Page 1

Cat. No. W359-E1-04

CS1W-MC221(-V1)/421(-V1)

Motion Control Units

OPERATION MANUAL

Page 2

CS1W-MC221(-V1)/421(-V1) Motion Control Units

Operation Manual

Revised February 2008

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

Windows is registered trademarks of the Microsoft Corporation.

Other product names and system names in this manual are trademarks or registered trademarks of

their respective companies.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-4 Control System Configuration and Principles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-6 Data Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-7 Overview of G-language Programs in the MC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1-8 Commands Listed According to Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1-9 Comparison with Earlier MC Unit Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-10 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

1-11 Methods for Using MC Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1-12 Overview of Version 1 Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SECTION 2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2-1 Nomenclature and Unit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

2-2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

2-4 Failsafe Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

2-5 Wiring Check Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

2-6 Changing the Mechanical Direction of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

2-7 Connecting Peripheral Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

SECTION 3

MC Unit Internal Data Configuration . . . . . . . . . . . . . . . . . 147

3-1 Data Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

3-2 Determining the Task Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3-3 System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

3-4 Position Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

3-5 Monitor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

3-6 Command Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

vii

Page 7

TABLE OF CONTENTS

SECTION 4

Data Transfer and Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . 201

4-1 Data Transfer and Storage: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

4-2 IOWR and IORD Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

4-3 Saving Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

SECTION 5

Exchanging Data with the CPU Unit . . . . . . . . . . . . . . . . . . 223

5-1 Overall Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

5-2 Controlling the MC Unit from the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

5-3 PLC Interface Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

5-4 Interface Specifics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

SECTION 6

Basic Positioning Operations . . . . . . . . . . . . . . . . . . . . . . . . . 325

6-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

6-2 PTP Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

6-3 Linear Interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

6-4 Circular Interpolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

6-5 Helical Circular Interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .332

6-6 Interrupt Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

6-7 Traverse Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

6-8 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

6-9 Changing Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

6-10 Stopover Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

6-11 CPU Unit Interrupt Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

6-12 Override Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

6-13 Resetting the Error Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

6-14 Servo Lock and Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

6-15 Backlash Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

6-16 Automatic Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

6-17 Present Position Preset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

6-18 Electronic Gear Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

6-19 Acceleration and Deceleration Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

6-20 Unlimited Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

6-21 Stopping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

SECTION 7

G-language Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

7-1 Programs and Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

7-2 G Language Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .377

7-3 G-language Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

7-4 M Code Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

viii

Page 8

TABLE OF CONTENTS

SECTION 8

G-Language Programming Examples . . . . . . . . . . . . . . . . . 445

8-1 Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 446

8-2 Executing MC Programs from the Ladder Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 462

SECTION 9

Establishing the Origin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

9-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

9-2 Input Signals Required for an Origin Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

9-3 Origin Search Methods and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

9-4 Origin Search Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .470

9-5 Absolute Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

9-6 Setting the Origin With an Absolute Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

9-7 Absolute Encoder Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

SECTION 10

Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

10-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488

10-2 Setting the Teaching Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .488

10-3 Performing Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

10-4 Errors during Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 492

SECTION 11

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

11-1 Operation Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 496

11-2 System Configuration and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

11-3 Considerations When Starting Up the MC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

SECTION 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

12-1 Troubleshooting Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 522

12-2 Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 531

12-3 System Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 532

12-4 Task Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 536

12-5 Axis Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 541

12-6 Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 546

SECTION 13

Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 549

13-1 Routine Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550

ix

Page 9

TABLE OF CONTENTS

Appendices

A Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 553

B G-language Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 563

C PLC Interface Area Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .565

D System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 589

E Control Bit/Flag Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 613

F Origin Search Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 629

G Encoder Divider Rate and Rotation Speed for OMRON Servo Drivers . . . . . . . . . . . . . . . . 657

H MC Program Coding Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 659

I System Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 661

J Position Data Coding Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 667

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 669

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 677

x

Page 10

About this Manual:

This manual describes the features, specifications, and operation of the CS1W-MC421/221 Motion

Control Unit and includes the sections described below.

Please read this manual and the other manuals related to the CS1W-MC421/221 Motion Control Unit

carefully and be sure you understand the information provided before attempting to install and operate

the Motion Control Unit.

Refer to 1-12 Overview of Version 1 Upgrades for an outline of the new features added to the CS1WMC421-V1 and CS1W-MC221-V1. (“-V1” is omitted in this manual.)

Section 1 explains the features and system configuration of the CS1W-MC421 and CS1W-MC221

Motion Control Units (MC Units), and outlines some of the differences with the features of the earlier

C200H-MC221 MC Unit.

Section 2 describes the MC Unit components and provides the information required for installing the

MC Unit.

Section 3 describes the data contained within the MC Unit.

Section 4 describes the means used to store data of various types and explains how data is trans-

ferred between the MC Unit and the CPU Unit.

Section 5 describes the ways in which data can be transferred between the CPU Unit and the MC

Unit, including using the IOWR/IORD instructions, using the PLC Interface Area, and using dedicated

bits/flags in memory.

Section 6 explains the basic positioning operations executed by the MC Unit.

Section 7 describes using the G language to program motion control in the MC Unit.

Section 8 provides examples of G-language programming for the CS1W-MC421/221.

Section 9 explains how to search for and establish the origin using either an incremental encoder or

an absolute encoder, and gives a general overview of absolute encoders.

Section 10 describes the teaching function. This function can be used to teach new positions by moving to a given position and then reading the present position of each axis as position data.

Section 11 explains how to get started using the MC Unit. It provides information on the MC Unit’s

startup procedures, system configuration, wiring, creating I/O tables, inputting MC programs, creating

ladder programs, transferring data, saving data, and conducting trial operation.

Section 12 explains the troubleshooting procedures to be employed if problems should occur in MC

Unit operation.

Section 13 explains the maintenance and inspection procedures that must be followed to keep the MC

Unit operating in optimum condition. It includes instructions on the proper procedure to follow when

replacing an MC Unit, and precautions to observe when replacing a Servomotor.

The Appendices provide MC Unit performance information, control bit/flag timing charts, MC program

coding sheet, sheets for recording system parameter settings, and position data coding sheet.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xi

Page 11

xii

Page 12

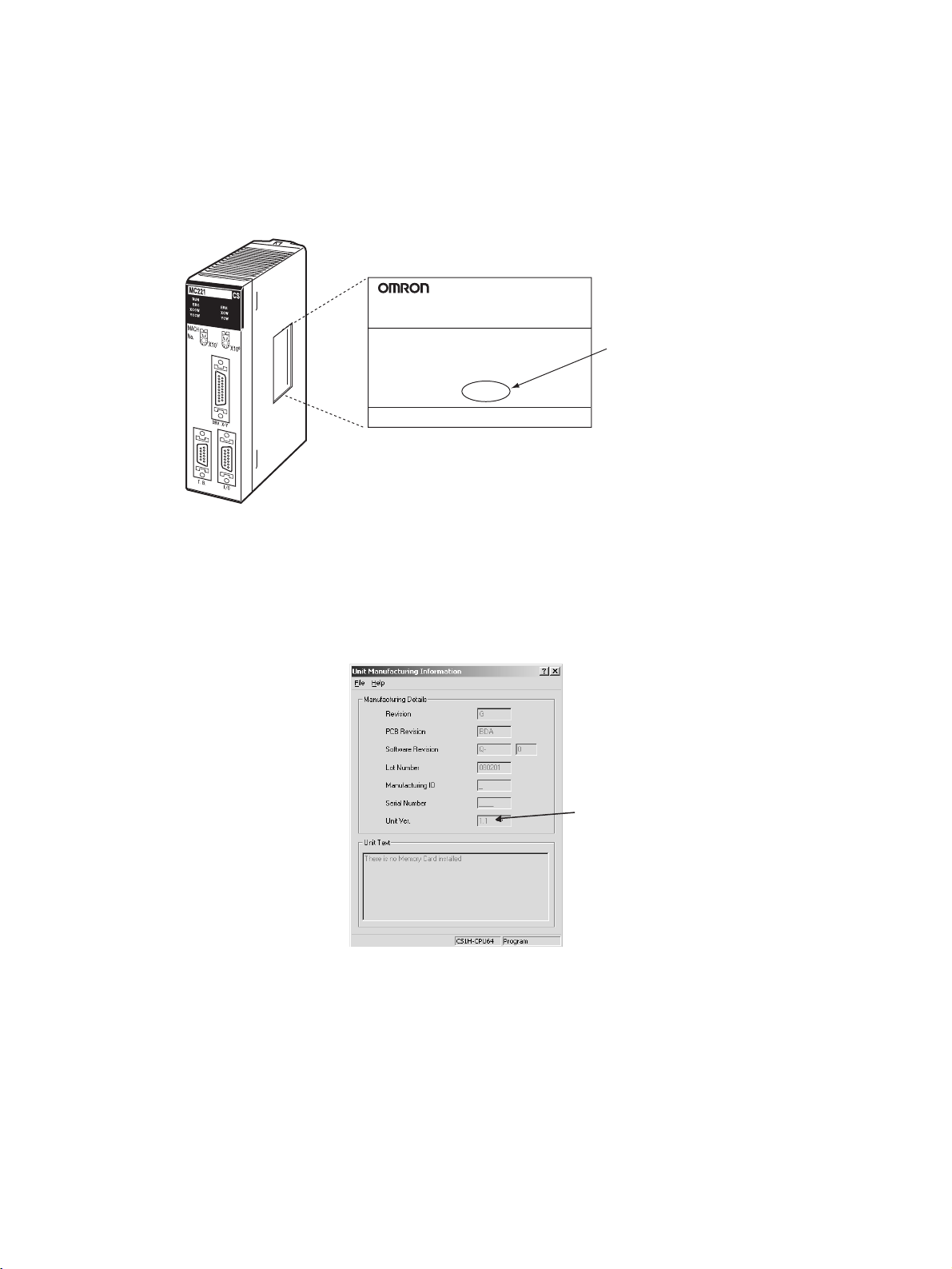

Unit Versions

A “unit version” has been introduced to manage Motion Control Units according to differences in functionality accompanying Unit upgrades.

Notation of Unit Versions

on Products

Confirming Unit Versions

with Support Software

1,2,3... 1. In the IO Table Window, right-click the Motion Control Unit and select Unit

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

Product nameplate

CS1W-MC221-V1

MC UNIT

Unit version

Example for unit version 1.1

Lot No. 080201 Ver.1.1

OMRON Corporation MADE IN JAPAN

The unit versions of Motion Control Units start with unit version 1.1.

CX-Programmer version 4.0 or higher can be used to confirm the unit version

using the Unit Manufacturing Information.

Manufacturing information.

2. The following Unit Manufacturing information Dialog Box will be displayed.

Unit version

xiii

Page 13

The unit version is displayed as 1.1 in the Unit Version Number field of the

above example. Use this display to confirm the unit version of the Motion Control Unit connected online.

Using the Unit Version

Label

A unit version label is provided with the Motion Control Unit. This label can be

attached to the front of the Motion Control Unit to differentiate between Motion

Control Units with different unit versions.

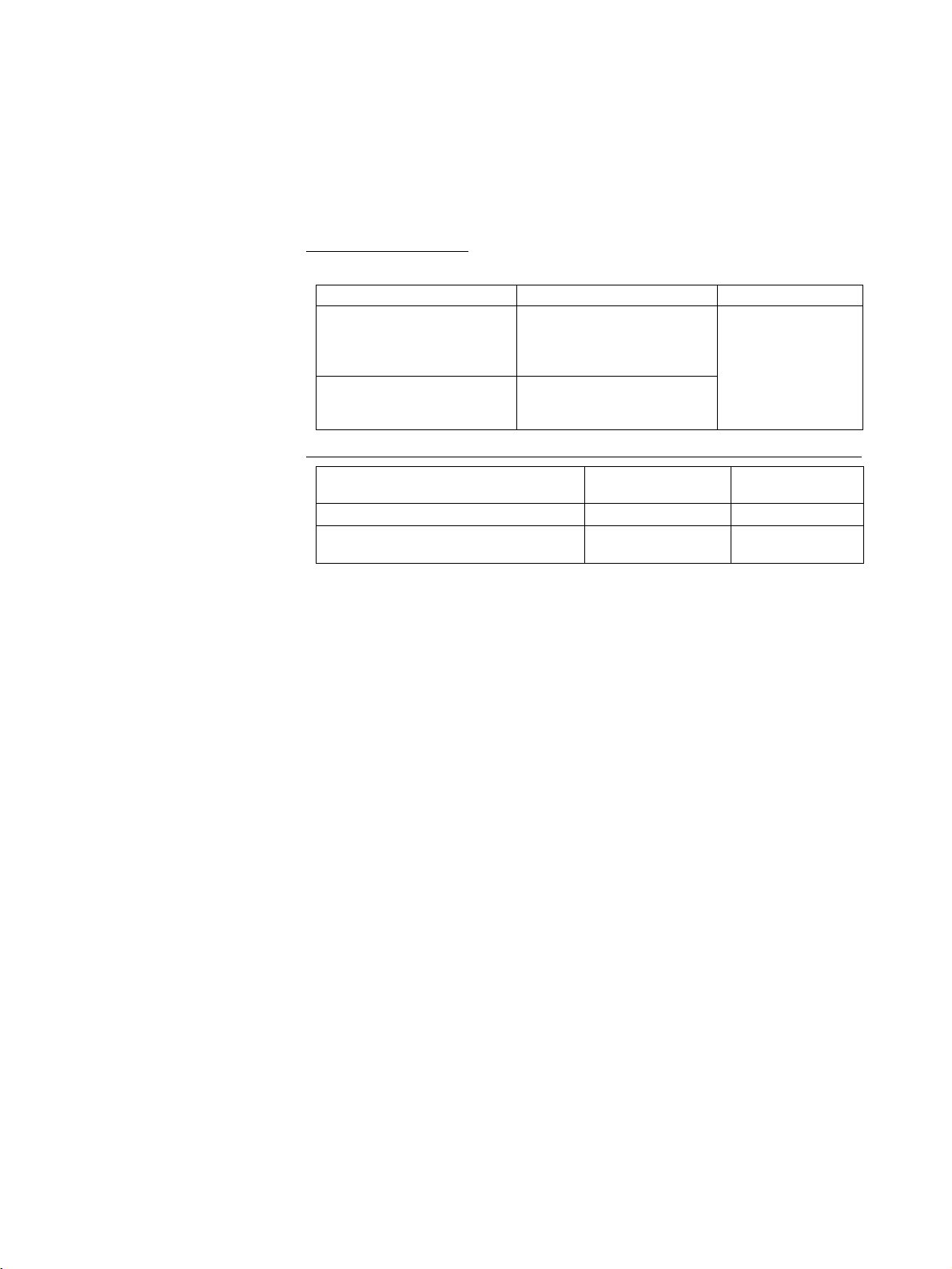

■ Unit Version Notation

Unit versions are given in this manual as shown in the following table.

Product label Notation in this manual Remarks

The version number is given

to the right of the lot number

for unit versions 1.1 and later,

e.g., “Ver. 1.1”

No version number is given to

the right of the lot number for

unit versions earlier than 1.1.

CS-series Motion Control Unit

with unit version 1.1 or later

Pre-Ver. 1.1 CS-series Motion

Control Unit

The contents of this

manual applies to all

unit version whenever the unit version

is not specified.

■ Functions Supported According to Unit Versions of Motion Control Units

Unit version Pre-Ver. 1.1 Units Units with unit

Internal system version Versions 1.01 to 3.01 Version 3.02

Absolute encoder functionality for

OMNUC G-series Servo Drivers

Not supported. Supported.

version 1.1

xiv

Page 14

Version Upgrade Information

Improvements from Pre-Ver. 1.1 to Version 1.1

The following improvements have been made.

Pre-Ver. 1.1 Ver. 1.1

The absolute encoder functionality for

OMNUC G-series Servo Drivers is not

supported.

The absolute encoder functionality for

OMNUC G-series Servo Drivers is supported.

xv

Page 15

xvi

Page 16

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xvii

Page 17

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xviii

Page 18

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xix

Page 19

xx

Page 20

PRECAUTIONS

This section provides general precautions for using the Motion Control Units (MC Units) and related devices.

The information contained in this section is important for the safe and reliable application of the Motion Control

Unit. You must read this section and understand the information contained before attempting to set up or operate

a Motion Control Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6-1-1 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6-1-2 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

xxi

Page 21

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the MC Unit. Be sure to read this

manual before attempting to use the Unit and keep this manual close at hand

for reference during operation.

!WARNING It is extreme important that Motion Control Units and related devices be used

for the specified purpose and under the specified conditions, especially in

applications that can directly or indirectly affect human life. You must consult

with your OMRON representative before applying Motion Control Units and

related devices to the above mentioned applications.

3 Safety Precautions

!WARNING Never attempt to disassemble any Units while power is being supplied. Doing

so may result in serious electrical shock or electrocution.

!WARNING Never touch any of the terminals while power is being supplied. Doing so may

result in serious electrical shock or electrocution.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller or MC Unit) to ensure safety in the system if an abnormality occurs

due to malfunction of the CPU Unit, malfunction of the MC Unit, or external

factors affecting the operation of the CPU Unit or MC Unit. Not providing sufficient safety measures may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The CPU Unit will turn OFF all outputs when its self-diagnosis function

detects any error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures

must be provided to ensure safety in the system.

xxii

Page 22

Operating Environment Precautions 4

• The CPU Unit or MC Unit outputs may remain ON or OFF due to deposits

on or burning of the output relays, or destruction of the output transistors.

As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

• When the 24-VDC output (service power supply to the CPU Unit) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm the safety of the destination node before transferring a program to the

node or changing the contents of I/O memory. Doing either of these without

confirming safety may result in injury.

!Caution Connect the RUN command output (RUN signal) to the Servo Driver. Other-

wise, the motor may run when the power is turned ON or OFF or when en

error occurs in the Unit.

!Caution Do not save data into the flash memory during program execution or while the

motor is running. Otherwise, unexpected operation may be caused.

!Caution Do not reverse the polarity of the 24-V power supply. The polarity must be cor-

rect. Otherwise, the motor may start running unexpectedly and may not stop.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

xxiii

Page 23

Application Precautions 5

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the MC Unit or the CPU Unit.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100

protect against electrical shock.

• Always turn OFF the power supply to the Unit before attempting any of the

following. Not turning OFF the power supply may result in malfunction or

electric shock.

• Mounting or dismounting the MC Unit or any other Units.

• Assembling the Units.

• Setting rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions may lead to faulty operation of

the CPU Unit, the MC Unit. or the system, or could damage the CPU Unit or

MC Unit. Always heed these precautions.

• Check the task configuration before creating MC program for the MC Unit.

Set the task configuration (axis configuration, number of tasks, and task

axis definition) using the unit parameters within the system parameters. If

changes are made to the task configuration, the MC program must be

changed as well.

• After transferring the system parameters, G-language program, or position data to the MC Unit, be sure to save the data in flash memory within

the MC Unit (using the data save command from the CX-Motion or CPU

Unit) before turning OFF the power supply to the Unit. Transferring the

data to the MC Unit will simply save the data in the internal memory (SRAM) of the MC Unit and this data will be deleted when the power supply

to the Unit is turned OFF.

• After transferring the system parameter data to the MC Unit and saving

the data to flash memory, be sure to reset the power supply to the Unit or

restart the Unit. Otherwise, the unit parameters and machine parameters

will not be changed and the System Set Error, which can occur when the

system parameters are transferred to the MC Unit, will not be cleared.

• Do not turn OFF the power supply to the Unit while data is being written to

flash memory. Doing so may cause problems with the flash memory.

• Confirm that no adverse effects will occur in the system before changing

the operating mode of the Teaching Box.

• When a wiring error occurs, be sure to reset the power supply to the Unit,

check the wiring, and reset the machine parameters within the system

parameters.

Ω or less when installing the system to

xxiv

Page 24

Application Precautions 5

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the CPU Unit (including the setting of

the startup operating mode).

• Changing the present value of any word or any set value in memory.

• Force-setting/force-resetting any bit in memory.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in this manual. Incorrect

tightening torque may result in malfunction.

• Tighten the mounting screws at the bottom of the Unit to a torque of

0.4 N • m. Incorrect tightening torque may result in malfunction.

• Before touching the Unit, be sure to first touch a grounded metallic object

in order to discharge any static built-up. Not doing so may result in malfunction or damage.

• Check the pin numbers before wiring the connectors.

• Be sure that the connectors, terminal blocks, I/O cables, cables between

drivers, and other items with locking devices are properly locked into

place. Improper locking may result in malfunction.

• Always use the power supply voltages specified in this manual. An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Separate the line ground terminal (LG) from the functional ground terminal (GR) on the Power Supply Unit before performing withstand voltage

tests or insulation resistance tests. Not doing so may result in burning.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so

may break the cables.

• Resume operation only after transferring to the new MC Unit the contents

of the parameters, position data, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

xxv

Page 25

Conformance to EC Directives 6

• Resume operation only after transferring to the new CPU Unit the contents of the DM Area, HR Area, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Confirm that set parameters and data operate properly.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Do not attempt to take any Units apart, to repair any Units, or to modify

any Units in any way.

• Perform wiring according to specified procedures.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-1-1 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or

machines. The actual products have been checked for conformity to EMC

standards (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the

customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel in which the OMRON devices are installed.

The customer must, therefore, perform final checks to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61131-2

EMI (Electromagnetic Interference): EN61000-6-4

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC or 75 to

1,500 VDC meet the required safety standards for the PLC (EN61131-2).

6-1-2 Conformance to EC Directives

The CS-series PLCs comply with EC Directives. To ensure that the machine

or device in which a CS-series PLC is used complies with EC directives, the

PLC must be installed as follows:

1,2,3... 1. The PLC must be installed within a control panel.

2. Reinforced insulation or double insulation must be used for the DC power

supplies used for the communications and I/O power supplies.

3. PLCs complying with EC Directives also conform to the Common Emission

Standard (EN61000-6-4). When a PLC is built into a machine, however,

noise can be generated by switching devices using relay outputs and

cause the overall machine to fail to meet the Standards. If this occurs,

(Radiated emission: 10-m regulations)

xxvi

Page 26

Conformance to EC Directives 6

surge killers must be connected or other measures taken external to the

PLC.

The following methods represent typical methods for reducing noise, and

may not be sufficient in all cases. Required countermeasures will vary depending on the devices connected to the control panel, wiring, the configuration of the system, and other conditions.

xxvii

Page 27

Conformance to EC Directives 6

xxviii

Page 28

SECTION 1

Features and System Configuration

This section explains the features and system configuration of the CS1W-MC421 and CS1W-MC221 Motion Control Units

(MC Units), and outlines some of the differences with the features of the earlier C200H-MC221 MC Unit.

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Description of Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-1 System Configuration Example (CS1W-MC421) . . . . . . . . . . . . . . 4

1-3 Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3-1 Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3-2 Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-3-3 Summary of Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-4 Control System Configuration and Principles. . . . . . . . . . . . . . . . . . . . . . . . . 12

1-4-1 Servo System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-4-2 Feedback Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-4-3 CW and CCW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-5-1 Overview of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-5-2 Performance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-5-3 CX-Motion Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-5-4 Teaching Box Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-6 Data Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-6-1 Overall Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-6-2 Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-6-3 Internal Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1-6-4 Data Transfer Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1-7 Overview of G-language Programs in the MC Unit . . . . . . . . . . . . . . . . . . . . 30

1-7-1 Programs and Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1-7-2 Manual and Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1-7-3 G Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1-7-4 G-language Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1-8 Commands Listed According to Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1-9 Comparison with Earlier MC Unit Model . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-9-1 Changing From the C200H-MC221 to the CS1W-MC421/MC221 . 40

1-10 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1-11 Methods for Using MC Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1-12 Overview of Version 1 Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1-12-1 Using Customized Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1-12-2 Easy Backup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

1

Page 29

Fe at ur e s Section 1-1

1-1 Features

1-1-1 Overview

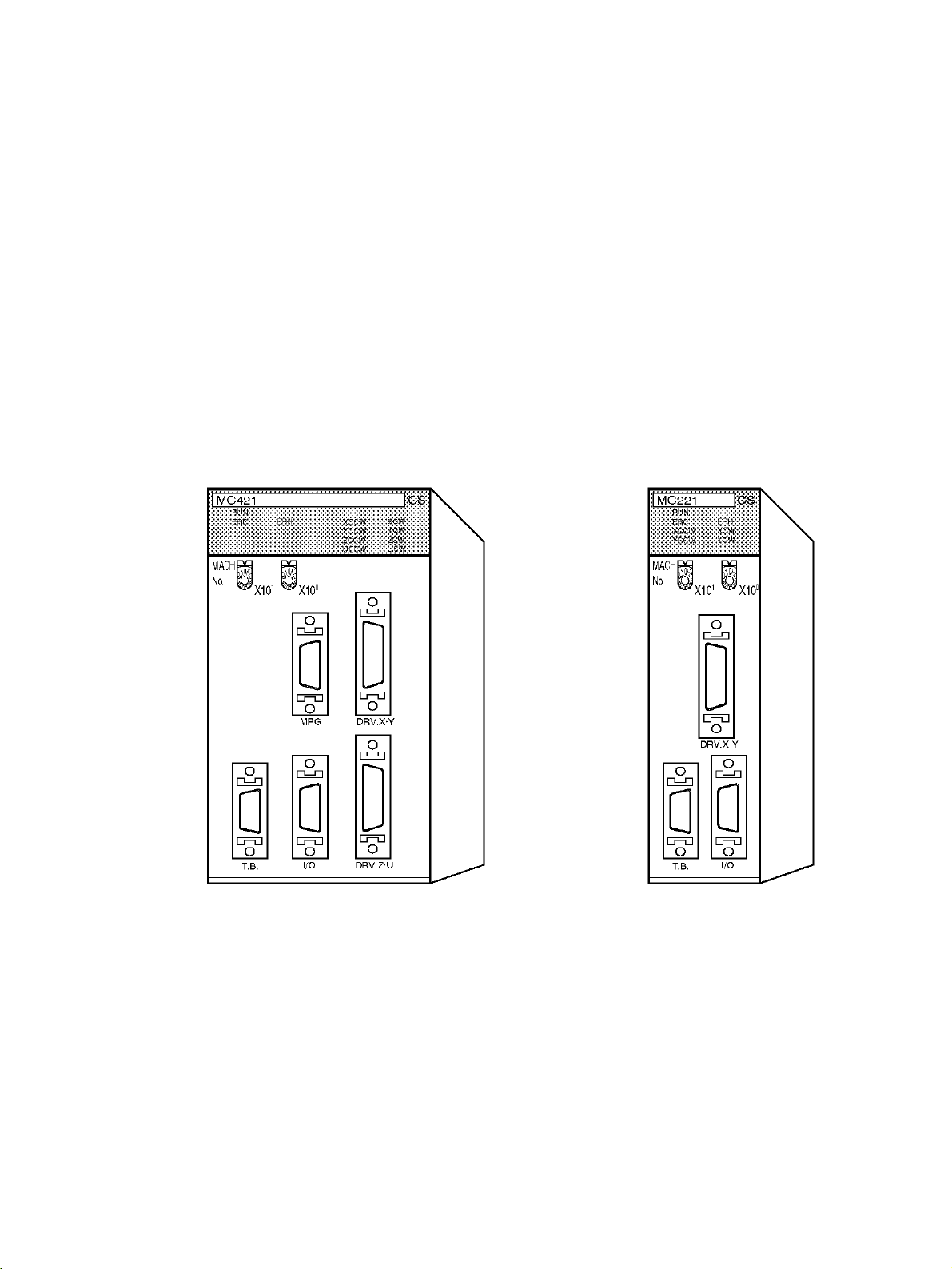

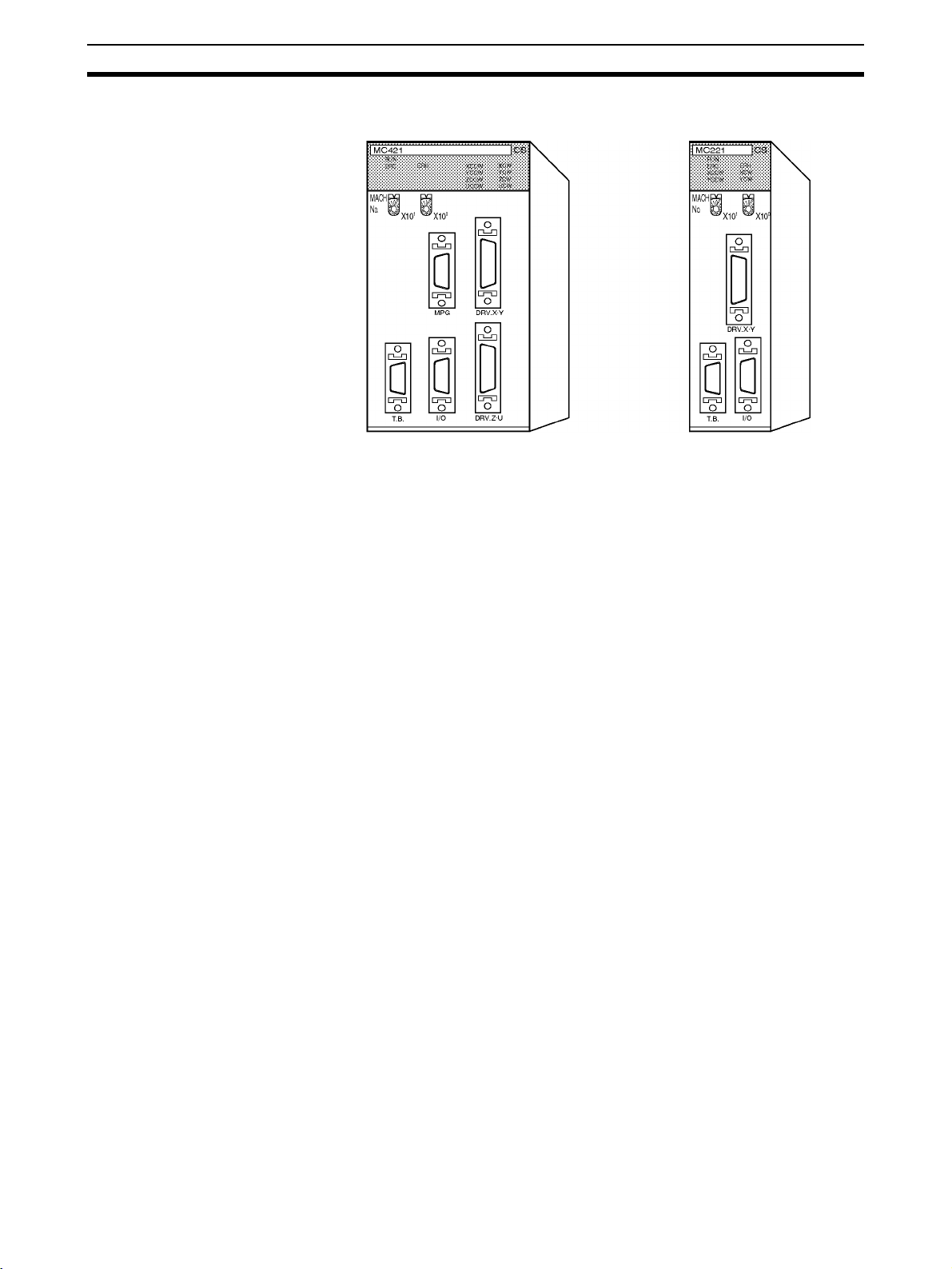

The CS1W-MC421 and CS1W-MC221 are CS-series Motion Control Units

that can control four axes and two axes, respectively. With their internal G-language programming, they can be used for advanced motion control operations, such as traversing, and their multi-tasking capability allows operations

to be performed independently for each axis.

Two types of motion control are possible: point-to-point and continuous path.

Point-to-point Control With point-to-point (PTP) control, positioning is controlled independently for

each axis. The pathway varies according to the travel distances, the feed

rates, and so on, that are set.

Continuous Path Control With continuous path (CP) control, not only the start position and target posi-

tion can be controlled but also the path between those points. Linear interpolation, circular interpolation, helical circular interpolation, and traversing are all

possible.

The MC Unit has been developed for use in simple positioning applications

using servomotors. Applicable machines are as follows:

• Conveyor Systems: X/Y tables, palletizers/depalletizers, loaders/unloaders, etc. (Palletizers and depalletizers are devices used for loading goods

onto pallets or for unloading them from pallets. Loaders and unloaders

are devices that have shelves corresponding with the steps of a multistep

press and used for inserting or removing all the materials at one time.)

• Assembling Systems: Simple robots (including orthogonal robots), simple

automated assembling machines (such as coil winding, polishing, hole

punching), etc.

Note The MC Unit is not designed to perform linear interpolation, circular interpola-

tion, or helical circular interpolation with horizontal articulated robots or cylindrical robots, because it does not support coordinate conversions. The MC

Unit can, however, perform PTP control with these robots.

2

Page 30

Fe at ur e s Section 1-1

1-1-2 Description of Features

Multi-tasking G Language The MC Unit is provided with a multi-tasking G language, which is the opti-

mum language for motion control. The G language makes it simple to create

programs for multi-axis control, without placing a burden on the CPU Unit’s

ladder diagram program.

Simple and Fast Traverse

Operations

Fast Pick-and-place

Operations

Supports Absolute

Encoders

High-speed Response to

Start Commands from

CPU Unit

Two-axis MC Unit This function applies to the X axis when a 2-axis, 1-task configuration is used.

Four-axis MC Unit This function applies to the X axis when a 4-axis, 1-task configuration is used.

500-kp/s Encoder

Response Frequency

CPU Unit Interrupts A CPU Unit external interrupt task can be started by outputting a D code

Commands for 2-axis traverse operations enable simple and fast traverse

operations.

After a positioning command has been output, the in-position check OFF

function allows the next positioning operation to be started without waiting for

the first positioning operation to be completed. This makes it possible to perform high-speed pick-and-place operations.

The MC Unit is compatible with absolute encoders (such as the OMNUC W

Series) as a standard feature, eliminating the need to perform an origin

search. Incremental encoders can be used as well.

The response time from when a start command is received from the CPU Unit

until the command voltage is output from the MC Unit is 8 ms for two axes and

12 ms for four axes (MC421 only). This is 1.5 times faster than the previous

models.

The maximum feedback encoder response frequency is 500 kp/s, so the MC

Unit can be used with high-speed and high-precision servomotors. This is

double the response frequency of the earlier models.

(interrupt code) for the CPU Unit when positioning is completed or when passing through a particular position. This feature is ideal for high-speed synchronization between the MC Unit and CPU Unit.

Windows-based MC

Support Software

Data Creation Using

Teaching Box

Operate with MPG Positioning and simple sync operations can be performed using an MPG

Single-port Multi-access Function

A Windows-based Support Software package called CX-Motion can be used

on the same computer and through the same port as the CX-Programmer,

enabling multiple programming environments on a single computer.

Servo Information Trace Function

Speed reference values, the present speed, and the error counter can be

traced with specified starting conditions and a specified sampling period using

the MC Support Software. Up to 500 items can be traced, making it easy to

adjust the servo system.

Automatic Loading Function

When it is necessary to use more programs or position data than can be

stored in the MC Unit, programs or position data stored in an external memory

device at the computer where the MC Support Software is installed can be

automatically downloaded to the MC Unit’s internal memory.

In addition to entering numbers in the Position Data Edit Window of the MC

Support Software (CX-Motion), it is possible to create position data by using

the Teaching Box to teach positions while actually moving the machinery.

(manual pulse generator).

3

Page 31

System Configuration Section 1-2

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

Motor Driver Connection

Cables are provided for connecting to the motor driver.

Cables

1-2 System Configuration

The MC Unit receives control signals (CW limit, CCW limit, origin proximity,

and emergency stop input signals) from the Rack and control panel, and outputs command voltages to the servo driver.

1-2-1 System Configuration Example (CS1W-MC421)

Used for trial

operation,

debugging,

teaching, etc.

Teaching Box

Teaching Box

connector

SYSMAC

CS-series

PLC

I/O connector

• Monitoring (PV, I/O signals)

• Origin search

• Jogging

• Error reset

• Teaching

DRV X,Y connectors

MC

ERH

RUN

ERC

XCW

ZCW

XCCW

ZCCW

YCW

UCW

YCCW

UCCW

MACH

No.

1

0

X10

X10

WPC

DRV.X·Y

I/O

DRV.Z·U

TOOL

Terminal Block

(See note 2.)

MPG connector

Etc.

MC Unit

CPU Unit

Power Supply Unit

Peripheral port connector

RS-232C port

connector

DRV Z, U connectors

Driver Connection Cable (See note 1.)

Used for setting

data and programming in G

language.

• G language program editing

• Status monitoring

• File administration

Etc.

Personal computer

CX-Motion

CX-Programmer

External I/O

CCW limit input

CW limit input

Origin proximity input

Emergency stop input

One each for 4 axes

General-purpose inputs (4)

General-purpose outputs (4)

24-V power supply

for interface

ABS data backup battery (+2.8 V to +4.5 V) (See note 3.)

Servo driver

24-V power supply for interface

Either an absolute or incremental encoder

can be used.

Driver Connection Cable is available as an option for OMRON

H-, M-, U-, W-, and G-series

Servo Drivers.

MPG

MPG 1 channel

5-V power supply

for interface

Used when

precise positioning is required, as in

teaching.

•

Axis selection

•

Pulse ratio

selection

Etc.

4

Page 32

System Configuration Section 1-2

Note 1. A special Driver Connection Cable is available for OMRON U-, H-, M-,

W-, and G-series Servo Drivers. A cable can also be prepared by the user.

2. A special cable is available for connecting to a Terminal Block. The cable

can also be prepared by the user.

3. A data backup battery is required when using an absolute encoder.

The equipment and models used in this example system configuration are

shown in the following table.

Devices Model

Motion Control Unit CS1W-MC421/MC221

SYSMAC CS-series CPU

Unit

Power Supply Unit One of the following:

CPU Backplane CS1W-BC023/BC033/BC053/BC083/BC103

Teaching Box CVM1-PRO01 (Programming Console) + CVM1-MP702

Personal computer (for

CX-Motion and

CX-Programmer)

CX-Motion/CX-Programmer

Servo Driver R88D-M, -H, -U, -W, -G-series

Servomotor R88M-M, -H, -U, -W, -G-series

One of the following:

CS1H-CPU6@

CS1G-CPU4@

C200HW-PA204

C200HW-PA204S

C200HW-PA204R

C200HW-PA209R

C200HW-PD024

(ROM Cassette)

IBM PC/AT or compatible

CXONE-AL@@C-EV@/-AL@@D-EV@

Items Supplied by the

User

If you are using a manual pulse generator (MPG) in your system, prepare the

following items.

LGF-003-100 MPG (line driver output)

5-V power supply for the MPG

Sync encoders can also be connected to MPG connectors. Connecting a sync

encoder makes it possible, for example, to synchronize axis feeding with a

conveyer. If this is to be done, prepare the required sync encoder.

A data backup battery is required when using an absolute encoder. For

details, refer to the Servo Driver manual.

5

Page 33

System Configuration Section 1-2

In addition to the above, prepare power supplies for the Servo Driver interface

and for external I/O.

Power supply for the Servo Driver interface: 24 V

Power supply for the external I/O: 24 V

Cable to Connect CPU Unit to a IBM PC/AT or Compatible Running CX-Motion and CX-Programmer

Unit Port on Unit Port on

CPU Unit Peripheral 9-pin D-sub

RS-232C

(9-pin D-sub

female)

Serial Communications Board/

Unit

RS-232C

(9-pin D-sub

female)

computer

male

Serial

communications

mode (network)

Peripheral bus or

Host Link

Host Link XW2Z-200S-CV 2.0 m

Model numbers Length Remarks

CS1W-CN226 2.0 m --CS1W-CN626 6.0 m

XW2Z-200S-CV 2.0 m ESD (static

XW2Z-500S-CV 5.0 m

XW2Z-500S-CV 5.0 m

electricity)-resistant connectors

used.

Driver Connection Cable The Driver Connection Cable is a special cable for connecting the MC Unit to

the Servo Driver. It can be used for connecting OMRON H-, M-, U-, W-, and

G-series Servo Drivers.

I/O Cable and Terminal

Block

Connected Driver Cable model for 1

axis

R88D-H Series R88A-CPH001M1

R88A-CPH002M1

R88D-M Series R88A-CPM001M1

R88D-U Series (for

30-W to 750-W

Drivers)

R88D-U Series (for

1-KW to 5-KW

Drivers)

R88D-W Series R88A-CPW001M1

R88D-G Series R88A-CPG001M1

R88A-CPM002M1

R88A-CPU001M1

R88A-CPU002M1

R88A-CPUB001M1

R88A-CPUB002M1

R88A-CPW002M1

R88A-CPW003M1

R88A-CPW005M1

R88A-CPG002M1

R88A-CPG003M1

R88A-CPG005M1

The following table shows the model numbers of the I/O Cable and Terminal

Blocks for connecting CCW limit input signals, CW limit input signals, proxim-

Cable model for 2

axes

R88A-CPH001M2

R88A-CPH002M2

R88A-CPM001M2

R88A-CPM002M2

R88A-CPU001M2

R88A-CPU002M2

R88A-CPUB001M2

R88A-CPUB002M2

R88A-CPW001M2

R88A-CPW002M2

R88A-CPW003M2

R88A-CPW005M2

R88A-CPG001M2

R88A-CPG002M2

R88A-CPG003M2

R88A-CPG005M2

Length (m)

1.0

2.0

1.0

2.0

1.0

2.0

1.0

2.0

1.0

2.0

3.0

5.0

1.0

2.0

3.0

5.0

ity input signals, etc., to the MC Unit.

Name Model Remarks

MC Unit Terminal Block Connecting Cable

MC Unit Terminal Block XW2B-20J6-6 For CS1W-MC221 (2 axes)

XW2Z-100J-F1 Length: 1 m (for 2 or 4 axes)

XW2B-40J6-7 For CS1W-MC421 (4 axes)

6

Page 34

Basic Operations Section 1-3

1-3 Basic Operations

The MC Unit has been developed for use in simple positioning applications

using servomotors. Depending on the machine being controlled, the accuracy

of the MC Unit should be about five to ten times higher than the machine

being controlled. Applicable machines are as follows:

Conveyor Systems: X/Y tables, palletizers/depalletizers, loaders/unloaders,

etc.

Assembling Systems: Simple robots (including orthogonal robots), simple

automated assembling machines, etc.

Orthogonal Robots

One-axis robot Two-axis robot

Note The CS1W-MC221 can control one or two axes.

Horizontal Articulated Robots

Three-axis robot Four-axis robot

PTP control can be performed when horizontal articulated robots or cylindrical

robots are used, but linear interpolation, circular interpolation, and helical circular interpolation are not possible.

Two-axis robot

Three-axis robot

X: Although point-to-point control is

possible, linear and circular

interpolation are not possible for

the ends of the robot arms.

Four-axis robot

7

Page 35

Basic Operations Section 1-3

Cylindrical Robots

Two-axis robot

X: Although point-to-point control is

possible, linear and circular

interpolation are not possible for

the ends of the robot arms.

Four-axis robot

Three-axis robot

1-3-1 Motion Control

The MC Unit offers the following three types of motion control:

PTP Control

CP Control (linear interpolation and circular interpolation)

Interrupt Feeding

Control programs are created in the G language.

PTP Control PTP control is used to control each axis (X and Y axis) independently. Posi-

tioning time depends on the travel distance and speed of each axis.

Example: Moving from the origin to the X-axis coordinate of 100 and Y-axis

coordinate of 50 at the same speed.

Positioning is executed separately for each

axis, so travel between the two points is

carried out as shown in the diagram.

8

Page 36

Basic Operations Section 1-3

CP Control CP control is used to position by designating not only the starting point and

the target point, but also the path between these two points. Both linear interpolation and circular interpolation are possible.

Circular

interpolation

Target point

Linear interpolation

Starting point

Interrupt Feeding Interrupt feeding is used to perform speed control until an external signal is

input and to perform position control for a fixed distance when the external

signal is input. Positioning with no interrupt signal is also possible.

Multiturn Circular

Interpolation

Speed

Speed control Position control

Signal input

(fixed distance)

The multiturn circular interpolation function has been added to the existing circular and helical circular interpolation functions. This function can be used for

applications such as winding machine operations.

Central axis Z

End point (target position)

Movement in direction of central axis

Feed

pitch

Beginning point

(present position)

9

Page 37

Basic Operations Section 1-3

Traversing

The following illustration shows the action of the winder (traverse function) for

a winding machine.

Winder

Traverse axis

Unlimited Feeding This function executes unlimited feeding for the specified axis.

1-3-2 Other Functions

Origin Search Establishes the origin for a specified axis.

Jogging Starts and stops positioning at a specified speed along a specified axis.

Error Counter Reset Forcibly resets the error counter to zero and stops axis operation after a

deceleration command.

Present Position Preset Changes the present position according to specified position data.

Teaching Obtains the present position to create position data.

Zones A Zone Flag turns ON when the present position is within a preset range.

Override (Real Time

Speed Change)

Backlash Correction Compensates for inaccurate meshing in the mechanical system.

Electronic Gears Sets a pulse ratio for the input pulses with MPG/sync encoders.

Changes the speed during PTP, linear interpolation, or circular interpolation

operations.

10

Page 38

Basic Operations Section 1-3

1-3-3 Summary of Function

The following diagram summarizes the MC Unit functions.

Stop Mode

MC Unit functions

Automatic Mode

(Executes G-language programs

in the MC Unit.)

Manual Mode

(Executes manual commands

from the CPU Unit or Teaching

Box.)

Common to Automatic

and Manual Modes

Position control

Speed control

Origin search

Interrupt feeding

Traversing

Arithmetic operations, etc.

Deceleration stop

Origin search (manual)

Standard origin return

Jogging

Error counter reset

Forced origin

Absolute origin setting

Servo lock/Servo unlock

Present position preset

Teaching

Zones

Backlash correction

Override

Electronic gear

Pass Mode

In-position

Check OFF Mode

Dwell timer

Note Positioning operations using the MC Unit are performed based on two coordi-

nate systems: A reference coordinate system and a workpiece coordinate

system.

The reference coordinate system is the most fundamental one for positioning

operations. The workpiece coordinate system is offset from the reference

coordinate system by a specified amount, allowing the user to freely set a

coordinate system.

Offset of the

workpiece

coordinate

system

Workpiece

coordinate

system

Offset of the workpiece

Reference

coordinate

system

coordinate system

11

Page 39

Control System Configuration and Principles Section 1-4

1-4 Control System Configuration and Principles

1-4-1 Servo System

The servo system used by and the internal operations of the MC Unit are

briefly described below.

Semi-closed Loop System The servo system of the MC Unit uses a semi-closed loop system. This sys-

tem is designed to detect actual machine movements by rotation of the motor

in relation to a target value. It computes the error between the target value

and actual movement, and zeroes the error through feedback.

Ta bl e

Servomotor

Encoder

Actual

movement

Ball screw

Decelerator

Target value

Semi-closed loop systems occupy the mainstream in modern servo systems

applied to positioning devices for industrial applications.

Position controller

Internal Operations of the

MC Unit

1,2,3... 1. The error counter receives a target position in units of encoder pulses. This

Commands to the MC Unit, speed control voltage to the servo driver, and the

feedback signals from the encoder are described in the next few pages.

Speed

control

voltage

Desired position

Pulse string

Error

counter

D/A

converter

Position feedback

Feedback pulses

Servo driver Servomotor

Speed

feedback

Encoder

is called a pulse string.

2. The error counter is directly connected to the D/A converter where the

pulses received by the error counter are converted to analog voltages.

These analog voltages are sent to the servo driver as the speed control

voltages.

12

Page 40

Control System Configuration and Principles Section 1-4

3. When the speed control voltage is received by the servo driver, it rotates

the motor at a speed corresponding to the speed control voltage. The rotational speed is in proportion to the speed control voltage.

Servo Driver Speed Characteristics

Rotational speed +N (r/min)

Speed control voltage

4. The rotary encoder directly connected to the motor axis rotates in sync

with the motor and generates feedback pulses.

5. The error counter is reduced by the feedback pulses until the error counter

goes to zero. When the error counter goes to zero, the speed control voltage to the servo driver becomes zero and the motor stops rotating.

Target position value

(pulses)

Error counter count

(pulses)

Speed control voltage

Time

Time

Positioning end

Time

13

Page 41

Control System Configuration and Principles Section 1-4

6. Unless the target position is given, the error counter constantly maintains

the stopped position.

7. If the motor axis moves slightly due to a drift in the driver or voltage output,

the error counter receives a feedback pulse from the rotary encoder and a

speed control voltage is output in the reverse direction, causing the motor

to rotate toward its original position. This corrective operation for maintaining the present position is called servolock or servoclamp.

8. Using this principle, positioning with acceleration and deceleration is executed by continuously setting target positions in the error counter.

9. The target position set in the error counter becomes the error counter

count as shown below. The count is converted to a speed control voltage

for the servo driver to control the motor.

Target position value

(pulses)

Time

Error counter count

(pulses)

Time

Speed control voltage

Time

Thus, the position equals the total count of target positions (shaded area in

the figure), and the speed will depend on the target position value per unit

time.

14

Page 42

Control System Configuration and Principles Section 1-4

1-4-2 Feedback Pulses

Standard OMRON Servomotors are designed for an advanced phase-A for

forward rotation and an advanced phase-B for reverse rotation. The MC Unit

is designed to comply with this phase advancement, allowing OMRON Driver

Connecting Cables to be connected without modification.

Forward Rotation (Positive Speed Reference)

Phase A

Phase B

Reverse Rotation (Negative Speed Reference)

Phase A

Phase B

When using Servomotors by other manufacturers, check carefully the encoder

specifications. If the definition differs from the ones given above, take one of

the following actions:

• Reverse the phase-B wiring between the MC Unit and the servo driver.

(Reverse the +B terminal and the –B terminal.)

• Set the machine parameter “encoder polarity” in the system parameters

to “reverse rotation for encoder increase.” It is initially set to the “forward

rotation at the encoder increase.”

1-4-3 CW and CCW

The abbreviations “CW” and “CCW” used in this manual to describe the operation of the MC Unit are defined as follows:

CW (Clockwise) Clockwise is the direction in which the present position increases.

CW

Negative limit

CCW (Counterclockwise) Counterclockwise is the direction in which the present position decreases.

Positive limit

Negative limit

CCW

Positive limit

15

Page 43

Specifications Section 1-5

1-5 Specifications

General Specifications

Item Specifications

Model CS1W-MC221 CS1W-MC421

Power supply

voltage

Voltage fluctuation

tolerance

Internal current

consumption

Weight (Connectors excluded)

Safety standards Conforms to UL (Class 2), CSA (class 2), and EC specifica-

External

dimensions

Specifications other than those shown above conform to those for the

SYSMAC CS Series.

5 VDC (from Backplane)

24 VDC (from external power supply)

4.75-5.25 VDC (from Backplane)

21.6-26.4 VDC (from external power supply)

600 mA or less for 5 VDC (with

Teaching Box connected:

800 mA or less)

0.2 A or less for 24 VDC

450 g max. 540 g max.

tions.

130.0 x 35.0 x 100.5 mm

(H x W x D)

700 mA or less for 5 VDC (with

Teaching Box connected:

1,000 mA or less)

130.0 x 70.0 x 100.5 mm

(H x W x D)

Functions and Performance Specifications

Item Specifications

Applicable PLC CS Series

Type of Unit CS Special I/O Unit

Backplanes on which MC Unit can

be mounted

Method for data

transfer with

CPU Unit

Controlled Driver Analog input servo driver (Example: OMRON OMNUC H, M, U,

Built-in program language G language (Started by receiving a start command from the CPU

Control Control method Speed reference voltage output-type semi-closed loop system,

Words allocated

to Special I/O

Units in CIO Area

Words allocated

to Special I/O

Units in DM Area

Number of

controlled axes

CS1W-MC221 CS1W-MC421

CPU Backplane or CS Expansion I/O Backplane (See note 1.)

30 words/Unit (uses 3 unit

numbers.) (See note 2.)

CPU Unit to MC Unit:

Commands: G-language program execution/stop, origin search,

manual operation, etc.

Data transfer: Position data, acceleration/ deceleration data, etc.

MC Unit to CPU Unit:

Status: Positioning completed, zones, busy flag, etc.

Monitor data: Present position, error codes, M codes, etc.

Not used. Not used.

W, or G Series)

Unit ladder diagram program.)

using incremental and absolute encoder inputs.

2 max. 4 max.

Multitasking can be used to execute independent operating

modes and programs for each axis.

50 words/Unit (uses 5 unit

numbers.) (See note 2.)

16

Page 44

Specifications Section 1-5

Item Specifications

CS1W-MC221 CS1W-MC421

Automatic/Manual Mode (for each

task)

Encoder interface Line receiver input; maximum response frequency: 500 kp/s

Control unit Minimum setting

unit

Units mm, inch, degree, pulse (There is no unit conversion function.)

Maximum command value –39,999,999 to +39,999,999

Number of controlled axes 2 axes max. 4 axes max.

Positioning

operations

Speed reference 1 pps to 2,000 kp/s (when ratio is 4)

Acceleration/deceleration curve Trapezoidal or S-curve

Acceleration/deceleration time Individual acceleration/deceleration settings possible: 0 to

PTP (independent) control

Linear interpolation

Circular interpolation

Helical circular

interpolation

Traverse function Traverse operation for two axes

Speed control Speed control for each axis

Unlimited Feed

Mode

Interrupt feeding Feeding a fixed distance after an interrupt input, for each axis.

Automatic Mode: Mode for executing MC program created in G

language.

Manual Mode: Mode for executing manual commands from CPU

Unit (PLC interface area) or Teaching Box.

• The Automatic or Manual Mode is set according to the PLC

interface area of the CPU Unit.