Page 1

Ultrasonic Sensor with Separated Digital Amplifier

Amplifier Unit

E4C-UDA__

Instruction Manual

Thank you for purchasing this Amplifier Unit.

When using this Amplifier Unit, be sure to observe the following:

• The Amplifier Unit must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Omron Corporation

© OMRON Corporation 2005 All Rights Reserved.

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

1636705-7B

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

- 1 -

Page 2

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED UPON

AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer to

separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Please observe the following precautions for safe use of the product:

1) Do not use the product in environments where it can be exposed to inflammable/explosive gas.

2) Do not use this product in locations where it will be sprayed by water, oil or chemical fumes, or in steamy locations.

3) Do not attempt to dismantle, repair, or modify the product.

4) The supply voltage and current must be within the rated ranges.

5) Do not wire the product incorrectly (e.g. mistake the polarity of the power supply, or mistake wiring terminals).

6) Correctly connect the load to both control and analog outputs.

7) Both ends of the load on control outputs and analog outputs should not be short-circuited.

8) Do not use the product with the case damaged.

9) Dispose of this product as industrial waste.

1) Electrical lines and power lines must be wired separately from this product. Wiring them together or placing them in the

same duct may cause induction, resulting in malfunction or damage.

2) Limit cable extensions to 10 m. Use extension cable of 0.3 mm

3) Sensing is possible 200 ms after the product is turned on.

When the load and product are powered by different power supplies, be sure to turn the product on before the load.

4) Be sure to use the product with its protective cover attached.

5) When a write error occurs (ERR/EEP flashes) due to power being cut off, or static electricity or other noise, initialize the

product settings by its setting keys.

6) After the product is turned on, it sometimes takes time for the displayed distance value to stabilize in some operating

environments.

7) An output pulse is sometimes generated when the product power is cut. For this reason, cut the power of the load or

load line before turning the product off.

8) Do not use paint thinner, benzene, acetone, or kerosene for cleaning.

9) Before connecting or disconnecting connectors to the Sensor Head, be sure to turn the product off.

Only the E4C Sensor Head can be used. Other Sensor Heads cannot be used. Use of a different model of Sensor

Head may damage the product.

10)The distance value displayed in the amplifier's display is different from the value measured using a tape measure or

other apparatuses. When the value must be adjusted for use, adjust the value using the scaling function.

Precautions for Safe Use

Precautions for Correct Use

2

in diameter or thicker.

- 2 -

Page 3

.

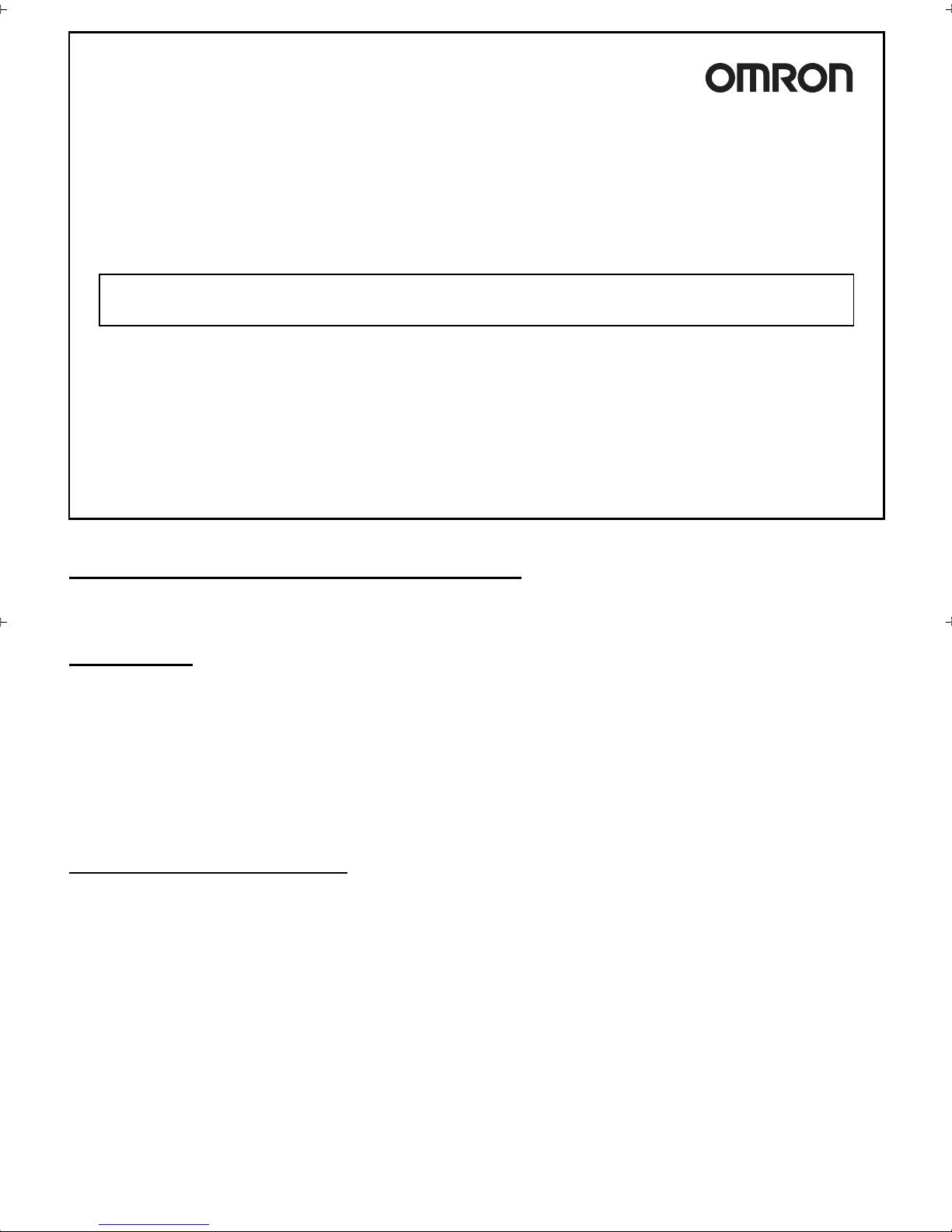

1. Part Names and Functions

(2) Main display (red display)

(3) Twin output model: Operation indicator (2CH side)

(1) Operation indicator

(1CH)

Analog output model: None

(4) Sub-display (green display)

UP

DOWN MODE

SET RUN

12

(7) Control keys

(5) SET/RUN switch

(6) Twin output type: Channel switch

Analog output type: Operating mode switch

NF

(1) This indicator lights when the output turns ON.

In the case of the twin output model, this indicator lights when the output of 1CH turns ON.

(2) This display shows the distance to the workpiece and function name.

(3) In the case of the twin output model, this indicator lights when the output of 2CH turns ON.

(4) This sub-display shows additional information and function settings for sensing.

(5) This switch selects the operating mode.

(6) In the case of the twin output model, this switch selects the channel to be displayed and set.

In the case of the analog output model, this switch selects whether to turn output ON when the workpiece is in the near

distance or the workpiece is in the far distance.

(7) These keys switch the display and set functions.

2. List of Functions

Function Name Overview

Operating mode setting This function sets the operating mode. P.7

Threshold setting This function sets the threshold values. P.8

Bank setting/call This function saves and reads settings. P.10

Scaling setting This function changes the display values for specific measurement values to the

desired values. (twin output model only)

Judgment output setting This function selects the output method. P.12

Analog output range setting This function sets the range and display ratio of the analog output with respect to the

display value.

(analog output model only)

Zero reset/offset This function sets the current distance to 0 (zero) or to any value. P.15, P.15

Display inversion This function inverts how the display for the distance to the workpiece is

incremented/decremented.

Keylock This function disables key operation. P.16

Initialization This function returns the amplifier settings to their factory settings. P.16

Page for Description

of Operation

P. 11

P. 1 3

P. 1 5

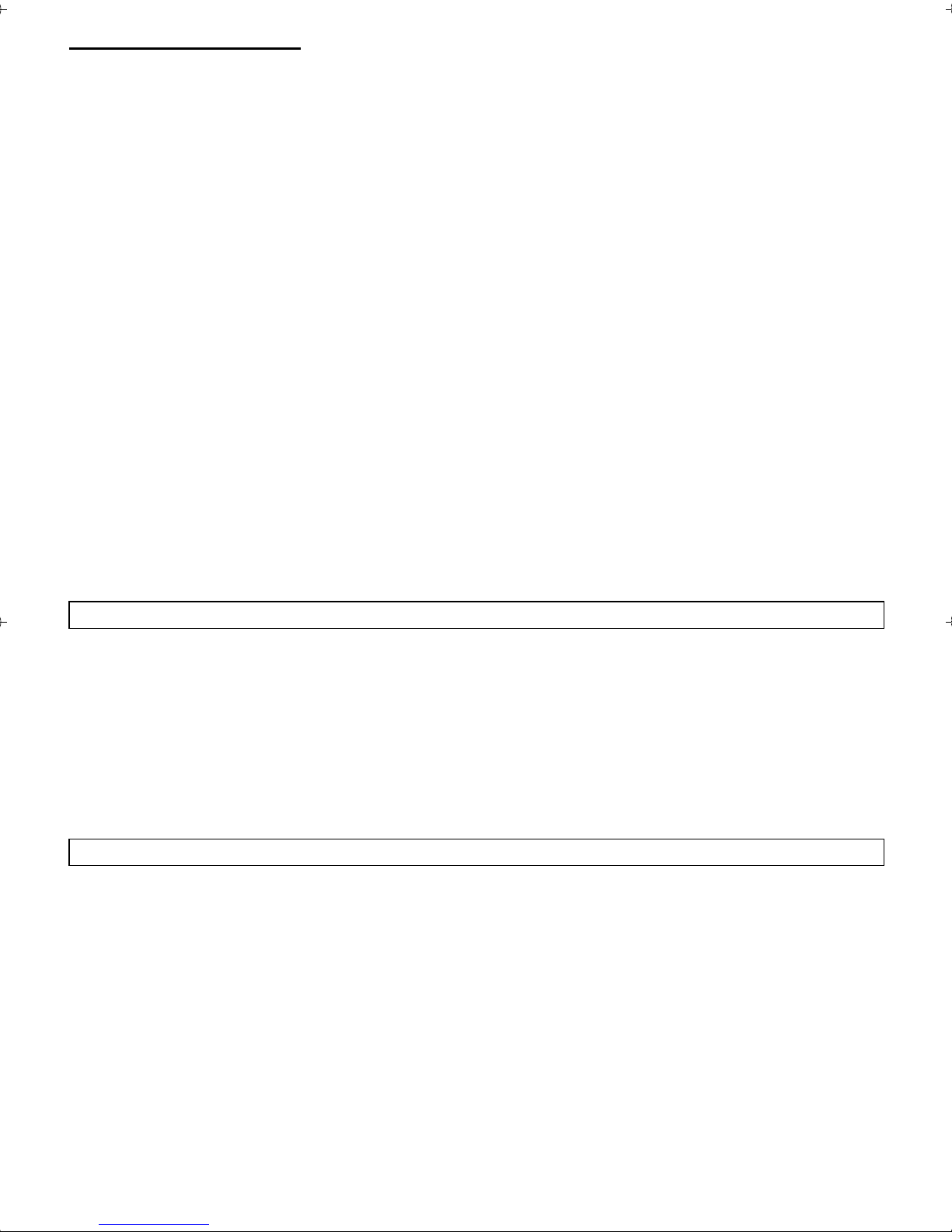

3. Installation & Connection

Connecting the Sensor Head

1. Open the protective cover.

2. Orient the Amplifier Unit so that the lock lever of the Sensor

Head connector is facing up, and push the Sensor Head into the

connector insertion slot as far as it can go.

To remove the Sensor Head, press down on the lock lever and draw

the Sensor Head out.

1

2

Lock lever

- 3 -

Page 4

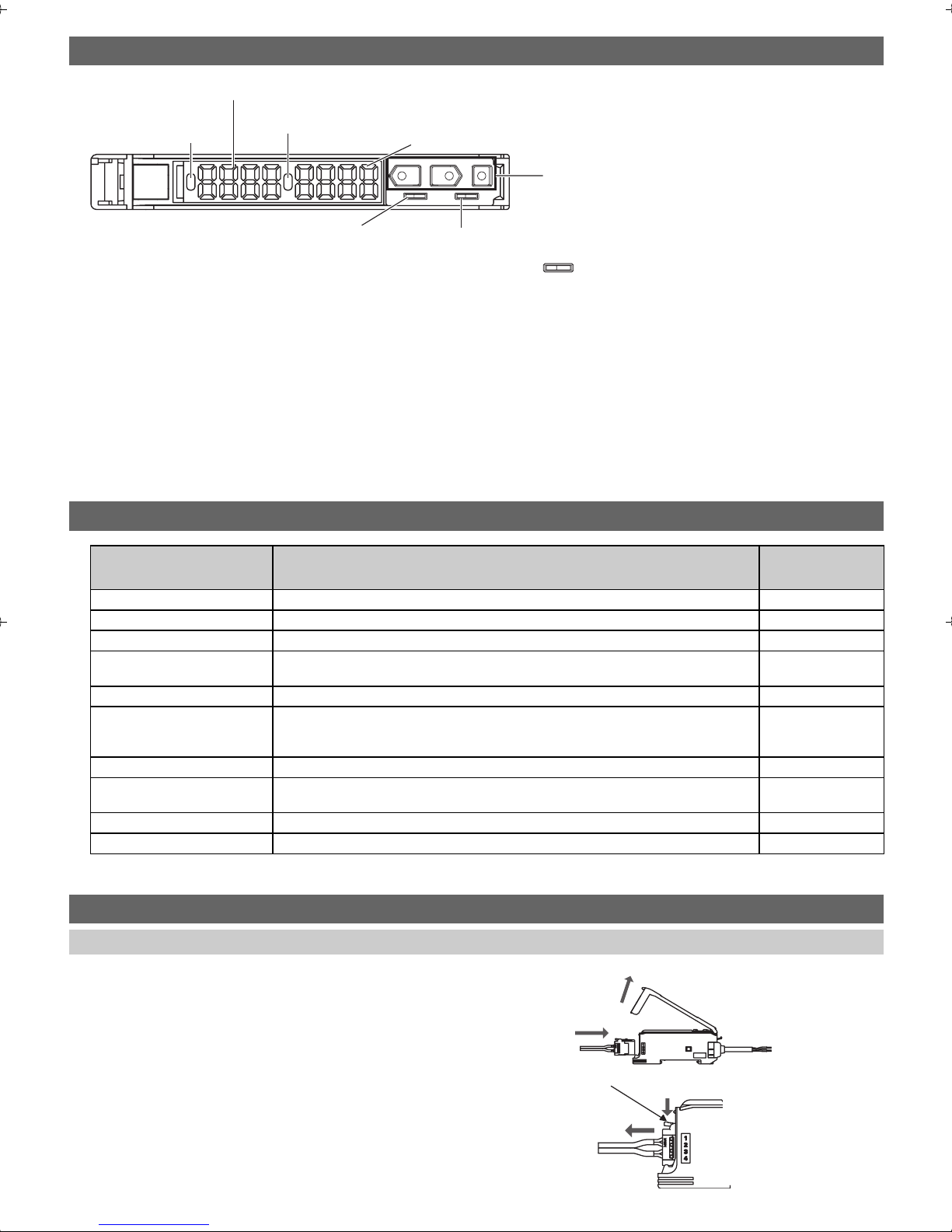

Installing the Amplifier Unit

JInstallation procedure

Hook the Sensor Head connector end of the Amplifier Unit on the

DIN Track and press in at the bottom until the Amplifier Unit locks

into place.

Be sure to mount the Amplifier Unit by hooking the Sensor Head

connector end of the Amplifier Unit on the DIN Track.

Hooking the other end may impair the mounting strength of the DIN

Track attachment.

JRemoval procedure

Push the Amplifier Unit in direction 1 and pull out the Sensor Head

connector end in direction 2.

4. Basic Knowledge for Operation

Switching Modes

To switch the operating mode, use the SET/RUN Switch.

Switch to the desired mode before operating the Amplifier Unit.

Mode Details

SET Select this mode to set the sensing conditions or threshold value by teaching.

RUN Select this mode to perform actual sensing or to set the following:

Manual adjustment of the threshold value, power adjustment, zero reset, key lock

Key Operations

Use the Control Keys to change the display and set sensing conditions.

The currently selected mode determines the key functions.

DIN track

Hook on sensor head connector

1

2

DIN track

Key

UP key Increases the threshold value. The function changes depending on the settings.

DOWN key Decreases the threshold value. The function changes depending on the settings.

MODE key

The function changes depending on the "MODE key

setting".

• Executes a zero reset

• Teaching with and without a workpiece

RUN Mode SET Mode

Function

• Executes teaching.

• Changes the setting value in the forward direction.

• Executes teaching.

• Changes the setting value in the reverse direction.

Changes the display to the function to be set.

About key pressing time

Unless otherwise mentioned in text descriptions, press keys for about one second.

Example: Press the UP key.

This means that you hold down the key for about one second and then release the key.

Reading Displays

The data displayed on the main and sub-displays depends on the currently selected mode. When the power is first turned

ON after shipment, RUN mode data is displayed.

Mode Main Display (Red Display) Sub-Display (Green Display)

SET Displays distance values and function names in order when

the Control Keys are pressed.

RUN* Displays the current distance value. (default) Displays the current threshold value. (default)

Displays the threshold values and setting values of

functions currently displayed on the main display in order

when the Control Keys are pressed.

* Display details can be changed by the display switch function. Refer to "Function Transition Charts" in "5. Function

Overview."

- 4 -

Page 5

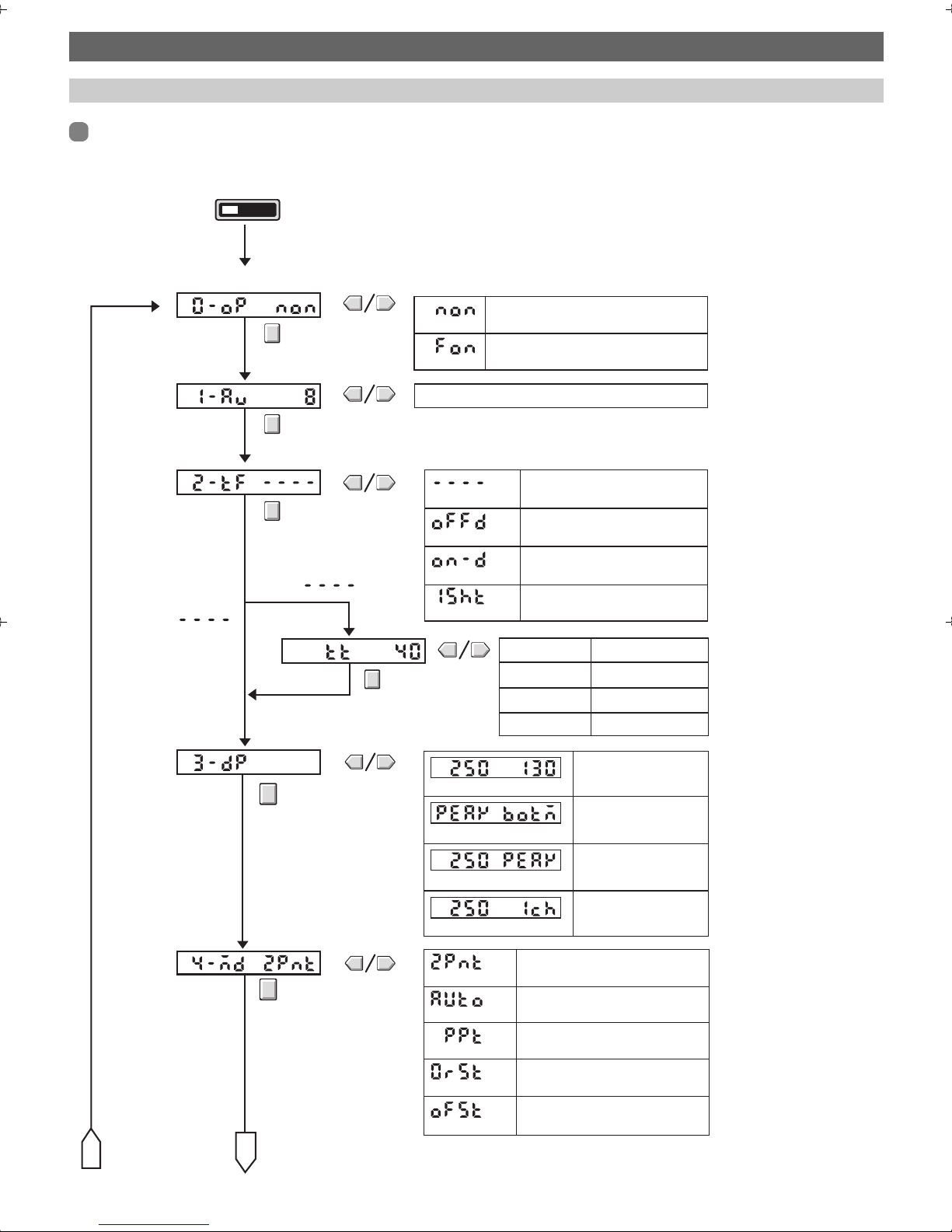

5. Function Overview

Function Transition Charts

SET mode

The following function can be set in SET mode.

The following explanation is for the SET mode on both the twin output model and analog output model.

Switch to the SET mode.

RUNSET

0. Operation mode

* In the case of an analog output, "0. Operation mode" is not provided.

Near distance ON

NON

Far distance ON

1. Number of samples

to average

2. Timer

FON

1 to 256

3. Display switch

4. MODE key setting

Not

Timer time

----

OFFD

ON-D

1SHT

Current distance Threshold value

PEAK BOTM

Current distance PEAK

Current distance Channel

2PNT

Timer disabled.

OFF-delay timer

ON-delay timer

One-shot timer

20 ms to 200 ms

Teaching with and without a

workpiece

1 ms increments1 to 20 ms

5 ms increments

100 ms increments200 ms to 1 s

1 s increments1 s to 5 s

Current distance

and threshold value

Distance between the

nearest workpiece on the

Near side and the farthest

workpiece within the Far side

Current distance

and distance at peak

Current distance

and channel No.

A

B

AUTO

PPT

0RST

OFST

- 5 -

Automatic-teaching

Position teaching

Executes a zero reset

Offset

Page 6

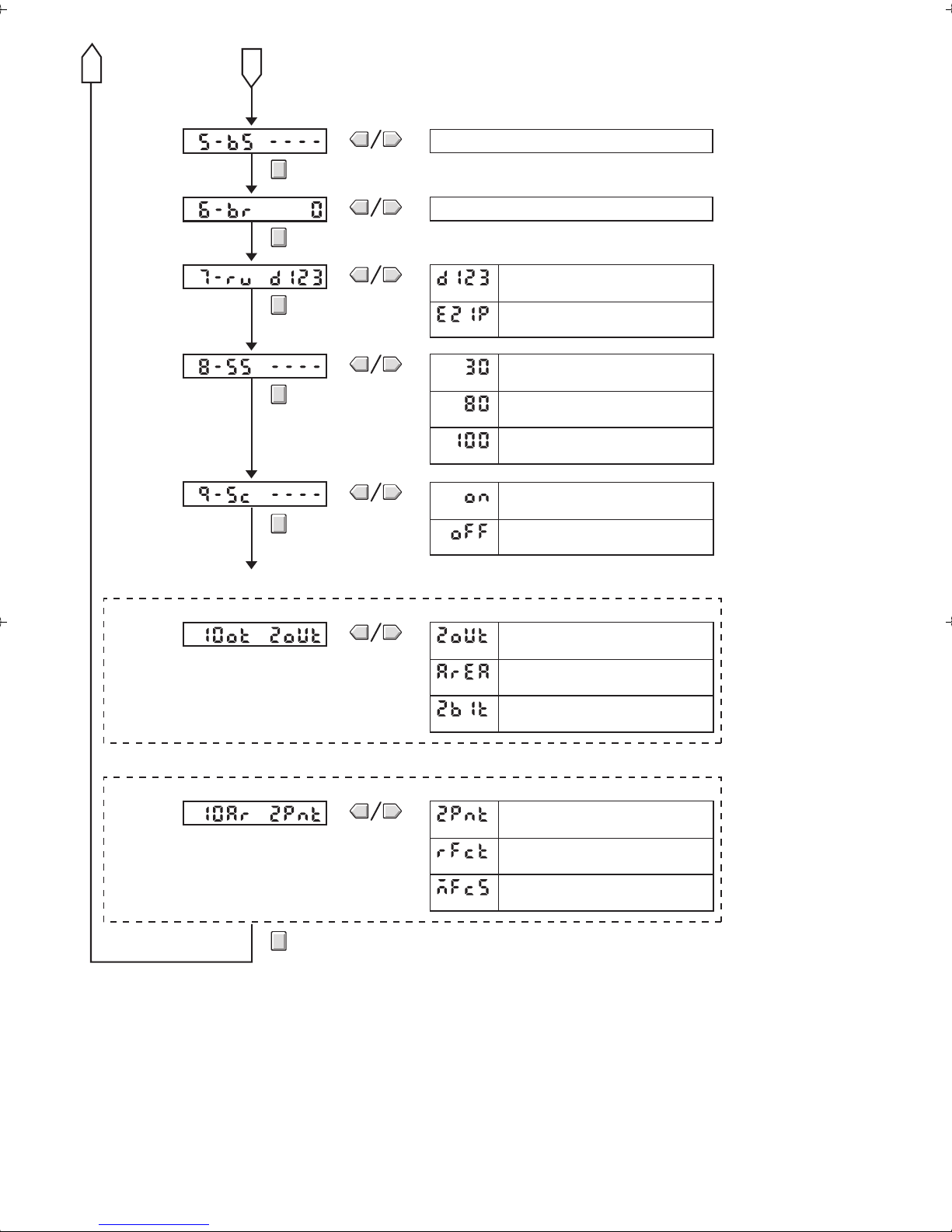

A

5. Bank selection

6. Bank registration

7. Display orientation

8.

Sensor model selection

9. Scaling

B

0 to 3

0 to 3

Normal display

D123

E21P

Reversed display

E4C-DS30

30

E4C-DS80

80

E4C-DS100

100

Scaling set

ON

Scaling not set

OFF

* In the case of the twin output model

10. Output method setting

* In the case of the analog output model

10. Output area setting

2OUT

AREA

2BIT

2PNT

RFCT

MFCS

Output on each channel

This is output only when there is a workpiece

between two threshold value distances.

2BIT output

Range of two preSET points is

output as 1 to 5 V.

Near-distance side rated distance to background setting range is output as 1 to 5 V.

Range of two points preset by

direct entry is output as 1 to 5 V.

- 6 -

Page 7

6. Basic Settings

N

p

1. Setting the Head Type

Initial setting of the head type

Set the head type when the power is first turned ON after the Amplifier Unit is purchased.

JSetting procedure

When the power is first turned ON, the following is displayed.

Sub-display:Main display:

Select the model (30, 80, 100) by the UP or DOWN key,

and then press the MODE key to apply the setting.

(In this example, E4C-DS30(L) is selected.)

The sub-display stops flashing and lights.

After one second, measurement starts.

Note: The head type does not need to be set from the second time that the power is turned ON.

Changing the head type

This feature is used to display the type of head to connect the

Amplifier Unit to.

Switch the SET/RUN switch to SET and change the head type by

following the procedure below.

SET

RU

JChange procedure

Sub-display:Main display:

Select [8-SS] by the MODE key.

Select the model (30, 80, 100) by the UP or DOWN key,

and then press the MODE key to apply the setting.

(In this example, E4C-DS30(L) is selected.)

Switch the SET/RUN switch to RUN.

RUNSET

This com

letes setting, and the display returns to regular measurement.

2. Setting the Operating Mode

Select whether to turn output ON when the distance between workpiece and the Sensor Head is shorter than the threshold

value (near distance) or when it is longer than the threshold value (far distance).

Selection Details

NON (near ON)

(default)

FON (far ON) Output turns ON when the distance between the workpiece and the Sensor Head is longer than the threshold value.

Output turns ON when the distance between the workpiece and the Sensor Head is shorter than the threshold value.

• The setting method varies depending on the Amplifier Unit model.

Model Method

Twin output model The setting method is set by the "operating mode" in the SET mode.

Analog output

model

Refer to "Function Transition Charts" in "5. Function Overview."

Select this method by the operating mode switch.

FN

- 7 -

Page 8

3. Setting Threshold Values

1) Teaching settings

(1) Teaching with and without a workpiece

Set two points one with a workpiece and another without a workpiece to be respectively sensed, and set the point between

these two points as the threshold value. This setting can be made in both of the RUN and SET modes.

When this setting is made in the RUN mode, make sure that the "MODE key setting" function is set to [2PNT]. The default

setting is [2PNT]. Refer to "Function Transition Charts" in "5. Function Overview."

Operation

RUN

mode

operation

SET

mode

operation

Display

RUNSET

Switch to the

RUN mode.

RUNSET

Switch to the

SET mode.

Hold down the MODE key

for more than 3 seconds.

Press the UP or

DOWN key.

The sub-display flashes.

Workpiece

Workpiece present

More than

3 seconds

TECH -

No workpiece present

More than

3 seconds

Hold down the MODE key

for more than 3 seconds

Press the UP or

DOWN key.

2PNT Threshold

value

The preset threshold value

flashes twice.

RUNSET

Switch to the

RUN mode.

(2) Teaching without a workpiece (background teaching)

Set the threshold value referenced to a state in which a workpiece is not present (background).

Set the threshold value 10% in front the sensing range width referenced to the distance in a workpiece absent state.

Example: In the case of a 50 to 300 mm type, set the threshold value about 25 mm in front.

Operation

RUNSET

Switch to the

SET mode.

Display

No workpiece present

Press the UP or

DOWN key

TECH -

The sub-display flashes

More than

3 seconds.

Hold down the UP or DOWN

key for more than 3 seconds.

RFCT Threshold

The preset threshold

value flashes twice.

value

- 8 -

RUNSET

Switch to the

RUN mode.

Page 9

(3) Automatic-teaching (set by a moving workpiece)

Measure the sensing distance while the key is held down, and set the value between the minimum and maximum distance

values as the threshold value.

Before making this setting, make sure that the MODE key setting is set to [AUTO]. The default setting is [2PNT]. Refer to

"Function Transition Charts" in "5. Function Overview."

Operation

Display

Workpiece Workpiece

Hold down the MODE key

for more than 3 seconds.

Sensing distance AUTO

"AUTO" is displayed as the subdisplay value, and sampling of

the sensing distance is started.

Workpiece

AUTO Threshold

The preset threshold

value flashes twice.

value

(4) Position teaching

Set the sensing distance of the workpiece as the threshold value.

Before making this setting, make sure that the MODE key setting is set to [PPT]. The default setting is [2PNT]. Refer to

"Function Transition Charts" in "5. Function Overview."

Operation

Workpiece Workpiece

Hold down the MODE key

for more than 3 seconds.

Workpiece

Display

PPT Sensing

"PPT" is displayed on the main

display and the preset threshold

value flashes on the sub-display.

Threshold

value

distance

"PPT" changes to the current

sensing distance to indicate that

the setting is completed.

Threshold

value

• Teaching error display

An error occurs if the following is displayed on the sub-display after teaching is executed.

Execute teaching again.

Flashes twice.

OVER

Flashes twice.

NEAR

OVER error

The taught distance is outside the sensing range.

Check the position of the workpiece, and then execute teaching again.

NEAR error

The difference between the maximum taught distance and the minimum

taught distance is too small.

Check the teaching position, and then execute teaching again.

(This error occurs with teaching with and without a workpiece, and

automatic-teaching.)

- 9 -

Page 10

2) Manual setting

N

N

(

)

Manually set the threshold value.

Operation

Switch to the RUN mode.

RUNSET

Set the threshold value by

the UP or DOWN key.

Increments the threshold value.

Decrements the threshold value.

Display

Sensing distance

Threshold value

4. Setting Banks

Switch the SET/RUN switch to SET and register by following the

procedure below.

JRegistration procedure

Sub-display:Main display:

Select [6-BR] by the MODE key.

Select the desired bank No. (0 to 3) by the UP or DOWN key.

(In this example, bank 2 is selected.)

Switch the SET/RUN switch to RUN.

RUNSET

Select YES by the UP or DOWN key,

and then press the MODE key to complete registration.

After about 3 seconds, the display returns

to the display set in the display setup.

SET

RU

The display returns to regular measurement.

Note: If you perform the following at this stage,

Selecting bank information

Switch the SET/RUN switch to SET and select the bank

information by following the procedure below.

JSelection procedure

Sub-display:Main display:

Press the MODE key.

registration is canceled.

• Select NO and press the MODE key.

• Set the SET/RUN switch to SET without

pressing the MODE key.

SET

RU

Select [5-BS] by the MODE key.

Select the desired bank No. (0 to 3) by the UP or DOWN key.

(In this example, bank 2 is selected.)

Switch the SET/RUN switch to RUN.

RUNSET

Selection is completed, and the display moves to [6-BR].

Refer to "Function Transition Charts in "5. Function Overview."

Registration is completed, and the display returns to regular measurement.

- 10 -

Page 11

5. Setting Scaling

JSetting procedure

Sub-display:Main display:

Select [9-SC] by the MODE key,

and then press the UP or DOWN key once.

Displays the current scaling execution state.

Press the UP or DOWN key to select "ON",

and press the MODE key to apply the setting.

Place the workpiece at the first point,

and press the MODE key.

Press the UP or DOWN key to set the distance,

and press the MODE key to apply the setting.

Place the workpiece at the second point,

and press the MODE key.

Press the UP or DOWN key to set the distance,

and press the MODE key to apply the setting.

(The display flashes twice.)

RUNSET

Switch the SET/RUN switch

to RUN.

This completes setting, and the display

returns to regular measurement.

The display moves to the next setting.

Press the MODE key.

(This display example is for a twin output model.)

Note: The scalable width is 1/2 to 2 times the current distance value.

Note: When the values of the first and second points are the same, "NEAR" flashes twice on the error display, and the points

must be set again.

Note: "OVER" is sometimes displayed and the setting cannot be made depending on the setting value. In this case, change

and then set the setting value again.

- 11 -

Page 12

JCancel procedure

g

N

(

)

)

Sub-display:Main display:

Select [9-SC] by the MODE key,

and then press the UP or DOWN key once.

Displays the current scaling execution state.

Press the UP or DOWN key to select [OFF],

and press the MODE key to cancel the setting.

(The display flashes twice.)

RUNSET

Switch the SET/RUN switch

to RUN.

This completes setting, and the display

returns to regular measurement.

The display moves to the next settin

Press the MODE key.

(This display example is for a twin output model.)

.

6. Output Settings

Setting the output method (twin output model)

The output method can be selected.

This function is mounted only on the twin output model.

Switch the SET/RUN switch to MODE, and select from [100T].

(Refer to "Function Transition Charts" in "5. Function Overview"

for detailed settings.)

SET

JOutput method details

Display Output method Overview Timing Chart (Near ON mode)

2OUT Output on each

channel

Independent control signals are output in

response to the threshold values of each

of channels 1CH and 2CH.

RU

1ch threshold value (a) 2ch threshold value (b

(ON)

(1ch)

(OFF)

(ON)

(2ch)

OFF

AREA Output during threshold

2BIT 2-bit output The distance is divided into four areas by

value

Control signals are output in response

during the threshold values of each of

channels 1CH and 2CH.

The regular independent control signal is

output for channel 1CH.

the threshold values of each of channels

1CH and 2CH and the three mid-points

between each of these threshold values.

Four states are judged according to the

relationship between the outputs of

channels 1CH and 2CH.

- 12 -

1ch threshold value (a) 2ch threshold value (b)

(ON)

(1ch)

(OFF)

(ON)

(2ch)

(OFF)

1ch threshold value (a) 2ch threshold value (b)

(ON)

(1ch)

(OFF)

(ON)

(2ch)

(OFF)

(a+b)/2

Page 13

Setting the output range (analog output model)

p

JFunction

• This function sets the range and display ratio of linear output with respect to the display value.

• This function is mounted only on the analog output model.

Note: The preset output range is canceled by initializing the product settings.

Note: When the output range is set, zero reset and offset are automatically cleared.

1) 2-point setting

• Determine the 1 V and 5 V ranges at the workpiece position.

• The output ramp is as follows according to the positional

relationship between the first and second points.

JSetting procedure

Sub-display:Main display:

5 V

First point

< second point

1 V

First point

5 V

First point

> second point

1 V

Second point

Select [10AR] by the MODE key,

and then press the UP or DOWN key to select [2PNT].

Press the MODE key to apply the setting.

The current distance is displayed on the sub-display.

Press the MODE key for 1 second or more to apply the setting.

Place the workpiece at the second point.

"B 5V" is displayed on the main display,

and the current distance is displayed on the sub-display.

Second point

oint

First

Press the MODE key for 1 second or more to apply the setting.

"OK" is displayed on the sub-display to indicate that the setting

is completed.

RUNSET

Switch the SET/RUN switch

to RUN.

This completes setting, and the display

returns to regular measurement.

The display moves to the next setting.

Press the MODE key.

Note: When the values of the first and second points are the same, "NEAR" flashes twice on the error display, and the points

must be set again.

2) Background setting

Set the analog output referenced to the background distance (5

V).

5 V

1 V

Nearest point

Distance to rear

- 13 -

Page 14

JSetting procedure

(mm)

(mm)

Sub-display:Main display:

Select [10AR] by the MODE key,

and then press the UP or DOWN key to select [RFCT].

Press the MODE key to apply the setting. The current

distance is displayed on the sub-display.

Align with the rear, and hold down the MODE key for

more than 3 seconds.

"OK" is displayed on the sub-display to indicate that

the setting is completed.

RUNSET

Switch the SET/RUN switch

to RUN.

This completes setting, and the display returns

to regular measurement.

The display moves to the next setting.

3) Direct setting

Directly set the distance with respect to output (1 V, 5 V).

JSetting procedure

Sub-display:Main display:

Press the MODE key.

Output voltage

(V)

5

1

0

50 300

Select [10AR] by the MODE key,

and then press the UP or DOWN key to select [MFCS].

The distance value currently assigned to 1 V is displayed.

Measured

value

Output voltage

(V)

5

1

0

100 200

Measured

value

RUNSET

Switch the SET/RUN switch

to RUN.

This completes setting, and the display

returns to regular measurement.

Note: When the values of the first and second points are the same, "NEAR" flashes twice on the error display, and the points

must be set again.

Press the UP or DOWN key to set the distance to assign to 1 V,

and press the MODE key to apply the setting.

The distance value currently assigned to 5 V is displayed.

Press the UP or DOWN key to set the distance to assign to 5 V,

and press the MODE key to apply the setting.

"OK" is displayed on the sub-display to indicate that the setting

is completed.

Press the MODE key.

The display moves to the next setting.

- 14 -

Page 15

7. Handy Ways of Setting Functions

g

Setting the Display to Zero (zero reset)

Before making this setting, make sure that the "MODE key setting" is set to [0RST] (zero reset).

The default setting is [2PNT] (teaching with and without a workpiece). (Refer to "Function Transition Charts" in "5. Function

Overview.")

JSetting method JCancel method

Switch to the RUN mode.

RUNSET

Hold down the MODE key

for more than 3 seconds.

The current distance

display stops fluctuating.

Current distance Threshold

value

The zero reset is

executed, and the

current distance display

es to "0".

chan

Current distance Threshold

+

Setting the Display to Any Value (offset)

Before making this setting, make sure that the "MODE key setting" is set to [oFST] (offset).

The default setting is [2PNT] (teaching with and without a workpiece). (Refer to "Function Transition Charts" in "5. Function

Overview.")

JSetting method JCancel method

Switch to the RUN mode.

RUNSET

Hold down the DOWN key for more

than 3 seconds

with the MODE key pressed.

Press the MODE key and then

immediately press the DOWN key.

The zero reset is

canceled.

value

Switch to the RUN mode.

RUNSET

Hold down the MODE key

for more than 3 seconds.

The current distance

display stops fluctuating.

Current distance Threshold

value

Press the UP or DOWN

key to change the

current distance.

Press the MODE key to

execute offset.

+

Current distance Threshold

Switch to the RUN mode.

RUNSET

Hold down the DOWN key for more

than 3 seconds with the MODE key

pressed.

Press the MODE key and then

immediately press the DOWN key.

The offset is

canceled.

value

Inverting the Increment/decrement Direction of the Main Display (display inversion)

When display inversion is executed, how the display to the reference distance is indicated is inverted.

Before making this setting, make sure that the MODE key setting is set to [0RST] (zero reset) or [oFST] (offset).

JSetting method JCancel method

(In the zero reset mode)

Current

distance

Display inversion is

executed together

with the zero reset.

Threshold

value

Switch to the RUN mode.

RUNSET

Hold down the UP key for more

than 3 seconds with the MODE

+

key pressed.

Press the MODE key and then

immediately press the UP key.

(In the offset mode)

Current

distance

Threshold

value

Press the UP

or DOWN key

to change the

current

distance.

Press the

MODE key to

execute display

inversion

together with

the offset.

Current

distance

+

Switch to the RUN mode.

RUNSET

Hold down the UP key for more

than 3 seconds with the MODE

key pressed.

Press the MODE key and then

immediately press the UP key.

Both zero reset (offset) and

Threshold

value

display inversion are

canceled.

- 15 -

Page 16

Keylock

JSetting method JCancel method

Switch to the RUN mode.

RUNSET

Hold down the UP key for more

than 3 seconds with the MODE

+

LOC ON

key pressed.

Press the MODE key and then

immediately press the UP key.

The sub-display flashes twice,

and key entry is disabled.

Initializing all Setting Data (initialization processing)

JSetting method

Switch to the SET mode.

RUNSET

+

INIT NO?

INIT GOOD

Hold down the UP and DOWN keys for

more than 3 seconds.

When "YES?" is displayed,

press the MODE key.

Initialization is completed.

YES?

NO?

Data is not

initialized.

Data is

initialized.

Switch to the RUN mode.

RUNSET

Hold down the UP key for more

than 3 seconds with the MODE

+

LOC OFF

key pressed.

Press the MODE key and then

immediately press the UP key.

The sub-display flashes twice,

and key entry is enabled.

The head type setting is not cleared even if all setting data is initialized.

Refer to "1. Setting the Head Type" in "6. Basic Settings."

- 16 -

Page 17

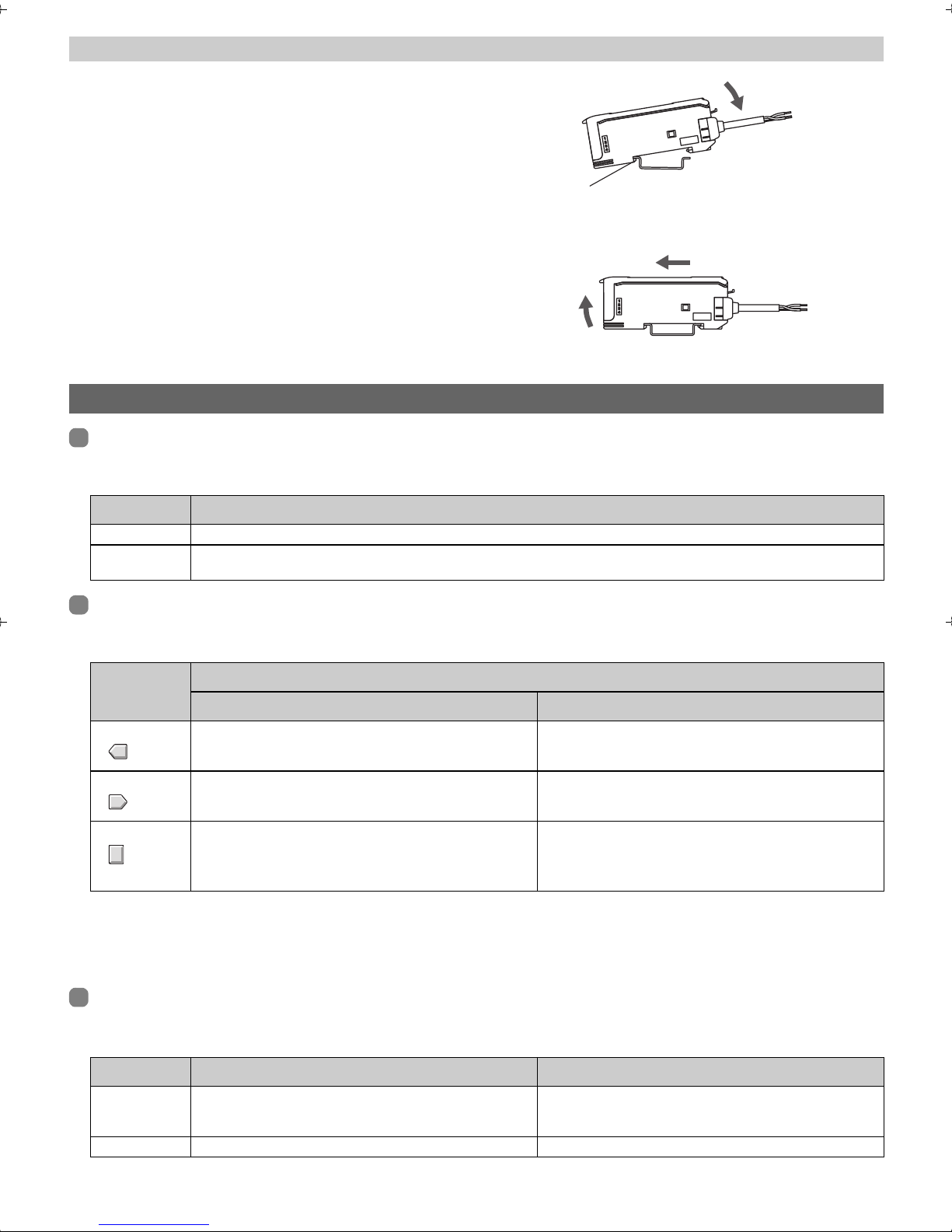

8. Ratings

Ratings and Specifications

Type Twin output model Analog output model

Model E4C-UDA11 E4C-UDA41 E4C-UDA11AN E4C-UDA41AN

NPNoutput PNPoutput NPNoutput PNPoutput

Connection method Prewired

Supply voltage 12 to 24 VDC ± 10%, ripple 10% max.

Current consumption 80 mA max.

Control output NPN open collector (26.4 VDC max.)

Hysteresis

Timer OFF/OFF-delay/ON-delay/one-shot

Timer time 1 ms to 5 s

Analog

output

Operating temperature Operating: -25 to +55°C Storage: -30 to +70°C (with no icing)

Operating humidity Operating and storage: 35% to 85% (with no condensation)

Insulation resistance 50 MΩ min. (by 500 VDC)

Dialectic strength 1,000 VAC, 50/60 Hz for 1 min

Vibration resistance 10 to 150 Hz, 0.75 mm double amplitude, 80 min each in X, Y, and Z directions

Shock resistance

Materials Case: PBT (polybutylene terephthalate), Cover: Polycarbonate

Weight Approx. 150 g

Accessories Instruction Manual

Output form - Voltage output (DC 1 to 5 V)

Connected load - 10 kΩ min.

Temperature

characteristics

Resolution - 2.0% F.S.max. *

Linearity - 2.0% F.S.max.

* Value one hour after the product is turned on. Note, however, that external disturbance sometimes causes minute output.

Load current: 50 mA max., Residual voltage: 1 V max.

2.0% F.S.max.

- 0.3% F.S./°C

500 mm/s2, 3 times each in X, Y and Z directions

I/O Circuit Diagrams

JE4C-UDA11 (NPN type) JE4C-UDA41 (PNP type)

Brown

Black 1CH output

Orange 2CH output

Internal circuit

Blue

Load

Load

DC

12 to 24 V

Internal circuit

JE4C-UDA11AN (NPN type) JE4C-UDA41AN (PNP type)

Brown

Black Control output

Orange Analog output

Internal circuit

Blue

Load

10 KW min.

Load

DC

12 to 24 V

Internal circuit

Brown

Black

Orange

Blue

Brown

Black control output

Orange

Blue

1CH

2CH

Analog

output

Load

output

output

10kǡ

MIN

DC

12 to 24 V

Load

Load

DC

12 to 24 V

Load

- 17 -

Page 18

External Dimensions

S

C

G

T

1

T

S

JE4C-UDA11/-UDA41

JE4C-UDA11AN/-UDA41AN

18.15

21.1

18.15

21.1

38.8

35.8

3.9 x 3=11.7

38.8

3.9 x 3=11.7

3.9 x 3=11.7

3.9 x 3=11.7

(Unit: mm)

(Unit: mm)

13.8

10

2.5 50.3

32

9.93.4

24.7

76

36.7

8.1

32

12.50

S

ens

ing

D

evices

D

ivision

hiokoji Horikawa, Shimogyo-ku,Kyoto, 600-8530 Japan Tel: (81)75-344-7068/Fax: (81)75-344-7107

R

e

gional

H

ea

OMRON EUR

ensor Business Unit,

arl-Benz-Str. 4, D-71154 Nufringen,

ermany

el: (49)7032-811-0/Fax: (49)7032-811-199

OMRON

East Commerce Drive, Schaumburg, IL 60173 U.S.A.

el: (1)847-843-7900/Fax: (1)847-843-8568

dquarters

OPE B.V.

ELECTRONICS LL

H.Q.

C

In the intereste of product improvement,specifications are subject to change without notice.

A

pplicat

OMRON C

ion Sensor

s

- 18 -

orporation

D

ivision

OMRON ASIA PAC

83 Clemenceau Avenue,

#11-01, UE Square,

239920 Singapore

Tel: (65)6835-3011/Fax: (65)6835-2711

OMRON (CHINA) C

Room 2211, Bank of China Tower,

200 Yin Cheng Road (M),

Shanghai, 200120 China

Tel: (86)21-5037-2222/Fax: (86)21-5037-2200

I

ndustrial

IFIC PTE. LTD.

O., LTD.

A

utomation

C

ompan

y

Loading...

Loading...