Cat. No. W420-E1-06

SYSMAC CS and CJ Series

CS1W-ETN21 (100Base-TX)

CJ1W-ETN21 (100Base-TX)

Ethernet Units

Construction of Networks

OPER ATION MANUAL

CS1W-ETN21 (100Base-TX) CJ1W-ETN21 (100Base-TX) Ethernet Units Construction of Networks

Operation Manual

Revised April 2009

iv

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

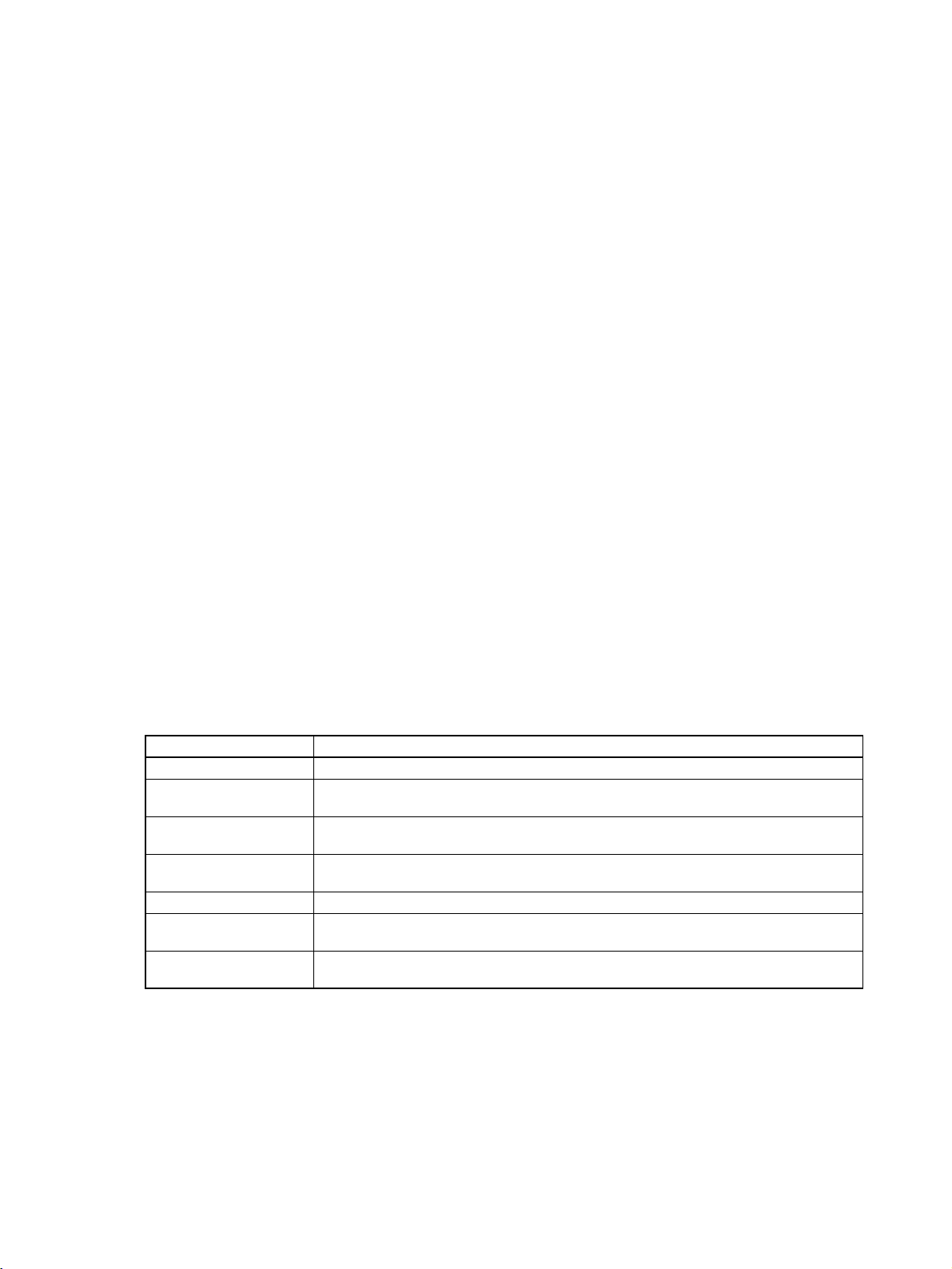

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2003

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

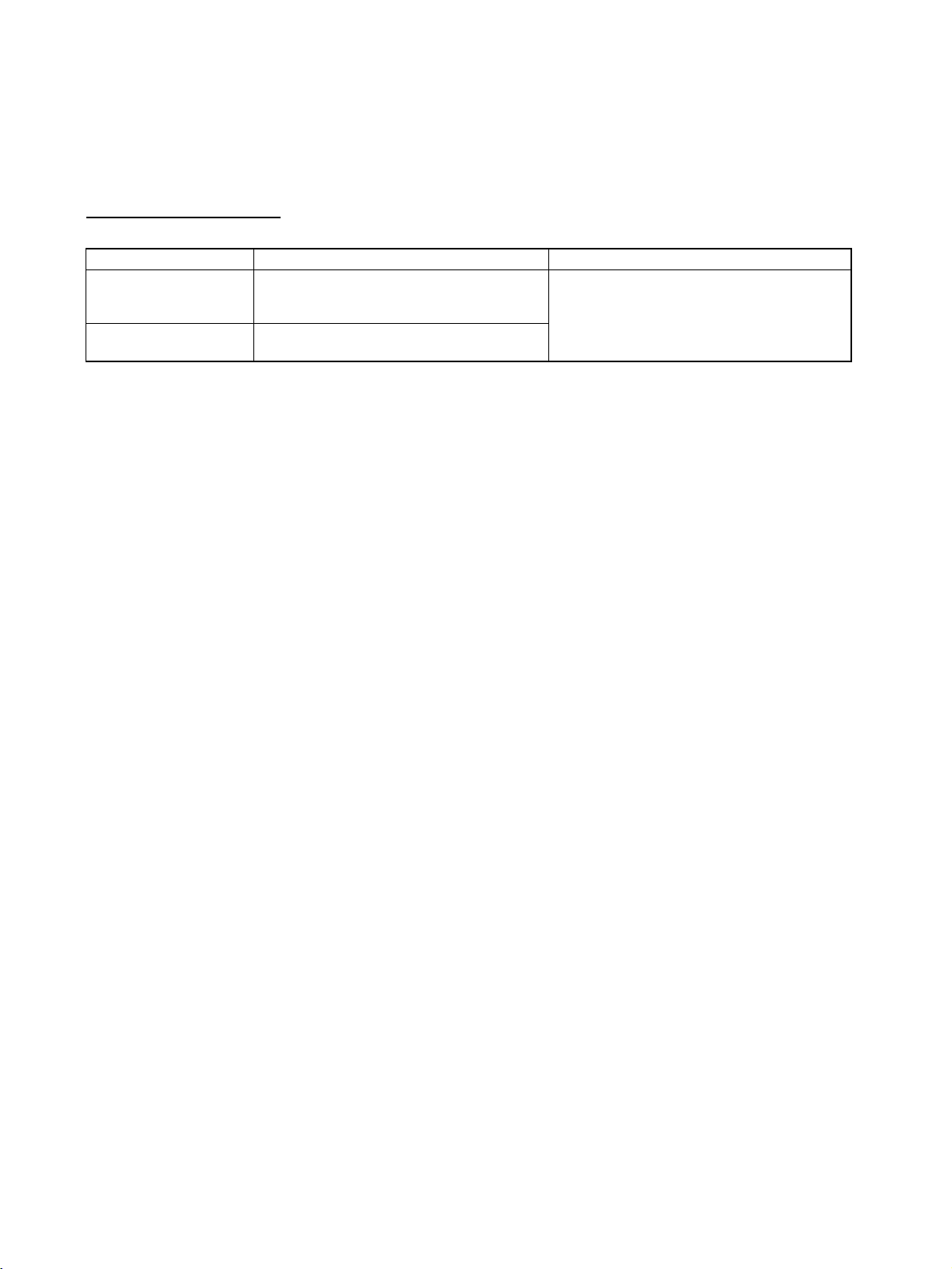

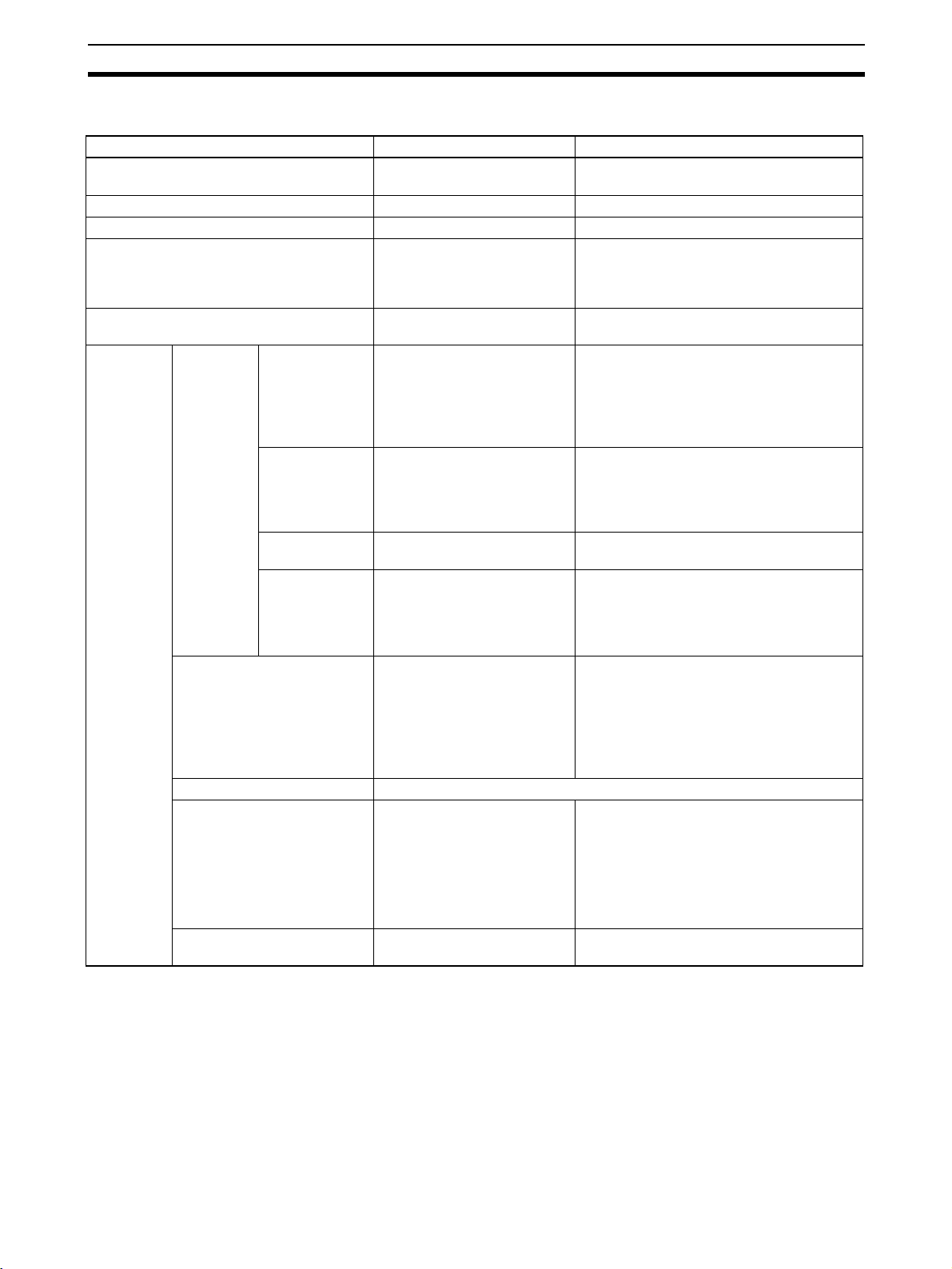

Unit Versions of CS/CJ-series

Unit Versions A “unit version” has been introduced to manage Units in the CS/CJ Series

according to differences in functionality accompanying Unit upgrades.

Notation of Unit Versions

on Products

Confirming Unit Versions

with Support Software

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

Product nameplate

CS1W-

UNIT

Lot No.

Lot No. 040401 0000 Ver.1.3

OMRON Corporation MADE IN JAPAN

Unit version

Example for unit version 1.3

CX-Programmer version 4.0 can be used to confirm the unit version using the

Unit Manufacturing Information.

Note The (unit versions of) Pre-Ver. 2.0 Units cannot be confirmed Unit Manufac-

turing Information. The following dialog box is displayed.

In the IO Table Window, right-click and select Unit Manufacturing informa-

tion - CPU Unit.

The following Unit Manufacturing information Dialog Box will be displayed.

Unit version

Use the above display to confirm the unit version of the Unit connected online.

vi

Using Unit Version Label The following unit version label is provided with the Ethernet Unit.

This label can be attached to the front of the Ethernet Unit to differentiate

between Ethernet Units with different unit versions.

Unit Version Notation In this manual, the unit version of a Ethernet Unit is given as shown in the fol-

lowing table.

Product nameplate Notation used in this manual Special remarks

Ver. 2.0 or later number

shown to right of the lot

number

Blank to the right of lot

number

Ethernet Unit Ver. 1.3 or later Information without reference to specific Unit

Versions applies to all versions of the Unit

Pre-Ver. 1.3 Ethernet Units

vii

viii

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . . . 1

1-1 Ethernet Unit Function Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-5 Overview of Communications Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-6 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-7 Comparison with Previous Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-8 Unit Version Upgrade Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SECTION 2

Installation and Initial Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-1 Overview of Startup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-3 Mounting to a PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-4 Network Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

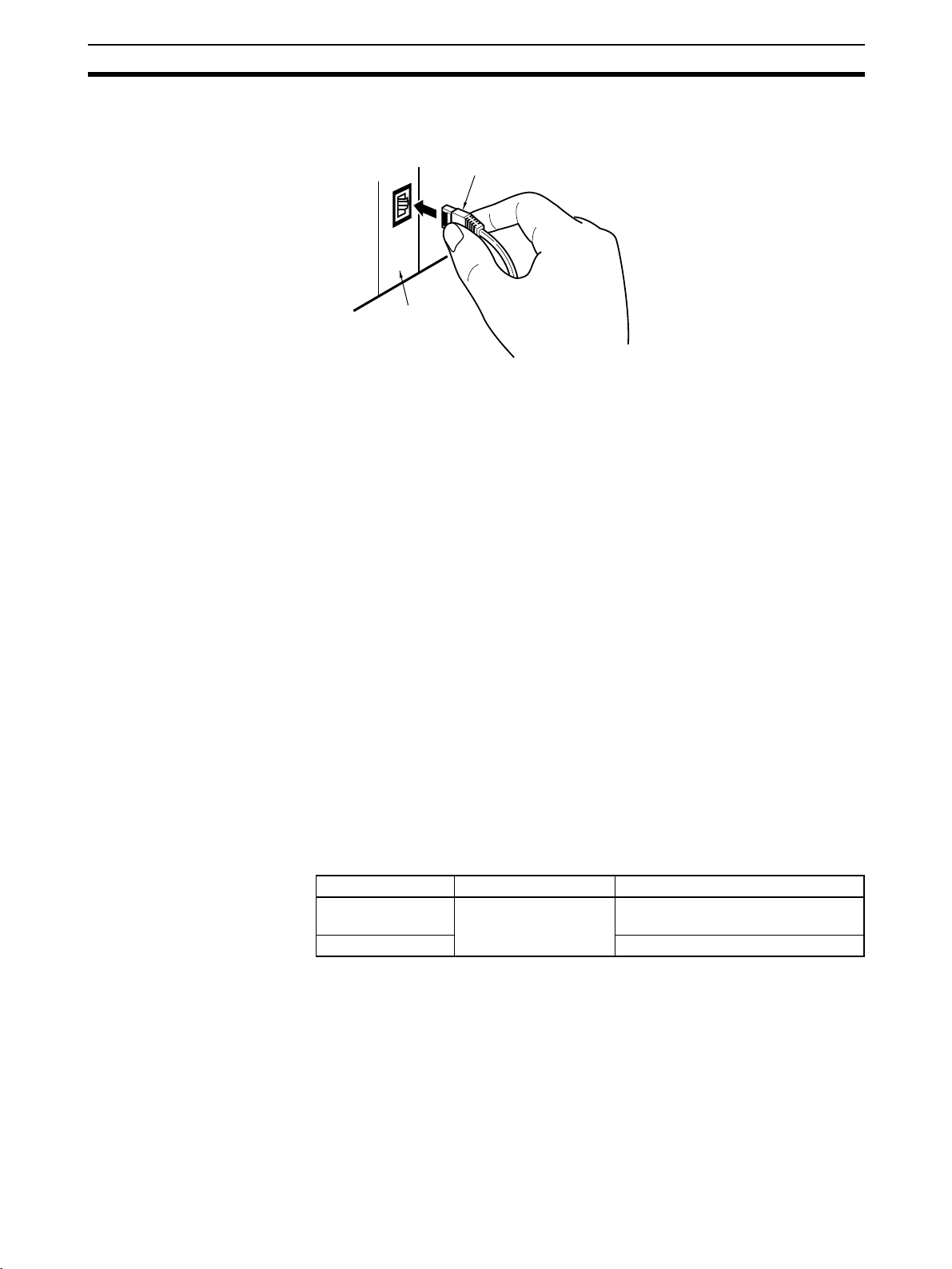

2-5 Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2-6 Creating I/O Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

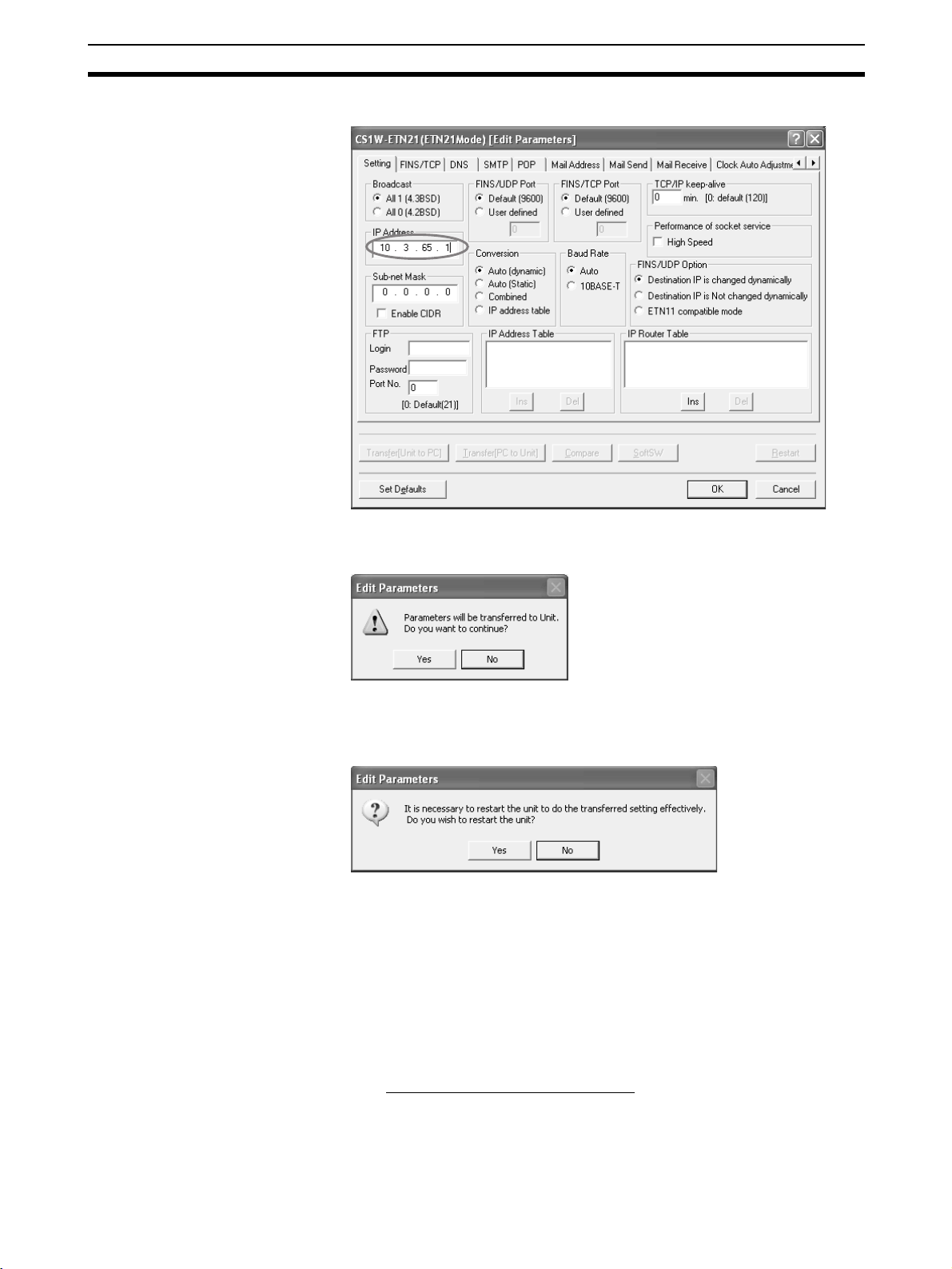

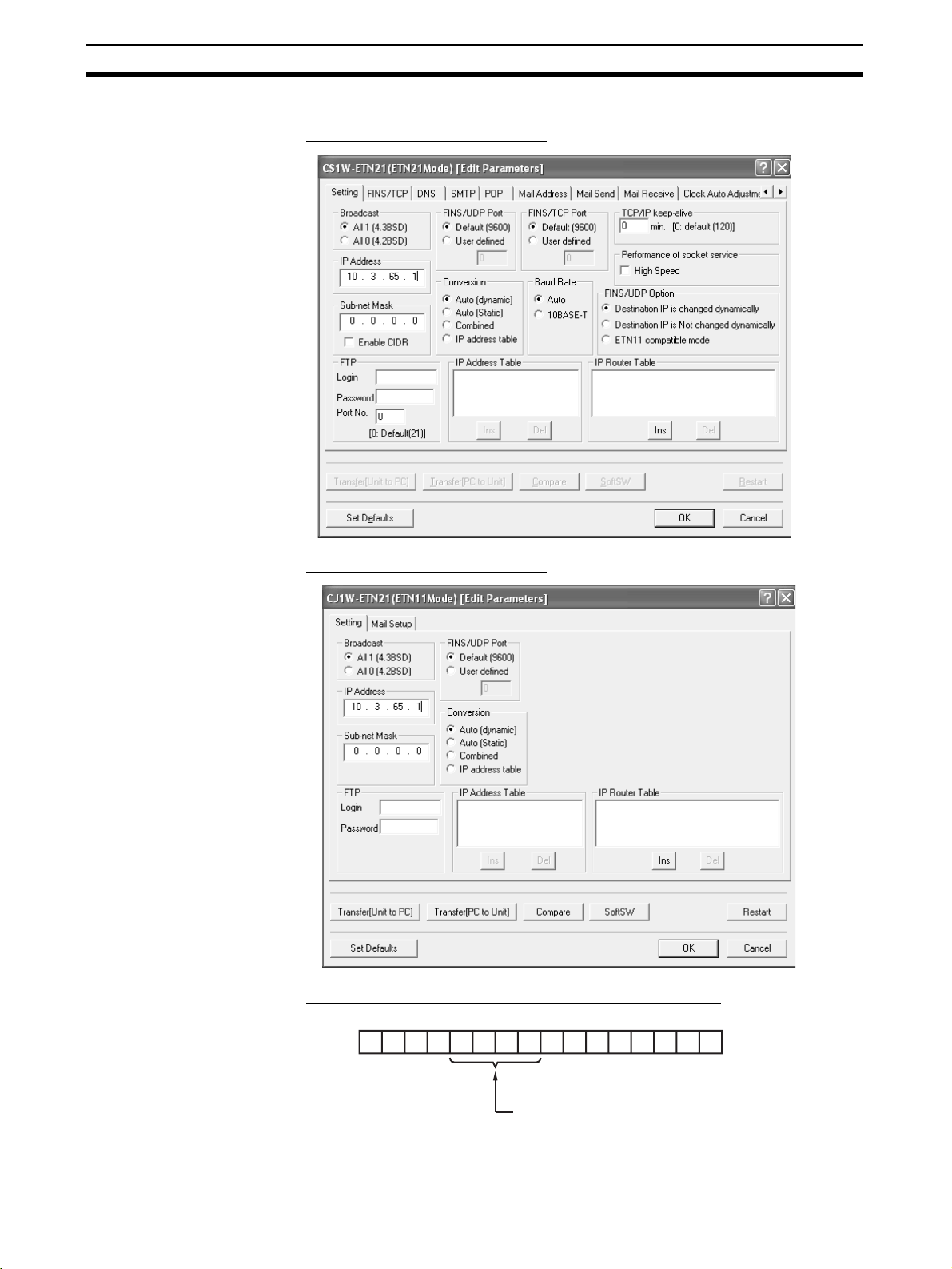

2-7 Unit Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-8 Basic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2-9 Unit Setup for Particular Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2-10 Communications Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2-11 Converting from Previous Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

SECTION 3

CX-Programmer Unit Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3-1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3-2 FINS/TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3-3 DNS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3-4 SMTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3-5 POP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3-6 Mail Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3-7 Send Mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3-8 Receive Mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

ix

TABLE OF CONTENTS

3-9 Auto Adjust Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3-10 HTTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

SECTION 4

Ethernet Unit Memory Allocations. . . . . . . . . . . . . . . . . . . . . . 77

4-1 CIO Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4-2 DM Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

4-3 Auxiliary Area Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

SECTION 5

Determining IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5-1 IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5-2 IP Addresses in FINS Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5-3 Private and Global Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

SECTION 6

FINS Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6-1 Overview of FINS Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

6-2 FINS/UDP Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

6-3 FINS/TCP Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6-4 Creating Routing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

6-5 Using FINS Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

6-6 Communicating between OMRON PLCs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

6-7 Precautions on High Traffic in FINS Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

SECTION 7

FINS Commands Addressed to Ethernet Units. . . . . . . . . . . . 157

7-1 Command Codes and Response Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

7-2 Socket Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

7-3 Command/Response Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

SECTION 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

8-1 Troubleshooting with Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

8-2 Error Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

8-3 Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

8-4 Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

8-5 Results Storage Area Response Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

x

TABLE OF CONTENTS

Appendices

A Ethernet Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

B Buffer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

C TCP Status Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

D ASCII Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

E Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

F Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

G Ethernet Unit Web Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

xi

xii

About this Manual:

This manual describes the installation and operation of the CS1W-ETN21 and CJ1W-ETN21 Ethernet

Units (100Base-TX) and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the Ethernet Unit. Be sure to read the precautions provided in the following section.

Precautions provides general precautions for using the CS1W-ETN21 and CJ1W-ETN21 Ethernet

Units (100Base-TX).

Section 1 introduces the features, describes the system configuration and Unit parts, and provides

Unit specifications.

Section 2 explains how to install the Ethernet Unit and make the initial settings required for operation.

Section 3 provides information for setting communications using CX-Programmer.

Section 4 describes the words allocated in the CIO Area and the DM Area for Ethernet Units.

Section 5 explains how to manage and use IP addresses.

Section 6 provides information on communicating on Ethernet Systems and interconnected networks

using FINS commands.

Section 7 describes the FINS commands that can be sent to an Ethernet Unit and the responses that

are returned by the Ethernet Unit.

Section 8 describes information and procedures that can be used to troubleshoot problems that sometimes occur with Ethernet Unit and Ethernet communications.

Appendices provide information on Ethernet network parameters, the buffer configuration, TCP status

transitions, ASCII characters, maintenance, and inspections.

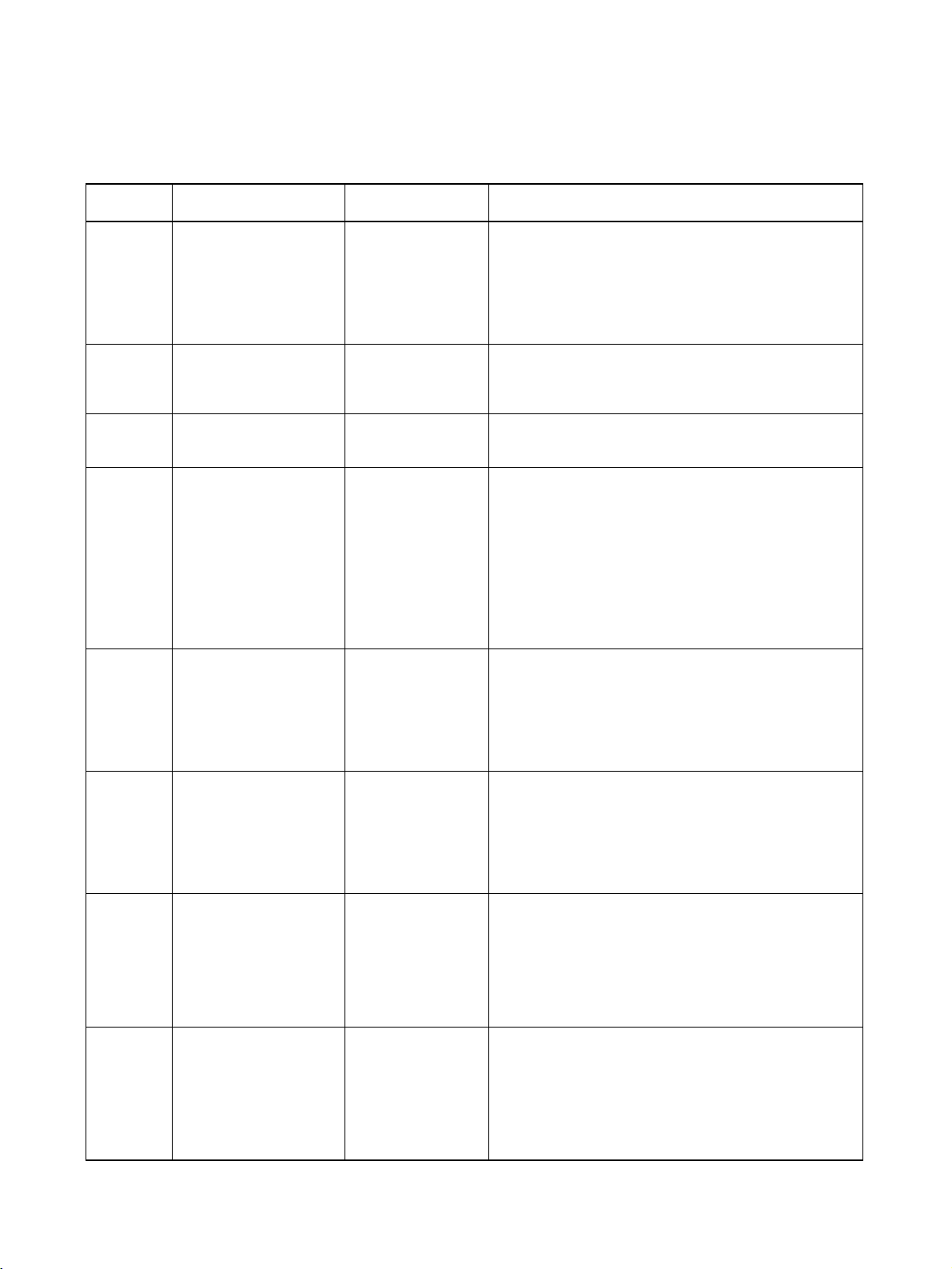

The related Ethernet Units Operation Manual Construction of Applications (W421) provides the following information.

Section Contents

Section 1 Overview of functions for constructing applications.

Section 2 Information on using mail functions to automatically send I/O memory data from

OMRON PLCs to personal computers.

Section 3 Information on using mail functions to send commands from OMRON PLCs to per-

sonal computers.

Section 4 Information on transferring large files between personal computers and OMRON

Section 5 Information on automatically adjusting the OMRON PLC’s built-in clock.

Section 6 Information on communicating between general applications (applications not using

Section 7 Information on using personal computer and UNIX machine socket interfaces to cre-

PLCs.

FINS) and OMRON PLCs.

ate applications using FINS communications.

xiii

Relevant Manuals

The following table lists CS and CJ-series manuals that contain information relevant to Ethernet Units.

Manual

number

W420

W421 CS1W-ETN21

W343

W342

W339

W393

W394 CS1G/H-CPU@@H

W340

CS1W-ETN21

CJ1W-ETN21

CJ1W-ETN21

CS1W-ETN01

CS1W-ETN11

CJ1W-ETN11

CS1G/H-CPU@@H

CS1G/H-CPU-@@EV1

CS1D-CPU@@H

CS1D-CPU@@S

CJ1M-CPU@@

CS1W-SCU21-V1

CS1W-SCB21-V1/41-V1

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1G-CPU@@

CJ1W-SCU21-V1/41-V1

CS1G/H-CPU@@H

CS1G/H-CPU@@-EV1

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1M-CPU@@

CJ1G-CPU@@

CS1G/H-CPU@@EV1

CS1D-CPU@@H

CS1D-CPU@@S

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1G-CPU@@

CJ1M-CPU@@

CS1G/H-CPU@@H

CS1G/H-CPU@@EV1

CS1D-CPU@@H

CS1D-CPU@@S

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1G-CPU@@

CJ1M-CPU@@

Model Name Contents

Ethernet Units Operation Manual

Construction of Networks

(this manual)

Ethernet Units Operation Manual

Construction of

Applications

Ethernet Units Operation Manual

Communications

Commands Reference Manual

Programmable Controllers Operation

Manual

Programmable Controllers Operation

Manual

Programmable Controllers Programming Manual

Programmable Controllers Instructions

Reference Manual

Provides information on operating and installing

100Base-TX Ethernet Units, including details on basic

settings and FINS communications.

Refer to the Communications Commands Reference

Manual (W342) for details on FINS commands that can

be sent to CS-series and CJ-series CPU Units when

using the FINS communications service.

Provides information on constructing host applications for

100Base-TX Ethernet Units, including functions for sending/receiving mail, socket service, automatic clock adjustment, FTP server functions, and FINS communications.

Describes the installation and operation of the 10Base-5

and 10Base-T Ethernet Units.

Describes the C-series (Host Link) and FINS communications commands used when sending communications

commands to CS-series and CJ-series CPU Units.

Provides an outline of, and describes the design, installation, maintenance, and other basic operations for the CSseries PLCs. Information is also included on features,

system configuration, wiring, I/O memory allocations, and

troubleshooting.

Use together with the Programmable Controllers Pro-

gramming Manual (W394).

Provides an outline of, and describes the design, installation, maintenance, and other basic operations for the CJseries PLCs. Information is also included on features,

system configuration, wiring, I/O memory allocations, and

troubleshooting.

Use together with the Programmable Controllers Pro-

gramming Manual (W394).

Describes programming, tasks, file memory, and other

functions for the CS-series and CJ-series PLCs.

Use together with the Programmable Controllers Opera-

tion Manual (W339 for CS-series PLCs and W393 for CJseries PLCs).

Describes the ladder diagram programming instructions

supported by CS-series and CJ-series PCs. Use together

with the Programmable Controllers Operation Manual

(W339 for CS-series PLCs and W393 for CJ-series

PLCs), and Programmable Controllers Programming

Manual (W394).

xiv

Manual

number

W446 WS02-CXPC@-V8 CX-Programmer

W444 CXONE-AL@@C-E CX-One Setup Man-

W445 CXONE-AL@@C-E CX-Integrator Opera-

W341

W336

CQM1H-PRO01-E

CQM1-PRO01-E

C200H-PRO27-E

CS1W-SCB21-V1/41-V1

CS1W-SCU21-V1

CJ1W-SCU21-V1/41-V1

Model Name Contents

Ver. 8.0 Operation

Manual

ual

tion Manual

Programming Consoles Operation

Manual

Serial Communications Boards and

Serial Communications Units Operation

Manual

Provides information on how to use the CX-Programmer,

a Windows-based programming device, and CX-Net, a

Windows-based network configuration tool.

Use together with the Programmable Controllers Opera-

tion Manual (W339 for CS-series PLCs and W393 for CJseries PLCs), Programmable Controllers Programming

Manual (W394) and the Programmable Controllers

Instructions Reference Manual (W340) to perform pro-

gramming.

Describes operating procedures for the CX-One FA Inte-

grated Tool Package.

Refer to this manual for operating procedures for the CX-

One FA Integrated Tool Package.

Describes operating procedures for the CX-Integrator net-

work configuration support software for CS/CJ-series

PLCs.

Refer to this manual for operating procedures for the CXIntegrator network configuration support software for CS/

CJ-series PLCs.

Provides information on how to operate the Programming

Console.

Use together with the Programmable Controllers Opera-

tion Manual (W339 for CS-series PLCs and W393 for CJseries PLCs), Programmable Controllers Programming

Manual (W394) and the Programmable Controllers

Instructions Reference Manual (W340) to perform pro-

gramming.

Accessing the PLC connected to the CX-Programmer via

Ethernet or the host computer or other device connected

to the Serial Communications Board or Unit.

Describes the use of Serial Communications Units and

Boards, including details on hardware, software, and

standard system protocols.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xv

xvi

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xvii

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xviii

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xix

xx

PRECAUTIONS

This section provides general precautions for using the CS1W-ETN21 and CJ1W-ETN21 Ethernet Units (100Base-TX).

The information contained in this section is important for the safe and reliable application of Ethernet Units. You

must read this section and understand the information contained before attempting to set up or operate an Ethernet

Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

xxi

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!Caution Execute online editing only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

xxii

Operating Environment Precautions 4

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5 Application Precautions

Observe the following precautions when using the Ethernet Unit.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

connecting to a ground of 100

Ω or less when installing the Units. Not

Ω or less may result in electric shock.

xxiii

Application Precautions 5

• Always turn OFF the power supply to the CPU Unit, Slaves, and Communications Units before attempting any of the following. Not turning OFF

the power supply may result in malfunction or electric shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Packs, or

Master Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the Ethernet Unit or the system, or could damage the Ethernet Unit. Always

heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not install the Unit near devices that generate strong high-frequency

noise.

• Do not drop the Unit or subject it to excessive vibration or shock.

• Make sure that all the Backplane mounting screws, terminal block screws,

and cable connector screws are tightened to the torque specified in the

relevant manuals. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Wire all connections correctly.

• Mount Units only after checking terminal blocks and connectors completely.

• Make sure that the terminal blocks, expansion cables, and other items

with locking devices are locked in place.

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impacts during transportation.

xxiv

Conformance to EC Directives 6

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in unexpected operation.

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables past their natural bending radius.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Always lay communications cable inside ducts.

• Use appropriate communications cables.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including the setting of the

startup operation mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

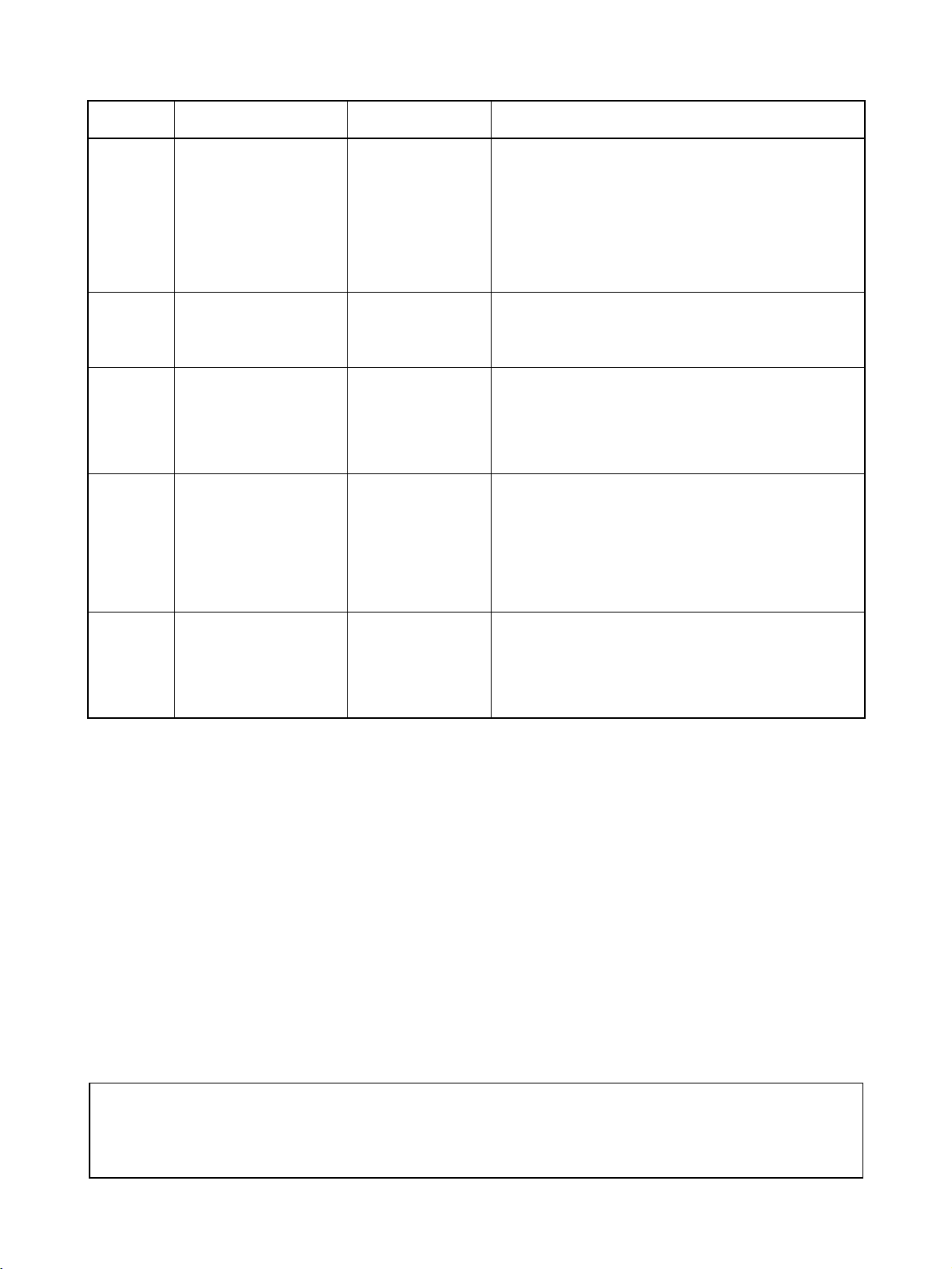

Note Applicable EMS (Electromagnetic Susceptibility) and EMI (Electromagnetic

Interference) Standards in the EMC (Electromagnetic Compatibility) standards are as follows:

Unit/Board EMS EMI

CS1W-ETN21

CJ1W-ETN21

EN61000-6-2

EN61000-6-4

(Radiated emission: 10-m

regulations)

xxv

Conformance to EC Directives 6

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the PLC (EN61131-2).

xxvi

SECTION 1

Features and System Configuration

This section introduces the features, describes the system configuration and Unit parts, and provides Unit specifications.

1-1 Ethernet Unit Function Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overall System Configuration Example . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Determining the Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3-1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3-2 Devices Required for Constructing a Network . . . . . . . . . . . . . . . . . 11

1-3-3 Setup Area and Related Peripheral Devices . . . . . . . . . . . . . . . . . . . 12

1-4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-4-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-4-2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-4-3 Software Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-5 Overview of Communications Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-5-1 FINS Communications Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-5-2 Socket Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-5-3 FTP Server Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-5-4 Mail Send Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-5-5 Mail Receive Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-5-6 Automatic Clock Adjustment Function . . . . . . . . . . . . . . . . . . . . . . 22

1-5-7 Specifying Servers by Host Name . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-6 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-6-1 Component Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-6-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-7 Comparison with Previous Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-8 Unit Version Upgrade Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1

Ethernet Unit Function Guide Section 1-1

1-1 Ethernet Unit Function Guide

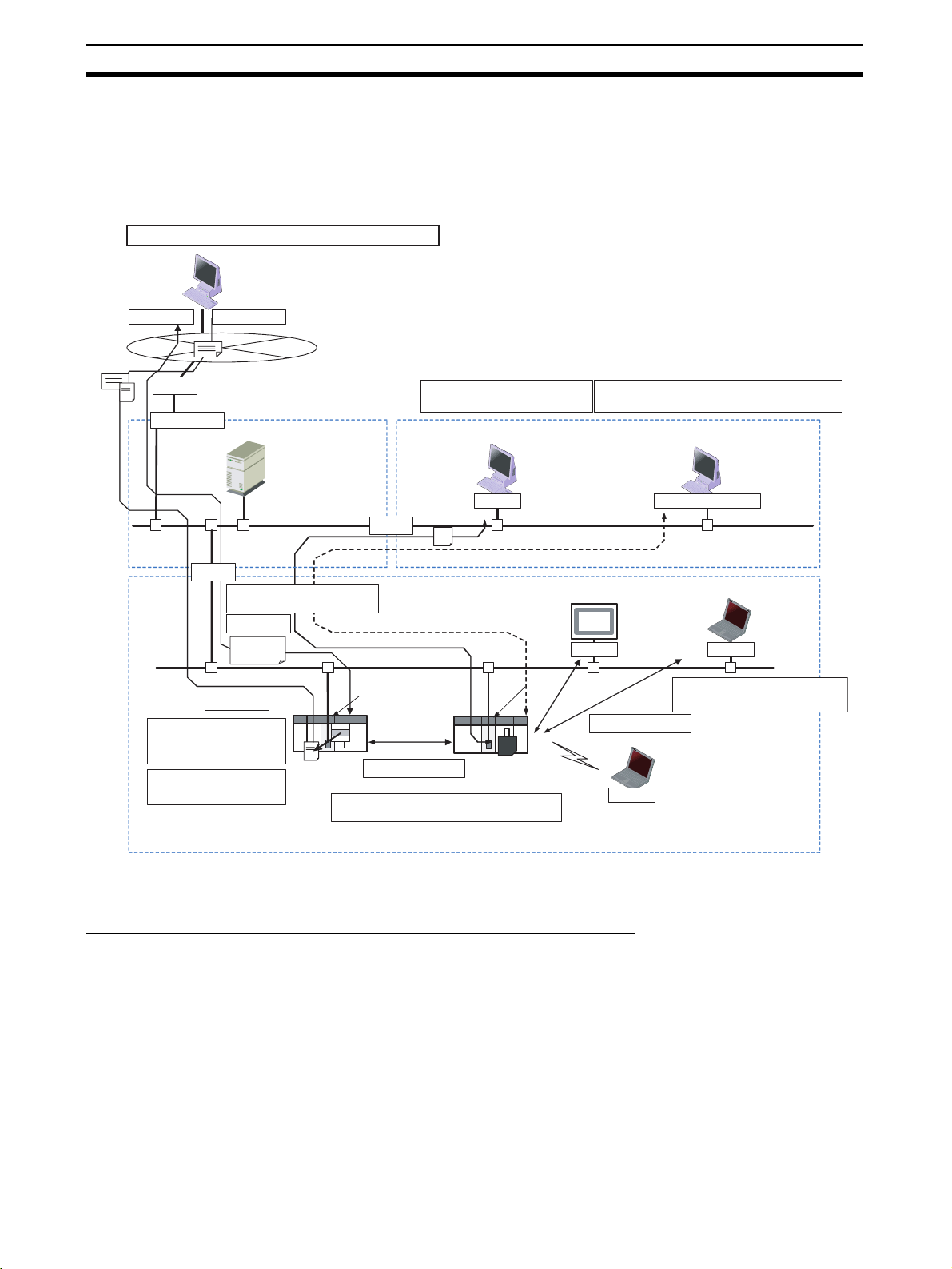

1-1-1 Overall System Configuration Example

The following diagram shows an example of an overall system configuration

using Ethernet Units.

(1) Connecting the CX-Programmer to the PLCs online via Ethernet

CX-Programmer

Mail software

Mail FINS

Mail

IP router

Firewall

(3) Capturing PLC changes

and sending the status of

equipment to an operator

(7) Automatically adjusting the

PLC's internal clock

periodically

Internet

Server Room

Router

(4) Receiving mail (data, files) at

PLCs

Receiving mail

Writing

commands

Sending mail

DNS server

POP3 server

SMTP server

SNTP server

Ethernet

(5) Transferring large data files between

Intranet

Router

Ethernet Unit Ethernet Unit

PLC PLC

FINS message

communications

(2) Sending and receiving data via Ethernet

between OMRON PLCs

personal computers and PLCs

FTP software

Mail software

Large files

(Factory line)

Ethernet

FTP

Memory Card

(6) Configuring an independent communications protocol

for the host application using TCP/IP (UDP/IP)

Office Floor

CX-Programmer

SCADA software

PLC Reporter, Compolet

FinsGateway

(communications driver)

Ethernet

FINS

FINS message

communications

Wireless

FINS

NS-series PT

Independent user

application

UDP/TCP socket

(1) Connecting the CX-Programmer to

PLCs online via Ethernet

CX-Programmer

FINS

1-1-2 Determining the Objectives

Connecting the CX-Programmer to PLCs Online via Ethernet

Connecting within the

Same Segment

2

Use the UDP/IP version of the FINS communications service (i.e., FINS/

UDP). FINS/UDP is supported by many OMRON products and is compatible

with earlier Ethernet Units (CS1W-ETN01/ETN11 and CJ1W-ETN11). The

CX-Programmer can be connected and used with FINS/UDP even if personal

computer middleware (FinsGateway) is not used. FinsGateway (any version)

can also be used together with the CX-Programmer.

Ethernet Unit Function Guide Section 1-1

Connecting through

Multiple Segments

Using Media with

Unreliable Connections,

Such as a Wireless LAN

Connecting from a

Personal Computer with a

Dynamic Private IP

Address

Use the TCP/IP version of the FINS communications service (i.e., FINS/TCP).

FINS/TCP is a new function supported by these Ethernet Units (CS1WETN21 and CJ1W-ETN21). It provides automatic recovery at the TCP/IP layer

from communications errors (such as packet loss) that occur during multilevel

routing. For CX-Programmer (version 4.0 or higher), FINS/TCP can be used

to directly connect to the PLC online. To use lower versions of the CX-Programmer with FINS/TCP, use FinsGateway (version 2003 or higher) as personal computer middleware.

Use the TCP/IP version of the FINS communications service (i.e., FINS/TCP).

FINS/TCP is a new function supported by these Ethernet Units (CS1WETN21 and CJ1W-ETN21). It provides automatic recovery at the TCP/IP layer

from communications errors (such as packet loss) resulting from unreliable

connections. For CX-Programmer (version 4.0 or higher), FINS/TCP can be

used to directly connect to the PLC online. To use lower versions of the CXProgrammer with FINS/TCP, use FinsGateway (version 2003 or higher) as

personal computer middleware.

Depending on whether or not the connection will be within the same segment,

either use an IP address conversion method for dynamic IP addresses in the

UDP/IP version of the FINS communications service or use the TCP/IP version of the FINS communications service.

It is possible to connect online to a PLC using the CX-Programmer from a

computer serving as a temporarily connected node or a permanent DHCP client.

For CX-Programmer (version 4.0 or higher), FINS/TCP can be used to directly

connect to the PLC online. To use lower versions of the CX-Programmer with

FINS/TCP, use FinsGateway (version 2003 or higher) as personal computer

middleware.

3

Ethernet Unit Function Guide Section 1-1

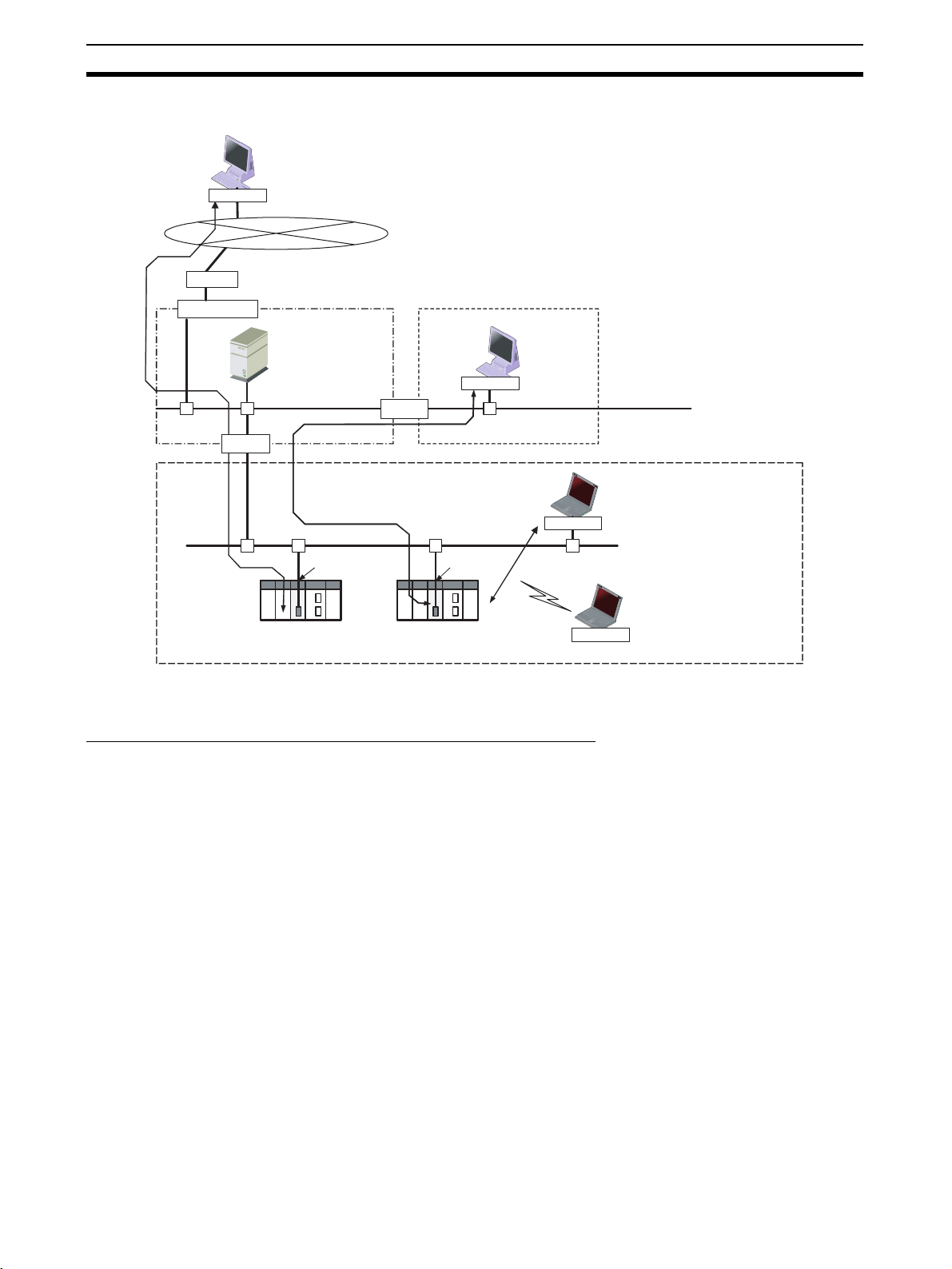

Connecting through multiple segments, such as over the Internet:

Use FINS/TCP.

CX-Programmer

FINS

Internet

IP router

Firewall

Router

(Server room)

DNS server

POP3 server

SMTP server

SNTP server

Intranet

Router

Connecting from a computer with a dynamic private IP address:

Use FINS/TCP or FINS/UDP.

(Office floor)

CX-Programmer

FINS

EthernetEthernet

(Production line)

Ethernet

Ethernet Unit Ethernet Unit

CX-Programmer

PLC

FINS

Wireless

Reference SECTION 6 FINS Communications

Exchanging Data between OMRON PLCs using Ethernet

Connecting within the

Same Segment

Use the UDP/IP version of the FINS communications service (i.e., FINS/

UDP), and construct applications using the SEND(090), RECV(098), and

CMND(490) instructions in the ladder program. FINS/UDP is supported by

many OMRON products, and is compatible with earlier Ethernet Units (CS1WETN01/ETN11 and CJ1W-ETN11). The protocol processing for FINS/UDP is

simpler than for FINS/TCP, giving FINS/UDP certain advantages in terms of

performance. Another feature of FINS/UDP is that it can be used for broadcasting.

On the other hand, with FINS/UDP it is necessary to provide measures, such

as retries, for handling communications errors.

Connecting within the same segment:

Use FINS/UDP.

CX-Programmer

Using media with unreliable

connections, such as wireless

FINS

LAN: Use FINS/TCP.

Connecting through

Multiple Segments

4

Use the TCP/IP version of the FINS communications service (i.e., FINS/TCP),

and construct applications using the SEND(090), RECV(098), and

CMND(490) instructions in the ladder program. FINS/TCP is the initial function supported by this Ethernet Unit (CS1W-ETN21 and CJ1W-ETN21). It provides automatic recovery at the TCP/IP layer from communications errors

(such as packet loss) that occur during multilevel routing.

Ethernet Unit Function Guide Section 1-1

Intranet

Production line A

Ethernet Unit

Ethernet

Router

Mail

communications

FINS message

communications

Ethernet Unit

Connecting within the same segment:

Use FINS/UDP.

Router

Connecting through multiple segments:

Use FINS/TCP.

Production line B

PLC

FINS message

communications

Ethernet Unit

PLC

Memory Card

Reference SECTION 6 FINS Communications

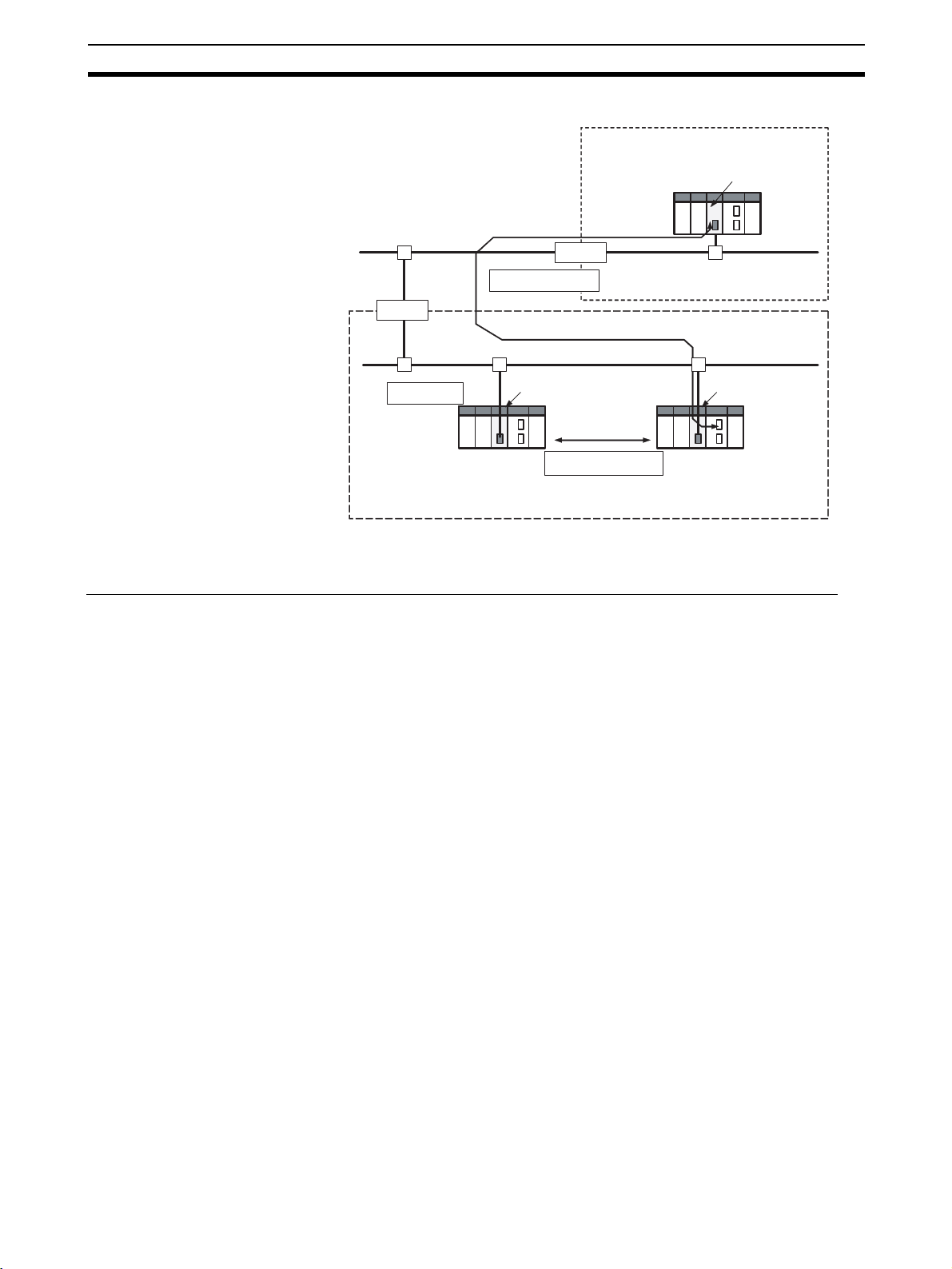

Monitoring PLC Changes and Sending Equipment Status to the Operator by E-mail

Operation When the mail send function is used, automatic communications applications

via the Internet can be constructed relatively easily. With this Ethernet Unit,

the following mail triggers can be set as PLC changes. When these settings

can be used, no special ladder program is required for sending e-mail.

• When a particular bit (the Mail Send Switch) turns ON

• When values change in particular words (=, <>, <, <=, >=, >)

• When a particular bit changes (either OFF to ON or ON to OFF)

• When a change occurs at the Ethernet Unit (stored in error log)

• When a change occurs at the CPU Unit (e.g., a non-fatal error, a fatal

error, or a mode change)

• At regular intervals

The following data can be sent by e-mail:

• Text (user-created text strings (ASCII data), Ethernet Unit error log data,

and status data)

• Attached files (IOM data created automatically by the Ethernet Unit, data

tables, and files in File Memory)

To use the mail send function, there must be a separate SMTP server on the

network. When using the SMTP server of an Internet Service Provider (ISP),

security measures, such as POP before or SMTP, may be required. (This Unit

handles POP before SMTP.) In addition to the IP address, the host name used

for the DNS service can be specified for the SMTP/POP3 server.

5

Ethernet Unit Function Guide Section 1-1

Mail software

Receiving

e-mail

E-mail

Internet

IP router

Intranet

(Office floor)

Router

(Production line)

Ethernet Unit

PLC's I/O memory data

sent as attached file

Receiving

e-mail

Mail software

Router

Sending

e-mail

(Server room)

Ethernet

Firewall

Monitoring PLC changes and

sending equipment status to

the operator by e-mail

DNS server

POP3 server

SMTP server

SNTP server

Ethernet Ethernet

Reference SECTION 2 Mail Send Function in the Operation Manual Construction of

Applications

Receiving E-mail (Data and Files) at the PLC

Operation Use the mail receive function.

When the mail receive function is used, the PLC can be accessed through a

mail address, enabling remote applications via the Internet to be constructed

relatively easily. With the mail receive function, any of the following remote

commands can be specified as e-mail subjects.

• FileWrite (File Write)

• FileRead (File Read)

• FileDelete (File Delete)

• FileList (File List Read)

• UMBackup (User Memory

Backup)

• PARAMBackup (Parameter Area

Backup)

• IOMWrite (I/O Memory Write)

• IOMRead (I/O Memory Read)

To use the mail receive function, there must be a separate POP3 server on

the network. Aside from the IP address, the host name used for DNS service

can be specified for the POP3 server.

• ChangeMode (Operating Mode

Change)

• ErrorLogRead (Error Log Read)

• ErrorLogClear (Error Log Clear)

• MailLogRead (Mail Log Read)

• MailLogClear (Mail Log Clear)

• Test (Mail Test)

• FinsSend (FINS Command

Send)

6

Ethernet Unit Function Guide Section 1-1

Mail software

Sending e-mail

Internet

IP router

Firewall

(Server room)

Intranet

(Office floor)

Router

Writing command

File attachment enabled

Receiving e-mail

Receiving e-mail at the PLC

DNS server

POP3 server

SMTP server

SNTP server

Ethernet

Writing command

File attachment enabled

Ethernet

Sending e-mail

Router

(Production line)

Ethernet Unit

Mail software

Ethernet

Reference SECTION 3 Mail Receive Function in the Operation Manual Construction of

Applications

Exchanging Large Files between a Personal Computer and PLC

Operation Use the FTP server function.

The FTP server function makes it possible to log in to the Ethernet Unit from a

computer (FTP client) as required, and to specify folders and files to be transferred. The following items can be used as PLC File Memory.

• A Memory Card (mounted to the CPU Unit)

• EM File Memory (The portion of the EM Area in the CPU Unit's I/O memory used by the CX-Programmer as File Memory)

Reference SECTION 4 FTP Server Function in the Operation Manual Construction of

Applications

Creating an Original Communications Procedure Using TCP/IP (UDP/IP) for the Host

Application or Communicating with PLCs from Another Manufacturer

Operation Using the socket services function, create a communications application in

the ladder program.

With the socket services function, TCP/IP or UDP/IP can be used directly to

receive data. Use the socket services to create applications based on manipulating control bits or the CMND(490) instruction.

Reference SECTION 4 Socket Service Function in the Operation Manual Construction of

Applications

7

Fe at ur e s Section 1-2

Automatically Adjusting the PLC's Internal Clock at Regular Intervals

Operation Use the automatic clock adjustment function.

With the automatic clock adjustment function, the SNTP server's clock is

taken as the standard for automatically adjusting the built-in clock of the PLC

connected to the Ethernet Unit. The adjustment can be regularly executed at

a specified time (once a day) and it can be executed each time by the ladder

program.

To use the automatic clock adjustment function, there must be a separate

SNTP server on the network. Aside from the IP address, the host name used

for DNS service can be specified for the SNTP server.

Reference SECTION 5 Automatic Clock Adjustment Function in the Operation Manual

Construction of Applications

1-2 Features

Compatibility and Speed

The transmission medium has been upgraded to 100Base-TX, while compatibility with the functions and application interfaces of the existing Ethernet Unit

models (CS1W-ETN01, CS1W-ETN11, and CJ1W-ETN11) has been maintained. Moreover, processing speed has been improved so that the system

response performance for the same FINS message applications is now up to

four times faster.

Various Protocols Available on Ethernet

A variety of protocols makes available a wide range of applications for use on

an Ethernet network. The protocols that can be selected include sending and

receiving data by TCP/IP or UDP/IP (socket services), sending and receiving

commands by OMRON's standard protocol FINS, transferring files by FTP,

sending and receiving e-mail by SMTP/POP3, and automatically adjusting the

PLC's internal clock by SNTP.

A communications service can be selected according to need, allowing the

PLC to be flexibly integrated with the Ethernet information network.

Communications by UDP/IP and TCP/IP (Socket Services Function)

The standard Ethernet protocols, UDP/IP and TCP/IP, are supported, making

it possible to communicate with a wide range of devices, workstations, computers, and Ethernet Units from other manufacturers.

Up to eight ports can be used for various protocols, enabling the use of various applications.

Simplified Socket Services

Without using the CMND(490) instruction, the socket services function for

TCP or UDP can be simplified by presetting parameters and using dedicated

bits. In addition, the size of received data accumulated in the reception buffer

is now stored, and a Data Received Flag has been added. These new features eliminate the need for ladder programs to monitor the timing for completion of instructions and socket service processing, and thus reduce the

amount of labor required for program development.

8

Fe at ur e s Section 1-2

Starting with unit version 1.5, the performance of sending and receiving has

been improved using optional settings for the TCP or UDP socket services

using specific bits in memory. Also, a linger socket option has been added to

the TCP socket services. Specifying this option enables open processing

immediately with the same port number without having to wait (approximately

1 min.) until the port number opens after the socket closes.

Improved FINS Message Communications

The following functions have been improved over previous Ethernet Unit models. They allow the scale of the system to be increased, and can give greater

flexibility to the system configuration including the host computer.

• Expanded number of nodes (to 254 max., from 126 max.)

• Communications are now enabled even if the host computer's IP address

is dynamic. (DHCP client computers can be handled, including TCP/IP

and UDP/IP.)

→ Previously IP addresses for host computers could be fixed only.

→ For Ethernet Units with Unit Ver. 1.3 or later, the Unit can be protected

against access from nodes with dynamically changed IP addresses (set

to be fixed only).

• An automatic client FINS node address allocation function now makes it

possible to connect online to the PLC even if no FINS node address has

been set for the host computer.

→ Previously online connection to the PLC was possible only after a FINS

node address was set for the host computer.

• FINS message communications are now enabled in TCP/IP (with up to 16

simultaneous connections), so a system can now utilize FINS message

communications in both UDP/IP and TCP/IP.

→ Previously only UDP/IP could be used.

• Multiple FINS applications (such as the CX-Programmer) on the same

computer can now be connected online to the PLC via Ethernet (in either

TCP/IP or UDP/IP).

→ Previously when one FINS application on a computer was connected

online to the PLC, it was impossible to connect any other at the same

time.

Transferring Data Files between Host Computers (FTP Server Function)

A built-in FTP server function enables data files in the PLC to be read from a

workstation or computer with an FTP client function, and for data to be written

to the PLC. Large amounts of data can be transferred at a time from clients,

without requiring ladder programming.

Additional E-mail Functions

With previous Ethernet Unit models (CS1W-ETN01/CS1W-ETN11/CJ1WETN11), e-mail could sent only from the Ethernet Unit, and the data that could

be sent was limited to user-created ASCII text data and system data. Now the

following e-mail functions have been added.

Mail Receive Function

(Receiving Commands for

the PLC by E-mail)

E-mail File Attachment

Function

Commands for the PLC (mail remote commands) can be written into e-mail,

and the Ethernet Unit can receive them, execute them, and send responses

by e-mail.

This function can be linked to the CS/CJ File Memory function.

9

Fe at ur e s Section 1-2

• The Ethernet Unit can automatically generate data files (6,000 words

maximum per file) from the CPU Unit's I/O memory status, and send them

to specified e-mail addresses as e-mail attachments. It can also send program files from the Memory Card (up to 1 MB) to specified e-mail

addresses as e-mail attachments.

• In addition to using the existing Mail Send Switch, or having e-mail sent at

regular intervals, it is possible to set triggers for sending e-mail (for example, by having e-mail sent when a PV in the CPU Unit's I/O memory

reaches a certain value (size comparison), or when the bit at a specified

address turns ON).

• Up to eight of these e-mail send conditions (destination, trigger type, etc.)

can be preregistered so that e-mail will be sent automatically whenever

the conditions are met.

Note The e-mail functions require a separate mail server (SMTP/POP3).

Automatic PLC Internal Clock Adjustment

The built-in clock of the PLC connected to the Ethernet can be automatically

adjusted, with the SNTP server clock taken as the standard. Automatic adjustments through the entire system enable the various records generated by production equipment to be managed according to clock information and

analyzed.

Note The automatic clock adjustment requires a separate SNTP server.

Specification of Servers by Host Name

In addition to directly specifying the IP address for a SMTP, POP3, or SNTP

server, it is also possible (by means of the Ethernet Unit's DNS client function)

to specify the server by host name. This enables automatic searches for IP

addresses for purposes such as system checking, even when the IP

addresses for servers have been changed.

Note (1) A separate DNS server is required to specify servers by host name using

DNS.

(2) The IP address is specified directly for the DNS server.

Classless IP Address Settings Using CIDR

Starting from unit version 1.5, it is possible to use classless inter-domain routing (CIDR) by specifying the subnet class using an option setting. This

enables greater flexibility in specification by eliminating the need to have the

network ID component of the IP address be dependent on the class.

Use Web Function to Read Ethernet Unit Settings and Status

A Web function is provided in Ethernet Units with Unit Ver. 1.3 or later. This

enables use of a Web browser to read the Ethernet Unit’s system settings and

statuses.

Network Connection with Controller Link

The Ethernet information network can be connected to the Controller Link

control system network by using the FINS communications service function.

This enables a PLC on a Controller Link network to be monitored from a PLC

on an Ethernet network, and it allows data to be exchanged between them.

10

System Configuration Section 1-3

Full Range of Functions for Handling Troubles

A full range of functions is provided for promptly handling any troubles that

may arise.

• Self-diagnostic function when power is turned ON

• Remote node connection check by PING command

• Remote node connection check by internode test

• Error log for recording error information when an error occurs

• Notification by e-mail when an error occurs

1-3 System Configuration

1-3-1 System Configuration

CX-Programmer

CX-Integrator

FinsGateway

(3) Hub

100 m

max.

(2) Twisted-pair cable

(1) CS1W-ETN21

Ethernet Unit

(100Base-TX)

CS-series

PLC

1-3-2 Devices Required for Constructing a Network

The basic configuration for a 100Base-TX Ethernet System consists of one

hub to which nodes are attached in star form using twisted-pair cable.

The devices shown in the following table are required to configure a network

with 100Base-TX-type CS1W-ETN21 and CJ1W-ETN21 Ethernet Units, so

prepare them in advance.

Network device Contents

(1) CS-series Ethernet

Units (CS1W-ETN21)

or CJ-series Ethernet

Units (CJ1W-ETN21)

(2) Twisted-pair cable This is twisted-pair cable for connecting 100Base-TX-type

(3) Hub This is a relay device for connecting multiple nodes in a

These Ethernet Units are Communications Units that

connect a CS-series or CJ-series PLC to 100Base-TX

Ethernet networks. (They can also be used as 10Base-T.)

Ethernet Units to the hub, with an RJ45 Modular Connector at each end.

Use a category 3, 4, 5, or 5e UTP (unshielded twistedpair) or STP (shielded twisted-pair) cable.

star LAN.

(1) CJ1W-ETN21

Ethernet Unit

(100Base-TX)

CJ-series

PLC

Recommended Hubs For details on recommended devices for constructing a network, refer to 2-4

Network Installation.

11

System Configuration Section 1-3

1-3-3 Setup Area and Related Peripheral Devices

Making Settings in the

CPU Bus Unit System

Setup Area (with the CXProgrammer)

For the Ethernet Unit to function as a node on an Ethernet network, make the

settings, as required, in the CPU Bus Unit System Setup Area allocated in

non-volatile memory in the CPU Unit.

Use the CX-Programmer to make the settings (by connecting online from the

I/O Table Window, selecting the Ethernet Unit, and then selecting Unit Setup).

Each time the Ethernet Unit is turned ON or restarted, it reads and uses the

contents of the CPU Bus Unit System Setup Area as the settings for the communications services.

If setting items for expanded functionality of the Ethernet Unit are not displayed, make the settings after updating the Support Software using an auto

update or by using the Web function of the Ethernet Unit.

Personal computer

running Windows

CX-Programmer

Unit Setup

Ethernet Unit

CPU Bus Unit System

Setup Area

CS/CJ-series CPU Unit

Making Settings in the

Routing Table Area (with

CX-Integrator)

Middleware for FINS

Communications

Applications on a

Personal Computer

(FinsGateway)

OMRON Communications Units use OMRON's original FINS network system.

Make the settings for the FINS network and the relay path, as required, in the

Routing Table Area allocated to the non-volatile memory in the CPU Unit.

Use CX-Integrator to make the settings. (CX-Integrator is software that comes

with the CX-One and is automatically installed when the CX-One is installed.)

Each time the Ethernet Unit is turned ON or restarted, it reads the contents of

the Routing Table Area as the settings for FINS network.

Personal computer

running Windows

CX-Integrator

Routing table

settings

Ethernet Unit

Routing Table Area

CS/CJ-series CPU Unit

FinsGateway can be used as middleware when constructing communications

applications on a personal computer for a FINS network, using Visual C++ or

Visual BASIC. The CX-Programmer and CX-Integrator can also be connected

online through FinsGateway. When FINS/UDP is used in the FINS communications service, all versions of FinsGateway can be used.

When FINS/TCP is used in the FINS communications service, only FinsGateway Version 2003 or higher can be used.

12

System Configuration Section 1-3

t

When the CX-Programmer and CX-Integrator are connected online by FINS/

TCP, FinsGateway Version 2003 or higher must be used.

For CX-Programmer Ver. 4.0 or higher, FINS/TCP can be used to directly connect to the PLC online.

Personal computer running Windows

User-created

software

FinsGateway

CX-Programmer

Windows

Ethernet Uni

CS/CJ-series CPU Unit

13

Specifications Section 1-4

1-4 Specifications

1-4-1 General Specifications

CS-series Ethernet Unit

Item Specifications

Model number CS1W-ETN21

Type 100Base-TX (Can be used as 10Base-T)

Applicable PLCs CS-series PLCs

Unit classification CS-series CPU Bus Unit

Mounting location CPU Rack or Expansion Rack

Number of Units that can be mounted 4 max. (including Expansion Racks)

Tr an s fe r

specifications

Current consumption (Unit) 380 mA max. at 5 V DC

Weight 200 g max.

Dimensions 35 × 130 × 101 mm (W × H × D)

Other general specifications Conform to general specifications for the SYSMAC CS Series.

Media access method CSMA/CD

Modulation method Baseband

Transmission paths Star form

Baud rate 100 Mbit/s (100Base-TX) 10 Mbit/s (10Base-T)

Transmission media Unshielded twisted-pair (UDP) cable

Categories: 5, 5e

Shielded twisted-pair (STP) cable

Categories: 100 Ω at 5, 5e

Transmission distance 100 m (distance between hub and node)

Number of cascade con-

nections

No restrictions if switching hubs are used.

Unshielded twisted-pair (UDP) cable

Categories: 3, 4, 5, 5e

Shielded twisted-pair (STP) cable

Categories: 100 Ω at 3, 4, 5, 5e

CJ-series Ethernet Unit

Item Specifications

Model number CJ1W-ETN21

Type 100Base-TX (Can be used as 10Base-T)

Applicable PLCs CJ-series PLCs

Unit classification CJ-series CPU Bus Unit

Mounting location CPU Rack or Expansion Rack

Number of Units that can be mounted 4 max. (including Expansion Racks)

Tr an s fe r

specifications

Current consumption (Unit) 370 mA max. at 5 V DC

Weight 100 g max.

Dimensions 31 × 90 × 65 mm (W × H × D)

Other general specifications Conform to general specifications for the SYSMAC CJ Series.

Media access method CSMA/CD

Modulation method Baseband

Transmission paths Star form

Baud rate 100 Mbit/s (100Base-TX) 10 Mbit/s (10Base-TX)

Transmission media Unshielded twisted-pair (UDP) cable

Categories: 5, 5e

Shielded twisted-pair (STP) cable

Categories: 100 Ω at 5, 5e

Transmission distance 100 m (distance between hub and node)

Number of cascade con-

nections

No restrictions if switching hubs are used.

Unshielded twisted-pair (UDP) cable

Categories: 3, 4, 5, 5e

Shielded twisted-pair (STP) cable

Categories: 100 Ω at 3, 4, 5, 5e

14

Specifications Section 1-4

1-4-2 Dimensions

CS1W-ETN21

CJ1W-ETN21

130

ETN21

RUN

ERC

SD

RD

LNK

NODE

NO.

100BASE-TX

Front

UNIT

0

×16

10BASE-T

NO.

100M

ERH

TCP

FTP

HOST

0

1

0

1

×16

10135

(Unit: mm)

Back

• Unit Version 1.5 or Later

31

90 2.72.7

ETN21

RUN ERC SD RD

ERH TCP FTP HOST100M

5

4

6

3

7

2

8

1

9

0

A

F

B

E

C

D

100BASE-TX

10BASE-T

x16

LINK

5

4

UNIT

6

3

7

2

8

1

9

0

A

F

No.

B

E

C

D

5

4

NODE

6

3

7

2

8

1

9

0

A

F

No.

B

E

C

D

0

1

x16

• Unit Version 1.4 or Earlier

31

90 2.72.7

ETN21

RUN ERC SD RD

ERH TCP FTP HOST100M

100BASE-TX

10BASE-T

LINK

5

4

UNIT

6

3

7

2

8

1

9

0

A

F

No.

B

E

C

D

5

4

NODE

6

3

7

2

8

1

9

0

A

F

No.

B

E

C

D

1

x16

5

4

6

3

7

2

8

1

9

0

A

F

B

E

C

D

0

x16

65

(Unit: mm)

15

Specifications Section 1-4

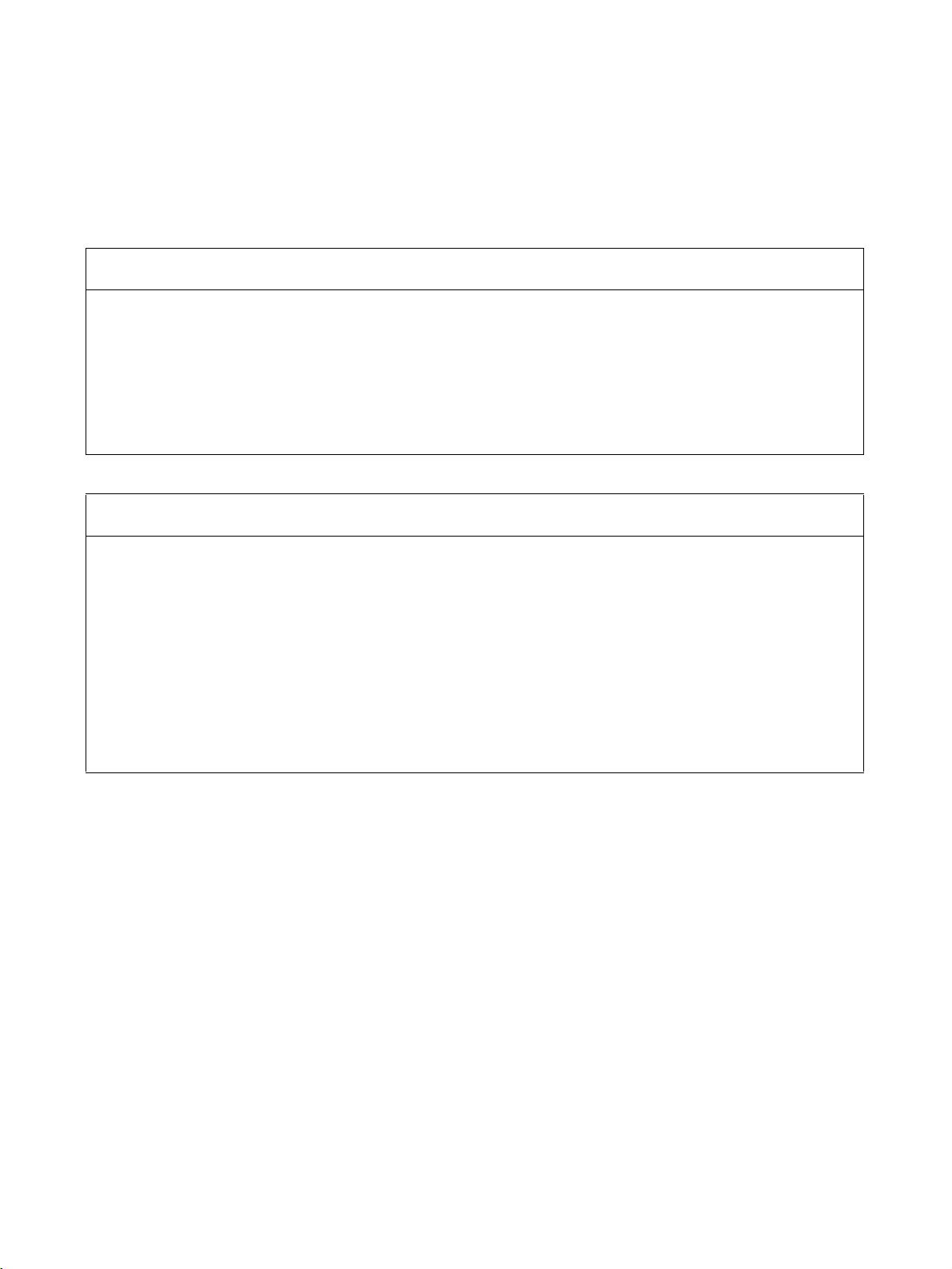

1-4-3 Software Configuration

The software supported by the Ethernet Unit runs in the layers shown in the

following diagram. The components that form the various layers are defined

below the diagram.

11. SMTP

CS/CJ-series CPU Unit

FINS communi-

Socket

services

FINS/UDP

5. UDP

cation service

7. FINS

2. IP

1. Ethernet (Ver. 2.0)

1,2,3... 1. Ethernet (Ver. 2.0)

The Version 2.0 Ethernet frame format is used for communications.

2. IP (Internet Protocol)

Transfers datagrams to destination nodes using IP addresses.

3. ICMP (Internet Control Message Protocol)

Supports IP communications by signalling errors in data transfers.

4. ARP (Address Resolution Protocol)

Determines the Ethernet address (i.e., physical address) by broadcasting

based on the target IP address.

5. UDP (User Datagram Protocol)

Performs data communications. Data resends, priority control, flow control,

and other measures to ensure communications reliability are not performed for UDP communications, so the transmitted data may not arrive at

the destination node. To increase reliability, it is necessary to program special measures into the user applications.

6. TCP (Transmission Control Protocol)

Performs communications after establishing a connection (i.e., a virtual circuit) with the destination node, providing a highly reliable communications

service.

7. FINS (Factory Interface Network Service)

A protocol that sends messages between PLCs on any of various OMRON

FA networks. To ensure that transmitted messages arrive at the destination

node, it is necessary to program special measures such as retry processing into the user's applications.

8. FTP (File Transfer Protocol)

Transfers data files.

9. SMTP (Simple Mail Transfer Protocol)

A communications protocol for sending e-mail by TCP/IP.

10. POP3 (Post Office Protocol Ver. 3.0)

A communications protocol for receiving e-mail by TCP/IP.

11. SNTP (Simple Network Time Protocol)

A communications protocol for automatic clock adjustment by UDP/IP.

12. DNS (Domain Name System)

A communications protocol for determining IP address names according

to UDP/IP and TCP/IP.

FINS/TCP

Socket

services

3. ICMP 4. ARP

E-mail

transmission

6. TCP

E-mail

reception

10. POP3

Memory Card /

EM File Memory

FTP

8. FTP server9. SMTP

CS/CJ-series

CPU Unit

Ethernet

Unit

16

Overview of Communications Functions Section 1-5

1-5 Overview of Communications Functions

1-5-1 FINS Communications Service

Basic Functions FINS commands can be sent to or received from other PLCs or computers on

the same Ethernet network by executing SEND(090), RECV(098), or

CMND(490) instructions in the ladder diagram program. This enables various

control operations such as the reading and writing of I/O memory between

PLCs, mode changes, and file memory operations.

Ethernet

UDP or TCP

IP

CS/CJ-series

CPU Unit

Ethernet Unit Ethernet Unit Ethernet Unit

FINS IP FINS

UDP or TCP

User program

SEND(090),

RECV(098), or

CMND(490)

instruction

Executing, from the host computer, FINS commands with UDP/IP or TCP/IP

headers enables various control operations, such as the reading and writing

of I/O memory between PLCs, mode changes, and file memory operations.

For example, it is possible to connect online via Ethernet from FINS communications applications such as the CX-Programmer, and to perform remote programming and monitoring. (See note.)

Note Use CX-Programmer version 4.0 to use TCP/IP. For lower versions of CX-Pro-

grammer, FinsGateway Version 2003 or higher is required to use TCP/IP.

Ethernet

UDP or TCP

IP

FINS

CS/CJ-series

CPU Unit

Ethernet Unit

The FINS gateway function enables access to PLCs on not only the same

Ethernet network but on various other networks, including SYSMAC LINK and

Controller Link.

Upgraded Functions With the CS1W-ETN21 and CJ1W-ETN21, the following functions have been

upgraded.

• The FINS communications service can be executed not only with UDP/IP

but also with TCP/IP, and it is even possible to use FINS communications

with both UDP/IP and TCP/IP together on the same network. Using TCP/

IP makes FINS communications highly reliable.

17

Overview of Communications Functions Section 1-5

• Even if the IP address and UDP port number of the host computer (a