Page 1

iii

CS1W-LC001

Loop Control Unit

Version 2.5

OPERATION MANUAL

Revised August 2001

Page 2

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or

damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING Indicates an imminently hazardous situation which, if not avoided, could result in

death or serious injury.

Caution Indicates an imminently hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The work "Unit" is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation "Ch" which appears in some displays and on some ONROM products, often means

"word" and is abbreviated "Wd" in documentation in this sense.

The abbreviation "PC" means Programmable Controller and is not used as an abbreviation for

anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient

operation of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists,

etc.

OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual.

Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the user of the information contained in this publication.

Page 3

vii

TABLE OF CONTENTS

PRECAUTIONS.....................................................................................................xviii

1 Intended Audience.................................................................................................................................................... xix

2 General Precautions.......................................................................................................... ........................................ xix

3 Safety Precautions.................................................................................................................................................... xix

4 Operating Environment Precautions......................................................................................................................... xxi

5 Application Precautions............................................................................................................................................ xxi

6 EC Directives.......................................................................................................................................................... xxiv

7 Other Applicable Directives................................................................................................................................... xxiv

SECTION 1

SPECIFICATIONS .................................................................................................... 1

1-1 Outline................................................................................................................................................................... 2

1-2 Configuration of Instrumentation System............................................................................................................26

1-3 Specifications ...................................................................................................................................................... 37

1-4 How to Use Function Blocks for Specific Operations......................................................................................... 48

1-5 Basic Procedure for Using the Loop Control Unit............................................................................................... 52

SECTION 2

COMPONENTS, INSTALLATION AND WIRING.............................................59

2-1 Names and Functions of Parts.............................................................................................................................60

2-2 Installation........................................................................................................................................................... 64

2-3 Connecting to CX-Process Tool and CX-Process Monitor ................................................................................. 66

SECTION 3

MECHANISM OF THE LOOP CONTROL UNIT .............................................. 69

3-1 Configuration of Function Blocks....................................................................................................................... 70

3-2 Description of Operation.....................................................................................................................................84

3-3 Exchanging Data with the CPU Unit................................................................................................................. 114

3-4 Exchanging Data with CX-Process Monitor/SCADA Software and with Other Nodes.................................... 122

3-5 Fail-safe Countermeasure Guidelines................................................................................................................ 135

SECTION 4

SIMPLE EXAMPLE OF USE............................................................................... 139

4-1 Simple Example of Use..................................................................................................................................... 140

Page 4

viii

TABLE OF CONTENTS

SECTION 5

EXAMPLES OF FUNCTION BLOCK COMBINATIONS............................... 151

5-1 Basic Examples of PID Control......................................................................................................................... 152

5-2 Examples of Applied Control Types.................................................................................................................161

SECTION 6

HOW TO USE FINS COMMANDS ..................................................................... 173

6-1 How to Use FINS Commands........................................................................................................................... 174

6-2 FINS Command List.......................................................................................................................................... 177

6-3 Description of FINS Commands ....................................................................................................................... 178

SECTION 7

SERRORS AND ALARM TROUBLESHOOTING............................................ 191

7-1 Errors and Alarm Troubleshooting.................................................................................................................... 192

7-2 Maintenance ...................................................................................................................................................... 199

APPENDICES

1 How to Use the Step Ladder Program Block........................................................................................................... 205

2 How to Use the Node Terminal Blocks................................................................................................................... 217

3 List of Operation Execution Times.......................................................................................................................... 231

INDEX...................................................................................................................... 239

REVISION HISTORY............................................................................................241

Page 5

ix

About this Manual:

This manual describes the installation and operation of the CS1W-LC001 Loop Control Unit, and

includes the sections described below.

The CS1W-LC001 Loop Control Unit (CS1W-LC001) helps you build an instrumentation system

comprising multiple loops and is intended as a CPU Bus Unit on a PC (Programmable Controller).

Please read this manual and the other manuals related to the CS1W-LC001 Loop Control Unit

carefully and be sure you understand the information provided before attempting to install and operate

the Loop Control Unit.

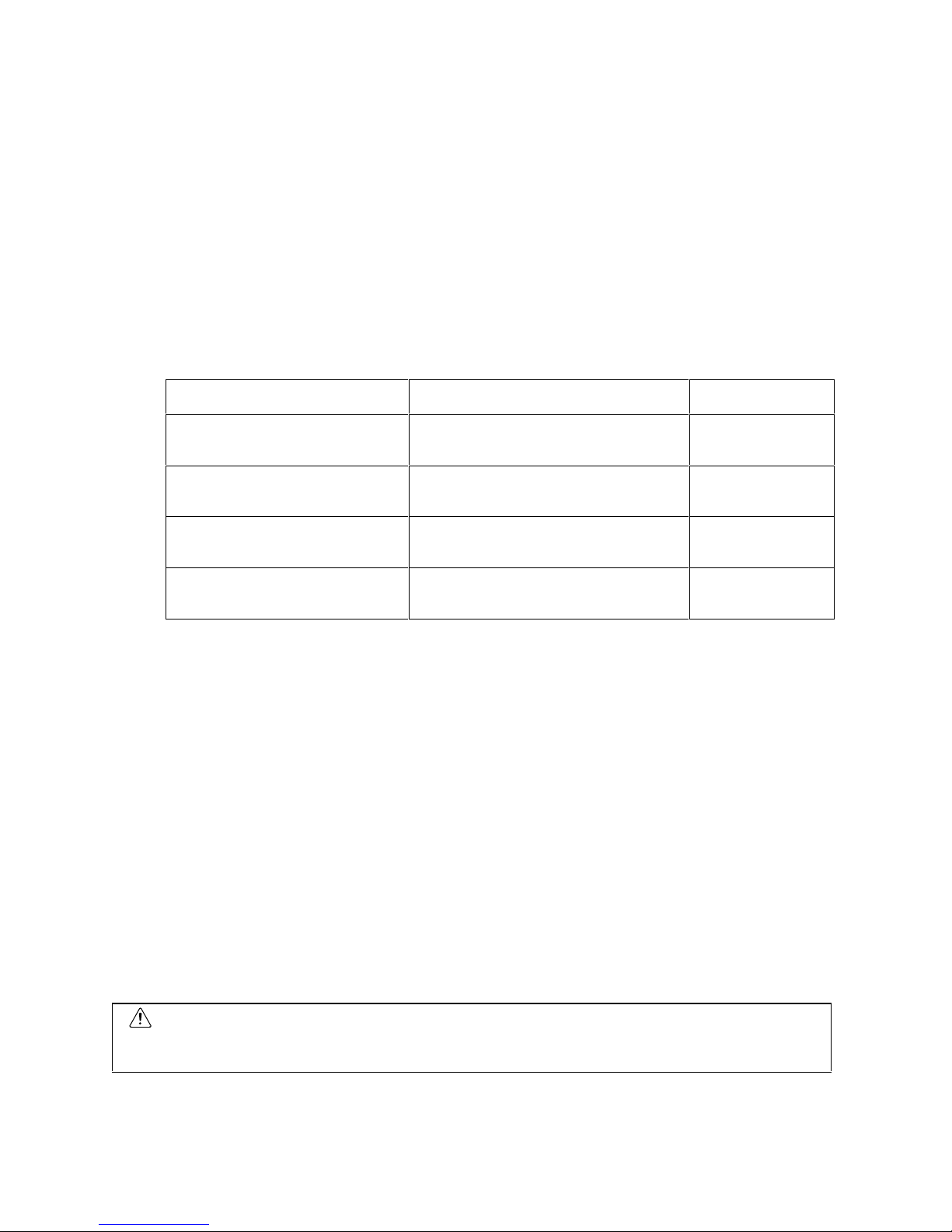

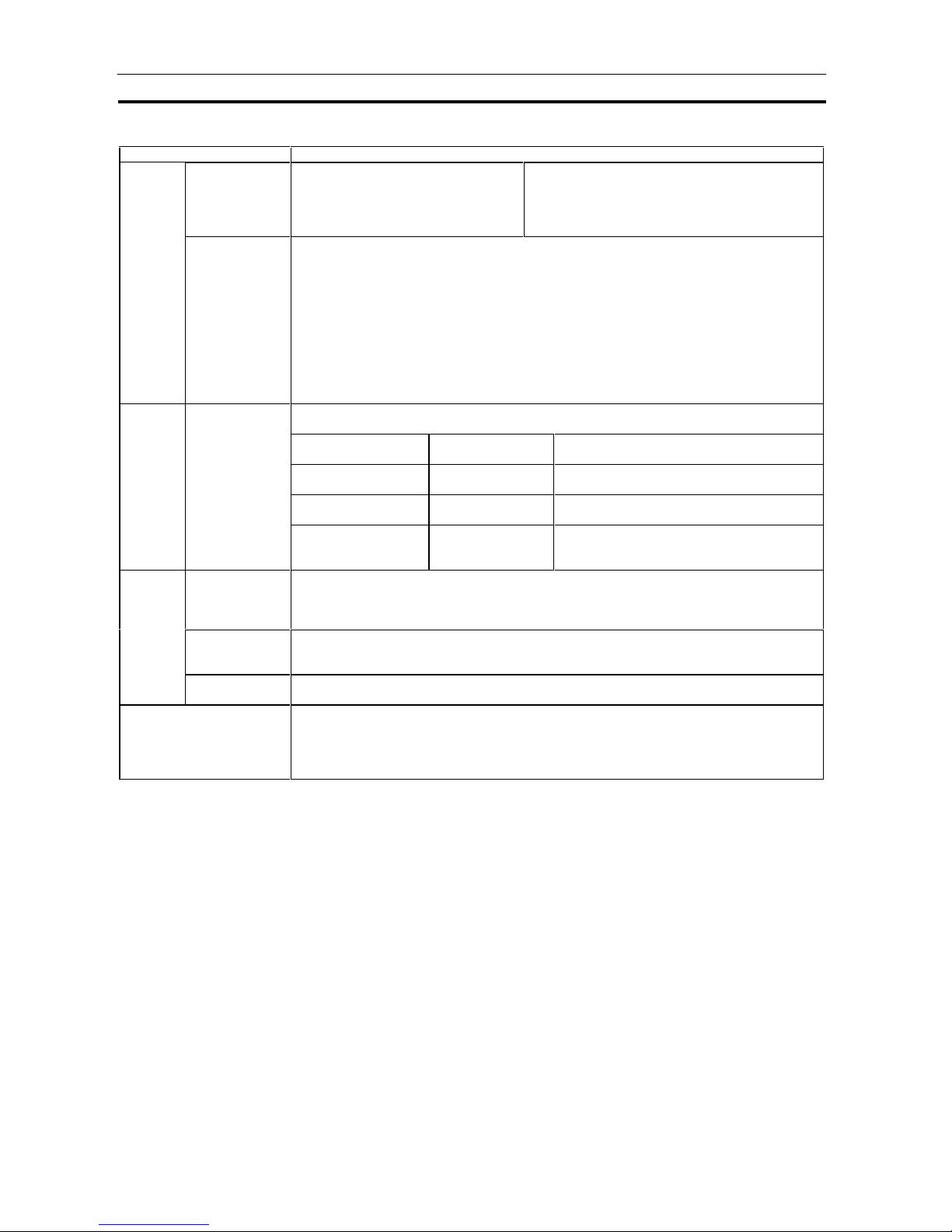

There are four manuals used with the CS1W-LC001. These manuals are listed in the following table.

The suffixes have been omitted from the catalog numbers. Be sure you are using the most recent

version for your area.

Name Contents

Cat. No.

(suffixes omitted)

SYSMAC CS1 Series

CS1W-LC001 Loop Control Unit

Operation Manual

Describes the basic running of the Loop

Control Unit (excluding detailed

descriptions of the function blocks).

W374

SYSMAC CS1 Series

CS1W-LC001 Loop Control Unit

Function Block Reference Manual

Provides detailed information on the

function blocks.

W375

SYSMAC CS1 Series

CS1W-LC001 CX-Process Tool

Operation Manual

Describes operation of the CX-Process

Tool.

W372

SYSMAC CS1 Series

CS1W-LC001 CX-Process Monitor

Operation Manual

Describes operation of the CX-Process

Monitor.

W373

Section 1 describes the features and system configuration of CS1W-LC001 Loop Control Units.

Section 2 describes the names and functions of parts, and provides other information required to

install and operate CS1W-LC001 Loop Control Units.

Section 3 provides information on the control mechanism, basic operation, exchanging data with other

Units and software, and fail-safe countermeasures for CS1W-LC001 Loop Control Units.

Section 4 describes a simple example of how to use CS1W-LC001 Loop Control Units.

Section 5 describes basic examples of PID control and examples of applied control types.

Section 6 provides information on how to use FINS commands.

Section 7 provides information on errors that may occur during running of CS1W-LC001 Loop Control

Units and guidelines for troubleshooting these errors.

Appendix 1 describes how to use the Step Ladder Program block on CS1W-LC001 Loop Control

Units, Appendix 2 describes how to use the Node Terminal blocks on CS1W-LC001 Loop Control

Units, and

Appendix 3 provides information on how to calculate the load rate, and operation execution times of

each function block and the execution times of sequence commands.

WARNING

Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you unders ta nd the inf or mation provided in the section

and related sections before attempting any of the procedures or operations given.

Page 6

x

New Version Features: Ver. 2.0 to Ver.2.5

The following features had been added to the CS1W-LC001 Loop Control

Unit in upgrading from version 2.0 to version 2.5.

New Function Blocks

The following function blocks have been added: Fuzzy Logic (Block Model

016), Range Conversion (Block Model 127), Ramped Switch (Block Model

167), Level Check (Block Model 210), Ai4 Terminal (DRT1-AD04) (Block

Model 588), and Ao2Terminal (DRT1-DA02) (Block Model 589).

Notifying the CPU Unit of Function Block Changes

The CPU Unit can be informed when function blocks are downloaded by

block from the CX-Process Tool software to the Loop Control Unit. (See

note.)

*1: Similar to online editing for the Loop Control Unit.

Notification is achieved by monitoring the Function Block Change Flag (bit

15 in word n) allocated to the Loop Control Unit as a CPU Bus Unit.

Changes in the status of this flag can be used to trigger required

processing, such as notification that function blocks have changed.

Operation Specifications for Contact Type Control Target Operation

Blocks when Changing from AUTO to MAN or from Site to Central

Operation

For the ON/OFF Valve Manipulator block (Block Model 221), Motor

Manipulator block (Block Model 222), Reversible Motor Manipulator block

(Block Model 223), and Motor Opening Manipulator block (Block Model

224) only MAN status was switched to previously, but now the MAN input

is made to agree with the AUTO input to enter MAN status.

Also when the Site Manipulation Switch was changed from site to central

for these blocks, only operation was changed to the site, but now the

status is changed to MAN and the MAN input is made to agree with the

answer (feedback) input to switch to maintain status at the site while

allowing central operation.

Shorter I/O Refresh Cycle for Analog I/O Units

Although previously the external I/O refresh cycle for Mixed Analog I/O

Units was one cycle longer for Ai/Ao Terminals, specifications have been

changed so that the additional cycle is no longer required.

A Periodic Initialization Function Added to the Receive All Blocks

block (Block Model 461)

ITEM 030 (periodic initialization) and ITEM 031 (initialization interval) have

been added to the Receive All Blocks block (Block Model 461). These

ITEMs can be used to periodically initialize function block ITEM data in the

I/O memory of the CPU Unit.

ITEM Additions and Specification Changes for Other Blocks

A Block Registration Flag (ITEM 039) and the Tool Version (ITEM 110)

have been added to the System Common block (Block Model 000).

A Warning Limit (ITEM 012) has been added to the Basic PID block

(Block Model 011, Advanced PID block (Block Model 020), 2-Position

ON/OFF block (Block Model 001), 3-Position ON/OFF block (Block Model

002), Indication and Setting block (Block Model 031), Indication and

Operation block (Block Model 032), Ratio Setting block (Block Model

Page 7

xi

033), Indicator block (Block Model 034), and 4-Point Warning Indicator

block (Block Model 110).

An SP Rate-of-change Limit Time Unit (ITEM 030) has been added to

the Advanced PID block (Block Model 012).

In the Batch Flowrate Capture block (Block Model 014, the following

ITEMs have been added: Local SP Setting, Upper 4 Digits (ITEM 024),

Remote SP Setting, Upper 4 Digits (ITEM 028), Current SP Value, Upper

4 Digits (ITEM 030), Preset Value, Upper 4 Digits (ITEM 061), and Batch

Accumulated Value, Upper 4 Digits (ITEM 065) because the number of

digits has been increased from 4 to 8 digits for the Local SP, Remote SP,

Preset Value, and Batch Accumulated Value.

A Time Unit (ITEM 013) was added to the Rate-of-change Limit block

(Block Model 143).

A Reference Input Disable Switch (ITEM 020) was added to the Segment

Program 2 block (Block Model 157) to enable starting from the initial

value rather than the reference input value even when the source of the

reference input is specified.

An Output Type (ITEM 006) was added to the Contact Distributor block

(Block Model 201) to enable selecting between a constant output and a

one-shot output.

Range settings were added for individual points for the AI Terminal from

CPU Unit block (Block Model 453), AO Terminal to CPU Unit block

(Block Model 454), Ai4 Terminal block (Block Model 561), Pi4 Terminal

block (Block Model 562), and Ai8 Terminal block (Block Model 564).

A Receive Disable Switch (ITEM 225) was added to the Expanded DI

Terminal from CPU Unit block (Block Model 455) and Expanded AI

Terminal from CPU Unit block (Block Model 457) and a Send Disable

Switch (ITEM 225) was added to the Expanded DO Terminal from CPU

Unit block (Block Model 456) and Expanded AO Terminal from CPU Unit

block (Block Model 458).

A limit was set for writing ITEMs during execution of autotuning for Basic

PID (Block Model 011) and Advanced PID (Block Model 012). (Although

there was previous no limit on writing ITEMs during autotuning, ITEMs

could not be written except while process in g was disab le d, autot uning

was specified or executing, or A/M was being switched.)

Floating point decimal data can now be specified as the source data for

inputs X1 to X8. (Previously, normalized data was specified for inputs X1

to X8 and this data was scaled to floating point data. The source data

was automatically detected as normalized or floating point data and

scaling was disabled if the source data was already floating point data.

Page 8

xii

New Version Features: Ver. 1.5 to 2.0

The following features had been added to the CS1W-LC001 Loop Control

Unit in upgrading from version 1.5 to version 2.0.

New Function Blocks

The following function blocks have been added: ES100X Controller

Terminal (Block Model 045), 4-point Warning Indicator (Block Model

110), Arithmetic Operation (Block Model 126), Time Sequence Data

Statistics (Block Model 153), Receive All Blocks (Block Model 461), and

Send All Blocks (Block Model 462).

New ITEMS in Previous Function Blocks

PV Error Detection MV Output Value Traceback Time has been added to

2-position ON/OFF (Block Model 001), 3-position ON/OFF (Block Model

002), Basic PID (Block Model 011), and Advanced PID (Block Model

012).

MV Upper Limit Output Value and MV Lower Limit Output Value have

been added to Basic PID (Block Model 011), Indication and Operation

(Block Model 032), and Ratio Setting (Block Model 033).

MV Error Contact Input and MV Error Contact Display have been added

to Batch Flowrate Capture (Block Model 014), Indication and Operation

(Block Model 032), and Ratio Setting (Block Model 033).

PV Error Contact Input and PV Error Contact Display have been added

to Indication and Setting (Block Model 031), Indication and Operation

(Block Model 032), Ratio Setting (Block Model 033), and Indicator (Block

Model 034).

Inputs X1 to X8 have been added to Constant Comparator (Block Model

202).

Inputs X1 to X8 and Comparison Input R1 to R8 have been added to

Variable Comparator (Block Model 203)

Contact Inputs S33 to S224 have been added to Internal Switch (Block

Model 209).

Improved SCADA Software Support

Functions to monitor or set Loop Control Unit data from standard SCADA

software have been improved. Two new function blocks, Receive All

Blocks (Block Model 462) and Send all Blocks (Block Model 461) can be

used to access Control Block (e.g., Basic PID), Operation Block, and

External Controller Block data in the I/O memory of the CPU Unit using

CSV tags created from the CX-Process Tool software.

Flash Memory

Data Transfer between RAM and Flash Memory

The CX-Process Tool can be used to transfer function block data from

RAM in the Loop Control Unit to flash memory in the Loop Control Unit.

Data Transfer from Flash to RAM at Startup (Battery-free Operation)

Turn ON pin 2 of the DIP switch on the front of the Loop Controller Unit

will cause the contents of flash memory to be transferred to RAM in the

Loop Controller Unit each time the Unit is started. This enables operation

without worrying about the backup battery.

RS-232C Communications

A new ES100X Controller Terminal Block enables connecting an

OMRON ES100X Controller to the RS-232C port on the Loop Control

Page 9

xiii

Unit to monitor or set the ES100X via RS-232C communications or RS485 communications via RS-232C.

Restrictions in Use of Function Blocks According to Version

The following function blocks described in this manual can be used only

when Loop Control Unit CS1W-LC001 Ver.1.20 and onwards and CXProcess Tool Ver.1.20 and onwards are used:

The following function blocks can be registered on CX-Process Tool

when Loop Control Unit Ver.1.0 and CX-Process Tool Ver1 .20 or

onwards are used. However, if the data of these function blocks is

downloaded to the Loop Control Unit in major item units (units of Loop

Control Unit) when these function blocks are registered on CX-Process

Tool, an error occurs, and the download is canceled. (Other function

blocks also are not downloaded.)

The following function blocks cannot be registered on CX-Process Tool

when Loop Control Unit Ver.1.20 and onwards and CX-Process Tool

Ver.1.00 are used. For this reason, these function blocks cannot also be

downloaded to the Loop Control Unit.

If the following function blocks already exist on the Loop Control Unit and

are uploaded to CX-Process Tool, only the following function blocks are

not uploaded. (When a new upload is performed, these blocks become

empty.)

2-position ON/OFF (Block Model 001), 3-position ON/OFF (Block Model 002),

Blended PID (Block Model 013), 3-input Selector (Block Model 163), 3-output

Selector (Block Model 164), Batch Data Collector (Block Model 174), DI

Terminal from Expanded CPU Unit (Block Model 455), DO Terminal from

Expanded CPU Unit (Block Model 456), AI Terminal from Expanded CPU

Unit (Block Model 457), AO Terminal from Expanded CPU Unit (Block Model

458)

Note The version of the Loop Control Unit can be verified in the Monitor run status

screen ([Execute]-[Run]-[Monitor run status]) on CX-Process Tool.

When the above function blocks are used, check in the Check System

Operation screen on CX-Process Tool beforehand that the content of ITEM

099 onwards in the System Common block (Block Model 000) is as follows.

ITEM Data name Data

099 MPU/FROM version indication V1.20V1.20

Version V1.20 and onwards must be indicated.

The following function blocks described in this manual can be used only

when Loop Control Unit CS1W-LC001 Ver.1.50 and onwards and CXProcess Tool Ver.1.50 and onwards are used:

The following function blocks can be registered on CX-Process Tool

when versions of Loop Control Unit earlier than Ver.1.50 (Ver.1.0 or

Ver.1.20) and CX-Process Tool Ver1.50 or onwards are used. However,

if the data of these function blocks is downloaded to the Loop Control

Unit in major item units (units of Loop Control Unit) when these function

blocks are registered on CX-Process Tool, an error occurs, and only

those function blocks are not downloaded. (Other function blocks are

downloaded successfully.)

The following function blocks cannot be registered on CX-Process Tool

when Loop Control Unit Ver.1.50 and onwards and versions of CX-

Page 10

xiv

Process Tool earlier than Ver.1.50 (Ver.1.00 or Ver. 1.20) are used. For

this reason, these function blocks cannot also be downloaded to the Loop

Control Unit.

If the following function blocks already exist on the Loop Control Unit and

are uploaded to CX-Process Tool, only the following function blocks are

not uploaded. (When a new upload is performed, these blocks become

empty.)

Segment Program (Block Model 157), Accumulated Value Input Adder (Block

Model 182), Accumulated Value Input Multiplier (Block Model 183), Constant

Comparator (Block Model 202), Variable Comparator (Block Model 203),

Clock Pulse (Block Model 207), ON/OFF Valve Manipulator (Block Model

221), Motor Manipulator (Block Model 222), Reversible Motor Manipulator

(Block Model 223), Motor Opening Manipulator (Block Model 224)

Likewise, the following functions can be used only when Loop Control Unit

CS1W-LC001 Ver.1.50 and onwards and CX-Process Tool Ver.1.50 and

onwards are used:

The following ITEMs can be set on CX-Process Tool when versions of

Loop Control Unit earlier than Ver.1.50 (Ver.1.0 or Ver.1.20) and CXProcess Tool Ver1.50 or onwards are used. However, if the data of these

ITEMs is downloaded to the Loop Control Unit when these ITEMs are set

on CX-Process Tool, only those ITEMs are not downloaded. (Other

ITEMs are downloaded successfully.)

The following ITEMs cannot be set on CX-Process Tool when Loop

Control Unit Ver.1.50 or onwards and versions of CX-Process Tool earlier

than Ver.1.50 (Ver.1.00 or Ver. 1.20) are used. For this reason, these

ITEMs cannot also be downloaded to the Loop C ontro l Unit.

If a download in major item units (units of Loop Control Unit) or a

download in function blocks units including initial setting data is

performed, the respective defaults are set to the following ITEMs on the

Loop Control Unit.

If the following ITEMs are already set on the Loop Control Unit and are

uploaded to the CX-Process Tool, only the following ITEMs are not

uploaded.

AT (auto-tuning) functions of Basic PID block (Block Model 011) and

Advanced PID (Block Model 012), and wait function and additional steps

(step numbers 8 to 15) of the Ramp Program block (Block Model 155)

Note 1 For details on which actual ITEM this restriction applies to, refer to the ITEM

list for the relevant function block in the Function Block Reference Manual.

Note 2 The version of the Loop Control Unit can be verified in the Monitor run status

screen ([Execute]-[Run]-[Monitor run status]) on CX-Process Tool.

When the above function blocks are used, check in the Check System

Operation screen on CX-Process Tool beforehand that the content of ITEM

099 onwards in the System Common block (Block Model 000) is as follows.

ITEM Data name Data

099 MPU/FROM version indication V1.50V1.50

Version V1.50 and onwards must be indicated.

Page 11

xv

The following function blocks described in this manual can be used only

when Loop Control Unit CS1W-LC001 Ver. 2.00 and onwards and CXProcess Tool Ver. 2.00 and onwards are used:

The following function blocks can be registered on CX-Process Tool

when versions of Loop Control Unit earlier than Ver. 2.00 (Ver. 1.0,

Ver. 1.20, or Ver. 1.50) and CX-Process Tool Ver 1.50 or onwards are

used. However, if the data of these function blocks is downloaded to the

Loop Control Unit in major item units (units of Loop Control Unit) when

these function blocks are registered on CX-Process Tool, an error

occurs, and only those function blocks are not downloaded. (Other

function blocks are downloaded successfully.)

The following function blocks cannot be registered on CX-Process Tool

when Loop Control Unit Ver. 2.00 and onwards and versions of CXProcess Tool earlier than Ver. 2.00 (Ver. 1.00 Ver. 1.20, or Ver. 1.50) are

used. For this reason, these function blocks cannot also be downloaded

to the Loop Control Unit.

If the following function blocks already exist on the Loop Control Unit and

are uploaded to CX-Process Tool, only the following function blocks are

not uploaded. (When a new upload is performed, these blocks become

empty.)

ES100X Controller Terminal (Block Model 045), 4-point Warning Indicator

(Block Model 110), Arithmetic Operation (Block Model 126), Time Sequence

Data Statistics (Block Model 153), Receive All Blocks (Block Model 461),

Send All Blocks (Block Model 462)

Likewise, the following functions can be used only when Loop Control Unit

CS1W-LC001 Ver. 2.00 and onwards and CX-Process Tool Ver. 2.00 and

onwards are used:

The following ITEMs can be set on CX-Process Tool when versions of

Loop Control Unit earlier than Ver. 2.00 (Ver. 1.00 Ver. 1.20, or Ver. 1.50)

and CX-Process Tool Ver, 2.00 or onwards are used. However, if the

data of these ITEMs is downloaded to the Loop Control Unit when these

ITEMs are set on CX-Process Tool, only those ITEMs are not

downloaded. (Other ITEMs are downloaded successfully.)

The following ITEMs cannot be set on CX-Process Tool when Loop

Control Unit Ver. 2.0 or onwards and versions of CX-Process Tool earlier

than Ver. 2.00 (Ver. 1.00 Ver. 1.20, or Ver. 1.50) are used. For this

reason, these ITEMs cannot also be downloaded to the Loop Control

Unit.

If a download in major item units (units of Loop Control Unit) or a

download in function blocks units including initial setting data is

performed, the respective defaults are set to the following ITEMs on the

Loop Control Unit.

If the following ITEMs are already set on the Loop Control Unit and are

uploaded to the CX-Process Tool, only the following ITEMs are not

uploaded.

Page 12

xvi

MV Output Retrace Time for PV Error has been added to 2-position ON/OFF (Block

Model 001), 3-position ON/OFF (Block Model 002), Basic PID (Block Model 011), and

Advanced PID (Block Model 012).

High MV Limit Output and Low MV Limit Output have been added to Basic PID (Block

Model 011), Indication and Operation (Block Model 032), and Ratio Setting (Block

Model 033).

MV Error Input and MV Error Display have been added to Batch Flowrate Capture

(Block Model 014), Indication and Operation (Block Model 032), and Ratio Setting

(Block Model 033).

PV Error Input and PV Error Display have been added to Indication and Setting (Block

Model 031), Indication and Operation (Block Model 032), Ratio Setting (Block Model

033), and Indicator (Block Model 034).

Inputs X1 to X8 have been added to Constant Comparator (Block Model 202).

Inputs X1 to X8 and Comparison Input R1 to R8 have been added to Variable

Comparator (Block Model 203)

Contact Inputs S33 to S224 have been added to Internal Switch (Block Model 209).

Note 1 For details on which actual ITEM this restriction applies to, refer to the ITEM

list for the relevant function block in the Function Block Reference Manual.

Note 2 The version of the Loop Control Unit can be verified in the Monitor run status

screen ([Execute]-[Run]-[Monitor run status]) on CX-Process Tool.

When the above function blocks are used, check in the Check System

Operation screen on CX-Process Tool beforehand that the content of ITEM

099 onwards in the System Common block (Block Model 000) is as follows.

ITEM Data name Data

099 MPU/FROM version indication V2.00V2.00

Version V2.00 and onwards must be indicated.

The following function blocks described in this manual can be used only

when Loop Control Unit CS1W-LC001 Ver.2.50 and onwards and CXProcess Tool Ver.2.50 and onwards are used:

The following function blocks can be registered on CX-Process Tool

when the Loop Control Unit is pre-Ver.2.50 and the CX-Process Tool is

Ver 2.50 or later. However, if the data of these function blocks is

downloaded to the Loop Control Unit in major item units (units of Loop

Control Unit) when these function blocks are registered on CX-Process

Tool, an error occurs, and the download is canceled. (Other function

blocks will be downloaded normally.)

The following function blocks cannot be registered on CX-Process Tool

when the Loop Control Unit is Ver. 2.50 or later and CX-Process Tool is

pre-Ver.2.50. For this reason, these function blocks cannot also be

downloaded to the Loop Control Unit.

If the following function blocks already exist on the Loop Control Unit and

are uploaded to CX-Process Tool, only the following function blocks are

not uploaded. (When a new upload is performed, these blocks become

empty.)

Fuzzy Logic (Block Model 016), Range Conversion (Block Model 127), Level

Check (Block Model 210), Ai4 Terminal (DRT1-AD04) (Block Model 588),

Ao2 Terminal (DRT1-DA02) (Block Model 589)

Likewise, the following functions can be used only when Loop Control Unit

CS1W-LC001 Ver. 2.50 or onwards and CX-Process Tool Ver. 2.50 or

onwards are used:

Page 13

xvii

The following ITEMs can be set on CX-Process Tool when versions of

Loop Control Unit earlier than Ver. 2.50 and CX-Process Tool Ver. 2.50

or onwards are used. However, if the data of these ITEMs is downloaded

to the Loop Control Unit when these ITEMs are set on CX-Process Tool,

only those ITEMs are not downloaded. (Other ITEMs are downloaded

successfully.)

The following ITEMs cannot be set on CX-Process Tool when Loop

Control Unit Ver. 2.50 or onwards and versions of CX-Process Tool

earlier than Ver. 2.50 are used. For this reason, these ITEMs cannot also

be downloaded to the Loop Control Unit.

If a download in major item units (units of Loop Control Unit) or a

download in function blocks units including initial setting data is

performed, the respective defaults are set to the following ITEMs on the

Loop Control Unit.

If the following ITEMs are already set on the Loop Control Unit and are

uploaded to the CX-Process Tool, only the following ITEMs are not

uploaded.

Block Registration Flag (ITEM 039) and Tool Version (ITEM 110) in System Common

(Block Model 000).

Warning Limit (ITEM 012) in Basic PID (Block Model 011, Advanced PID (Block

Model 020), 2-Position ON/OFF (Block Model 001), 3-Position ON/OFF (Block Model

002), Indication and Setting (Block Model 031), Indication and Operation (Block Model

032), Ratio Setting (Block Model 033), Indicator (Block Model 034), and 4-Point

Warning Indicator (Block Model 110).

SP Rate-of-change Limit Time Unit (ITEM 030) in Advanced PID (Block Model 012).

Local SP Setting, Upper 4 Digits (ITEM 024), Remote SP Setting, Upper 4 Digits

(ITEM 028), Current SP Value, Upper 4 Digits (ITEM 030), Preset Value, Upper 4

Digits (ITEM 061), and Batch Accumulated Value, Upper 4 Digits (ITEM 065) in Batch

Flowrate (Block Model 014).

Time Unit (ITEM 013) in Rate-of-change Limit (Block Model 143).

Reference Input Disable Switch (ITEM 020) in Segment Program 2 (Block Model

157).

Output Type (ITEM 006) in Contact Distributor (Block Model 201).

Range settings in AI Terminal from CPU Unit (Block Model 453), AO Terminal to CPU

Unit (Block Model 454), Ai4 Terminal (Block Model 561), Pi4 Terminal (Block Model

562), and Ai8 Terminal (Block Model 564).

Receive Disable Switch (ITEM 225) in Expanded DI Terminal from CPU Unit (Block

Model 455) and Expanded AI Terminal from CPU Unit (Block Model 457) and Send

Disable Switch (ITEM 225) in Expanded DO Terminal from CPU Unit (Block Model

456) and Expanded AO Terminal from CPU Unit (Block Model 458).

Note 1 For details on which actual ITEM this restriction applies to, refer to the ITEM

list for the relevant function block in the Function Block Reference Manual.

Note 2 The version of the Loop Control Unit can be verified in the Monitor run status

screen ([Execute]-[Run]-[Monitor run status]) on CX-Process Tool.

When the above function blocks are used, check in the Check System

Operation screen on CX-Process Tool beforehand that the content of ITEM

099 onwards in the System Common block (Block Model 000) is as follows:

ITEM Data name Data

099 MPU/FROM version indication V2.50V2.50

Version V2.50 and onwards must be indicated.

Page 14

xviii

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the

Programmable Controller. You must read this section and understand the information contained

before attempting to set up or operate a PC system.

1 Intended Audience................................................................................................................................................. xix

2 General Precautions .............................................................................................................................................. xix

3 Safety Precautions ................................................................................................................................................ xix

4 Operating Environment Precautions................................................................................................................... xxi

5 Application Precautions ........................................................................................................................................ xxi

6 EC Directives........................................................................................................................................................ xxiv

7 Other Applicable Directives................................................................................................................................ xxiv

Page 15

Safety Precautions 3

xix

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent) and

knowledge about instrumentation system.

Personnel in charge of installing FA systems

Personnel in charge of designing FA systems

Personnel in charge of managing FA systems and facilities

2 General Precautions

The user must operate the product according tot he performance

specifications described in the operation manuals.

Before using the product under conditions which are not described in this

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment,

amusement machines, safety equipment, petrochemical plants, and other

systems, machines, and equipment that may have a serious influence on

lives and property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the system, machines and equipment with double safety mechanism.

This manual provides information for running OMRON Loop Control Units. Be

sure to read this manual before attempting to use the Loop Control Units and

related software (CX-Process Tool and CX-Process Monitor) and keep this

manual close at hand for reference during running.

WARNING

It is extremely important that a PC and all PC Units be used for the specified

purpose and under the specified conditions, especially in applications that

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned

applications.

3 Safety Precautions

WARNING

Do not attempt to take any Unit apart while power is being supplied. Doing

so may result in electric shock.

WARNING

Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

Emergency stop circuits, interlock circuits, limit circuits, and similar

safety measures must be prov ided in external control circuit s.

The PC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

Page 16

Safety Precautions 3

xx

The PC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a

countermeasure for such problems, external safety measures must be

provided to ensure safety in the system.

When the 24-VDC output (service power supply to the PC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

WARNING

Check the following items before starting to run the Loop Control Unit:

Analog Input/Output Units used in combination with the Loop Control Unit

must be mounted correctly, and the unit number set on the front panel of

the Analog Input/Output Unit must match the unit number set on the Field

Terminal block. If the unit numbers do not match, input/output (read/write)

is performed on the data of another Special I/O Unit (whose unit number

is set on the Field Terminal block).

The defaults of the System Common block on the Loop Control Unit must

be set correctly. In particular, make sure that the Data Memory (D) for the

Node Terminals on the CPU Unit used by the Loop Control Unit is not set

in duplicate for other applications on the PC. If the application of the Data

Memory is set in duplicate, the PC system may act unexpectedly and

cause injury.

When writing data to the I/O memory in the CPU Unit with function blocks

(e.g., using Send All Blocks, Expanded DO/AO Terminal to CPU Unit, or

DO/AO Terminal to CPU Unit), be sure that the words written to in the I/O

memory are not being used for any other purpose. If I/O memory words

are allocated to more than one purpose, the PC system may act

unexpectedly and cause injur y.

WARNING

Do not perform processing in such a way that the Loop Control Unit and

CPU Unit perform writing on identical I/O memory addresses allocated to an

contact output or analog output to an external Unit. If writing is performed on

identical addresses, the externally connected load may act unexpectedly

and cause injury.

Page 17

Application Precautions 5

xxi

4 Operating Environment Precautions

Caution

Do not operate the control system in the following places:

Locations subject to direct sunlight

Locations subject to temperature or humidity outside the range specified

in the specifications

Locations subject to condensation as the result of severe changes in

temperature

Locations subject to corrosive or flammable gases

Locations subject to dust (especially iron dust) or salts

Locations subject to exposure to water, oil, or chemicals

Locations subject to shock or vibration

Caution

Take appropriate and sufficient countermeasures when installing systems in

the following locations:

Locations subject to static electricity or other forms of noise

Locations subject to strong electromagnetic fields

Locations subject possible exposure to radioactivity

Locations close to power supplies

Caution

The operating environment of the PC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PC

System. Be sure that the operating environment is within the specified

conditions at installation and remains within the specified conditions during

the life of the system.

5 Application Precautions

Observe the following precautions when using the PC.

WARNING

Always heed these precautions. Failure to abide by the following

precautions could lead to serious or possibly fatal injury.

Always connect to a class-3 ground (to 100

or less) when installing the

Units. Not connecting to a class-3 ground may result in electric shock.

Always turn OFF the power to the PC before attempting any of the

following. Not turning OFF the power may result in malfunction or electric

shock.

Mounting or dismounting I/O Units

Assembling the Units

Setting DIP switches or unit number setting switches

Connecting or wiring the cables

Connecting or disconnecting the connectors

Page 18

Application Precautions 5

xxii

Caution

Failure to abide by the following precautions could lead to faulty operation of

the PC or the system, or could damage the PC or PC Units. Always heed

these precautions.

To hold analog outputs or contact outputs at specific values (for example,

maximum value or minimum value) when the Loop Control Unit has

stopped running, create a Step Ladder Program on the CPU Unit so that

each of the allocated relays on the Analog Output Unit or Contact Output

Unit are set to a specific value taking the b contact of the Loop Control

Unit Running flag (bit 00 allocated relay n word) as the input conditions.

When a fatal error occurs on the CPU Unit (including during execution of

the FALS command), the Loop Control Unit also stops running. To hold

the analog output to the previous value before the stop occurred, and to

set the analog output to either the minimum value or maximum value, use

the output hold function of the Analog Output Unit or Analog Input/Output

Unit.

Before turning ON the power to the PC, make sure that the facilities are

safe.

The analog output values and contact outputs from the Loop Control Unit

are updated at the same time that the power to the PC is turned ON

regardless of the operation mode of the CPU Unit (including the

PROGRAM mode). (Internally, the analog output values and contact

outputs are sent via the CPU Unit to the Basic I/O Unit and Analog Output

Unit.)

The Loop Control Unit itself does not have a human interface. So, an

external interface such as CX-Process Monitor must be provided.

Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions or other causes.

Before touching the PC, be sure to first touch a grounded metallic object

in order to discharge any static build-up.

Otherwise, it might result in a malfunction or damage.

Before you replace the battery while the Loop Control Unit is ON, be sure

to touch a grounded metal object to discharge any static electricity from

your body

Never short-circuit the plus and minus poles of the battery, charge,

disassemble or heat the battery, or throw the battery into a fire.

Interlock circuits, limit circuits, and similar safety measures in external

circuits (i.e. not in the Programmable Controller) must be provided by the

customer.

Always use the power supply voltage specified in this manual. An

incorrect voltage may result in malfunction or burning.

Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

Install external breakers and take other safety measures against short-

circuiting in external wiring. Insufficient safety measures against shortcircuiting may result in burning.

Do not apply voltages to input sections in excess of the rated input

Page 19

Application Precautions 5

xxiii

voltage. Excess voltages may result in burning.

Do no apply voltages or connect loads in excess of the maximum

switching capacity to output sections. Excess voltage or leads may result

in burning.

Turn OFF the power to the PC before performing the following operations:

Mounting or removing the Loop Control Unit, CPU Unit, or the Memory

Pack

Assembling Racks

Setting the DIP switch or unit number setting switch

Performing wiring or connecting cables

When connecting or disconnecting cables

Do not attempt to disassemble, repair, or modify any Units.

Be sure to confirm that the DIP switch and the Data Memory (D) are

properly set.

Leave the dust-protection label attached to the top Unit when wiring.

Removing the label ma y result in malf unc tion.

Remove the labels after the completion of wiring to ensure proper heat

dissipation. Leaving the label attached may result in malfunction.

Mount the Unit only after checking the terminal block and switch settings

completely.

Be sure that all mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the user manuals.

Incorrect tightening torque may result in malfunction.

Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected

operation.

Use crimp terminals for wiring. Do not connect stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

Double-check all the wiring before turning ON the power supply. Incorrect

wiring may result in burning.

Confirm that no adverse effect will occur in the system before attempting

any of the following:

Changing the operating mode of the PC

Force-setting/force-resetting of any contact in memory

Changing the present value or any set value in memory

Page 20

Other Applicable Directives 7

xxiv

6 EC Directives

CS1 Series Units confirm to EC Directives. For the system to conform to EC

Directives, however, the following precautions must be adhered to.

CS1 Series Units must be installed within control panel.

Use reinforced insulation of double insulation for the DC power supplies

used for the I/O power supplies.

CS1 Series Units that meet EC Directives also meet the Common Emission

Standard (EN50081-2). The measure necessary to ensure that standards,

such as the radiated emission standard (10 m), are met, however, will vary

depending on the overall configuration of the control panel, the other

devices to the control panel, and wiring. You must therefore confirm that

EC Directives are met for the overall machine or device.

7 Other Applicable Directives

Applicable Directives

EMC Directive

Low Voltage Directive

EMC and Low Voltage Directives

EMC Directive

In order that OMRON products can be used with any machinery and in

combination with other manufacturer’s equipment, the products themselves

are designed to comply with EMC standards (see Note), so that the

assembled machinery or device can then also easily comply with EMC

standards.

Even if machinery and equipm ent complies with EMC standards befor e

assembly, this compliance may change depending on the device, the

configuration of the control panel, and wiring, so OMRON cannot guarantee

that a particular system complies with the directive. You must therefore

confirm that EMC Directives are met for the overall machine or device.

Note EMC: One directive relating to Electro-Magnetic Compatibility

EMS: Electro-Magnetic Susceptibility standard EN61131-2

EMI: Electro-Magnetic Interference standard EN50081-2

Common Emission Standard EN50081-2, radiated emission standard (10 m)

Low Voltage Directive

The Low Voltage Directive provides that necessary safety standards are

guaranteed for devices operating at voltages of 50 to 1,000 VAC or 75 to

1,500 VDC.

Page 21

Outline Section 1-1

1

SECTION 1

Specifications

1-1 OUTLINE ........................................................................................................... 2

1-1-1 Outline........................................................................................................................................................... 2

1-1-2 Features.......................................................................................................................................................... 3

1-1-3 Basic System Configuration.......................................................................................................................... 6

1-1-4 Application Examples.................................................................................................................................... 6

1-1-5 Loop Control Unit Mechanism...................................................................................................................... 9

1-1-6 Overall Mechanism of Data Exchange........................................................................................................ 16

1-1-7 Internal Mechanism of Loop Control Unit .................................................................................................. 19

1-1-8 List of Function Blocks ............................................................................................................................... 20

1-2 CONFIGURATION OF INSTRUMENTATION SYSTEM ....................... 26

1-2-1 Mounting Location...................................................................................................................................... 26

1-2-2 Determining the System Configuration....................................................................................................... 27

1-2-3 Description of Basic System Configuration ................................................................................................ 29

1-3 SPECIFICATIONS.......................................................................................... 37

1-3-1 General Specifications................................................................................................................................. 37

1-3-2 Specifications............................................................................................................................................... 37

1-3-3 Function Specifications ............................................................................................................................... 38

1-3-4 Outline of PID Block Specifications............................................................................................................ 41

1-3-5 Software Specifications............................................................................................................................... 43

1-4 HOW TO USE FUNCTION BLOCKS FOR SPECIFIC OPERATIONS.48

1-5 BASIC PROCEDURE FOR USING THE LOOP CONTROL UNIT........ 52

Page 22

Outline Section 1-1

2

1-1 Outline

1-1-1 Outline

The Loop Control Unit is capable of the following:

- PID operation with up to 32 loops

1

- Operation of up to 250 various processes

- Basic logic sequence control

- Process progression control

The Loop Control Unit can also be used as an alarm/monitor terminal on a

computer without the need to use PID control functions.

The Loop Control Unit belongs to the CPU Bus Unit group for the CS1 series

PCs.

1 The maximum number of control loops is restricted by the operation

cycle. In most cases (when there is no Step Ladder Program), the

maximum number of control loops is 32 loops at operation cycles of 2, 1,

and 0.5 seconds; 16 loops at an operation cycle of 0.2 seconds; and

eight loops at an operation cycle of 0.1 seconds.

The Loop Control Unit itself has no external I/O functions. So, it must be used

in a pair with a unit having an external interface such as an Analog I/O Unit or

Basic I/O Unit. The Loop Control Unit exchanges data with the Unit having

the external interface via the CPU Unit I/O memory.

You can achieve all functions (operation functions/designation of field

input/output) simply by combining Control blocks, Operation blocks, and

other function blocks. This allows you to easily build a professional

instrumentation system on your PC (programmable controller).

The following functions can be achieved by function blocks:

Internal Operations

Control (max. 32 function blocks): 2-position ON/OFF Basic PID,

Advanced PID, Ratio Setting, etc.

Operation (max. 250 function blocks): Alarm/Signal restrictions/Hold,

Arithmetic (addition, subtraction, multiplication and division), Functions

(Square Root, Absolute Value, Segment Linearizer, etc.), Time Functions

(Lead/Delay, Dead Time, Ramp Program, etc.), Pulse Train Operation

(Accumulator), Signal Selection/Switching (Rank Selector, Constant

Selector, etc.), Sequential Control (Timers, Counter, etc.)

External controllers (max. 32 function blocks): ES100X Controller Terminal

Logic sequence/step progression control (max. 100 function blocks): Step

Ladder Program

External I/O

Each of the points on the Analog I/O Unit and Basic I/O Unit is read and

written by the Field Terminal block (max. 80 function blocks).

Specified contacts or analog data on the CPU Unit is read and written by

the CPU Unit Terminal block (max. 16 function blocks) and the Expanded

CPU Unit Terminal block (max. 32 function blocks).

Page 23

Outline Section 1-1

3

Data for Control, Operation, and External Controller blocks can be read

and written for SCADA software by using the Send All Blocks block and

Receive All Blocks block .

Contacts, analog data, and Control blocks (max. 32 function blocks) are

sent to the computer, and contacts with a Loop Control Unit mounted on a

networked PC or analog data are read and written (send: max. 50 function

blocks, receive: max. 100 function blocks) by the Node Terminal block.

Note Data in each of the function blocks can also be read and written by issuing

the FINS command to the Loop Control Unit by the CMND (DELIVER

COMMAND) command in the Step Ladder Program on the CPU Unit.

1-1-2 Features

All Functions Achieved by Using Only Function Blocks (operation

functions/designation of field input/output)

Wiring function blocks in the software allows you to achieve not only

combinations of operation blocks but also all functions including specification

of field I/Os.

Almost All Control Types Freely Achieved by Combining Function

Blocks

In addition to regular PID control, cascade control, feedforward control, dead

time compensation control, override control and other special control types

can be achieved as desired by combining function blocks for up to 32 loops.

Control can also be easily configured for processes with prolonged dead

time, non-linear processes, and processes involving fluctuating loads.

Changes in control type after start of operation can also be flexibly

accommodated.

Easy Integration of Loop Control and Sequence control

Data exchange with the CPU Unit and logic sequence/step progression

control on the Loop Control Unit can be achieved. This allows you to easily

integrate analog loop control and sequence control.

Data Exchange with Analog I/O Unit and Basic I/O Unit Achieved by

Function Blocks

External analog I/O and contact I/O can be easily input and output by

specifying the Analog I/O Unit on the PC and the Basic I/O Unit as the

function block.

Logic Sequence Control and Step Progression Control Achieved by

Function Blocks

Up to 4000 commands (mnemonic LOAD, OUT, etc.) can be programmed as

a function block. This block can be further divided into separate steps so that

program execution moves between steps when preset conditions are

satisfied. This allows you to easily control step progression, for example, on

devices that are analog process intensive.

Page 24

Outline Section 1-1

4

Note Command execution on the Loop Control Unit is slower (0.1 to 2 second

operation cycle) than that on a CPU Unit. So, these commands are used for

programming AND and OR conditions when combining function blocks and

specifying (Remote/Local, Auto/Manual, etc.) function block operating

conditions.

Data Exchange with CPU Unit Achieved by Function Blocks

Contacts and analog data in CPU Unit I/O memory can also be read and

written constantly (at each operation cycle) by specifying the I/O numbers of

function blocks. This facilitates cooperative control in setting up and

monitoring Step Ladder Programs on the CPU Unit.

Functions to monitor or set Loop Control Unit data from standard SCADA

software have been improved. Two new function blocks, Receive All Blocks

(Block Model 462) and Send all Blocks (Block Model 461) can be used to

access Control Block (e.g., Basic PID), Operation Block (e.g., math

functions), and External Controller Block (ES100X) data in the I/O memory of

the CPU Unit using CSV tags created from the CX-Process Tool software.

I/O with Host Computer (via CPU Unit) Achieved by Function Blocks

Data can also be sent to the host computer connected on the Host Link or

the computer (on which the Controller Link Support Boar d is m ounted)

connected on the Controller Link by designating the function block. (Note,

however, that data is only stored to the Data Memory for the Node Terminals

on the CPU Unit. Subsequent processing is dependent on accessing by FINS

commands issued from the host computer or on the Data Link with the

computer on the Controller Link.)

The contacts and analog data of the Loop Control Unit mounted on a

networked PC can also be read and written via the Controller Link by

designating the function blocks. (Note, however, that data is only stored to

the Data Memory for the Node Terminals on the CPU Unit. Subsequent

processing is dependent on the Data Link with the PC on the Controller Link.

Message Communications by FINS Commands

Data on each of the function blocks can also be read and written as desired

by issuing FINS commands by the CMND (DELIVER COMMAND) command

in the Step Ladder Program on the CPU Unit or by issuing FINS commands

from the host computer. Function block data can also be read and written

from PCs (CPU Units) on other networked nodes.

Simulated Software Wiring between Function Blocks

CX-Process Tool allows you to simulate wiring between function blocks in the

software by joining lines on your computer’s screen.

Simulated Monitoring of Monitor, Graphic Monitor, and Alarms

CX-Process Monitor or SCADA software can be used to monitor the control

state and change settings on the Loop Control Unit in a screen that is similar

to a field device. CX-Process Monitor also supports graphic monitoring,

generation of trend graphs, alarm monitoring, alarm logging and operation

logging of each of the instrumentation components. Commercially available

SCADA software can also be used to create a monitoring system.

Page 25

Outline Section 1-1

5

The CX-Process Tool is used to create tags for the CX-Process Monitor or

for SCADA software to enable accessing Loop Control Unit Data.

Connect ES100X Controllers Ext e rnall y

ES100X Controllers can be connected to the RS-232C port on the Loop

Control Unit and ES100X External Controller Terminal function blocks can be

used to monitor ES100X parameters, such as the SP, PV, and MV, and to

set ES100X parameters, such as the SP and PID constants. Converting from

RS-232C to RS-422A/485 enables connecting up to 32 ES100X Controllers.

Battery-free Operation

You now have a choice. You can either store function block data in RAM in

the Loop Control Unit and back it up with a battery or you can eliminate the

need for a backup battery by setting the Loop Control Unit to transfer flash

memory contents to RAM each time power is turned ON. (Automatic transfer

from flash memory is set using the DIP switch.)

Page 26

Outline Section 1-1

6

1-1-3 Basic System Configuration

1, 2, 3… 1. Unit Having External Interfac e Functi ons

The Loop Control Unit itself does not have external analog I/O and

external contact I/O functions. So, it must be used in combination with a

Unit having external interface functions such as an Analog I/O Unit as

shown in the example figures in the following pages.

2. CX-Process Tool

The Loop Control Unit itself does not have a human-machine interface for

preparing function block data. So, function block data must be prepared

on CX-Process Tool, and then downloaded to the Loop Control Unit for

use as shown in the example figures in the following pages.

3. CX-Process Monitor

The Loop Control Unit itself does not have a human-machine interface for

setting the Set Point and PID constant values, and displaying the PV. So,

the Set Point and PID constant values must be set, and PV monitored on

CX-Process Monitor as shown in the example figures in the following

pages.

1-1-4 Application Examples

The Loop Control Unit can be used, for example, to build control systems

capable of high-density monitoring of analog data through to advanced

control of instrumentation such as in the following four examples.

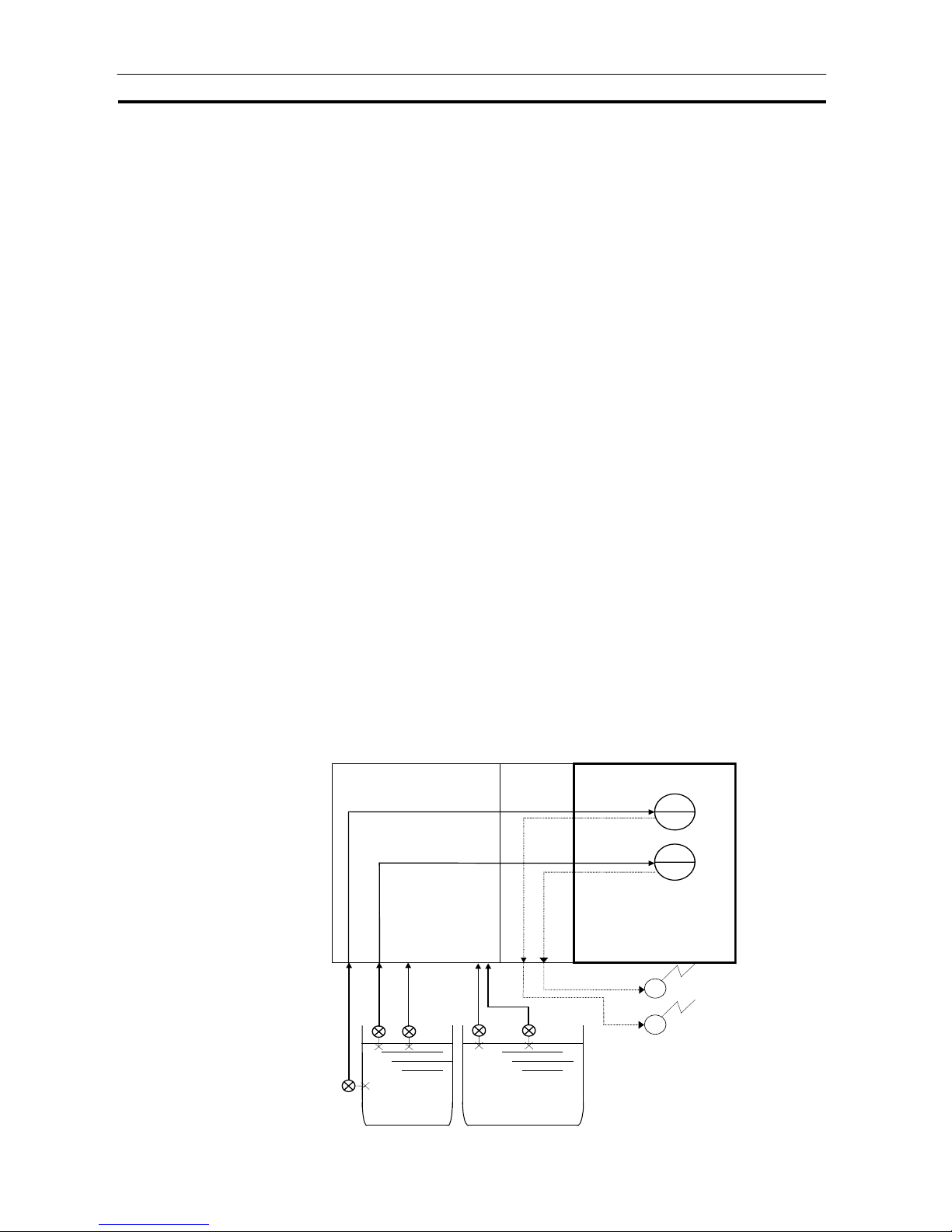

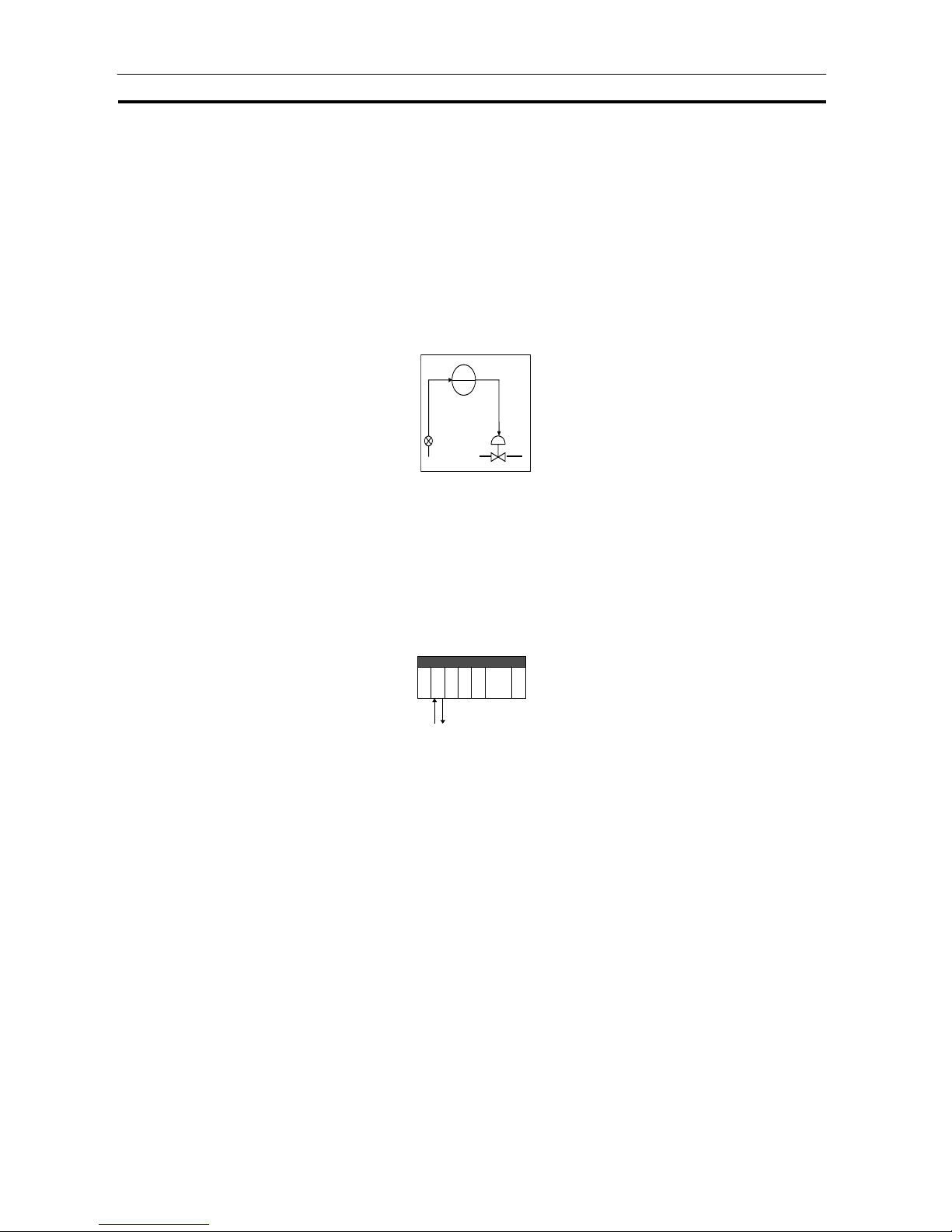

High-density Monitoring of Waterworks and Sewage Systems

Loop Control Unit

Contact

Output Un it

Analog Input

Unit

Alarm

Alarm

Temperature

PH

Temper-

ature

PH

Alarm

output

Alarm

output

Alarm

Alarm

Temper-

ature

Page 27

Outline Section 1-1

7

Temperature Control of Kettle Reboiler (cascade control)

CPU Unit

Temperat ure

Temperature

Cold water

Vapor

Drain

Loop Control

Analog

Output Unit

Analog Input

Unit

PV 2

PV 1

MV 1

PID1

PID2

MV 2

RSP1

Liquid-vapor

separation

converter

Temperature

Conversion

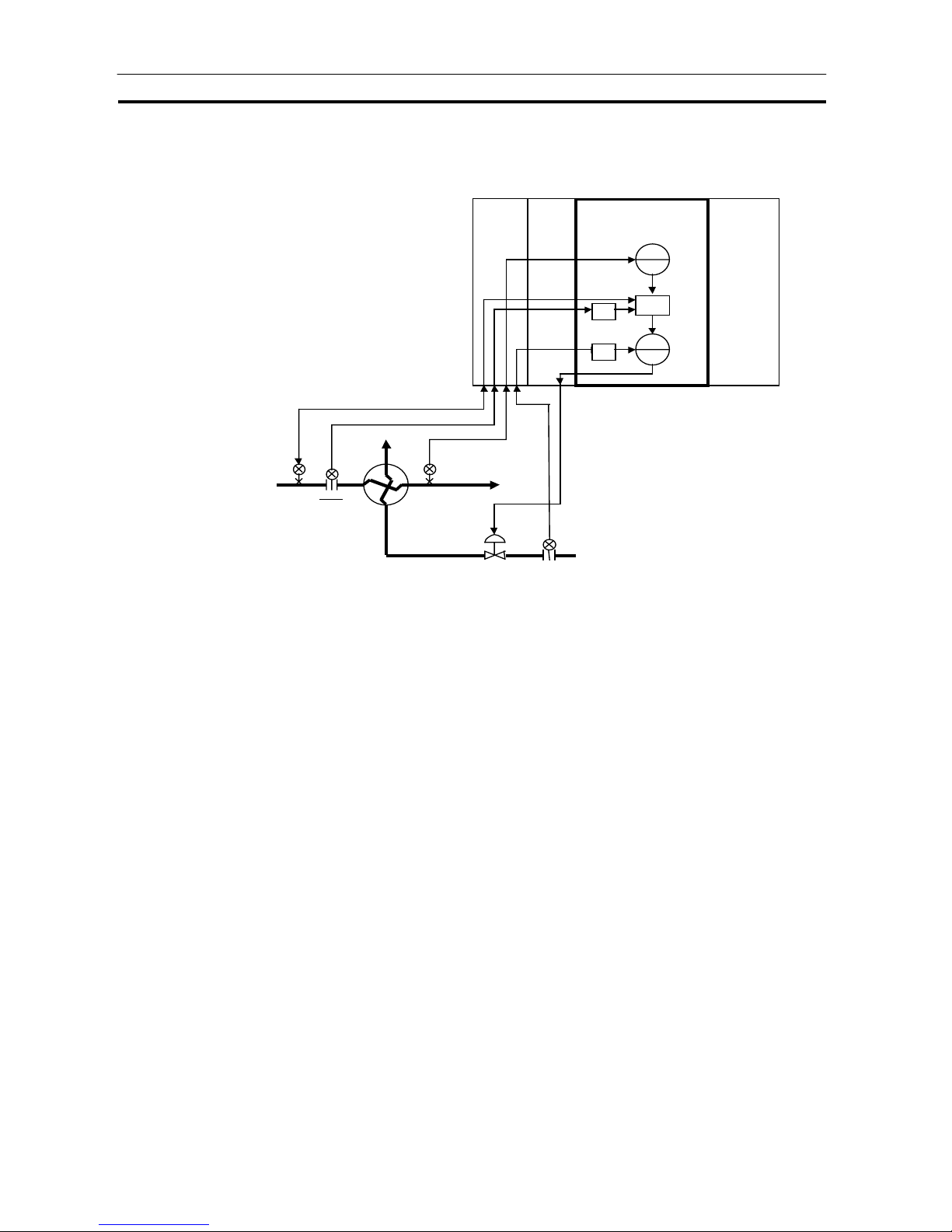

Boiler Drum Level Control (with cascade feedforward control function)

Water supply

Flow rate

Steam flow rate

Steam

MV2

PID2

MV 2

PV 2

MV 1

PID1

+

PV 1

Loop Control Unit

Analog

Output Unit

Analog

Input Unit

Level

CPU Unit

RSP

Page 28

Outline Section 1-1

8

Heat Exchanger Exit Temperature Control (with cascade feedforward

control)

Inlet

temperature

Steam flowrate

MV2

PID2

MV 2

PV 2

MV 1

PID1

FF

∗

PV 1

Loop Control UnitAnalog

Output

Unit

A nalog

Input U nit

Steam

Flowrate

Flowrate

CPU Unit

Exit temperature

Inlet

flowrate

Inlet temperature

Exit temperature

Steam

flowrate

Heat

exchanger

*1: Pr epar e a feedforw ar d m odel for c om pens ating M V 1 in

combination with lead/delay, segment linearizer and

rate-of-change operation.

RSP

Page 29

Outline Section 1-1

9

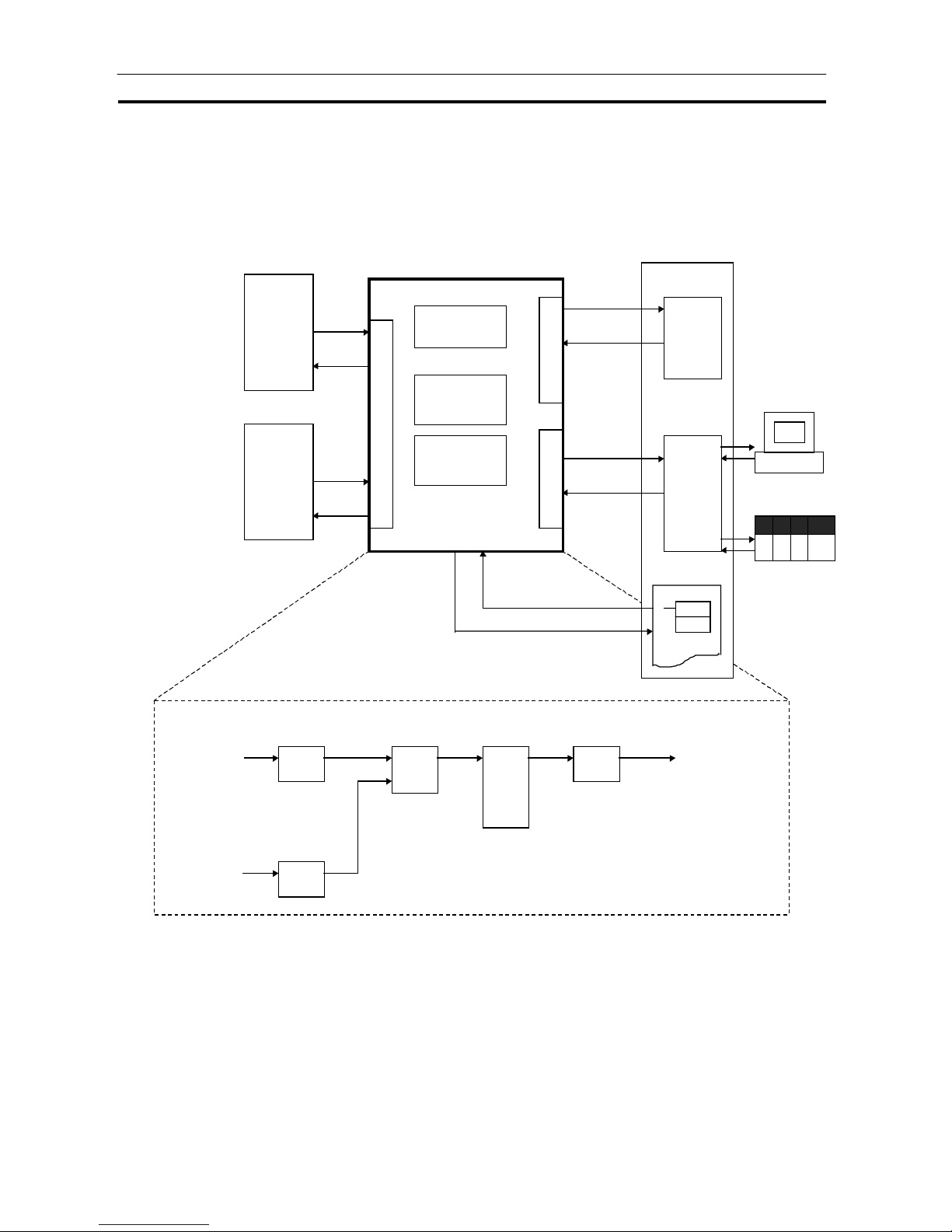

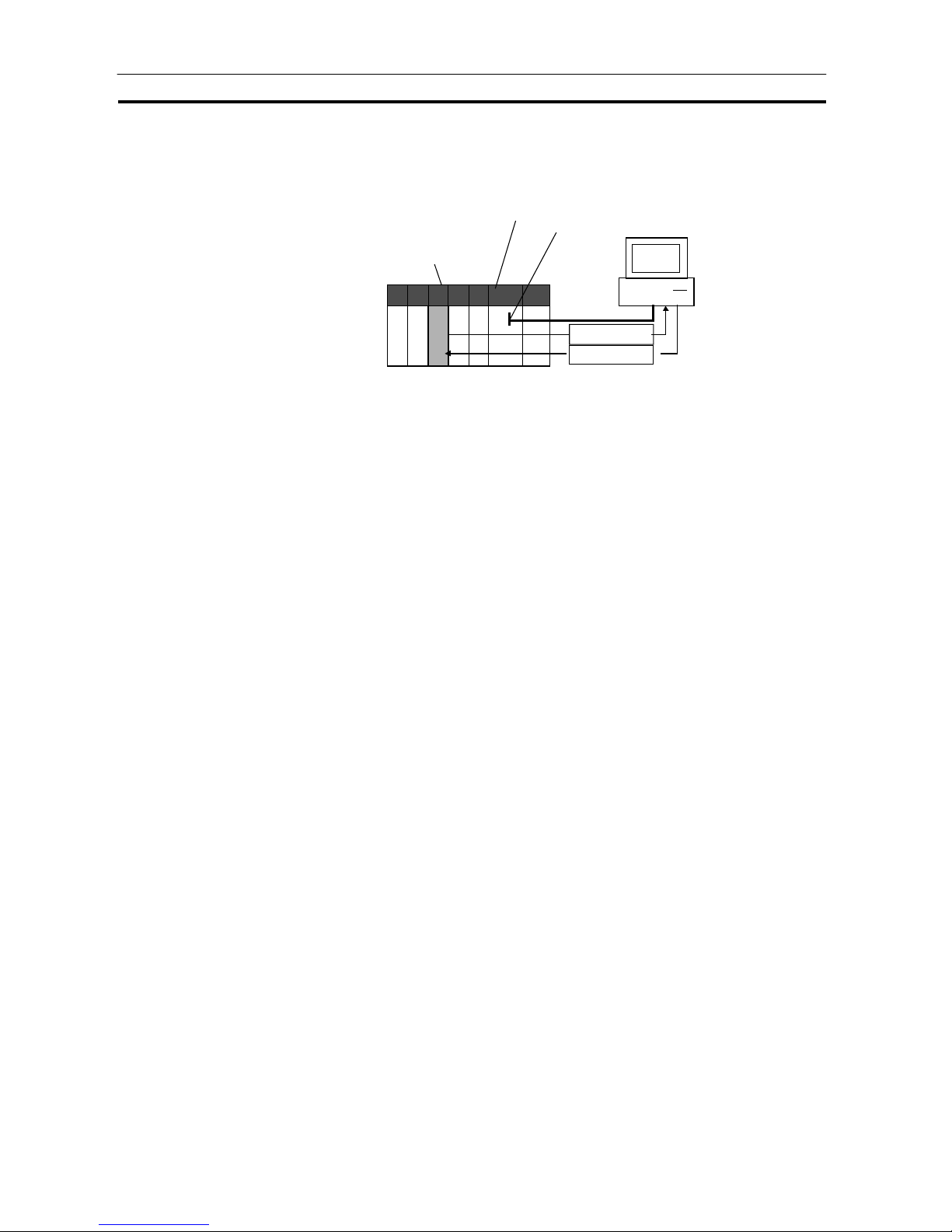

1-1-5 Loop Control Unit Mechanism

Overall Mechanism

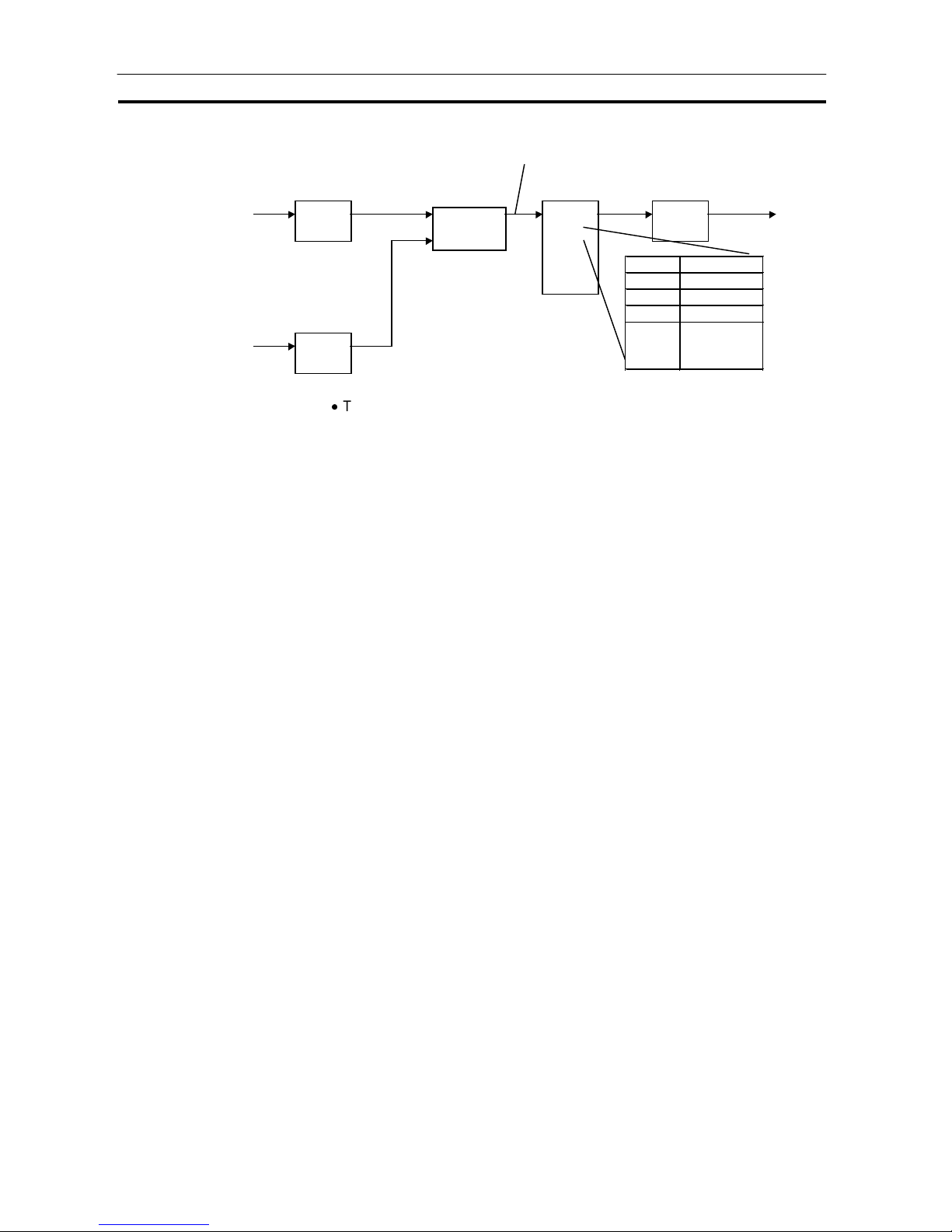

The following illustration shows a block diagram of the overall mechanism.

Loop Control Unit

Control block

Operation bloc k

Step Ladder

Program bloc k

Fiel d Termin al s

CPU Termina lsNode Terminals

CPU Unit

I/O

memory

Analog

Input/Output Unit

Basic I/O Unit

Data

Memory

for No de

Terminals

Computer

Lo op Con tr ol Un it s a t

other node

CMND

User Program

Ex: Wi ring of ITEM

data in operati on

blocks using FINS

commands

Input 1 of Analog

Input Unit

Input 2 of Analog

Input Unit

Field Terminal

block

Analog

Input

Analog

input

Field Terminal

block

Addition

/Subtrac

-tion

Output of Anal og

Output Unit

Field Terminal

block

Analog

output

PID

Control block

All func tions are achieved by software wiring between any c om binations of functi on blocks.

Operation block

∗

1

∗

1

∗

1: Data is ex changed via

alloc at ed relay Area on

the CPU Unit

Page 30

Outline Section 1-1

10

The following describes each of the functions of the Loop Control Unit.

1) External I/O

WARNING

Do not perform writing operations on the same I/O memory address allocated

to contact outputs or analog outputs between the Loop Control Unit and the

CPU Unit.

If writing is performed on the same address, the externally connected load

may function unexpectedly, causing an injury.

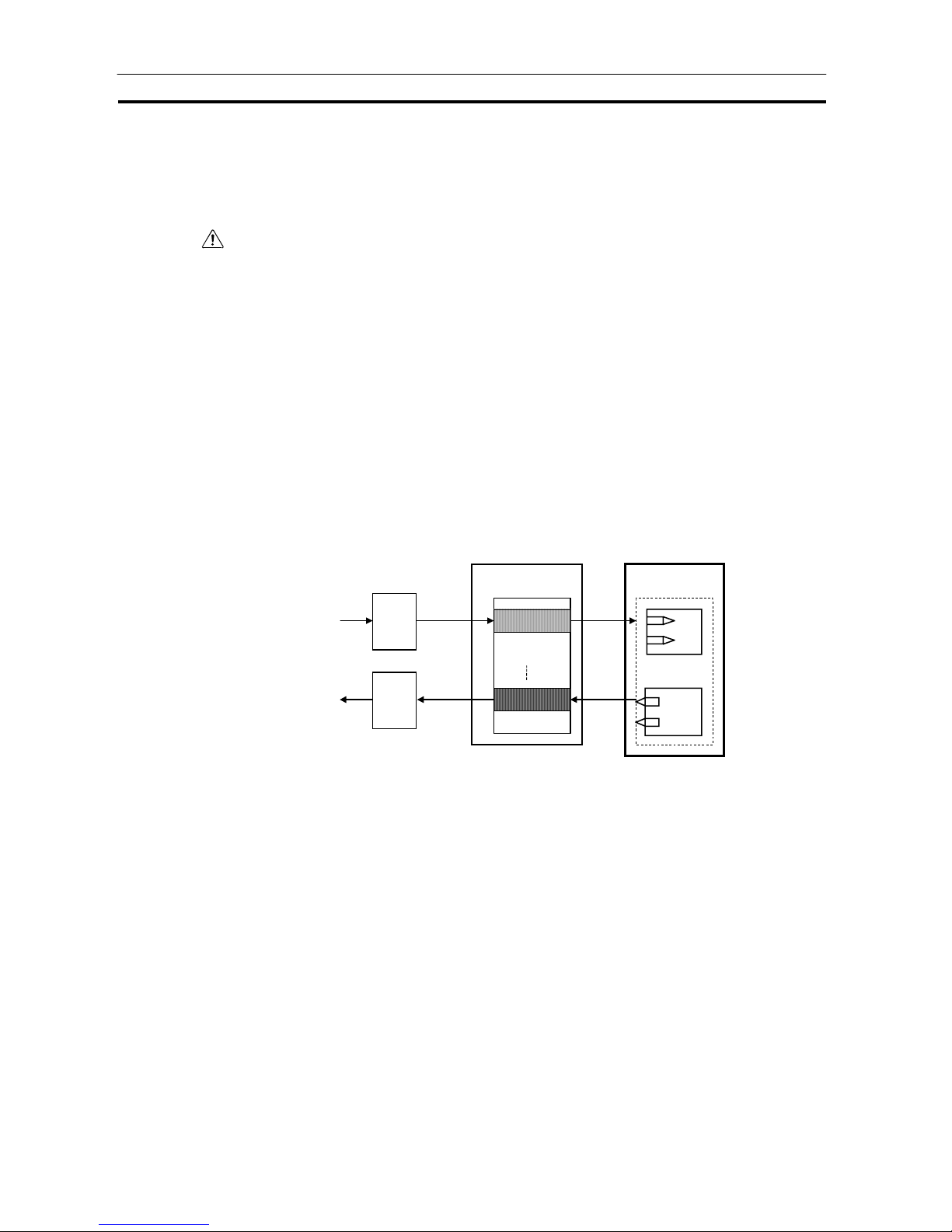

Analog I/O or Contact I/O

Analog signals or contact signals are input and output constantly (at each

operation cycle) between the Analog I/O Unit or Basic Unit on the same PC

and the CPU Unit I/O memory. At this time, the user is not required to be

aware of I/O memory addresses as the Field Terminal block is used.

With analog I/O, only the unit number of the Analog I/O Unit is set. With

contact I/O, however, the leading allocated address in I/O memory must be

set.

At each I/O

refresh

At each I/O

refresh

Analog Input Unit

CPU Unit

I/O memory

Loop Control Unit

Analog Output Unit

Field Terminal

block

At each

operation

cycle

At each

operation

cycle

Note The Loop Control Unit uses the Field Terminal block (regardless of the user

program on the CPU Unit) to read and write areas allocated for contact or

analog signals. So, do not perform write operations on the same allocated

areas between the Loop Control Unit and the CPU Unit.

Page 31

Outline Section 1-1

11

Data Exchange with Specified CPU Unit I/O Memory

I/O operations can be performed internally on the Loop Control Unit

constantly (at each operation cycle) with any specified CPU Unit I/O memory.

In this case, the CPU Unit Terminal block or the Expanded CPU Unit

Terminal block is used, and the I/O memory address must be specified.

Data exchange is possible with the following I/O memories:

- CIO (channel I/O) Area

- Work Area (W)

- Holding Area (H)

- Data Memory (D)

- Extended Data Memory (E) bank No. 0

Note 1 This function can also be used to designate units (CompoBus/D,

CompoBus/S and other Communications Units) on which field terminals are

not supported, and CPU Unit I/O memory (remote I/O allocated area, etc.) for

enabling I/O.

CPU Unit

I/O memory

Loop Control Unit

CPU Unit Terminal block

or Expanded CPU Unit

Terminal block

At each

operation

cycle

At each

operation

cycle

Note 2 The Loop Control Unit uses the CPU Unit Terminal block or the Expanded

CPU Unit Terminal block (regardless of the user program on the CPU Unit) to

read and write to specified CPU Unit I/O memory. So, do not perform write

operations on the same I/O memory addresses between the Loop Control

Unit and the CPU Unit.

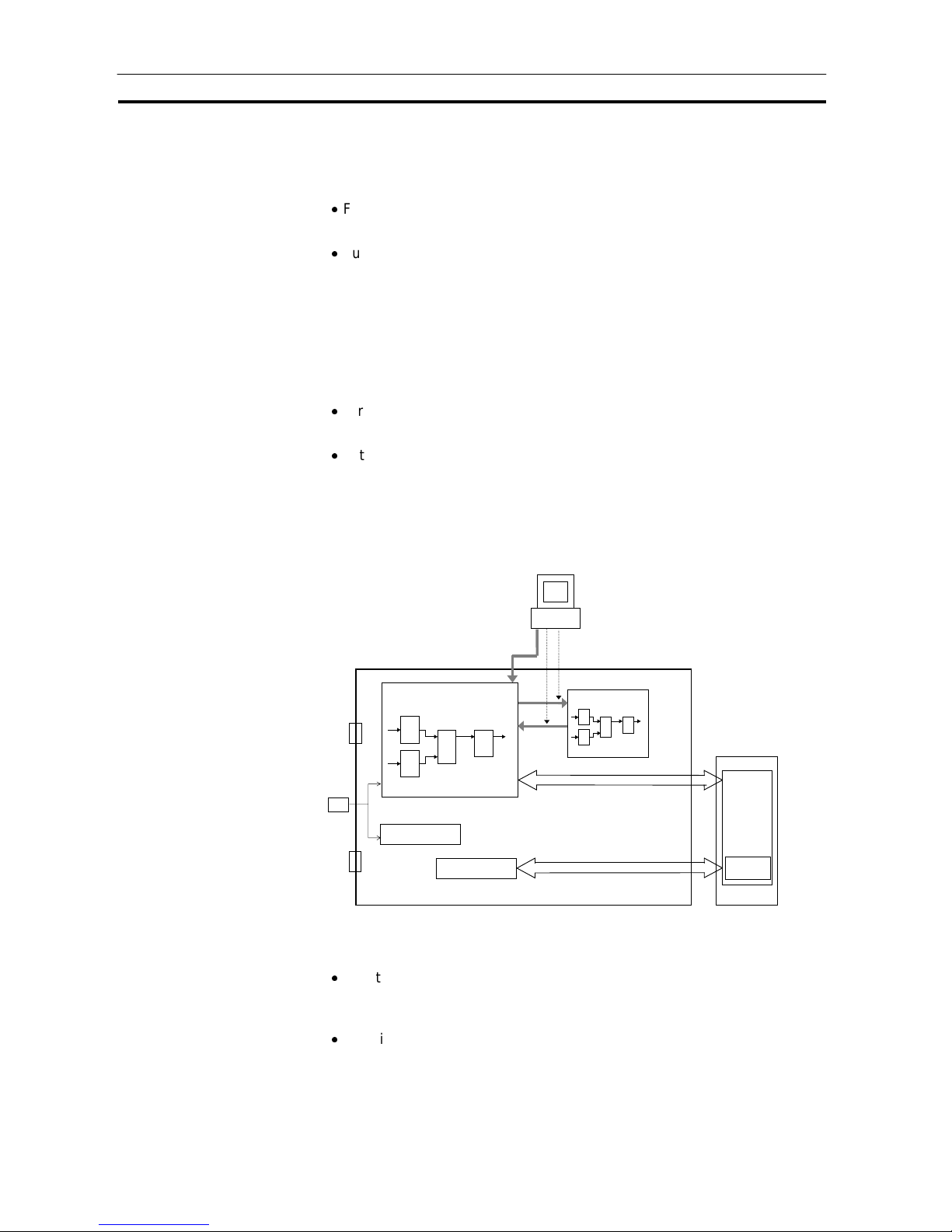

Data Exchange with CX-Process Monitor

Loop Control Unit data can be exchanged with CX-Process Monitor. Data or

analog signals for controller use can be uploaded to CX-Process Monitor

running on a computer connected via the RS-232C interface or a network

such as Controller Link.

Data such as the Set Point Values can also be changed on CX-Process

Monitor.

There are two data exchange modes: on-demand mode and Data Link mode.

(For details, see 3-4 Exchanging Data with CX-Process Monitor/SCADA

Software and Other Nodes and Appendix-2 How to Use the Node Terminal

Blocks.)

Page 32

Outline Section 1-1

12

CPU Unit

Data Memory

for Node

Terminals

Loop Control Unit

Node Terminal

block

I/O memory

CX-Process Monitor

Uploading of

data to be

monitored

Manipulation of data

such as changes to

Set Point

At each

operation

cycle

Control block

PID, etc.

Data Exchange with SCADA Software

Commercially available SCADA software can also be used to read and write

function block data for the Loop Control Unit. Words in the I/O memory of the

CPU Unit are allocated for function block data so that Control Block,

Operation Block, and External Controller Block data can be read and written

using CSV tags with SCADA software. Expanded CPU Unit Terminal blocks

can also be used to read and write data using CSV tags for other ITEMs.

CSV tags are created using the CX-Process Tool.

Data Exchange with Loop Control Units at Other Nodes

Loop Control Unit data can be exchanged with Loop Control Units at other

nodes via Controller Link .

The following two methods can be selected.

1) When part of the data link is used (CPU Unit Terminal or Expanded

CPU Unit Terminal block)

CPU Unit

Specified words

Specified words

Words specifed

for Receive A ll

Blocks

Words specified

for Send All

Blocks

Loop Control Unit

Expansion CPU Unit

Terminals

Send All

Blocks

I/O memory

SCADA software

Set CSV tags

and read

Set CSV tags

and write

Set CSV tags

and write

Set CSV tags

and read

Control Block

ITEMs

Operation

Block ITEMs

External

Controller

Block ITEMs

Each

execution

cycle

Receive All

Blocks

Page 33

Outline Section 1-1

13

The PC on which the Loop Control Unit is mounted is linked via the regular

Controller Link Data Link with the PC at the other node. On this link, the Loop

Control Unit reads and writes analog signals or contact signals on part of the

Data Link Area on the CPU Unit by the CPU Unit Terminal or Expanded CPU

Unit Terminal block.

CPU Unit

Data Memory

for Node

Terminals

Loop Control Unit

CPU Unit Terminal or

Expanded CPU Unit

Terminal b lock

I/O memory

Loop Control Unit at

other node

Analog data or

contact data

At each

operation

cycle

At each

operation

cycle

Controller Link

Data Link

2) When Data Link Area 1 or 2 are occupied (Node Terminal block used)

The PC on which the Loop Control Unit is mounted occupies Data Link Area

1 or 2 for Loop Control Unit use, and is linked via the Controller Link Data

Link with the PC at the other node. Data Memory (D) for the Node Terminals

of the CPU Unit is allocated to Data Link Area. On this link, the Loop Control

Unit can exchange data with the other Loop Control Unit at the other node

PC by reading and writing Data Memory (D) for the Node Terminals of that

CPU Unit by the Node Terminal block.

CPU Unit

Data Memory

for Node

Terminals

Loop Control Unit

Node Terminal block

I/O mem ory

Loop Control Unit at

other node

Analog data or

contact data

At each

operation

cycle

Controller Link

Data Link is

occupied.

At each

operation

cycle

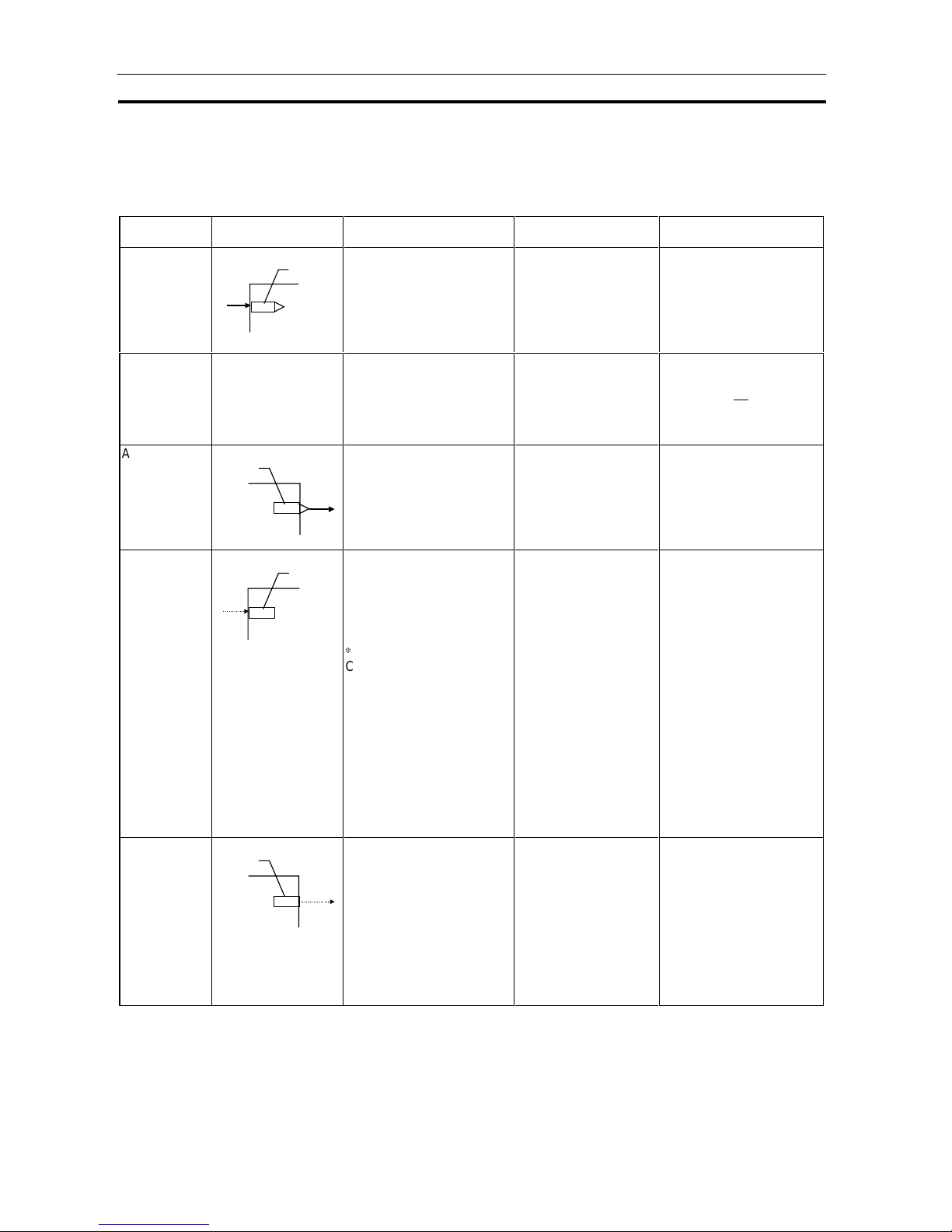

2) Internal processing

Prepare a data sheet for the function blocks shown below on CX-Process

Tool, and store the data sheet on the Loop Control Unit. The function block

data sheet describes: (a) software wiring of each function block and (b)

parameters in each function block.

Page 34

Outline Section 1-1

14

Fi el d Terminal

block

Analog

input

Analog

input

Field Terminal

block

Addition/

Subtraction

Fi el d Terminal bloc k

Analog

output

PID