Cat. No. W309-E1-07

SYSMAC

CS1W-CLK21-V1

CJ1W-CLK21-V1

C200HW-CLK21

CVM1-CLK21

CQM1H-CLK21

(CS1W-RPT01/02/03 Repeater Units)

Controller Link Units

OPERATION MANUAL

CS1W-CLK21-V1

CJ1W-CLK21-V1

C200HW-CLK21

CVM1-CLK21

CQM1H-CLK21

(CS1W-RPT01/02/03 Repeater Units)

Controller Link Units

Operation Manual

Revised June 2003

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1997

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Applications Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Specifications and Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3 Selection of Communications Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-4 Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SECTION 2

Basic Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-1 Data Links Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-2 Message Service Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-1 Component Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-2 Unit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3-4 Constructing Networks with Repeater Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

SECTION 4

Preparations for Communications . . . . . . . . . . . . . . . . . . . . 83

4-1 CS-series Controller Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4-2 CJ-series Controller Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4-3 C200HX/HG/HE Controller Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4-4 CVM1 and CV-series Controller Link Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4-5 CQM1H-series Controller Link Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4-6 Repeater Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

vii

TABLE OF CONTENTS

SECTION 5

Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

5-1 What Are Data Links? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

5-2 Setting Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5-3 Starting and Stopping Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

5-4 Checking Data Link Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

SECTION 6

Message Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

6-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

6-2 Selecting Communications Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

6-3 Using the Message Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

6-4 FINS Commands and Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

6-5 Commands and Responses for Controller Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

6-6 Commands and Responses for C200HX/HG/HE and CQM1H-series PLCs . . . . . . . . . . . . 210

6-7 Response Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

SECTION 7

Network Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

7-1 What is Network Interconnection? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

7-2 Remote Programming and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

7-3 Routing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

7-4 Setting Routing Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

SECTION 8

Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

8-1 Communications Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

8-2 Communications Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

8-3 Data Link I/O Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

8-4 Message Delay Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

SECTION 9

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 271

9-1 Troubleshooting Using Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

9-2 Status Area and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

9-3 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

9-4 Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

9-5 Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

viii

TABLE OF CONTENTS

SECTION 10

Adding Nodes and Editing Active Data Link Tables . . . . . 323

10-1 Adding Nodes Using a Repeater Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

10-2 Changing the Data Link Tables with Active Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Appendices

A Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

B Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

C Using the Relay Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

ix

TABLE OF CONTENTS

x

About this Manual:

This manual describes the installation, setup, and operation of the C200HW-CLK21, CS1W-CLK21V1, CJ1W-CLK21-V1, CVM1-CLK21, and CQM1H-CLK21 Controller Link Units for C200HX/HG/HE,

CS/CJ-series, CVM1, CQM1H-series, and CV-series PLCs, and includes the sections described

below. The Controller Link Units are used to connect these PLCs to a Controller Link Network. Information is also provided in this manual on CS1W-RPT01/02/03 Repeater Units. The following three

manuals are directly related to application of the Controller Link Network.

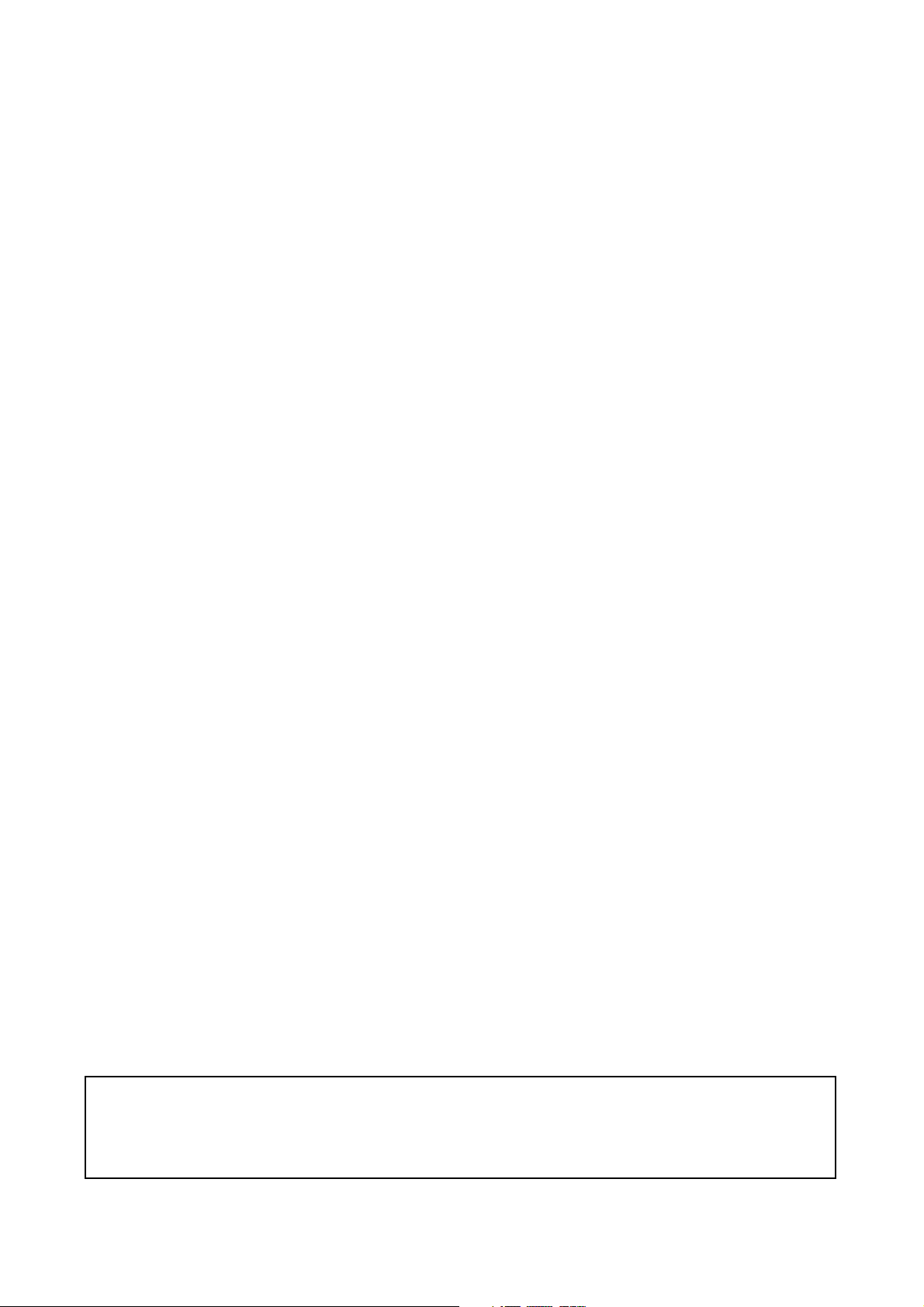

Name Contents Cat. No.

SYSMAC CS1W-CLK21, CJ1W-CLK21,

C200HW-CLK21, CVM1-CLK21.

CQM1H-CLK21 Controller Link Units

Operation Manual (this manual)

3G8F7-CLK12-E-V1/CLK52-E-V1/

CLK21-E-V1 Controller Link Support

Boards for PCI Bus

Operation Manual

3G8F7-CLK12-E/CLK52-E/CLK21-E Controller Link Support Boards for PCI Bus

Installation Guide

3G8F5-CLK11-E, 3G8F5-CLK21-E Controller Link Support Boards for ISA Bus

Operation Manual

CS1W-CLK12, CVM1-CLK12 Optical

Ring Controller Link Units

Operation Manual

C200HW-ZW3AT2-E-V2 Controller Link

Support Software

Operation Manual

Installation, setup, and operating procedures for the Controller Link Units. Controller Link Units are used to connect

PLCs to a Controller Link Network.

Operating procedures for Controller Link Support Boards

for PCI bus connections. Controller Link Support Boards

are used to connect IBM PC/ATs or compatibles to a Controller Link Network.

Installation and setup procedures for Controller Link Support Boards for PCI bus connections. Controller Link Support Boards are used to connect IBM PC/ATs or

compatibles to a Controller Link Network.

Installation, setup, and operating procedures for Controller

Link Support Boards for ISA bus connections. Controller

Link Support Boards are used to connect IBM PC/ATs or

compatibles to a Controller Link Network.

Installation, setup, and operating procedures for the Optical

Ring Controller Link Units. Controller Link Units are used to

connect C200HX/HG/HE CV-series, and CS1-series PLCs

to a Controller Link Network.

Installation and operating procedures for the Controller

Link Support Software. The Controller Link Support Software enables manually set data links and other procedures

for a Controller Link Network.

(suffixes omitted)

W309

W383

W388

W307

W370

W369

Depending on the system, you may also need the SYSMAC or CV Support Software, the CX-Programmer, or a Programming Console. Refer to the body of this manual for details. Please read this manual

and related manuals carefully and be sure you understand the information provided before attempting

to install and operate a Controller Link Unit.

Precautions provides general precautions for using the Controller Link Unit and related devices.

Section 1 provides basic information on Controller Link Networks, and will give the reader an overview

of what Controller Link Networks can do and how best to use them.

Section 2 describes the basic procedures to use the Controller Link Unit. The settings necessary for

using each of the functions are also explained briefly. For more details, refer to the following sections

on individual functions.

Section 3 describes how to install a Controller Link Unit and how to wire the Controller Link Network.

Details are also provided on installation, wiring, and basic operating procedures of Repeater Units,

including information on using them to construct networks.

Section 4 describes the settings required for starting communications. These basic settings are

required for both data links function and the message service. Carry out the settings described here

before turning on power to the Controller Link Unit.

Section 5 describes how to use data links in a Controller Link Network. Refer to SECTION 2 Basic

Procedures for an outline of data link application.

Section 6 explains how to use the message service provided by a Controller Link Unit. It also explains

the FINS commands and responses supported by Controller Link Units and those supported by

C200HX/HG/HE, CVM1, and CV-series PLCs.

xi

Section 7 describes the method used to connect multiple networks through CS/CJ-series, CVM1, and

CV-series PLCs. The section also describes remote programming and monitoring with Programming

Devices.

Section 8 explains details on Controller Link Network communications. Refer to this section for network communications that require accurate communications timing.

Section 9 provides information on troubleshooting errors that occur during Controller Link Unit operation, as well as daily inspection, cleaning, and other maintenance procedures.

Section 10 provides information on functions that can be performed without turning OFF the PLC

power to the existing network, such as adding nodes to the Controller Link Network using a Repeater

Unit and changing data link tables while the data links are active.

Appendix A provides a list of standard OMRON products related to Controller Link Networks.

Appendix B provides easy reference to the words in PLC memory areas used by Controller Link Net-

works.

Appendix C provides information on how to use the CJ1W-TB101 Wired Controller Link Unit Relay

Terminal Block, including details on connection and replacement.

!WARNING Failure to read and understand the information provided in this manual may

result in personal injury or death, damage to the product, or product failure.

Please read each section in its entirety and be sure you understand the information provided in the section and related sections before attempting any of

the procedures or operations given.

xii

PRECAUTIONS

This section provides general precautions for using the Controller Link Unit and related devices.

The information contained in this section is important for the safe and reliable application of the Controller Link

Unit. You must read this section and understand the information contained before attempting to set up or operate

a Controller Link Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Applications Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

xiii

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON

PLCs and related devices. Be sure to read this manual before attempting to

use the software and keep this manual close at hand for reference during

operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

xiv

Operating Environment Precautions 4

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-VDC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

xv

Applications Precautions 5

5 Applications Precautions

Observe the following precautions when using the Controller Link Unit.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100

protect against electrical shock.

• Always turn OFF the power supply or the backup power supply to the PLC

or the computer before attempting any of the following. Performing any of

the following with the power supply turned ON may lead to electrical

shock:

• Installing or removing the Controller Link Unit.

• Assembling the Units.

• Setting DIP or rotary switches.

• Connecting or disconnecting any cables or wiring.

• Connecting or disconnecting any terminal block.

!Caution Failure to abide by the following precautions could lead to faulty operation or

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Do not attempt to disassemble, repair, or modify any Units. Any attempt to

do so may result in malfunction, fire, or electric shock.

• Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

Ω or less when installing the system to

xvi

Applications Precautions 5

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Wire all connections correctly.

• Mount Units only after checking terminal blocks completely.

• Be sure that the Bus Connection Units and other items with locking

devices are properly locked into place. Improper locking may result in

malfunction.

• Use special packing box when transporting the Controller Link Unit. Handle the product carefully so that no excessive vibration or impact is

applied to the product during transportation.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Inappropriate settings in data link tables or routing tables can cause unexpected system operation. Always check table settings before starting

operation, and always test the settings in trial operation before starting or

stopping the data links in actual operation.

• CPU Bus Units will be automatically restarted when routing tables are

transferred from a Programming Device to the CPU Unit. Resetting is

required to use the new tables. Confirm that restarting the CPU Bus Units

will not adversely affect system operation before transferring routing

tables.

• Observe the following precautions when wiring the communications

cables.

• Separate the cables from the power lines or high-tension lines.

• Do not bend the cables.

• Do not pull on the cables.

• Do not place heavy objects on top of the cables.

• Route cables inside conduits.

• Before touching the Unit, be sure to first touch a grounded metallic object

in order to discharge any static build-up.

xvii

Conformance to EC Directives 6

6 Conformance to EC Directives

The Controller Link Units conform to EMC and Low Voltage Directives as follows:

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMS (Electro-Magnetic Susceptibility) and EMI (Electro-Magnetic

Interference) standards in the EMC (Electro-Magnetic Compatibility) standards are as follows:

EMS EMI

CQM1H-CLK21

C200HW-CLK21

CVM1-CLK21

CS1W-CLK21(-V1)

CJ1W-CLK21(-V1) EN61000-6-2

EN61131-2 EN50081-2

EN61000-6-4

1,2,3...

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75

to 1,500 VDC meet the required safety standards for the PLC (EN61131-2).

The Controller Link Units that comply with EC Directives (CVM1-CLK21,

C200HW-CLK21, CS1W-CLK21(-V1), CJ1W-CLK21(-V1), and CQM1HCLK21) must be installed as follows:

1. The Controller Link Units are designed for installation inside control panels. All Controller Link Units must be installed within control panels.

2. Use reinforced insulation or double insulation for the DC power supplies

used for the communications power supply and I/O power supplies.

3. The Controller Link Units that comply with EC Directives also conform to

the Common Emission Standard (EN50081-2 or EN61000-6-4). Radiated

emission characteristics (10-m regulations) may vary depending on the

configuration of the control panel used, other devices connected to the

control panel, wiring, and other conditions. You must therefore confirm that

the overall machine or equipment complies with EC Directives.

xviii

SECTION 1

Features and System Configuration

This section provides basic information on Controller Link Networks, and will give the reader an overview of what

Controller Link Networks can do and how best to use them.

1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 What Is the Controller Link? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-2 Specifications and Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-2-1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-2-2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-2-3 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-2-4 Controller Link Unit Models and PLCs . . . . . . . . . . . . . . . . . . . . . . 16

1-2-5 Devices for Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-2-6 Programming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-3 Selection of Communications Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-4 Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1

Overview Section 1-1

pp

1-1 Overview

1-1-1 What Is the Controller Link?

The Controller Link is an FA network that can send and receive large data

packets flexibly and easily among the OMRON C200HX/HG/HE Programmable Controllers (PLCs), CS-series PLCs, CJ-series PLCs, CVM1 PLCs, CVseries PLCs, CQM1H-series PLCs, and IBM PC/AT or compatible computers.

The Controller Link supports data links that enable data sharing and a message service that enables sending and receiving data when required. Data

link areas can be freely set to create a flexible data link system and effectively

use data areas.

High-volume data transmissions are possible at high speed and so a wide

range of networks, from low-level systems to high, can be easily created.

There are two types of networks: networks connected with shielded twistedpair cable and networks connected with optical fiber cable. Using a Repeater

Unit in networks connected with twisted-pair cable makes it possible to use a

variety of different wiring configurations, such as T-branch wiring, long-distance wiring, and partial conversion to optical fiber. (Refer to the CS1W-

CLK12, CVM1-CLK12 Optical Ring Controller Link Units Operation Manual

(W370) for detail on optical fiber connections.)

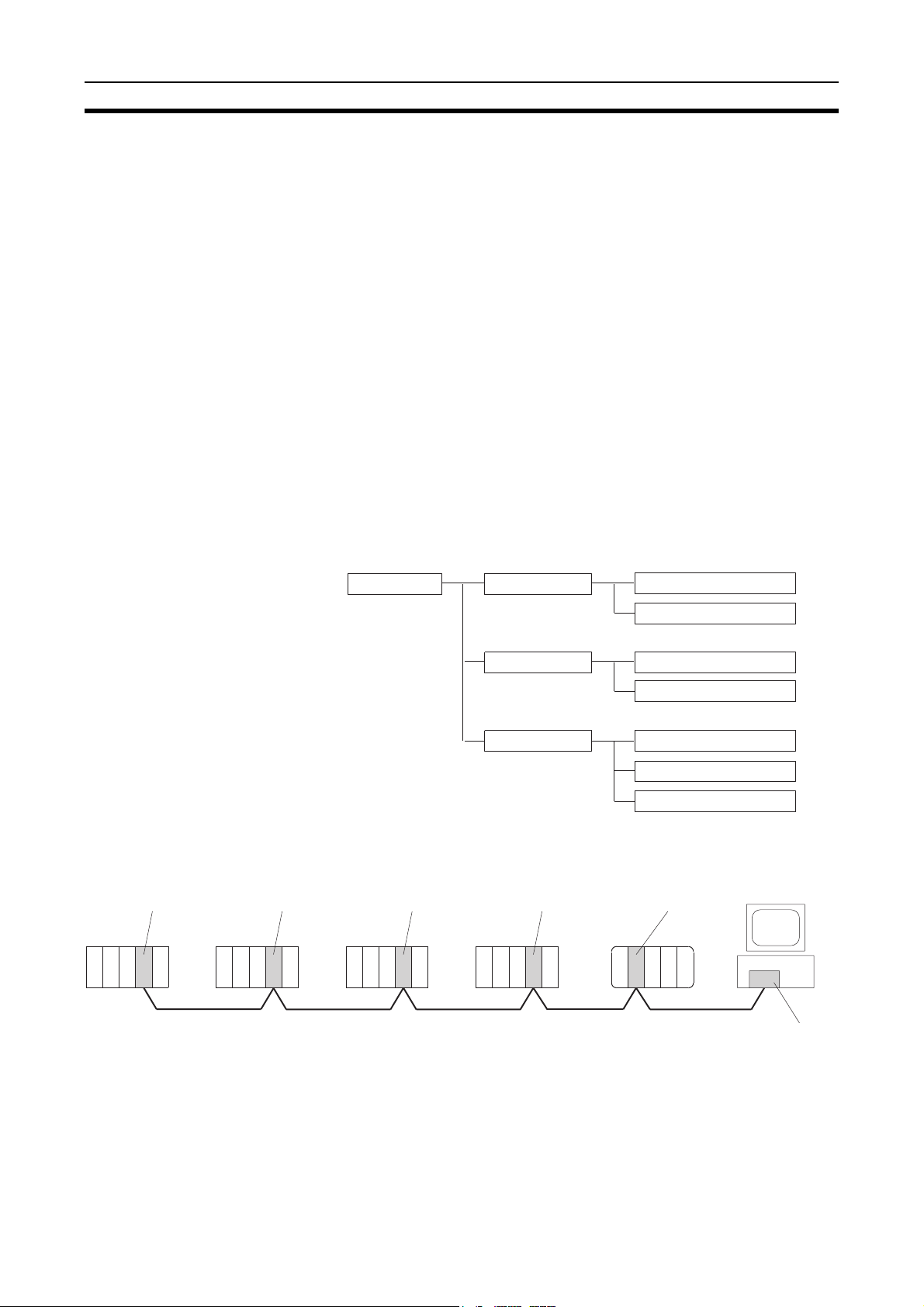

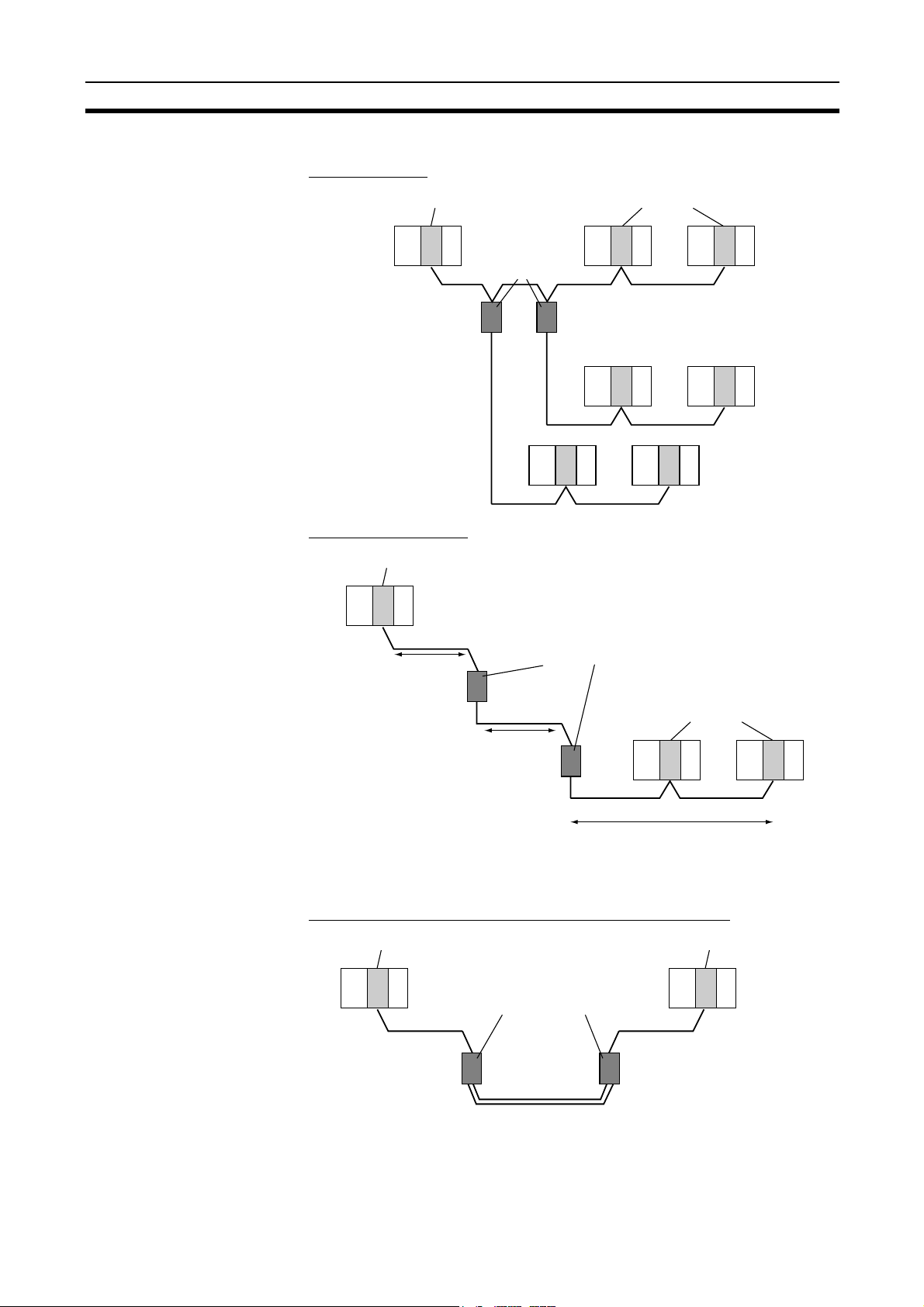

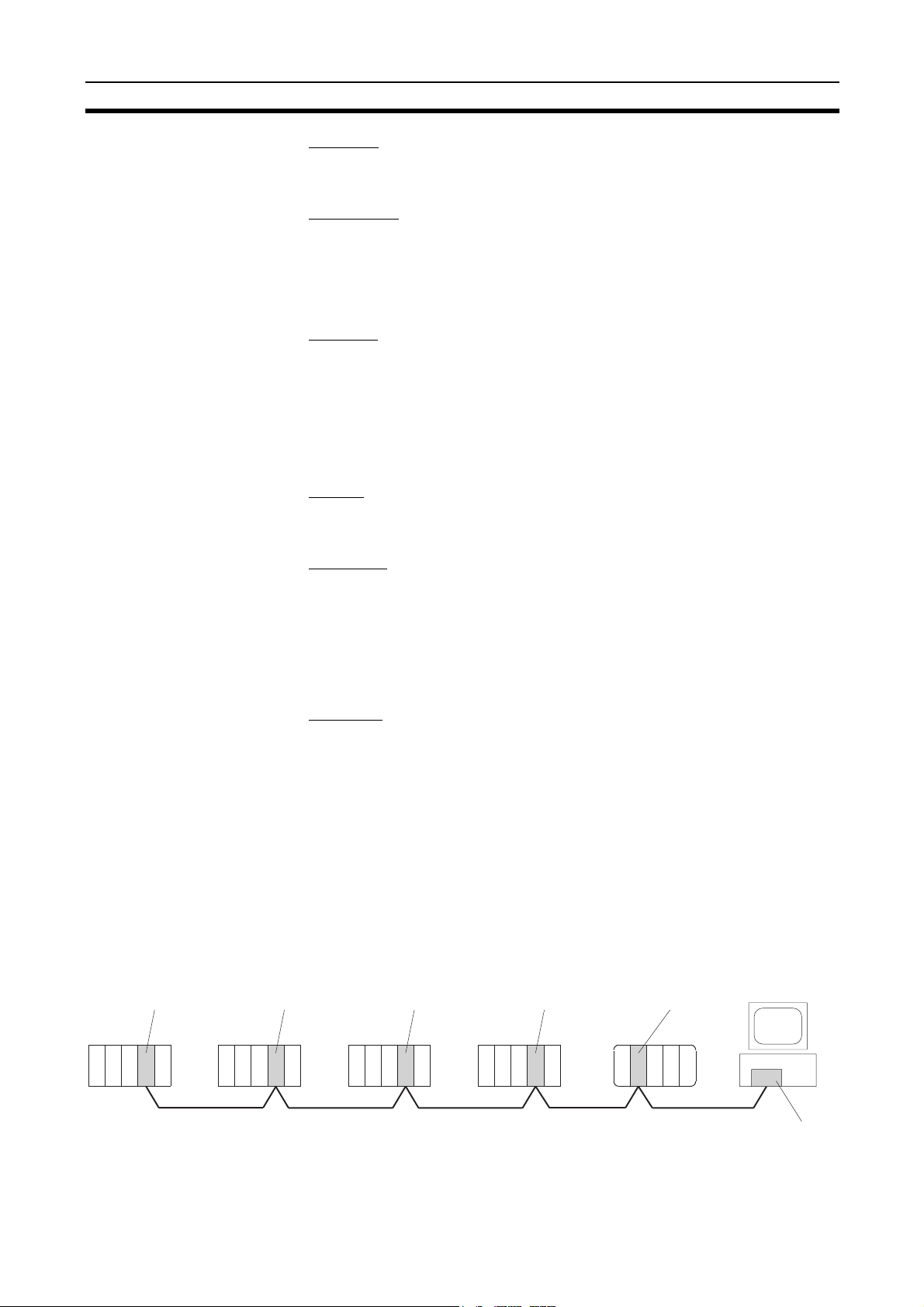

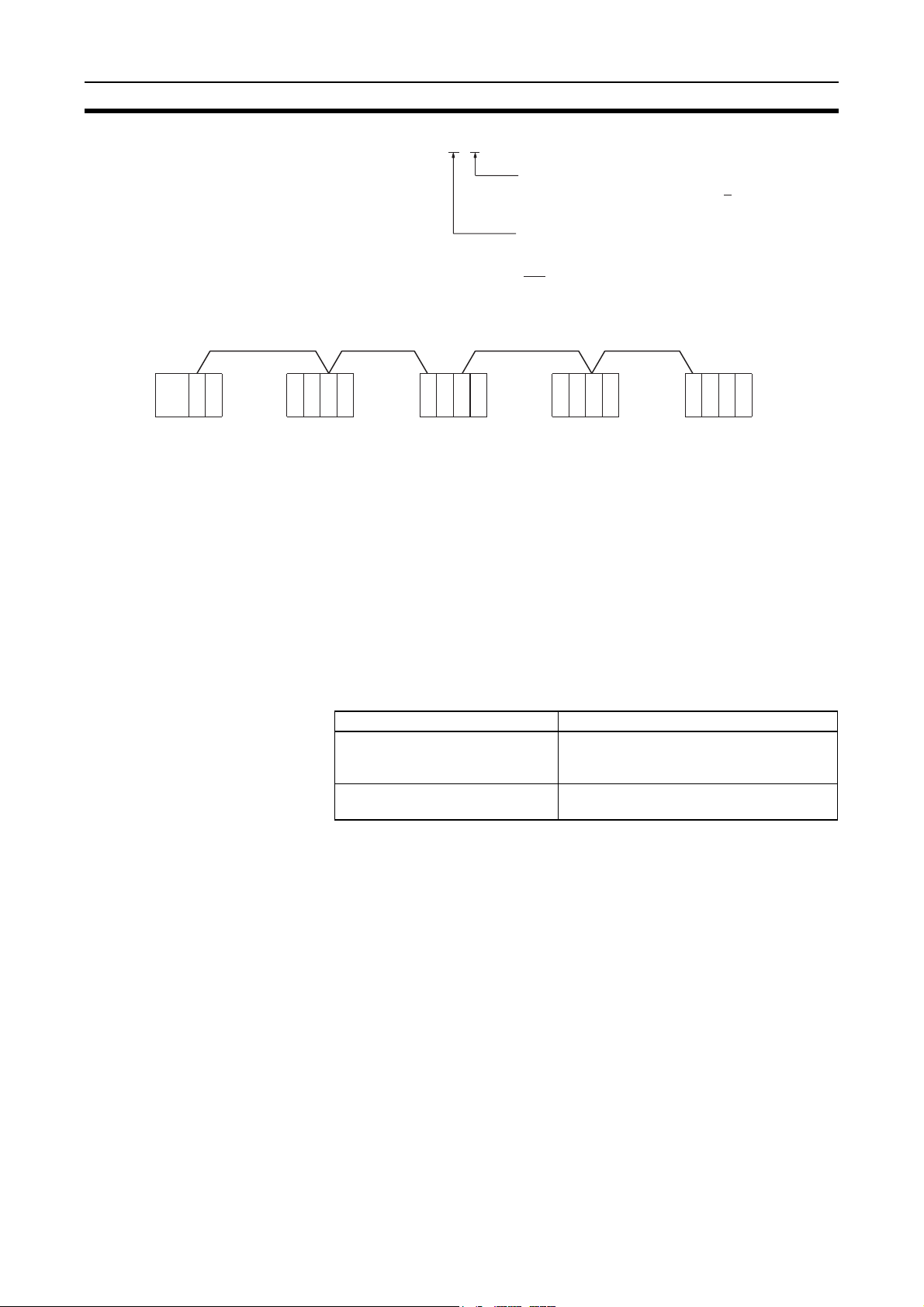

The functions of a Controller Link Network are illustrated below.

Wired System

(Twisted-pair Cable)

CS1W-CLK21-V1

Controller Link Unit

CS-series

PLC

C

P

U

CJ-series PLC

CS-series, CJ-series, C200HX/HG/HE, CVM1, CV-series, and CQM1H-series

PLCs

CJ1W-CLK21-V1

Controller Link Unit

C

P

U

Controller Link

C200HW-CLK21

Controller Link Unit

C200HX/HG/HE

PLC

Data link

Message service

RAS functions Status area function

CVM1-CLK21

Controller Link Unit

CVM1, CV-series

PLC

C

P

U

Twisted-pair cable

CQM1H-series

PLC

C

P

U

Manual settings

Automatic settings

SEND/RECV instructions

CMND instruction

Error log function

Polling node backup

CQM1H-CLK21

Controller Link Unit

C

P

U

IBM PC/AT or

compatible

3G8F7-CLK21-E-V1

Controller Link

ort Board

Su

2

Overview Section 1-1

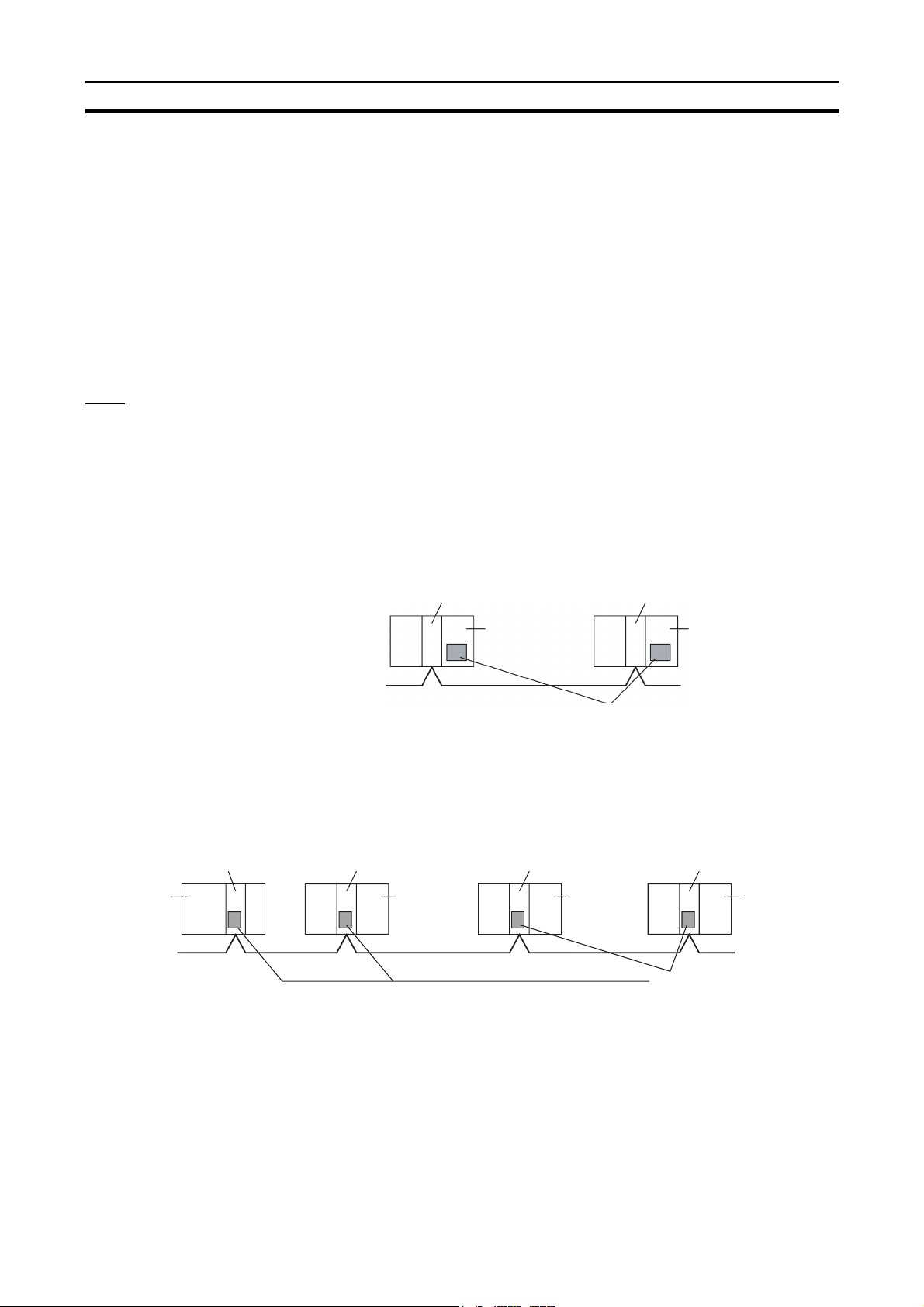

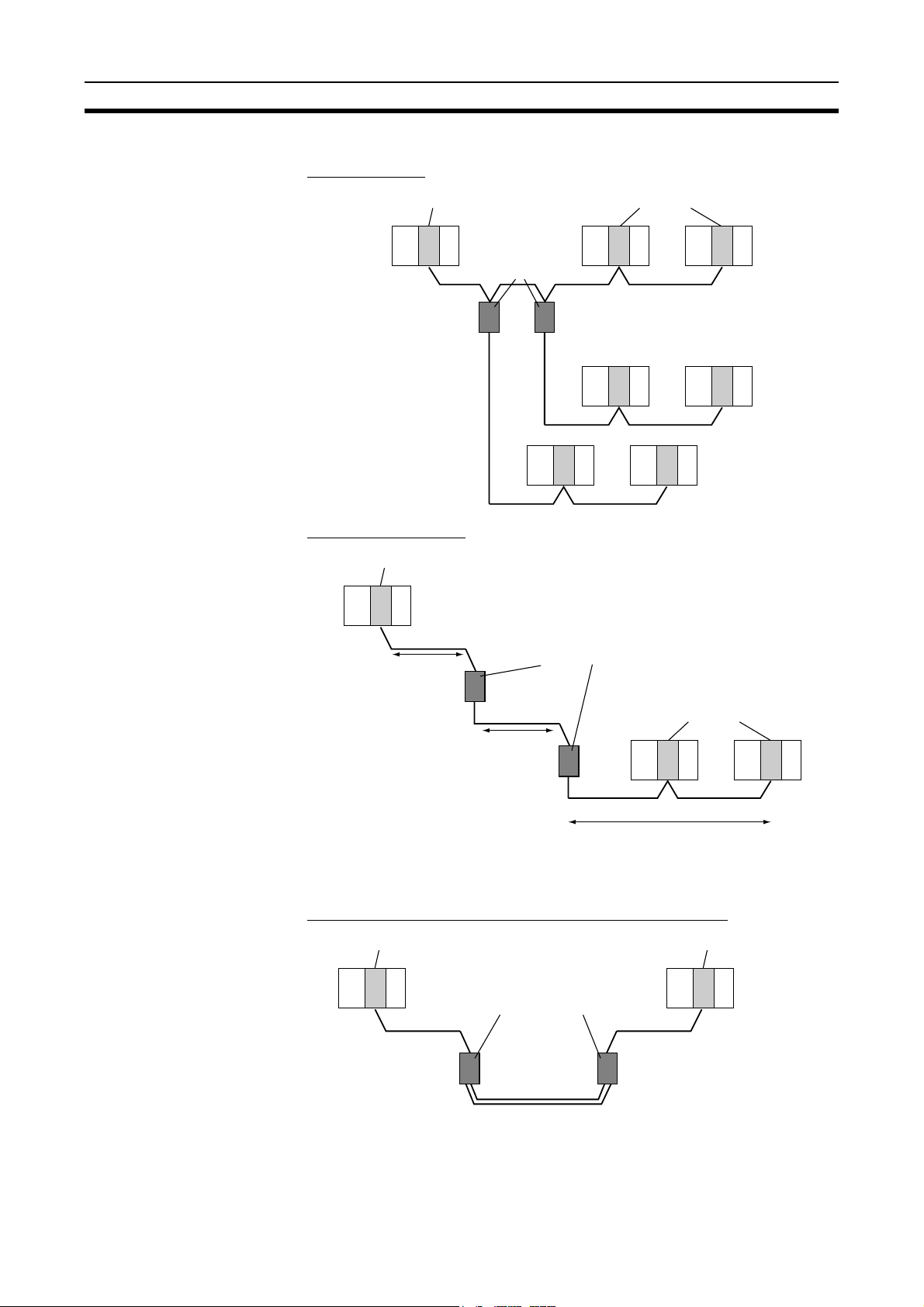

Connecting Repeater Units Using Twisted-pair Cable (Wired Units)

T-Branch Wiring

Wired Controller Link Unit Wired Controller Link Unit

CS1W-RPT01

Repeater Units

Twisted-pair cable

Twisted-pair cable

Long-distance Wiring

Wired Controller Link Unit

Twisted-pair cable

500 m max.

(See note.)

CS1W-RPT01

Repeater Units

Twisted-pair

cable

500 m max.

(See note.)

Wired Controller Link Unit

Twisted-pair cable

500 m max. (See note.)

Note: At 2 Mbit/s

Converting Part of the Transmission Line to Optical Fiber

Wired Controller Link Unit Wired Controller Link Unit

CS1W-RPT02 or

CS1W-RPT03

Repeater Units

Twisted-pair cableTwisted-pair cable

Optical cable (H-PCF or GI)

Two Repeater Units of the same model must be used when part of the transmission line uses optical fiber.

3

Overview Section 1-1

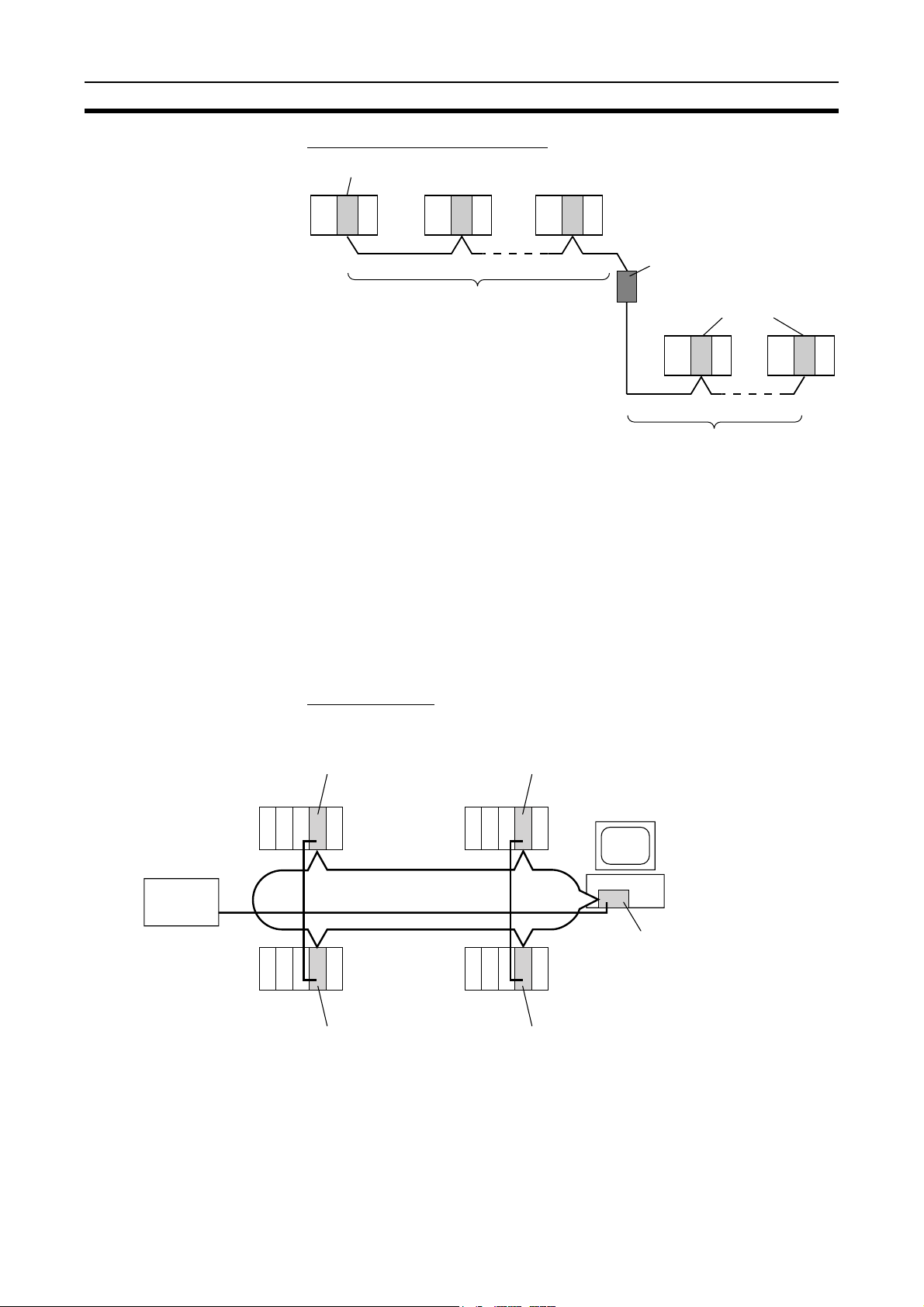

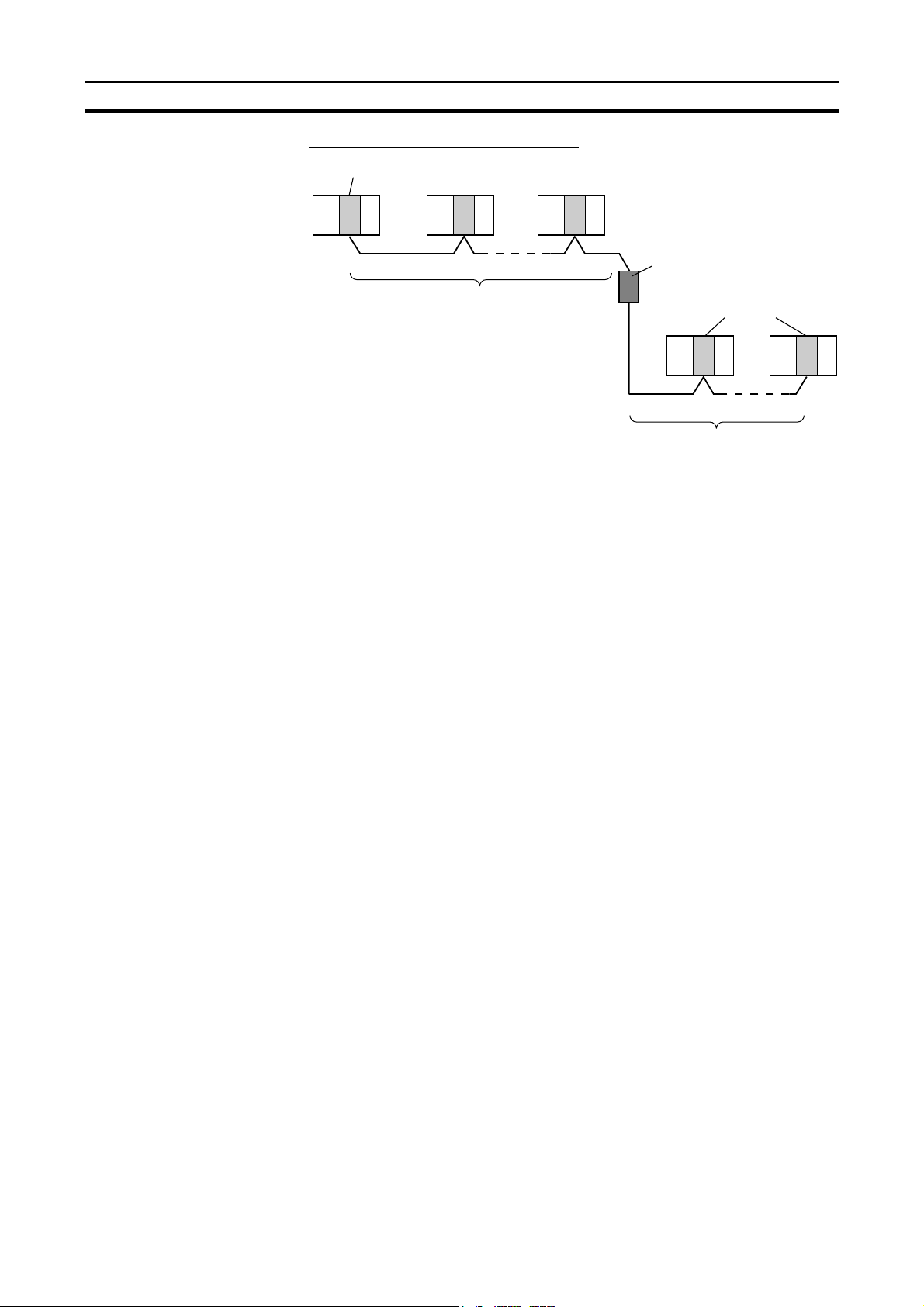

Maximum 62-node Configuration

Wired Controller Link Unit

Note 1. The network will not operate correctly unless all nodes within the network

Connecting Repeater

Units Using H-PCF Optical

Fiber Cable

Twisted-pair cable

31 nodes max.

CS1W-RPT01

Repeater Unit

Wired Controller Link Unit

Twisted-pair cable

31 nodes max.

The following Controller Link Units/Support Boards must be used to construct

a network with more than 32 nodes:

CS1W-CLK21-V1

CJ1W-CLK21-V1

3G8F7-CLK21-V1

use the above Units/Boards.

2. Only node addresses 1 through 32 can be used on networks for which 62

nodes have not been enabled.

CS-series and CVM1/CV-series PLCs only.

Token Ring Mode

Backup

power supply

(DC24V)

CS1W-CLK12-V1

Controller Link Unit

(token ring mode)

C

P

U

H-PCF Optical fiber cable

(ring connection)

C

P

U

CS1W-CLK12-V1

Controller Link Unit

(token ring mode)

CVM1-CLK12

Controller Link Unit

(token ring mode)

CVM1/CV-series PLCCS-series PLC

CVM1/CV-series PLCCS-series PLC

CVM1-CLK12

Controller Link Unit

(token ring mode)

Personal computer

C

P

U

C

P

U

3G8F7-CLK12-V1

Controller Link Support Board

for PCI Bus (token ring mode)

4

Overview Section 1-1

Token Bus Mode

Personal

CS1W-CLK12-V1

Controller Link Unit

(token bus mode)

CS1W-CLK11

Controller Link Unit

CS-series PLC CS-series PLC

C

P

U

CVM1/CV-series

PLC

C

P

U

CVM1-CLK12

Controller Link Unit

(token bus mode)

C

P

U

computer

PC/AT or

compatible

Personal computer

Backup

power supply

(24 V DC)

Connecting Repeater

Units Using GI Optical

Fiber Cable

Backup

power supply

(24 V DC)

H-PCF Optical

fiber cable

(daisy chain

connection)

CS-series and CVM1/CV-series PLCs only.

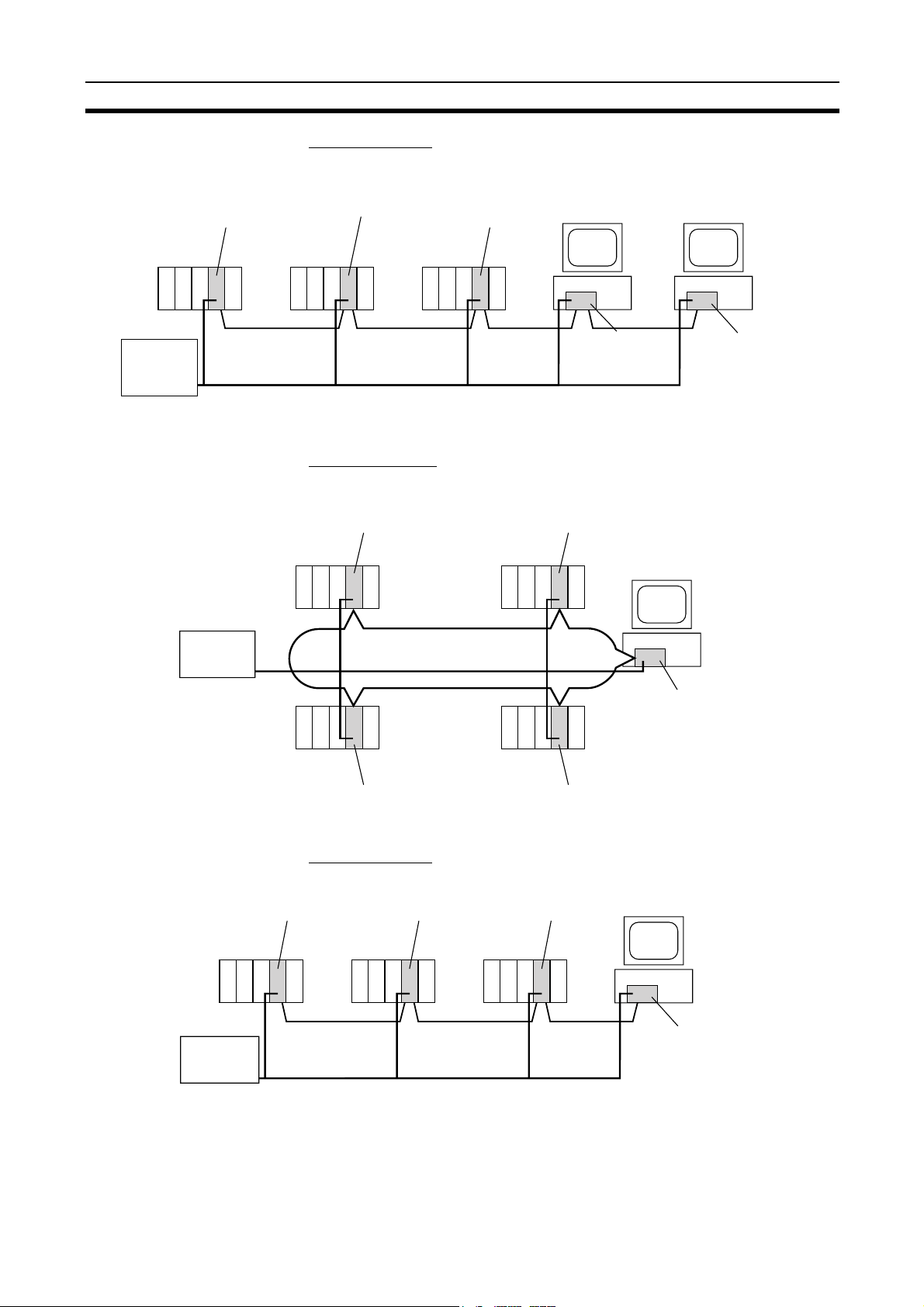

Token Ring Mode

CS1W-CLK52-V1

Controller Link Unit

(token ring mode)

CS-series PLC CVM1/CV-series PLC

C

C

P

P

U

U

GI Optical fiber cable

(ring connection)

C

P

U

CS-series PLC CVM1/CV-series PLC

CVM1-CLK52

Controller Link Unit

(token ring mode)

3G8F5-CLK11

Controller Link

Support Board for

ISA Bus

Personal computer

C

C

P

P

U

U

3G8F7-CLK52-V1

C

P

U

Controller Link

Support Board

for PCI Bus

(token ring mode)

3G8F7-CLK12-V1

Controller Link

Support Board

for PCI Bus

(token bus mode)

CS1W-CLK52-V1

Controller Link Unit

(token ring mode)

Token Bus Mode

CS1W-CLK52-V1

Controller Link Unit

(token bus mode)

CS-series PLC CS-series PLC

C

P

U

Backup

power supply

(24 V DC)

CS1W-CLK52-V1

Controller Link Unit

(token bus mode)

CVM1-CLK52

Controller Link Unit

(token ring mode)

CVM1-CLK52-V1

Controller Link Unit

(token bus mode)

CVM1/CV-series

PLC

C

P

U

GI Optical fiber cable

(daisy chain

connection)

Personal computer

C

P

U

3G8F7-CLK52-V1

Controller Link

Support Board

for PCI Bus

(token bus mode)

5

Overview Section 1-1

ge (

g)

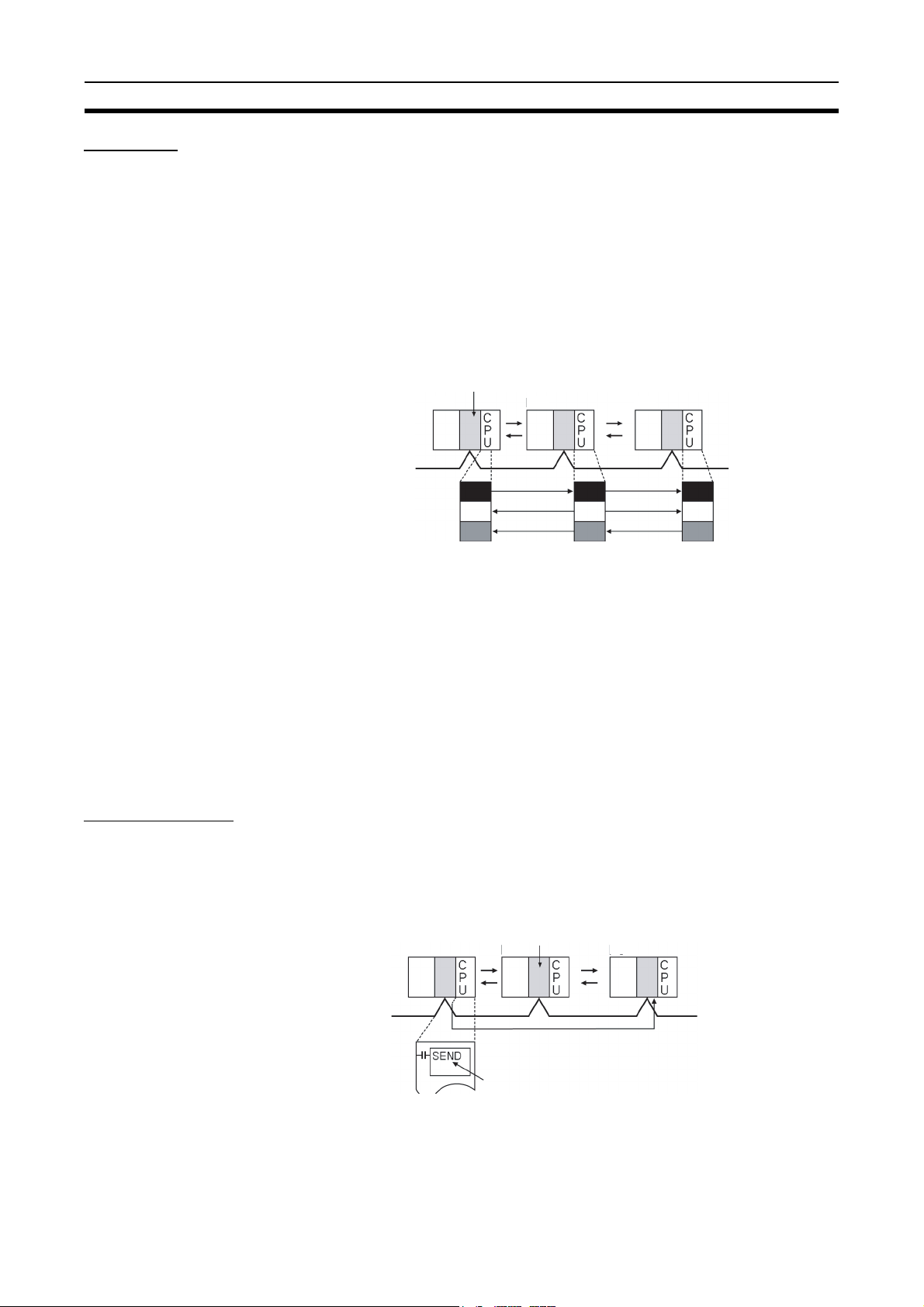

Data Links

Data links allow the constant sharing of data in predetermined data areas

between nodes, between PLCs, or between a PLC and an IBM PC/AT or

compatible computer on the network. Data links do not require the use of

communications programs on the PLC (CPU Unit) or IBM PC/AT or compatible computer. Data written in the send area of the local node will be automatically sent to the receive area of other nodes.

The I/O area (CIO area), link area (LR area), DM Area area (DM area), and

extended DM Area area (EM area) can be freely set in the send or receive

area. (The area used for sending or receiving data using the data link function

is called “data link area.”)

The data link area can be set automatically or manually.

Controller Link Unit

PLC

Constant data exchan

PLC

PLC

sharin

Automatic Setting Used for simple data link processing. Data link can be performed by simply

setting parameters in the DM area of the PLC.

Send data size per node is the same for all nodes. All nodes participating in

the data link share the same data.

Manual Setting Used for flexible data link processing depending on each system.

Using the Controller Link Support Software, individual data link tables can be

set for each node and the data link area can be freely allocated for each node.

Send data size per node can be freely set. It is also possible to set nodes for

only send or receive data. With the Controller Link Unit, the data link can be

set to receive only a part of the data link area of other nodes.

Message Service

This function controls data transmission with particular nodes, reading or writing of status data, changing of operation modes, etc., by executing communications instructions on a program. The communications instructions include

SEND/RECV instructions for data transmission and CMND instructions for

issuing various commands.

PLC

Controller Link Unit

PLC

PLC

Data transmission (under certain conditions)

as required

Communications instruction

User program

6

Overview Section 1-1

k

SEND/RECV The SEND or RECV instruction sends or receives data in an area of a particu-

lar node.

The SEND instruction sends data from an area of the local node and writes to

an area in the designated node.

The RECV instruction requests the designated node to send area data and

writes the data to the local node.

CMND The CMND instruction issues a command to read or write data of other nodes,

control, or read error logs. With the Controller LInk Unit, OMRON’s command

protocol called “FINS commands” is used.

Note Since the C200HX/HG/HE PLCs do not support the CMND instructions, arbi-

trary commands cannot be issued.

RAS

RAS performs real-time monitoring of the network status. If an error occurs in

the network, RAS records and displays the time and contents of the error.

Status Area Data Link Status Area

When the data link function is used, the data link status is reflected in the data

link status area of the PLC.

Network Status Area Other than the Data Link:

The network status such as the state of node participation is reflected in the

status area of the PLC.

Controller Link Unit

CPU Unit

Controller Link Unit

CPU Unit

Status Area

• Data link status

• Status other than the data lin

Error Log The error log function records contents (codes) and times of errors that occur

in the network into the RAM or EEPROM, up to the maximum of 39 errors.

The recorded errors can be read using the Controller Link Support Software

or the message service function.

Controller Link UnitController Link Unit Controller Link UnitController Link Unit

CJ-series

CPU Unit

CS-series

CPU Unit

C200HX/HG/

HE CPU Unit

Error log table

CVM1, CVseries CPU

Unit

7

Overview Section 1-1

1-1-2 Features

The Controller Link Network has the following features to meet the various

requirements of FA sites.

Data Links

Flexible and efficient data links can be created for large capacities of data as

listed below.

Item Specifications

Number of send words

per node

Number of send and

receive words per node

Data links can be automatically set, or they can be set by the user to freely

change the sizes of the data areas used. A data link can also be created so

that one node receives only part of the data sent from another node. This

function enables users to receive only the required data, thereby increasing

data link efficiency.

Message Service

The message service can send and receive up to 2,012 bytes of data (including the FINS header), allowing high volumes of data to be sent and received

without having to split it up.

1,000 max.

C200HX/HE/HG, CVM1, CV-series, and CQM1H-series PLCs: 8,000 max.

CS/CJ-series PLCs: 12,000 max.

IBM PC/AT or compatible: 32,000 max. (PCI or ISA Board)

Twisted-pair Cable or Optical Fiber Cable Connection

The Controller Link Units can be connected to the network using either

shielded twisted-pair cables or optical fiber cables. Select the system that

suits your application.

Features of Twisted-pair Cable

Twisted-pair cable is easy to connect and maintain. The cable can be processed much more easily than coaxial or optical cable, thereby reducing the

cost of tools and assembly time.

Connections are made to a terminal block on the Controller Link Unit and to a

special connector on the Controller Link Support Board for easy system

assembly and modification.

The network is equipped with the required terminating resistance built into the

Units allowing the terminating resistance to be easily set at both ends of the

network using a simple switch.

Features of Optical Fiber Cable

Optical Fiber Cable has superior noise resistance, so this system can provide

highly reliable communications even in very noisy conditions.

The communications distance can be up to 20 km total (1 km max. between

nodes) if H-PCF cable is used and up to 30 km total (2 km max. between

nodes) if GI cable is used, which allows long-distance or large-scale networks.

Once the Optical Fiber Cable has been fitted with special connectors, the

cables can be easily connected or disconnected.

8

Overview Section 1-1

Compatible with Different Node Configurations

The following Controller Link Units are available for communications between

different models. It must be noted, however, that the wired system and optical

system cannot exist in one Controller Link Network.

Wired System

• Controller Link Unit for CS/CJ-series Programmable Controllers

• Controller Link Unit for C200HX/HG/HE Programmable Controllers

• Controller Link Unit for CVM1 and CV-series Programmable Controllers

• Controller Link Unit for CQM1H-series Programmable Controllers

• Controller Link Support Board for IBM PC/ATs or compatibles (ISA or

PCI bus)

Flexible Inter-network Connections

The Controller Link Network can connect to other networks (Ethernet, SYSMAC NET, SYSMAC LINK, and another Controller Link network) via CVM1,

CV-series, CS-series, or CJ-series PLCs. By installing a Communications Unit

for the Ethernet, SYSMAC NET or SYSMAC LINK on the same CS/CJ-series

or CV-series PLC as a Controller Link Unit, a message service can be created

with nodes in interconnected networks through the CVM1 or CV-series PLC.

Up to three network levels are possible.

Note CS/CJ-series PLC cannot be connected directly to SYSMAC NET networks

and CJ-series PLC cannot be connected directly to SYSMAC LINK networks

The programming and monitoring of other PLCs on the network can be conducted from Programming Devices connected to the PLC’s CPU Unit. Internetwork connections are possible in this case also and can cover up to three

network levels.

Improved Error Handling

An error log enables quick handling of errors by recording the time the error

occurred and error details. The current Controller Link Unit and Support Board

status are also available, as are the data link and network status.

When an error occurs in the polling node that controls the Controller Link Network, another node automatically becomes the polling node. This prevents an

error at a single node from influencing other nodes on the network, achieving

a highly reliable system.

Using Repeater Units for T-Branches, Network Extensions, Network Expansions,

Converting Network Sections to Optical Fiber, and Device Modularization

T-Branches enable greater wiring freedom during layout, restructuring, and expansion of

networks.

Wire-to-Wire Repeater Units enable Controller Link T-Branches. T-Branches

provide the following advantages:

• Cabling can conform to the layout of equipment.

• It is possible to add nodes by adding or inserting Repeater Units at

branch points of an existing wired Controller Link system.

• If Repeater Units are installed at likely future branch points in the network

in advance, new nodes can be added by simply connecting them to these

Repeater Units.

9

Overview Section 1-1

The total length of wired networks can be extended.

At a baud rate of 2 Mbps, conventional wired networks can be up to 500 m

long. By using two Repeater Units, this can be extended to a maximum of

1.5 km.

The maximum number of nodes can be extended to 62 for wired networks.

By combining version-1 Controller Link Units/Support Boards and a Repeater

Unit, it is possible to construct networks containing up to 62 nodes.

Improved noise resistance through the use of optical cabling.

By installing two Wire-to-Optical Repeater Units, optical cabling can be used

for sections of the network that are the source of noise.

Devices can be modularized.

• Devices can be modularized according to Repeater Units, making wiring

easier when adding, removing, or modifying devices.

• When starting up devices, components can be added to the network and

debugged as they are completed.

Features and Functions of Version-1 Models

The following features and functions apply to the CS1W-CLK21-V1 and

CJ1W-CLK21-V1 Controller Link Units and the 3G8F7-CLK21-V1 Controller

Link Support Board only.

Up to 62 nodes can be connected.

Overview

When a CS1W-RPT01 Repeater Unit is used, the maximum number of nodes

that can be used in the network increases to 62. (The previous limit was 32.)

Method

Use Repeater Units and turn ON bit 11 (Wired Network 62 Node Enable Bit) in

the DM Parameter Area software switch D30000 + 100

to enable a maximum of 62 nodes.

Restrictions

The maximum 62 nodes cannot be achieved if version-1 models and pre-version-1 models are used together in the same network.

Automatic data link creation is possible with 1:N allocations.

Overview

It is possible to perform unequal 1:N allocations of data between nodes with

automatic data link creation. This makes it easy to perform data links that formerly required the user to manually edit data link parameters.

The following four automatic data link creation patterns can be used:

• Equality layout (the previous pattern)

• 1:N allocation, common type

• 1:N allocation, 1 to 1 type

• 1:N allocation, chain type

× Unit No. of all nodes

10

Method

Allocation addresses and sizes are all specified using the Automatic Data Link

Creation Parameters (D30000

Area. These values can be set using the CX-Net in the CX-Programmer version 3.2 or later.

× Unit No. + 12 to 20) in the DM Parameter

Specifications and Configurations Section 1-2

pp

Objective

This function is effective in applications that collect data from slave PLCs into

a master PLC.

Restrictions

Automatic data link creation with 1:N allocations cannot be performed if version-1 models and pre-version-1 models are used together in the same network.

Change manually created data link tables during data link operation.

Overview

It is possible to modify a manually created data link table while data links are

running.

Note This is possible only with manually created data link tables. Any attempt to

change automatically created data link tables when data links are running will

fail with an error message saying that the tables cannot be edited during data

link operation will be displayed.

Method

This function can be set using the CX-Net in CX-Programmer version 3.2 or

later.

Objectives

• In systems that operate non-stop and cannot be turned OFF, this function

makes it possible to change the data link table to accommodate the addition of new nodes and to transfer data link tables without having to stop

manually set data link communications.

• If this function is combined with the use of Repeater Units to add network

nodes, it becomes possible to construct systems of greater flexibility.

Operation

When a node is being modified online, this function temporarily stops refreshing of data link data until modifications have been completed.

Nodes will participate in data links after changes to the data link table have

been completed.

1-2 Specifications and Configurations

1-2-1 System Configuration

Wired Systems Wired systems can be used to connect CS/CJ-series PLCs, C200HX/HG/HE

PLCs, CVM1 PLCs, CV-series PLCs, and IBM PC/AT or compatible computers.

CS1W-CLK21-V1

Controller Link Unit

CS-series

PLC

C

P

U

CJ1W-CLK21-V1

Controller Link Unit

CJ-series PLC

C200HX/HG/HE

PLC

C

P

U

C200HW-CLK21

Controller Link Unit

CVM1, CV-series

PLC

C

P

U

CVM1-CLK21

Controller Link Unit

C

P

U

CQM1H-CLK21

Controller Link Unit

CQM1H-series

PLC

C

P

U

IBM PC/AT or

compatible

Twisted-pair cable

3G8F7-CLK21-E-V1

Controller Link

ort Board

Su

11

Specifications and Configurations Section 1-2

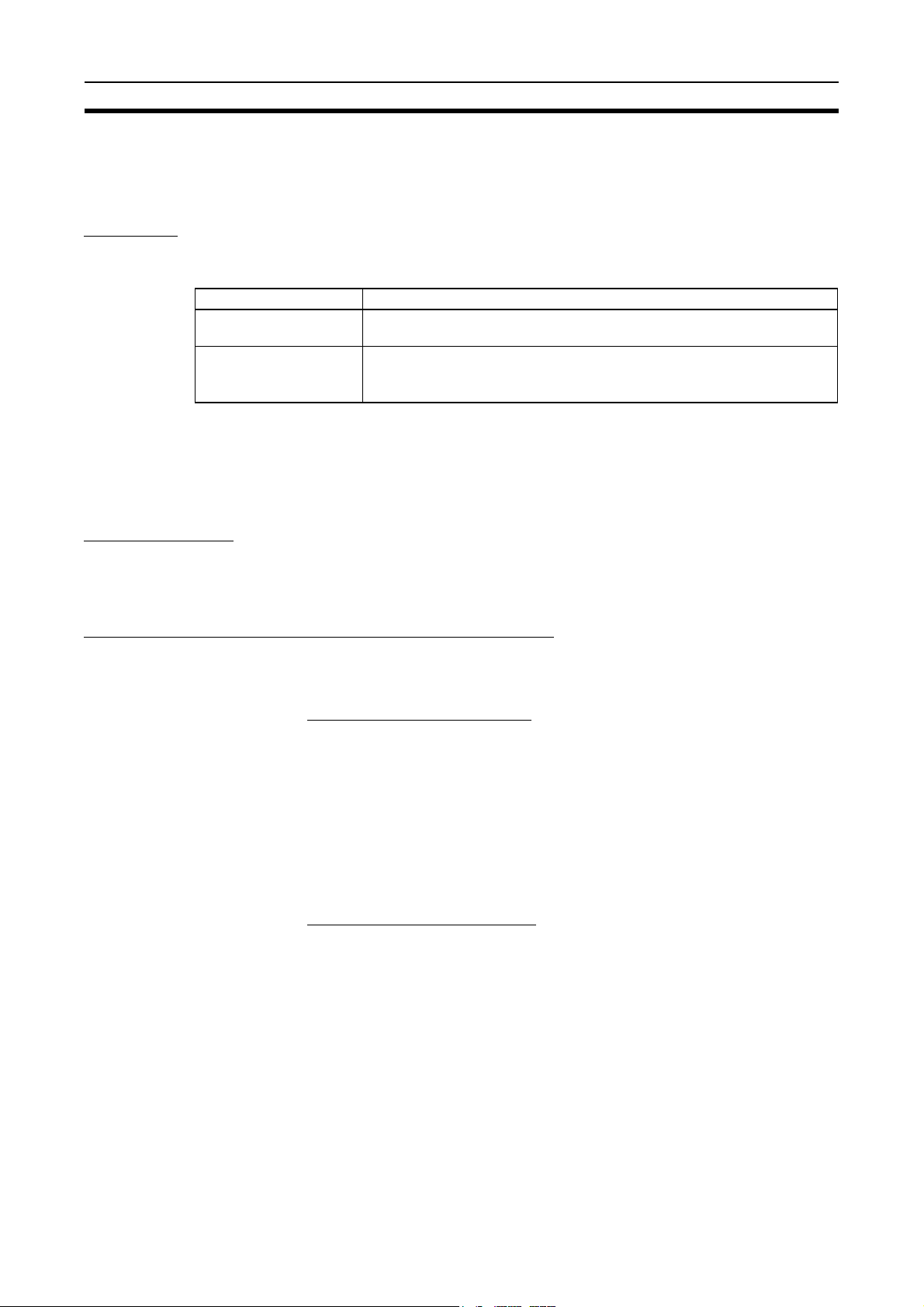

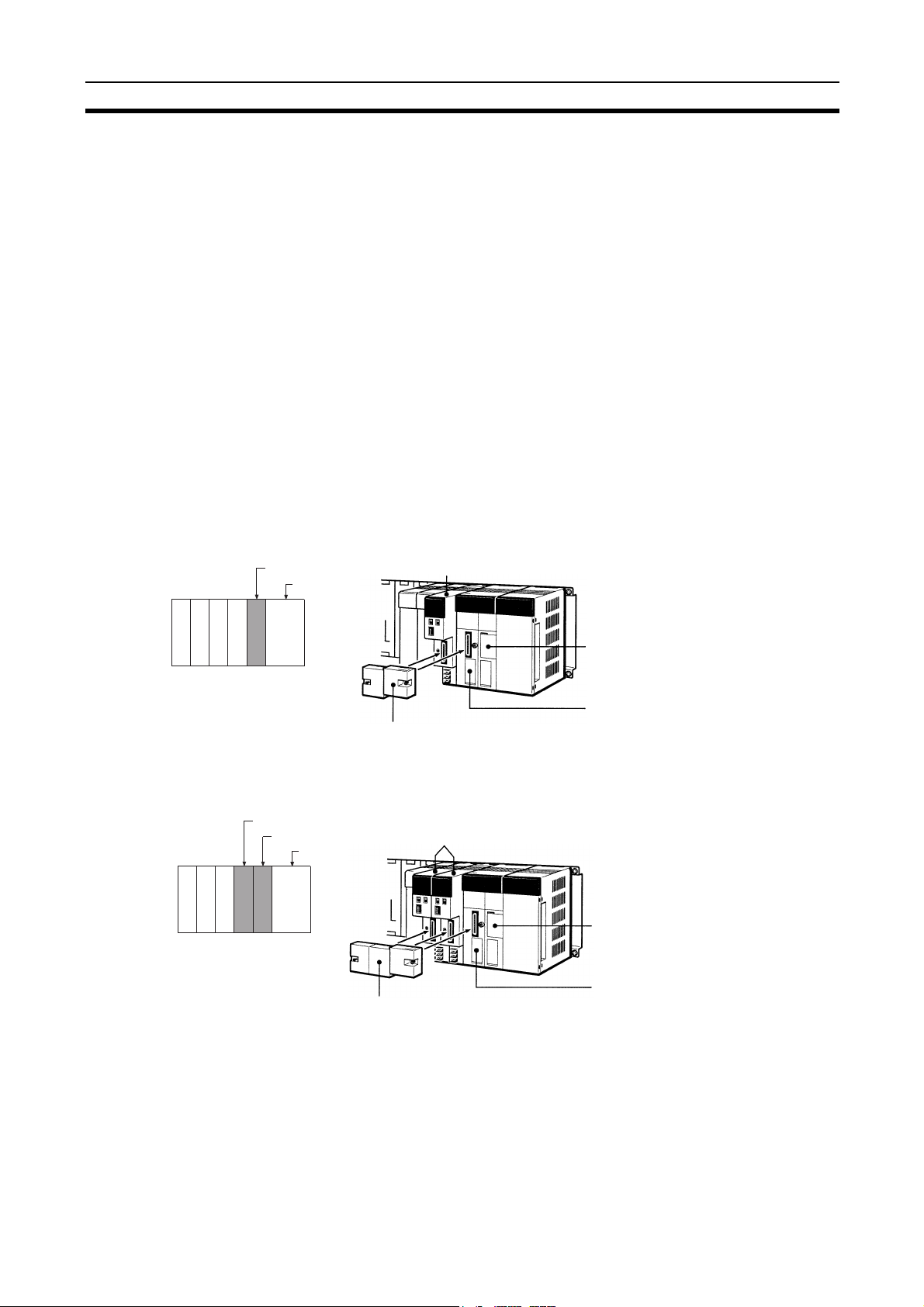

Connecting Repeater Units Using Twisted-pair Cable in Wired Systems

T-Branch Wiring

Wired Controller Link Unit Wired Controller Link Unit

CS1W-RPT01

Repeater Units

Twisted-pair cable

Twisted-pair cable

Long-distance Wiring

Wired Controller Link Unit

Twisted-pair cable

500 m max.

(See note.)

500 m max.

(See note.)

CS1W-RPT01

Repeater Units

Twisted-pair

cable

Wired Controller Link Unit

Twisted-pair cable

500 m max. (See note.)

Note: At 2 Mbit/s

Converting Part of the Transmission Line to Optical Fiber

Wired Controller Link Unit Wired Controller Link Unit

CS1W-RPT02 or

CS1W-RPT03

Repeater Units

12

Twisted-pair cableTwisted-pair cable

Optical cable (H-PCF or GI)

Two Repeater Units of the same model must be used when part of the transmission line uses optical fiber.

Specifications and Configurations Section 1-2

Maximum Configuration of 62 Nodes

Wired Controller Link Unit

The following Controller Link Units/Support Boards must be used to construct

a network with more than 32 nodes:

CS1W-CLK21-V1

CJ1W-CLK21-V1

3G8F7-CLK21-E-V1

Note 1. The network will not operate correctly unless all nodes within the network

use the above Units/Boards.

2. Only node addresses 1 through 32 can be used on networks for which 62

nodes have not been enabled.

1-2-2 General Specifications

Twisted-pair cable

32 nodes max.

CS1W-RPT01

Repeater Unit

Wired Controller Link Unit

Twisted-pair cable

32 nodes max.

General specifications are the same for the C200HX/HG/HE, CS-series, CJseries, CVM1, CV-series, and CQM1H-series PLCs.

13

Specifications and Configurations Section 1-2

1-2-3 Communications Specifications

Wired System

Items Specifications

Communications method N:N token bus

Code Manchester code

Modulation Baseband code

Synchronization Flag synchronization (conforms to HDLC frames)

Transmission path form Multi-drop bus

Baud rate and maximum

transmission distance

Media Specified shielded twisted-pair cable

Node connection method PLC: Connected to a terminal block

Maximum number of nodes 32 or 62 nodes (See note 2.)

Communications functions Data links and message service

Number of data link words

Data link areas Bit-access areas (IR, AR, LR, CIO), DM Area (DM), and extended DM Area (EM)

Message length 2,012 bytes max. (including the header)

RAS functions Polling node backup function

Error control Manchester code check

The maximum transmission distance varies with the baud rate as follows:

2 Mbps: 500 m

1 Mbps: 800 m

500 Kbps: 1 km

Number of signal lines: 2, shield line: 1

IBM PC/AT or compatible: Connected via a special connector (included)

Transmission area per node: 1,000 words (2,000 bytes) max.

Data link area in one C200HX/HG/HE, CVM1, CV-series, or CQM1H-series PLC (send/

receive): 8,000 words (16,000 bytes) max.

Data link area in one CS/CJ-series PLC (send/receive):

12,000 words (24,000 bytes) max.

Data link area in one IBM PC/AT or compatible (transmission/reception):

32,000 words (64,000 bytes) max.

Number of data link words in one network (total transmission):

32,000 words (64,000 bytes) max.

Self-diagnosis function (hardware checking at startup)

Echoback test and broadcast test (using the FINS command)

Watchdog timer

Error log function

16

CRC check (CCITT X

+ X12 + X5 + 1)

14

Note 1. The maximum distance between nodes depends on the connector and ca-

ble processing methods.

2. At least one Repeater Unit is required to construct networks that uses a

node address higher than 32. The following Controller Link Units/Support

Boards must also be used, and the Wired Network 62 Node Enable Bit of

the DM Parameter Area software switch of all nodes must be turned ON

(62 nodes max.).

CS1W-CLK21-V1, CJ1W-CLK21-V1, and 3G8F7-CLK21-V1

3. Only node addresses 1 through 32 can be used on networks for which 62

nodes have not been enabled.

Specifications and Configurations Section 1-2

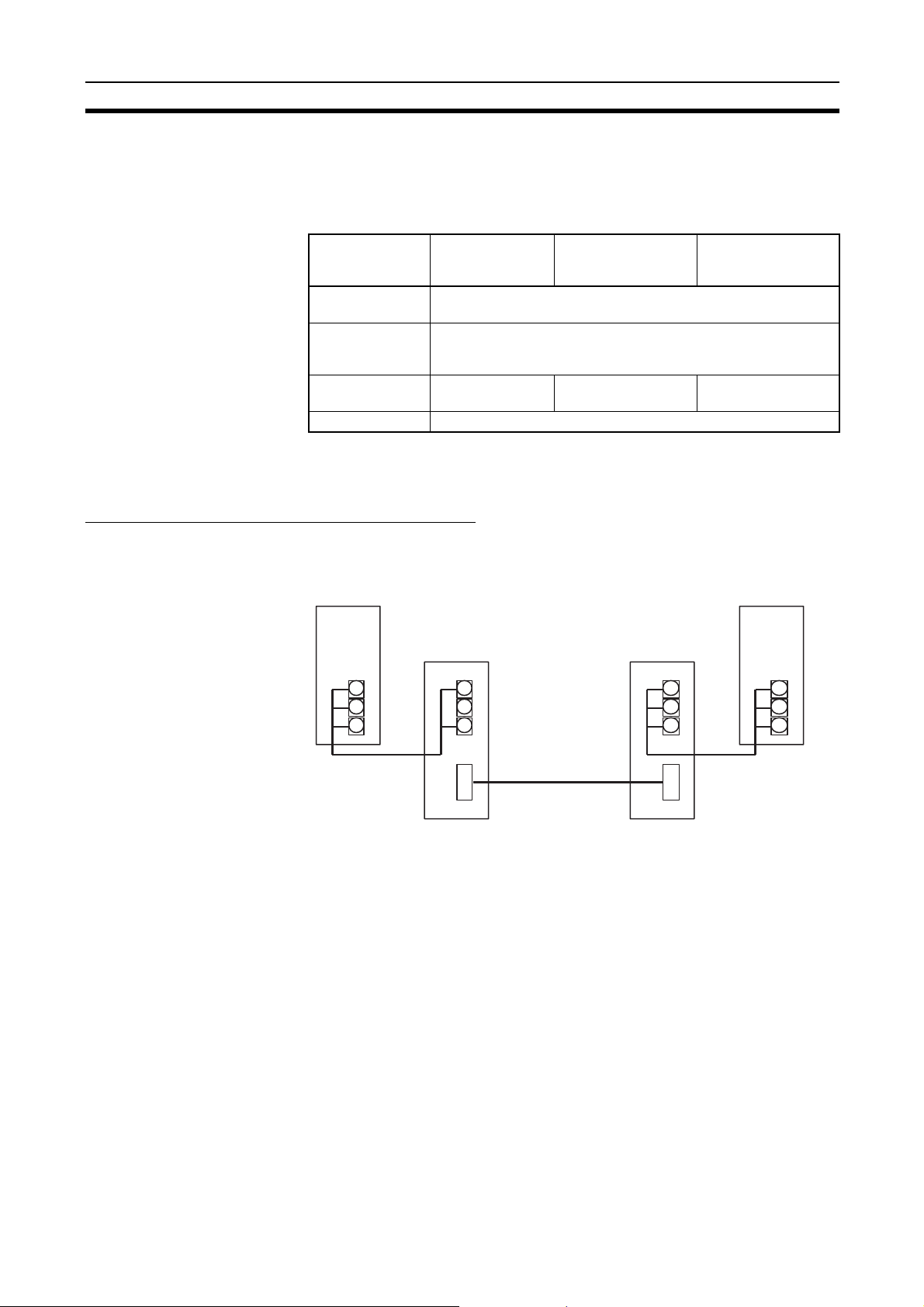

Communications Specifications when Using the CS1W-RPT01 Repeater Unit in a Wired

Network

Item Within 1 segment (See

note 1.)

Transmission path form Multi-drop Tree type (Connection of

Baud rate and maximum transmission distance (See note 2.)

Maximum number of nodes Total number of Control-

Maximum number of Repeater

stages (See note 4.)

2 Mbps: 500 m

1 Mbps: 800 m

500 Kbps: 1 km

ler Link Units + Repeater

Units: 32 nodes (See

note 5.)

--- 2 stages

Note 1. Specifications within a segment are identical to the specifications of a

Wired Controller Link Network.

2. Maximum transmission distance: Total length of cables in the longest path

connecting any two nodes.

3. A maximum of 62 nodes is possible only when using CS1W-CLK21-V1,

CJ1W-CLK21-V1 and 3G8F7-CLK21-V1 Units.

4. Maximum number of Repeater stages: The maximum number of Repeater

Units that can be inserted into the path connecting any two nodes. For

wire-to-optical connection, two Repeater Units make up a single set, which

is counted as a single Repeater stage.

5. The Repeater Units each have a unique node address. Up to 32 Units,

consisting of Controller Link Units and Repeater Units, can be connected

within a single segment.

Entire network

segments with Repeaters)

2 Mbps: 1.5 km

1 Mbps: 2.4 km

500 Kbps: 3.0 km

Controller Link Units/Support Boards (See note 3.):

62 nodes

Wire

Optical

fiber

cable

: Controller Link Unit/Support

Board

: Wire-to-wire Repeater Unit

: Wire-to-optical Repeater Unit

(two Units used in a pair)

: Range of a single segment

Note: The Repeater Unit will be

counted in the number of

nodes for each segment that

it is connected to.

Specifications of Optical Fiber Cables Used with Wire-to-Optical

Connections

Item H-PCF type GI type

Optical fiber cable H-PCF 200/230 µm two-

Maximum transmission

distance (See note 2.)

core cable

Adhesion-polished: 1 km

Crimp cut: 800 m

GI 50/125 µm two-core cable

or GI 62.5/125 µm two-core

cable

50/125 µm: 1 km

62.5/125 µm: 2 km

15

Specifications and Configurations Section 1-2

1-2-4 Controller Link Unit Models and PLCs

Wired System

There are five Controller Link Units: One for CVM1 and CV-series PLCs, one

each for CS-series and CJ-series PLCs, one for the C200HX/HG/HE PLC,

and one for CQM1H-series PLCs.

Item Specifications

Model CS1W-CLK21-V1 CJ1W-CLK21-V1 C200HW-CLK21

External appearance

C

L

K

2

1

RUN

ERC

INS

SD

TER

ERH

M/A

LNK

RD

4

5

3

6

2

7

1

8

U

N

IT

0

9

F

A

E

B

D

C

No.

3

2

4

1

5

NODE

0

6

9

7

8

No.

1

x10

3

2

4

1

5

0

6

9

7

8

ON

0

x10

1

ON

SW1

2

1

BAUD

RATE

2

TER SW

ON

BD H

BD L

SHLD

Installation

devices

None required. None required. C200HW-COM01/04 Commu-

nications Board and

C200HW-CE001/002/012 Bus

Connection Unit

PLC CS-series PLCs CJ-series PLCs C200HX/HG/HE PLCs

(Except C200HE-CPU11(-Z))

Max No. of Units

per PLC

Installation site Install onto a CPU Backplane or

Storage location

4 maximum including optical

models

CPU

CPU Backplane

Unit

4 maximum on CPU or Expansion Rack

2 maximum

CPU Backplane

2 max.

2/3/5/8/10 slots

Expansion

Of these

slots,

installation

is possible

in up to 4

slots.

Backplane

3/5/8/10 slots

CS-series Expansion Backplane

(Classified as a CPU Bus Unit.)

Install onto a CPU Rack or

Expansion Rack (Classified as a

CPU Bus Unit.)

Install onto a CPU Backplane. (Classified as a Special

I/O Unit for communications.)

CPU Bus Unit Area (in the CPU Unit parameter area) Controller Link Unit

CPU

Unit

for network

parameters

Storage location

for routing tables

CPU Unit parameter area DM 6450 to DM 6499 in CPU

Unit

Weight 400 g 110 g 400 g

Current con-

330 mA 350 mA 300 mA

sumption

16

Specifications and Configurations Section 1-2

Item Specifications

Model CVM1-CLK21 CQM1H-CLK21

External

appearance

Installation

None required. None required.

devices

PLC CVM1 and CV-series PLCs CQM1H-CPU51/61

Max No. of

Units per PLC

Installation site Install onto a CPU Backplane or

Storage location for net-

4 maximum 1 maximum

CPU Backplane

3/5/10 slots

Expansion CPU

Backplane

11 slots

CPU

Unit

Of these

14, 16, or

21 slots,

installa

tion is

possible

in up to 4

slots.

Power Supply

Unit

Connect

here.

Connected as a CommuniExpansion CPU Backplane (Classified as a CPU Bus Unit.)

CPU Bus Unit Area (in the CPU Unit

cations Unit between Power

Supply Unit and CPU Unit.

Controller Link Unit

parameter area)

CPU

Unit

work

parameters

Storage location for routing

CPU Unit parameter area DM 6450 to DM 6499 in

CPU Unit

tables

Weight 550 g 200 g

Current con-

300 mA 290 mA

sumption

Note A Controller Link Support Board can be installed into an IBM PC/AT or com-

patible computer to connect the computer to the network. Refer to the Controller Link Support Boards Operation Manual (W307) for details.

17

Specifications and Configurations Section 1-2

Functional Differences between Version-1 and Pre-version-1 Models

Item Pre-version-1 models Version-1 models

Model Controller Link

Unit

Controller Link

Support Board

Automatic data link creation

Changing manually created data link tables during operation

Maximum number of

nodes that can be connected

Combined usage Possible (See note.)

Note Automatic data link creation with 1:N allocation and 62-node configurations

cannot be used if version-1 models are used together with pre-version-1 models.

CS1W-CLK21 and

CJ1W-CLK21

3G8F7-CLK21 3G8F7-CLK21-V1

Equality layout only Either equality layout or 1:N allo-

Not supported. Supported (The data link tables

32 nodes 62 nodes

CS1W-CLK21-V1 and CJ1WCLK21-V1

cation (common type, 1 to 1 type,

or chain type) can be selected.

can be changed with active data

links.)

A CS1W-PRT01 Repeater Unit is

required.

1-2-5 Devices for Connection

Communications Cables

Note Use the special connector provided with the Board to connect the Controller

To set up a Controller Link Network, the following devices are needed in addition to a Controller Link Unit and a PLC.

The following shielded twisted-pair cables are recommended for Wired Controller Link Network connections.

Model Manufacturer Remarks

Li2Y-FCY2 x 0.56 qmm Kromberg & Schubert,

Komtec Department

1 x 2 x AWG

Tr.CUSN + PVC

#9207 Belden USA company

ESVC 0.5 x 2 C-1362 Bando Densen Co. Japanese company

ESNC 0.5 x 2 C-99-087B Nihon Electric Wire &

– 20PE +

Draka Cables Industrial Spanish company

Cable Co.

German company

Japanese company

Link Support Board to the network.

18

Specifications and Configurations Section 1-2

Repeater Units (when Required)

The following Repeater Units can be used to facilitate the use of T-Branch wiring, long-distance wiring, and the addition or removal of nodes.

Three types of Repeater Unit are available for use with different transmission

line types (i.e., connection methods).

Item Specifications

Model CS1W-RPT01 CS1W-RPT02 CS1W-RPT03

External appearance

Supported Units/

Boards

Transmission line Twisted-pair cable H-PCF cable (optical

All Controller Link Units/Boards for wired networks.

Note To construct a network that can contain up to 62 nodes, it is necessary to use version-1

models, which support 62 nodes.

two-core cable)

GI cable (optical twocore cable; 62.5/125 µm,

50/125 µm)

19

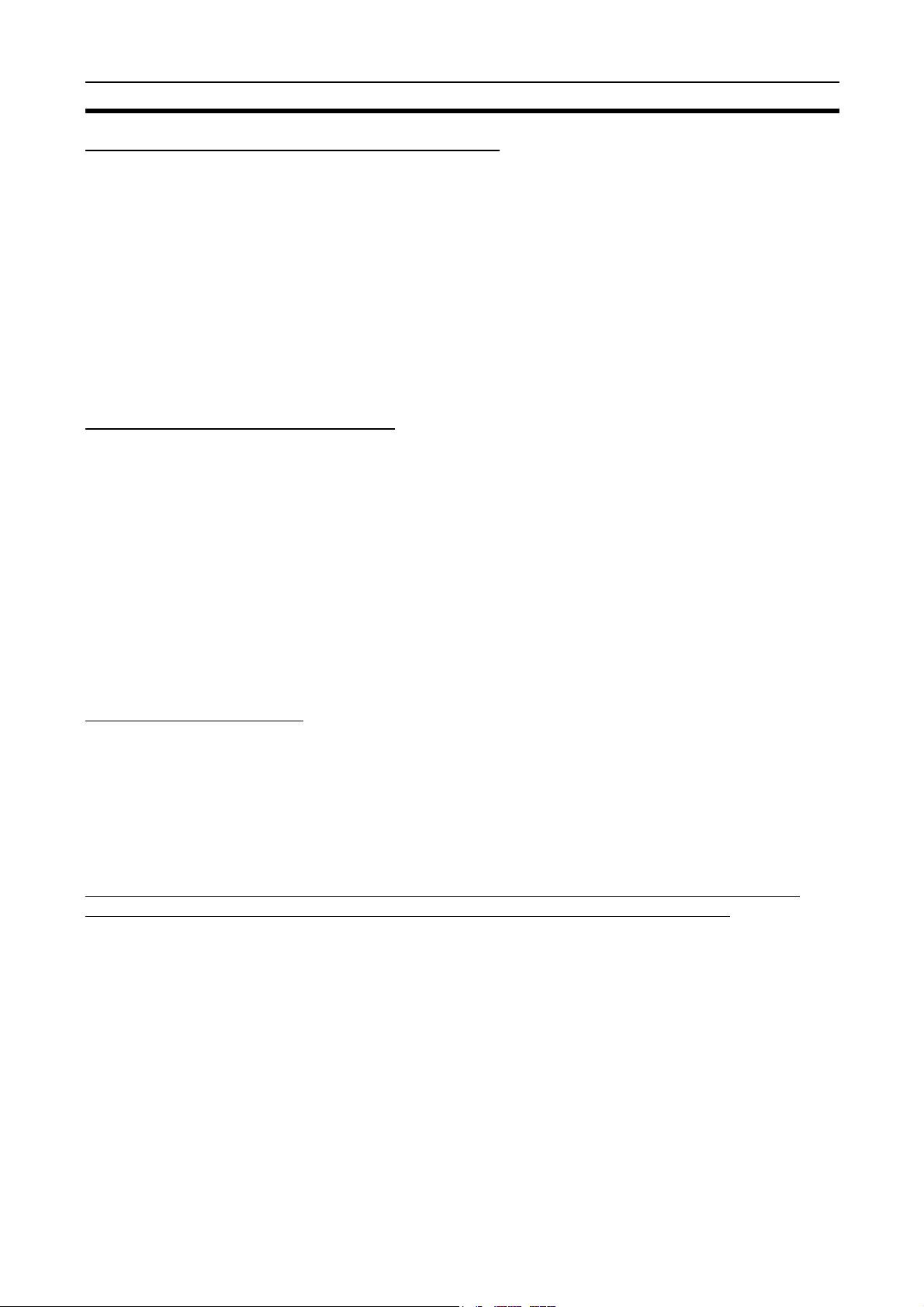

Specifications and Configurations Section 1-2

Item Specifications

Transmission line

format

Multi-drop

Tr ee

T-Branch Wiring

Repeater Unit

Long-distance Wiring

500 m max.

(at 2 Mbit/s)

Repeater Unit

500 m max.

(at 2 Mbit/s)

1:1 type 1:1 type

Partial Conversion to Optical

Wire cable Wire cable

Repeater Unit

Optical cable

Repeater Unit

62-node Configuration

31 nodes max.

Repeater Unit

31 nodes max.

Installation Units are not mounted on the PLC, but are attached to DIN Track or screw-mounted.

Weight 126 g 113 g (excluding mount-

ing bracket)

116 g (excluding mounting bracket)

Current consumption 24 V DC at 60 mA max. 24 V DC at 60 mA max. 24 V DC at 70 mA max.

Power supply volt-

24 V DC

age

Allowable power

20.4 to 26.4 V DC (24 V DC −15 to 10%)

supply voltage range

Inrush current 2.5 A max. at 24 V DC (5 ms after startup)

Note 1. Repeater Units do not use a node address.

2. See

Connection Procedure for an explanation of how Repeater Units are

used.

3. The following Power Supply Unit is recommended: OMRON S82K Series

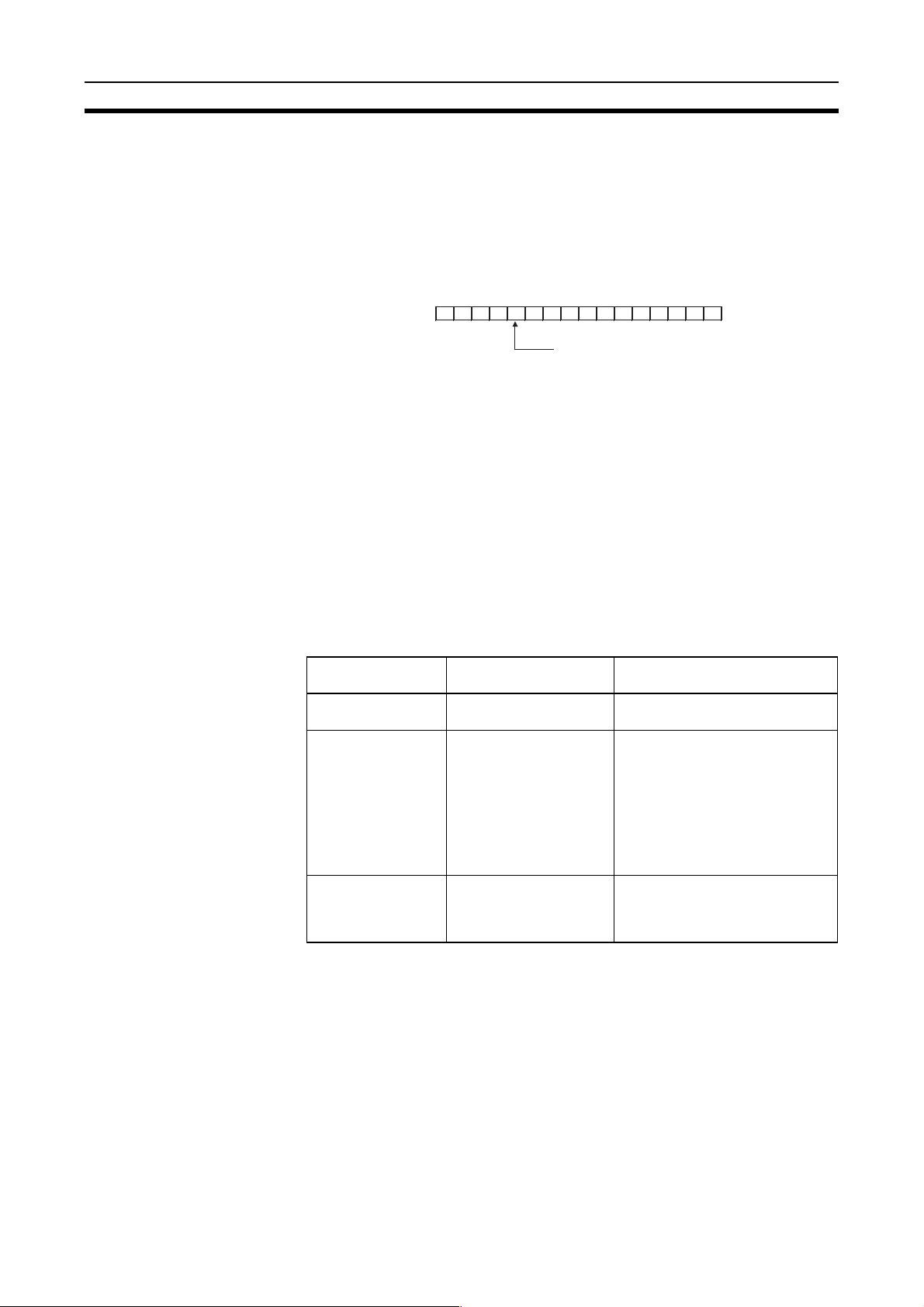

Relay Terminal Blocks

The following Relay Terminal Block can be used to make maintenance easier

by facilitating replacement of the Controller Link Unit after system operation

has begun.

Name Model Remarks

Relay Terminal Block for

Wired Controller Link Units

CJ1W-TB101 Cannot be used on the nodes

on the ends of the network

20

Specifications and Configurations Section 1-2

k

Note Normally, the communications cable must be disconnected from a Wired Con-

troller Link Unit to replace it. Doing this, however, will interrupt communications on the network, requiring that all node be turned OFF to ensure safety

before replacing a Unit. With the above Relay Terminal Block, a Controller

Link Unit can be replaced by turning OFF only the specific Unit being

replaced, i.e., without turning OFF any other Units. The communications

cables are left connected to the Relay Terminal Block and only the Relay Terminal Block is removed from the Controller Link Unit. (The built-in terminating

resistance connected at the Units at the end of the network prevents using the

Relay Terminal Block on the end Units.) Refer to

Terminal Block

for details on using the Terminal Relay Block.

Appendix C Using the Relay

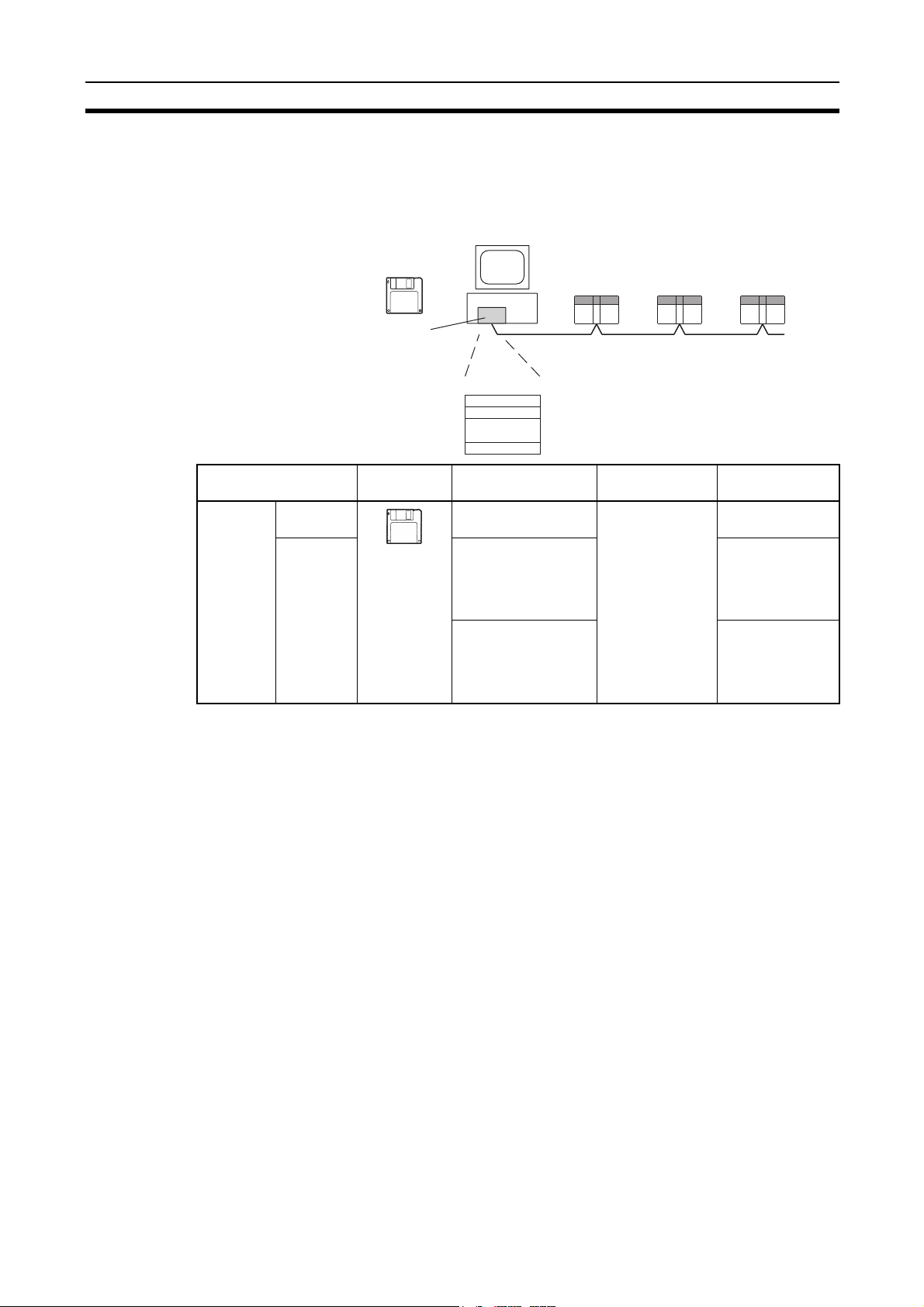

1-2-6 Programming Devices

A Programming Device for the PLC, the Controller Link Support Software, or

CX-Programmer are needed to use a Controller Link Network.

Programming Device for the PLC

One of the following Programming Devices is necessary when using the automatically setting data links or the message service.

Programming

Console

Start-up node

or

CPU Unit

Controller Lin

+

IBM PC/AT or

compatible

CX-Programmer

Software switches (DM Area)

The following operations are possible.

• Selecting manual or automatic setting for data links.

• Setting the data link mode to “automatic” (software switch setting).

• Starting/stopping data links (Start Bit: ON/OFF)

• Programming for the message service.

• Reading (monitoring) the network status.

Programming

Device

CX-Programmer

(for PLC)

SYSMAC Support

Software (for PLC)

CV Support Software (for PLC)

SYSMAC-CPT

(for PLC)

External

appearance

Model Applicable PLCs

WS02-CXP

C500-ZL3AT1-E C200HX/HG/HE and

CV500-ZS3AT1-EV2 CVM1 and

WS01-CPTB1-E C200HX/HG/HE and

@@-E

CS/CJ-series,

C200HX/HG/HE,

CVM1-series, and

CQM1H-series PLCs

CVM1 PLCs

CV-series PLCs

CVM1 PLCs

21

Specifications and Configurations Section 1-2

Programming

Device

Programming

Console

External

appearance

Note For automatic data link creation with 1:N allocations or when changing data

link tables while the data link is active (CS1W-CLK21-V1 and CJ1W-CLK21V1), use the CX-Net in CX-Programmer version 3.2 or later.

Controller Link Support Software (Version 2.00)

The Controller Link Support Software can be used to manually set data links,

to set Controller Link parameters, and to monitor the Controller Link Network.

The Controller Link Support Software is run on a personal computer connected to a C200HX/HG/HE, CVM1, or CV-series PLC or a personal computer in which a Controller Link Support Board has been mounted.

• Setting the data link mode to “manual” (creating and storing data link

tables).

• Starting/stopping data links.

• Reading (monitoring) network status.

• Reading error logs.

• Setting routing tables.

• Testing the Network.

• Changing network parameters.

• Reading the network connection configuration data and status (in tokenring mode only).

Model Applicable PLCs

CQM1-PRO01-E

C200H-PRO27-E

CVM1-PRS21-EV1 CVM1 and

C200HX/HG/HE,

C200H/C200HS,

CQM1, and

CQM1H-series PLCs

CV-series PLCs

Using an Independent

Computer

IBM PC/AT or

compatible

Setting data link tables

…

A computer that is not part of the Network can be used to control the Controller Link Network.

C200HX/HG/HE and

+

Controller Link

Support Software

Nodes

RS-232C

Transmissions

CS1-series PLCs

Nodes

RS-232C

C200HX/HG/HE,

CVM1, and CV-series

PLCs

CQM1H-series PLCs

Controller

Link Unit

CPU Unit

Controller

Link Unit

CPU Unit

CVM1 and CV-series PLCs

Nodes

CS1-series PLC

Controller

Link Unit

CPU Unit

Note 1. The Controller Link Support Software cannot be connected to a CS/CJ-se-

ries PLC. It is possible to monitor and set a Controller Link Unit on a CS/

CJ-series via the network by connecting the computer running the Controller Link Support Software to a C200HX/HG/HE, CVM1, CV-series, or

CQM1H-series PLC.

22

Specifications and Configurations Section 1-2

2. The Controller Link Support Software can be used as a part of the SYSMAC Support Software.

Using a Computer Node A computer that is a node on the Network can also be used to control the

Controller Link Network.

IBM PC/AT or compatible

Controller Link

Support Software

+

Controller Link

Support Board

Setting data link tables

…

Software External

Controller

Link Support Software

Purchased

separately

Provided

with Controller Link

Support

Board

Note Use Controller Link Support Software version 1.1 for an ISA Controller Link

Support Board.

The Controller Link Support Software can also be used with the Controller

Link Support Board.

appearance

Model Applicable PLCs Remarks

C200HW-ZW3AT2EV2

3G8F5-CLK21-EV2 For Controller

3G8F5-CLK11-E For IBM PC/AT or

CS/CJ, C200HX/

HG/HE, CVM1,

CV-series, or

CQM1H-series

PLC

For IBM PC/AT or

compatible

Link Support

Board (included

with the Board)

(Wired systems)

compatible

(included with the

Board) (Optical

systems)

23

Specifications and Configurations Section 1-2

g

Controller Link Support Software Menu Overview

•

Menu items: •

Data Link

Set Network parameters

Edit table

•

Copy table

•

Save table

•

Retrieve table

Print table

•

Start/Stop

Routing tables

Echoback test

Broadcast test

Monitor Network

Display Error log

Display Node status

Display Board setup

Maintenance

Connection Info*

Edit PC ID

System setup

• Initialize table

• Check table

• Unit backup

• Board backup

• Initialize network parameters

• Transfer table

• Delete table

*Optical Rin

• Monitor status

• Device info set

Link Systems only.

Note 1. Refer to the Controller Link Support Software Operation Manual (W308)

for detailed operating procedures.

2. For automatic data link creation with 1:N allocations or when changing

data link tables while the data link is active (CS1W-CLK21-V1 and CJ1WCLK21-V1), use the CX-Net in CX-Programmer version 3.2 or later. Controller LInk Support Software cannot be used to perform these functions.

CX-Programmer

The CX-Net operations within the CX-Programmer is required when using

user-set data links, or when setting or monitoring detailed settings of the Controller Link Unit. This software can be used with a CS/CJ-series PLC and is

ideal for the following applications.

• Setting the data link mode to “manual” (creating and storing data link

tables).

• Starting/stopping data links.

• Reading (monitoring) network status.

• Reading error logs.

• Setting routing tables.

• Testing the Network.

• Changing network parameters.

24

Selection of Communications Functions Section 1-3

When Operating on Personal Computer as Peripheral Software

+

IBM PC/AT or

compatible

Setting data link tables

…

CX-Net in

CX-Programmer

Transmissions

When Operating on Personal Computer Connected as a Node

IBM PC/AT or compatible

CX-Net in

CX-Programmer

+

Controller Link

Support Board

Setting data link tables

…

Nodes