Cat. No. W380-E1-05

SYSMAC CS/CJ Series

CS Series: CS1W-DRM21(-V1)

CJ Series: CJ1W-DRM21

DeviceNet Units

OPERATION MANUAL

CS-series DeviceNet Unit: CS1W-DRM21(-V1) CJ-series DeviceNet Unit: CJ1W-DRM21

Operation Manual

Revised July 2005

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Reference Indicates supplementary information on related topics that may be of interest

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

to the user.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Trademarks and Copyrights

r

f

DeviceNet is a registered trademark of the Open DeviceNet Vendor Association, Inc.

Windows, Windows 95, Windows 98, Windows Me, Windows NT, and Windows 2000 are registered

trademarks of the Microsoft Corporation.

Other product names and company names in this manual are trademarks or registered trademarks of

their respective companies.

The copyright of the DeviceNet Unit belongs to OMRON Corporation.

OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 1

1-1 Overview of DeviceNet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 DeviceNet Unit Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-4 Comparison with Previous Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1-5 Outline of the Configurator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1-6 Basic Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1-7 List of Usage Methods by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SECTION 2

Nomenclature and Installation . . . . . . . . . . . . . . . . . . . . 45

2-1 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2-2 Installing the DeviceNet Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SECTION 3

Allocated CIO and DM Words . . . . . . . . . . . . . . . . . . . . 57

3-1 Overview of Word Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-2 Allocated CIO Area Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-3 Allocated DM Area Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

SECTION 4

Remote I/O Master Communications . . . . . . . . . . . . . . . 91

4-1 Master Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4-2 Scan List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4-3 Fixed Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4-4 User-set Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4-5 Starting and Stopping Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . 116

4-6 Example of Ladder Programming for Remote I/O Communications . . . . . . . . . . . 116

4-7 Errors that May Occur in Remote I/O Communications . . . . . . . . . . . . . . . . . . . . 118

vii

TABLE OF CONTENTS

SECTION 5

Remote I/O Slave Communications. . . . . . . . . . . . . . . . . 121

5-1 Slave Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

5-2 Fixed Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

5-3 User-set Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

SECTION 6

Message Communications . . . . . . . . . . . . . . . . . . . . . . . . 133

6-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

6-2 FINS Commands and Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

6-3 Using FINS Message Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

6-4 Sending Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

6-5 Receiving Explicit Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

SECTION 7

Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

7-1 Connecting to the CX-Programmer via the DeviceNet . . . . . . . . . . . . . . . . . . . . . 178

7-2 Memory Card Backup Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

7-3 Simple Backup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

SECTION 8

Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . 189

8-1 Remote I/O Communications Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

8-2 Message Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

SECTION 9

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . 201

9-1 Troubleshooting with the DeviceNet Unit Indicators . . . . . . . . . . . . . . . . . . . . . . 202

9-2 Error Log Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

9-3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

9-4 Maintenance and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Appendices

A Allocation Differences from C200H DeviceNet Master Units . . . . . . . . . . . . . . . 231

B DeviceNet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

C FINS Commands and Responses for DeviceNet Units . . . . . . . . . . . . . . . . . . . . 243

D Multi-vendor Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

E DeviceNet Explicit Message Send Command for Other Manufacturer Nodes . . 259

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

viii

About this Manual:

This manual describes the installation and operation of CS1W-DRM21(-V1) (see note) DeviceNet Unit

for SYSMAC CJ-series PLCs and the CJ1W-DRM21 DeviceNet Unit for SYSMAC CJ-series PLCs,

and includes the sections described below.

Note In this manual, both the CS1W-DRM21 and the CS1W-DRM21-V1 are indicated by the follow-

ing notation: CS1W-DRM21(-V1)

Please read this manual and all manuals for related products carefully and be sure you understand the

information provided before attempting to install and operate the DeviceNet Unit. Be sure to read the

precautions provided in the following section.

Section 1 provides an overview of the DeviceNet network, including features, specifications, and system.

Section 2 describes the nomenclature and installation of the DeviceNet Unit.

Section 3 describes the words allocated to the DeviceNet Unit in the CIO Area and DM Area. These

words both enable controlling the DeviceNet Unit and accessing Unit and network status.

Section 4 describes the remote I/O communications performed as a master by the DeviceNet Unit.

Section 5 describes the remote I/O communications performed as a slave by the DeviceNet Unit.

Section 6 describes message communications using FINS commands sent from the ladder program

in the CPU Unit of the PLC.

Section 7 describes connecting to CX-Programmer via the DeviceNet and the Memory Card backup

function.

Section 8 describes the time required for remote I/O communications and message communications.

Section 9 describes error processing, periodic maintenance, and troubleshooting procedures needed

to keep the DeviceNet network operating properly. We recommend reading through the error processing procedures before operation so that operating errors can be identified and corrected more quickly.

The Appendices provide information on allocation differences with C200H-series DeviceNet Units,

DeviceNet connections, remote programming and monitoring, Memory Card backups, FINS commands and responses, sending DeviceNet explicit message to Non-OMRON nodes, and multi-vendor

applications.

The following manuals provide information on the DeviceNet and OMRON DeviceNet products.

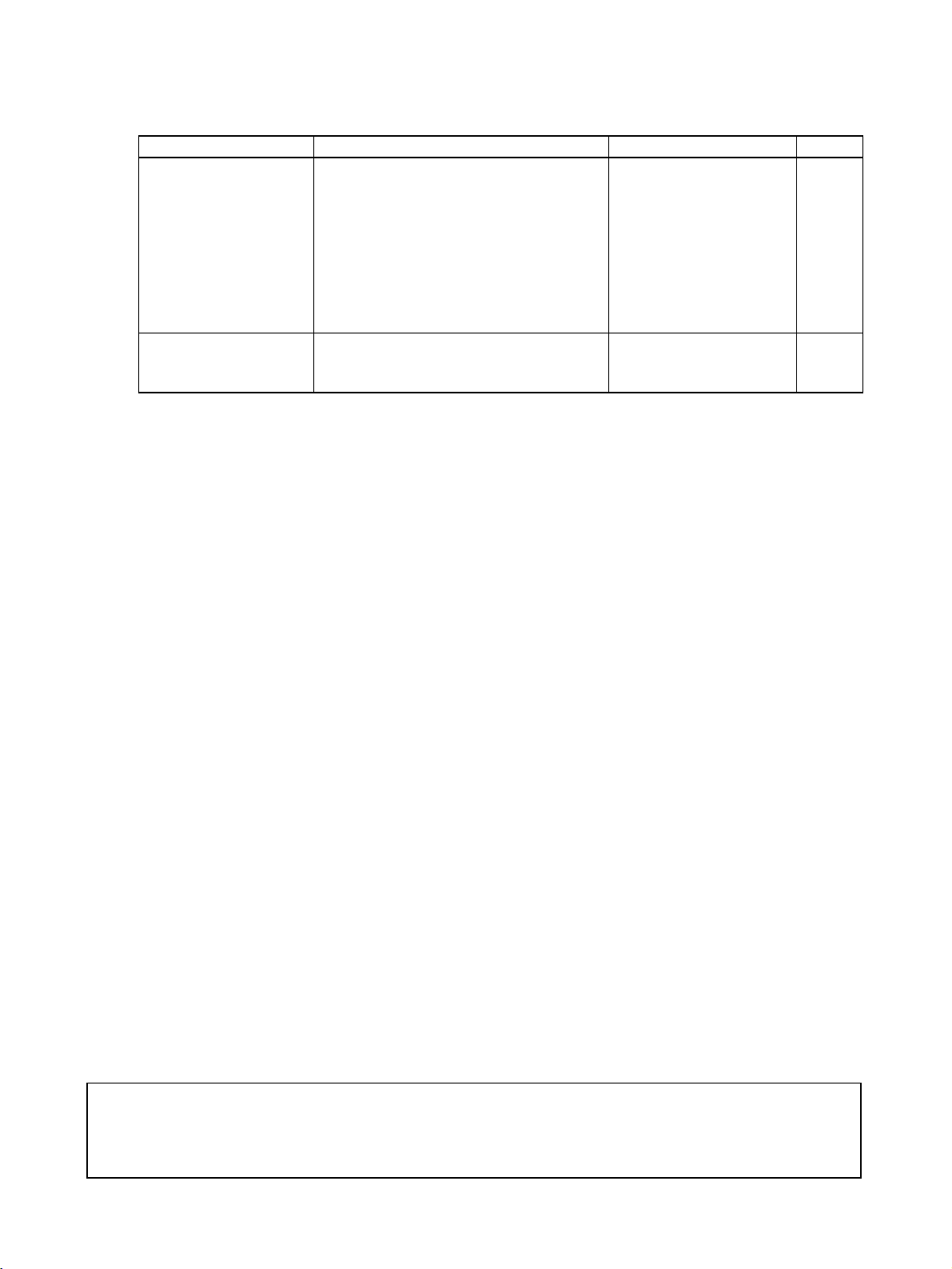

Manual Products Contents Cat. No.

CS/CJ-series DeviceNet

Unit Operation Manual

(This manual)

DeviceNet

Operation Manual

DeviceNet Configurator

Ver. 2.@

Operation Manual

DeviceNet Slaves Operation Manual

DeviceNet MULTIPLE I/O

TERMINAL Operation

Manual

CS1W-DRM21(-V1) and CJ1W-DRM21

DeviceNet Units

CVM1-DRM21-V1 DeviceNet Master Unit

C200HW-DRM21-V1 DeviceNet Master Unit

CQM1-DRT21 I/O Link Unit

DRT1-series DeviceNet Slaves

GT1-series DeviceNet Slaves

WS02-CFDC1-E DeviceNet Configurator

3G8F5-DRM21 ISA Board

3G8E2-DRM21 PCMCIA Board

C200HW-DRT21

CQM1-DRT21

DRT1 Series

DRT1-COM

GT1 Series

Information on CS/CJseries DeviceNet Units.

Information on C200Hseries, CVM1, and CVseries DeviceNet Units, as

well as general DeviceNet

communications specifications and wiring methods.

Information on using the

Configurator.

Information on DeviceNet

Slaves.

Information on MULTIPLE

I/O TERMINALs, one type

of DeviceNet slave.

W380

W267

W382

W347

W348

ix

Manual Products Contents Cat. No.

SYSMAC CS/CJ Series

Communication Commands Reference Manual

CX-Programmer

Operation Manual

About this Manual, Continued

CS1G/H-CPU@@H

CS1G/H-CPU@@-EV1

CS1D-CPU@@H

CS1W-SCU21-V1

CS1W-SCB21-V1/41-V1

CJ1G/H-CPU@@H

CJ1G-CPU@@

CJ1M-CPU@@

CJ1W-SCU21/41

WS02-CXPC1-EV3 Information on setting and

Information on FINS and

Host Link commands that

can be sent to CS/CJ-series

CPU Units.

monitoring networks, such

as the use of routing tables.

W342

W414

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

x

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

xiv

PRECAUTIONS

This section provides general precautions for using the DeviceNet Unit and related devices.

The information contained in this section is important for the safe and reliable application of the DeviceNet Unit

and Programmable Controller (PLC) You must read this section and understand the information contained before

attempting to set up or operate a DeviceNet Unit as part of a PLC.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-3 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

xv

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating the DeviceNet

Unit. Be sure to read this manual before operation and keep this manual close

at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your

OMRON representative before applying a PLC System to the above mentioned applications.

3 Safety Precautions

!WARNING Never attempt to disassemble a Unit or touch the inside of Unit while power is

being supplied. Doing so may result in serious electrical shock or electrocution.

!WARNING Provide safety measures in external circuits, i.e., not in the Programmable

Controller (CPU Unit including associated Units; referred to as “PLC”), in

order to ensure safety in the system if an abnormality occurs due to malfunction of the PLC or another external factor affecting the PLC operation. Not

doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a counter-

xvi

Operating Environment Precautions 4

measure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-VDC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a

network.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

4 Operating Environment Precautions

Do not install the Unit in any of the following locations.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidities outside the range specified in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salt.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near to power supply lines.

xvii

Application Precautions 5

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the DeviceNet Unit.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always connect to a class-3 ground (100

Units.

!Caution Failure to abide by the following precautions could lead to faulty operation or

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Install double safety mechanisms to ensure safety against incorrect signals that may be produced by broken signal lines or momentary power

interruptions.

• Enable the scan list to before operating the system.

• When adding a new node to the network, make sure that the baud rate is

the same as other nodes.

• Use specified communications cables.

• Do not extend connection distances beyond the ranges given in the specifications.

• Always turn OFF the power supply to the personal computer, Slaves, and

Communications Units before attempting any of the following.

• Mounting or dismounting the DeviceNet Unit, Power Supply Units, I/O

Units, CPU Units, or any other Units.

• Assembling a Unit.

• Setting DIP switches or rotary switches.

• Connecting or wiring the cables.

• Connecting or disconnecting connectors.

• Be sure that the terminal blocks, connectors, Memory Units, expansion

cables, and other items with locking devices are properly locked into

place. Improper locking may result in malfunction.

• Be sure that all the mounting screws, terminal screws, Unit mounting

screws, and cable connector screws are tightened to the torque specified

in the relevant manuals. Incorrect tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Always use the power supply voltage specified in this manual.

Ω or less) when installing the

xviii

Application Precautions 5

• Double-check all the wiring and connection of terminal blocks and connectors before mounting the Units.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Be sure to wire communications cable inside ducts.

• Use appropriate communications cables.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Double-check all the wiring and switch settings before turning ON the

power supply.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• After replacing Units, resume operation only after transferring to the new

CPU Unit and/or Special I/O Units the contents of the DM Area, HR Area,

and other data required for resuming operation. Not doing so may result

in an unexpected operation.

• When transporting or storing the product, cover the PCBs with electrically

conductive materials to prevent LSIs and ICs from being damaged by

static electricity, and also keep the product within the specified storage

temperature range.

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impacts during transportation.

• Do not attempt to disassemble, repair, or modify any Units.

xix

Conformance to EC Directives 6

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or

machines. The actual products have been checked for conformity to EMC

standards. (See the following note.) Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel in which the OMRON devices are installed.

The customer must, therefore, perform final checks to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMS (Electromagnetic Susceptibility) and EMI (Electromagnetic

Interference standards in the EMC (Electromagnetic Compatibility) standards

are as follows:

Unit EMS EMI

CS1W-DRM21 EN61000-6-2 EN50081-2

CJ1W-DRM21

6-3 Conformance to EC Directives

DeviceNet products that meet EC directives must be installed as follows:

1,2,3...

1,2,3...

1. DeviceNet Units are designed for installation inside control panels. All DeviceNet Units must be installed within control panels.

2. Used reinforced insulation or double insulation for the DC power supplies

used for the communications power supply, internal circuit power supply,

and the I/O power supplies.

3. DeviceNet products that meet EC directives also meet the common emission standard (EN50081-2). When DeviceNet products are built into equipment, however, the measure necessary to ensure that the standard is met

will vary with the overall configuration of the control panel, the other devices connected to the control panel, and other conditions. You must therefore confirm that EC directives are met for the overall machine or device,

particularly for the radiated emission requirement (10 m).

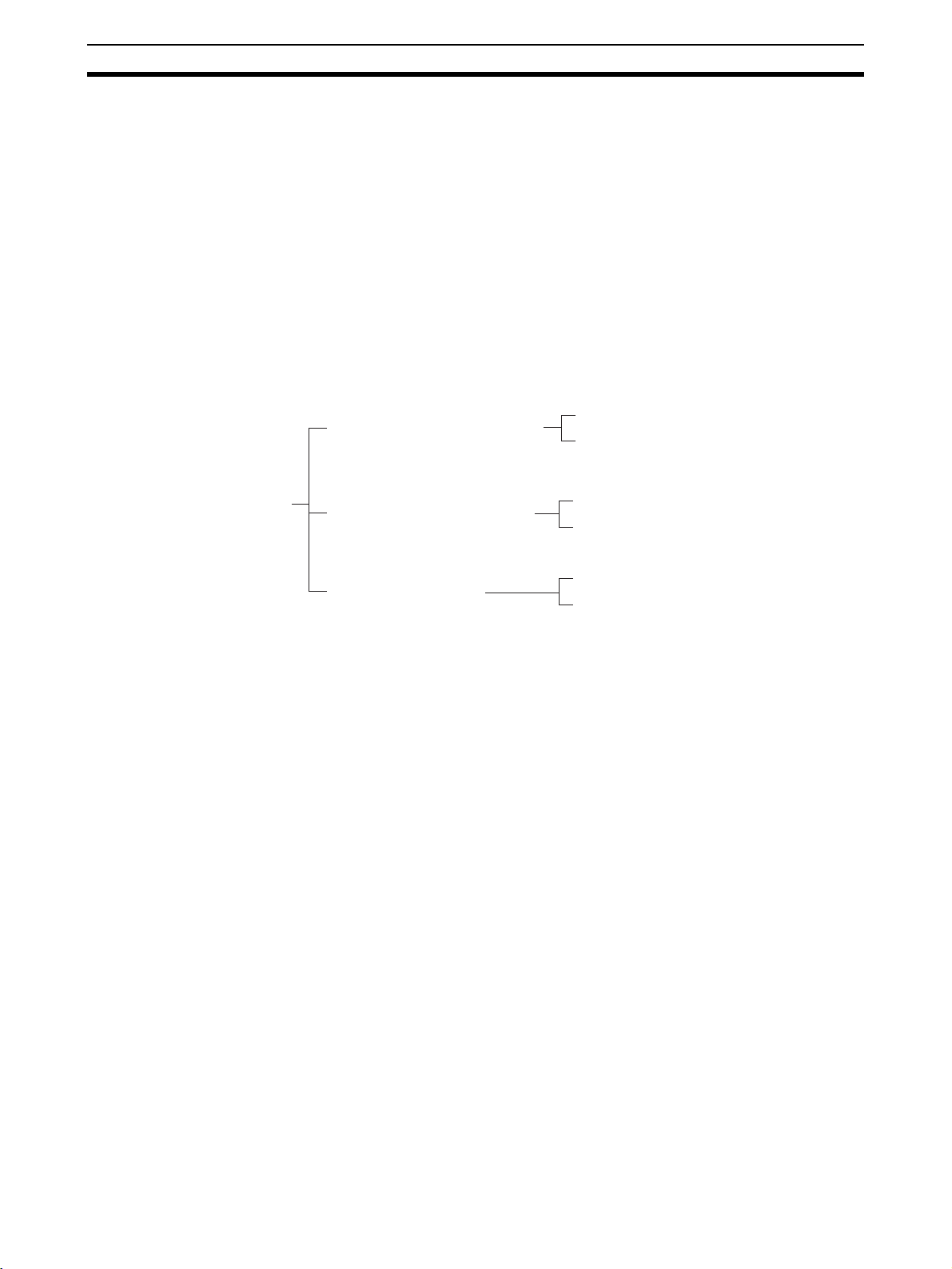

The following examples show means of reducing noise.

. 1. Noise from the communications cable can be reduced by installing a ferrite

core on the communications cable within 10 cm of the DeviceNet Unit.

xx

Conformance to EC Directives 6

Ferrite Core (Data Line Filter): 0443-164151 (manufactured by

Impedance specifications

25 MHZ: 156 Ω

100 MHZ: 250 Ω

30 mm

13 mm

29 mm

Fair-Rite Products Co., Ltd.)

33 mm

2. Wire the control panel with as thick and short electric lines as possible and

ground to 100 Ω min.

3. Keep DeviceNet communications cables as short as possible and ground

to 100 Ω min.

xxi

SECTION 1

Features and System Configuration

This section provides an overview of the DeviceNet network, including features, specifications, and system configurations.

1-1 Overview of DeviceNet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overall System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-1-2 Applicable Units and DeviceNet Functions . . . . . . . . . . . . . . . . . . . 6

1-1-3 Masters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-1-4 Types of Slave. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-1-5 DeviceNet Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-2 DeviceNet Unit Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-3-1 DeviceNet Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-3-2 Comparison between CS1W-DRM21(-V1) and CJ1W-DRM21 . . . 29

1-4 Comparison with Previous Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1-5 Outline of the Configurator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1-5-1 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1-5-2 Configurator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1-6 Basic Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1-6-1 Network Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1-6-2 Hardware Preparations for Communications . . . . . . . . . . . . . . . . . . 37

1-6-3 Creating Routing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-6-4 Procedures Prior to Starting Communications . . . . . . . . . . . . . . . . . 39

1-7 List of Usage Methods by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1

Overview of DeviceNet Section 1-1

1-1 Overview of DeviceNet

DeviceNet is a multi-bit, multi-vendor network that combines controls and data

on a machine/line-control level and that conforms to DeviceNet open field network specifications.

Three types of communications are supported: 1) Remote I/O master communications that automatically transfer I/O between slaves and the CPU Unit to

which a DeviceNet Unit is mounted without any special programming in the

CPU Unit, 2) Remote I/O slave communications that automatically transfer I/O

between the Master and the CPU Unit to which a DeviceNet Unit is mounted,

and 3) Message communications that read/write messages, control operation,

or perform other functions for other CPU Units to which a DeviceNet Unit is

mounted and slaves. Message communications are achieved by executing

specific instructions (SEND (192), RECV (193), and CMND (194)) from the

program in the CPU Unit to which the DeviceNet Unit is mounted.

DeviceNet functions

1,2,3... 1. Without the Configurator Software Tool

Remote I/O master communications

Remote I/O slave communications

Message communications

Fixed allocations

User-set allocations

Fixed allocations

User-set allocations

Explicit message communications

FINS message communications

The following functions are supported with a CS/CJ-series DeviceNet Unit.

a) I/O area words can be flexibly allocated for remote I/O Master and

Slave communications. Three types of fixed allocations as well as

user-set allocations through allocated DM Area words are possible.

b) More than one DeviceNet Unit can be mounted under a single PLC.

c) More than one DeviceNet Unit can be connected in a single network.

With the Configurator, remote I/O can be allocated in any order, i.e.,

not necessarily in the other of node addresses.

Note The Configurator that is connected through a dedicated Board or

Card uses one node in the DeviceNet network. It does not use a

node if it is connected by a serial line.

2. A CS/CJ-series DeviceNet Unit can function as either a master or slave in

remote I/O communications. Both can be used simultaneously.

3. With a CS/CJ-series DeviceNet Unit, the DeviceNet network can be treated exactly like a Controller Link, Ethernet, or other network for message

communications or remote programming and monitoring by a CX-Programmer.

2

Overview of DeviceNet Section 1-1

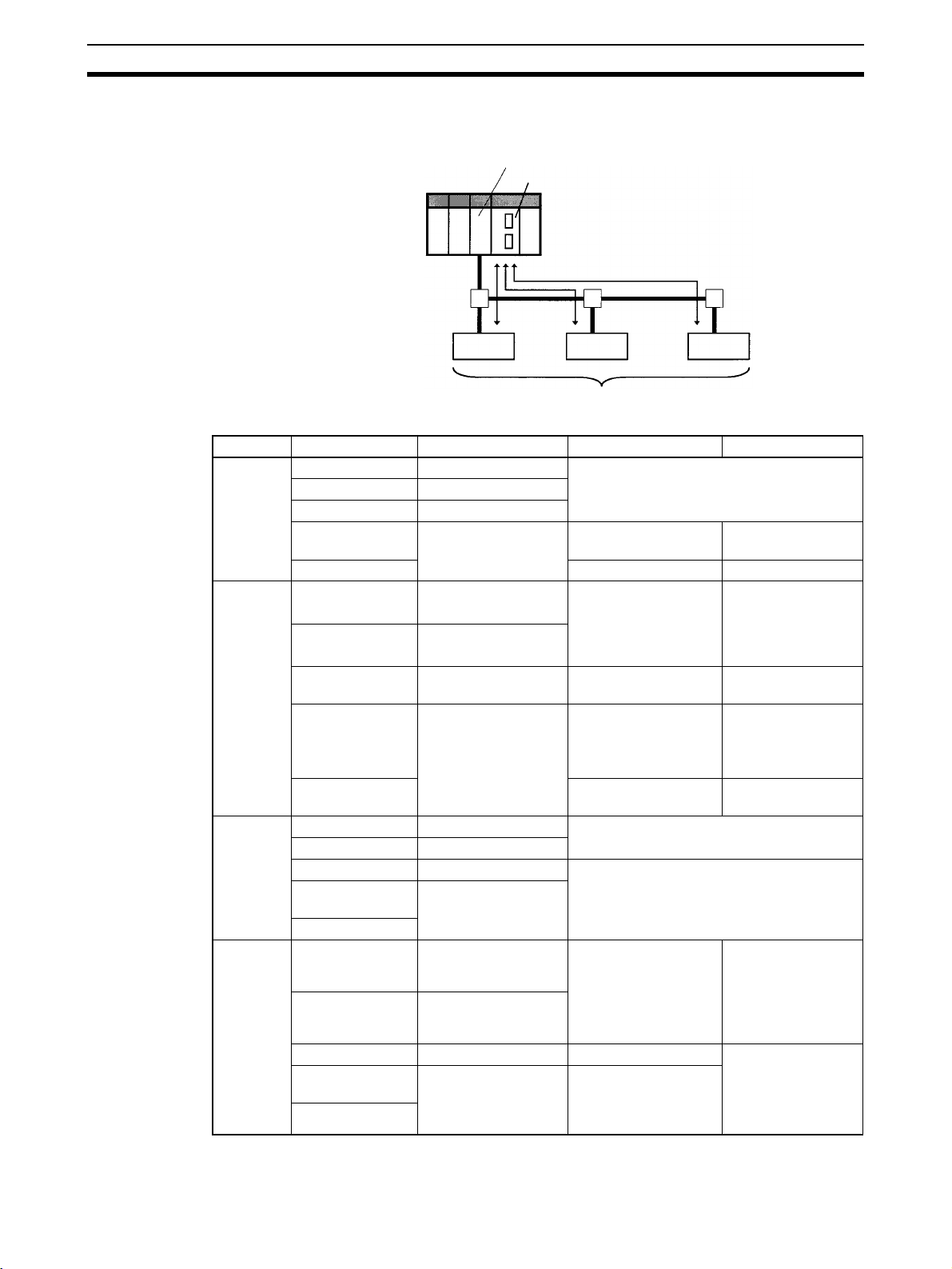

1-1-1 Overall System Configuration

DeviceNet Unit or

DeviceNet Master Unit

CS Series

CS1W-DRM21(-V1)

CJ Series

CJ1W- DRM21

DeviceNet

Configurator

(personal computer)

: T-branch Taps or multi-drop connections

CQM1

C200HZ/HX/HG/E/HS:

C200HW-DRM21-V1

CVM1/CV Series:

CVM1-DRM21-V1

I/O Link

Unit

Photoelectric

sensors, proximity sensors, limit

switches, etc.

Input

Terminal

Output

Terminal

Solenoids,

valves, etc.

Photoelectric

sensors, proximity sensors, limit

switches, etc.

Input Remote

Adapter (used

with Input Block)

Output Remote

Adapter (used

with Output

Block)

Solenoids,

valves, etc.

Photoelectric

sensors or proximity sensors

with connectors

Photoelectric

sensors,

proximity

sensors, limit

switches, etc.

Sensor

Terminal

Environment-resistant Terminal

(Inputs, outputs,

or mixed I/O)

Solenoids,

valves, etc.

Analog

Input

Terminal

Analog sensors,

etc.

Master Features

DeviceNet Unit or

DeviceNet Master Unit

(See note.)

Analog

Output

Terminal

Inverters,

valves, etc.

Temperature Input Terminal

Thermocouple,

platinum resistance

thermometer

Bar code

readers, etc.

C200H I/O Link Unit

RS-232C

Unit

Inputs Outputs Outputs

MULTIPLE I/O TERMINAL

Inputs

Note The Configurator is required if more than one Master is connected in a single

network when a CVM1-DRM21-V1 or C200HW-DRM21-V1 is used.

DeviceNet Master Units and DeviceNet Units

Support remote I/O communications between OMRON PLCs (CS-series, CJseries, CVM1, CV-series, or C200HX/HG/HE/HS) and slaves.

Support message communications between OMRON PLCs, or between an

OMRON PLC and slaves and masters from other companies.

VME Master Boards

Supports remote I/O communications between a VME System and slaves.

3

Overview of DeviceNet Section 1-1

Configurator Features

• Enables user-set allocations for remote I/O (choice of node address order,

2 area allocations, etc.).

• Enables serial connection to the Programming Device Port of a PLC.

• Enables user settings for DeviceNet remote I/O communications connections.

• Enables multiple Masters on a single PLC.

• Enables multiple Masters in a single network.

Slave Features

I/O Terminals

• Provide general-purpose I/O via terminal blocks (M3).

• Available in the following models:

• 8-point Transistor Input Terminal

• 16-point Transistor Input Terminal

• 8-point Transistor Output Terminal

• 16-point Transistor Output Terminal

Environment-resistant Terminals

• Improved I/O Terminals that conform to IP66 for spatter-, water-, and oilresistance.

• Available in the following models:

• 8-point Transistor Input Terminal

• 8-point Transistor Output Terminal

• 16-point Transistor I/O Terminal (8 inputs and 8 outputs)

Remote Adapters

• Used in combination with G70D and other I/O Blocks to handle relay outputs, power MOS FET Relay outputs, etc.

• Available in 16-point input and 16-point output models.

I/O Link Units

• More than one I/O Link Unit can be mounted to a CQM1 PLC.

• Link 16 inputs and 16 outputs between the PLC and the Master.

Sensor Terminals

• Accept inputs from photoelectric and proximity sensors with connectors.

• Available in 16-point input and 8-point input/8-point output models.

• Output signals can be used for sensor teaching and external diagnosis.

Analog Input Terminals

• Convert analog inputs to binary.

• Switchable between 2 and 4 input points using the DIP switch.

• Handle inputs of 0 to 5 V, 1 to 5 V, 0 to 10 V, –10 to +10 V, 0 to 20 mA, or

4to20mA.

• Available in models with a resolution of either 1/6,000 or 1/3,000.

Analog Output Terminals

• Convert binary data to analog outputs.

• Provides outputs of 1 to 5 V, 0 to 10 V, –10 to +10 V, 0 to 20 mA, or 4 to

20mA.

4

Overview of DeviceNet Section 1-1

• Available in models with a resolution of 1/6,000.

Temperature Input Terminals

• Temperature data is input as binary data for 4 inputs.

• Thermocouple and platinum resistance thermometer inputs are available.

C200H I/O Link Units

• Special I/O Slaves that mount to C200HX/HG/HE PLCs and read/write

data from the Master to the specified words in the CPU Unit.

• Read and write areas specified for up to 512 bits each (32 words each).

• Any memory area words can be read or written using DeviceNet explicit

messages.

RS-232C Units

• Special I/O Slaves that provide two RS-232C ports and control I/O from

the Masters.

MULTIPLE I/O TERMINALs

• Multiple I/O Units can be combined under a Communications Unit and

treated as a single Slave.

• Special I/O Units, such as Analog I/O Units, and High-speed Counter

Units are also available.

5

Overview of DeviceNet Section 1-1

1-1-2 Applicable Units and DeviceNet Functions

Remote I/O Master

DeviceNet Unit (Master)

CPU Unit

Remote I/O communications

DeviceNet

Slaves

Item Master Model Without Configurator With Configurator

Max. No.

of Slave

nodes per

Master

Max. No.

of control

points per

Master

CS Series CS1W-DRM21(-V1) 63 nodes

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1

CS Series,

C200HX/HG/HE

C200HS 32 nodes 63 nodes

CS Series CS1W-DRM21(-V1) 2,048 pts (64 input /64

CJ Series CJ1W-DRM21

C200HW-DRM21-V1 50 nodes 63 nodes

32,000 pts (500

output words) or

16,000 pts (500 input/

500 output words)

words x 4 blocks)

Max. No.

of I/O

points per

Slave controllable by

Master

Remote I/

O allocation areas

CVM1, CV Series CVM1-DRM21-V1 2,048 pts (64 input/ 64

output words)

CS Series,

C200HX/HG/HE

C200HS 1,024 pts (32 input/32

CS Series CS1W-DRM21(-V1) 100 input/100 output words

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 32 input/32 output words

CS Series,

C200HX/HG/HE

C200HS

CS Series CS1W-DRM21(-V1) CS/CJ DeviceNet

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 DeviceNet Area User-allocated

CS Series,

C200HX/HG/HE

C200HS

C200HW-DRM21-V1 1,600 pts (50 input/50

output words)

output words)

C200HW-DRM21-V1

words in CIO Area,

and user-allocated

words in CIO Area,

DM Area, and other

areas.

C200HW-DRM21-V1 C200H DeviceNet

words in CIO Area

(including dedicated

words/ bits)

6,400 (100 words x

4 blocks

Without messages:

4,800 pts

With messages:

1,600 pts

1,280

User-allocated

words in CIO Area,

DM Area, and other

areas.

words in CIO Area,

DM Area, and other

areas.

6

Overview of DeviceNet Section 1-1

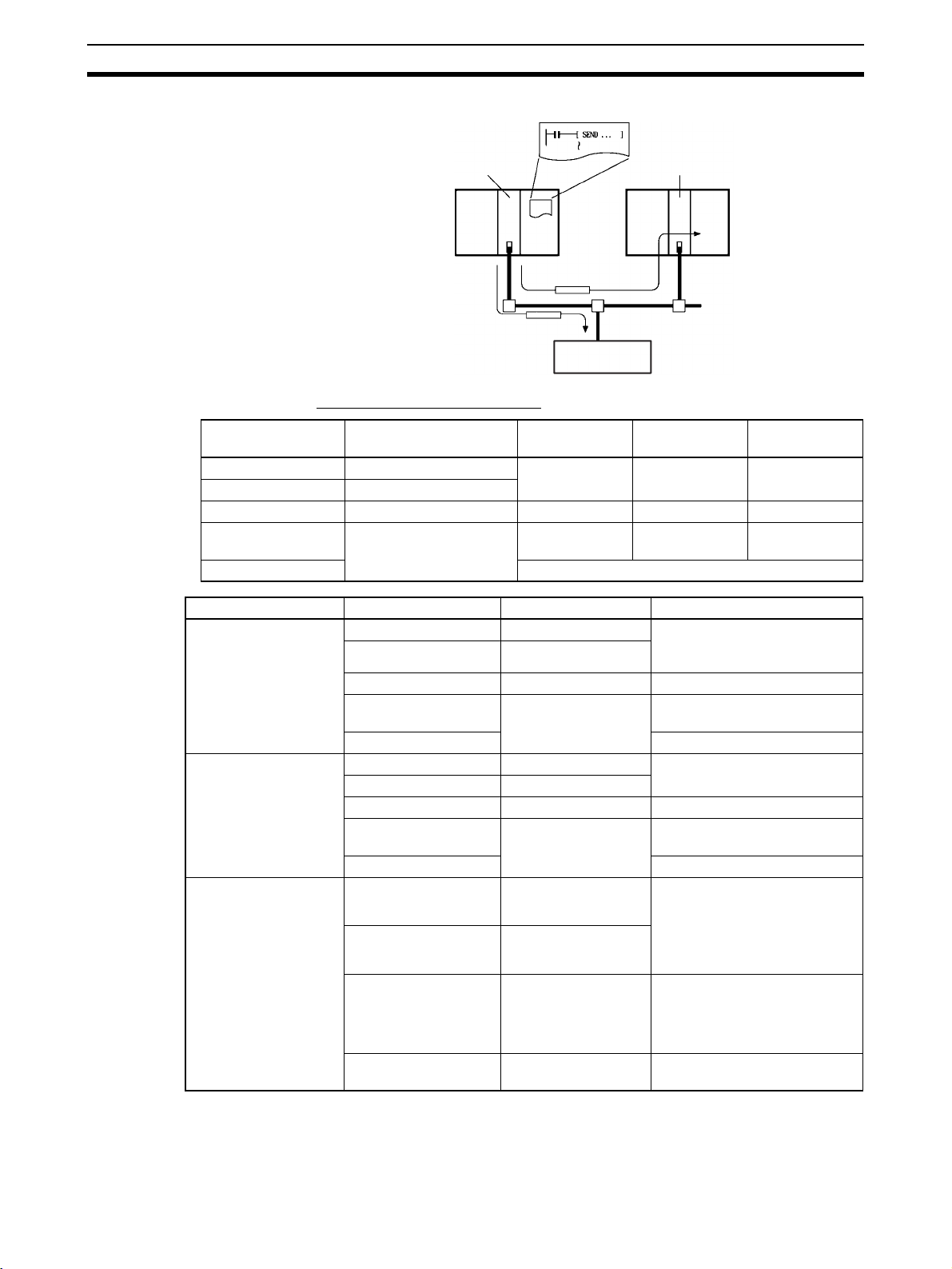

Remote I/O Slave (only Units Mounted in a PLC)

DeviceNet Unit (Master)

CPU Unit

IN area OUT area

Item CPU Unit to

Max. No. of I/O pts

per Slave

Allocation areas in

the CPU Unit to

which this Slave is

mounted

Remote I/O communications

DeviceNet Unit (Slave)

DeviceNet

Slaves

CPU Unit

IN area

Unit Model Without the

which a Slave is

Configurator

mounted

CS Series CS1W-DRM21(-V1) 32 pts (1 input/

1 output word) or

CJ Series CJ1W-DRM21

3,200 pts (100

input/100 output

words)

CS Series,

C200HW-DRT21 1,024 pts (32 input/32 output words)

C200HX/HG/HE

CQM1H

CQM1-DRT21 32 pts (1 input/1 output word)

CQM1 Series

CS Series CS1W-DRM21(-V1) CIO, WR, DM, EM, HR

CJ Series CJ1W-DRM21

CS Series,

C200HW-DRT21 CIO, DM, EM, AR, LR, T/C

C200HX/HG/HE

CQM1H

CQM1-DRT21 CIO

CQM1 Series

OUT area

With the

Configurator

4,800 pts

(100 input words x

2/100 output words

x 1)

7

Overview of DeviceNet Section 1-1

Message Communications

Master Master

RS-232C

Interface Unit

Communications Instructions

Master Unit model Send Receive FINS

commands

CS Series CS1W-DRM21(-V1) SEND(192) RECV(193) CMND(194)

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 SEND(192) RECV(193) CMND(194)

CS Series,

C200HX/HG/HE

C200HS ---

C200HW-DRM21-V1 None None IOWR

Item Master model Model Capacity

Max. No. of nodes per

Master for message

communications using

FINS commands

Max. No. of nodes per

Master for message

communications using

explicit messages

Max. message length CS Series CS1W-DRM21(-V1) SEND(192): 267 words

CS Series CS1W-DRM21(-V1) 62 nodes

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 8 nodes

CS Series,

C200HX/HG/HE

C200HS Not supported

CS Series CS1W-DRM21(-V1) 63 nodes

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 63 nodes

CS Series, C200HX/

HG/HE

C200HS Not supported

CJ Series CJ1W-DRM21

CVM1, CV Series CVM1-DRM21-V1 SEND(192): 76 words

CS Series,

C200HX/HG/HE

C200HW-DRM21-V1 8 nodes

C200HW-DRM21-V1 63 nodes

C200HW-DRM21-V1 IOWR(223): 160 bytes (start-

(Node address 0 cannot be

used in FINS communications.)

RECV(193): 269 words

CMND(194): 542 bytes (start-

ing with command code)

RECV(193): 78 words

CMND(194): 160 bytes

(starting with command code)

ing with command code)

Note FINS message communications are supported between any two PLCs with a

CS/CJ-series DeviceNet Unit (CS1W-DRM21(-V1)/CJ1W-DRM21). They are

not supported for PLCs with a C200H DeviceNet Master Unit (C200HW-

8

Overview of DeviceNet Section 1-1

DRM21-V1) or a CVM1/CV-series DeviceNet Master Unit (CVM1-DRM21V1). Refer to

Communications Software Switches and Communications Status

Dedicated words in the CPU Unit are allocated for DeviceNet communications

software switches and status.

Master

6-3 Using FINS Message Communications for details.

Software

switches

Status area

Control scan list registration/clearing, remote I/O

communications start/stop, and other parameters

Enables monitoring communications errors, communications

status of Masters, registered Slave data, normal Slave data,

etc.

1-1-3 Masters

PLC Model Mountable position Master/Slave

function

CS Series CS1W-DRM21(-V1)

CJ Series CJ1W-DRM21 CPU Rack or Expansion

CVM1/CV Series CVM1-DRM21-V1

CS Series C200HW-DRM21-V1

C200HX/HG/HE 10 or 16

C200HS 10

DeviceNet Unit

DeviceNet Master

Unit

DeviceNet Master

Unit

CPU or Expansion CPU

Rack (Classified as CPU

Bus Units)

Rack (Classified as CPU

Bus Units)

CPU or Expansion CPU

Rack (Classified as CPU

Bus Units)

CPU Rack or Expansion

I/O Rack (Classified as

Special I/O Units)

Master and Slave 16

Master only 16 1

Maximum number of

Configurator

16

mountable units

With

Without

Configurator

1-1-4 Types of Slave

The following classifications are used for DeviceNet Slaves.

• General-purpose Slaves:

Slave with I/O functions for I/O that uses an ordinary connector connected

to a communications cable.

• Environment-resistant Slaves:

Slave with I/O functions for I/O that uses a round, waterproof connector

connected to a communications cable.

• Special Slaves:

Slave with functions not related to I/O (e.g., message communications) for

I/O that uses an ordinary connector connected to a communications

cable.

9

Loading...

Loading...