Page 1

At the end of this document you will find links to products related to this catalog. You can go directly to our shop by

clicking HERE. HERE

Page 2

Digital Temperature Controllers

Programmable Type

User’s Manual

E5@C-T

H185-E1-01

Appendices

Index

Preparations

Introduction

Advanced

Operations

Basic

Operation

Part Names and

Basic Procedures

User Calibration

Parameters

1

2

3

4

5

6

7

A

I

Page 3

Page 4

1

Preface

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Preface

Thank you for purchasing an E5@C-T Digital Controller.

This manual describes how to use the E5@C-T. Read this manual thoroughly and be sure you understand it before attempting to use the Digital Controller and use the Digital Controller correctly according

to the information provided. Keep this manual in a safe place for easy reference. Refer to the E5

@

C-T

Digital Controllers Programmable Type Communications Manual (Cat. No. H186) for information on

communications.

© OMRON, 2014

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form,

or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information

contained in this publication.

Page 5

Terms and Conditions Agreement

2

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Terms and Conditions Agreement

z Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and

workmanship for a period of twelve months from the date of sale by Omron (or such other period

expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

z Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

z Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an

amount equal to the purchase price of the non-complying Product; provided that in no event shall

Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the

Products unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate

modification. Return of any Products by Buyer must be approved in writing by Omron before

shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from

the use of Products in combination with any electrical or electronic components, circuits, system

assemblies or any other materials or substances or environments. Any advice, recommendations or

information given orally or in writing, are not to be construed as an amendment or addition to the

above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Warranty, Limitations of Liability

Warranties

Limitation on Liability; Etc

Page 6

3

Terms and Conditions Agreement

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Application Considerations

Suitability of Use

Programmable Products

Disclaimers

Performance Data

Change in Specifications

Errors and Omissions

Page 7

Safety Precautions

4

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Safety Precautions

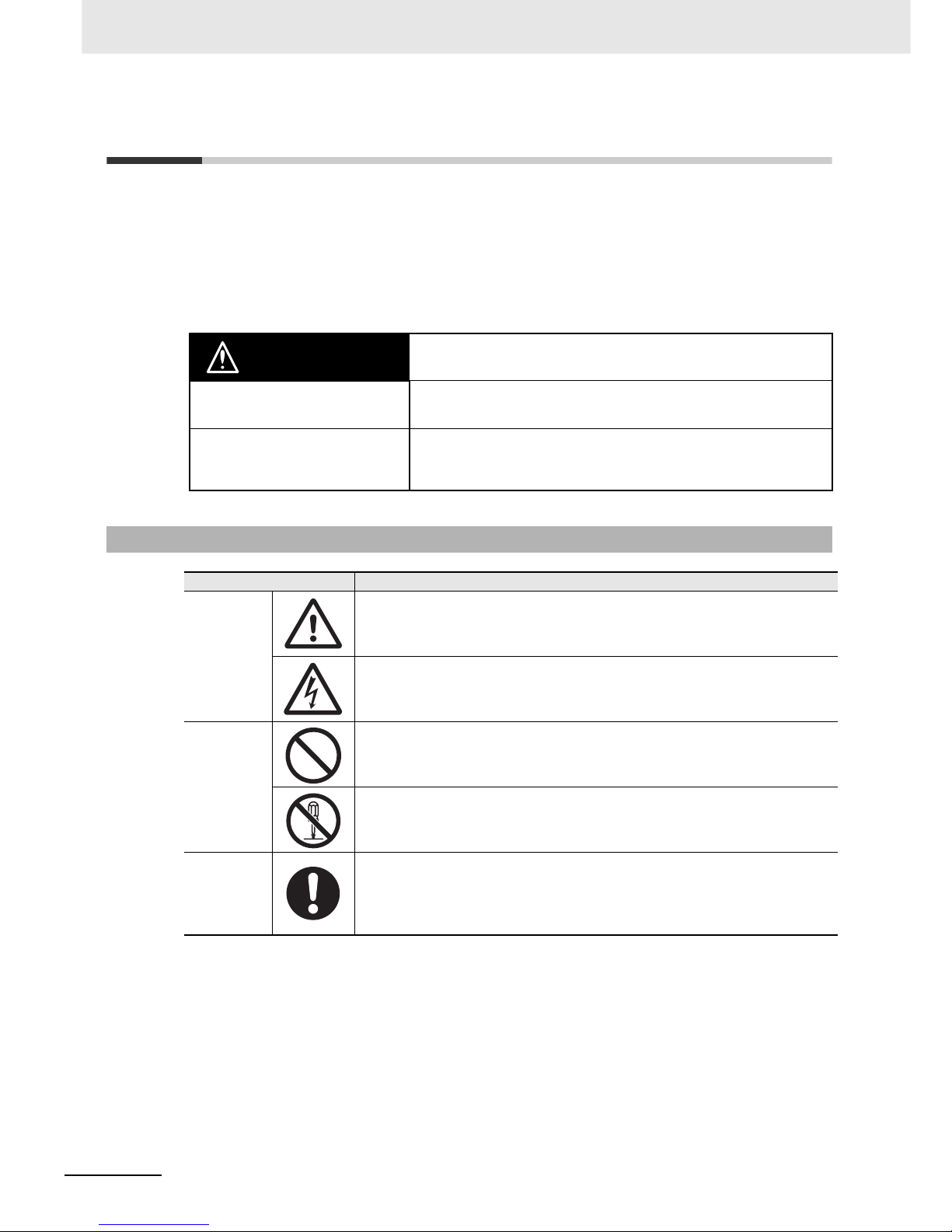

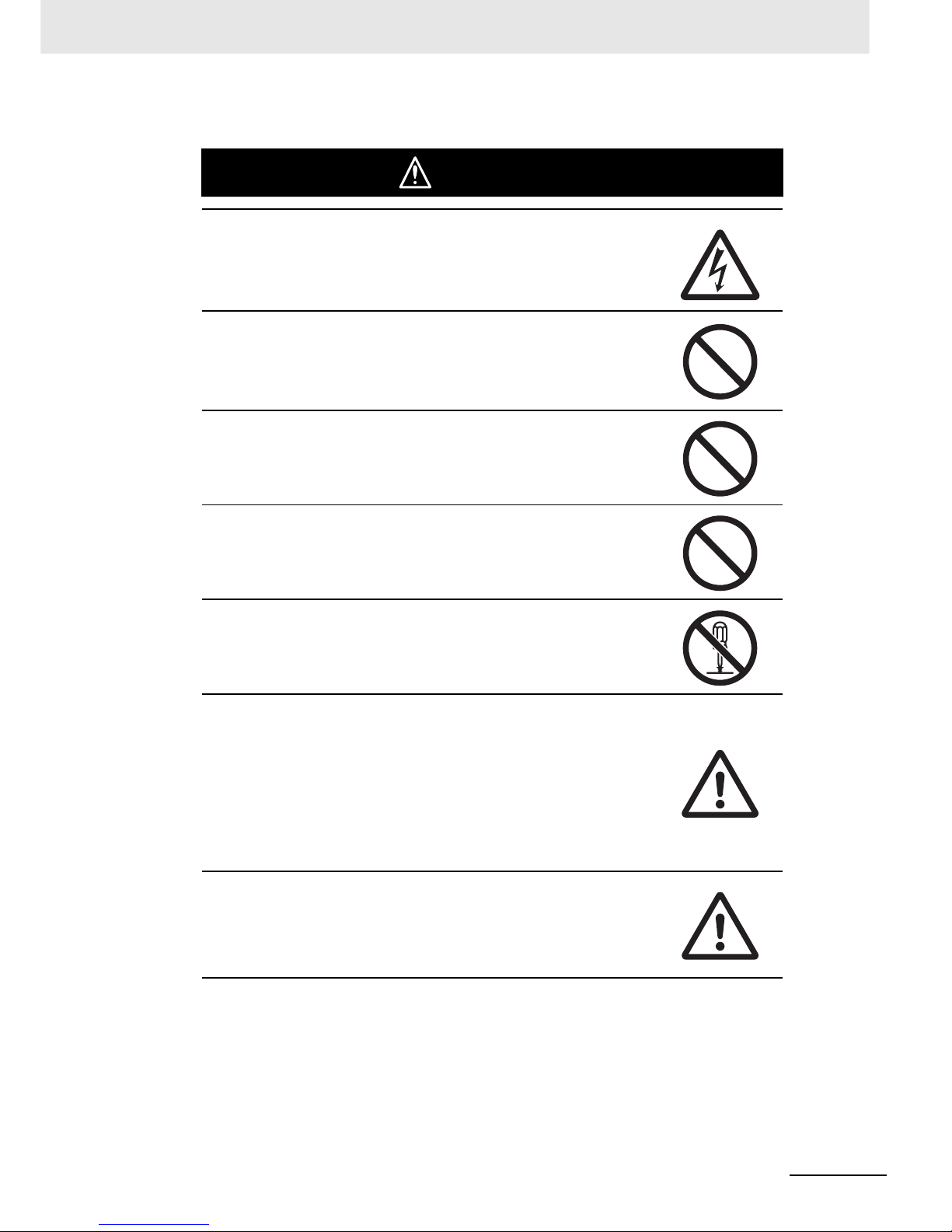

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the E5@C-T Digital Controllers.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

The following notation is used.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or in property damage.

Precautions for

Safe Use

Supplementary comments on what to do or avoid doing, to use

the product safely.

Precautions for

Correct Use

Supplementary comments on what to do or avoid doing, to prevent failure to operate, malfunction or undesirable effect on

product performance.

Symbols

Symbol Meaning

Caution

• General Caution

Indicates non-specific general cautions, warnings, and dangers.

• Electrical Shock Caution

Indicates possibility of electric shock under specific conditions.

Prohibition

• General Prohibition

Indicates non-specific general prohibitions.

• Disassembly Prohibition

Indicates prohibitions when there is a possibility of injury, such as from electric

shock, as the result of disassembly.

Mandatory

Caution

• General Caution

Indicates non-specific general cautions, warnings, and dangers.

Page 8

5

Safety Precautions

E5@C-T Digital Temperature Controllers User’s Manual (H185)

z Safety Precautions

*1 An SELV (separated extra-low voltage) system is one with a power supply that has double or reinforced

insulation between the primary and the secondary circuits and has an output voltage of 30 V r.m.s. max.

and 42.4 V peak max. or 60 VDC max.

*2 A class 2 circuit is one tested and certified by UL as having the current and voltage of the secondary

output restricted to specific levels.

CAUTION

Minor injury due to electric shock may occasionally occur.

Do not touch the terminals while power is being supplied.

Electric shock, fire, or malfunction may occasionally occur.

Do not allow metal objects, conductors, cuttings from installation

work, or moisture to enter the Digital Controller or a Setup Tool port.

Attach the cover to the front-panel Setup Tool port whenever you are

not using it to prevent foreign objects from entering the port.

Minor injury from explosion may occasionally occur.

Do not use the product where subject to flammable or explosive gas.

Fire may occasionally occur.

Do not allow dirt or other foreign objects to enter a Setup Tool port,

or between the pins on the connectors on the Setup Tool cable.

Minor electric shock, fire, or malfunction may occasionally occur.

Never disassemble, modify, or repair the product or touch any of the

internal parts.

CAUTION - Risk of Fire and Electric Shock

(a) This product is UL listed as Open Type Process Control

Equipment. It must be mounted in an enclosure that does not

allow fire to escape externally.

(b) More than one disconnect switch may be required to

de-energize the equipment before servicing.

(c) Signal inputs are SELV, limited energy.

*1

(d) Caution: To reduce the risk of fire or electric shock, do not

interconnect the outputs of different Class 2 circuits.

*2

If the output relays are used past their life expectancy, contact fusing

or burning may occasionally occur.

Always consider the application conditions and use the output relays

within their rated load and electrical life expectancy. The life

expectancy of output relays varies considerably with the output load

and switching conditions.

Page 9

Safety Precautions

6

E5@C-T Digital Temperature Controllers User’s Manual (H185)

CAUTION

Loose screws may occasionally result in fire.

Tighten the terminal screws to the specified torque of 0.43 to

0.58 N·m.

Set the parameters of the product so that they are suitable for the

system being controlled. If they are not suitable, unexpected

operation may occasionally result in property damage or accidents.

A malfunction in the Digital Controller may occasionally make control

operations impossible or prevent alarm outputs, resulting in property

damage. To maintain safety in the event of malfunction of the Digital

Controller, take appropriate safety measures, such as installing a

monitoring device on a separate line.

Page 10

7

Precautions for Safe Use

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Precautions for Safe Use

Be sure to observe the following precautions to prevent operation failure, malfunction, or adverse

affects on the performance and functions of the product. Not doing so may occasionally result in unexpected events. Do not handle the Digital Controller in ways that exceed the ratings.

• The product is designed for indoor use only. Do not use or store the product outdoors or in any of the

following places.

Places directly subject to heat radiated from heating equipment.

Places subject to splashing liquid or oil atmosphere.

Places subject to direct sunlight.

Places subject to dust or corrosive gas (in particular, sulfide gas and ammonia gas).

Places subject to intense temperature change.

Places subject to icing and condensation.

Places subject to vibration and large shocks.

• Use and store the Digital Controller within the rated ambient temperature and humidity.

Gang-mounting two or more Digital Controllers, or mounting Digital Controllers above each other may

cause heat to build up inside the Digital Controllers, which will shorten their service life. In such a

case, use forced cooling by fans or other means of air ventilation to cool down the Digital Controllers.

• To allow heat to escape, do not block the area around the Digital Controller. Do not block the

ventilation holes on the Digital Controller.

• Be sure to wire properly with correct polarity of terminals.

• Use the specified size of crimped terminals (M3, width of 5.8 mm or less) for wiring. To connect bare

wires to the terminal block, use copper braided or solid wires with a gage of AWG24 to AWG18

(equal to a cross-sectional area of 0.205 to 0.8231 mm

2

). (The stripping length is 6 to 8 mm.) Up to

two wires of the same size and type, or two crimped terminals can be inserted into a single terminal.

• Do not wire the terminals that are not used.

• To avoid inductive noise, keep the wiring for the Digital Controller's terminal block away from power

cables that carry high voltages or large currents. Also, do not wire power lines together with or

parallel to Digital Controller wiring. Using shielded cables and using separate conduits or ducts is

recommended.

Attach a surge suppressor or noise filter to peripheral devices that generate noise (in particular,

motors, transformers, solenoids, magnetic coils or other equipment that have an inductance

component).

When a noise filter is used at the power supply, first check the voltage or current, and attach the noise

filter as close as possible to the Digital Controller.

Allow as much space as possible between the Digital Controller and devices that generate powerful

high frequencies (high-frequency welders, high-frequency sewing machines, etc.) or surge.

• Use the Digital Controller within the rated load and power supply.

• Make sure that the rated voltage is attained within 2 seconds of turning ON the power using a switch

or relay contact. If the voltage is applied gradually, the power may not be reset or output malfunctions

may occur.

• Make sure that the Digital Controller has 30 minutes or more to warm up after turning ON the power

before starting actual control operations to ensure the correct temperature display.

• A switch or circuit breaker must be provided close to Digital Controller. The switch or circuit breaker

must be within easy reach of the operator, and must be marked as a disconnecting means for Digital

Controller.

• Wipe off any dirt from the Digital Controller with a soft dry cloth. Never use thinners, benzine, alcohol,

or any cleaners that contain these or other organic solvents. Deformation or discoloration may occur.

Page 11

Precautions for Safe Use

8

E5@C-T Digital Temperature Controllers User’s Manual (H185)

• Design the system (e.g., control panel) considering the 2 seconds of delay in setting the Digital

Controller’s output after the power supply is turned ON.

• The output will turn OFF when you move to the Initial Setting Level. Take this into consideration when

performing control.

• The number of non-volatile memory write operations is limited. Therefore, use RAM write mode when

frequently overwriting data, e.g., through communications.

• Use suitable tools when taking the Digital Controller apart for disposal. Sharp parts inside the Digital

Controller may cause injury.

• Do not connect cables to both the front-panel Setup Tool port and the top-panel Setup Tool port at the

same time.

• Do not exceed the communications distance that is given in the specifications and use the specified

communications cable.

• Do not turn the power supply to the Digital Controller ON or OFF while the USB-Serial Conversion

Cable is connected. The Digital Controller may malfunction.

• Do not bend the communications cables past their natural bending radius. Do not pull on the

communications cables.

Page 12

9

Precautions for Correct Use

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Precautions for Correct Use

z Service Life

Use the Digital Controller within the following temperature and humidity ranges:

Temperature: −10 to 55°C (with no icing or condensation), Humidity: 25% to 85%

If the Digital Controller is installed inside a control board, the ambient temperature must be kept to

under 55°C, including the temperature around the Controller.

The service life of electronic devices like Digital Controllers is determined not only by the number of

times the relay is switched but also by the service life of internal electronic components. Component

service life is affected by the ambient temperature: the higher the temperature, the shorter the

service life and, the lower the temperature, the longer the service life. Therefore, the service life can

be extended by lowering the temperature of the Digital Controller.

When two or more Digital Controllers are mounted horizontally close to each other or vertically next

to one another, the internal temperature will increase due to heat radiated by the Digital Controllers

and the service life will decrease. In such a case, use forced cooling by fans or other means of air

ventilation to cool down the Digital Controllers. When providing forced cooling, however, be careful

not to cool down the terminals sections alone to avoid measurement errors.

z Ensuring Measurement Accuracy

When extending or connecting the thermocouple lead wire, be sure to use compensating wires that

match the thermocouple types.

When extending or connecting the lead wire of the platinum resistance thermometer, be sure to use

wires that have low resistance and keep the resistance of the three lead wires the same.

Mount the Digital Controller so that it is horizontally level.

If the measurement accuracy is low, check to see if input shift has been set correctly.

z Resistance to Water

The degree of protection is as shown below. Sections without any specification on their degree of

protection or those with IP@0 are not waterproof.

Front panel: IP66

Rear case: IP20, Terminal section: IP00

When waterproofing is required, insert the Waterproof Packing on the backside of the front panel.

Keep the Port Cover on the front-panel Setup Tool port of the E5EC-T/E5AC-T securely closed. The

degree of protection when the Waterproof Packing is used is IP66. To maintain an IP66 degree of

protection, the Waterproof Packing and the Port Cover for the front-panel Setup Tool port must be

periodically replaced because they may deteriorate, shrink, or harden depending on the operating

environment. The replacement period will vary with the operating environment. Check the required

period in the actual application. Use 3 years or sooner as a guideline. If the Waterproof Packing and

Port Cover are not periodically replaced, waterproof performance may not be maintained. If a

waterproof structure is not required, then the Waterproof Packing does not need to be installed.

Page 13

Precautions for Operation

10

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Precautions for Operation

• It takes approximately two seconds for the outputs to turn ON from after the power supply is turned

ON. Design the system (e.g., control panel) to allow for this delay.

• The Digital Controller requires 30 minutes to warm up after the power supply is turned ON. Always

turn ON the power supply at least 30 minutes before starting actual control operations.

• Avoid using the Digital Controller in places near a radio, television set, or wireless installing. The

Digital Controller may cause radio disturbance for these devices.

Page 14

11

Preparations for Use

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Preparations for Use

Be sure to thoroughly read and understand the manual provided with the product, and check the following points.

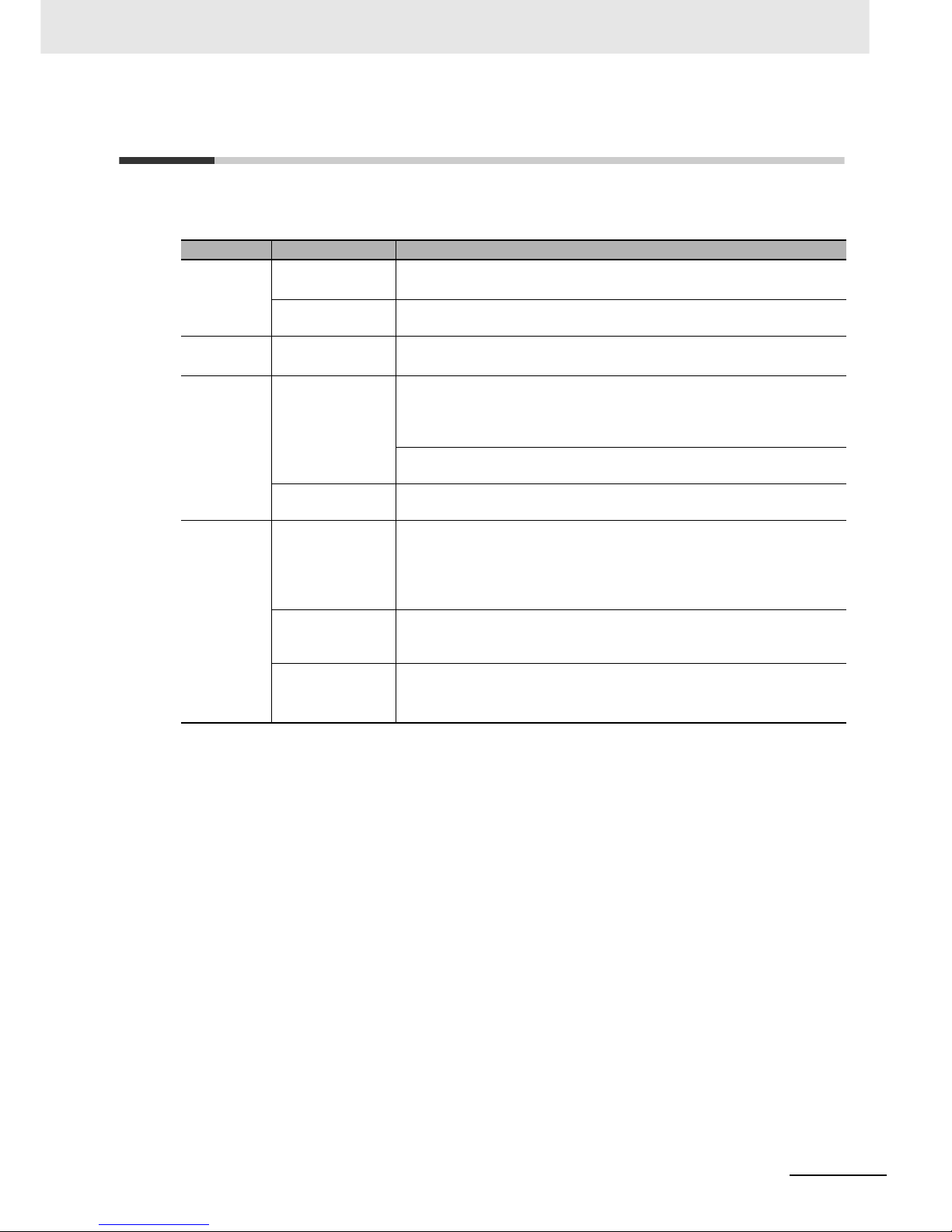

Timing Check point Details

Purchasing

the product

Product

appearance

After purchase, check that the product and packaging are not dented or

otherwise damaged. Damaged internal parts may prevent optimum control.

Product model and

specifications

Make sure that the purchased product meets the required specifications.

Setting the

Unit

Product installation

location

Provide sufficient space around the product for heat dissipation. Do not

block the vents on the product.

Wiring Terminal wiring Do not subject the terminal screws to excessive stress (force) when

tightening them.

Make sure that there are no loose screws after tightening terminal screws to

the specified torque of 0.43 to 0.58 N·m.

Be sure to confirm the polarity for each terminal before wiring the terminal

block and connectors.

Power supply

inputs

Wire the power supply inputs correctly. Incorrect wiring will result in damage

to the internal circuits.

Operating

environment

Ambient

temperature

The ambient operating temperature for the product is −10 to 55°C (with no

condensation or icing). To extend the service life of the product, install it in a

location with an ambient temperature as low as possible. In locations

exposed to high temperatures, if necessary, cool the products using a fan or

other cooling method.

Vibration and

shock

Check whether the standards related to shock and vibration are satisfied at

the installation environment. (Install the product in locations where the

contactors will not be subject to vibration or shock.)

Foreign particles Install the product in a location that is not subject to liquid or foreign

particles entering the product.

Page 15

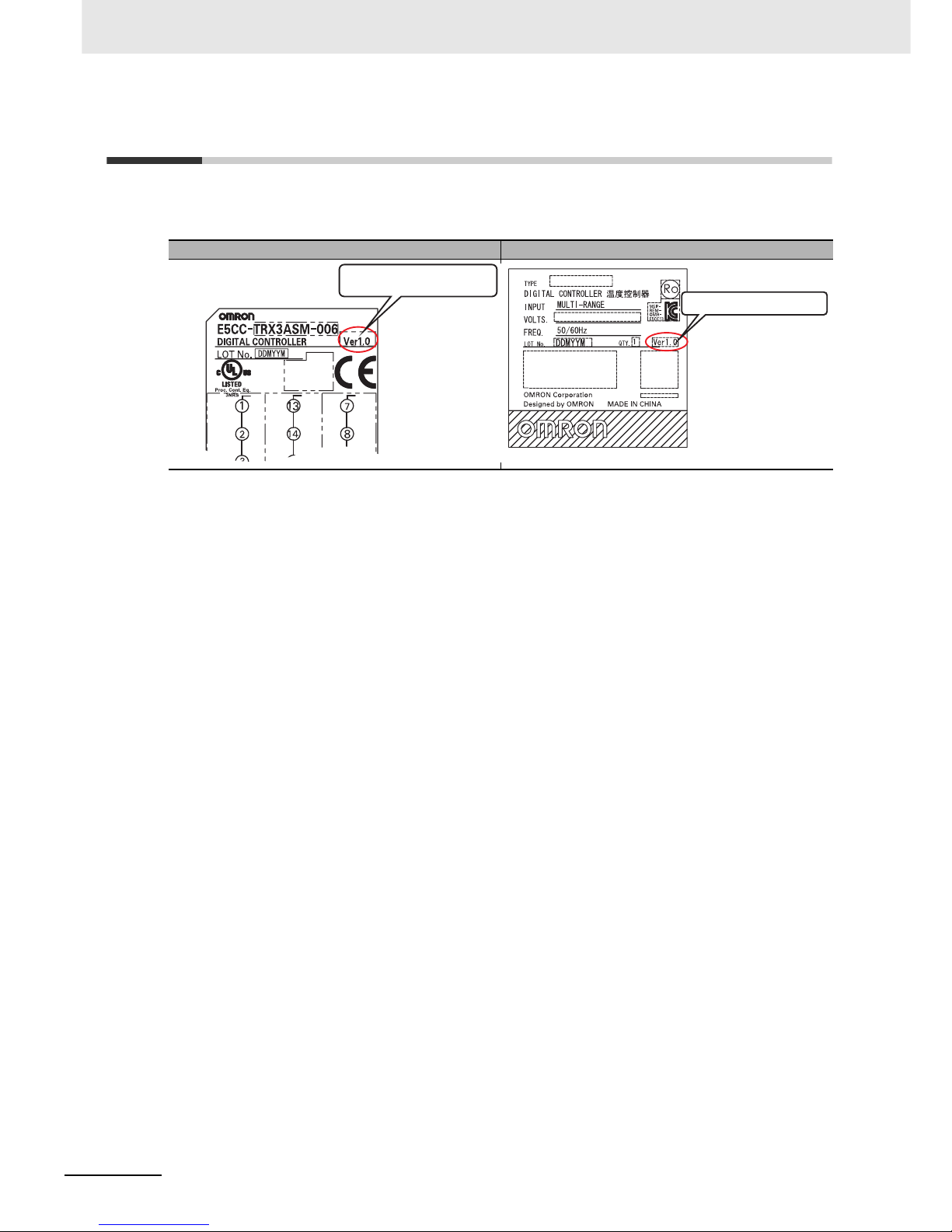

Versions

12

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Versions

Check the version on the nameplate on the E5@C-T Digital Controller or on the label on the packing

box. If the version is not given, the version of the E5@C-T Digital Controller is version 1.0.

Product nameplate Package label

The version is given here.

The version is given here.

Page 16

13

Revision History

E5@C-T Digital Temperature Controllers User’s Manual (H185)

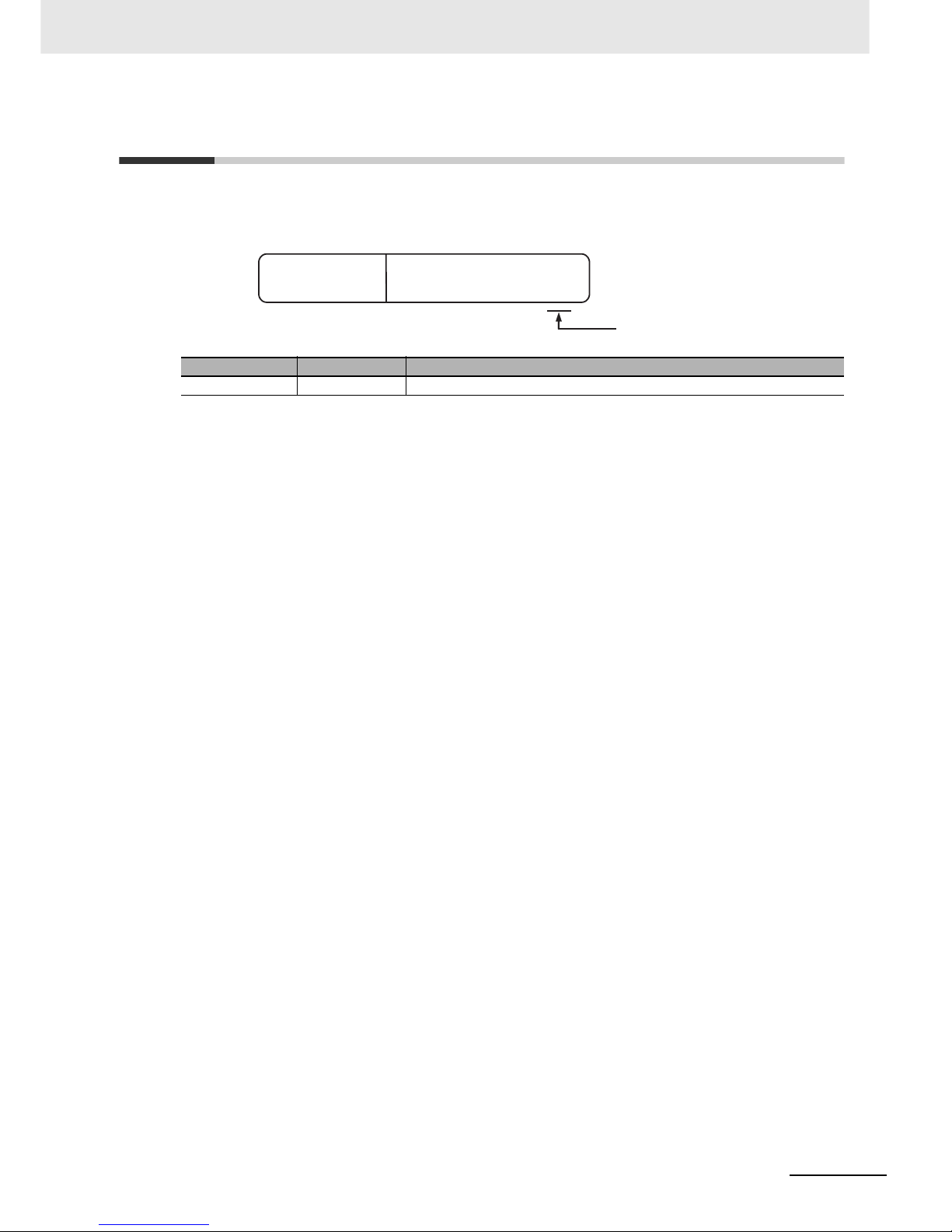

Revision History

A manual revision code appears as a suffix to the catalog number on the front cover of the manual.

Revision code Date Revised content

01 January 2014 Original production

H185-E1-01

Revision code

Cat. No.

Page 17

Conventions Used in This Manual

14

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Conventions Used in This Manual

“E5@C-T” is used to indicate information that is the same for the E5CC-T, E5EC-T, and E5AC-T Digital

Controllers. Also, “E5EC-TPR@,” “ E 5AC-T PR@,” or “Position-proportional Models” indicates the Digital

Controllers with position-proportional control. “Standard Models” indicates other Digital Controllers.

The following abbreviations are used in parameter names, figures, and other descriptions. These

abbreviations mean the following:

* “EU” stands for Engineering Unit. EU is used as the minimum unit for engineering units such as °C, m, and g.

The size of the EU depends on the input type. For example, when the input temperature setting range is −200

to 1,300°C, 1 EU is 1°C, and when the input temperature setting range is −20.0 to 500.0°C, 1 EU is 0.1°C.

For analog inputs, the size of the EU depends on the decimal point position of the scaling setting, and 1 EU is

the minimum scaling unit.

Model Notation

Meanings of Abbreviations

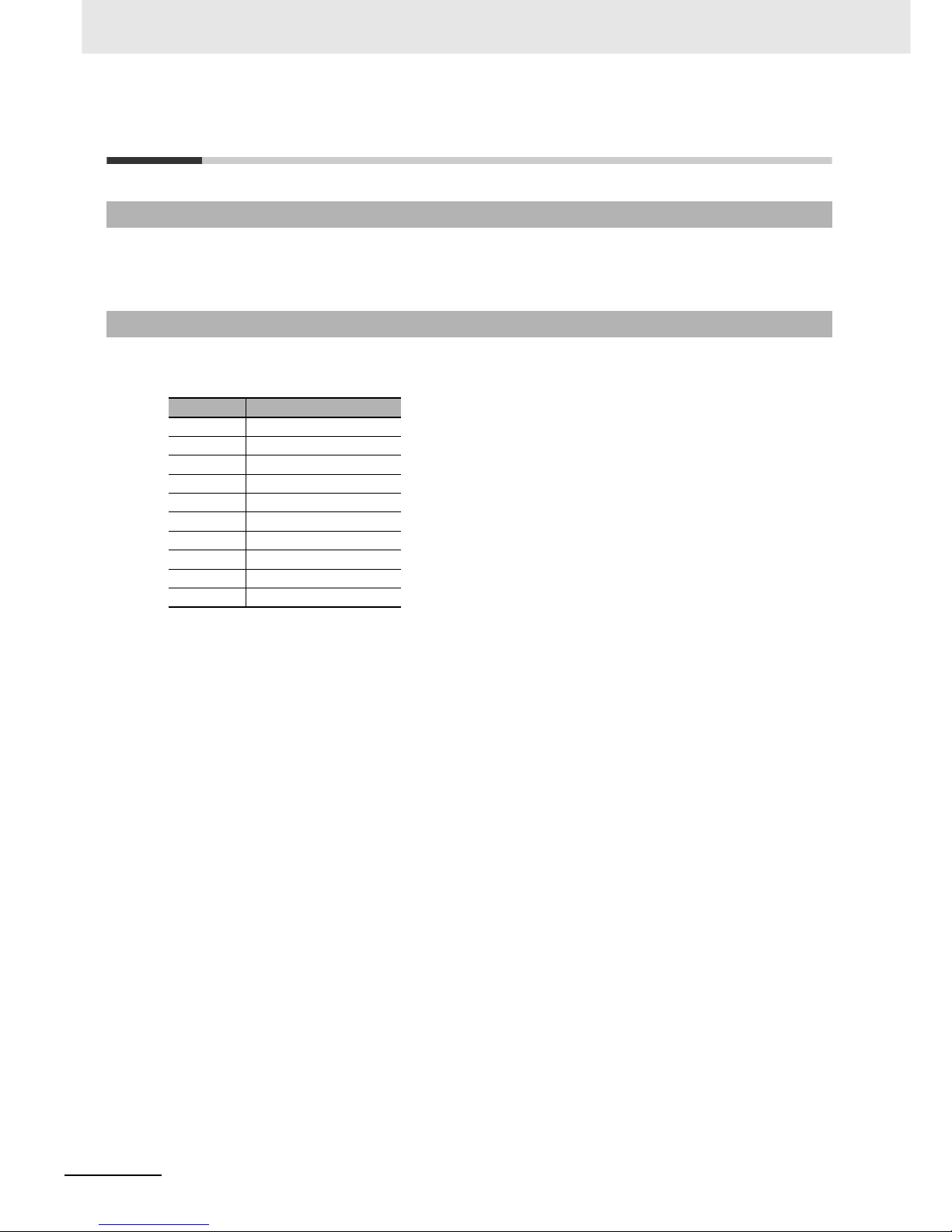

Symbol Term

PV Process value

SP Set point

SV Set value

AT A ut o - tu n i ng

EU Engineering unit*

LBA Loop burnout alarm

HB Heater burnout

HS Heater short

FSP Fixed SP

PSP Program SP

Page 18

15

Conventions Used in This Manual

E5@C-T Digital Temperature Controllers User’s Manual (H185)

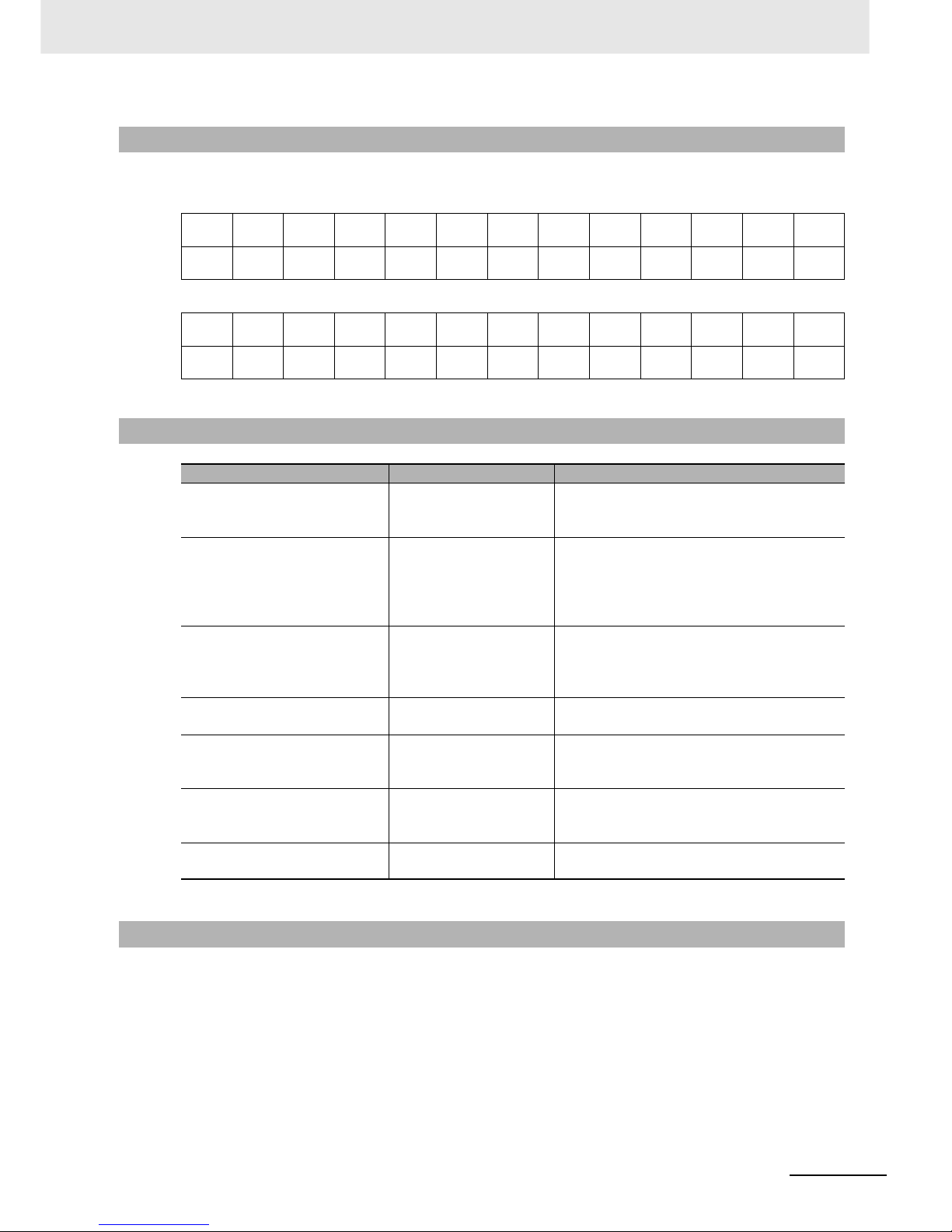

The following tables show the correspondence between the symbols displayed on the displays and

alphabet characters.

Also refer to the E5

@

C-T Digital Controllers Communications Manual (Cat. No. H186) for information on

communications.

How to Read Display Symbols

abcdefghijklm

ABCDE FGH I J KLM

nopqrstuVwxyz

NOPQRS T U VWXY Z

How This Manual is Organized

Goal Related sections Contents

Learning about the

appearance, features,

functions, and model numbers

Section 1 Introduction ---

Setting up the E5@C-T Section 2 Preparations This section describes the steps that are

required before turning ON the power supply

(including installation, terminal usage, wiring,

and isolation/insulation block diagram). It also

describes how to use the Setup Tool ports.

Learning the basic procedures

from turning ON the power

supply to starting actual

operation

Section 3 Part Names and

Basic Procedures

This section serves as a basic tutorial for

first-time users of the E5@C.

Learning the basic operating

methods

Section 4 Basic Operation

Section 6 Parameters

These sections describe basic operating

methods.

Learning advanced operating

methods

Section 5 Advanced

Operations

Section 6 Parameters

These sections describe advanced operating

methods.

Calibrating the E5@C-T Section 7 User Calibration This section describes the procedures that you

can use to calibrate the sensor or transfer

output of the E5@C-T.

Learning the specifications

and parameters of the E5@C-T

Appendices ---

Related Manuals

Page 19

Conventions Used in This Manual

16

E5@C-T Digital Temperature Controllers User’s Manual (H185)

Page 20

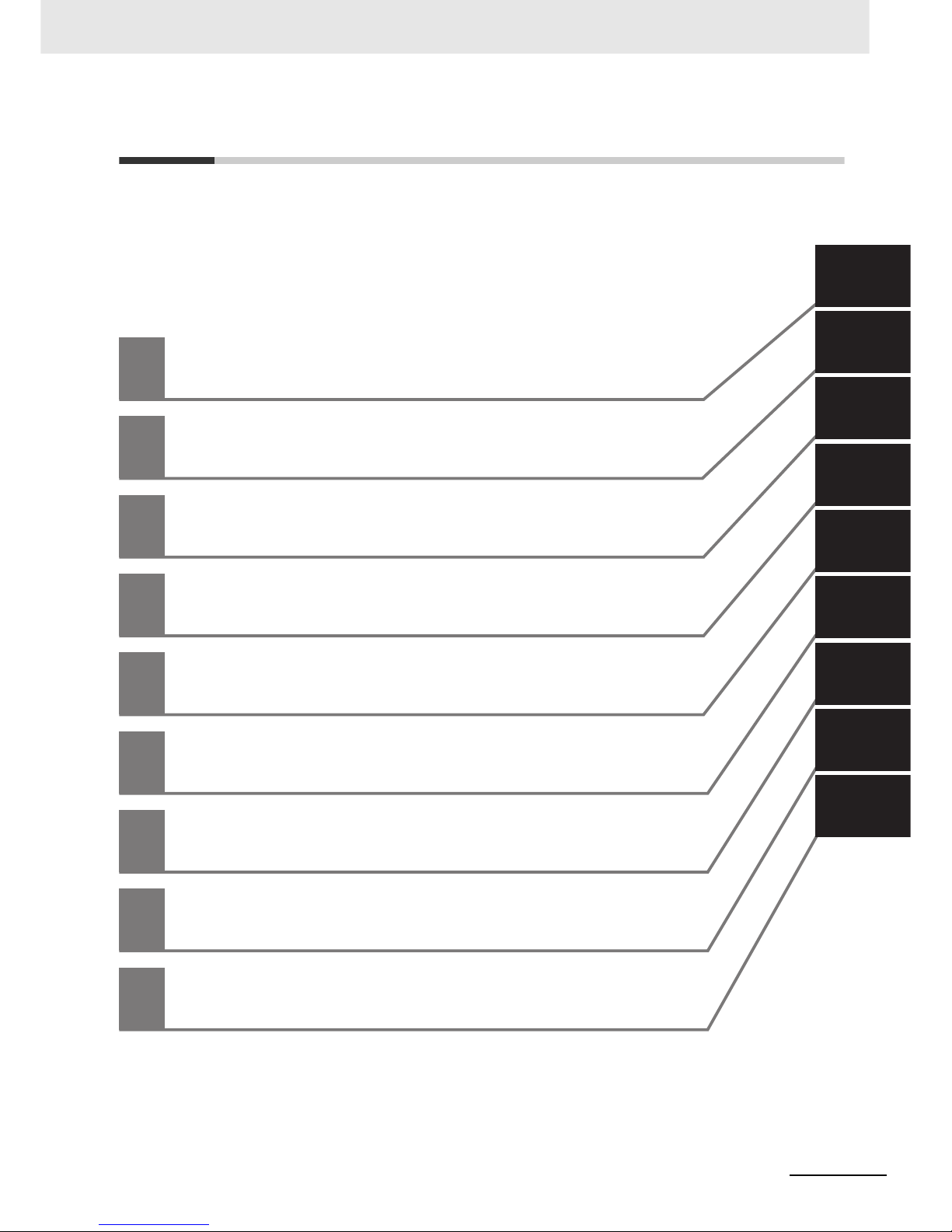

17

Sections in this Manual

E5@C-T Digital Temperature Controllers User’s Manual (H185)

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Introduction

Preparations

Part Names and Basic Procedures

Basic Operation

Advanced Operations

Parameters

User Calibration

A

A

Appendices

I

I

Index

Sections in this Manual

Page 21

18

E5@C-T Digital Temperature Controllers User’s Manual (H185)

CONTENTS

Preface .......................................................................................................................1

Terms and Conditions Agreement...........................................................................2

Warranty, Limitations of Liability ...................................................................................................................2

Application Considerations ........................................................................................................................... 3

Disclaimers ................................................................................................................................................... 3

Safety Precautions.................................................................................................... 4

Definition of Precautionary Information .........................................................................................................4

Symbols .......................................................................................................................................................4

Precautions for Safe Use..........................................................................................7

Precautions for Correct Use.....................................................................................9

Precautions for Operation ...................................................................................... 10

Preparations for Use............................................................................................... 11

Versions ...................................................................................................................12

Revision History...................................................................................................... 13

Conventions Used in This Manual.........................................................................14

Model Notation ............................................................................................................................................14

Meanings of Abbreviations ..........................................................................................................................14

How to Read Display Symbols .................................................................................................................... 15

How This Manual is Organized ...................................................................................................................15

Related Manuals ......................................................................................................................................... 15

Sections in this Manual ..........................................................................................17

Section 1 Introduction

1-1 Appearance, Features, and Functions of the E5@C-T ......................................................... 1-2

1-1-1 Appearance.................................................................................................................................1-2

1-1-2 Features......................................................................................................................................1-2

1-1-3 Main Functions............................................................................................................................1-3

1-2 I/O Configuration and Model Number Legend ...................................................................... 1-5

1-2-1 I/O Configuration.........................................................................................................................1-5

1-2-2 Model Number Legends..............................................................................................................1-7

Section 2 Preparations

2-1 Installation................................................................................................................................ 2-2

2-1-1 Dimensions (Unit: mm)................................................................................................................2-2

2-1-2 Panel Cutout (Unit: mm)..............................................................................................................2-3

2-1-3 Mounting .....................................................................................................................................2-5

2-2 Using the Terminals................................................................................................................. 2-7

2-2-1 E5CC-T Terminal Block Wiring Example.....................................................................................2-7

2-2-2 E5EC-T/E5AC-T Terminal Block Wiring Example .....................................................................2-11

2-2-3 Precautions when Wiring ..........................................................................................................2-16

2-2-4 Wiring........................................................................................................................................2-16

Page 22

19

E5@C-T Digital Temperature Controllers User’s Manual (H185)

2-3 Insulation Block Diagrams....................................................................................................2-23

2-4 Using the Setup Tool Port..................................................................................................... 2-24

2-4-1 Procedure ................................................................................................................................. 2-24

2-4-2 Connection Method................................................................................................................... 2-24

2-4-3 Installing the Driver................................................................................................................... 2-27

Section 3 Part Names and Basic Procedures

3-1 Basic Application Flow ........................................................................................................... 3-2

3-2 Power ON.................................................................................................................................. 3-3

3-3 Part Names, Part Functions, and Setting Levels .................................................................. 3-4

3-3-1 Part Names and Functions ......................................................................................................... 3-4

3-3-2 Entering Numeric Values............................................................................................................ 3-8

3-3-3 Setting Levels ............................................................................................................................. 3-9

3-4 Procedures after Turning ON the Power Supply................................................................. 3-14

3-4-1 Basic Flow of Operations.......................................................................................................... 3-14

3-4-2 Basic Procedure ....................................................................................................................... 3-15

Section 4 Basic Operation

4-1 Moving between Setting Levels ............................................................................................. 4-3

4-1-1 Moving to the Initial Setting Level ............................................................................................... 4-3

4-1-2 Moving to the Program Setting Level.......................................................................................... 4-4

4-1-3 Moving to the Adjustment Level.................................................................................................. 4-5

4-1-4 Moving to the PID Setting Level.................................................................................................. 4-5

4-1-5 Moving to the Protect Level ........................................................................................................ 4-6

4-1-6 Moving to the Advanced Function Setting Level......................................................................... 4-7

4-1-7 Moving to the Communications Setting Level............................................................................. 4-9

4-2 Initial Setup Examples through Starting Program Operation............................................ 4-10

4-2-1 Program Operation................................................................................................................... 4-10

4-2-2 Initial Setup Example for Step Time Programming................................................................... 4-11

4-2-3 Initial Setup Example for Rate of Rise Programming................................................................ 4-14

4-3 Setting the Input Type ........................................................................................................... 4-18

4-3-1 Input Type................................................................................................................................. 4-18

4-4 Selecting the Temperature Unit............................................................................................ 4-20

4-4-1 Temperature Unit...................................................................................................................... 4-20

4-5 Selecting PID Control or ON/OFF Control

(Not Supported for Position-proportional Models.)............................................................ 4-21

4-6 Setting Output Specifications .............................................................................................. 4-22

4-6-1 Control Periods (Not Supported for Position-proportional Models.).......................................... 4-22

4-6-2 Direct and Reverse Operation .................................................................................................. 4-22

4-6-3 Assigned Output Functions (Assigning Control Outputs Is Not Supported

for Position-proportional Models.) ............................................................................................. 4-23

4-6-4 Auxiliary Output Opening or Closing in Alarm .......................................................................... 4-26

4-7 Setting Programs................................................................................................................... 4-27

4-7-1 Programming............................................................................................................................ 4-27

4-7-2 Program Patterns...................................................................................................................... 4-30

4-7-3 Setting Flow for Program-related Settings................................................................................ 4-32

4-7-4 Making the Initial Program-related Settings.............................................................................. 4-33

4-7-5 Creating the Program ............................................................................................................... 4-39

4-7-6 Changing Programs during Operation...................................................................................... 4-45

4-8 Setting the Fixed SP .............................................................................................................. 4-47

4-8-1 Fixed SP Setting Methods ........................................................................................................ 4-47

Page 23

20

E5@C-T Digital Temperature Controllers User’s Manual (H185)

4-9 Determining PID Constants (Autotuning and Manual Setting).......................................... 4-49

4-9-1 AT (Auto-tuning) ........................................................................................................................4-50

4-9-2 RT (Robust Tuning) (Used for Autotuning) ................................................................................4-52

4-9-3 Manual Setup............................................................................................................................4-54

4-10 Alarm Outputs........................................................................................................................ 4-56

4-10-1 Alarm Types ..............................................................................................................................4-56

4-10-2 Alarm Values.............................................................................................................................4-59

4-11 Alarm Hysteresis ................................................................................................................... 4-62

4-11-1 Standby Sequence....................................................................................................................4-62

4-11-2 Alarm Latch...............................................................................................................................4-63

4-12 Using Heater Burnout (HB) and Heater Short (HS) Alarms

(Not Supported for Position-proportional Models.)............................................................ 4-64

4-12-1 HB Alarm...................................................................................................................................4-64

4-12-2 HS Alarm...................................................................................................................................4-66

4-12-3 Installing Current Transformers (CT).........................................................................................4-68

4-12-4 Calculating Detection Current Values .......................................................................................4-70

4-12-5 Application Examples................................................................................................................4-70

4-13 Using ON/OFF Control (Not Supported for Position-proportional Models.) .................... 4-74

4-13-1 ON/OFF Control........................................................................................................................4-74

4-13-2 Settings.....................................................................................................................................4-75

4-14 Customizing the PV/SP Display ........................................................................................... 4-76

4-14-1 PV/SP Display Selections .........................................................................................................4-76

Section 5 Advanced Operations

5-1 Shifting Input Values............................................................................................................... 5-3

5-2 Setting Scaling Upper and Lower Limits for Analog Inputs ................................................ 5-5

5-3 Executing Heating/Cooling Control (Not Supported for Position-proportional Models.) . 5-7

5-3-1 Heating/Cooling Control..............................................................................................................5-7

5-4 Using Event Inputs ................................................................................................................ 5-11

5-4-1 Event Input Settings..................................................................................................................5-11

5-4-2 Using Event Inputs....................................................................................................................5-11

5-5 Setting the SP Upper and Lower Limit Values .................................................................... 5-16

5-5-1 Set Point Limiter........................................................................................................................5-16

5-5-2 Setting.......................................................................................................................................5-17

5-6 Using the Key Protect Level ................................................................................................. 5-18

5-6-1 Protection..................................................................................................................................5-18

5-6-2 Entering the Password to Move to the Protect Level.................................................................5-19

5-7 Hiding Parameters ................................................................................................................. 5-21

5-7-1 Parameter Mask Settings..........................................................................................................5-21

5-8 OR Output of Alarms ............................................................................................................. 5-23

5-8-1 Integrated Alarm .......................................................................................................................5-23

5-9 Alarm Delays .......................................................................................................................... 5-25

5-9-1 Alarm Delays.............................................................................................................................5-25

5-10 Loop Burnout Alarm (Not Supported for Position-proportional Models.)........................ 5-27

5-10-1 Loop Burnout Alarm (LBA)........................................................................................................5-27

5-11 Performing Manual Control...................................................................................................5-31

5-11-1 Manual MV................................................................................................................................5-31

5-12 Using the Transfer Output .................................................................................................... 5-34

5-12-1 Transfer Output Function...........................................................................................................5-34

5-13 Using PID Sets ....................................................................................................................... 5-37

5-13-1 PID Sets....................................................................................................................................5-37

5-13-2 Settings for PID Sets.................................................................................................................5-41

5-13-3 Setting PID Set Parameters......................................................................................................5-44

Page 24

21

E5@C-T Digital Temperature Controllers User’s Manual (H185)

5-14 Determining PID Constants for PID Sets (Autotuning for All PID Sets) ........................... 5-45

5-14-1 Autotuning All PID Sets (Autotuning)........................................................................................ 5-45

5-14-2 Executing Autotuning for All PID Sets....................................................................................... 5-48

5-15 Program-related Functions...................................................................................................5-53

5-15-1 Advance.................................................................................................................................... 5-53

5-15-2 Segment Jump.......................................................................................................................... 5-54

5-15-3 Hold .......................................................................................................................................... 5-54

5-15-4 Wait........................................................................................................................................... 5-55

5-15-5 Program Repetition................................................................................................................... 5-56

5-15-6 Program Links........................................................................................................................... 5-56

5-15-7 SP Shift..................................................................................................................................... 5-57

5-15-8 Time Signals............................................................................................................................. 5-57

5-15-9 Program end outputs................................................................................................................ 5-59

5-15-10 RUN Output .............................................................................................................................. 5-60

5-15-11 Stage Outputs........................................................................................................................... 5-61

5-15-12 PV Start .................................................................................................................................... 5-61

5-15-13 Standby Operation.................................................................................................................... 5-63

5-15-14 Changing the SP Mode............................................................................................................. 5-64

5-15-15 SP Tracking............................................................................................................................... 5-65

5-15-16 Operations Related to Other Functions ....................................................................................5-66

5-16 Output Adjustment Functions.............................................................................................. 5-67

5-16-1 Output Limits............................................................................................................................. 5-67

5-16-2 MV at Reset.............................................................................................................................. 5-67

5-16-3 MV at PV Error.......................................................................................................................... 5-68

5-17 Using the Extraction of Square Root Parameter ................................................................ 5-70

5-17-1 Extraction of Square Roots....................................................................................................... 5-70

5-18 Setting the Width of MV Variation ........................................................................................ 5-72

5-18-1 MV Change Rate Limit.............................................................................................................. 5-72

5-19 Setting the PF Key ................................................................................................................. 5-74

5-19-1 PF Setting (Function Key) ........................................................................................................ 5-74

5-20 Displaying PV/SV Status ....................................................................................................... 5-77

5-20-1 PV and SV Status Display Functions........................................................................................5-77

5-21 Controlling Valves (Can Be Used with a Position-proportional Model)............................ 5-79

5-22 Logic Operations ................................................................................................................... 5-82

5-22-1 The Logic Operation Function (CX-Thermo) ............................................................................ 5-82

5-22-2 Using Logic Operations ............................................................................................................ 5-82

5-23 Using the CX-Thermo to Set Programs ............................................................................... 5-91

5-23-1 Introduction............................................................................................................................... 5-91

5-23-2 Using the Program Setting Functions.......................................................................................5-92

5-23-3 Names and Functions of Objects in the Programmer Editor .................................................... 5-93

5-23-4 Program Setting Procedures .................................................................................................... 5-97

Section 6 Parameters

6-1 Conventions Used in this Section.......................................................................................... 6-2

6-2 Protect Level ............................................................................................................................ 6-3

6-3 Operation Level ....................................................................................................................... 6-7

6-4 Program Setting Level........................................................................................................... 6-16

6-5 Adjustment Level................................................................................................................... 6-24

6-6 PID Setting Level ................................................................................................................... 6-44

6-7 Monitor/Setting Item Level.................................................................................................... 6-50

6-8 Manual Control Level ............................................................................................................ 6-52

6-9 Initial Setting Level ................................................................................................................ 6-54

Page 25

22

E5@C-T Digital Temperature Controllers User’s Manual (H185)

6-10 Advanced Function Setting Level ........................................................................................ 6-80

6-11 Communications Setting Level .......................................................................................... 6-111

Section 7 User Calibration

7-1 User Calibration ....................................................................................................................... 7-2

7-2 Parameter Structure ................................................................................................................ 7-3

7-3 Thermocouple Calibration ...................................................................................................... 7-4

7-4 Resistance Thermometer Calibration .................................................................................... 7-7

7-5 Calibrating Analog Input ........................................................................................................ 7-9

7-6 Calibrating the Transfer Output............................................................................................ 7-11

7-7 Checking Indication Accuracy ............................................................................................. 7-13

Section A Appendices

A-1 Specifications ..........................................................................................................................A-2

A-1-1 Ratings ........................................................................................................................................A-2

A-1-2 Characteristics ............................................................................................................................A-4

A-1-3 Program Controls ........................................................................................................................A-5

A-1-4 Waterproof Packing.....................................................................................................................A-6

A-1-5 Setup Tool Port Cover for Front Panel.........................................................................................A-7

A-2 Current Transformer (CT)........................................................................................................A-8

A-2-1 Specifications ..............................................................................................................................A-8

A-2-2 Dimensions (Unit: mm)................................................................................................................A-8

A-3 USB-Serial Conversion Cable and Conversion Cable..........................................................A-9

A-3-1 E58-CIFQ2 USB-Serial Conversion Cable..................................................................................A-9

A-3-2 E58-CIFQ2-E Conversion Cable...............................................................................................A-10

A-4 Error Displays ........................................................................................................................A-11

A-5 Troubleshooting.....................................................................................................................A-15

A-6 Parameter Operation Lists....................................................................................................A-18

A-6-1 Operation Level.........................................................................................................................A-18

A-6-2 Program Setting Level...............................................................................................................A-19

A-6-3 Adjustment Level.......................................................................................................................A-20

A-6-4 PID Setting Level.......................................................................................................................A-22

A-6-5 Initial Setting Level ....................................................................................................................A-23

A-6-6 Manual Control Level ................................................................................................................A-26

A-6-7 Monitor/Setting Item Level.........................................................................................................A-26

A-6-8 Advanced Function Setting Level..............................................................................................A-27

A-6-9 Protect Level .............................................................................................................................A-31

A-6-10 Communications Setting Level..................................................................................................A-32

A-6-11 Initialization According to Parameter Changes .........................................................................A-33

A-7 Sensor Input Setting Range, Indication Range, Control Range........................................A-36

A-8 Setting Levels Diagram .........................................................................................................A-37

A-9 Parameter Flow ......................................................................................................................A-38

Index

Page 26

1 - 1

E5@C-T Digital Temperature Controllers User’s Manual (H185)

1

1-1 Appearance, Features, and Functions of the E5@C-T . . . . . . . . . . . . . . . . 1-2

1-1-1 Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-3 Main Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2 I/O Configuration and Model Number Legend . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-2-1 I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-2-2 Model Number Legends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Introduction

Page 27

1 Introduction

1 - 2

E5@C-T Digital Temperature Controllers User’s Manual (H185)

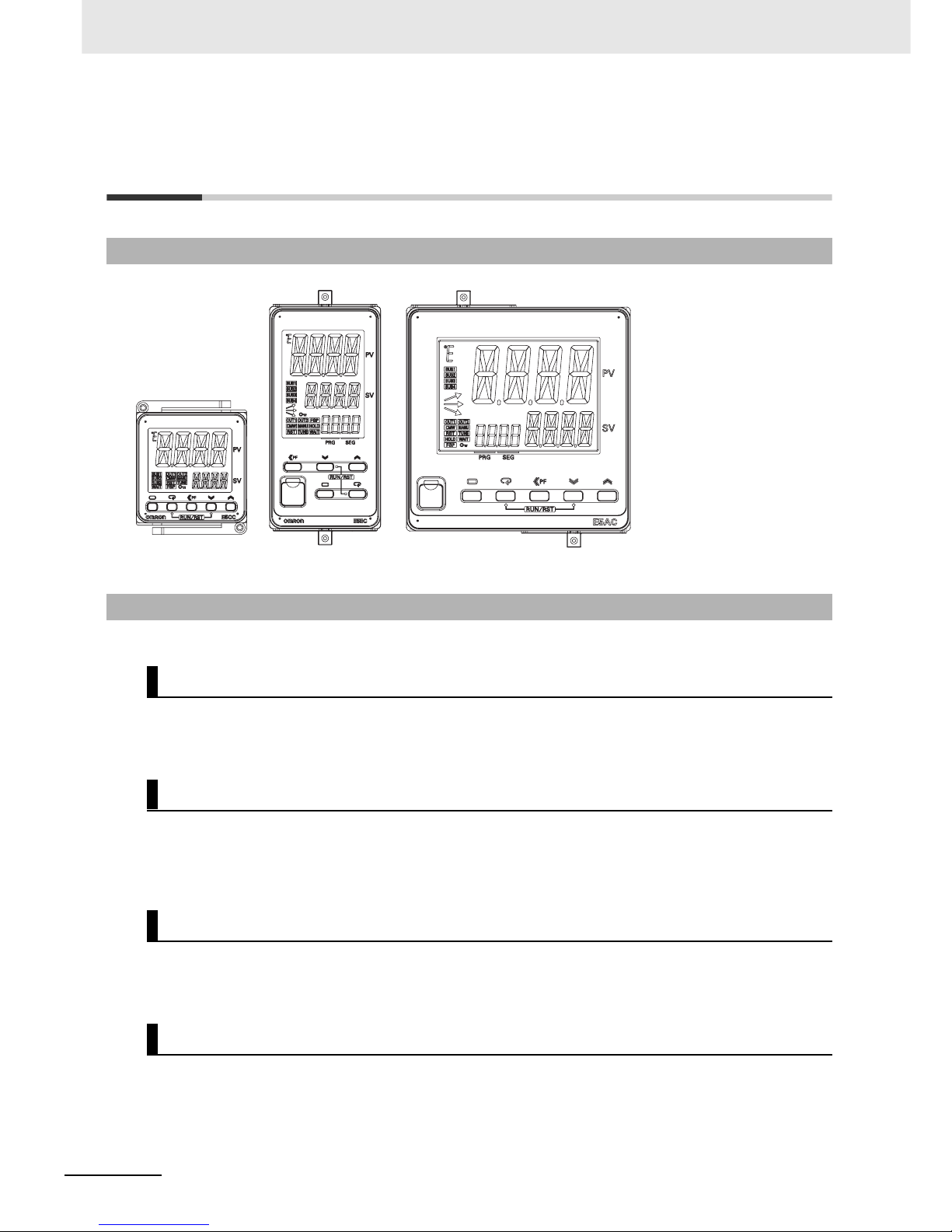

1-1 Appearance, Features, and

Functions of the E5@C-T

This section compares the features of the E5@C-T with the previous E5@N-HT Controllers.

Input sampling cycle: 50 ms

Control period: 0.1 s and 0.2 s have been added.

Integral/differential time unit: Setting in increments of 0.1 s has been added.

• Number of event inputs: Increased from 2 to 4 for the E5CC-T and from 4 to 6 for the

E5EC-T/E5AC-T.

• Number of auxiliary outputs: Increased from 2 to 3 for the E5CC-T and from 3 to 4 for the

E5EC-T/E5AC-T.

Digit shift: When setting the SP or other parameters, you can use a Shift Key (i.e.,

the PF Key) to shift the digit that is being set to aid in changing the set

values.

This port allows you to change or set parameters from the Setup Tool even when the Controller is

installed in a panel.

1-1-1 Appearance

• A stylish design that

gives a new look to

control panels.

• Large display characters

and white backlight for

better visibility.

• A compact size to help

downsize control panels.

• Much faster sampling

and greater expandability

than expected in this

class of Controller.

• Even easier to use than

previous models.

1-1-2 Features

High-speed Control Capability

I/O Expandability

Easier Numeric Inputs with a Digit Shift Key

Setup Tool Port on Front Panel of the E5EC-T/E5AC-T

E5CC-T E5EC-T E5AC-T

Page 28

1 - 3

1 Introduction

E5@C-T Digital Temperature Controllers User’s Manual (H185)

1-1 Appearance, Features, and

Functions of the E5@C-T

1

1-1-3 Main Functions

You can use a key operation to freely jump to another segment and execute it.

From the initial display in Operation Level, you can change to the display to edit segment data with one

key.

When you use more than one PID set, you can set all of the PID constants at the same time to reduce

adjustment work.

You can press the M (Mode) Key and the D Key simultaneously for 1 second or longer to change the

program between run status and reset status.

You can use key operations to hide parameters that do not need to be displayed to prevent incorrectly

setting parameters and to simplify the parameter configuration.

For details on particular functions and how to use them, refer to Section 3 Part Names and Basic Proce-

dures and following sections.

z Input Sensor Types

You can connect the following sensors and signals to the universal input.

z Control Outputs

• A control output can be a relay output, voltage output (for driving SSR), or linear current output,

depending on the model.

z Program Controls

Program Patterns

• Programs: 8 patterns max., Segments: 32 max. per program

• Program initial set point: Segment 0 set point, present value (PV), or fixed SP

• Program start time: Standby operation (delay) can be set.

• Repeating and linking programs are also possible.

Controlling the Program

• Run (program operation started)/Reset (program operation stopped)

• Advancing the segment

Controlling the Program

Editing the Program

AT for All PID Sets

Addition of Operation to Change Program between Run and Reset

Parameter Mask Settings

1-1-3 Main Functions

Thermocouple (temperature input): K, J, T, E, L, U, N, R, S, B, W, PLII

Resistance thermometer (temperature input): Pt100, JPt100

Infrared Temperature Sensor (temperature input): ES1B

10 to 70°C, 60 to 120°C, 115 to 165°C, 140 to 260°C

Current input (analog input): 4 to 20 mA DC, 0 to 20 mA DC

Voltage input (analog input): 1 to 5 VDC, 0 to 5 V DC, 0 to 10 V DC

Page 29

1 Introduction

1 - 4

E5@C-T Digital Temperature Controllers User’s Manual (H185)

• Holding

• Waiting to advance to the next segment

• Jumping to segments with a key operation

Program Status Outputs

• Time signals

• ON output in run status

• ON output at program end

• Stage outputs (one-pulse output at start of each segment)

z Adjusting PID Constants

• You can easily set the optimum PID constants for the current PID set or for all PID sets by

performing AT (auto-tuning) with the limit cycle method .

• You can also add RT (robust tuning) to give priority to controlling stability.

z Alarms

Standard Alarms

• You can output an alarm when the deviation, process value, set point, or manipulated value

reaches a specified value.

• You can also output alarms for the PV rate of change and for loop burnouts.

• If necessary, a more comprehensive alarm function can be achieved by setting a standby

sequence, alarm hysteresis, auxiliary output close in alarm/open in alarm, alarm latch, alarm ON

delay, and alarm OFF delay.

HB and HS Alarms

• With models with the optional HB and HS alarms, you can detect heater burnout and heater short

alarms based on CT inputs.

Integrated Alarm

• You can output an integrated alarm if a standard alarm, HB alarm, or HS alarm turns ON.

z Event Inputs

• With any model that supports event inputs, you can use external contact or transistor inputs to

achieve any of the following functions: You can control the following: changing programs

(changing program number, 8 max.), changing between run and reset status, changing between

automatic and manual operation, inverting direct/reverse operation, changing between program

SP and fixed SP, 100% AT execute/cancel, 40% AT execute/cancel, 100% AT execute/cancel for

all PID sets, 40% AT execute/cancel for all PID sets, setting change enable/disable,

communications write enable/disable, canceling the alarm latch, hold/clear hold, advance, and

wait enable/disable.

z Communications Functions

With any E5@C-T model that supports communications, you can use CompoWay/F, Modbus-RTU,

*1

programless, and component communications.

*1 Modbus is a registered trademark of Schneider Electric.

z Transfer Output

With any model that provides a transfer output, you can output the set point, process value,

manipulated variable, or other values as a 4 to 20-mA or 1 to 5-V transfer output.

Page 30

1 - 5

1 Introduction

E5@C-T Digital Temperature Controllers User’s Manual (H185)

1-2 I/O Configuration and Model

Number Legend

1

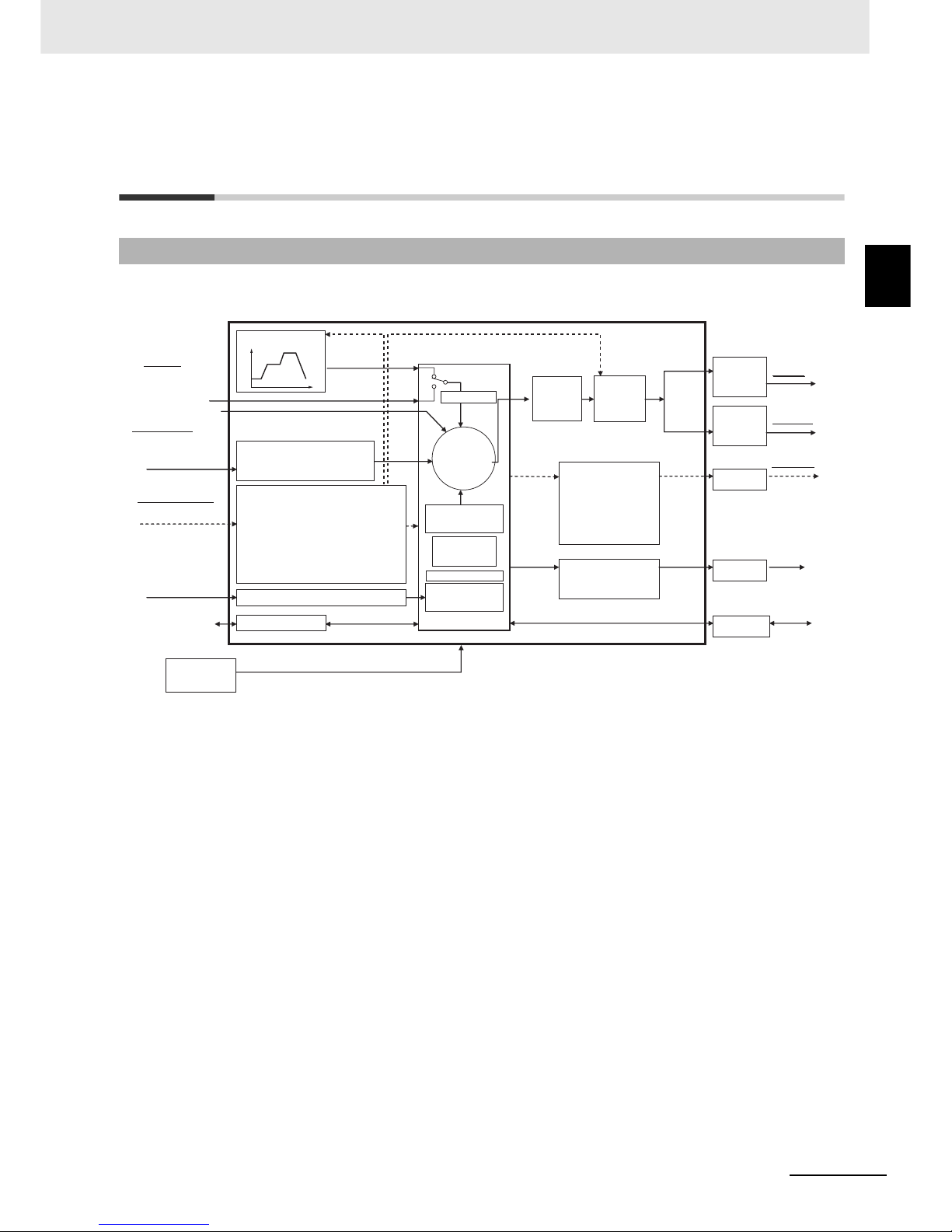

1-2-1 I/O Configuration

1-2 I/O Configuration and Model Number

Legend

z I/O Configuration of E5C-T

Note: Not all models support these functions. For details, refer to 1-2-2 Model Number Legends.

1-2-1 I/O Configuration

E5C-T

Input signals

Event inputs (EV1 to EV6)

• External inputs

(contact or non-contact input)

Setting and monitoring

PV

Setup Tool (CX-Thermo)

CT input

Potentiometer input

Input voltage from CT

Inputs

Set point (SP)

Fixed SP

Control

Power supply

Process value (PV) input

• Thermocouple

• Resistance thermometer

• Infrared Temperature Sensor

• Analog input (current/voltage)

Program SP

SP mode

SP

FB

• Run/Reset switching

• Program number switching

• Program SP Mode/Fixed SP

Mode switching

•

All PID 100% AT Execute/Cancel

•

All PID 40% AT Execute/Cancel

• Hold/Clear Hold

• Program No.

• Advance

• Wait Enable/Disable

• Set point limiter

Program control

SP

t

• Input type • Input shift

• Input filter • Moving average

• Extraction of square root

• Analog scaling

A: 100 to 240 VAC

or

D: 24 VAC/DC

•

Auto/manual selection

• Invert direct/reverse

operation

• Communications

write enable/disable

• 40% AT execute/cancel

•

100% AT execute/cancel

• Alarm latch cancel

• Setting change

enable/disable

• HB alarm

• HS alarm

Alarms

• PID or

• ON/OFF control

• Standard control

•

Heating/cooling control

•

Position-proportional control

Automatic setting of

PID constants with AT

Manipulated

value

(MV)

• Direct/reverse

• Auto/manual

•

Standard alarms (alarms 1 to 4)

• HB alarm

• HS alarm

• Input error (S.ERR)

•

Integrated alarm

•

RUN status

•

Program end

•

Work bits 1 to 8

Limits

• Present SP

• Process value

• Manipulated value

Analog status

Contact status

Operation

Cooling

Close

• MV limit

• MV

rate-ofchange limit

Heating

Open

*

Functions can be assigned individually for each output by

changing the set values for the Control Output 1 and 2

Assignments and the Auxiliary Output 1 to 4 Assignments in the

parameters in the advanced function setting level.

Auxiliary outputs 1 to 4

• Linear current

• Voltage

(for driving SSR)

• Relay

Outputs

• RS-485

Output signals

• CompoWay/F

• Modbus-RTU

Communications

• Linear current

• Linear voltage

Transfer output

• Relay

Control output 1

• Linear current

• Voltage

(for driving SSR)

• Relay

Control output 2

*

*

*

Page 31

1 Introduction

1 - 6

E5@C-T Digital Temperature Controllers User’s Manual (H185)

z I/O Related to Programmed Models

Time

Program No. 1

Program No. 0

Program No. 7

Time

Segment 0

Segment 1

Segment 31

Segment 2

Segment 30

ON

OFF

Time

Setting of operation end operation

Continue final segment SP, fixed SP, or reset

Setting of startup operation

Continue pre-power-OFF status, reset, run, or Manual Mode

Run

SP

SP

SP

Time

Program SP Mode

Fixed SP Mode

SP

Fixed

SP

Changing SP mode or

between run and reset status

Output

Other functions

• Operation at start of program: PV start or SP start

• Program start time: Standby operation (delay) can be set.

• Segment operation: Advance segment, hold, wait to advance to next segment, or

key-operation-initiated segment jumps

• Program link operations: Repeating and linking programs

• SP tracking: Overwriting fixed SP with current SP when changing to Fixed SP Mode

• Shifting the program SP

Run/Reset Switching

Press the M (Mode) and

D (Down) Key

simultaneously for at

least 1 second.

Setting Key Operations

• Run/Reset switching

• Segment jump

• Hold

• Wait band setting, Etc.

PF Key

• Run/Reset switching

• Hold/Clear hold

• Advance, Etc.

Event Inputs

• Run/Reset switching

• Hold/Clear hold

• Advance

• Program SP Mode/Fixed

SP Mode

• Program No. specification,

etc.

Auxiliary output 1 or 2

Control output 1 or 2

• Time signal outputs

•

Program end outputs

• RUN output

•

Stage outputs can be assigned.

Time signals or other

ON/OFF signals

Input

Program Start Point for Segment 0

One of the following depending on

the settings of the Operation at

Reset and Step Time/Rate of Rise

Programming parameters.

• Segment 0 set point

• Process value (PV)

• Fixed SP

Page 32

1 - 7

1 Introduction

E5@C-T Digital Temperature Controllers User’s Manual (H185)

1-2 I/O Configuration and Model

Number Legend

1

1-2-2 Model Number Legends

z E5CC-T

*1 Options with HB and HS alarms (001, 002, or 003) cannot be selected.

*2 The linear current output cannot be used as a transfer output.

*3 This cannot be selected if 5 (screw terminals with cover) is selected for the terminal type.

1-2-2 Model Number Legends

(1) (2) (3) (4) (5) (6) (7) Meaning

C48 × 48 mm

Control output 1 Control output 2

R X Relay output None

Q X Voltage output (for driving SSR) None

*2*1 C X Linear current output None

Q Q Voltage output (for driving SSR) Voltage output

(for driving SSR)

*2 C Q Linear current output Voltage output

(for driving SSR)

33

A 100 to 240 VAC

D 24 VAC/DC

S Screw terminals

5 Screw terminals (with cover)

M Universal input

Event

inputs

Communications

HB alarm and HS

alarm

Transfer

output

000 --- --- --- --001 2 --- 1 ---

*3 002 --- RS-485 1 ---

003 --- RS-485 2 (for 3-phase

heaters)

---

004 2 RS-485 --- --005 4 --- --- --006 2 --- --- Provided.

-

E5CC-T

-

(1) (2) (3) (4) (5) (6) (7)

Size

Control Outputs 1 and 2

No. of auxiliary outputs

Power supply voltage

Terminal type

Input type

Options

Page 33

1 Introduction

1 - 8

E5@C-T Digital Temperature Controllers User’s Manual (H185)

z E5EC/AC-T

*1 The options that can be selected depend on the type of control output.

*2 The linear current output cannot be used as a transfer output.

*3 This cannot be selected if 5 (screw terminals with cover) is selected for the terminal type.

(1) (2) (3) (4) (5) (6) (7) Meaning

E 48 × 96 mm

A 96 × 96 mm

Control output 1 Control output 2

*1 R X Relay output None

*1 Q X Voltage output (for driving SSR) None

*2*1 C X Linear current output None

*1 Q Q Voltage output (for driving SSR) Voltage output (for driving SSR)

*1 Q R Voltage output (for driving SSR) Relay output

*1 R R Relay output Relay output

*2*1 C C Linear current output Linear current output

*2*1 C Q Linear current output Voltage output (for driving SSR)

*1 P R Position-proportional relay output Position-proportional relay output

44

A 100 to 240 VAC

D 24 VAC/DC

S Screw terminals

5 Screw terminals (with cover)

M Universal input

Event

inputs

Communications

HB alarm and

HS alarm

Transfer

output

For RX,

QX, RR,

QQ, QR, or

CQ

For CX or

CC

For PR

000 --- --- --- --- Selectable Selectable Selectable

004 2 RS-485 --- --- --- Selectable Selectable

005 4 --- --- --- --- Selectable --008 2 RS-485 1 --- Selectable --- --010 4 --- 1 --- Selectable --- --019 6 --- 1 Provided. Selectable --- ---

*3 020 4 RS-485 2 (for 3-phase

heaters)

Provided. Selectable --- ---

021 6 --- --- Provided. --- Selectable --022 4 RS-485 --- Provided. --- Selectable Selectable

-

-

E5 C-T

-

(1) (2) (3) (4) (5) (6) (7)

Size

Control Outputs 1 and 2

No. of auxiliary outputs

Power supply voltage

Terminal type

Input type

Options

Page 34

2 - 1

E5@C-T Digital Temperature Controllers User’s Manual (H185)

2

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-1 Dimensions (Unit: mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-2 Panel Cutout (Unit: mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-1-3 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-2 Using the Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-2-1 E5CC-T Terminal Block Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-2-2 E5EC-T/E5AC-T Terminal Block Wiring Example . . . . . . . . . . . . . . . . . . . . . . 2-11

2-2-3 Precautions when Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-2-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-3 Insulation Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2-4 Using the Setup Tool Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2-4-1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24