CIMR-A

Copy

V

erify

Re

a

d

L

O

C

K

Y

A

S

K

A

W

A

JV

O

P

-

1

8

1

U

S

B

C

o

p

y

U

n

i

t

C

O

M

ER

R

LCD Remote

Operator

MCCB

A1000

Filter

AC Reactor

Motor

Ground

Power

Supply

CX-Drive

CX-One

RJ-45 / USB

Adapter

Remote Operator

Extansion Cable

USB Cable

24 VDC Control Board Power Supply

Communication Option Board

Braking Resistor

DC Reactor

Feedback Speed Option Cards

Choke

Communications cable with PC

A1000

High performance Vector Control

• Current vector control, with or without PG

• High starting torque (200% / 0.3 Hz, spd range 1:200 OLV),

(200% at 0 r/min, spd range 1:1500 CLV)

• Double rating ND 120%/1min and HD 150%/1 min

• IM&PM motor control

• Advanced Auto-Tuning for IM & PM Motors

• Open Loop Control of PM Motors

• Low-noise Low carrier technology

• 10 years lifetime design

• Screw-less terminals

• Control Terminals with memory backup

• 24 VDC control board power supply option

• Fieldbus communications: Modbus, Profibus, CanOpen,

DeviceNet, ML-II

• Safety embedded: EN954-1 safety cat. 3, stop category 0,

IEC EN 61508 SIL 2 and EN61800-5-1 with EDM

• CE, UL, cUL and TUV

Ratings

• 200 V Class three-phase 0.4 to 110 kW

• 400 V Class three-phase 0.4 to 315 kW

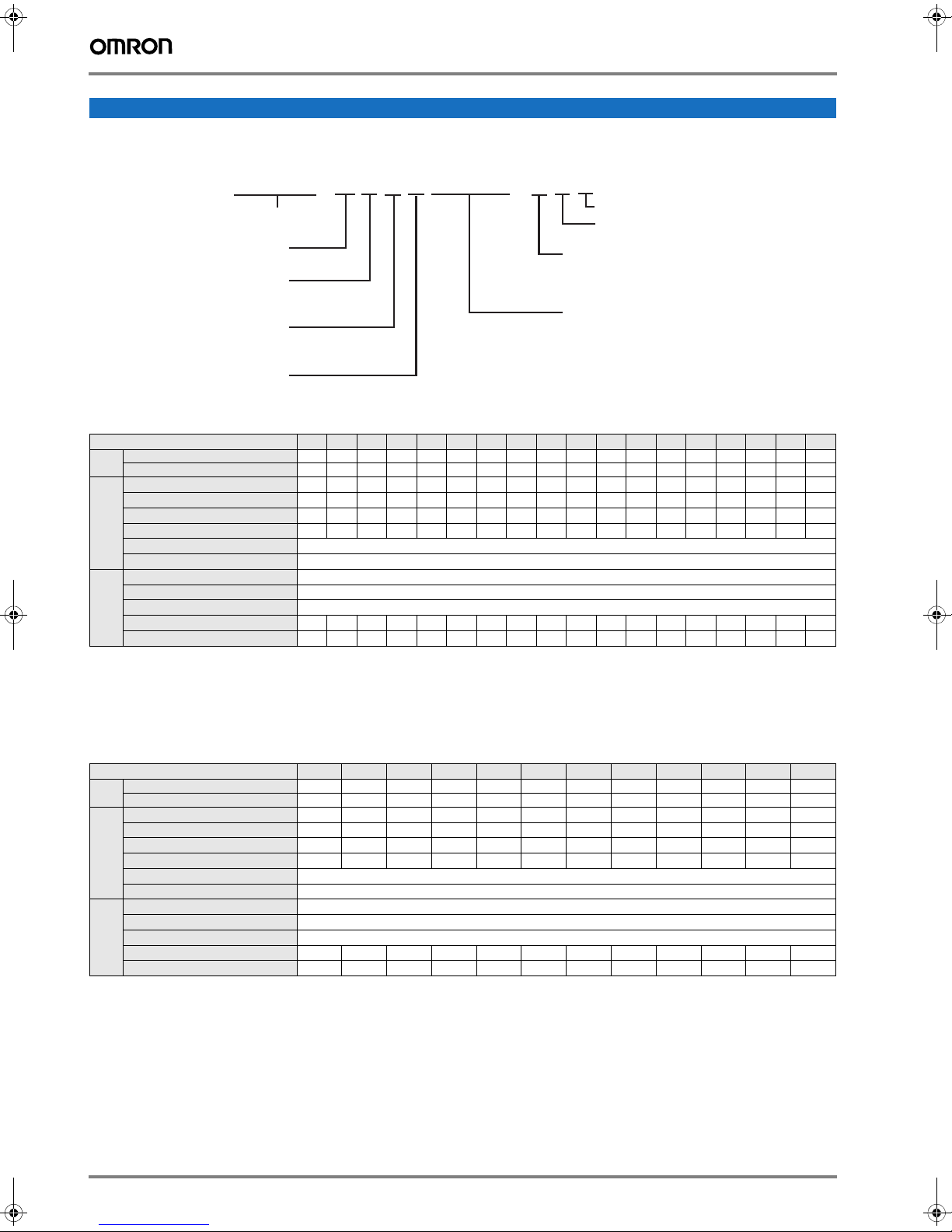

System configuration

1A1000

Specifications

Type designation

CIMR AC4A0004 FAA

AC Drive

A1000 series

C: European standard

specifications

Voltage:

2: Three-phase 200 VAC

4: Three-phase 400 VAC

A: Standard specs

200 V class

Three-phase: CIMR-A@2A 0004 0006 0010 0012 0021 0030 0040 0056 0069 0081 0110 0138 0169 0211 0250 0312 0360 0415

Motor

1

kW

Output

characteristics

Rated input voltage and frequency

Power

supply

1. Based on a standard 4-pole motor for maximum applicable motor output:

2. Rated Motor Capacity is calculated with a rated output voltage of 220 V:

3. Carrier frequency is set to 2kHz. Current derating is required in order to raise the carrier frequency:

4. Carrier frequency can be increased up to 8 kHz while keeping this current rating. Higher carrier frequency settings require derating:

5. Carrier frequency can be increased up to 5 kHz while keeping this current rating. Higher carrier frequency settings require derating:

6. Assumes operation at rated output current. Input current rating varies depending on the power supply transformer, input reactor,

For HD setting 0.40 0.75 1.5 2.2 4.0 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90 110

For ND setting 0.75 1.1 2.2 3.0 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90 110 110

Inverter capacity kVA at HD

Inverter capacity kVA at ND

Rated output current (A) at HD

Rated output current (A) at ND

Max. output voltage

Max. output frequency

Allowable voltage fluctuation

Allowable frequency fluctuation

Input Current (A) at HD

Input Current (A) at ND

Wiring conditions, and power supply impedance:

2

1.2 1.9 3 4.2 6.7 9.5 12.6 17.9 23 29 32 44 55 69 82 108 132 158

2

1.3 2.3 3.7 4.6 8 11.4 15.2 21 26 31 42 53 64 80 95 119 137 158

3.24548411417.54254334474604754854115414551805215528353465415

3

3.5 6 9.6 12 21 30 40 56 69 81 110 138 169 211 250 312 360 415

Proportional to input voltage: 0..240 V

400 Hz

3-phase 200..240 V 50/60 Hz

-15%..+10%

+5%

6

6

5.8 7.5 11 18.9 28 37 52 68 80 82 111 136 164 200 271 324 394

2.9

7.3 10.8 13.9 24 37 52 68 80 96 111 136 164 200 271 324 394 471

3.9

Ver sion

Coating specs:

A: Standard

Enclosure, Fin:

A: IP00

F: IP20 / Nema 1

Rated output Current

Normal Duty

0004: 3.5 [A]

~

0675: 675 [A]

3

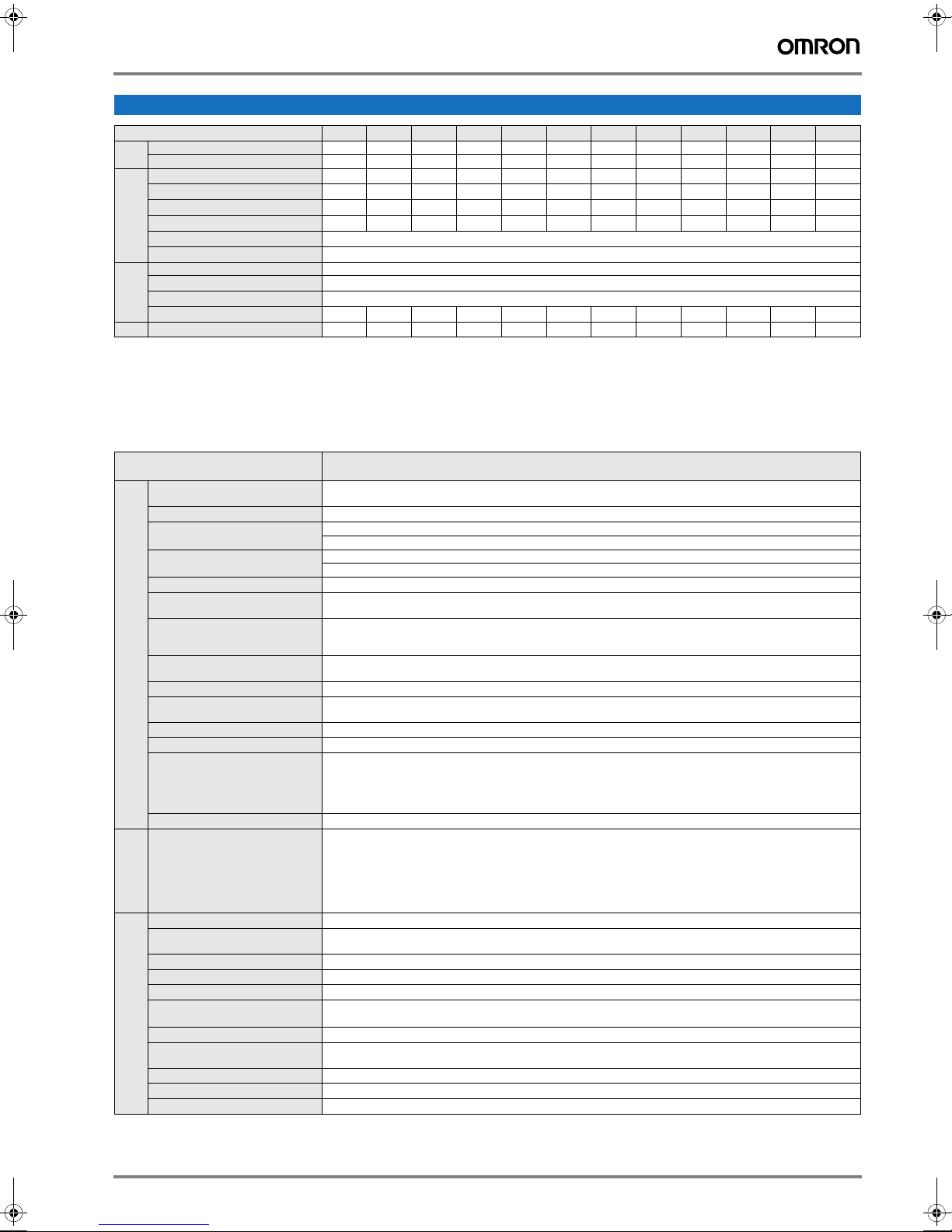

400 V class

Three-phase: CIMR-A@4A

Motor

1

kW

Output

characteristics

Rated input voltage and frequency

Power

supply

For HD setting 0.4 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11 15 18.5 22

For ND setting 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11 15 18.5 22 30

Inverter capacity kVA at HD

Inverter capacity kVA at ND

Rated output current (A) at HD

Rated output current (A) at ND

Max. output voltage

Max. output frequency

Allowable voltage fluctuation

Allowable frequency fluctuation

Input Current (A) at HD

Input Current (A) at ND

0002 0004 0005 0007 0009 0011 0018 0023 0031 0038 0044 0058

2

1.4 2.6 3.7 4.2 5.5 7 11.3 13.7 18.3 24 30 34

2

1.6 3.1 4.1 5.3 6.7 8.5 13.3 17.5 24 29 34 44

4

1.8

3

2.1 4.1 5.4 6.9 8.8 11.1 17.5 23 31 38 44 58

380..480V (proportional to input voltage)

400 Hz

3-phase 380..480 VAC, 50/60 Hz

-15%..+10%

+5%

6

1.8

6

2.1

2 Frequency inverters

4

4

3.444.845.547.249.2414.8418

3.2 4.4 6 8.2 10.4 15 20 29 39 44

4.3 5.9 8.1 9.4 14 20 24 38 44 52

24

4

31

4

39

4

45

49

58

Specifications

Three-phase: CIMR-A@4A

Motor

kW

1

For HD setting 30 37 45 55 75 90 110 132 160 185 220 315

For ND setting 37 45 55 75 90 110 132 160 185 220 250 355

Inverter capacity kVA at HD

Inverter capacity kVA at ND

Rated output current (A) at HD

Rated output current (A) at ND

Output

characteristics

Max. output voltage

Max. output frequency

Rated input voltage and frequency 3-phase 380..480 VAC, 50/60 Hz

Allowable voltage fluctuation

Allowable frequency fluctuation

Power

supply

Input Current (A) at HD

Input Current (A) at ND

1. Based on a standard 4-pole motor for maximum applicable motor output:

2. Rated Motor Capacity is calculated with a rated output voltage of 440 V:

3. Carrier frequency is set to 2kHz. Current derating is required in order to raise the carrier frequency:

4. Carrier frequency can be increased up to 8 kHz while keeping this current rating. Higher carrier frequency settings require derating:

5. Carrier frequency can be increased up to 5 kHz while keeping this current rating. Higher carrier frequency settings require derating:

6. Assumes operation at rated output current. Input current rating varies depending on the power supply transformer, input reactor,

Wiring conditions, and power supply impedance:

Commom specifications

Model number

CIMR-A

Control methods

Output frequency range

Frequency tolerance

Resolution of frequency set value

Resolution of output frequency

Frequency set value

Starting Torque

Speed Control Range

Speed Control Accuracy

Control functions

Speed Response

Torque Limit

Accel/Decel Time

Braking torque

V/f Characteristics

Main Control Functions

Functionality

Motor protection Motor overheat protection based on output current

Momentary overcurrent

Protection

Overload Protection Drive stops after 60 s at 150% of rated output current (Heavy Duty Rating)*

Overvoltage Protection 200 V class: Stops when DC bus exceeds approx. 410 V, 400 V class: Stops when DC bus exceeds approx. 820V

Undervoltage Protection 200 V class: Stops when DC bus exceeds approx. 190 V, 400 V class: Stops when DC bus exceeds approx. 380V

Momentary power loss Ride-Thru

Heatsink Overheat Protection Protected by thermister

Braking Resistance Overheat

Protection functions

Protection

Stall prevention Stall prevention during acceleration/deceleration and constant speed operation

Ground fault Protected by electronic circuit*

Power charge indication Charge LED remains lit until DC bus has fallen below approx. 50 V.

0072 0088 0103 0139 0165 0208 0250 0296 0362 0414 0515 0675

2

48 57 69 85 114 137 165 198 232 282 343 461

2

55 67 78 106 126 159 191 226 276 316 392 514

4

60

3

72 88 103 139 165 208 250 296 362 414 515 675

4

75

91411251505180521652605304

3

370 450 605

380..480V (proportional to input voltage)

400 Hz

-15%..+10%

+5%

6

6

58 71 86 105 142 170 207 248 300 346 410 584

71 86 105 142 170 207 248 300 346 410 465 657

Specifications

Sine wave PWM (V/f control, V/f control with PG, Open loop vector control, Closed loop vector control, Open loop vector

control for PM, Closed loop vector control for PM, Advanced Open Loop Vector Control for PM)

0.01..400 Hz

Digital set value: ±0.01% of the max. output frequency (-10..+40 ºC)

Analogue set value: ±0.1% of the max. output frequency (25 ±10 ºC)

Digital set value: 0.01 Hz

Analogue set value: 0.03 Hz / 60 Hz (11 bit)

0.001 Hz

-10..+10 V (20 kΩ),0..10 V (20 kΩ), 4..20 mA (250 Ω),

Pulse train input, frequency setting value (selectable)

150%/3Hz (V/f control, V/f control with PG), 200%/0.3Hz*1 (Open loop vector control), 200%/ 0 r/min*1 (Closed loop vector control, Closed loop vector control for PM, Advanced Open Loop Vector Control for PM), 100% / 5% speed (Open

loop vector control for PM),

1:1500 (Closed loop vector control, Closed loop vector control for PM), 1:200 (Open loop vector control), 1:40 (V/f control, V/f control with PG), 1:20 (Open Loop Vector Control for PM), 1:100 (Advanced Open Loop Vector Control for PM)

±0.2% in Open loop vector control (25 ±10 ºC) *2, 0.02% in Closed loop vector control (25 ±10 ºC)

10 Hz in Open loop vector control (25 ±10 ºC), 50Hz in Closed loop Vector Control (25 ±10 ºC), )(excludes temperature

fluctuation when performing Rotational Auto-Tuning)

All Vector Control allows seperate settings in four quadrants

0.00 to 6000.0 s (4 selectable combinations of independent acceleration and deceleration settings)

Drives of 200/400 V 30 kW or less have a built-in braking transistor.

1. Short-time decel torque*

and above motors (over excitation braking/High-Slip Braking approx. 40%)

2. Continuous regen, torque approx. 20% (approx. 125% with dynamic braking resistor option*

braking transistor)

3

, over 100% for 0.4/0.75 kW motors, over 50% for 1.5 kW motors, and over 20% for 2.2 kW

4

, 10% ED,10 s, internal

User-selected programs and V/f preset pattens possible

Torque Control, Droop control, Speed/torque control switching, Feedforward control, Zero-servo control, Momentary

power loss ride-thru, Speed search, Overtorque detection, Torque Limit, 17-step speed (max), Accel/Decel time switch

S-curve Accel/Decel, 3-wire sequence, Auto-tuning (rotational, stationary), Online Tuning, Dwell Cooling fan on/off

switch, slip compensation, Torque compensation, Frequency Jump, Upper/lower limits for frequency, DC injection braking at start and stop, Over excitation braking, High Slip braking, PID control (with sleep function), Energy saving control,

MEMOBUS comm. (RS-485/422 max. 115.2kbps), Fault restart, Application presets, Removable terminal block with parameter backup function...

Drive stops when ouput current exceeds 200% of Heavy Duty Rating

5

Immediately stop after 15 ms or longer power loss (default),

Continuous operation during power loss than 2 s (srandard)*

6

Overheat sensor for braking resistor (optional)

7

A1000 3

Area of Use

Ambient Temperature

Ambient humidity

Storage temperature

Altitude

Vibration / Shock

Ambient conditions

Safety Standard

Protection Design

1. Requires a drive with recommended capacity.

2. Speed control accuracy may vary slightly depending on installation conditions or motor used.

3. Momentary average deceleration torque refers to the deceleration torque form 60 Hz down to 0 Hz. This may vary depending on the motor.

4. If L3-04 is enabled when using a braking resistor or braking resistor unit, the motor may not stop in the specified deceleration time.

5. Overload protection may be triggered when operating with 150% of the rated output current, if the output frequency is less than 6 Hz.

6. Varies in accordance with the drive capacity and load. Drives with a capacity of smaller than 11 kW in the 200 V (model CIMR- AA0056 or 400 V (model

CIMR- AA0031) require a seperate Momentary Power Loss Unit to continue operating.

7. Protection may not be provided under the following conditions as the motor windings are grounded internally during run:

the motor cable or terminal block.

Indoor (no corrosive gas, dust, etc.)

-10ºC..+50ºC(open chassis) up to 60ºC with output current derating, -10ºC..+40ºC (NEMA Type 1)

95% RH or less (without condensation)

-20ºC..+60ºC (short-term temperature during transportation)

Up to 1000 meters (output derating of 1% per 100 m above 1000 m, max. 3000 m)

10 Hz to 20 Hz, 9.8 m/s2 max. 20 Hz to 55Hz, 5.9 m/s2 (200 V: 45kW or more, 400 V: 55kW or more) or

2

max. (200 V: 55 kW or less, 400 V: 75 kW or less)

2.0 m/s

EN954-1 safe category 3 stop category 0; EN ISO 13849-1; IEC EN 61508 SIL2

IP00 open-chassis, IP20, NEMA Type 1 enclosure

#Drive already has a short-circuit when the power is turned on.

#Low resistance to ground from

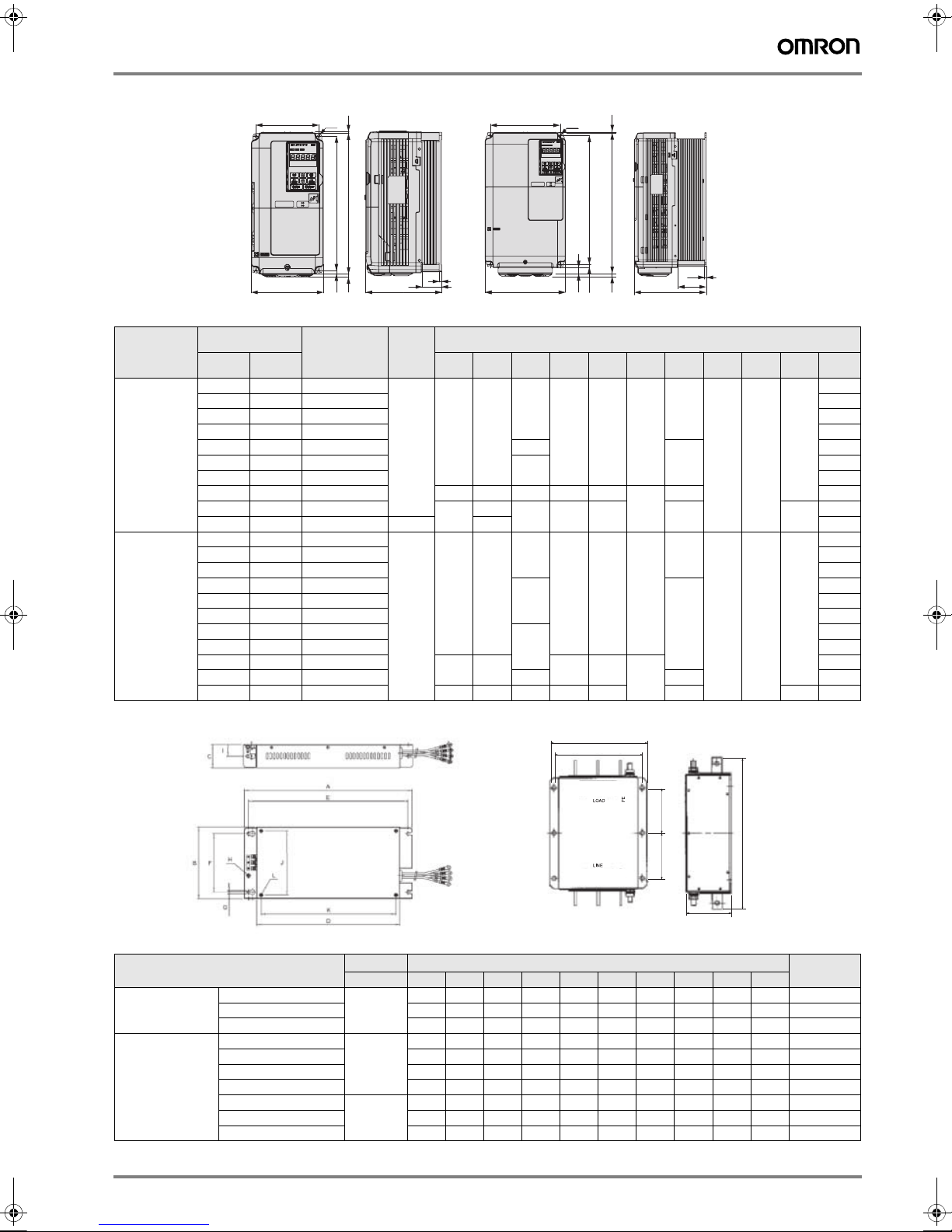

Dimensions

Open-Chassis [IP00]

W1

4-d

H

H1

t2

W1

4-d

t2

H

H1

W1

4-d

H

H1

t2

Max 10

Voltage class

Three-phase

200 V

Three-phase

400 V

t1

H2

W

Max 10

Figure 1

Max. applicable

motor output kW

ND HD W H D W1 H1 H2 D1 t1 t2 d

30 22 0110

37 30 0138 275 450 220 435 25

45 37 0169

55 45 0211 38

75 55 0250

90 75 0312 80

110 90 0360

110 110 0415 99

30 22 0058

37 30 0072 275 450 220 435 25

45 37 0088

55 45 0103 36

75 55 0139

90 75 0165 42

D1

D

Inverter model

CIMR-A@

Figure

1

1

W

250 400

H2

Max 7.7Max 7.7

Figure 2

258

325 550 283 260 535 110

450 705 330 325 680 12.5

500 800 350 370 773 13 4.5 4.5 M12

250 400

258

510

325

550 283 535 110 2.3

110 90 0208 450 705 330 325 680 12.5

132 110 0250

160 132 0296 102

185 160 0362 107

500

800 350

220 185 0414 2 950

250 220 0515

355 315 0675 221

3 670 1140 440 1110 15 150

370

t1

D1

D

W

H2

Max 6Max 6

Figure 3

Dimensions in mm

195 385

7.5

100

2.3 2.3 M6

3.2 3.2 M10

130

195 385

495 105 3.2

7.5

100

2.3

2.3

260

3.2 3.2 M10 79

773

370

923 135 125

130

13

4.5 4.5 M12

M6

t1

D1

D

Weight

(kg)

21

37

76

98

21

36

41

96

216

4 Frequency inverters

Enclosed Panel [NEMA Type1]

W

1

1.5

D

1

W

㧔5㧕

H

H

1

H

2

t

1

D

W

1

W

D

H

H

1

H

2

H

3

㧔8㧕

D

1

t

1

W

1.5

4

-

d

4

-

d

Figure

1

Figure

2

Figure 1

Max. applicable

Voltage class

motor output kW

ND HD W H D W1 H1 H2 D1 t1 t2 d

0.75 0.4 0004

1.1 0.75 0006 3.1

2.2 1.5 0010 3.2

3 2.2 0012 3.2

Three-phase

200 V

5.5 4.0 0021 164

7.5 5.5 0030

11 7.5 0040 4.0

15 11 0056 180 300 187 160 284

18.5 15 0069

22 18.5 0081 2 365 9.7

0.75 0.4 0002

1.5 0.75 0004 3.2

2.2 1.5 0005 3.2

3 2.2 0007

Three-phase

400 V

4.0 3 0009 3.5

5.5 4.0 0011 3.5

7.5 5.5 0018

11 7.5 0023 3.9

15 11 0031

18.5 15 0038 187 75 5.7

22 18.5 0044 220 350 197 192 335 78 M6 8.3

Schaffner Flat Filters

Inverter model

CIMR-A@

Figure

1

1

Dimensions in mm

147

140 260

122 248 6

167

350

220

197 192 335 78 M6

147

140 260

164

122 248 6

167

180 300 160 284

C

F

38

5-

55

75 5.6

8

38

5-

55

8

M5

M5

Weight

(kg)

3.1

3.5

4.0

8.7

3.2

3.4

3.9

5.4

Flat Filters

3G3RV-PFI2035-SE

200 V

3G3RV-PFI2060-SE 355 206 60 302 336 175 6.5 M6 30 M6 3

3G3RV-PFI2100-SE 408 236 80 355 390 205 6.5 M6 40 M6 4.9

3G3RV-PFI3010-SE

3G3RV-PFI3018-SE 330 141 46 281 313 115 5.5 M4 23 M5 1.3

3G3RV-PFI3035-SE 355 206 50 302 336 175 6.5 M5 25 M6 2.2

400 V

3G3RV-PFI3060-SE 408 236 65 355 390 205 6.5 M6 32.5 M6 4

3G3RV-PFI3410-SE

A1000 5

3G3RV-PFI3600-SE 386 135 260 - 120 235 12.0 M12 - - 11.0

3G3RV-PFI3800-SE 564 160 300 - 210 275 9.0 M12 - - 31.0

EE

A

B

Figure 2

Fig

A B C D E F G H I L

Dimensions

Weight

KG

330 141 46 281 313 115 5.5 M5 23 M5 1.4

1

330 141 46 281 313 115 5.5 M4 23 M5 1.2

1

386 115 260 - 120 235 12.0 M12 - - 8.5

2

Bookform Filters

C

A

E

B

F

H

G

D

X

H

YW

Ø m

L

Ø d

Bookform Filters

200 V

400 V

3G3RV-PFI2130-SE 310 180 90 280 295 65 6.5 M10 4.3

3G3RV-PFI2160-SE 380 170 120 350 365 102 6.5 M10 6.0

3G3RV-PFI2200-SE 518 240 130 480 498 90 8.2 M10 11.0

3G3RV-PFI3070-SE 329 185 80 300 314 55 6.5 M6 3.4

3G3RV-PFI3130-SE 310 180 90 280 295 65 6.5 M10 4.7

3G3RV-PFI3170-SE 380 170 120 350 365 102 6.5 M10 6.0

3G3RV-PFI3250-SE 610 240 130 480 498 90 8.3 M10 11.7

3G3RV-PFI3410-SE 386 115 260 - 120 235 12.0 M12 8.5

3G3RV-PFI3600-SE 386 135 260 - 120 235 12.0 M12 11.0

3G3RV-PFI3800-SE 564 160 300 - 210 275 9.0 M12 31.0

Remote LCD operator

Dimensions

A B C D E F G H

Installation holes

(2-M3 screws, depth 5 (0.19))

15

(0.59)

44 (1.73)

78 (3.07)

60 (2.36)

90 (3.54)

12.2

1.6 (0.06)

(0.48)

<1>

7.9

(0.31)

minimum 50 (1.96) Unit : mm (in)

Weight

KG

Chokes

Description D

diameter

A1000-FEV2102-RE 21 < 2.2 85 22 46 70 - 5 0.1

A1000-FEV2515-RE 25 < 15 105 25 62 90 - 5 0.2

A1000-FEV5045-RE 50 < 45 150 50 110 125 30 5 0.7

A1000-FEV6045-RE 60 > 45 200 65 170 180 45 6 1.7

6 Frequency inverters

Motor

KW

Dimensions Weight

L W H X Y m

Kg

Braking Unit

Lead Wire Inlet

(28 Dia. Rubber Bush)

2-lead Wire Inlet

(35 Dia. Rubber Bush)

156.5

210

104

118.5

50

210

250

200

156

111

9

36.5

100 or more

100 or more

317

355

370

70

4-M6

MTG Holes

Main Circuit

Ter m in al

M6

30

or

more

30

or

more

168

11.5

45

20

182

105

27

36

MTG Screw

200 or more

50 or more 50 or more

A

260

C

D

B

MTG Screw

30 or more 30 or more

A

C

D

B

150

150 or more 150 or more

(KI

Model CDBR-2015 B, -2022 B, -4030B, -4045 B Model CDBR-2110 B

36.5

4-M4 MTG Holes

30 or

more

3-lead Wire Inlet

(20 Dia. Rubber Bush)

72

66.5

100 or more

150

138

3838

128

30 or

more

140

138.5

114.5

100 or more

12

370

350

317

100

73

59

30

or

more

Mass 1.8 K

Model CDBR-4220 B

Mass 12 Kg

Resistor Dimensions

A1000-REJ0K15___ A1000-REJ0K10___

140

Main Circuit

Terminal

M6

50

140

180

4-M6

MTG Holes

30

or

more

Mass 8.5 Kg

100 or less

Lead Wire Inlet

104

(28 Dia. Rubber Bush)

2-lead Wire Inlet

(35 Dia. Rubber Bush)

111

156

200

100 or less

Braking Resistor Unit

Voltage

Model

LKEB-_

A B C D MTG Screw

21P5

22P2

130 350 75 335 M5 x 3

23P7 5.0

220 V

Class

25P5

27P5 8.5

2011 266 543 246 340 M8 x 4 10

250 350 200 335 M6 x 4

2015 356 543 336 340 M8 x 4 15

2018

2022

41P5

42P2

446 543 426 340 M8 x 4 19

130 350 75 335 M5 x 4 4.5

43P7 130 350 75 335 M5 x 4 5.0

45P5

47P5 8.5

400 V

Class

4011

4015 18

4018

4022

A1000 7

4030 356 956 336 740 M8 x 4 25

4037 446 956 426 740 M8 x 4 33

4045 446 956 426 740 M8 x 4 33

250 350 200 335 M6 x 4

350 412 330 325 M6 x 4

446 543 426 340 M8 x 4 19

Dimensions in mm

Mass

kg

4.5

7.5

7.5

16

Installation

+

㧙

+

+

++

M

U/T

1

V/T2

W/T

U

V

W

3

Ground

Terminals -, +1, +2, B1, B2 are

for connection options. Never

connect power supply lines to

these terminals

DC reactor

(option)

UX

Thermal relay

(option)

+

㧙

+

+

++

+

㧙

UX

S

1

S2

S3

S4

S5

S6

S7

MP

DM

DM

RP

A

1

A2

A3

0

V

AC

R

R

S

S

IG

H

1

H2

HC

A1000

B112

B2

2

kΩ

S8

SC

0 V

0 V

AC

FM

AM

AC

E (G)

S

1

S2

㧙

+24 V

+V

MA

M

1

M2

MB

MC

Jumper

Braking resistor

(option)

Forward Run / Stop

Reverse Run / Stop

External fault

Fault reset

Multi-speed step 1

Multi-speed step 2

External Baseblock

Jog speed

Multi-function

digtial inputs

(default setting)

Sink / Source mode

selection wire link

(default: Sink)

CN5-C

CN5-B

CN5-A

Option card connectors

Pulse Train Input (max 32 kHz)

Shield ground terminal

Multi-function

analog/ pulse

train inputs

Power supply +10.5 Vdc, max. 20 mA

Analog Input 1 (Frequency Reference Bias)

-10 to +10 Vdc (20 kΩ)

Analog Input 2 (Frequency Reference Bias)

-10 to +10 Vdc (20 kΩ)

0 or 4 to 20 mA (250 Ω)

Analog Input 3 / PTC Input (Aux. frequency

reference)

-10 to +10 Vdc (20 kΩ)

−V

Power supply, -10.5 Vdc, max. 20 mA

Safety

switch

MEMOBUS/Modbus

comm. RS485/422

max. 115.2 kBps

Safe Disable inputs

Wire

jumper

Open

Safety relay /

controller

Termination resistor

(120 Ω, 1/2 W)

DIP

Switch S2

Fault relay output

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

Multi-function relay output (During Run)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

Multi-function pulse train output

(Output frequency)

0 to 32 kHz (2.2 kΩ)

Multi-function analog output 1

(Output frequency)

-10 to +10 Vdc (2mA) or 4 to 20 mA

Multi-function analog output 2

(Output current)

-10 to +10 Vdc (2mA) or 4 to 20 mA

EDM (Safety Electronic Device Monitor)

Main Circuit

Control Circuit

shielded line

twisted-pair shielded line

main circuit terminal

control circuit terminal

R/L1

S/L2

T/L3

Three-phase

power supply

200 to 400 V

50/60 Hz

R/L1

S/L2

T/L3

Main

Switch

Fuse

EMC

Filter

Motor

Shielded

Cable

M3

M4

Multi-function relay output (Zero Speed)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

M5

M6

Multi-function relay output (Speed Agree 1)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

SP

SN

AMFM

V

I

V

I

DIP Switch S1

A2 Volt/Curr. Sel

DIP Switch S4

A3 Analog/PTC

Input Sel

PTC

AI

Off

On

DIP Switch S2

Term. Res. On/Off

Jumper S3

H1, H2

Sink/Source Sel.

Jumper S5

AM/FM Volt./Curr.

Selection

Terminal board

jumpers and switches

FM

+

㧙

AM

Standard connections

Main circuit

Terminal Name Function (signal level)

R/L1, S/L2, T/L3

U/T1, V/T2, W/T3

B1, B2

+2, +1

+1, –

+3

8 Frequency inverters

Main circuit power supply input Used to connect line power to the drive.

Inverter output Used to connect the motor

Braking resistor connection Available for connecting a braking resistor or the braking resistor unit option.

DC reactor connection Remove the short bar between +2 and +1 when connecting DC reactor (option)

DC power supply input For power supply input (+1: positive electrode; – : negative electrode)*

Braking Unit Connection for Braking Unit between terminals +3 and –

Grounding For grounding (grounding should conform to the local grounding code.)

Control Circuit

Type No.

S1

S2

S3

S4

S5

S6

Digital input signals

Analog input signals

Safety Input

Safety

monitor

Digital output signals

Analog output

PulseI/O

RS-485/422

signals

S7

S8

SC

+V

–V

A1

A2

A3

AC

HC

H1

H2

DM+

DM–

output

MA

MB

MC

M1

M2

P1

P2

PC

FM

AM

AC

RP

MP

R+

R–

S+

S–

Signal name Function Signal level

Multi-function input selection 1 Factory setting: runs when CLOSED, stops when OPEN.

Multi-function input selection 2 Factory setting: runs when CLOSED, stops when OPEN.

Multi-function input selection 3 Factory setting: External Fault (N.O.)

Multi-function input selection 4 Factory setting: Fault reset

Multi-function input selection 5 Factory setting: Multi-step speed cmd 1

Multi-function input selection 6 Factory setting: Multi-step speed cmd 2

Multi-function input selection 7 Factory setting: Jog Frequency

Multi-function input selection 8 Factory setting: Closed gives external baseblock

Multi-function input selection

Common

Power Supply for Frequency Setting +10.5 V (allowable max current 20 mA)

Power Supply for Frequency Setting –10.5 V (allowable max current 20 mA)

Multi-function analogue input 1 Main Frequency Reference -10 to +10 VDC, 0 to +10 VDC (20 kΩ)

Multi-function analogue input 2

Multi-function analogue input 3 –10 to +10 V, 0 to +10 V (20 kΩ)

Frequency reference common 0V

Safety Input Common

Safety Input 1

Safety Input 2

Safety monitor output

Safety monitor output common

NO contact output

NC Output

Relay Output common

Multi-function contact output (N.O ) Factory setting Closed: During run

Photocoupler output 1 Factory setting: Zero speed

Photocoupler output 2 Factory setting: Frequency Agree

Photocoupler output common 0V

Multi-function analog monitor (1) Factory setting: Output frequency

Multi-function analog monitor (2) Factory setting: "Current monitor, 5 V/drive rated current

Analog monitor common 0V

Main Speed Cmd Pulse Train Input 32 kHz max. (3 kΩ)

Pulse Train Output Factory setting: Frequency reference input (H6-01=0) 0 to 33 kHz (2.2 kΩ)

Communication input (+)

Communication input (–)

Communication output (+)

Communication output (–)

Common for control signal

Voltage input or current input

-10 to +10 VDC, 0 to +10 VDC (20 kΩ)

4 to 20 mA (250 Ω)

+24 V (max allowable current 10 mA)

Open: Stop Closed: Normal Operation

Open: Safety inputs 1 and 2 are open 48 Vdc, 50mA or less

Factory setting: "fault"

For MEMOBUS communication

operation by RS-485 or RS-422 communication is available.

24 VDC, 8 mA

photocoupler

insulation

Photocoupler 24 V

DC, 8 mA

Contact capacity

250 VAC,

1 A or less

30 VDC, 1 A

or less

Photocoupler output:

+48 VDC, 50 mA or

less

–10 to 10 V ±5%,

(2 mA or less)

0 to 10 V

4 - 20 mA

RS-485/422

MEMOBUS

protocol

A1000 9

Inverter heat loss

Three-phase 200 V class

Model Number

CIMR-A

2A0004 3.2 14.8 44 59 3.5 18.4 47 66

2A0006 5.0 24 48 72 6.0 31 51 82

2A0010 8.0 43 52 95 9.6 57 58 115

2A0012 11.0 64 58 122 12.0 77 64 141

2A0021 17.5 101 67 168 21 138 83 222

2A0030 25 194 92 287 30 262 117 379

2A0040 33 214 105 319 40 293 145 437

2A0056 47 280 130 410 56 371 175 546

2A0069 60 395 163 558 69 491 205 696

2A0081 75 460 221 681 81 527 257 785

2A0110 85 510 211 721 110 719 286 1005

2A0138 115 662 250 912 138 842 312 1154

2A0169 145 816 306 1122 169 1014 380 1394

2A0211 180 976 378 1354 211 1218 473 1691

2A0250 215 1514 466 1980 250 1764 594 2358

2A0312 283 1936 588 2524 312 2020 665 2686

2A0360 346 2564 783 3347 360 2698 894 3591

2A0415 415 2672 954 3626 415 2672 954 3626

Rated Amps (A)

Heatsink Loss

Heavy Duty Normal Duty

(W)

Interior Unit

Loss (W)

Total Loss (W) Rated Amps (A)

Heatsink Loss

(W)

Interior Unit

Loss (W)

Total Loss (W)

Three-phase 400 V class

Model Number

CIMR-A

4A0002 1.8 15.9 45 61 2.1 20 48 68

4A0004 3.4 25 46 70 4.1 32 49 81

4A0005 4.8 37 49 87 5.4 45 53 97

4A0007 5.5 48 53 101 6.9 62 59 121

4A0009 7.2 53 55 108 8.8 66 60 126

4A0011 9.2 69 61 130 11.1 89 73 162

4A0018 14.8 135 86 221 17.5 177 108 285

4A0023 18.0 150 97 247 23 216 138 354

4A0031 24 208 115 323 31 295 161 455

4A0038 31 263 141 403 38 340 182 521

4A0044 39 330 179 509 44 390 209 599

4A0058 45 349 170 518 58 471 215 686

4A0072 60 484 217 701 72 605 265 870

4A0088 75 563 254 817 88 684 308 993

4A0103 91 723 299 1022 103 848 357 1205

4A0139 112 908 416 1325 139 1215 534 1749

4A0165 150 1340 580 1920 165 1557 668 2224

4A0208 180 1771 541 2313 208 1800 607 2408

4A0250 216 2360 715 3075 250 2379 803 3182

4A0296 260 2391 787 3178 296 2448 905 3353

4A0362 304 3075 985 4060 362 3168 1130 4298

4A0414 370 3578 1164 4742 414 3443 1295 4738

4A0515 450 3972 1386 5358 515 4850 1668 6518

4A0675 605 4191 1685 5875 675 4861 2037 6898

Rated Amps (A)

Heavy Duty Normal Duty

Heatsink Loss

(W)

Interior Unit

Loss (W)

Total Loss (W) Rated Amps (A)

Heatsink Loss

(W)

Interior Unit

Loss (W)

Total Loss (W)

10 Frequency inverters

Connections for braking unit and braking resistor

Thermal

relay

Power

supply

MCCB

THRX

Thermal relay switch for

external braking resistor

MC

FLT-A FLT-B

Fault contact

TRX

TRX

MC

MCONMCOFFTHRX

SA

SA

SA

B1 B2

R/L1

S/L2

T/L3

A1000

AC reactor

Power supply

MCCB

U/T1

V/T2

W/T3

Braking resistor

Motor

AC reactor

V

W

A1000

R/L1U

X

YZS/L2

T/L3

Braking Resistor

Overheat Contact

(Thermal Relay Trip Contact)

−

3

+

−

Level Detector

SLAVE

1

2

Braking Unit 1

34

Cooling Fin Overheat Contact

(Thermoswitch Contact)

1P2

MASTER

Braking

Resistor

Unit

B

− 0+ 0+

+15

5

6

A1000

Max. applicable

motor output kW

0.75 5 2.1 0.75 2.5 8.4

18.5 90 0.12 18.5 50 0.42

110 600 0.02 132/160 330 0.06

DC reactor

200 V class 400 V class

Current value

0.4 2.5 4.2 0.4

1.5101.11.5 5 4.2

2.2 15 0.71 2.2 7.5 3.6

A

Inductance

mH

Max. applicable

motor output kW

Current value

A

1.3 18

Inductance

mH

4.0 20 0.53 4.0 10 2.2

5.5 30 0.35 5.5 15 1.42

7.5 40 0.265 7.5 20 1.06

11 60 0.18 11 30 0.7

15 80 0.13 15 40 0.53

22 120 0.09 22 60 0.36

30 160 0.07 30 80 0.28

37 200 0.05 37 90 0.24

45 240 0.044 45 120 0.18

55 280 0.039 55 150 0.15

75 360 0.026 75 200 0.11

90 500 0.02 90/110 250 0.09

- 160/185/220 490 0.04

315 660 0.03

Power

supply

MCCB

A1000

R/L1

S/L2

T/L3

+1 +2

Max. applicable

motor output kW

0.4

0.75 0.75

Current value

A

5.4 8

1.5

200 V class 400 V class

2.2 2.2

18 3

4.0 4.0 12 6.3

5.5

7.5 7.5

11

15 15

18.5

36 1

72 0.5

90 0.4

22 to 110

A1000 11

Built-in

Inductance

mH

DC reactor

Max. applicable

motor output kW

0.4

1.5

5.5

11

18.5

22 to 315

Current value

A

3.2 28

5.7 11

23 3.6

33 1.9

47 1.3

Built-in

Inductance

mH

Safety System

EN954-1 Safety Cat.3

Compliance

Safety

controller

Feedback loop

Power

supply

Controller

Motor

• A1000 provides Safe Torque Off (STO)

functional safety in compliance with

EN954-1 safety category 3 stop

category 0, EN ISO 13849-1, PLC,

IEC/EN61508 SIL2.

• An External Device Monitor (EDM)

function has also been added to

monitor the safety status of the drive.

12 Frequency inverters

Ordering information

C

C

C

C

D

E

F

A

B

C

C

A

C

o

py

V

e

ri

fy

R

e

a

d

L

O

C

K

Y

A

S

K

A

W

A

JV

O

P

-

1

8

1

U

SB

C

o

p

y

U

n

i

t

C

O

M

ER

R

LCD Remote

Operator

MCCB

A1000

Filter

AC Reactor

Motor

Ground

Power

Supply

CX-Drive

CX-One

RJ-45 / USB

Adapter

Remote Operator

Extansion Cable

USB Cable

24 VDC Control Board Power Supply

Communication Option Board

Braking Resistor

DC Reactor

Feedback Speed Option Cards

Choke

Communications cable with PC

A1000

Heavy Duty Normal Duty Standard

0.4 kW 3.2 A 0.75 kW 3.5 A CIMR-AC2A0004FAA

0.75 kW 5.0 A 1.1 kW 6.0 A CIMR-AC2A0006FAA

1.5 kW 8.0 A 2.2 kW 9.6 A CIMR-AC2A0010FAA

2.2 kW 11.0 A 3.0 kW 12.0 A CIMR-AC2A0012FAA

4.0 kW 17.5 A 5.5 kW 21.0 A CIMR-AC2A0021FAA

5.5 kW 25.0 A 7.5 kW 30.0 A CIMR-AC2A0030FAA

7.5 kW 33.0 A 11.0 kW 40.0 A CIMR-AC2A0040FAA

11 kW 47.0 A 15.0 kW 56.0 A CIMR-AC2A0056FAA

200 V

15 kW 60.0 A 18.5 kW 69.0 A CIMR-AC2A0069FAA

18.5 kW 75 A 22 kW 81 A CIMR-AC2A0081FAA

22 kW 85 A 30 kW 110 A CIMR-AC2A0110AAA

30 kW 115 A 37 kW 138 A CIMR-AC2A0138AAA

37 kW 145 A 45 kW 169 A CIMR-AC2A0169AAA

45 kW 180 A 55 kW 211 A CIMR-AC2A0211AAA

55 kW 215 A 75 kW 250 A CIMR-AC2A0250AAA

75 kW 283 A 90 kW 312 A CIMR-AC2A0312AAA

90 kW 346 A 110 kW 360 A CIMR-AC2A0360AAA

110 kW 415 110 kW 415 A CIMR-AC2A0415AAA

0.4 kW 1.8 A 0.75 kW 2.1 A CIMR-AC4A0002FAA

0.75 kW 3.4 A 1.5 kW 4.1 A CIMR-AC4A0004FAA

1.5 kW 4.8 A 2.2 kW 5.4 A CIMR-AC4A0005FAA

2.2 kW 5.5 A 3.0 kW 6.9 A CIMR-AC4A0007FAA

3.0 kW 7.2 A 4.0 kW 8.8 A CIMR-AC4A0009FAA

4.0 kW 9.2 A 5.5 kW 11.1 A CIMR-AC4A0011FAA

5.5 kW 14.8 A 7.5 kW 17.5 A CIMR-AC4A0018FAA

7.5 kW 18.0 A 11.0 kW 23.0 A CIMR-AC4A0023FAA

11 kW 24.0 A 15.0 kW 31.0 A CIMR-AC4A0031FAA

400 V

15 kW 31.0 A 18.5 kW 38.0 A CIMR-AC4A0038FAA

18.5 kW 39 A 22 kW 44 A CIMR-AC4A0044FAA

22 kW 45 A 30 kW 58 A CIMR-AC4A0058AAA

30 kW 60 A 37 kW 72 A CIMR-AC4A0072AAA

37 kW 75 A 45 kW 88 A CIMR-AC4A0088AAA

45 kW 91 A 55 kW 103 A CIMR-AC4A0103AAA

55 kW 112 A 75 kW 139 A CIMR-AC4A0139AAA

75 kW 150 A 90 kW 165 A CIMR-AC4A0165AAA

90 kW 180 A 110 kW 208 A CIMR-AC4A0208AAA

110 kW 216 A 132 kW 250 A CIMR-AC4A0250AAA

132 kW 260 A 160 kW 296 A CIMR-AC4A0296AAA

160 kW 304 A 185 kW 362 A CIMR-AC4A0362AAA

185 kW 370 A 220 kW 414 A CIMR-AC4A0414AAA

220 kW 450 A 250 kW 515 A CIMR-AC4A0515AAA

315 kW 605 A 355 kW 675 A CIMR-AC4A0675AAA

A1000 13

Specifications Model

A Line filters

Voltage Model CIMR-A Reference Rated current (A) Weight (kg)

3-Phase 200 VAC

3-Phase 400 VAC

Chokes

Model Diameter Description

A1000-FEV2102-RE 21

A1000-FEV2515-RE 25

A1000-FEV5045-RE 50

A1000-FEV6045-RE 60

B

Communication cards

Type Model Description Function

option board

Communication

Inverter Line filter

2CA0004 / 2CA0006 / 2CA0008 3G3RV-PFI3010-SE 10 1.2

2CA0010 / 2CA0012 / 2CA0018 / 2CA0021 3G3RV-PFI3018-SE 18 1.3

2CA0030 / 2CA0040 / 2CA0056 3G3RV-PFI2035-SE 35 1.4

2CA0069 / 2CA0081 3G3RV-PFI2060-SE 60 3

2CA00110 / 2CA0138 3G3RV-PFI2100-SE 100 4.9

4CA0002 /4CA0004 / 4CA0005 / 4CA0007 3G3RV-PFI3010-SE 10 1.2

SI-N3 DeviceNet option card

SI-P3 PROFIBUS-DP option card

SI-S3 Can open option card

SI-T3 Mechatrolink II option card

2CA0169 / 2CA0211 3G3RV-PFI3170-SE 170 6.0

4C0009 /4C0011 3G3RV-PFI3018-SE 18 1.3

4CA0018 / 4CA0023 / 4CA0031 3G3RV-PFI3035-SE 35 2.2

4CA0038 /4CA0044 / 4CA0058 3G3RV-PFI3060-SE 60 4.0

4CA0072 /4CA0088 3G3RV-PFI3100-SE 100 4.5

4CA0103 / 4CA0139 / 4CA0165 3G3RV-PFI3170-SE 170 6.0

4CA0208 / 4CA0250 3G3RV-PFI3200-SE 250 11

4CA0296 / 4CA0362 3G3RV-PFI3400-SE 400 8.5

4CA0414 / 4CA0515 3G3RV-PFI3600-SE 600 11.0

4CA0675 3G3RV-PFI3800-SE 800 31.0

Recommended for motors below 2.2 KW

Recommended for motors below 15 KW

Recommended for motors below 45 KW

Recommended for motors above 45 KW

• Used for running or stopping the inverter, setting or referencing parameters, and monitoring output frequency, output current, or similar items through DeviceNet communication with the host controller.

• Used for running or stopping the inverter, setting or referencing parameters, and monitoring output frequency, output current, or similar items through PROFIBUS-DP communication with the host controller.

• Used for running or stopping the inverter, setting or referencing parameters, and monitoring output frequency, output current, or similar items through CANopen communication with the host controller.

• Used for running or stopping the inverter, setting or referencing parameters, and monitoring output frequency, output current, or similar items through Mechatrolink II communication with the host controller.

C Accessories

Types Model Description Functions

Digital

operator

Accessories

Computer software

D

Types Model Description Installation

Software

JVOP-180 LCD remote operator LCD Display operator with language support

3G3AX-CAJOP300-EE Remote operator cable 3 meters cable for connecting remote operator

JVOP-181 USB converter / USB cable USB converter unit with copy and backup function

PS-V10S

PS-V10M 24V DC control board power supply VZA-2/4 from 5.5 to 15 KW

A1000-CAVPC232-EE PC connection cable RS232 PC tool connection cable

CX-drive Computer software Configuration and monitoring software tool

CX-One Computer software Configuration and monitoring software tool

24 VDC option board

24V DC control board power supply VZA-B/2/4 from 0.1 to 4 KW

14 Frequency inverters

E Braking unit, braking resistor unit

Inverter Braking unit

Max.

Applicable

Motor kW

200 V Class

400 V Class

Model

Model

CIMR-

A@2A_

0.4 0004 HD

0004 ND

0.75

0006 HD --− --

0006 ND 85 --− --

1.1

0008 HD

0008 ND

1.5

0010 HD 1

0010 ND

2.2

0012 HD 116

0012 ND

3

0018 HD 1

0018 ND

3.7

0021 HD 1

0021 ND 2 110

5.5

0030 HD - 1

0030 ND -

7.5

0040 HD - 19.6

0040 ND -

11

0056 HD - 1

0056 ND -

15

0069 HD - 1

0069 ND -

18.5

0081 HD - 1

0081 ND - 2015 3000W 10Ω 185 9.6

22

0110 HD - 2022 4800W 6.8Ω 1 125 6.4

0110 ND -

30

0138 HD - 1

0138 ND - 2022 4800W 6.8Ω 170 6.4

37

0169 HD 2015B 2 - 2015 3000W 10Ω 2 100 9.6

0169 ND

45

0211 HD - 2022 4800W 6.8Ω 2120

0211 ND

55

0250 HD - 6.4

0250 ND

75

0312 HD 0312 ND

90

0360 HD 0360 ND

110

0415 HD -

0.4 0002 HD

0002 ND

0.75

0004 HD -----

0004 ND

1.5

0005 HD 64

0005 ND

2.2

0007 HD

0007 ND

3

0009 HD 43P7 390W 150Ω 1150 32

0009 ND

3.7

0011 HD

0011 ND

5.5

0018 HD

0018 ND

7.5

0023 HD

0023 ND

11

0031 HD

0031 ND

15

0038 HD

0038 ND

18.5

0044 HD

0044 ND

22

0058 HD

0058 ND

30

0072 HD

0072 ND

37

0088 HD 4045B 1

0088 ND

45

0103 HD

0103 ND 4045B 2

55

0139 HD 4030B 2

0139 ND 4030B 2

75

0165 HD 4045B 2

0165 ND

90

0208 HD

0208 ND

110

0250 HD

No. of

CDBR_

Built-in

2022B 2

2022B 2

2110B 1

2110B 1

2110B 1

Built in

4045B 1

4045B 2

4220B 1

used

Braking Resistor

Type

Model

A1000-RE_

J0K15200-IE 190W 200 Ω 1

J0K15100-IE 190 W 100 Ω 1

J0K15070-IE 190 W 70 Ω 1 120 22P2 260W 70Ω

J0K15062-IE 190 W 62 Ω

- 2015 3000W 10Ω 280

-

-

-

-

J0K10750-IE

J0K10750-IE

J0k15400-IE

J0k15300-IE

J0k15200-IE

J0k15200-IE

J0k15200-IE

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Specifications of

Resistor

60 W 750 Ω 1 230

60 W 750 Ω 1 130

190 W 400 Ω 1 125

190 W 300 Ω 1 115

190 W 200 Ω 1 125

190 W 200 Ω 1 105

190 W 100 Ω 2 135

Braking

Qty

torque %

(3% ED)

220 --− -- 48

125

150

125

100

1

80

1

Model

LKEB-

21P5 260W 100Ω 1150

21P5 260W 100Ω

23P7 390W 40Ω

23P7 390W 40Ω

25P5 520W 30Ω

27P5 780W 20Ω

2011 2400W 13.6Ω

2015 3000W 10Ω

2015 3000W 10Ω

2022 4800W 6.8Ω

2022 4800W 6.8Ω 2100

2022 4800W 6.8Ω 3 110 1.6

2022 4800W 6.8Ω 4 120 1.6

2018 4800W 8Ω 5 100 1.6

41P5 260W 400Ω 1125

42P2 260W 250Ω 1135 64

42P2 260W 250Ω 1100 64

43P7 390W 150Ω 1135 32

45P5 520W 100Ω 1135 32

47P5 780W 75Ω 1130 32

4011 1040W 50Ω 1135

4015 1560W 40Ω 1125 20

4018 4800W 32Ω 1125

4022 4800W 27.2Ω 1 125 19.2

4030 6000W 20Ω 1 125 19.2

4030 6000W 20Ω 1 100 19.8

4037 9600W 16 1 125 12.8

4045 9600W 13.6Ω 1 125 12.8

4045 9600W 13.6Ω 1 100 12.8

4030 6000W 20Ω 2 135 19.2

4030 6000W 20Ω 2 100 19.2

4045 9600W 13.6Ω 2 145 12.8

4045 9600W 13.6Ω 2 120 12.8

4030 6000W 20Ω 3 100 3.2

Specifications of

Resistor

--− --

-----96

-----

Qty

1

1

1

1

1

1

1

1

1

1

Braking

torque %

(10% ED)

125 48

120

150 16

125 16

115 16

125

125 9.6

125 9.6

100 9.6

90 6.4

Min

Resist

Value Ω

48

48

48

16

6.4

6.4

96

96

32

20

20

19.2

A1000 15

Inverter Braking unit

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I79E-EN-01

Max.

Applicable

Motor kW

400 V Class

1. When connecting a mounting type resistor or braking resistor unit, set system constant L3-04 to 0 (Stall prevention disabled during deceleration). Motor

will not stop at set deceleration time if this constant is not changed. Additionally the Internal braking transistor protection (L8-55) should be set to “0” when

a external braking unit (CDBR-) is used.

Model

CIMR-

A@2A_

0250 ND

132

0296 HD

0296 ND

160

0362 HD

0362 ND

185

0414 HD

0414 ND

220

0515 HD

250 0515 ND 4220B 1

315 0675 HD 4220B 2

355 0675 ND 4220B 2

Model

CDBR_

4220B 1

4220B 1

4220B 1

4220B

No. of

used

Model

A1000-RE_

-

-

-

-

-

1

-

-

-

-

-

-

Specifications of

Resistor

Braking Resistor

Braking

torque %

Qty

(3% ED)

Type

1

Model

LKEB-

4045 9600W 13.6Ω 4 140 3.2

4045 9600W 13.6Ω 4 120 3.2

4045 9600W 13.6Ω 4 100 3.2

4037 9600W 16Ω 5

4045 9600W 13.6Ω 6

Specifications of

Resistor

Qty

Braking

torque %

(10% ED)

110 3.2

105

F Feedback speed option card

Type Model Description Function

PG-B3 Complementary PG

PG-X3 Line Driver PG

PG option card

• For speed feedback input by connecting a motor encoder

Input: 3 track (one or two tracks), for HTL encoder connection, 50 KHz max

Output: 3 track open collector

Encoder power supply: 12 V, 200 mA max

• For speed feedback input by connecting a motor encoder

Input: 3 track, line driver, 300 kHz max

Output: 3 track, line driver

Encoder power supply: 5 V or 12 V, 200 mA max

Min

Resist

Value Ω

95 3.2

3.2

90

16 Frequency inverters

Loading...

Loading...