Page 1

Cat. No. W393-E1-07

SYSMAC CJ Series

CJ1G/H-CPU䡺䡺H, CJ1G-CPU䡺䡺P

CJ1M-CPU䡺䡺, CJ1G-CPU䡺䡺

OPERATION MANUAL

Programmable Controllers

Page 2

SYSMAC CJ Series

CJ1G/H-CPU@@H, CJ1G-CPU@@P,

CJ1M-CPU@@

, CJ1G-CPU@@

Programmable Controllers

Operation Manual

Revised July 2004

Page 3

Certain Terms and Conditions of Sale

1. Offer; Acceptance. These terms and conditions (these "Terms") are deemed

part of all catalogs, manuals or other documents, whether electronic or in writing, relating to the sale of goods or services (collectively, the "Goods

Omron Electronics LLC and its subsidiary companies ("Seller

objects to any terms or conditions proposed in Buyer's purchase order or other

documents which are inconsistent with, or in addition to, these Terms. Please

contact your Omron representative to confirm any additional terms for sales

from your Omron company.

2. Prices.

3. Discounts.

4. Orders.

5. Governmental Approvals.

6. Taxes.

7. Financial.

8. Cancellation; Etc.

9. Force Majeure.

10. Shipping; Delivery. Unless otherwise expressly agreed in writing by Seller:

11. Claims.

All prices stated are current, subject to change without notice by

Seller. Buyer agrees to pay the price in effect at time of shipment.

invoices sent to Buyer after deducting transportation charges, taxes and

duties, and will be allowed only if (i) the invoice is paid according to Seller's

payment terms and (ii) Buyer has no past due amounts owing to Seller.

costs involved in, obtaining any government approvals required for the importation or sale of the Goods.

real property and income taxes), including any interest or penalties thereon,

imposed directly or indirectly on Seller or required to be collected directly or

indirectly by Seller for the manufacture, production, sale, delivery, importation,

consumption or use of the Goods sold hereunder (including customs duties

and sales, excise, use, turnover and license taxes) shall be charged to and

remitted by Buyer to Seller.

to Seller, Seller reserves the right to stop shipments or require satisfactory

security or payment in advance. If Buyer fails to make payment or otherwise

comply with these Terms or any related agreement, Seller may (without liability

and in addition to other remedies) cancel any unshipped portion of Goods sold

hereunder and stop any Goods in transit until Buyer pays all amounts, including amounts payable hereunder, whether or not then due, which are owing to it

by Buyer. Buyer shall in any event remain liable for all unpaid accounts.

unless Buyer indemnifies Seller fully against all costs or expenses arising in

connection therewith.

resulting from causes beyond its control, including earthquakes, fires, floods,

strikes or other labor disputes, shortage of labor or materials, accidents to

machinery, acts of sabotage, riots, delay in or lack of transportation or the

requirements of any government authority.

a. Shipments shall be by a carrier selected by Seller;

b. Such carrier shall act as the agent of Buyer and delivery to such carrier

c. All sales and shipments of Goods shall be FOB shipping point (unless oth-

d. Delivery and shipping dates are estimates only.

e. Seller will package Goods as it deems proper for protection against normal

Goods occurring before delivery to the carrier must be presented in writing to

Seller within 30 days of receipt of shipment and include the original transportation bill signed by the carrier noting that the carrier received the Goods from

Seller in the condition claimed.

Cash discounts, if any, will apply only on the net amount of

Seller will accept no order less than $200 net billing.

All taxes, duties and other governmental charges (other than general

If the financial position of Buyer at any time becomes unsatisfactory

Seller shall not be liable for any delay or failure in delivery

shall constitute delivery to Buyer;

erwise stated in writing by Seller), at which point title to and all risk of loss of

the Goods shall pass from Seller to Buyer, provided that Seller shall retain a

security interest in the Goods until the full purchase price is paid by Buyer;

handling and extra charges apply to special conditions.

Any claim by Buyer against Seller for shortage or damage to the

Buyer shall be responsible for, and shall bear all

Orders are not subject to rescheduling or cancellation

"). Seller hereby

") by

12. Warranties.

Goods will be free from defects in materials and workmanship for a period of

twelve months from the date of sale by Seller (or such other period expressed

in writing by Seller). Seller disclaims all other warranties, express or implied.

(b) Limitations.

EXPRESS OR IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE GOODS.

BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

GOODS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. Seller further disclaims all warranties and responsibility of

any type for claims or expenses based on infringement by the Goods or otherwise of any intellectual property right. (c) Buyer Remedy.

tion hereunder shall be to replace (in the form originally shipped with Buyer

responsible for labor charges for removal or replacement thereof) the noncomplying Good or, at Seller's election, to repay or credit Buyer an amount

equal to the purchase price of the Good; provided that in no event shall Seller

be responsible for warranty, repair, indemnity or any other claims or expenses

regarding the Goods unless Seller's analysis confirms that the Goods were

properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any goods by

Buyer must be approved in writing by Seller before shipment. Seller shall not

be liable for the suitability or unsuitability or the results from the use of Goods

in combination with any electrical or electronic components, circuits, system

assemblies or any other materials or substances or environments. Any

advice, recommendations or information given orally or in writing, are not to be

construed as an amendment or addition to the above warranty.

13. Damage Limits; Etc.

RECT OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

GOODS, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY,

NEGLIGENCE OR STRICT LIABILITY. Further, in no event shall liability of

Seller exceed the individual price of the Good on which liability is asserted.

14. Indemnities.

its employees from and against all liabilities, losses, claims, costs and

expenses (including attorney's fees and expenses) related to any claim, investigation, litigation or proceeding (whether or not Seller is a party) which arises

or is alleged to arise from Buyer's acts or omissions under these Terms or in

any way with respect to the Goods. Without limiting the foregoing, Buyer (at

its own expense) shall indemnify and hold harmless Seller and defend or settle

any action brought against Seller to the extent that it is based on a claim that

any Good made to Buyer specifications infringed intellectual property rights of

another party.

15. Property; Confidentiality.

the exclusive property of Seller and its affiliates and Buyer shall not attempt to

duplicate it in any way without the written permission of Seller. Notwithstanding any charges to Buyer for engineering or tooling, all engineering and tooling

shall remain the exclusive property of Seller. All information and materials

supplied by Seller to Buyer relating to the Goods are confidential and proprietary, and Buyer shall limit distribution thereof to its trusted employees and

strictly prevent disclosure to any third party.

16. Miscellaneous.

and no course of dealing between Buyer and Seller shall operate as a waiver

of rights by Seller. (b) Assignment.

without Seller's written consent. (c) Amendment.

entire agreement between Buyer and Seller relating to the Goods, and no provision may be changed or waived unless in writing signed by the parties.

(d) Severability.

provision shall not invalidate any other provision. (e) Setoff.

no right to set off any amounts against the amount owing in respect of this

invoice. (f) As used herein, "including

(a) Exclusive Warranty. Seller's exclusive warranty is that the

SELLER MAKES NO WARRANTY OR REPRESENTATION,

Seller's sole obliga-

SELLER SHALL NOT BE LIABLE FOR SPECIAL, INDI-

Buyer shall indemnify and hold harmless Seller, its affiliates and

The intellectual property embodied in the Goods is

(a) Waiver. No failure or delay by Seller in exercising any right

Buyer may not assign its rights hereunder

If any provision hereof is rendered ineffective or invalid, such

" means "including without limitation".

These Terms constitute the

Buyer shall have

Certain Precautions on Specifications and Use

1. Suitability of Use. Seller shall not be responsible for conformity with any standards, codes or regulations which apply to the combination of the Good in the

Buyer's application or use of the Good. At Buyer's request, Seller will provide

applicable third party certification documents identifying ratings and limitations

of use which apply to the Good. This information by itself is not sufficient for a

complete determination of the suitability of the Good in combination with the

end product, machine, system, or other application or use. The following are

some examples of applications for which particular attention must be given.

This is not intended to be an exhaustive list of all possible uses of this Good,

nor is it intended to imply that the uses listed may be suitable for this Good:

(i) Outdoor use, uses involving potential chemical contamination or electrical

interference, or conditions or uses not described in this document.

(ii) Energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety

equipment, and installations subject to separate industry or government

regulations.

(iii) Systems, machines and equipment that could present a risk to life or

property. Please know and observe all prohibitions of use applicable to

this Good.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM

AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT

THE SELLER'S PRODUCT IS PROPERLY RATED AND INSTALLED FOR

THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

2. Programmable Products.

gramming of a programmable Good, or any consequence thereof.

3. Performance Data.

guide for the user in determining suitability and does not constitute a warranty.

It may represent the result of Seller's test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the

Seller's Warranty and Limitations of Liability.

4. Change in Specifications.

changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Good may be changed without any notice. When in doubt, special

part numbers may be assigned to fix or establish key specifications for your

application. Please consult with your Seller's representative at any time to confirm actual specifications of purchased Good.

5. Errors and Omissions.

checked and is believed to be accurate; however, no responsibility is assumed

for clerical, typographical or proofreading errors, or omissions.

Seller shall not be responsible for the user's pro-

Performance data given in this catalog is provided as a

Product specifications and accessories may be

The information in this catalog has been carefully

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures

by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this

manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also

capitalized when it refers to an OMRON product, regardless of whether or not

it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON

products, often means “word” and is abbreviated “Wd” in documentation in

this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

© OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

The following headings appear in the left column of the manual to help you

locate different types of information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

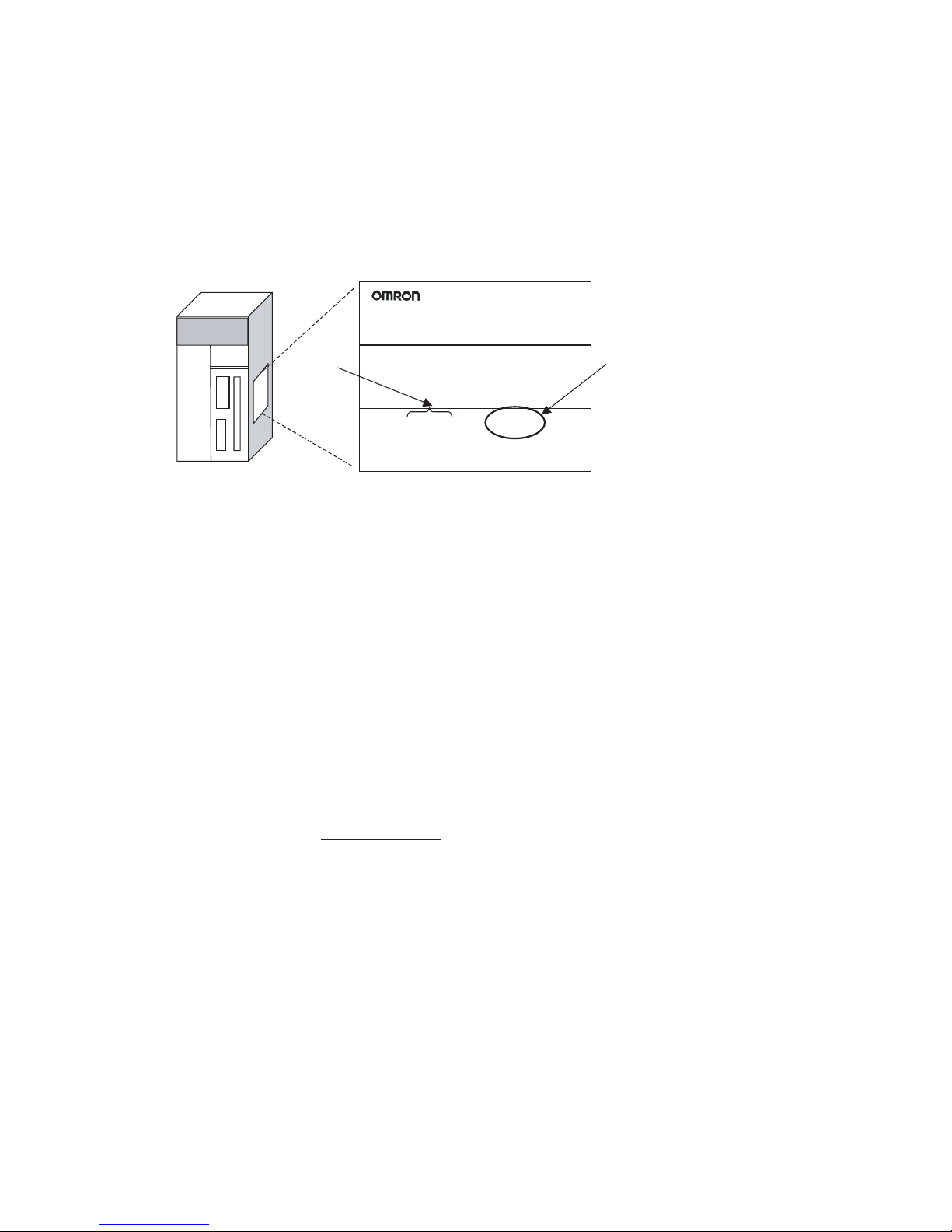

Unit Versions of CS/CJ-series CPU Units

Unit Versions A “unit version” has been introduced to manage CPU Units in the CS/CJ

Series according to differences in functionality accompanying Unit upgrades.

This applies to the CS1-H, CJ1-H, CJ1M, and CS1D CPU Units.

Notation of Unit Versions

on Products

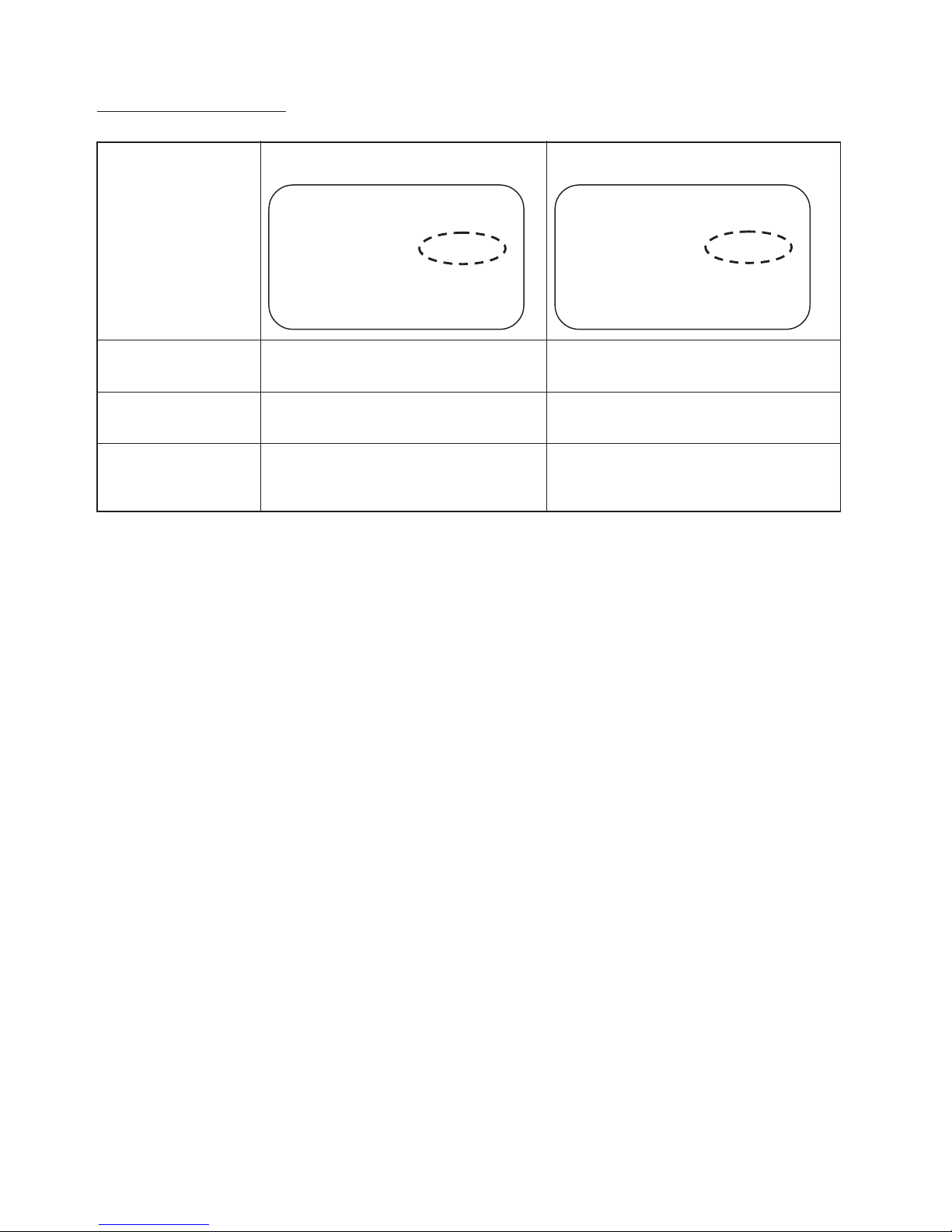

CS/CJ-series CPU Unit

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

Product nameplate

CS1H-CPU67H

CPU UNIT

Lot No.

Lot No. 040715 0000 Ver.3.0

OMRON Corporat ion MADE IN JAPA N

Unit version

Example for Unit version 3.0

• CS1-H, CJ1-H, and CJ1M CPU Units (except for low-end models) manufactured on or before November 4, 2003 do not have a unit version given

on the CPU Unit (i.e., the location for the unit version shown above is

blank).

• The unit version of the CS1-H, CJ1-H, and CJ1M CPU Units, as well as

the CS1D CPU Units for Single-CPU Systems, begins at version 2.0.

• The unit version of the CS1D CPU Units for Duplex-CPU Systems, begins

at version 1.1.

• CPU Units for which a unit version is not given are called Pre-Ver. @.@

CPU Units, such as Pre-Ver. 2.0 CPU Units and Pre-Ver. 1.1 CPU Units.

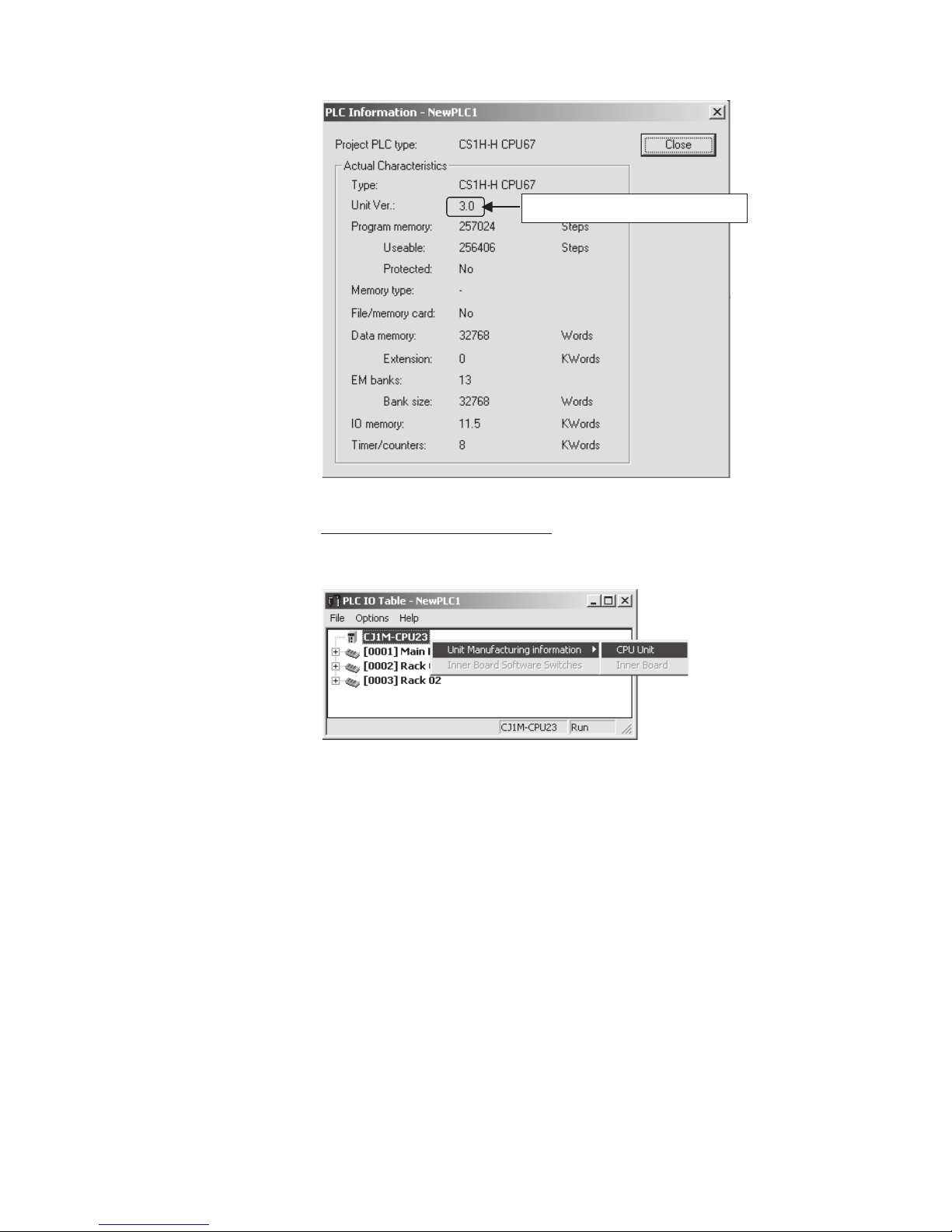

Confirming Unit Versions

with Support Software

CX-Programmer version 4.0 can be used to confirm the unit version using one

of the following two methods.

• Using the PLC Information

• Using the Unit Manufacturing Information (This method can be used for

Special I/O Units and CPU Bus Units as well.)

Note CX-Programmer version 3.3 or lower cannot be used to confirm unit versions.

PLC Information

• If you know the device type and CPU type, select them in the Change

PLC Dialog Box, go online, and select PLC - Edit - Information from the

menus.

• If you don't know the device type and CPU type, but are connected

directly to the CPU Unit on a serial line, select PLC - Auto Online to go

online, and then select PLC - Edit - Information from the menus.

In either case, the following PLC Information Dialog Box will be displayed.

vi

Page 6

Unit version

Use the above display to confirm the unit version of the CPU Unit.

Unit Manufacturing Information

In the IO Table Window, right-click and select Unit Manufacturing information - CPU Unit.

The following Unit Manufacturing information Dialog Box will be displayed.

vii

Page 7

Unit version

Use the above display to confirm the unit version of the CPU Unit connected

online.

Using the Unit Version

Labels

The following unit version labels are provided with the CPU Unit.

These labels can be attached to the front of previous CPU Units to differentiate between CPU Units of different unit versions.

viii

Page 8

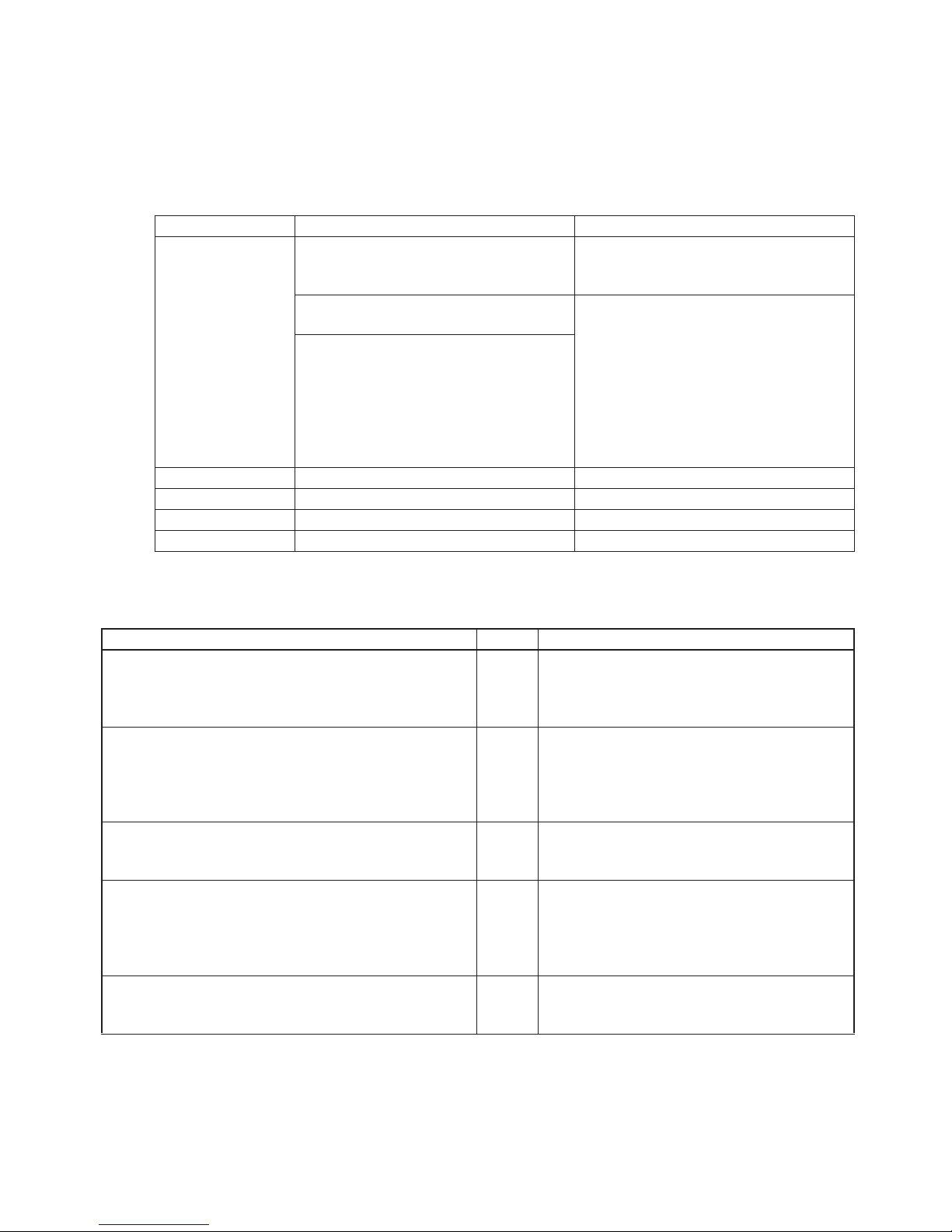

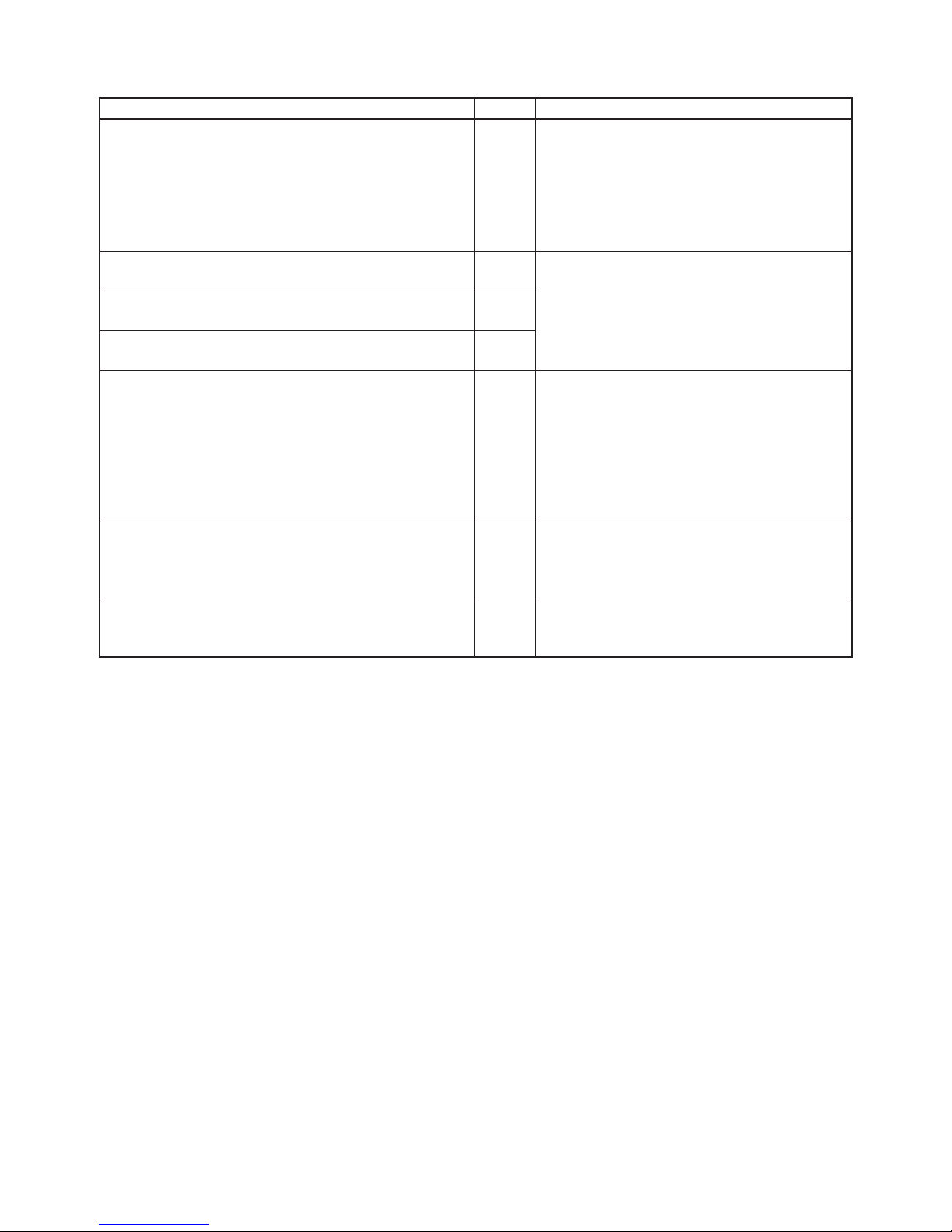

Unit Version Notation

In this manual, the unit version of a CPU Unit is given as shown in the following table.

Product nameplate

Meaning

Designating individual

CPU Units (e.g., the

CS1H-CPU67H)

Designating groups of

CPU Units (e.g., the

CS1-H CPU Units)

Designating an entire

series of CPU Units

(e.g., the CS-series CPU

Units)

CPU Units on which no unit version is

given

Lot No. XXXXXX XXXX

OMRON Corporation MADE IN JAPAN

Pre-Ver. 2.0 CS1-H CPU Units CS1H-CPU67H CPU Unit Ver. @.@

Pre-Ver. 2.0 CS1-H CPU Units CS1-H CPU Units Ver. @.@

Pre-Ver. 2.0 CS-series CPU Units CS-series CPU Units Ver. @.@

Units on which a version is given

Lot No. XXXXXX XXXX

(Ver. @.@)

Ver. @ @ .@

ix

Page 9

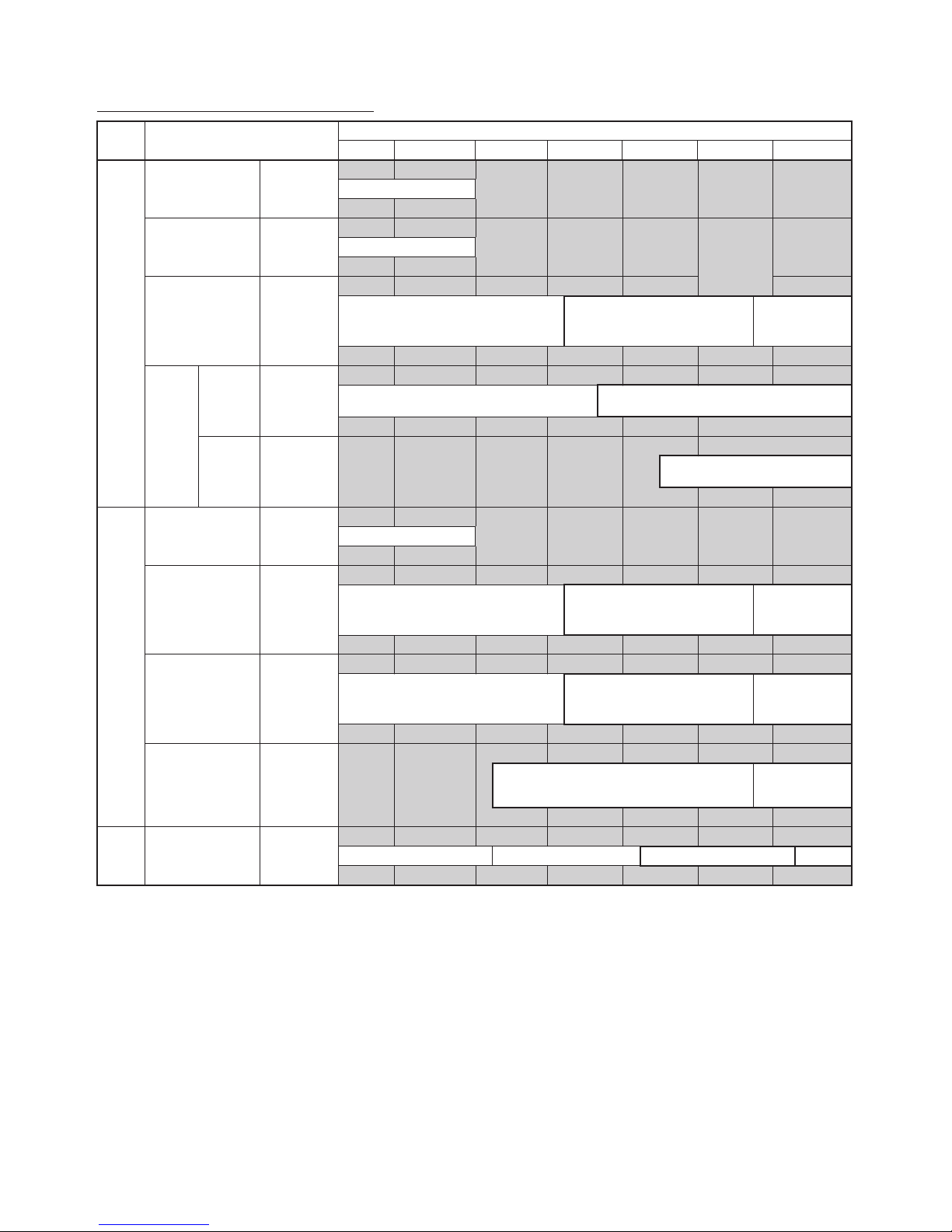

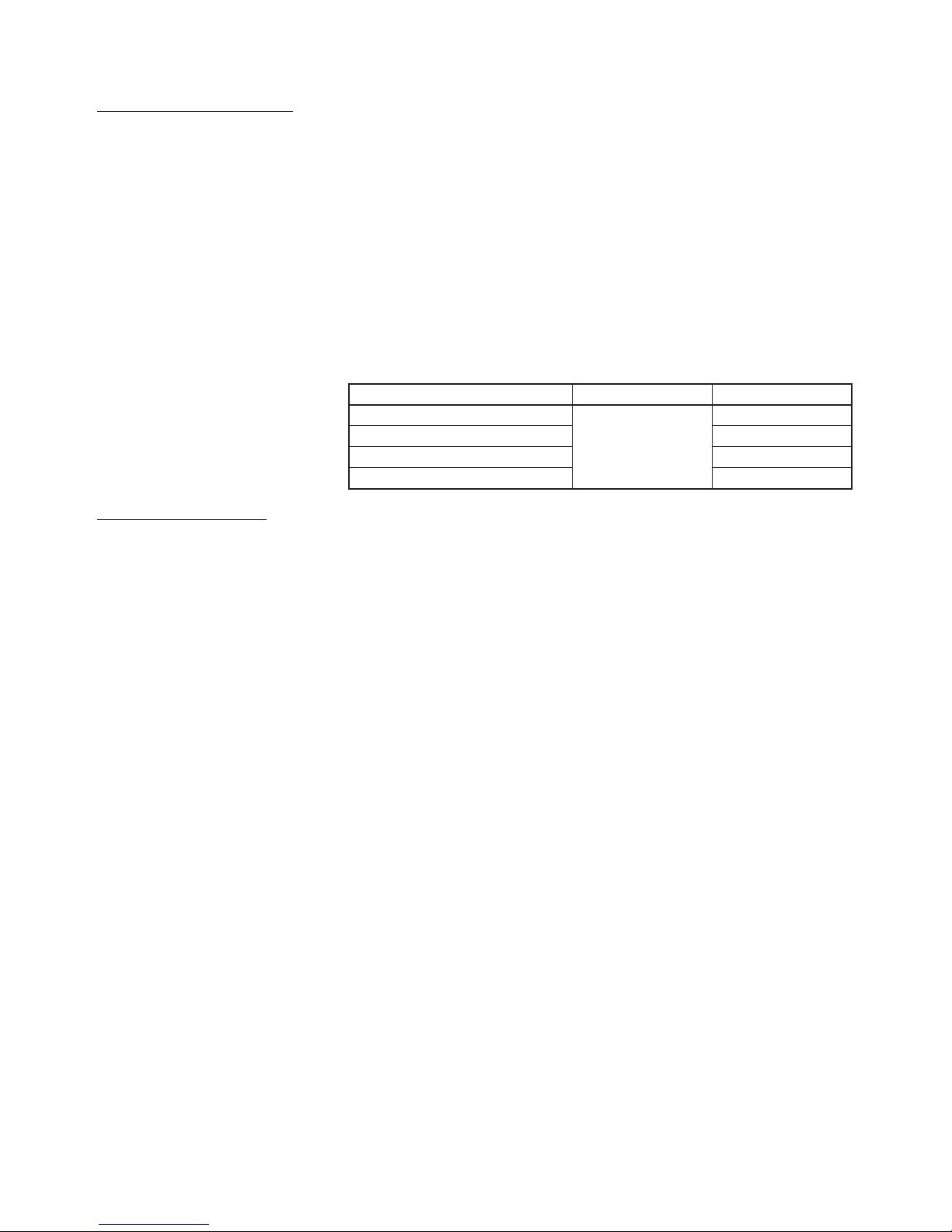

Unit Versions and Lot Numbers

Series Model Data of manufacture

Earlier Sept. 2003 Oct. 2003 Nov. 2003 Dec. 2003 Jun. 2004 Later

CS

Series

CS1 CPU Units CS1@-

CPU@@

No unit version

CJ

Series

CS1-V1 CPU

Units

CS1-H CPU Units CS1@-

CS1D

CPU

Units

CJ1 CPU Units CJ1G-

CJ1-H CPU Units CJ1@-

CJ1M CPU Units

except low-end

models

CPU

Units for

DuplexCPU

System

CPU

Units for

SingleCPU

System

CS1@-

CPU@@-V1

CPU@@H

CS1DCPU@@H

CS1DCPU@@S

CPU@@

CPU@@H

CJ1MCPU@@

No unit version

Pre-Ver. 2.0 CPU Units

Pre-Ver. 1.1 CPU Units

Pre-Ver. 2.0 CPU Units

Pre-Ver. 2.0 CPU Units

Pre-Ver. 2.0 CPU Units

CPU Units Ver. 2.0

(Lot No.: 031105 on)

CPU Units Ver.1.1

(Lot No.: 031120 on)

CPU Units Ver. 2.0

(Lot No.: 031215 on)

CPU Units Ver. 2.0

(Lot No.: 031105 on)

CPU Units Ver. 2.0

(Lot No.: 031105 on)

CPU Units Ver.

3.0 (Lot No.:

040622 on)

CPU Units Ver.

3.0 (Lot No.:

040623 on)

CPU Units Ver.

3.0 (Lot No.:

040624 on)

Support

Software

x

CJ1M CPU Units,

low-end models

CX-Programmer WS02-

CJ1MCPU11/21

CXPC1EV@

Unit Ver. 2.0

(Lot No.: 031002 on)

Ver.3.2 Ver.3.3 Ver.4.0 Ve r.5 .0

CPU Units Ver.

3.0 (Lot No.:

040629 on)

Page 10

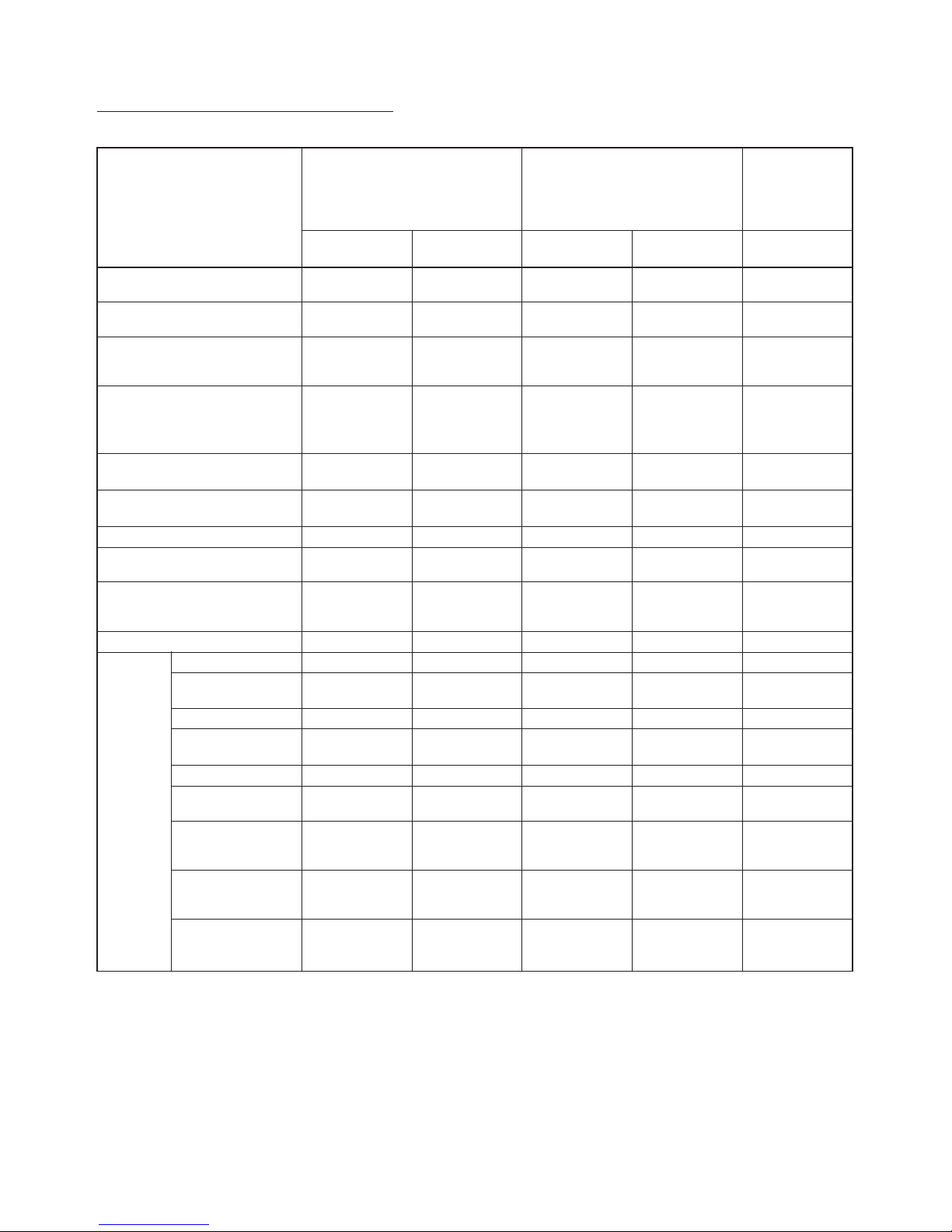

Function Support by Unit Version

CJ1-H/CJ1M CPU Units

Function CJ1-H CPU Units

(CJ1@-CPU@@H)

Pre-Ver. 2.0

CPU Units

Downloading and Uploading

Individual Tasks

Improved Read Protection

Using Passwords

Write Protection from FINS

Commands Sent to CPU Units

via Networks

Online Network Connections

without I/O Tables

Communications through a

Maximum of 8 Network Levels

Connecting Online to PLCs via

NS-series PTs

Setting First Slot Words --- OK --- OK OK

Automatic Transfers at Power

ON without a Parameter File

Automatic Detection of I/O Allo-

cation Method for Automatic

Transfer at Power ON

Operation Start/End Times --- OK --- OK OK

New

Application

Instructions

MILH, MILR, MILC --- OK --- OK OK

=DT, <>DT, <DT,

<=DT, >DT, >=DT

BCMP2 --- OK OK OK OK

GRY OK from lot

TPO --- OK --- OK OK

DSW, TKY, HKY,

MTR, 7SEG

EXPLT, EGATR,

ESATR, ECHRD,

ECHWR

Reading/Writing

CPU Bus Units with

IORD/IOWR

PRV2 --- --- --- OK, but only for

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

OK, but only if

I/O table allocation at power

ON is set

OK for up to 8

groups

OK from lot

number 030201

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

number 030201

--- OK --- OK OK

--- OK --- OK OK

--- OK --- OK OK

CPU Units Ver.

2.0

OK OK, but only if

I/O table allocation at power

ON is set

OK for up to 64

groups

OK OK from lot

OK OK from lot

OK for up to 8

groups

number 030201

number 030201

CJ1M CPU Units,

except low-end models

(CJ1M-CPU@@)

Pre-Ver. 2.0

CPU Units

CPU Units Ver.

OK OK

OK for up to 64

groups

OK OK

OK OK

models with

built-in I/O

2.0

CJ1M CPU

Units, low-end

models

(CJ1M-

CPU11/21)

CPU Units Ver.

2.0

OK for up to 64

groups

OK, but only for

models with

built-in I/O

xi

Page 11

Functions Supported by Unit Version 3.0 or Later

CJ1-H/CJ1M CPU Units (CJ1@-CPU@@H, CJ1G-CPU@@P, C J 1 M - C P U @@)

Function Unit version

Pre-Ver. 2.0, Ver. 2.0 Ver. 3.0

Function blocks (supported for CX-Programmer Ver. 5.0 or higher) --- OK

Serial Gateway (converting FINS commands to CompoWay/F com-

mands at the built-in serial port)

Comment memory (in internal flash memory) --- OK

Expanded simple backup data --- OK

New Applica-

tion Instructions

Additional

instruction functions

TXDU(256), RXDU(255) (support no-protocol

communications with Serial Communications

Units with unit version 1.2 or later)

Model conversion instructions: XFERC(565),

DISTC(566), COLLC(567), MOVBC(568),

BCNTC(621)

Special function block instructions: GETID(286) --- OK

PRV(881) and PRV2(883) instructions: Added

high-frequency calculation methods for calculating pulse frequency. (CJ1M CPU Units only)

--- OK

--- OK

--- OK

--- OK

xii

Page 12

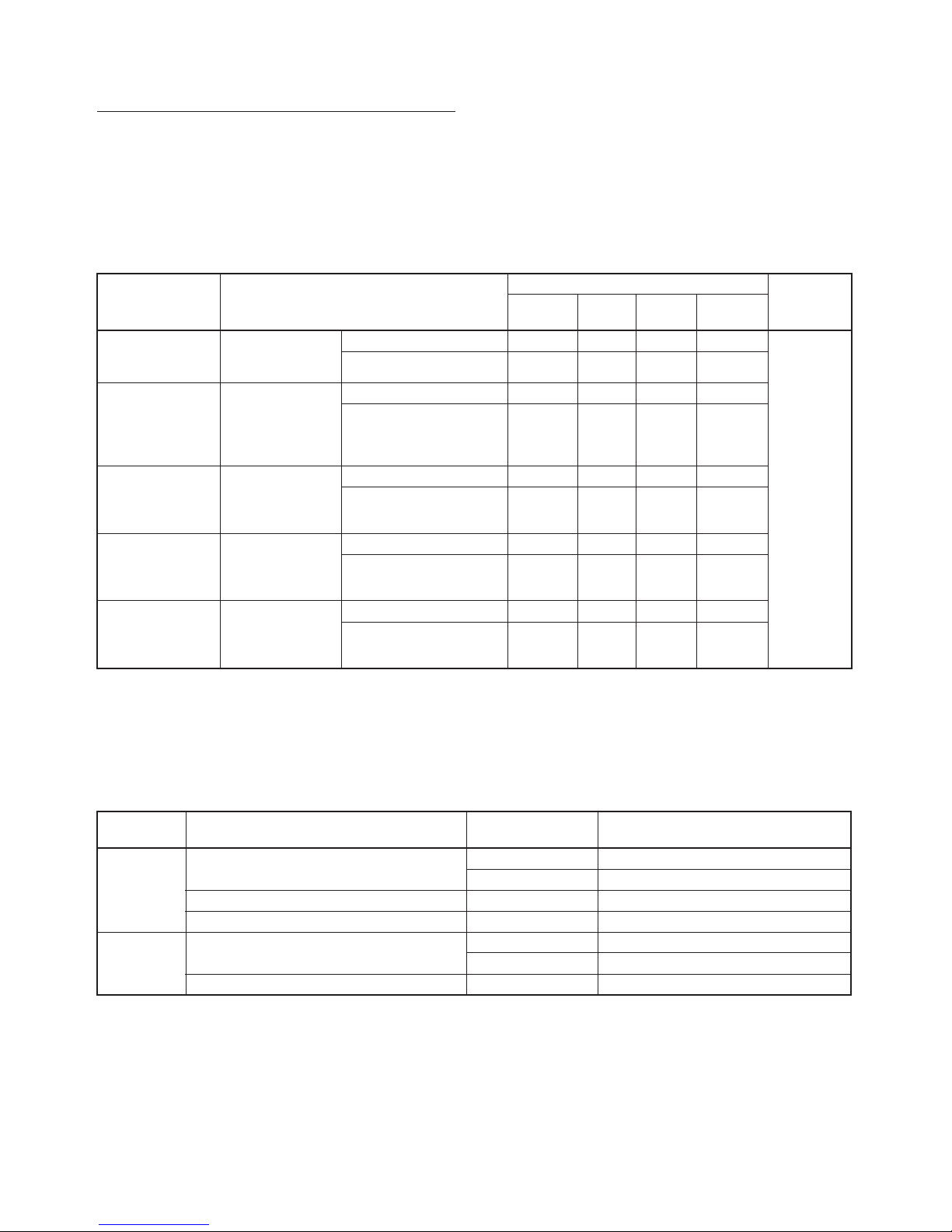

Unit Versions and Programming Devices

CX-Programmer version 4.0 or higher must be used to enable using the functions added for CPU Unit version 2.0.

CX-Programmer version 5.0 or higher must be used to enable using function

blocks added for CPU Unit version 3.0.

The following tables show the relationship between unit versions and CX-Programmer versions.

Unit Versions and Programming Devices

CPU Unit Functions CX-Programmer Program-

CJ1M CPU Units,

low-end models,

unit Ver. 2.0

CS1-H, CJ1-H,

and CJ1M CPU

Units except lowend models, unit

Ver. 2 .0

CS1D CPU Units

for Single-CPU

Systems, unit Ver.

2.0

CS1D CPU Units

for Duplex-CPU

Systems, unit

Ver.1 .

CS/CJ-series unit

Ver. 3 .0

Functions added

for unit version

2.0

Functions added

for unit version

2.0

Functions added

for unit version

2.0

Functions added

for unit version

1.1

Function block

functions added

for unit version

3.0

Ver. 3.2

or lower

Using new functions --- --- OK OK No

Not using new functions --- OK OK OK

Using new functions --- --- OK OK

Not using new functions OK OK OK OK

Using new functions --- --- OK OK

Not using new functions OK

Using new functions --- --- OK OK

Not using new functions OK OK OK OK

Using function blocks --- --- --- OK

Not using function blocks OK OK OK OK

Ver. 3.3 Ver. 4.0 Ver. 5.0

or higher

ming Con-

sole

restrictions

Note As shown above, there is no need to upgrade to CX-Programmer version 4.0

as long as the functions added for unit version 2.0 or unit version 1.1 are not

used.

Device Type Setting The unit version does not affect the setting made for the device type on the

CX-Programmer. Select the device type as shown in the following table

regardless of the unit version of the CPU Unit.

Series CPU Unit group CPU Unit model Device type setting on

CS Series CS1-H CPU Units

CS1D CPU Units for Duplex-CPU Systems

CS1D CPU Units for Single-CPU Systems

CJ Series CJ1-H CPU Units

CJ1M CPU Units

CS1G-CPU@@H CS1G-H

CS1H-CPU@@H CS1H-H

CS1D-CPU@@H CS1D-H (or CS1H-H)

CS1D-CPU@@S CS1D-S

CJ1G-CPU@@H CJ1G-H

CJ1H-CPU@@H CJ1H-H

CJ1M-CPU@@ CJ1M

CX-Programmer Ver. 4.0 or higher

xiii

Page 13

Troubleshooting Problems with Unit Versions on the CX-Programmer

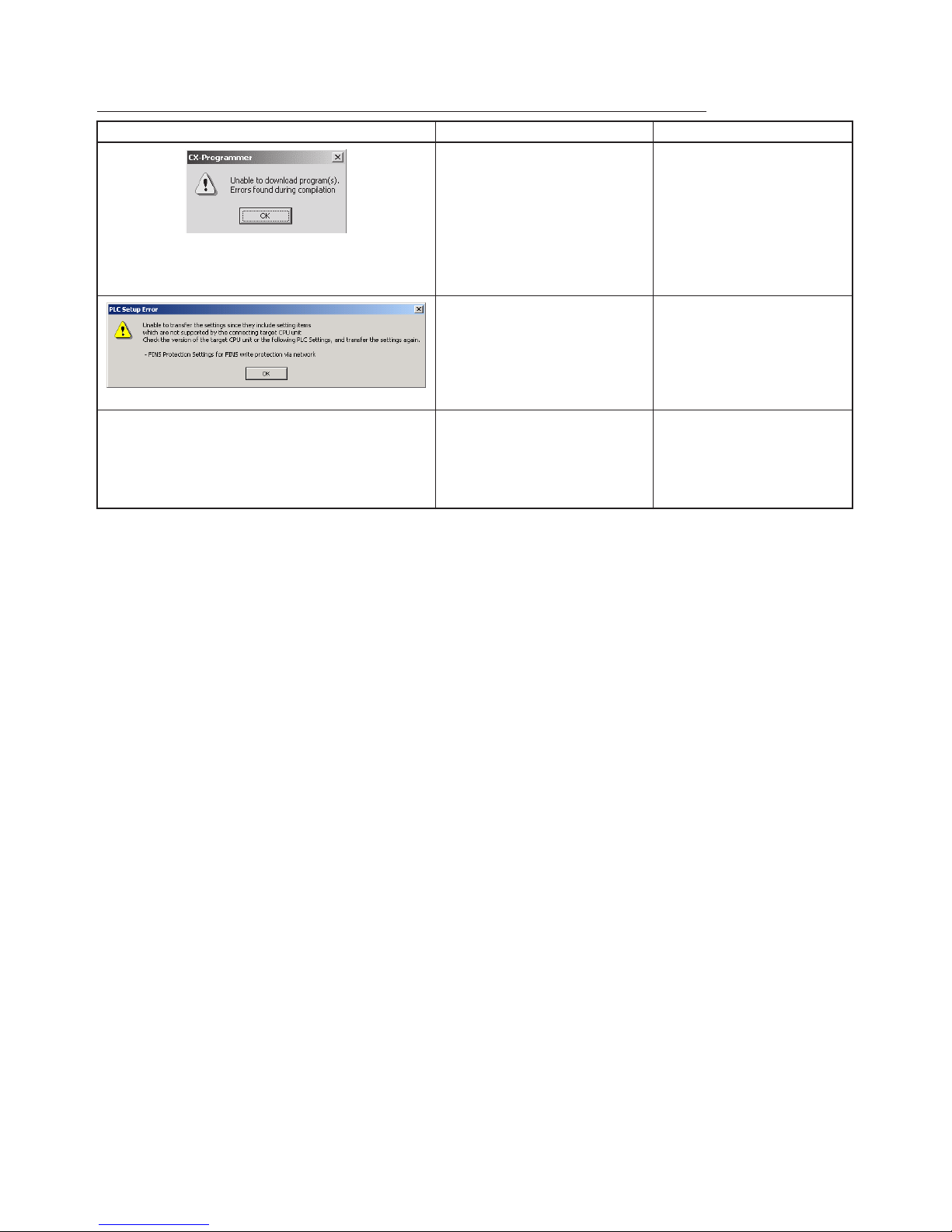

Problem Cause Solution

After the above message is displayed, a compiling

error will be displayed on the Compile Tab Page in the

Output Window.

“????” is displayed in a program transferred from the

PLC to the CX-Programmer.

An attempt was made using CXProgrammer version 4.0 or higher

to download a program containing instructions supported only by

CPU Units Ver. 2.0 or later to a

Pre-Ver. 2.0 CPU Units.

An attempt was made using CXProgrammer version 4.0 or higher

to download a PLC Setup containing settings supported only by

CPU Units Ver. 2.0 or later (i.e.,

not set to their default values) to a

Pre-Ver. 2.0 CPU Units.

CX-Programmer version 3.3 or

lower was used to upload a program containing instructions supported only by CPU Units Ver. 2.0

or later from a CPU Unit Ver. 2.0

or later.

Check the program or change

the CPU Unit being downloaded to a CPU Unit Ver. 2.0

or later.

Check the settings in the PLC

Setup or change the CPU Unit

being downloaded to a CPU

Unit Ver. 2.0 or later.

The new instructions cannot

be uploaded using CX-Programmer version 3.3 or lower.

Use CX-Programmer version

4.0 or higher.

xiv

Page 14

Loop-control CPU Units

Overview Loop-control CPU Units are CPU Units with a pre-installed Loop Controller

functional element.

Note The Loop Controller functional element is an inseparable part of the CPU Unit

and cannot be removed.

Model Numbers,

Functional Elements,

and Versions

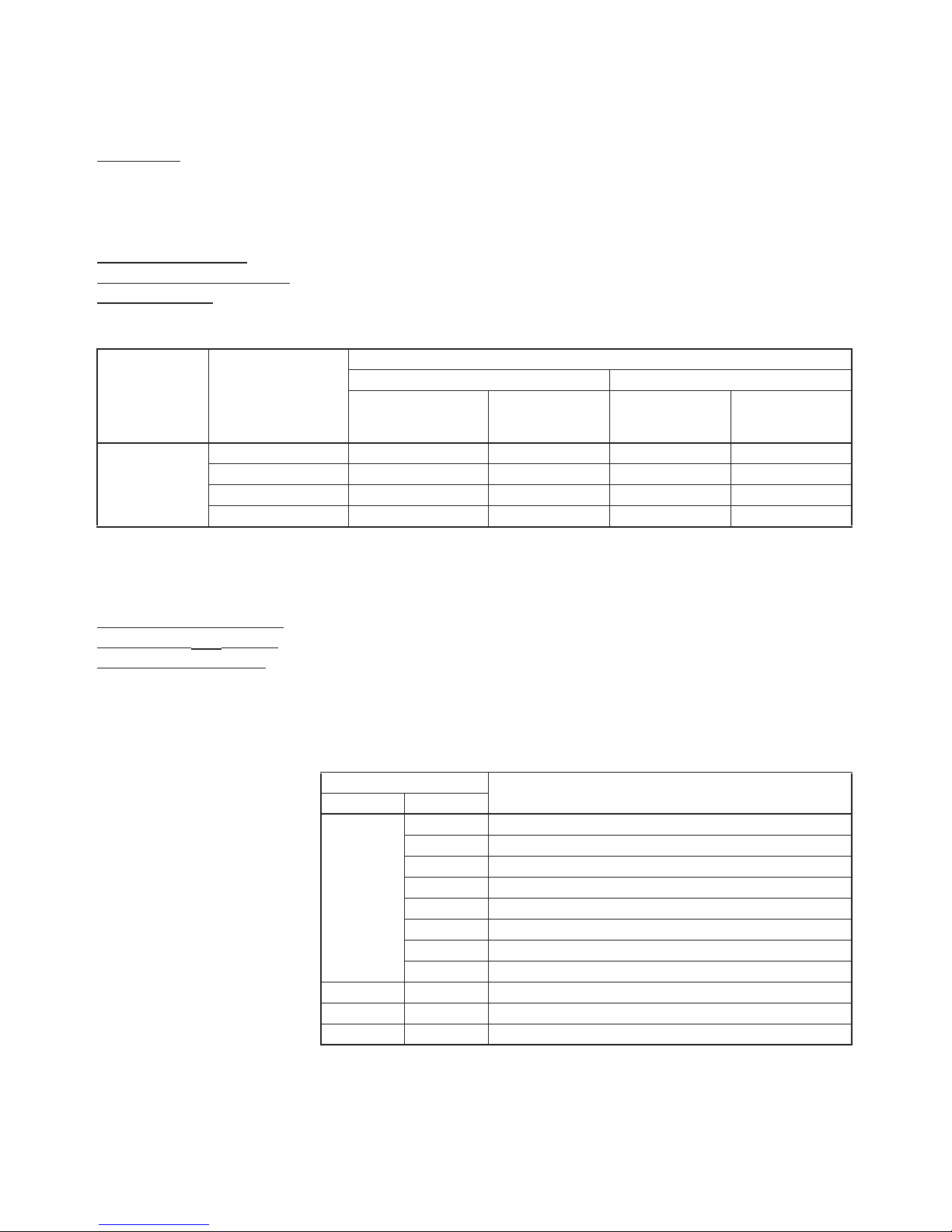

Product name Product model

Loop-control

CPU Units

number

CJ1G-CPU42P CJ1G-CPU42H Ver. 3.0 or higher LCB01 Ver. 2.0

CJ1G-CPU43P CJ1G-CPU43H Ver. 3.0 or higher LCB03 Ver. 2.0

CJ1G-CPU44P CJ1G-CPU44H Ver. 3.0 or higher LCB03 Ver. 2.0

CJ1G-CPU45P CJ1G-CPU45H Ver. 3.0 or higher LCB03 Ver. 2.0

Note A single unit version for the Loop-control CPU Unit as a whole is not provided.

Differences between

CJ1G-CPU@@H and

CPU Unit Elements

Note The functions added in the version upgrade for unit version 3.0 and later are

The CJ1G-CPU@@P Loop-control CPU Unit is comprised of a CPU Unit element with the same functionality as a CJ1G-CPU@@H CPU Unit with version

3.0 or later (see note) and a Loop Controller element. The following table lists

the model numbers for CJ1G Loop-control CPU Units, the types of CPU Unit

element, Loop Controller element, and the functional element version codes.

Configuration

CPU Unit element Loop Controller element

CPU Unit model

with same function-

ality

Functional ele-

ment unit ver-

sion

Functional ele-

ment name

Functional ele-

ment version

The unit versions for the CJ1-H CPU Unit with unit version 3.0 or later and the

functional element version code.

The differences between the CPU Unit element in the Loop-control CPU Unit

and the CJ1G-CPU@@H CPU Unit are shown here. The two types of CPU

Unit are otherwise the same.

also the same.

Additional Auxiliary Area

Flags and Bits

Loop-control CPU Units can use the following Auxiliary Area flags and bits,

which are not supported for CJ1G-CPU@@H CPU Units.

Address Name

Word Bit

A424 00 Inner Board WDT Error Flag (fatal error)

01 Inner Board Bus Error Flag (fatal error)

02 Cyclic Monitor Error Flag (fatal error)

03 Flash Memory Data Error Flag (fatal error)

04 Incompatible CPU Unit Error Flag (non-fatal error)

08 Loop Controller High Load Flag (non-fatal error)

11 Backup Data (Flash Memory) Error Flag

12 Specified EM Bank Unusable Error Flag

A608 00 Inner Board Restart Bit

A609 01 Start Mode at Power ON: Hot Start

A609 02 Start Mode at Power ON: Cold Start

For details on the Auxiliary Area bits and flags, refer to the section on SYS-

MAC CS/CJ Series Loop Control Boards, Process-control CPU Units, Loopcontrol CPU Units Operation Manual (W406).

xv

Page 15

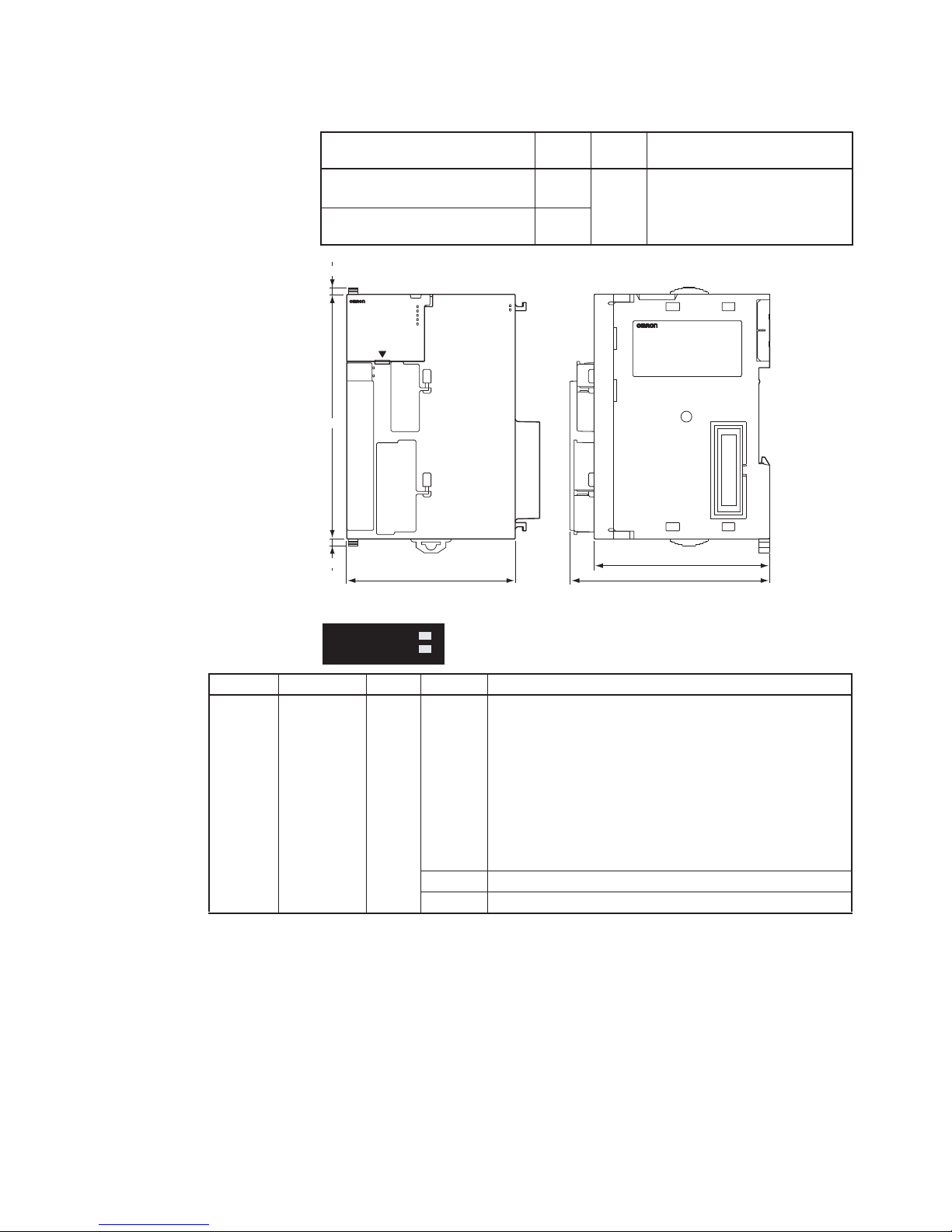

Loop-control CPU Unit

Dimensions

Product name and model W

CJ1G-CPU45P/44P/43P/42P

Loop-control CPU Unit

CJ1G-CPU45H/44H/43H/42H

CJ1-H CPU Unit (reference)

2.7

(mm)H(mm)

D (mm)

69 90 65 (not including connector)

73.9 (including connector)

62

Indicators

LCB03

EXEC

RDY

65

90

2.7

SYSMAC

CJ1G-CPU44P

PROGRAMMABLE

CONTROLLER

OPEN

MCPWR

BUSY

RUN

ERR/ALM

INH

PRPHL

COMM

PERIPHERAL

PORT

INNER LOOP CONTROLLER

69 73.9

RDY

EXEC

Indicator Name Color Status Description

RDY Ready Green Not lit The Loop Control Board is not operating for one of the fol-

lowing reasons:

• A Fatal Inner Board Error occurred (A40112 ON.)

• Initialization is not completed yet.

• A fatal error occurred.

• The flash memory backup data is invalid.

• The Loop Control Board is initializing.

• A hardware failure occurred in the Loop Control Board.

• Power is not being supplied from the Power Supply Unit.

• A Loop Control Board WDT error occurred.

Flashing • A WDT error occurred in the CPU Unit.

Lit The Loop Control Board is ready for operation.

xvi

Page 16

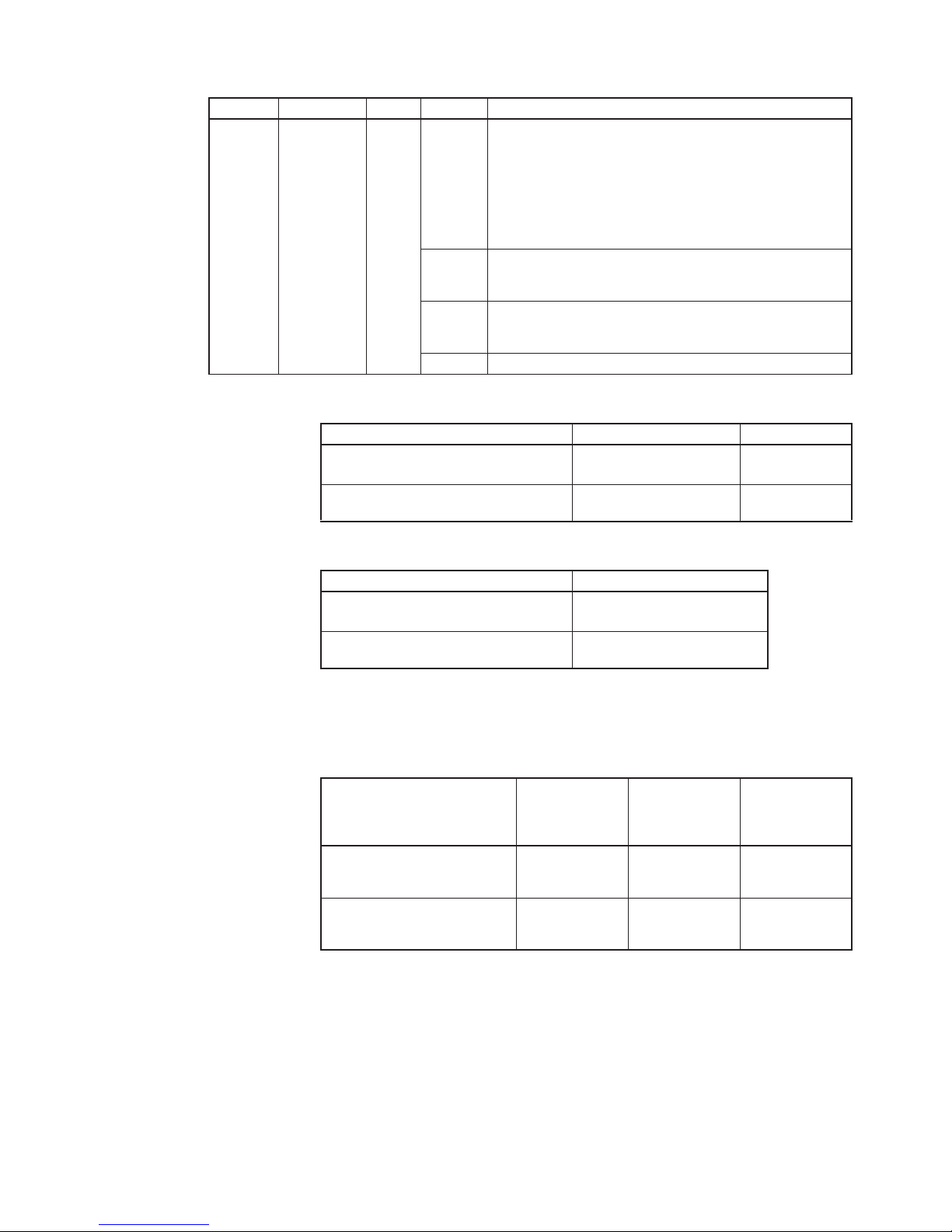

Indicator Name Color Status Description

EXEC Running Green Not lit The system is stopped for one of the following reasons:

Current Consumption and

Weight

Common Processing Time

(Overhead Time)

• The Loop Control Board is initializing.

• A hardware failure occurred in the Loop Control Board.

• Power is not being supplied from the Power Supply Unit.

• A Loop Control Board WDT error occurred.

• The Loop Control Board is not running.

• Data is being written to flash memory.

Flashing

(at 0.5-s

intervals)

Flashing

(0.2-s

intervals)

Lit The Loop Control Board is not running.

Product name and model Current consumption Weight

CJ1G-CPU45P/44P/43P/42P

Loop-control CPU Unit

CJ1G-CPU45H/44H/43H/42H

CJ1-H CPU Unit (reference)

Product name and model Common processing time

CJ1G-CPU45P/44P/43P/42P

Loop-control CPU Unit

CJ1G-CPU45H/44H/43H/42H

CJ1-H CPU Unit (reference)

Erasing flash memory.

Backup operation to function block flash memory in

progress

1.06 A 220 g max.

0.91 A 190 g max.

0.8 ms max.

0.3 ms

Battery Backup Time At 25

whether or not power is supplied to the CPU Unit while the battery is installed.

This is the same as for CJ1G-CPU@@H CPU Units. The following table shows

the approximate minimum lifetimes and typical lifetimes for the backup battery

(total time with power not supplied).

CJ1G-CPU45P/44P/43P/42P

Loop-control CPU Unit

CJ1G-CPU45H/44H/43H/42H

CJ1-H CPU Unit (reference)

Note The minimum lifetime is the memory backup time at an ambient temperature

of 55

ature of 25

°C, the battery life (maximum service life) for batteries is five years

Model Approx.

maximum

lifetime

5 years 5,600 hours

5 years 6,500 hours

Approx.

minimum

lifetime

(See note.)

(approximately

0.64 years)

(approximately

0.75 years)

Typ ical lifetime

(See note.)

43,000 hours

(approximately 5

years)

43,000 hours

(approximately 5

years)

°C. The typical lifetime is the memory backup time at an ambient temper-

°C.

xvii

Page 17

Programming Devices

Loop Controller Element Using CX-Process Tool Ver. 4.0 or later, select the Loop-control CPU

Unit/Process-control CPU Unit from the LC Type field in the LCB/LC001 Dia-

log Box. Then select either CJ1G-CPU42P, CJ1G-CPU43P, CJ1G-CPU44P,

orCJ1G-CPU45P, from the Number-Model pull-down list in the Unit Informa-

tion field.

CPU Unit Element Use CX-Programmer Ver. 5.0 or later. The CPU Unit functions are the same

as the CJ1G-CPU@@H, except for the differences provided in the previous

table. Therefore, select CJ1G-H as the device type when using CX-Programmer.

1,2,3... 1. Select New from the File Menu.

2. Select one of the following CPU Unit types in the Change PLC Dialog Box.

Loop-control CPU Unit Device type CPU Unit type

CJ1G-CPU42P CJ1G-H CPU42

CJ1G-CPU43P CPU43

CJ1G-CPU44P CPU44

CJ1G-CPU45P CPU45

Reference Manuals • The CPU Unit functions are the same as the CJ1G-CPU@@H, except for

the differences provided in the previous table. Therefore, for details on the

CPU Unit functions, refer to the SYSMAC CJ Series Programmable Con-

trollers Operation Manual (W393), SYSMAC CS/CJ Series Programmable

Controllers Programming Manual (W394), SYSMAC CS/CJ Series Programmable Controllers Instructions Reference Manual (W340), and Communications Commands Reference Manual (W342).

• For details on the Loop Controller functions (LCB@@ functional element)

refer to the section on SYSMAC CS/CJ Series Loop Control Boards, Pro-

cess-control CPU Units, Loop-control CPU Units Operation Manual

(W406).

xviii

Page 18

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxix

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

SECTION 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 CJ-series Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 CJ1-H and CJ1M CPU Unit Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-4 CJ1-H/CJ1M CPU Unit Ver. 3.0 Upgrades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-5 CJ1-H/CJ1M CPU Unit Ver. 2.0 Upgrades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1-6 CJ1 and CJ1-H CPU Unit Comparison. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1-7 Function Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1-8 CJ1-H Functions Arranged by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

1-9 CJ1M Functions Arranged by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

1-10 Comparison to CS-series PLCs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

SECTION 2

Specifications and System Configuration. . . . . . . . . . . . . . . 77

2-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2-2 CPU Unit Components and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2-3 Basic System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2-4 I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

2-5 Expanded System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2-6 Unit Current Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

2-7 CPU Bus Unit Setting Area Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

2-8 I/O Table Settings List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

SECTION 3

Nomenclature, Functions, and Dimensions . . . . . . . . . . . . . 135

3-1 CPU Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

3-2 File Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

3-3 Programming Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

3-4 Power Supply Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

3-5 I/O Control Units and I/O Interface Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

3-6 CJ-series Basic I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

3-7 B7A Interface Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

xix

Page 19

TABLE OF CONTENTS

SECTION 4

Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

4-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

4-2 Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

SECTION 5

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

5-1 Fail-safe Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

5-2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

5-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

SECTION 6

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

6-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

6-2 Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

SECTION 7

PLC Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

7-1 PLC Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

7-2 Explanations of PLC Setup Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

SECTION 8

I/O Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

8-1 I/O Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

8-2 Creating I/O Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

8-3 Reserving I/O Words for Expected Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

8-4 Allocating First Words to Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

8-5 Allocating First Words to Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

8-6 Detailed Information on I/O Table Creation Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

8-7 Data Exchange with CPU Bus Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

SECTION 9

Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

9-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

9-2 I/O Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

9-3 I/O Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

9-4 Data Link Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

9-5 CPU Bus Unit Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

9-6 Special I/O Unit Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

9-7 Serial PLC Link Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

9-8 DeviceNet Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

xx

Page 20

TABLE OF CONTENTS

9-9 Internal I/O Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

9-10 Holding Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362

9-11 Auxiliary Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

9-12 TR (Temporary Relay) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

9-13 Timer Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

9-14 Counter Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

9-15 Data Memory (DM) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

9-16 Extended Data Memory (EM) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

9-17 Index Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

9-18 Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

9-19 Task Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

9-20 Condition Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

9-21 Clock Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

9-22 Parameter Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

SECTION 10

CPU Unit Operation and the Cycle Time. . . . . . . . . . . . . . . 411

10-1 CPU Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

10-2 CPU Unit Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

10-3 Power OFF Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

10-4 Computing the Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

10-5 Instruction Execution Times and Number of Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437

SECTION 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 473

11-1 Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

11-2 Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

11-3 Troubleshooting Racks and Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

SECTION 12

Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 501

12-1 Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 502

12-2 Replacing User-serviceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 504

Appendices

A Specifications of Basic I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

B CJ1M CPU Unit Built-in I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 565

C Auxiliary Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 569

D Memory Map of PLC Memory Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 613

E PLC Setup Coding Sheets for Programming Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 615

F Connecting to the RS-232C Port on the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 631

G CJ1W-CIF11 RS-422A Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 641

xxi

Page 21

TABLE OF CONTENTS

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 647

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 657

xxii

Page 22

About this Manual:

This manual describes the installation and operation of the CJ-series Programmable Controllers

(PLCs) and includes the sections described on the following page. The CS Series and CJ Series are

subdivided as shown in the following table.

Unit CS Series CJ Series

CPU Units CS1-H CPU Units: CS1H-CPU@@H

CS1 CPU Units: CS1H-CPU@@-EV1

CS1D CPU Units:

CS1D CPU Units for Duplex-CPU System:

CS1D-CPU@@H

CS1D CPU Units for Single-CPU System:

CS1D-CPU@@S

CS1D Process CPU Units:

CS1D-CPU@@P

Basic I/O Units CS-series Basic I/O Units CJ-series Basic I/O Units

Special I/O Units CS-series Special I/O Units CJ-series Special I/O Units

CPU Bus Units CS-series CPU Bus Units CJ-series CPU Bus Units

Power Supply Units CS-series Power Supply Units CJ-series Power Supply Units

CS1G-CPU@@H

CS1G-CPU@@-EV1

CJ1-H CPU Units: CJ1H-CPU@@H

CJ1G-CPU@@H

CJ1G-CPU@@P

CJ1 CPU Units: CJ1G-CPU@@-EV1

CJ1M CPU Units: CJ1M-CPU@@

Please read this manual and all related manuals listed in the following table and be sure you understand information provided before attempting to install or use CJ-series CPU Units CPU Units in a PLC

System.

Name Cat. No. Contents

SYSMAC CJ Series

CJ1G-CPU@@, CJ1M-CPU@@, CJ1G-CPU@@P,

CJ1G/H-CPU@@H

Programmable Controllers Operation Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1G-CPU@@,

CJ1M-CPU@@, CJ1G-CPU@@P, CJ1G/H-CPU@@H

Programmable Controllers Programming Manual

SYSMAC CJ Series

CJ1M-CPU21/22/23

Built-in I/O Operation Manual

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1G-CPU@@,

CJ1M-CPU

Programmable Controllers Instructions Reference Manual

SYSMAC CS/CJ Series

CQM1H-PRO01-E, C200H-PRO27-E, CQM1-PRO01-E

Programming Consoles Operation Manual

@@, CJ1G-CPU@@P, CJ1G/H-CPU

@@H

W393 Provides an outlines of and describes the design,

installation, maintenance, and other basic operations for the CJ-series PLCs. (This manual)

W394 This manual describes programming and other

methods to use the functions of the CS/CJ-series

PLCs.

W395 Describes the functions of the built-in I/O for

CJ1M CPU Units.

W340 Describes the ladder diagram programming

instructions supported by CS/CJ-series PLCs.

W341 Provides information on how to program and

operate CS/CJ-series PLCs using a Programming

Console.

xxiii

Page 23

Name Cat. No. Contents

SYSMAC CS/CJ Series

CS1G/H-CPU@@-EV1, CS1G/H-CPU@@H,

CS1D-CPU@@H, CS1D-CPU@@S, CJ1G-CPU@@,

CJ1M-CPU@@, CJ1G-CPU@@P, CJ1G/H-CPU@@H,

CS1W-SCB21-V1/41-V1, CS1W-SCU21-V1,

CJ1W-SCU21-V1/41-V1

Communications Commands Reference Manual

SYSMAC WS02-CXP@@-E

CX-Programmer Operation Manual Version 3.@

SYSMAC WS02-CXP@@-E

CX-Programmer Operation Manual Version 4.@

SYSMAC WS02-CXP@@-E

CX-Programmer Operation Manual Version 5.@

SYSMAC WS02-CXP@@-E

CX-Programmer Operation Manual Function Blocks

SYSMAC CS/CJ Series

CS1W-SCB21-V1/41-V1, CS1W-SCU21-V1,

CJ1W-SCU21-V1/41-V1

Serial Communications Boards/Units Operation Manual

SYSMAC WS02-PSTC1-E

CX-Protocol Operation Manual

W342 Describes the C-series (Host Link) and FINS

communications commands used with CS/CJseries PLCs.

W414 Provide information on how to use the CX-Pro-

grammer, a programming device that supports the

W425

W437

W438 Describes specifications and operation methods

W336 Describes the use of Serial Communications Unit

W344 Describes the use of the CX-Protocol to create

CS/CJ-series PLCs, and the CX-Net contained

within CX-Programmer.

related to function blocks. This information is

required only when using function blocks with the

combination of CX-Programmer Ver. 5.0 and

CS1-H/CJ1-H/CJ1M CPU Unit Ver. 3.0. Refer to

CX-Programmer Operation Manual Version 5.@

(W437) for details on other operations for CX-Pro-

grammer Ver. 5.0.

and Boards to perform serial communications

with external devices, including the usage of standard system protocols for OMRON products.

protocol macros as communications sequences

to communicate with external devices.

This manual contains the following sections.

Section 1 introduces the special features and functions of the CJ-series PLCs and describes the differences between these PLCs and the earlier CS-series and C200HX/HG/HE PLCs.

Section 2 provides tables of standard models, Unit specifications, system configurations, and a comparison between different Units.

Section 3 provides names of Unit components and their functions. Dimensions are also provided.

Section 4 outlines the steps required to assemble and operate a CJ PLC system.

Section 5 describes how to install a PLC System, including mounting and wiring Units. Follow instruc-

tions carefully. Improper installation can cause the PLC to malfunction, resulting in very dangerous situations.

Section 6 describes DIP switch settings.

Section 7 describes initial hardware and software settings in the PLC Setup.

Section 8 describes I/O allocation to Basic I/O Units, Special I/O Units, and CPU Bus Units, as well as

and data exchange with CPU Bus Units.

Section 9 describes the structure and functions of the I/O Memory Areas and Parameter Areas.

Section 10 describes the internal operation of CPU Units and the cycle used for internal processing.

Section 11 provides information on hardware and software errors that occur during PLC operation.

Section 12 provides information on hardware maintenance and inspections.

The Appendices provide Unit specifications, current/power consumptions, Auxiliary Area words and

bits, internal I/O addresses, and PLC Setup settings, and information on RS-232C ports,.

xxiv

Page 24

PRECAUTIONS

This section provides general precautions for using the CJ-series Programmable Controllers (PLCs) and related devices.

The information contained in this section is important for the safe and reliable application of Programmable

Controllers. You must read this section and understand the information contained before attempting to set up or

operate a PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxix

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

6-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxiii

6-4 Relay Output Noise Reduction Methods . . . . . . . . . . . . . . . . . . . . . xxxiii

xxv

Page 25

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a

network.

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

xxvi

so may result in electric shock.

Page 26

Safety Precautions 3

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Do not touch the Power Supply Unit while power is being supplied or immedi-

ately after power has been turned OFF. Doing so may result in electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!Caution Confirm safety before transferring data files stored in the file memory (Mem-

ory Card or EM file memory) to the I/O area (CIO) of the CPU Unit using a

Programming Device. Otherwise, the devices connected to the output unit

may malfunction regardless of the operation mode of the CPU Unit.

!Caution Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes. Serious accidents may

result from abnormal operation if proper measures are not provided.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

xxvii

Page 27

Operating Environment Precautions 4

!Caution A CJ1-H or CJ1M CPU Unit automatically back up the user program and

parameter data to flash memory when these are written to the CPU Unit. I/O

memory (including the DM, EM, and HR Areas), however, is not written to

flash memory. The DM, EM, and HR Areas can be held during power interruptions with a battery. If there is a battery error, the contents of these areas may

not be accurate after a power interruption. If the contents of the DM, EM, and

HR Areas are used to control external outputs, prevent inappropriate outputs

from being made whenever the Battery Error Flag (A40204) is ON. Areas

such as the DM, EM, and HR Areas, the contents of which can be held during

power interrupts, is backed up by a battery. If a battery error occurs, the contents of the areas that are set to be held may not be accurate even though a

memory error will not occur to stop operation. If necessary for the safety of the

system, take appropriate measures in the ladder program whenever the Battery Error Flag (A40204) turns ON, such as resetting the data in these areas.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

xxviii

Page 28

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the PLC System.

• You must use the CX-Programmer (programming software that runs on

Windows) if you need to program more than one task. A Programming

Console can be used to program only one cyclic task plus interrupt tasks.

A Programming Console can, however, be used to edit multitask programs originally created with the CX-Programmer.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

connecting to a ground of 100

• A ground of 100

terminals on the Power Supply Unit.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units, or

any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always heed

these precautions.

• A CJ-series CPU Unit is shipped with the battery installed and the time

already set on the internal clock. It is not necessary to clear memory or

set the clock before application, as it is for the CS-series CPU Units.

• The user program and parameter area data in CJ1-H/CJ1M CPU Units is

backed up in the internal flash memory. The BKUP indicator will light on

the front of the CPU Unit when the backup operation is in progress. Do

not turn OFF the power supply to the CPU Unit when the BKUP indicator

is lit. The data will not be backed up if power is turned OFF.

• If, when using a CJ-series CPU Unit, the PLC Setup is set to specify using

the mode set on the Programming Console and a Programming Console

is not connected, the CPU Unit will start in RUN mode. This is the default

setting in the PLC Setup. (A CS1 CPU Unit will start in PROGRAM mode

under the same conditions.)

• When creating an AUTOEXEC.IOM file from a Programming Device (a

Programming Console or the CX-Programmer) to automatically transfer

data at startup, set the first write address to D20000 and be sure that the

size of data written does not exceed the size of the DM Area. When the

data file is read from the Memory Card at startup, data will be written in

the CPU Unit starting at D20000 even if another address was set when

the AUTOEXEC.IOM file was created. Also, if the DM Area is exceeded

(which is possible when the CX-Programmer is used), the remaining data

will be written to the EM Area.

Ω or less must be installed when shorting the GR and LG

Ω or less when installing the Units. Not

Ω or less may result in electric shock.

xxix

Page 29

Application Precautions 5

• Always turn ON power to the PLC before turning ON power to the control

system. If the PLC power supply is turned ON after the control power supply, temporary errors may result in control system signals because the

output terminals on DC Output Units and other Units will momentarily turn

ON when power is turned ON to the PLC.

• Fail-safe measures must be taken by the customer to ensure safety in the

event that outputs from Output Units remain ON as a result of internal circuit failures, which can occur in relays, transistors, and other elements.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

• Do not turn OFF the power supply to the PLC when data is being transferred. In particular, do not turn OFF the power supply when reading or

writing a Memory Card. Also, do not remove the Memory Card when the

BUSY indicator is lit. To remove a Memory Card, first press the memory

card power supply switch and then wait for the BUSY indicator to go out

before removing the Memory Card.

• If the I/O Hold Bit is turned ON, the outputs from the PLC will not be

turned OFF and will maintain their previous status when the PLC is

switched from RUN or MONITOR mode to PROGRAM mode. Make sure

that the external loads will not produce dangerous conditions when this

occurs. (When operation stops for a fatal error, including those produced

with the FALS(007) instruction, all outputs from Output Unit will be turned

OFF and only the internal output status will be maintained.)

• The contents of the DM, EM, and HR Areas in the CPU Unit are backed

up by a Battery. If the Battery voltage drops, this data may be lost. Provide

countermeasures in the program using the Battery Error Flag (A40204) to

re-initialize data or take other actions if the Battery voltage drops.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Separate the line ground terminal (LG) from the functional ground terminal (GR) on the Power Supply Unit before performing withstand voltage

tests or insulation resistance tests. Not doing so may result in burning.

• Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

xxx

Page 30

Application Precautions 5

• Be sure that all the terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals. Incorrect tightening

torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Wire all connections correctly.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check switch settings, the contents of the DM Area, and other preparations before starting operation. Starting operation without the proper settings or data may result in an unexpected operation.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including the setting of the

startup operating mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of the DM Area, HR Area, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so

may break the cables.

• Do not use commercially available RS-232C personal computer cables.

Always use the special cables listed in this manual or make cables

according to manual specifications. Using commercially available cables

may damage the external devices or CPU Unit.

• Do not connect pin 6 (+5 V power supply line) of the RS-232C port on the

CPU Unit to any external device except the CJ1W-CIF11 RS-422A

Adapter or NT-AL001 RS-232C/RS-422A Adapter. Doing so may damage

the external device or CPU Unit.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

xxxi

Page 31

Conformance to EC Directives 6

• When transporting or storing circuit boards, cover them in antistatic material to protect them from static electricity and maintain the proper storage

temperature.

• Do not touch circuit boards or the components mounted to them with your

bare hands. There are sharp leads and other parts on the boards that

may cause injury if handled improperly.

• Do not short the battery terminals or charge, disassemble, heat, or incinerate the battery. Do not subject the battery to strong shocks. Doing any

of these may result in leakage, rupture, heat generation, or ignition of the

battery. Dispose of any battery that has been dropped on the floor or otherwise subjected to excessive shock. Batteries that have been subjected

to shock may leak if they are used.

• UL standards required that batteries be replaced only by experienced

technicians. Do not allow unqualified persons to replace batteries.

• After connecting Power Supply Units, CPU Units, I/O Units, Special I/O

Units, or CPU Bus Units together, secure the Units by sliding the sliders at

the top and bottom of the Units until they click into place. Correct operation may not be possible if the Units are not securely properly. Be sure to

attach the end cover provided with the CPU Unit to the rightmost Unit. CJseries PLCs will not operate properly if the end cover is not attached.

• Unexpected operation may result if inappropriate data link tables or

parameters are set. Even if appropriate data link tables and parameters

have been set, confirm that the controlled system will not be adversely

affected before starting or stopping data links.

• CPU Bus Units will be restarted when routing tables are transferred from

a Programming Device to the CPU Unit. Restarting these Units is required

to read and enable the new routing tables. Confirm that the system will

not be adversely affected before allowing the CPU Bus Units to be reset.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.