Page 1

Cat. No. W406-E1-09

SYSMAC CS/CJ Series

Loop Control Boards

CS1W-LCB01/LCB05

Process-control CPU Units

CS1D-CPU@@P

(CPU Unit: CS1D-CPU@@H, Loop Controller: LCB05D)

Loop-control CPU Units

CJ1G-CPU42P

(CPU Unit: CJ1G-CPU42H, Loop Controller: LCB01)

CJ1G-CPU43P/44P/45P

(CPU Unit: CJ1G-CPU43H/44H/45H, Loop Controller: LCB03)

OPER ATION M ANUAL

Page 2

Page 3

SYSMAC CS/CJ Series

Loop Control Boards

CS1W-LCB01/LCB05

Process-control CPU Units

CS1D-CPU@@P

(CPU Unit: CS1D-CPU@@H, Loop Controller: LCB05D)

Loop-control CPU Units

CJ1G-CPU42P

(CPU Unit: CJ1G-CPU42H, Loop Controller: LCB01)

CJ1G-CPU43P/44P/45P

(CPU Unit: CJ1G-CPU43H/44H/45H, Loop Controller: LCB03)

Operation Manual

Revised January 2013

Page 4

iv

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury . Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury . Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this man ual. The w ord “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON produc ts, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displa ys to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2002

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of th e information contained herein. Moreo v er, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevert heless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another , such as procedures, checklists, etc.

v

Page 6

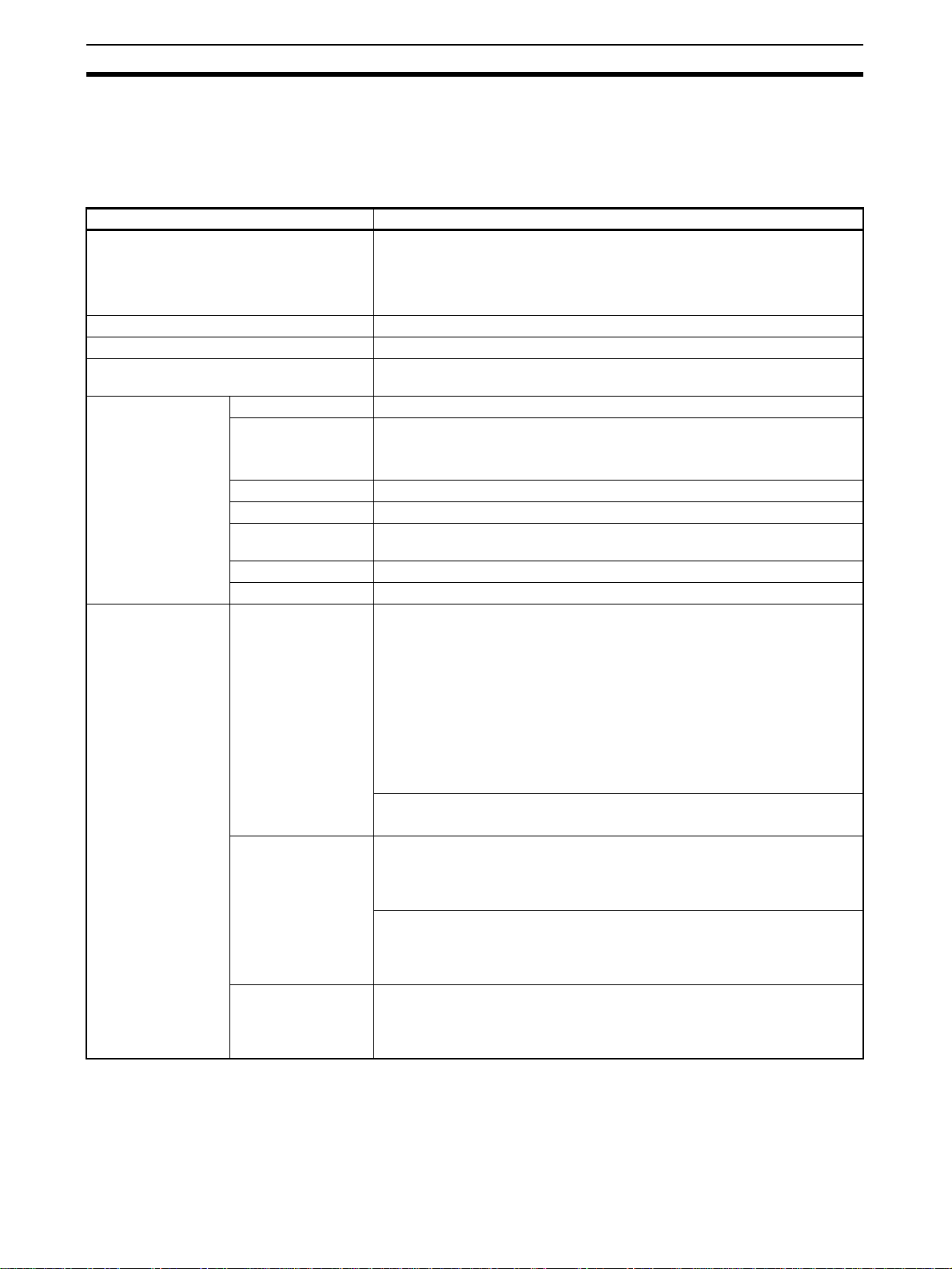

About Loop Controllers

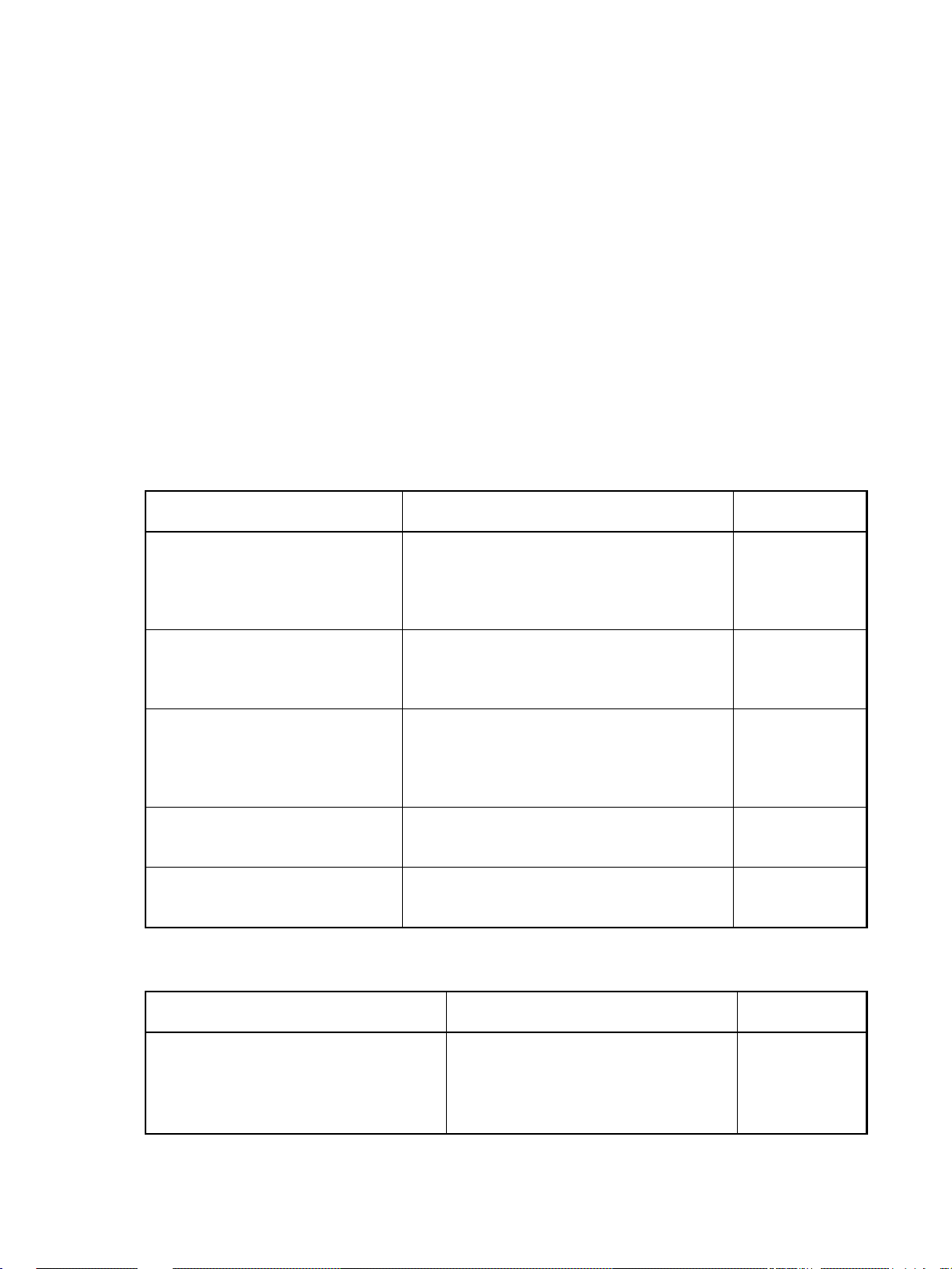

Loop Control Types, Functional Elements, and Versions

Loop Controller Types

There are two types of CS/CJ-series Loop Controller: Separate Loop Controllers and Loop Controllers Pre-installed in CPU Units

Loop Controller

type

Separate Separate Loop

Pre-installed in

CPU Unit

Type name Product name Model PLC series and Unit type

Controller

CPU Unit with

Pre-installed

Loop Controller

Loop Control Unit CS1W-LC001 CS-series CPU Bus Unit Loop Controller

Loop Control Board CS1W-LCB01/05 CS-series Inner Board Loop Controller

Process-control

CPU Unit

Loop-control CPU

Unit

Loop Controller Functional Elements

• Separate Loop Controllers consist of only the Loop Contr oller f uncti onal element (i.e., the Loop Controller element).

• CPU Units with Pre-installed Loop Controller consists of a CPU Unit functional element (i.e., the CPU Unit element) and the Loop Controller functional element (i.e., the Loop Controller element).

Versions

The functional elements (i.e., the CPU Unit element and Loop Controller element) have versions.

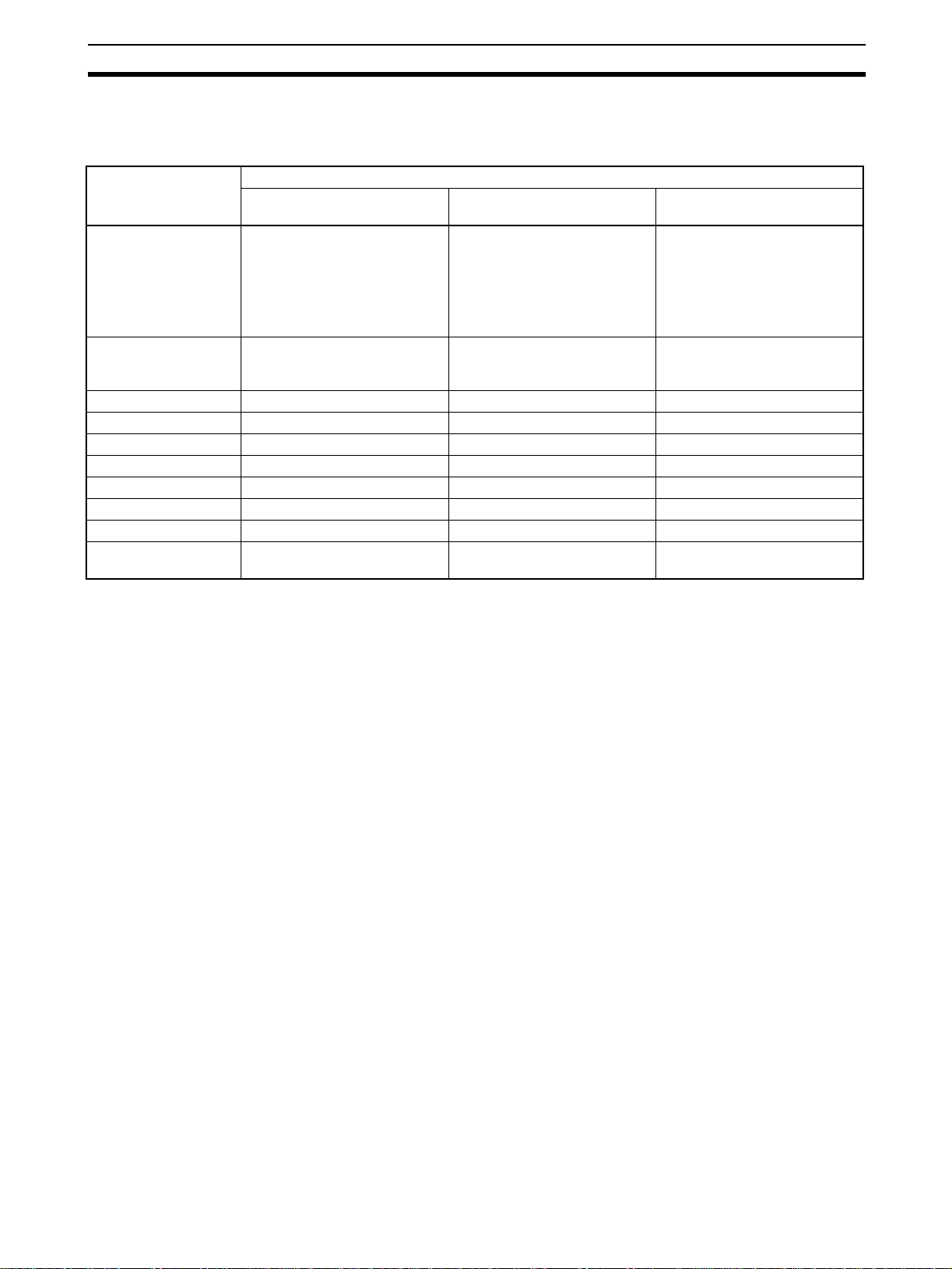

Model Numbers and Functional Elements

The following table lists the Loop Controller product model numbers, the functional element names for the CPU Unit elements and Loop Controller elements, and the versions of the functional elements.

CS1D-CPU@@P A one-Unit Loop Controller consisting of

an Inner Board pre-installed in a CSseries CS1D-H CPU Unit

CJ1G-CPU@@P A one-Unit Loop Controller consisting of

an Inner Board pre-installed in a CJseries CJ1-H CPU Unit

Product name Product model

number

Loop Control

Unit

Loop Control

Board

Process-control

CPU Unit

Loop-control

CPU Unit

CS1W-LC001 Pre-Ver. 2.0 --- LC001 Ver. 2.5

CS1W-LCB01 Ver. 2.0 to Ver.

CS1W-LCB05 LCB05

CS1D-CPU65P --- CS1D-CPU65H Ver. 1.0 or higher LCB05D Ver. 1.0

CS1D-CPU67P CS1D-CPU67H Ver. 1.0 or higher LCB05D

CJ1G-CPU42P --- CJ1G-CPU42H Ver. 3.0 or higher L C B 01 Ver. 2.0 to

CJ1G-CPU43P CJ1G-CPU43H Ver. 3. 0 or higher LC B03

CJ1G-CPU44P CJ1G-CPU44H Ver. 3. 0 or higher LC B03

CJ1G-CPU45P CJ1G-CPU45H Ver. 3. 0 or higher LC B03

Note Only Separate Loop Controllers have a unit version for the product model.

Unit version of

the product

model

(See note.)

3.6

CPU unit element Loop Controller element

CPU Unit

model with

same function-

ality

--- LCB01 V er. 2.0 to

Configuration

Functional ele-

ment unit version

Functional

element

name

Functional

element

Ver. 3.6

Ver. 3.6

CPU Units with Pre-installed Loop Controllers do not have a unit version for

the product model.

vi

Page 7

Notation in this Manual

This manual uses the following notation.

• “Loop Controller” is used as a generic term to refer to the L oop Controllers i n

general.

•“LCB@@” is used to refer to specific Loop Controller functional elements.

For example, the Loop Controller function element in a CS1W-LCB05 Loop

Control Board is the LCB05, so “LCB05” is used to ref er to th e Loop Controller functional element. The Loop Controller function element in a CJ1GCPU44P Loop-control CPU Unit is the LCB03, so “LCB03” is used to refer to

the Loop Controller functional elem ent.

• Model numbers are used to refer to specific Loop Controller models.

In the CX-Process Tool Operation Manual for version 3.2 or lower, functional

element names (LCB@@) are given as “Loop Control Board.” In the CX-Pro-

cess Tool Operation Manual for version 4.0 or higher, simply “LCB@@” is

used.

vii

Page 8

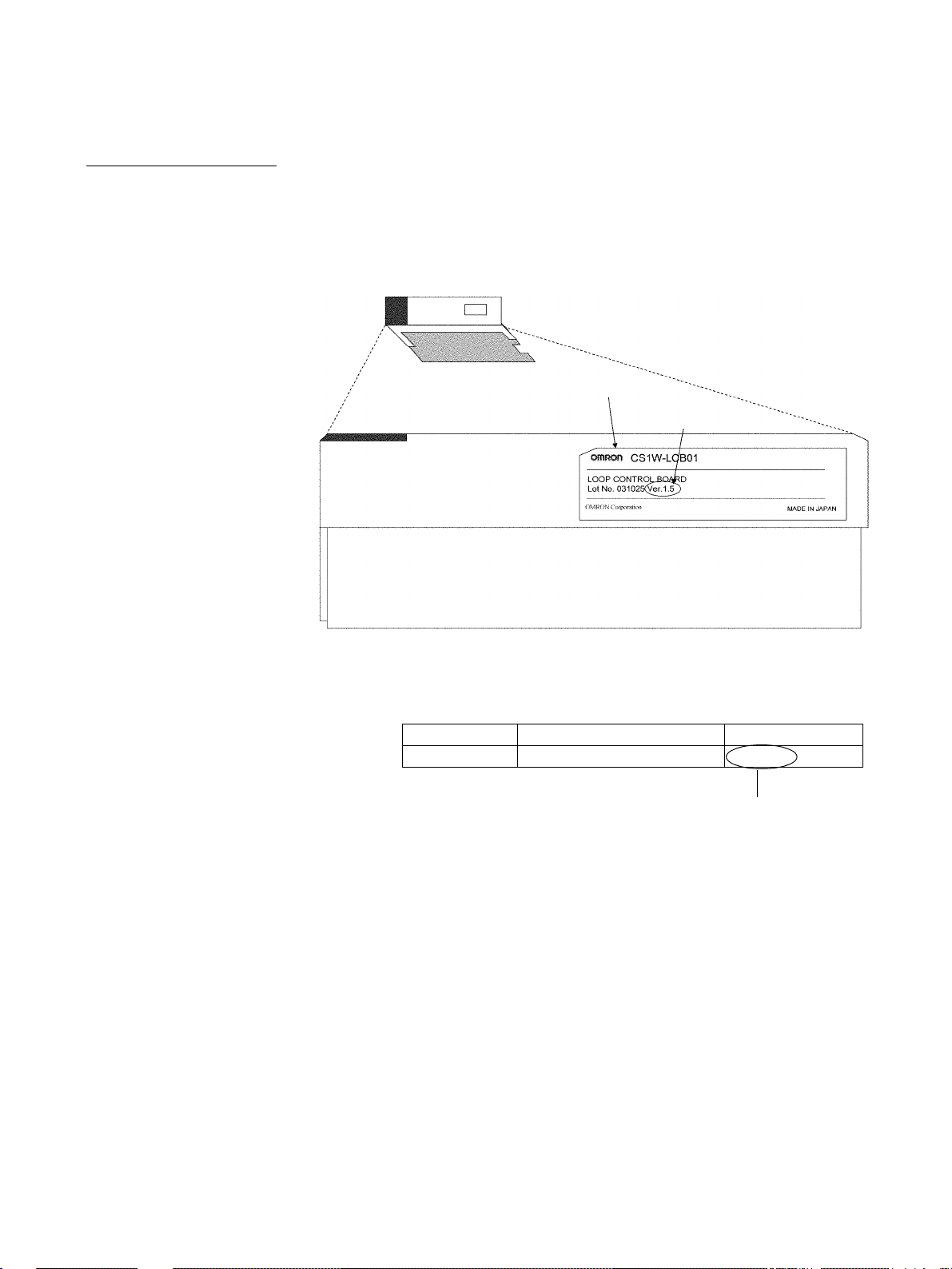

Unit Version Notation on Products

Loop Control Boards A “unit version” has been introduced to manage CPU Units, Special I/O Units,

and Inner Boards in the CS/CJ Series according to differences in functionality

accompanying upgrades. This system applies to Units manufactured since

October 1, 2003. The unit version code is provided on the nameplate of the

product for which unit versions are being managed, as shown below for the

Loop Control Board.

Loop Control Board

Product nameplate

Unit version

Example for unit version 1.5

The CX-Process Tool can be used to co nfirm the un it versions of Loop Control Boards in the Monitor

Run Status Window. After connecting the CX-Process Tool online, select Operation – Monitor Run

Status from the Execute Menu. Confirm the unit version in ITEM099 (MPU/FROM version display)

under from the System Common Block (Block Model 000) in the Monitor Run Status Window.

ITEM Data name Data

099 MPU/FROM version indication V1.50

Version V1.50 and onwards must be indicated.

viii

Page 9

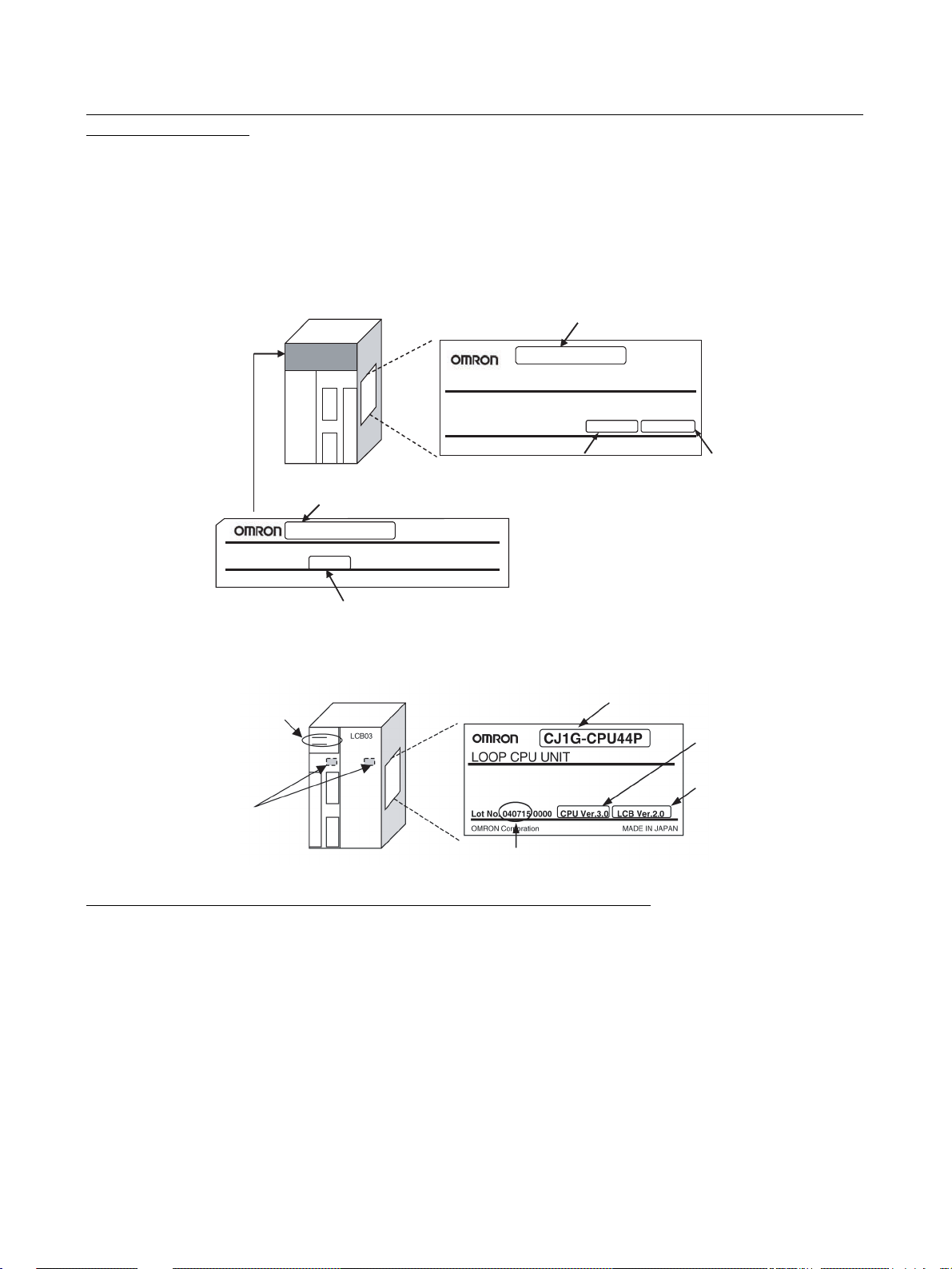

Functional Element Name and Ver sion Code for Process-control CPU Units and Loopcontrol CPU Units

The functional element name and functional element version code for Process-control CPU Units and Loop-control CPU Units are provided on the

nameplate as shown in the following diagrams.

Process-control CPU Units

Note CPU Unit elements for which no version code is provided are pre-Ver. 2.0

CPU Units.

Nameplate on

left side of Unit

LOOP CONTROL BOARD

Lot No. 031025 Ver.1.5

OMRON Corporation

Loop-control CPU Units

Product model and functional

element name

Recommended location for

attaching version label

Process-control CPU Unit

Product nameplate

Lot No. 031001 0000

OMRON Corporation

Functional element name for

Loop Controller element

CS1D-LCB05D

MADE IN JAPAN

Functional element version code for

Loop Controller element

Loop-control CPU Unit

Functional element name for

CPU Unit element

CS1D-CPU67P

PROCESS CPU UNIT

Functional element

version code for the

CPU Unit element

Product nameplate

Lot No.

CPU Ver.1.0 LCB Ver.1.0

MADE IN JAPAN

Functional element

version code for Loop

Controller element

Unit model number

Functional element

version code for

CPU unit element

Functional element

version code for

Loop Controller

element

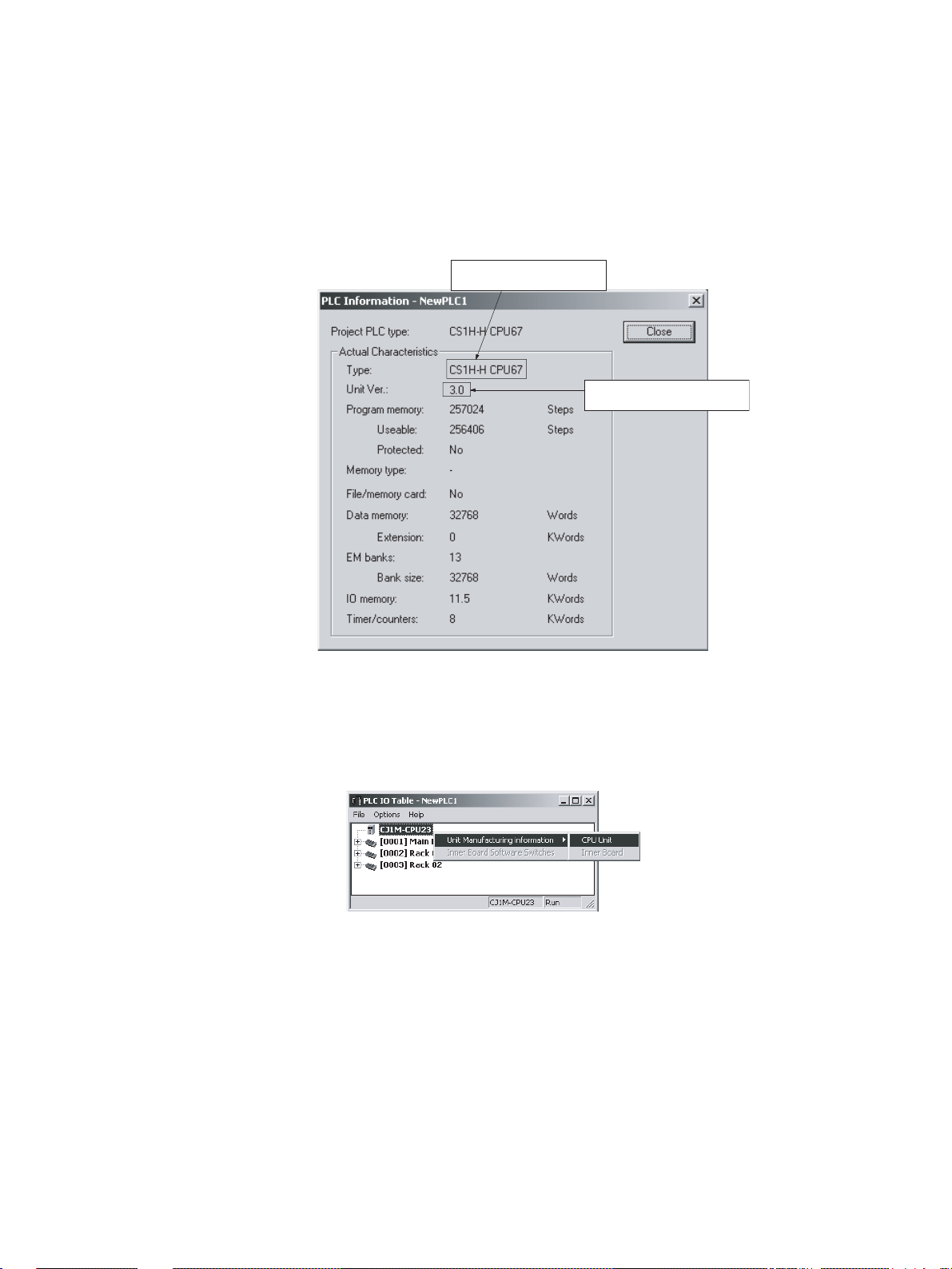

Confirming CPU Unit Element Versions with Support Software

CX-Programmer version 4.0 can be used to confirm the unit version using

either of the following two methods.

• Using the PLC Information

• Using the Unit Manufacturing Information (This method can also be used for

Special I/O Units and CPU Bus Units.)

Note CX-Programmer version 3.3 or lower cannot be used to confirm unit versions.

ix

Page 10

PLC Information

1,2,3... 1. If you know the de vice type and CPU type , select them in the Change PL C

dialog box, go online, and select PLC – Edit – Information from the

menus. If y ou do not know t he de vice type and CPU type , b ut ar e connected directly to the CPU Unit on a serial line, select PLC – Auto Online to

go online, and then select PLC – Edit – Information from the menus.

2. In either case, the following PLC Information Dialog Box will be displayed.

Functional element name

for CPU Unit element

Functional element version

code for CPU Unit element

Unit Manufacturing Information

1,2,3... 1. In the I/O Table Window, right-click and select Unit Manufacturing Infor-

Use the above display to confirm the unit version of the CPU Unit that is

connected online.

mation – CPU Unit.

2. The following Unit Manuf acturing Information Dialog Box will be displa yed.

x

Page 11

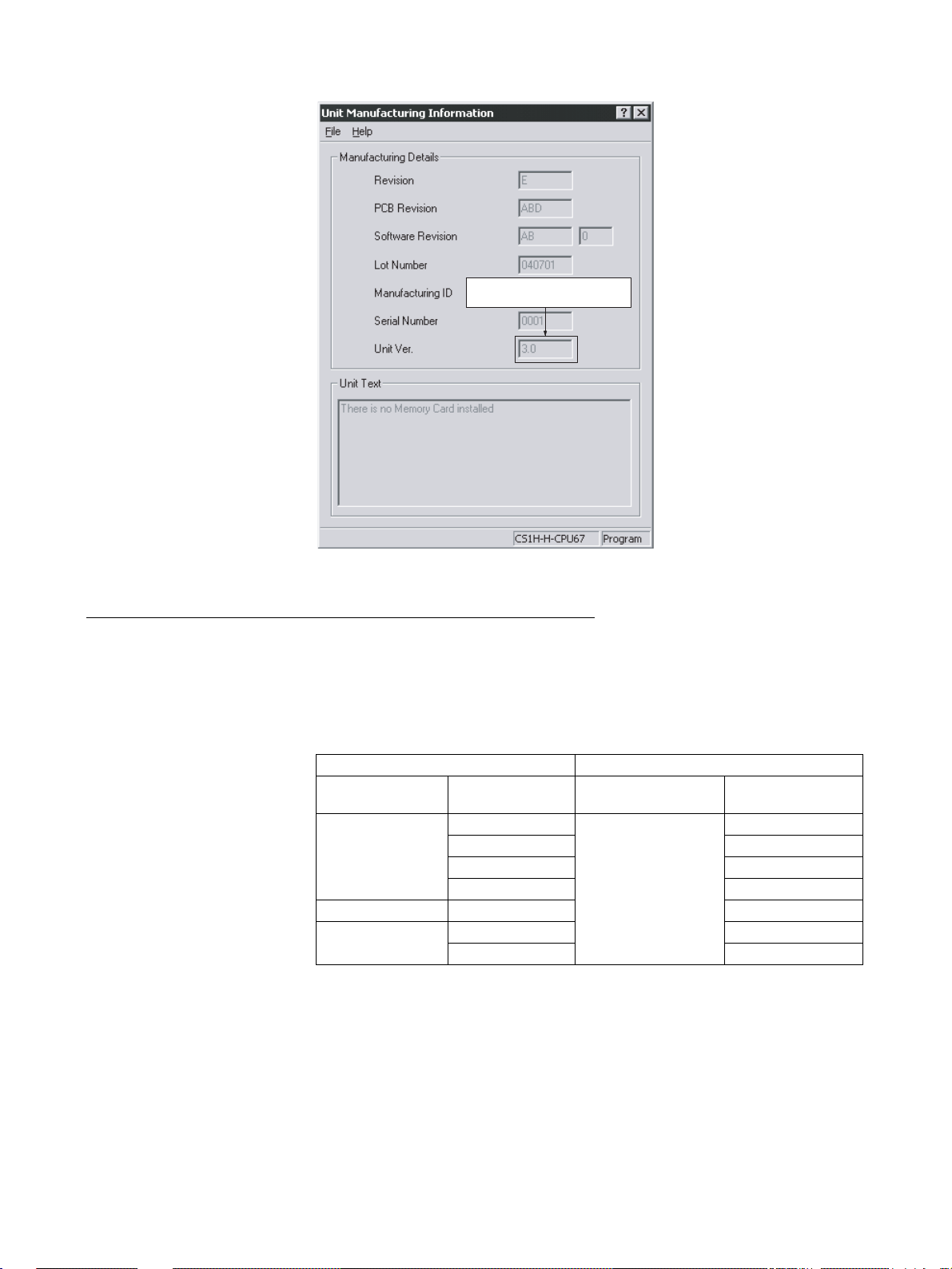

Functional element version

code for CPU Unit element

Use the above displa y to conf irm the unit version of the CPU Unit connected online.

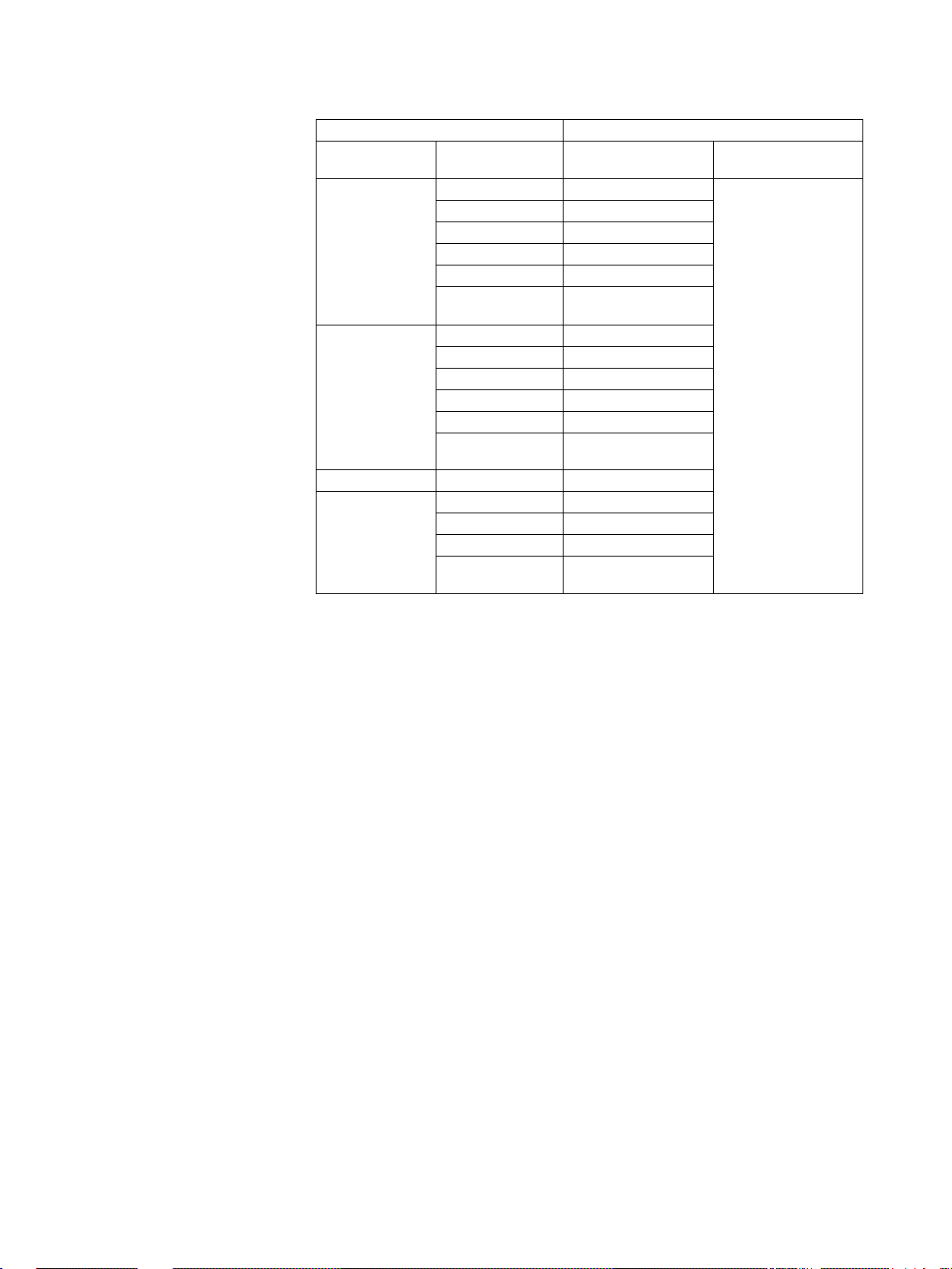

Functional Element Versions and Programming Devices

The Programming Device that suppor ts the functional element version code

must be used to enable all the functions in the corresponding functional element.

Note Upgrading versions is not necessar y if only the basic functions of the CPU

Unit element are required.

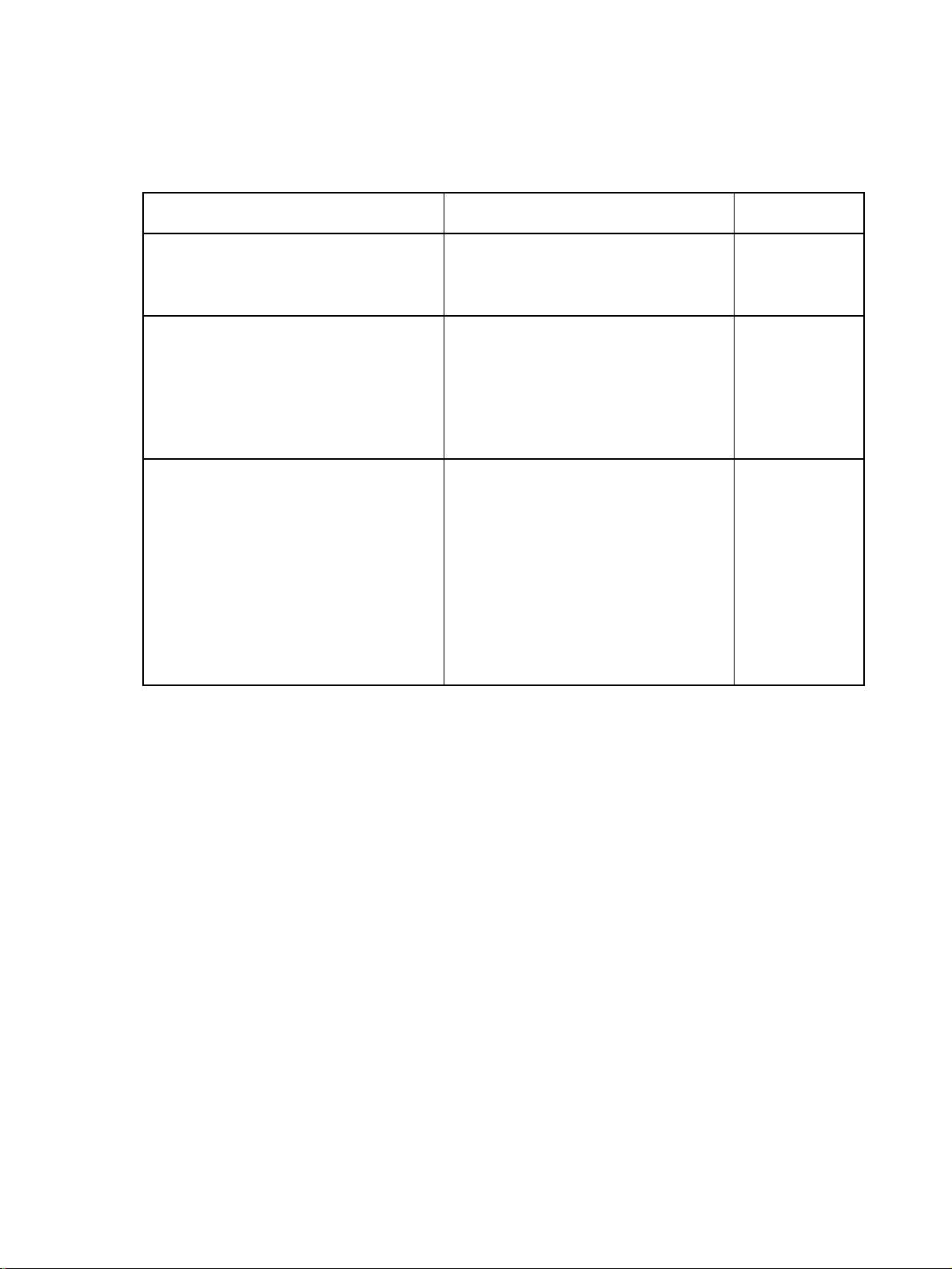

CPU Unit Element

Loop Controller Programming Device

Functional

element name

CS1G/H-CPU@@H Pre-Ver. 2.0 --- ---

CS1D-CPU@@H Ver. 1.1 Ver. 4.0 or higher

CJ1G-CPU@@H Ver. 3.0 Ver. 5.0 or higher

Functional

element version

Ver. 2.0 Ver. 4.0 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 4.0 Ver. 7.0 or higher

Ver. 4.0 Ver. 7.0 or higher

CX-Process Tool CX-Programmer

(See note.)

xi

Page 12

Loop Controller Element

Loop Controller Programming Device

Functional

element name

LCB01 Ver. 1.0 Not specific ---

LCB05 Ver. 1.0 Not specific

LCB05D Ver. 1.0 Ver. 3.2 or higher

LCB03 Ver. 2.0 Ver. 4.0 or higher

Functional

element version

Ver. 1.5 Ver. 3.2 or higher

Ver. 2.0 Ver. 4.0 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 3.5 Ver. 5.2 or higher

Ver. 3.6 Ver. 5.2 or higher

Ver. 1.5 Ver. 3.2 or higher

Ver. 2.0 Ver. 4.0 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 3.5 Ver. 5.2 or higher

Ver. 3.6 Ver. 5.2 or higher

Ver. 3.0 Ver. 5.0 or higher

Ver. 3.5 Ver. 5.2 or higher

Ver. 3.6 Ver. 5.2 or higher

CX-Process Tool CX-Programmer

(See note.)

(See note.)

(See note.)

(See note.)

Note When using function component version 3.6 for LCB01, LCB03, or

LCB05, use the CX-One Auto Update function to update the CX-Process Tool Software to version 5.23 or higher.

xii

Page 13

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxix

6 EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxi

7 Other Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxi

SECTION 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Configuration of Instrumentation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-3 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1-4 How to Use Function Blocks for Specific Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

1-5 Basic Procedure for Using the Loop Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

SECTION 2

Components, Installation, and Wiring . . . . . . . . . . . . . . . . . 71

2-1 Names and Functions of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2-3 Connecting to CX-Process Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

SECTION 3

Mechanism of the Loop Controller. . . . . . . . . . . . . . . . . . . . 81

3-1 Configuration of Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3-2 Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3-3 Exchanging Data with the CPU Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

3-4 Exchanging Data Using SCADA an d Other Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

3-5 Duplex Operation of Loop Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

3-6 Fail-safe Countermeasure Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

SECTION 4

Simple Example of Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

4-1 Simple Example of Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

SECTION 5

Examples of Function Block Combinations . . . . . . . . . . . . . 183

5-1 Basic Examples of PID Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 84

5-2 Examples of Applied Control Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

xiii

Page 14

TABLE OF CONTENTS

SECTION 6

How to Use FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . 203

6-1 How to Use FINS Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

6-2 FINS Commands for Loop Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

6-3 Description of FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

SECTION 7

Errors and Alarm Troubleshooting . . . . . . . . . . . . . . . . . . . 221

7-1 Errors and Alarm Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

7-2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Appendices

A How to Use the Step Ladder Program Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

B How to Use the Sequence Table Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

xiv

Page 15

About this Manual:

This manual describes the installation and operation of the CS-series CS1W-LCB01 and CS1WLCB05 Loop Control Boards, CS1D-CPU@@P Process-control CPU Units, and CJ1G-CPU@@P Loopcontrol CPU Units, and includes the sections described below.

The CS-series CS1W-LCB01 and CS1W-LCB05 Loop Control Boards, CS1D-CPU@@P Process-control CPU Units, and CJ1G-CPU@@P Loop-control CPU Units help you build an instrumentation system

comprising multiple loops. A Loop Control Board is installed as an Inner Board in the CPU Unit of a

CS-series PLC (Programmable Controller).

The CS1W-LCB01 and CS1W-LCB05 Loop Control Boards must be installed in CS1-H CPU Units.

They cannot be used in CS1 CPU Units.

Please read this manual and the other manuals related to the CS1W-LCB01 and CS1W-LCB05 Loop

Control Boards, CS1D-CPU@@P Process-control CPU Units, and CJ1G-CPU@@P Loop-control CPU

Units carefully and be sure you understand the information provided before attempting to install and

operate the products. The manuals used with the CS1W-LCB01 and CS1W-LCB05 Loop Control

Boards, CS1D-CPU@@P Process-control CPU Units, and CJ1G-CPU@@P Loop-control CPU Units

are listed in the follo wing t able. The suffixes have bee n omit ted f ro m the cat alog numbers. Be sure you

are using the most recent version for your area.

Name Contents Cat. No.

SYSMAC CS/CJ Series

CS1W-LCB01, CS1W-LCB05, CS1DCPU@@P, and

CJ1G-CPU@@P

Operation Manuals

SYSMAC CS/CJ Series

CS1W-LCB01, CS1W-LCB05,CS1DCPU@@P, and CJ1G-CPU@@P

Function Block Reference Manual

SYSMAC CX-One FA Integrated Tool

Package

CXONE-AL@@C-V4/AL@@D-V4

CXONE-LT@@C-V4

Setup Manual

SYSMAC CS/CJ Series

CX-Process Tool

Operation Manual

Faceplate Auto-Builde r for NS

Operation Manual

(suffixes omitted)

Describes the basic running of the Loop Control

Boards (excluding detailed descriptions of the

function blocks).

Provides detailed information on the function

blocks.

Provides an overview of the CX-One FA Integrated

Tool and installation procedures.

Describes operation of the CX-Process Tool. W372

Describes operation of the software that generates

NS-series PT projects from a SCADA CSV file output by the CX-Process Tool.

W406

W407

W463

W418

When using CS1D Process-control CPU Units, refer to the following manuals for information on the

CS1D CPU Unit elements.

Name Contents Cat. No.

(suffixes omitted)

SYSMAC CS Series

CS1D-CPU

CS1D-PA/PD

CS1D Duplex System

Operation Manual

@@H, CS1D-DPL01

@@@

Describes the setup and operation of CS1D

Duplex systems.

W405

xv

Page 16

About this Manual, Continued

When using CJ Series Loop-c ontrol CPU Units, refer to the following manuals for infor mation on the

CJ1-H CPU Unit elements.

Name Contents Cat. No.

(suffixes omitted)

SYSMAC CJ Series

Programmable Controllers Operation Manual

CJ1G/H-CPU@@H, CJ1G-CPU@@P,

CJ1MCPU

SYSMAC CS/CJ Series

Programmable Controllers

Programming Manual

CS1G/H-CPU

CS1DCPU@@H, CS1D-CPU@@S,

CJ1G/H-CPU

CJ1M-CPU

SYSMAC CS/CJ/NSJ Series

CJ2H-CPU6

CJ2M-CPU

CS1G/H-CPU

CS1D-CPU@@S, CJ1H-CPU@@H-R,

CJ1G/H-CPU

CJ1M-CPU

NSJ@-@@@@(B)-G5D,

NSJ

Programmable Controllers Instructions Refer-

ence Manual

@@,CJ1G-CPU@@

@@-EV1, CS1G/H-CPU@@H,

@@H, CJ1G-CPU@@P,

@@, CJ1G-CPU@@

@-EIP, CJ2H-CPU6@,

@@, CS1G/H-CPU@@H,

@@-EV1, CS1D-CPU@@H,

@@H, CJ1G-CPU@@P,

@@, CJ1G-CPU@@,

@-@@@@(B)-M3D

Provides an outlines of and describes the

design, installation, maintenance, and other

basic operations for the CJ-series PLCs.

This manual describes programming and

other methods to use the functions of the

CS/CJ-series PLCs.

Provides detailed descriptions of the instructions. When programming, use this manual

together with the manuals for your CPU

Unit.

W393

W394

W474

Section 1 outlines the features and application of the Loop Controllers and provides Loop Controller

specifications.

Section 2 describes the names and functions of parts, and provides other information required to

install and operate Loop Controllers.

Section 3 provides info rmation on the cont rol mech anism, basic operation, exchanging data with other

Units and software, and fail-safe countermeasures for Loop Controllers.

Section 4 describes a simple example of how to use Loop Controllers.

Section 5 describes basic examples of combining function blocks.

Section 6 provides information on how to use FINS commands.

Section 7 provides information on errors that may occur while running of Loop Controllers and guide-

lines for troubl eshooting these errors.

Appendix A describes how to use the Step Ladder Program block on the LCB@@s and Appendix B

describes how to use the Sequence Table block on the LCB@@s.

xvi

Page 17

WARNING

Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Plea se read each

section in its entirety and be sure you understand the information provided in the

section and related sections before attempting any of the procedures or operations

given.

xvii

Page 18

xviii

Page 19

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in mat erials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no eve nt shall the responsibil ity of OMR ON fo r any act e xcee d the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xix

Page 20

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an e xhaustive list of all possible uses of the products, nor is it inte nded to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable pr oduct, or any

consequence thereof.

xx

Page 21

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, sp ecial model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON represe ntative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Perf ormance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been ca refully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xxi

Page 22

xxii

Page 23

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PLC) and related devices.

The information contained in this section is important for the safe and reliable application of the Programmable

Controller. You must read this section and understand the information contained before attempting to set up or

operate a PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

4 Oper a ting Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxix

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxi

7 Other Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxi

xxiii

Page 24

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an elec trical engineer or the equivalent) and

knowledge about instrumentation systems.

• Personnel in charge of installing FA systems

• Personnel in charge of designing FA system s

• Personnel in charge of managing FA systems and facilities

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in this

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safe ty equipment, petrochemical plants, and other systems,

machines, and equipment that may have a serious influence on lives and

property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the system, machines and equipment with double safety mechanism.

This manual provides information for running CS1W-LCB01 and CS1WLCB05 Loop Control Boards, CS1D-CPU@@P Process-control CPU Unit, and

CJ1G-CPU@@P Loop-control CPU Unit. Be sure to read this manual before

attempting to use these products and related software (CX-Process Tool) and

keep this manual close at hand for reference during running.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in a pplications that

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

xxiv

Page 25

Safety Precautions 3

3 Safety Precautions

!WARNING Do not attempt to take any Unit or Board apar t while power is being supplied.

Doing so may result in electric shock.

!WARNING Do not touch live terminals. Electric shock will result.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• When using a CS1D-CPU@@P Process-control CPU Unit, the CS1D

Duplex System will stop operating and all outputs will be turned OFF in

the following cases:

• The self-diagnostic function detected errors at the same time in both

the active side (CPU Unit or Loop Controller) and the standby side

(CPU Unit or Loop Controller).

• A SEVERE F AILURE ALARM (FALS) instruction is executed and generated fata l errors at the same time in both the a ctive CPU Unit and t he

standby CPU Unit.

• The self-diagnostic function detected an error while operating in simplex mode or performing duplex initialization in duplex mode.

• A SEVERE FAILURE ALARM (FALS) instruction was executed and

generated a fatal error while operating in simplex mode or performing

duplex initialization in duplex mode.

Unexpected operation, however, may still occur for errors in the I/O control section, errors in I/O memory, and other errors that cannot be

detected by the self-diagnosis function. As a countermeasure for all such

errors, external safety measures must be provided to ensure safety in the

system.

• When a CS1W-LCB01 or CS1W-LCB05 Loop Control Board is mounted

in a CS1-H CPU Unit, the CPU Unit will stop operating and all outputs will

be turned OFF if the self-diagnostic function detected an error or a

SEVERE FAILURE ALARM (FALS) instruction was executed. As a countermeasure for such errors, external safety measures must be provided to

ensure safety in the system.

• The PLC outputs may remain ON or OFF due to depos ition or burning o f

the output relays or destr uction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!WARNING Check the following items before starting to run the Loop Controller:

xxv

Page 26

Safety Precautions 3

• Do not allow the bank of the EM Area wit h the number specified f or a llocation to the HMI (human-machine interface) data to overlap with any other

area used by the CPU Unit or other Units. The block allocated for the HMI

is specified in ITEM 050 (EM Area Bank Allocated for HMI Memory = 0 to

12) of the System Common block (Block Model 000). If areas overlap, the

system may operate in an unexpected manner, which may result in injury.

• Do not allow the area to which user link table data is written to overlap

with any other area used by the CPU Unit or other Units. If areas over lap,

the system may operate in an unexpected manner, which may result in

injury.

• When using a user link table to write bit data to I/O memor y in the CPU

Unit. Never allow ladder programming or communications processes in

the CPU Unit to write to any bits in the words in which bits are written from

a user link table. Depending on the timing, any attempts to write to these

words from ladder programming or communications processes may be

ignored. Example: If tag A in a user link table writes to bit 00 of W000 and

an OUT instruction in the ladder program in the CPU Unit write to bit 01 of

W000, the write from the ladder program may be ignored.

• Analog Input/Output Units used in combination with the Loop Controller

must be mounted correctly, and the unit number set on the front panel of

the Analog Input/Output Unit must match the unit number set on the Field

Terminal block. If the unit numbers do not match, input/output (read/write)

is performed on the data of another Special I/O Unit (whose unit number

is set on the Field Terminal block).

• The defaults of the System Common block on the Loop Controller must

be set correctly.

• Always stop the operation of the Loop Controller before converting any of

the EM Area to file memory. If any part of the EM Area that is being used

by the Loop Controller for the s is converted to file memory during Board

operation, the system may operate in an unexpected manner, which may

result in injury.

!WARNING Do not use battery-fr ee operation for the CS1-H CPU Unit or the CPU Unit

element of a Process-control CPU Unit or Loop-control CPU Unit. If batteryfree operation is used for the CPU Unit or CPU Unit element, the contents of

the EM Area will not be stable when the power supply is turned ON, possibly

causing illegal values in the HMI data in the Loop Controller.

!WARNING Do not perform processing in such a way that the Loop Controller and CPU

Unit perform writing on identical I/O memory addresses allocated to an contact output or analog output to an e xternal Unit. If writing is perf ormed on identical addresses, the externally connected load may act unexpectedly and

cause injury.

xxvi

Page 27

Safety Precautions 3

!WARNING The Loop Controller will automatically start using a cold star t even if the star-

tup mode is set to a hot star t if the power is turned ON after being OFF for

24 hours or longer. If this happens, the auto/manual setting for the Control

Block will be set to manual mode (MV=0%) and the remote/local setting will

be set to local. To automatically switch to auto mode at th e same time as starting operation after the power is turned ON after being OFF for 24 hours or

longer, the ladder diagrams in the Sequence Table or Step Ladder Program

blocks must be programmed as follows (same as the procedure for switching

to remote operation):

Processing: ITEM 086 (Auto/Manual switch) of the Basic PID block or

Advanced PID block is set to 1 using ITEM019 (Run Start Flag) and ITEM017

(cold start in progress) of the System Common block as the input conditions.

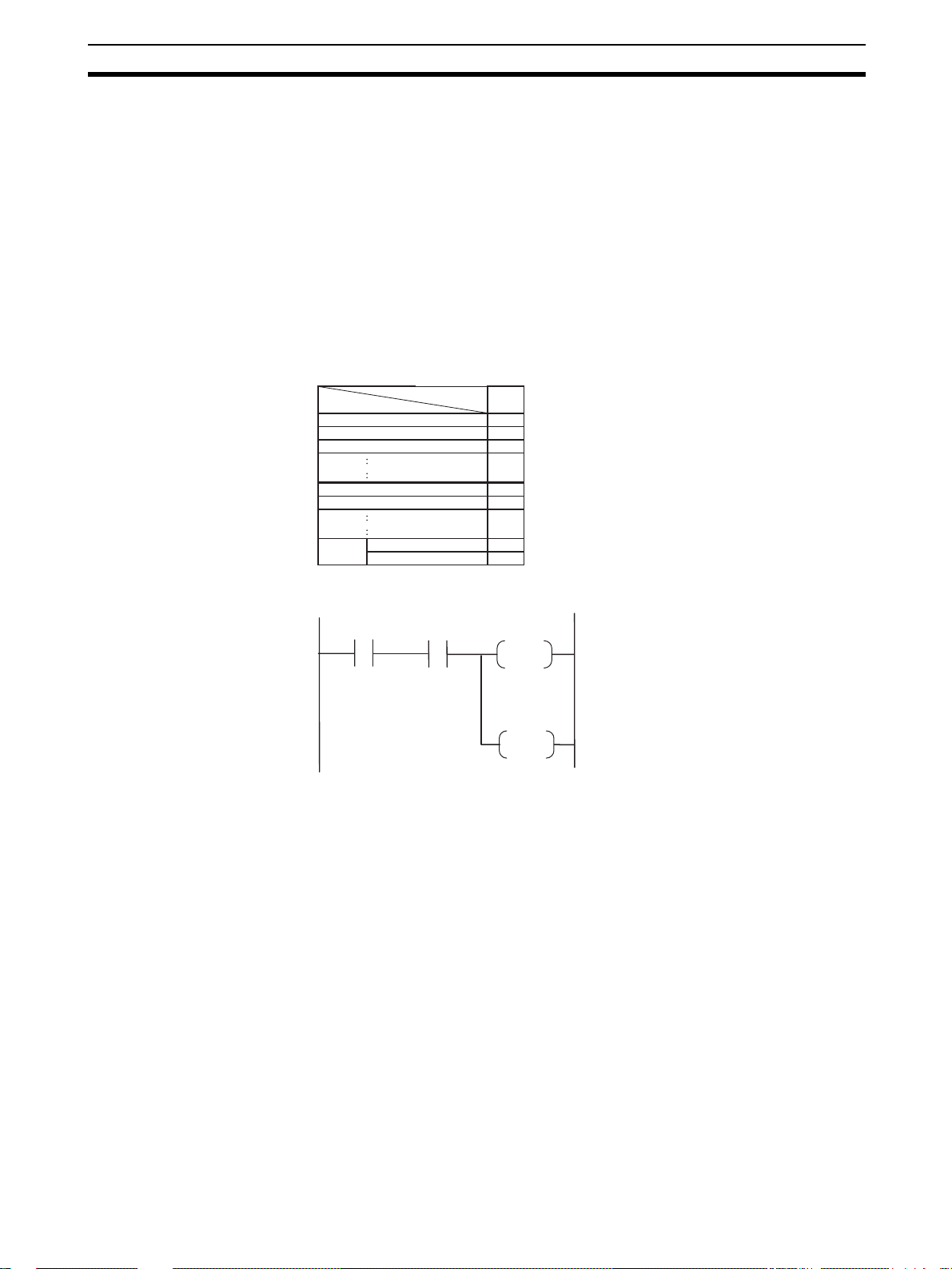

Sequence Table

Signal

000.019 Y

000.017 Y

001.086 Y

000.019 N

STEP

STEP

Run Start flag

Cold start in progress

A/M

Run Start flag

THENNEXT

ELSE

00

Step Ladder Program

000-019 000-017

Run Start

flag

Cold start in

progress

S

A/M

000-019

R

Run Start

flag

PID1 is Auto at power ON.

For details on hot and cold start operations, refer to 3-2-3 Details of Hot Start,

Cold Start and Stop State.

!WARNING When using the CS1D-CPU@@P Process-control CPU Unit, both the CPU

Unit’s cycle time and the Loop Controller’s operation cycle will be temporarily

longer than normal during duplex initialization (i n duple x mode). The extended

cycle time and operation cycle may temporarily worsen the control characteristics, so verify the system’s operation in test runs before actually running the

system.

!Caution When downloading a sequence table for the Loop Control Board (version 1.5

or higher) that has been edited online with the CX-Process Tool version 3.2 or

higher, confirm that the system will operate normally with the edited

sequence. If the sequence is not suitable for operation, unexpected operation

may result.

xxvii

Page 28

Operating Environment Precautions 4

!Caution Confirm in advance the conditions at an y node for which the sequence table is

being edited over a Controller Link or Ethernet network. Not doing so may

result in unexpected operation.

!Caution Do not use the HMI function to write a value that is ou tside of the data range

shown in the ITEM list in the Function Block Reference Manual (Cat. No.

W407) to the receive area (CPU Unit to Loop Controller) in the EM Area. Writing an out-of-range value can result in unexpected operation by the controlled

machine or equipment.

!Caution When executing calibration functions, the MV (manipulated variable) will be

changed when the PV (process value) is changed in the control block. Therefore, before executing this function, make sure that the equipment will be safe

even if the MV changes by setting pseudo-inputs. Otherwise, unexpected

equipment operation may result, causing a serious accident.

4 Operating Environment Precautions

4-1 CS1D-CPU@@P Process-control CPU Unit Precautions

• Normal operation will be possible only if the CS1D-CPU@@P Processcontrol CPU Unit is used in the combination in which it was shipped. Normal operation may not be po ssible if the CS1D-CPU@@P Process-control

CPU Unit is used in any other combination. Therefore, do not remove the

Loop Controller component from the CPU Unit. Always replace the entire

CS1D Process-control CPU Unit as on e Unit even if only the Loop Controller or CPU Unit has failed.

• The CS1D CPU Unit’s cycle time and the Loop Controller component’s

LCB load rate are different in duplex mode and simplex mode. Verify the

system’s oper ation in bo th modes in trial opera tion before actually running

the system.

• When replacing a CS1D Process-control CPU Unit while powe r is supplied to the PLC, always switch the DPL Unit’s CPU U SE/NO USE switch

to “NO USE.” Removing the CS1D Process-control CPU Unit with the

switch set to “USE” (power supplied) may damage the CPU Duplex Backplane, CS1D CPU Unit, DPL Unit, and Loop Controller component of the

Process-control CPU Unit.

4-2 CS1W-LCB01/CS1W-LCB05 Loop Control Board Precautions

Do not use a CS1W-LCB01 or CS1W-LCB05 Loop Control Board in any CPU

Unit other than the CS1-H.

• If a CS1W-LCB01 or CS1W-LCB05 Loop Control Board is used in a CS1

CPU Unit, a non-fatal INNER Board error will occur and the Loop Control

Board will not operate. (The CPU Unit itself will be able to operate.)

• If a CS1W-LCB01 or CS1W-LCB05 Loop Control Board is used in a

CS1D CPU Unit, a fatal INNER Board error will occur. (In this case, neither the Loop Control Board nor the CPU Unit will operate.)

• Loop Control Boards before version 1.5 cannot be used with CS1DCPU@@S CS1D CPU Units for Single-CPU Systems.

• Do not connect pin 6 (+5 V power supply line) of the RS-232C port on the

CPU Unit to any external device except the CJ1W-CIF11 RS-422A

Adapter or NT-AL001 RS-232C/RS-422A Adapter. Doing so may damage

the external device or Loop Control Board.

xxviii

Page 29

Application Precautions 5

4-3 Precautions for All Loop Control Boards, Process-control CPU

Units, and Loop-control CPU Units

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight

• Locations subject to temperature or humidity outside the range specified

in the specifications

• Locations subject to condensation as the r esult of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject possible exposure to radioactivity

• Locations close to power supplies

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the PLC.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always turn OFF the power to the PLC before attempting any of the following. Not turning OFF the power may result in malfunction or electric

shock.

• Mounting or dismounting I/O Units, including Inner Boards

• Assembling the Racks

• Setting DIP switches or unit number setting switches

• Connecting or wiring the cables

• Connecting or disconnecting the connectors

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always heed

these precautions.

xxix

Page 30

Application Precautions 5

• If the power supply is turned OFF while function block data is being

backed up from RAM to flash memory, the backup will not be completed

normally. If the power supply is turned back ON within 24 hours, however,

the super capacitor will have held the RAM data. The backup operation

will restart when power is turned ON and operation will start when the

backup has been completed. If the power supply is turned OFF for more

than 24 hours, however, RAM data will be lost and operation will be

started with the data that was previously saved to flash memory. If this

happens, the Cold Start Auto-execution Flag (A35807) will turn ON to

show that the previous data has been used. Use this bit in programming

to take whatever steps are necessary, such as downloading the most

recent function block data.

• To hold analog outputs o r contact outp uts at spec ific values (for example,

maximum value or minim um v alue ) when the Loop Controller has stop ped

running, create a Step Ladd er Program on the CPU Unit so that each of

the allocated bits on the Analog Output Unit or Contact Output Unit are

set to a specific value taking the N.C. condition of the Loop Controller

Running flag (A35801) as the input condition.

• When a fatal error occurs on the CPU Unit (including execution of the

FALS instruction), the Loop Controller also stops running. To hold the

analog output to the previous value before the stop occurred, and to set

the analog output to either the minimum value or maximum value, use the

output hold function of the Analog Output Unit or Analog Input/Output

Unit.

• Before turning ON the power to the PLC, make sure that the facilities are

safe.

• The analog output values and contact outputs from the Loop Controller

are updated at the same time that the power to the PLC is turned ON

regardless of the operation mode of the CPU Unit (including the PROGRAM mode). (Internally, the analog output values and contact outputs

are sent via the CPU Unit to the Basic I/O Unit and Analog Output Unit.)

• The Loop Controller itself does not have a human-machine interface. So,

an external interface such as SCADA software must be provided.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruption s or other causes.

• Before touching the PLC, be sure to first touch a grounded metallic object

in order to discharge any static build-up. Otherwise, it might result in a

malfunction or damage.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Do not attempt to disassemble, repair, or modify any Units or Boards.

• Leave the dust-protection label attached to the top Unit when wiring.

Removing the label may result in malfunction.

• Remove the label afte r the co mpletio n of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Check the user program for proper execution before actually running it on

the Unit or Board. Not checking the program may result in an unexpected

operation.

xxx

Page 31

EC Directives 6

• Double-check all the wiring before turning ON the power supply. Incorrect

wiring may result in burning.

• Tighten the PLC Backplane mounting screws, terminal block screws, and

cable (connector) screws to the torque specified in user manuals.

• Confirm that no adverse effect will occur in the system before attempting

any of the following:

• Changing the operating mode of th e PLC

• Force-setting/force-resetting of any contact in memory

• Changing the present value or any set value in memory

6 EC Directives

CS-series products confirm to EC Directives. For th e system to conf o rm to EC

Directives, however, the following precautions must be adhered to.

• CS-series Units must be installed within control panel.

• Use reinforced insulation of double insulation for the DC power supplies

used for the I/O power supplies.

• CS-series products that meet EC Directives also meet the Common

Emission Standard (EN61000-6-4). The measure necessary to ensure

that standards, such as the radiated emission standard (10 m), are met,

however, will vary depending on the overall configuration of the control

panel, the other devices to the control panel, and wiring. You must therefore confirm that EC Directives are me t for the overall machine or device.

7 Other Applicable Directives

Applicable Directives

• EMC Directive

• Low Voltage Directive

EMC and Low Voltage Directives

EMC Directive

In order that OMRON products can be used with an y machine ry and in combination with other manufacturer's equipment, the products themselves are

designed to comply with EMC standards (see Note), so that the assembled

machinery or device can then also easily comply with EMC standards.

Even if machinery and equipment complies with EMC standards before

assembly, this compliance may change depending on the device, the configuration of the control panel, and wiring, so OMRON cannot guarantee that a

particular system complies with the directive. You must therefore confir m that

EMC Directives are met for the overall machine or device.

Note EMC: One directive relating to Electro-Magnetic Compatibility

EMS: Electro-Magnetic Susceptibility standard EN6100-6-2

EMI: Electro-Magnetic Interference standard EN61000-6-4

Common Emission Standard EN61000-6-4, radiated emission standard

(10 m)

xxxi

Page 32

Other Applicable Directives 7

Low Voltage Directive

The Low Voltage Directive provides that necessary safety standards are guaranteed for devices operating at voltages of 50 to 1,000 V AC or 75 to 1,500 V

DC to comply with EN61131-2.

xxxii

Page 33

SECTION 1

Introduction

This section outlines the features and application of the Loop Controllers and provides Loop Controller specifications.

1-1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-1-3 LCB01/05 Version 1.5 Upgrade Information. . . . . . . . . . . . . . . . . . 7

1-1-4 LCB01/05 Version 2.0 Upgrade Information. . . . . . . . . . . . . . . . . . 9

1-1-5 LCB01/03/05 Version 3.0 Upgrade Information . . . . . . . . . . . . . . . 10

1-1-6 Upgraded Functions for LCB01/05 and LCB03 Version 3.5 . . . . . . 12

1-1-7 Upgraded Functions for LCB01/05 and LCB03 Version 3.6 . . . . . . 13

1-1-8 Basic System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-1-9 Application Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-1-10 Loop Controller Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-1-11 Overall Mechanism of Data Exchange. . . . . . . . . . . . . . . . . . . . . . . 21

1-1-12 Internal Mechanism of Loop Controll er s . . . . . . . . . . . . . . . . . . . . . 23

1-1-13 List of Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-1-14 Differences between Loop Control Units and Boards . . . . . . . . . . . 32

1-1-15 Version Upgrade Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1-2 Configuration of Instrumentation System. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-2-1 Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-2-2 Determining the System Configuration . . . . . . . . . . . . . . . . . . . . . . 40

1-2-3 Description of Basic System Configuration . . . . . . . . . . . . . . . . . . . 45

1-3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1-3-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1-3-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1-3-3 Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1-3-4 Outline of PID Block Specifications . . . . . . . . . . . . . . . . . . . . . . . . 57

1-3-5 Software Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1-4 How to Use Function Blocks for Specific Operations . . . . . . . . . . . . . . . . . . 62

1-5 Basic Procedure for Using the Loop Controller . . . . . . . . . . . . . . . . . . . . . . . 66

1

Page 34

Outline Section 1-1

1-1 Outline

1-1-1 Outline

Var ious process operations, including PID control, can be performed for up to

500 blocks with the LCB05 and LCB05D, up to 300 blocks with th e LCB03, or

up to 50 blocks with the LCB01. (See note.) Process operations include basic

logic sequence control and step-progression control. The Loop Controller can

also be used to implement an alarm/monitor terminal on a computer without

using PID control functions.

Note The maximum number of control loops is determined by the operation cycle.

In most cases, such as when each loop consists of an Ai4 Terminal, a Segment Linearizer, a Basic PID, and an Ao4 Terminal block the maximum number of control loops would be as shown in the following tables.

Loop Control Boards

CS1W-LCB01 and CS1W-LCB05 (LBC01/05)

Operation cycle Maximum number of loops

0.01 s 20 loops

0.02 s 35 loops

0.05 s 70 loops

0.1 s 100 loops

0.2 s 180 loops

0.5 s 250 loops

1 s 250 loops

2 s 250 loops

Process-control CPU Units

CS1D-CPU@@P (LCB05D)

Operation cycle Maximum number of loops

0.1 s 80 loops

0.2 s 140 loops

0.5 s 250 loops

1 s 250 loops

2 s 250 loops

Loop-control CPU Units

CJ1G-CPU43P/44P/45P (LCB03)

Operation cycle Maximum number of loops

0.01 s 20 loops

0.02 s 35 loops

0.05 s 70 loops

0.1 s 100 loops

0.2 s 150 loops

0.5 s 150 loops

1 s 150 loops

2 s 150 loops

2

Page 35

Outline Section 1-1

CJ1G-CPU42P (LCB01)

Operation cycle Maximum number of loops

0.01 s 20 loops

0.02 s 25 loops

0.05 s 25 loops

0.1 s 25 loops

0.2 s 25 loops

0.5 s 25 loops

1 s 25 loops

2 s 25 loops

The Loop Control Boards, Process-control CPU Units, and Loop-control CPU

Units have no external I/O functions. So, they must be used in a pair with a

Unit having an external interface, such as an Analog I/O Unit or Basic I/O Unit.

The Loop Controller exchanges data with the Unit having the external interface via the CPU Unit I/O memory.

You can achieve all functions (operation functions/designation of field

input/output) simply by combining Control blocks, Operation blocks, and other

function blocks. This allows you to easily build a professional instrumentation

system on your PLC (Programmable Controller).

The following f unctions can be achieved by function blocks:

Internal Operations • Control and operation blocks (500 function blocks max. for LCB05 and

LCB05D (See note.), 300 function blocks max. for LCB03, or 50 function

blocks max. for LCB01): 2-position ON/OFF, Basic PID, Advanced PID,

Ratio Setting, Alarm/Signal Restrictions/Hold, Arithmetic (addition, subtraction, multiplication and division), Functions (Square Root, Absolute

Value, Segment Linearizer, etc.), Time Functions (Lead/Delay, Dead

Time, Ramp Program, etc.), Pulse Train Operation (Accumulator), Signal

Selection/Switching (Rank Selector, Constant Selector, etc.), Sequential

Control (Timers, Counter, etc.)

Note Only 100 function blocks can be used on the LCB05 and LCB05D

if Fuzzy Logic, Arithmetic Operation, or Time Sequence Data Statistics blocks are used.

• External controllers (32 function blocks max.):

ES100X Controller Terminal (Cannot be used on the CS1D-CPU@@P

and CJ1G-CPU@@P.)

• Logic sequence/step progression control (200 function blocks max. for

LCB03, LCB05, and LCB05D, 20 blocks max. for LCB01. 2,000 commands in total.):

Step Ladder Program and sequence table (LCB05 and LCB05D only)

External I/O • Each of the points on the Analog I/O Unit and Basic I/O Unit is read and

written by the Field Terminal block (max. 80 function blocks).

• Specified contacts or analog data in the CPU Unit I/O memo ry is read and

written by user link tables.

• Data for Control, Operation, and External Controller blocks can be read

and written for SCADA software using the HMI function.

Note The CMND instruction can be executed in the ladder program in the CPU Unit

to send FINS commands to the Loop Controller to read and write function

block data.

3

Page 36

Outline Section 1-1

Loop Control Boards Loop Control Boards (CS1W-LCB01 and CS1W-LCB05) are classified as CS-

series Inner Boards. The CS1W-LCB01 and CS1W-LCB05 Loop Control

Boards must be mounted in a CS1-H CPU Unit. (They will not operate and

cannot be used in a CS1 CPU Unit.)

Loop Control Boards before version 1.5 cannot be used with CS1D-CPU@@S

CS1D CPU Units for Single-CPU Systems.

The following table shows available Loop Control Board models.

Model Mountable

PLCs

CS1W-LCB01 CS1-H CPU

CS1W-LCB05 500 blocks max. Supported 200 blocks max.

Units

Duplex Mode Number of control

and operation blocks

Not supported 50 blocks max. Not supported 20 blocks max.

Sequence tables

(See note.)

Step Ladder

Programs (See note.)

Note Sequence tables and Step Ladder Programs cannot be used simultaneously.

Process-control CPU

Units

The Process-control CPU Unit (CS1D-CPU@@P) is a CS1D CPU Unit for

CS1D Duplex Systems. It consists at a Duplex Loop Control Board mounted

in a CS1D CPU Unit. The Duplex Loop Control Board cannot be purchased as

separate products. The Board is sold only when mounted in a CS1D CPU Unit

as a set called the CS1D-CPU@@P Process-control CPU Unit.

The Duplex Loop Control Boards (Inner Boards) included with Process-control CPU Units cannot be removed and mounted in other CS1D CPU Units.

Note For duplex operation, always use two CS1D Process-control CPU Units of the

same model mounted to a CPU Duplex Backplane.

The following table shows available Process-control CPU Units models.

Model Duplex

Mode

CS1D-CPU65P Supported 500 blocks max. Supported 200 blocks max. Select the CS1D-CPU65H as the

CS1D-CPU67P Select the CS1D-CPU67H as the

Number of

control and

operation blocks

Sequence

tables (See

note.)

Step Ladder

Programs (See

note.)

Remarks

PLC type from the Programming

Device.

CPU Unit program capacity:

60 Kwords

PLC type from the Programming

Device.

CPU Unit program capacity:

250 Kwords

Note Sequence tables and Step Ladder Programs cannot be used simultaneously.

Unlike Loop Control Boards (CS1W-LCB01 or CS1W-LCB05), the Processcontrol CPU Units have the following restrictions.

• External Controller Terminal Blocks (Block Model 045) are not supported.

• The operation cycle for function blocks and the refresh cycle for user link

tables cannot be set to 0.01, 0.02, or 0.05 seconds.

• The minimum operation cycle for function blocks is 5 times the cycle time

of the mounted CS1D CPU Unit and must be set to 0.1, 0.2, 0.5, 1, or

2 seconds.

4

Page 37

Outline Section 1-1

Loop-control CPU

Units

Model Block name Number of

CJ1G-CPU42P CJ1G-CPU42H LCB01 50 blocks max. 20 blocks max. Select the CJ1G-

CJ1G-CPU43/44/45P CJ1G-CPU43/44/45H LCB03 300 blocks max. 200 blocks max. Select the CJ1G-

Loop Control Boards are built into the CJ1 CPU. The following table shows

available Loop-control CPU Unit models.

CPU Unit Loop

Controller

component

control and

operation

blocks

Step Ladder

Programs

Remarks

CPU42H as the PLC

type from the

Programming Device.

CPU Unit program

capacity: 60 Kwords

CPU@@H as the PLC

type from the Programming Device.

CPU Unit program

capacity: 250 Kwords

Unlike Loop Control Boards (CS1W-LCB01/05), Loop-control CPU Units have

the following restrictions.

• External Controllers (ES100X Controller Ter minal (Block Model 045)) are

not supported.

• Sequence tables are not supported.

1-1-2 Features

Common Features of

Loop Controllers

High-speed Execution of Function Blocks for Multi-loop Control with an

Operation Cycle of 10 ms

Function blocks are executed at high speed approximately ten times faster

than for the Loop Control Units. For example, with a standard loop containing

an Ai4 Terminal, a Segment Linearizer, a Basic PID, and an Ao4 Terminal

block, 20 loops can be executed in 10 ms (except for the CS1D-CPU@@P).

All Functions Achieved by Using Only Function Blocks (Operation

Functions/Designation of Field Input/Output)

Wiring function blocks in the sof tware allows you to achieve not o nly combinations of operation blocks but also all functions including specification of field

I/O.

Almost All Control T ypes Freel y Achieved b y Combining Function Blocks

In addition to regular PID control, cascade control, feedforward control, dead

time compensation control, override control and other special control types

can be achieved as desired by combining function blocks for up to 250 loops

for the LCB03, LCB05, and LCB05D or 50 loops for the LCB01. Control can

also be easily configured for processes with prolonged dead time, non-linear

processes, and processes involving fluctuating loads. Changes in control type

after start of operation can also be flexibly accommodated.

Function Blocks with High-speed Execution

Operation cycles for control, ope ration, and other function b loc ks can be se t to

10 ms, 20 ms, or 50 ms as well as to longer per iods. The shortest operation

cycle that could be set for Loop Control Units was 100 ms. With faster execution, for example, four loops of PID control can all be executed in a 10-ms

operation cycle.

5

Page 38

Outline Section 1-1

Note Operation cycles of 10 ms, 20 ms, and 50 ms cannot be set for the CS1D-

CPU@@P.

High-speed I/O Refreshing with the CPU Unit Using User Link Tables

User link tables can be set to refresh cycles of 10 ms, 20 ms, or 50 ms, and

the Loop Controller with refresh data with the CPU Unit at the specified cycle.

With this speed, the Loop Controller can quickly (within one cycle time)

refresh contact and analog value s.

Note With the Loop Control Unit, there was a delay of up to 2 cycle times for field

terminal blocks (e.g., Di, Do, Ai, and Ao).

Designate I/O Memory in the CPU Unit Using Registered Tags

User-specified tags and CPU Unit data exchange conditions (such as I/O

memory addresses) can be registered in user link tables on the CX-Process

Tool. The tags registered in a user link table is u sed to pe rform data exchange

with the CPU Unit on the specified refresh cycle. In seque nce tab les and other

function blocks, tags can then be used to specify CPU Unit I/O memory (or bit

or analog I/O values).

User link tables can also be pasted into block diagrams as virtual blocks, or

tags can be automatically registered in the user link table when a field terminal block is pasted.

Note User link tables provide the same type of functionality as expanded CPU ter-

minals do in Loop Control Units. With the previous method, however, it was

necessary to use expanded CPU terminals or CPU terminals to achieve data

exchange with the CPU Unit, ma king it necessary to keep trac k o f I/O memory

addresses in the CPU Unit and function block ITEM numbers in expanded

CPU terminals or CPU terminals.

Execute Sequence or Step-progression Control Using Sequence Tables

(CS1W-LCB05 Only)

In process control, the commonly used sequence control operations are often

written in sequence tables. With a LCB@@, you can select either step ladder

programming, the same method used b y Loop Control Un its , or use sequence

tables, whichever you prefer.

Process progression for step transition (even to other tables), timer/counter

functions, wiring to function block ITEM variables, or comparison operations

using relational expressions are al so supported for sequence tables.

Simulated Software Connections between Function Blocks

CX-Process Tool allows you to simulate wiring between function blocks in the

software by joining lines on your computer's screen.

Specify the Order of Operations in Function Block Diagrams

ITEMs can be set in function blocks in block diagrams to specify the order of

processing control and operation blocks. (Blocks are processed left to right

and then top to bottom by default.) With Loop Control Units, operation blocks

were processed first followed by control blocks in the order of block

addresses.

Easily Create a SCADA Interface with the HMI Function

Space for HMI data for control, operation, and external controller blocks is

automatically allocated in the specified bank of the EM area. The bank number is specified in the System Common block.

With SCADA software, the HMI data in the control, operation, and external

controller blocks can be read and written by specifying the CSV tags.

6

Page 39

Outline Section 1-1

Note The HMI functions corresponds to the Receive All (Block Model 461) and

Send All (Block Model 462) blocks in the Loop Control Units.

It is also possible to add tags from the user link table as CSV tags following

the HMI tags. Doing so enables using User Link Table tags from the SCADA

software to read and write CPU Unit I/O memory.

Connect ES100X Controllers Externally (CS1W-LCB01/05 Only)

ES100X Controllers can be connected to the RS-232C port on the Loop Controller and ES100X Exter nal Controller Ter minal function blocks can be used

to monitor ES100X parameters, such as the SP, PV, and MV, and to set

ES100X parameters, such as the SP and PID constant s . Converting from RS232C to RS-422A/485 enables connecting up to 32 ES100X Controllers.

Message Communications by FINS Commands

Data on each of the function blocks can also be read and written as desired

by issuing FINS commands by the CMND (DELIVER COMMAND) command

in the Step Ladder Program on the CPU Unit or by issuing FINS commands

from the host computer . Functi on bl ock da ta can also be r ead and written from

PLCs (CPU Units) on other networked nodes.

Process-control CPU

Unit Features (CS1DCPU@@P Only)

Note When using a Process-control CPU Unit (CS1D-CPU@@P), the function block

Duplex Systems

In a duplex system with two CS1D Process-control CPU Units, the Processcontrol CPU Unit (CS1D-CPU@@P) will continue to operate even if a fatal

Inner Board error occurs in the Loop Controller of one Process-control CPU

Unit. The system will switch to the Loop Controller of the other Process-control CPU Unit and Loop Controller operation (loop control) will continue. Furthermore, when the cause of the error is removed, the Loop Controllers will

automatically reset to the original duplex operation status, just like duplex

CPU Units. This makes the Loop Controllers of Process-control CPU Units

suitable for 24-hour continuous operation systems.

operation cycle must be a minimum of 5 times the CS1D CPU Unit cycle time

and also must be set to either 100 ms, 200 ms, 500 ms, 1 s, or 2 s.

1-1-3 LCB01/05 Version 1.5 Upgrade Information

The following funct ions have been added to the LCB01/05 with the upgrade to

version 1.5.

Change Sequences during

Sequence Execution

(Supported by CX-Process

Tool Version 3.2 or Higher)

When validating sequence tables, sequence tables can be edited online while

the Loop Controller and sequence tables are operating. Sequence table operation continues even after the sequence tables have been edited online and

downloaded.

To perform this function, select Edit - Start from the Sequence Table Action

Validation Screen, and after editing the table, select Edit - Download.

Note Previously, sequence tables could be downloaded one at a time while the

Display PVs and Change

SPs for Timers and

Counters in Sequence

Tables

(Supported by CX-Process

Tool Version 3.2 or Higher)

Loop Controller was operating. After downloading, however, the tables would

be executed from step 1. As a result, operation did not continue during the

time the tables were downloading.

When validating sequence tables, the present values of eleme nts (timer s and

counters) are displayed. The set values for the elements (timers, counters)

can also be changed during operation of the Loop Controller and sequence

tables.

7

Page 40

Outline Section 1-1

PID Constant Bank

Selector Block

(Block Model 168)

Split Converter Block

(Block Model 169)

The PID constant bank selection function supported by OMRON Thermac Rseries Temperature Controllers can now be used simply with PLCs. The Bank

Selector block (Block Model 168) is used together with the Basic PID block

(Block Model 011), Advanced PID block (Block Model 012), or Blended PID

block (Block Model 013).

Up to 8 sets (bank numbers 1 to 8) can be r ecorded f or ea ch of the P, I, D , MH,

ML, and local SP values. The bank numbers can be switched and the

recorded bank data can be written all at once to the P, I, D, MH, ML, and local

SP values in the Basic PID or Advanced PID block at the connection destination, according to the analog input range or the ON status of input bits 1 to 8.

The autotuning results of Basic PID and Advanced PID blocks can also be

reflected in the PID setting for the current bank.

The Split Conver ter block (Block Model 169) is used in combination with the

Basic PID block (Block Model 011) or Advanced PID block (Block Model 012).

The MV output value is converted into two analog outputs f or V characteristics

or parallel characteristics (e.g., MV f or heatin g and MV f or cooling) and outpu t.

Both a heating side PID SP and coolin g side PID SP are provided, and the

PID block SP at the MV connection source can be changed according to

whether the output is for heating or cooling. Conversely, autotuning results for

the PID blocks can also be reflected in either the PID constant for heating or

cooling.

This block simplifies cont inuous pro portional control fo r heating/coo ling, which

previously needed to be combined with segment approximation.

Disturbance Overshooting

Suppression

Note This function is disabled during autotuning, while changing the target value

MV Limit Alarm Stop

Switch

MV Error Control Stop

Switch

Calculate High Speeds

with Ramped Switch

(Block Model 167)

A disturbance overshooting suppression function has been added for the

Basic PID block (Block Model 011) and Advanced PID block (Block Model

012). Therefore, the influence of disturbance can be suppressed in applications that require high-speed response control, in particular (such as ceramic

heater control, flowrate control, and pressure control).

When disturbance overshooting suppression is enabled, the influence of disturbance can be suppressed by setting the characteristics for disturbance

(disturbance gain and time constant of disturbance) that enters the control

system. Once the error has entered the disturbance stabilization zone (error

considered to be stabilized), the disturbance overshooting control function is

automatically started if the disturbance width is exceeded.

(changing width exceeding the disturbance stabilization band), and during PD

control.

In Control blocks, such as Basic PID, even if the MV reaches the MV upper or

lower limit when the MV Limit Alarm Stop Switch turns ON, the MV Upper

Limit Flag or MV Lower Limit Flag is disabled and will not be set to ON. (The

MV limit will operate, however.).

In Control blocks, such as Basic PID, the MV Error Control Stop Switch turn s

ON when an MV error occurs at the MV output value before MV traceback,

and the MV is maintained.

The calculation cycle for the Ramped Switch (Block Model 167) can be specified as 0.01 s, 0.02 s, or 0.05 s.

8

Page 41

Outline Section 1-1

1-1-4 LCB01/05 Version 2.0 Upgrade Information

Simple Memory Card

Backup for Function

Block Data

Tag Settings,

Comments, and User

Link Table

Connection Data

LCB01/05 Version 2.0 is supported by the easy backup function for data for

specified Units and Boards of the CS1-H CPU Unit. The function block data in

Loop Control Board RAM can be easily backed up in the same ways as data

from Motion Control Units, Position Control Units, and DeviceNet Units.

The simple backup function can back up, recover, and verify all PLC data,

including data for Loop Control Boards. This simplifies the task of replacing

damaged Boards or making co pies of entire PL C-based proces s control systems.

The tag settings, comments , an d user link tab le conne ction data creat ed using

the CX-Process Tool can be b acked up on PLC Memory Card. This means

that tag data and other settings do not have to be reset when it is uploaded

from PLC Memory Card using the CX-Process Tool.

Back Up

Enhanced Segment Program 2 (Block Model 157)

First or Second Refer ence

Input Match for Program

Start

Note An error occurred with the original function if there was no match. With the

With the previous version of the reference input function, Y1 was output starting from the first set value that matched reference input X1. The enhanced

version offers a choice so you can specify whether to start from the first or

second set value that matches the reference input.

enhanced function, the progra m can be sta rted from B0 (def ault settin g) when

there is no match.

Synchronized Segment

Programs

Hot Start Enabled

Time Setting

A Segment Program (Block Model 156) was used originally to synchronize