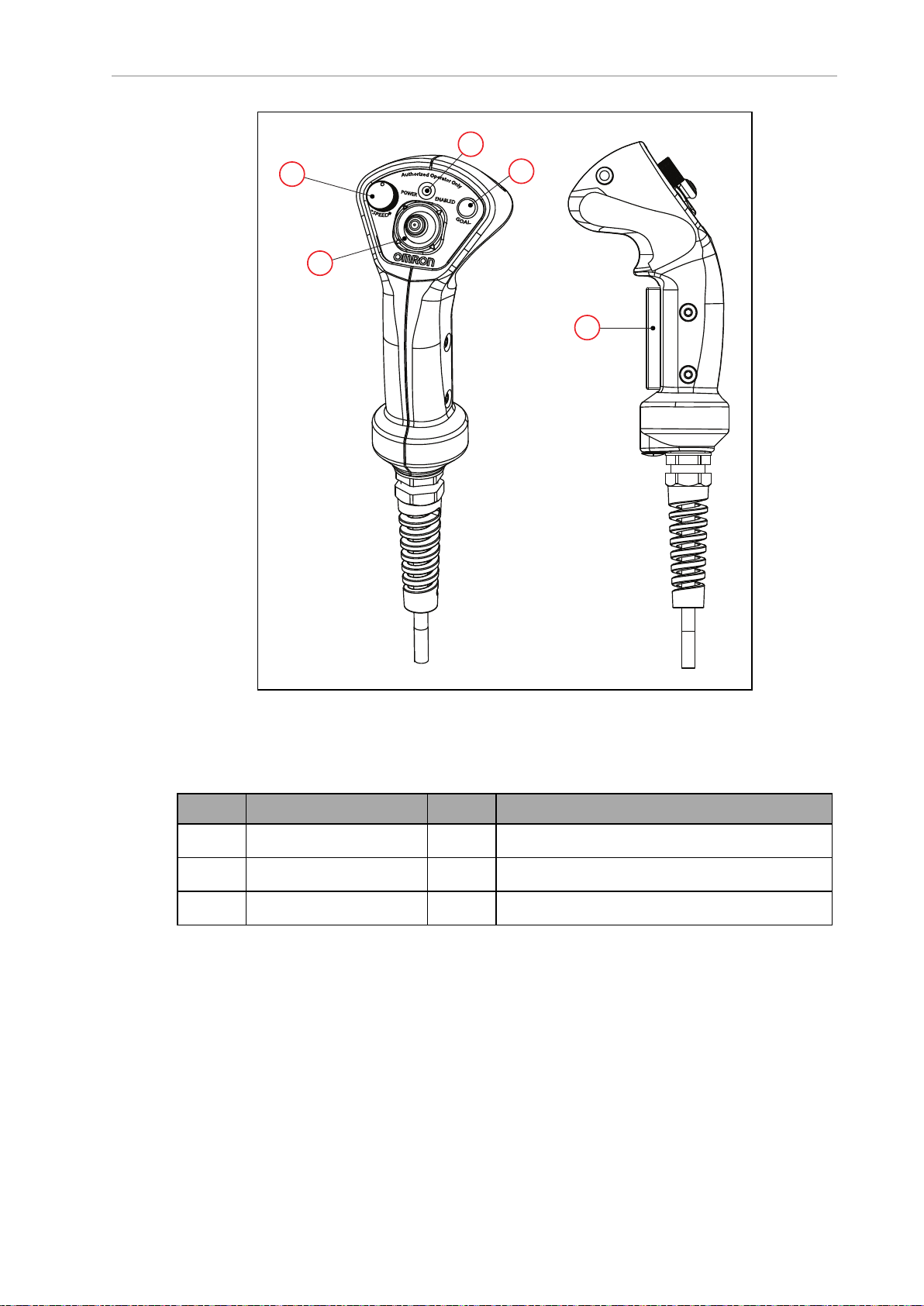

E

N

ABLED

P

OWER

A

B

C

D

E

Figure 1-7. Pendant Controls

This is used for manually controlling the platform, mostly when making a scan to be used for

generating a map.

Callout Control Function Callout Control Function

A Speed control D Power indicator LED

B Goal button E Trigger switch Three-position enabling device

C Directional control stick

31500-000 Rev B HD-1500 Platform User's Manual 18

Page 20

1.3 Software Overview

A

C

B

A

C

B

Figure 1-8. (A) Pendant, (B) Pendant port on the Operator Panel, and (C) Operator Panel on the HD-

1500

Figure 1-9. (A) PC, (B) Maintenance Ethernet Port on the Operator Panel, and (C) Operator Panel on

1.3 Software Overview

Your HD-1500 requires the licensed software described in this section. Software is factoryinstalled on its AMR Controller.

19 HD-1500 Platform User's Manual 31500-000 Rev B

the HD-1500

Page 21

Chapter 1: Introduction

Fleet Manager Appliance

ARAMCentral

AMR Controller

SetNetGo OS

ARAM

ARCL Protocol

Polo

Operator Panel

Tablet

MobilePlanner

Operator PC

MobilePlanner

HTTP

SetNetGo UI

Manufacturing

Execution System/

Enterprise Resource

Planning System

Onboard Control Panel

Access to software features is permitted by use of a USB license dongle that contains secure,

encrypted electronic copies of the operating licenses. Some licenses might have a restricted

term and expire after a specific date. You will receive several warning alerts before the license

expires.

HD-1500 Software

The minimal operating configuration for an HD-1500 consists of the AMR managed by a

human operator using a Microsoft Windows® PC or optionally from an Android or iOS tablet.

If you have more than one AMR, you must install and configure an EM2100 appliance (running the Fleet Operations Workspace software) to manage multiple AMRs as a fleet. Fleet management prevents job contention or collisions between AMRs and provides efficient processing

of all tasks that you assign to the AMR fleet.

See the following documents for detailed information:

l

Enterprise Manager 2100 User's Guide (Cat. No. I631)

l

Fleet Operations Workspace Core User's Manual (Cat. No. I635)

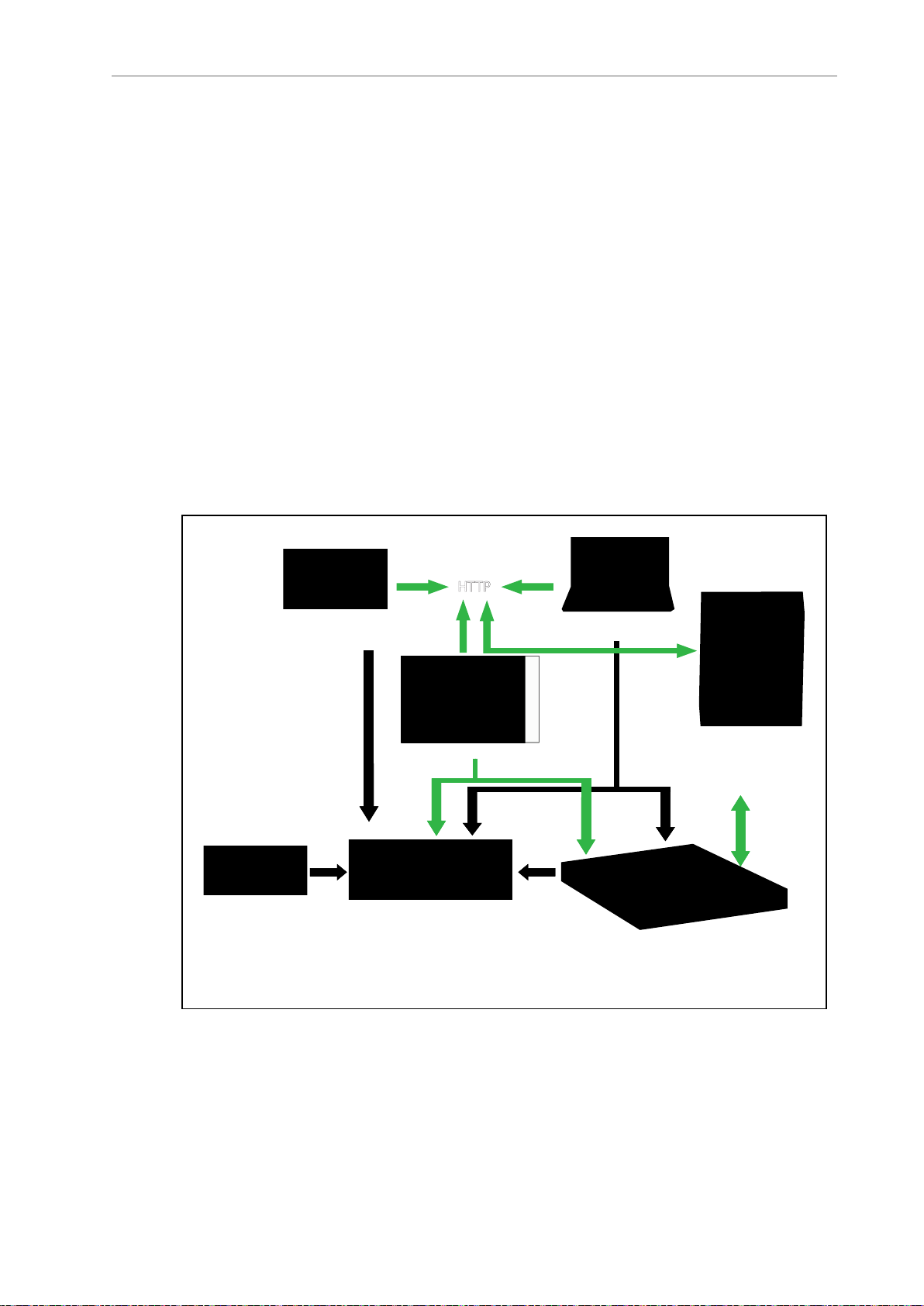

Figure 1-10. shows the devices that you might use to manage one or more AMRs and the software components required for each device, if applicable.

Figure 1-10. Devices and Software in the AMR's Operating Configuration

31500-000 Rev B HD-1500 Platform User's Manual 20

Page 22

1.3 Software Overview

AMR administration includes both configuring and operating an AMR and also using the

AMR (or a fleet of AMRs) to perform useful work. The software that enables you to do this

management consists of:

l

The FLOW Core software, an integrated set of programs that run on different devices in

the environment (FLOW Core). You use the MobilePlanner or MobilePlanner Tablet

graphical interfaces to manage individual AMRs or fleets of AMRs. You can also access

lower-level functions through a command-line interface, ARCL. The Integration Toolkit

(ITK) can also be used to interface your MES or WMS system with the Fleet Manager.

l

The SetNetGo OS, a host operating system (OS) that provides a Web interface you use to

assign network addresses, perform configuration, upgrade software, and obtain debugging files.

User-Supplied Components and System Requirements

To configure and manage an HD-1500 you require a personal computer (PC) running a supported version of Microsoft Windows

l

200 megabytes of available hard-disk storage.

l

Ethernet connection. OMRON recommends that you use a stable and high-speed wire-

®. The PC requires:

less connection.

Additional Information: Wireless is a requirement for managing multiple AMRs

as a fleet. See: Fleet Operations Workspace Core User's Manual (Cat. No. I635).

Also, you may optionally use an Android or iOStablet to run the MobilePlanner Tablet software.

ARAM

The Advanced Robotics Automation Management software (ARAM) runs on the AMR Controller. ARAM is responsible for the following AMR functions and features:

l

Interaction with on-board sensors such as the safety scanning lasers, low lasers, and

optional side lasers.

l High-level, autonomous robotics functions such as:

o

Obstacle avoidance

o

Path planning

o

Localization

o

Navigation

l

Motion commands to the Polo firmware.

l

Battery management.

ARAM provides the AMR with an interface to external entities by managing the following:

l

Wired and wireless Ethernet communications with external software for external monitoring, development, and systems coordination.

l

Fleet coordination of AMRs through the optional Fleet Manager.

21 HD-1500 Platform User's Manual 31500-000 Rev B

Page 23

Chapter 1: Introduction

l

Integration with other systems.

l External monitoring, setup, and control via the MobilePlanner graphical interface.

l

Digital and analog I/O ports accessible from the user access panel that enable you to

integrate application-specific sensors and effectors into your payload structure. Refer to

Fleet Operations Workspace Core User's Manual (Cat. No. I635) for instructions on how

to configure I/O connections.

ARAMCentral

ARAMCentral runs on the Fleet Manager as part of the Fleet Operations Workspace software.

When managing a fleet, the ARAMCentral software does the following:

l

Stores and distributes:

o

The shared workspace map used by all AMRs in a fleet.

o

The common AMR configuration.

l

Controls AMR traffic, including:

o

Multi-AMR avoidance

o

AMR Destinations

o

AMR Standby

o

Charging dock access

l

Queuing of jobs

l

Remote I/O (if used)

MobilePlanner Administrator Mode

MobilePlanner is part of the Fleet Operations Workspace software and runs on the user's PC,

or as a portable tablet version (on Android and iOS tablets). It provides a tabbed graphical

user interface on the PC and a touchscreen interface on tablets. Depending on your level of

access (controlled by your account) the graphical interface provides many options, including:

l

Managing AMR fleet jobs.

l

Creating and editing workspace maps.

l

Accessing the AMR through the SetNetGo Web interface.

l

Commissioning and configuring an AMR and modifying its configuration by changing

ARAM parameters.

l

Issuing custom ARCL commands.

Operator access or View access restricts the tasks that you can perform when using

MobilePlanner.

Before you assign tasks to an AMR, you use MobilePlanner to create and edit a digitized map

of its work space. During this procedure, you use the pendant to drive the AMR around the

workspace. In mapping mode, the safety scanning laser scans features of the workspace, such

as walls, columns, doorways and corners. After you create the map, you open it in

31500-000 Rev B HD-1500 Platform User's Manual 22

Page 24

1.3 Software Overview

MobilePlanner and edit it to add or remove features. For example, if there is an area of the

map where you want the AMR to follow a specific path, you can draw a PreferredLine feature

on the map. Be aware that the AMR will deviate from the PreferredLine if an obstacle enters its

path.

You then use MobilePlanner to configure ARAM operating parameters that control the AMR's

operation in the mapped workspace. For example, you might assign a preferred charging Station (docking target) to the AMR or the Fleet Manager by specifying the unique map identifier

for that docking target. This configuration can be shared with identically-equipped AMRs in

your fleet. The map generated by one AMR can be shared across a fleet, with both identical

and non-identical OMRON AMRs.

Refer to the separate Fleet Operations Workspace Core User's Manual (Cat. No. I635) for instructions about mapping a workspace and preparing the virtual elements, goals, routes, and tasks

for your application. In particular, refer to the descriptions of the following software options:

l

Working With Map Files - Editing a Map File

l

Using the Drawing Tools - Adding Goals and Docks

MobilePlanner, Operator Mode

MobilePlanner can operate in a restricted Operator mode that permits only limited access to

user interface features and functions.

MobilePlanner’s Operator Mode allows you to monitor one or more AMR's activities and

assign tasks in the mapped space. For more information, see: Fleet Operations Workspace Core

User's Manual (Cat. No. I635).

Polo

The AMR Controller contains a powerful multi-processor that runs the Polo firmware.

This firmware controls low-level AMR functions, including:

l

Maintaining the AMR’s driving speed and heading (direction of travel).

l

Acquiring sensor data from the encoders, and internal orientation sensors.

l

Reading emergency stop (E-Stop) status to enable and disable the drive motors.

l

Reading pendant input.

l

Computing and reporting the AMR's odometry (the change in X, Y coordinates and the

heading) and other low-level operating conditions to the ARAM software.

ARCL Protocol

The Advanced Robotics Command Language (ARCL) is a programming language integrated

into ARAM and ARAMCentral. Its operating format is a text-based command and response

server. Use ARCL to integrate an AMR (or fleet of AMRs) into an external automation system.

You do not need access to MobilePlanner to use ARCL.

Typical uses of ARCL are:

l

Operating and monitoring the AMR.

l

Operating accessories and peripherals.

23 HD-1500 Platform User's Manual 31500-000 Rev B

Page 25

Chapter 1: Introduction

l

Sending commands to your payload structure.

For more information, See: Advanced Robotics Command Language Reference Guide.

Integration Toolkit (ITK)

The Integration Toolkit (ITK) is OMRON's newest interface application enabling the integration

of Fleet Manager with the end user's client application. ITK facilitates the full management

and monitoring of all AMR job types, and allows tracking of the AMR data directly. ITK has a

flexible architecture which provides multiple, and simultaneous communication channel

options allowing the user to command, and monitor fleet operations using Rest, SQL, and/or

RabbitMQ. These communication channels provide flexibility, and choice in how a system

interacts with an AMR fleet, and the Fleet Manager.

ITK runs only on the Fleet Manager.

For more information, refer to: Fleet Operation Workspace Core Integration Toolkit User’s Guide

(Cat. No. I637).

SetNetGo

The SetNetGo OS runs on the AMR Controller and EM2100 appliance. It is the host OS in

which the FLOW components ARAM and ARAMCentral run. SetNetGo has a Web interface

that you access either from a Web browser or from within MobilePlanner as a tab. After you

use a wired Ethernet connection to configure the AMR's wireless settings you may choose to

enable wireless access to SetNetGo from the web interface's Security tab.

To access the SetNetGo web interface, at a minimum, you need:

l

A hardwired connection to the HD-1500 Maintenance Ethernet port, located on the Operator panel.

l

A LANconnection or direct Ethernet port connection to the EM2100 maintenance port.

Your ITdepartment can use SetNetGo to configure network settings without using MobilePlanner.

Use SetNetGo to configure Ethernet settings, upgrade software, or perform diagnostics such as

retrieving log files.

1.4 How Can I Get Help?

Refer to the OMRON corporate website: http://www.ia.omron.com.

Related Manuals

This manual covers the installation, setup, operation, and maintenance of an HD-1500. There

are additional manuals that cover configuring the platform. See the following table. These

manuals are available on the USB flash drive delivered with your HD-1500.

Manual Title Description

Table 1-1. Related Manuals

Mobile Robot HDSafety Manual (Cat.

No. I647)

Contains general safety information for all OMRON

HD-1500-based AMRs.

31500-000 Rev B HD-1500 Platform User's Manual 24

Page 26

1.4 How Can I Get Help?

Manual Title Description

HDPlatform Peripherals User's Manual

(Cat. No. I646)

Safety Laser Scanner OS32C Series

User's Manual (Cat. No. Z296-E1)

Fleet Operations Workspace Core User's

Manual (Cat. No. I635)

Enterprise Manager 2100 User's Guide

(Cat. No. I631)

Fleet Simulator User's Manual (Cat. No.

I649)

Fleet Operation Workspace Core Integration Toolkit User’s Guide (Cat. No.

I637)

Advanced Robotics Command Language Enterprise Manager Integration

Guide (Cat. No. I618)

Covers peripherals, such as the , Side Lasers, HAPS,

and Acuity Localization options.

Describes the use of the OS32C laser.

Describes Fleet management, MobilePlanner software, the SetNetGo OS, and most of the configuration procedures for an HD-1500.

Describes the installation of an EM2100 appliance,

which runs the Fleet Operations Workspace software

to manage a fleet of AMRs.

Describes the configuration and use of the Fleet Simulator software on an EM2100 appliance.

Contains information that is necessary to use the

Integration Toolkit facilitating integration between

the Fleet Manager and the end user's client application.

Describes how to use the Advanced Robotics Command Language (ARCL) a text-based, command line

operating language Use ARCL to integrate a fleet of

AMRs with an external automation system.

Support

Contact your OMRON representative if you have further inquiries with your HD-1500 that are

not described in this manual.

When you contact support, it is useful to provide a DebugInfo file. This is a collection of configuration, log, and system status files that support personnel can use for debugging and

troubleshooting.

Visit the OMRON Web site for your locale to obtain local support telephone numbers and

information.

Download a Debuginfo File for Support

You can download a debuginfo file for troubleshooting problems or if you need to contact your

OMRON representative.

If your HD-1500 is already configured to use a wireless network:

1.

Open MobilePlanner and connect to the AMR's IP address.

2.

Click the SetNetGo tab to open its Web Interface.

3.

Click Status and select Debug Info from the left pane.

4.

Click Download Debug Info and then specify a location to save the file.

Otherwise, you must first create a TCP/IP connection to the AMR's Maintenance Ethernet port

as described in: Network Setup on page 26.

25 HD-1500 Platform User's Manual 31500-000 Rev B

Page 27

Chapter 1: Introduction

Network Setup

If you have not configured your HD-1500 for access over a wireless network, you must follow

the instructions provided in Maintenance Ethernet Connection on page 128. This is when you

use a hardwired connection to the HD-1500 Maintenance Ethernet port.

Obtain a DebugInfo File from SetNetGo

After you access SetNetGo as described in the preceding sections, you will see the following

screen:

1.

In the SetNetGo screen, click the Status tab and then select Debug Info to activate the

Download debug info button.

2.

Click Download debug info.

3.

When prompted, save the downloaded file, and attach it to your support request email.

See: Support on page 25.

Figure 1-11. SetNetGo Status Tab

31500-000 Rev B HD-1500 Platform User's Manual 26

Page 28

Page 29

This chapter provides an overview of important safety considerations for your HD-1500. All

!

!

!

persons operating or working in the vicinity of an HD-1500 must thoroughly read and understand this information. For more information on safety, refer to the Mobile Robot HDSafety

Manual (Cat. No. I647).

2.1 General Hazards

This section describes potentially hazardous situations and conditions.

WARNING: The following situations could result in injury or damage to the

equipment.

l

Do not ride on the AMR.

l

Do not exceed the maximum weight limit.

l

Do not drive the AMR on inclined floors or surfaces.

l

Do not exceed the maximum recommended speed, acceleration, deceleration, or rotation

limits. See Center of Gravity (CG) on page 147 and Acceleration, Deceleration, and Rotation Limits on page 136.

Chapter 2: Safety

Rotational speed becomes more significant when the payload’s center of gravity is

increasingly offset from the AMR's center of gravity.

l

Do not drop the AMR, run it off a ledge, or otherwise operate it irresponsibly.

CAUTION: PERSONALINJURYRISK

The user must not stand close to the AMR while it is rotating with no

forward motion.

l

Do not allow the AMR to drive through an opening that has an automatic gate or door

unless the door and AMR are configured correctly with the Call/Door Box option.

l

Do not throw an object in front of the AMR or suddenly step into the path of the AMR.

The AMR braking system cannot be expected to function as designed and specified in

such instances.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

Abrupt appearance of objects or persons in the path of the AMR could

result in personal injury or property damage. You must make sure that

the operating environment of the AMR is adequately controlled.

l

Do not expose the AMR to rain or moisture.

l

Do not use unauthorized parts to repair the AMR.

31500-000 Rev B HD-1500 Platform User's Manual 28

Page 30

2.2 Unprotected Areas

!

!

A

B

l

Do not power on the AMR without its wireless antennas in place.

l

Although the lasers used are Class 1 (eye-safe), OMRON recommends that you not look

into the laser light.

l

Reflective surfaces can interfere with the AMR's laser operation.

l

Do not operate the AMR in areas where it may be exposed to intense interference light,

such as direct sunlight.

l

Do not operate the AMR in a flammable gas environment.

l

Do not operate the AMR with the safety interlock switches disabled.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

Do not operate the AMR in hazardous environments where there is

explosive gas, and oil mist.

WARNING: ELECTRICAL SHOCKRISK, FIRERISK, BURNRISK

The safety interlock switches shall not be defeated or bypassed as this

could potentially result in short circuit.

l

The HD-1500 shall only be powered by an HD-1500 battery. Do not use any other batteries.

l

The HD-1500 battery shall only be charged by an HD-1500 charger. Do not use any

other chargers.

2.2 Unprotected Areas

The HD-1500 charges its battery autonomously by driving itself to the docking target where it

mates with the docking target's charging paddle, as displayed in the following figure.

Figure 2-1. HD-1500 Mating with the Charging Paddle, (A) HD-1500, and (B) Charging Paddle

29 HD-1500 Platform User's Manual 31500-000 Rev B

Page 31

Chapter 2: Safety

!

!

The HD-1500 travels at a low speed when docking:

l

When traveling between 0 to 20 mm/s (or angular speed of less than 3 deg/s), there are

no hardware-based safety laser protection zones. The HD-1500 beeps any time it moves

at a linear speed below 20 mm/s, or an angular speed of less than 3 deg/sec for longer

than 2 seconds. The AMR respects its software-based obstacle-avoidance clearances at

all speeds, but it will not use a hardware-based safety laser protection zone at speeds

below 20 mm/s or 3 deg/sec. This is done intentionally to allow operators to manually

drive the AMR away from any obstacles that are too close to the AMR. It also allows

the operators to back the AMR when needed.

l

At speeds between 20 to 115 mm/s (or angular speed of less than 12 deg/s), the AMR's

hardware-based laser protection zones exclude the area where the charging paddle

enters the laser channel. The safety zones of the two safety scanning lasers are identical,

and therefore, the unprotected areas are present at both front and rear ends of the AMR.

The operator must take necessary precautions to ensure that the operator's hands or

other body parts do not get stuck in between the charging pad and the platform when

docking.

l

At speeds above 115 mm/s, the hardware-based laser protective zones are fully active

and there are no unprotected areas.

The following table lists the hardware-based safety laser protection zones for the speeds mentioned in the preceding paragraph:

Table 2-1. Hardware-Based Safety Laser Protective Zones

Linear speed

(mm/s)

0≥ and < 20 0≥ and <3 No protective zones.

20≥ and <115 3≥ and <12 Two unprotected areas. Area

≥115 ≥12 No unprotected areas.

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

Although the AMR respects its software-based obstacle-avoidance clearances at

all speeds, the user must be aware of the location of the E-Stop buttons at all

times, and keep out of the unprotected areas.

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

It is the end user's responsibility to ensure that the area within the radius of

2 m from the center of the HD-1500 is kept clear, when the AMR is traveling at

less than 115 mm/s.

Angular speed

(deg/s)

Hardware-based safety laser

protective Zones

where the charging paddle enters

the laser channel (both at front

and rear of the AMR).

31500-000 Rev B HD-1500 Platform User's Manual 30

Page 32

2.2 Unprotected Areas

A

B

C

D

E

F

F

A

B

Figure 2-2. HD-1500 Protective Zones with Openings for the Charging Paddle - Movement at Less

Than 115 mm/s (Dimensions are in mm)

ID Description ID Description

A AMR Y-axis D Front laser zone

B AMR X-axis E HD-1500

C Rear laser zone F Safety scanning laser

The following figure provides dimensions of the HD-1500 unprotected area. The same dimensions are true for the rear laser unprotected area.

Figure 2-3. HD-1500's Unprotected Zone Dimensions - Movement at Less Than 115 mm/s, (A) AMR

Y-Axis, and (B) AMR X-Axis

31 HD-1500 Platform User's Manual 31500-000 Rev B

Page 33

2.3 What to Do in an Emergency

!

In case of an emergency such as a fire or collision, you should stop the AMR quickly and

safely. If the emergency situation is near the charging station, you must turn off the power

using the main disconnect switch. See Figure 7-10.

CAUTION: Combustible LithiumBattery.

For AMR fire suppression use either foam, dry chemical extinguisher, ABC, AB,

powdered graphite, copper powder, or a CO2extinguisher.

The HD-1500 has four E-Stop buttons, two on either side of the platform (a red push-lock button). The Operator Panel provides an additional E-Stop button (a red push-lock button on a yellow background). See the following figures.

Chapter 2: Safety

Figure 2-4. E-Stop Button on the Platform

Figure 2-5. E-Stop Button on the Operator Panel

Use the User Safety Interface connection, located on the user access panel, to add E-Stop buttons to your payload structure, if required. See: SCPU on page 165.

31500-000 Rev B HD-1500 Platform User's Manual 32

Page 34

2.3 What to Do in an Emergency

In the event of an emergency stop:

l

The AMR uses motor power to come to a controlled stop then engages its motor brakes

and removes power to its drive motors.

l

Indicator lights on the AMR, and the pendant (if attached) show the E-Stop state. See:

Light Discs and Beacon on page 204 and Front and Back Light Strips on page 208.

A user-initiated E-Stop differs from a laser-initiated protective stop (they both are category 1

stop). The latter occurs when one or both of the AMR's safety scanning laser detects an object

within its protected zone. In such cases, the AMR safely stops, and then resumes operation

after a delay of at least two seconds, and after confirming that its protected zone is clear of

obstacles. See: Protective Stops Initiated by AMR Safety Lasers on page 50.

An emegency stop initiated by pressing one of the E-Stop buttons, is a controlled stop function.

In this case, the power to the AMR motors remains on in order to achieve a controlled stop.

Once the controlled stop is achieved, the power to the motors is disconnected. If for any reason

the controlled stop function fails or does not function as expected, the power will still be disconnected to the motors. Activating an emergency stopby pressing one of the E-Stop buttons

requires manual deactivation of the E-Stop button, and manual reset of the AMR through the

ON button for the AMR to restart its operation. The AMR will not automatically recover from

an emergency stop initiated by pressing one of the E-Stop buttons on the AMR.

To use an E-Stop button:

1. Push firmly on the red button so that it latches.

2.

Follow your site-specific emergency and safety procedures.

If you need to move the AMR manually after correcting the emergency condition, press and

hold the brake release button and move the AMR. You can also use the pendant to drive the

AMR manually, if it is safe to do so. In order to use the pendant, you must first release the

E-Stop.

To enable the AMR's drive motors and put it back into service, follow the procedure described

in: Releasing an E-Stop on page 35.

Releasing the Brakes

In case of an emergency or abnormal situation, the AMR can be manually moved. However,

only qualified personnel who have read and understood this manual and the Mobile Robot

HDSafety Manual (Cat. No. I647) should manually move the platform. The brakes on the drive

wheels can be released with the brake release button. This requires battery power, and an EStop must be pressed on the AMR.

NOTE: You should move the HD-1500 manually only when absolutely necessary during an emergency, for safety, or if it is lost or stuck. If you find that you

must frequently move the HD-1500, use MobilePlanner to reconfigure its route to

avoid problem areas.

33 HD-1500 Platform User's Manual 31500-000 Rev B

Page 35

Chapter 2: Safety

!

!

!

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

Using the brake release button while the HD-1500 is positioned on a slope of

greater than 3% will cause the HD-1500 to roll down. You must not use the

brake release button to move the HD-1500 manually, when positioned on a

slope of greater than 3%, unless necessary precautions have been taken to prevent uncontrolled rolling of the HD-1500. The HD-1500 is not intended to be

operated on ramps or sloped surfaces.

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

Pushing an HD-1500 requires significant effort and might cause personal

injury or property damage. Take appropriate care and follow all safety instructions.

WARNING: PINCHRISK

Take necessary precautions when moving an

AMRwithout its skins attached. The motor and

motor assemblies will be exposed when the side

skins are removed, exposing the potential pinch

points. Refer to the following figure.

The rear and top of the AMR also pose pinch

hazard when the rear skin and the top plate are

removed.

Figure 2-6. Side Skin Removed - Exposing Motor and Motor Assemblies

Application-specific attachments can affect an AMR's stability. All operators should know the

locations on the AMR (or its payload) where they can push safely without tipping the AMR

over or damaging its components. This should be as low as possible and near the center of

gravity.

OMRON recommends that you train personnel on the safe use of the brake release button, and

procedures for safely pushing an HD-1500. For instructions on how to safely use the brake

release button, see: Brake Release Button on page 203.

31500-000 Rev B HD-1500 Platform User's Manual 34

Page 36

2.4 Dangers, Warnings, and Cautions

!

!

!

!

CAUTION: PERSONALINJURYRISK

The pushing locations of the AMR are low. You must use safe pushing/

pulling practices when manually moving the AMR.

Releasing an E-Stop

This section describes how to release an E-Stop and bring the AMR back into service.

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

If an AMR’s E-Stop is triggered, ensure that the cause of the E-Stop is resolved,

and all surrounding areas are clear before releasing the E-Stop.

To release an E-Stop:

1.

Make sure that all surrounding areas are clear before you release the E-Stop button so

that the AMR has room to maneuver.

2.

Rotate the E-Stop button in the direction of the arrows on the button and allow it to pop

up.

3.

After you release the E-Stop button, you must enable the motors manually by pressing

the green ON button on the operator panel.

After you enable the motors there is a delay of several seconds before the AMR can resume

operation.

NOTE: If you manually move the AMR while it is powered off, it may not be

able to determine its current location. Use the localization feature in MobilePlanner to localize the AMR.

Enabling motor power, either at the start-up or after an E-Stop release, must be done through a

manual action at the system, and only after the operator has confirmed that it is safe to return

the AMR to operation. Enabling the motor power must be an additional act after releasing an

E-Stop, and it is done by pressing the Operator Panel's On button.

2.4 Dangers, Warnings, and Cautions

Alert Levels

There are three levels of alert notation used in this document. In descending order of importance, they are:

DANGER: Identifies an imminently hazardous situation which, if not

avoided, is likely to result in serious injury, and might result in fatality or

severe property damage.

WARNING: Identifies a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, and might result in serious injury, fatality, or significant property damage.

35 HD-1500 Platform User's Manual 31500-000 Rev B

Page 37

Chapter 2: Safety

!

!

!

CAUTION: Identifies a potentially hazardous situation which, if not avoided,

might result in minor injury, moderate injury, or property damage.

Alert Icons

The icon that starts each alert can be used to indicate the type of hazard. These will be used

with the appropriate signal word - Danger, Warning, or Caution - to indicate the severity of the

hazard. The text following the signal word will specify what the risk is, and how to avoid it.

Icon Meaning Icon Meaning

Falling Hazards

This is a generic alert

icon. Any specifics on the

risk will be in the text following the signal word.

This identifies a hazardous electrical situation.

This warning icon warns

against riding on the

AMR.

This warning icon warns

against hazardous

magnetic field.

This warning icon warns

against a pinch hazard.

This identifies a hazardous burn-related situation, or a Hot surface.

This identifies a hazardous ESD situation.

This identifies a fire risk.

This identifies a tip hazard.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

The AMR can cause serious injury to personnel or damage to itself or other

equipment if it drives off of a ledge, such as a loading dock, or down stairs.

Physical Barriers

Use physical barriers together with logical barriers (map restrictions) to prevent the AMR from

approaching any fall hazard that is within its operating area. Such hazards include:

l

The edge of a loading dock or ramp.

l

Entrance to downward stairs.

l

Any other vertical drop that exceeds the AMR's maximum step height.

31500-000 Rev B HD-1500 Platform User's Manual 36

Page 38

2.4 Dangers, Warnings, and Cautions

Required characteristics of physical barriers are:

l

Strength—The barrier must be attached to a solid wall or floor and should be strong

enough to stop a fully-laden AMR traveling at maximum speed.

l Continuity—The barrier must extend around the hazard completely.

l

Visibility—Mark all physical barriers to make sure that the AMR's safety lasers can

detect them easily. Barriers must extend above and below the laser's sensing plane, particularly if the floor is not flat.

Logical Barriers

In addition to physical barriers, use MobilePlanner to create forbidden areas or lines on the

workspace map to prevent AMRs from closely approaching a fall hazard. These restrictions

must be continuous so that the AMR cannot plan a path around the logical barrier.

The map features mentioned in the preceding paragraph are not interlocked methods of preventing an AMR from entering a specific zone. These map features assume proper AMR localization, and therefore, if the AMR is not able to properly localize its current position it may

enter the forbidden zones. You must always install physical barriers where there is a risk of

property damage or safety hazard.

You can also use the configuration parameters FrontPaddingAtSlowSpeed and FrontPad-

dingAtFastSpeed to increase the AMR's safety clearances. This causes the AMR to decelerate as

it approaches a hazard. See: Fleet Operations Workspace Core User's Manual (Cat. No. I635).

Special Information

This manual uses the following typographic styles to identify specific types of information:

IMPORTANT: Information to ensure safe use of the product.

NOTE: Information for more effective use of the product.

Additional Information: Offers helpful tips, recommendations, and best prac-

tices.

Version Information: Information on differences in specifications for different

versions of hardware or software.

37 HD-1500 Platform User's Manual 31500-000 Rev B

Page 39

2.5 User's Responsibilities

!

!

!

!

You are responsible for continuous safe use of the AMR.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

Any modifications made to the AMR can lead to loss of safety or functionality

of the AMR. It is the end-user's responsibility to perform complete risk assessment after making any modifications to the AMR, and to confirm that all safety

features of the AMR are fully functional.

WARNING: PERSONALINJURYRISK

It is the end-user's responsibility to perform a task-based risk assessment and

to implement appropriate safety measures at the point of use of the AMR in

accordance with local regulations.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

It is the end-user's responsibility to make sure that the AMR design and implementation complies with all local standards and legal requirements.

Chapter 2: Safety

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

It is the end-user's responsibility to make sure that the AMR is operated within

its specifications, intended use, and intended environments.

Safe use of the AMR requires that you:

l

Read the installation and operation instructions, in addition to the Mobile Robot

HDSafety Manual (Cat. No. I647), before using the AMR.

l Review, and understand the safety protections (E-Stops, safety laser stopping distances,

overhanging load, etc.) associated with your specific application and environment.

l

Make sure that the environment is suitable for safe operation of the AMR.

l

Make use of the Fleet Manager when two or more AMRs are used in the same environment, and are not confined to separate workspaces. See: Fleet Operations Workspace

Core User's Manual (Cat. No. I635).

l

Make sure that any person working with or near an AMR is trained, and has read the

Mobile Robot HDSafety Manual (Cat. No. I647) for safe AMR operation.

l

Mechanically maintain and service AMRs for proper operation of all control and safety

functions.

Electrical Hazards

WARNING: ELECTROCUTIONRISK

The charging station has ACpower inside. Its covers are not interlocked. You

must disconnect the power prior to maintenance work.

31500-000 Rev B HD-1500 Platform User's Manual 38

Page 40

2.5 User's Responsibilities

!

!

WARNING: FIRE RISK, ELECTRICAL BURNRISK

The HD-1500 battery, and the charger outputs have high current. You must

take appropriate precautions to avoid potential short circuit.

l

Never access the interior of the platform with the charger attached.

l

Avoid shorting the battery terminals or connectors.

l

Do not use any charger or battery not supplied by OMRON. The charger shall only be

used to charge an HD-1500 battery.

l

The HD-1500 battery shall only be charged by an HD-1500 Charger.

l

If any liquid is spilled on the AMR, power off the AMR, clean up all possible liquid,

and allow the AMR to air dry thoroughly before restoring power.

Contact your OMRON representative if you suspect that liquid has penetrated the skins

or contaminated the AMR's interior.

l

Avoid liquid near the charging station, and the AMR.

l

Do not open the power supply box, electrician access box, or even the docking target

until you have read the appropriate sections of this user's guide, and performed appropriate Lock-Out, Tag-Out (LOTO) procedure. See: Lock-Out, Tag-Out Procedure on page

222.

Magnetic Field Hazards

The rare-earth magnet embedded in the HD-1500 charging contacts create a strong magnetic

field. Persons with medical implants must not approach the HD-1500. See the following figure

for location of the charging contacts.

WARNING: MAGNETIC FIELD MEDICAL IMPLANT RISK

Magnetic fields can be hazardous if

you have a medical implant. Keep a

minimum of 30 cm away from the

HD-1500.

Figure 2-7. HD-1500 Charging Contacts Location

39 HD-1500 Platform User's Manual 31500-000 Rev B

Page 41

Chapter 2: Safety

Burn Hazard

CAUTION: BURNRISK

The charging station and the charging contacts on both the docking target, and

the AMR can get hot during the operation. The operator must allow for cool

down prior to servicing.

CAUTION: BURNRISK

The AMR drive wheel motors can get extremely hot during the operation. The

operator must allow the drive wheel motors to cool down prior to performing

any maintenance work near or around them.

Qualification of Personnel

It is the end-user’s responsibility to ensure that all personnel who will work with or around

AMRs have attended an appropriate training, and have a working knowledge of the system.

The user must provide the necessary additional training for all personnel who will be working

with the system.

As described in this guide, and the Mobile Robot HDSafety Manual (Cat. No. I647), you should

allow only skilled persons or instructed persons to do certain procedures:

l

Skilled persons have technical knowledge or sufficient experience to enable them to

avoid either electrical or mechanical dangers.

l

Instructed persons are adequately advised or supervised by skilled persons to enable

them to avoid either electrical or mechanical dangers.

For example, replacing a battery is a task for a skilled person, while an instructed person can

complete the task of charging a battery.

All personnel must observe industry-prescribed safety practices during the installation, operation, and testing of all electrically-powered equipment.

IMPORTANT: Before working with the AMR, every person must confirm that

they:

l

Have the necessary qualifications and training.

l

Have received the guides (both this user’s guide, and the Mobile Robot HDSafety

Manual (Cat. No. I647)).

l

Have read the guides.

l

Understand the guides.

l

Will work in the manner specified by the guides.

Payload Movement and Transfer

A typical AMR application uses a payload structure to transport objects within a facility. For

example, the AMR might pick up and carry a crate of engine parts from one conveyor belt

then deliver it to another conveyor belt.

31500-000 Rev B HD-1500 Platform User's Manual 40

Page 42

2.5 User's Responsibilities

!

!

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

It is the end user's responsibility to ensure that the payload is properly secured

to the HD-1500 platform, and that the payload does not experience any shifting

during movement of the AMR. For example, when transporting containers of

liquids, the operator must take necessary precautions to prevent sloshing of the

fluid as it affects the stability of the AMR.

Intentional movement of the payload structure (such as conveyor or AMR arm) during the

AMR movement is prohibited. It is the end-user's responsibility to design an appropriate interlock to prevent this.

During movement and transfer, you must actively monitor and confirm the transfer operation

to make sure that it completes successfully. If any operation fails, a fail-safe interlock must trigger an AMR E-Stop condition. An E-Stop condition prevents the AMR from moving until you

resolve the problem and confirm that it is safe to restart operations.

Your facility should provide such fail-safe interlocks between the AMR and any facility equipment with which it interfaces. After you attach your payload to the AMR, verify the correct

operation of the fail-safe as part of your risk assessment.

Configurable Warning Buzzer

The HD-1500 has a configurable warning buzzer. You should configure this buzzer as appropriate for the facility in which the AMR will be operating. The warning buzzer is configured

with MobilePlanner.

The buzzer must be audible above the ambient noise of the environment that the HD-1500

operates in. In environments with higher levels of noise, you may need to supply and install

an additional warning buzzer to an appropriate location on the payload structure. For information on how to install an additional warning buzzers, see: Warning Buzzer on page 141.

You can also configure the buzzer to activate in other specific situations, or to operate continuously whenever the AMR moves.

l

Any time the AMR moves at a linear speed below 20 mm/s, or a rotational speed of less

than 3 deg/sec for longer than 2 seconds. This is done to alert the users of a very slowly

moving AMR which is not configured with hardware-based safety zones by default.

NOTE: The software-based obstacle protection is used regardless of the

AMR speed.

l

For 2 seconds prior to starting motion any time it has stopped moving for at least 10

seconds. This includes the first motion after start-up.

l

For 2 seconds when an emergency stop or a protective stop from hardware-based safety

zones is triggered.

NOTE: These parameters are only available with the Fleet Operations Workspace 1.1 and later.

CAUTION: PERSONALINJURYRISK

Changing buzzer parameter values might make the AMR unsafe and affect its

compliance to safety standards. Refer to the applicable safety standards for

your locale before you change any parameter values.

41 HD-1500 Platform User's Manual 31500-000 Rev B

Page 43

Chapter 2: Safety

Speakers

The HD-1500 is equipped with two speakers, located at the front of the AMR as displayed in

Figure 1-1.

When speakers are used as a means of notifying personnel of an approaching AMR, you must

routinely verify that they are still functioning normally. Verify that the speakers are audible,

and the sound level is at the same level as needed during the operation.

Mechanical Brakes

Perform annual inspection of the mechanical brakes for proper function. Follow these steps to

verify that the mechanical brakes engage and disengage properly.

Before you begin, make sure it is safe to manually move the AMR to an open area with level

floor.

1.

Connect the pendant to the AMR, and drive forward approximately 2 m in order to

align the casters in the direction of motion. For instructions on how to use the pendant,

refer to Pendant Controls and Operation Description on page 215.

2.

Next, release the three-position enabling device to ensure that the AMR is in protective

stop mode.

3.

Then, press and hold the brake release button, and push the AMR straight forward. One

or two people should be able to push an unloaded or lightly loaded platform. For a

heavily loaded platform, you may need more people.

You will hear a click sound when the brake release button is pressed. The AMR should

roll smoothly at this point. contact your OMRON representative if the AMR does not

move.

4.

Next, release the brake release button and then try to push the AMR forward with the

same amount of force used in the last step. The AMR should not move.

5.

If the AMR moves, stop using the AMR, and contact your OMRON representative.

Fleet Management

When two or more AMRs operate in the same workspace they may not be able to accurately

detect each other or to precisely determine each other's dimensions. This is due to the fact that

the AMRs' scanning lasers are positioned inside of the platform perimeter. There are channels

along the front, rear, and sides of the platform that allow a clear line of sight for the scanning

laser. When two similar AMRs approach each other their scanning lasers will detect the inner

surface of that channel and not the outer perimeter of the other AMR. Operating an HD-1500

with any of its skins detached will worsen this effect. Typically this will not present a problem,

however, in close proximity each AMR will plan its motion more accurately with information

from the Fleet Manager about the position of the other AMR.

To manage and administer multiple AMRs in the same workspace, you must use a EM2100

appliance configured as a Fleet Manager, running the Fleet Operations Workspace (FLOW) software.

31500-000 Rev B HD-1500 Platform User's Manual 42

Page 44

2.6 Environment

!

!

The Fleet Manager controls AMRs over a wireless network (WiFi), improving the efficiency of

AMR operations by sharing the information between all AMRs in the fleet. The shared information includes: improving the efficiency of AMR operations.

l

Dynamic position and heading (velocity and direction of travel) of the AMR.

l

AMR size (including payload structure).

l

Path planning information (the individual AMR's intended route).

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

Improper path planning can result in personal injury or property damage.

IMPORTANT: Do not leave an AMR that is not localized, not connected to the

Enterprise Manager, or not powered on in a location that can be accessed by

other AMRs.

AMRs factor this data into their path planning.

IMPORTANT: Fleet Manager is not an interlocked method of collision prevention. It is your responsibility to implement interlocked methods of collision

prevention where necessary.

For operational redundancy and fail-over you can add a second EM2100. See the Fleet Oper-

ations Workspace Core User's Manual (Cat. No. I635) for more information.

2.6 Environment

General Environmental Conditions

Make sure that the HD-1500's operating environment remains safe for the HD-1500.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

An AMR can be unsafe if operated under environmental conditions other than

those specified in this manual.

l

Environmental Hazards—These are areas where it is unsafe for the HD-1500 to operate.

Provide physical barriers that the HD-1500 can detect accurately with its scanning laser

so that it does not attempt to drive near the hazard. Be aware that in addition to being

easily detectable, a barrier must be strong enough to resist a fully-loaded HD-1500 traveling at its maximum speed.

l

Restricted Zones—These are zones of inadequate clearance which cannot be protected

by the AMR detection devices. Only authorized persons are permitted to enter. You can

use map features such as forbidden areas to keep HD-1500s within their designated

area of operation. See the Fleet Operations Workspace Core User's Manual (Cat. No. I635) for

information about editing your workspace map.

l

Operating Hazard Zones—These operating zones are areas of inadequate clearance

(less than 500 mm) between the sides of the AMR (or front/rear of the AMR) and an

43 HD-1500 Platform User's Manual 31500-000 Rev B

Page 45

Chapter 2: Safety

obstacle such as a wall that would not leave sufficient room for a person to escape and

avoid getting crushed between the AMR and the obstacle. It can also be an area which

cannot be protected by the AMR detection devices. These areas shall be clearly indicated

by suitable signs or preferably floor markings. In this operating hazard zone, the AMR

speed shall be in accordance with ISO 3691-4, and shall emit additional audible or

visual warnings.

l

Confined Zones—These are zones of inadequate clearance, and where the AMR detection devices may be omitted, at any speed. The confined zones shall be marked, and be

enclosed with fixed guards that are at least 2.1 m high.

l

Load Transfer Stations—These are the designated locations for load transfer. When the

load transfer stations are outside the restricted or confined zones, these stations shall be

designed to prevent personal injury by the rigid parts of the AMR or its payload. These

load transfer stations shall be designated as operating hazard zones as defined in this

section of the manual.

Although the HD-1500's software provides the option of using the map features to keep the

HD-1500 within its designated workspace, you must always install physical barriers where

there is a risk of property damage or personal hazard.

Public Access

The HD-1500 is designed to operate in indoor industrial environments, and in presence of

trained personnel. You must deploy it only in applications where you anticipate and mitigate

potential risks to personnel and equipment.

OMRON intends for the HD-1500 to be used in controlled areas for which a risk assessment

has been conducted. OMRON does not intend the HD-1500 to be used in, for example, areas

open to general public access.

Operating Clearances

This section provides information regarding the side clearances, rotation clearances, and the

docking clearances when operating.

Side Clearances

The HD-1500 is designed to operate in environments that contain doors, passageways, or other

constrained areas that are wide enough for it to traverse.

However, you must maintain adequate side clearance (free space) on both sides of the AMR so

that it cannot trap a person against a wall or other fixed object. Consult the applicable

Autonomous Vehicle and Robotics operating standards for your locale.

An AMR must often maneuver close to machinery, conveyors, or other fixed objects. In such

cases, operating standards usually allow an exception to side clearance requirements.

For information about software parameters that you can use to control the HD-1500's front and

side clearance zones, see: Fleet Operations Workspace Core User's Manual (Cat. No. I635).

Rotation Clearances

The HD-1500 travels in forward and backward directions. To change its direction, the HD1500 rotates on its center of rotation (turns in place). The HD-1500 has a full safety coverage of

360°, and therefore, obstacles will trigger a safety system event when the AMR rotates.

31500-000 Rev B HD-1500 Platform User's Manual 44

Page 46

2.6 Environment

A

B

1300

The HD-1500's Light Discs as well as its front and back light strips display a distinct turn signal pattern when it rotates. For more information, see: Light Discs and Beacon on page 204

and Front and Back Light Strips on page 208.

Docking Clearances

You should set a 2.5 m distance between the docking target (the goal defined in the map) and

the dock goal position of the AMR. This distance provides sufficient room for the AMR to

align with the docking target when docking. See: Figure 2-8. and Figure 2-9.

When docked, the distance between the AMR and the docking target is less than 500 mm, and

therefore, this area is considered to be a hazard zone.

Figure 2-8. Goal Position - Measured From the Center of the Docking Target to the Center of

the HD-1500, (A) Docking Target, and (B) HD-1500

Figure 2-9. Goal Position - Measured from the Front Face of the HD-1500 to the Charging Paddle

45 HD-1500 Platform User's Manual 31500-000 Rev B

Page 47

Chapter 2: Safety

A

B

Figure 2-10. HD-1500 Docked with the Docking Target, (A) 500 mm, and (B) Floor Marking

Obstacles

Before an AMR enters a high-traffic area, you must take appropriate precautions to alert people

working in those areas:

l

The HD-1500 provides programmable warning features such as a warning buzzer,

speech synthesis, and warning indicator lights.

l