Page 1

Cat. No. W367-E1-02

SYSMAC

CS1W-SLK11/21

SYSMAC LINK Units

Page 2

CS1W-SLK11/21

SYSMAC LINK Units

Operation Manual

Revised June 2004

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

SECTION 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 SYSMAC LINK Unit Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 SYSMAC LINK Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4 Programming Devices and Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-5 Data Link Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-6 Message Service Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 2

Unit Components and Switch Settings . . . . . . . . . . . . . . . . . 15

2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3 Mounting to Backplanes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2-4 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SECTION 3

Basic Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-1 SYSMAC LINK System Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-2 Unit Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-3 Setting Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-4 Network Address Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3-5 Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-6 Memory Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SECTION 4

Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-2 Data Link Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-3 Data Link Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-4 Data Link Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-5 Creating Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4-6 Data Link Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

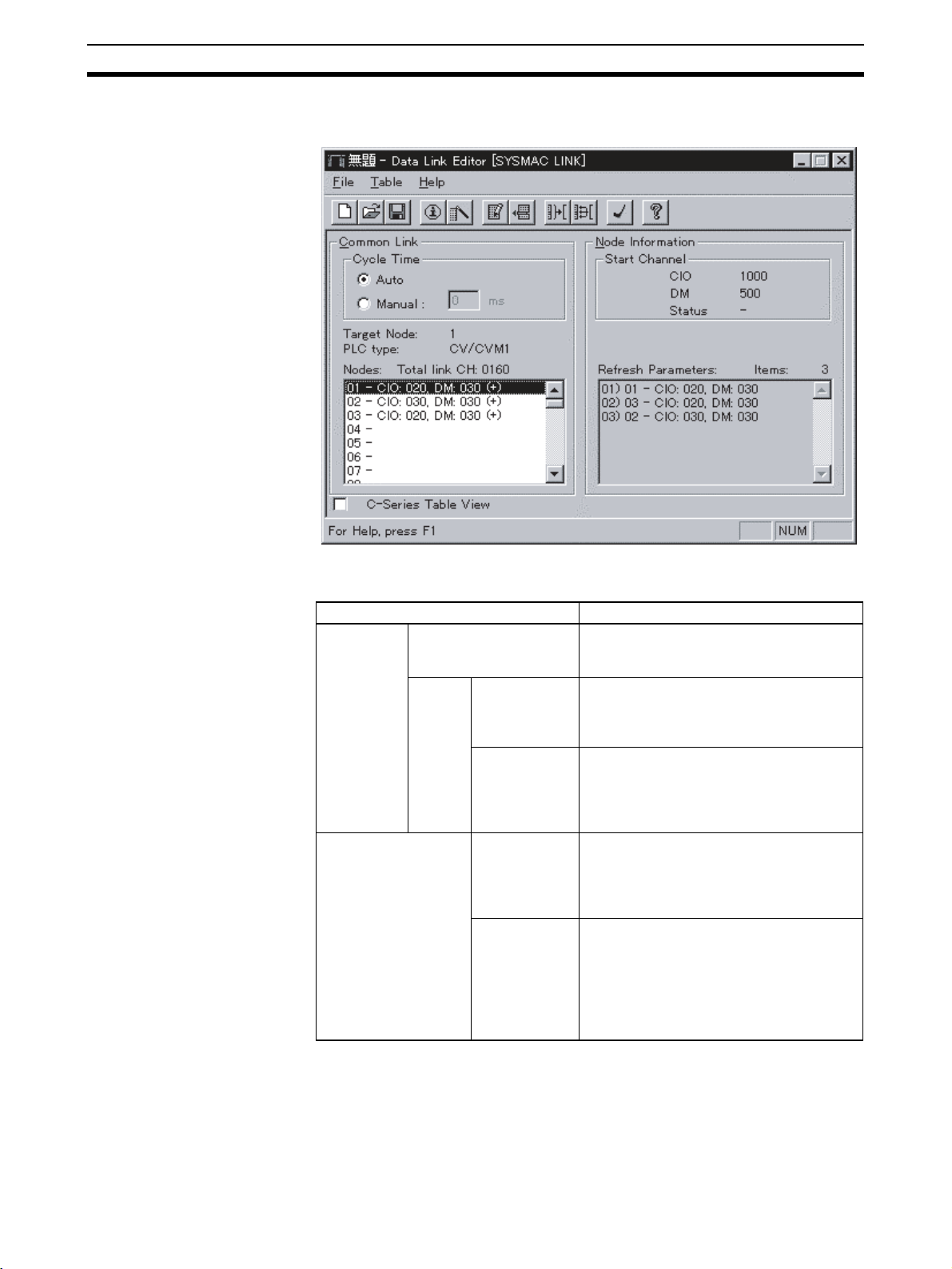

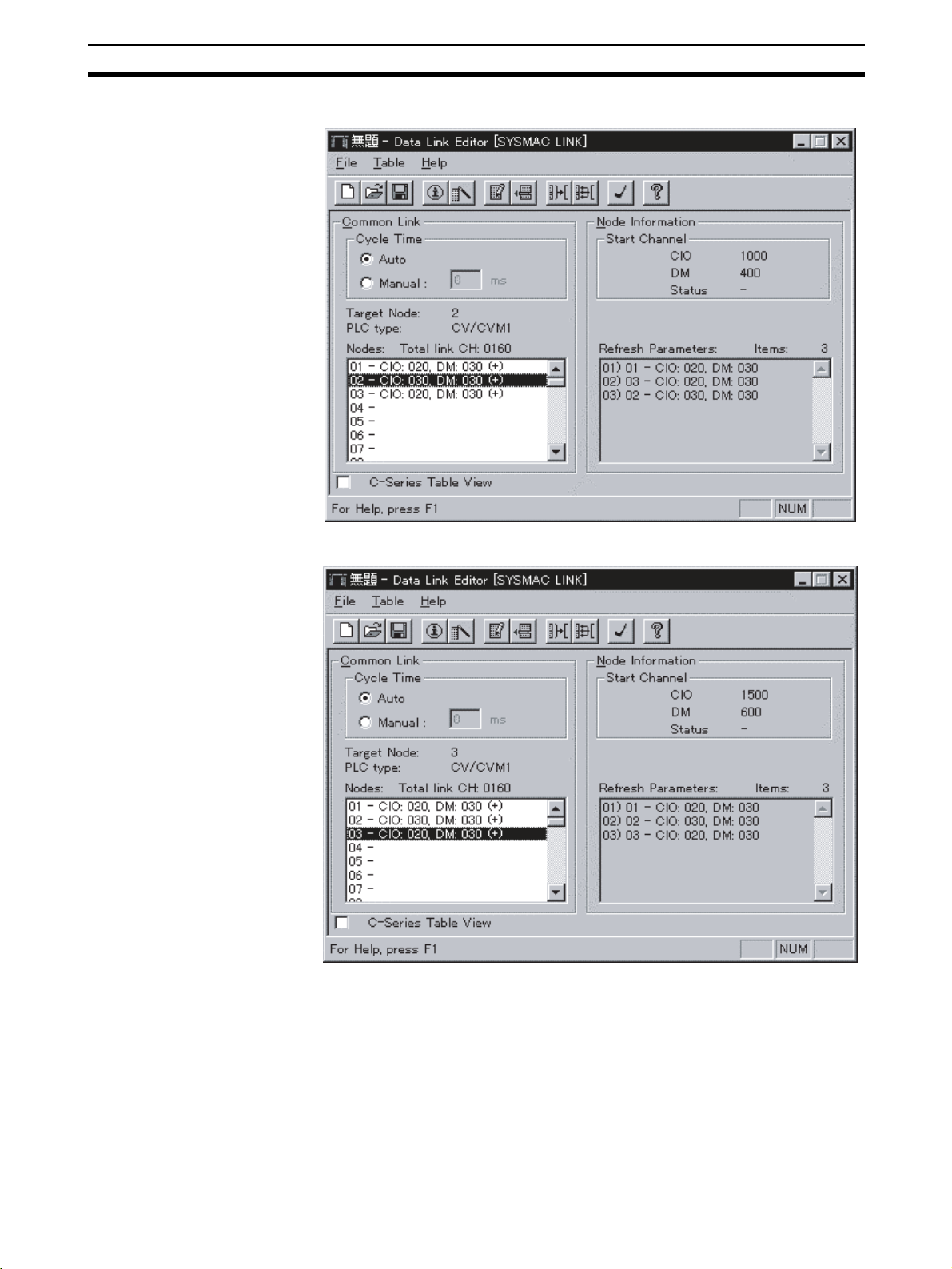

4-7 Data Link Table Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

vii

Page 7

TABLE OF CONTENTS

4-8 Controlling Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4-9 Data Link Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-10 Data Link Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4-11 Data Link Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4-12 CX-Programmer Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

SECTION 5

Network Data Exchange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5-1 What is Network Interconnection? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5-2 Routing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5-3 Routing Table Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

SECTION 6

Message Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6-1 About Data Read/Write Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6-2 PLC Network Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

6-3 FINS Command/Response Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6-4 FINS Commands for SYSMAC LINK Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

SECTION 7

Remote Monitoring and Programming . . . . . . . . . . . . . . . . 123

7-1 Remote Programming and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

SECTION 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8-2 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8-3 Polling Node Backup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

8-4 Node Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

SECTION 9

Unit Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

9-1 Replacing the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

9-2 Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

9-3 Using the C200H-SLK21 or C1000H-SLK21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

SECTION 10

Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 149

10-1 Periodic Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

10-2 Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

10-3 Tools and Equipment Needed for Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

viii

Page 8

TABLE OF CONTENTS

Appendices

A Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

B Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

C Related Auxiliary Area Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

D CPU Bus Unit Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

E DM Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

ix

Page 9

Page 10

About this Manual:

This manual describes the installation and operation of CS-series SYSMAC LINK Units and includes

the sections described below.

Please read this manual completely and be sure you understand the information provide before

attempting to install and operate a SYSMAC LINK System including CS-series SYSMAC LINK Units.

Section 1 Introduction introduces the features and operations of the SYSMAC LINK Units.

Section 2 Unit Components and Switch Settings describes the names and functions of the SYS-

MAC LINK Unit components and switch settings.

Section 3 Basic Communications describes the token bus method of communications used in SYSMAC LINK Systems, as well as the basic settings necessary for operation.

Section 4 Data Links describes the operation of data links, procedures required to establish data

links, and methods of monitoring data link operations.

Section 5 Network Data Exchange provides the details of the data exchange functions of the CSseries PLCs via SYSMAC LINK Networks.

Section 6 Message Service describes the PLC ladder network instructions and FINS commands that

can be used to transfer data and control operation via a SYSMAC LINK System.

Section 7 Remote Monitoring and Programming provides information on remote programming and

monitoring.

Section 8 Troubleshooting provides information to help identify and correct errors that might occur.

Section 9 Unit Replacement describes the replacement procedure and provides cautions for Unit

replacement.

Section 10 Inspection and Maintenance contains information describing periodic inspections

required by the System.

Appendices contain information describing SYSMAC LINK Unit models, their dimensions, and area

allocations.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xi

Page 11

Page 12

PRECAUTIONS

This section provides general precautions for using the CS-series SYSMAC LINK Units and related devices.

The information contained in this section is important for the safe and reliable application of the CS-series

SYSMAC LINK Units. You must read this section and understand the information contained before attempting

to set up or operate a SYSMAC LINK System.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

6 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6-1 Applicable Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6-2 Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

xiii

Page 13

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, in order to ensure safety in the system if an abnormality occurs due to malfunction of the PLC or another external factor affecting the PLC operation. Not doing so may result in serious

accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

xiv

Page 14

Operating Environment Precautions 4

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-VDC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing the I/O memory area. Doing either of these without

confirming safety may result in injury.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5 Application Precautions

Observe the following precautions when using the SYSMAC LINK Unit.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100

protect against electrical shock.

• Always turn OFF the power supply or the backup power supply to the PLC

or the computer before attempting any of the following. Performing any of

the following with the power supply turned ON may lead to electrical

shock:

• Installing or removing the SYSMAC LINK Unit.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units, Inner Boards, or any other Units.

• Assembling the Units.

• Setting DIP or rotary switches.

Ω or less when installing the system to

xv

Page 15

Application Precautions 5

• Connecting or disconnecting any cables or wiring.

• Connecting or disconnecting any connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation or

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Do not attempt to disassemble, repair, or modify any Units. Any attempt to

do so may result in malfunction, fire, or electric shock.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Wire all connections correctly.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the communications cable connectors and other items with

locking devices are properly locked into place. Improper locking may

result in malfunction.

• Use special packing box when transporting the SYSMAC LINK Unit. Handle the product carefully so that no excessive vibration or impact is

applied to the product during transportation.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Observe the following precautions when wiring the communications cable

or backup power supply cables.

• Separate the cables from the power lines or high-tension lines.

• Do not bend the cables beyond their natural bending radius.

• Do not pull on the cables.

xvi

Page 16

Conformance to EC Directives 6

• Do not place heavy objects on top of the cables.

• Route cables inside conduits.

• Before touching the Unit, be sure to first touch a grounded metallic object

in order to discharge any static build-up.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives conform to the related EMC

standards so that they can be more easily built into other devices or

machines. The actual products have been checked for conformity to EMC

standards (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the

customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel in which the OMRON devices are installed.

The customer must, therefore, perform final checks to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN50082-2

EMI (Electromagnetic Interference): EN61000-6-2

6-3 Conformance to EC Directives

The CS1W-SLK11 and CS1W-SLK21 SYSMAC LINK Units comply with EC

Directives. To ensure that the machine or device in which these SYSMAC

LINK Units are used complies with EC directives, the SYSMAC LINK Units

must be installed as follows:

1,2,3...

1. In order to conform with EC Directives, the SYSMAC LINK Units must be

installed within a control panel. Use an SA20-712 (made by NITTO ELECTRIC WORKS) or a similar model.

2. Reinforced insulation or double insulation must be used for the DC power

supplies used for the communications and I/O power supplies.

3. SYSMAC LINK Units complying with EC Directives also conform to the

Common Emission Standard (EN50081-2). When a SYSMAC LINK Unit is

built into a machine, however, noise can be generated by switching devices using relay outputs and cause the overall machine to fail to meet the

Standards, particularly with radiated emission for 10-m regulations. The

customer must, therefore, take measures to ensure and perform final

checks to confirm that devices and the overall machine conform to EMC

standards.

xvii

Page 17

Page 18

This section introduces the features and operations of the SYSMAC LINK Units.

1-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 SYSMAC LINK Unit Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2-1 Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 SYSMAC LINK Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3-1 Basic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3-2 Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3-3 Network Data Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3-4 Message Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3-5 Remote Programming and Monitoring . . . . . . . . . . . . . . . . . . . . . . 8

1-3-6 RAS Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-4 Programming Devices and Support Software . . . . . . . . . . . . . . . . . . . . . . . . 8

1-4-1 Basic Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-4-2 CX-Programmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5 Data Link Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-5-1 Manually Setting Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-5-2 Automatically Setting Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-6 Message Service Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 1

Introduction

1

Page 19

Overview Section 1-1

.

1-1 Overview

The SYSMAC LINK is an FA network that can send and receive large data

packets flexibly and easily among the OMRON CS-series, C200HX/HG/HE,

CVM1, CV-series, C1000H, C1000HF, C2000H, and CQM1H-series Programmable Controllers (PLCs), as well as IBM PC/AT or compatible computers.

The SYSMAC LINK supports data links that enable data sharing and a message service that enables sending and receiving data when required. Data

link words can be freely set to create a flexible data link system and effectively

use memory areas.

The network is connected using coaxial cable or optical fiber cable.

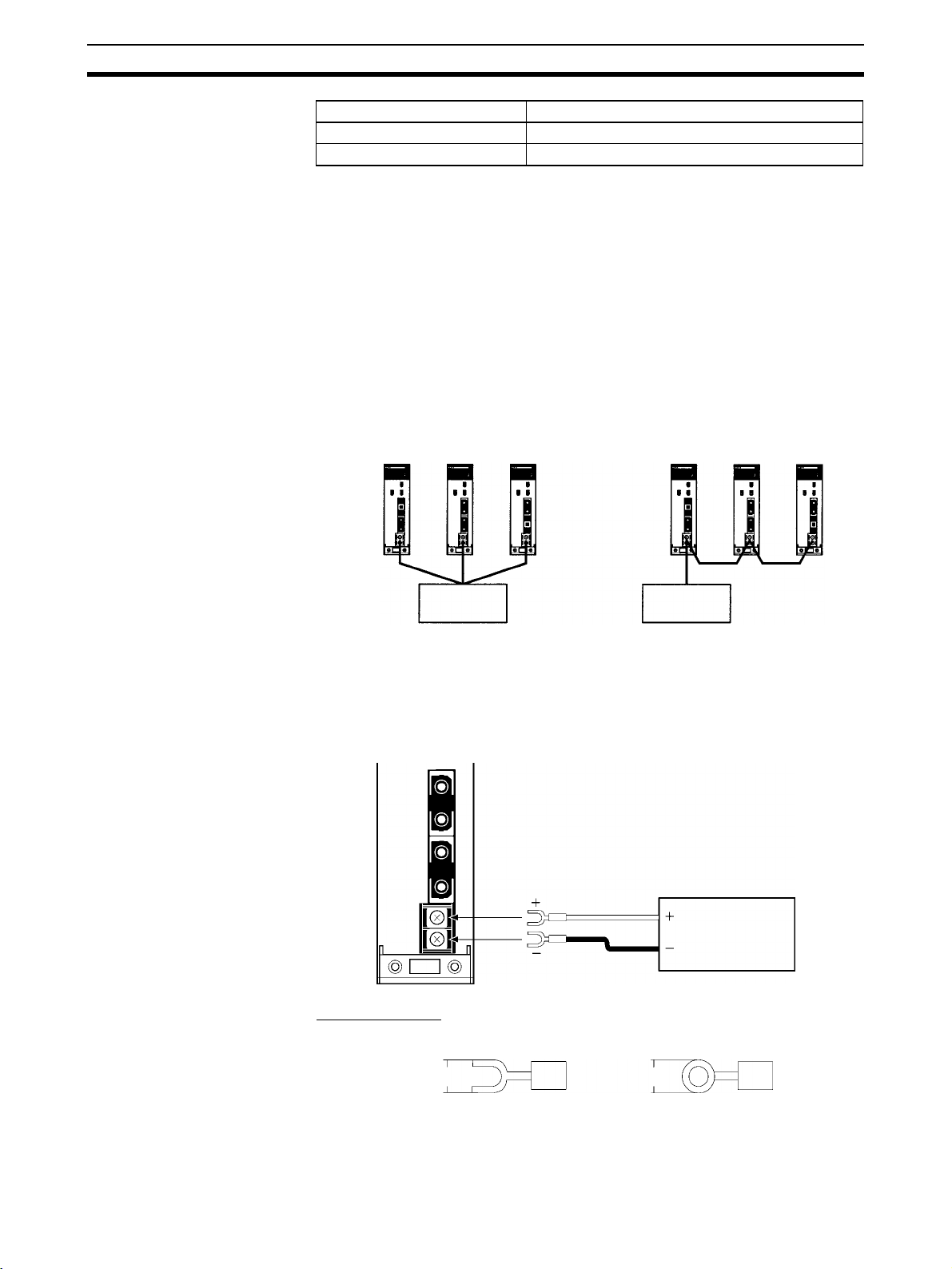

Coaxial System (Coaxial Cable)

CS1W-SLK21

SYSMAC LINK Unit

CS-series

PLC

C200HX/HG/HE

C200HW-SLK23/SLK24

SYSMAC LINK Unit

CVM1,

CV-series PLC

CV500-SLK21

SYSMAC LINK Unit

C1000H-SLK21-V1

SYSMAC LINK Unit

C1000H,

C1000HF,

C2000H

IBM PC/AT or

compatible

IBM PC/AT or

compatible

Coaxial cable

3G8C2-SLK21-E

SYSMAC LINK

Support Board

3G8C2-SLK21-E

SYSMAC LINK

Support Board

Optical System (Optical Fiber Cable)

CS1W-SLK11

SYSMAC LINK Unit

CS-series PLC

24-VDC

Backup Power

Supply

100-VAC

Backup Power

Supply

Optical fiber cable

(Daisy-chain

connection)

C200HW-SLK13/SLK14

SYSMAC LINK Unit

C200HX/HG/HE

C200H-APS03

Power Supply

Unit

CV500-SLK11

SYSMAC LINK Unit

CVM1,

CV-series PLC

C1000H, C1000HF,

C2000H

C1000H-APS01

Power Supply

Unit

C1000H-SLK11

SYSMAC LINK Unit

Internetwork Connections Communications across bridges or gateways can include up to three net-

works, including the local network. A CS-series, CVM1, or CV-series PLC can

be used as the bridge or gateway to easily and economically create networks

controlling multiple lines.

Network 1 (local network) Network 2 Network 3

SYSMAC LINK

Controller Link, Ethernet, SYSMAC LINK, SYSMAC NET, etc.

Controller Link, Ethernet, SYSMAC LINK, SYSMAC NET, etc

2

Page 20

SYSMAC LINK Unit Features Section 1-2

1-2 SYSMAC LINK Unit Features

CS-series SYSMAC LINK Units are equipped with a variety of special features

including some developed from those incorporated by the C-series SYSMAC

LINK Unit. These features allow PLCs in a SYSMAC LINK Network to communicate with or automatically exchange data with other PLCs in the same Network and to communicate with interconnected Networks.

High Speed, Reliability,

and Flexibility

Distributed Control with

Data Links

Active Communications Communications can also be programmed using ladder-diagram instructions

The specialized communications LSIs used in all SYSMAC LINK Units deliver

high speed, reliability, and flexibility in an advanced data link system, while

optical fiber cable systems provide high-speed communications with unparalleled immunity to noise.

In the event of an error or failure in the polling node, another node automatically takes over management of the SYSMAC LINK System without stopping

the entire network. The CX-Net within the CX-Programmer can monitor and/or

program PLCs anywhere in the network via the SYSMAC LINK System.

The data link function transfers data to and from other nodes automatically,

establishing simple but powerful peer-to-peer links between nodes. Data links

can be generated automatically or the user can use the flexibility of manually

generating data links to eliminate unused link words, improve data link I/O

response time, and to even create several data link groups in one network.

The data link communications cycle time can be fixed at a constant value, so

even simultaneous remote programming/monitoring and NETWORK READ/

WRITE instructions (RECV(98)/SEND(90)) execution have no effect on the

data link I/O response time.

The data link function allows data exchange not only between PLCs but also

between PLCs and host computers in the network, making it possible to

develop communications software with ease.

(SEND(90), RECV(98), and CMND(490)) to facilitate communications with

other PLCs and host computers on an as-needed basis. Use of these instructions enables the following:

1,2,3... 1. Broadcast transmissions

2. Response monitoring time setting (response time-out setting)

3. Transmit retry setting

4. Enabling/disabling responses

Internetwork

Communications

Remote Access The CX-Net within the CX-Programmer can access PLCs on the local net-

RAS Functions SYSMAC LINK Units are equipped with three RAS functions (RAS is an acro-

Routing tables can be set up in network PLCs so that communications are

possible with interconnecting networks or networks one network away from

the local network. This includes both bridging to other SYSMAC LINK Networks or passing gateways to other OMRON networks, including those in

SYSMAC NET Link Systems or SYSMAC BUS/2 Remote I/O Systems.

work, on adjacent networks, or on networks one removed from the local network, including Controller Link and Ethernet Networks. Access can be used to

monitor operation and/or manipulate data and programs.

nym for reliability, availability, and serviceability). The Polling Node Backup

and Failed Node Bypass (optical systems only) functions prevent the network

from failing when one Unit fails. The Internode Echo Test function aids in communications troubleshooting.

Remote monitoring of the network’s operating status and error logs also aids

in troubleshooting and quick correction of communications problems.

3

Page 21

SYSMAC LINK Unit Features Section 1-2

1-2-1 Standard Models

SYSMAC LINK Units

Applicable

PLCs

CS-series

PLCs

(CS1-H, CS1)

Unit

classification

CPU Bus Unit Coaxial SYSMAC

Name Transmission

LINK Unit

Optical SYSMAC

LINK Unit

path

Coaxial cable Data links (manually set or auto-

Optical fiber

cable

matically set), messages (through

SEND(90), RECV(98), and

CMND(490) instructions)

Communications Model

CS1W-SLK21

CS1W-SLK11

SYSMAC LINK Programming Devices

Product Specifications Model

CX-Net (within CX-Programmer)

Setting manually set data links, starting/stopping data links, reading

network status, reading error logs, setting routing tables, testing networks, changing network parameters settings

Note The CS-series SYSMAC LINK Unit cannot be directly con-

nected to SYSMAC Support Software.

WS02-CX@@E

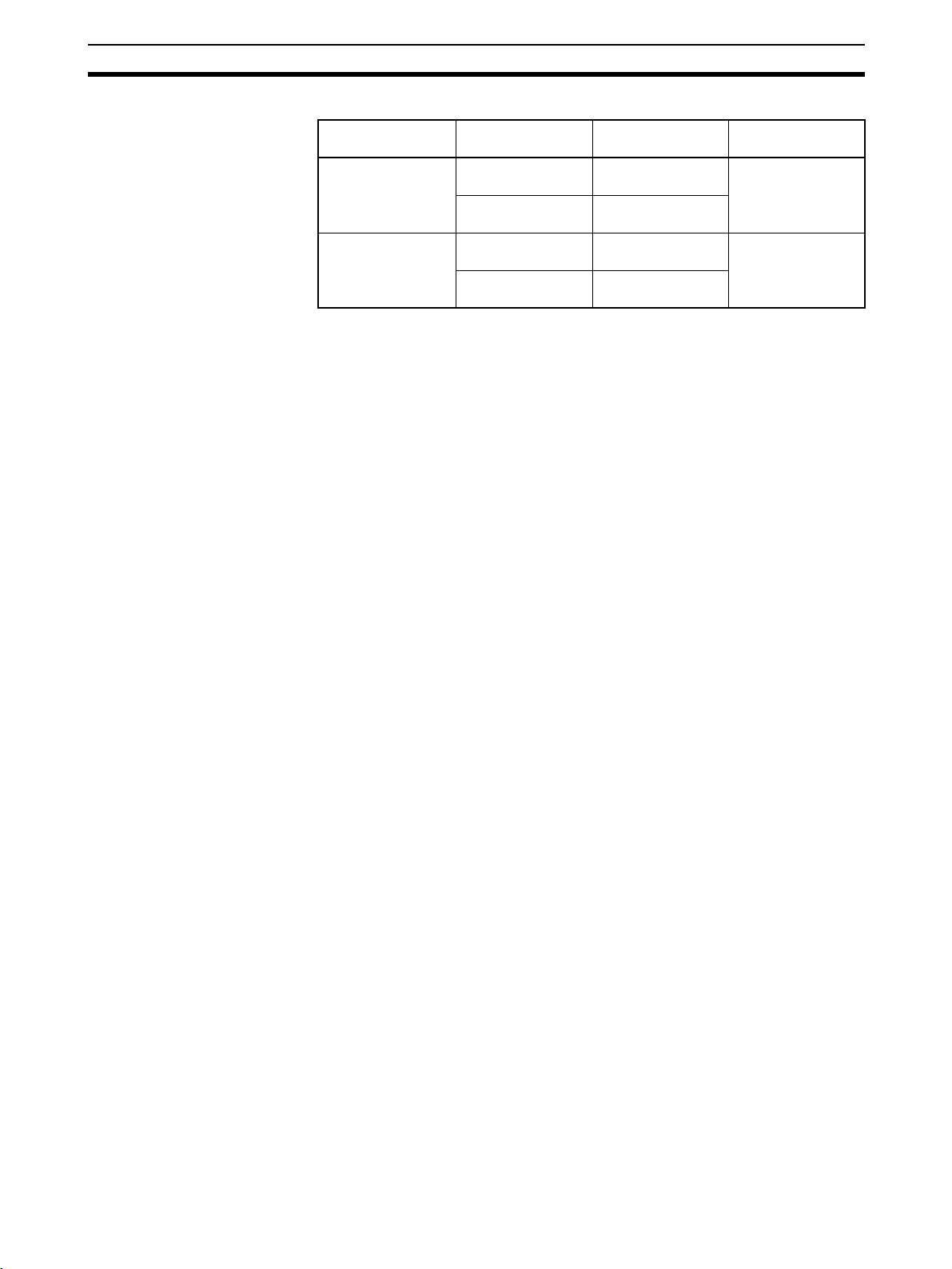

1-2-2 Specifications

General Specifications

Conform to the specifications of the CS Series.

SYSMAC LINK Unit Specifications

Item Specifications

Model CS1W-SLK21 CS1W-SLK11

Type Coaxial Optical fiber

Unit classification CS-series CPU Bus Unit

Applicable PLCs CS-series PLCs

Max. number of Units 4 Units max. (total Coaxial Units and Optical Units)

Mounting position Four slots on the CPU Racks and CS-series Expansion Racks

Allowable unit number settings 0 to F

CPU Unit data

exchange areas

Settings Rotary switch: Unit number

Indicators LEDs: 9 on Optical Unit, 8 on Coaxial Unit

Front panel connectors BNC connector Two optical fiber connectors

Effect on CPU Unit cycle time 0.2 ms

Current consumption (supplied

from Power Supply Unit)

Dimensions 35 × 130 × 101 mm (W x H x D)

CPU Bus Unit

Area

Words allocated to CPU

Bus Units in

DM Area

25 words/Unit

SYSMAC Link Unit to CPU Unit:

Data link status, network participation status, error information, etc.

100 words/Unit (Only first word of the 100 words is used.)

CPU Unit to SYSMAC LINK Unit:

Polling/polled node setting, starting data links, data link mode (automatic/manual) settings, number of data link words for automatic data links, etc.

Rotary switches: Node addresses

Coaxial and Optical Units:

Running, communications error, CPU Unit error, network participation, polling, send,

receive, data link active

Optical Unit Only: Power ON

Power supply terminal block (24 V DC)

Requires an additional 1.5 ms + (No. of words transferred x 0.001 ms) when data links

are used.

Requires additional event processing time when servicing messages.

480 mA at 5 V DC 470 mA at 5 V DC

4

Page 22

SYSMAC LINK Unit Features Section 1-2

Item Specifications

Weight 302 g (including F adapter) 332 g (including cable bracket)

Standard accessories F Adapter, insulating cover Cable bracket

SYSMAC LINK Communications Specifications

Item Specifications

Type Coaxial Optical fiber

Communications functions Data links, messages

Communications method Token bus (N:N)

Transmission method Manchester encoding

Modulation Baseband

Synchronization Flag synchronization (HDLC frames)

Transmission path Bus Daisy chain

Baud rate and maximum

transmission distance

Transmission path Coaxial cable (5C-2V) 2-carrier hard-plastic-clad quartz optical

Node connection BNC connector Special full-lock connector (a half-lock con-

Number of nodes 62 max.

Number of data link words Send words per node: 508 words max. (254 words in CIO Area + 254 words in DM Area)

Data link words Automatic settings: CIO 1000 to CIO 1063 (Data Link Area), D00000 to D00127 (DM

Message length 552 bytes max. (including header)

RAS functions Automatic polling node backup, self-diag-

Error control

2 Mbps (fixed)

Maximum transmission distance: 1 km

Data link words (send and receive) that can be created in a single SYSMAC LINK Unit:

2,966 words max. (CIO Area + DM Area)

Area)

Manual settings: CIO 0000 to CIO 6143 (entire CIO), entire DM Area (D00000 to D32767)

When creating manually set data link tables using CX-Programmer Ver. 1.2 or earlier, the

words that can be set by the user are limited to the same words as for CVM1/CV, as follows:

CIO Area: CIO 0000 to CIO 2555

DM Area: D00000 to D24575

nostics (startup hardware check), internode

testing, broadcast test (using FINS command), watchdog timer, error log

Manchester encoding check, error (CRC-CCITT) detection = X

2 Mbps (fixed)

Maximum transmission distance: 10 km

Maximum distance between nodes:

Crimp cut: 800 m, adhesive polishing: 1 km

(The maximum distance between nodes is

determined by the connector cable processing method.)

fiber cable

nector can also be used)

Automatic polling node backup, self-diagnostics (startup hardware check), internode

testing, broadcast test (using FINS command), watchdog timer, error log, failed

node bypass

16

+ X12 + X5 + 1

5

Page 23

SYSMAC LINK Unit Functions Section 1-3

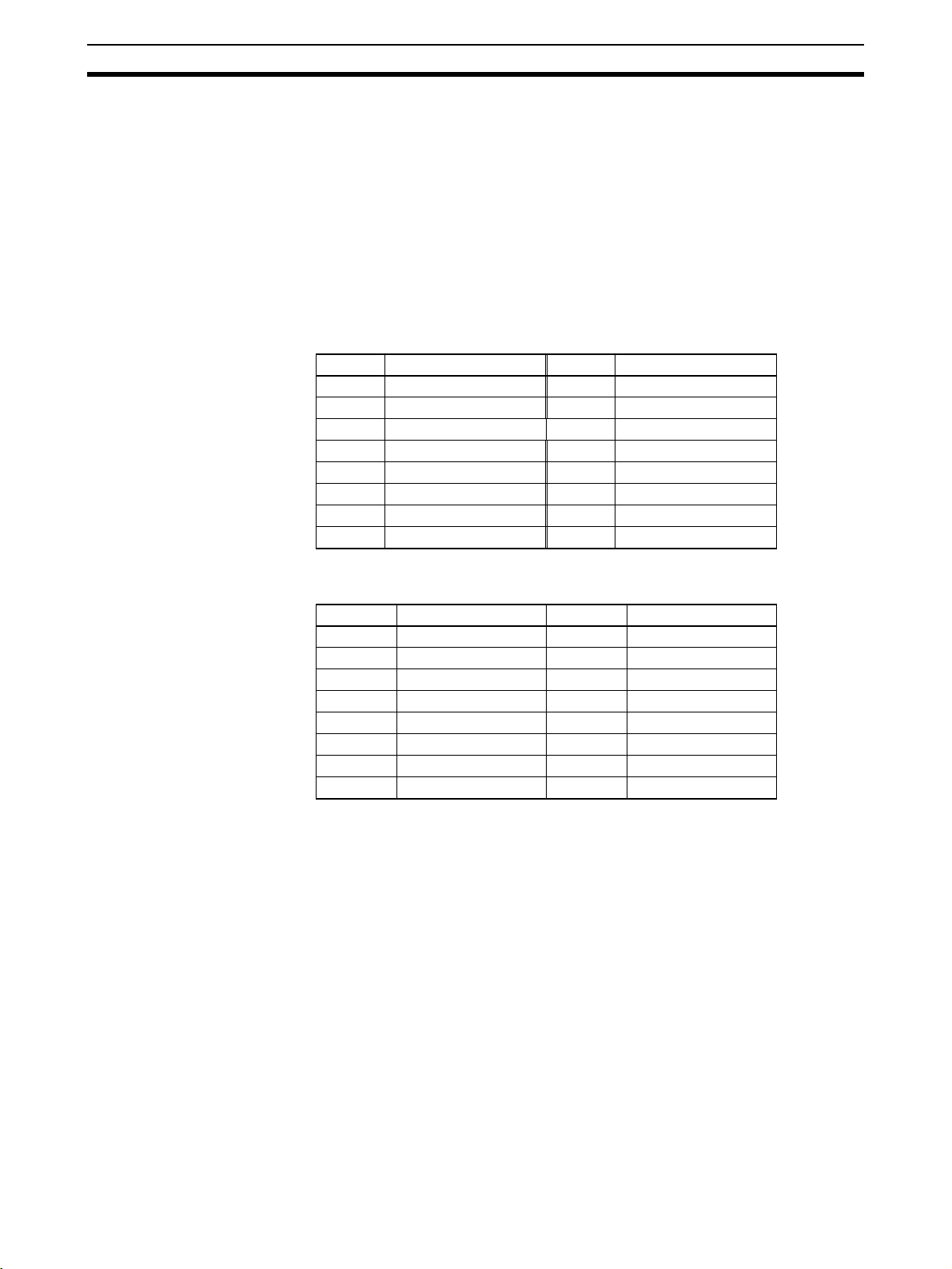

Data Link Specifications

Type of data link Automatic settings Manual settings

Number of data link nodes 62 nodes max. (2 nodes min.)

Number of words per node (sending

and receiving)

Areas supporting

data links

Starting data link

word

Number of words

sent per node

Allocating data

link words

CIO Area Data Link Area:

DM Area D00000 to

CIO Area CIO 1000 Manual settings can be made between

DM Area D00000 Manual settings can be made between

CIO Area Either 4, 8, 16, or 32 words (same for

DM Area Either 8, 16, 32, or 64 words (same for

CIO Area Each node has the same number of

DM Area

2,966 words max. (CIO Area + DM Area total)

Select from the

CIO 1000 to

CIO 1063

D00127

each node)

each node)

data link words and words are allocated to nodes in the order of node

addresses.

following: CIO

Area only, DM

Area only, CIO +

DM Areas

CIO Area (CIO 0000 to CIO 6143)

DM Area (D00000 to D32767)

CIO 0000 to CIO 6143

D00000 to D32767

0 to 254 words (separate for each

node)

The number of data link words and the

order of allocation can be set for each

node. The same order of allocation

must be used for both the CIO Area

and the DM Area.

Message Communications Specifications

Instructions SEND(90)/RECV(98) CMND(490)

Application Data sending and receiving Reading and writing data at other nodes

(e.g., reading/writing file memory), controlling operation (e.g., controller operating modes), reading error logs, etc.

Message contents Commands for sending and receiving

Local node to

partner node

Local node: partner node SEND(90): 1:1 or 1:N (broadcast)

Number of words sent and

received

PLC to PLC Possible Possible

PLC to computer Possible (requires program that returns

Computer to PLC Possible (requires program that receives

data

responses from the computer)

responses at the computer)

RECV(98): 1:1

256 words max. (512 bytes) 542 bytes max.

Any supported FINS commands

Possible (requires program that returns

responses from the computer)

Possible (requires program that receives

responses at the computer)

1:1 or 1:N (broadcast)

1-3 SYSMAC LINK Unit Functions

This section explains the settings and functions for the SYSMAC LINK Unit.

For details, refer to the relevant sections.

1-3-1 Basic Settings

Node Address

(See pages 18 and 35)

Unit Number

(See pages 18 and 35)

6

Perform the basic settings to use the SYSMAC LINK Unit.

Set the address of the local node in the network using the rotary switches on

the front of the SYSMAC LINK Unit.

Up to 16 CPU Bus Units (SYSMAC LINK Units, Controller Link Units, Ethernet

Units, Serial Communication Units, etc.) can be mounted on one PLC. Of

these, however, only a maximum of four Units may be SYSMAC LINK Units.

Page 24

SYSMAC LINK Unit Functions Section 1-3

Set the unit number of each Unit manually from between 0 to F Hex (0 to 15)

using the rotary switches on the front of the SYSMAC LINK Unit.

Network Parameters

(See page 36)

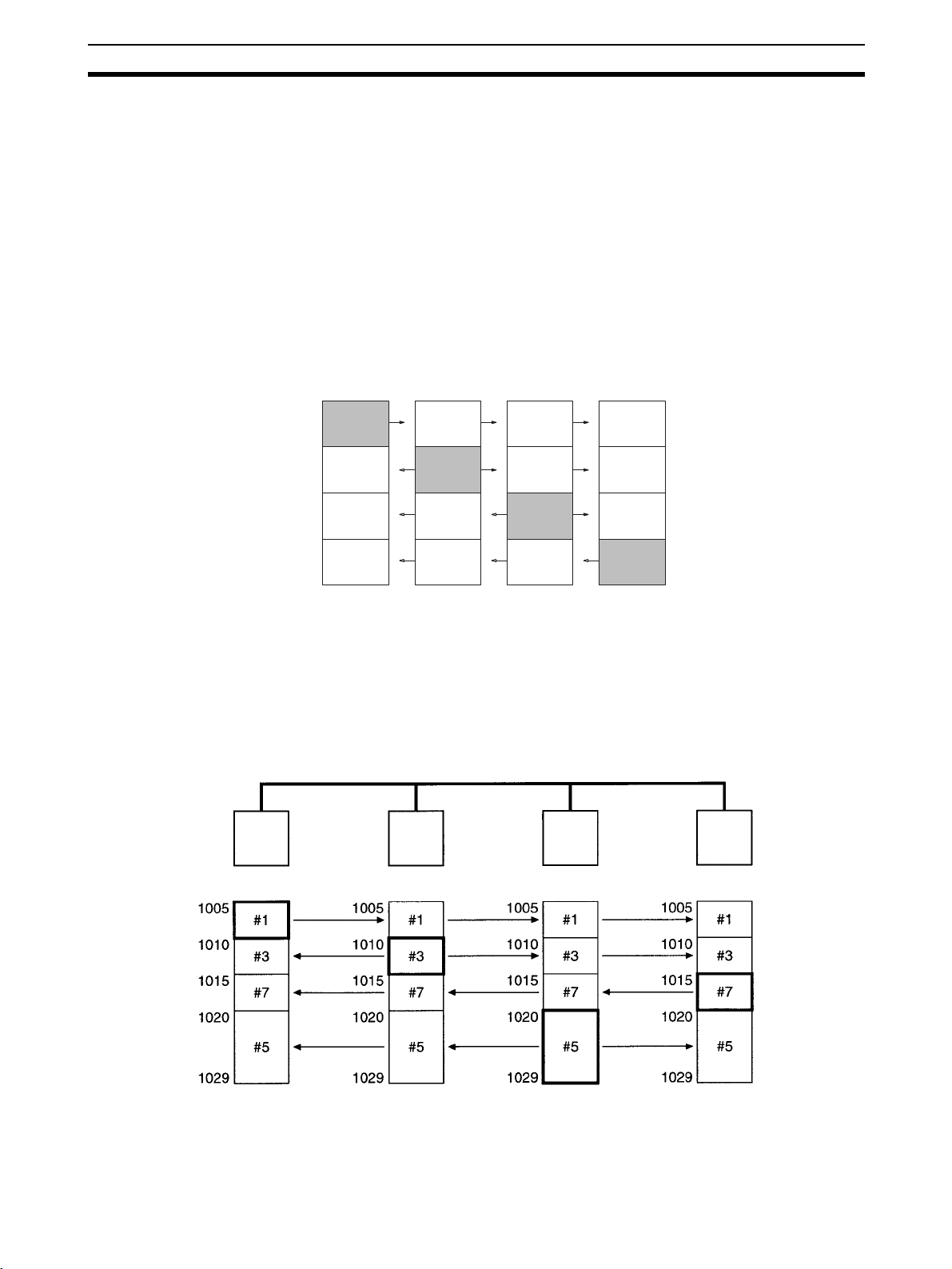

1-3-2 Data Links

Automatic Settings

(See page 49)

Manual Settings

(See page 49)

The following parameters are set with the Support Software (CX-Net within

the CX-Programmer).

• Communications cycle time

• Maximum node address

• Number of polled nodes

• Maximum number of frames

SYSMAC LINK Units can be used to create data links between PLCs and

computers on the same network. The data links support the following functions: Automatic settings (communications using data link words with settings

made automatically from settings made in PLC memory), and manual settings

(communications using data link tables with settings made using the CX-Net

within the CX-Programmer).

The areas to be used in creating the data links (CIO Area and/or DM Area)

and the number of data link words for each node are set in parameters in the

DM Area.

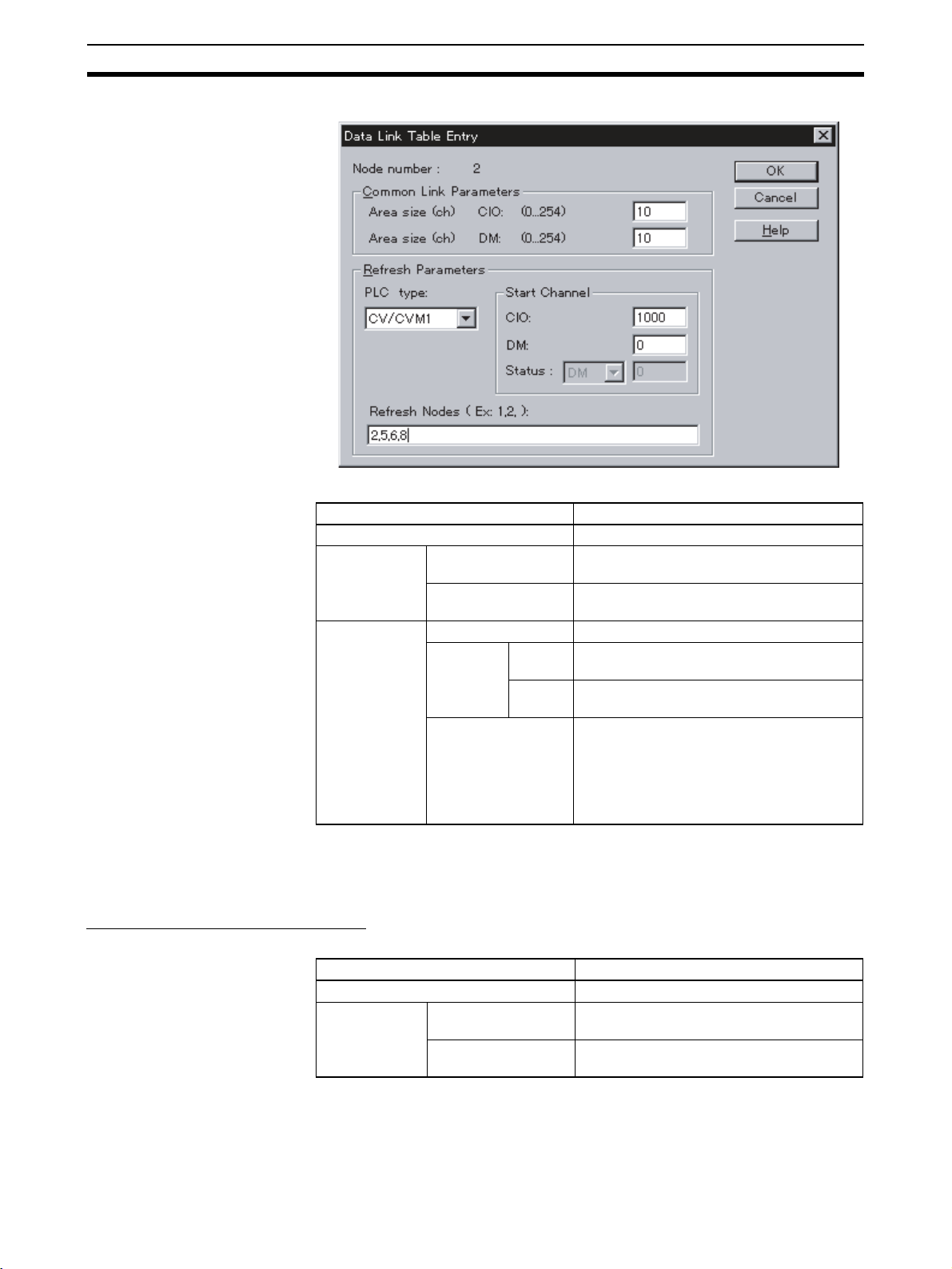

• Data Link Table Settings

The common link parameters and refresh parameters required by data

links are set using Support Software.

Common link parameters:The same for all nodes

Refresh parameters: Unique to each node

• Data Link Area Settings

The data areas (i.e., CIO Area and/or DM Area) to be used in the data links

are specified in the common link parameters.

• Number of Words in Data Links

The number of data link words for each node is specified in the common

link parameters.

• Data Link Node Settings

The nodes to be linked to the local node are specified in the refresh parameters. It is possible to use these settings to set multiple groups within a single network. The settings are made for each node individually.

1-3-3 Network Data Exchange

The SYSMAC LINK Unit can send and receive data by connecting to other

networks of the same type or to different networks.

• Bridges: Commands can be used to send and receive between SYSMAC

LINK Networks.

• Gateways: Commands can be used to send and receive between networks with different communications protocols, such as Controller Link

and Ethernet.

Commands and data can be sent and received across a maximum of three

networks (including the local network).

7

Page 25

Programming Devices and Support Software Section 1-4

Routing Tables (See page 86)

Routing tables are set using the Support Software to specify paths for sending

and receiving data between networks. The routing tables consist of the following two tables.

• Local Network Table: Set the combination of unit numbers and network

addresses for each Communications Unit.

• Relay Network Table: Set the communications path between the sender

and receiver.

1-3-4 Message Service

The SYSMAC LINK Units support SEND(90) and RECV(98) instructions for

reading data from and writing data to other node PLCs. The SYSMAC LINK

Units also support CMND(490) instructions for sending and receiving FINS

commands that control PLCs and CPU Bus Units. Using these instructions, it

is possible to control complicated functions without creating a communications program.

Refer to SECTION 6 Message Service for details.

1-3-5 Remote Programming and Monitoring

Remote programming and monitoring can be performed between SYSMAC

LINK, Controller Link, and Ethernet Networks. A maximum of three levels of

network communications (including the local network) are supported.

Refer to SECTION 7 Remote Monitoring and Programming for details.

1-3-6 RAS Functions

The SYSMAC LINK Unit supports RAS functions to help protect the network

and recover from errors.

Internode Test Communications between the local node and a specified node within the net-

work can be tested. The test settings are made using the Support Software.

Broadcast Test All the nodes within a specified network can be tested using the Support Soft-

ware broadcast test function.

Error Log

(See page 137)

Polling Node Backup

(See page 143)

Node Bypass

(See page 143)

If an error occurs in the Unit, the time of the error and the error contents are

logged in EEPROM within the Unit. The logged error information can be read

using the Support Software.

If an error occurs in the polling node, the Unit at another node automatically

becomes the polling node and rebuilds the network.

If a backup power supply is used with an Optical SYSMAC LINK System, any

node that goes down will be automatically bypassed, preventing the entire

network from going down.

1-4 Programming Devices and Support Software

The CX-Programmer is needed to use a SYSMAC LINK Network.

8

Page 26

Programming Devices and Support Software Section 1-4

1-4-1 Basic Programming

One of the following Programming Devices can be connected to the CPU Unit

to automatically set data links or use the message service.

The following operations are possible.

1-4-2 CX-Programmer

The CX-Net operations within the CX-Programmer are required when using

manually set data links, or when setting or monitoring detailed settings of the

SYSMAC LINK Unit. This Support Software can be used with a CS-series

PLC and is ideal for the following applications.

Programming

Console

Startup node

or

CPU Unit

SYSMAC LINK

+

CX-Programmer

IBM PC/AT or

compatible

• Selecting manual or automatic setting for data links.

• Setting the data links for automatic data link allocation (software

switches).

• Starting/stopping data links (Start Bit: ON/OFF)

• Programming the message service.

• Reading (monitoring) network status.

• Setting manual data links (i.e., creating and storing data link tables).

• Starting/stopping data links.

• Reading (monitoring) network status.

• Reading error logs.

• Setting routing tables.

• Testing the Network.

• Changing network parameters.

Software switches (DM Area)

Using a Personal Computer as a Peripheral Device

IBM PC/AT or

compatible

Setting data link tables

+

CX-Net in

CX-Programmer

Transmissions

CS-series PLC

Nodes

RS-232C

SYSMAC

LINK Unit

CPU Unit

9

Page 27

Data Link Procedures Section 1-5

Using a Personal Computer as a Node

CX-Net in

CX-Programmer

IBM PC/AT or compatible

+

SYSMAC LINK

Support Board

Setting data link tables

Software External

CX-Programmer WS02-CX@@E

Note (1) The CS-series SYSMAC LINK Units cannot be directly connected to

SYSMAC Support Software.

(2) For further details about the CX-Programmer, refer to the CX-Program-

mer Operation Manual.

(3) The CX-Net in the CX-Programmer cannot set data link tables for the

C200H-SLK21 or C1000H-SLK21. Refer to

or C1000H-SLK21

1-5 Data Link Procedures

1-5-1 Manually Setting Data Links

When the data link mode is set for manual data link table creation, the data

link tables can be input using the CX-Net within the CX-Programmer. Use the

following procedure.

1,2,3... 1. Install and wire the Units.

Contents Method Nodes Page

a. Mount the Units to

the PLCs.

b. Wire the Network. --- All nodes 19

c. Connect terminat-

ing resistance

Model

appearance

9-3 Using the C200H-SLK21

for details.

--- All nodes 18

Use C100H-TER01

Te r m i n a to r .

Coaxial systems only.

End nodes on the net-

work: Connect Terminator

10

2. Prepare for communications.

Contents Method Nodes Page

a. Set the unit num-

ber.

b. Set the node

address.

Use the front rotary

switches.

Use the front rotary

switches.

CS-series, CVM1, and

CV-series PLCs only

All nodes

18

Page 28

Data Link Procedures Section 1-5

3. Turn ON the power to the PLC.

Contents Method Nodes Page

Turn ON the power to

the PLC.

4. Connect the Programming Device.

Contents Method Nodes Page

Connect the Programming Console or Support Software.

5. Create I/O tables.

Contents Method Nodes Page

Input the I/O tables. Use the SYSMAC

6. Set the data link mode.

Contents Method Nodes Page

Set data link mode to

manual.

--- All nodes ---

Use the special connection cable.

Support Software or

Programming Console.

Use the SYSMAC

Support Software or

Programming Console.

CS-series, CVM1, and

CV-series PLCs

CS-series, CVM1, and

CV-series PLCs only

Data link startup node

only

The node that is used

to start the data link is

called the startup

node. It is necessary

to decide beforehand

which node will be the

startup node.

8

---

45

Note Be sure that the data link mode in the data link parameters in the DM

Area is set to 00 when using manually set data links.

7. Register the data link tables by making the following settings for each

node.

Contents Method Nodes Page

First data link status word Use the CX-Net

Data link nodes

Area 1First data link sta-

tus words

Numbers of data

link words

Area 2First data link sta-

tus words

Numbers of data

link words

within the CX-Programmer.

All nodes within the

network

Delete from the data

link tables all nodes

that are not in a data

link.

46, 67

Note Offsets are used to control where data is placed within the receive ar-

ea.

11

Page 29

Data Link Procedures Section 1-5

8. Start the data links.

Contents Method Nodes Page

Start the data links. Switch the Data link

Start/Stop Bit (see

below) from OFF to

ON using either the

Programming Device,

the user program, the

CX-Net within the CXProgrammer.

Note (a) Data link Start/Stop Bit (N= unit number):

CS Series: Word 0 of DM30000 + 100

(b) The data links will not start if there is an error in the data link ta-

bles in the startup node.

9. Stop the data links.

Contents Method Nodes Page

Stop the data links. Switch the Data link

Start/Stop Bit (listed

below) from OFF to

ON using either the

Programming Device,

the user program, the

CX-Net within the CXProgrammer.

Data link startup node

(The Start Bit can be

turned ON in more

then one node to

make sure the data

links start even when

the startup node is

down.)

× N

Any node that is active

in the data link

55, 67

55, 67

Note Data link Start/Stop Bit (N= unit number):

CS Series: Word 0 of DM30000 + 100

1-5-2 Automatically Setting Data Links

Data link tables can be automatically created by setting the data link mode to

automatic data link table creation. Use the following procedure.

1,2,3... 1. Install and wire the Units.

Contents Method Nodes Page

a. Mount the Units to

the PLCs.

b. Wire the Network. --- All nodes 19

c. Connect terminat-

ing resistance

2. Prepare for communications.

Contents Method Nodes Page

a. Set the unit num-

ber.

b. Set the node

address.

3. Turn ON the power to the PLC.

Contents Method Nodes Page

Turn ON the power to

the PLC.

× N

--- All nodes 18

Use C100H-TER01

Te r m i n a to r .

Use the front rotary

switches.

Use the front rotary

switches.

--- All nodes ---

Coaxial systems only.

End nodes on the net-

work: Connect Terminator

CS-series, CVM1, and

CV-series PLCs only

All nodes

18

12

Page 30

Data Link Procedures Section 1-5

4. Connect the Programming Device.

Contents Method Nodes Page

Connect the Programming Console or Support Software.

5. Create I/O tables.

Contents Method Nodes Page

Create the I/O tables. Use the SYSMAC

6. Set the parameters for automatic data link creation.

Contents Method Nodes Page

a. Set the data link

mode to automatic.

b. Set the number of

data link words.

Use the special connection cable.

Support Software or

Programming Console.

Use the SYSMAC

Support Software or

Programming Console.

CS-series, CVM1, and

CV-series PLCs only

CS-series, CVM1, and

CV-series PLCs only

Data link startup node

only

The node that is used to

start the data link is

called the startup node.

It is necessary to decide

beforehand which node

will be the startup node.

Data link startup node

only

8

---

45

7. Start the data links.

Contents Method Nodes Page

Start the data links. Switch the Data link

Start/Stop Bit (listed

below) from OFF to

ON using either the

Programming Device,

or the user program.

Note Data link Start/Stop Bit (N= unit number):

CS Series: Word 0 of DM30000 + 100

8. Stop the data links.

Contents Method Nodes Page

Stop the data links. Switch the Data link

Start/Stop Bit (listed

below) from OFF to

ON using either the

Programming Device,

or the user program.

Note (a) Data link Start/Stop Bit (N= unit number):

CS Series: Word 0 of DM30000 + 100

(b) The data links will not start if there is an error in the data link ta-

bles in the startup node. Data links can be started and stopped

using the CX-Net within the CX-Programmer.

Data link startup node

(The Start Bit can be

turned ON in more

then one node to

make sure the data

links start even when

the startup node is

down.)

× N

Any node that is active

in the data link

× N

55, 67

55, 67

13

Page 31

Message Service Procedure Section 1-6

1-6 Message Service Procedure

The following steps outline the basic procedure for using the message service.

1,2,3... 1. Install and wire the Units.

Contents Remarks Page

a. Mount the Units to the PLCs. --- 18

b. Wire the Network. --- 19

c. Connect terminating resistance Coaxial systems only.

2. Prepare for communications.

Contents Remarks Page

a. Set the unit number. CS-series, CVM1, and CV-series

PLCs only

b. Set the node address. ---

3. Turn ON the power to the PLC.

Contents Remarks Page

Turn ON the power to the PLC. --- ---

4. Create the I/O tables.

Contents Remarks Page

Create the I/O tables. CS-series, CVM1, and CV-series

PLCs only

18

---

5. Register routing tables if using internetwork connections.

Contents Remarks Page

a. Set the local network table --- 86

b. Set the relay network table ---

6. Create the user program.

Contents Remarks Page

a. Prepare the send and receive

data in memory.

b. Prepare the control data for the

communications instruction.

c. Check the conditions for exe-

cuting the SEND/RECV or

CMND instruction.

d. Execute the SEND/RECV or

CMND instruction.

e. Execute other instructions are

required for the results of the

communications instruction,

(e.g., retry or error processing

if an error occurs).

Stored in the memory areas of the

source node

The standard input conditions are

the Active Node Flags for the

source and destination nodes, and

the Port Enabled Flag.

---

The standard input condition is the

Port Error Flags.

CS-series PLCs have 8 communications ports. When 9 or more

communications instructions are

executed at the same time, exclusive control is necessary.

92

14

Page 32

SECTION 2

Unit Components and Switch Settings

The names and functions of the SYSMAC LINK Unit components and switch settings are described in this section.

2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-1-1 Component Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-1-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3 Mounting to Backplanes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-4 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-4-1 Coaxial Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-4-2 Optical Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-4-3 Backup Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

15

Page 33

Nomenclature Section 2-1

2-1 Nomenclature

This section describes the names and components of the SYSMAC LINK

Unit.

2-1-1 Component Names and Functions

This section describes the names and functions of the SYSMAC LINK Unit

components.

CS1W-SLK11 Optical SYSMAC LINK Units

Indicators

LED indicators that display the Unit and network status.

Unit number switch

One rotary switch. The unit number is set in single-digit

hexadecimal for the network to which the PLC is connected.

Node address switches

Two rotary switches. The node address of the Unit on the

SYSMAC LINK Network is set in 2-digit decimal.

CS1W-SLK21 Coaxial SYSMAC LINK Units

Optical connectors

Connectors to connect to the SYSMAC LINK Network communications

cable (optical fiber cable).

Power Supply Terminal Block

Connect the backup battery for the node bypass function.

Indicators

LED indicators that display the Unit and network status.

Unit number switch

One rotary switch. The unit number is set in single-digit

hexadecimal for the network to which the PLC is connected.

Node address switches

Two rotary switches. The node address of the Unit on the

SYSMAC LINK Network is set in 2-digit decimal.

16

Coaxial connector

Connects to the SYSMAC LINK network communications coaxial cable.

Page 34

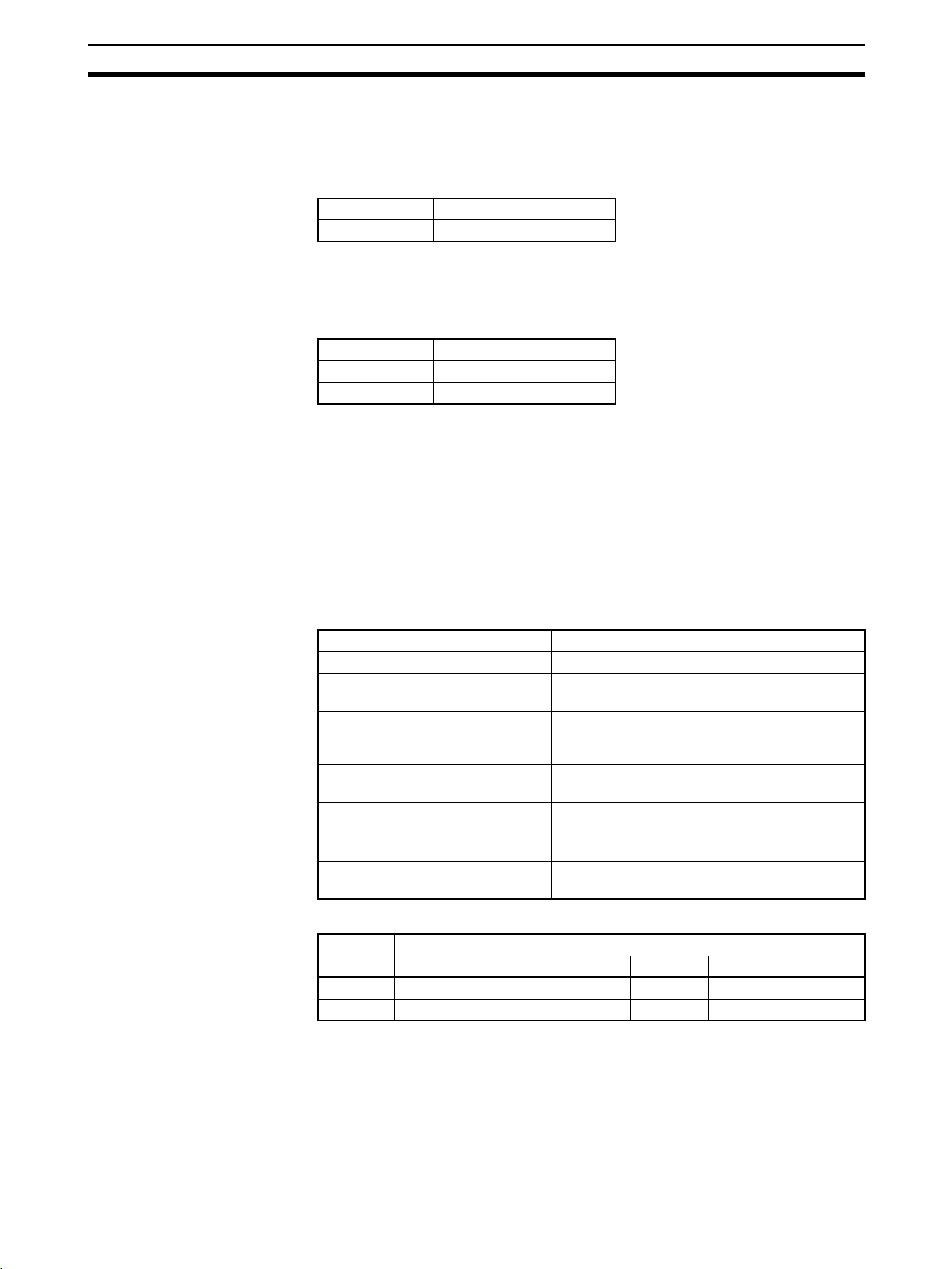

Nomenclature Section 2-1

2-1-2 Indicators

The status of the SYSMAC LINK Units is shown by the indicators listed below.

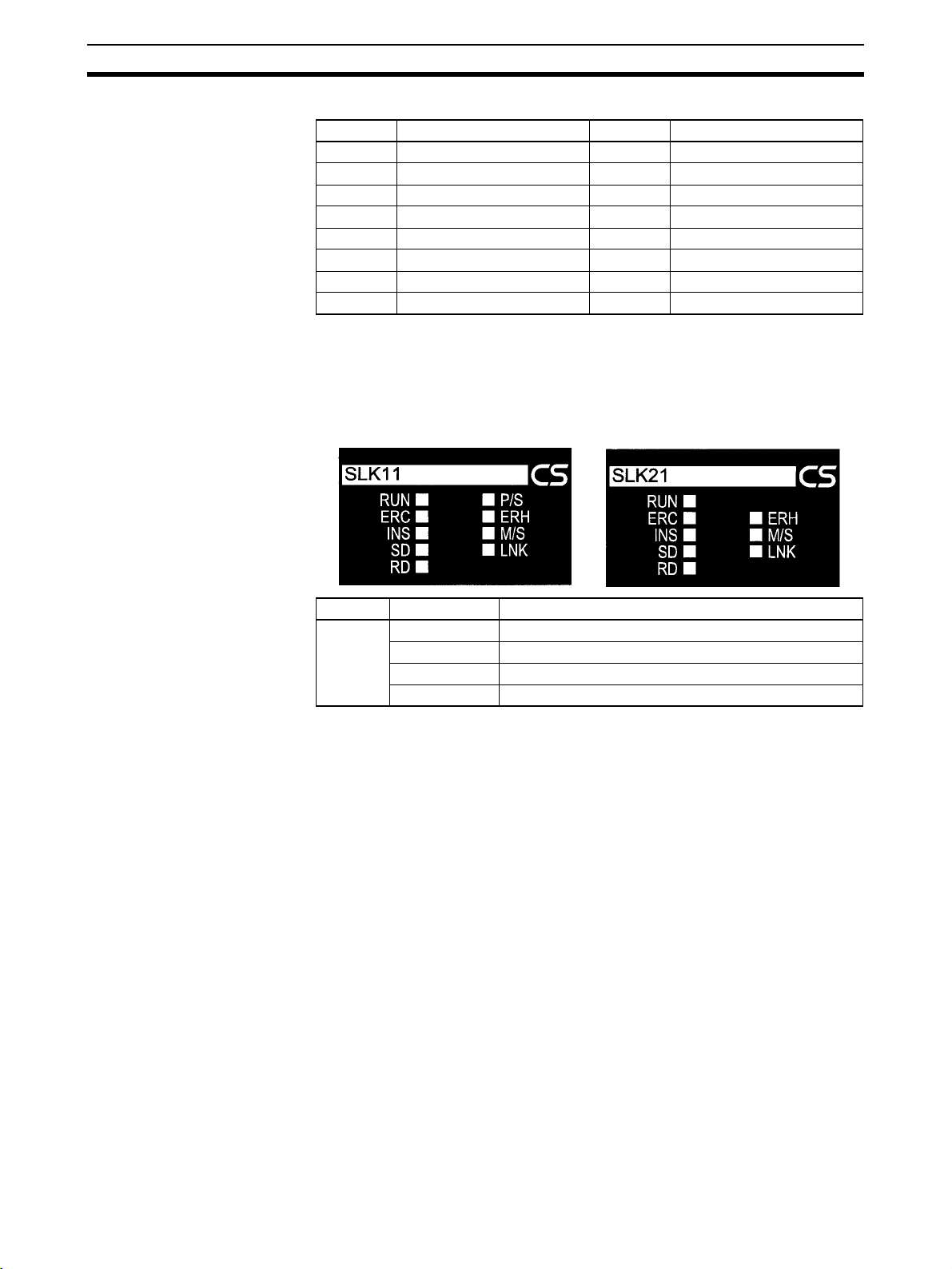

Optic al SYSMAC LINK

Unit (CS1W-SLK11)

Indicator name Color Condition Meaning

RUN Green Lit Unit is operating normally.

Not lit Watchdog timer error has occurred.

P/S

(power supply ON,

CS1W-SLK11 only)

ERC (communications error)

ERH (PLC error) Red Lit No I/O table has been set or PLC CPU, PLC model, PLC version, PLC

INS (Network inclusion)

M/S (polling node) Orange Lit Unit is polling node.

SD (send) Orange Lit Unit is sending data.

RD (receive) Orange Lit Unit is receiving data.

LNK (data link) Orange Lit Unit is part of active data link.

Green Lit Power is being supplied from the backup power supply.

Not lit Power is not being supplied from the backup power supply.

Red Lit Communications error has occurred, node address setting is incorrect,

Not lit None of the above errors has occurred.

Not lit None of the above errors has occurred.

Orange Lit Unit is part of Network.

Not lit Unit is not part of Network.

Not lit Unit is not part of Network or is polled node.

Not lit Unit is not sending data.

Not lit Unit is not receiving data

Flashing Data link error has occurred.

Rapid flash-

ing

Not lit Unit is not part of active data link.

or same node address has been set twice.

interface, EEPROM, unit number setting, or a unit number duplication

error has occurred.

Data link table communications cycle time is too short.

Coaxial SYSMAC LINK

Unit (CS1W-SLK21)

Note If the Unit is participating in the network, the SD and RD indicators will light

when sending and receiving the token.

17

Page 35

Switch Settings Section 2-2

2-2 Switch Settings

The SYSMAC LINK Unit provides rotary switches on the front panel with

which to set the node address (“NODE NO.”) and unit number. You must turn

OFF the PLC before setting the rotary switches. If you have changed the settings when the PLC is not turned OFF, you must restart the SYSMAC LINK

Unit or the PLC to use the new settings.

Switch Positions The switches are positioned as shown in the following diagram.

Set the unit number with SW1. Set the node address with SW2 and SW3. The

setting ranges are given in the following table.

Settings Values

Switches Range Remarks Page

Unit number

(UNIT No.)

Node address

(NODE No.

×101, ×100)

2-3 Mounting to Backplanes

Up to a total of four SYSMAC LINK Units (coaxial and optical) can be

mounted on the CPU Rack or CS-series Expansion Racks. SYSMAC LINK

Units cannot be mounted on C200H Expansion Racks or Slave Racks.

Note Tighten the screws on the Backplane to a torque of 0.9 N • m.

Tighten the mounting screws on the Units to a torque of 0.4 N • m.

0 to F Hex Each Unit in the PLC must

have a unique unit number.

01 to 62 decimal Each node on the network

must have a unique address.

35

35

18

Page 36

Cable Connections Section 2-4

CPU Rack

(CS1W-BC103, CS1W-BC083, CS1W-BC053, CS1W-BC033, CS1W-BC023)

CPU Rack

SYSMAC LINK Units can be mounted to the

2/3/5/8/10 slots shown in the diagram on the right.

2/3/5/8/10 slots

CS-series Expansion Racks

(CS1W-BI108, CS1W-BI083, CS1W-BI053, CS1W-BI033)

3/5/8/10 slots

C200H Expansion Rack

Note Up to 16 CPU Bus Units may be installed to on PLC.

2-4 Cable Connections

SYSMAC LINK Units can be connected with either coaxial cable or optical

fiber cable. This section describes the procedures required to connect these

cables.

2-4-1 Coaxial Units

This section describes the procedures required to connect SYSMAC LINK

Units with coaxial cables.

CS1 Expansion Rack

SYSMAC LINK Units can be mounted to the

3/5/8/10 slots shown in the diagram on the right.

C200H Expansion I/O Rack

SYSMAC LINK Units cannot be

mounted to Expansion I/O slots.

Mount to up to four

of these slots.

PS: Power Supply Unit

CPU: CPU Unit

Required Components

1,2,3... 1. Coaxial cable and Connectors:

Use the 5C-2V coaxial cable designed for indoor use. Install connectors on

each end of the cable. Cables must be continuous. No intervening cable

connectors or breaks are permitted. OMRON recommends the following

cables and connectors.

2. F Adapters (C1000H-CE001):

Coaxial cables are connected to the SYSMAC LINK Units via F Adapters.

One F Adapter is included as an accessory with SYSMAC LINK Units that

use coaxial cables (CV500-SLK21).

3. Terminator (C1000H-TER01):

Two Terminator units (sold separately) are required, one for the F Adapter

at each end of the network.

19

Page 37

Cable Connections Section 2-4

Connection Procedure

The connection procedure is described briefly below.

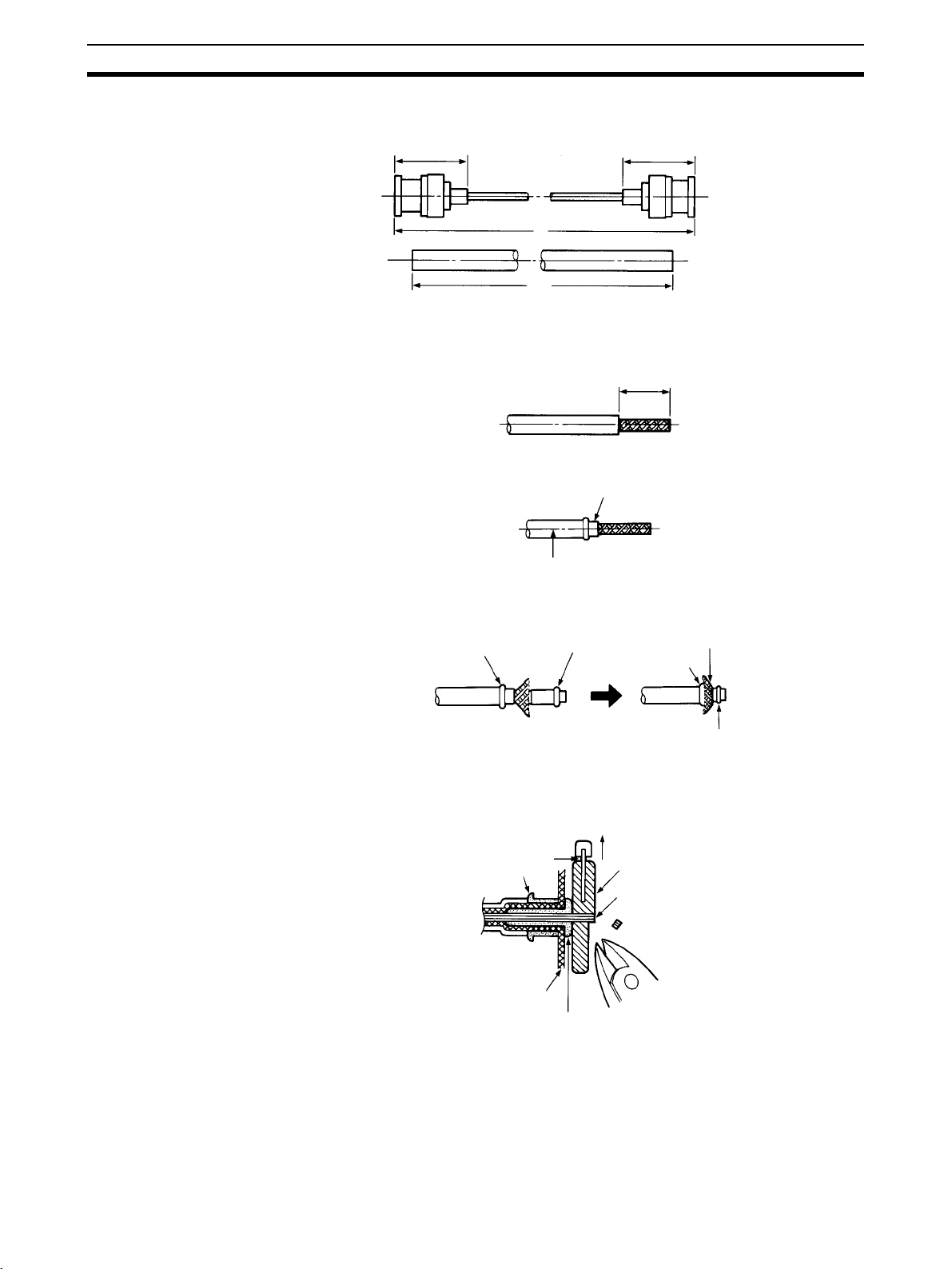

1,2,3... 1. Install connectors on each end of the cables.

2. Connect Terminator to the F Adapter at each end of the network (i.e., to the

unused connectors at the last Unit on each end). Hold the connector in one

hand and press the resistance into it firmly with the other.

3. Connect the F Adapters to the SYSMAC LINK Units by firmly pushing the

adapter onto the coaxial connector on the Unit and turning the locking ring

to the right until it locks. Start at one end of the network and connect the F

Adapters to the other end in order.

F Adapter

Connector

Cable Connection

Terminator

5C-2V coaxial cables

Terminator

1,2,3... 1. Firmly press the F-Adapter into the Unit, and turn the locking ring to the

right until it locks.

Turn locking ring to

the right.

20

Page 38

Cable Connections Section 2-4

2. Place an insulation cover over the F Adapter.

Insulation cover

3. Any bends in the coaxial cable must be 45 mm in radius or greater (six

times the outer diameter of the cable). When laying the cable, make bends

of 110 mm in radius or greater (15 times the outer diameter of the cable).

Note (1) Before connecting or removing the coaxial cable, always touch a ground-

ed metal object to discharge static electricity from your body.

(2) Always make sure the power is OFF before connecting the coaxial cable.

(3) Insert the coaxial connectors firmly. Also, be sure that the coaxial cable

is locked before use.

Attaching Connectors to Coaxial Cable

Assemble the connector parts as shown below.

Ferule

A hand crimp tool (CR-H-1130 by Dai-ichi Denshi Kogyo) is required when

crimping.

Sleeve

Radius

Contact clip

Contact

45 mm minimum

Body

Approx. 24.3 mm

21

Page 39

Cable Connections Section 2-4

1,2,3... 1. Cut the cable to the required length.

Approx. 24.5 mm Approx. 24.5 mm

Cable

LA mm = L mm − 12 mm

L

LA

(Unit: mm)

2. Remove 15 mm of the outer covering. Be careful not to damage or to distort the braiding.

15 mm

3. Insert the ferrule as shown below.

Ferrule

Cable

4. Spread the tip of the braiding, and insert the sleeve. Using the trimming

tool, push in the sleeve flange forcefully until it fits flush with the braiding.

Ferrule

Sleeve

Shield

Ferrule

Sleeve

5. Align A of the central conductor polyethylene projecting towards the outside of the trimming tool with the outside of the tool as shown below and

then cut the polyethylene.

B

C

Trimming tool

Conductor

A

Ferrule

Blade

Shield

Sleeve

22

Page 40

Cable Connections Section 2-4

6. Using your fingertips, press down on B on the trimming tool blade, forcing

the blade into the polyethylene, and twist several times. Continuing to

press down on B, withdraw in the direction of arrow D as shown below.

B

D

Conductor

7. Use scissors to cut off any protruding braiding as shown below.

8. Insert the contact into the contact crimp adapter, and set them inside the

crimp tool die. Insert the cable central conductor into the contact hole until

the severed face of the polyethylene meets the contact guard. Firmly grasp

the crimp tool handle and crimp.

9. Insert the completed contact subassembly into the body. Gently rotate and

press until the contact wings enter the insulator cavity, and align the contact tip with the insulator tip. After inserting the contact wings into the cavity, rotate the cable and the body until the body is crimped.

Contact

subassembly

Body

Insulator

23

Page 41

Cable Connections Section 2-4

10. Open the crimp tool handle, hold the tip of the body to the body stopper as

shown below, and close the handle until the ratchet can no longer turn.

Align the body hole with the hexagonal part of the die and crimp. A correct

crimp should resemble the diagram below.

Checks After Attaching

the Connector to the

Coaxial Cable

Body stopper

Cable

Crimp height

Body

Check that the body crimp is correct. If you crimp without holding the tip of the

body to the body stopper, the crimp will be partway along the body as shown

in the diagram on the right.

OK

Wrong

Check that the contact tip is in the same position as the open mouth of the

connector.

Body

Using a tester, check the following:

• Are the central conductor and the braiding insulated in the plug shell on

the coaxial cable connector?

• Are the plug shells conducting through the connectors at both ends of the

coaxial cable?

• Are the central conductors conducting through the connectors at both

ends of the coaxial cable?

24

Page 42

Cable Connections Section 2-4

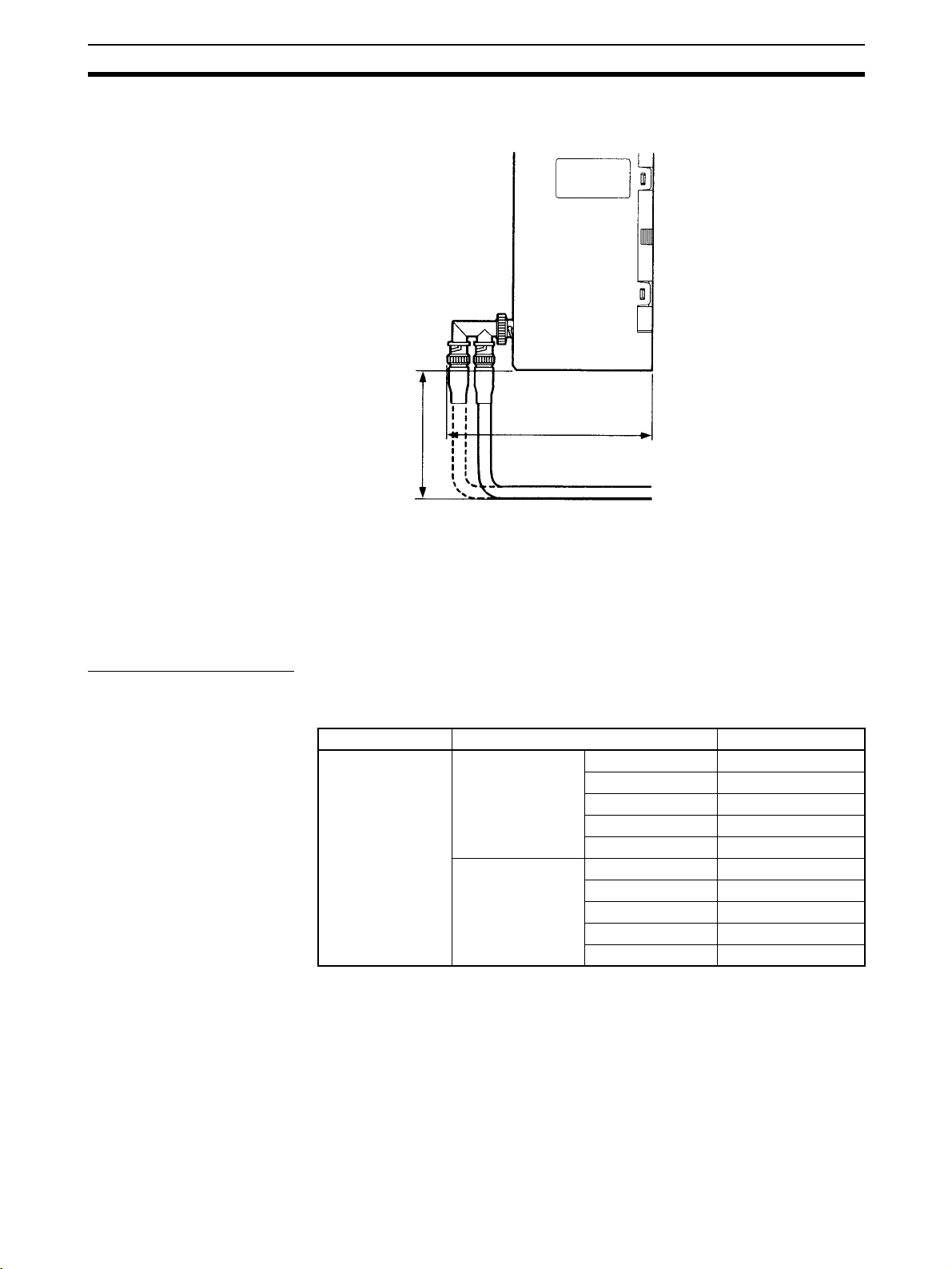

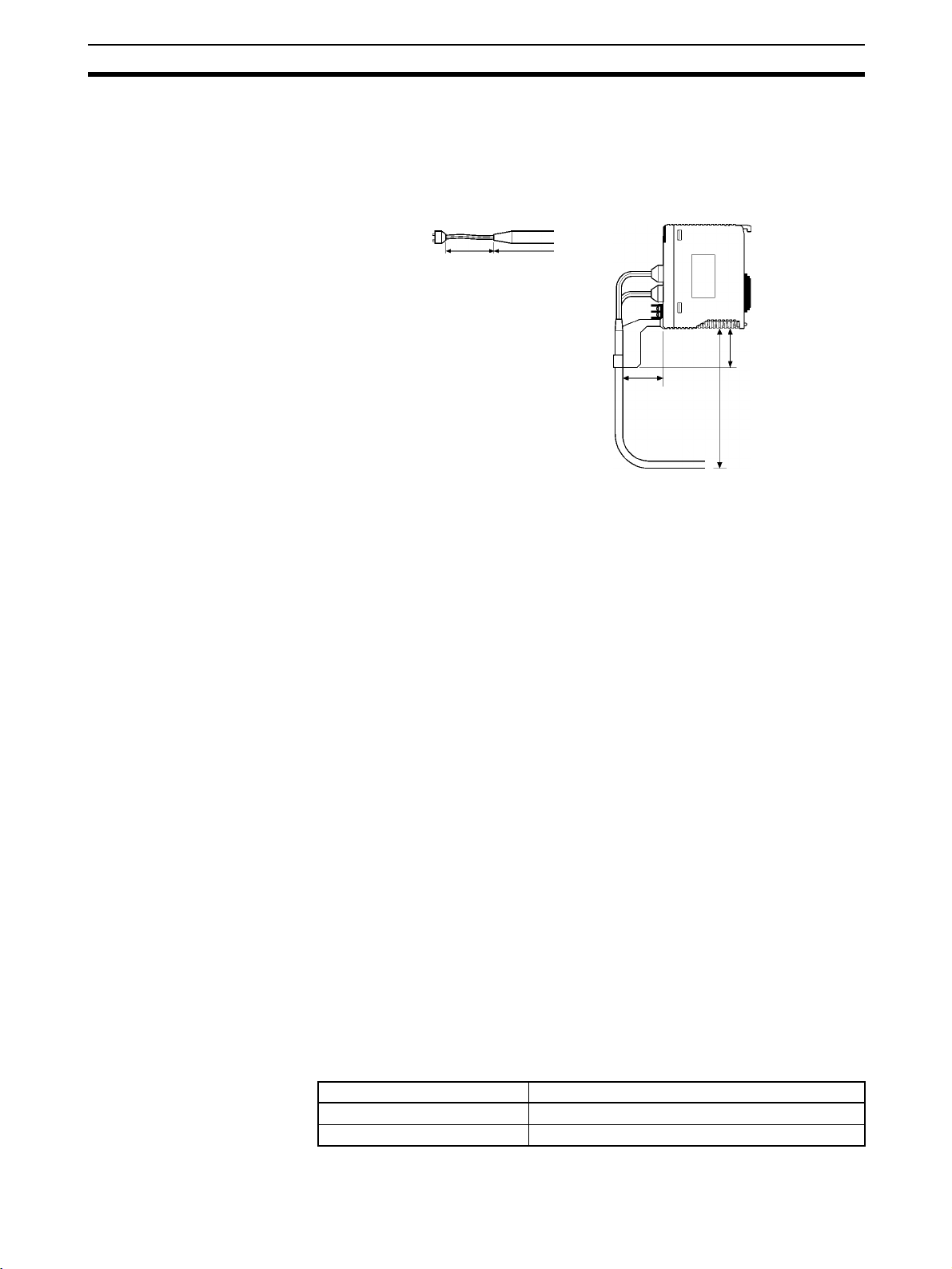

Provide a space between the bottom of the Unit and the cable as shown

below to ensure a suitable bend radius.

200

137

(Unit: mm)

Note Separate the coaxial cable from other power lines and high-voltage lines to

prevent noise.

2-4-2 Optical Units

The following devices are required for the Optical SYSMAC LINK Network.

Required Components

Optical Fiber Cables Use the following adhesive-polished Optical Fiber Cables (Hard Plastic-clad

Fiber: H-PCF).

Name Specifications Model

H-PCF cables Black 10 m S3200-HCCB101

50 m S3200-HCCB501

100 m S3200-HCCB102

500 m S3200-HCCB502

1,000 m S3200-HCCB103

Orange 10 m S3200-HCCO101

50 m S3200-HCCO501

100 m S3200-HCCO102

500 m S3200-HCCO502

1,000 m S3200-HCCO103

25

Page 43

Cable Connections Section 2-4

Note The Optical Fiber Cable model numbers are as follows:

Connectors

S3200-H

Name Model Specifications

Connector S3200-COCF2071

Inline Adapter S3200-COIAT2000 Use to connect or extend cables.

(((((((

(See note 1.)

S3200-COCF2571

(See note 1.)

Tensioner option

None: Standard (with tension member)

N: Without tension member

Cable length

(((

A B

(A/10) x 10

Cable color

B: Black

O: Orange

Cable specification

L: With power supply line

C: Without power supply line

Type

B: Cord

C: Cable

Use to connect a cable to a node.

(Full-lock connector for crimp-cut cable.)

Use to connect a cable to a node.

(Half-lock connector for crimp-cut cable.)

(Use one adapter for each connection.)

B

m

Note (1) Production of S3200-COCF2011 (full-lock) and S3200-COCF2511 (half-

Optical Fiber Cable with

Connectors

lock) Connectors has been stopped. Use the above Connectors as replacements.

(2) Either full-lock or half-lock connectors can be used in a SYSMAC LINK

Network, but we recommend full-lock connectors to prevent accidental

disconnections during operation.

(3) The maximum distance between nodes is slightly shorter for connectors

with crimp-cut cables compared to connectors assembled with adhesive.

Also, the maximum distance is reduced due to extension loss when Inline

Adapters are used to extend cables.

The following adhesive-polished Optical Fiber Cables are available with Connectors already attached.

Specifications Length Model

Optical Fiber Cable Connectors:

S3200-COCF2011

ß

S3200-COCF2011

2 m S3200-CN201-20-20

5 m S3200-CN501-20-20

10 m S3200-CN102-20-20

15 m S3200-CN152-20-20

20 m S3200-CN202-20-20

Over 20 m S3200-CN-20-20

(Specify length (m) when ordering.)

26

Page 44

Cable Connections Section 2-4

Specifications Length Model

Optical Fiber Cable Connectors:

S3200-COCF2011

ß

S3200-COCF2511

Optical Fiber Cable Connectors:

S3200-COCF2511

ß

S3200-COCF2511

Note (1) The cables listed above are black and have power supply lines and ten-

sion members, although the power supply lines aren’t used in the SYSMAC LINK Network.

(2) All of the cables listed above are attached to the connectors with adhe-

sive.

(3) Special training is required to assemble Optical Fiber Cables and connec-

tors with adhesive.

2 m S3200-CN201-20-25

5 m S3200-CN501-20-25

10 m S3200-CN102-20-25

15 m S3200-CN152-20-25

20 m S3200-CN202-20-25

Over 20 m S3200-CN-20-25

(Specify length (m) when ordering.)

2 m S3200-CN201-25-25

5 m S3200-CN501-25-25

10 m S3200-CN102-25-25

15 m S3200-CN152-25-25

20 m S3200-CN202-25-25

Over 20 m S3200-CN-25-25

(Specify length (m) when ordering.)

Optical Fiber Cable

Use the following accessories to assemble and test Optical Fiber Cables.

Accessories

Optical Fiber

Assembly Tool

Optical Power Tester S3200-CAT2700 With S3200-CAT2702 Head Unit and

Master Fiber Set S3200-CAT2001H One meter cable for use with the

Note Use the CAK-0057 (made by Sumitomo Electric Industries, Ltd.) to assemble

the S3200-COCF2071/2571 Connectors. (Production of the S3200-CAK1062

Assembly Tool has been stopped.) The S3200-COCF2071/2571 Connectors

can be assembled using the S3200-CAK1062 by adding the JRFK-57PLUS

(made by Sumitomo Electric Industries, Ltd.).

This manual does not provide details on Optical Fiber Cable preparation. For

details, refer to the instructions provided with the CAK-0057 or S3200CAK1062 Assembly Tool.

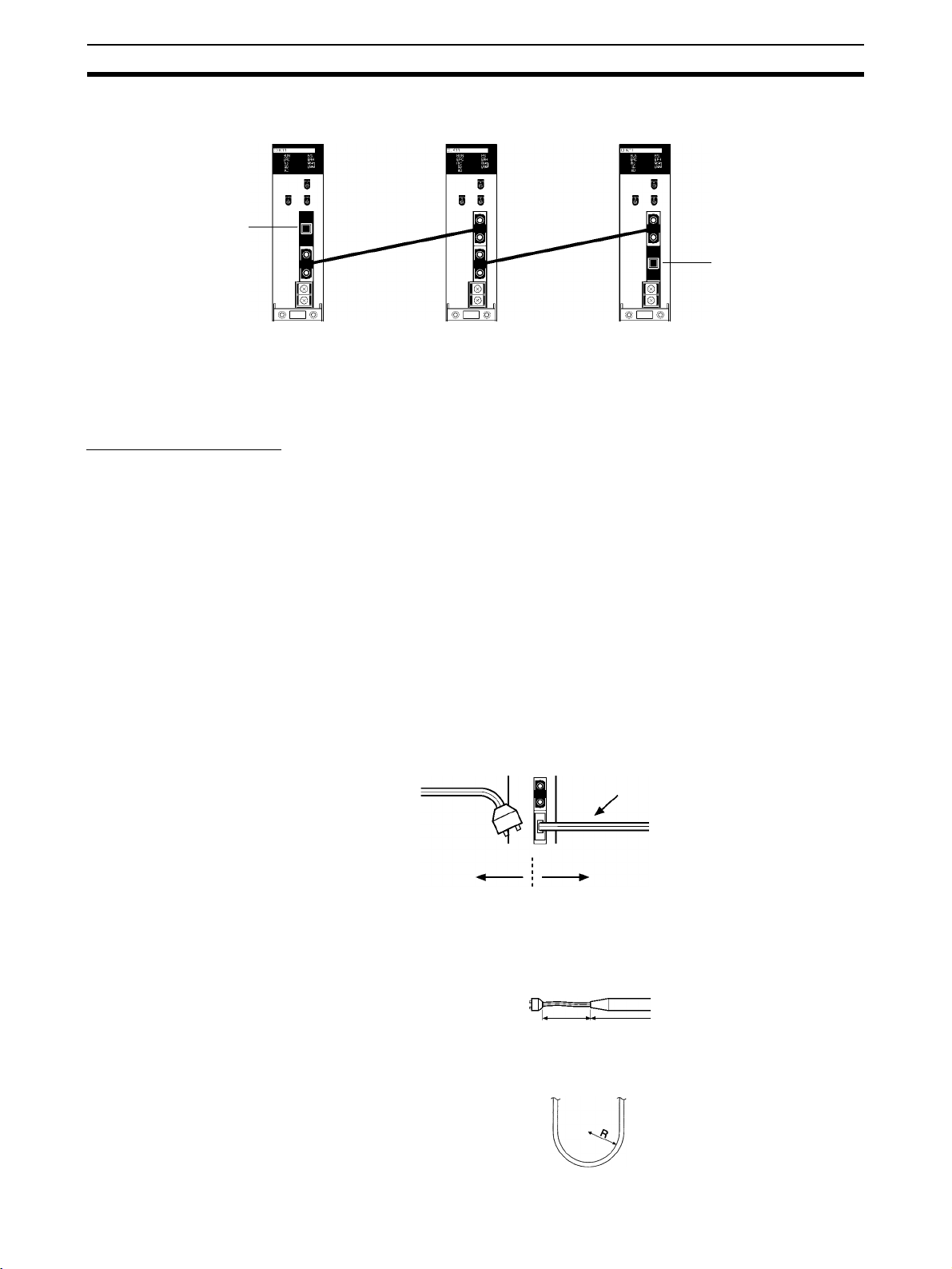

Optical Fiber Cable Connections

All of the nodes in an Optical SYSMAC LINK Network are connected in a line

(daisy-chain configuration) with H-PCF Optical Fiber Cable.

The nodes can be connected in any order, but be sure to begin with the upper

connector (SL1) of the highest node in the network and connect to the lower

connector (SL2) in the next lower node, as shown in the following diagram.