Page 1

Machine Automation Controller

CJ-series

User Defined CAN Unit

Operation Manual

for NJ-series CPU Unit

CJ1W-CORT21

User Defined

CAN Unit

W517-E2-01

Page 2

Page 3

Introduction

Thank you for purchasing a CJ-series CJ1W-CORT21 User Defined CAN Unit.

This manual contains information that is necessary to use the CJ-series CJ1W-CORT21 User Defined

CAN Unit for an NJ-series CPU Unit. Please read this manual and make sure you understand the functionality and performance of the NJ-series CPU Unit before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B3503.

Introduction

Applicable Products

This manual covers the following products.

CJ-series CJ1W-CORT21 User Defined CAN Unit

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

1

Page 4

Introduction

NJ-series User’s Manuals

Basic information

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Using CJ-series Units

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

Programming

Using motion control

Using EtherCAT

Using CJ-series Units

Programming error processing

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Maintenance

Using EtherCAT

Using EtherNet/IP

Using CJ-series Units

NJ-series CPU Unit

Hardware User´s Manual

NJ-series CPU Unit

Software User´s Manual

NJ-series Instructions

Reference Manual

NJ-series CPU Unit Motion

Control User´s Manual

NJ-series CPU Unit Built-in

EtherCAT Port User´s Manual

NJ-series Motion Control

Instructions Reference Manual

NJ-series CPU Unit Built-in

EtherNet/IP Port User´s Manual

NJ-series Troubleshooting Manual

CJ-series Special Unit Operation

Manuals for NJ-series CPU Unit

Troubleshooting and managing

errors in an NJ-series Controller

Use the

relevant

manuals for

references

according to

any error that

occurs.

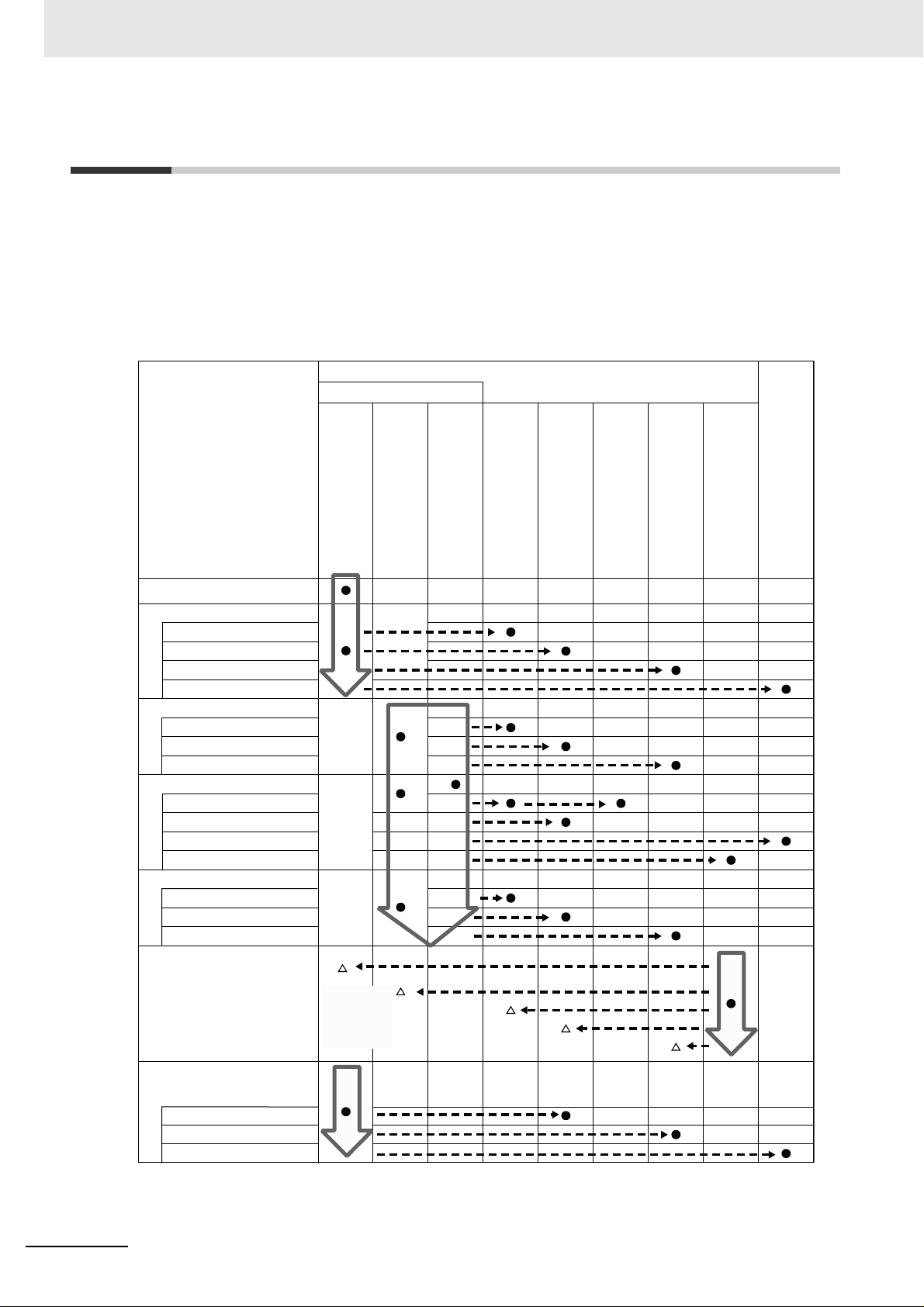

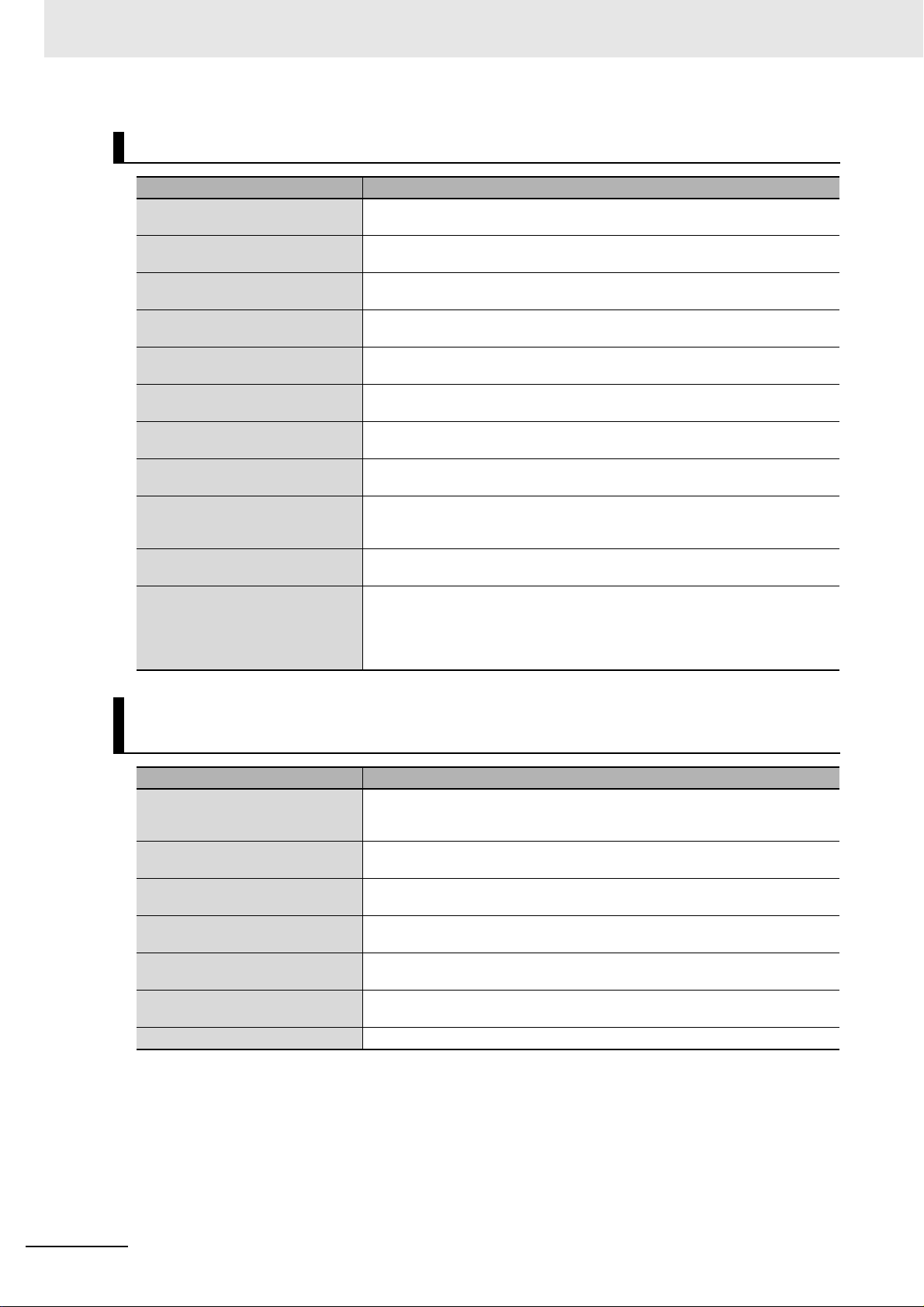

Relevant Manuals

There are three manuals that provide basic information on the NJ-series CPU Units: the NJ-series CPU

Unit Hardware User’s Manual, the NJ-series CPU Unit Software User’s Manual, and the NJ-series

Instructions Reference Manual.

Most operations are performed from the Sysmac Studio Automation Software. Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

Other manuals are necessary for specific system configurations and applications.

Read all of the manuals that are relevant to your system configuration and application to make the most

of the NJ-series CPU Unit.

2

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 5

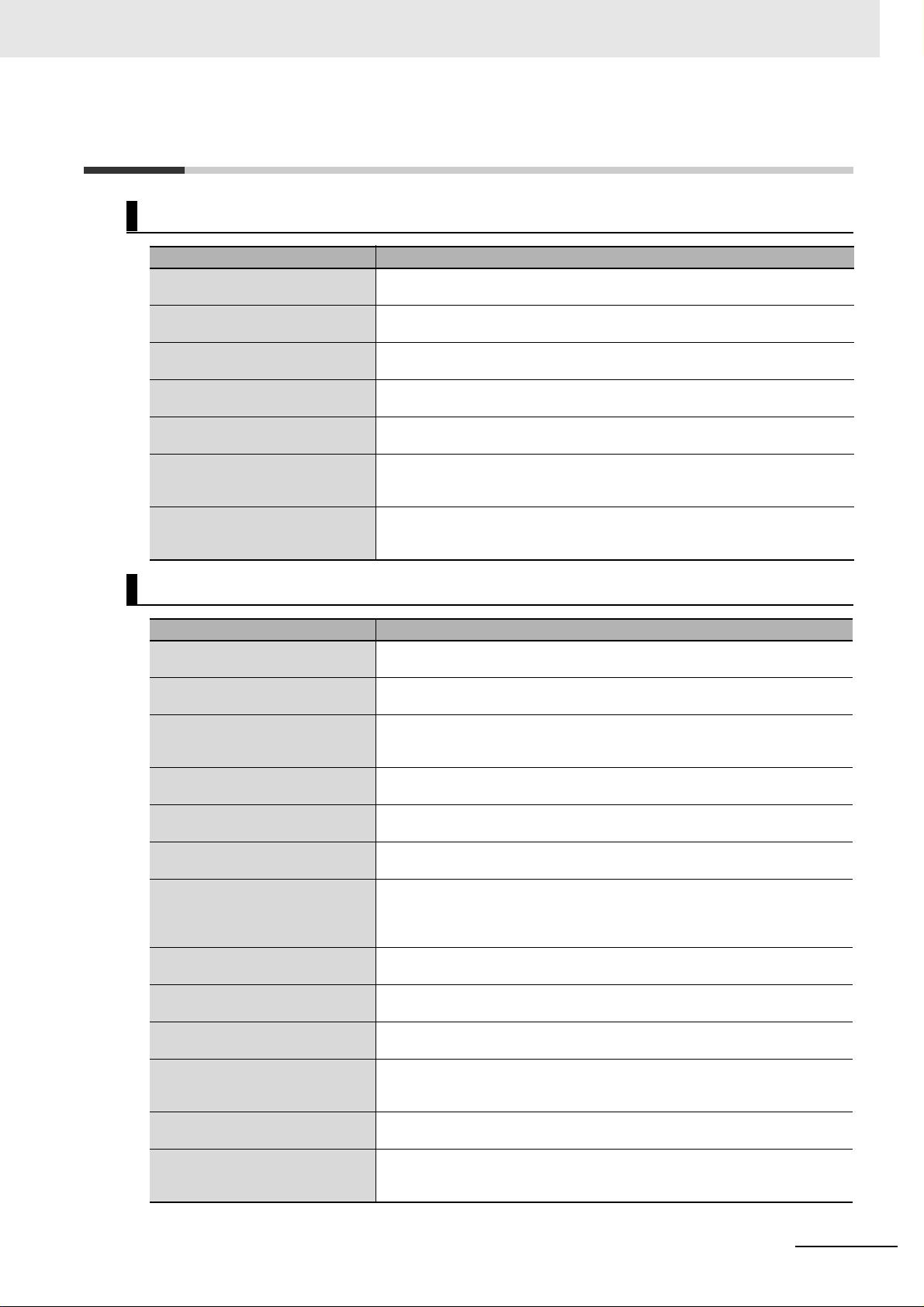

Manual Configuration

NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

Section Description

Section 1

Introduction

Section 2

System Configuration

Section 3

Configuration Units

Section 4

Installation and Wiring

Section 5

Troubleshooting

Section 6

Inspection and Maintenance

Appendices

This section provides an introduction to the NJ-series Controllers and their features,

and gives the NJ-series Controller specifications.

This section describes the system configuration used for NJ-series Controllers.

This section describes the parts and functions of the configuration devices in the NJseries Controller configuration, including the CPU Unit and Configuration Units.

This section describes where and how to install the CPU Unit and Configuration Units

and how to wire them.

This section describes the event codes, error confirmation methods, and corrections

for errors that can occur.

This section describes the contents of periodic inspections, the service life of the Battery and Power Supply Units, and replacement methods for the Battery and Power

Supply Units.

The appendices provide the specifications of the Basic I/O Units, Unit dimensions,

load short-circuit protection detection, line disconnection detection, and measures for

EMC Directives.

Introduction

NJ-series CPU Unit Software User’s Manual (Cat. No. W501)

Section Description

Section 1

Introduction

Section 2

CPU Unit Operation

Section 3

I/O Ports, Slave Configuration, and

Unit Configuration

Section 4

Controller Setup

Section 5

Designing Tasks

Section 6

Programming

Section 7

Simulation, Transferring Projects to

the Physical CPU Unit, and Operation

Section 8

CPU Unit Status

Section 9

CPU Unit Functions

Section 10

Communications Setup

Section 11

Example of Actual Application Procedures

Section 12

Troubleshooting

Appendices

This section provides an introduction to the NJ-series Controllers and their features,

and gives the NJ-series Controller specifications.

This section describes the variables and control systems of the CPU Unit and CPU

Unit status.

This section describes how to use I/O ports, how to create the slave configuration

and unit configuration and how to assign functions.

This section describes the initial settings of the function modules.

This section describes the task system and types of tasks.

This section describes programming, including the programming languages and the

variables and instructions that are used in programming.

This section describes simulation of Controller operation and how to use the results

of simulation.

This section describes CPU Unit status.

This section describes the functionality provided by the CPU Unit.

This section describes how to go online with the CPU Unit and how to connect to

other devices.

This section describes the procedures that are used to actually operate an NJ-series

Controller.

This section describes the event codes, error confirmation methods, and corrections

for errors that can occur.

The appendices provide the CPU Unit specifications, task execution times, systemdefined variable lists, data attribute lists, CJ-series Unit memory information, CJseries Unit memory allocation methods, and data type conversion information.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

3

Page 6

Introduction

Sysmac Studio Version 1 Operation Manual (Cat. No. W504)

Section 1

Introduction

Section 2

Installation and Uninstallation

Section 3

System Design

Section 4

Programming

Section 5

Online Connections to a Controller

Section 6

Debugging

Section 7

Other Functions

Section 8

Reusing Programming

Section 9

Support Software Provided with the

Sysmac Studio

Section 10

Troubleshooting

Appendices

Section Description

This section provides an overview and lists the specifications of the Sysmac Studio

and describes its features and components.

This section describes how to install and uninstall the Sysmac Studio.

This section describes the basic concepts for designing an NJ-series System with the

Sysmac Studio and the basic operating procedures.

This section describes how to create programs with the Sysmac Studio.

This section describes how to go online with a Controller.

This section describes how to debug the programs online on the Controller or debug

it offline with the Simulator.

This section describes Sysmac Studio functions other than system design functions.

This section describes how to reuse the programs that you create with the Sysmac

Studio.

This section describes the Support Software that is provided with the Sysmac Studio.

This section describes the error messages that are displayed when you check a program on the Sysmac Studio and how to correct those errors.

The appendices describe the following:

Driver Installation for Direct USB Cable Connection

Specifying One of Multiple Ethernet Interface Cards

Online Help

Simulation Instructions

CJ-series User Defined CAN Unit Operation Manual for NJ-series

CPU Unit (Cat. No. W517) (This Manual)

Section Description

Section 1

Features and System Configuration

Section 2

Nomenclature and Installation

Section 3

Data Exchange with the CPU Unit

Section 4

Message Communications

Section 5

Communications Timing

Section 6

Troubleshooting and Maintenance

Appendices ---

This section provides an introduction to the User Defined CAN Units and their features. It also describes the operating procedure and the specifications of the User

Defined CAN Units.

This section describes the nomenclature, functionality and installation of the User

Defined CAN Unit.

This section describes the data exchange between the CPU Unit and User Defined

CAN Unit and the definitions of the device variables for CJ-series Unit.

This section describes the message communications of the User Defined CAN Unit.

This section describes the communications timing of the User Defined CAN Unit and

the performances of the remote I/O communications and message communications.

This section describes the troubleshooting procedure, event logs and maintenance

procedure for the User Defined CAN Unit.

4

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 7

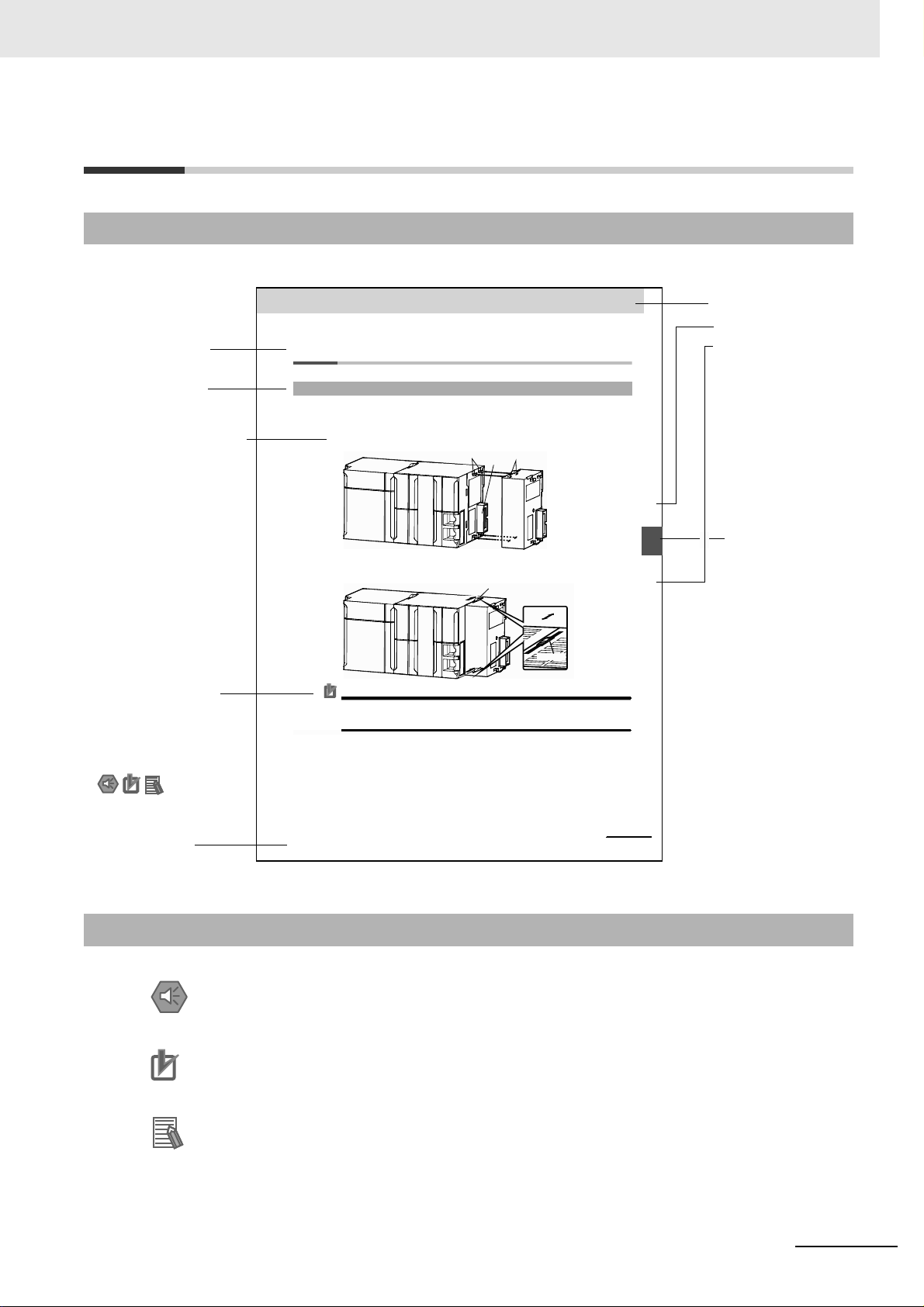

Manual Structure

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

s

t

i

n

U

gnitn

u

oM

3-4

4

s

t

ne

no

p

m

o

C

rel

l

o

r

t

n

oC

g

n

i

tc

e

n

noC

1

-

3-

4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

The sliders on the tops and bottoms of the Powe r Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

This illustration is provided only as a sample. It may not literally appear in this manual.

Page Structure

The following page structure is used in this manual.

Introduction

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Note References are provided to more detailed or related information.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

5

Page 8

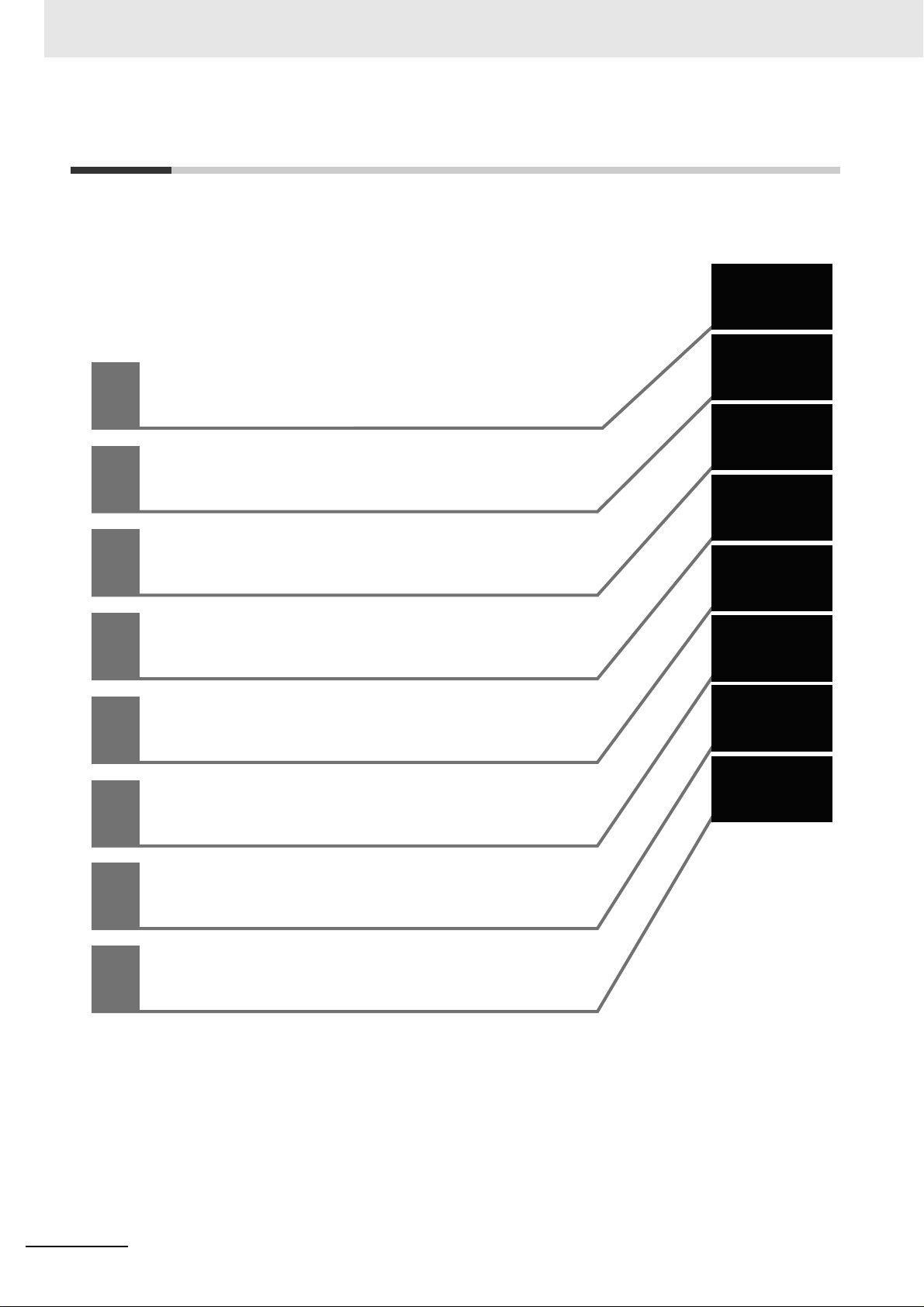

Introduction

Troubleshooting and Maintenance

Appendices

Communications Timing

6

5

Nomenclature and Installation

Data Exchange with the CPU Unit

Message Communications

4

3

2

1

2

3

4

5

6

A

1

1

I

A

I

Features and System Conguration

Index

Sections in this Manual

6

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 9

CONTENTS

Introduction............................................................................................................... 1

Relevant Manuals ..................................................................................................... 2

Manual Configuration............................................................................................... 3

Manual Structure ...................................................................................................... 5

Sections in this Manual............................................................................................ 6

CONTENTS ................................................................................................................ 7

Read and Understand this Manual........................................................................ 10

Safety Precautions ................................................................................................. 13

Precautions for Safe Use ....................................................................................... 18

Precautions for Correct Use .................................................................................. 24

Regulations and Standards ................................................................................... 27

Unit Versions........................................................................................................... 29

Related Manuals ..................................................................................................... 31

Revision History ..................................................................................................... 32

Section 1 Features and System Configuration

1-1 User Defined CAN Unit Features ........................................................................................... 1-2

1-2 Overview of CAN Bus ............................................................................................................. 1-5

1-2-1 CAN Communication Protocol ................................................................................................... 1-6

1-2-2 Physical CAN Connection ........................................................................................................ 1-10

1-2-3 Principles of Data Exchange .....................................................................................................1-11

1-2-4 Principles of Non-Destructive Bitwise Arbitration ......................................................................1-11

1-2-5 Efficiency of Bus Allocation ...................................................................................................... 1-12

1-2-6 Message Frame Formats ......................................................................................................... 1-14

1-2-7 Detecting and Signaling Errors ................................................................................................ 1-15

1-2-8 Data Reliability of the CAN Protocol ........................................................................................ 1-17

1-2-9 Extended Format CAN Message ............................................................................................. 1-18

1-2-10 Implementations of the CAN Protocol ......................................................................................1-19

1-2-11 Configuring a CAN Network ..................................................................................................... 1-19

1-3 Specifications ....................................................................................................................... 1-20

1-3-1 User Defined CAN Unit ............................................................................................................ 1-20

1-4 Basic Operating Procedures ............................................................................................... 1-22

1-4-1 Network Installation Procedure ................................................................................................ 1-22

1-4-2 User Defined CAN Unit Startup Procedure .............................................................................. 1-23

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

7

Page 10

Section 2 Nomenclature and Installation

2-1 Nomenclature and Installation .............................................................................................. 2-2

2-1-1 Nomenclature and Functions .....................................................................................................2-2

2-1-2 Switch Settings ........................................................................................................................... 2-5

2-2 Installing the User Defined CAN Unit .................................................................................... 2-8

2-2-1 System Configuration Precautions .............................................................................................2-8

2-2-2 Mounting ....................................................................................................................................2-8

2-2-3 Handing Precautions ..................................................................................................................2-9

2-2-4 External Dimensions .................................................................................................................. 2-9

2-2-5 Unit States ................................................................................................................................ 2-10

Section 3 Data Exchange with the CPU Unit

3-1 Data Exchange with the CPU Unit ......................................................................................... 3-2

3-1-1 Data Flow ................................................................................................................................... 3-2

3-1-2 Accessing From the User Program ............................................................................................ 3-5

3-2 Device Variable for CJ-series Unit ........................................................................................ 3-8

3-2-1 Enable CAN Communications ....................................................................................................3-8

3-2-2 Status Communication ...............................................................................................................3-9

3-2-3 Number of Delayed Messages .................................................................................................3-12

3-2-4 Number of Received Messages Waiting to be Processed .......................................................3-12

Section 4 Message Communications

4-1 Overview .................................................................................................................................. 4-2

4-1-1 Outline of Message Communications ........................................................................................4-2

4-2 Unit Configuration and Control ............................................................................................. 4-4

4-2-1 Configure Memory Areas (2902) ................................................................................................ 4-4

4-2-2 Configure 11-Bit ID Output Message Buffer (2903) .................................................................4-10

4-2-3 Configure 29-Bit ID Output Message Buffer (2904) .................................................................4-12

4-2-4 Configure 11-Bit ID Input Message Buffer (2905) ....................................................................4-14

4-2-5 Configure 29-Bit ID Input Message Buffer (2906) ....................................................................4-16

4-2-6 Direct Transmit of an 11-bit ID CAN Message (2907) ..............................................................4-17

4-2-7 Direct Transmit of an 29-bit ID CAN Message (2908) ..............................................................4-19

4-2-8 Setting the CAN Bit Rate and Sample Point (2909) ................................................................. 4-21

4-2-9 Error Log Read (2102) .............................................................................................................4-22

4-2-10 Error Log Clear (2103) .............................................................................................................4-23

Section 5 Communications Timing

5-1 Performance ............................................................................................................................ 5-2

5-1-1 I/O Refresh Time ........................................................................................................................5-2

5-1-2 Output Message Evaluation Time .............................................................................................. 5-2

5-1-3 Input Message Processing Time ................................................................................................ 5-4

5-1-4 CAN Interface .............................................................................................................................5-5

5-1-5 I/O Response Time .................................................................................................................... 5-5

5-1-6 Transmission of CAN Messages ................................................................................................5-8

5-1-7 Reception of CAN Messages .....................................................................................................5-9

8

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 11

Section 6 Troubleshooting and Maintenance

6-1 Overview .................................................................................................................................. 6-2

6-1-1 Troubleshooting the User Defined CAN Unit ............................................................................. 6-2

6-2 Troubleshooting with the User Defined CAN Unit Indicators ............................................. 6-4

6-2-1 Run LED Indicator ..................................................................................................................... 6-4

6-2-2 ERR LED Indicator .................................................................................................................... 6-5

6-2-3 Two 7-segment Display ............................................................................................................. 6-5

6-2-4 Two Dot Indicators ..................................................................................................................... 6-6

6-3 Error Log Functions ............................................................................................................... 6-7

6-3-1 Error Log Table .......................................................................................................................... 6-7

6-3-2 Error Codes and Detail Codes ................................................................................................... 6-8

6-3-3 Status Information ...................................................................................................................... 6-8

6-4 Troubleshooting ................................................................................................................... 6-10

6-4-1 CPU Unit’s ERR/ALM Indicator Lit or Flashing ........................................................................ 6-10

6-5 Event Logs ............................................................................................................................ 6-11

6-5-1 Overview of the Event Logs ......................................................................................................6-11

6-5-2 Error Table ............................................................................................................................... 6-12

6-5-3 Error Descriptions .................................................................................................................... 6-12

6-6 Maintenance and Replacement ........................................................................................... 6-16

6-6-1 Cleaning ................................................................................................................................... 6-16

6-6-2 Inspection ................................................................................................................................ 6-16

6-6-3 Replacing Faulty Units ............................................................................................................. 6-17

Appendices

A-1 Differences in Available Functions Depending on the CPU Unit (NJ/CJ-series) to be

Connected ...............................................................................................................................A-2

A-1-1 Differences in Available Functions .............................................................................................A-2

A-1-2 Differences in Accessing from User Program ............................................................................A-2

A-2 User Program Example ..........................................................................................................A-4

Index

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

9

Page 12

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON representative

if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

10

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 13

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

11

Page 14

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

12

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 15

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of an

NJ-series Controller. The safety precautions that are provided are extremely important to safety. Always

read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

could result in death or serious injury. Additionally, there may be

severe property damage.

Caution

Precautions for Safe Use

Indicates precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Indicates precautions on what to do and what not to do to ensure proper operation and performance.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or property damage.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

13

Page 16

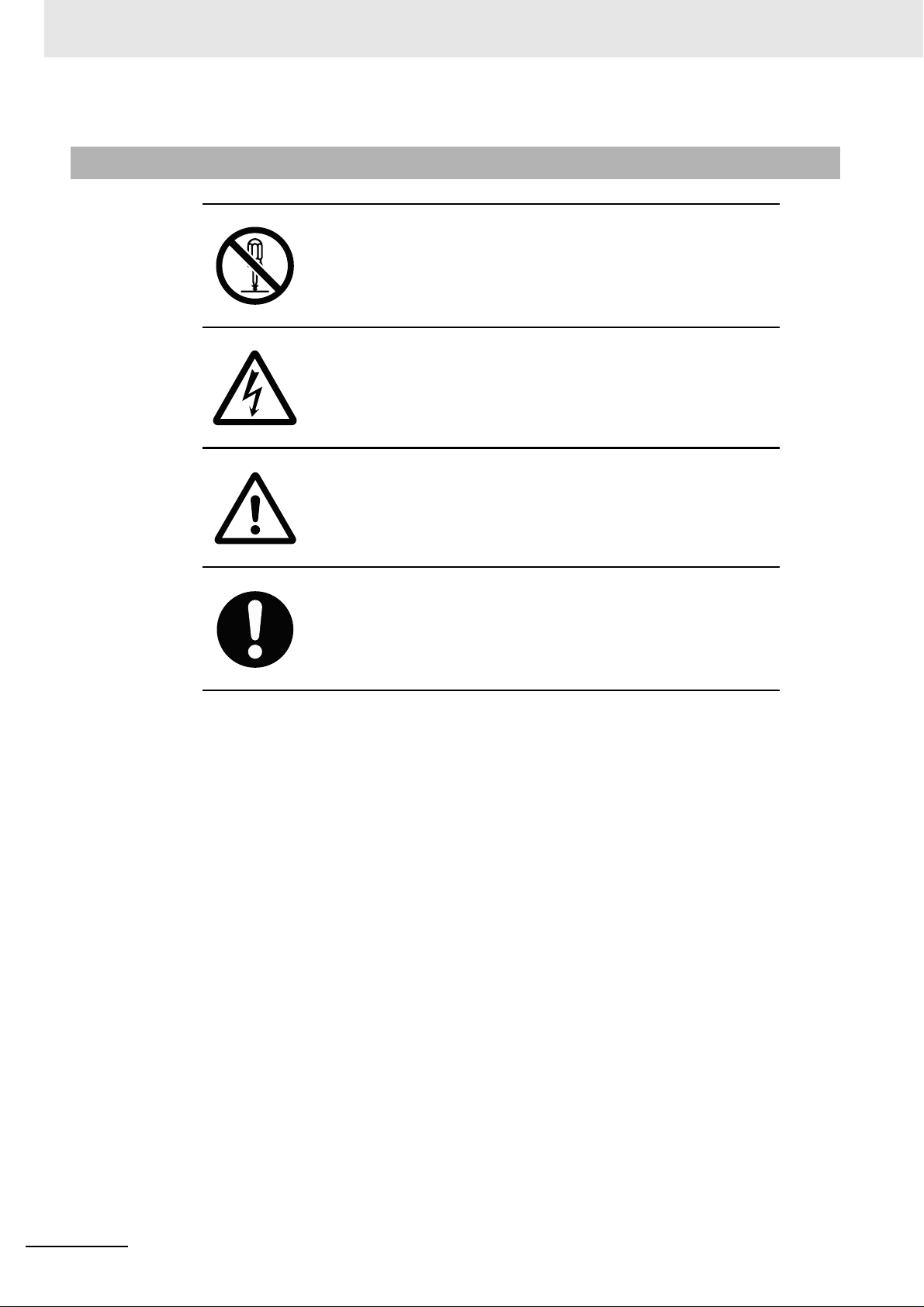

Symbols

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for something that you must do.

14

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 17

WARNING

During Power Supply

Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

Do not attempt to take any Unit apart. In particular, high-voltage parts are

present in the Power Supply Unit while power is supplied or immediately

after power is turned OFF. Touching any of these parts may result in electric

shock. There are sharp parts inside the Unit that may cause injury.

Fail-safe Measures

Provide safety measures in external circuits to ensure safety in the system if

an abnormality occurs due to malfunction of the CPU Unit, other Units, or

slaves or due to other external factors affecting operation. Not doing so may

result in serious accidents due to incorrect operation.

Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

The Controller outputs may remain ON or OFF due to deposition or burning

of the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided to

ensure safe operation of the system.

The CPU Unit will turn OFF all outputs from Basic Output Units in the following cases.

• If an error occurs in the power supply

• If the power supply connection becomes faulty

• If a CPU watchdog timer error or CPU reset occurs

• If a major fault level Controller error occurs

• While the CPU Unit is on standby until RUN mode is entered after the

power is turned ON

External safety measures must be provided to ensure safe operation of the

system even if the outputs turn OFF.

If external power supplies for slaves or other devices are overloaded or

short-circuited, the voltage will drop, outputs will turn OFF, and the system

may be unable to read inputs. Provide external safety measures in controls

with monitoring of external power supply voltage as required so that the system operates safely in such a case.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

15

Page 18

WARNING

Fail-safe Measures

Unintended outputs may occur when an error occurs in variable memory or

in memory used for CJ-series Units. As a countermeasure for such problems, external safety measures must be provided to ensure safe operation of

the system.

Provide measures in the communications system and user program to

ensure safety in the overall system even if errors or malfunctions occur in

data link communications or remote I/O communications.

If there is interference in remote I/O communications or if a major fault level

error occurs, output status will depend on the products that are used.

Confirm the operation that will occur when there is interference in communications or a major fault level error, and implement safety measures.

Correctly set all of the EtherCAT slaves.

The NJ-series Controller continues normal operation for a certain period of

time when a momentary power interruption occurs. This means that the NJseries Controller may receive incorrect signals from external devices that are

also affected by the power interruption. Accordingly, take suitable actions,

such as external fail-safe measures and interlock conditions, to monitor the

power supply voltage of the external device as required.

You must take fail-safe measures to ensure safety in the event of incorrect,

missing, or abnormal signals caused by broken signal lines, momentary

power interruptions, or other causes. Not doing so may result in serious accidents due to incorrect operation.

Voltage and Current Inputs

Make sure that the voltages and currents that are input to the Units and

slaves are within the specified ranges.

Inputting voltages or currents that are outside of the specified ranges may

cause accidents or fire.

16

Downloading

Always confirm safety at the destination before you transfer a user program,

configuration data, setup data, device variables, or values in memory used

for CJ-series Units from the Sysmac Studio. The devices or machines may

perform unexpected operation regardless of the operating mode of the CPU

Unit.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 19

Caution

Application

Do not touch any Unit when power is being supplied or immediately after the

power supply is turned OFF. Doing so may result in burn injury.

Wiring

Be sure that all terminal screws and cable connector screws are tightened to

the torque specified in the relevant manuals. The loose screws may result in

fire or malfunction.

Online Editing

Execute online editing only after confirming that no adverse effects will be

caused by deviations in the timing of I/O. If you perform online editing, the

task execution time may exceed the task period, I/O may not be refreshed

with external devices, input signals may not be read, and output timing may

change.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

17

Page 20

Precautions for Safe Use

Disassembly and Dropping

• Do not attempt to disassemble, repair, or modify any Units. Doing so may result in malfunction or fire.

• Do not drop any Unit or subject it to abnormal vibration or shock. Doing so may result in Unit malfunction or burning.

Mounting

• The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O Unit,

and CPU Bus Units must be completely locked (until they click into place) after connecting the adjacent Unit connectors.

Installation

• Always connect to a ground of 100 Ω or less when installing the Units. A ground of 100 Ω or less

must be installed when shorting the GR and LG terminals on the Power Supply Unit.

Wiring

• Follow the instructions in this manual to correctly perform wiring.

Double-check all wiring and switch settings before turning ON the power supply.

• Use crimp terminals for wiring.

Do not connect bare stranded wires directly to terminals.

• Do not pull on the cables or bend the cables beyond their natural limit.

Do not place heavy objects on top of the cables or other wiring lines. Doing so may break the cables.

• Mount terminal blocks and connectors only after checking the mounting location carefully.

• Be sure that the terminal blocks, expansion cables, and other items with locking devices are properly

locked into place.

• Always remove any dustproof labels that are on the top of the Units when they are shipped before

you turn ON the power supply. If the labels are not removed, heat will accumulate and malfunctions

may occur.

• Before you connect a computer to the CPU Unit, disconnect the power supply plug of the computer

from the AC outlet. Also, if the computer has an FG terminal, make the connections so that the FG

terminal has the same electrical potential as the FG (GR) terminal on the Power Supply Unit. A difference in electric potential between the computer and Controller may cause failure or malfunction.

• If the external power supply to an Output Unit or slave has polarity, connect it with the correct polarity.

If the polarity is reversed, current may flow in the reverse direction and damage the connected

devices regardless of the operation of the Controller.

18

Power Supply Design

• Do not exceed the rated supply capacity of the Power Supply Units in the NJ-series Controller. The

rated supply capacities are given in the NJ-series CPU Unit Hardware User’s Manual

(Cat. No. W500).

If the capacity is exceeded, operation may stop, malfunctions may occur, or data may not be backed

up normally for power interruptions.

Use NJ-series Power Supply Units for both the NJ-series CPU Rack and Expansion Racks.

Operation is not possible if a CJ-series Power Supply Unit is used with an NJ-series CPU Unit or an

NJ-series Power Supply Unit is used with a CJ-series CPU Unit.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 21

• Do not apply voltages or connect loads to the Output Units or slaves in excess of the maximum ratings.

• Surge current occurs when the power supply is turned ON. When selecting fuses or breakers for

external circuits, consider the above precaution and allow sufficient margin in shut-off performance.

Refer to the relevant manuals for surge current specifications. Refer to the NJ-series CPU Unit Hard-

ware User’s Manual (Cat. No. W500) for surge current specifications.

• If the full dielectric strength voltage is applied or turned OFF using the switch on the tester, the generated impulse voltage may damage the Power Supply Unit. Use the adjustment on the tester to gradually increase and decrease the voltage.

• Apply the voltage between the Power Supply Unit's L1 or L2 terminal and the GR terminal when testing insulation and dielectric strength. You do not have to disconnect the LG and GR terminals to perform these tests.

• Do not supply AC power from an inverter or other device with a square-wave output. Internal temperature rise may result in smoking or burning. Always input a sinusoidal wave with the frequency that is

given in the NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500).

• Install external breakers and take other safety measures against short-circuiting in external wiring.

Turning ON the Power Supply

• It takes up to approximately 10 to 20 s to enter RUN mode after the power is turned ON. During that

time, outputs will be OFF or will be the values specified in the Unit or slave settings, and external

communications cannot be performed. Use the RUN output on the Power Supply Unit, for example,

to implement fail-safe circuits so that external devices do not operate incorrectly.

• Configure the external circuits so that the power supply to the control system turns ON only after the

power supply to the Controller has turned ON. If the power supply to the Controller is turned ON after

the control power supply, temporary errors may result in incorrect control system signals because the

output terminals on Output Units may momentarily turn ON when power supply is turned ON to the

Controller.

Actual Operation

• Check the user program, data, and parameter settings for proper execution before you use them for

actual operation.

Turning OFF the Power Supply

• Never turn OFF the power supply to the Controller when the BUSY indicator is flashing. While the

BUSY indicator is lit, the user program and settings in the CPU Unit are being backed up in the builtin non-volatile memory. This data will not be backed up correctly if the power supply is turned OFF.

Also, a major fault level Controller error will occur the next time you start operation, and operation will

stop.

• Do not turn OFF the power supply or remove the SD Memory Card while SD Memory Card access is

in progress (i.e., while the SD BUSY indicator flashes). Data may become corrupted, and the Controller will not operate correctly if it uses corrupted data. To remove the SD Memory Card from the CPU

Unit while the power supply is ON, press the SD Memory Card power supply switch and wait for the

SD BUSY indicator to turn OFF before you remove the SD Memory Card.

• Do not disconnect the cable or turn OFF the power supply to the Controller when downloading data

or the user program from Support Software.

• Always turn OFF the power supply to the Controller before you attempt any of the following.

• Mounting or removing I/O Units or the CPU Unit

• Assembling the Units

• Setting DIP switches or rotary switches

• Connecting cables or wiring the system

• Connecting or disconnecting the connectors

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

19

Page 22

The Power Supply Unit may continue to supply power to the rest of the Controller for a few seconds

after the power supply turns OFF. The PWR indicator is lit during this time. Confirm that the PWR

indicator is not lit before you perform any of the above.

Operation

• Confirm that no adverse effect will occur in the system before you attempt any of the following.

• Changing the operating mode of the CPU Unit (including changing the setting of the Operating

Mode at Startup)

• Changing the user program or settings

• Changing set values or present values

• Forced refreshing

• Always sufficiently check the safety at the connected devices before you change the settings of an

EtherCAT slave or Special Unit.

• If two different function modules are used together, such as when you use CJ-series Basic Output

Units and EtherCAT slave outputs, take suitable measures in the user program and external controls

to ensure that safety is maintained in the controlled system if one of the function modules stops. The

relevant outputs will stop if a partial fault level error occurs in one of the function modules.

• Always confirm safety at the connected equipment before you reset Controller errors with an event

level of partial fault or higher for the EtherCAT Master Function Module.

When the error is reset, all slaves that were in any state other than Operational state due to a Controller error with an event level of partial fault or higher (in which outputs are disabled) will go to Operational state and the outputs will be enabled.

Before you reset all errors, confirm that no Controller errors with an event level of partial fault have

occurred for the EtherCAT Master Function Module.

• Always confirm safety at the connected equipment before you reset Controller errors for a CJ-series

Special Unit. When a Controller error is reset, the Unit where the Controller error with an event level

of observation or higher will be restarted.

Before you reset all errors, confirm that no Controller errors with an event level of observation or

higher have occurred for the CJ-series Special Unit. Observation level events do not appear on the

Controller Error Tab Page, so it is possible that you may restart the CJ-series Special Unit without

intending to do so.

You can check the status of the _CJB_UnitErrSta[0,0] to _CJB_UnitErrSta[3,9] error status variables

on a Watch Tab Page to see if an observation level Controller error has occurred.

20

Battery Backup

• The user program and initial values for the variables are stored in non-volatile memory in the CPU

Unit. The present values of variables with the Retain attribute and the values of the Holding, DM, and

EM Areas in the memory used for CJ-series Units are backed up by a Battery. If the Battery is not

connected or the Battery is exhausted, the CPU Unit detects a Battery-backup Memory Check Error.

If that error is detected, variables with a Retain attribute are set to their initial values and the Holding,

DM, and EM Areas in memory used for CJ-series Units are cleared to all zeros. Perform thorough

verifications and provide sufficient measures to ensure that the devices perform safe operation for

the initial values of the variables with Retain attributes and the resulting operation.

Debugging

• Forced refreshing ignores the results of user program execution and refreshes I/O with the specified

values. If forced refreshing is used for inputs for which I/O refreshing is not supported, the inputs will

first take the specified values, but they will then be overwritten by the user program. This operation

differs from the force-set/reset functionality of the CJ-series PLCs.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 23

• You cannot upload or download information for forced refreshing with the Sysmac Studio.

After downloading data that contains forced refreshing, change to RUN mode and then use the

Sysmac Studio to perform the operation for forced refreshing.

Depending on the difference in the forced status, the control system may operate unexpectedly.

• Do not specify the same address for the AT specification for more than one variable.

Doing so would allow the same entity to be accessed with different variable names, which would

make the user program more difficult to understand and possibly cause programming mistakes.

General Communications

• When you use data link communications, check the error information given in the status flags to

make sure that no error has occurred in the source device. Write the user program to use the

received data only if there is no error. If there is an error in the source device, the data for the data

link may contain incorrect values.

• Unexpected operation may result if inappropriate data link tables are set. Even if appropriate data link

tables have been set, confirm that the controlled system will not be adversely affected before you

transfer the data link tables. The data links start automatically after the data link tables are transferred.

• All CPU Bus Units are restarted when routing tables are transferred from Support Software to the

CPU Unit. Restarting these Units is required to read and enable the new routing tables. Confirm that

the system will not be adversely affected by restarting before you transfer the routing tables.

• Tag data links will stop between related nodes while tag data link parameters are transferred during

Controller operation. Confirm that the system will not be adversely affected before you transfer the

tag data link parameters.

EtherNet/IP Communications

• All related EtherNet/IP nodes are reset when you transfer settings for the built-in EtherNet/IP port

(including IP addresses and tag data links settings). This is performed to read and enable the settings. Confirm that the system will not be adversely affected by resetting nodes before you transfer

the settings.

• If EtherNet/IP tag data links (cyclic communications) are used with a repeating hub, the communications load on the network will increase. This will increase collisions and may prevent stable communications. Do not use repeating hubs on networks where tag data links are used. Use an Ethernet

switch instead.

EtherCAT Communications

• Make sure that the communications distance, number of nodes connected, and method of connection for EtherCAT are within specifications.

Do not connect EtherCAT communications to EtherNet/IP, a standard in-house LAN, or other networks. An overload may cause the network to fail or malfunction.

• Malfunctions or unexpected operation may occur for some combinations of EtherCAT revisions of the

master and slaves. If you disable the revision check in the network settings, use the Sysmac Studio

to check the slave revision settings in the master and the actual slave revisions, and then make sure

that functionality is compatible in the slave manuals or other references. You can check the actual

slave revisions from the Sysmac Studio or on slave nameplates.

• After you transfer the user program, the CPU Unit is restarted. Communications with the EtherCAT

slaves are cut off for up to 45 seconds. During that period, the slave outputs behave according to the

slave settings.

Before you transfer the user program, confirm that the system will not be adversely affected.

• If the Fail-soft Operation parameter is set to stop operation, process data communications will stop

for all slaves when an EtherCAT communications error is detected in a slave. For this reason, if

Servo Drives are connected, the Servos for all axes will be turned OFF. Make sure that the Fail-soft

Operation parameter setting results in safe operation when a device error occurs.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

21

Page 24

• EtherCAT communications are not always established immediately after the power supply is turned

ON. Use the system-defined variables in the user program to confirm that communications are established before attempting control operations.

• If frames sent to EtherCAT slaves are lost due to noise or other causes, slave I/O data is not communicated, and the intended operation is sometimes not achieved. If noise countermeasures are

required, use the _EC_InDataInvalid (Input Data Disable) system-defined variable as an interlock

condition in the user program.

Refer to the NJ-series CPU Unit Built-in EtherCAT Port User’s Manual (Cat. No. W505) for details.

The slave outputs behave according to the slave settings. Refer to the manuals for the slaves for

details.

• When an EtherCAT slave is disconnected, communications will stop and control of the outputs will be

lost not only for the disconnected slave, but for all slaves connected after it. Confirm that the system

will not be adversely affected before you disconnect a slave.

• If you disconnect the cable from an EtherCAT slave to disconnect it from the network, any current

communications frames may be lost. If frames are lost, slave I/O data is not communicated, and the

intended operation is sometimes not achieved. Perform the following processing for a slave that

needs to be replaced.

Program the _EC_InDataInvalid (Input Data Disable) system-defined variable as an interlock condition.

Set the Impermissible Number of Continuous Timeouts setting in the EtherCAT master to at

least 2.

Refer to the NJ-series CPU Unit Built-in EtherCAT Port User’s Manual (Cat. No. W505) for details.

Motion Control

• Confirm the axis number carefully before you perform an MC Test Run.

• The motor is stopped if communications are interrupted between the Sysmac Studio and the CPU

Unit during an MC Test Run. Connect the communications cable between the computer and CPU

Unit securely and confirm that the system will not be adversely affected before you perform an

MC Test Run.

• Always execute the Save Cam Table instruction if you change any of the cam data from the user program in the CPU Unit or from the Sysmac Studio. If the cam data is not saved, the previous condition

will be restored when the power is turned ON again, possibly causing unexpected machine operation.

• The positive drive prohibit input (POT), negative drive prohibit input (NOT), and home proximity input

(DEC) of the Servo Drive are used by the MC Function Module as the positive limit input, negative

limit input, and home proximity input. Make sure that the signal widths for all of these input signals

are longer than the control period of the MC Function Module. If the input signal widths are shorter

than the control period, the MC Function Module may not be able to detect the input signals, resulting

in incorrect operation.

Battery Replacement

• The Battery may leak, rupture, heat, or ignite. Never short-circuit, charge, disassemble, heat, or

incinerate the Battery or subject it to strong shock.

• Dispose of any Battery that has been dropped on the floor or otherwise subjected to excessive

shock. Batteries that have been subjected to shock may leak if they are used.

• UL standards require that only an experienced engineer replace the Battery. Make sure that an experienced engineer is in charge of Battery replacement.

• Apply power for at least five minutes before changing the Battery. Install a new Battery within five

minutes (at 25°C) of turning OFF the power supply. If power is not supplied for at least 5 minutes, the

saved data may be lost.

22

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 25

Unit Replacement

• We recommend replacing the Battery with the power turned OFF to prevent the CPU Unit’s sensitive

internal components from being damaged by static electricity and to prevent malfunctions. The Battery can be replaced without turning OFF the power supply. To do so, always touch a grounded piece

of metal to discharge static electricity from your body before you start the procedure.

After you replace the Battery, connect the Sysmac Studio and clear the Low Battery Voltage error.

• Make sure that the required data, including the user program, configurations, settings, variables, and

memory used for CJ-series Units, is transferred to a CPU Unit that was replaced and to externally

connected devices before restarting operation.

Be sure to include the routing tables, network parameters, and other CPU Bus Unit data, which are

stored in the CPU Unit.

Disposal

• Dispose of the product and Batteries according to local ordinances as they apply.

• The following information must be displayed for all products that contain primary lithium batteries with

a perchlorate content of 6 ppb or higher when shipped to or transported through the State of California, USA.

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate.

• The CPU Unit contains a primary lithium battery with a perchlorate content of 6 ppb or higher. Place

the above information on the individual boxes and shipping boxes when shipping finished products

that contain a CPU Unit to the State of California, USA.

Using the User Defined CAN Units

• When adding a new node to the network, make sure that the baud rate is the same as other nodes.

• Use specified communications cables.

• Do not extend connection distances beyond the ranges given in the specifications.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

23

Page 26

Precautions for Correct Use

Storage, Mounting, and Wiring

• Do not operate or store the Controller in the following locations. Operation may stop or malfunctions

may occur.

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

• Take appropriate and sufficient countermeasures when installing the Controller in the following locations.

• Locations subject to strong, high-frequency noise

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power lines

• Before touching a Unit, be sure to first touch a grounded metallic object in order to discharge any

static build-up.

• Install the Controller away from sources of heat and ensure proper ventilation. Not doing so may

result in malfunction, in operation stopping, or in burning.

• An I/O bus check error will occur and the Controller will stop if an I/O Connecting Cable’s connector is

disconnected from the Rack. Be sure that the connectors are secure.

• Do not allow foreign matter to enter the openings in the Unit. Doing so may result in Unit burning,

electric shock, or failure.

• Do not allow wire clippings, shavings, or other foreign material to enter any Unit. Otherwise, Unit

burning, failure, or malfunction may occur. Cover the Units or take other suitable countermeasures,

especially during wiring work.

• For EtherCAT and EtherNet/IP, use the connection methods and cables that are specified in the NJ-

series CPU Unit Built-in EtherCAT Port User’s Manual (Cat. No. W505) and the NJ-series CPU Unit

Built-in EtherNet/IP Port User’s Manual (Cat. No. W506). Otherwise, communications may be faulty.

• Use the rated power supply voltage for the Power Supply Units. Take appropriate measures to

ensure that the specified power with the rated voltage and frequency is supplied in places where the

power supply is unstable.

• Make sure that the current capacity of the wire is sufficient. Otherwise, excessive heat may be generated. When cross-wiring terminals, the total current for all the terminals will flow in the wire. When

wiring cross-overs, make sure that the current capacity of each of the wires is not exceeded.

• Do not touch the terminals on the Power Supply Unit immediately after turning OFF the power supply.

Residual voltage may cause electrical shock.

• If you use reed switches for the input contacts for AC Input Units, use switches with a current capacity of 1 A or greater.

If the capacity of the reed switches is too low, surge current may fuse the contacts.

24

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 27

Error Processing

• In applications that use the results of instructions that read the error status, consider the affect on the

system when errors are detected and program error processing accordingly. For example, even the

detection of a minor error, such as Battery replacement during operation, can affect the system

depending on how the user program is written.

Unit Replacement

• If you replace a CPU Bus Unit or Special I/O Unit, refer to operation manual for the Unit for information on the data required for individual Units and redo the necessary settings.

• The absolute encoder home offset is backed up with a Battery in the CPU Unit.

When you change the combination of the CPU Unit and Servomotor, e.g., when you add or replace a

Servomotor, define home again.

To restore the information without changing the CPU Unit-Servomotor combination, remove the

absolute encoder home offset from the data to restore.

Task Settings

• If a Task Period Exceeded error occurs, shorten the programs to fit in the task period or increase the

setting of the task period.

Motion Control

• Use the system-defined variable in the user program to confirm that EtherCAT communications are

established before you attempt to execute motion control instructions. Motion control instructions are

not executed normally if EtherCAT communications are not established.

• Use the system-defined variables to monitor for errors in communications with the slaves that are

controlled by the motion control function module. Motion control instructions are not executed normally if an error occur in slave communications.

• Before you start an MC Test Run, make sure that the operation parameters are set correctly.

• Do not download motion control settings during an MC Test Run.

EtherCAT Communications

• Do not disconnect the EtherCAT slave cables during operation. The outputs will become unstable.

• Set the Servo Drives to stop operation if an error occurs in EtherCAT communications between the

Controller and a Servo Drive.

Battery Replacement

• Be sure to install a replacement Battery within two years of the production date shown on the Battery

label.

• Turn ON the power after replacing the Battery for a CPU Unit that has been unused for a long time.

Leaving the CPU Unit unused again without turning ON the power even once after the Battery is

replaced may result in a shorter Battery life.

• When you replace the Battery, use the CJ1W-BAT01 Battery Set.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

25

Page 28

SD Memory Cards

• Insert the SD Memory Card all the way.

• Do not turn OFF the power supply to the Controller during SD Memory Card access. The files may be

corrupted.

If there is a corrupted file in the SD Memory Card, the file is automatically deleted by the restoration

function when the power supply is turned ON.

26

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 29

Regulations and Standards

Conformance to EC Directives

Applicable Directives

• EMC Directives

• Low Voltage Directive

Concepts

EMC Directive

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2 and EN 61000-6-2

EMI (Electromagnetic Interference): EN 61131-2 and EN 61000-6-4 (Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to 1,500 VDC meet the

required safety standards. The applicable directive is EN 61131-2.

Conformance to EC Directives

The NJ-series Controllers comply with EC Directives. To ensure that the machine or device in which

the NJ-series Controller is used complies with EC Directives, the Controller must be installed as follows:

• The NJ-series Controller must be installed within a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies connected to

DC Power Supply Units and I/O Units.

• NJ-series Controllers that comply with EC Directives also conform to the Common Emission Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending

on the configuration of the control panel used, other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies with EC Directives.

The following examples show means of reducing noise.

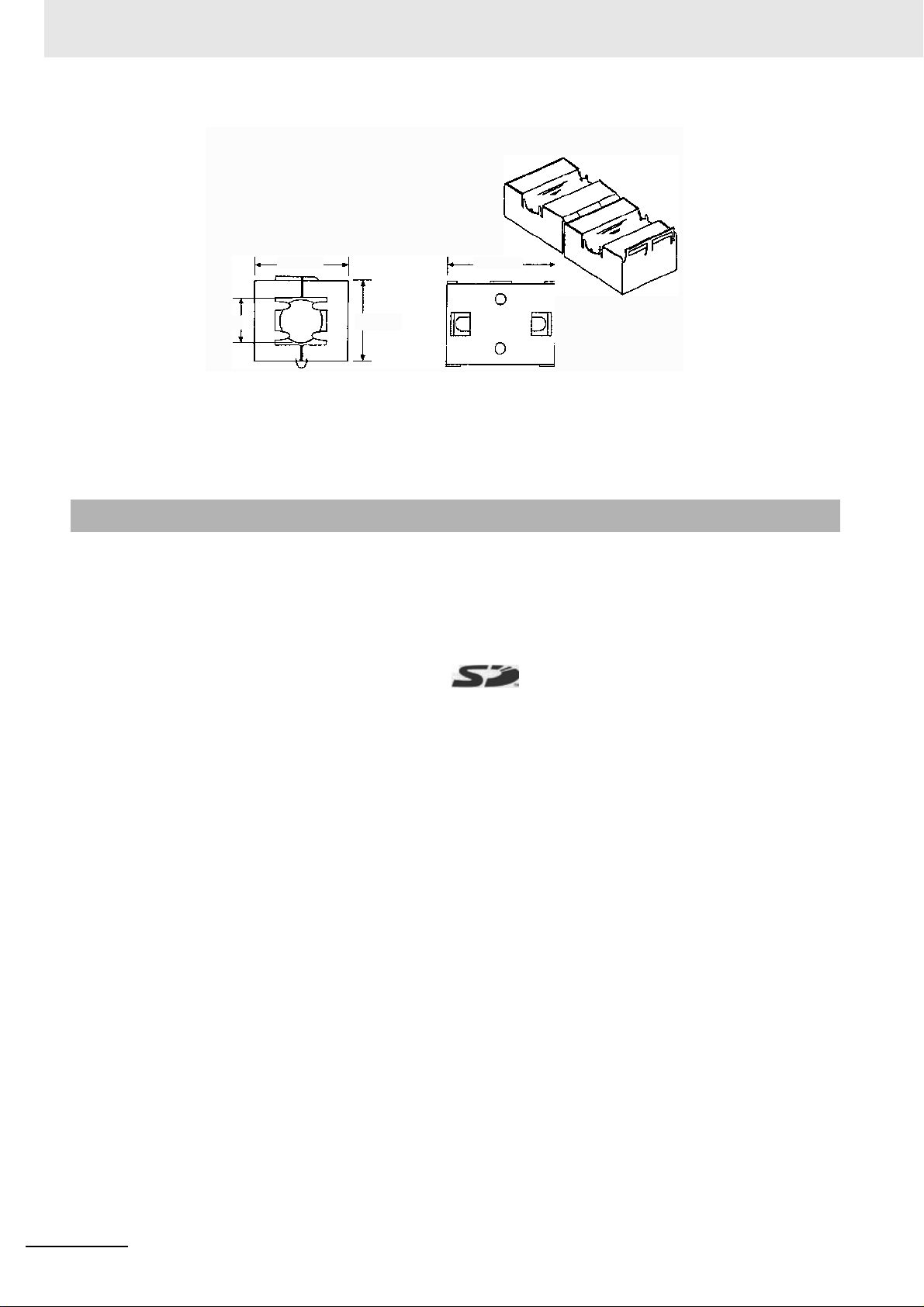

1 Noise from the communications cable can be reduced by installing a ferrite core on the commu-

nications cable within 10 cm of the User Defined CAN Unit.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

27

Page 30

Ferrite Core (Data Line Filter): 0443-164151 (manufactured by

Fair-Rite Products Co., Ltd.)

Impedance specifications

25 MHZ: 156 Ω

100 MHZ: 250 Ω

30 mm

13 mm

29 mm

33 mm

[Contact]

Nisshin Electric Co., Ltd.

2 Wire the control panel with as thick and short electric lines as possible and ground to 100 Ω min.

3 Keep communication cables as short as possible and ground to 100 Ω min.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• Windows, Windows 98, Windows XP, Windows Vista, and Windows 7 are registered trademarks of

Microsoft Corporation in the USA and other countries.

•EtherCAT® is a registered trademark of Beckhoff Automation GmbH for their patented technology.

• The SD logo is a trademark of SD-3C, LLC.

• CAN Protocol is developed by Robert Bosch GmbH and protected by patents.

• SAE is the trademark of The Society of Automotive Engineers.

• CiA is the trademark of CAN in Automation(CiA), CiA is the international users’ and manufacturers’

organization that develops and supports CAN-based higher-layer protocols.

Other company names and product names in this document are the trademarks or registered trademarks of their respective companies.

28

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 31

Unit Versions

Unit Versions

A “unit version” has been introduced to manage CPU Units in the NJ Series according to differences in

functionality accompanying Unit upgrades.

Notation of Unit Versions on Products

The unit version is given on the ID information label of the products for which unit versions are managed, as shown below.

Example for NJ-series NJ501-

□□□□ CPU Unit:

ID information label

Unit model Unit version

NJ501 - 1500 Ver.1.@@

PORT1 MAC ADDRESS: @@@@@@@@@@@@

PORT2 MAC ADDRESS: @@@@@@@@@@@@

Lot No. DDMYY @ xxxx

Lot number and serial number MAC address

The following information is provided on the ID information label.

Item Description

Unit model Gives the model of the Unit.

Unit version Gives the unit version of the Unit.

Lot number and

serial number

MAC address Gives the MAC address of the built-in port on the Unit.

Gives the lot number and serial number of the Unit.

DDMYY: Lot number,

“M” gives the month (1 to 9: January to September, X: October, Y: November, Z: December)

□: For use by OMRON, xxxx: Serial number

Confirming Unit Versions with Sysmac Studio

You can use the Unit Production Information on the Sysmac Studio to check the unit version of the CPU

Unit, CJ-series Special I/O Units, CJ-series CPU Bus Units, and EtherCAT slaves. The unit versions of

CJ-series Basic I/O Units cannot be checked from the Sysmac Studio.

CPU Unit and CJ-series Units

1 Double-click CPU/Expansion Racks under Configurations and Setup in the Multiview

Explorer. Or, right-click CPU/Expansion Racks under Configurations and Setup and select

Edit from the menu.

The Unit Editor is displayed for the Controller Configurations and Setup layer.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

29

Page 32

2 Right-click any open space in the Unit Editor and select Production Information.

The Production Information Dialog Box is displayed.

Simple Display Detailed Display

In this example, “Ver.1.0” is displayed next to the unit model.

The following items are displayed.

CPU Unit CJ-series Units

Unit model

Unit version

Lot number

Unit model

Unit version

Lot number

Rack number, slot number, and unit number

EtherCAT Slaves

1 Double-click EtherCAT under Configurations and Setup in the Multiview Explorer. Or, right-

click EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Configuration Tab Page is displayed for the Controller Configurations and Setup

layer.

2 Right-click the master in the EtherCAT Configurations Editing Pane and select Display Produc-

tion Information.

The Production Information Dialog Box is displayed.

30

The following items are displayed.

Node address

Type information*

Serial number

* If the model number cannot be determined (such as when there is no ESI file), the vendor ID, product

code, and revision number are displayed.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 33

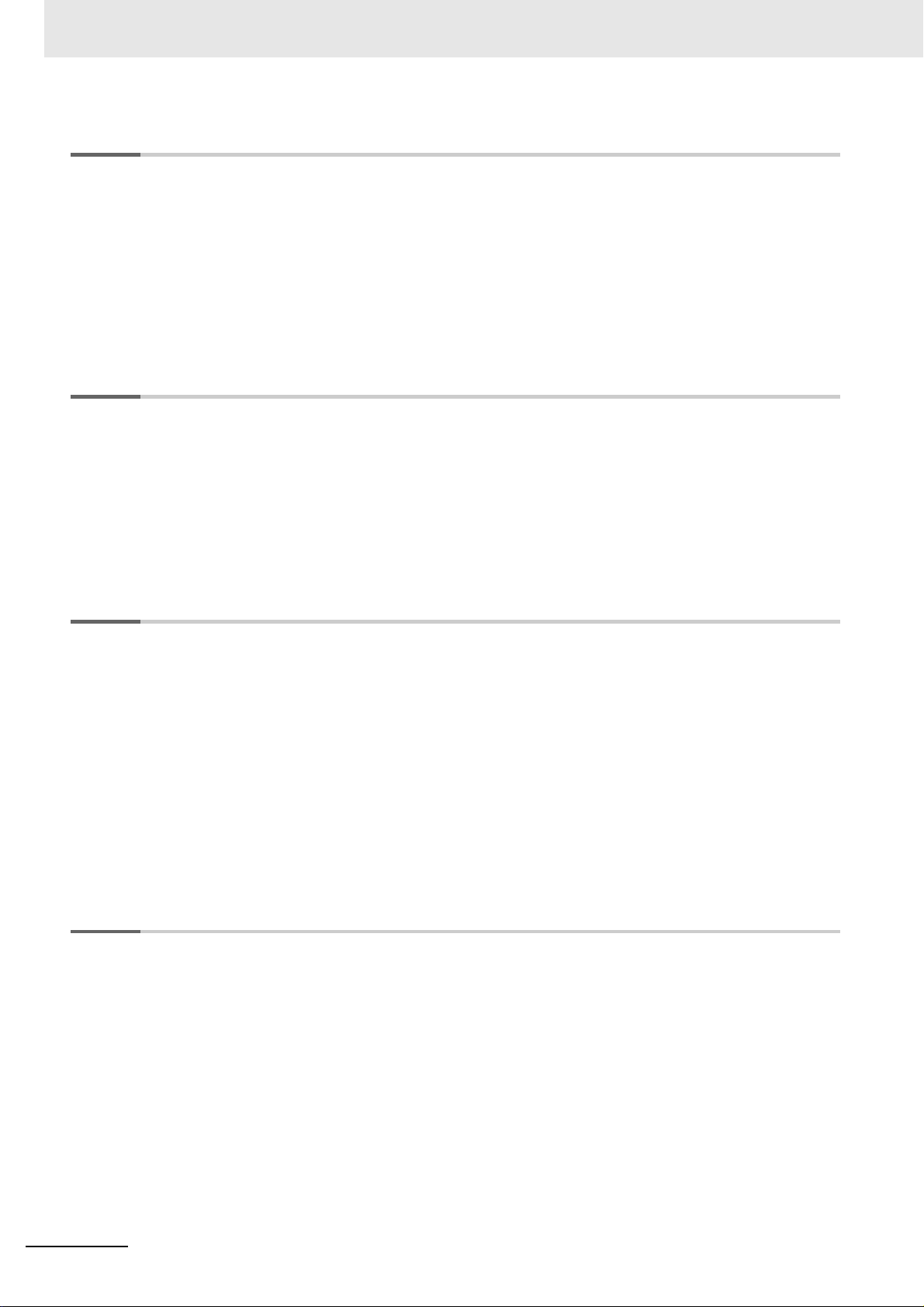

Related Manuals

The following manuals are related to the NJ-series Controllers. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NJ-series CPU Unit

Hardware User’s Manual

NJ-series CPU Unit Software User’s Manual

Sysmac Studio Version 1

Operation Manual

CJ-series User Defined

CAN Units Operation

Manual for NJ-series

CPU Unit (This document)

W500

W501

W504 SYSMAC-

W517 CJ1W-CORT21 Learning about the func-

NJ501-

NJ501-

SE2

□□□

□□□□

□□□□

Learning the basic specifications of the NJ-series

CPU Units, including introductory information,

designing, installation, and

maintenance. Mainly hardware information is provided.

Learning how to program

and set up an NJ-series

CPU Unit. Mainly software

information is provided.

Learning about the operating procedures and functions of the Sysmac Studio.

tions and operating procedures when the CJ-series

User Defined CAN Unit is

used in an NJ-series system configuration.

An introduction to the entire NJ-series system is

provided along with the following information on

a Controller built with an NJ501 CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the NJ-series

CPU Unit Software User’s Manual (Cat. No.

W501).

The following information is provided on a Controller built with an NJ501 CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3 language specifications

Use this manual together with the NJ-series

CPU Unit Hardware User’s Manual (Cat. No.

W500).

Describes the operating procedures of the

Sysmac Studio.

The functions and operating procedures when

the CJ-series User Defined CAN Unit is used in

an NJ-series system configuration are

described.

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

31

Page 34

W517-E1-01

Revision code

Cat. No.

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 April 2012 Original production

32

CJ-series User Defined CAN Unit Operation Manual for NJ-series CPU Unit (W517)

Page 35

Features and System

Configuration

This section provides an introductory overview of CAN bus, its functions and how to

setup and configure a network. It also addresses the User Defined CAN Unit its configuration, features and specifications.

1-1 User Defined CAN Unit Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Overview of CAN Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5