Page 1

Cat. No. W309-E1-09

SYSMAC

CS1W-CLK21-V1

CJ1W-CLK21-V1

C200HW-CLK21

CVM1-CLK21

CQM1H-CLK21

(CS1W-RPT01/02/03 Repeater Units)

Controller Link Units

OPER ATION MANUAL

Page 2

CS1W-CLK21-V1

CJ1W-CLK21-V1

C200HW-CLK21

CVM1-CLK21

CQM1H-CLK21

(CS1W-RPT01/02/03 Repeater Units)

Controller Link Units

Operation Manual

Revised January 2006

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use accordin g to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to ind icate and classify pr ecautions in this manual . Always heed

the information provided with them . Failure to heed precautions can result in in jur y to people or damage to property.

!DANGER Indicates an immine ntly hazardous situation whi ch, if not avoided, will result in death or

serious injury. Additionally , there may be severe property damage.

!WARNING Indicates a potentially hazardous situatio n which, if not avoided, could resu lt in death or

serious injury. Additionally , there may be severe property damage.

!Caution Indicates a potentially ha zardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which ap pears in some displays and on some OMRON produ cts, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means P rogrammable Controller. “PC” is used, however, in som e Programming Device displays to mean Programmable Controller.

Vi sual Aids

The following headings appear in the left co lumn of the manual to help you locate different types of

information.

OMRON, 1997

All rights reserved. No part of this publicatio n may b e repro d uced, sto red in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of pa rticular interest for efficient and convenient opera-

tion of the product.

1,2,3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

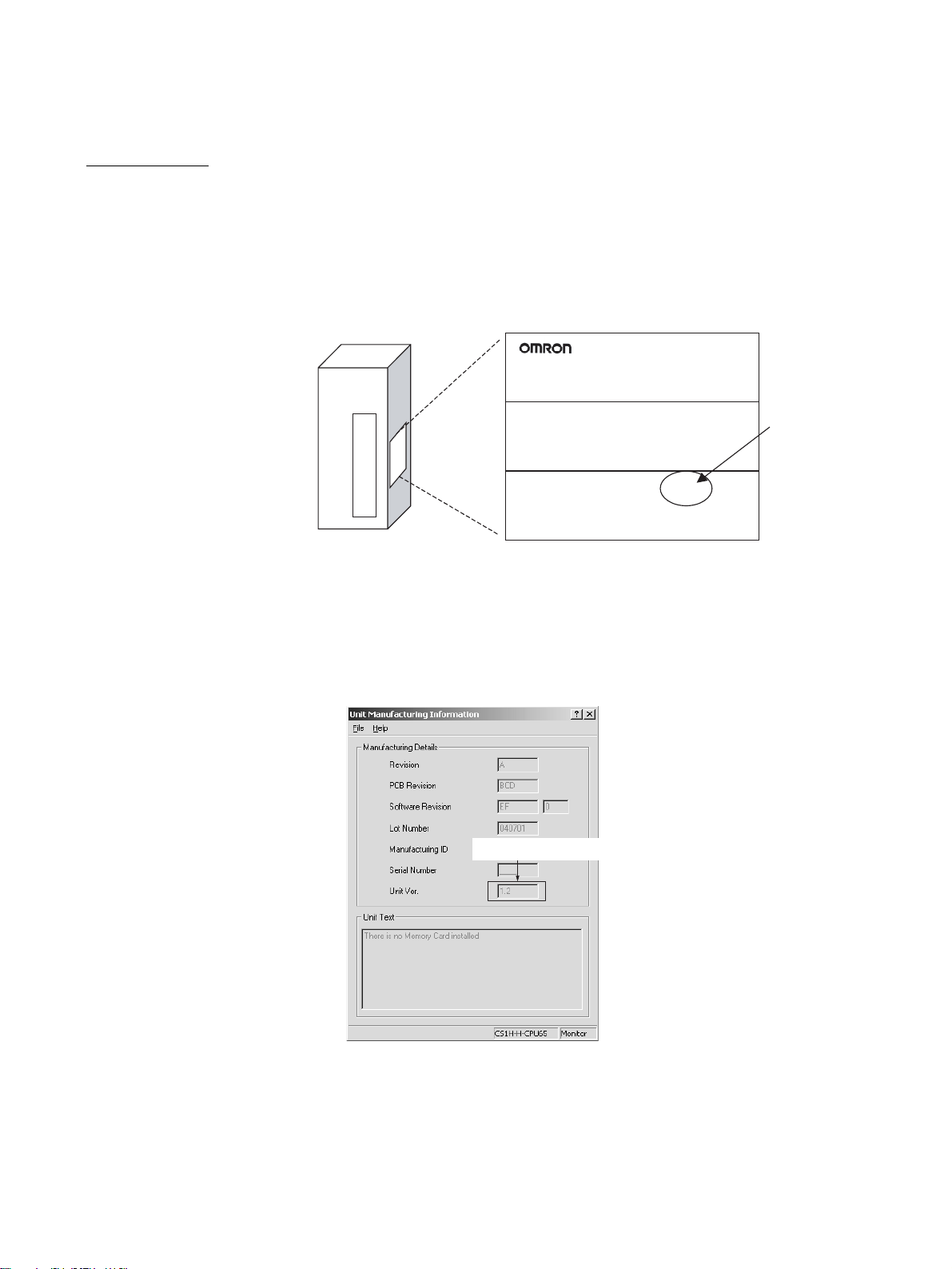

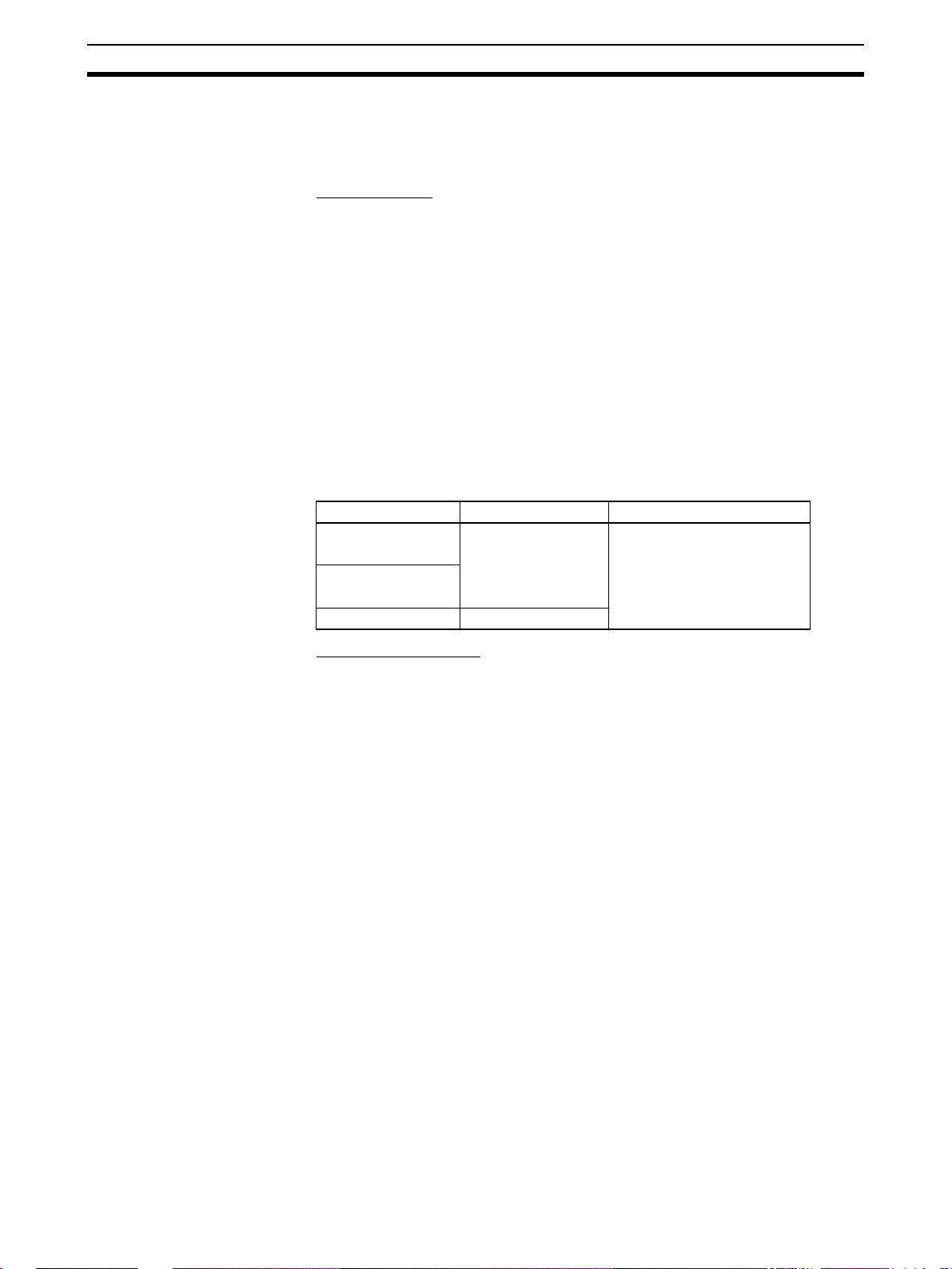

Unit Versions of CS/CJ-series Controller Link Units

2

Unit Versions

A “unit version” has been introduced to manage CS/CJ-series Controller Link Units according to differences in functionality accompanying upgrades.

Unit Version Notation on Products

The unit version code is provided on the nameplate of the CS/CJ-series Controller Link Units for which

unit versions are being managed . This syste m applies to Controller Link Units wi th unit version 1. 2 or

later.

Example: CS1W-CLK21-V1

CS-series Controller Link Unit

Confirming Unit Versions with Support Software

CX-Programmer version 5.0 or higher can be used to confirm the unit version in the Unit Manufacturing

Information.

Nameplate

CS1W-CLK21-V1

CONTROLLER LINK UNIT

Lot No. 040901 0000 Ver.1.2

OMRON Corporation MADE IN JAPAN

Unit version 1.

1,2,3... 1. 1. In the I/O Table Window, right-click on the Controller Link Unit, and then

select Unit Manufacturing Information.

2. The following Unit Manufacturing Information Dialog Box will be displayed.

Indicates the unit version.

Example: In this Uni t Manufacturing Information D ialog Box, unit version

1.2 is displayed. Use this dialog box to confirm the unit version of the Controller Link Unit that is connected online.

vi

Page 6

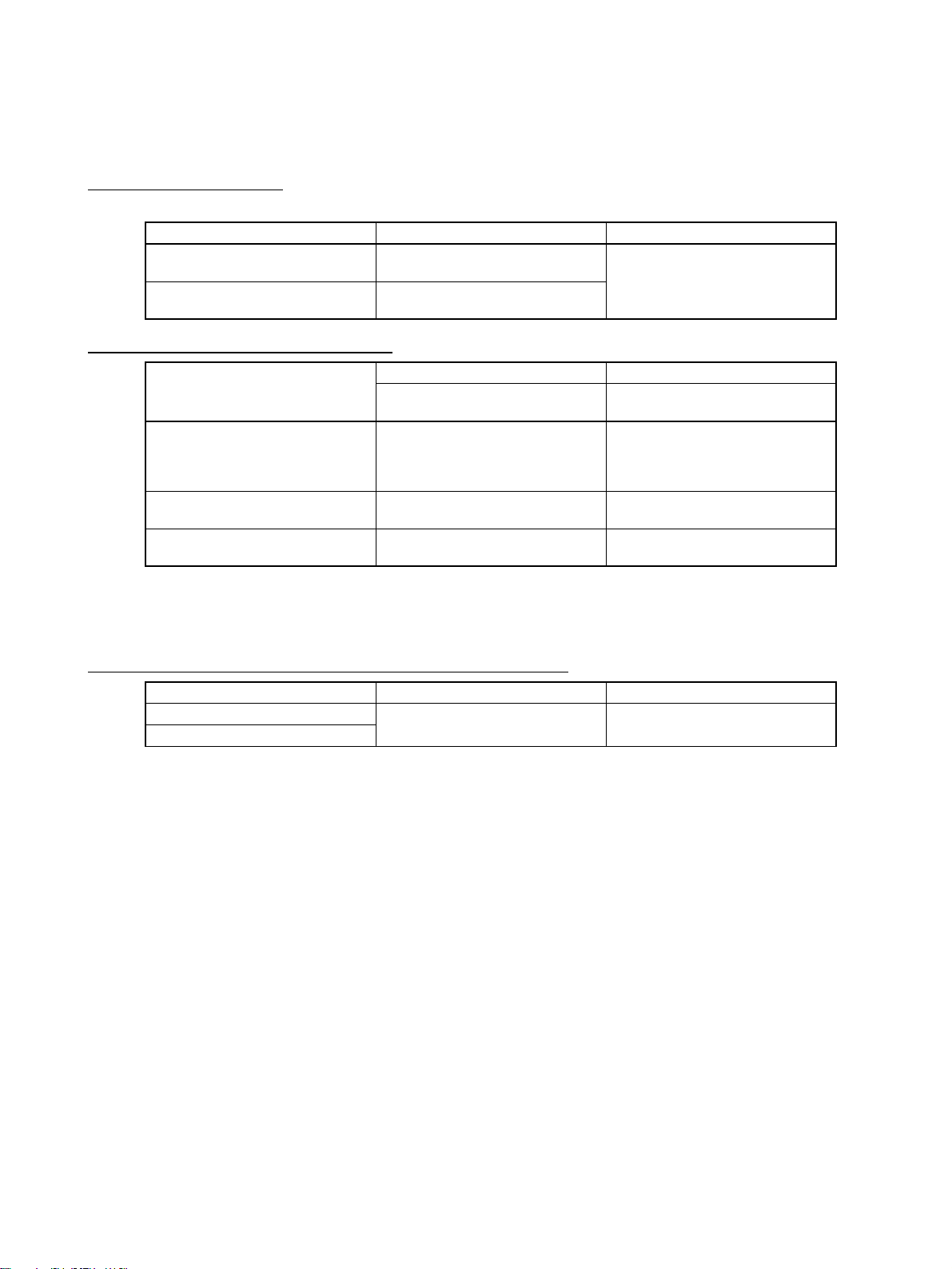

Using the Unit Version Labels

Unit version labels are provided with the product. These labels can be attached to the front of previous

Controller Link Units to differentiate between Controller Link Units of different unit versions.

Unit Version Notation

The unit versions are indicated in this manual as follows:

Notation in product nameplate Notation in this manual Remarks

V e r.1.2 or later after the lot numb er CS/CJ-series Controller Link Units

Blank after the lot number Pre-Ver. 1.2 CS/CJ-series Control-

Function Support by Unit Version

Functions Earlier version (Pre-Ver. 1.2) Unit version 1.2

Maximum number of data link

words (data link area for sending/

receiving that is created for a single node in a single CPU Unit)

Data Link Area The same area cannot be allo-

Maximum number of Un its connected to a single CPU Unit

Information for which no particular

with unit version 1.2 or later

ler Link Units

CS1W-CLK21-V1

CJ1W-CLK21-V1

12,000 max. 20,000 max.

cated for both Area 1 and Area 2.

4 Units 8 Units

version is specified applies to all

unit versions .

CS1W-CLK21-V1

CJ1W-CLK21-V1

The same area can be allocated

for both Area 1 and Area 2.

Note Use the CX-Net in CX-Programmer version 5.0 or later to set a data link area

in which the number of se nd and receive words exceeds 12,000 words, or to

set data link tables that allocate the same area for Area 1 and Area 2.

Unit Versions and Manufacturing Dates/Lot Numbers

Model Until August 2004 From September 2004

CS1W-CLK21-V1 Pre-Ver. 1.2 Unit version 1.2

CJ1W-CLK21-V1

(Lot No. 040901 and later)

vii

Page 7

viii

Page 8

TABLE OF CONTENTS

PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

5 Applications Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Specifications and Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3 Selection of Communications Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-4 Basic Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SECTION 2

Basic Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-1 Data Links Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-2 Message Service Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-1 Component Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-2 Unit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3-4 Constructing Networks with Repeater Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

SECTION 4

Preparations for Communications . . . . . . . . . . . . . . . . . . . . 85

4-1 CS-series Controller Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4-2 CJ-series Controller Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

4-3 C200HX/HG/HE Controller Link Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4-4 CVM1 and CV-series Controller Link Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4-5 CQM1H-series Controller Link Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4-6 Repeater Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

ix

Page 9

TABLE OF CONTENTS

SECTION 5

Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5-1 What Are Data Links?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5-2 Setting Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5-3 Starting and Stopping Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

5-4 Checking Data Link Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

SECTION 6

Message Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

6-2 Selecting Communications Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

6-3 Using the Message Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

6-4 FINS Commands and Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

6-5 Commands and Responses for Controller Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

6-6 Commands and Responses for C200HX/HG/HE and CQM1H-series PLCs . . . . . . . . . . . . 212

6-7 Response Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

SECTION 7

Network Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

7-1 What is Network Interconnection? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

7-2 Remote Programming and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

7-3 Routing Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

7-4 Setting Routing Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

SECTION 8

Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

8-1 Communications Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

8-2 Communications Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

8-3 Data Link I/O Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

8-4 Message Delay Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

SECTION 9

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 275

9-1 Troubleshooting Us ing Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

9-2 Status Area and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

9-3 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

9-4 Troubleshooting Error Messages in CX-Net Data Link Table Check. . . . . . . . . . . . . . . . . . 320

9-5 Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

9-6 Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

x

Page 10

TABLE OF CONTENTS

SECTION 10

Adding Nodes and Editing Active Data Link Tables . . . . . 331

10-1 Adding Nodes Using a Repeater Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

10-2 Changing the Data Link Tables with Active Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Appendices

A Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

B Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

C Using the Relay Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

xi

Page 11

TABLE OF CONTENTS

xii

Page 12

About this Manual:

This manual descr ibes the installation, setu p, and operation of the C200HW-CLK21, CS1W-CLK21V1, CJ1W-CLK21-V1, CVM1-CLK21, and CQM1 H-CLK21 Controller Link Units for C200HX/HG/HE,

CS/CJ-series, CVM1, CQM1H-series, and CV-series PLCs, and includes the sections described

below. The Controller Link Units are used to connect these PLCs to a Contr oller Link Network. Information is also provided in thi s manual on CS1W- RPT01/02/03 Repeater Units. The following three

manuals are directly related to application of the Controller Link Network.

Name Contents Cat. No.

SYSMAC CS1W-CLK21, CJ1W-CLK21,

C200HW-CLK21, CVM1-CLK21.

CQM1H-CLK21 Controller Link Units

Operation Manual (this manual)

3G8F7-CLK12-E-V1/CLK52-E-V1/

CLK21-E-V1 Controller Link Support

Boards for PCI Bus

Operation Manual

3G8F7-CLK12-E/CLK52-E/CLK21-E Controller Link Support Boards for PCI Bus

Installation Guide

3G8F5-CLK11-E, 3G8F5-CLK21-E Controller Link Support Boards for ISA Bus

Operation Manual

CS1W-CLK12, CVM1-CLK12 Optical

Ring Controller Link Units

Operation Manual

C200HW-ZW3AT2-E-V2 Controller Link

Support Software

Operation Manual

Installation, setup, and operating procedures for the Controller Link Units. Controller Link Units are used to connect

PLCs to a Controller Link Network.

Operating procedures for Controller Link Support Boards

for PCI bus connections. Controller Link Support Boards

are used to connect IBM PC/ATs or compatibles to a Controller Link Network.

Installation and setup procedures for Controller Link Support Boards for PCI bus connections. Controller Link Support Boards are used to connect IBM PC/ATs or

compatibles to a Controller Link Network.

Installation, setup, and operating procedures for Contr oller

Link Support Boards for ISA bus connections. Controller

Link Support Boards are used to connect IBM PC/ATs or

compatibles to a Controller Link Network.

Installation, setup, and operating procedures for the Optical

Ring Controller Link Units. Controller Link Units are used to

connect C200HX/HG/HE CV-series, and CS-series PLCs

to a Controller Link Network.

Installation and operating procedures for the Controller

Link Support Software. The Controller Link Support Software enables manually set data links and other procedures

for a Controller Link Network.

(suffixes omitted)

W309

W383

W388

W307

W370

W369

Depending on the system, you may also need the CX -Pr ogrammer, or a Programming Console. Refer

to the body of this ma nual for details. Please read t his manual and rel ated manuals carefu lly and be

sure you understand the information provided before attempting to install and operate a Controller Link

Unit.

Precautions provides general precautions for using the Controller Link Unit and related devices.

Section 1 provides basic information on Controller Link Networks, and will give the reader an overview

of what Controller Link Networks can do and how best to use them.

Section 2 describes the basic procedures to use the Controller Link Unit. The settings necessary for

using each of the functions are also explained briefly. Fo r more details, refer to the following sections

on individual functions.

Section 3 describes how to inst all a Co ntrolle r Link Un it and h ow to wire th e Contr oller Li nk Networ k.

Details are also provided on installation, wiring, and basic ope rating procedures of Repeater Units,

including information on using them to construct networks.

Section 4 describes the settings required for starting communications. These basic settings are

required for both data links function and the message ser vice. Carr y out the s ettings descri bed here

before turning on power to the Controller Link Unit.

Section 5 describes how to use data l inks in a Controller Link Networ k. Refer to SECTION 2 Basic

Procedures for an outline of data link application.

Section 6 explains how to use the message service provided by a Controller Link Unit. It also explains

the FINS commands and responses supported by Controller Link Units and those supported by

C200HX/HG/HE, CVM1, and CV-series PLCs.

xiii

Page 13

Section 7 describes the method used to connect multiple networks through CS/CJ-series, CVM1, and

CV-ser ies PLCs. The sec tion also descri bes remote programmi ng and monitorin g with Programming

Devices.

Section 8 explains details on Controller Link Network communicati ons. Refer to this section for network communications that require accurate communications timing.

Section 9 provides information on tr oubleshoot ing er rors tha t occu r dur ing Cont roller Link Un it operation, as well as daily inspection, cleaning, and other maintenance procedures.

Section 10 provides information on functions that can be performed without tur ning OFF the PLC

power to the existing network, such as adding node s to the Contro ller Link Net work using a Repeater

Unit and changing data link tables while the data links are active.

Appendix A provides a list of standard O MRON products rel ated to Controller Link Networks.

Appendix B provides easy reference to the words i n P LC mem ory areas used by Controller Link Net-

works.

Appendix C provides information on how to use th e CJ1W-TB101 Wired Controller Link Unit Relay

Terminal Block, including details on connection and replacement.

!WARNING Failure to read and unders tand the in formation pr ovided in th is manual may

result in per sonal injur y or d eath, damage to the product, or p roduct failure.

Please read each section in its entirety and be sure you understand the information provided in the s ection a nd rel ated s ectio ns before attempti ng any of

the procedures or operations given.

xiv

Page 14

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xv

Page 15

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xvi

Page 16

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xvii

Page 17

xviii

Page 18

PRECAUTIONS

This section provides general precautions for using the Controller Link Unit and related devices.

The information contained in this section is important for the safe and reliable application of the Controller Link

Unit. You must read this section and understand the information contained before attempting to set up or op erate

a Controll er Link Un it.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

5 Applications Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

xix

Page 19

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate t he product according to t he performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the produ ct to nuclear control s ystems, railroad systems,

aviation systems, vehicles, combustion systems, me dical equipmen t, amusement machines, safety equipment, and oth er systems, machines, and equi pment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performan ce charact er is ti cs of the pr od uc t are

sufficient for the systems, machi nes, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON

PLCs and related devices. Be sure to read this manual before attempting to

use the software and keep this manual close at hand for reference during

operation.

!WARNING It is extremely impor tant that a PLC and al l PLC Units b e used for the spec i-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the ab ove mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the te r minals o r ter minal blocks while the power is bein g

supplied. Doing so may result in electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), includin g the following items, to ensure safety in the system if an

abnormality occurs due to malfunc tion of the PLC or anoth er external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnorm al signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Emergency sto p cir cuits, inter lock circui ts, limit circu its, and sim ilar safety

measures must be provided in external control circuits.

xx

Page 20

Operating Environment Precautions 4

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a counterme asure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs m ay remain ON or OFF due to depos ition or bur ning of

the output relays or destr uction of the output transistors. As a cou ntermeasure for such problems, extern al safety measures must be provide d

to ensure safety in the system.

• When the 24-VDC output (service power supply to the PLC) is overloaded

or short- circuited, the voltage may drop and result in the outputs b eing

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Other wise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing c ontents of the I/O memory ar ea. Doing either of

these without confirming safety may result in injury.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and su fficient counterm easures when installing sys tems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the P LC Syste m can h ave a large effect on the

longevity and reliability of the sy stem. Improper operating environme nts can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the op erating environment is within the sp ecified cond itions at installation and remai ns within the specifi ed conditions dur ing the life

of the system.

xxi

Page 21

Applications Precautions 5

5 Applications Precautions

Observe the following precautions when using the Controller Link Unit.

!WARNING Failure to abide by the following precautions c ould lead to ser ious or pos sibly

fatal injury. Always heed these precautions.

• Always ground the system to 100

protect against electrical shock.

• Always turn OFF the power supply or the backup power supply to the PLC

or the computer before attemptin g any of the following. Performing any of

the following with the power supply turned ON may lead to electrical

shock:

• Installing or removing the Controller Link Unit.

• Assembling the Units.

• Setting DIP or rotary switches.

• Connecting or disconnecting any cables or wiring.

• Connecting or disconnecting any terminal block.

!Caution Failure to abide by the fol lowing precautions could le ad to faulty operation or

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropr iate measures to ensure that the spec ified power with the

rated voltage and frequency is supplied. Be partic ularly car eful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures agai nst short-circuiting may result in burning.

• Separate the line ground termi nal (LG) from the functional ground te rminal (GR) on the Power Supply Unit before performing withstand voltage

tests or insulation resistance tests. Not doing so may result in burning.

• Do not attempt to disassemble, repair, or modify any Units. Any attempt to

do so may result in malfunction, fire, or electric shock.

• Install the Uni ts prope rly as s pecified in the op eration manuals. Imp roper

installation of the Units may result in malfunction.

• Be sure that al l the mou nti ng s c rews, ter m ina l s crews, and c able co nne ctor screws are tightene d to the torque s pecified in the r elevant manuals.

Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the U nit .

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

Ω or less when installi ng the system to

xxii

Page 22

Applications Precautions 5

• Double-check all wir ing and switch settings before turning ON th e power

supply. Inco rre ct wir ing may result in bur ni ng.

• Wire all connections correctly.

• Mount Units only after checking terminal blocks completely.

• Be sure that the Bus Connection Units and other items with locking

devices are properly locked into place. Improper locking may result in

malfunction.

• Use special packing box when tran sporting the Contr oller Link Uni t. Handle the product carefully so that no excessive vibration or impact is

applied to the product during transportation.

• Check the user program for proper execution before actually r unn ing it o n

the Unit. Not checking the program may result in an unexpected operation.

• Confirm th at no adverse effect will occur in the system before attemp ting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC. (including the setting of the

startup operating mode)

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Inappropriate settings in data link tables or routing tables can cause unexpected system operation. Always check table settings before starting

operation, and always test the settings in tr ial op eration be fore star tin g or

stopping the data links in actual operation.

• CPU Bus Units will be automatically restarted when routing tables are

transferred from a Programming Device to the CPU Unit. Resetting is

required to use the new tables. Confirm that restarting the CPU Bus Units

will not adversely affect system operation before transferring routing

tables.

• Observe the following precautions when wiring the communications

cables.

• Separate the cables from the power lines or high-tension lines.

• Do not bend the cables.

• Do not pull on the cables.

• Do not place heavy objects on top of the cables.

• Route cables inside conduits.

• Before touching the Un it, be su re to fir s t to uch a grounded metallic objec t

in order to discharge any static build-up.

xxiii

Page 23

Conformance to EC Directives 6

6 Conformance to EC Directives

The Controller L ink Units conform t o EMC and Low Voltage Directives as follows:

EMC Directives

OMRON devices that comply with EC Directives also conform to the r elated

EMC standards so tha t they can be more eas il y built i nto ot her d evices or th e

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the s ystem used by the custo mer, however, must be che cked by

the customer.

EMC-related perfor ma nce o f th e O M RON devices that c omp ly wi th EC Di re ctives will vary depending on the configuration, wi ring, an d other conditio ns of

the equipment or control panel on which the OMRON devices are installed .

The customer must, therefore, perform the fi nal c heck to confir m th at devices

and the overall machine conform to EMC standards.

Note Applicable EMS (Elec tro-Magnetic Susceptib ility) and EMI (Electr o-Magnetic

Interference) standards in the EMC (Electro-Magnetic Compatibility) standards are as follows:

EMS EMI

CQM1H-CLK21

C200HW-CLK21

CVM1-CLK21

CS1W-CLK21(-V1)

CJ1W-CLK21(-V1) EN61000-6-2

EN61131-2 EN61000-6-4

1,2,3...

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75

to 1,500 VDC meet the required safety standards for the PLC (EN61131-2).

The Controller Link Units that comply with EC Directives (CVM1-CLK21,

C200HW-CLK21, CS1W-CLK21(-V1), CJ1W-CLK21(-V1), and CQM1HCLK21) must be installed as follows:

1. The Controller Link Units are desig ned for ins tallation inside control panels. All Controller Link Units must be installed within control panels.

2. Use reinforced insu lation or double insulati on for the DC power supplies

used for the communications power supply and I/O power supplies.

3. The Controller Link Units that compl y with EC Direc tives also c onform to

the Common Emission Standard (EN61000-6-4). Radiated emission characteristics (10-m r eg ula tio ns ) may v ar y depending on the con f ig urati on o f

the control panel used, o ther d evices conne cted to the c ontrol panel , wiring, and other cond iti ons . You must therefore confirm t hat the overall machine or equipment complies with EC Directives.

xxiv

Page 24

SECTION 1

Features and System Configuration

This section provides basic information on Controller Link Networks, and will give the reader an overview of what

Controller Link Networks can do and how best to use them.

1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 What Is the Controller Link? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-2 Specifications and Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-2-1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-2-2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-2-3 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-2-4 Controller Link Unit Models and PLCs . . . . . . . . . . . . . . . . . . . . . . 16

1-2-5 Devices for Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-2-6 Programming Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-3 Selection of Communications Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-4 Basic Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1

Page 25

Overview Section 1-1

pp

1-1 Overview

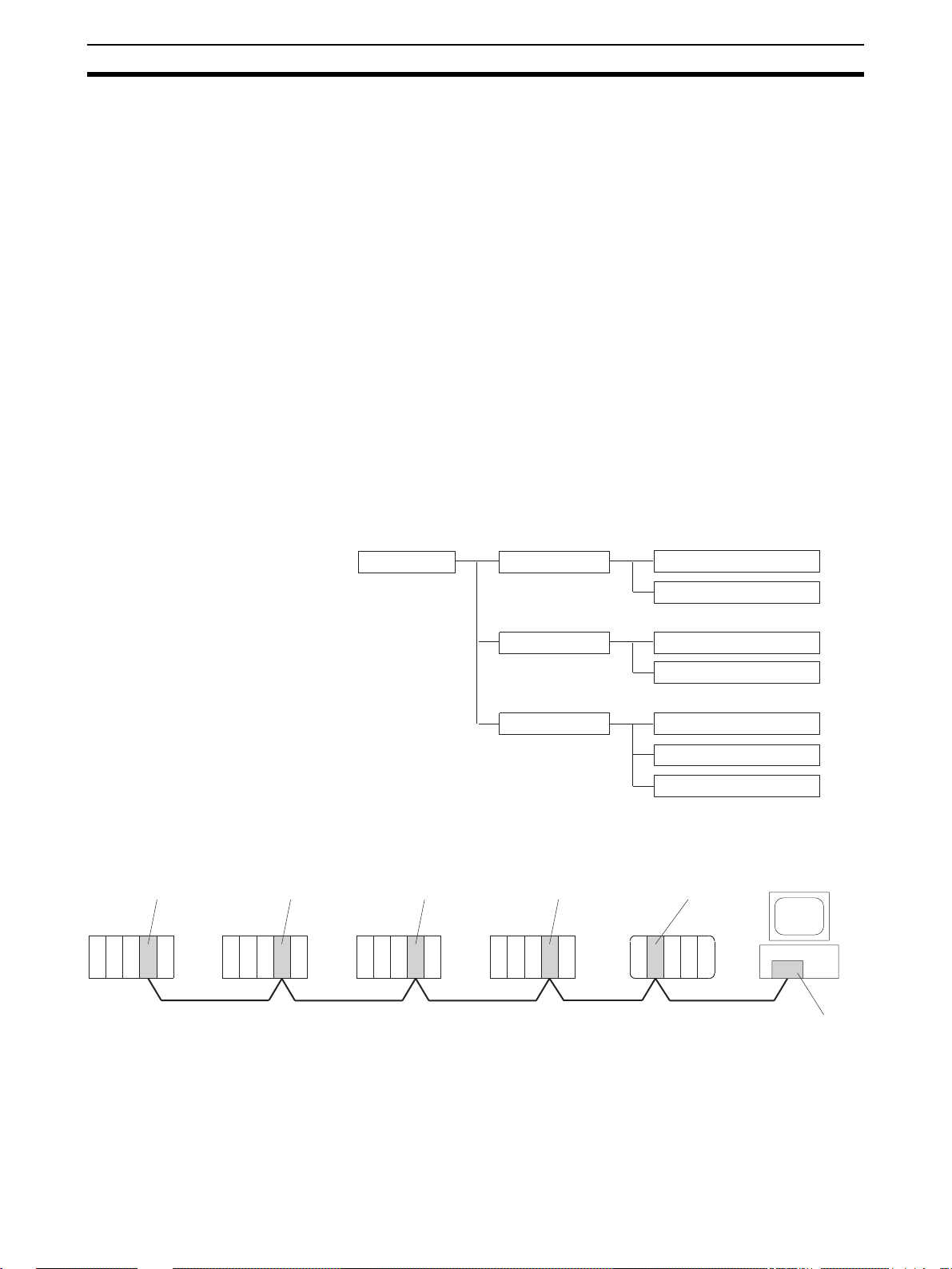

1-1-1 What Is the Controller Link?

The Controller Link is a n FA network that can se nd and receive large data

packets flexibly and easily among the OMRON C 200HX/H G/HE Programmable Controllers (PLCs), CS-series PLCs, CJ-ser ies PLCs, CVM1 PLCs, CVseries PLCs, CQM1H-series PLCs, and IBM PC/AT or compatible computers.

The Controller Link suppo rts data links that enable data shar ing and a message service that enables sending and receiving data when required. Data

link areas can be freely set to create a flexible data link system and effectively

use data areas.

High-volume data transmissions are possible at high speed and so a wide

range of networks, from low-level systems to high, can be easily created.

There are two types of networks: networ ks connected with shielded twist edpair cable and networks con nected with optical fiber c able. Using a Repeater

Unit in networks co nnected with t wisted-pair cable makes it possible to use a

variety of different wiring configurations, such as T-branch wiring, long-distance wiring, and partial conversion to optical fiber. (Refer to the CS1W-

CLK12, CVM1-CLK12 Optical Ring Controller Link Units Operation Manual

(W370) for detail on optical fiber connections.)

The functions of a Controller Link Network are illustrated below.

Wired System

(Twisted-pair Cable)

CS1W-CLK21-V1

Controller Link Unit

CS-series

PLC

C

P

U

CJ-series PLC

CS-series, CJ-series, C200HX/HG/HE, CVM1, CV -series, and CQM1H-series

PLCs

CJ1W-CLK21-V1

Controller Link Unit

C

P

U

Controller Link

C200HW-CLK21

Controller Link Unit

C200HX/HG/HE

PLC

Data link

Message service

RAS functions Status area function

CVM1-CLK21

Controller Link Unit

CVM1, CV-series

PLC

C

P

U

Twisted-pair cable

CQM1H-series

PLC

C

P

U

Manual settings

Automatic settings

SEND/RECV instructions

CMND instruction

Error log function

Polling node backup

CQM1H-CLK21

Controller Link Unit

C

P

U

IBM PC/AT or

compatible

3G8F7-CLK21-E-V1

Controller Link

ort Board

Su

2

Page 26

Overview Section 1-1

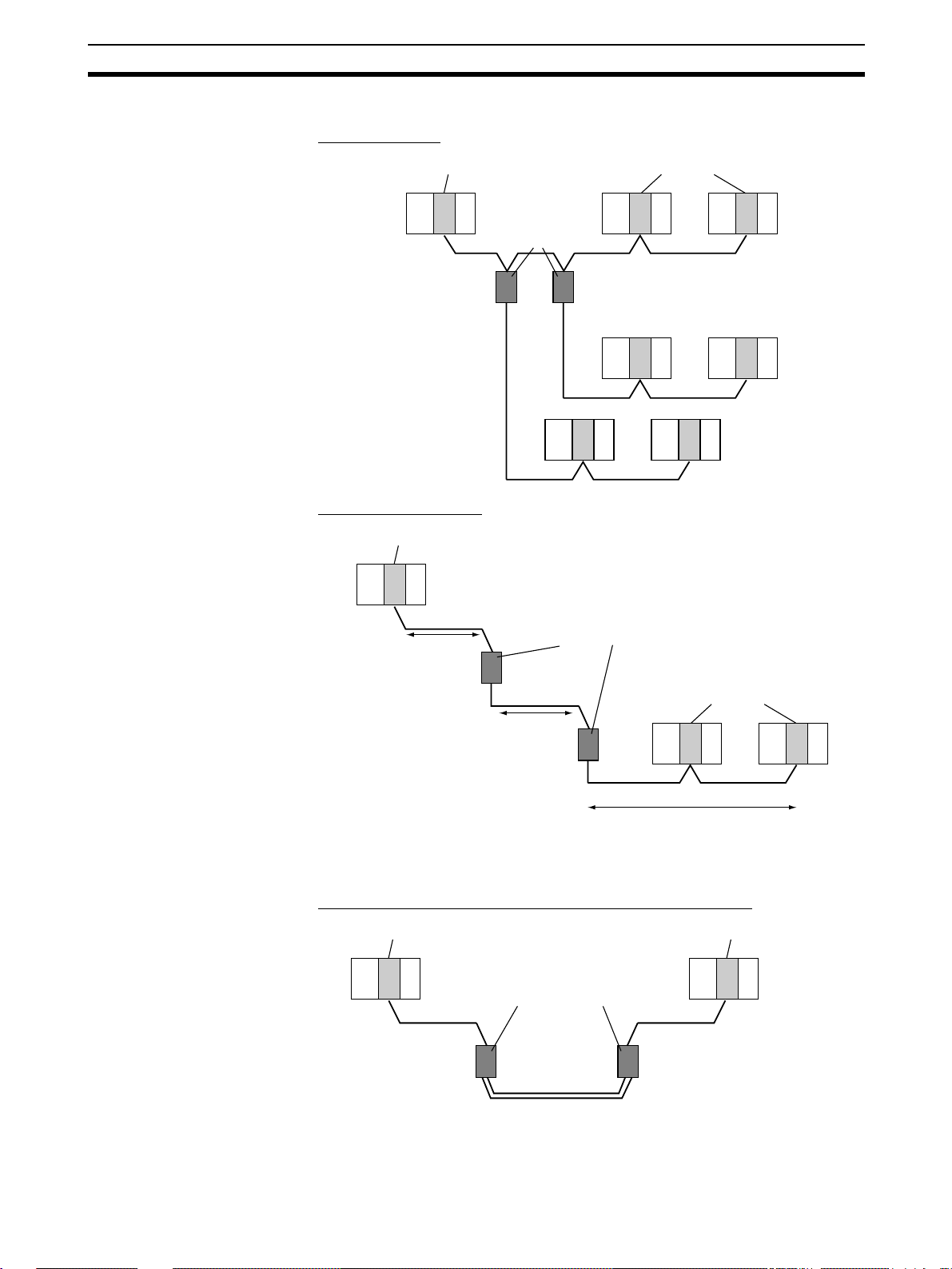

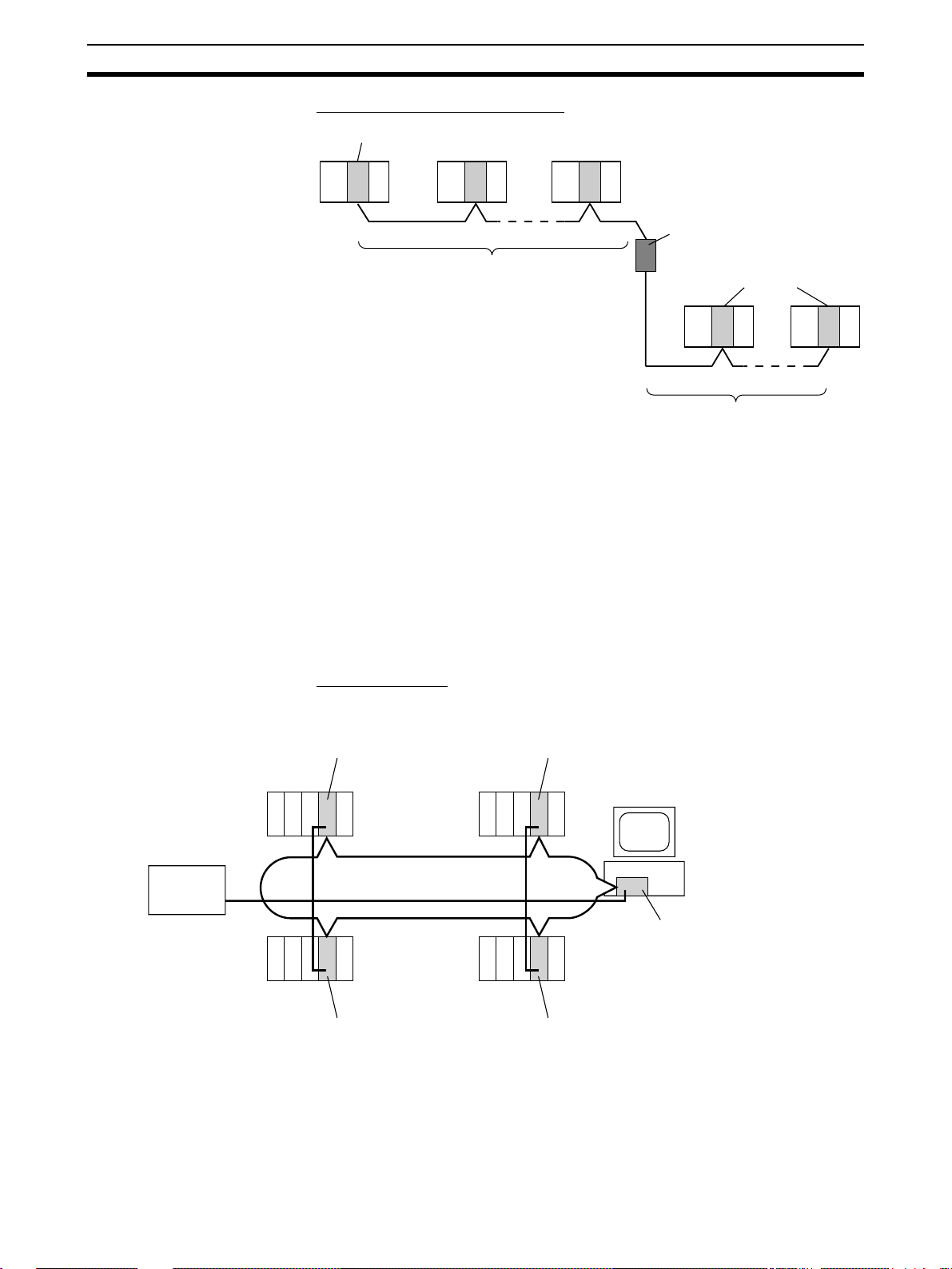

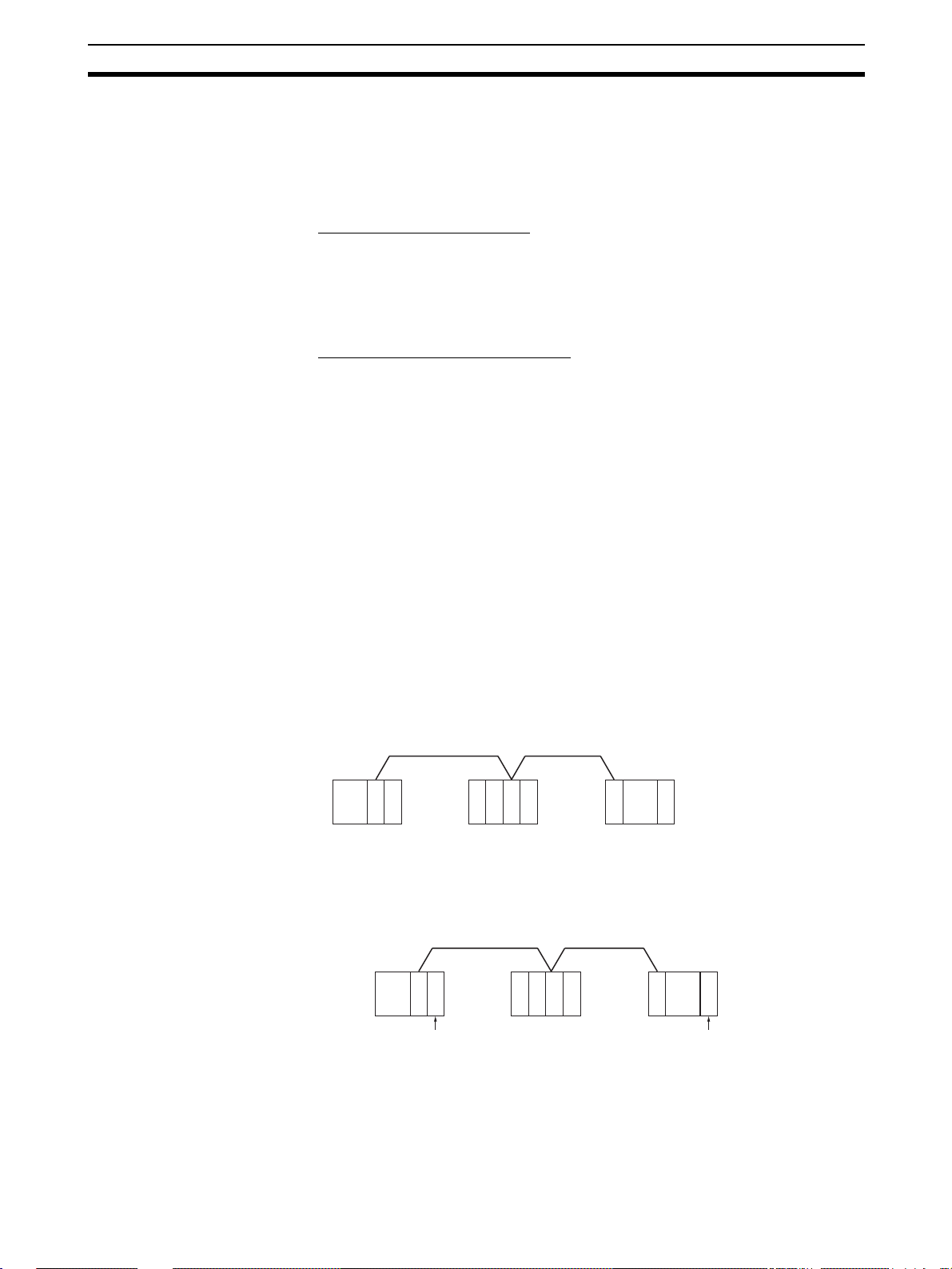

Connecting Repeater Units Using Twisted-pair Cable (Wired Units)

T-Branch Wiring

Wired Controller Link Unit Wired Controller Link Unit

CS1W-RPT01

Repeater Units

Twisted-pair cable

Twisted-pair cable

Long-distance Wiring

Wired Controller Link Unit

Twisted-pair cable

500 m max.

(See note.)

CS1W-RPT01

Repeater Units

Twisted-pair

cable

500 m max.

(See note.)

Wired Controller Link Unit

Twisted-pair cable

500 m max. (See note.)

Note: At 2 Mbit/s

Converting Part of the Transmission Line to Optical Fiber

Wired Controller Link Unit Wired Controller Link Unit

CS1W-RPT02 or

CS1W-RPT03

Repeater Units

Twisted-pair cableTwisted-pair cable

Optical cable (H-PCF or GI)

Two Repeater Units of the sam e model must be used whe n par t of the tran smission line uses optical fiber.

3

Page 27

Overview Section 1-1

Maximum 62-node Configuration

Wired Controller Link Unit

Note 1. The networ k wil l n ot o perate c or rectl y unl es s all no des wi thi n the ne twor k

Connecting Repeater

Units Using H-PCF Optical

Fiber Cable

Twisted-pair cable

31 nodes max.

CS1W-RPT01

Repeater Unit

Wired Controller Link Unit

Twisted-pair cable

31 nodes max.

The following Controller Link Units/S uppo rt Boards must b e us ed t o co ns truct

a network with more than 32 nodes:

CS1W-CLK21-V1

CJ1W-CLK21-V1

3G8F7-CLK21-V1

use the above Units/Boards.

2. Only node addresses 1 through 32 can be used on networks for which 62

nodes have not been enabled.

CS-series and CVM1/CV-series PLCs only.

Token Ring Mode

Backup

power supply

(24 V DC)

CS1W-CLK12-V1

Controller Link Unit

(token ring mode)

C

P

U

H-PCF Optical fiber cable

(ring connection)

C

P

U

CS1W-CLK12-V1

Controller Link Unit

(token ring mode)

CVM1-CLK12

Controller Link Unit

(token ring mode)

CVM1/CV-series PLCCS-series PLC

CVM1/CV-series PLCCS-series PLC

CVM1-CLK12

Controller Link Unit

(token ring mode)

Personal computer

C

P

U

C

P

U

3G8F7-CLK12-V1

Controller Link Support Board

for PCI Bus (token ring mode)

4

Page 28

Overview Section 1-1

Toke n Bus Mode

Personal

CS1W-CLK12-V1

Controller Link Unit

(token bus mode)

CS1W-CLK11

Controller Link Unit

CS-series PLC CS-series PLC

C

P

U

CVM1/CV-series

PLC

C

P

U

CVM1-CLK12

Controller Link Unit

(token bus mode)

C

P

U

computer

PC/AT or

compatible

Personal computer

Backup

power supply

(24 V DC)

Connecting Repeater

Units Using GI Optical

Fiber Cable

Backup

power supply

(24 V DC)

H-PCF Optical

fiber cable

(daisy chain

connection)

CS-series and CVM1/CV-series PLCs only.

Token Ring Mode

CS1W-CLK52-V1

Controller Link Unit

(token ring mode)

CS-series PLC CVM1/CV-series PLC

C

C

P

P

U

U

GI Optical fiber cable

(ring connection)

C

P

U

CS-series PLC CVM1/CV-series PLC

CVM1-CLK52

Controller Link Unit

(token ring mode)

3G8F5-CLK11

Controller Link

Support Board for

ISA Bus

Personal computer

C

C

P

P

U

U

3G8F7-CLK52-V1

C

P

U

Controller Link

Support Board

for PCI Bus

(token ring mode)

3G8F7-CLK12-V1

Controller Link

Support Board

for PCI Bus

(token bus mode)

CS1W-CLK52-V1

Controller Link Unit

(token ring mode)

Toke n Bus Mode

CS1W-CLK52-V1

Controller Link Unit

(token bus mode)

CS-series PLC CS-series PLC

C

P

U

Backup

power supply

(24 V DC)

CS1W-CLK52-V1

Controller Link Unit

(token bus mode)

CVM1-CLK52

Controller Link Unit

(token ring mode)

CVM1-CLK52-V1

Controller Link Unit

(token bus mode)

CVM1/CV-series

PLC

C

P

U

GI Optical fiber cable

(daisy chain

connection)

Personal computer

C

P

U

3G8F7-CLK52-V1

Controller Link

Support Board

for PCI Bus

(token bus mode)

5

Page 29

Overview Section 1-1

ge (

g)

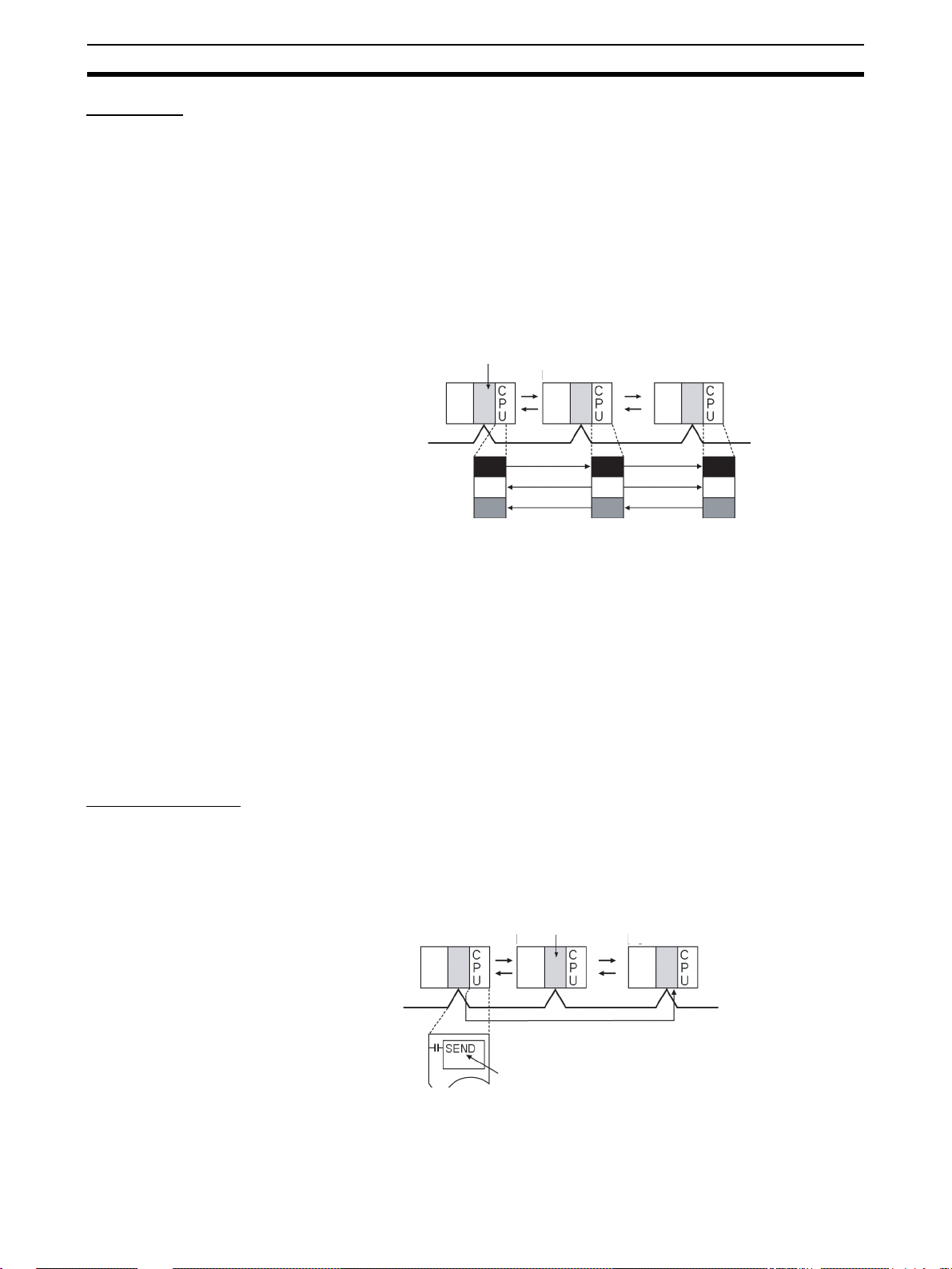

Data Links

Data links allow the constant sharing of data in predetermined data areas

between nodes, between PLCs, or between a PLC and an IBM PC/AT or compatible computer on the network. Dat a lin ks do not requ ir e the use of communications programs on the PLC (CPU Unit) or IBM PC/AT or compatible

computer. Data written in the send area of the local node will be automatically

sent to the receive area of other nodes.

The I/O area (CIO area), link area (LR area), DM Area area (DM area), an d

extended DM Area area (EM area) c an be freely set in the send or rece ive

area. (The area used for sending or receiving data using the data link function

is called “data link area.”)

The data link area can be set automatically or manually.

Controller Link Unit

PLC

Constant data exchan

PLC

PLC

sharin

Automatic Setting Used for simple data link processing. Data link can be performed by simply

setting parameters in the DM area of the PLC.

Send data size per n ode is the sa me for all nodes. All no des par ticipating i n

the data link share the same data.

Manual Setting Used for flexible data link processing depending on each system.

Using the Controll er L ink Su pport Software, indivi dual data link tables can be

set for each node and the data link area can be freely allocated for each node.

Send data size per node can be fre ely set. It is als o possible to set nod es for

only send or rece ive data. With the Controller Link Unit, the data link can be

set to receive only a part of the data link area of other nodes.

Message Service

This function controls data transmission with particular nodes, reading or writing of status data, c hangi ng of op eration mod es, etc., by executing communications instruc tions on a program. The communications instr uctions include

SEND/RECV instructions for data transmission and CMND instructions for

issuing various commands.

PLC

Controller Link Unit

PLC

PLC

Data transmission (under certain conditions)

as required

Communications instruction

User program

6

Page 30

Overview Section 1-1

k

SEND/RECV The SEND or RECV instruction sends or receives data in an area of a particu-

lar node.

The SEND instruction sends data from an area of the local node and writes to

an area in the designated node.

The RECV instructio n requests the designated node to send ar ea data and

writes the data to the local node.

CMND The CMND instruction issues a command to read or write data of other nodes,

control, or read erro r logs. With t he Control ler LInk Unit, O MRON’s command

protocol called “FINS commands” is used.

Note Since the C200HX/HG/HE PLCs do not s upport the CMND instr ucti ons, arbi-

trary commands cannot be issued.

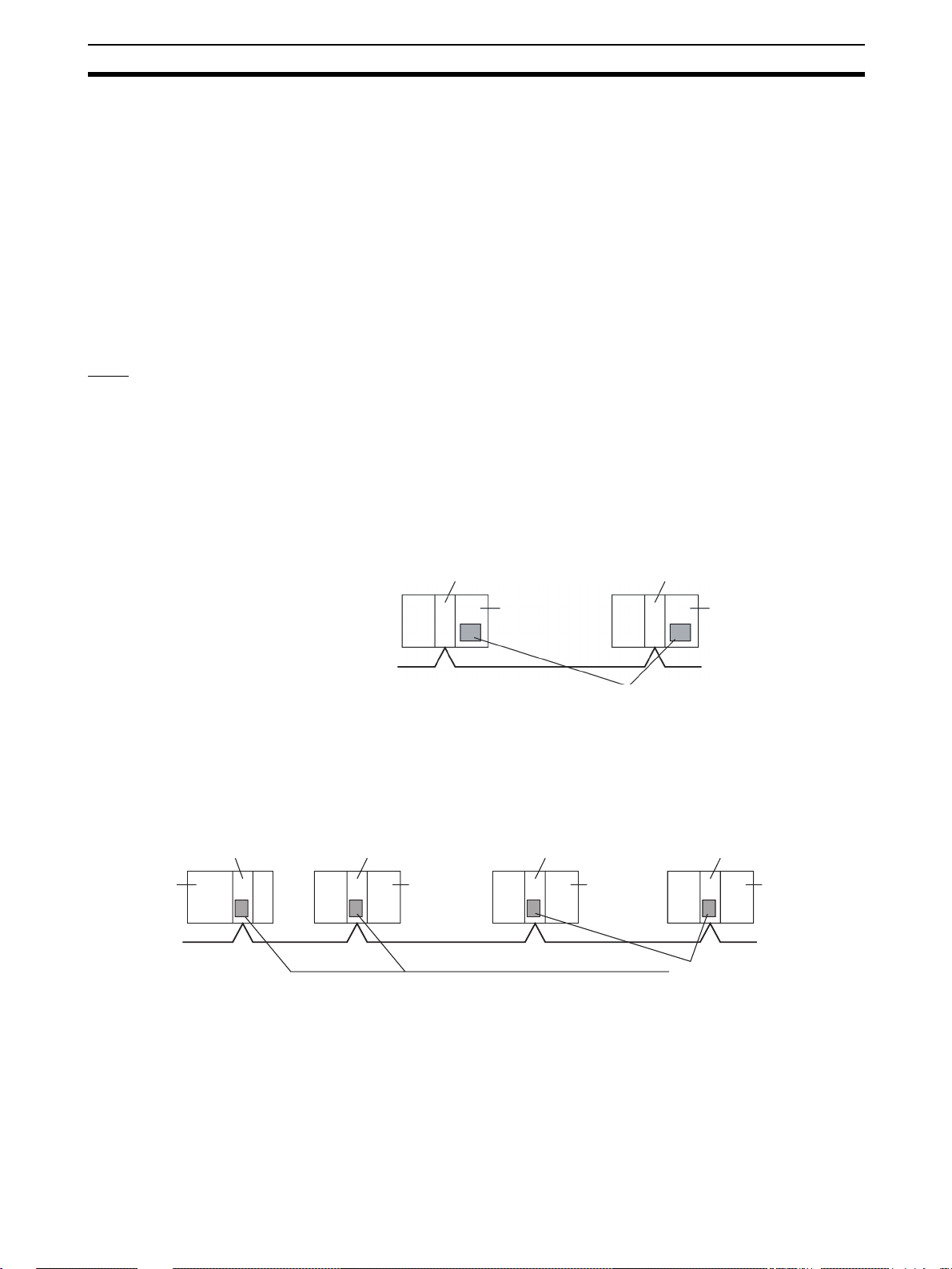

RAS

RAS performs real-time monitoring of the network status. If an er ro r oc cu rs i n

the network, RAS records and displays the time and contents of the error.

Status Area Data Link Status Area

When the data link function is used, the data link status is reflected in the data

link status area of the PLC.

Network Status Area Other than the Data Link:

The network sta tus such as the sta te of node par ticipati on is reflect ed in the

status area of the PLC.

Controller Link Unit

CPU Unit

Controller Link Unit

CPU Unit

Status Area

• Data link status

• Status other than the data lin

Error Log The error log function records co ntents (c odes ) and times of errors that occur

in the network into the RAM or EEPROM, up to the maximum of 39 errors.

The recorded errors ca n be read using the Controll er Link Suppor t Software

or the message service function.

Controller Link UnitController Link Unit Controller Link UnitController Link Unit

CJ-series

CPU Unit

CS-series

CPU Unit

C200HX/HG/

HE CPU Unit

Error log table

CVM1, CVseries CPU

Unit

7

Page 31

Overview Section 1-1

1-1-2 Features

The Controller Lin k Network has the following features to meet the vari ous

requirements of FA sites.

Data Links

Flexible and efficient data link s can be cr eated for large c apacitie s of data as

listed below.

Item Specifications

Number of send words

per node

Number of send and

receive words per node

Data links can be auto matically set, or th ey can be set by the user to free ly

change the sizes of th e data areas u sed. A data link can also be created so

that one node receives only part of the data sent from another node. This

function enables users to receive only the required data, thereby increasing

data link efficiency.

Data link tables for which the number of send and receive words exceeds

12,000 words can be set using CX-Net in CX-Programmer Ver. 5.0 or higher.

1,000 max.

C200HX/HE/HG, CVM1, CV-series, and CQM1H-series PLCs: 8,000 max.

CS/CJ-series PLCs:

Pre-Ver. 1.2: 12,000 words max.

Unit Ver. 1.2 or later: 20,000 words max.

IBM PC/AT or compatible: 32,000 max. (PCI or ISA Board)

Message Service

The message ser v ic e c an send and r ec ei ve up to 2,012 bytes of data ( incl uding the FINS head er), allowing hi gh volumes of data t o be sent an d received

without having to split it up.

Twisted-pair Cable or Optical Fiber Cable Connection

The Controller Link Units can be connected to the network using either

shielded twisted-pair cables or optical fiber cables. Select the system that

suits your application.

Features of Twisted-pair Cable

Twisted-pair cable is easy to connect and maintain. The cable can be processed much more easi ly than coaxial or optica l cable, thereby reducing the

cost of tools and assembly time.

Connections are made to a ter mi nal block on the Controller Lin k Unit and to a

special connector on the Controller Link Support Board for easy system

assembly and modification.

The network is equipped with the required terminating resistance built into the

Units allowing the ter minating res istance to be easily set at bo th ends of the

network using a simple switch.

Features of Optical Fiber Cable

Optical Fiber Cable has superior noise resi sta nc e, so this sys tem c an pr ovid e

highly reliable communications even in very noisy conditions.

The communications d istance can b e up to 20 km total (1 km max. be tween

nodes) if H-PCF cable is used and up to 30 km total (2 km max. between

nodes) if GI cable is used, which allows long-distance or large-scale networks.

Once the Optical Fiber Cable has been fitted with special connectors, the

cables can be easily connected or disconnected.

8

Page 32

Overview Section 1-1

Compatible with Different Node Configurations

The following Controller Link Units are available for communications between

different models. It must be noted, however, that the wired system and o ptic al

system cannot exist in one Controller Link Network.

Wired System

• Controller Link Unit for CS/CJ-series Programmable Controllers

• Controller Link Unit for C200HX/HG/HE Programmable Controllers

• Controller Link Unit for CVM1 and CV-series Programmable Controllers

• Controller Link Unit for CQM1H-series Programmable Controllers

• Controller Link Su pport Board for IBM PC/ATs or compatibles (ISA or

PCI bus)

Flexible Inter-network Connections

The Controller Lin k Network can connec t to other networks (Ethernet, SY SMAC NET, SYSMAC LINK, and another Controller Link networ k) via CVM1,

CV -series, CS-series, or CJ-series PLCs. By installing a Communications Unit

for the Ethernet, S Y SMAC NET or S YSMAC LINK on t he same CS/CJ-ser i es

or CV -series PLC as a Controller Link Unit, a message service can be created

with nodes in interconne cted networks through the CVM 1 or CV-ser ies PLC.

Up to eight network levels are possible.

Note CS/CJ-series PLC c annot be connected directly to SY SMAC NET networks

and CJ-series PLC cannot be connected directly to SYSMAC LINK networks

The programming and monitor ing of other PL Cs on the network c an be con-

ducted from Programming Devices connec ted to the PLC’s CPU Unit. Internetwork connectio ns are possible in thi s case also an d can cover up to eight

network levels.

Use a CS/CJ-series CP U Unit with unit version 2.0 or later and CX -Programmer Ver. 4.0 or hi gher to enable inter networ k connec tions for up to e ight networks.

Improved Error Handling

An error log enables qu ick handling of errors by reco rding the time th e error

occurred and error details. The current Controller Link Unit and Support Board

status are also available, as are the data link and network status.

When an error occurs in the polling node that controls the Controller Link Network, another node automatically becomes the polling node. This prevents an

error at a single n ode from influe ncing other nodes on t he n etwor k, achieving

a highly reliable system.

Using Repeater Units for T-Branches, Network Extensions, Network Expansions,

Converting Network Sections to Optical Fiber, and Device Modularization

T-Branches enable greater wiring freedom during layout, restructuring, and expansion of

networks.

Wire-to-Wire Repeat er Units enable Controller Link T-Branches. T-Branc hes

provide the following advantages:

• Cabling can conform to the layout of equipment.

• It is possible to add nodes by adding or inserting Repeater Units at

branch points of an existing wired Controller Link system.

9

Page 33

Overview Section 1-1

• If Repeater Units are install ed at li ke ly futur e bran ch points in the network

in advance, new nodes can be added by simply connecting them to these

Repeater Units.

The total length of wired networks can be extended.

At a baud rate of 2 Mbps, conventional wired networks can be up to 500 m

long. By using two R epeater Units, this can be extended to a maximum of

1.5 km.

The maximum number of nodes can be extended to 62 fo r wired networks.

By combining version-1 Co ntrol ler Lin k Uni ts/Support B oar ds a nd a Repeater

Unit, it is possible to construct networks containing up to 62 nodes.

Improved noise resistance through the use of optical cabling.

By installing two Wir e-to-Optical Re peater Units, optica l cabling can be used

for sections of the network that are the source of noise.

Devices can be modularized.

• Devices can b e modularized ac cording to Repe ater Units, making w iring

easier when adding, removing, or modifying devices.

• When starting up devi ces, compon ents can be added to the network an d

debugged as they are completed.

Features and Functions of Version-1 Models

The following features and functions apply to the CS1W-CLK21-V1 and

CJ1W-CLK21-V1 Controller Link Units and th e 3G8F7-CLK21-V1 Controller

Link Support Board only.

Up to 62 nodes can be connected.

Overview

When a CS1W-RPT01 Repeater Unit is used, the maximum number of nodes

that can be used in the network increases to 62. (The previous limit was 32.)

Method

Use Repeater Units and tu rn ON bit 11 (Wired Network 62 Nod e Enable Bit)

in the DM Parameter Area software switch D30000 + 100

nodes to enable a maximum of 62 nodes.

Restrictions

The maximum 62 nodes cannot be ach ieved if version-1 models a nd pr e-version-1 models are used together in the same network.

Automatic data link creation is possible with 1:N allocations.

Overview

It is possible to perform unequal 1:N all ocations of data between nodes wit h

automatic data li nk c r eati on . Thi s ma kes it e a sy to per for m d ata l inks th at formerly required the user to manually edit data link parameters.

The following four automatic data link creation patterns can be used:

• Equality layout (the previous pattern)

• 1:N allocation, common type

• 1:N allocation, 1 to 1 type

• 1:N allocation, chain type

× Unit No. of all

10

Page 34

Specifications and Configurations Section 1-2

Method

Allocation addresses and sizes are all specified using the Automatic Data Link

Creation Parameters (D30000

Area. These values can be set using the CX-Net i n the CX-Pro grammer version 3.2 or higher.

Objective

This function is effective in applica tions that col lect da ta from sl ave PLCs into

a master PLC.

Restrictions

Automatic data link creation with 1:N allocat ions cannot be performed if version-1 models and pre-version- 1 models are used together in the same network.

Change manually created data link tables during data link operation.

Overview

It is possible to modify a manuall y created d ata link table whil e data links are

running.

Note This is possible only wit h manually created data link tables. Any attem pt to

change automatical ly cr ea ted data lin k ta bles when data li nk s are running will

fail with an error message saying that t he ta bles cann ot be ed ite d during data

link operation will be displayed.

× Unit No. + 12 to 20) in the DM Parameter

Method

This function can be s et using the CX-Ne t in CX-Programmer version 3.2 or

higher.

Objectives

• In systems that ope rate non -s to p and cann ot be tu rn ed O FF, this function

makes it possible to change the da ta link ta ble to acc om mo date the add ition of new nodes and to transfer data link tables w ithout having to stop

manually set data link communications.

• If this function is co mbined with the use of Repeater Un its to a dd n etwo rk

nodes, it becomes possible to construct systems of greater flexibility.

Operation

When a node is being modified online, this function temporarily stops refreshing of data link data until modifications have been completed.

Nodes will par ticipate in data links after changes to the data link table have

been completed.

1-2 Specifications and Configurations

1-2-1 System Configuration

Wired Systems Wired systems can be used to connect CS/CJ-ser ies PLCs, C200HX/HG/HE

PLCs, CVM1 PLCs, CV-series PLCs, and IBM PC/AT o r compatible computers.

11

Page 35

Specifications and Configurations Section 1-2

pp

CS1W-CLK21-V1

Controller Link Unit

CS-series

PLC

C

P

U

CJ1W-CLK21-V1

Controller Link Unit

CJ-series PLC

C200HX/HG/HE

PLC

C

P

U

C200HW-CLK21

Controller Link Unit

CVM1, CV-series

PLC

C

P

U

Twisted-pair cable

CVM1-CLK21

Controller Link Unit

C

P

U

CQM1H-CLK21

Controller Link Unit

CQM1H-series

PLC

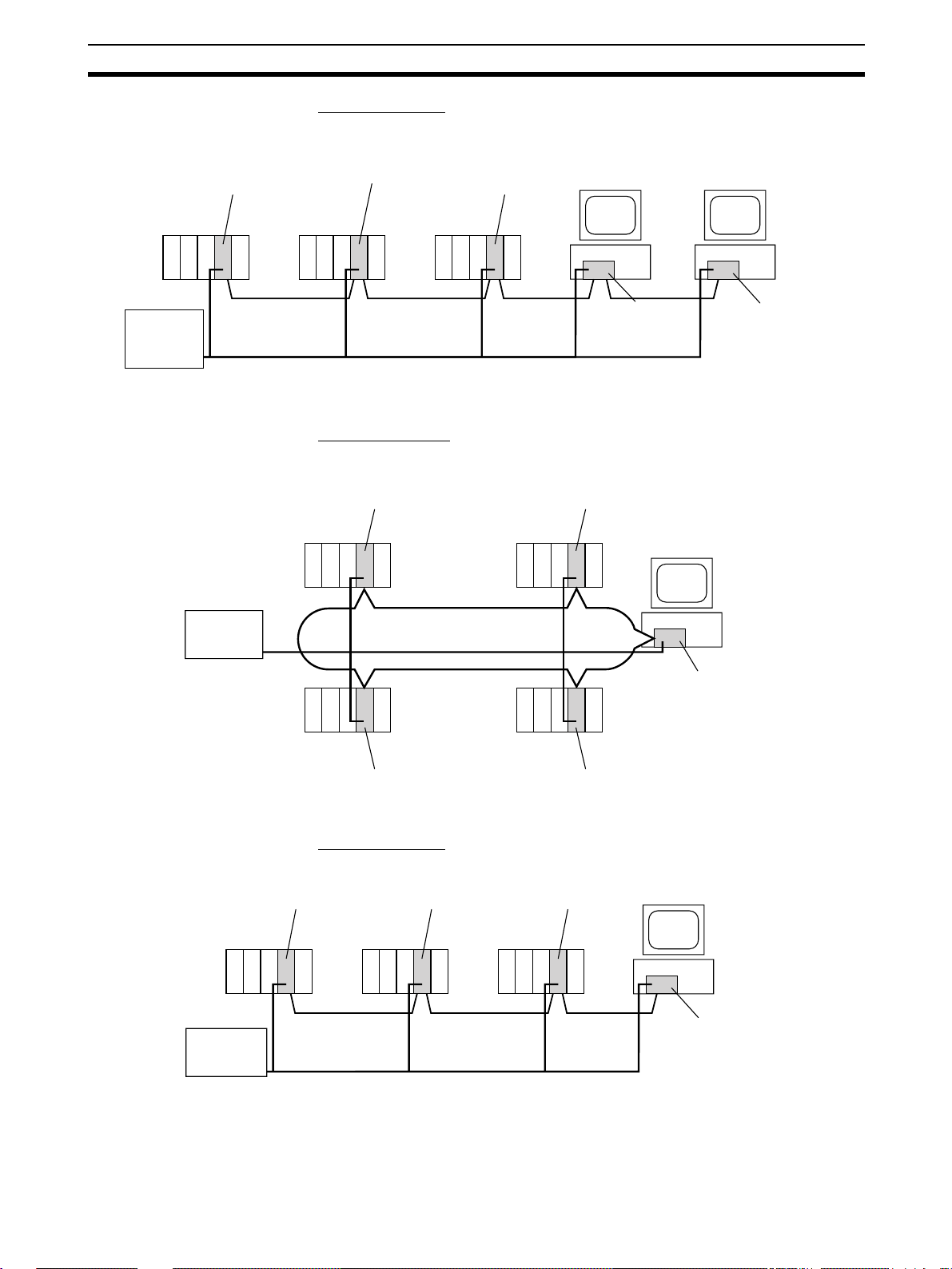

Connecting Repeater Units Using Twisted-pair Cable in Wired Systems

T-Branch Wiring

Wired Controller Link Unit Wired Controller Link Unit

CS1W-RPT01

Repeater Units

Twisted-pair cable

Twisted-pair cable

IBM PC/AT or

compatible

C

P

U

3G8F7-CLK21-E-V1

Controller Link

ort Board

Su

Long-distance Wiring

Wired Controller Link Unit

Twisted-pair cable

500 m max.

(See note.)

CS1W-RPT01

Repeater Units

Twisted-pair

cable

500 m max.

(See note.)

Wired Controller Link Unit

Twisted-pair cable

500 m max. (See note.)

Note: At 2 Mbit/s

12

Page 36

Specifications and Configurations Section 1-2

Converting Part of the Transmission Line to Optical Fiber

Wired Controller Link Unit Wired Controller Link Unit

CS1W-RPT02 or

CS1W-RPT03

Repeater Units

Twisted-pair cableTwisted-pair cable

Optical cable (H-PCF or GI)

Two Repeater Units of the sam e model must be used whe n par t of the tran smission line uses optical fiber.

Maximum Configuration of 62 Nodes

Wired Controller Link Unit

The following Controller Link Units/S uppo rt Boards must b e us ed t o co ns truct

a network with more than 32 nodes:

CS1W-CLK21-V1

CJ1W-CLK21-V1

3G8F7-CLK21-E-V1

Note 1. The networ k wil l n ot o perate c or rectl y unl es s all no des wi thi n the ne twor k

use the above Units/Boards.

2. Only node addresses 1 through 32 can be used on networks for which 62

nodes have not been enabled.

1-2-2 General Specifications

Twisted-pair cable

32 nodes max.

CS1W-RPT01

Repeater Unit

Wired Controller Link Unit

Twisted-pair cable

32 nodes max.

General specifications are the same for the C200HX/HG/HE, CS-series, CJseries, CVM1, CV-series, and CQM1H-series PLCs.

13

Page 37

Specifications and Configurations Section 1-2

1-2-3 Communications Specifications

Wired System

Items Specifications

Communications method N:N token bus

Code Manchester code

Modulation Baseband code

Synchronization Flag synchronization (conforms to HDLC frames)

Transmission path form Multi-drop bus

Baud rate and maximum

transmission distance

Media Specified shielded twisted-pair cable

Node connection method PLC: Connected to a terminal block

Maximum number of nodes 32 or 62 nodes (See note 2.)

Communications functions Data links and message service

Number of data link words

Data link areas Bit-access areas (IR, AR, LR, CIO), DM Area (DM), and extended DM Area (EM)

Message length 2,012 bytes max. (including the header)

RAS functions Polling node backup function

Error control Manchester code check

The maximum transmission distance varies with the baud rate as follows:

2 Mbps: 500 m

1 Mbps: 800 m

500 Kbps: 1 km

Number of signal lines: 2, shield line: 1

IBM PC/AT or compatible: Connected via a special connector (included)

Transmission area per node: 1,000 words (2,000 bytes) max.

Data link area (send/receive words) per node

CS/CJ Series: 20,000 words max. (unit Ver. 1.2 or later)

C200HX/HG/HE, CVM1/CV, CQM1H: 8,000 words max.

Personal computer: 32,000 or 62,000 words max. (See note 3.)

Number of data link words in one network (total transmission):

Self-diagnosis function (hardware checking at startup)

Echoback test and broadcast test (using the FINS command)

Watchdog timer

Error log function

CRC check (CCITT X

12,000 words max. (pre-Ver. 1.2)

32,000 words (64,000 bytes) or 62,000 words max. (See note 3.)

16

+ X12 + X5 + 1)

14

Note 1. The maximum distance between nodes depends on the connector and ca-

ble pr ocessing methods.

2. At least one Repeater Unit is required to constr uct networks that us es a

node address higher t han 32. The following Controller Link Units /Suppo rt

Boards must also be us ed , an d th e W ired Network 62 Node Enable Bit of

the DM Parameter Area software switch of all nodes mus t be turne d ON

(62 nodes max.).

CS1W-CLK21-V1, CJ1W-CLK21-V1, and 3G8F7-CLK21-V1

3. 62,000 data link words applies to configurations of 62 nodes.

Page 38

Specifications and Configurations Section 1-2

Communications Specifications when Using the CS1W-RPT01 Repeater Unit in a Wired

Network

Item Within 1 se gment (See

note 1.)

Transmission path form Multi-drop Tree type (Connection of

Baud rate and maxim um tr ans mission distance (See note 2.)

Maximum number of node s Total number of Control-

Maximum numb er of Repeat er

stages (See note 4.)

2 Mbps: 500 m

1 Mbps: 800 m

500 Kbps: 1 km

ler Link Units + R epeater

Units: 32 nodes (See

note 5.)

--- 2 stages

Note 1. Specifications within a segment are identical to the specifications of a

Wired Controller Link Network.

2. Maximum transmission distance: Total length of cables in the longest path

connecting any two nodes.

3. A maximum of 62 nodes is pos sible only when using CS1W-CLK21-V1,

CJ1W-CLK21-V1 and 3G8F7-CLK21-V1 Units.

4. Maximum number of Repeater stages: The maximum number of Repeater

Units that can be in serted into the path co nnecting any two nodes. For

wire-to-optical connection, two Repeater Units make up a single set, which

is counted as a single Repeater stage.

5. The Repeater Units e ach have a unique node address. Up to 32 Units,

consisting of Contr oller L ink Units and Repeater Units, can be conne cted

within a single segment.

Entire network

segments with Repeaters)

2 Mbps: 1.5 km

1 Mbps: 2.4 km

500 Kbps: 3.0 km

Controller Link Units/Support Boards (See note 3.):

62 nodes

Wire

Optical

fiber

cable

: Controller Link Unit/Support

Board

: Wire-to-wire Repeater Unit

: Wire-to-optical Repeater Unit

(two Units used in a pair)

: Range of a single segment

Note: The Repeater Unit will be

counted in the number of

nodes for each segment that

it is connected to.

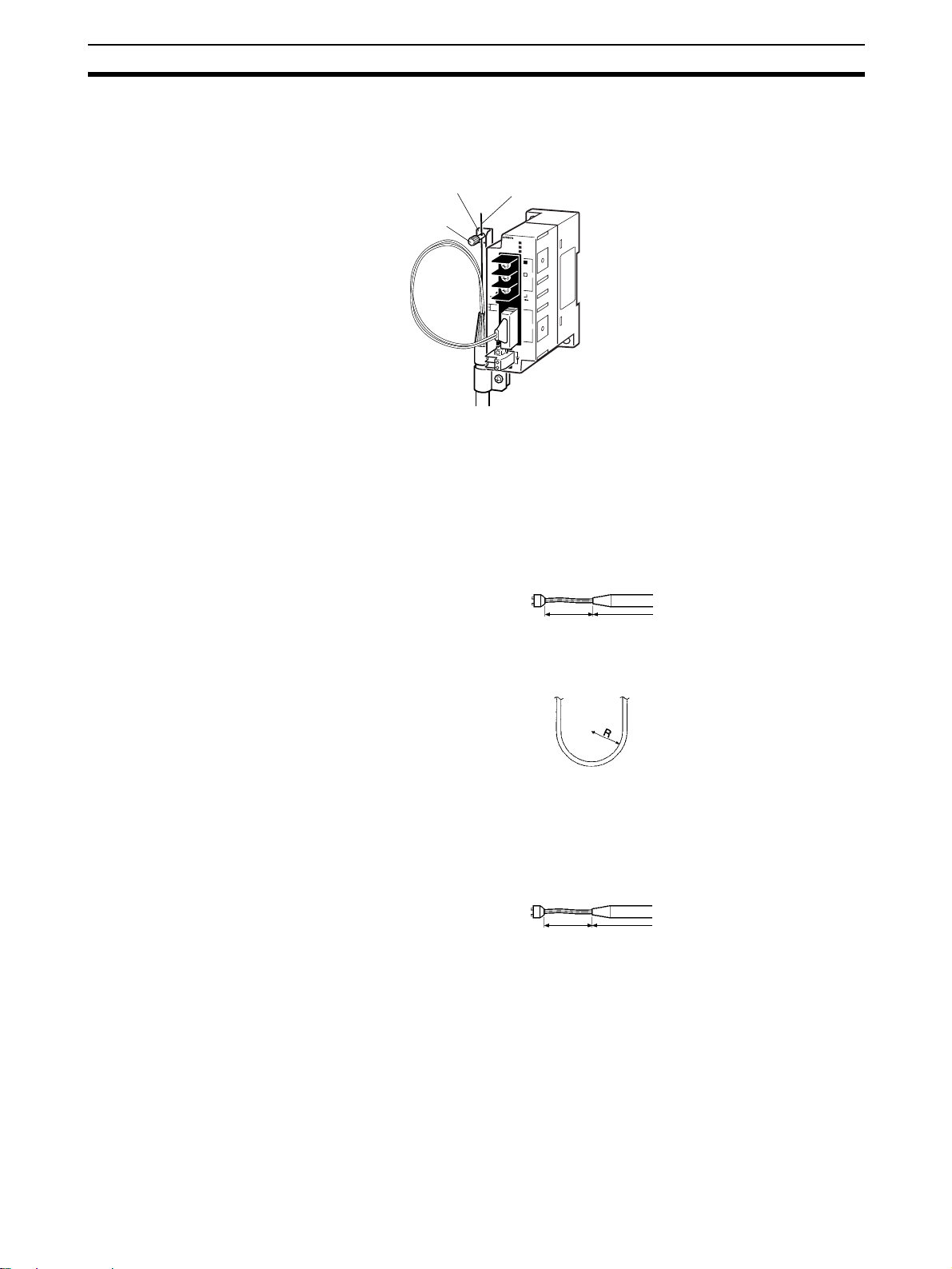

Specifications of Optical Fiber Cables Used with Wire-to-Optical

Connections

Item H-PCF type GI type

Optical fiber cable H-PCF 200/230 µm tw o-

Maximum trans mi ss ion

distance (See note 2.)

core cable

Adhesion-polished: 1 km

Crimp cut: 800 m

GI 50/125 µm two-core cable

or GI 62.5/125 µm two-core

cable

50/125 µm: 1 km

62.5/125 µm: 2 km

15

Page 39

Specifications and Configurations Section 1-2

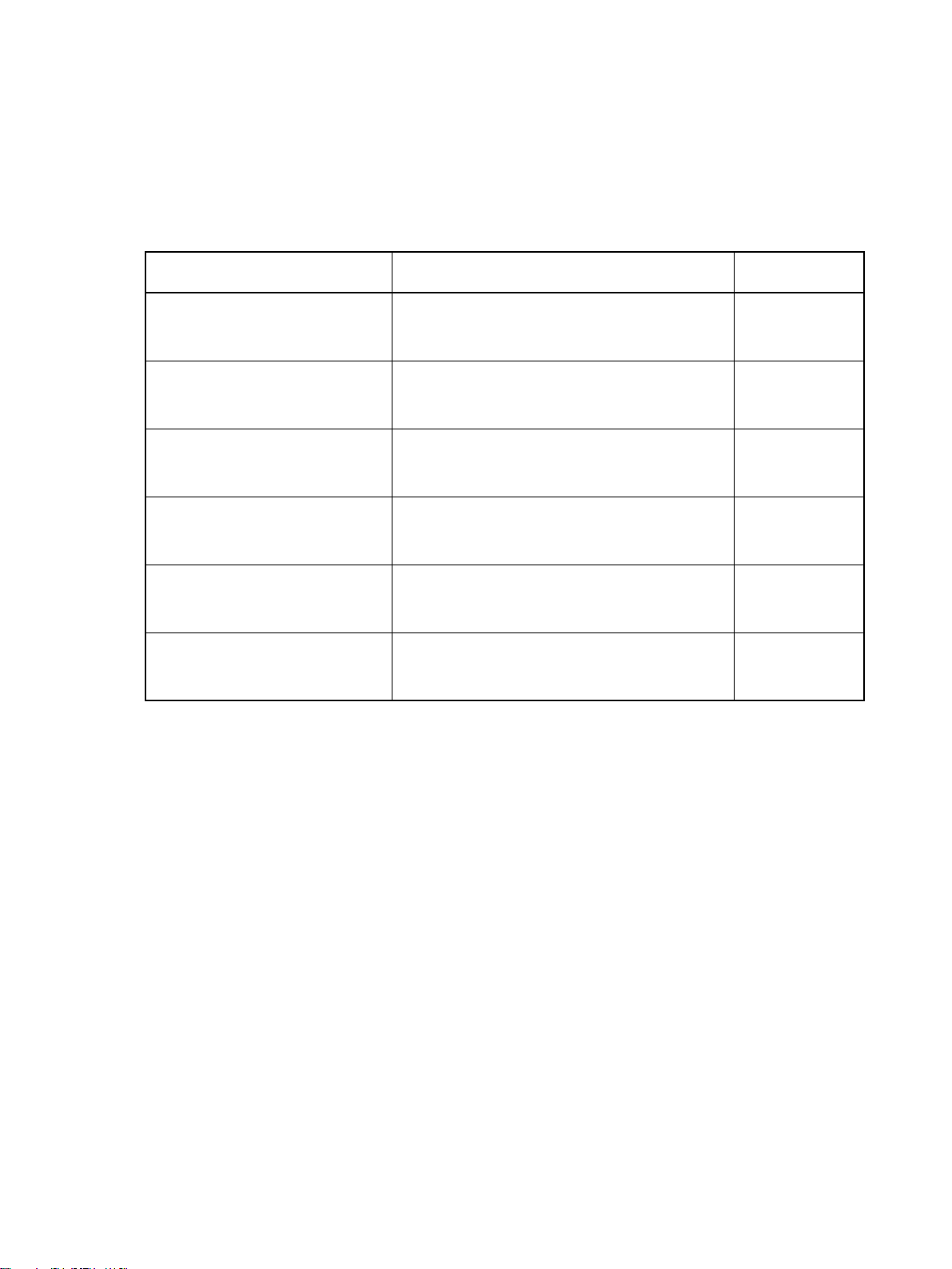

1-2-4 Controller Link Unit Models and PLCs

Wired System

There are five Controller Link Units: One for CVM1 and CV-series PLCs, one

each for CS-series and CJ-series PLCs, one for the C200HX/HG/HE PLC,

and one for CQM1H-series PLCs.

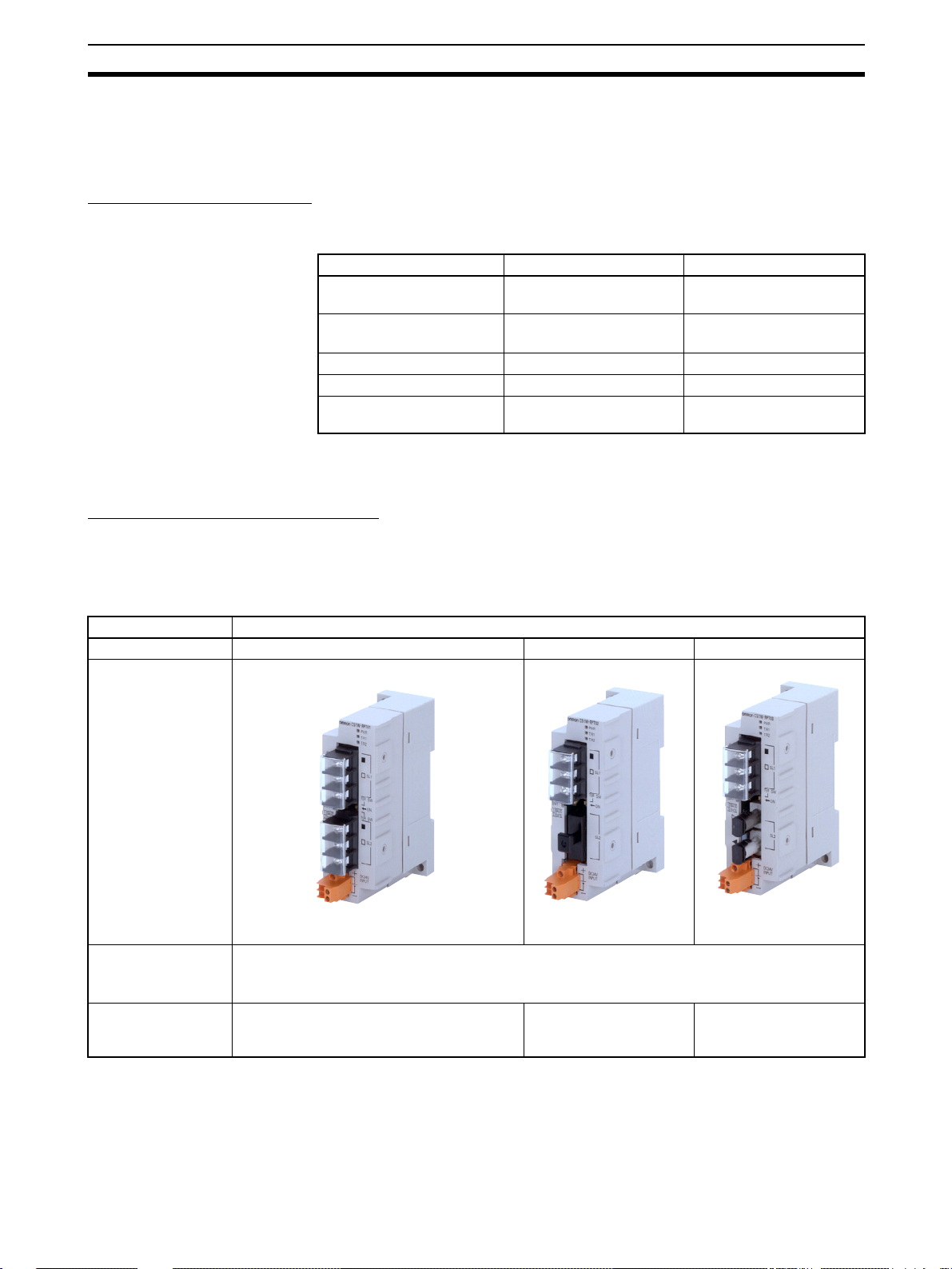

Item Specifications

Model CS1W-CLK21-V1 CJ1W-CLK21-V1 C200HW-CLK21

External appear-

ance

C

L

K

2

1

RUN

ERC

INS

SD

TER

ERH

M/A

LNK

RD

4

5

3

6

2

7

1

8

U

N

IT

0

9

F

A

E

B

D

C

No.

3

2

4

1

5

NODE

0

6

9

7

8

No.

1

x10

3

2

4

1

5

0

6

9

7

8

ON

0

x10

1

ON

SW1

2

1

BAUD

RATE

2

TER SW

ON

BD H

BD L

SHLD

Installation

devices

None required. None required. C200HW-COM01/04 Commu-

nications Board and

C200HW -CE001/002/012 Bus

Connection Unit

PLC CS-series PLCs CJ-series PLCs C200HX/HG/HE PLCs

(Except C200HE-CPU11(-Z))

Max No. of Units

per PLC

Installation site Install onto a CPU Backplane or

Storage location

8 maximum for unit Ver. 1.2 or

later and 4 maximum for pre-Ver.

1.2 Units.

CPU

CPU Backplane

Unit

Of these

8 maximum for unit Ver. 1.2 or

later and 4 m aximum for pre-Ver.

1.2 Units on CPU or Expansion

Rack

2 maximum

CPU Backplane

2 max.

slots,

installation is

2/3/5/8/10 slots

possible in up

to 8 slots (unit

Ver. 1.2 or

later).

Expansion

Backplane

Installation in

up to 4 slots

is possible for

pre-Ver. 1.2

Units.

3/5/8/10 slots

CS-series Expansion Backplane

(Classified as a CPU Bus Unit.)

Install onto a CPU Rack or

Expansion Rack (Classified as a

CPU Bus Unit.)

Install onto a CPU Backplane. (Classi fied as a Spec ial

I/O Unit for communications.)

CPU Bus Unit Area (in the CPU Unit parameter area) Controller Link Unit

CPU

Unit

for network

parameters

Storage location

for routing tables

CPU Unit parameter area DM 6450 to DM 6499 in CPU

Unit

Weight 400 g 110 g 400 g

Current con-

330 mA 350 mA 300 mA

sumption

16

Page 40

Specifications and Configurations Section 1-2

Item Specifications

Model CVM1-CLK21 CQM1H-CLK21

External

appearance

Installation

None required. None required.

devices

PLC CVM1 and CV-series PLCs CQM1H-CPU51/61

Max No. of

Units per PLC

Installation site Install onto a CPU Backplane or

Storage location for net-

4 maximum 1 maximum

CPU Backplane

3/5/10 slots

Expansion CPU

Backplane

11 slots

CPU

Unit

Of these

14, 16, or

21 slots,

installa

tion is

possible

in up to 4

slots.

Power Supply

Unit

Connect

here.

Connected as a CommuniExpansion CPU Backplane (Classified as a CPU Bus Unit.)

CPU Bus Unit Area (in the CPU Unit

cations Unit be tween P o wer

Supply Unit and CPU Unit.

Controller Link Unit

parameter a rea)

CPU

Unit

work

parameters

Storage location for routing

CPU Unit parameter area DM 6450 to DM 6499 in

CPU Unit

tables

Weight 550 g 200 g

Current con-

300 mA 290 mA

sumption

Note A Controller Link Suppor t Boa rd can be installed into an IBM PC/AT or com-

patible computer to connect the comp uter to the network. Refer to the Controller Link Support Boards Operation Manual (W307) for details.

17

Page 41

Specifications and Configurations Section 1-2

CS/CJ-series Controll er Link Unit Models

Item Unit Ver. 1.2 (-V1

suffix)

Model CS1W-CLK21-V1

Maximum number of send/receive data link

words (data link area for sending/receiving that

is created for a single node in a single CPU Unit)

Data Link Area Area 1 and Area 2 can

Maximum numb er of Units connect ed to a si ngle

CPU Unit

Automatic data link setting Select from equality layout, 1:N allocations

Changing data link allocations during activ e data

links

Maximum number of nodes that can be connected

Mixed use Supported (See note.)

CJ1W-CLK21-V1

20,000 words max. 12,000 words max.

be allocated in the

same area.

8 Units 4 Units

(common type, 1:1 type, chain type)

Supported. (Data link tables can be changed

during active data links.)

62 Units (requires CS1W-RPT01 Repeater

Unit).

Note A network can cont ain both nodes with maximum of 20,00 0 data link words

and nodes with 12,000 data link words. When models with -V1 suffix and

those without -V1 suffix are both used in the same network, 1:N automatic

data links and configurations of 62 nodes cannot be used.

Pre-Ver. 1.2 (-V1

suffix)

CS1W-CLK21-V1

CJ1W-CLK21-V1

Area 1 and Area 2 cannot be allocated in the

same area.

Without -V1 suffix

CS1W-CLK21

CJ1W-CLK21

Equality layout only

Not supported.

32 Units

Use the CX-Net in CX-P ro gram mer ver sion 5.0 or higher to set a data link

area in which the number of send and receive words exceeds 12,000 words.

CX-Programmer version 3.2 or higher can be used to change data link allocations while manually set data links are active.

Up to eight CS/CJ-s eries Controller Link Units with unit version 1.2 or later

can be connecte d to a single CP U Unit. When c onnectin g multiple Controller

Link Units to the CPU Unit, consider the current consumption of the CPU Unit

and each CPU Bus Unit before selecting the Power Supply Unit. For details on

Controller Link Unit current cons umption, refer to

and PLCs on page 16

. For details on current consum ption of ea ch Unit, refer

Controller Link Unit Models

to the operation manual of the PLC that is being used.

The following table provides an example of current consumption.

Example: Using the C200HW-PA204 Power Supply Unit supplying a maxi-

mum current of 4.6 A (5 V) and maximum power of 30 W.

Name Model Current consumption