Page 1

Cat. No. W456-E1-03

CompoNet

CS1W-CRM21/CJ1W-CRM21

CompoNet Master Units

OPER ATION MANUAL

Page 2

CompoNet

CS1W-CRM21/CJ1W-CRM21

CompoNet Master Units

Operation Manual

Revised March 2009

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2006

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

7 Conformance to Shipbuilding Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 CompoNet Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1-2 CompoNet Network Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3 Devices in a CompoNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-4 Overview of Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1-5 Overview of Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-6 Design and Operating Procedure Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 2

Master Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-1 Master Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

SECTION 3

Wiring Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-1 Wiring Formations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-2 CompoNet Network Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SECTION 4

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4-2 Connecting Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4-3 Preparing and Mounting Flat Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4-4 Power Supply Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

SECTION 5

Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . 101

5-1 Exchanging Data with the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

5-2 Allocations to Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

5-3 Remote I/O Communications Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

vii

Page 7

TABLE OF CONTENTS

SECTION 6

Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

6-1 Message Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

6-2 Overview of FINS Commands and Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

6-3 Using FINS Message Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

6-4 Sending Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

SECTION 7

Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

7-1 Simple Backup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

SECTION 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

8-1 Handling Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8-2 Error History Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Appendix

A FINS Commands Addressed to CompoNet Master Units and Responses . . . . . . . . . . . . . . 183

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

viii

Page 8

About this Manual:

This manual describes the installation and operation of the CS1W-CRM21 and CJ1W-CRM21 CompoNet Master Units and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate a CompoNet Master Unit. Be sure to read the precautions provided in

the following section. Also be sure to read the CompoNet Slave Unit Operation Manual (see following

table) together with this manual.

Precautions provides general precautions for using the CompoNet Master Unit, Programmable Controller, and related devices.

Section 1 provides an overview of CompoNet Networks.

Section 2 provides the specifications of the CompoNet Master Units.

Section 3 describes the configurations of CompoNet Networks.

Section 4 describes how to install and wire a CompoNet Network.

Section 5 describes the remote I/O communications that are possible with CompoNet Networks.

Section 6 describes the message communications that are possible with CompoNet Networks.

Section 7 provides information on dealing with problems that might occur with CompoNet Master

Units.

Related Manuals:

Cat. No. Models Name Description

W456

(this manual)

W457 CRT1 Series CompoNet Slave Units

W464 CXONE-AL@@C-V@

CS1W-CRM21 and CJ1WCRM21

CXONE-AL@@D-V@

CS/CJ-series CompoNet

Master Units Operation

Manual

and Repeater Unit Operation Manual

CX-Integrator Operation

Manual

Provides an overview of CompoNet Networks,

communications specifications, wring methods, and CompoNet Master Unit functions.

Provides the specifications of CompoNet

Slave Units and Repeater Unit.

Describes CX-Integrator operating methods,

e.g., for setting up and monitoring networks.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 9

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

This section provides general precautions for using the CS1W-CRM21 and CJ12-CRM21 CompoNet Master Units.

The information contained in this section is important for the safe and reliable application of the CompoNet Master

Units. You must read this section and understand the information contained before attempting to set up or operate

a CompoNet Network using CompoNet Master Units.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-3 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

7 Conformance to Shipbuilding Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

7-1 Applicable Shipping Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

7-2 Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

7-3 Conditions for Use Under Shipping Standards. . . . . . . . . . . . . . . . . xxi

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes. Serious accidents may

result from abnormal operation if proper measures are not provided.

xvi

Page 16

Operating Environment Precautions 4

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. (“PLC” includes CPU Units, other Units mounted

in the PLC, and Remote I/O Terminals) Not doing so may result in serious

accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposits on or burning of

the output relays, or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply) is overloaded or shortcircuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures

must be provided to ensure safety in the system.

!Caution Execute online editing only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before changing or transferring to

another node the contents of a program, the PLC Setup, I/O tables, or I/O

memory. Changing or transferring any of these without confirming safety may

result in unexpected equipment operation.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, of chemicals (including acids).

• Locations subject to shock or vibration.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Make sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the

life of the system.

xvii

Page 17

Application Precautions 5

5 Application Precautions

Observe the following precautions when using a CompoNet Network.

• When more than one CompoNet system use Flat Cables, always separate the Flat Cables from each other by at least 5 mm regardless of

whether Flat Cable I or II cables are used. Do not bundle the Flat Cables.

This is to prevent unstable operation of the system due to interference.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, emergency stop circuits, and similar safety

measures in external circuits (i.e., not in the Programmable Controller)

must be provided by the customer.

• Always configure control circuits so that they turn ON power to the I/O

Slave Units before turning ON power to the PLC. If the PLC power supply

is turned ON first, normal operation will not be possible temporarily.

• Do not attempt to disassemble, repair, or modify any Units. Any attempt to

do so may result in malfunction, fire, or electric shock.

• When installing the Unit, ground to 100

• Make sure that all the Backplane mounting screws, Slave Unit mounting

screws, terminal block screws, and cable connector screws are tightened

to the torque specified in the relevant manuals. Incorrect tightening torque

may result in malfunction.

• Wire all connections correctly according to instructions in this manual.

• Confirm the orientation and polarity before connecting terminal blocks or

connectors.

• Confirm voltage specifications before wiring communications lines, power

supplies, and I/O circuits. Incorrect specification may result in malfunctions.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Make sure that the terminal blocks, connectors, expansion cables, communications cables, and other items with locking devices are properly

locked into place. Improper locking may result in malfunction.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Always use the power supply voltages specified in the operation manual.

An incorrect voltage may result in malfunction or burning.

Ω min.

xviii

Page 18

Application Precautions 5

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in unexpected operation.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

Memory Cassettes, Master Units, or any other Units.

• Removing or attaching terminal blocks to Remote I/O Terminals.

•Assembling Racks.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• After replacing Units, resume operation only after transferring to the new

CPU Unit and/or Special I/O Units the contents of the DM Area, HR Area,

and other data required for resuming operation. Not doing so may result in

unexpected operation.

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impact during transportation.

xix

Page 19

Conformance to EC Directives 6

• Use only the specified communications cables.

• Do not extend connection distances beyond the ranges given in the specifications.

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables past their natural bending radius.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Always lay communications cable inside ducts.

Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices are designed so that they comply with the related EMC

Directives so that they can be more easily built into other devices or the overall machine. The actual products have been checked for conformity to EMC

Directives (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the

customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61000-6-2

EMI (Electromagnetic Interference): EN 61000-6-4

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for EN 61131-2.

(Radiated emission: 10-m regulations)

xx

Page 20

Conformance to Shipbuilding Standards 7

6-3 Conformance to EC Directives

The CompoNet Master Units comply with EC Directives. To ensure that the

machine or device in which a CompoNet Master Unit is used complies with

EC Directives, the CompoNet Master Unit must be installed as follows:

1,2,3... 1. The CompoNet Master Unit must be installed within a control panel.

2. You must use reinforced insulation or double insulation for the DC power

supplies used for the communications power supply and I/O power supplies.

3. CompoNet Master Units complying with EC Directives also comply with the

Common Emission Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the

control panel used, other devices connected to the control panel, wiring,

and other conditions. You must therefore confirm that the overall machine

or equipment complies with EC Directives.

7 Conformance to Shipbuilding Standards

The CS1W-CRM21 and CJ1W-CRM21 Master Units conform to shipbuilding

standards. Applicability of the shipbuilding standards is based on certain

usage conditions. It may not be possible to use a Master Unit in some locations. Contact your OMRON representative before attempting to use a Master

Unit on a ship.

7-1 Applicable Shipping Standards

The Master Units conform to the following standards: LR and DNV.

7-2 Installation Location

• The Master Unit cannot be installed on the bridge or on a deck.

• Install the Master Unit where there is not excessive vibration. Do not

install it in the engine room or any other location with excessive vibration.

7-3 Conditions for Use Under Shipping Standards

• The Master Unit must be installed in a control panel.

• The following DC Power Supply must be used to supply power for communications.

DC Power Supply

Manufacturer OMRON

Model S82J Series

The DC Power Supply must provide the following specifications.

Item Specification

Output voltage 24 VDC

Output current The capacity of the Power Supply must be equal to or greater

than the total of the current consumptions of the following

Units:

All Slaves, Repeater Units, and SmartSlice Units

xxi

Page 21

Conformance to Shipbuilding Standards 7

xxii

Page 22

This section provides an overview of CompoNet networks.

1-1 CompoNet Networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Overall System Configuration and Elements . . . . . . . . . . . . . . . . . . 2

1-1-3 System Configuration Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-4 Features of CompoNet Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2 CompoNet Network Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-1 Cable Types, Maximum Distances, and Number of Slave Units . . . 9

1-2-2 Branch Line Support for Cable Types and Baud Rates . . . . . . . . . . 11

1-2-3 Allocating Slave Units in the CPU Unit Memory Area by

Communications Mode Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-3 Devices in a CompoNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-3-1 Master Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-3-2 Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-3-3 Selecting Peripheral Devices Used According to Connection

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-4 Overview of Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-5 Overview of Operating Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-6 Design and Operating Procedure Examples . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-6-1 Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-6-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SECTION 1

Overview

1

Page 23

CompoNet Networks Section 1-1

1-1 CompoNet Networks

1-1-1 Overview

CompoNet Networks feature easy operation and installation in a componentlevel network connecting PLCs and on-site I/O.

The PLC and CompoNet Slave Units cyclically exchange I/O information

through a CompoNet Master Unit, refreshing I/O in sync with the PLC scan.

Message communications can also be used from host computers or the CPU

Unit of the PLC to read and write CompoNet Slave Unit data.

1-1-2 Overall System Configuration and Elements

A CompoNet Network is a remote I/O system that consists of the following

elements.

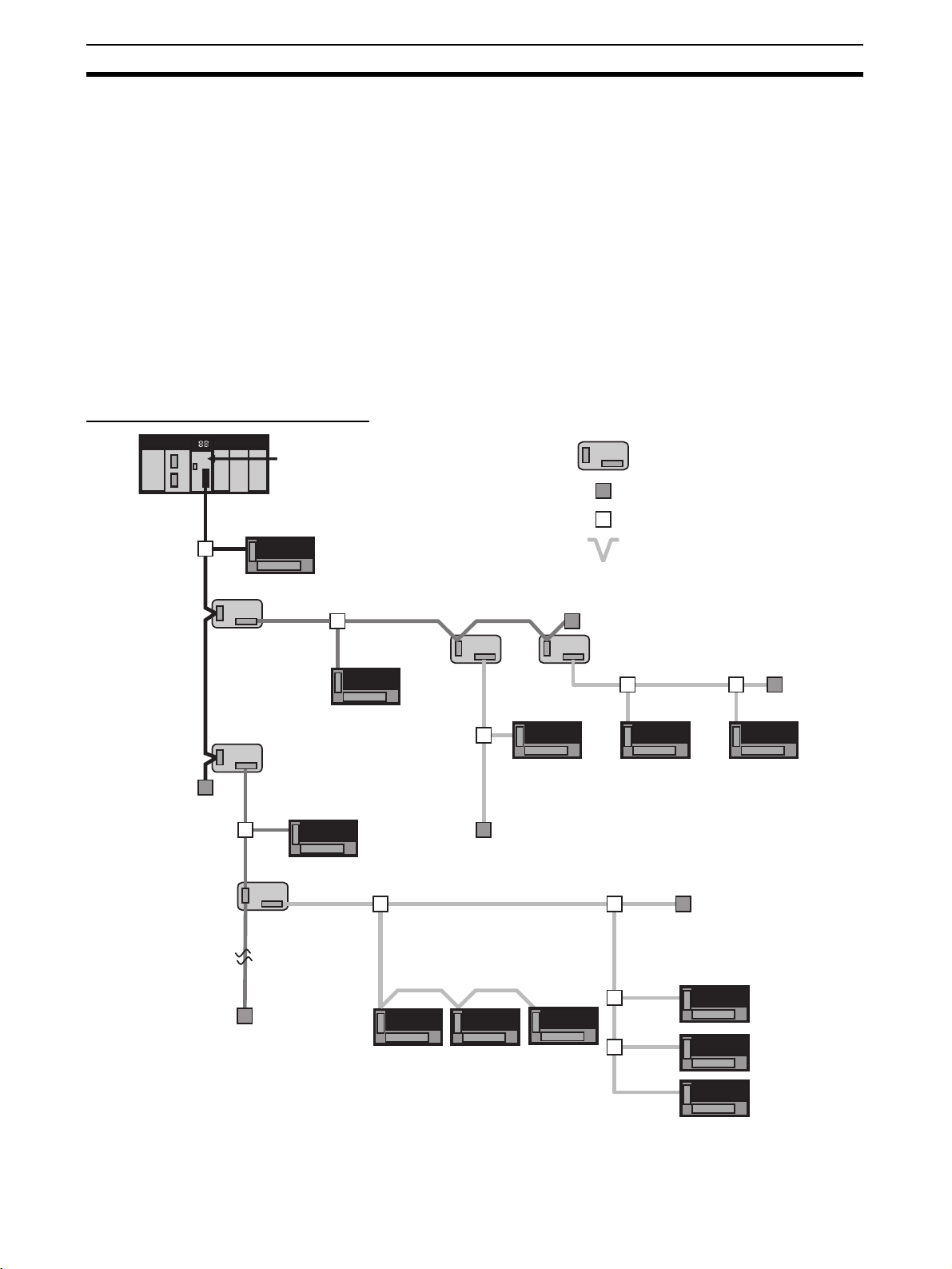

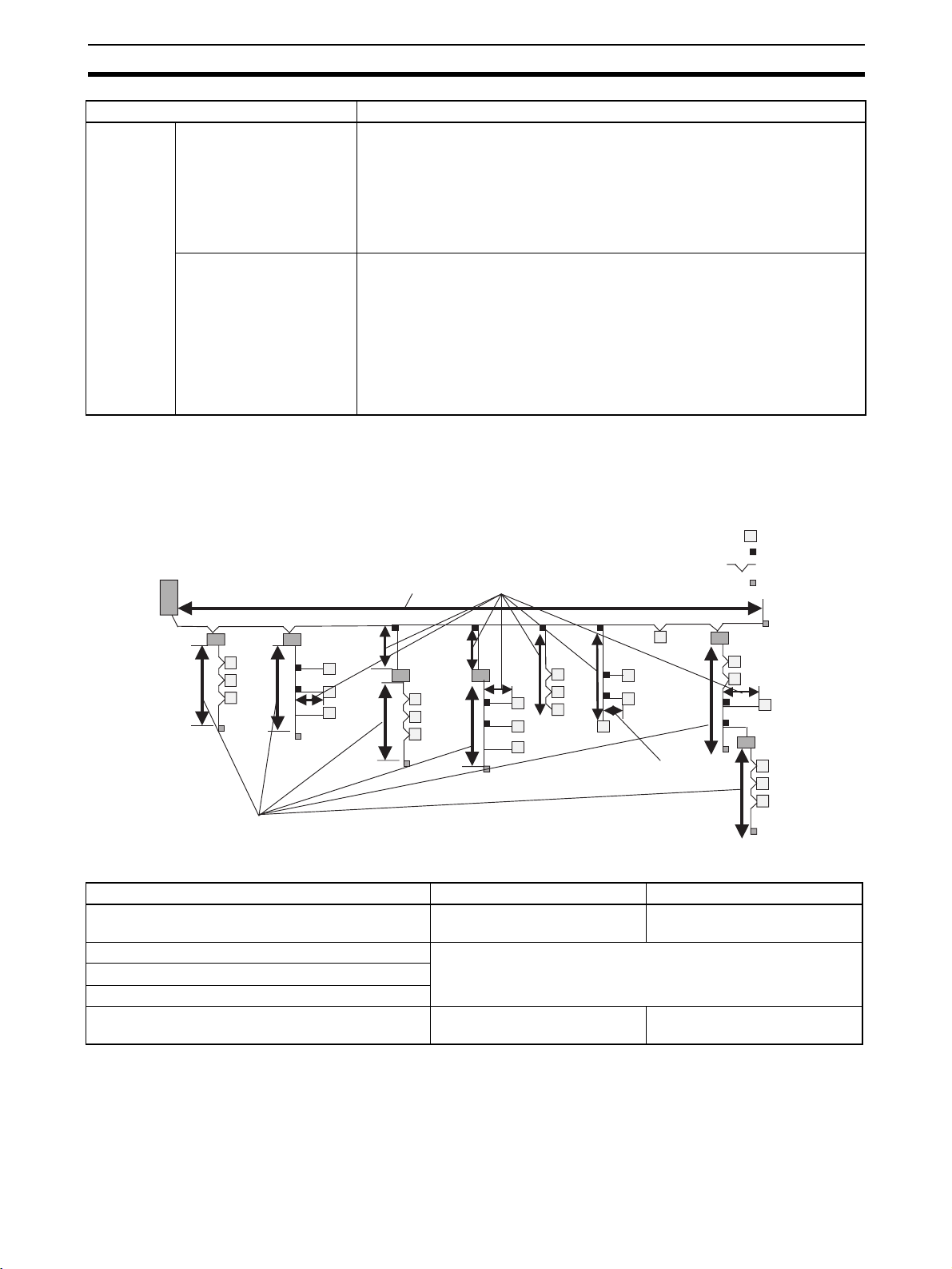

System Configuration Example

Trunk line

Terminating

Resistor

Sub-trunk

line

CompoNet Master Unit

Branch

line

Repeater Unit

Repeater

Unit

Branch

line

Repeater

Unit

Slave Unit

Sub-trunk line

Branch line

Slave Unit

: Repeater Unit

: Terminating Resistor

: T-branch

: Multidrop

Terminating

Resistor

Repeater Unit

Repeater

Unit

Sub-trunk

line

Terminating

Resistor

Sub-trunk line

Branch line Branch line

Sub-trunk line

Branch line Branch line

Terminating

Resistor

Terminating

Resistor

Sub-branch

lines

Terminating

Resistor

Multidrop connection on branch line

2

Page 24

CompoNet Networks Section 1-1

Communications Cables CompoNet Networks use Round Cable I, Round Cable II, Flat Cable I (DCA4-

4F10 Standard Flat Cable), and Flat Cable II (DCA5-4F10 Sheathed Flat

Cable) for Communications Cables.

Master Unit The Master Unit manages the CompoNet Network and transfers I/O data

between the PLC and the Slave Units.

There is only one Master Unit per network. The Master Unit must be connected to the end of the trunk line.

Slave Units Some Slave Units receive output data from the Master Unit across the Com-

poNet Network and output it. Other Slave Units send data that has been input

across the network to the Master Unit. There are two types of Slave Unit

according to the I/O capacity of the Slave Unit.

• Word Slave Units: A Word Slave Unit is allocated 16 bits (i.e., 16 I/O

points) in the I/O memory of the CPU Unit.

• Bit Slave Units: A Bit Slave Unit is allocated 2 bits (i.e., 2 I/O points) in the

I/O memory of the CPU Unit.

Repeater Unit Using Repeater Units enables expanding network connections as follows:

• Extending the Communications Cable

• Increasing the number of nodes (Units)

• Creating long-distance T-branches from the trunk line and sub-trunk lines

(See note.)

• Converting between different types of cable (round cable I, round cable II,

Flat Cable I, and Flat Cable II)

A sub-trunk line downstream from a Repeater Unit can be connected with the

same communications specifications (i.e., distances and number of Slave

Units) as the trunk line.

Up to 64 Repeater Units can be connected per network (i.e., per Master Unit).

When Repeater Units are connected in series from the Master Unit, up to two

layers can be created.

Note The physical layer is not connected across a Repeater Unit. The

connection is thus different from a branch connection, which

branches the same physical layer.

Terminating Resistors With a CompoNet Network, the Master Unit is located at one end of the trunk

line and a Terminating Resistor is connected to the other end of the trunk line.

If Repeater Units are used, each Repeater Unit is treated like a Master Unit,

i.e., Terminating Resistor is connected to the most remote end of the subtrunk line downstream from the Repeater Unit.

Note A Terminating Resistor reduces signal bouncing to stabilize com-

munications and must always be connected to the most remote end

of the network lines below the Master Unit and each Repeater Unit.

Always connect a Terminating Resistor to ensure the quality of the

transmission path.

Trunk Lines and Branch

Lines

The trunk lines and branch lines in a CompoNet Network are defined as follows:

• Trunk line: The transmission path between the Master Unit and the Terminating Resistor.

• Sub-trunk line: The transmission path between the Repeater Unit and the

Terminating Resistor (when a Repeater Unit is used)

• Branch line: The transmission path created using a T-branch from the

trunk line or sub-trunk line.

3

Page 25

CompoNet Networks Section 1-1

• Sub-branch line: The transmission path created using a T-branch from a

branch line. (T-branching is not possible from sub-branch lines.)

Note Due to differences in functionality, the same type of cable must be

used between the trunk line and a branch line, a sub-trunk line and

a branch line, and a branch line and a sub-branch line. Different

types of cable can be used between the trunk line and a sub-trunk

line.

Branches There are two ways to create branch lines.

1) T-branch Connections

• T-branch connections using Flat Connectors (when Flat Cable I or Flat

Cable II is used)

• T-branch connections using commercially available relay terminals (when

round cable I or round cable II is used)

2) Multidrop Connections

• Multidrop connections using Flat Connectors and Multidrop Connectors

(when Flat Cable I or Flat Cable II is used)

• Multidrop connections using Open Type Connectors (when round cable I

or round cable II is used)

Note Flat Connectors can also be used to extend the Communications

Cable.

Communications Power

Supply

This is the power supply for communications and internal operations for each

Unit.

A commercially available 24-VDC power supply is used for communications

and internal operations in each Unit.

One communications power supply can be connected for a trunk line or a subtrunk line. Communications power is supplied to the trunk line from the Master

Unit and to a sub-trunk line from the Repeater Unit.

One power supply cannot be used to supply communications power to more

than one line (i.e., to the trunk line and sub-trunk line or to two sub-trunk

lines).

I/O Power Supply A commercially available 24-VDC power supply is used to power the I/O oper-

ations of the external I/O device connected to a Unit. It is connected to the I/O

power supply terminal of the Unit.

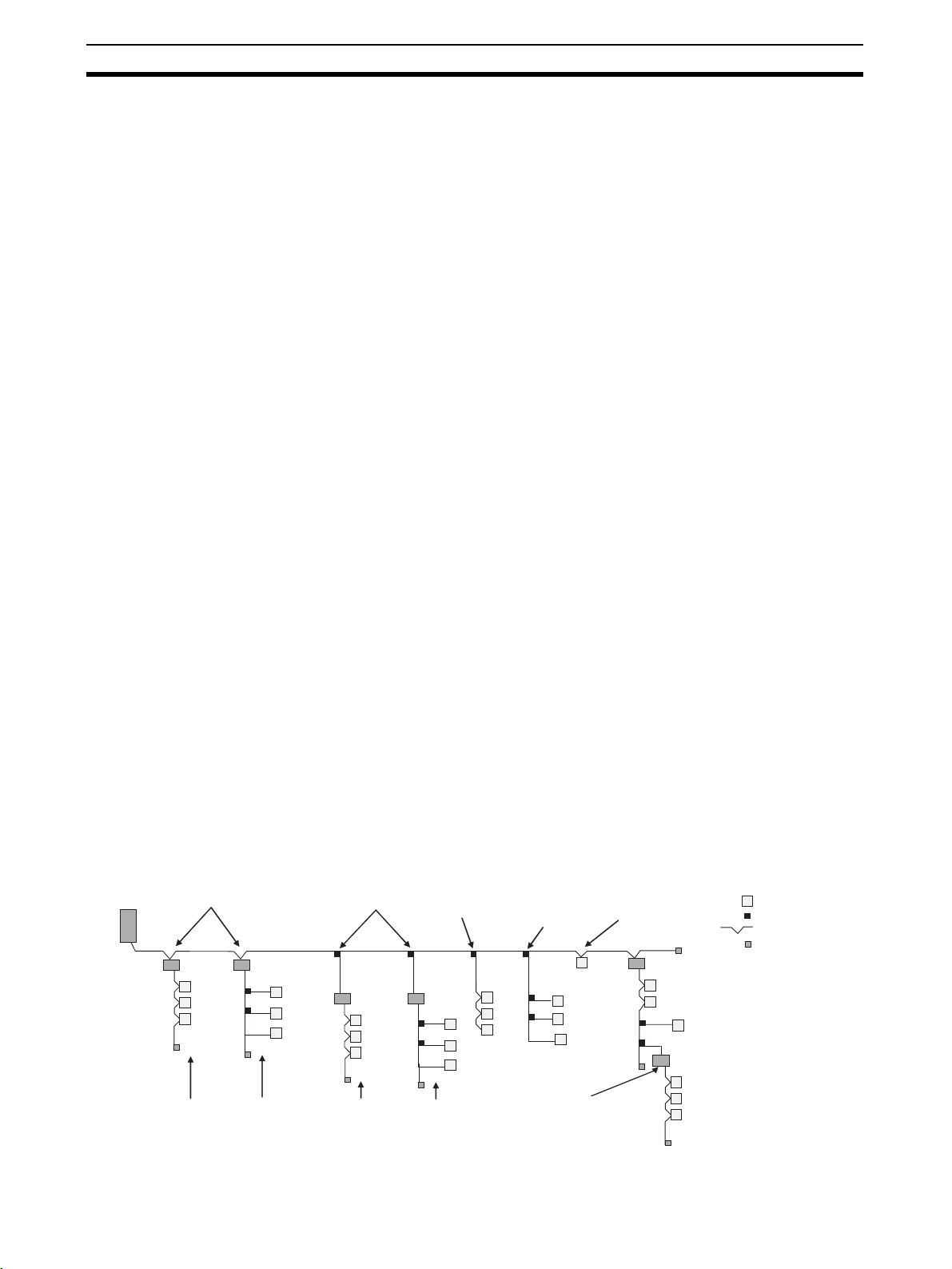

1-1-3 System Configuration Patterns

Repeater Units connected

with multidrop connections

Master

Unit

Repeater

Unit

Sub-trunk

line

Slave Units connected

with multidrop

connections

Sub-trunk

line

Slave Units

Tr unk line

Repeater

Unit

Branch line

Slave Units

Slave Units

connected with Tbranch

connections

Repeater Units connected

with T-branch connections

Branch line Branch line Branch line

Repeater

Unit

Sub-trunk

line

Sub-trunk

line

Slave Units

Slave Units

connected with

multidrop

connections

Slave Units connected

with T-branch and then

multidrop connections

Repeater

Unit

Branch line

Slave Units

Slave Units

Slave Units connected

with T-branch

connections

Slave Units connected

with T-branch and

then T-branch

connections

Slave Units

Slave

Unit

Sub-trunk

line

Branch line

Sub-branch line

Repeater Unit

connected to

create second

segment layer

Slave Units

connected with

multidrop

connections

Ter minating

Resistor

Repeater Unit

Branch line

Branch line

Sub-trunk

line

Repeater Unit

Slave Units

: Slave Unit

: T-branch

: Multidrop

: Terminating Resistor

4

Page 26

CompoNet Networks Section 1-1

1-1-4 Features of CompoNet Networks

Programless

Communications

High-speed Multi-point

Processing

Repeater Units for Greater

Flexibility

With the use of only Round Cable I, Round Cable II, Flat Cable I and Flat

Cable II cables, cyclic data exchange or remote I/O communications can be

achieved between a Master Unit mounted in a PLC and multiple Slave Units.

Remote I/O communications for up to 2,560 I/O points can be achieved at

approximately 1,000 points per millisecond (at 4 Mbps, see note). This

enables configuring CompoNet Network systems to replace systems previously configured with Basic I/O Units.

Note Branch lines cannot be used at 4 Mbps. Slave Units with Cables

(i.e., Bit Slave Units) can thus not be used.

Easy Introduction

Remote I/O communications can be started merely by connecting the Master

Unit and Slave Units with communications cables, setting the switches on the

Master Unit, and turning ON the power to the Slave Units and PLC.

Repeater Units can be used in a network to enable the following network

expansions.

• Extending the cable length

• Increasing the number of nodes

• Branching from the trunk line

• Changing the type of cable

Repeater Units can be used to extend up to two segment layers (called subtrunk lines) from the trunk line. Up to 64 Repeater Units can be connected per

Master Unit and up to 32 Repeater Units can be connected to the trunk line.

Note Communications power is supplied to a sub-trunk line from the Re-

peater Unit.

Bit-level Distribution Slave Units with industry-standard e-CON connectors or clamping terminal

blocks can be used to distribute I/O at the bit level. This enables distributed

control in distributed devices, such as sensors and other devices located over

a wide area on conveyors or in warehouses.

Bit Slave Units are available in two types: IP20 and IP54.

Five Communications

Modes According to

Number of Nodes, I/O

Points, and Allocated

Memory

Data Exchange with

Message Communications

Easy Maintenance with

Complete System

Monitoring Functions

There are five communications modes that can be used according to number

of Slave Units, the number of I/O points, and the location of allocated memory.

Memory can be allocated to Slave Units in the Special I/O Unit portion of the

CIO Area or, if the CX-Integrator software settings are used, in any part of the

CIO, DM, Work, and Holding Areas.

This enables efficient application of memory according to the size of the system.

Message communications can be used from the CX-Integrator running on a

host computer or from the CPU Unit of the PLC to access Slave Units and

Repeater Units on the CompoNet Network. This enables easily improving network and system maintenance.

The CompoNet Network is constantly monitored to enable confirming system

safety by quickly isolating errors and checking communications status.

■ CX-Integrator

The CX-Integrator provides the following network functionality.

• Uploading the network configuration

• Editing and transferring software setting tables

5

Page 27

CompoNet Networks Section 1-1

• Editing and transferring registration tables

• Setting Input Data Zero Clear Mode for when communications error occur

• Setting I/O Communications Manual Startup Mode

• Monitoring Master Unit status

• Monitoring the Master Unit error history

• Monitoring Slave Unit network participation status

• Setting and transferring Slave Unit parameters

• Monitoring Slave Unit information

• Managing files

• Managing hardware (EDS files)

■ Smart Slave Unit Functions

The Slave Units provide Smart Functions that can record various added-value

information in addition to the ON/OFF signals (I/O data). This enables preventive system maintenance (including operation time monitoring and contact

operation counter monitoring) and aids in faster system introduction (including

communications power voltage monitoring and I/O power status monitoring).

Settings are possible from either the CX-Integrator or through message communications.

■ Master Unit Detection of Network Participation, Errors, and Status

When a Slave Unit joins the network, a bit corresponding to the node address

called a Participation Flag will turn ON. If a Slave Unit that has been participating in the network leaves the network, a bit corresponding to the node

address called an Error Flag will turn ON.

Network status, such as communications errors and redundant Slave Unit

node address, and Slave Unit diagnostic results are detected by the Master

Unit and display on the seven-segment display on the front panel and

reflected in the Status Flags.

■ Registration Tables

Tables of the Slave Unit that should be participating at each node (i.e., the

node address and corresponding Slave Unit model number) can be registered

from the CX-Integrator to verify the Slave Units actually participating in the

network and prevent unregistered Slave Units from participating in the network. A monitoring time for registered Slave Unit participation after power is

turned ON can also be set.

Remote I/O communications can be stopped until all registered Slave Units

are participating and remote I/O communications can be started as soon as

all registered Slave Units are participating (called Registered Slave Unit Participation Standby Mode).

■ Stopping Communications at Communications Errors

A DIP switch on the front of the Master Unit can be set to stop remote I/O

communications when a communications error has occurred in any of the

Slave Units.

■ I/O Communications Manual Startup Mode

I/O Communications Manual Startup Mode can be set from the CX-Integrator

so that remote I/O communications are not started when the power is turned

ON. Remote I/O communications will not start until the Remote I/O Communications Start Switch is turned ON in memory.

6

Page 28

CompoNet Network Specifications Section 1-2

■ Communications Error Input Data Zero Clear Mode

Input Data Zero Clear Mode can be set from the CX-Integrator for communications error. If a communications error occurs for a Slave Unit in this mode,

all input data for that Slave Unit will be cleared to zeros. This can be used to

suppress triggering operations when communications errors have occurred in

systems where ON input data signals are used as triggers for operation.

■ Communications Status on Master Unit Seven-segment Display

The seven-segment display on the front of the Master Unit can be used to

check communications status.

The baud rate is normally displayed, but if an error occurs, the error code is

displayed in hexadecimal and the error node address is displayed in decimal.

Automatic Baud Rate

Detection

The Slave Units will automatically detect and use the baud rate set on the DIP

switch on the Master Unit. Setting the baud rate is not necessary for any of the

Slave Units.

1-2 CompoNet Network Specifications

Item Specifications

Communications method CompoNet protocol

Types of communications Remote I/O communications (programless, constant sharing of data with Slave

Baud rate 4 Mbps (See note)., 3 Mbps, 1.5 Mbps, 93.75 kbps

Modulation Base-band

Coding Manchester code

Error control Manchester code rules, CRC

Communications media The following cables can be used.

Communications distance and wiring Refer to 1-2-1 Cable Types, Maximum Distances, and Number of Slave Units.

Connectable Master Units CompoNet Master Units

Connectable Slave Units CompoNet Slave Units

Maximum I/O capacity Word Slave Units: 1,024 inputs and 1,024 outputs (2,048 I/O points total)

Maximum number of nodes Word Slave Units: 64 input nodes and 64 output nodes

Bits allocated per node address Word Slave Units: 16 bits

Maximum number of nodes per trunk line

or sub-trunk line

Applicable node addresses Word Slave Units: IN0 to IN63 and OUT0 to OUT63

Units) and message communications (explicit message communications as

required with Slave Units and FINS message communications as required with

PLCs)

Note A baud rate of 4 Mbps is not supported for branch lines and thus cannot

be used for Slave Units with Cables (i.e., Bit Slave Units).

• Round Cable I (VCTF 2-conductor cable, JIS C3306)

• Round Cable II (VCTF 4-conductor cable, JIS C3306)

• Flat Cable I (DCA4-4F10 Standard Flat Cable)

• Flat Cable II (DCA5-4F10 Sheathed Flat Cable)

Note Round Cable I, Round Cable II, Flat Cable I, and Flat Cable II cables are

all treated as different types of cables. When two or more type of cables

are used in a single network, a Repeater Unit must be used to separate

any two different types of cables between the trunk line and a sub-trunk

line.

Bit Slave Units: 256 inputs and 256 outputs (512 I/O points total)

Bit Slave Units: 128 input nodes and 128 output nodes

Bit Slave Units: 2 bits

32 nodes including Repeater Units

Bit Slave Units: BIT IN0 to BIT IN127 and BIT OUT0 to OUT127

Repeater Units: 0 to 63

7

Page 29

CompoNet Network Specifications Section 1-2

Item Specifications

Repeater Unit application conditions Up to 64 Repeater Units can be connected per network (i.e., per Master Unit).

Signal lines Two lines: BDH (communications data high) and BDL (communications data

Power lines Two lines: BS+ and BS- (power for communications and internal Slave Unit cir-

Communications power supply voltage 24 VDC ±10%

Connection forms Round Cable II, Flat Cable I, or Flat Cable II cables at a baud rate of 93.75

Remote I/O communications Automatic startup when power is turned ON (see note) or manual startup using

I/O Communications Manual Startup

Mode

Communications Error Communications

Stop Mode

Communications Error Input Data Zero

Clear Mode

Duplicated Slave Unit address check If the same address is set for two different Slave Units or the same memory is

Registration Tables The Slave Units that can participate for each node address are registered in a

Up to 32 Repeater Units can be connected per trunk line or per sub-trunk line.

When Repeater Units are connected in series from the Master Unit, up to two

extra segment layers can be created (i.e., up to 2 Repeater Units are allowed

between a Slave Unit and the Master Unit).

low)

cuits)

• Power is supplied from the Master Unit and Repeater Units.

kbps: No restrictions

Other cables or other baud rates: Trunk line and branch lines

Connections for Slave Units and Repeater Units: T-branch or multidrop connections

the Remote I/O Communications Start Switch in I/O Communications Manual

Start Mode

Note When power is turned ON to the PLC and the Slave Unit communica-

tions power is turned ON. Communications are not started in the following cases:

• In Registered Slave Unit Participation Standby Mode, communications is not

started until all registered Slave Units are participating in the network.

• In Communications Error Communications Stop Mode, communications stop

when a communications error occurs.

I/O Communications Manual Startup Mode can be set from the CX-Integrator

so that remote I/O communications are not started when the power is turned

ON. Remote I/O communications will not start until the Remote I/O Communications Start Switch is turned ON in memory.

All remote I/O communications are stopped if a communications error occurs in

any Slave Unit.

Note Communications will not stop for verification errors for registration tables

or duplicated address settings.

All input data will be cleared to zeros in any Slave Unit in which a communications error occurs.

allocated to two different nodes, the Slave Unit that joins communications last

will cause a duplicated address error and will leave the network. The Duplicated Address Error Flag will turn ON.

Note This error will also occur if a Slave Unit leaves the network and then a

different type of Slave Unit joins the network.

table so that only the registered Slave Units can participate. If a different Slave

Unit attempts to join the network, the Registration Table Verification Error Flag

will turn ON. The Registration Table is generated automatically or manually

edited from the CX-Integrator.

8

Page 30

CompoNet Network Specifications Section 1-2

g

Item Specifications

Slave Unit

status

Without Registration Table Participation Flag and Communications Error Flag for each Slave Unit

• Participation Flag: Turns ON and remains ON if the Slave Unit joins the network even one time after system power is turned ON.

• Communications Error Flag: Turns ON if the Slave Unit cannot communicate

with the Master Unit for any reason after the Slave Unit has joined the network

(i.e., if the Participation Flag is ON). (Turns OFF when the error is removed.)

Duplicated Address Error Flags and Alarm Flags

With Registration Table • Participation Flags and Communications Error Flags for each node address

for all Slave Units registered in the Registration Table

• Registration Table Verification Error Flags

• All Registered Slave Units Participating Flag

Note The Registered Slave Unit Participation Monitoring Time can be set (ver-

ification error check timing).

Registered Slave Unit Participation Standby Mode can be set. (Remote

I/O communications will not start until all registered Slave Units are participating.)

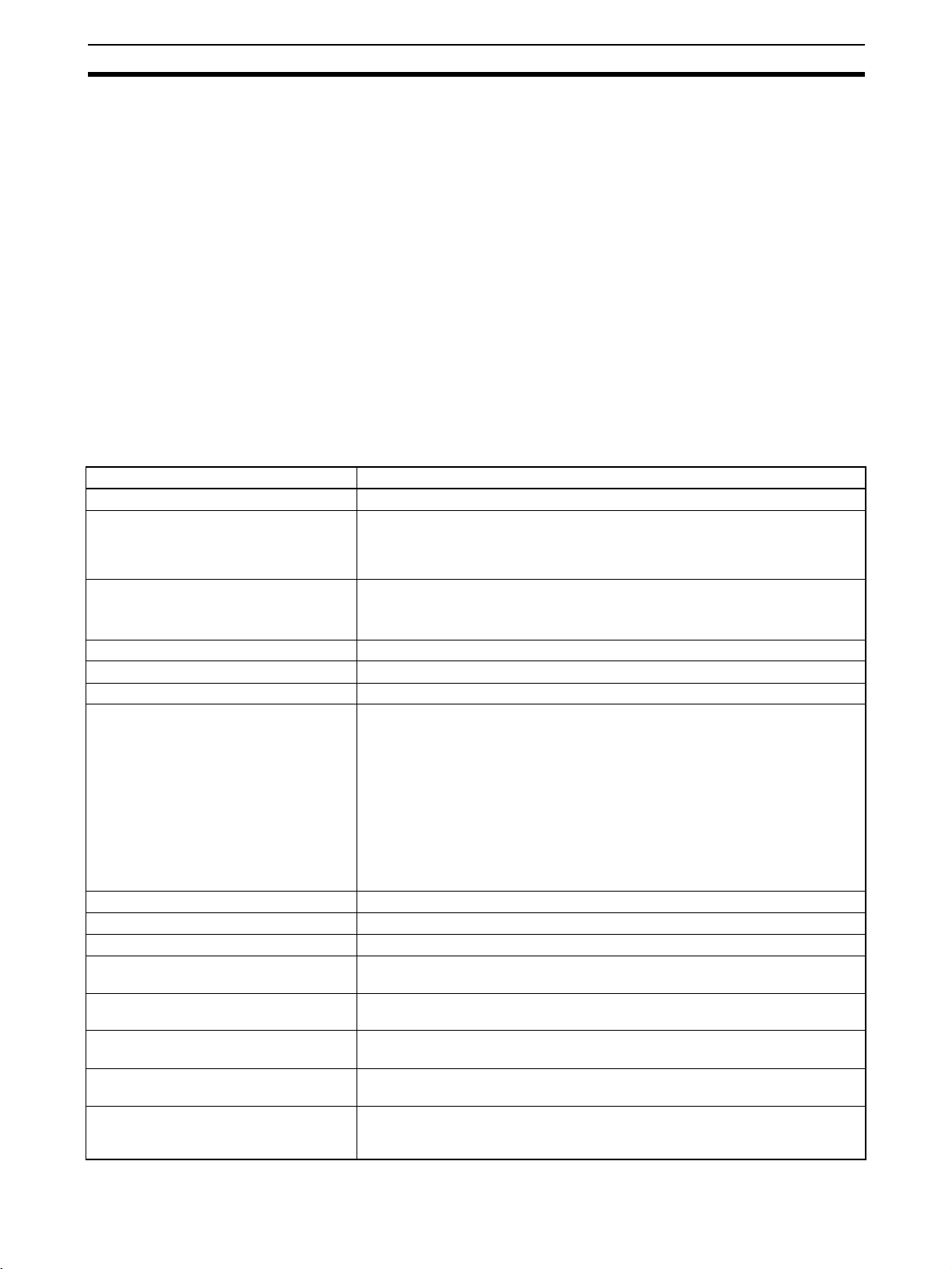

1-2-1 Cable Types, Maximum Distances, and Number of Slave Units

This section provides specifications on the maximum cable length and the

maximum number of connectable Slave Units for each type of cable. The

cables and Units must be used within the specifications.

: Slave Unit

: T-branch

: Multi-drop

Master Unit

Trunk line length

Branch line length

: Terminating Resistor

Sub-trunk

line length

Repeater

Unit

Subtrunk

line

length

Slave Units

Sub-trunk

line len

th

Trunk line

Repeater Unit

Branch line

Subtrunk

line

length

Branch line

Repeater

Unit

Sub-trunk

line length

Branch

line

Repeater

Unit

Branch

lines

Branch

line

Branch

line

Sub-branch

line

Sub-branch

line length

Slave

Unit

Sub-trunk

line length

Sub-trunk

line length

Terminating Resistor

Repeater Unit

Branch

line length

Branch

lines

Repeater Unit

Slave Units

■ Baud Rate of 4 Mbps (No branching allowed. See note.)

Item Round Cable I or II Flat Cable I or II

Length per trunk line or sub-trunk line (maximum

30 m (90 m) 30 m (90 m)

length with two Repeater Units)

Branch line length Lines cannot be branched from the trunk line. (Only multidrop con-

Total branch line length

nections are possible from the trunk line or subtrunk lines.)

Restrictions on branch line locations

Number of Slave Units (including Repeater Units)

32 32

per trunk line or sub-trunk line

Note Bit Slave Units come with Flat Cables and cannot be connected. The network

must consist of only Word Slave Units (use DCN4-MD4 Multidrop Connectors

for the Flat Cable I or Flat Cable II cables) and multidrop connections must be

used.

9

Page 31

CompoNet Network Specifications Section 1-2

■ Baud Rate of 3 Mbps

Item Round Cable I or II Flat Cable I or II

Length per trunk line or sub-trunk line (maximum

length with two Repeater Units)

Branch line length 0.5 m 0.5 m

Total branch line length 8 m 8 m

Restrictions on branch line locations 3 branches / m 3 branches / m

Number of Units per branch (See note.) 1 1

Maximum sub-branch line length Not supported Not supported

Total sub-branch line length Not supported Not supported

Number of Slave Units (including Repeater Units)

per trunk line or sub-trunk line

Note The maximum number of nodes per branch is the maximum number of Slave

Units or Repeater Units that can be connected to one branch line using multidrop or T-branch connections.

■ Baud Rate of 1.5 Mbps

Item Round Cable I Round Cable II, Flat

Length per trunk line or sub-trunk line (maximum

length with two Repeater Units)

Branch line length Not supported (See

Total branch line length Not supported (See

Restrictions on branch line locations --- 3 branches / m 3 branches / m

Number of Units per branch (See note 1.) 3 3

Maximum sub-branch line length Not supported 0.1 m (See note 3.)

Total sub-branch line length Not supported 2 m (See note 3.)

Number of Slave Units (including Repeater Units)

per trunk line or sub-trunk line

30 m (90 m) 30 m (90 m)

32 32

Without branch

lines

100 m (300 m) 30 m (90 m) 30 m (90 m)

note 2.)

note 2.)

32 32 32

With branch lines

2.5 m 2.5 m

25 m 25 m

Cable I, or Flat

Cable II

10

Note (1) This is the maximum number of Slave Units and Repeater Units com-

bined that can be connected to a branch line by using multidrop connections and/or T-branching. T-branching creates a sub-branch.

(2) The trunk line does not support branching. The trunk line and sub-trunk

lines support only multidrop connections.

(3) Branch lines support branching to sub-branch lines.

Page 32

CompoNet Network Specifications Section 1-2

■ Baud Rate of 93.75 kbps

Item Round Cable I or II Flat Cable I or II

Length per trunk line or sub-trunk line(maximum

length with two Repeater Units)

Branch line length 6 m

Total branch line length 120 m

Restrictions on branch line locations 3 branches / m

Number of Units per branch (See note.) 1

Maximum sub-branch line length ---

Total sub-branch line length ---

Number of Slave Units (including Repeater Units)

per trunk line or sub-trunk line

500 m (1500 m) Unrestricted wiring is enabled

for a total length of 200 m.

32 32

Note This is the maximum number of Slave Units and Repeater Units combined

that can be connected to a branch line by using multidrop connections and/or

T-branching. T-branching creates a sub-branch.

1-2-2 Branch Line Support for Cable Types and Baud Rates

Support for branch lines from the trunk line or sub-trunk lines and support for

sub-branch lines from branch lines is listed in the following tables.

■ Baud Rate of 4 Mbps (No Branch Lines)

Cable Branch lines Sub-branch lines

Round Cable I Not supported Not supported

Round Cable II, Flat Cable I, or Flat

Cable II

Not supported Not supported

Note A baud rate of 4 Mbit/s is not supported for branch lines and thus

cannot be used for Slave Units with Cables (i.e., Bit Slave Units).

The network must consist of only Word Slave Units and DCN4MD4 Multidrop Connectors must be used for Flat Cable I and Flat

Cable II cables.

■ Baud Rate of 3 Mbps

Cable Branch lines Sub-branch lines

Round Cable I Supported Not supported

Round Cable II, Flat Cable I, or Flat

Cable II

■ Baud Rate of 1.5 Mbps

Cable Branch lines Sub-branch lines

Round Cable I 100 m max. Not supported Not supported

30 m max. Supported

Round Cable II, Flat Cable I, or Flat

Cable II

Supported Not supported

Supported Supported

■ Baud Rate of 93.75 kbps

Cable Branch lines Sub-branch lines

Round Cable I Supported Not supported

Round Cable II, Flat Cable I, or

Flat Cable II

Supported (no restrictions)

11

Page 33

CompoNet Network Specifications Section 1-2

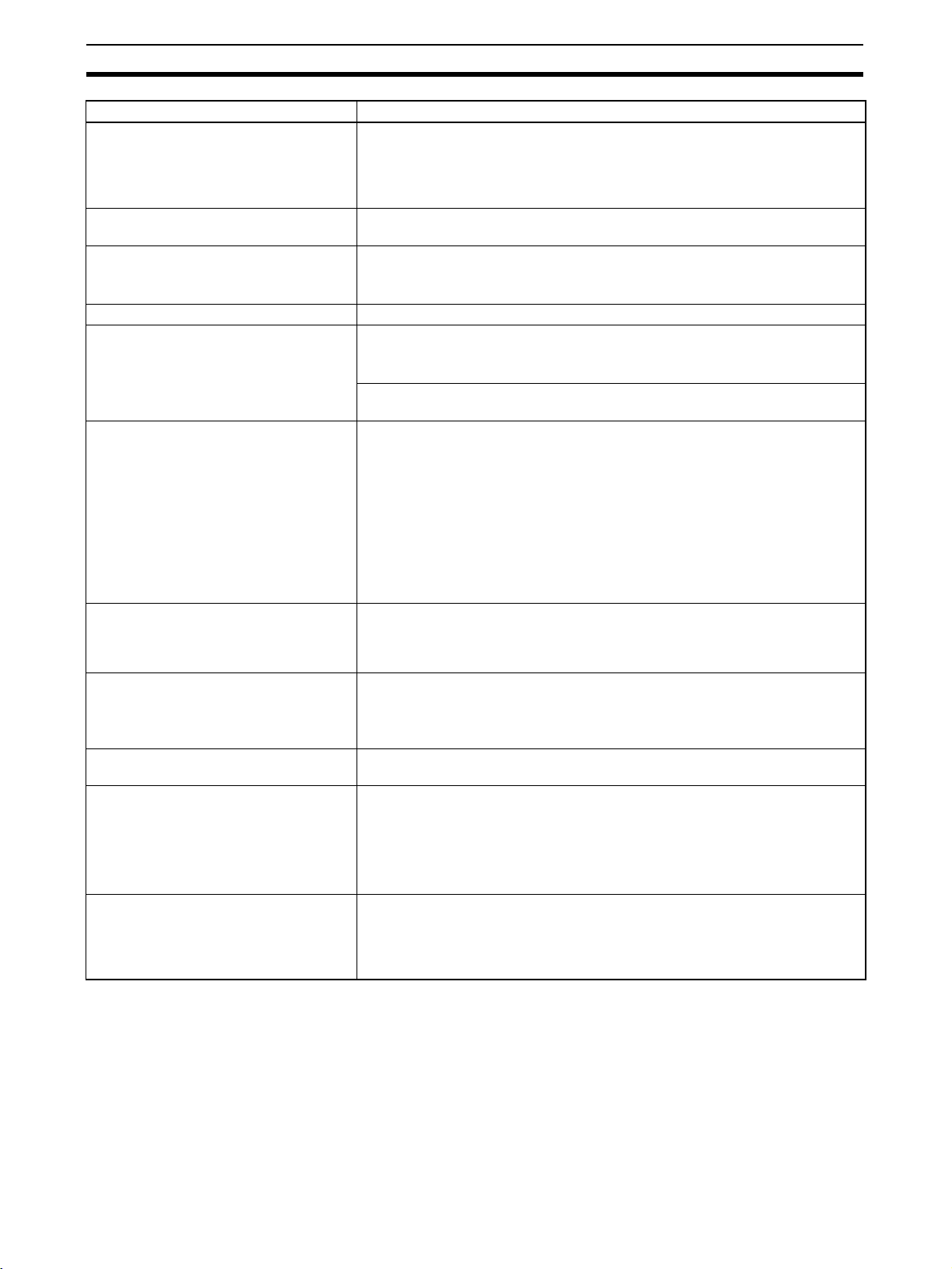

1-2-3 Allocating Slave Units in the CPU Unit Memory Area by

Communications Mode Number

Slave Unit I/O information and status information is allocated in the Special

I/O Unit memory area or a user-specified area of the CPU Unit to which the

Master Unit is mounted.

The area is determined by the unit number of the Master Unit as a Special I/O

Unit and by the communications mode number. The user specifies the communications mode number using the CX-Integrator. The bits used by Slave

Units are determined by the node address for each Slave Unit.

The relationship between communications mode numbers, the number of

connected nodes, and the number of points that can be controlled is

described next.

Number of Connected Nodes and Control Points Per Master Unit

Use the rotary switch on the front of the Master Unit to select the communications mode number.

Word: 64 nodes

Word: 32 nodes

1

Word: 16 nodes

0

9

Reserved

Software Setting Mode

Commu-

nications

mode

number

0 Mode 0 Word Slave Units: IN0 to

1 Mode 1 Word Slave Units: IN0 to

2 Mode 2 Word Slave Units: IN0 to

3 Mode 3 Word Slave Units: IN0 to

4 Reserved --- --- --- ---

5 Reserved --- --- --- ---

6 Reserved --- --- --- ---

7 Reserved --- --- --- ---

8 Software

9 Reserved --- --- --- ---

Mode

name

Setting

Mode

Connectable node

addresses

IN7 and OUT0 to OUT7

IN15 and OUT0 to OUT15

IN31 and OUT0 to OUT31

IN15 and OUT0 to OUT15

Bit Slave Units: IN0 to

IN63 and OUT0 to OUT63

Can be set within the following ranges:

Word Slave Units: IN0 to

IN63 and OUT0 to OUT63

Bit Slave Units: IN0 to

IN127 and OUT0 to

OUT127

128 inputs and 128 outputs (Word Slave Units)

256 inputs and 256 outputs (Word Slave Units)

512 inputs and 512 outputs (Word Slave Units)

256 inputs and 256 outputs (Word Slave Units)

128 inputs and 128 outputs (Word Slave Units)

Can be set within the following ranges:

Word Slave Units: 1,024

inputs and 1,024 outputs

Bit Slave Units: 256 inputs

and 256 outputs

Word: 32 nodes + Bit: 128 nodes

2 3

MODE

4

Reserved

5

6

7 8

Reserved

Control points Memory area

Special I/O Unit Area

(First word depends on

unit number of Master

Unit.)

Can be allocated anywhere in the CIO, DM,

WR, or HR Area.

Note Status and

parameters are

allocated in the

Special I/O Unit

Area.

Number of

unit numbers

used by each

Master Unit

2

4

8

8

1

12

Page 34

Devices in a CompoNet Network Section 1-3

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

Note (1) In a CompoNet Network, Word Slave Units have 16 bits per node ad-

dress. Bit Slave Units have two bits allocated per node address.

(2) Do not use the reserved communications mode numbers (4 to 7 and 9).

A communications mode setting error (H4 at the 7-segment LED indicator) will occur if any of these mode numbers is set.

1-3 Devices in a CompoNet Network

1-3-1 Master Units

CompoNet Master Units

Communications Cables

(Yes: Can be used. No: Cannot be

used.)

Round

Cable I

Ye s (S e e

note 1.)

Round

Cable II

Yes (See

note 1.)

Flat

Cable I

Ye s (S e e

note 2.)

Flat

Cable II

Ye s ( S ee

note 3.)

Name Model

CS-series

Master Unit

C

R

M

2

1

MS

+

1

0

0

NS

S

D

R

D

M

A

C

H

N

o

.

1

X

1

0

0

X

1

0

M

O

D

E

ON

1234

1

D

R

0

2

D

R

1

3

E

S

T

P

4

REGS

N

E

T

W

O

R

K

P

O

W

E

R

S

U

P

P

L

Y

B

S

+

B

S

-

D

C

2

4

V

I

N

P

U

T

B

S

+

B

D

H

B

D

L

B

-

S

CS1WCRM21

Unit

classifica-

tion

CS-series

Special I/O

Unit

Maximum number per CPU Unit

Communications

mode No.

8 (1 unit number

80

used)

0 (2 unit num-

48

bers used)

1 (4 unit num-

24

bers used)

2 or 3 (8 unit

12

numbers used)

CJ-series

Master Unit

C

R

M

2

1

+

1

M

0

0

S

N

S

SD

SW

RD

1234

O

N

MACH

3

No.

2

4

1

5

0

6

1

7

2

3

8

9

4

1

X

1

0

N

E

T

W

3

O

2

4

R

K

P

S

1

5

0

6

7

8

9

0

X

1

0

MODE

B

3

S

+

2

4

1

5

0

6

7

B

S

8

-

9

D

C

2

4

V

I

N

P

U

T

B

S

+

B

D

H

D

B

L

B

S

-

CJ1WCRM21

CJ-series

Special

Communications

mode No.

8 (1 unit number

CJ1-H/

CJ1 CPU

Units

CJ1M

CPU

Units

40 20

Ye s (S e e

note 1.)

Yes (See

note 1.)

Ye s (S e e

note 2.)

Ye s ( S ee

note 3.)

used)

0 (2 unit num-

40 20

bers used)

1 (4 unit num-

24 20

bers used)

2 or 3 (8 unit

12 12

numbers used)

Note (1) A DCN4-TB4 Open Type Connector is required to connect a Round Cable

I or Round Cable II cable to the Unit.

(2) A DCN4-TR4 Flat Connector Socket is required to connect a Flat Cable I

cable.

(3) A DCN5-TR4 Flat Connector Socket is required to connect a Flat Cable

II cable.

13

Page 35

Devices in a CompoNet Network Section 1-3

1-3-2 Peripheral Devices

Communications Cables

The following table shows the Communications Cables that can be used in a

CompoNet Network.

Name Model Specifications Remarks

Round Cable I --- JIS C 3306

Round Cable II

Flat Cable I DCA4-4F10 Standard 4-conductor flat cable (UL2555)

Nominal cross-sectional area: 0.75 mm

Finished conductor diameter: 2.3 mm

Length: 100 m

Conductor diameters:

0.75 mm2 × 2, 0.5 mm2 × 2

Cannot be used with Bit Slave

Units.

2

,

Approximately 50 cm of cable

comes connected to IP20 Bit

Slave Units.

Flat Cable II DCA5-4F10 Sheathed 4-conductor flat cable

Length: 100 m

Conductor diameters:

0.75 mm

2

× 2, 0.5 mm2 × 2

Approximately 50 cm of cable

comes connected to IP54 Bit

Slave Units.

Flat Connectors In a CompoNet Network, the connectors described below can be connected

to the Communications Cable to enable extending the cable length, branching

cables, and wiring to Slave Units.

Flat Connector Socket

■ Flat Cable I

Communications Cables

(Yes: Can be used.

Name Model Appearance Application

Flat Connector

Socket

DCN4-TR4 Use this Connector in a set with

a DCN4-BR4 Flat Connector

Plug for the following applications.

• Extending the trunk line or a

sub-trunk line

No: Cannot be used.)

Round

Cable I

Round

Cable II

Flat

Cable I

Flat

Cable II

14

No

• T-branching from the trunk line

or a sub-trunk line

• T-branching a sub-branch line

from a branch line

Ye s

(See

note.)

Ye s N o

Note The only case when the Socket is used with a Round Cable II is to connect

the Cable to a Terminating Resistor.

Page 36

Devices in a CompoNet Network Section 1-3

■ Flat Cable II

Communications Cables

(Yes: Can be used.

Name Model Appearance Application

Flat Connector

Socket

DCN5-TR4 Use this Connector in a set with

a DCN5-BR4 Flat Connector

Plug for the following applications.

• Extending the trunk line or a

sub-trunk line

• T-branching from the trunk line

or a sub-trunk line

• T-branching a sub-branch line

from a branch line

Note Use the Connector to

connect IP54 Bit Slave

Units.

Flat Connector Plug

■ Flat Cable I

Name Model Appearance Application

Flat Connector

Plug

DCN4-BR4 a. Use the Connector in a set

with a DCN4-TR4 Flat Connector Socket for the following applications.

• Extending the trunk line or a

sub-trunk line

• T-branching from the trunk line

or a sub-trunk line

• T-branching a sub-branch line

from a branch line

b. Use this Connector indepen-

dently for the following applications.

• Connecting Communications

Cable to a Master Unit, Word

Slave Unit, or Repeater Unit

• Connecting Communications

Cable to a Multi-wiring Connector

No: Cannot be used.)

Round

Cable I

No No No Yes

Round

Cable I

No No Yes No

Round

Cable II

Communications Cables

(Yes: Can be used.

No: Cannot be used.)

Round

Cable II

Flat

Cable I

Flat

Cable I

Cable II

Flat

Cable II

Flat

Note Although this product is called a Flat Connector Plug, it can be

used as a connector to connect a Master Unit, Slave Unit, or Repeater Unit.

15

Page 37

Devices in a CompoNet Network Section 1-3

■ Flat Cable II

Communications Cables

(Yes: Can be used.

Name Model Appearance Application

Flat Connector

Plug

DCN5-BR4 a. Use this Connector in a set

with a DCN5-TR4 Flat Connector Socket for the following

applications.

• Extending the trunk line or a

sub-trunk line

• T-branching from the trunk line

or a sub-trunk line

• T-branching a sub-branch line

from a branch line

b. Use this Connector indepen-

dently for the following applications.

• Connecting Communications

Cable to a Master Unit, Word

Slave Unit, or Repeater Unit

• Connecting Communications

Cable to connectors for wiring

Note Use for connecting IP54

Bit Slave Units.

No: Cannot be used.)

Round

Cable I

Round

Cable II

No No No Yes

Flat

Cable I

Flat

Cable II

Note Although this product is called a Flat Connector Plug, it can be

used as a connector to connect a Master Unit, Slave Unit, or Repeater Unit.

Multi-wiring Connector

Name Model Appearance Application

Multi-wiring Connector

DCN4-MD4 This Connector connects two

Flat Connector Plugs to two

ports.

Use Multi-wiring Connectors for

multi-drop wiring of Master

Units, Slave Units, or Repeater

Units to trunk lines, sub-trunk

lines, or branch lines.

Note When the baud rate is 4

Mbps (mainly when Flat

Cable is used), use this

Connector to connect to

Word Slave Units only.

Communications Cables

(Yes: Can be used.

No: Cannot be used.)

Round

Cable I

Round

Cable II

No No Yes No

Flat

Cable I

Flat

Cable II

16

Page 38

Devices in a CompoNet Network Section 1-3

Special Tools

Communications Cables

(Yes: Can be used.

Name Model Appearance Application

Special Tool (Pliers)

DWT-A01 A pressure welding tool for

DCN4-TR4 Flat Connector Socket and a DCN4BR4 Flat Connector Plug.

No: Cannot be used.)

Round

Cable I

No

Round

Cable II

Ye s

(See

note.)

Flat

Cable I

Ye s N o

Flat

Cable II

Special Tool (Pliers)

DWT-A02 A pressure welding tool for

DCN5-TR4 Flat Connector Socket and a DCN5BR4 Flat Connector Plug.

Note The only case when the Special Tool is used with a Round Cable II cable is to

connect the Cable to a Terminating Resistor.

Open Type Connector

Name Model Appearance Application

Open Type Connector

DCN4-TB4 Converts the communications

connector on a Unit to a screw

terminal block to enable connecting a Round Cable I or II

cable to a Slave Unit or

Repeater Unit.

Terminating Resistors

Name Model Appearance Application

Terminating

Resistor

DCN4-TM4 Connector-type Terminating

Resistor for a Round Cable II

or Flat Cable I cable. Connect

this Terminating Resistor to a

Flat Connector Socket (DCN4TR4) on the end of the trunk or

sub-trunk line.

DCN5-TM4 Connector-type Terminating

Resistor for a Flat Cable II