Omron CV500, CV2000, CV1000, CVM1 Installation Manual

Cat. No. W195-E1-5

Programmable Controllers

SYSMAC CV-series

CV500/CV1000/CV2000/CVM1

SYSMAC CV-series

CV500/CV1000/CV2000/CVM1

Programmable Controllers

Installation

Guide

Revised October 1999

iv

!

!

!

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit”

is also capitalized when it refers to an OMRON product, regardless of whether or not it appears in the

proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates

information of particular interest for ef

ficient and convenient operation

of the product.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 1992

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

vi

TABLE OF CONTENTS

vii

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Control Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Role of the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 PC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 CV-series Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 C-series–CV-series System Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Networks and Remote I/O Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 New CPUs and Related Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 CPU Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9 Improved Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

System Configuration and Components . . . . . . . . . . . . . .

2-1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Rack Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Mounting Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Power Supply Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Wiring I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Compliance with EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . .

4-1 CPU Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Memory Card Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Output Unit Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Output Unit Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Error Messages and Alarm Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Troubleshooting Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Error Processing and Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

About this Manual:

This manual describes the installation of the SYSMAC CV-series Programmable Controllers (CV500,

CV1000,

CV2000, and CVM1). This manual is designed to be used together with three CV

-series PC op

-

eration

manuals. The entire set of CV

-series PC manuals is listed

below

. Only the basic portions of the

catalog numbers are given; be sure you have the most recent version for your area.

Manual Cat. No.

CV-series PC Installation Guide W195

CV-series PC Operation Manual: SFC W194

CV-series PC Operation Manual: Ladder Diagrams W202

CV-series PC Operation Manual: Host Interface W205

Programming and operating CV-series PCs are performed with the CV Support Software (CVSS), the

SYSMAC

Support Software (SSS), and the CV

-series Programming Console

for which the following man

-

uals are available.

Product Manuals

CVSS The CV Series Getting Started Guidebook (W203) and the CV Support Software

Operation Manuals: Basics (W196), Offline (W201), and Online (W200).

SSS SYSMAC Support Software Operation Manuals: Basics (W247), C-series PC Op-

erations (W248), and CVM1 Operations (W249)

CV-series Programming

Console

CVM1-PRS21-E Programming Console Operation Manual (W222)

Note The

CVSS does not support new instructions added for version-2 CVM1 PCs. The SSS does not

support SFC programming (CV500, CV1000, or CV2000).

Section 1

introduces programmable controllers in general and provides tables of the Units the can be

used

with CV

-series PCs and operation manuals available for CV

-series products. Special products used

to

create networks, enable remote I/O, or provide additional programming capabilities are also provided.

Tables

are also provided of new products included for the first

time in this version of the manual, along with

a comparison of CPU capabilities, and a list of improvements made in recent CPU versions.

Section

2

describes the overall configuration that the PC System

can take and introduces the main Units

used in the system configuration.

Section 3

provides procedures on installing and wiring.

Section 4

provides information on ongoing maintenance.

Section 5

describes general troubleshoot and provides troubleshooting flowcharts.

Appendix A

provides tables of C- and CV-series products that can be used with CV-series PCs.

Appendix

B

provides general PC specifications, dimensions, and I/O Unit specifications (including inter

-

nal circuit configurations and wiring diagrams).

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section

in its entirety and be sure you understand the information provided

in the section

and related sections before attempting any of the procedures or operations given.

!

xi

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The

information contained in this section is important for the safe and r

eliable application of the Pr

ogrammable Con

-

troller. You must r

ead this section and understand the information contained befor

e attempting to set up or operate a

PC

system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

!

!

!

!

!

!

3Safety Precautions

xii

1 Intended Audience

This

manual is intended for the following personnel, who must also have knowl

-

edge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The

user must operate the product according to the performance specifications

described in the operation manuals.

Before

using the product under conditions which are

not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may

have a serious influence on lives and property if

used improperly

, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient

for

the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure

to read this manual before attempting to use the

Unit and keep this manual

close at hand for reference during operation.

WARNING It is extremely important that a PC and all PC Units be used for the specified

purpose

and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned

applications.

3 Safety Precautions

WARNING Do

not attempt to take any Unit apart while the power is being supplied. Doing

so

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

WARNING Do

not

attempt to disassemble, repair

. or modify any Units. Any attempt to do so

may result in malfunction, fire, or electric shock.

WARNING There is a lithium battery built into the SRAM Memory Cards. Do not short the

positive

and negative terminals of the battery

, charge the battery, attempt to take

it apart, subject it to pressures that would deform it, incinerate it, or otherwise

mistreat it. Doing any of these could cause the battery to erupt, ignite, or leak.

Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque

specified in the operation manual. The loose screws may result in

burning

or malfunction.

!

!

!

!

!

5Application Precautions

xiii

4 Operating Environment Precautions

Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations

subject to condensation as the result of severe changes in tempera

-

ture.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take

appropriate and suf

ficient countermeasures when installing systems in the

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Caution The

operating environment of the PC

System can have a large ef

fect on the lon

-

gevity

and reliability of the system. Improper operating environments can lead to

malfunction,

failure, and other

unforeseeable problems with the PC System. Be

sure

that the operating environment is within the specified conditions at installa

-

tion and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC System.

WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always

ground the system to 100 Ω or less when installing the Units. Not con

-

necting to a ground of 100 Ω or less may result in electric shock.

• Always

turn OFF the power supply to the PC before attempting any of the fol

-

lowing.

Not turning OFF the power supply may result in malfunction or

electric

shock.

• Mounting

or dismounting I/O Units, Memory Cassettes, or any other Units.

• Setting switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

Caution Failure

to abide by the following precautions could lead to faulty operation of the

PC

or the system, or

could damage the PC or PC Units. Always heed these pre

-

cautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event

of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

6Conformance to EC Directives

xiv

• Interlock

circuits, limit circuits,

and similar safety measures in external circuits

(i.e.,

not in the Programmable Controller) must be provided by the customer

.

• Always

use the power supply voltage specified in the operation manuals. An

incorrect voltage may result in malfunction or burning.

• Take

appropriate measures to ensure that the specified power with the rated

voltage

and frequency is supplied. Be particularly careful in places where the

power

supply is unstable. An incorrect power supply may result in malfunction.

• Install

external breakers and take other safety measures against short-circuit

-

ing

in external wiring. Insuf

ficient safety measures against short-circuiting may

result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum

switching capacity

. Excess voltages or loads may result in

burning.

• Disconnect

the functional ground terminal when

performing withstand voltage

tests.

Not disconnecting the functional ground terminal may result in burning.

• Install

the Unit properly as

specified in the operation manual. Improper installa

-

tion of the Unit may result in malfunction.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws

are tightened to the torque specified in the

relevant manuals. Incorrect

tightening torque may result in malfunction.

• Use

crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• Double-check

all the wiring before turning on the power supply

. Incorrect wir

-

ing may result in burning.

• Be

sure that the terminal blocks, Memory

Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check

the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm

that no adverse ef

fect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume

operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do

not pull on the cables or bend the cables beyond their natural limit.

Doing

either of these may break the cables.

• Do not place objects on top of the cables. Doing so may break the cables.

6 Conformance to EC Directives

The

CV

-series PCs that comply with EC Directives must be installed as follows:

1, 2, 3...

1. The

CV

-series PCs are designed for installation inside control panels. The

PC must be installed within a control panel.

2. Use

reinforced insulation or double

insulation for the DC power supplies to

be connected to the DC I/O Units for CV500-PS211. Use separate power

supplies

as the external power supplies for the Relay Output Units and the

power supplies for the DC I/O Units.

3. To

meet the EC Directives (Low V

oltage Directive), the maximum switching

capacity while the CV500-PS211 is being operated is 24 VDC/2 A.

6Conformance to EC Directives

xv

4. PCs

complying with EC Directives also conform to the Common Emission

Standard

(EN50081-2). When a PC is built

into a machine, however

, noise

can be generated by switching devices using relay outputs and cause the

overall machine to fail to meet the Standards. If this occurs, surge killers

must be connected or other measures taken external to the PC.

The following methods represent typical methods for reducing noise, and

may not be sufficient in all cases. Required countermeasures will vary

depending

on the devices connected to the

control panel, wiring, the config

-

uration of the system, and other conditions.

Countermeasures

Refer to EN50081-2 for more details.

Countermeasures are not required if the frequency of load switching for the

whole system including the PC is less than 5 times per minute.

Countermeasures

are required if the frequency of load switching for the whole

system including the PC is 5 or more times per minute.

Countermeasure Examples

When

switching an inductive load, connect a surge protector

, diodes, etc., in par

-

allel with the load or contact as shown below.

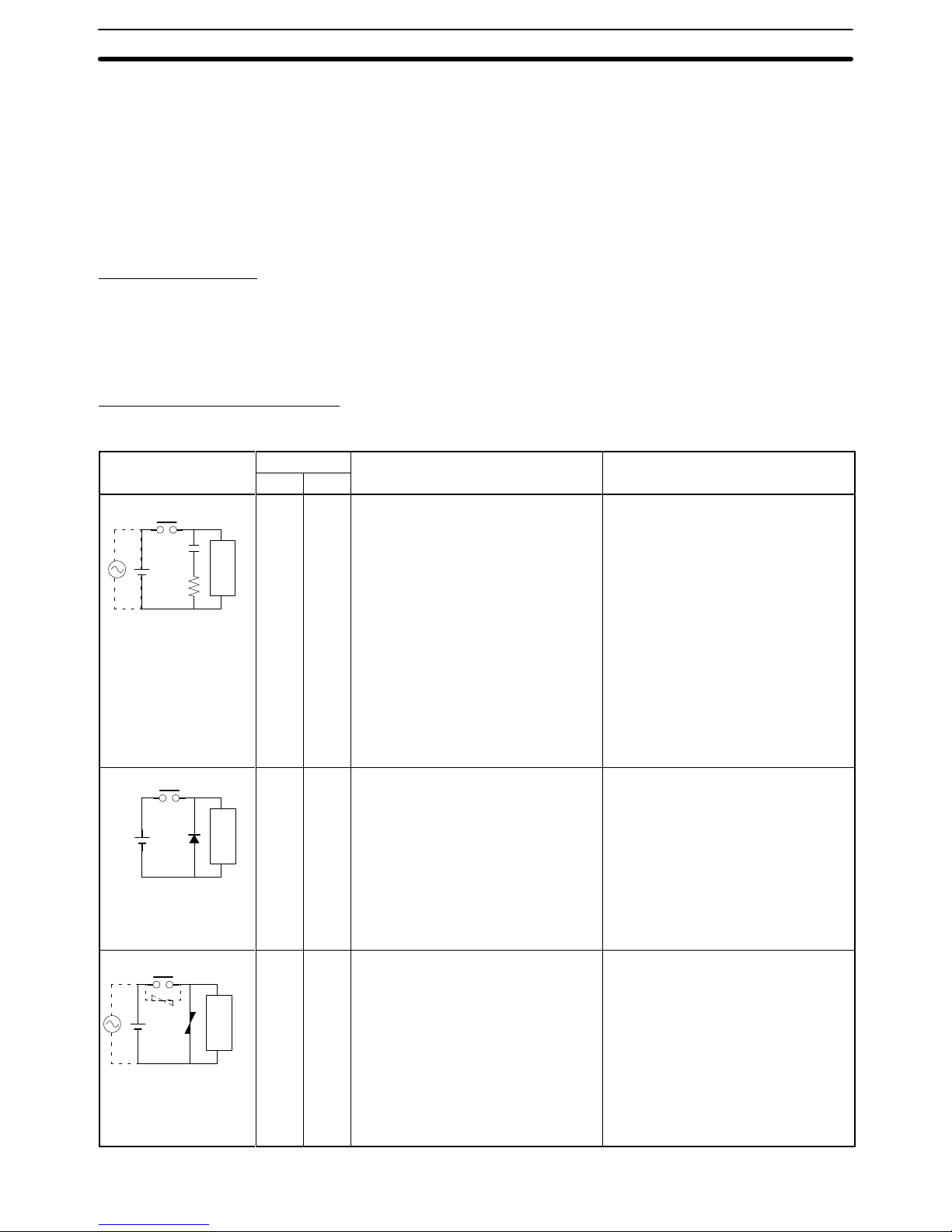

Circuit Current Characteristic Required element

AC DC

CR method

Power

supply

Inductive

load

Yes Yes If the load is a relay or solenoid, there

is a time lag between the moment the

circuit is opened and the moment the

load is reset.

If the supply voltage is 24 or 48 V,

insert the surge protector in parallel

with the load. If the supply voltage is

100 to 200 V, insert the surge

protector between the contacts.

The capacitance of the capacitor must

be 1 to 0.5

µF per contact current of

1

A and resistance of the resistor must

be 0.5 to 1

Ω per contact voltage of

1 V. These values, however, vary with

the load and the characteristics of the

relay. Decide these values from

testing, and take into consideration

that the capacitance suppresses spark

discharge when the contacts are

separated and the resistance limits

the current that flows into the load

when the circuit is closed again.

The dielectric strength of the capacitor

must be 200 to 300 V. If the circuit is

an AC circuit, use a capacitor with no

polarity.

Diode method

Power

supply

Inductive

load

No Yes The diode connected in parallel with

the load changes energy accumulated

by the coil into a current, which then

flows into the coil so that the current

will be converted into Joule heat by

the resistance of the inductive load.

This time lag, between the moment

the circuit is opened and the moment

the load is reset, caused by this

method is longer than that caused by

the CR method.

The reversed dielectric strength value

of the diode must be at least 10 times

as large as the circuit voltage value.

The forward current of the diode must

be the same as or larger than the load

current.

The reversed dielectric strength value

of the diode may be two to three times

larger than the supply voltage if the

surge protector is applied to electronic

circuits with low circuit voltages.

Varistor method

Power

supply

Inductive

load

Yes Yes The varistor method prevents the

imposition of high voltage between the

contacts by using the constant voltage

characteristic of the varistor. There is

time lag between the moment the

circuit is opened and the moment the

load is reset.

If the supply voltage is 24 or 48 V,

insert the varistor in parallel with the

load. If the supply voltage is 100 to

200 V, insert the varistor between the

contacts.

---

6Conformance to EC Directives

xvi

When

switching a load with a high

inrush current such as an incandescent lamp,

suppress the inrush current as shown below.

OUT

COM

R

OUT

COM

R

Countermeasure

1

Providing a dark current of approx.

one-third of the rated value through

an incandescent lamp

Countermeasure 2

Providing a limiting resistor

1

SECTION 1

Introduction

This

section provides general information about

Programmable Controllers and how they fit into a Control System. It also list

the

C-series products that can be used with the CV

-series PCs and operation manuals available for CV

-series products. Finally

,

this

section introduces Systems that can be used to create networks and enable remote I/O.

1-1

Control Systems

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Role of the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1

Input Devices

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2

Output Devices

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 PC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 CV

-series Manuals

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 C-series–CV-series System Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6

Networks and Remote I/O Systems

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7

New CPUs and Related Units

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8

CPU Comparison

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9 Improved Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9-1 Upgraded Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9-2 V

ersion-1 CPUs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9-3 V

ersion-2 CVM1 PCs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

1-1 Control Systems

A

Control

System is the electronic equipment needed to control a particular pro

-

cess.

It may include everything from a process control computer

, to the factory

computer,

down through the PCs, and then on down through the network to the

I/O

devices: control components like the switches, stepping motors,

solenoids,

and sensors which monitor and control mechanical operations.

PC PC PC

PCs

Process Control Computer

Factory Computer

I/O devices

A

Control System can involve very large applications where many dif

ferent mod

-

els

of PC are networked together or it could be an application as small as a single

PC controlling a number of output devices.

1-2 The Role of the PC

The

PC is the part of the Control System that directly controls the manufacturing

process. According to the program stored in its memory, the PC accepts data

from the input devices connected to it and uses this data to monitor the controlled system. When the program calls for some action to take place, the PC

sends data to the output devices connected to it to cause that action to take

place.

The PC may be used to control

a simple, repetitive task, or it may be con

-

nected

to other PCs or to a host computer in order to integrate the control of a

complex process.

The Role of the PC Section 1-2

3

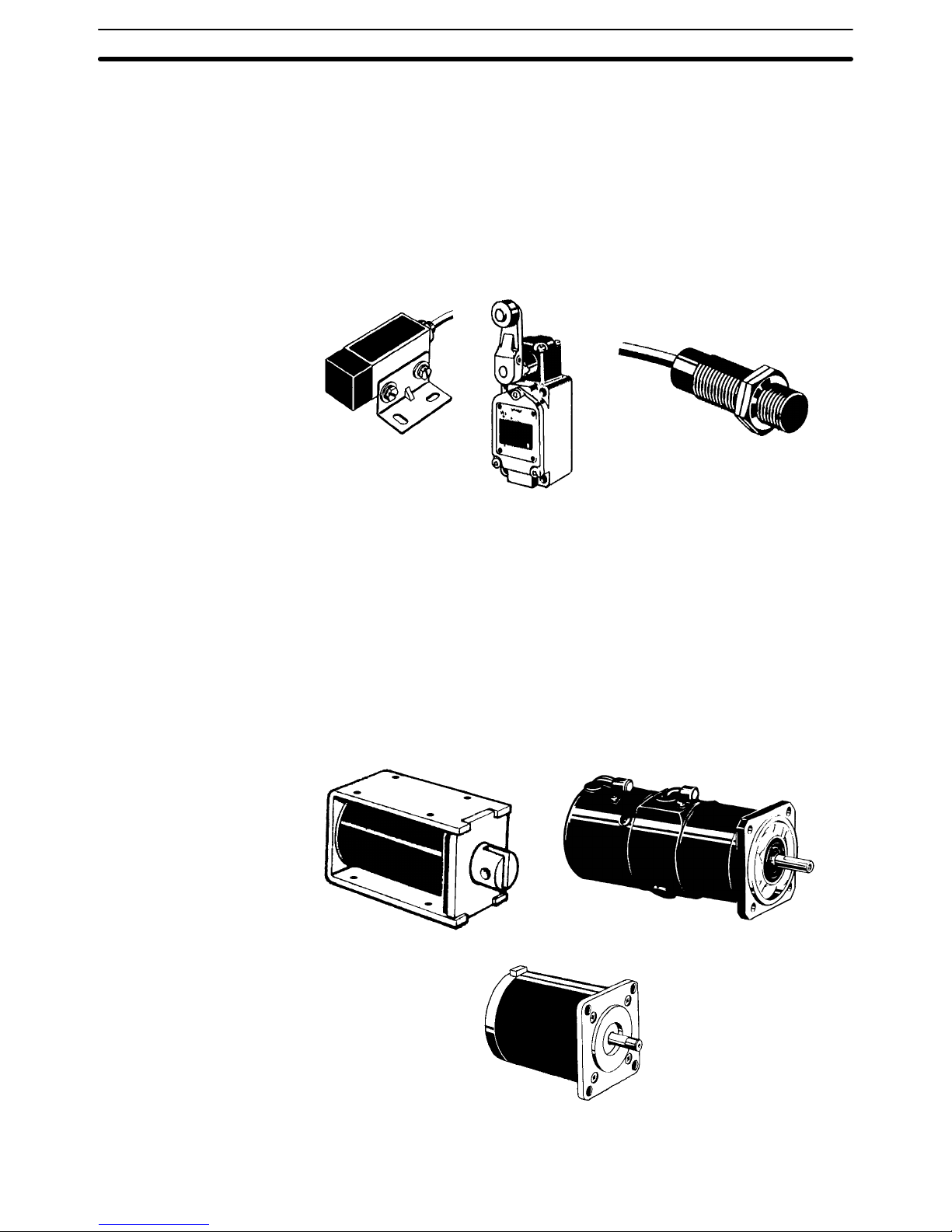

1-2-1 Input Devices

PCs

can receive inputs from either automated or

manual devices. The PC could

receive

data from the user via a pushbutton

switch, keyboard, or similar device.

Automated

inputs could come

from a variety of devices: micro-switches, timers,

encoders,

photoelectric sensors, and so on. Some devices, like the limit switch

shown

below

, turn ON or OFF

when the equipment actually makes contact with

them.

Other devices, like the photoelectric sensor and proximity sensor shown

below,

use other means, such as light or inductance, in order to get information

about the equipment being monitored.

Photoelectric

Sensor

Limit Switch

Proximity Sensor

1-2-2 Output Devices

A

PC can output to a myriad of devices for use in automated control. Almost

any

-

thing

that you can think of could be controlled by a PC. Some of the most com

mon devices are motors, solenoids, servomotors, stepping motors, valves,

switches,

indicator lights, buzzers, and alarms. Some of these output devices,

such

as the motors, solenoids, servomotors, stepping motors, and valves,

af

fect

the

controlled system directly

. Others, such as the indicator lights, buzzers, and

alarms,

provide outputs to notify personnel operating or monitoring the system.

Solenoid

Servomotor

Stepping Motor

The Role of the PC Section 1-2

4

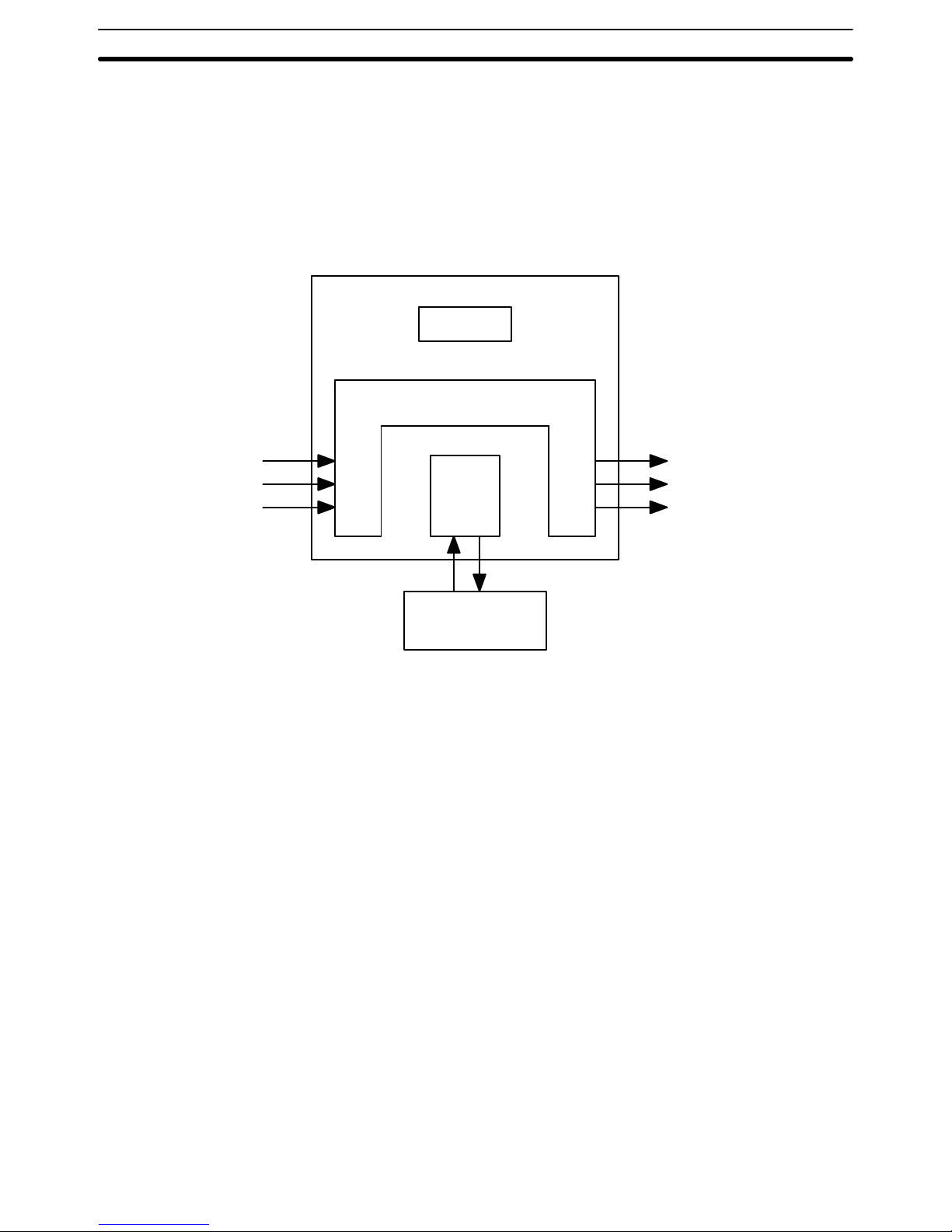

1-3 PC Operation

PCs operate by monitoring input signals and providing output signals. When

changes are detected in input signals, the PC reacts through the user-programmed

internal

logic to produce output signals. The PC continually executes

the program in its memory to achieve this control.

Block Diagram of PC

Power Supply

Input Output

CPU

Memory

Programming

Device

Signals

from

switches,

sensors,

etc.

Signals to

Solenoids,

motors,

etc.

A program for your applications must be designed and stored in the PC. This

program is then executed as part of the cycle of internal operations of the PC.

Execution Cycle When a PC operates, i.e., when it executes its program to control an external

system, a series of operations are performed inside the PC. These internal oper

ations can be broadly classified into the following four categories. Refer to the

CV-series PCs Operation Manual: Ladder Diagrams

for details.

1, 2, 3...

1. Common

(or overseeing) processes, such as watchdog timer operation and

testing the program memory.

2. Data input and output.

3. Program execution.

4. Peripheral device servicing.

Cycle Time The

total time required for a PC to perform all these internal operations is called

the cycle time.

Timing

is one of the most important factors in designing a Control System.

For

accurate

operations, it is necessary to have answers to such

questions as these:

• How

long does it take for the PC to execute all the instructions in its memory?

• How

long does it take for the PC to produce a control

output in response to a

given input signal?

PC Operation Section 1-3

5

The

cycle time of the PC can be automatically calculated and monitored,

but it is

necessary to have an understanding of the timing relationships within the PC

for

effective

System

design and programming. Refer to the

CV

-series PCs Opera

tion

Manual: Ladder Diagrams

for details on internal PC processing and to

the

CVSS Operation Manuals

for details on monitoring the cycle time.

1-4 CV-series Manuals

The

following manuals are available for the various CV

-series products. Other

manuals

are

also available for compatible C-series products (see next section).

Catalog

number suf

fixes have been omitted; be sure you have

the most recent

version for your region.

Product Manual Cat. No.

CV-series PCs CV-series PCs Installation Guide W195

CV-series PCs Operation Manual: SFC W194

CV-series PCs Operation Manual: Ladder Diagrams W202

CV-series PCs Operation Manual: Host Link System,

CV500-LK201 Host Link Unit

W205

CV Support Software (CVSS)

The CV Series Getting Started Guidebook W203

()

CV Support Software Operation Manual: Basics W196

CV Support Software Operation Manual: Offline W201

CV Support Software Operation Manual: Online W200

SYSMAC Support Software (SSS) SYSMAC Support Software Operation Manual: Basics W247

SYSMAC Support Software Operation Manual: CVM1 PCs W249

Graphic Programming Console (GPC) CV500-MP311-E Graphic Programming Console Operation Manual W216

Programming Console CVM1-PRS21-E Programming Console Operation Manual W222

SYSMAC NET Link System SYSMAC NET Link System Manual W213

SYSMAC LINK System SYSMAC LINK System Manual W212

SYSMAC BUS/2 Remote I/O System SYSMAC BUS/2 Remote I/O System Manual W204

CompoBus/D (DeviceNet) CompoBus/D (DeviceNet) Operation Manual W267

CV-series Ethernet Unit CV-series Ethernet System Manual W242

BASIC Unit BASIC Unit Reference Manual W207

BASIC Unit Operation Manual W206

Personal Computer Unit

Personal Computer Unit Operation Manual W251

Personal Computer Unit Technical Manual W252

Motion Control Unit

Motion Control Unit Operation Manual: Introduction W254

Motion Control Unit Operation Manual: Details W255

Temperature Controller Data Link Unit CV500-TDL21 Temperature Controller Data Link Unit W244

Memory Card Writer CV500-MCW01-E Memory Card Writer Operation Manual W214

Optical Fiber Cable Optical Fiber Cable Installation Guide W156

CV-series Manuals Section 1-4

6

1-5 C-series–CV-series System Compatibility

The

following table shows when C-series Units can be used and when CV

-series

Units must be used. Any C-series Unit or Peripheral Device not listed in this table

cannot be used with the CV-series PCs.

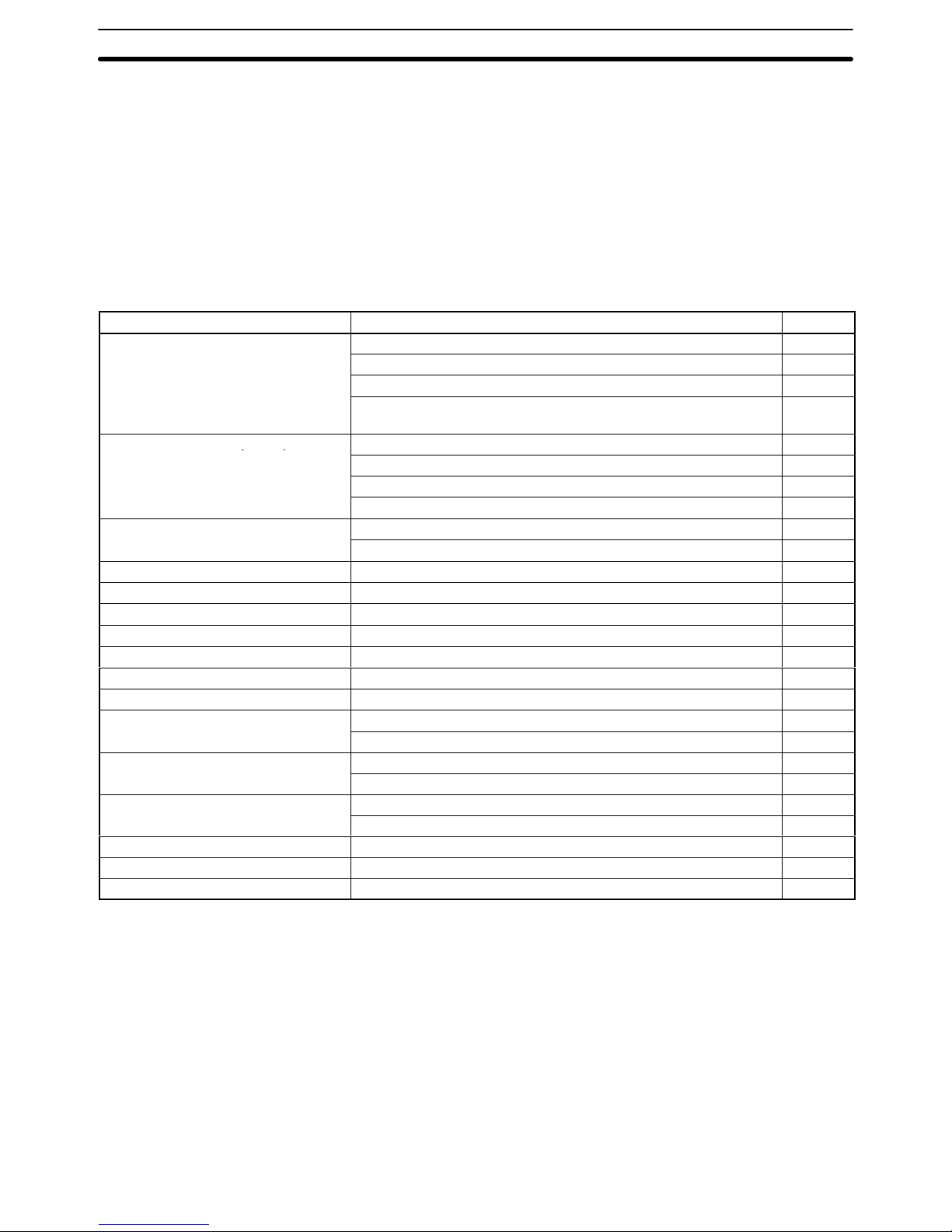

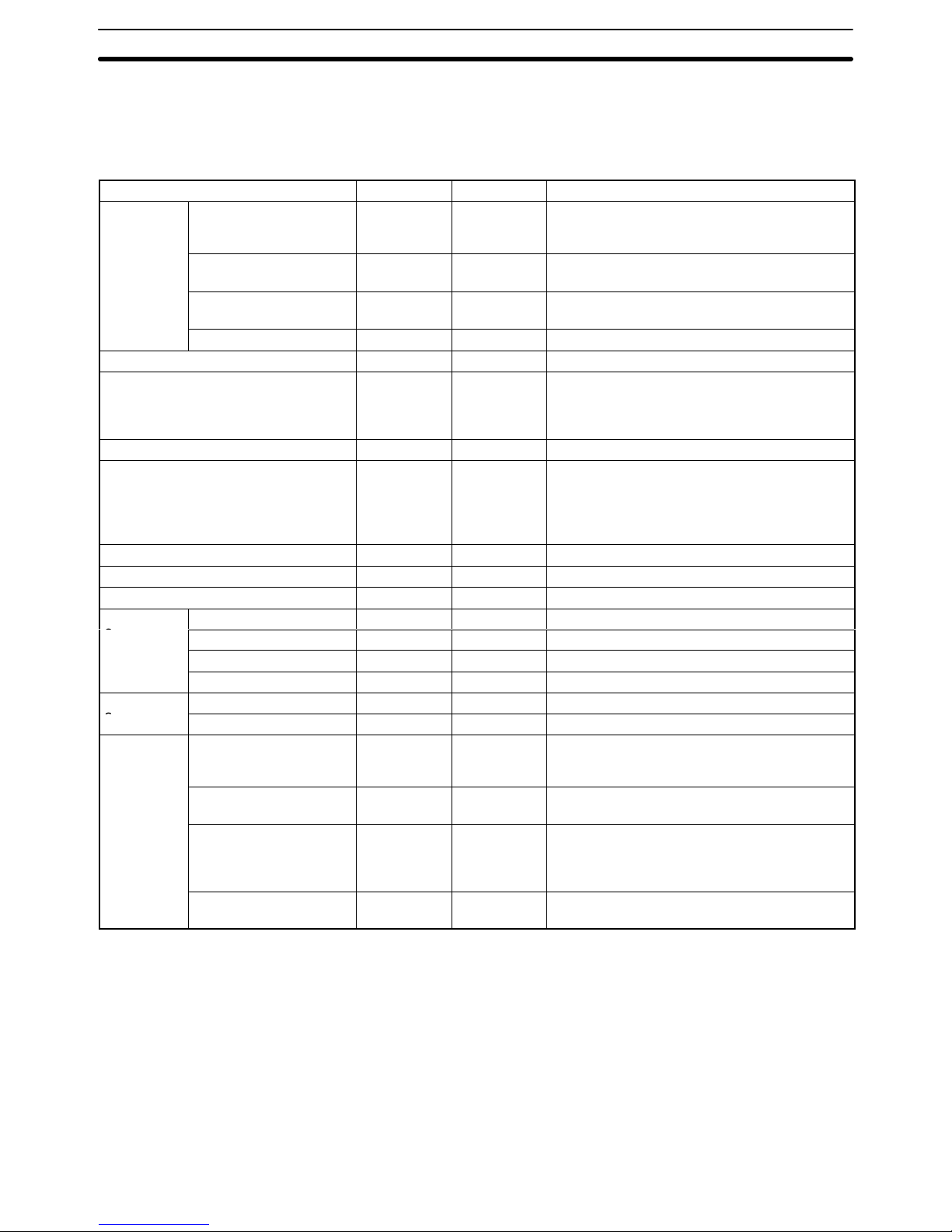

Unit C Series CV Series Remarks

CPU Rack CPU No Yes CV500-CPU01-EV1, CV1000-CPU01-EV1,

CV2000-CPU01-EV1, CVM1-CPU01-EV2,

CVM1-CPU11-EV2, and CVM1-CPU21-EV2

Power Supply No Yes CV500-PS221, CV500-PS21

1, and

CVM1-PA208

CPU Backplane No Yes CV500-BC031, CV500-BC051, CV500-BC101,

CVM1-BC103, and CVM1-BC053

I/O Control Unit No Yes CV500-ICj01

Expansion CPU Backplane No Yes CV500-BI111

Expansion I/O Backplane No Yes CV500-BI042, CV500-BI062, CV500-BI112,

CVM1-BI114, and CVM1-BI064 (C500

Expansion I/O Racks can be used with certain

limitations.)

16-/32-/64-point I/O Units Yes Yes --Special I/O Units Yes Yes Applicable Units include Analog Input, Analog

Output, High-speed Counter, PID, Position

Control, Magnetic Card, ASCII, ID Sensor

, and

Ladder Program I/O Units (The C500-ASC03

cannot be used.)

BASIC Unit No Yes CV500-BSCj1

Personal Computer Unit No Yes CV500-VP213-E/217-E/223-E/227-E

Temperature Control Data Link Unit No Yes CV500-TDL21

Link

SYSMAC NET No Yes CV500-SNT31

Systems

SYSMAC LINK No Yes CV500-SLK11 and CV500-SLK21

Host Link Unit No Yes CV500-LK201

Ethernet Unit No Yes CV500-ETN01

Remote I/O

SYSMAC BUS Units Yes Yes ---

Systems

SYSMAC BUS/2 No Yes CV500-RM211/221 and CV500-RT211/221

Peripheral

Devices

CV Support Software No Yes

(See note.)

CV500-ZS3AT1-EV2 (3 1/2” floppy disks) and

CV500-ZS5AT1-EV2 (5 1/4” floppy disks) for

IBM PC/AT compatible

SYSMAC Support

Software (SSS)

Yes Yes

(See note.)

C500-ZL3AT1-E (3.5” floppy disks) for IBM

PC/AT compatible

Graphic Programming

Console

Yes (Main

unit only)

Yes

(System

Cassette)

(See note.)

GPC: 3G2C5-GPC03-E

System Cassette: CV500-MP311-E

Programming Console No Yes

(See note.)

CVM1-PRS21-EV1 (set)

Note The

CVSS does

not support new instructions added for version-2 CVM1 PCs.

The

SSS does not

support SFC programming (CV500, CV1000, and CV2000).

New instructions added for version-2 CVM1 PCs are also supported by version-1

CV

-series Programming Consoles.

C-series–CV-series System Compatibility Section 1-5

7

1-6 Networks and Remote I/O Systems

Systems

that can be used to create networks and enable remote I/O are intro

-

duced

in this section. Refer

to the operation manuals for the Systems for details.

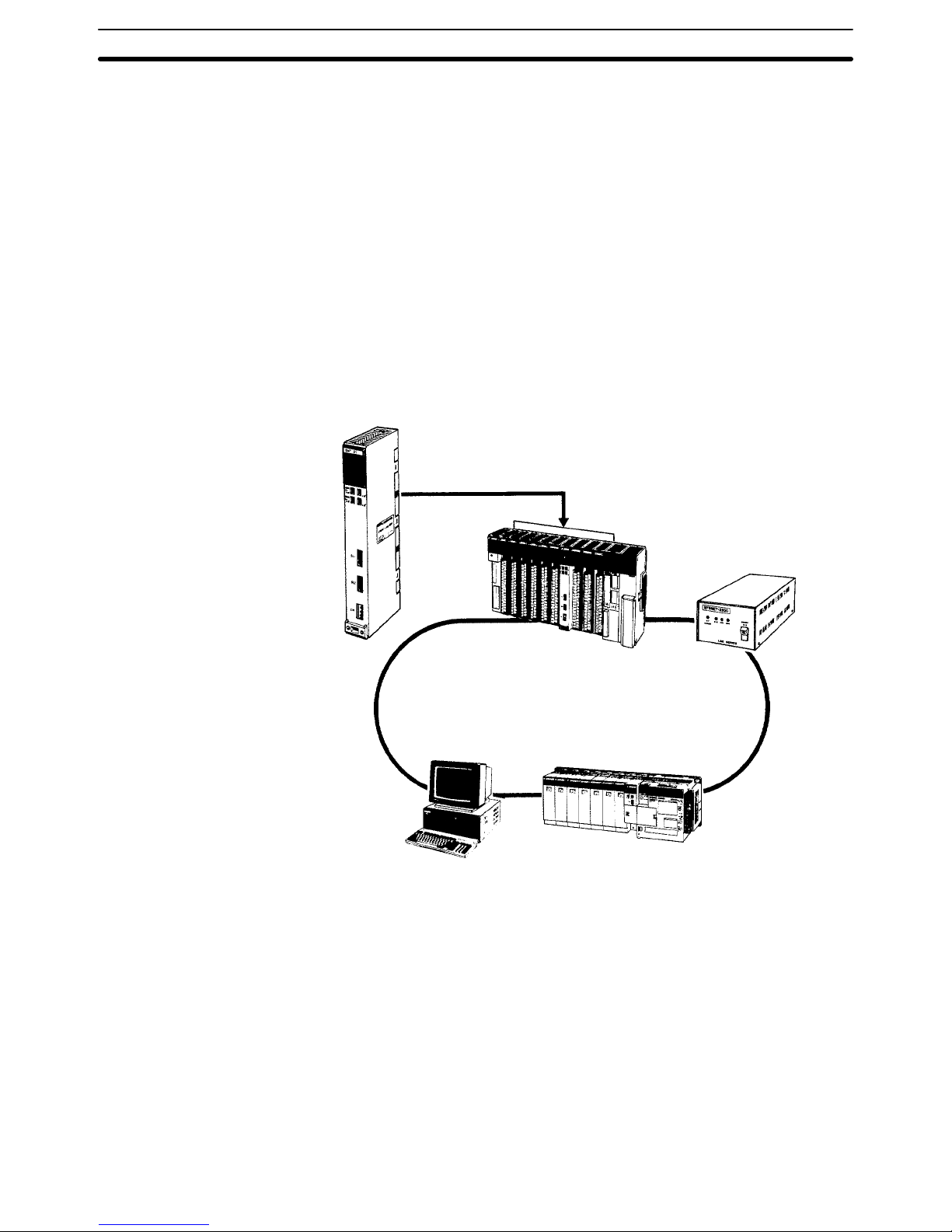

The

SYSMAC NET Link System is

a LAN (local area network) for use in factory

automation

systems. The SYSMAC NET Link System can consist of up to 128

nodes among which communications may be accomplished via datagrams,

data transfers, or automatic data links.

Datagrams

transmit and receive data using a

command/response format. Com

mands can be issued from the user program by the DELIVER COMMAND instruction (CMND(194)).

Data can also be transmitted and received using the NETWORK SEND and

NETWORK RECEIVE (SEND(192)/RECV(193)) instructions in the user program. Up to 256 words of data can be transferred for each instruction.

Automatic data links allow PCs and computers to create common data areas.

SYSMAC

NET Link Unit

CV500-SNT31

Up to 4 Units can

be mounted.

CV-series

CPU Rack/Expansion CPU Rack

Line Server

Center Power

Feeder

C200H

C500

C1000H

C2000H

Personal

computer

Note Up to four SYSMAC NET Link Units (CV500-SNT31) can be mounted to the

CPU Rack and/or Expansion CPU Rack of each CV-series PC.

SYSMAC NET Link System

Networks and Remote I/O Systems Section 1-6

8

SYSMAC LINK System Networks

can also be created using SYSMAC LINK Systems.

A SYSMAC LINK

System can consist of up to 62 PCs, including the CV500, CV1000, CV2000,

CVM1,

C200H, C1000H, and C2000H. Communications between the PCs is ac

-

complished

via datagrams, data transfers, or automatic data links in ways simi

-

lar to the SYSMAC NET Link System.

The

main dif

ferences between

SYSMAC NET Link and SYSMAC LINK Systems

is

in the structure of automatic data links and in the system configuration, e.g.,

only

PCs

can be linked in SYSMAC LINK Systems, whereas other devices can

form nodes in SYSMAC NET Link Systems.

Datagrams

transmit and receive data using a

command/response format. Com

mands can be issued from the user program by the DELIVER COMMAND instruction (CMND(194)).

Data can also be transmitted and received using the NETWORK SEND and

NETWORK RECEIVE (SEND(192)/RECV(193)) instructions in the user program. Up to 256 words of data can be transferred for each instruction.

Automatic data links allow PCs and computers to create common data areas.

SYSMAC

LINK Unit

CV500-SLK1

1 (optical)

CV500-SLK21 (wired)

Up to 4 Units can

be mounted.

CV-series

CPU Rack/Expansion CPU Rack

CV500/CV1000/

CV2000/CVM1

C200H/C1000H/

C2000H

Note Up to four SYSMAC LINK Units (CV500-SLK11/21) can be mounted the CPU

Rack and/or Expansion CPU Rack of each CV-series PC.

Networks and Remote I/O Systems Section 1-6

9

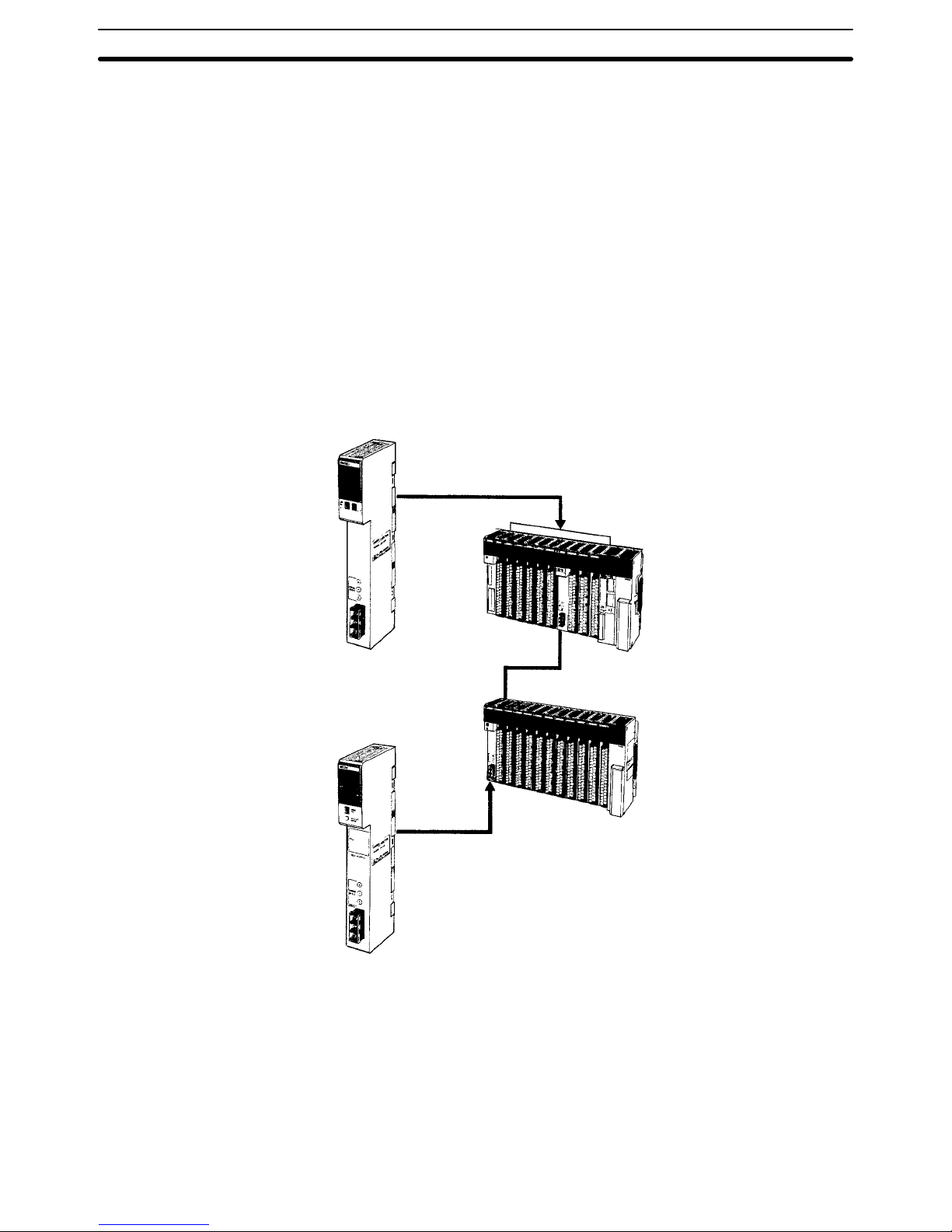

Remote

I/O can be enabled by adding a SYSMAC BUS/2 Remote I/O System

to

the

PC. The SYSMAC BUS/2 Remote I/O System is available in two types: opti

cal and wired.

Two

Remote

I/O Master Units, optical or wired, can be mounted to the CV500 or

CVM1-CPU01-EV2 CPU Rack or Expansion CPU Rack. Four Remote

I/O

Mas

ter Units can be mounted to the CV1000, CV2000, or CVM1-CPU11/21-EV2

CPU Rack or Expansion CPU Rack.

Up to eight Remote I/O Slave Racks can be connected per PC.

Slaves can be used to provide up to 1,024 remote I/O points for the CV500 or

CVM1-CPU01-EV2;

up to 2,048 remote I/O points for the CV1000, CV2000, or

CVM1-CPU11/21-EV2.

These limits are the totals for all Slaves control by one

PC.

A

Programming Device (such as the

CVSS) can be connected to up to two Re

mote I/O Slave Units for each Remote I/O Master Unit as long as a total of no

more than four Programming Devices are connected per PC.

Remote

I/O Master Unit

CV500-RM21

1 (optical)

CV500-RM221 (wired)

CV500, CVM1-CPU01-EV2:

4 Masters max. can be mounted

CV1000, CV2000, CVM1-CPU1

1/21-EV2:

8 Masters max. can be mounted

CV-series

CPU Rack/Expansion CPU Rack

Remote I/O Slave

Up to 8 Slave can be con

nected per PC for 58M

Slaves; 4 Slaves for 122M

or 54MH Slaves.

Remote I/O Slave Unit

CV500-RT21

1 (optical)

CV500-R

T221 (wired)

SYSMAC BUS/2 Remote I/O

System

Networks and Remote I/O Systems Section 1-6

10

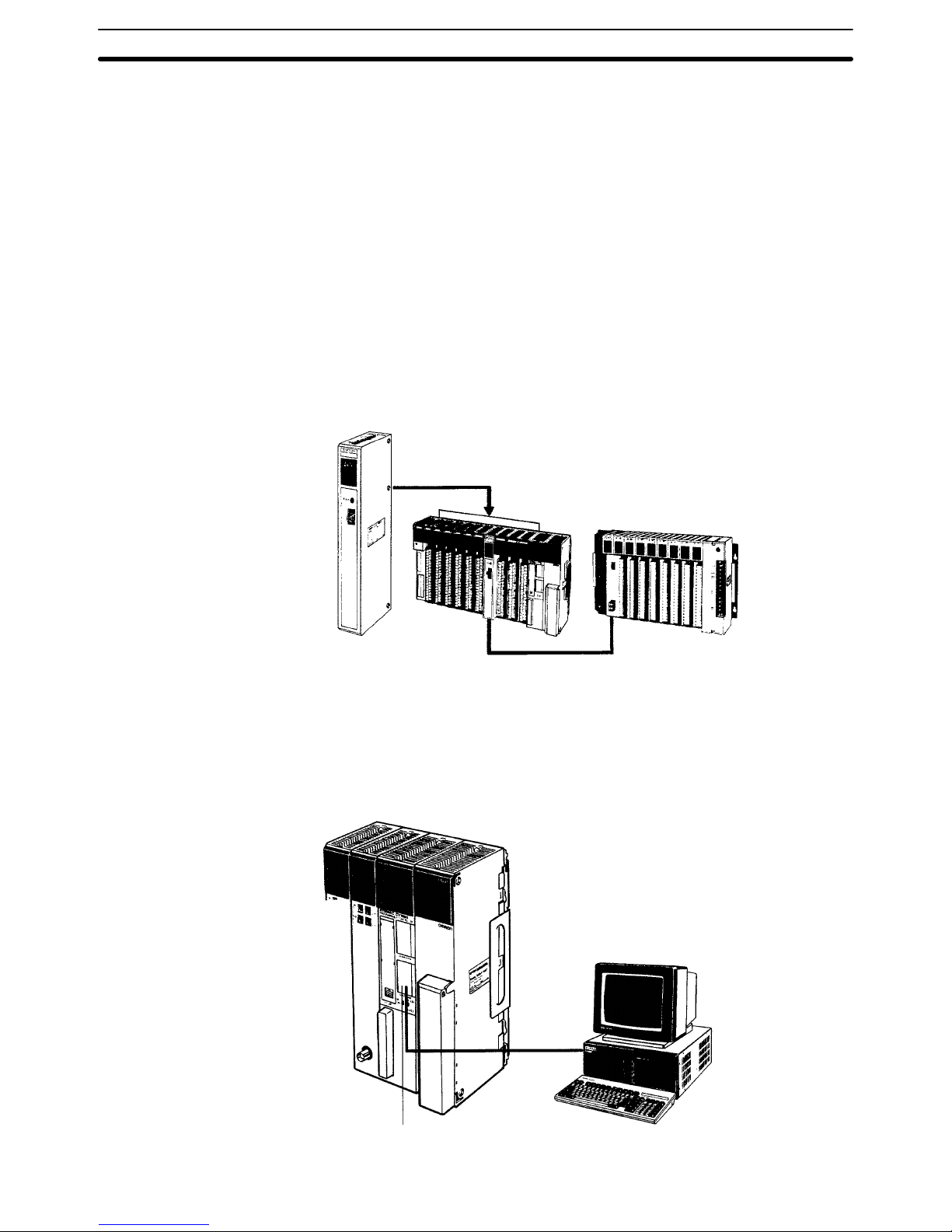

Remote

I/O can also be enabled by using the C-series

SYSMAC BUS Remote

I/O System with CV-series PC.

Remote

I/O

Master Units can be mounted on any slot of the CPU Rack, Expan

sion CPU Rack, or Expansion I/O Rack. Up to four Masters can be mounted for

the

CV500 or CVM1-CPU01-EV2, up to eight Masters for the CV1000, CV2000,

or CVM1-CPU11/21-EV2.

For each Master, up to two Slave Racks can be connected for the CV500 or

CVM1-CPU01-EV2; up to eight Slave Racks for the CV1000, CV2000, or

CVM1-CPU11/21-EV2.

No more than 16 Slave Racks can be connected per PC.

Slaves can be used to provide up to 512 remote I/O points for the CV500 or

CVM1-CPU01-EV2;

up to 1,024 remote I/O points for the CV1000, CV2000, or

CVM1-CPU11-EV2; up to 2,048 remote I/O points for the CVM1-CPU21-EV2.

These limits are the totals for all Slaves control by one PC.

Programming Devices cannot be connected to SYSMAC BUS Slave Racks.

Remote

I/O Master Unit

3G2A5-RM001-(P)EV1 (optical)

C500-RM201 (wired)

Up to 8 Units

CV-series

CPU Rack/Expansion CPU

Rack/Expansion I/O Rack

C-series

Remote I/O Slave Rack

CV500, CVM1-CPU01-EV2:

2 Masters max. can be mounted

CV1000, CV2000, CVM1-CPU1

1/21-EV2:

4 Masters max. can be mounted

The

CV

-series PCs can be connected to a host computer with the host link con

-

nector via the CPU or a CV500-LK201 Host Link Unit mounted to a Rack.

RS-232C

or RS-422 communications can be used depending on the switch set

-

ting.

When RS-422

is selected, up to 32 PCs can be connected to a single host.

Data is transmitted and received by commands and responses.

Host

link connector

Host

computer

SYSMAC BUS Remote I/O

System

Host Link System

(SYSMAC W

AY)

Networks and Remote I/O Systems Section 1-6

11

BASIC Unit The

BASIC Unit can be connected to a personal computer to enable communi

cations with the PC using the BASIC programming language. Up to 512 bytes

(256

words) of data

can be transferred between the BASIC Unit and the CPU by

the PC READ/WRITE command without using the PC program.

Up

to 256 words of data can also be transferred between the BASIC Unit and

the

PC’s CPU by using the NETWORK SEND and NETWORK RECEIVE

(SEND(192)/RECV(193)) instructions in the PC program.

Data

can also be transferred to other BASIC Units mounted on the same PC, or

to BASIC Units mounted to other PCs connected by networks formed using a

SYSMAC

NET Link

or SYSMAC LINK System. RS-232C, RS-422, Centronics,

and GPIB interfaces are available.

BASIC

Unit

CV500-BSCj1

Personal computer

CV-series

CPU Rack/Expansion

CPU Rack

Personal Computer Unit The

Personal Computer Unit is a full-fledged IBM PC/A

T compatible that can

be

used

to run independent programming directly on a

Rack to eliminate the need

for

separate installation space. It can run along or connected to any of the normal

peripherals

supported by IBM PC/A

T compatibles (mice, keyboards, monitors,

data

storage devices, etc.), and as a CPU Bus

Unit, the Personal Computer Unit

interfaces directly to the PC’

s CPU though the CPU bus to eliminate the need for

special interface hardware, protocols, or programming.

1-7 New CPUs and Related Units

The

following

new CV

-series CPUs and related Units are included in this version

of

the manual for the first time. Refer to relevant sections of this manual or the

CV-series PC Operation Manual: Ladder Diagrams

for further details.

Unit Model number Main specifications

CPU

CVM1-CPU01-EV2 I/O capacity: 512 pts; Ladder diagrams only

CVM1-CPU11-EV2 I/O capacity: 1,024 pts; Ladder diagrams only

CVM1-CPU21-EV2 I/O capacity: 2,048 pts; Ladder diagrams only

CV500-CPU01-EV1 I/O capacity: 512 pts; Ladder diagrams or SFC + ladder diagrams

CV1000-CPU01-EV1 I/O capacity: 1,024 pts; Ladder diagrams or SFC + ladder diagrams

CV2000-CPU01-EV1 I/O capacity: 2,048 pts; Ladder diagrams or SFC + ladder diagrams

Temperature Controller

Data Link Unit

CV500-TDL21 Connects up to 64 temperature control devices via 2 ports.

New CPUs and Related Units Section 1-7

12

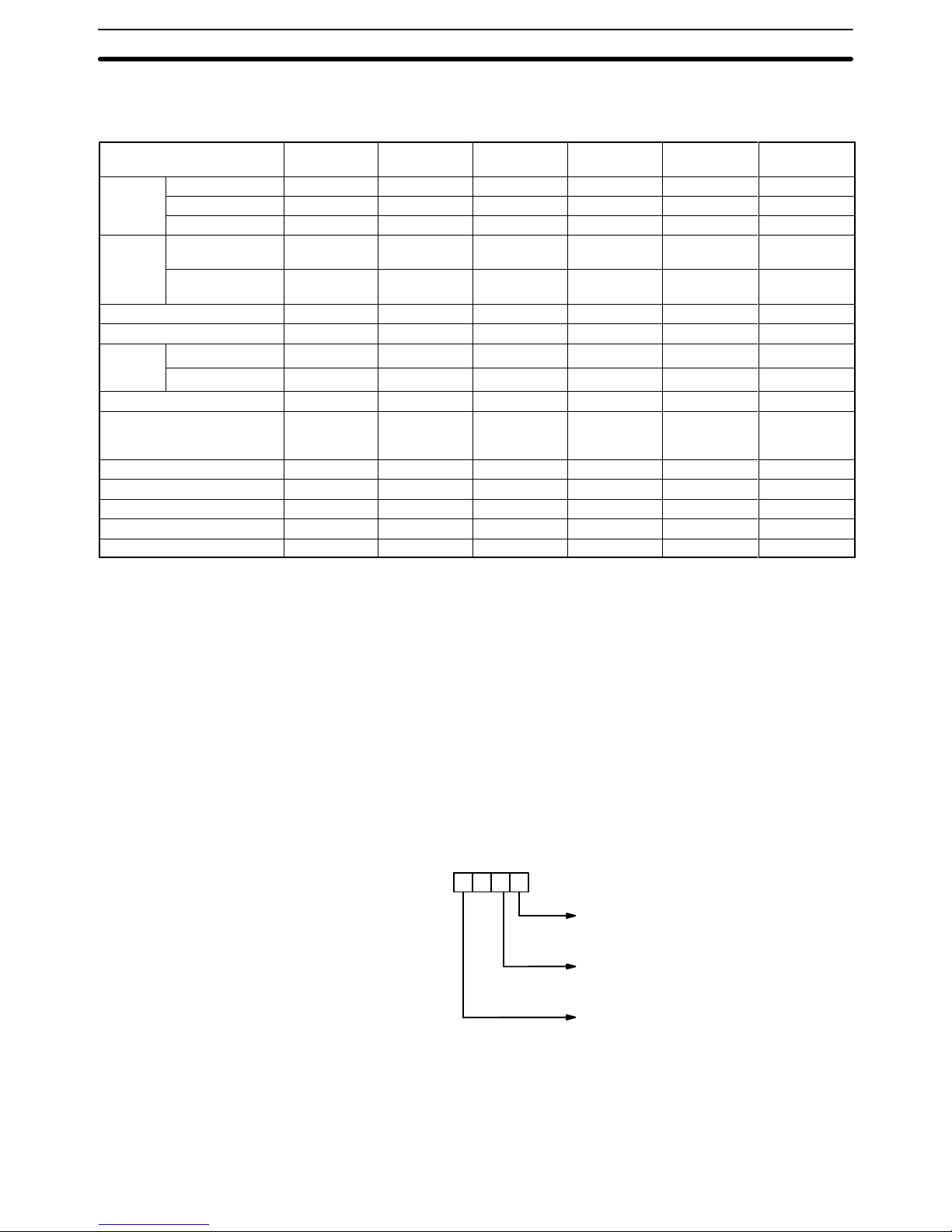

1-8 CPU Comparison

The following table shows differences between the various CV-series CPUs.

CPU

CVM1-

CPU01-EV2

CVM1-

CPU11-EV2

CVM1-

CPU21-EV2

CV500-

CPU01-EV1

CV1000-

CPU01-EV1

CV2000-

CPU01-EV1

Ladder diagrams

Supported Supported Supported Supported Supported Supported

Program-

SFC

Not supported Not supported Not supported

Supported Supported Supported

ming

Instructions 284 284 285 169 170 170

Speed

Basic

instructions (ms)

0.15 to 0.45 0.125 to 0.375 0.125 to 0.375 0.15 to 0.45 0.125 to 0.375 0.125 to 0.375

Other

instructions (ms)

0.6 to 9.9 0.5 to 8.25 0.5 to 8.25 0.6 to 9.9 0.5 to 8.25 0.5 to 8.25

Program capacity (see note)

30K words 30K words 62K words 30K words 62K words 62K words

Local I/O capacity

512 pts

1,024 pts 2,048 pts

512 pts

1,024 pts 2,048 pts

Remote

SYSMAC BUS/2

1,024 pts 2,048 pts 2,048 pts 1,024 pts 2,048 pts 2,048 pts

I/O

capacity

SYSMAC BUS

512 pts

1,024 pts 2,048 pts

512 pts

1,024 pts 1,024 pts

DM Area 8K words 24K words 24K words 8K words 24K words 24K words

Expansion DM Area

Not supported Not supported

32K words

each for 8

banks

Not supported

32K words

each for 8

banks

32K words

each for 8

banks

Timers 512 1,024 1,024 512 1,024 1,024

Counters 512 1,024 1,024 512 1,024 1,024

SFC steps

None None None 512 1,024 1,024

Step Flags

None None None 512 1,024 1,024

T

ransition Flags

None None None 512 1,024 1,024

Note The useable program capacity is 28K words or 60K words.

1-9 Improved Specifications

1-9-1 Upgraded Specifications

The following improvements are applicable to all CV500-CPU01-E and

CV1000-CPU01-E CPUs with lot numbers in which the rightmost digit is 3

(jjj3) or higher.

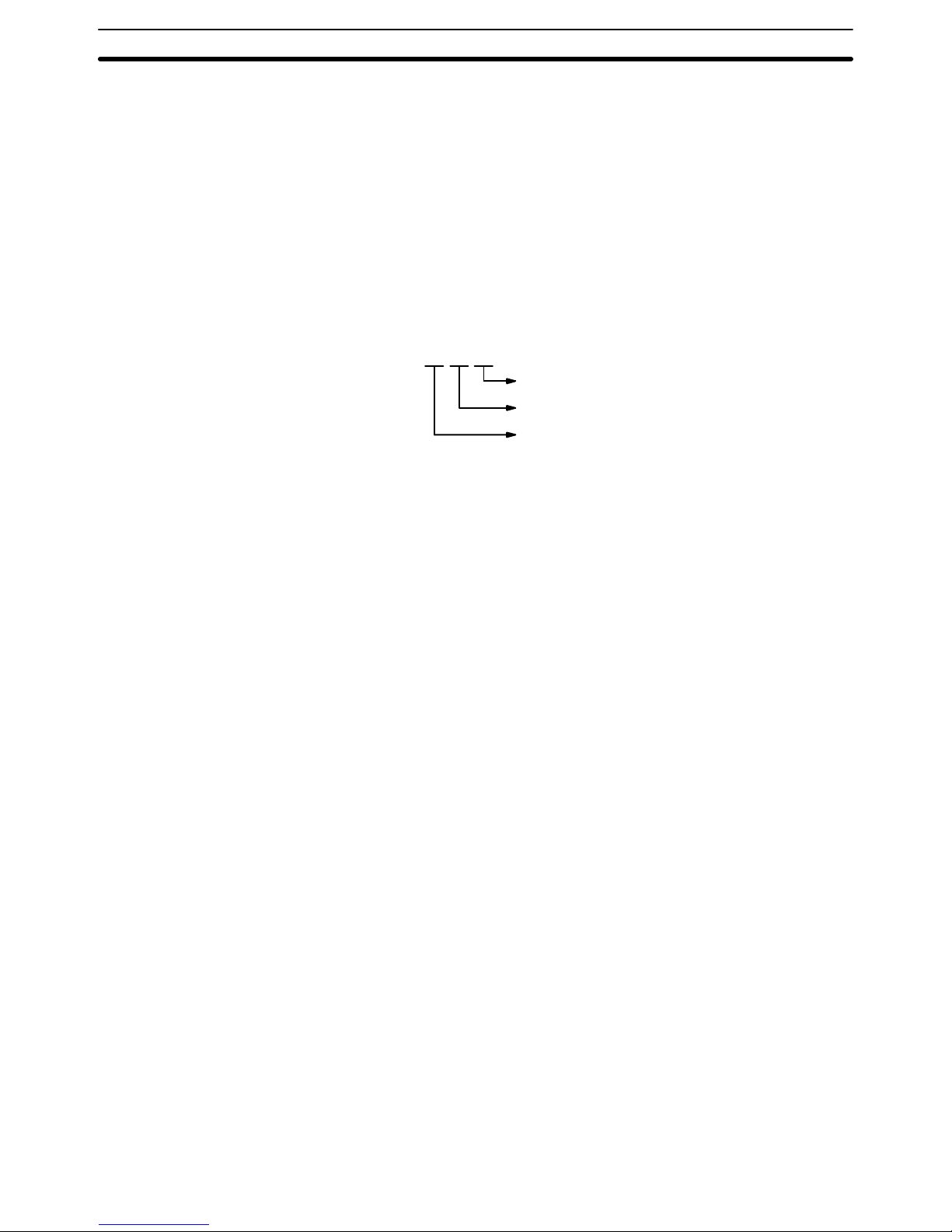

1, 2, 3...

1. The MLPX(110) (4-TO-16 DECODER) instruction has been improved to

also

function as a 8-to-256 decoder and the DMPX(111) (16-T

O-4 ENCOD

-

ER)

instruction has been improved to also function as a 256-to-8 encoder

.

To

enable this improvement, the digit designator

(Di) has been changed as

shown below.

Specifies

the first digit to be converted

4-to-16/16-to-4: 0 to 3

8-to-256/256-to-8: 0 or 1

Number of digits to be converted

4-to-16/16-to-4: 0 to 3 (1 to 4 digits)

8-to-256/256-to-8: 0 or 1 (1 or 2 digits)

Process

0: 4-to-16/16-to-4

1: 8-to-256/256-to-8

Digit number:

3210

0

2. The following operating parameter has been added to the PC Setup.

JMP(004) 0000 Processing

Y: Enable multiple usage (default)

N: Disable multiple usage

Improved Specifications Section 1-9

13

3. The

operation of Completion Flags for timers has been changed so that the

Completion Flag for a timer turns ON only when the timer instruction is

executed

with a PV of 0000

and not when the timer’s PV is refreshed to a PV

value of 0000, as was previously done.

Only

the timing of the activation of the Completion Flag

has been changed,

and

the

timer’s PV is still refreshed at the same times (i.e., when the timer

instruction is executed, at the end of user program execution, and every

80 ms if the cycle time exceeds 80 ms).

4. The

READ(190) (I/O READ) and WRIT(191) (I/O WRITE) instructions have

been improved so that they can be used for Special I/O Units on Slave

Racks under the following conditions.

a) The

lot number of the Remote I/O Master Unit and Remote I/O Slave Unit

must be the same as or latter than the following.

1992

October (Y

: November; Z: December)

1st

01 X 2

b) The DIP switch on the Remote I/O Slave Unit must be set to “54MH.”

c) The Special I/O Unit must be one of the following: AD101, CT012,

CT021,

CT041, ASC04, IDS01-V1, IDS02, IDS21, IDS22, or LDP01-V1.

(The

NC221-E, NC222, CP131, and FZ001 cannot be mounted to Slave

Racks.)

1-9-2 Version-1 CPUs

CV-series CPUs were changed to version 1 from December 1993. The new

model numbers are as follows: CVM1-CPU01-EV1, CVM1-CPU11-EV1,

CV500-CPU-EV1, CV1000-CPU-EV1, and CV2000-CPU-EV1. (Of these, all

CVM1

CPUs were changed to version 2 from December 1994; refer to the next

sections for details.)

The following additions and improvements were made to create the version-1

CPUs.

PT Link Function The

host

link interface on the CPU can be used to connect directly to Program

-

mable Terminals (PT

s) to create high-speed data links. T

o use the PT links,

turn

ON

pin 3 of the DIP switch on the CPU. Pin 3 must be turned OFF for host link

connections.

EEPROM Writes With

the new CPUs, you can write to EEPROM Memory Cards mounted to the

CPU

by using the file write operation from a

Peripheral Device. A Memory Card

Writer

is no longer required for this write operation. W

riting is possible in PRO

-

GRAM mode only.

New Command A

new I/O REGISTER command (QQ) has been added so that words from dif

fer-

ent data areas can be read at the same time.

Faster Host Links The

communications response time for the built-in host link interface

on the CPU

has been improved by a factor of approximately 1.2.

Faster Searches The search speed from Peripheral Devices for instructions and operands has

been nearly doubled.

1-9-3 Version-2 CVM1 PCs

CVM1 CPUs were changed to version 2 and a new CPU was added from December 1994. The new model numbers are as follows: CVM1-CPU01-EV2,

CVM1-CPU11-EV2, and CVM1-CPU21-EV2.

Improved Specifications Section 1-9

14

The following additions and improvements were made to create the version-2

CPUs.

CMP/CMPL New versions of the CMP(020) and CMPL(021) have been added that are not

intermediate

instructions. The new instructions are CMP(028) and CMPL(029)

and

are programs as right-hand (final) instructions. A total of 24 other new com

-

parison

instructions have also been

added with symbol mnemonics (e.g., >, +,

and <).

XFER(040) This instruction has been upgraded so that source and destination areas can

overlap.

DMPX(111) This instruction has been upgraded so that either the MSB or the LSB can be

specified

for use as the end code. Previously only the

the MSB could be used.

New Flags Underflow and Overflow Flags have been added at A50009 and A50010, re-

spectively.

These flags can be turned ON or OFF when executing ADB, ADBL,

SBB, and SBBL and can be saved or loaded using CCL and CCS.

New Instructions A total of 125 new instructions have been added. These instructions are sup-

ported by version-2 CPUs only.

Faster Online Editing The

time that operation is stopped for online editing has been reduced and is no

longer added to the cycle time. The following are just a couple of examples.

Edit Time operation is stopped

Adding or deleting one instruction block at the

beginning of a 62K-word program

Approx. 0.5 s

Deleting an instruction block containing JME

from the beginning of a 62K-word program

Approx. 2.0 s

The

above speed increase

also applies to all V1 CPUs with lot numbers in which

the rightmost digit is 5 (jjj5) or higher.

New Host Link Commands New

C-mode

commands for the CPU Host Interface have been added and the

functionality of existing commands has been improved as follows:

New Commands

• RL/WL: Read and write commands for the CIO Area.

• RH/WH: Read and write commands for the CIO Area.

• CR: Read command for the DM Area.

• R#/R$/R%: SV read commands.

• W#/W$/W%: SV change commands.

• *: Initialization command.

Improved Commands

• The Link Area (CIO 1000 to CIO 1063) and Holding Area (CIO 1200 to

CIO 1299) can now be specified for the KS, KR, KC, and QQ commands.

• CVM1-CPU21-EV2 can now be read for the MM command.

The above new and improved commands can also be used with all V1 CPUs

with lot numbers in which the rightmost digit is 5 (jjj5) or higher.

Note Only the following Programming Devices support version-2 CPUs: SSS

(C500-ZL3AT1-E) and the CVM1-PRS21-EV1 Programming Console

(CVM1-MP201-V1).

Of these, the SSS does not support SFC

and thus cannot

be used for the CV500, CV1000, and CV2000. Use the CVSS for these PCs.

Improved Specifications Section 1-9

15

SECTION 2

System Configuration and Components

This

section provides information about the types of system configuration in which the CV

-series PCs

can be used and the

individual

Units that make up these configuration. Refer to

Appendix A Standar

d Models

for a list of C- and CV

-series prod

-

ucts

that can be used in CV

-series PC Systems.

2-1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1

CPU Racks

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2

Expansion CPU Racks

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3

Expansion I/O Racks

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3

Rack Components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 CPUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 I/O Control Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 I/O Interface Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-4 Power Supply Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-5 T

ermination Resistance Units

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-6 I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

2-1 System Configuration

This

section provides illustrations of CV

-series PC Systems, which can be clas

-

sified into five different types of configuration.

• Systems with only a CPU Rack

• Systems with only CV-series Expansion I/O Racks.

• Systems with an Expansion CPU Rack.

• Systems with a Single CV-series Expansion I/O Rack.

• Systems with C500 Expansion I/O Racks.

If

only a CPU Rack is used, an I/O Control Unit is not required, but the CPU Rack

is otherwise the same as those in the following examples. The specific Units

used in the configuration are described in more detail later.

The maximum I/O capacity with any configuration is 512 points (32 words) for

the CV500 or CVM1-CPU01-EV2; 1,024 points (64 words) for the CV1000 or

CVM1-CPU11-EV2; and 2,048 points (128 words) for the CV2000 or

CVM1-CPU21-EV2.

The I/O capacity will be less depending on the Racks and

the types of Units mounted.

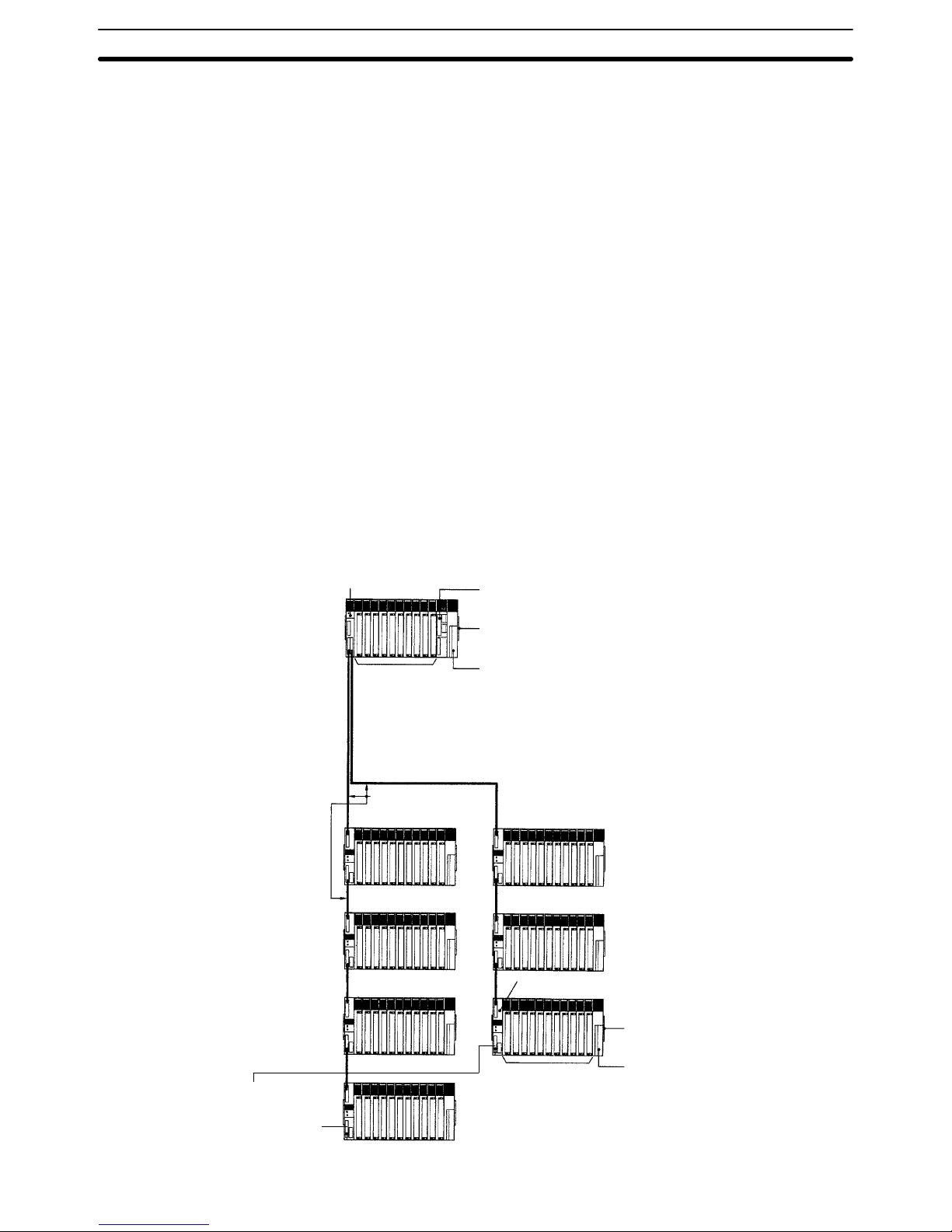

The

following figure shows an assembled CV

-series CPU Rack and seven Ex

-

pansion

I/O Racks. Up to seven Expansion I/O Racks may be connected in one

or

two series from the CPU Rack. The total length of I/O Connecting Cable must

be

50 m or less for each series and a T

ermination Resistance Unit must be be

connected to the last Rack or to the unused I/O Control Unit connector.

Units can be mounted to any slot on the Racks shown for them below.

I/O

Control Unit:

CV500-IC201/IC101

CPU: CV500-CPU01-EV1, CV1000-CPU01-EV1,

CV2000-CPU01-EV1, CVM1-CPU01-EV2, CVM1-CPU11-EV2,

or CVM1-CPU21-EV2

CPU Backplane: CV500-BC031/051/101

Power Supply Unit: CV500-PS221/PS21

1 or CVM1-P

A208

I/O Interface Unit

CV500-II201

I/O Backplane

CV500-BI042/062/112

Power Supply Unit

CV500-PS221/PS211

or CVM1-P

A208

3, 5, or 10 slots

SYSMAC NET Link Units

SYSMAC LINK Units

SYSMAC BUS/2 Masters

Personal Computer Units

BASIC Units

C500 I/O Units

C500 Special I/O Units

SYSMAC BUS Masters

I/O Connecting Cable

CV500-CNjj

2

(50 m max. total length

for 1 series)

4/6/11 slots

C500 I/O Units

C500 Special I/O Units

SYSMAC BUS Masters

T

ermination Resistance Unit:

CV500-TER01

(T

wo included with CV500-IC101/201

I/O Control Unit.)

Systems with only

CV-series Expansion I/O

Racks

System Configuration Section 2-1

17

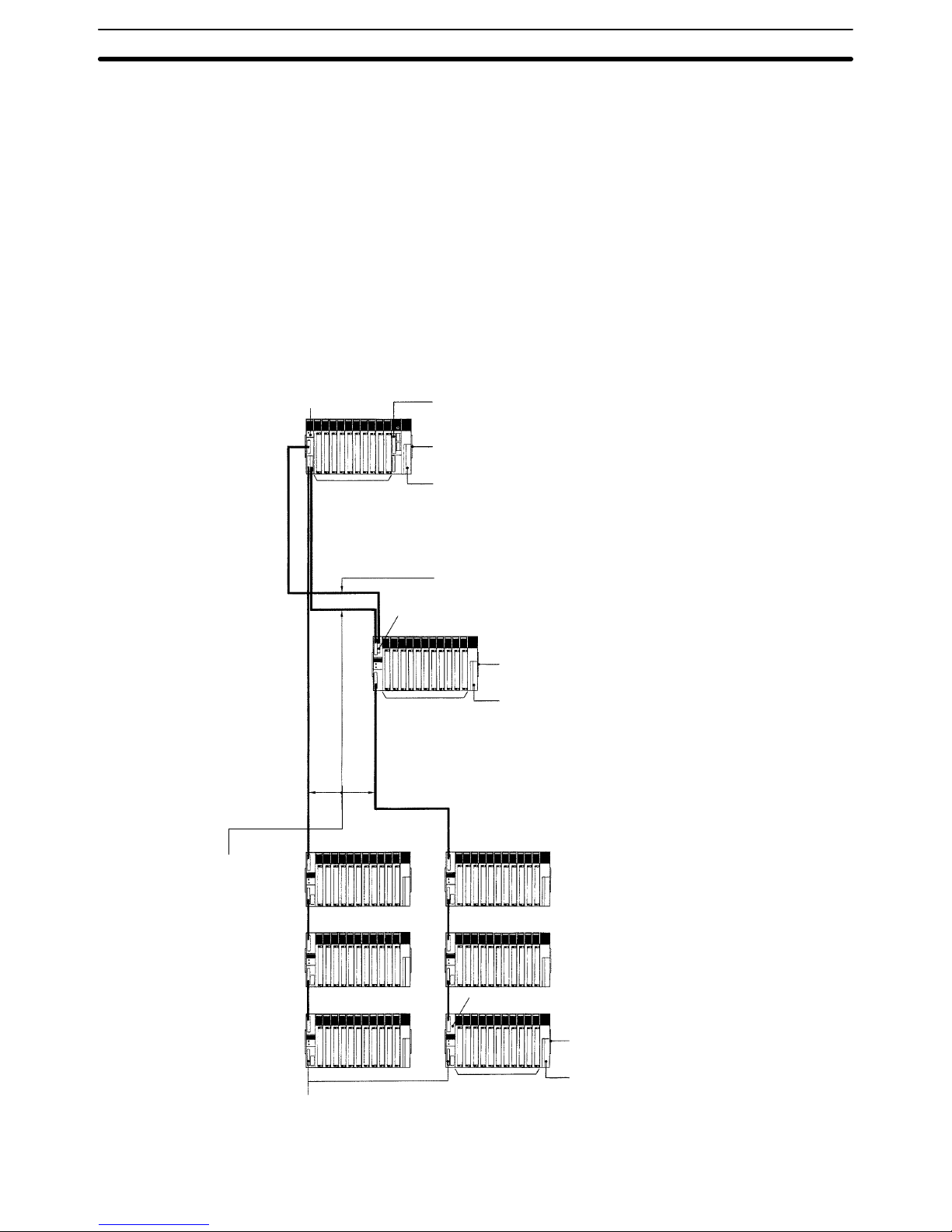

When nine or more CPU Bus Units (Temperature Controller Data Link Units,

SYSMAC

NET Link Units, SYSMAC LINK Units, SYSMAC BUS/2 Remote I/O

Master Units, Ethernet Units,

BASIC Units, and Personal Computer Units) are

required

in a System, the CPU Rack may be extended by connecting an Expan

-

sion CPU Rack to enable mounting up to 16 CPU Bus Units.

Only

one Expansion CPU Rack may be connected to a CPU Rack. A system that

includes

an Expansion CPU Rack can be extended by connecting up to six Ex

-

pansion

I/O Racks.

The Expansion I/O Racks may be connected in one or two

series from the CPU Rack. The total length of I/O Connecting Cable must be

50 m or less for each series and a Termination Resistance Unit must be connected to the last Rack or to the unused I/O Control Unit connector.

Using

an Expansion CPU Rack does not increase the maximum

I/O capacity of

the PC; it only increases the number of CPU Bus Units that can be used.

Units can be mounted to any slot on the Racks shown for them below.

CPU

Backplane: CV500-BC031/051/101

Power Supply Unit: CV500-PS221/PS21

1 or

CVM1-PA208

CPU Connecting Cable

CV500-CNjj1

Expansion CPU Backplane CV500-BI1

11

Power Supply Unit:

CV500-PS221/PS21

1 or CVM1-P

A208

I/O Connecting Cable

CV500-CNjj

2

(50 m max. total

length for 1 series)

T

ermination Resistance Unit CV500-TER01

(T

wo included with CV500-IC101/201 I/O Control Unit.)

I/O Backplane

CV500-BI042/062/112

4/6/11 slots

C500 I/O Units

C500 Special I/O Units

SYSMAC BUS Masters

I/O Interface Unit

CV500-II101

I/O Interface Unit

(CV500-II201)

I/O Control Unit: CV500-IC101

CPU: CV500-CPU01-EV1, CV1000-CPU01-EV1,

CV2000-CPU01-EV1, CVM1-CPU01-EV2, CVM1-CPU1

1-EV2, or

CVM1-CPU21-EV2

3, 5, or 10 slots

SYSMAC NET Link Units

SYSMAC LINK Units

SYSMAC BUS/2 Masters

Personal Computer Units

BASIC Units

C500 I/O Units

C500 Special I/O Units

SYSMAC BUS Masters

11 slots

SYSMAC NET Link Units

SYSMAC LINK Units

SYSMAC BUS/2 Masters

Personal Computer Units

BASIC Units

C500 I/O Units

C500 Special I/O Units

SYSMAC BUS Masters

Power Supply Unit:

CV500-PS221/PS21

1 or CVM1-P

A208

Systems with an Expansion

CPU Rack

System Configuration Section 2-1

Loading...

Loading...