Page 1

OPERATION MANUAL

CX-Integrator Ver. 1.1

SYSMAC

CXONE-AL

@@@@

C-E

Cat. No. W445-E1-02

Page 2

CXONE-AL@@C-E

CX-Integrator Ver. 1.1

Operation Manual

Revised November 2005

Page 3

iv

Page 4

g

p

j

y p

g

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or

damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some

Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient

operation of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form,

or by any means, mechanical, electronic, photocopying, recordin

OMRON.

atent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

No

constantly striving to improve its high-quality products, the information contained in this manual is sub

without notice. Ever

responsibility for errors or omissions. Neither is any liability assumed for damages resultin

contained in this publication.

recaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

, or otherwise, without the prior written permission of

ect to change

from the use of the information

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS

1 Intended Audience.......................................................................................................... xvi

2 Safety Precautions.......................................................................................................... xvi

3 Application Precautions .................................................................................................xviii

4 Operating Environment Precautions................................................................................ xx

5 Guide to Version Upgrade ..............................................................................................xxi

Section 1 Overview

1-1 The CX-Integrator ........................................................................................................ 1-2

1-2 Specifications............................................................................................................... 1-8

1-3 Installation.................................................................................................................. 1-14

1-4 PLC Connecting Cables ............................................................................................ 1-15

1-5 Window Descriptions ................................................................................................. 1-22

1-6 Menus ........................................................................................................................ 1-34

Section 2 Basic Operations

2-1 Basic Procedures......................................................................................................... 2-2

2-2 Connecting Online to the Relay PLC......................................................................... 2-10

2-3 Uploading Network Configurations and Checking for Communications Unit Errors . 2-21

2-4 Switching the Target PLC .......................................................................................... 2-27

2-5 Creating Virtual Network Configurations Offline........................................................ 2-29

2-6 Manipulating Component Parameters ....................................................................... 2-38

2-7 Uploading, Downloading, and Comparing Network Parameters ............................... 2-43

2-8 Comparing Network Configurations........................................................................... 2-44

2-9 File Operations .......................................................................................................... 2-45

2-10 Target PLC Online Operations .................................................................................. 2-49

2-11 Starting Specified Applications .................................................................................. 2-51

2-12 Printing....................................................................................................................... 2-52

Section 3 Routing Tables

3-1 Routing Table Overview .............................................................................................. 3-2

3-2 Setting the Routing Tables .......................................................................................... 3-9

3-3 Maintenance after Network Configuration ................................................................. 3-25

Section 4 Data Links for Controller Link and SYSMAC LINK

4-1 Overview...................................................................................................................... 4-2

4-2 User Interface Overview .............................................................................................. 4-4

4-3 Manually Setting Data Links ........................................................................................ 4-8

4-4 Automatically Set Data Links ..................................................................................... 4-41

Section 5 Ethernet

5-1 Broadcast Node Search .............................................................................................. 5-2

5-2 Ping Test...................................................................................................................... 5-4

vii

Page 7

Section 6 DeviceNet

6-1 DeviceNet Setting Procedures..................................................................................... 6-2

6-2 Setting Slave Parameters ............................................................................................6-4

6-3 Adding Slaves to the Master ........................................................................................ 6-8

6-4 Setting Master Properties .......................................................................................... 6-13

6-5 Editing Master Parameters ........................................................................................ 6-15

6-6 Parameter Wizard ...................................................................................................... 6-16

6-7 Master Parameter Editing Details (Tab Descriptions) ............................................... 6-21

6-8 Manual I/O Allocations ............................................................................................... 6-29

6-9 Advanced Settings (Connection, Communication Cycle Time, Slave Function Settings,

Etc.)............................................................................................................................ 6-36

6-10 Creating and Editing I/O Comments .......................................................................... 6-43

6-11 Displaying Device Properties..................................................................................... 6-45

6-12 Downloading the Network Configuration/Device Parameters to Devices.................. 6-51

6-13 Uploading and Verifying Device Parameters ............................................................. 6-57

6-14 Monitoring Devices .................................................................................................... 6-62

6-15 Using General-purpose Tools to Set Devices ........................................................... 6-70

6-16 Optional Functions ..................................................................................................... 6-72

Section 7 CompoWay/F

7-1 CompoWay/F System Configuration ........................................................................... 7-2

7-2 CompoWay/F Slaves Connected to a PLC ................................................................. 7-3

7-3 CompoWay/F Slaves Connected to a Computer....................................................... 7-10

Section 8 NT Links

8-1 NT Link Connection Auto-detect Function ................................................................... 8-2

8-2 Transferring Screen Data through the PLC ................................................................. 8-6

Section 9 Network Testing

9-1 Controller Link Network Diagnostic Tool...................................................................... 9-2

9-2 Echoback Test between Nodes ................................................................................. 9-22

9-3 Ethernet Ping Test ..................................................................................................... 9-25

Appendices

A-1 CPS File Management................................................................................................. A-2

A-2 EDS File Management................................................................................................. A-4

Revision History

viii

Page 8

About this Manual:

!

This manual describes the installation and operation of CX-Integrator and includes the sections

described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to use the CX-Integrator. Be sure to read the precautions provided in the following section.

Precautions provides general precautions for using the CX-Integrator.

Section 1 outlines the functions of the CX-Integrator and describes the menus and connecting to

networks.

Section 2 describes the basic operations required to use the CX-Integrator.

Section 3 describes how to set routing tables.

Section 4 describes how to set data links for Controller Link and SYSMAC LINK Networks.

Section 5 describes the how to use the diagnostic tools for Controller Link Networks.

Section 6 describes settings and operations unique to DeviceNet Networks, including registering

slaves in the master, allocating I/O, monitoring devices, etc.

Section 7 describes settings and operations unique to CompoWay/F Networks.

Section 8 settings and operations unique to NT Links.

The Appendix describes CPS files for Ethernet, Controller Link, CompoWay/F, and NT Link

Networks and EDS files for DeviceNet Networks.

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 9

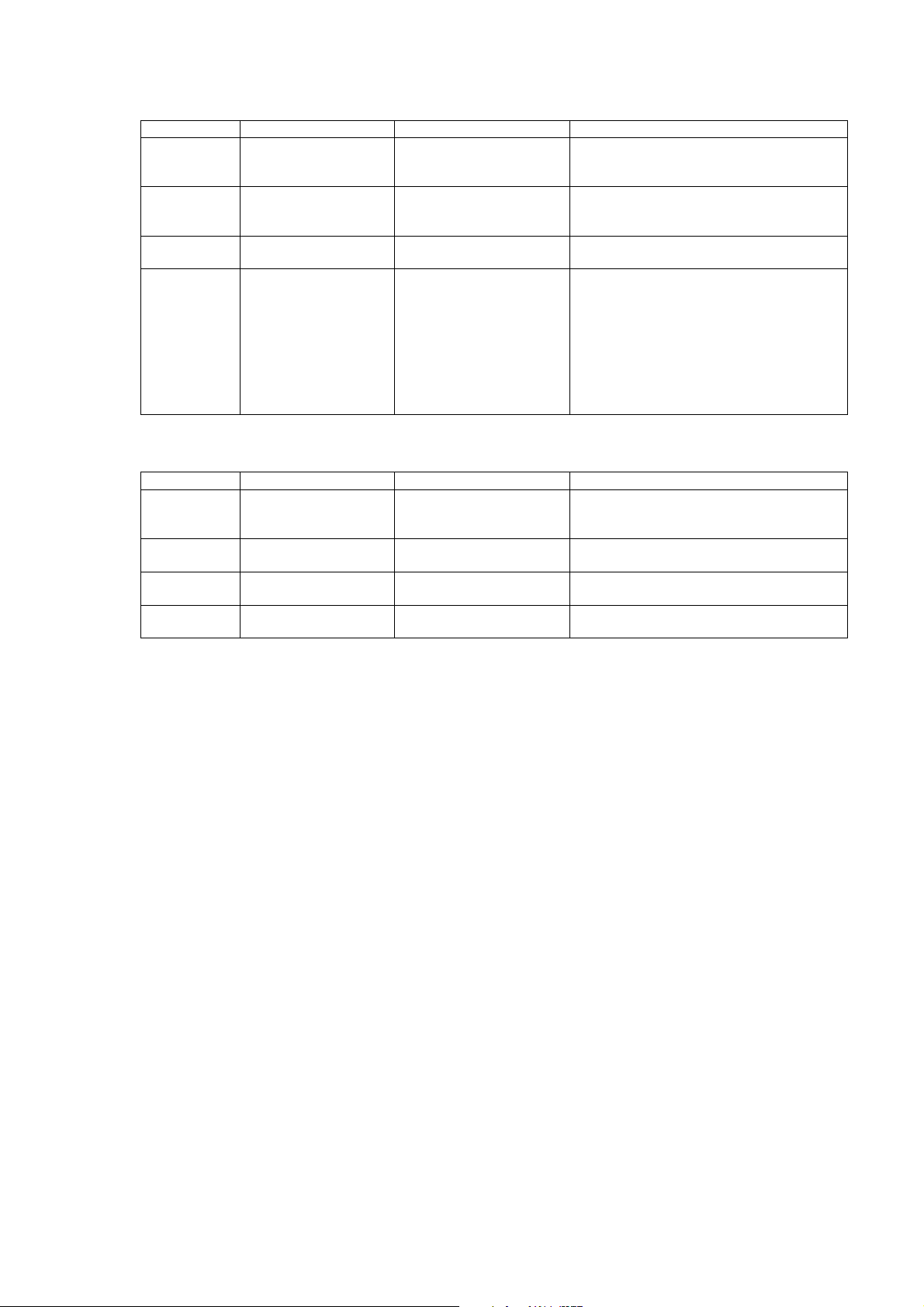

Manuals Related to the CX-Integrator

Cat No. Models Name Description

W445

(this manual)

W444

W446 WS02-CXPC1-E-V60 CX-Programmer Ver. 6.1

W447 WS02-CXPC1-E-V60

CXONE-AL@@C-E

CXONE-AL@@C-E

CS1G-CPU@@H

CS1H-CPU@@H

CJ1G- CPU@@H

CJ1H- CPU@@H

CJ1M- CPU@@

CP1H- X@@@@-@

CP1H- XA@@@@-@

CX-Integrator Operation

Manual

CX-One Setup Manual Describes installation and provides an

Operation Manual

CX-Programmer Ver. 6.1

Operation Manual:

Function Blocks

Describes CX-Integrator operating

methods, e.g., for setting up and

monitoring networks.

overview of the CX-One FA Integrated

Tool Package.

Describes CX-Programmer operations

except those related to function blocks.

Describes function blocks for

CS/CJ-series CPU Units unit version 3.0

or later and CP-series CPU Units, and

CX-Programmer operations related to

function blocks.

Refer to the W447 manual above for other

CX-Programmer operations.

Manuals Related to DeviceNet

Cat No. Models Name Description

W267 --- DeviceNet Operation

Manual

W380 CS1W-DRM21(-V1)

CJ1W-DRM21

W379 C200HW-DRM21-V1

CVM1-DRM21-V1

W381 3G8F7-DRM21 DeviceNet PCI Board

DeviceNet Unit Operation

Manual

DeviceNet Master Unit

Operation Manual

Operation Manual

Describes network communications

settings and wiring common to all

DeviceNet networks.

Describes CX/CJ-series DeviceNet Units.

Describes C200H and CV/CVM1-series

DeviceNet Master Units.

Describes the DeviceNet PCI Board.

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

•Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

•Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

•Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

This section provides precautions for using the CX-Integrator.

The information contained in this section is important for the safe and reliable application of the CX-Integrator.

You must read this section and understand the information contained before attempting to use the

CX-Integrator.

1 Intended Audience.......................................................................................... xvi

2 Safety Precautions .......................................................................................... xvi

3 Application Precautions.................................................................................. xviii

4 Operating Environment Precautions............................................................... xx

5 Guide to Version Upgrade.............................................................................. xxi

Page 15

1 Intended Audience

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems

• Personnel in charge of designing FA systems

• Personnel in charge of managing FA systems and facilities

2 Safety Precautions

!Caution When performing any of the following operations, always check the network

address and node address of the other node (PLC) and the node address

and unit number of the mounted Unit (PLC CPU Bus Unit or Special I/O Unit)

or the node address of the Component (DeviceNet Master/Slave or

CompoWay/F Slave), and be sure that these operations can be performed

safely for the current status of the node (Unit or Component):

• Transferring parameter or program data to the other node

• Changing the operating mode of the other node

Unexpected operation may result if parameter or program data is transferred

to the wrong node (DeviceNet Master/Slave or CompoWay/F Slave), the

operating mode of the wrong node is changed, or the other node is not in a

suitable status to receive the program or parameter data or the operating

mode change.

!Caution When changing the target PLC to any PLC other than the relay PLC, check

the node address and node number of the target PLC carefully before

executing the change. Unexpected operation and injury may result if the

wrong PLC is set as the target PLC.

• Changing the operating mode

• Transferring or verifying user-set data link tables

• Transferring or verifying routing tables

• Performing I/O table operations (including transferring CPU Bus Unit or

Special I/O Unit parameters)

Note Operations performed from the CX-Integrator are performed for the target

PLC, which is not necessarily the same as the relay PLC.

!Caution When transferring parameters that have been created or edited on the

computer to actual Units (PLC CPU Bus Units or PLC Special I/O Units) or to

actual Components (DeviceNet Masters/Slaves or CompoWay/F Slaves),

always check the identifying number of the actual Units or Components (i.e.,

the unit numbers and unit addresses or node addresses) before executing

the transfer. Unexpected operation and injury may result if parameters are

transferred to the wrong Unit or Component.

xvi

!Caution When changing or removing a routing table (see note), be sure to update the

display for the Online Connection Information Window. The display for the

Online Connection Information Window could possibly be different from the

actual network status. If operations are executed without first updating the

display, particularly online operations in the Network Configuration Window, it

could cause data to be mistakenly read or written for the wrong network or

node address or unit number.

Page 16

2 Safety Precautions

Note: Changing or removing a routing table refers to using the

CX-Integrator (or a CX-Integrator for another personal computer) to

start the Routing Table Component and then changing or removing

a routing table for the target PLC (either a local network table or a

relay network table).

!Caution Do not execute a broadcast node search if a node exists for something other

than an OMRON Ethernet Unit or FinsGateway within the same segment on

Ethernet, and when the Ethernet network system is in operation. When a

broadcast node search is executed, an OMRON FINS command is sent to all

nodes in the segment. Therefore, if a node exists for something other than an

OMRON Ethernet Unit or FinsGateway, the FINS command will not be

received at that node and unexpected operation may occur.

xvii

Page 17

3 Application Precautions

3 Application Precautions

Observe the following precautions when using the CX-Integrator.

General Communications Precautions

• Do not turn OFF the power to the PLC or disconnect the cable connecting

the PLC when the CX-Integrator is online with the PLC. Doing so may cause

the computer running CX-Integrator to malfunction.

• Before changing the operating mode, always confirm that doing so will not

adversely affect system operation.

• Always check the operation of parameters sufficiently before using them for

actual system operation.

• Confirm that resetting CPU Bus Units and Special I/O Units will not

adversely affect system operation before resetting these Units.

DeviceNet

• Enable the scan list to before operating the system.

• When adding a new node to the network, make sure that the baud rate is

the same as other nodes.

• Use specified communications cables.

• Do not extend connection distances beyond the ranges given in the

specifications.

• Always turn OFF the power supply to the personal computer, Slaves, and

Communications Units before attempting any of the following.

• Attaching or detaching the DeviceNet Board or Card

• Assembling the Units

• Setting rotary switches

• Connecting or wiring the cables

• Connecting or disconnecting connectors

• Be sure that the communications cables and other items with locking

devices are properly locked into place.

• Observe the following precautions when wiring the communications cable.

• Separate the communications cables from the power lines or

high-tension lines.

• Do not bend the communications cables.

xviii

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Be sure to wire communications cable inside ducts.

• Use appropriate communications cables.

• Before touching the PCI Board, be sure to first touch a grounded metallic

object in order to discharge any static build-up. Not doing so may result in

malfunction or damage.

• When transporting a Board or Card, use the special box in which it was

shipped to protect the LSIs and ICs from being damaged. Also do not

subject the Board or Card to excessive vibration or shock.

Page 18

3 Application Precautions

•

Because the devices are reset in order, communications errors will

temporarily occur in the master and slaves. For this reason, do not

download the network configuration while the master-side PLC (CPU Unit)

is operating.

• When downloading the network configuration, each of the devices is reset.

If the Master Unit is reset first, it may cause errors in writing parameters to

the subsequent slaves. For that reason, this method (downloading the

network configuration) should be used only when the Master Unit has been

given the highest address.

• Downloaded device parameters will be valid only after the devices are reset

unless they are the OMRON CVM1-DRM21-V1, C200HW-DRM21-V1,

CS1W-DRM21(-V1), or CJ1W-DRM21.

• When the devices are reset, communications errors will temporarily occur.

For this reason, do not reset the devices while the master-side PLC (CPU

Unit) is operating.

Data Links in Controller Link or SYSMAC LINK Networks

• The data link mode (manual setting or automatic setting) and data link

method are determined according to the data link setting in the startup node.

In the startup node, set a data link table for manual settings and data link

automatic setting parameters for automatic settings. If the settings are

incorrect, the data links will not start.

Check the following items before starting data links.

(1) Manually Set Data Links

Check the data link tables in each node participating in the data link to

see that they are correct.

Be sure that data link tables are deleted from nodes that are not

participating in the data links.

(2) Automatically Set Data Links

Be sure that the correct DM parameters have been set in the data link

startup node.

• If incorrect data link tables or parameters are set, injury may result due to

unexpected operation of the system. Even if the correct data link tables and

parameters have been set, do not start or stop data links before verifying

that there will be no adverse influence on the system.

Routing Tables

CPU Bus Units are reset when routing tables are transferred from a

Programming Device to a PLC to allow set routing tables to be read. Make

sure that resetting CPU Bus Units will not cause equipment damage or

dangerous system behavior before transferring tables.

xix

Page 19

4 Operating Environment Precautions

4 Operating Environment Precautions

!Caution Perform installation properly, according to the procedures described in this

manual.

!Caution Do not install in the following locations:

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in

the specifications

• Locations subject to condensation as the result of severe changes in

temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

!Caution Take appropriate and sufficient countermeasures when installing in the

following locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

xx

Page 20

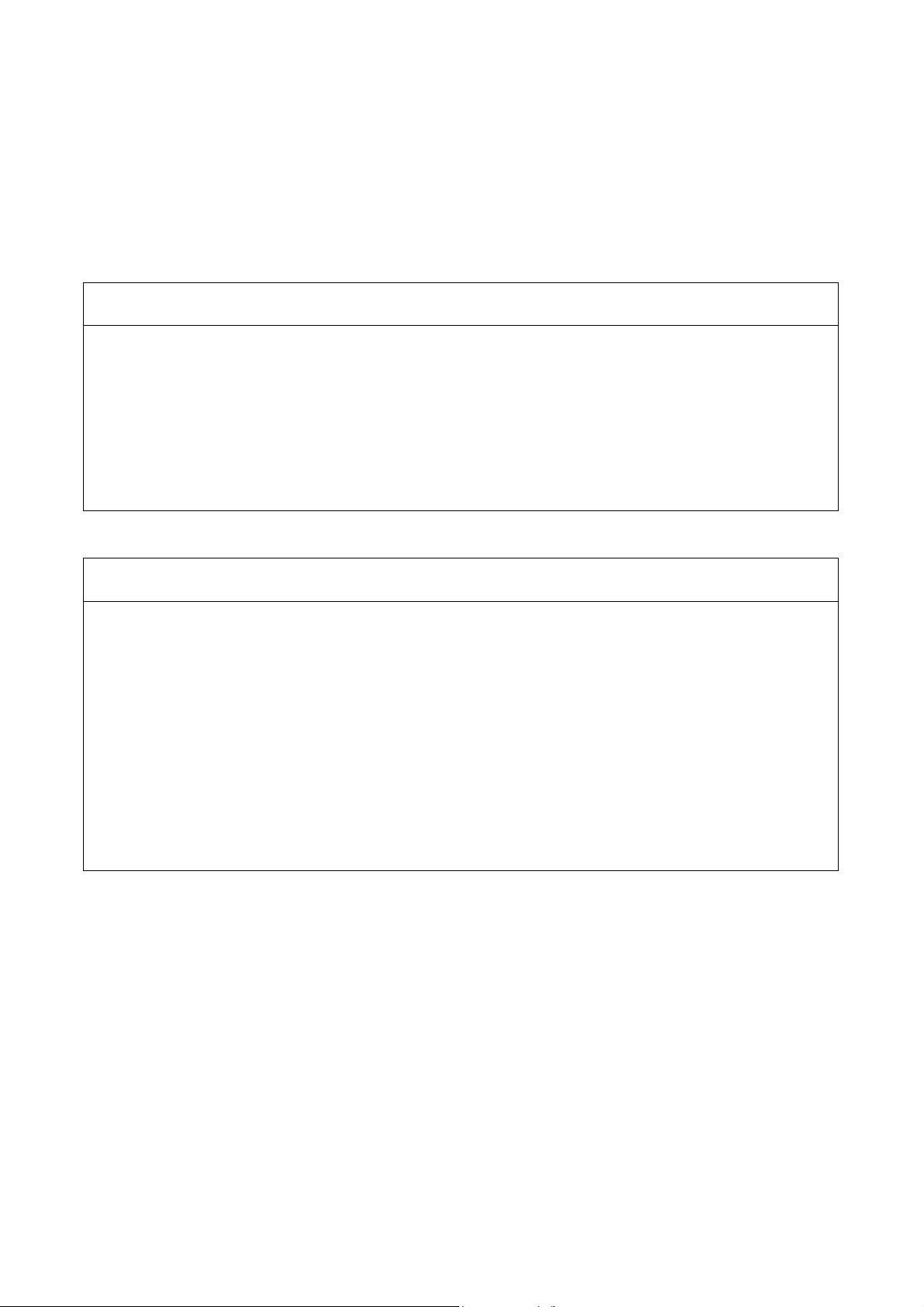

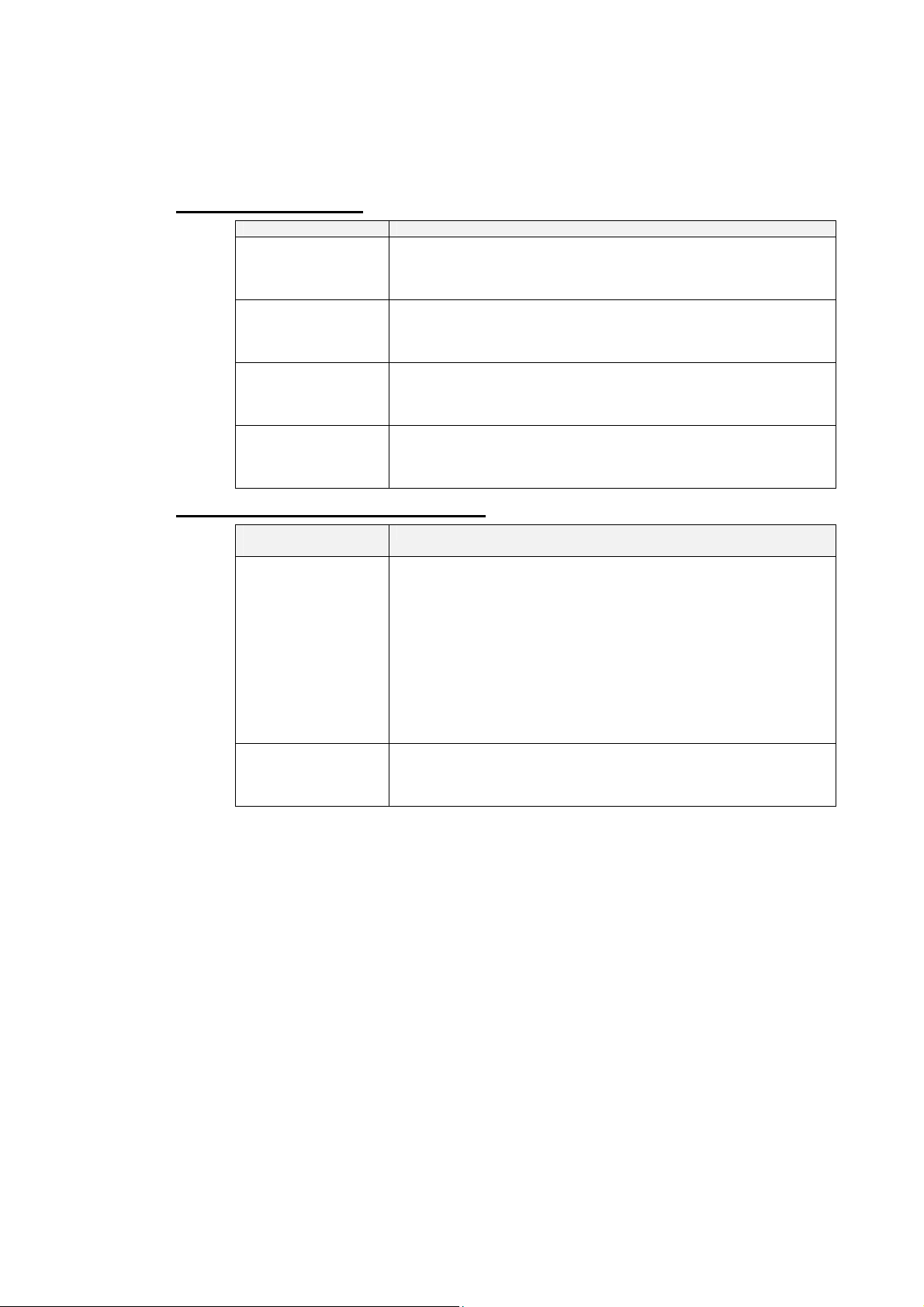

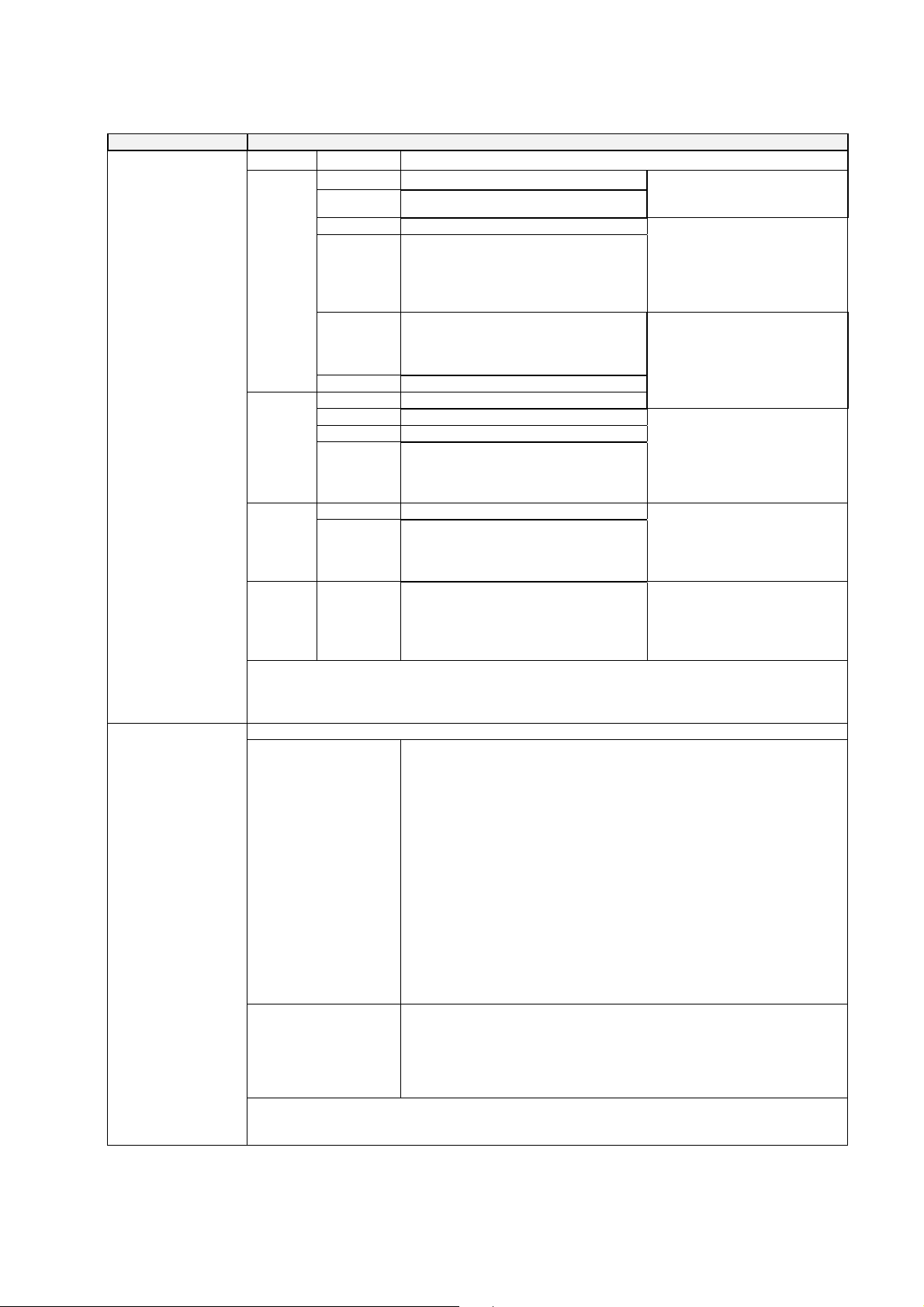

5 Guide to Version Upgrade

5 Guide to Version Upgrade

The following table shows the changes in the upgrade from CX-Integrator

Ver. 1.0 to Ver. 1.1.

Item Previous (Ver. 1.0) Ver. 1.1

CP1H supported as PLC model

Automatic

online

connection

Ethernet network PING test

Echoback test between nodes

on Ethernet, Controller Link,

SYSMAC LINK, and DeviceNet

Controller Link network

diagnosis Repeater display

Start Special Application

Support for NSJ Series

Automatic

USB

connection

No Yes

No

No Yes

No Yes. (Response time can be

No Branching information can be

No It is possible to select an Inverter

No Yes

Yes. When Automatic USB

Connection is selected from the

Network Menu, the PLC model

(such as the CP1H) is

automatically recognized and

connected online.

measured.)

displayed by Repeater Units.

on DeviceNet, and to start the

CX-Drive.

xxi

Page 21

1

Communications

Section 1 Overview

This section provides an overview of the CX-Integrator and describes CX-Integrator

menus and connections.

Page 22

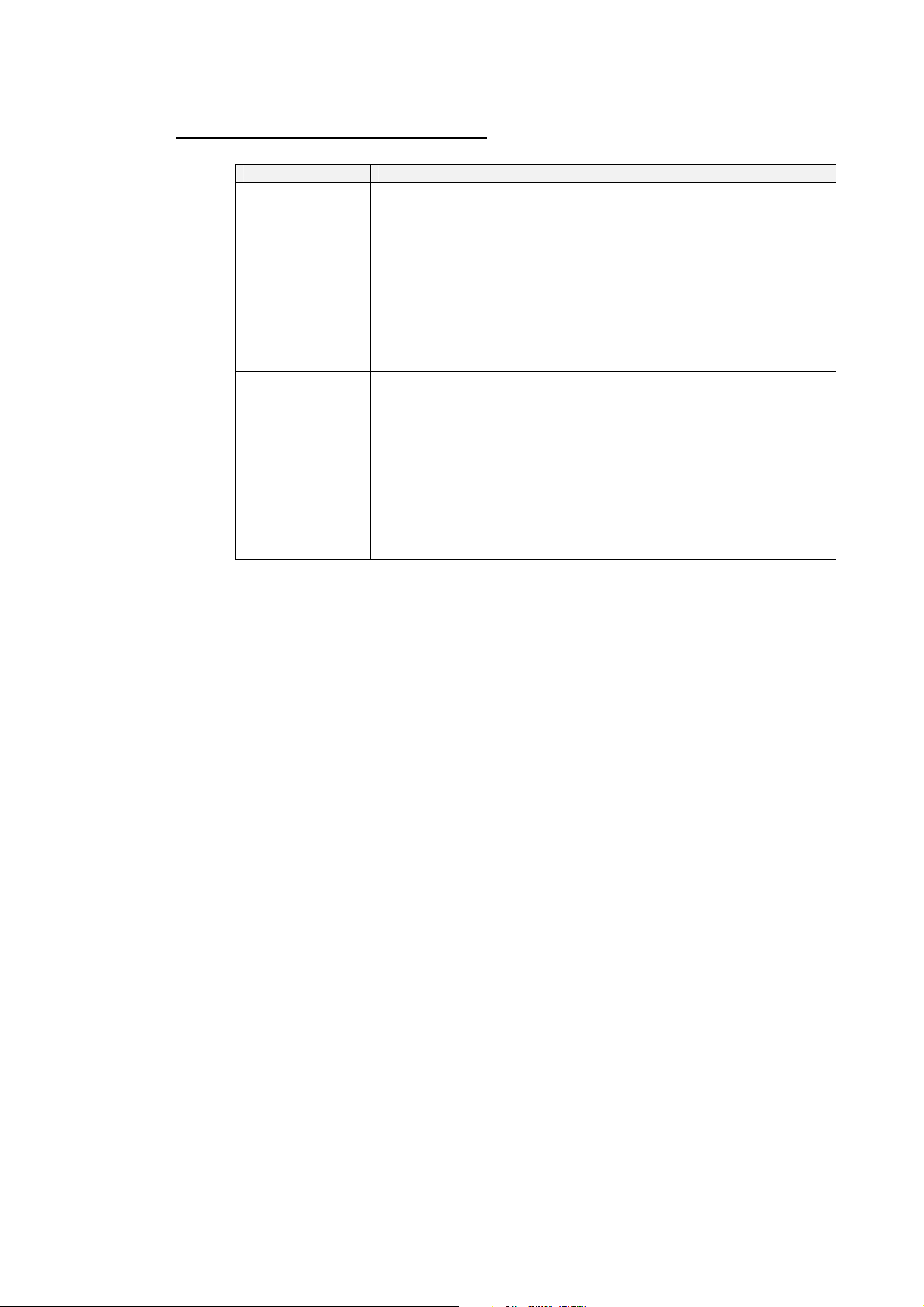

1-1 The CX-Integrator

1-1-1 Overview

1-1 The CX-Integrator

1-1-1 Overview

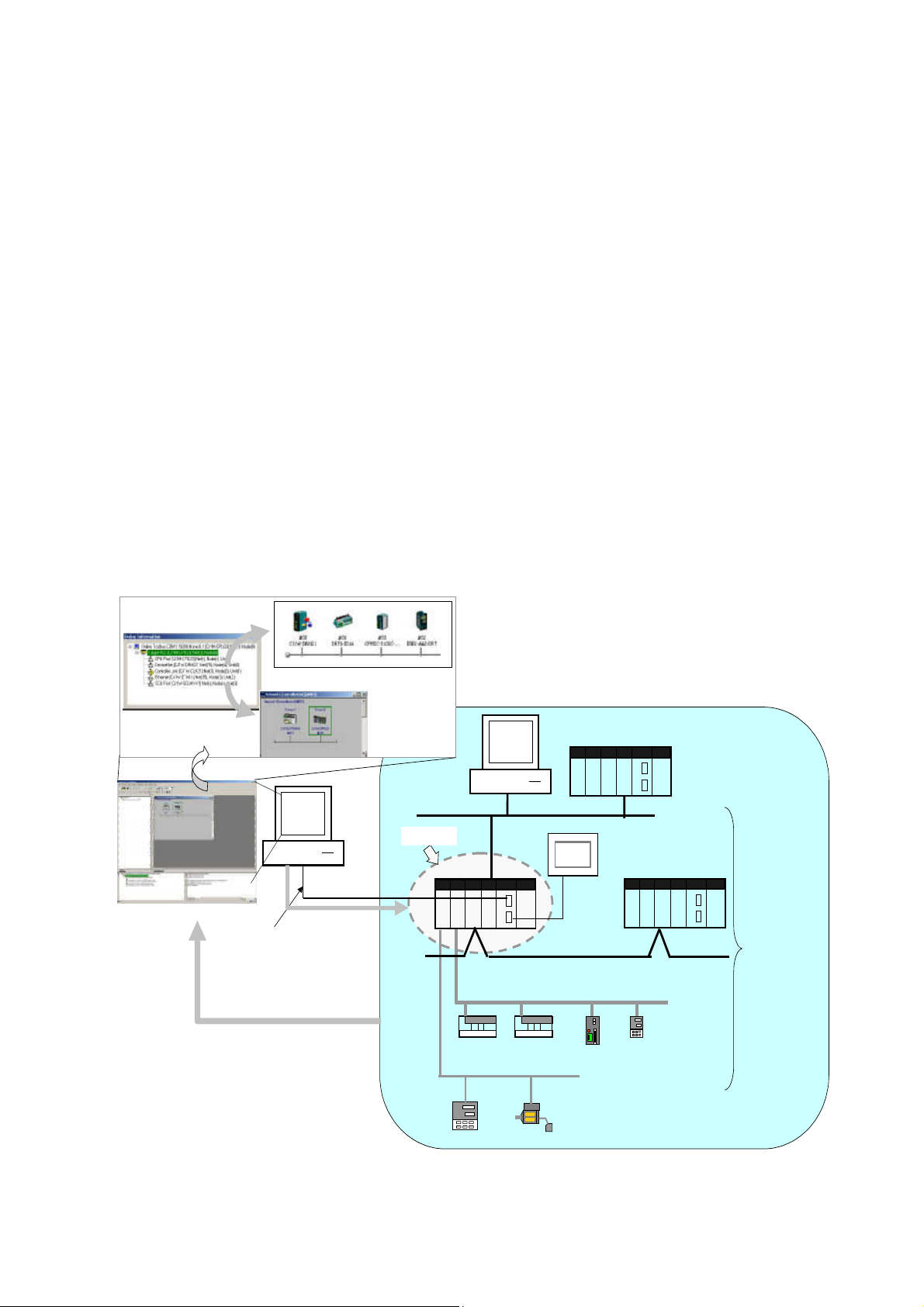

The CX-Integrator is a Programming Device software package that enables reading the

PLC's network and serial network configuration from a personal computer via an online

connection. This enables easily performing many operations, such as monitoring the

connection status of various networks, setting parameters, and diagnosing networks.

The CX-Integrator can be placed online manually or automatically with the CS/CJ-series

PLC to which it is directly connected to enable uploading and monitoring the network

configuration (including device parameters) for that PLC or other network PLCs for each

network.

Direction connection to serial communications using the CompoWay/F protocol is also

possible without going through a PLC. The CompoWay/F network configuration can be

uploaded or automatic connection is possible using the NT Link protocol for NS-series PTs

and CS/CJ-series PLCs.

Furthermore, parameters in slaves on the networks can be set, edited, uploaded, and

downloaded.

Whenever required, network configuration information can be saved in files. The

configuration information in previously saved files can be later compared to the actually

current configuration.

Uploading and displaying network and serial

communications configuration of t he target PLC for

each network

CS/CJ-series PLC

Computer r unning CX-Integ rator

Ethernet

Target PLC

CS/CJ-seri es PLC

General-purpose slaves,

such as I/O Terminals

CompoWay/ F

Temperature

Controll er

DeviceNet

Smart Sensor

Serial

connection

(NT Link)

Controller Link

PLC

Temperature Controller

or other device

Seri al

communications/net

works that can be

accessed

Direct serial connection

(Toolbus or Host Link) or

network connection

Uploaded to computer

Online connection

Access

1-2

Page 23

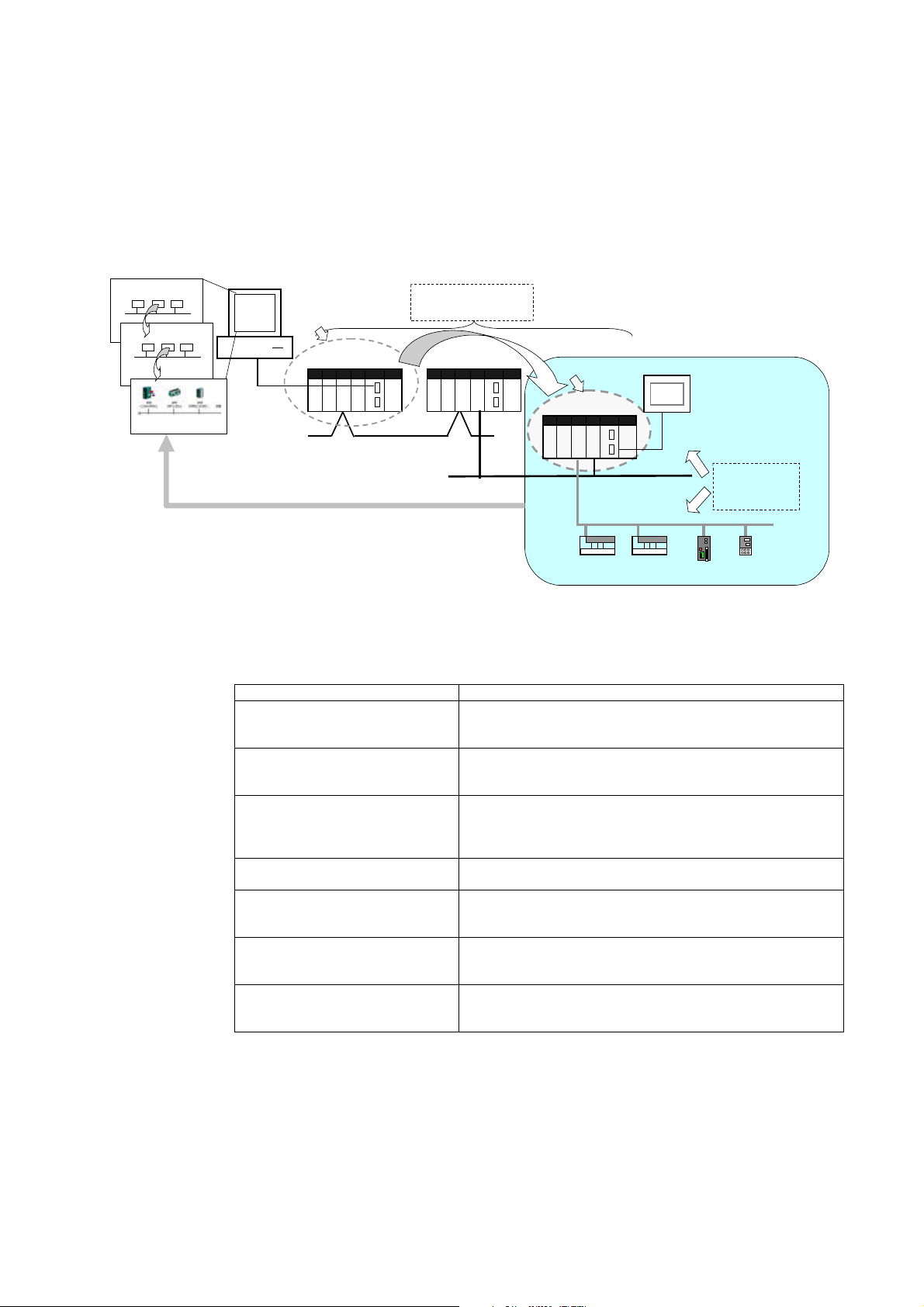

1-1 The CX-Integrator

g

1-1-1 Overview

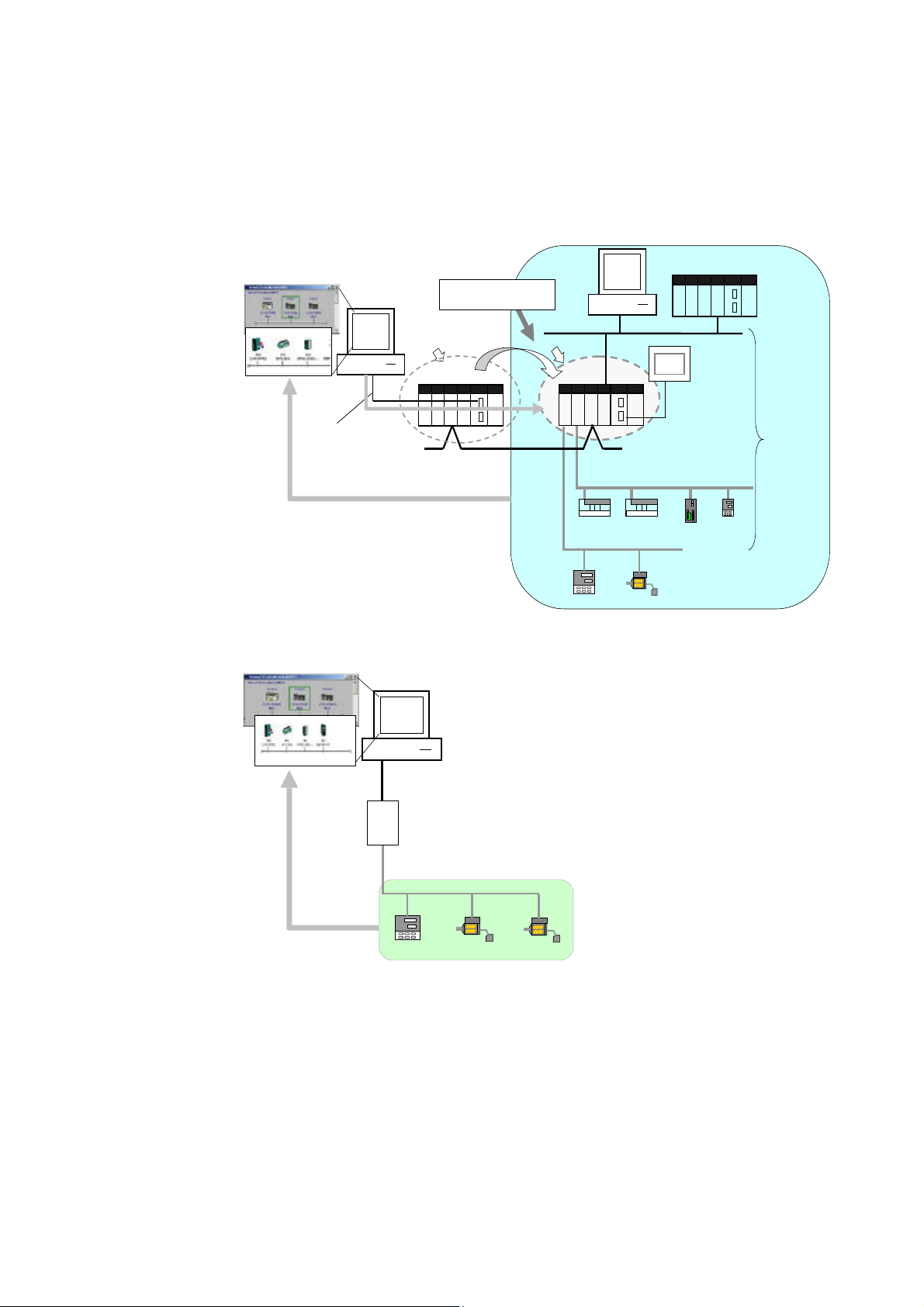

The network/serial communications configuration of a PLC other than the one originally

connected to online to can be set as the target. The PLC that was originally connected to

online (called the relay PLC, see note 1), is relayed through to connect to another PLC

(called the target PLC, see note 2) to switch the online connection.

Note 1: The relay PLC is the PLC to which an online connection was first made from the computer

through a network or serial connection.

Note 2: The target PLC is the PLC from which the network configuration can be uploaded.

Uploading and displaying network and serial

communications configuration of t he tar

network

Direct serial connection

(Toolbus or Host Link) or

network connection

et PLC for each

Computer running

CX-Integrator

Online

connection

Access

Uploaded to computer

A PLC other than the relay PLC

can be set as the target .

Relay PLC

CS/CJ-seri es PLC

Controller Link

Target PLC

CS/CJ-series

PLC

DeviceNe t

General-purpose slaves,

such as I/O Terminals

CompoWay/F

Ethernet

CS/CJ-seri es PLC

Serial connection

(NT Link)

PLC

Temperature

Controll er or

other device

Serial

communi cations /net

works that can be

accessed

Temperature

Controll er

Smart Sensor

Direction connection from the CX-Integrator to serial communications using the

CompoWay/F protocol is also possible using RS-232C or RS-485 communications without

going through a PLC. The CompoWay/F network configuration can also be uploaded.

Computer runnin g

CX-Integrator

Standard RS-232C cable (f emale-female)

K3SC RS-232C to RS-485 Interface

Converter

RS-485 cable connectio n

CompoWay/F protocol

Uploaded to computer

Temperature

Controller

Smart Sensor

Smart Sensor

1-3

Page 24

1-1 The CX-Integrator

1-1-2 Functions According to Network

1-1-2 Functions According to Network

The functions for each network are listed in the following table.

Network Functions

DeviceNet or CompoWay/F A virtual network or virtual serial communications

Controller Link or SYSMAC LINK User-set data link tables can be created offline

Controller Link A Controller Link Network Diagnostic Tool can be

Ethernet Broadcast node searches and ping tests are

NT Link Settings for an NS-series PT with a model number

FINS networks, such as Ethernet, Controller

Link, SYSMAC LINK, and DeviceNet

configuration can be created offline and connected

device parameters can be set, uploaded,

downloaded, and compared.

and then transferred online to CS/CJ-series PLCs.

Data link parameters can be set automatically

online and then transferred to CS/CJ-series PLCs.

started to diagnose Controller Link networks.

enabled (with CX-Integrator Ver. 1.1 or later).

ending in V1 or later serially connected to a

CS/CJ-series PLC via NT Link can be

automatically detected and set for the serial port of

the CS/CJ-series PLC. This is called NT Link Auto

Online Setting function.

Routing tables can be set offline and then

transferred online to CS/CJ-series PLCs.

Echoback tests between nodes are enabled (with

CX-Integrator Ver. 1.1 or later).

1-1-3 Connecting to the Relay PLC

Either of the following methods can be used to connect the CX-Integrator online to the relay

PLC.

Serial communications (Toolbus or Host Link Mode)

FINS network communications, such as Controller Link, SYSMAC LINK, Ethernet, Ethernet

FINS/TCP, or FinsGateway

Note: If the computer running the CX-Integrator is connected directly to a network, the network

address and node can be specified to set any PLC on the local network or an interconnected

network as the relay PLC.

1-4

Page 25

1-1-4 Accessible Network

The network configuration of the target PLC (i.e., either the relay PLC or a PLC connected to

the relay PLC) can be uploaded and monitored for each of the following networks.

Accessible Networks

Network Conditions

Ethernet Monitoring and editing parameters is possible for all CS/CJ-series PLCs

and NSJ-series NSJ Controllers on the Ethernet network. Only monitoring

the network configuration is possible for CVM1/CV-series PLCs and

computers with FinsGateway.

Controller Link Monitoring and editing parameters is possible for all CS/CJ-series PLCs

and NSJ-series NSJ Controllers on the Controller Link network. Only

monitoring the network configuration is possible for C200HX/HG/HS

PLCs, CVM1/CV-series PLCs, and computers with FinsGateway.

SYSMAC LINK Monitoring and editing parameters is possible for all CS-series PLCs on

the SYSMAC LINK network. Only monitoring the network configuration is

possible for C200HX/HG/HS PLCs, CVM1/CV-series PLCs, and

computers with FinsGateway.

DeviceNet Monitoring and editing parameters is possible for all CS/CJ-series

DeviceNet Units and NSJ-series NSJ Controllers. Only setting the

DeviceNet Master Unit is possible for C200H-series DeviceNet Master

Unit and CVM1/CV-series DeviceNet Master Units.

Accessible Serial Communications

Serial

communications

CompoWay/F The serial communications mode of the serial port must be Serial

Gateway Mode or Protocol Macro Mode. (See note.)

Note: To use the built-in serial ports on CS/CJ-series CPU Units,

unit version 3.0 or later must be used. For Serial Communications

Boards and Serial Communications Units, unit version 1.2 or later

must be used.

Monitoring and parameter editing is possible only for CompoWay/F slaves

for which CPS files have been installed on the computer running the

CX-Integrator.

(If the CompoWay/F slave is a Temperature Controller, however, only

monitoring the network configuration is possible. Parameters are edited

using the CX-Thermo.)

NT Link The serial communications mode of the serial port must be 1:N NT Link.

Monitoring is possible only for NS-series PTs with model numbers ending

in V1or later. (Monitoring is not possible for earlier NS-series PTs without

a model number suffix or for NT-series PTs.)

1-1 The CX-Integrator

1-1-4 Accessible Network

Conditions

1-5

Page 26

1-1 The CX-Integrator

1-1-4 Accessible Network

Local Network Table Requirements

A local network table must be registered in the target PLC in the following cases.

Communications Conditions

Network

communications

Serial

communications

Note: As an exception, local network tables are not required even when more than one Network

Communications Unit is mounted in the following situation:

Access is possible without a local network table when connecting online to the target PLC via a

direct serial connection and access is required only to the network of the Network

Communications Unit with the smallest unit number (set on the front panel rotary switches) of all

the Network Communications Units that are mounted to the target PLC.

• More than one Network Communications Unit is mounted to the target

PLC. (See note.)

Note: Network Communications Units include Ethernet Units, Controller

Link Units, SYSMAC LINK Units, DeviceNet Units, and FL-net Units.

Serial Communications Units and Serial Communications Boards are not

included except in the following case: If serial ports are registered in the

local network table to treat them as networks, the serial ports must be

treated as Network Communications Units, including the serial ports on

the CPU Unit.

• Routing tables are already registered in one or more nodes on the network.

• Communications are required between networks.

Serial ports on Serial Communications Units and Serial Communications

Boards are used as serial gateways to Host Link FINS and access is

required via networks via Host Link FINS to PLCs functioning as Host Link

slaves.

Note: Serial ports do not necessarily need to be registered in the local

network table (to treat them as networks) to enable using other serial

gateway functions. Registration is normally not required to convert from

serial to serial. Refer to 3-6 Overview of Serial Gateway Functions in the

CS/CJ-series Communications Commands Reference Manual (Cat. No.

W342) for details on whether local network tables are required to use

serial gateway functions.

1-6

Page 27

1-1-5 Communicating Across Network Layers

p

1-1-5 Communicating Across Network Layers

If relay network routing tables are set in the CPU Units of the PLCs, a PLC on a different

network layer than the network of the PLC connected to the CX-Integrator can be set as the

target PLC to enable uploading, saving, and comparing the network configuration of the

target PLC.

Uploading and displaying network and serial communications configurati on

of a target PLC on a remote network for each network

Computer running

CX-Integrator

Relay PLC

Relay network routing tables

set in the CPU Units

1-1 The CX-Integrator

CS/CJ-ser ies PLC

Controller Link

Serial connection

(Toolbus or Host

Link) or network

connection

Uploaded to computer

CS/CJ-series PLC

1-1-6 Starting Other Applications

The following applications can be started from the CX-Integrator.

Application Starting method

CX-Programmer Right-click the desired CS/CJ-series PLC in the Network

Configuration Window and select Start Special Application

from the pop-up menu.

Data Link Component Either select Tools – Start Data Link or right-click the desired

Routing Table Component Either select Tools – Start Routing table or right-click the

Controller Link Network Diagnostic

Tool

CX-Designer Right-click the desired NS-series PT in the Network

CX-Thermo Right-click the desired OMRON Temperature Controller in the

CX-Drive Right-click the desired Inverter or Servo in the Network

Controller Link Unit in the Online Connection Information

Window and select Start Data Link from the pop-up menu.

desired Communication Unit/port in the Online Connection

Information Window and select Start Routing table from the

pop-up menu.

Select Tools – Controller Link tool – Network diagnosis.

Configuration Window and select Start Special Application

from the pop-up menu.

Network Configuration Window and select Start Special

Application from the pop-up menu.

Configuration Window and select Start Special Application

from the pop-up menu.

Ethernet

Target PLC

CS/CJ-series PLC

General-purpose sl aves, such

as I/O Terminals

DeviceNet

Serial connection

(NT Link)

Network and serial

communications

structure can be

u

PLC

loaded.

Temperature

Controller or

other device

1-7

Page 28

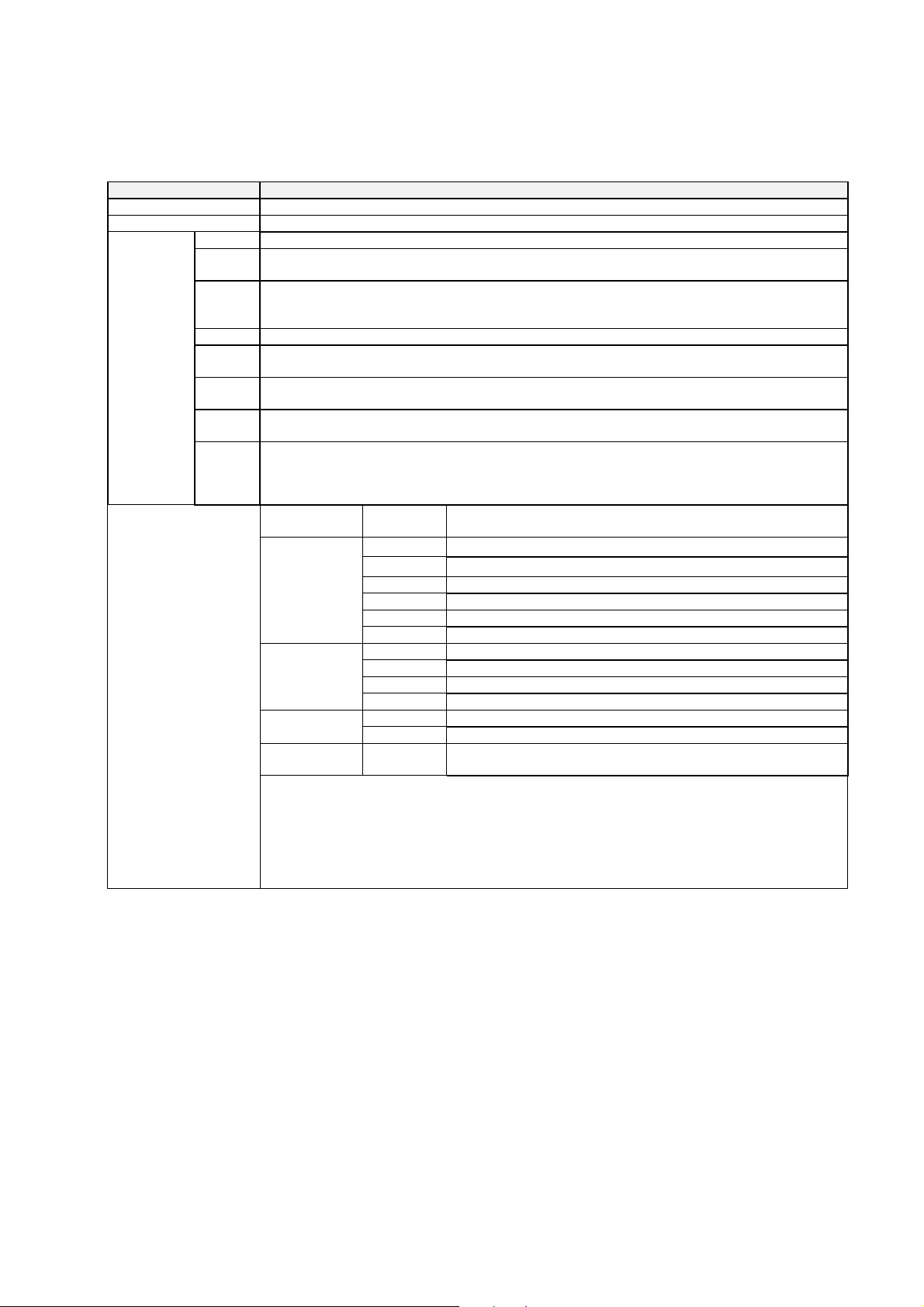

1-2 Specifications

1-2-1 CX-Integrator Specifications

1-2 Specifications

1-2-1 CX-Integrator Specifications

Item Specification

Model Provided in the CX-One FA Integrated Tool Package (CXONE-AL@@C-E).

Setup media CD-ROM

Applicable

computers

(with

FinsGateway)

PLCs that can be used

as relay PLC for online

connections

Note: A relay PLC is the

PLC to which the

CX-Integrator is

connected online.

Computer IBM PC/AT or compatible

CPU Pentium II, 333 MHz or better, for Windows 98 SE or NT 4.0 with service pack 6a Pentium III, 1

GHz or better, is recommended.

OS Microsoft Windows 98 SE, Me, 2000, or XP

Microsoft Windows NT version 4.0 service pack 6a

Note: CX-Integrator cannot be used with Windows 95.

Memory 64 MB min. for Windows 98 SE or NT 4.0 with service pack 6a

Hard disk

drive

Monitor SVGA, 800 x 600 pixels or better

CD-ROM

drive

Communi

cations

port

100 MB min. of available space

Note: Use the small font size.

At least one required.

At least one RS-232C or USB port (See note.)

Note: The USB port on a computer can be connected to if the CJ1W-CIF31 USB-Serial

Conversion Cable is used. (The driver software included with the CJ1W-CIF31 must be installed

on the computer.)

Series Device type

CS Series

CJ Series

(See note 3.)

NSJ Series NSJ G5D (Used for the NSJ5-TQ0@-G5D, NSJ5-SQ0@-G5D,

(See note 1.)

CS1H CS1H-CPU67/66/65/64/63(-V1)

CS1G/CJ1G CS1G-CPU45/44/43/42(-V1)

CS1G-H CS1G-CPU45H/44H/43H/42H

CS1H-H CS1H-CPU67H/66H/65H/64H/63H

CS1D-H CS1D-CPU67H/65H (See note 2.)

CS1D-S CS1D-CPU67S/65S/44S/42S

CS1G/CJ1G CJ1G-CPU45/44

CJ1M CJ1M-CPU23/22/21/13/12/11

CJ1G-H CJ1G- CPU45H/44H/43H/42H

CJ1H-H CJ1H-CPU67H/66H/65H

CP1H-XA CP1H-XA@@@@-@ CP-Series

CP1H-X CP1H-X@@@@-@

NSJ8-TV0@-G5D, NSJ10-TV0@-G5D, and NSJ12-TS0@-G5D.)

CPU Unit model

Note 1: To connect the computer running CX-Integrator directly as a CompoWay/F slave, set

the Device type to CompoWay/F Device.

Note 2: When using a pre-Ver. 1.1 CS1D-H CPU Unit, use it as if it were a CS1H-H CPU

Unit.

Note 3: Use commercially available USB cable (B type to A type connectors) for connecting

CP-series CPU Units.

1-8

Page 29

Item Specification

Connecting to the

Relay PLC

Either of the following can be used.

Serial

communications

FINS network

communications

Direction connection is possible to any of the following serial ports on a

CS/CJ-series PLC.

• CPU Unit peripheral port (Toolbus or Host Link)

• CPU Unit RS-232C port (Toolbus or Host Link)

• CPU Unit USB port (CP Series only)

• Serial Communications Board or Serial Communications Unit RS-232C

port or RS-422A/485 port (Host Link)

Direct connection is possible to any of the following serial ports on an

NSJ-series NSJ Controller.

• RS-232C port A (Toolbus) on NSJ Controller

• RS-232C port B (Toolbus) on NSJ Controller

• USB port on NSJ Controller

Note: Automatic online connection is possible for serial communications

ports. (The user does not have to set the computer communications

settings.) The communications settings will be automatically set to

those of the PLC. Connection is possible to a serial port on the CPU

Unit, a Serial Communications Board, or a Serial Communications

Unit. For PLC serial ports, however, only the Toolbus or Host Link

serial communications modes can be used and the baud rate must be

9600, 19200, 38400, or 115200 bits/s.

Direction connection is possible through any of the following networks on

a CS/CJ-series PLC or NSJ-series NSJ Controller.

• Ethernet (Ethernet, Ethernet FINS/TCP, or FinsGateway)

• Controller Link (Controller Link or FinsGateway)

• SYSMAC LINK (SYSMAC LINK or FinsGateway)

1-2 Specifications

1-2-1 CX-Integrator Specifications

1-9

Page 30

1-2 Specifications

1-2-1 CX-Integrator Specifications

Item Specification

PLCs that are

accessible as target

PLCs

Note: The target PLC

is the PLC actually

being accessed, e.g.,

to upload/download

the PLC’s network

configurations.

Supported

communications

Series Device type CPU Unit model

CS Series

CJ Series

NSJ

Series

Note: The CS/CJ-series PLC must have a lot number of 030201 or later (manufactured 1

The following communications are possible for a directly connected target PLC.

Supported network

communications

Supported serial

communications

Note: Accessing PLC Communications Across Network Layers

If relay network routing tables are set, a PLC on a different network layer than the network of the

PLC connected to the CX-Integrator can be set as the target PLC.

CS1H CS1H-CPU67/66/65/64/63(-V1)

CS1G/CJ1G CS1G-CPU45/44/43/42(-V1)

CS1G-H CS1G-CPU45H/44H/43H/42H

CS1H-H CS1H-CPU67H/66H/65H/64H/63H

CS1D-H CS1D-CPU67H/65H

CS1D-S CS1D-CPU67S/65S/44S/42S

CS1G/CJ1G CJ1G-CPU45/44

CJ1M CJ1M-CPU23/22/21/13/12/11

CJ1G-H CJ1G- CPU45H/44H/43H/42H

CJ1H-H CJ1H-CPU67H/66H/65H

CP1H-XA CP1H-XA@@@@-@ CP-Series

CP1H-X CP1H-X@@@@-@

NSJ G5D (Used for the NSJ5-TQ0@-G5D,

February 2003 or later) to start the CX-Designer and transfer screen data to an NS-series PT

from the CX-Designer through the PLC. The following PLCs can be used:

CS1G-H, CS1H-H, CS1D-S, CJ1M, or CJ1H-H. (The CS1D-H cannot be used.)

Note: CompoWay/F cannot be

used with a built-in serial

port on the CPU Unit.

Note: A CPU Unit with unit

version 3.0 or later must be

used when using

CompoWay/F with a

built-in serial port on the

CPU Unit

Note: CompoWay/F cannot be

Note: When using a pre-Ver. 1.1

CS1D-H CPU Unit, use it as if it

were a CS1H-H CPU Unit.

NSJ5-SQ0@-G5D, NSJ8-TV0@-G5D,

NSJ10-TV0@-G5D, and

NSJ12-TS0@-G5D.)

Ethernet (Access is possible only to CS/CJ-series PLCs, NS-series PTs,

and computers with FinsGateway on the Ethernet network. For

CVM1/CV-series PLCs, only display functions are supported.)

Controller Link (Access is possible only to CS/CJ/CP-series PLCs,

NS-series PTs, and computers with FinsGateway on the Controller Link

network.) For C200H-series PLCs and CVM1/CV-series PLCs, only

display functions are supported.)

Note: When the Controller Link Network Diagnosis application is

being used, it is possible to monitor and troubleshoot PLC models in

the Controller Link network other than CS/CJ-series PLCs.

SYSMAC LINK (Monitoring is possible only to CS/CJ-series PLCs,

NS-series PTs, and computers with FinsGateway on the SYSMAC LINK

network.)

DeviceNet (CS/CJ-series DeviceNet Units, C200H DeviceNet Master

Units, or CVM1/CV-series DeviceNet Master Units)

Note: A C200H-DRM21-V1 or CVM1-DRM21-V1 DeviceNet Master

Unit can be used through a CS/CJ-series DeviceNet Unit.

CompoWay/F (CS/CJ-series CPU Units must be unit version 3.0 or later.)

Serial Communications Boards and Serial Communications Units must be

unit version 1.2 or later. Only slaves for which CPS files are installed on

the computer can be accessed.

NT Links (Connection is possible only for NS-series PTs with model

numbers ending in V1 or later.)

used with a built-in serial

port on the CPU Unit.

Note: A CPU Unit with unit

version 3.0 or later must

be used when using

CompoWay/F with a

built-in serial port on the

CPU Unit

Note: CompoWay/F cannot be

used with a built-in USB

port on the CPU Unit. It

can be used with a serial

communications port.

Note: CompoWay/F can be used

on serial port C (RS-232C

port) on the Controller

Section of the NSJ

Controller.

1-10

Page 31

1-2-1 CX-Integrator Specifications

Item Specification

Online Connection

Information Window

Communications

monitoring functions

Setting functions

Verification functions Verifying communications/network configurations

Operations The following operations are possible for the CPU Unit at the target PLC.

When the target PLC is online, Communications Units connected to the target PLC (referred to here

as simple “Communications Units”) are displayed as follows:.

Target Device, Target PLC CPU Unit model (network address) (node address)

• CPU Unit name [model] (network address) (-) (serial port FINS unit address)

• Communications Unit name [model] (network address) (node address) (unit number)

• Communications Unit name [model] (network address) (node address) (unit number)

Communications configuration information can be uploaded by right-clicking a Communications Unit

and selecting Transfer – Network to PC.

Ethernet Node information for FINS communications (CPU Unit model, Ethernet

Unit mode, node address, and network address)

Controller Link Information on nodes participating in the Controller Link network (CPU

SYSMAC LINK Information on nodes participating in the SYSMAC LINK network (CPU

DeviceNet Information on nodes connected to DeviceNet for which EDS files are

CompoWay/F Information on nodes connected to a serial port in serial gateway mode or

NT Link Information on nodes connected to 1:N NT Links (NS-series PT model

Ethernet Ethernet Unit settings (CPU Bus Unit System Settings)

Controller Link

SYSMAC LINK

DeviceNet DeviceNet Unit master parameters (remote I/O allocations, connection

CompoWay/F CompoWay/F slave parameters (except for Temperature Controllers)

NT Link None

FINS networks, such

as Ethernet, Controller

Link, SYSMAC LINK,

and DeviceNet

Verifying component parameters

Creating, editing, and transferring I/O tables

Displaying current errors and error logs

Changing the operating mode

Transferring or verifying a manually set data link table

Transferring or verifying a routing table (FINS local routing table)

Unit model, Controller Link Unit mode, node address, and network

address)

The following functions are also possible if the Controller Link Network

Diagnostic Tool is started.

Configuration node diagnosis (network participation status, current

Controller Link Unit errors, current CPU Unit errors, and differences from

node files), setting diagnosis (e.g., DM Area parameter setting

consistency), line disconnection information diagnosis, transmission

status diagnosis, node status (displaying current error status and error

log), error log collection, and node file editing (node names, connection

order, and Repeater Units)

Unit model, Controller Link Unit mode, node address, and network

address)

installed on the computer (DeviceNet Unit model, slave model,

master/slave node addresses)

protocol macro mode for which CPS files are installed on the computer

(CompoWay/F SLAVE model and CompoWay/F node address).

Note: CS/CJ-series CPU Units with unit version 3.0 or later, or Serial

Communications Boards/Units with unit version 1.2 or later, or

CP-series Communications Option Boards must be used.

and NT Link unit number)

Note: Automatic detection of NS-series PTs connected serially to a

CS/CJ-series PLC is also possible. (The NT Link Automatic Setting

Function automatically changes the setting of the PLC’s serial port to

match those of the NS-series PT.)

User-set data link tables

Controller Link and SYSMAC LINK Unit settings (in allocated DM Area

words), including automatically set data link parameters (transferred to

the startup node set as the target PLC)

settings, device information check, communications cycle time, etc.)

Slave parameters

Note: Parameters for CompoWay/F-compatible Temperature Controllers

are set using the CX-Thermo, started as an application.

PLC serial port communications settings (CPU Unit: part of PLC Setup,

Serial Communications Boards/Units: allocated DM Area words)

Routing tables (FINS local routing tables and FINS network routing

tables)

Note: The FINS local routing table is transferred to the target PLC.

1-2 Specifications

1-11

Page 32

1-2 Specifications

1-2-2 Files Created by the CX-Integrator

1-2-2 Files Created by the CX-Integrator

The following files can be created by the CX-Integrator.

Files Contents Details

Project files (.cin) Connection

information to relay

PLC, all network

configurations for

target PLC, and

parameters for

DeviceNet masters,

DeviceNet slaves,

and CompoWay/F

slaves

Network

configuration files

Component

parameter files

Data link table files

DeviceNet network

structure files (.npf)

Controller Link node

files (.crg)

DeviceNet device

parameter files

(.dvf)

CompoWay/F

component

parameter files

(.xml)

Controller Link data

link table files (.cl2)

SYSMAC LINK data

link table files (.sl3)

These files are used offline to check network configurations and parameters

and for other purposes, such as printing. Each file consists of the following:

Device type setting information of the relay PLC

Communications Unit models connected to the target PLC (Ethernet Units,

Controller Link Units, SYSMAC LINK Units, DeviceNet Units, and Serial

Communications Boards/Units)

Device models connected to the above CPU Units or Communications

Units via communications (DeviceNet slaves, CompoWay/F slaves,

NS-series PTs, etc.)

Parameters for DeviceNet Master Unit and Device parameters and

DeviceNet slaves (for all devices for which EDS files are installed on the

computer including slaves from other manufacturers)

Parameters for CompoWay/F slaves (for all components for which CPS

files are installed on the computer (except for Temperature Controllers)

Controller Link network parameters

Controller Link and SYSMAC LINK Unit allocated DM Area words settings,

including automatically set data link parameters

Ethernet Unit CPU Bus Unit System Settings

Serial Communications Board/Unit serial communications settings

Note: Routing tables (local network tables and relay network tables) and

user-set data link tables are not included in project files.

Network configuration for one DeviceNet network connected directly to the

target PLC (including master and slave parameters)

Note: These are the same as the DeviceNet network structure files (.npf)

created with DeviceNet Configurator version 2.@. Files created with

DeviceNet Configurator version 2.@ can be imported/exported.

Network configuration for Controller Link networks connected directly to the

target PLC

Parameters for individual DeviceNet devices (master or slave)

Note: These are the same as the DeviceNet device parameter files (.dvf)

created with DeviceNet Configurator version 2.@. Files created with

DeviceNet Configurator version 2.@ can be imported.

Parameters for individual CompoWay/F slaves (except for Temperature

Controllers)

CPU Unit parameters (parts of PLC Setup: serial communications settings)

Controller Link or SYSMAC LINK network parameters

Controller Link and SYSMAC LINK Unit allocated DM Area words settings,

including automatically set data link parameters

Ethernet Unit CPU Bus Unit System Settings

Serial Communications Board/Unit serial communications settings

Controller Link user-set data link tables

Note: These are the same as the Controller Link data link table files (.cl3)

created with the CX-Net. Files created with the CX-Net can be

imported.

SYSMAC LINK user-set data link tables

Note: These are the same as the SYSMAC LINK data link table files (.sl3)

created with the CX-Net. Files created with the CX-Net can be

imported.

1-12

Page 33

File name Contents Details

Routing table files

FINS local routing

table files (.rtg)

FINS network

routing table files

(.rt3)

Routing tables of the target PLC

Note: These are the same as the FINS local routing table files (.rtg) created

with the CX-Net. Files created with the CX-Net can be imported.

Routing tables for all PLCs on networks to which the target PLC belongs

Note: These are the same as the FINS network routing table files (.rt3)

created with the CX-Net. Files created with the CX-Net can be

imported.

Note With DeviceNet only, the following files can also be exported and saved.

EDS files (.eds)

The device list saved in CSV format (.csv)

The I/O comments saved in CSV format (.csv)

The device parameters of an OMRON DeviceNet Master Unit saved as an Open

Network Controller DRM_UNIT (virtual unit) file

The device parameters of an OMRON DeviceNet Master Unit saved as a NetX Server

(NetX Server for DeviceNet) file

Note The CX-Integrator does not support files created in the DeviceNet Configurator Ver.

1.0 file format.

1-2 Specifications

1-2-2 Files Created by the CX-Integrator

1-13

Page 34

1-3 Installation

1-2-2 Files Created by the CX-Integrator

1-3 Installation

The CX-Integrator is installed from the CX-One Installer. Refer to the CX-One Setup Manual

(W444) for details.

1-14

Page 35

1-4-1 Direct Serial Connections to a PLC

1-4 PLC Connecting Cables

1-4-1 Direct Serial Connections to a PLC

When connecting the computer running the CX-Integrator directly to a PLC using a serial

line, make the connection correctly using the following Connecting Cables and connection

diagrams.

Connecting Cables to CS/CJ-series PLCs

Unit Unit port Computer

CPU Unit

Built-in

peripheral port

IBM PC/AT

or

Computer

port

D-sub

9-pin male

compatible

Built-in

RS-232C port

D-sub 9-pin

IBM PC/AT

or

compatible

D-sub

9-pin male

male

Serial

Communications

Boards/Units

RS-232C port

D-sub 9-pin

male

IBM PC/AT

or

compatible

Host Link

Refer to the following connection diagrams.

Connection to IBM PC/AT or Compatible

Connection to Peripheral Por t

IBM PC/AT or compatibl e

Connection to RS-232C Port

IBM PC/AT or compatibl e

Network type

(serial

communications

mode)

Peripheral bus

(Toolbus)

or Host Link

(SYSWAY)

Peripheral bus

(Toolbus)

or Host Link

(SYSWAY)

Host Link

(SYSWAY)

(SYSWAY)

1-4 PLC Connecting Cables

Model Length Remarks

CS1W-CN226/626 2 m/6 m ---

XW2Z-200S-CV/

500S-CV

XW2Z-200S-V/

500S-V

XW2Z-200S-CV/

500S-CV

XW2Z-200S-V/

500S-V

2 m/5 m Connector

with ESD

(electrostatic

discharge)

countermeasu

res used.

2 m/5 m ---

2 m/5 m Connector

with ESD

(electrostatic

discharge)

countermeasu

res used.

2 m/5 m -

9-pin

CS1W-CN2 26 (2.0 m)

CS1W-CN6 26 (6.0 m)

CPU Unit peripheral port

9-pin

XW2Z-200S-CV (2.0 m)

XW2Z-500S-CV (5.0 m)

9-pin

Built-in RS-232C

port on CPU Unit

or port on Serial

Communications

Board/Unit

Note

•When using an RS-232C cable for the computer running CX-Integrator and

connecting to a CS/CJ-series PLC with a Toolbus connection, use a

XW2Z-200S-CV/500S-CV Connecting Cable. (This cable can be used only with IBM

PC/AT or compatible computers.)

•The following connection methods can be used when connecting an RS-232C cable

to a peripheral port on a CS/CJ-series PLC.

1-15

Page 36

1-4 PLC Connecting Cables

p

p

1-4-1 Direct Serial Connections to a PLC

Unit Unit port Computer

CPU Unit Built-in

peripheral port

IBM

IBM

PC/AT or

compatible

PC/AT or

compatible

Connection to

RS-232C Port

XW2 Z-@@@S-@@

RS-232C cable

(listed above)

Computer

D-sub 9-pin

male

D-sub 9-pin

male

port

Network type

(serial

communications

mode)

Peripheral bus

(Toolbus)

or Host Link

(SYSWAY)

Host Link

(SYSWAY)

Model Length Remarks

CS1W-CN118 +

XW2Z-200S-CV/

500S-CV

CS1W-CN118 +

XW2Z-200S-V/

500S-V

0.1 m +

2 m/5 m

0.1 m +

2 m/5 m

The

XW2Z-@@@

S-CV uses a

connector

with ESD

(electrostatic

discharge)

countermeas

ures.

---

Peri

heral port

CS1W-CN118

Note The following connection methods can be used when connecting an CQM1-CIF01/02

cable to a peripheral port on a CS/CJ-series PLC.

Unit Unit port Computer

CPU Unit Built-in peripheral

port

IBM

PC/AT or

compatible

Computer

port

D-sub 9-pin

male

Network type

(serial

communications

mode)

Host Link

(SYSWAY)

Note: Baud rate

must be 19.2

Kbits/s or less.

Model Length Remarks

CS1W-CN114 +

CQM1-CIF02

05 m +

3.3 m

---

Connection to

RS-232C Port

CQM1-CIF01/02

Peripheral Cable

CS1W-CN114

Peri

heral port

1-16

Page 37

Note Connecting the PLC Using a USB Port on the Computer

Computer

running

CX-Integrator

1-4 PLC Connecting Cables

1-4-1 Direct Serial Connections to a PLC

A USB port on the computer can be used to connect the computer running the

CX-Integrator to a PLC. To do so, connect the computer to the PLC as shown below

using a CS1W-CIF31 USB-Serial Conversion Cable. When connecting the computer to

a CP-series PLC, it is possible to make a direct connection using a

commercially-available USB cable (B type – A type connectors).

The driver software included with the CJ1W-CIF31 must be installed on the computer

to use a USB port to connect the CX-Integrator. Refer to the PDF User’s Manual

included with the CS1W-CIF31 USB-Serial Conversion Cable for details.

PLC Connection Methods

CS1W-CIF31 Cable 1

CS1W-N226/626 CS/CJ-series

Peripheral Port Programming

Device Connecting Cable

or

CS1W-CIF31

USB Connecting Cable

+

CQM1H-CIF02 C-series

Peripheral Port Programming

Device Connecting Cable

+

or

@@@

XW2Z-

RS-232C Programming

Device Connecting Cable

Cable 2

(when required)

CS1W-CN114

C-series-CS/CJ-series

Peripheral Conversion Cable

CS1W-CN118

RS-232C-CS/CJ-series

Peripheral Conversion Cable

PLC

CS/CJ-series CPU Unit Connection Patterns

USB

Connecting

Cable

Model Connector Model Connector Connector Model Connector

CS1W-CIF31

D-sub 9-pin

female

D-sub 9-pin

female

D-sub 9-pin

female

D-sub 9-pin

female

D-sub 9-pin

female

D-sub 9-pin

female

Cable 1

CS1W-CN226/626

(length: 2 m/6 m)

CQM1-CIF02

(length: 3.3 m)

XW2Z-200S-CV

/500S-CV

(length: 2 m/5 m)

XW2Z-200S-V

/500S-V

(length: 2 m/5 m)

XW2Z-200S-CV

/500S-CV

(length: 2 m/5 m)

XW2Z-200S-V

/500S-V

(length: 2 m/5 m)

CS/CJ

peripheral

C peripheral C peripheral CS1W-CN114

D-sub 9-pin

male

D-sub 9-pin

male

RS-232C

D-sub 9-pin

male

RS-232C

D-sub 9-pin

male

D-sub 9-pin

female

D-sub 9-pin

female

Cable 2

Not needed.

(length: 5 cm)

CS1W-CN118

(length: 0.1 m)

CS1W-CN118

(length: 0.1 m)

Not needed.

Not needed.

CS/CJ

peripheral

CS/CJ

peripheral

CS/CJ

peripheral

Port Serial

communications

CS/CJ

peripheral

RS-232C

D-sub 9-pin

female

mode

(network

type)

Peripheral

(Toolbus)

or Host Link

(SYSWAY)

Host Link

(SYSWAY)

Peripheral

(Toolbus)

or Host Link

(SYSWAY)

Host Link

(SYSWAY)

Peripheral

(Toolbus)

or Host Link

(SYSWAY)

Host Link

(SYSWAY)

1-17

Page 38

1-4 PLC Connecting Cables

1-4-1 Direct Serial Connections to a PLC

Connection diagrams are shown below.

Connecting to the Peripheral Port

-Using the CS1W-CN226/626 Connecting Cable

USB A-plug connector,

male

CS1W-CIF31

D-sub connector

(9-pin male)

D-sub connector

(9-pin female)

Recommended cable:

CS1W-CN226/6 26

-Using the CQM1-CIF02 Connecting Cable

●

●

CS/CJ peripheral connector

CS/CJ-series PLCs

Customizable Counter Units

Peripheral port

USB A-plug connector,

male

CS1W-CIF31

D-sub connector

(9-pin male)

D-sub connector

(9-pin female)

Recommended cable:

CQM1-CIF02

C peripheral connector

●

CS/CJ-series PLCs (See note.)

CS1W-CN114

CS/CJ peripheral connector

Peripheral p ort

Note: Only a Host Link connection is possible for CS/CJ-series PLCs.

1-18

Page 39

1-4 PLC Connecting Cables

1-4-1 Direct Serial Connections to a PLC

-Using the XW2Z-200S-CV/500S-CV or XW2Z-200S-V/500S-V Connecting Cable for

RS-232C

USB A-plug connector,

male

CS1W-CIF31

D-sub connector

(9-pin male)

CS/CJ peripheral

connector

Peripheral port

D-sub connector

(9-pin female)

XW2Z-200S-CV/500S-CV

XW2Z-200S-V/500S-V (See note.)

or

CS/CJ-series PLCs

D-sub connector (9-pin male)

D-sub connector

(9-pin female)

CS1W-CN118

Note: Only a Host Link connection is possible for CS/CJ-series PLCs.

-Using the XW2Z-200S-CV/500S-CV or XW2Z-200S-V/500S-V Connecting Cable for

RS-232C

USB A-plug connector,

male

CS1W-CIF31

D-sub connector

(9-pin male)

D-sub connector

(9-pin female)

CS/CJ-series PLCs

D-sub connector

(9-pin male)

RS-232C port

D-sub connector

(9-pin female)

Recommended cable:

XW2Z-200S-CV/500S-CV

or

XW2Z-200S-V/500S-V (See note.)

Note: Only a Host Link connection is possible for CS/CJ-series PLCs.

1-19

Page 40

1-4 PLC Connecting Cables

1-4-1 Direct Serial Connections to a PLC

Connecting Cables for CP1H-series PLCs

Connecting to USB Port in CPU Unit Using Commercially-available USB Cable

Unit Port at

Unit

CPU Unit USB port

(B

connector)

USB port

Commerciallyavailable USB

cable

Peripheral USB port

Computer Port at

computer

DOS/V USB port

(A

connector)

DOS/V computer

CP1H CPU Unit

Network type

Model Length Remarks

(serial

communications

mode)

USB Cable

for USB

1.1 or

2.0

Connecting by RS-232C Cable to the RS-232C Port in a Serial Communications

Option Board

Unit Unit port Computer Computer

CP1WCIF01

Serial

Option

Board

RS-232C

port, D-SUB

9-pin,

female

IBM

PC/AT or

compatible

port

D-SUB

9-pin, male

Network type

(serial

communications

mode)

Host Link

(SYSWAY)

Model Length Remarks

XW2Z200S-CV/

500S-CV

2 m/

5 m

5 m max.

Connect

or with

ESD

(electrostatic discharge)

counterm

easure

used.

---

1-20

Page 41

1-4 PLC Connecting Cables

1-4-2 Direct Connections to a Relay PLC via a Network

1-4-2 Direct Connections to a Relay PLC via a Network

When connecting the computer running the CX-Integrator directly to the relay PLC via a

network, make the connection correctly using the following connection diagrams.

Ethernet

CS/CJ-series

Ethernet Unit

Ethernet port

CS/CJ-series

relay PLC

Ethernet

DeviceNet network

Controller Link or SYSMAC LINK

PCI Controller Link Support Board

(See note.)

Controller Link

Note:

Optical ring with H-PCF cable 3G8F7-CLK12-V1

Optical ring with GI cable 3G8F7-CLK52-V1

Wired (twisted-pair cable)

Type Board Model

CS/CJ-series

Controller Link Unit

Controller Link PCI-bus

Support Board

CS/CJ-series

relay PLC

DeviceNet network

3G8F7-CLK21-V1

1-21

Page 42

1-5 Window Descriptions

1-5-1 Starting Methods

1-5 Window Descriptions

1-5-1 Starting Methods

The CX-Integrator can be started with any of the following three methods.

1) When using the CX-Programmer Ver. 6.0 or later, select Tools

2) When using the CX-Programmer that was installed from the CX-One, right-click a

Communication Unit in the CX-Programmer’s I/O table display and select Start Special

Application from the pop-up menu.

Note: If the Communication Unit is a Serial Communications Board/Unit, a Start Special Application

Dialog Box will be displayed. Select CX-Integrator in the dialog box to start the CX-Integrator.

3) Select CX-Integrator from the Start Menu.

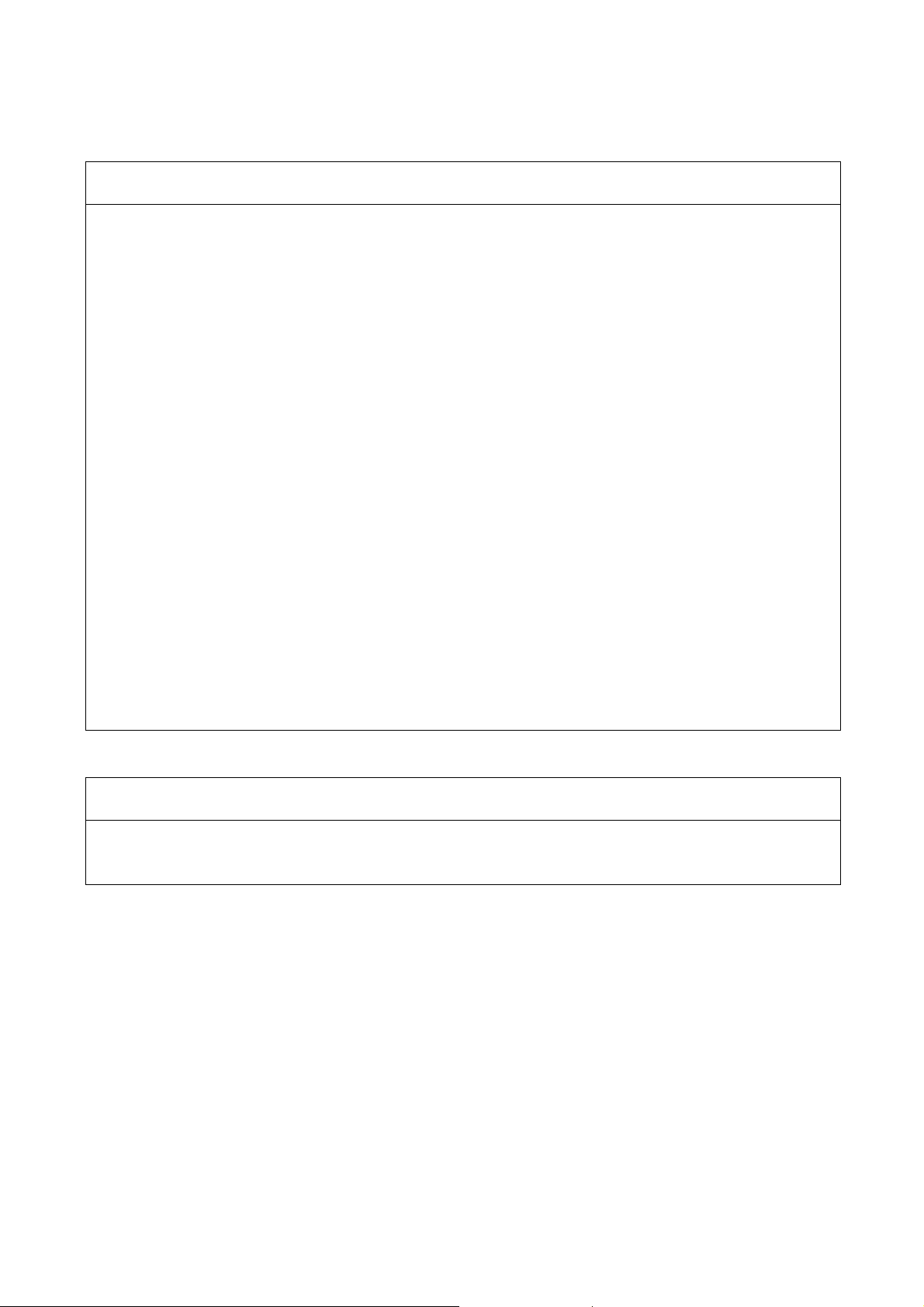

1-5-2 Main Window

One of the following windows will appear when the CX-Integrator is started.

Offline Window

−

Network Settings.

Workspace Window

Online Window

Workspace Window

Online Conn ection

Information Window

Network Configuration Window

Network Configuration Window

Output Wind ow

1-22

Page 43

1-5 Window Descriptions

=

1-5-2 Main Window

Note The following operations can be performed on the Workspace Window, Output

Window, Component List Window, and Outline Window.

Moving a Window and Displaying the Window Separately

Drag the window by its top border to move it.

Closing a Window

Click the X Button (Close Button) at the upper-right corner of the window.

Displaying a Window

−

Select the desired window from the View

next to the windows that are displayed.)

Windows Menu. (A check mark appears

Online Connection Information Window

The Online Connection Information Window displays the online/offline status and the Relay

PLC’s communications settings.

When online, the target PLC will be displayed in a tree structure with all of the

Communications Units and ports that belong to it.

Online Operation

The target PLC and Communication Units/ports mounted to the target PLC will be listed

below the relay PLC.

Relay PLC Communications Settings

The relay PLC’s communications settings will be displayed to the right of the Online icon

Online).

(

Relay PLC

Target PLC

Target PLC Information

The target PLC’s CPU Unit model, Net (network address), and Node (node address) will be

displayed to the right of the Target icon (

Display format: Target PLC [Target PLC’s CPU Unit model] Net (network address) Node (node address)

Description:

In brackets

[ ] to the right of

TargetPLC

Target PLC’s

CPU Unit model

[Target PLC’s CPU Unit

Target PLC’s CPU Unit

model

After Connecting Online

The target PLC is displayed in green.

model]

When the computer is directly

connected to a PLC, the same

PLC will be both the relay PLC

and the target PLC.

Target PLC).