Omron CJ1W-NC214, CJ1W-NC434, CJ1W-NC234 DATASHEET

CJ1W-NC@@4

Position control units

Point-to-point positioning controller with

pulse train output and motion control unit

functionality

• Position control units with 2 or 4 axes

• Position and speed control

• Linear interpolation and feeder control function

• Electronic CAM profiles and axes synchronization

• Positioning of 500 points per axis done from

memory

• S-curve acceleration/deceleration, origin search,

backlash compensation, and other features are also

supported.

• Programming languages: ladder, function blocks.

• Use Windows-based support software to easily create positioning data and store data and parameters

in files.

Function

Motion controllers

These position control units support positioning control via pu lse-train outputs. Positioning is performed using trapezoidal o r Scurve acceleration and deceleration. Models are available with 2 or 4 axes control, and can be used in combination wi th servo

drives or stepping motors what accept pulse-train control. When these units are used in a CJ2 PLC CPU can perform also

synchronous operation by use of electronic CAMs and other function blocks.

System configuration

Personal computer

software: CX-One

CJ1 series

Position control unit

External signals for

Axis 1 and Axis 2

Emergency stop input,

home and limit switche s

CJ1W-NC__4

Axes 1

Axes 2

Servo

relay unit

G-Series

Servo motors

SmartStep 2

Servo drive

I/O signals

(CN1 connector)

K

Pos

unit

Accurax G5

Servo drive

I/O signals

(CN1 connector)

Accurax G5

Servo motors

51Position control units

Specifications

Model CJ1W-NC214

Unit name Position control unit

Classification CJ series special I/O units

Applicable PLCs CJ series

Unit numbers 0 to 94

Maximum number of units per rack 5 units

Maximum number of units per CJ system 20 units (3 expansion racks maximum)

Occupied unit 2

Control method Open-loop control by pulse train output

Control output signals CJ1W-NC@14: Open-collector output

Controlled axes 2 4

I/O allocations Axis operating memory area Allocated in one of the following areas(u ser-specified): CIO, WR, HR, DM or EM area.

Control function Operating modes Direct operation or memory operation

Linear interpolation 2 axes maximum 4 axes maximum

Circular interpolation 2 axes maximum

Interrupr feeding Independent, 2 axes Independent, 4 axes

Position data -2147483648 to +2147483647

No. of positions 500 per axis

Speed data 4 Mpps maximum speed (NC234/434) or 500 kpps (NC214/414)

No. of speeds 500 per axis

Acceleration/deceleration times 0 to 250 s (time to max. speed)

Acceleration/deceleration curves Trapezoidal or S-curve

Auxiliary functions Override Multiplies the axis command speed by a specified ratio. Value: 0.01% to 500.00%

Sofware limits Limits software operation for controlling positioning

Backlash compensation Compensates for the amount of play in the mechanical system according to a set value

Torque limit Restrics the torque upper limit during position control

Saving data in PCU Flash memory

Ambient operating temperature 0 to 55°C

External power supply 24 VDC

Internal current consumption 270 mA or less at 5 VDC 310 mA or less at 5 VDC

Weight 170 g 220 g

CJ1W-NC234

CJ1W-NC@34: Line-driver output

CJ1W-NC414

CJ1W-NC434

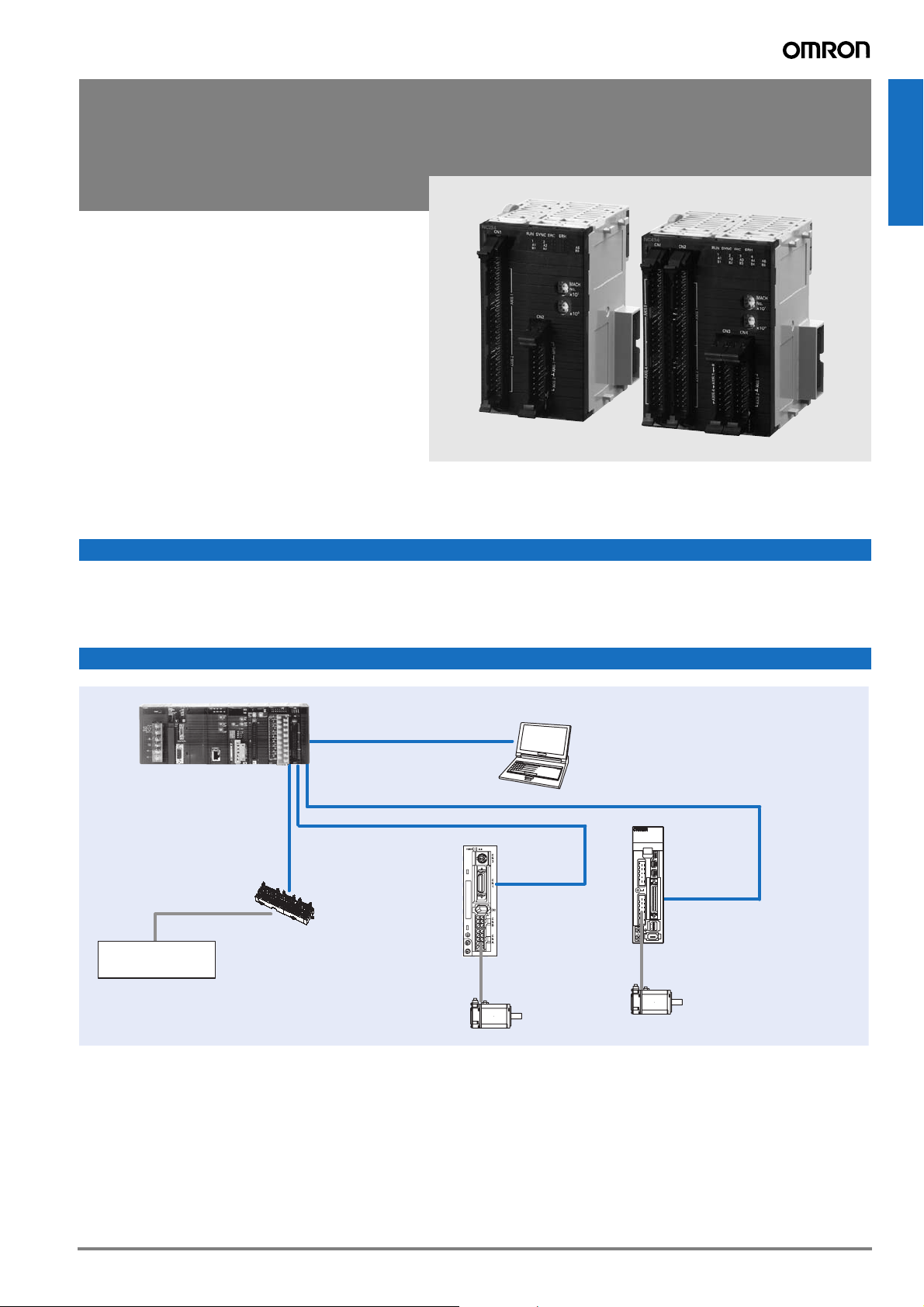

Nomenclature

CJ1W-NC214/234/414/434 - position control unit

CJ1W-NC414/-NC434 CJ1W-NC214/-NC234

Axes 1 and 2

connector

Connects to the

servomotor drive

or stepping

motor driver

(2-axis control).

Axes 3 and 4

connector

Connects to the

servomotor drive

or stepping

motor driver

(2-axis control).

LED indicator

Indicates the

operation status

of the PCU.

Unit number

setting switch

Set the PCU

unit number.

External signal

connector for

axes 1 and 2

Connect

s to

external input.

External signal

connector and

MPG connector

for axes 3 and 4

Connects to external

input and MPG.

Axes 1 and 2

connector

Connects to the

servomotor drive

or stepping

motor driver

(2-axis control).

External signal

connector and

MPG connector

for axes 1 and 2

Connects to

external input and

MPG.

52 Motion controllers

Loading...

Loading...