Series

Programmable Controllers

CJ1G-CPU P Loop-control CPU Unit

Unit Version 3.5 (Version Upgrade)

CJ1 Special I/O Units

Process Analog Input Units

(Isolated Units with Fully Universal Inputs)

CJ1W-PH41U (High-resolution Unit) and CJ1W-AD04U (General-purpose Unit)

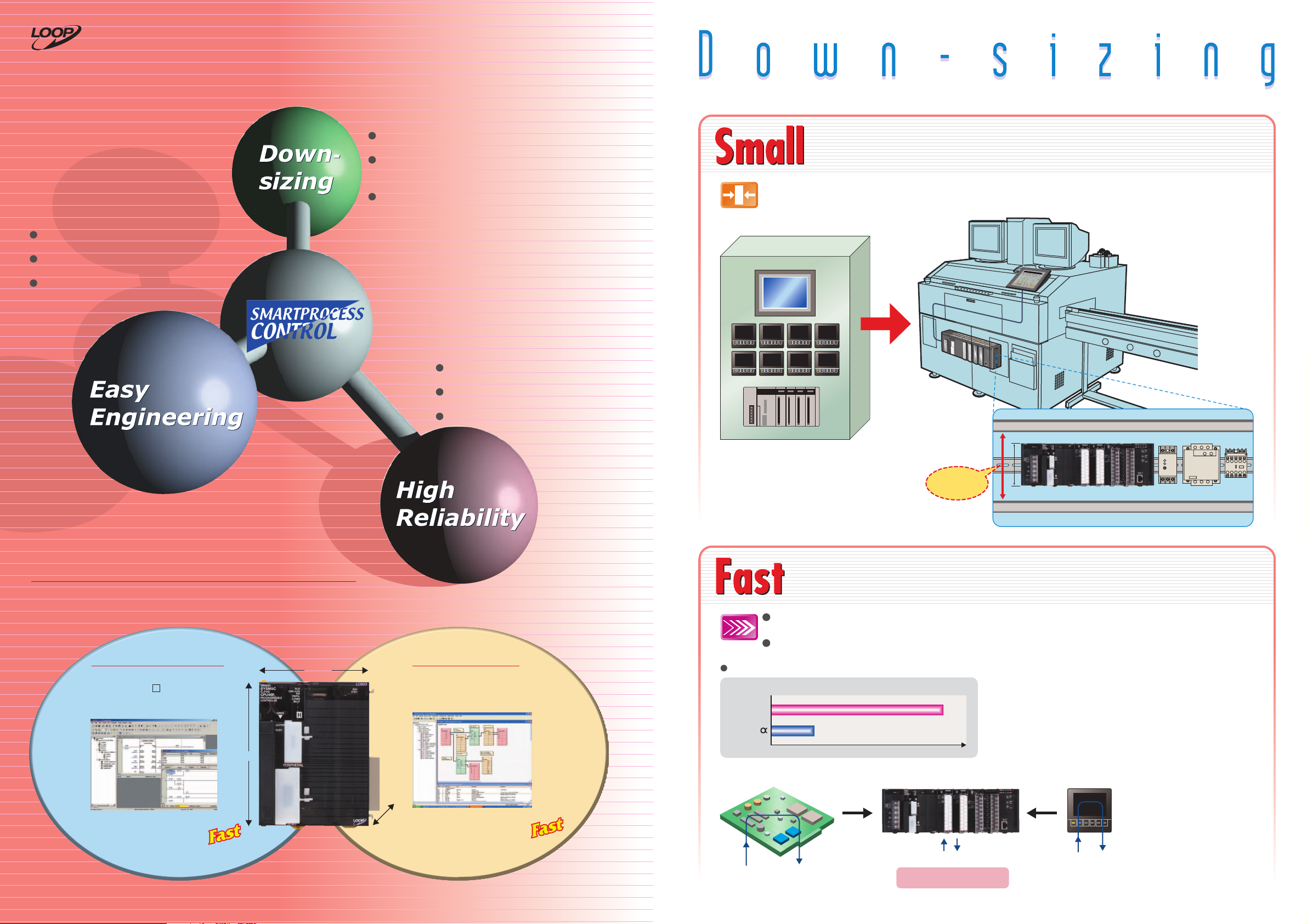

Fully Integrated Sequence and Loop Control

New Built-in Loop Controller

Introducing the New Style of Loop Control

Advanced controller functions integrated with the same CJ-series

functionality and high-speed capabilities

Function block programming for

easy engineering

Seamless integration of sequence

control and loop control.

HMI windows can be simply

generated from function blocks

automatically.

Ultra-small size fits in most

devices

Backplane-free structure provides

the functions you need in

minimum space.

Low-cost solution for controlling

multiple loops

Control functions have the added

ability to control multiple loops.

Consolidating the proven CSseries loop-control technology

Effective maintenance functions

Super compact: Only 90 mm High and 65 mm Deep, and

Backplane-free structure enables flexible width design.

Compact PLC Aids Machine Downsizing by Fitting Just About Anywhere.

Wide Array of I/O Units, Special I/O Units, and CPU Bus Units Are Available to Suit Your Application.

Duct

90 mm high

Power supply SSR Contactor

Integrated Loop Control and Sequence Control

An engine for controlling analog quantities (e.g., temperature, pressure, flowrate) is built into the CPU Unit together

with the engine for executing sequence control, delivering high-speed sequence control and high-speed, advanced

analog quantity control in a single Unit.

Sequence Control Engine Loop Control Engine

CPU Unit element:

CJ1G-CPU4 H

CX-Programmer sequence control program

(ladder, function block, structured text)

90 mm

69 mm

Loop Controller Element:

Up to 300 or 50 function blocks

CX-Process loop control program (function blocks)

Sequencing

PCMIX Values

CJ1G

SYSMAC

Greatly

reduces space

between ducts

Duct

S82K G3J J7AN

High-speed sequence control functions can be used directly for

high-speed, advanced loop control.

Sequence control: Executes 20-Kstep ladder programs in 1 ms (with basic instructions only).

PCMIX = 7.4 LD or OUT executed in 40 ns

Loop control: Executes PID operations for 20 loops in up to 10 ms. This is a guide for general

1.4

(See note.)

Note: Loop configuration: Ai4 Terminal + Segment Linearizer + Basic PID + Ao4 Terminal

The external I/O response time in the overall system refers to the conversion time.

7.4

SYSMAC CJ-series PLCDedicated microcomputer board

Digital Controller

applications.

Execute 20-Kstep ladder

programs in 1 ms

Note: Basic instructions only

20-Kstep

1 ms

(See note.)

D: 65 mm

Loop-control

CPU Unit

2

Execute PID Control for

20 Loops 10 ms

20 Loops in 10 ms

Note: General application (e.g., loop

configuration: Ai4 Terminal + Segment

Linearizer + Basic PID + Ao4 Terminal)

(See note.)

High-speed processing

(Example: 1-ms response)

The same level of high-speed processing

Only One CPU Unit Needed

High-speed processing

(Example: 50 ms)

3

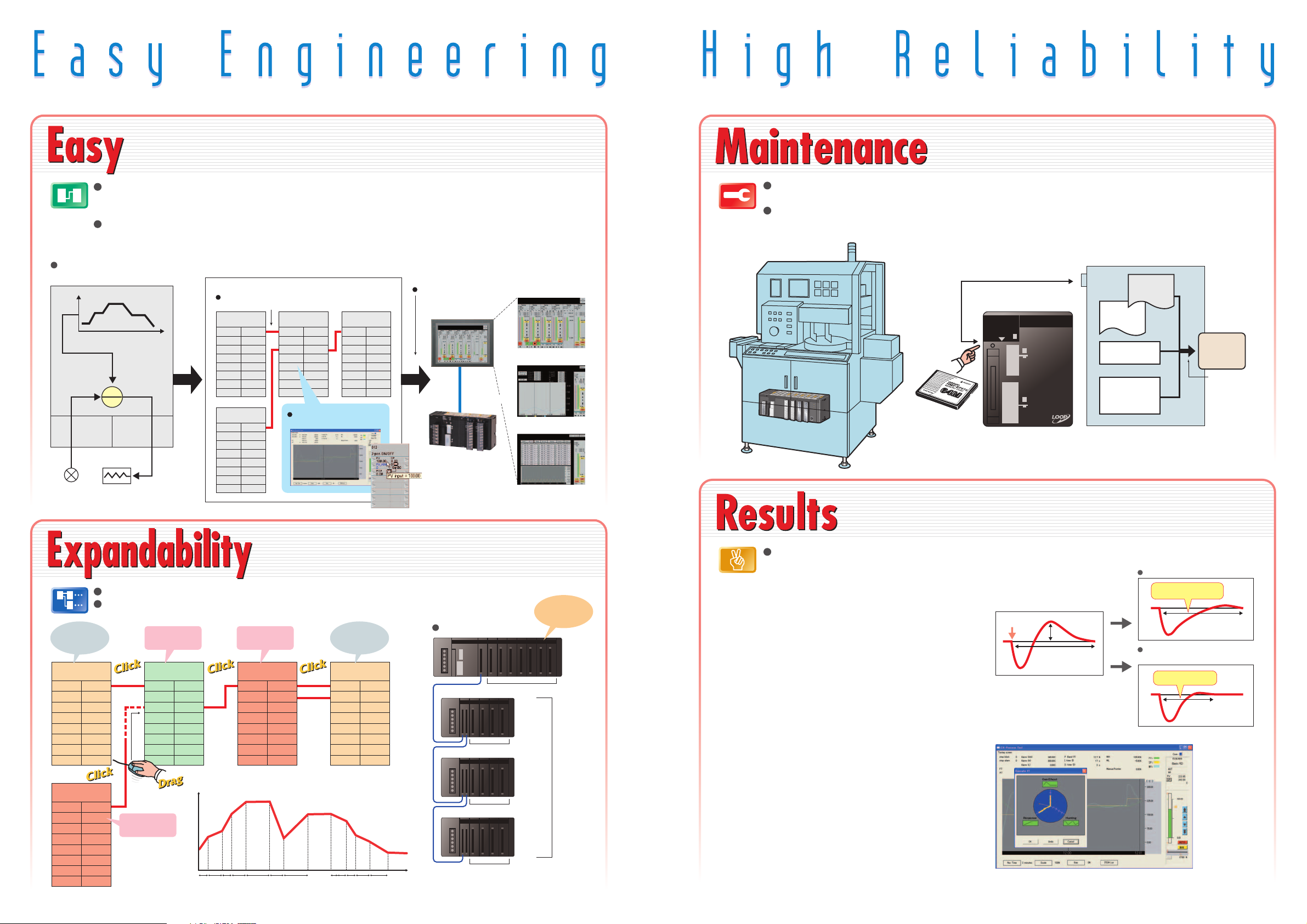

Function blocks make loop-control programming easy. You can also create

CX-Process Tool tuning windows to help adjust loops. Controller faceplates

can be created automatically for touch panel displays.

Simply turn the DIP Switch ON/OFF to save or read the

user program including function blocks using the

Memory Card.

Engineering Example: Program Control

Loop-control CPU Unit

SP

Analog

Input

Unit

Input

channel 1

Temperature

input

Read data from

Analog Input

Units

Analog Input

Field Terminal

Segment

Program 2

X1

4

Sequence control programs: Standardize and simplify programs using structured programming. Special I/O

Unit and CPU Bus Unit settings are easy with function blocks (using ladder programming language or

structured text).

Loop control programs: By combining function blocks, a wide array of control methods can be easily

configured, from basic PID control used by Temperature Controllers to program, cascade, and feed-forward

control. Easily display values, such as temperatures, in engineering units, allowing you to check operation.

Face Plate Auto-Builder for NS

3

Touch panel windows are automatically generated.

NT-series PT

Control window

Serial or

Ethernet

communications

Tuning window

Loop-control CPU Unit

Segment program

parameter setting window

RSP

PV

MV

TIC

Analog

Output

Unit

Output

channel 1

Heater output

Time

CX-Process Tool (Software for Personal Computer)

1

Combine function blocks and connect graphically

using the mouse.

Analog Input

Field Terminal

Y1

Y2

Y3

Y4

Segment

Program

Y1

Basic PID

PV

RSP

MV

2

Adjust PID and other parameters

in the tuning window.

Analog Output

Field Terminal

X1

X2

X3

X4

Lineup includes low-cost models that use up to 50 function

blocks and models that allow up to 300 blocks designed for

large-scale systems and complicated operations.

Loop control: Programming with function blocks to suit the application.

System configuration: Choose and combine functions from a broad selection of I/O Units.

System Configuration

Expansion Rack

Expansion Rack

Expansion Rack

Note: CJ1G-CPU44P/45P

(CJ1G-CPU42P/43P: Expand up to 2 Racks)

10 Units max.

10 Units max.

10 Units max.

10 Units max.

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

Y1

Y2

Perform PID

control

Basic PID

PV

RSP

Perform program

control

Perform

heating/cooling

control

Split Conversion

SP

DV

MV

Set point (SP)

T0 T1 T2 T3 T4 T5 T6 T97 T98 T99 T100 TIME

Y1X1

Y2

Control output

from Analog

Output Unit

Analog Output

Field Terminal

X1

X2

X3

X4

X5

X6

X7

X8

Process Input

Units, Analog

I/O Units, etc.

Expansion

Rack: 3

Racks

max.

(See note.)

Simple backup function enables backup, recovery, and comparison of all PLC data including the

function block programs for the Loop Control Board using the Memory Card.

Save tag settings, comments, annotations, and connection data created using the CX-Process

Tool to either a Memory Card or a Loop-control CPU Unit.

Press the

Memory Card

power supply

switch for 3 s.

Consolidating OMRON's expertise in temperature and process control

cultivated over many years to provide you with effortless solutions

using proven algorithms.

Loop control: Proven functionality of Temperature Controllers and CS-series Loop Control

Boards (see note 1) in a compact size.

New Algorithm Further Enhances Control

Stability

Disturbance Overshoot Adjustment

This function restrains overshoot when a disturbance is

generated, allowing faster stabilization.

[Example]

• Temperature drops when adding objects to a furnace

• Control disturbances when retooling

Optimum Tuning to Suit the Application

Fine Tuning

Adjust PVs, SPs, and MVs while monitoring, and save

data as CSV files from the software tuning window.

Autotuning (AT) and fine-tuning functions can also be

used for automatically calculating PID constants (see note

2).

Note 1: For details on CS-series Loop Control Boards, refer to the PLC-based

Process Control Catalog (Cat. No. P051).

2: Control can be fine-tuned by automatically tuning PID parameters using

previous control parameters and three user-set requirements to execute

fuzzy logic.

Note: Supported by unit version 3.0 or later.

CPU Unit

Parameter Area

Condition: Pin 7 is ON

Disturbance generated

Disturbance

Overshoot

Time required to

stabilize

CS-Process Tool Tuning Window

Sequence

program

I/O memory

Function

block

program

Memory

Card

Simple backup

to Memory

Card, including

function block

data.

Conventional PID gain adjustment

Longer time required

to stabilize

Using the Disturbance

Overshoot Adjustment function

Faster stabilization

5

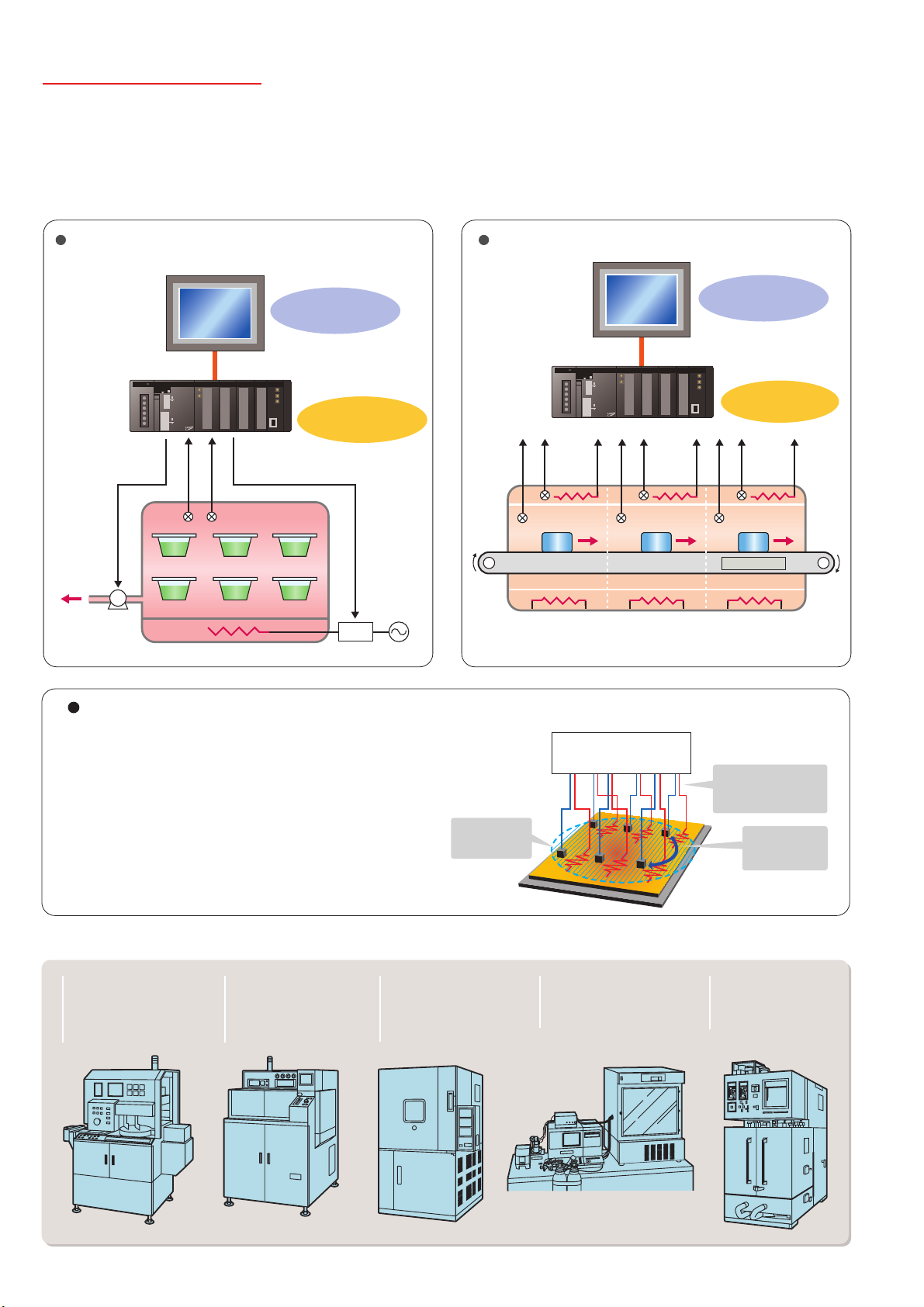

Applications

The Loop-control CPU Unit Provides You with Solutions for the Complex and Advanced

Functions Demanded by Control Devices in an Increasingly Diverse Range of Equipment.

Sterilization and Disinfection of

Pharmaceuticals, Food and Beverages

NS-series PT

Logging Trend Data

(monitoring and operation

windows)

Loop-control CPU Unit

Program pattern

Control outputsControl outputs

Pressure

Temperature

Thyristor

control

SCR

Industrial Furnace

NS-series PT

Workpiece

Conveyor

Heater

Temperature

sensor

Monitoring and operation

windows or heaters and

temperature sensors

Loop-control CPU Unit

Cascade control of

tunnel furnace

N2 atmosphere

Solder

Gradient Temperature Control for Planar

Temperature Control Across Multiple Points

Note: CJ1G-CPU45P-GTC only.

Gradient temperature control equalizes the temperatures at

multiple points, providing high-quality heat processing,

reducing energy loss until temperatures stabilize, and saving

labor in adjustments due to interference between heaters.

For details, refer to the SYSMAC CS/CJ Series Controllers for Gradient

Temperature Control Catalog (R141).

Providing Solutions to Other Problems

Electrical parts equipment

requiring high-speed

temperature control for

higher precision and

improved tact time.

Diffusion furnaces that

perform cascade control

of heater temperatures

and internal chamber

temperatures.

Example: Planar Temperature Control of Multi-stage Furnaces,

Wafer and Glass Surface Temperatures, and Other Applications.

Average

temperature

controlled.

Food machines, semiconductor devices and

other machines requiring

multipoint temperature

control.

Gradient temperature

control

Fermentation equipment

requiring temperature,

pressure, flowrate, and pH

control.

CPU: CJ1G-CPU45P-GTC

Interference at other

control output points

suppressed.

Temperature

differences

controlled.

Testing devices that

frequently change

setting conditions and

program settings.

6

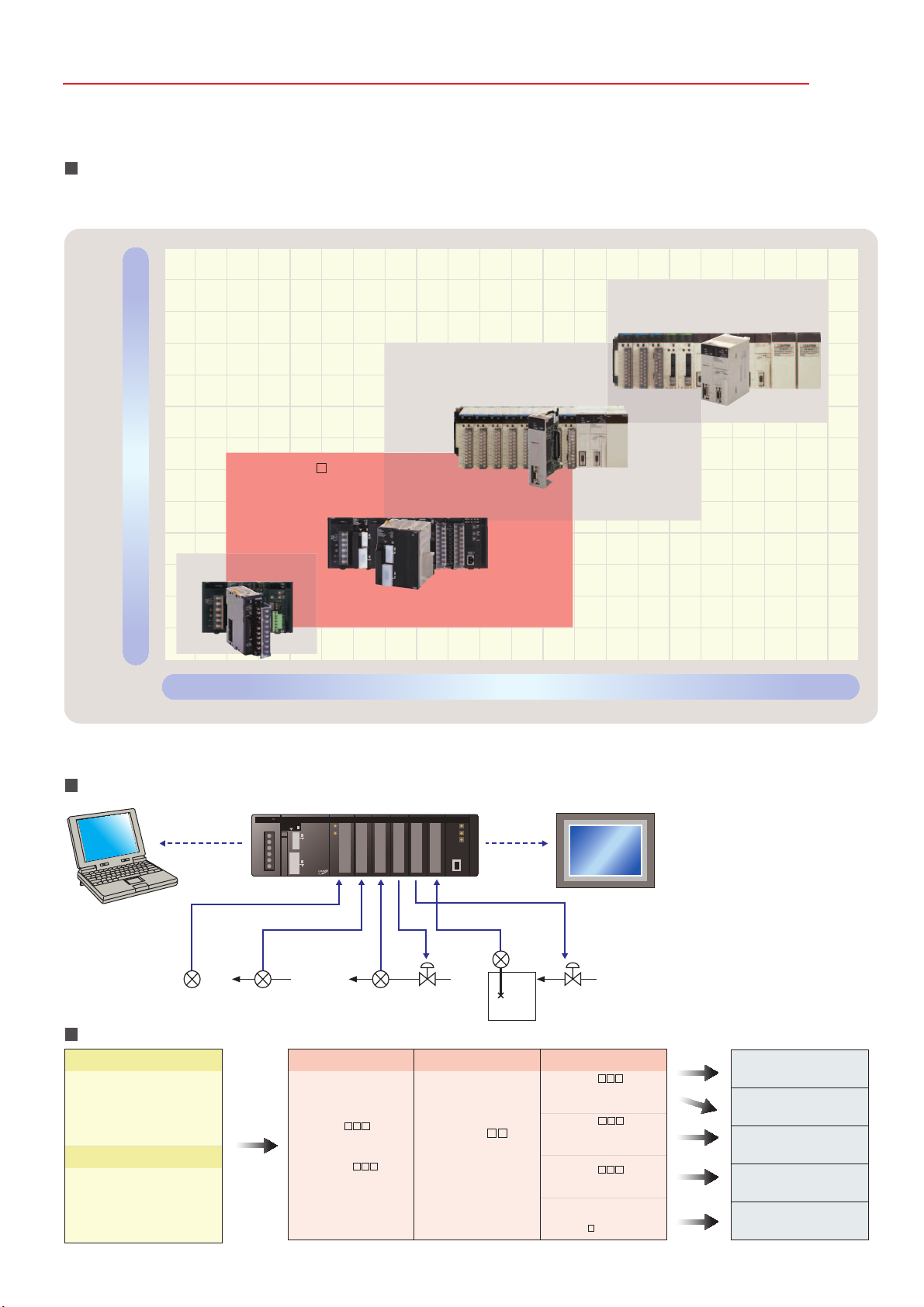

Loop Control Machines and Product Variations

Model Selection

Compact CJ-series Loop-control CPU units are ideal for equipment with built-in applications. CS-series and CS1D

models designed for duplex systems are also available for processing equipment that requires high reliability.

Processing facilities

• Chemical/

pharmaceutical

• Utilities

• DCS replacement

• Water treatment

Etc.

Machinery

• Semi-conductor/

electrical components

• Industrial furnaces

(firing)

• Food machines

(sterilization)

• Testing equipment

Etc.

CJ1G-CPU4 P CJ-series

Loop-control CPU Unit

CJ-series

Temperature Control Unit

See note 1.)

(

CS-series/CS1D-S

Loop Control Board

(See note 2.)

CS1D-series

Process-control CPU Unit

(See note 2.)

• Packaging

machines

• General food

machines

High-speed and highly reliable (duplex)Easy Controlling analog quantities

Note 1: The Temperature Control Unit integrates control and I/O for either 2 loops or 4 loops.

Temperature control is achieved simply by setting parameters. (CX-Process cannot be used.)

2: For details on CS-series Loop Control Boards and Process-control CPU Units, refer to the PLC-based Process Control Catalog (Cat. No. P051).

System Configuration Example

Personal computer for

programming/

monitoring

PLC

4 to 20 mA

20 mA

Sensor Flow Rate Sensor Capacitive

4 to

20 mA

Flow Rate Sensor

Compensating

Conductor

4 to 20 mA4 to

Thermocouple

Process

4 to 20 mA

PT

Example of Peripheral Devices

Temperature Sensors

E52

Thermocouples

Platinum-resistance

Thermometers

Analog quantities (e.g., temperature,

flowrate, concentration)

ES1/ES1B

Infrared Thermosensors

Flow Rate Sensors,

Displacement Sensors,

Signal Converters, etc.

CJ1W-P

Analog Process

Input Unit

CJ1W-AD

Analog Input Unit

CJ1G-CPU P

Loop-control

CPU Unit

SYSMAC CJ Series

OutputControlInput

CJ1W-DA

Analog Output Unit

(linear output)

CJ1W-OD

Transistor Output Unit

(pulse output)

CJ1W-OC

Relay Output Unit

RS-485 communications:

Built-in serial port on CPU Unit

CJ1W-SCU 1-V1

• Position Control

G3PX Power Controller

• Cycle Control

G32A-EA + G3PA

• SSR

G3PA/B/C, G3NA, etc.

• ON/OFF Control

• Optimum Cycle Control

G3ZA

7

Peripheral Devices

Input Devices

Input Devices

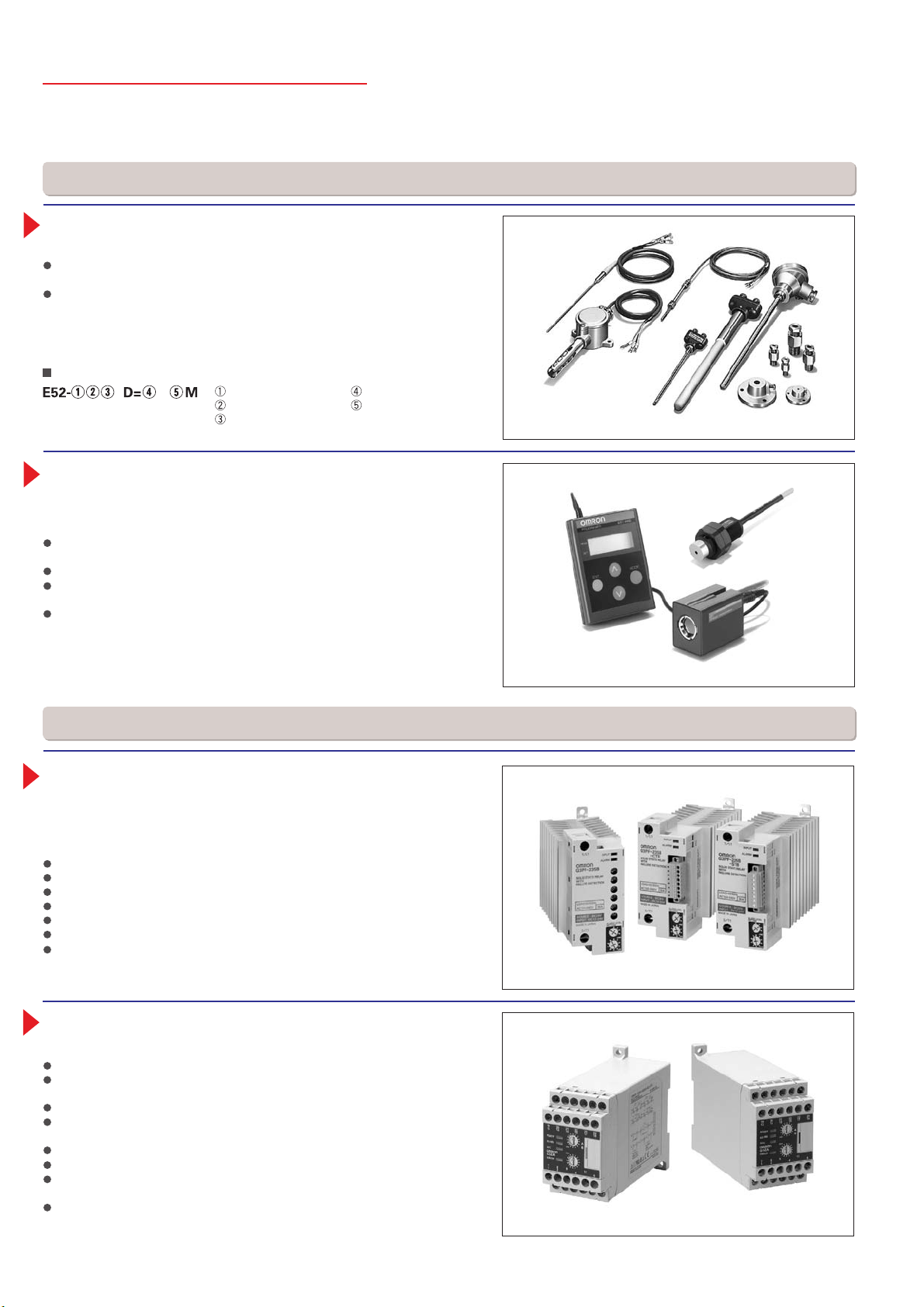

E52-series Temperature Controllers

Plenty of Variation to Suit an Extensive Range of Applications

Select from a variety of choices in number of elements, shape, protective

tubing length, and terminal type.

Economical models and special models are available as well as general purpose models. Select from a diverse range of models to suit the application:

Models for high temperatures, metal patterns, surface measurement, and

room temperatures, waterproof and anti-corrosive models, models for moving

parts, and models with double elements.

Model Structure

Element type

Protective tubing length

Example: E52-CA15A D:3.2 2M

Terminal type

ES1/ES1B-series Infrared Thermosensors

Hygienic temperature measurement without damaging the workpiece. Ideal for

workpieces on conveyors or other applications in which contact measurement is

difficult.

ES1 Series: Designed for high-precision, small-spot, high-temperature

measurements.

Two types of small spot: 3-mm dia. and 8-mm dia.

High-precision and high-speed measurement with a repeatability of ±0.5°C

and response speed of 0.4 s (95%).

Models are available for medium (–500 to 500°C), mid-low (–50 to 500°C),

and high (0 to 1000°C) temperature ranges.

Protective tubing model

Lead wire length

Output Devices

Output Devices

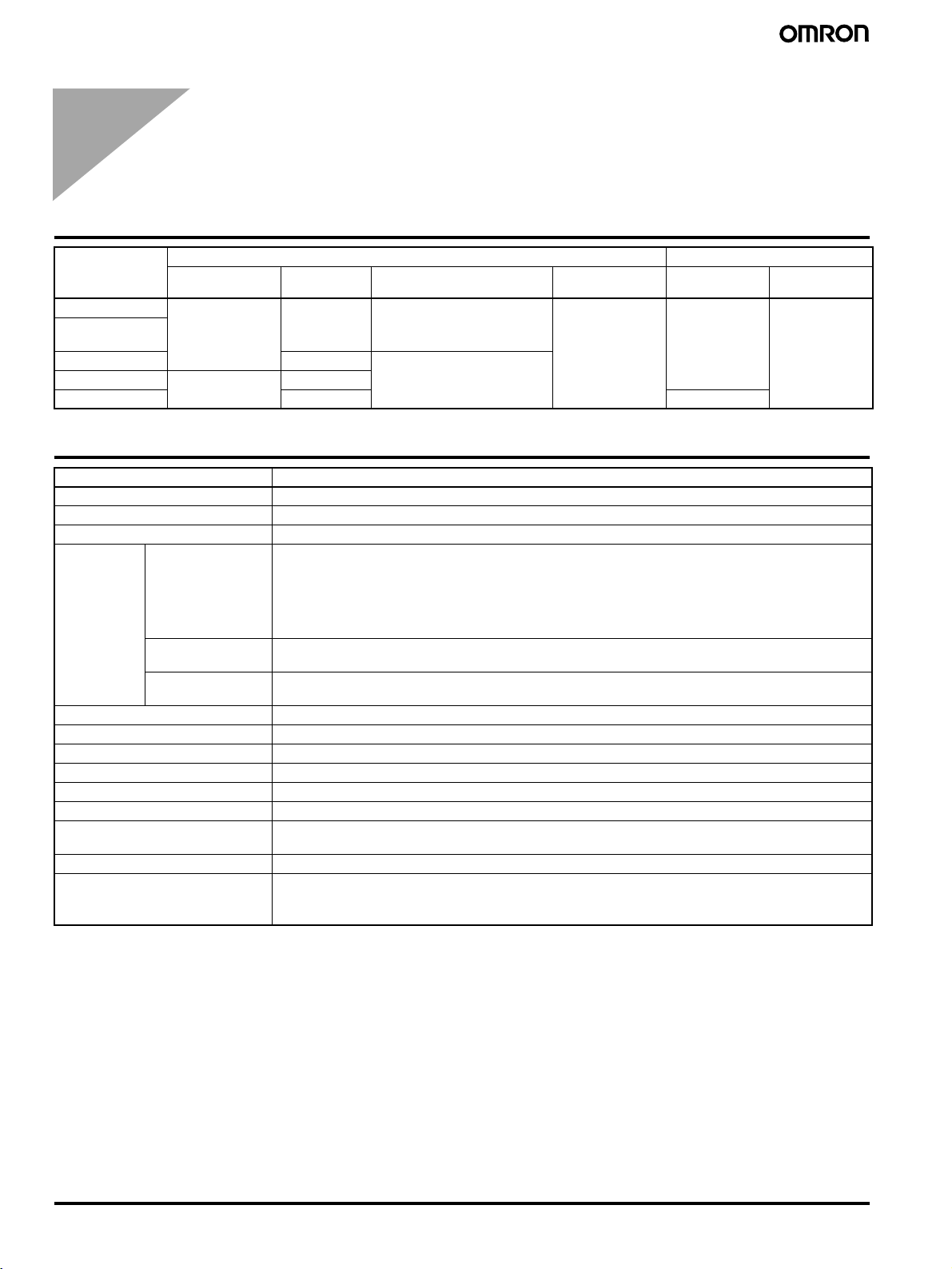

G3PF Solid-state Relay with Built-in

Current Transformer (CT)

Built-in current transformer is provided and heater burnouts and SSR shortcircuits can be detected.

Built-in current transformer reduces wiring work.

Detects the burnout of any one of multiple heaters.

Detects burnouts in 3-phase heaters.

Detects SSR short-circuits.

Error detection level can be easily set with a switch.

Can be mounted to a DIN Track or with screws.

Three types of input terminals are available: M3 terminals, screwless clamp

terminals (detachable), or compact slotted terminals (detachable).

G3ZA Multi-channel Power Controller

Optimum Cycle Control for High-precision Control with Low Noise

Smaller than power conditioners.

Power control with little noise is enabled by combining the Power Controller

with zero-cross SSRs. (See note.)

One Controller can control up to 8 SSRs.

RS-485 communications can be used to set output values and heater burnout

detection.

The G3ZA Smart FB Library is also available.

A soft-start function that can be used for lamp heaters has been added. (See note.)

A 3-phase optimum cycle control function has been added for use with 3-cycle

heaters.

Detection of 150-A currents has been added along with a special current

transformer.

Note: Non-zero-cross SSRs must be used in combination with the soft-start function.

8

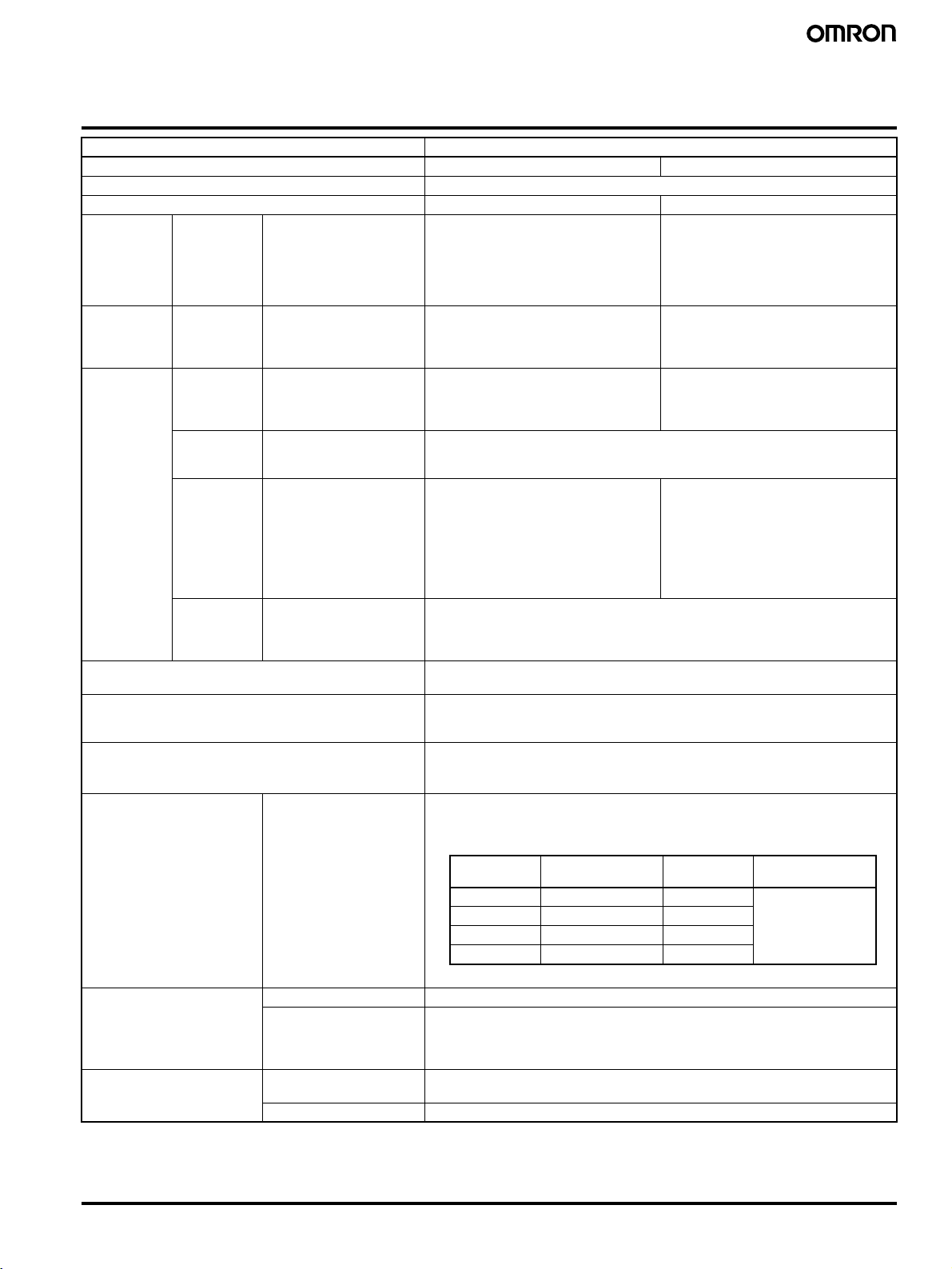

New Products

CJ1W-PH41U Process Analog I/O Unit

(High-resolution Unit with Fully Universal Inputs)

CJ1W-AD04U Process Analog I/O Unit

(General-purpose Unit with Fully Universal Inputs)

A single Unit handles all types of inputs, including

temperature sensor inputs (e.g., thermocouple or

platinum resistance thermometer), analog signal

inputs (e.g., 4 to 20 mA or 1 to 5 V), and

potentiometer inputs.

Fully Universal Inputs, Including Thermocouple

Inputs, Platinum Resistance Thermometer Inputs, and

DC/Voltage Inputs

The input type can be selected for each input channel, saving

space and reducing costs for compact devices that use a mix of

input types. And trouble-free selection of input types improves

inventory control and maintenance.

General-purpose Models for Great Cost Performance

and High-resolution Models for Applications Such as

Semiconductor Production Equipment

These compact CJ-series Units provide four insolated input

channels per Unit. Depending on the application, choose either the

high-resolution CJ1W-PH41U, which provides a selection of

combinations of resolutions and conversion speeds in addition to

a PLC-first 1/1,000°C range (0.000 to 50.000°C, 4-wire Pt100), or the

general-purpose CJ1W-AD04U, which provides superior cost

performance. (See note.)

Note: According to OMRON investigation.

Resolutions and Sampling Speeds for High-resolution Models

Resolution: 1/256,000

60 ms/4 points

Resolution: 1/64,000

10 ms/4 points

Resolution: 1/16,000

5 ms/4 points

9

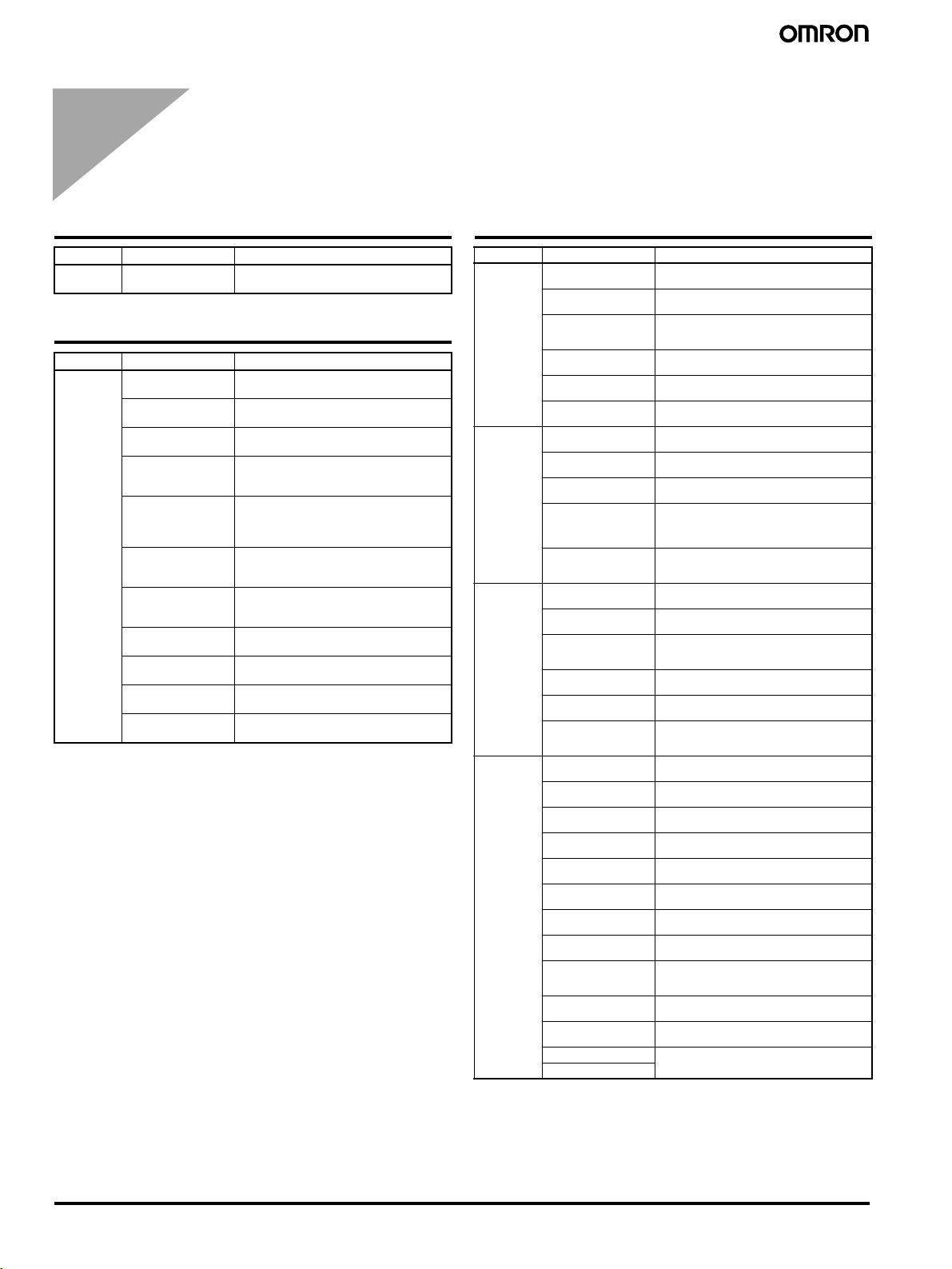

Loop-control CPU Units

Loop-control CPU Units

Loop-control CPU Units

Loop-control CPU Units

Model CPU Unit element Loop Controller

I/O capacity Program

CJ1G-CPU45P 1,280 points

CJ1G-CPU45PGTC

CJ1G-CPU44P 30 Ksteps 64 K words (DM: 32 K words,

CJ1G-CPU43P 960 points (Up to 2

CJ1G-CPU42P 10 Ksteps 50 blocks

(Up to 3 Expansion

Racks)

Expansion Racks)

capacity

60 Ksteps 128 K words (DM: 32 K words,

20 Ksteps

Loop Controller Element Specifications

Item Specification

Name Loop-control CPU Unit

Model Number CJ1G-CPU@@P(-GTC)

Applicable PLCs CJ-series PLCs

Area for data

exchange

with CPU Unit

Settings None

Indicators Two LED indicators: RUN and ready

Super capacitor backup data All function block data (including sequence tables, step ladder program commands), stored error log data

Super capacitor backup time 5 minutes at 25

Data stored in flash memory Function block data

Backup from RAM to flash memory Executed from CX-Process Tool (as required).

Recovery from flash memory to

RAM

Influence on CPU Unit cycle time 0.8 ms max. (depends on function block data contents)

Current consumption (supplied

from Power Supply Unit)

CPU Unit's

Auxiliary Area

User allocations in

I/O Memory

Allocations for all

data

• Loop Controller element-to-CPU Unit element:

Run Status Flag, PV Error Input Flag, MV Error Input Flag, Execution Error Flag, Function Block Database (RAM) Error Flag, Automatic Cold Start Execution Flag, Backup during Operation Flag, Function

Block Changed Flag, etc.

• CPU Unit element-to-Loop Controller element:

Start Mode at Power ON: Hot/Cold Start bit.

User link tables are used to allocate function block ITEM data in any par t of I/O memory in the CPU Unit.

(CIO, Work, Holding, or DM Areas, or EM Area bank 0)

HMI function used to allocate function block ITEM data for Control, Operation, External Controller, and

System Common blocks in the specified bank of the EM Area in the CPU Unit.

Automatically transferred when power to CPU Unit is turned ON if startup mode is set for a cold start, or

executed from CX-Process Tool (as required).

1.06 A for 5 VDC (current consumption for Loop-control CPU Unit including CPU Unit element and Loop

Controller element)

Note: Increased by 150 mA when NT-AL001 Link Adapter is used.

Data memory capacity Programming

EM: 32 K words

EM: 32 K words

°C

× 3 banks)

× 1 bank)

CX-Programmer,

CX-Simulator, etc.

software

Number of

function blocks

300 blocks CX-Process

Programming

software

10

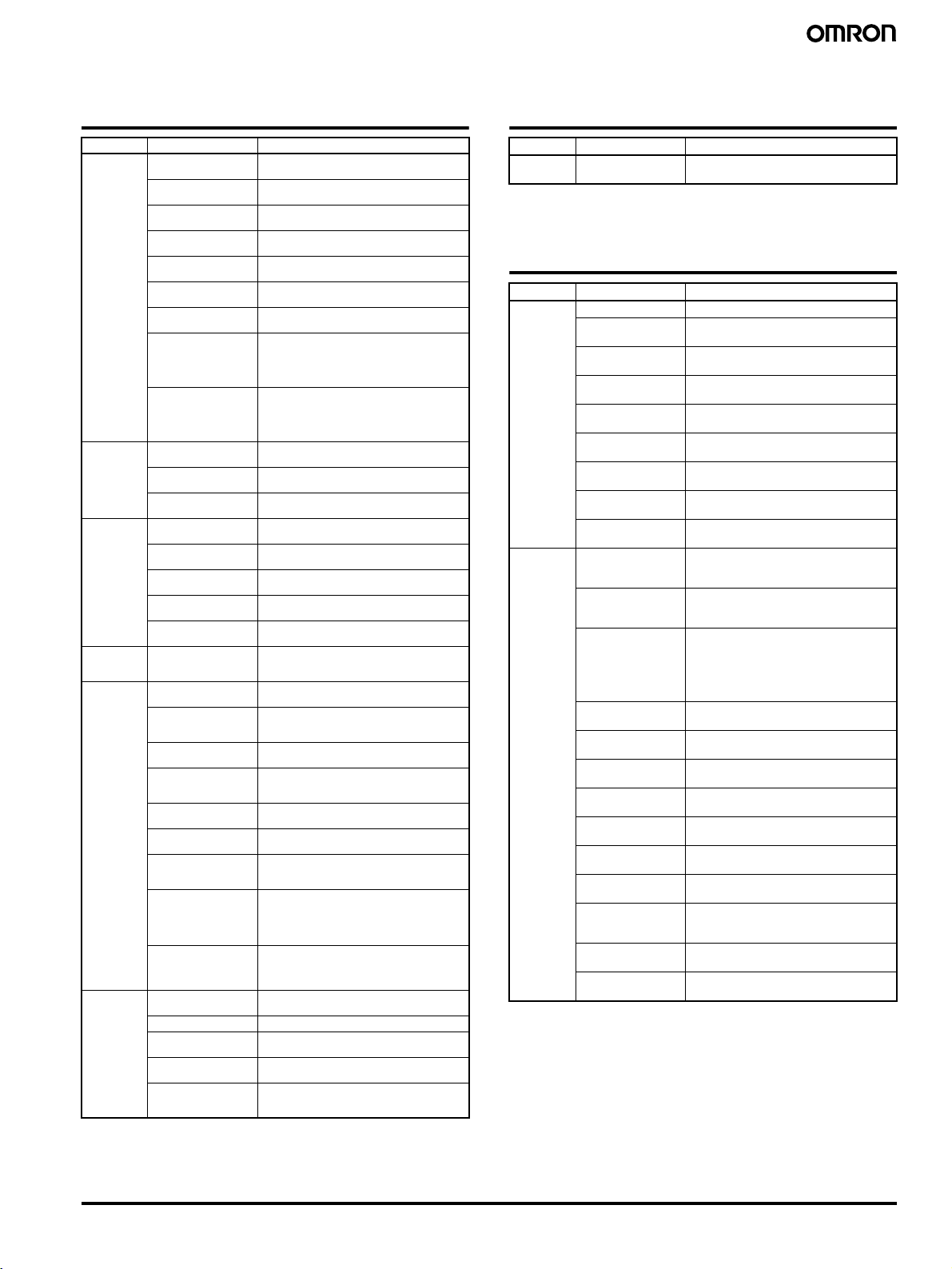

Loop-control CPU Units

Loop Controller Element Specifications

Loop Controller Element Specifications

Item Specifications

Model CJ1G-CPU42P CJ1G-CPU43/44/45P(-GTC)

Operation method Function block method

Loop Controller element LCB01 LCB03

Function

block analog

operations

Sequence

control

I/O blocks Field terminal

Method for creating and transferring function blocks Created using CX-Process Tool (purchased separately) and transferred to Loop

External I/O response time The time from external input of analog signals up to external output of analog signals

Operation cycle 0.01, 0.02, 0.05, 0.1, 0.2, 0.5, 1, or 2 s (default: 1 s) (See note.)

Internal operation Number of control loops • The maximum number of loops that can be used if the LCB load rate is 80% for a

Control and

operation

blocks

Step ladder

program

blocks

blocks

User link

tables

HMI function I/O function for the speci-

System

Common

block

PID and other control

functions, square root operation, time operations,

pulse train operation, and

other operation functions

for various processes.

Logic sequence and step

sequence functions

Analog I/O function with

Analog I/O Unit, contact

I/O function with Basic I/O

Unit

Analog data I/O and contact data I/O function for

CPU Unit

fied bank of the EM Area

in the CPU Unit for function block ITEM data used

for Control, Operation,

External Controller, and

System Common blocks

for the HMI function.

System common operation cycle setting, run/

stop command, load rate

monitor, etc.

50 blocks max. 300 blocks max.

20 blocks max.

2,000 commands total

100 commands max. per block

Separable into 100 steps max.

30 blocks max. CJ1G-CPU43P: 30 blocks max.

2,400 data items max.

Allocated 1 EM Area bank

Operation and Control blocks:

50 blocks max.

System Common blocks:

20 send/receive words

Single block

Controller.

on a single control loop depends on the function block's operation cycle and the

CPU Unit's cycle time.

Can be set for each function block.

Note: 0.01, 0.02, and 0.05 s cannot be set for some blocks.

standard applications (e.g., with each loop consisting of one Ai4 Terminal, Segment Linearizer, Basic PID, and A04 terminal) is shown in the following table.

× 20 send/receive words

200 blocks max.

4,000 commands total

100 commands max. per block

Separable into 100 steps max.

CJ1G-CPU44/45P: 40 blocks max.

Allocated 1 EM Area bank

Operation and Control blocks:

300 blocks max.

System Common blocks:

20 send/receive words

× 20 send/receive words

Operation

cycle

0.01 s 20 loops 0.2 s 150 loops

0.02 s 35 loops (see note) 0.5 s

0.05 s 70 loops (see note) 1 s

0.1 s 100 loops (see note) 2 s

Note: Loop Controller element LCB01: 25 loops max.

Control method PID control method PID with 2 degrees of freedom

Control combinations Any of the following function blocks can be combined:

Basic PID control, cascade control, feed-forward control, sample PI control, Smith

dead time compensation control, PID control with differential gap, override control,

program control, time-proportional control, etc.

Alarms PID block internal alarms 4 PV alarms (upper upper-limit, upper limit, lower limit, lower lower-limit) and 1

deviation alarm per PID block

Alarm blocks High/low alarm blocks, deviation alarm blocks

Maximum number

of loops

Operation

cycle

Maximum number

of loops

(See note.)

11

List of Function Blocks

List of Function Blocks

System Common Block

System Common Block

Type Block Name Function

--- System Common Makes settings common to all function

blocks and outputs signals for the system.

Control Blocks

Type Block Name Function

Controller 2-position ON/OFF

(See note 1.)

3-position ON/OFF

(See note 1.)

Basic PID

(See note 1.)

Advanced PID

(See note 1.)

Blended PID

(See note 2.)

Batch Flowrate

Capture (See note 2.)

Fuzzy Logic

(See note 2.)

Indication and Setting

(See note 1.)

Indication and Operation (See note 1.)

Ratio Setting

(See note 1.)

Indicator

(See note 1.)

Note: 1. The Function Blocks dealing with high-speed operation

(operation cycle: 0.01, 0.02, and 0.05 seconds is possible).

2. Cannot be used with the CJ1G-CPU45P-GTC.

2-position type ON/OFF controller

3-position type ON/OFF controller for

heating/cooling ON/OFF control

Performs basic PID control.

Performs advanced PID control for

enabling deviation/MV compensation,

MV tracking, etc.

Performs PID control on the cumulative

value (cumulative deviation) between the

accumulated value PV and accumulated

value Remote Set Point.

Functions to open the valve at a fixed opening until a fixed batch accumulated value is

reached.

Outputs up to 2 analog outputs based on

fuzzy logic performed on up to 8 analog

inputs.

Manual setter with PV indication and SP

setting functions

Manual setter with PV indication and MV

setting functions

Ratio and bias setter w ith PV indication and

ratio setting function

PV indicator with PV alarm

Operation Blocks

Type Block Name Function

Alarm/Signal

restrictions/

Hold

Arithmetic Addition or Subtraction

Functions Square Root

Time Function First-order Lag

High/Low Alarm

(See note 1.)

Deviation Alarm

(See note 1.)

Rate-of-change Operation and Alarm

(See note 1.)

High/Low Limit

(See note 1.)

Deviation Limit

(See note 1.)

Analog Signal Hold

(See note 1.)

(See note 1.)

Multiplication

(See note 1.)

Division (See note 1.) Performs division with gain and bias on up to 2

Arithmetic Operation

(See note 1.)

Range Conversion

(See note 1.)

(See note 1.)

Absolute Value

(See note 1.)

Non-linear Gain

(Dead Band)

(See note 1.)

Low-end Cutout

(See note 1.)

Segment Linearizer

(See note 1.)

Temperature and

Pressure Correction

(See note 1.)

(See note 1.)

Rate-of-change Limit

(See note 1.)

Moving Average

(See note. 1)

Lead/Delay (See note 1.) Performs lead/delay operation on single analog

Dead Time (See note 1.) Performs dead time and first-order lag operations

Dead Time Compensation

Accumulator for instantaneous value input

Run Time Accumulator Accumulates the operating time, and outputs the

Time Sequence Data

Statistics (See note 1.)

Ramp Program Ramp program setter for combining ramps for time

Segment Program Segment program setter setting the output values

Segment Program 2 Segment program setting with wait function for

Segment Program 3

Provides the alarm contact outputs for the high

and low limits of single analog signals.

Provides the alarm contact outputs for the deviation of two analog signals.

Provides the alarm contact outputs for the high

and low limits of rate-of-change operation when

the analog signal rate-of-change is output.

Limits the high and low limits of single analog

signals.

Calculates the deviation between two analog

signals, and limits the deviation within that range.

Holds the maximum, minimum or instantaneous

value of single analog signals.

Performs addition/subtraction with gain and bias

on up to 4 analog signals.

Performs multiplication with gain and bias on up to

2 analog signals.

analog signals.

Performs various math operation (trigonometric,

logarithmic, etc.) on floating-point decimal values

converted (to industrial units) from up to 8 analog

inputs.

Easily converts up to 8 analog signals simply by

inputting the 0% and 100% input values and 0%

and 100% output values.

Performs square root extraction (with low end

cutout) on single analog signals.

Outputs the absolute value of single analog signals.

Performs non-linear (3 gain values) operation on

single analog signals. Analog signals can also set

as a dead band (with different gap).

Sets output to zero close to the zero point of single

analog signals.

Converts single analog signals to 15 segments

before the signals are output.

Performs temperature and pressure correction.

Performs first-order lag operation on single analog

signals.

Performs rate-of-change restriction on single

analog signals.

Performs moving average operation on single

analog signals.

signals.

on single analog signals.

Used for Smith's dead time compensation PID

control.

Accumulates analog signals, and outputs 8-digit

accumulated value signals.

pulse signal per specified time.

Records time sequence data from analog signals

and calculates statistics, such as averages and

standard deviations.

and hold values.

with respect to time.

setting the output values with respect to time.

12

List of Function Blocks

Sequence Control

Type Block Name Function

Signal Selection/Switching

Constant

ITEM Setting

Pulse Train

Operation

Others Analog/Pulse Width

Sequence

Operation

Contact Type

Control Target

Rank Selector

(See note 1.)

Input Selector

(See note 1.)

3-input Selector

(See note 1.)

3-output Selector

(See note 1.)

Constant Selector

(See note 1.)

Constant Generator

(See note 1.)

Ramped Switch Switches two analog inputs (or constants) with a

Bank Selector Records the PID parameters (SP, P, I, D, MH, ML)

Split Converter Inputs the MV from the Basic PID block or Ad-

Constant ITEM Setting

(See note 1.)

Variable ITEM Setting

(See note 1.)

Batch Data Collector

(See note 1.)

Accumulated Value Input Adder

Accumulated Value Analog Multiplier

Accumulator for accumulated value input

Contact input/Accumulated value output

Accumulated Value Input/Contact Output

Converter (See note 1.)

Contact Distributor Connect contact signals between function blocks

Constant Comparator

(See note 1.)

Variable Comparator

(See note 1.)

Timer (See note 1.) 2-stage output type addition timer for forecast

ON/OFF Timer

(See note 1.)

Clock Pulse

(See note 1.)

Counter (See note 1.) 2-stage output type addition timer for forecast

Internal Switch

(See note 1.)

Level Check

(See note 1.)

ON/OFF Valve Manipulator

Motor Manipulator Manipulates and monitors motor operation.

Reversible Motor Manipulator

Motor Opening Manipulator

Switch Meter

(See note 2.)

Selects the rank of up to 8 analog signals.

Selects the specified analog signals specified by

the contact signal from up to 8 analog signals.

Selects and outputs one of three analog input

signals.

Outputs one analog input signal in three switched

directions.

Selects 8 preset constants by the contact signal.

Outputs 8 independent constants.

ramp.

in up to 8 sets in advance, and switches the PID

parameter for Basic/Advanced/Blended PID

Blocks according to the analog input range

(zone) or input bits.

vanced PID block, converts the MV into two

analog outputs for V characteristics or parallel

characteristics (e.g., MV for heating or cooling)

and outputs them.

Writes the constant to the specified ITEM at the

rising edge of the send command contact.

Writes the analog signal to the specified ITEM at

the rising edge of the send command contact.

Stores each of max. 8 analog inputs to buffer by

a certain timing within sequential processing.

Adds up to four accumulated value signals.

Multiplies analog signals by the accumulated

value signals.

Converts 4-digit accumulated value signals to 8

digits.

Counts low-speed contact pulses, and outputs

8-digit accumulated signals.

Converts 4-digit accumulated value signals to

low-speed contact pulses before they are output.

Changes the ON/OFF duration ratio in a constant

cycle duration so that it is proportional to the

analog signal.

in a 1:1 connection.

Compares up to eight sets of analog signals and

constants, and outputs the comparison results as

contacts.

Compares up to eight pairs of analog signals,

and outputs the comparison results as contacts.

values and reached values. Can also output the

present value.

Timer for performing ON-OFF operation at preset

ON and OFF times.

Outputs a clock pulse at the setting time interval

for a single operation cycle.

values and arrival values. Can also output the

current va lue.

Temporary storage contact for accepting relays in

the Step Ladder Program block.

Note: (One internal switch is already allocated

as “temporary storage” in CX-Process

To ol .)

Checks an analog input for 8 levels and outputs

a contact corresponding to the level. The level

number is also output as an analog value at the

same time.

Manipulates and monitors ON/OFF valves with

open/close limit switches.

Manipulates and monitors reversible motor

operation.

Inputs a target opening, and manipulates an

electric positional-proportional motor.

Manipulates and monitors multiple (up to 8)

devices such as ON/OFF valves, motors, or

pumps.

Type Block Name Function

--- Step Ladder Program (See note.)

Performs logic sequence and step progression control.

Note: The Function Blocks dealing with high-speed operation (oper-

ation cycle: 0.01, 0.02, and 0.05 seconds is possible).

Field Terminals

Type Block Name Function

Contact

I/O

(See note.)

Analog I/O

(See note.)

Note: The Function Blocks dealing with high-speed operation

DI 8-point Terminal Inputs 8 contacts from 8-point Input Unit.

DI 16-point Terminal Inputs 16 contacts from 16-point Input

DI 32-point Terminal Inputs 32 contacts from 32-point Input

DI 64-point Terminal Inputs 64 contacts from 64-point Input

DO 8-point Terminal Outputs 8 contacts from 8-point Output

DO 16-point Terminal

DO 32-point Terminal

DO 64-point Terminal

DI 16-point/Do

16-point Terminal

AI 4-point Terminal

(PTS51)

AI 4-point Terminal

(PTS52)

AI 2-point Terminal

(PTS15/16, PDC15)

AI 8-point Terminal

(AD081)

AO 8-point Terminal

(DA08V/C)

AI 4-point Terminal

(AD041)

AO 4-point Terminal

(DA041)

AO 2-point Terminal

(DA021)

AI 4-point/AO 2-point

Terminal (MAD42)

AI 4-point Terminal

(DRT1-AD04)

AO 2-point Terminal

(DRT 1-DA02 )

AI 4-point Terminal

(AD04U)

AI 4-point Terminal

(PH41U)

Unit.

Unit.

Unit.

Unit.

Outputs 16 contacts from 16-point Output

Unit.

Outputs 32 contacts from 32-point Output

Unit.

Outputs 64 contacts from 64-point Output

Unit.

Inputs and outputs 16 contacts each from

16-point Input/16-point Output Units.

Inputs 4 analog signals from CJ1WPTS51 (Isolated-type Thermocouple

Input Unit)

Inputs 4 analog signals from CJ1WPTS52 (Isolated-type Temperature Resistance Input Unit).

Inputs 2 analog signals from CJ1WPTS15 (Isolated-type Thermocouple

Input Unit), CJ1W-PTS16 (Isolated-type

Temperature Resistance Input Unit), or

CJ1W-PDC15 (Isolated-type DC Input

Unit).

Inputs 8 analog signals from the CJ1WAD081(-V1).

Outputs 8 analog signals from the CJ1WDA08V/DA08C.

Inputs 4 analog signals from the CJ1WAD041(-V1).

Outputs 4 analog signals from the CJ1WDA041(-V1).

Outputs 4 analog signals from the CJ1WDA021.

Inputs 4 analog signals and outputs 2 analog signals each from the CJ1W-MAD42.

Inputs 4 analog signals from a DRT1AD04 DeviceNet Slave Analog Input Unit.

Outputs two analog signals from a DRT1DA02 DeviceNet Slave Analog Output

Unit.

Inputs 4 analog signals from the CJ1WAD04U.

Inputs 4 analog signals from the CJ1WPH41U.

(operation cycle: 0.01, 0.02, and 0.05 seconds is possible).

Note: 1. The Function Blocks dealing with high-speed operation

(operation cycle: 0.01, 0.02, and 0.05 seconds is possible).

2. Cannot be used with the CJ1G-CPU45P-GTC.

13

Loading...

Loading...