Page 1

Cat. No. W02E-EN-01

SYSMAC CJ-series

CJ1W-CTL41-E

4-Channel Counter Unit

OPERATION MANUAL

Page 2

SYSMAC CJ-series

CJ1W-CTL41-E

4-Channel Counter Unit

Operation Manual

Produced September 2004

i

Page 3

ii

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator and

only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always pay attention to the information provided with them. Failure to comply with the precautions can result in injury to people or damage to the product.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

!Caution Indicates an potentially hazardous situation which, if not avoided, may

result in minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalised in this manual. The word “Unit” is also capitalised when it refers to an

OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Logic Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

1, 2, 3… Indicates lists of one sort or another, such as procedures, checklists, etc.

©

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this man ual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless,

OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for dam ages resulting

from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation of

the product.

iii

Page 5

iv

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

SECTION 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Specifications and Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Quick Start Up Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5 Operating Procedure Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-6 Application Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SECTION 2

Components, Installation and Wiring . . . . . . . . . . . . . . . . . 15

2-1 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 3

Operation and Configuration . . . . . . . . . . . . . . . . . . . . . . . . 27

3-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-2 Counter Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-3 Input Signal Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-4 Controlling a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-5 Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-6 Reset Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3-7 Extra Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

SECTION 4

Exchanging Data with CPU. . . . . . . . . . . . . . . . . . . . . . . . . . 57

4-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4-2 Memory Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4-3 IOWR-Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4-4 IORD-Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4-5 Supported IOWR/IORD-Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4-6 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

v

Page 7

TABLE OF CONTENTS

SECTION 5

Error Processing, Maintenance and Inspection . . . . . . . . . 91

5-1 Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5-2 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5-3 Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendices

A Using Input Terminal Block Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

B Assigning External Interrupt Tasks to Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

C Application Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

D Comparison between CJ1W-CTL41-E and other Counter Units . . . . . . . . . . . . . . . . . . . . . 107

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

vi

Page 8

About this Manual:

This manual describes the installation and operation of the CJ1W-CTL41-E Counter Unit and includes the

sections described below. Please read this manual carefully and be sure you understand the information

provided before attempting to install or operate the CJ1W-CTL41-E Counter Unit.

Be sure to read the precautions provided in the following sections.

Section 1 introduces the CJ1W-CTL41-E Counter Unit and describes the features, functions, and specifi-

cations. It gives short instructions on how to operate the Unit.

Section 2 provides information about components, wiring and installation of the CJ1W-CTL41-E Counter

Unit.

Section 3 provides information about configuration and operation of the CJ1W-CTL41-E Counter Unit.

Section 4 provides information on the data-exchange and the communication interface between the

CJ1W-CTL41-E Counter Unit and the PLC CPU.

Section 5 provides details of the CJ1W-CTL41-E Counter Unit’s errors, error -codes and indicators and

guidelines for troubleshooting.

The Appendices describe a comparison with CQM1-CBT41 and CJ1W-CTL41-E Counter Units, the use

of Terminal Block Units, and the numbering of External Interrupt Tasks to Outputs.

All through this manual where a double word is defined as for instance “n+2, n+3” this must be interpreted

as follows:

n+3 (MSW) n+2 (LSW)

sign x106x105x104x103x102x101x100 :BCD Double Word

0 = + (positive)

F = - (negative)

n+3 (MSW) n+2 (LSW)

x167x166x165x164x163x162x161x160 :Hexadecimal Double Word

LSW = Least Significant Word

MSW = Most Significant word

!WARNING Failure to read and understand the information provided in this manual may

result in personal injury or death, damage to the product, or product failure.

Please read each section in its entirety and be sure you understand the information provided in the section and related sections before attempting any of the procedures or operations given.

vii

Page 9

viii

Page 10

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PLC) and the Counter Unit.

The information contained in this section is important for the safe and reliable application of the Counter Unit. You

must read this section and understand the information contained before attempting to set up or operate a Counter

Unit and PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

ix

Page 11

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines,

safety equipment, and other systems, machines, and equipment that may have a

serious influence on lives and property if used improperly, consult your OMRON

representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating OMRON Counter

Units. Be sure to read this manual before operation and keep this manual close at

hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the specified

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON representative before applying a PLC system to the above mentioned applications.

3 Safety Precautions

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data from a Programming Device to the CPU Unit.

• Changing present values in memory with a Programming Device.

• Force-setting/-resetting bits with a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to the

CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a network.

x

Page 12

Operating Environment Precautions 4

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

may result in malfunction, fire, or electric shock.

!Caution Execute online edit only after confirming that no adverse effects will be caused

by extending the cycle time. Otherwise, the Input signals may not be readable.

!Caution Confirm safety at the destination node before transferring a program to another

node or changing contents of the I/O memory area. Doing either of these without

confirming safety may result in injury.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. Loose screws may result in burning or

malfunction.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in the

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the lon-

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PLC System. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

xi

Page 13

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the Counter Unit or the PLC.

!WARNING Failure to comply with the following precautions could lead to serious or possibly

fatal injury. Always follow these precautions.

• Always ground the system with 100 Ω or less when installing the system, to

protect against electrical shock.

• Always turn OFF the power supply to the PLC before attempting any of the

following. Performing any of the following with the power supply turned ON

may lead to electrical shock

• Mounting or removing any Units (e.g., I/O Units, CPU Unit, etc.) or memory

cassettes.

• Assembling any devices or racks.

• Connecting or disconnecting any connectors, cables or wiring.

• Setting DIP switch or rotary switches.

!Caution Failure to comply with the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always follow

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the customer.

• If the IOM Hold Bit is turned ON, the outputs from the PLC will not be turned

OFF and will maintain their previous status when the PLC is switched from

RUN or MONITOR mode to PROGRAM mode. Make sure that the external

loads will not produce dangerous conditions when this occurs. (When operation stops for a fatal error, including those produced with the FALS instruction, all outputs from Output Unit will be turned OFF and only the internal

output status will be maintained.)

• Use the Units only with the power supplies and voltages specified in the

operation manuals. Other power supplies and voltages may damage the

Units.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting

may result in burning.

• Do not apply voltages to Input sections in excess of the rated Input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads in excess of the maximum switching

capacity to output sections. Excess voltage or loads may result in burning.

xii

Page 14

Application Precautions 5

!Caution • Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the relevant manuals. Incorrect

tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may result

in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• Double-check all the wiring and the connectors before turning ON the power

supply. Incorrect wiring or bad connections may result in burning or malfunction.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking may

result in malfunction.

• Check switch settings, the contents of the DM Area, and other preparations

before starting operation. Starting operation without the proper settings or data

may result in an unexpected operation.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or damage.

• Do not touch circuit boards or the components mounted to them with your bare

hands. There are sharp leads and other parts on the boards that may cause

injury if handled improperly.

• Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near power supply lines.

• Do not attempt to take any Units apart, to repair any Units, or to modify any

Units in any way.

• After connecting Power Supply Units, CPU Units, I/O Units, Special I/O Units,

or CPU Bus Units together, secure the Units by sliding the sliders at the top and

bottom of the Units until they click into place. Correct operation may not be possible if the Units are not securely properly. Be sure to attach the end cover pro-

xiii

Page 15

Application Precautions 5

vided with the CPU Unit to the right most Unit. CJ-series PLCs will not operate

properly if the end cover is not attached.

xiv

Page 16

EC Directives Section

6 EC Directives

6-1 Applicable Directives

• EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related EMC

standards so that they can be more easily built into other devices or the overall

machine. The actual products have been checked for conformity to EMC standards (see the following note). Whether the products conform to the standards in

the system used by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC Directives

will vary depending on the configuration, wiring, and other conditions of the equipment or control panel on which the OMRON devices are installed. The customer

must, therefore, perform the final check to confirm that devices and the overall

machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility):EN61000-6-2

EMI (Electromagnetic Interference):EN61000-6-4

(Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to

1,500 VDC meet the required safety standards for the PLC (EN61131-2).

6-3 Conformance to EC Directives

6-3-1 Applicable Directives

•EMC Directives

• Low voltage directive

6-3-2 Concepts

EMC Directives

OMRON Units complying with EC Directives also conform to related EMC standards making them easier to incorporate in other Units or machines. The actual

products have been checked for conformity to EMC standards. (See the following

note.) Whether the products conform to the standards in the system used by the

customer, however, must be checked by the customer.

EMC-related performance of OMRON Units complying with EC Directives will

vary depending on the configuration, wiring, and other conditions of the equipment or control panel in which OMRON devices are installed. The customer

must, therefore, perform final checks to confirm that units and the overall system

conforms to EMC standards.

xv

Page 17

EC Directives Section

Note Applicable EMS (Electromagnetic Susceptibility) and EMI (Electromagnetic Inter-

ference standards in the EMC (Electromagnetic Compatibility) standards are as

follows:

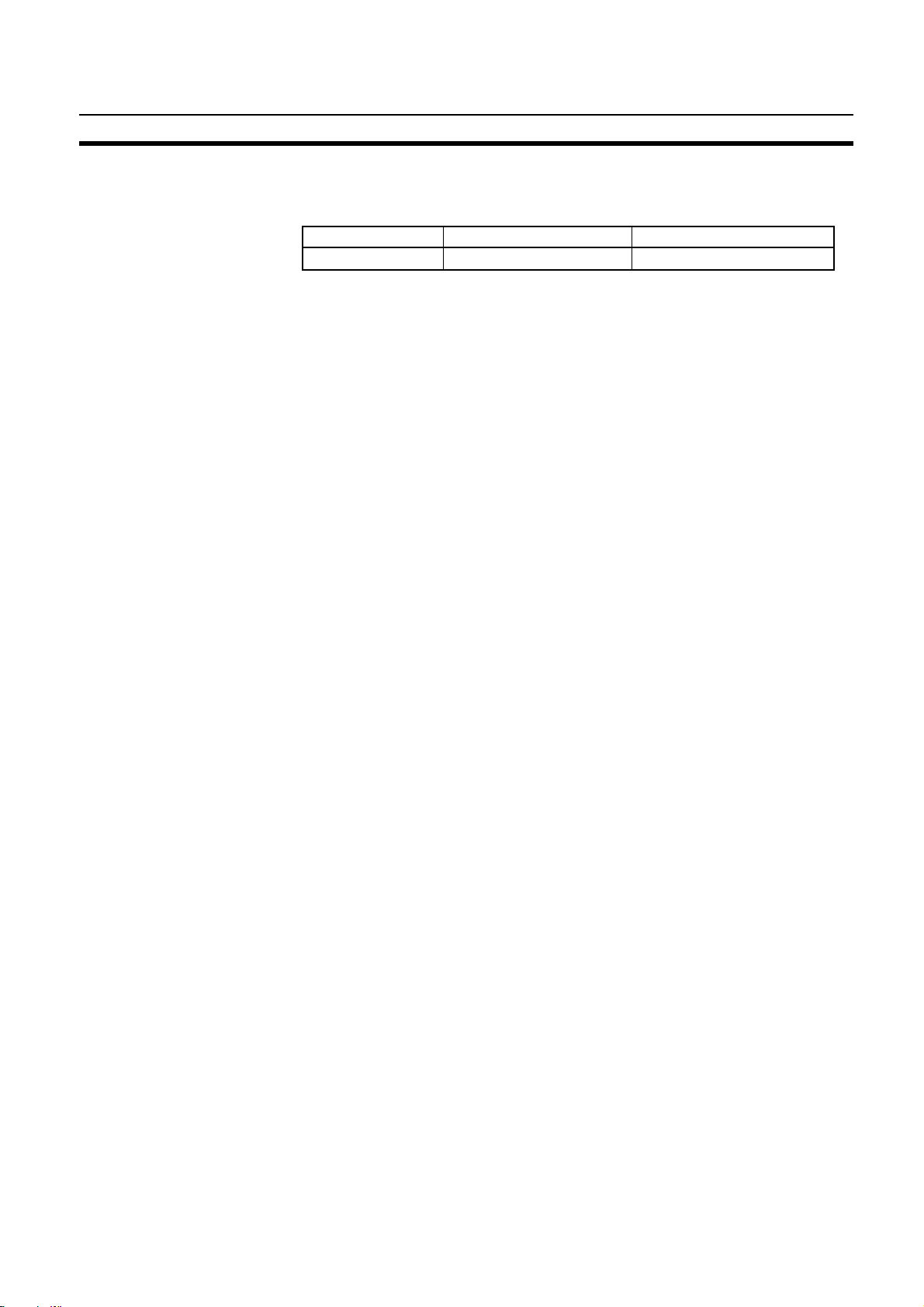

Unit EMS EMI

CJ1W-CTL41-E EN 61000-6-2:2001 EN 61000-6-4:2001

6-3-3 Conformance to EC Directives

Units that meet EC directives also meet the common emission standard

(EN61000-6-4). The measures necessary to ensure that the standard is met will

vary with the overall configuration. You must therefore confirm that EC directives

are met for the overall configuration, particularly any radiated emission requirement (10 m).

xvi

Page 18

SECTION 1

Introduction

This section gives specifications of the CJ1W-CTL41-E and a brief description of the functions and features of the Unit and

the areas of application.

1-1 Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Specifications and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3-2 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3-3 Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-4 Quick Start Up Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-4-1 Configuring the Counter Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-5 Operating Procedure Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-6 Application Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1

Page 19

Features and Functions

1-1 Features and Functions

CTL41

RUN

C

H4

CH

3

CH

2

C

H

1

ERC

ERH

CH1

CH2

Section 1-1

CH3

CH4

3

4

2

5

1

6

0

7

9

8

3

4

2

5

1

6

0

7

9

8

CJ1W-CTL41-E The CJ1W-CTL41-E, a Special I/O Unit for CJ-series PLC-systems, is a freely

configurable Counter Unit. Depending on the requirements of your application, the specific behaviour of the Unit can be adjusted by changing the configuration settings.

CJ1W-CTL41-E Counters The CJ1W-CTL41-E Counter Unit is equipped with 4 Counters and counts

over a maximum binary range of 32-bits. Accepting input pulse frequencies of

up to 100 kHz allows precise control of fast motions. The Unit’s bi-directional

counting ability allows movement detecting in either direction. Each Counter

of the Unit can be configured independently. The Unit is equipped with 32

Software Outputs, each of which can be linked to Counter events. The Unit

can generate interrupts to the PLC CPU, to allow immediate CPU action upon

Counter events.

Counter Type Configuring the Unit starts with choosing one out of two Counter Types:

• Circular Counter (refer to section 3-2-1 Circular Counter)

• Linear Counter (refer to section 3-2-2 Linear Counter)

By default each Counter is set to Circular Counter. For all Counter Types the

full counting range is available. Circular and Linear Counters can be fully (DM) configured according to the application that is to be controlled.

Input Signal Type Depending on the type of input signal your application requires, every Counter

allows a choice out of three input signal types:

• Phase Differential Inputs (multiplication by either 1, 2 or 4)

(refer to section 3-3-1 Phase Differential)

• Up/Down Pulse Inputs (refer to section 3-3-2 Up & Down)

• Pulse & Direction Inputs (refer to section 3-3-3 Pulse & Direction)

Output Control Modes To control the Software Outputs the Unit can be configured in one of the two

following Output Control Modes:

• Range Mode (refer to section 3-5-1 Range Mode)

• Comparison Mode (refer to section 3-5-2 Comparison Mode)

In Range Mode, a configurable number of up to 4 Ranges can be applied to

individual Counters. Every Range can control up to a maximum of 32 Soft-

2

Page 20

Features and Functions

ware Outputs. An Output is turned ON when the Counter is in the corresponding Range.

In Comparison Mode a configurable number of up to 8 Comparison Values

can be applied to individual Counters. Depending on the direction of counting,

an Output can be set or reset (configurable) on reaching the Comparison

Value. Every Comparison Value can control up to maximum 32 Outputs.

Resetting Counter Value Resetting of the Counter Value can be configured depending on the applica-

tion needs. The following sources can trigger a reset:

• CIO bit in the PLC

• Z-Input

To enable resetting a Counter Value, the Software Enable Reset bit can be used

(refer to section 3-6 Reset Signals).

Hysteresis For Counters in Range Mode a hysteresis can be configured [1 to 255

counts], to prevent Outputs from toggling due to unwanted oscillating of

encoding equipment (e.g. rotary incremental encoder). Refer to section 3-7-1

Hysteresis.

Noise Filtering For the purpose of suppressing noise on the signal lines A, B of every

Counter, noise filters are provided. The cut-off frequencies for all signal lines

A and B are fixed to 100 kHz.

Section 1-1

Run-time Configurable Configuration settings of the Unit can be changed at Run-time by using the

IOWR-instruction to be able to quickly adjust to changing application needs

without the need of restarting the Unit or stopping the Counters. Care, however, must be taken when changing configuration settings. Refer to section 3-

5 Output Control for information.

Interrupt Support All Outputs can be configured to generate interrupts to the PLC. Generating

interrupts is only possible when the Counter Unit is mounted in a CPU-rack.

Support Software The Unit can be configured by using CX-Programmer Support Software or a

Programming Console.

Quick Start Up Reference

Guide

For a quick overview of all the features and functions the Counter Unit offers,

refer to section 1-4 Quick Start Up Reference Guide. This section also contains references to the particular section(s) in the Manual where more detailed

information about specific features and functions of the Counter Unit can be

found.

3

Page 21

Basic Configuration

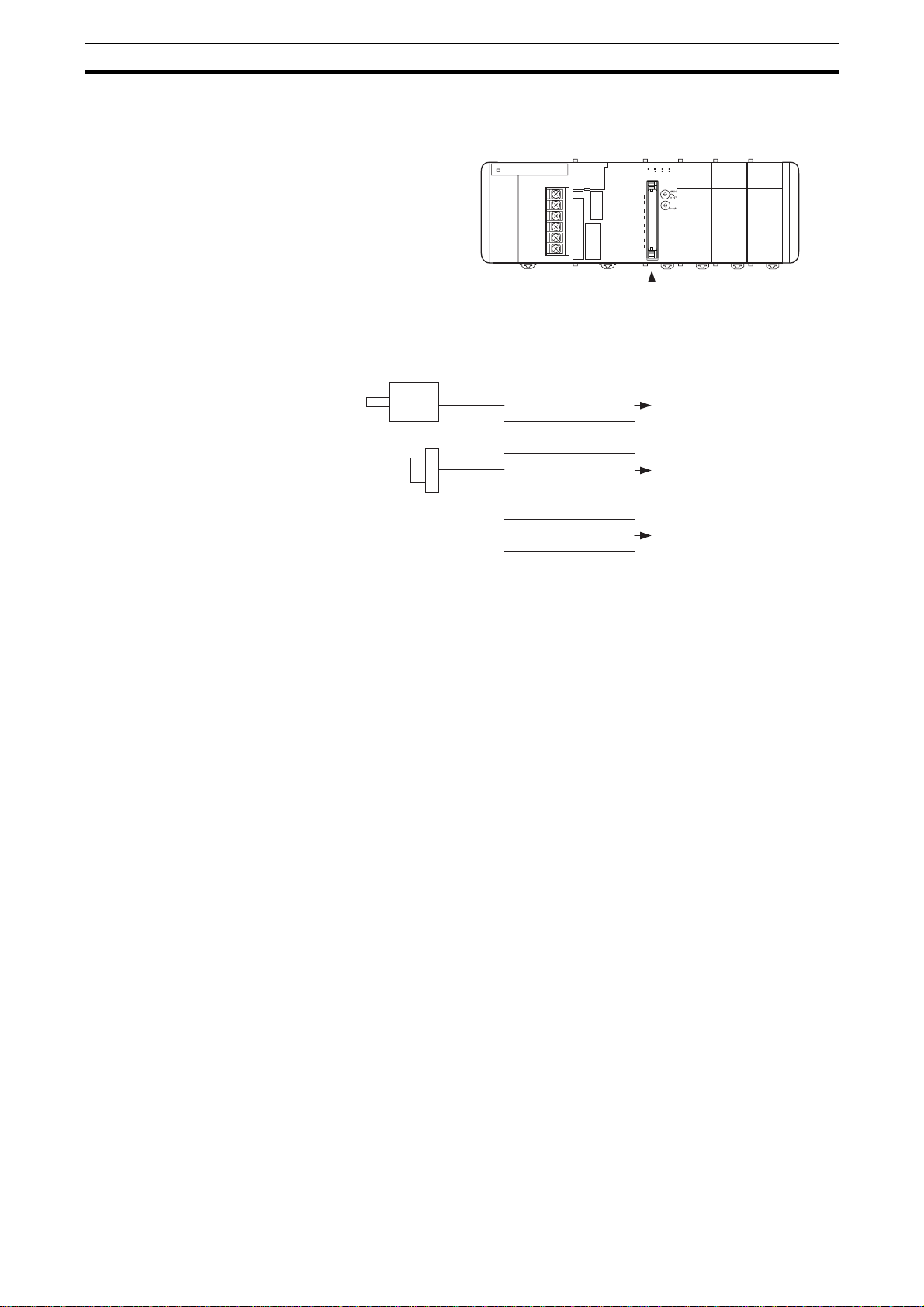

1-2 Basic Configuration

Typical applicable Pulse Generators for

Counter Inputs

Incremental Encoder

Proximity Sensor

CTL41

RUN CH1

CH4

CH3

CH2

CH1

Section 1-2

CH3

ERC

CH2

CH4

ERH

3

4

2

5

1

6

0

7

9

8

3

4

2

5

1

6

0

7

9

8

Other Pulse

Generators

Mounting Restrictions The CJ1W-CTL41-E Counter Unit is a Special I/O Unit belonging to the CJ

Series. A CJ1W-CTL41-E Counter Unit can be mounted to either a CJ CPU

Rack or CJ Expansion Rack.

Note 1. In case of a CJ1-H CPU Unit, the Counter Unit must be in one of the five

positions immediately to the right of the CJ1-H CPU Unit on the CPU Rack,

in order to allow the CJ1W-CTL41-E Counter Unit to generate interrupts

which activate interrupt tasks in a CJ1-H CPU Unit.

2. In case of a CJ1M CPU Unit, the Counter Unit must be in one of the three

positions immediately to the right of the CJ1M CPU Unit on the CPU Rack,

in order to allow the CJ1W-CTL41-E Counter Unit to generate interrupts

which activate interrupt tasks in a CJ1M CPU Unit

3. No interrupt tasks can be activated in CJ1-H or CJ1M CPU Units if the

CJ1W-CTL41-E Counter Unit is in any other position (i.e., 6th Unit position

or further away from the CJ1-H CPU Unit, or 4th Unit position or further

away from the CJ1M CPU Unit), or if it is on a CJ-series Expansion Rack.

Maximum Number of

CJ1W-CTL41-E Units

The maximum number of CJ1W-CTL41-E Counter Units which can be

mounted to a CJ CPU Rack or CJ Expansion Rack is equal to the number of

slots of the Rack. In a configuration with multiple Racks the maximum number

of CJ1W-CTL41-E Counter Units is limited to 24.

Furthermore, the number of Counter Units that can be mounted to one Rack

(i.e., a CPU Rack or Expansion Rack) depends on the maximum supply current from the Power Supply Unit that supplies the Rack and the current consumption of other Units on the Rack.

I/O Connection Methods To connect the Input signal wires to the Unit two methods are available:

4

Page 22

Specifications and Characteristics

• Directly connecting the wires by soldering them to the external connector.

• Indirectly connecting the wires by connecting them to screwless terminals

on an XW2G-40G7-E Input Terminal Block Unit. This Input Terminal Block

Unit allows connection of Line Driver or 24 V Encoder signals. The

XW2G-40G7-E is connected to the Unit via standard available OMRON I/

O-cables (XW2Z-xxxK).

• Indirectly connecting the wires by connecting them to screw terminals on

a standard XW2B-40G4, XW2B-40G5 or XW2D-40G6 OMRON Terminal

Block Unit, i.e. the Terminal Block Unit is connected to the Unit via standard available OMRON I/O-cables (XW2Z-xxxK).

Refer to section 2-3-2 Connector Wiring Methods for more details.

1-3 Specifications and Characteristics

1-3-1 General Specifications

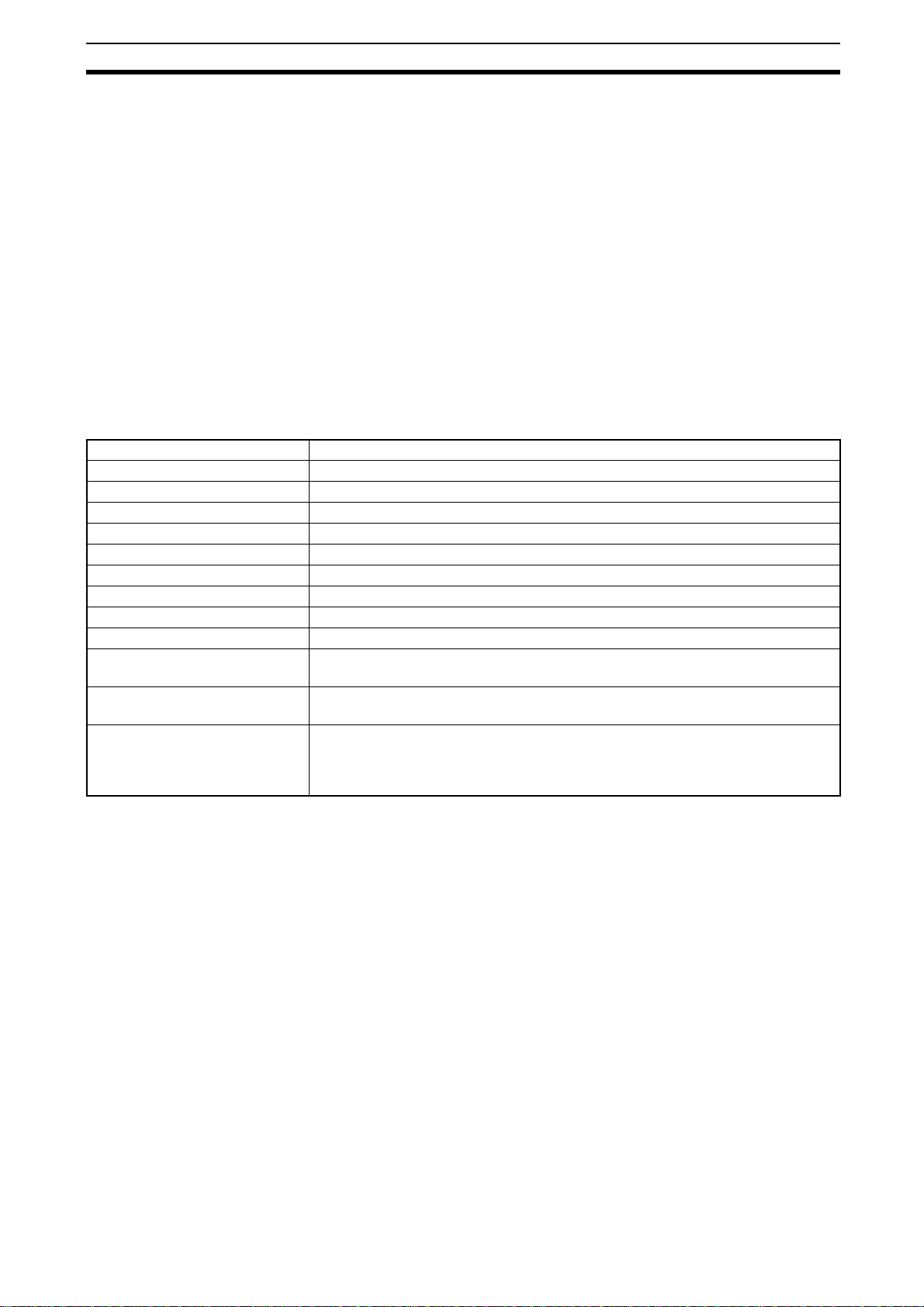

Item CJ1W-CTL41-E

Unit type CJ-series Special I/O Unit

General Specifications Conform to general specifications for SYSMAC CJ-series

Operating Temperature 0 to 55 ° C

Storage Temperature -20 to 70 ° C

Humidity 10% to 90% without condensation

Internal Current Consumption 320 mA (at 5 V)

Dimensions (mm) 31 x 90 x 65 (W x H x D)

Weight 100 g

Mounting Position CJ-series CPU Rack or CJ-series Expansion Rack

Maximum Number of CTL41-E

Units per Rack

Maximum Number of CTL41-E

Units per basic CJ PLC

Data Exchange with CPU Unit • I/O Refresh Data Area: CIO-words 2000 to 2959. See Note 2.

Equal to the number of slots of the Rack (see Note 1)

24

• Special I/O Unit DM-Area: D-words 20000 to 29599: 90 DM-words per Unit are

transmitted from the CPU to the Unit at Power Up or when the Unit is restarted.

See Note 3.

Section 1-3

Note 1. The maximum number of Units per Rack also depends on the maximum

supply current of the Power Supply Unit and the current consumption of

other Units on the Rack.

2. The CJ1W-CTL41-E Special I/O Unit allocates space for 33 words in the

Special I/O Unit (CIO) Area (refer to section 4-2-3 CIO-Memory Mapping).

3. For a CJ1W-CTL41-E Special I/O Unit the same space as for 4 Units in the

Special I/O Unit DM Area are reserved. However, only the first 90 words

are used to make the DM-settings. The remaining 310 words can be used

as work-words (refer to section 4-2-4 DM-Memory Mapping).

5

Page 23

Specifications and Characteristics

Section 1-3

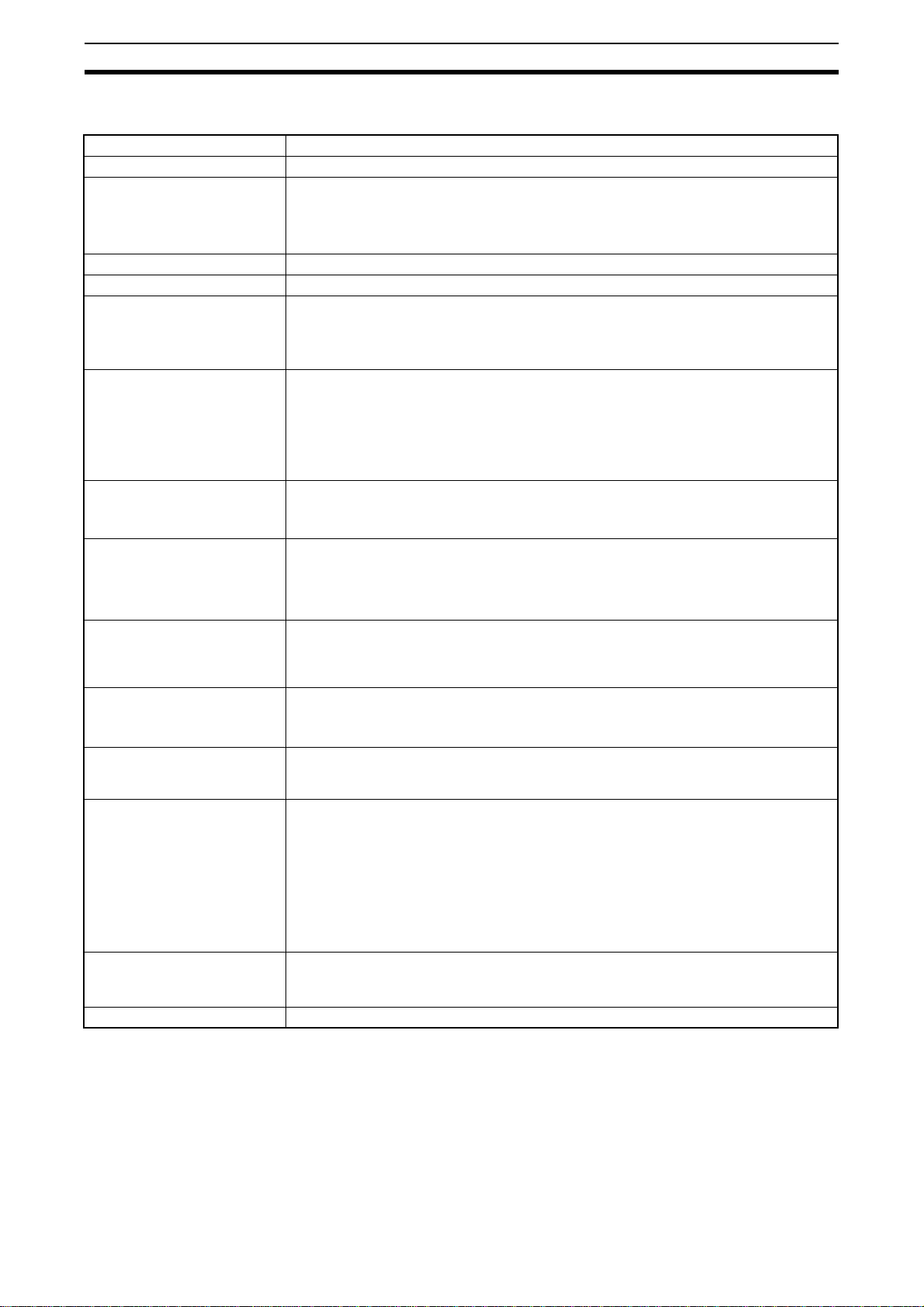

1-3-2 Functional Specifications

Item CJ1W-CTL41-E

Number of Counters 4

Counter Type • Circular Counter (refer to section 3-2-1 Circular Counter)

• Linear Counter (refer to section 3-2-2 Linear Counter)

The Counter Type can be selected using the appropriate DM bits (refer to section 4-2-4

DM-Memory Mapping).

Maximum Input Frequency 100 kHz, refer to section 1-3-3 Input Specifications for details

Signals per Counter Phase A, B and Z

Input Signal Types • Phase Differential (multiplication x1), (multiplication x2) and (multiplication x4) (refer to

section 3-3-1 Phase Differential)

• Up/Down (refer to section 3-3-2 Up & Down)

• Pulse & Direction (refer to section 3-3-3 Pulse & Direction)

Counter Control using CIOsoftware bits

Output Control Mode • Automatic Output Control in:

Reset Signals Every Counter can be reset to zero by (a combination of) the following sources:

Extra Functions • Hysteresis: To prevent Outputs from being switched On and Off by very small fluctua-

Noise Filtering Counter Inputs To suppress noise on the signal lines of the Counter Inputs (A, B) a fixed Noise Filter is

Initial Counter Value • The Initial Counter Value is transferred to the Unit when the Unit is Powered Up or

IORD- and IOWR-instructions Run-time configuration (See Note 2) and operation of the Counter Unit is possible by

Interrupts of Outputs The Soft Outputs of the Unit Output Pattern can all be configured to generate interrupts

Error History Log Function Stores up to 30 error log records (refer to section 5-2 Error codes)

• Open Gate / Start Counter: Counter is enabled to count pulses

• Close Gate / Stop Counter: Counter is disabled to count pulses

• Preset Counter: Preset Value can be set in CIO

• Reset Counter to zero

• Capture Counter Value: Captured Counter Value can be read using IORD-instruction

(refer to section 4-5-3-1 Captured Counter Value)

• Range Mode (Refer to section 3-5-1 Range Mode)

• Comparison Mode (Refer to section 3-5-2 Comparison Mode)

• Software Counter Reset Bit

• Z-Input

Refer to section 3-6 Reset Signals.

tions in the Counter Value around Range Limits, for every Counter an Hysteresisvalue [1, 255] can be defined (the Unit must in Range Mode). Refer to section 3-7-1

Hysteresis.

provided:

• Counter Inputs A and B: 100 kHz

Restarted. The Initial Counter Value is very useful to overcome problems in case of

power failure. Refer to section 3-7-2 Initial Counter Value.

using IORD- and IOWR-instructions. The following data can be read or written:

• DM-configuration data (refer to section 4-5-1 DM-data).

• Range- and Comparison Data (refer to section 4-5-2 Range- and Comparison data).

• Captured Counter Value (refer to section 4-5-3-1 Captured Counter Value)

• Counter Value (refer to section 4-5-3-2 Counter Value)

• (Re) Configure Counter Unit (refer to section 4-5-3-3 (Re) Configure Unit).

• Error Clear (refer to section 4-5-3-4 Error Clear Command)

to the CJ1-H/CJ1M CPU Unit. Refer to section 4-6-1 Outputs Generating Interrupts. See

also Note 1.

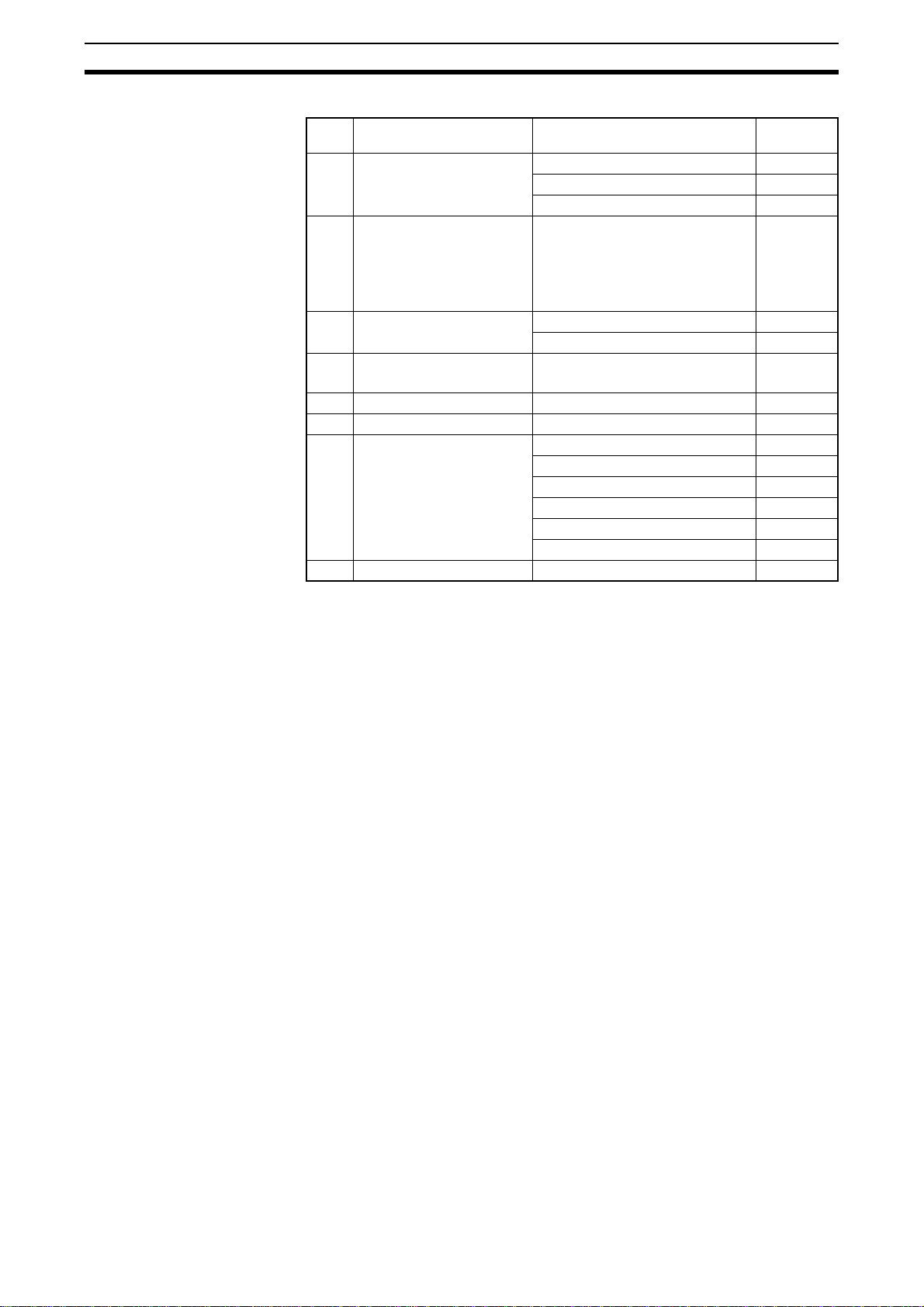

Note 1. A CJ1G-CPU@@H, CJ1H-CPU@@H or CJ1M-CPU@@ CPU Unit must be

used. The older CJ1G-CPU@@ CPU Units (without H suffix) do not support external interrupt tasks. To activate external interrupt tasks in a CJ1GH/ CJ1H-H CPU Unit, the CJ1W-CTL41-E Counter Unit must be in one of

6

Page 24

Specifications and Characteristics

Section 1-3

the five positions immediately to the right of the CPU Unit. For CJ1M CPU

Units, the CJ1W-CTL41-E Counter Unit must be in one of the three positions immediately to the right of the CJ1M CPU Unit. No external interrupt

tasks can be activated if the Unit is in any other position (i.e., 6th Unit position or further away from the CJ1-H CPU Unit, or 4th Unit position or further away from the CJ1M CPU Unit), or if it is on a CJ-series Expansion

Rack.

Power Supply Unit

CJ1-H or CJ1M CPU Unit

1st Unit

2ndUnit

3rd Unit

4th Unit

5th Unit

6thUnit

10th Unit

2. If an IOWR- or IORD-instruction is used during operation, comparison will

stop during instruction execution. Care must be taken, therefore, with the

timing of executing instructions. (Refer to section 3-5 Output Control for details.)

1-3-3 Input Specifications

Input Voltage Line Driver

Input Current

(typical)

Voltage levels Connectable to RS-422 compatible Line Drivers.

Note The Counter Inputs (A, B, Z) are insulated from each other. All Counter Inputs

are reverse polarity protected and insulated from the I/O-bus.

For CJ1-H CPU Units: External interrupt tasks can be

activated only from these Units.

For CJ1M CPU Units: External interrupt tasks can be

activated only from these Units.

Item Counter Inputs A, B and Z

11 mA

7

Page 25

Specifications and Characteristics

24V input signals (via Input Terminal Block) RS-422 Line Driver signals

Section 1-3

Counter Inputs A, B and Z

Counter inputs A and B

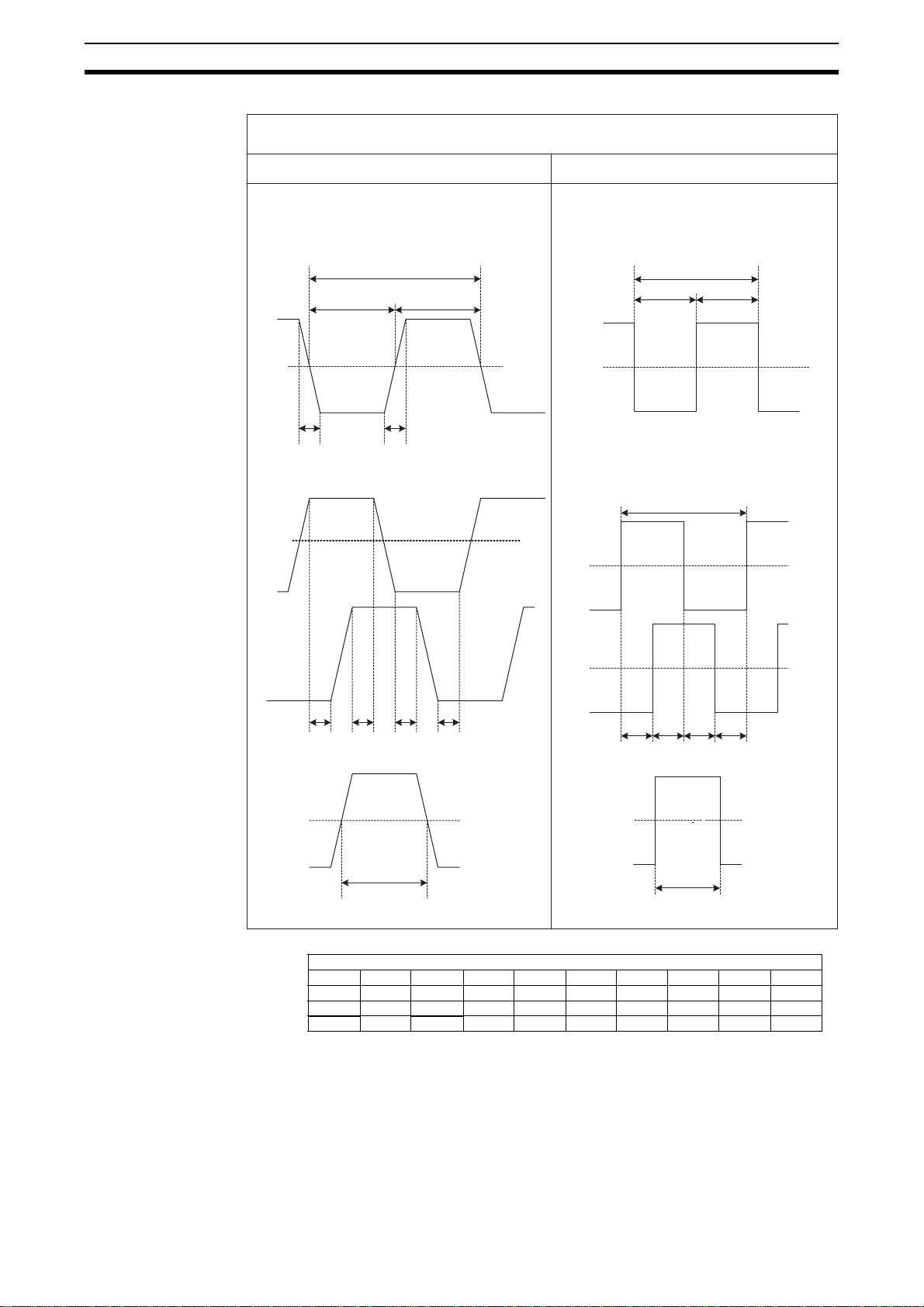

Input pulses with a duty factor of 50%

C

BB

On

50%

Off

AA

Relationship between A and B phases with phase

differential inputs

Phase A

On

50%

Off

Phase B

Counter inputs A and B

Input pulses with a duty factor of 50%

F

GG

On

0V

Off

Relationship between A and B phases with phase

differential inputs

On

0V

Off

Phase A

On

0V

Off

DDD

D

Counter Input Z *

On

50%

Off

Z

*Maximum allowed frequency of Z-pulses is 10 kHz *Maximum allowed frequency of Z-pulses is 10 kHz

E

Phase B

II

On

0V

Off

Z

Counter Input Z *

I

J

I

Timing requirement [µs]

JIHGFEDCBA

<3

>50<3

>10<3

>2

>100

>20

>4

>1

>10>4.5

>10

>20

>2

>50>100>10>23

>10

>1

>100

>20

>4

>23

>4.5

>10

>10

>10>1

Note As a general guideline it can be stated that if you want the timing requirements

for the Counter Inputs to satisfy the above mentioned specifications, you must

pay attention to the type of output driver of the encoder being used, the length

of the encoder cable and the frequency of the count pulses generated. For

8

Page 26

Quick Start Up Reference Guide

example, if you use an Open Collector encoder (e.g. E6B2-CWZ6C) at 24 V

with 10 m cable, you can typically generate count pulses up to 20 kHz. Therefore,

if you want to generate count pulses with higher frequencies, you should use a

different type of encoder (e.g. E6B2-CWZ1X with Line Driver output or a fast

push-pull 24 V encoder, e.g. E6C2-CWZ5GH) or reduce the length of the

encoder cable.

1-4 Quick Start Up Reference Guide

Section 1-4

Operation and

Configuration

Counter Inputs

1

(A, B, Z

Each individual Counter of the Counter Unit can be configured as Circular or

Linear Counter (refer to section the section 1-5 Operating Procedure Guide-

lines for quick start up information).

The diagram below shows the functions the Unit has available to operate and

configure the Unit (refer to SECTION 3 Operation and Configuration). The

numbers in grey refer to section the table on page 16.

Capture

2 2

Register

Circular

Linear

Counter

Preset

Register

Automatic

3

Output Control

5

Hysteresis

Outputs

8

Counter

2, 4 2, 4

Start/Stop

Counter

Reset

Exchanging data with CPU The diagram below shows the functions the Unit provides to exchange data

with the CPU (refer to section SECTION 4 Exchanging Data with CPU).

CJ-series CPU Unit

7

7

8

IOWR

IORD

Interrupts

CJ1W-CTL41-E

Unit Output Pattern

9

Page 27

Quick Start Up Reference Guide

Section 1-4

Ref Item Circular/Linear Counter Reference

1 Input Signal types Phase Differential (x1, x2, x4) 3-3-1

Up & Down 3-3-2

Pulse & Direction 3-3-3

2 Counter control • Open Gate / Start Counter

• Close Gate / Stop Counter

• Preset Counter

• Reset Counter

• Capture Counter Value

3 Output control • Range Mode 3-5-1

• Comparison Mode 3-5-2

4 Counter reset • Software Reset Bit

• Z-signal

5 Hysteresis Yes 3-7-1

6 Initial counter values Yes 3-7-2

7 Supported IORD / IOWR-

instructions

8 Interrupts of Outputs Yes 4-6-1

Captured Counter Value 4-5-3-1

Counter Value 4-5-3-2

Error Clear 4-5-3-4

DM-data 4-5-1

Range- and Comparison Data 4-5-2

(Re) Configure Unit 4-5-3-3

section

3-4

3-6

1-4-1 Configuring the Counter Unit

Configuring the Counter

Type

Configuring the Input

Type

Configuring the Output

Mode

Indirect Addressing for

Circular and Linear

Counters

Configuring each Counter starts with choosing the Counter Type, i.e. it must

be configured for Circular or Linear Counter (refer to section 3-2-1 Circular

Counter, section 3-2-2 Linear Counter and section 1-5 Operating Procedure

Guidelines for details).

Next, the Input Type (Phase Differential, Up/Down, or Pulse & Direction) for

every Counter has to be defined. During operation of the Counter, the Counter

can be Started, Stopped, Reset, Captured or Preset by using the corresponding

bits in CIO.

In order to link the Units Software Outputs to Counter events, the Output Control Mode (Range or Comparison Mode) must be selected. Furthermore, an

additional Hysteresis mechanism is available to control the Outputs. Refer to

section 3-5 Output Control.

The CJ1W-CTL41-E Counter Unit allocates 90 DM-words in the Special I/O

Unit DM-Area and a block of 34 CIO-words in the Special I/O Unit Area of the

PLC. The configuration of the Unit is done by making the appropriate DM-settings in the Special I/O Unit DM-Area allocated to the Unit.

The Special I/O Unit DM-Area is divided in an area of 10 words to make the

General Unit Settings and 4 blocks of 20 DM-words each to make the Counter

Specific Settings, which are unique for every Counter.

10

Page 28

Operating Procedure Guidelines

Depending on the Output Control Mode, Counter Range or Comparison Data

can be set. For each Counter, up to a maximum of 4 Ranges or 8 Comparison

Values can be assigned. You can set the Range or Comparison Data in a part

of DM or EM which is not being used. If you only intend to use a limited number of Ranges or Comparison Values then it is also possible to use the workwords of the Special I/O Unit DM-Area to store the Range or Comparison

Data (287 work-words for the CJ1W-CTL41-E are available). Therefore, at the

end of every block with Counter Specific Settings, you can specify an Indirect

Address. This Indirect Address points to the actual memory location where

the Range- or Comparison Settings of that specific Counter are stored.

For a detailed description about the CIO- and DM-Memory Allocation refer to

section 4-2 Memory Allocation.

Note During operation of the Unit, for Circular and Linear Counters run-time config-

uration is possible by using the IOWR-instruction from the PLC Ladder Program (refer to section 4-5 Supported IOWR/IORD-Instructions). Additionally,

Outputs can be configured to generate interrupts to the PLC by setting the

appropriate Interrupt Masks in DM. (refer to section 4-6 Interrupts)

Section 1-5

1-5 Operating Procedure Guidelines

In order to setup the Counter, follow the steps outlined below.

1, 2, 3… 1. Set the Machine Number to assign the start addresses of the allocated

CIO and DM areas. Refer to section 2-1-3 Machine Number Switch for further details.

CTL41

RUN

ERC

CH1

CH3

ERH

CH2

CH4

3

4

2

5

1

6

0

7

9

8

3

4

2

5

1

6

0

7

9

8

2. Install and wire the Unit. Refer to section 2-2 Installation and 2-3 Wiring for

further details.

Machine Number Switch:

3

MACH

2

4

1

5

0

6

No.

7

9

8

1

×

10

3

2

4

1

5

0

6

7

9

8

0

×

10

Set between 00 - 92

C

T

L

4

1

RUN

ERC

CH1

CH3

ERH

CH2

CH4

3

2

4

1

5

0

6

7

9

8

3

2

4

1

5

0

6

7

9

8

11

Page 29

Operating Procedure Guidelines

3. Turn ON the Power to the PLC.

Power ON

4. Create the I/O table. The I/O table can be created by using CX-Program-

CX-Programmer

CTL41

R

U

N

ER

C

H

C

1

C

H

3

ER

H

C

H

2

C

H

4

3

2

4

1

5

0

6

7

9

8

3

2

4

1

5

0

6

7

9

8

mer Support Software or a Programming Console.

CTL41

RUN

ERC

CH1

CH3

ERH

CH2

CH4

3

2

4

1

5

0

6

7

9

8

3

2

4

1

5

0

6

7

9

8

Section 1-5

Programming Console

Unit Configuration After the I/O table is created in step 4, you have to configure the Unit by mak-

ing the appropriate DM-settings. The Unit can be configured by using CX-Programmer Support Software or a Programming Console. Two Programming

Consoles can be used with the CJ-series CPU Units: the C200H-PRO27-E

and the CQM1-PRO01-E. The CS1W-KS001 Key Sheet must be used for

both.

1, 2, 3… 1. Every Counter can now be separately (DM-) configured. The configuration

of the Counter Type (Linear or Circular Counter) is done by DM-setting.

Refer to section SECTION 3 Operation and Configuration for detailed information about configuring the Unit.

2. Power up the PLC again or turn the Special I/O Unit Restart Bit to ON (to

transfer the DM-settings). All data related to Circular /Linear Counters is now

being exchanged between the PLC and the Unit in CIO-memory and available for usage in the Ladder Program.

3. Create and RUN a Ladder Program in the PLC. Refer to section SECTION

4 Exchanging Data with CPU for details on the interface between the CJseries Counter Unit and the CPU. Refer to section sections 6-2 to 6-5 for

application examples using Circular and Linear Counters.

12

Page 30

Application Areas

Refer to section 3-2-1 Circular Counter and 3-2-2 Linear Counter for more

details about both Counter Types. Refer to section 4-1-2 Special I/O Units

Restart bits for more information about restarting the Unit.

1-6 Application Areas

The main application areas of the Counter Unit are where signals with high

frequencies are counted and high-speed responses have to be triggered at

predefined Counter Values. Application areas include:

• Packaging and Sorting plants

• Dosing or proportioning plants

• Process Industry

Typical applications in which the CJ1W-CTL41-E can be used:

• (CAM)-Positioning

• Position Monitoring

• Length Measurement

• Flow Control

• Energy Measurement

Section 1-6

13

Page 31

Page 32

SECTION 2

Components, Installation and Wiring

This section provides details of the components, switch settings and other information required to install and operate

CJ1W-CTL41-E Counter Units.

2-1 Components and Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-1-1 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-1-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-1-3 Machine Number Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-2-1 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-2-2 Installing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-3-1 Connector Pin-layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-3-2 Connector Wiring Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-3-3 Important Wiring Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-3-4 Internal Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-3-5 Counter Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

15

Page 33

Components and Switch Settings Section 2-1

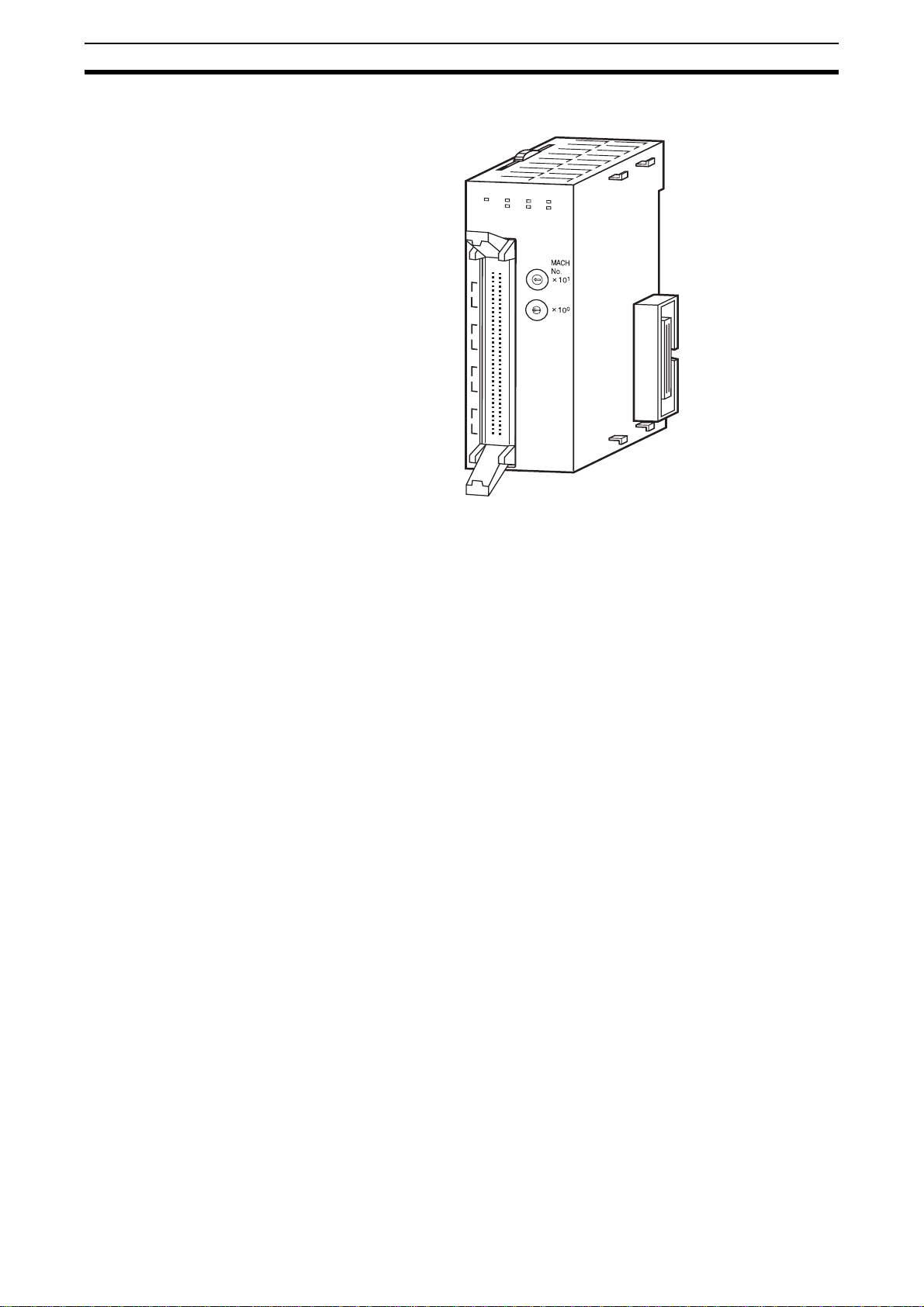

2-1 Components and Switch Settings

2-1-1 Components

Front and Side View

83.6

2.7

31

65

2-1-2 Indicators

90

2.7

CTL41

RUN

CH4

CH3

CH2

CH1

ERC

ERH

CH1

CH2

CH3

CH4

3

2

4

1

5

0

6

7

9

8

3

2

4

1

5

0

6

7

9

8

Indicators

Machine

Number Switch

Units in mm

16

CTL41

RUN

The indicators on the LED-display show the operating status of the Unit. The following table shows the meaning of the indicators.

LED Colour State Description

RUN Green ON Unit is in operation (i.e. Unit has initialised normally

ERC Red ON Unit has operational failure due to a detected error.

CH1

CH2

CH3

CH4

ERC

ERH

after (re-) starting the Unit).

OFF Unit is not in operation (i.e. Unit was not able to

initialise normally after (re-) starting the Unit or the

power to the Unit is switched OFF).

(For a list of all the errors that can cause an

operational failure, see 5-2 Error codes”.)

OFF Unit has no operational failure.

Page 34

Components and Switch Settings Section 2-1

LED Colour State Description

ERH Red ON CPU Unit has operational failure. (For a list of all the

errors that can occur at the CPU Unit see 5-1 Error

Indicators)

OFF CPU Unit has no operational failure.

CH1 Yellow ON Counter 1 is counting, i.e. the corresponding

counting gate is enabled and at least one pulse has

been detected.

OFF Counter 1 is not counting, i.e. the corresponding

counting gate is closed or no pulses have been

detected.

CH2 Yellow ON Counter 2 is counting, i.e. the corresponding

counting gate is enabled and at least one pulse has

been detected.

OFF Counter 2 is not counting, i.e. the corresponding

counting gate is closed or no pulses have been

detected.

CH3 Yellow ON Counter 3 is counting, i.e. the corresponding

counting gate is enabled and at least one pulse has

been detected.

OFF Counter 3 is not counting, i.e. the corresponding

counting gate is closed or no pulses have been

detected.

CH4 Yellow ON Counter 4 is counting, i.e. the corresponding

counting gate is enabled and at least one pulse has

been detected.

OFF Counter 4 is not counting, i.e. the corresponding

counting gate is closed or no pulses have been

detected.

2-1-3 Machine Number Switch

The CPU Unit and the Counter Unit exchange data via the Special I/O Unit Area

(CIO) and the Special I/O Unit DM Area. The Counter Unit is allocated 34 CIO

words and 90 DM words, starting at the addresses for this Machine number. The

Machine Number is set by using the two Machine Number rotary switches on the

front panel of the Unit.

As a result of this amount of allocated words, the subsequent 3 Machine Number

addresses cannot be used by other Special I/O Units, as their allocations would

overlap with this data.

Always turn OFF the power before setting the Machine Number. Use a flat-blade

screwdriver, being careful not to damage the switch. Be sure not to leave the

switch midway between settings.

3

2

4

1

5

0

6

7

9

8

3

2

4

1

5

0

6

7

9

8

17

Page 35

Components and Switch Settings Section 2-1

Note The Machine Number determines which words in the CPU Unit’s Special I/O Unit

Area (CIO 2000 to CIO 2959 and DM 20000 to DM 29599) are allocated to the

Counter Unit. The CJ1W-CTL41-E Unit occupies 4 Special I/O Unit Areas, i.e.

the next Special I/O Unit Machine Number must at least be set to this Unit’s

Machine Number plus 4. The Machine Number can only be set between 00 and

92. The Machine Numbers 93, 94 and 95 can not be set.

Switch

Setting

0 #0 CIO 2000 to CIO 2039 D20000 to D20399

1 #1 CIO 2010 to CIO 2049 D20100 to D20499

2 #2 CIO 2020 to CIO 2059 D20200 to D20599

3 #3 CIO 2030 to CIO 2069 D20300 to D20699

4 #4 CIO 2040 to CIO 2079 D20400 to D20799

5 #5 CIO 2050 to CIO 2089 D20500 to D20899

6 #6 CIO 2060 to CIO 2099 D20600 to D20999

7 #7 CIO 2070 to CIO 2109 D20700 to D21009

8 #8 CIO 2080 to CIO 2119 D20800 to D21199

9 #9 CIO 2090 to CIO 2129 D20900 to D21299

10 #10 CIO 2100 to CIO 2139 D21000 to D21399

…… … …

n #n CIO 2000 + (n * 10) to

…… … …

92 #92 CIO 2920 to CIO 2959 D29200 to D 29599

93 Cannot be set Not Applicable Not Applicable

94

95

Machine

Number

I/O Refresh Data Area

Addresses

CIO 2000 + (n * 10) + 39

Special I/O Unit DM Area

Addresses

D 20000 + (n * 100) to

D 20000 + (n * 100) + 399

Note 1. If two or more Special I/O Units are assigned the same Machine Number, a fatal

error “Unit No. Duplication Error” (in the PLC-CPU) will be generated (A40113

will turn ON) and the PLC will not operate.

2. The Counter Unit is allocated the words for 4 Units. If you use Special I/O Units

that are allocated more than 100 DM-words and 10 CIO-words, like the CJ1WCTL41-E Counter Unit, you should make sure that no memory overlapping

occurs. If the Machine Number for the Counter Unit is set to ‘n’ the Machine

Numbers 'n+1' through 'n+3' cannot be used on other units. In case two or more

Special I/O Units have set Machine Numbers causing an overlap of allocated

memory, a fatal error “Unit No. Duplication Error” (in the PLC-CPU) will be generated (A40113 will turn ON) and the PLC will not operate.

3. Besides the memory that is allocated to the Counter Unit in the Special I/O Unit

DM Area, for every Counter additional memory can be allocated in DM/EM.

This extra allocated amount of memory is used to make the Counter Specific

Settings related to Range or Comparison Mode. Memory is allocated by specifying an Indirect Address for every Counter in the Special I/O Unit DM Area.

For details about Indirect Addressing refer to section 4-2-2 Indirect Addressing.

18

Page 36

Installation Section 2-2

2-2 Installation

2-2-1 Installation Precautions

When installing the CJ1W-CTL41-E Counter Unit on the PLC system, observe

the following handling precautions

• Always turn OFF the power supply to the PLC before mounting or dismounting a Unit or connecting or disconnecting cables.

• Provide separate conduits or ducts for the I/O lines to prevent noise from

high-tension lines or power lines.

• Leave the label on top of the Unit attached when wiring. Removing the label

prior to wiring may result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

Up to 24 Units can be connected for each PLC (CPU Unit), with a maximum of 10

on each Rack (CPU Rack and Expansion Racks).

Note The Unit must be mounted to one of the five positions immediately to the right of

the CJ1-H CPU Unit (when facing the PLC) to generate interrupts to the CPU

Unit to execute external interrupt tasks. Interrupts are not supported from any

other location on the CPU Rack and are not supported at all from Expansion

Rack. They are also not supported by CJ1G-CPU44 and -45, without ‘H’ suffix.

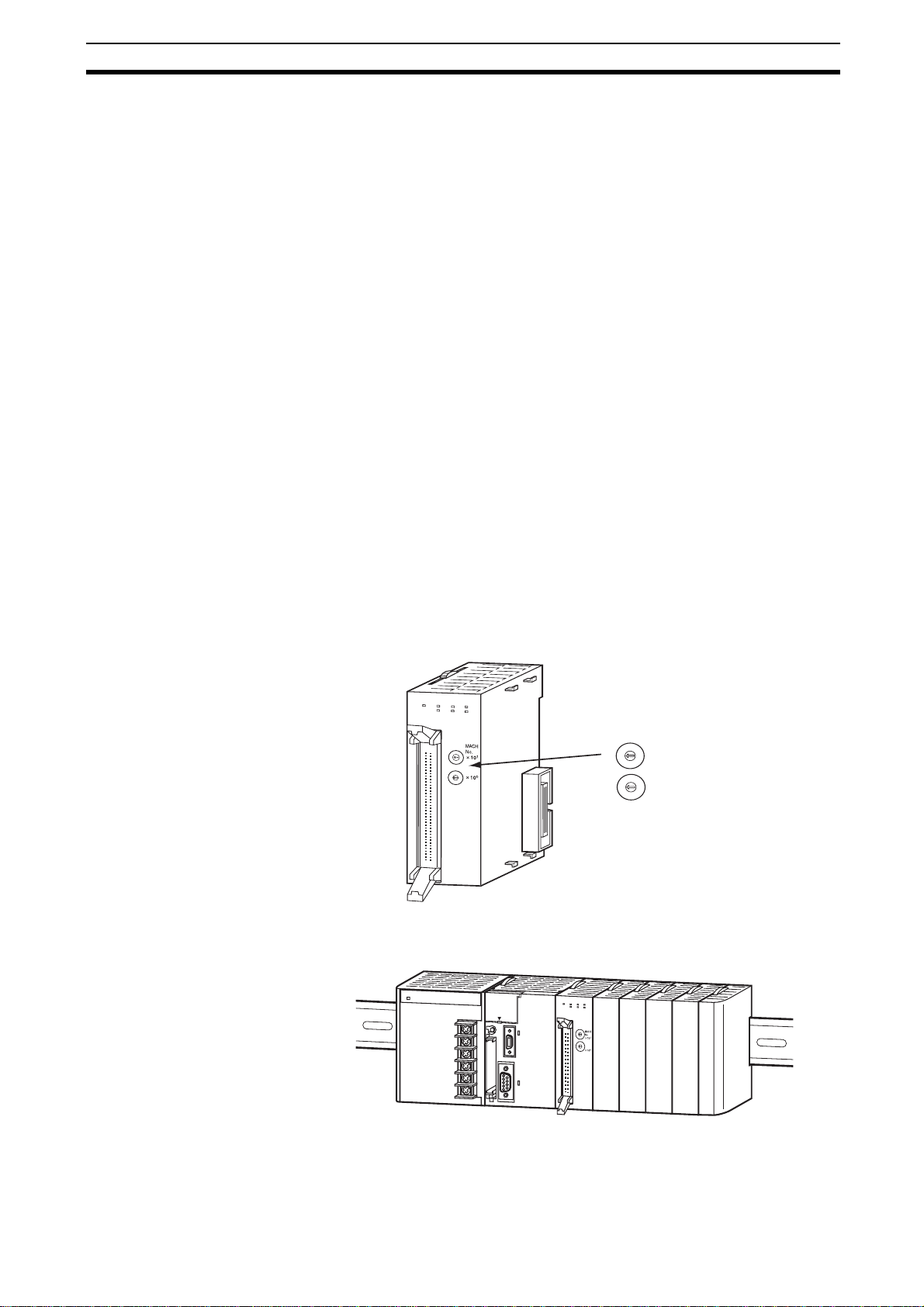

2-2-2 Installing Units

!Caution Be sure to turn OFF the power supply to the PLC before installing or removing

1, 2, 3… 1. Align the connectors and hooks accurately and press the Units together firmly

Units or connecting or disconnecting connectors.

Use the following procedure to install CJ1W-CTL41-E Counter Units. Connect the

Units before mounting them to DIN-rail.

when connecting them.

PA205R

Hook

PO

W

ER

L1

AC100-24

0V

INPUT

L2/N

RUN

OUTPUT

AC240V

DC24V

SYSMAC

CJ1G-CPU44

P

R

O

G

R

A

M

M

A

C

O

N

T

R

O

L

L

E

R

B

L

E

OPEN

M

CP

W

R

BUSY

PERIPHERAL

PORT

ERR/ALM

RUN

INH

PRPHL

COM

M

Connector

CTL41

RUN

1

1

B

ERC

CH1

ERH

CH2

1

1

Hook holes

CH3

CH4

3

4

2

5

1

6

0

7

9

8

3

4

2

5

1

6

0

7

9

8

19

Page 37

Installation Section 2-2

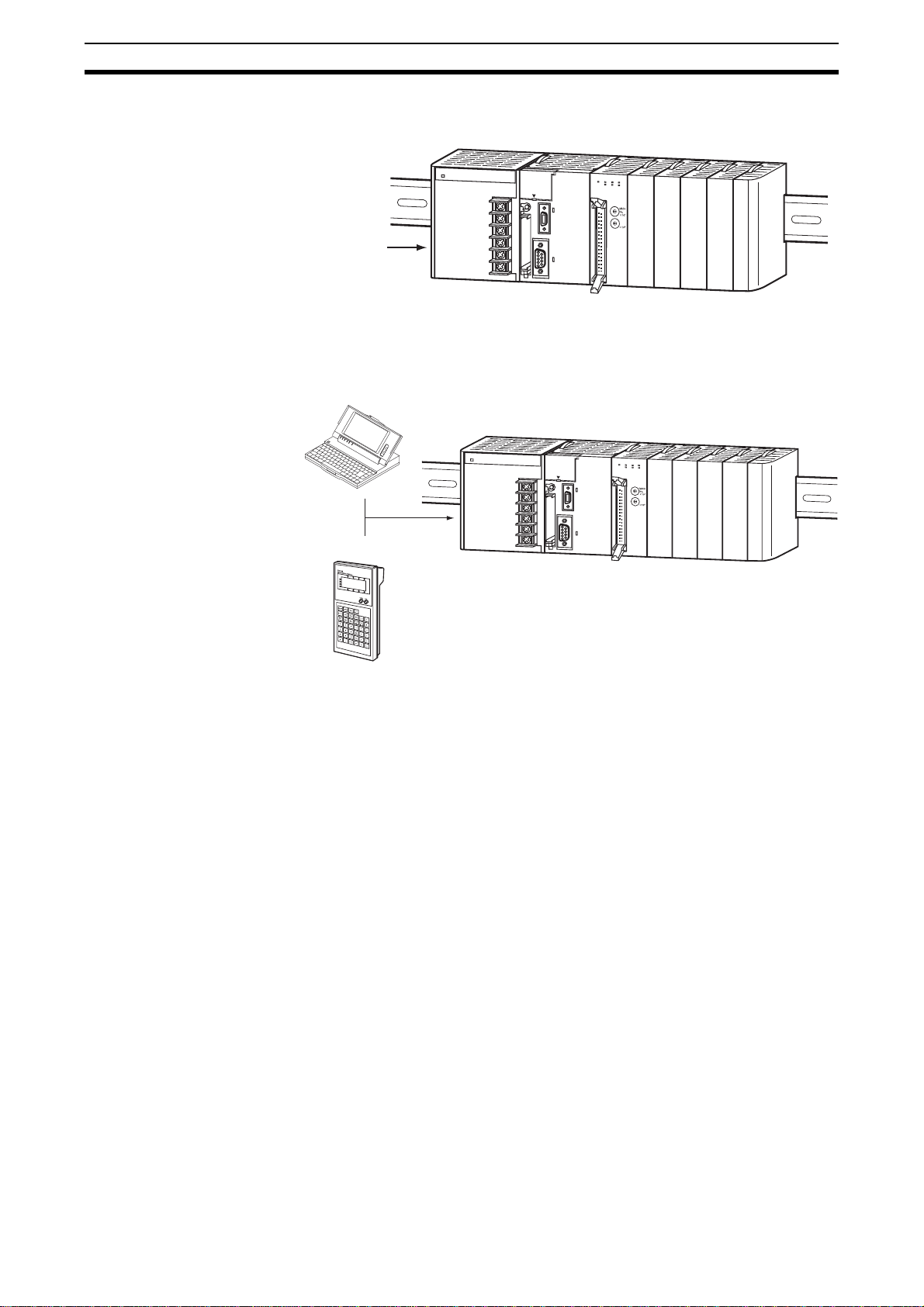

2. Slide the yellow sliders on the top and bottom of the Units until they click into

place, firmly locking the Units together.

Slide the sliders toward the back

until they click into place.

Slider

PA205R

POWER

AC100-240V

INPUT

OUTPUT

AC240V

DC24V

SYSMAC

CJ1G-CPU44

P

C

L1

L2/N

RUN

RUN

ERR/ALM

INH

R

O

G

R

A

MM

A

B

L

E

PRPHL

O

N

T

R

O

LLE

R

COMM

OPEN

M

C

P

W

R

B

U

S

Y

PERIPHE

RAL

PORT

CTL41

RUN

ERC

CH1

ERH

CH2

2

1

0

1

0

1

1

MODE

1

1

1

1

BA

B

A

CH3

CH4

Release

3

4

5

6

7

9

8

3

4

2

5

6

7

9

8

3. Attach an End Plate to the Unit on the right end of the Rack.

Note The Units may not function properly if the sliders are not locked into place.

Always connect the End Plate to the rightmost Unit. The CJ-series PLC will not

function properly without the End Plate connected. The End Plate is provided with

the CPU Unit.

Lock

20

Page 38

Wiring Section 2-3

2-3 Wiring

2-3-1 Connector Pin-layout

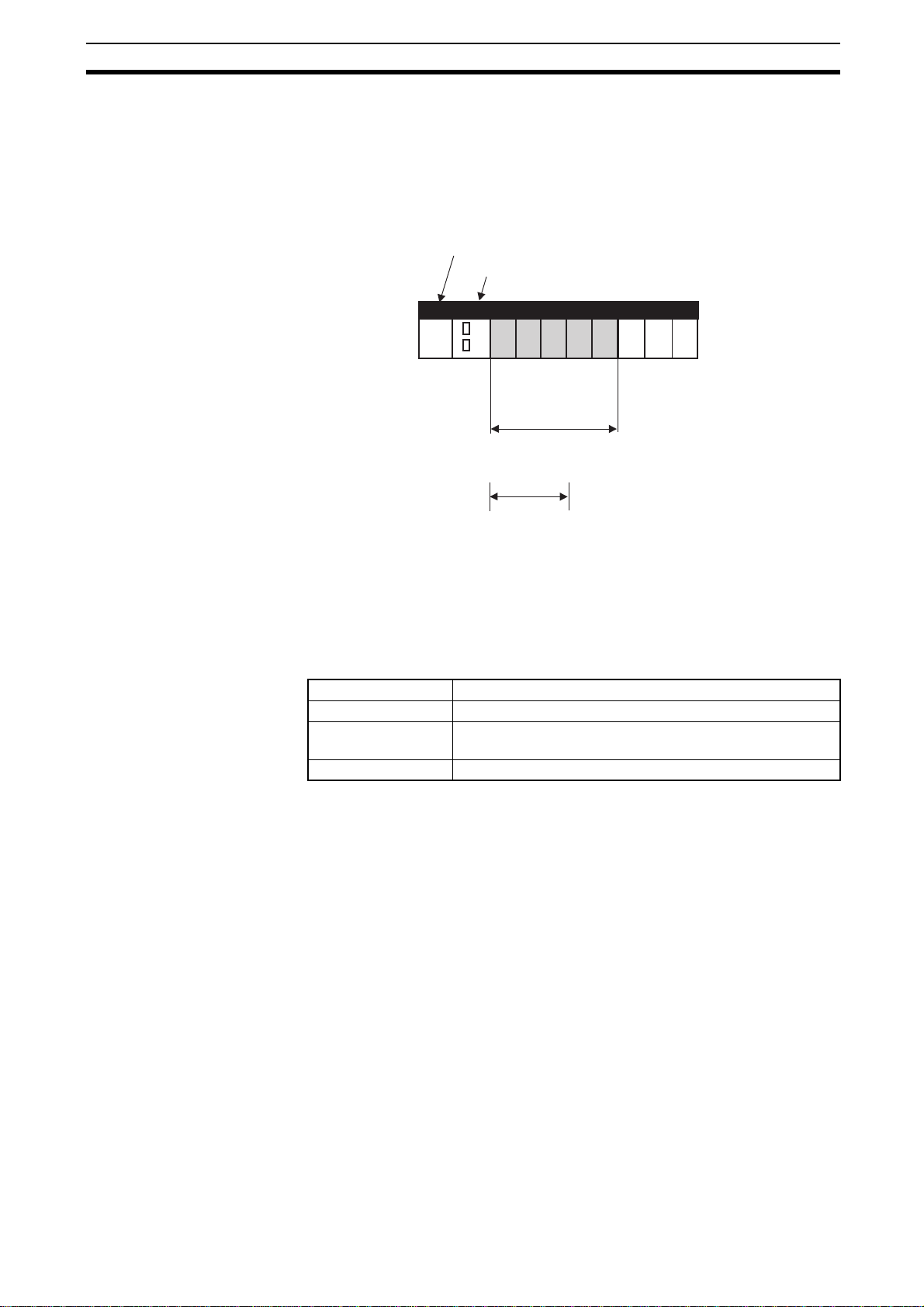

The 40-pin connector on the front of the Unit is divided in two rows, each row containing 20-pins as indicated in the figure below. The Counter Inputs of the Unit are

logically grouped together and allocated to the pins of the connector. The following

table lists the allocation of the external signals to the respective pins.

Pin No. Signal Pin No. Signal

40 Not Connected 39 Not Connected

PIN 40 PIN 39

CH4

CH3

CH2

CH1

PIN 2 PIN 1

38 37

36 Z- 35 Z+

34 B- 33 B+

32 A- 31 A+

Channel 4

30 Not Connected 29 Not Connected

28 27

26 Z- 25 Z+

24 B- 23 B+

22 A- 21 A+

Channel 3

20 Not Connected 19 Not Connected

18 17

16 Z- 15 Z+

14 B- 13 B+

12 A- 11 A+

Channel 2

10 Not Connected 9 Not Connected

8 7

6Z- 5Z+

4B- 3B+

2A- 1A+

Channel 1

Counter Inputs To the Counter Inputs of the Counter Unit signals can be applied originating from

one of the following driver types:

• RS-422 Line Driver, either directly connected to the connector on the front of

the Unit or through a separate Input Terminal Block, e.g. the OMRON XW2G40G7-E or XW2D-40G6.

• 24 Vdc signals from NPN- or PNP Drivers, only through the separate

OMRON XW2G-40G7-E Input Terminal Block.

21

Page 39

Wiring Section 2-3

2-3-2 Connector Wiring Methods

!Caution Be sure that all the connectors are wired correctly and properly connected to the

Counter Unit, to prevent the Unit from malfunctioning.

To wire the CJ1W-CTL41-E in order to connect the external signals three methods

are available:

1. Directly connecting the wires and cables to an external connector. Recommended connectors are 40-pin MIL-C-83503 (or DIN 41651 or IEC 60603-1)

compatible 40-pole connectors.

2. Indirectly connecting the wires and cables to the screw terminals of an XW2B40Gx Terminal Block Unit, which is connected to the Unit with a standard

XW2Z I/O cable. Both parts can be ordered separately.

3. Indirectly connecting the wires and cables to the screw-less terminals of an

XW2G-40G7-E Terminal Block Unit, which is connected to the Unit with a

standard XW2Z I/O cable. Both parts can be ordered separately.

The figures below show the XW2B-40Gx and XW2G-40G7-E Input Terminal

Blocks.

Terminal Block Unit

22

The following Terminal Block Units are recommended for using together with the

CJ1W-CTL41-E Counter Unit:

Item Description Input type supported

XW2B-40G4 40 screw terminals (M2.4) Line driver only

XW2B-40G5 40 screw terminals (M3.5) Line driver only

XW2D-40G6 40 screw terminals, compact Line driver only

XW2G-40G7-E 36 screwless terminals Line driver / 24 Vdc

Page 40

Wiring Section 2-3

These Terminal Block Units can be mounted to a DIN-rail or to a flat surface using

screws. The connector on front of the Unit must be connected to a Terminal Block

Unit through a standard (40 wire) cable. For this purpose you can use the standard

available cables with product-number XW2Z-xxxK. The length of the cable is indicated by ‘xxx’ in centimetres. The following cables are available:

• XW2Z-050K (0.5 m)

• XW2Z-100K (1 m)

• XW2Z-150K (1.5 m)

• XW2Z-200K (2 m)

• XW2Z-300K (3 m)

• XW2Z-500K (5 m)

The next figure shows how to use the Terminal Block Unit in a typical configuration

together with the CJ1W-CTL41-E Counter:

CTL41

RUN

ERC

CH1

CH3

ERH

CH2

CH1

3

4

2

5

1

6

0

7

9

8

3

4

2

5

1

6

0

7

9

8

2

Refer to section Appendix A Using Input Terminal Block Units for information on

the numbering of the screw-terminals. You need this information in case you want

to connect the external signals via Terminal Block Units to the Counter Unit.

2-3-3 Important Wiring Considerations

Use the following guidelines when planning the system wiring of the Unit:

• Disconnect the power to the PLC-system before wiring the Unit.

• Make sure the PLC-system is properly grounded.

• Use shielded, twisted pair cables and ground the shield when wiring the Coun-

ter Inputs (A, B, Z). When grounding the shield at the side of the Unit, use the

same reference as the ground terminal of the PLC-Power Supply is connected

to.

• Make the wiring for the Counter Inputs A, B and Z as short as possible and do

not route the wires parallel to lines that produce a lot of noise, such as high-voltage power lines.

• Use a separate stabilised Power Supply for the Counter Unit and another Power

Supply for other Units.

23

Page 41

Wiring Section 2-3

2-3-4 Internal Circuitry

Counter Input Circuitry

The figure below shows the internal input circuitry for all three input signals for

each of the four Counter channels.

Phase A

LD+

LD-

Phase B

LD+

LD-

2-3-5 Counter Input Configuration

The following example illustrates how to wire the Counter Inputs in a typical configuration according to the output-driver of the encoder or proximity switch being

used. In the example Counter channel 1 is used. The configuration shown here,

related to a specific output-driver, can also be referred to in case other pulse generating equipment with similar output-drivers is being used.

Phase Z

LD+

LD-

24

Page 42

Wiring Section 2-3

n

x

Line Driver (RS422)

CJ1W-CTL41-E Counter U

Terminals:

Encoder

Black: Phase A+

Black/red: Phase AWhite: Phase B+

White/red: Phase BOrange: Phase Z+

Orange/red: Phase Z-

1 (Phase A, LD+)

2 (Phase A, LD-)

3 (Phase B, LD+)

4 (Phase B, LD-)

5 (Phase Z, LD+)

6 (Phase Z, LD-)

Power Supply

. E6B2-CWZ1X

ne Driver outputs

A+

A-

B+

B-

Z+

Brown: 5 VDC

Blue: 0 V (COM)

Shielded twisted-pair cable

Counter 1

0 V

+5 V

5 VDC

Power Supply

CJ1W-CTL41-E Counter Unit

1

2

3

4

5

Z-

Encoder

6

Connector

25

Page 43

Page 44

SECTION 3

Operation and Configuration

This section describes how to configure the CJ1W-CTL41-E Counter Unit and how to operate the Unit according to the

specific requirements of your application.

3-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-2 Counter Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-2-1 Circular Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-2-2 Linear Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-3 Input Signal Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-3-1 Phase Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-3-2 Up & Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-3-3 Pulse & Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-4 Controlling a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-5 Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-5-1 Range Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-5-2 Comparison Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-6 Reset Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3-7 Extra Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3-7-1 Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3-7-2 Initial Counter Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

27

Page 45

Overview Section 3-1

3-1 Overview

After you have installed and wired the CJ1W-CTL41-E Counter Unit as described

in Section 2-2 Installation and Section 2-3 Wiring, you have to configure the Unit

by making DM-settings.

In this section you will learn how to configure the CJ1W-CTL41-E Counter Unit in

order to adjust the behaviour of the Unit according to the specific requirements of

your application (refer to section Section 1-4 Quick Start Up Reference Guide for

an overview of the configuration items for every Counter). Also throughout this

section, the CIO-words that are relevant to operate the Unit from the PLC ladder

program are mentioned (refer to section Section 4-2-3 CIO-Memory Mapping for

an overview). For an overview of all the DM-settings that can be made refer to section Section 4-2-4 DM-Memory Mapping.

All the features and functions that the Counter Unit offers are (DM-) configurable.

In the Special I/O Unit DM-area which is allocated to the Counter after the Unit has

been properly installed (see Section 1-5 Operating Procedure Guidelines), all the

available features and functions of the Unit are represented by their corresponding

DM-words. You are free to choose the sequence in which you configure the different functions. However, it is are recommended to follow the sequence of configuring the features and functions in the order as described in this section.

Note 1. Throughout this section for the DM- and CIO- addresses an offset is defined

with respect to the physical address of the first word of the block that is allocated to the Counter Unit (N = Machine Number):

• m = DM20000 + (Nx100), address of the first word of the block of 90 DMwords reserved for the Unit

• n = CIO2000 + (Nx10), address of the first word of the block of 34 CIO-words

reserved for the Unit

• Example: m+2 indicates the DM-word located at DM20000 +(Nx100) + 2.

2. Double words are indicated as for example “n+22, n+23” (double word in CIO)

or “m+57, m+58” (double word in DM). How to distinguish between the leastand most significant words (LSW and MSW) within double words, you should

refer to section the section called “About this Manual” at the beginning of this

Manual.

28

Page 46

Counter Types Section 3-2

3-2 Counter Types

Every single Counter of the Counter Unit can be set independently to one of the

following Counter Types:

• Circular Counter (refer to section Section 3-2-1 Circular Counter)

• Linear Counter (refer to section Section 3-2-2 Linear Counter)

Each Counter can be configured Circular or Linear Counter by giving the corresponding word in DM the appropriate setting:

CNT1: CNT2:

m+10 m+30

CNT3: CNT4:

m+50 m+70

15 14 13 12 11 10 9 876543210

For Circular and Linear Counters all the functions and features of the Counter Unit

are available and configurable.

Counter Value For all Counter Types the 32-bit Counter Value is reflected in CIO.

CNT1: CNT2:

n+19 n+23

n+20 n+24

CNT3: CNT4:

n+27 n+31

n+28 n+32