Page 1

Cat.No. W369–E1–1

SYSMAC

C200HW-ZW3AT2-E-V2

Controller Link Support Software

Ver. 2.00

OPERATION MANUAL

Page 2

SYSMAC

C200HW-ZW3AT2-E-V2

Controller Link Support Software

Ver. 2.00

Operation Manual

Revised March 2000

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

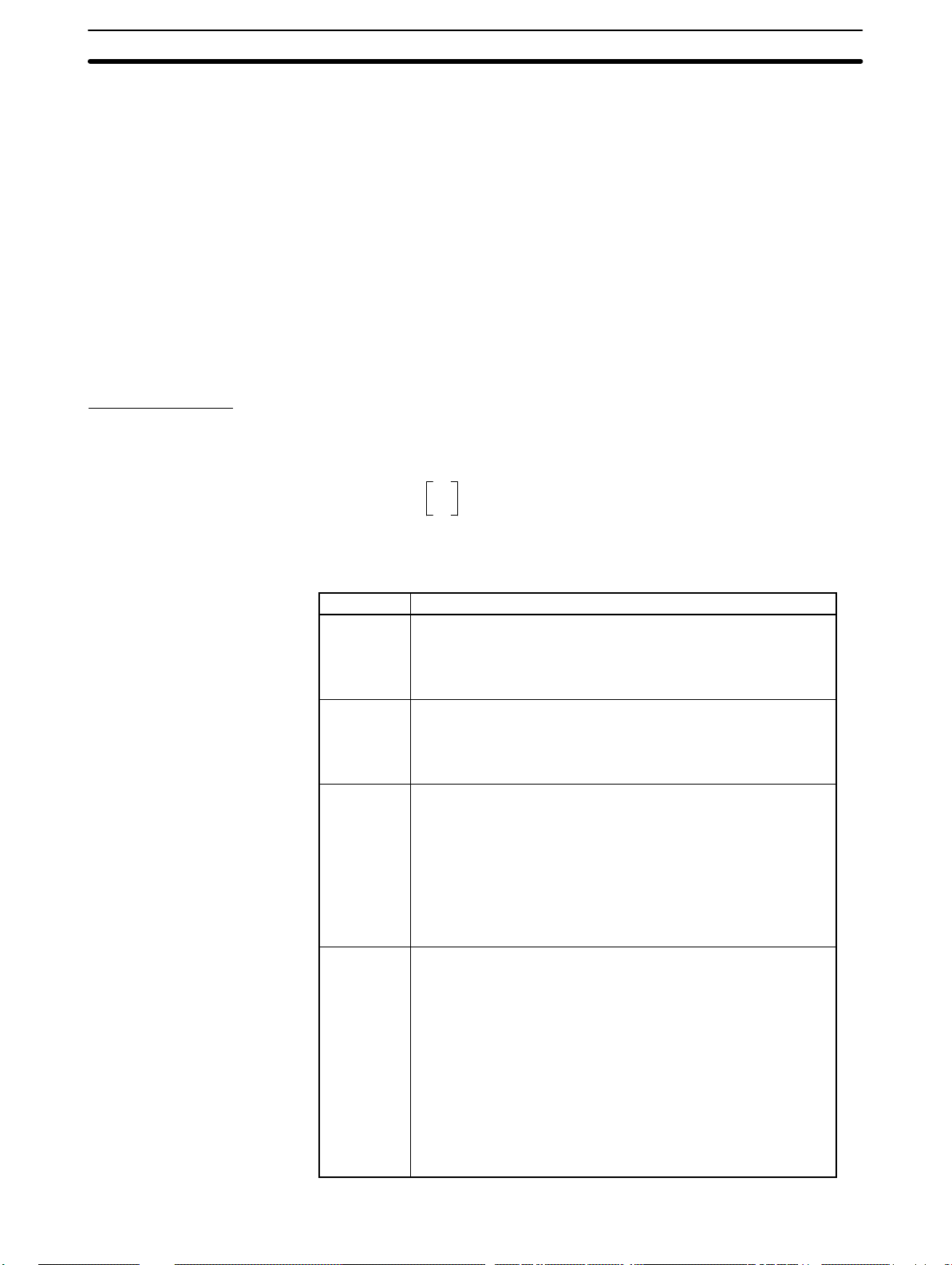

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

DOS, Windows and Microsoft C are registered trademarks of Microsoft Corporation.

IBM is a registered trademark of International Business Machines Corporation.

All other product names or company names that appear in this manual are trademarks or registered trademarks of each

respective company.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 4

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Application Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Trademarks xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Checking the Contents xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Features 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 About the Controller Link Support Software 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Checking Components 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Operating Environment 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Overall Flow of Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Menu Hierarchy 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Installation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Preparations for Installation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Installation Procedure 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Basic Operations and Connections 15. . . . . . . . . . . . . . . . . .

3-1 Starting and Exiting the Controller Link Support Software 16. . . . . . . . . . . . . . . . . . . . . . .

3-2 Basic Operations 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Connecting to a Node 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Basic Operating Procedures 37. . . . . . . . . . . . . . . . . . . . . . .

4-1 Starting the Network for the First Time 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Starting Data Links 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Interconnecting Networks 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Operating Procedures 41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Keyboard Operation 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

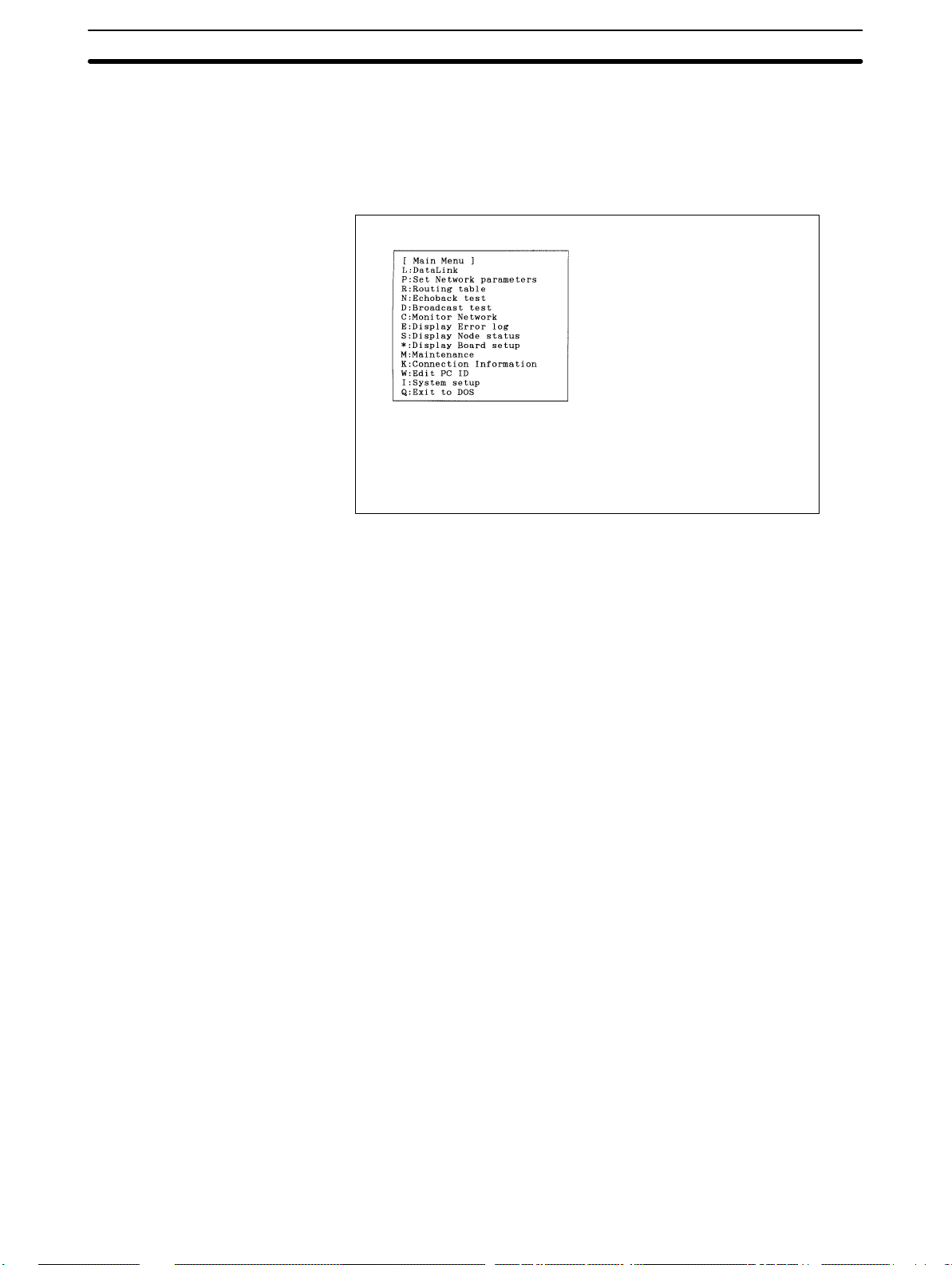

5-2 Main Menu 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 L: Data Link 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 P: Set Network Parameters 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 R: Routing Table 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 N: Echoback Test 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 D: Broadcast Test 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8 C: Monitor Network 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-9 E: Display Error Log 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-10 S: Display Node Status 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-11 M: Maintenance 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-12 K: Connection Information 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-13 W: Edit PC ID 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14 I: System Setup 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-15 Q: Exit to DOS 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Troubleshooting 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 5

TABLE OF CONTENTS

Appendices

A Error Messages 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Using Modems 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Registering the Controller Link Support Software in the SYSMAC Support Software 163. . . . .

D Running the Controller Link Support Software under Windows 95 165. . . . . . . . . . . . . . . . . . . .

E Editing the Device Information Setting File 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 6

About this Manual:

This manual describes the installation and operation of the C200HW-ZW3AT2-E-V2 Controller Link Support Software (Ver. 2.00) and includes the sections described below. The Controller Link Support Software is used to set up and manage a Controller Link Network (Wired type, Optical type, Optical Ring type).

The C200HW-ZW3AT2-E-V2 is for use on a computer that is not part of the Controller Link Network (i.e., a

computer connected to the Network via a PC, not as a Network node).

The following three manuals are directly related to application of the Controller Link Network.

Name Contents Cat. No.

(suffixes omitted)

SYSMAC C200HW-ZW3AT2-E-V2, Controller

Link Support Software

Operation Manual (this manual)

SYSMAC 3G8F5-CLK11-E, 3G8F5-CLK21-E

Controller Link Support Boards

Operation Manual

SYSMAC CS1W-CLK11/21, C200HW-CLK21,

CVM1-CLK21, CQM1H-CLK2 Controller Link

Units

Operation Manual

SYSMAC CS1W-CLK12, CVM1-CLK12

Optical Ring Controller Link Units

Operation Manual

SYSMAC C200HW-ZW3AT2-E,

3G8F5-CLK11-E/CLK21-E

Controller Link Support Software

Operation Manual

Installation and operating procedures for the Controller Link

Support Software Ver 2.00. The Controller Link Support Software

enables manual setting of data links and other procedures for a

Controller Link Network. Use this software for Optical Controller

Link Networks.

Installation, setup, and operating procedures for Controller Link

Support Boards. Controller Link Support Boards are used to

connect IBM PC/ATs or compatibles to a Controller Link Network.

Installation, setup, and operating procedures for the Controller Link

Units. Controller Link Units are used to connect CS1-series,

CV-series, CVM1, C200HX/HG/HE, and CQM1H PCs to a

Controller Link Network.

Installation, setup, and operating procedures for Optical Ring

Controller Link Units. Optical Ring Controller Link Units are used

to connect CS1-series, CV-series, and CVM1 PCs to an Optical

Ring Controller Link Network.

Installation and operating procedures for the Controller Link

Support Software Ver. 1.10 (or earlier versions). This manual is

included with Controller Link Support Boards. Use Controller Link

Support Software Ver. 1.10 (or earlier versions) with Controller

Link Support Boards.

W308

W307

W309

W370

W308

Please read this manual and related manuals carefully and be sure you understand the information provided before attempting to use the Controller Link Support Software.

Precautions provides general precautions for using the Controller Link Support Software.

Section 1 explains the features of the Controller Link Support Software and its operating environment.

Section 2 describes how to install the C200HW-ZW3AT2-E-V2 Controller Link Support Software. Refer to the Controller Link

Support Boards Operation Manual (W307) for installation procedures for the 3G8F5-CLKj1-E Controller Link Support Software.

Section 3 describes the Controller Link Support Software menu structure and basic operations, such as starting and exiting the

software. It also describes how to connect the computer running the Controller Link Support Software to the Network.

Section 4 outlines operating procedures for the Controller Link Support Software. Actual procedures are provided in Section 5

Operating Procedures.

Section 5 describes individual operating procedures for the Controller Link Support Software.

Section 6 describes troubleshooting methods for some of the problems that can occur with the Controller Link Support Software.

Appendix A provides a list of error messages displayed by the Controller Link Support Software.

Appendix B describes how to connect a remote computer running the Controller Link Support Software to a PC on a Controller

Link Network via modem.

Appendix C tells how to register the Controller Link Support Software on the Option Menu of the SYSMAC Support Software.

Appendix D tells how to run the Controller Link Support Software under Windows 95.

Appendix E tells how to edit the device information setting file.

Appendix F provides forms that can be used to help structure data links.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 7

PRECAUTIONS

This section provides general precautions for using the Controller Link Support Software.

The information contained in this section is important for the safe and reliable application of the product. You must

read this section and understand the information contained before attempting to set up or operate the Controller Link

Support Software.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Application Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Trademarks xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Checking the Contents xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 8

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

4Application Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned

applications.

3 Safety Precautions

WARNING Do not attempt to disassemble the Board or touch the inside of the Unit while the

!

power is being supplied. Doing so may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

WARNING Be sure to turn OFF the power supply before assembling the Unit or connecting

!

cables. Not doing so may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

4 Application Precautions

Observe the following precautions when using the PC System.

xii

Caution Before starting data links, make sure that data link tables have been appropri-

!

ately set at each node for which the data links are to be established. If the data

link tables have been inappropriately set, the equipment may perform unexpected operation and result in injury. Even if the data link tables have been appropriately set, always make sure that the equipment will not be affected before

starting or stopping the data link.

Page 9

Caution Once routing tables are transferred to a PC, all CPU Bus Units at the node (ex-

!

cept SYSMAC BUS/2 Master Units) will be reset. Before transferring the routing

tables, always make sure that the equipment will not be affected.

5 Trademarks

MS-DOS, Windows, Microsoft C, and Quick BASIC are registered trademarks of

Microsoft Corporation.

IBM and IBM PAC-DOS are registered trademarks of International Business

Machines Corporation (U.S.A.).

PC-PR210H is a registered trademark of NEC Corporation.

ESC/P is a registered trademark of Seiko Epson Corporation.

Other brands and their products are trademarks or registered trademarks of

their respective holders and should be noted as such.

6 Checking the Contents

Confirm that the following items are included with your purchase. These items

are required to configure the C200HW-ZW3AT2-E-V2

• Installation disk (3.5 inch, 1 disk)

• Operation manual (B5 size, English)

• User registration cards (English and Japanese)

• Mailing label

• One operation manual (this manual)

6Checking the Contents

xiii

Page 10

SECTION 1

This section explains the features of the Controller Link Support Software and its operating environment.

1-1 About the Controller Link Support Software 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-2 Functions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-3 Additional Functions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-4 Main Functions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-5 Connecting to the Network 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Checking Components 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 C200HW-ZW3AT2-E-V2 Controller Link Support Software 7. . . . . . . . . . . . . . .

1-3 Operating Environment 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1 Compatible Computers 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-2 Printers 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Overall Flow of Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Menu Hierarchy 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features

1

Page 11

1-1 About the Controller Link Support Software

The Controller Link Support Software is used to set up, control, and monitor

Controller Link Networks.

Functionality for Optical Ring Controller Link Networks has been added with this

version. Ver. 2.00 of the Controller Link Support Software is required for Optical

Ring Controller Link Networks. For other types of network, Ver. 1.10 (or earlier

versions) can be used.

1-1-1 Features

1-1SectionAbout the Controller Link Support Software

Sets Data Link Tables

Run from Programming

Device or from a Node

Compatible with All

Controller Link Models

Print the Current Screen

or Data

The Controller Link Support Software can be used to create data link tables to

manually set data links. It can also create data link areas used for automatically

set data links.

The Controller Link Support Software can be run on an IBM PC/AT or compatible

computer as a programming device connected to a PC via an RS-232C interface, or it can be run on an IBM PC/AT or compatible computer connected as a

node to the Controller Link Network via a Controller Link Support Board.

The Controller Link Support Software supports all Controller Link Units and Controller Link Support Boards.

Note The following products are available for the Controller Link Network.

• Controller Link Unit for SYSMAC CS1-series PCs (wired, and optical, and optical ring)

• Controller Link Unit for SYSMAC C200HX/HG/HE PCs (wired only)

• Controller Link Unit for SYSMAC CVM1 and CV-series PCs (wired and optical

ring)

• Controller Link Unit for SYSMAC CQM1H PCs (wired only)

• Controller Link Support Board for IBM PC/AT or compatible computer (wired

and optical)

The Controller Link Support Software can print the current screen or data.

Create Routing Tables

Set PC IDs

Connect from Remote

FA Networks

Facilitate Unit

Replacement

2

The Controller Link Support Software can create routing tables, which allow inter-network connections. Data files for routing tables can be shared with the

SYSMAC Support Software.

The Controller Link Support Software allows you to create and edit PC IDs,

which facilitate node management. Data files for PC IDs can be shared with the

SYSMAC Support Software.

When multiple FA networks are inter-connected, the Controller Link Support

Software can be used to set and display all Controller Link Networks within a

three-level hierarchy (including the local network).

Note Here, FA networks include Controller Link, SYSMAC NET, and SYSMAC LINK

Networks.

The Controller Link Support Software can save in the computer all the settings

stored in Controller Link Units or Controller Link Support Boards. Therefore, before replacing a Controller Link Unit or Controller Link Support Board, you can

save all the settings in the computer and restore them to the new Controller Link

Unit or Controller Link Support Board. This will save you the trouble of redoing

settings after replacement.

Page 12

1-1-2 Functions

1-1SectionAbout the Controller Link Support Software

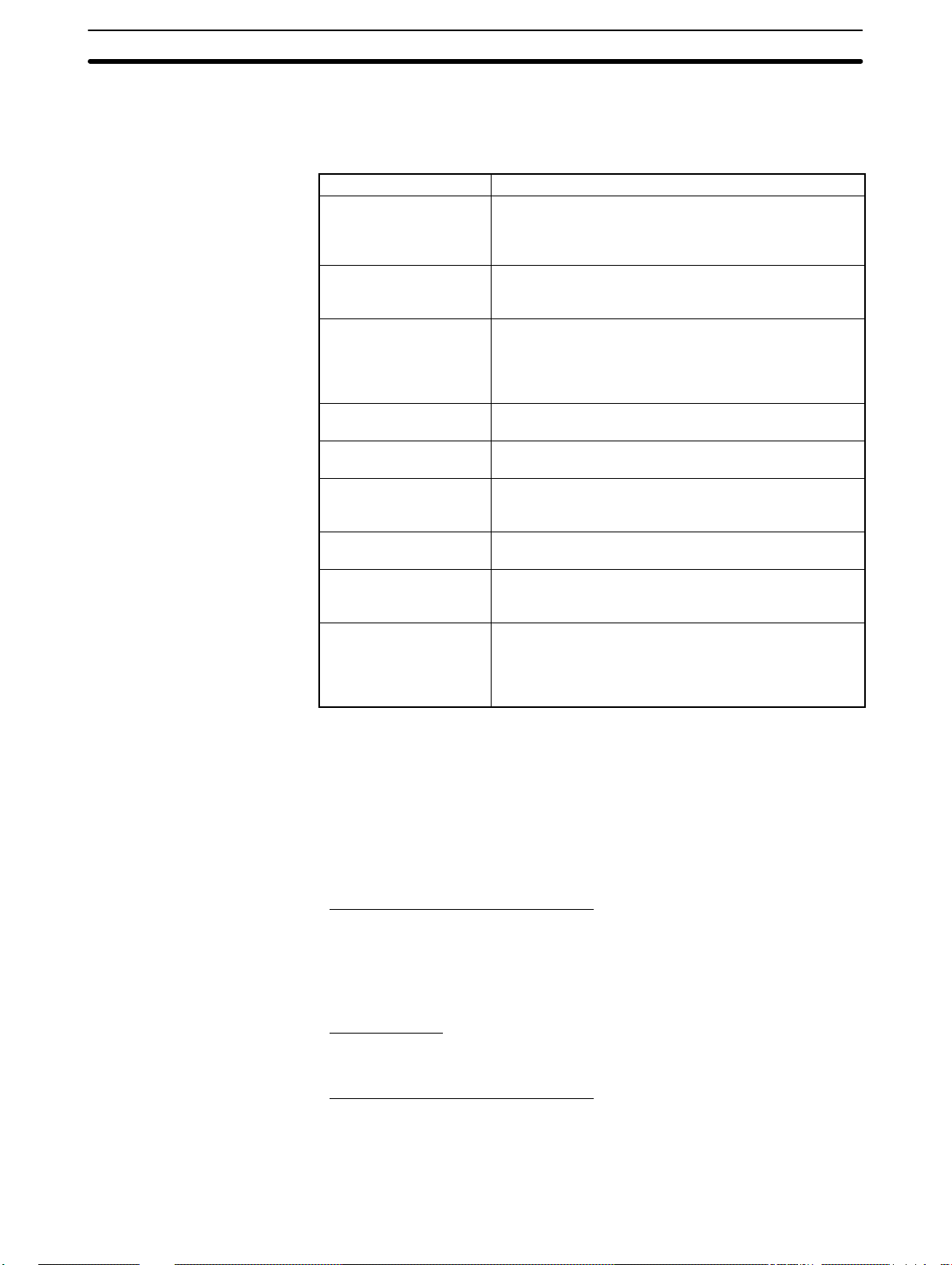

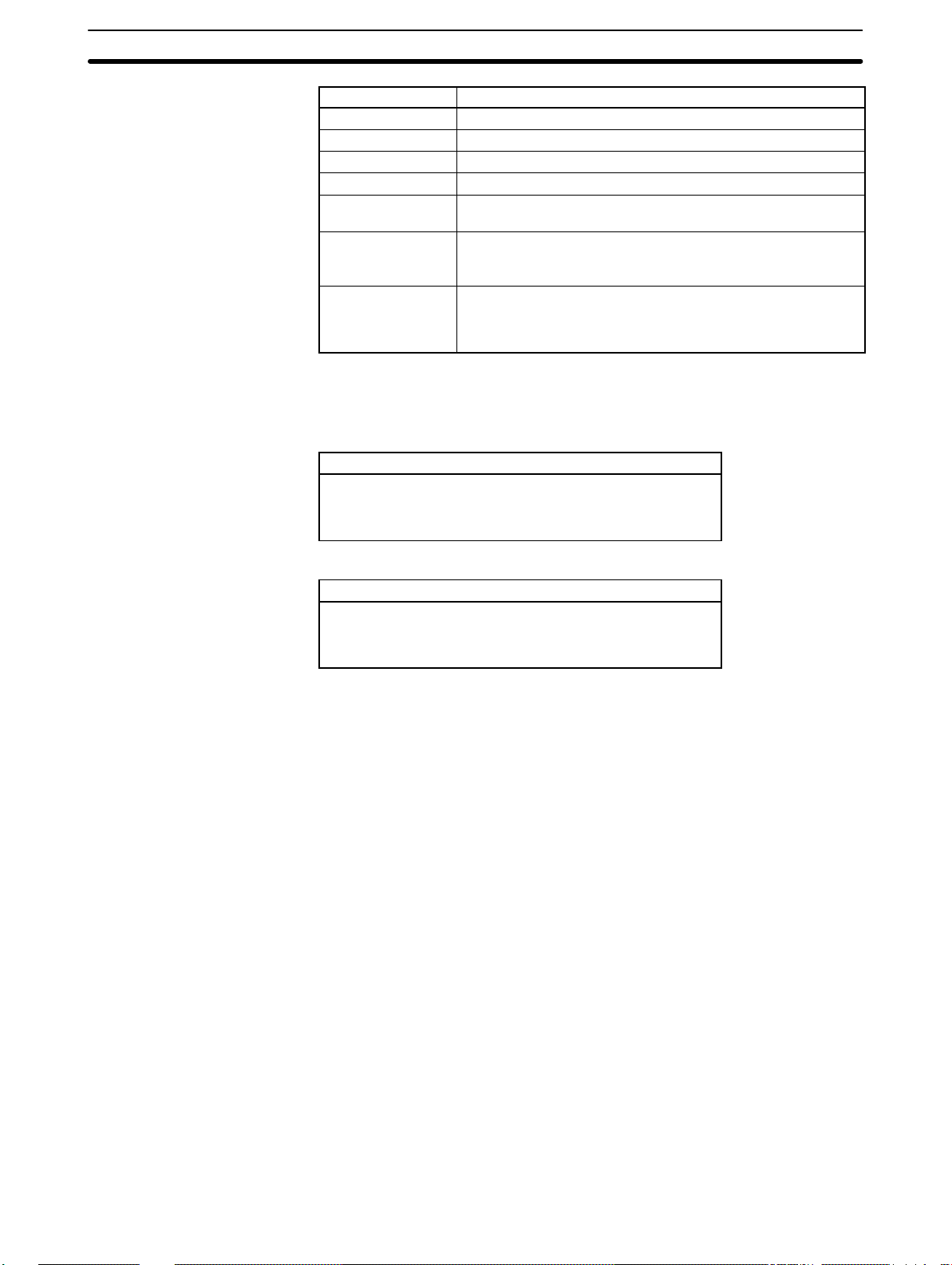

The functions of the Controller Link Support Software are outlined in the following table.

Function Explanation

Data link management Creates and edits data link tables for manually set data

Network parameter

setting

Routing table

management

Communications testing Checks whether the Controller Link Network is working

Status display Displays the network and node status, data link status,

Maintenance Backs up the contents of the EEPROM in the Controller

Connection information

reading

PC ID editing Assigns a unique ID to each PC. Using PC IDs allows

System setup Sets the communications parameters for the Controller

links, registers data link tables at nodes, saves data link

tables as files, and performs other processing related to

data links.

Adjusts network communications parameter settings to

provide the most suitable Controller Link

communications for the user application.

Creates and edits routing tables, registers routing tables

at nodes, and saves routing tables as files. Routing

tables are used to specify data communications paths

when data is transferred to/from remote FA networks.

(See note.)

properly.

error logs, and so on.

Link Unit or Controller Link Support Board as a file and

restores the file to the EEPROM.

Reads node configurations and the status of networks.

(Only available for Optical Ring Networks.)

easier PC management than using network and node

addresses.

Link Support Software, the PC to be connected, the

service conditions for the Controller Link Support

Software, and so on. These must be set before the

Controller Link Support Software is connected to a node.

Note Other FA net wo r k s , s u c h a s C o n t r ol l e r Link Networks, SYSMAC NET

1-1-3 Additional Functions

The following functions were added to the Controller Link Support Software for

when upgrading from Ver. 1.1j to Ver. 2.00.

• Optical Ring Controller Link Networks

Connection configuration data for Optical Ring Controller Link Networks can

be read using the Connection Information Menu. In addition, since an Optical

Ring Network can have up to 62 nodes, the maximum number of nodes for

which each menu’s functions can be used has been increased to 62 (from 32

with Ver. 1.10).

• CS1-series PCs

This version of the Controller Link Support Software can be directly connected

to, and used with, CS1-series PCs.

• Saving and Printing of Error Log Files

Error logs read from specified nodes can be saved to files, and this data can be

read from the file and displayed. The error log data saved to files in this way,

can be displayed and edited using a standard text editor, and used in other

applications. It can also be printed out.

Networks, and SYSMAC LINK Networks, can be inter-connected.

3

Page 13

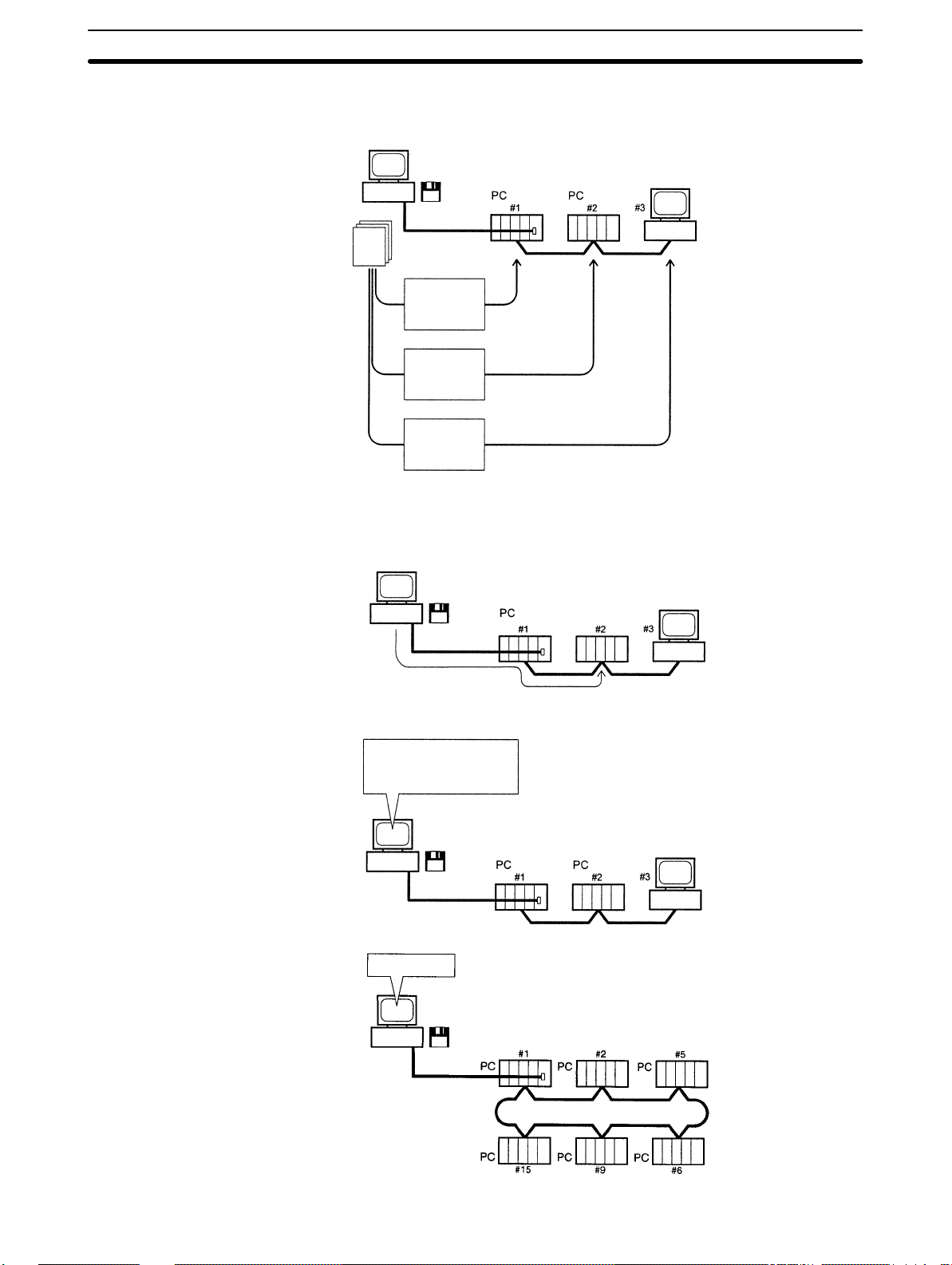

1-1-4 Main Functions

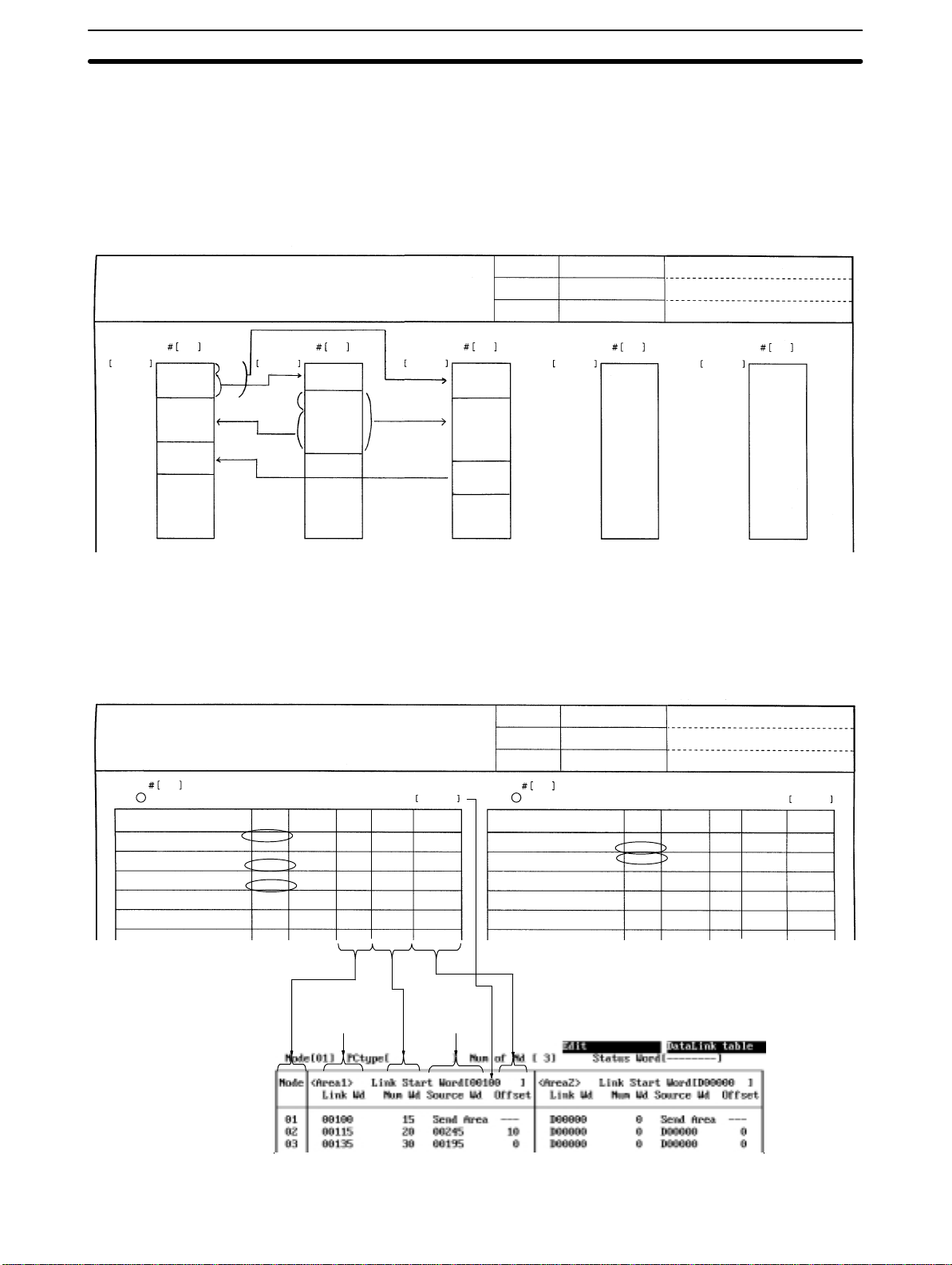

Registering Data Link Tables

Create

Data

link

tables

Controller Link

Support Software

Data link table

for #1 node

(send and

receive areas)

Data link table

for #2 node

(send and

receive areas)

Data link table

for #3 node

(send and

receive areas)

Transfer

Transfer

Transfer

1-1SectionAbout the Controller Link Support Software

IBM PC/AT computer

Controller Link

Network

Data link tables: Tables that specify the send areas at the local node and the numbers

Starting and Stopping Data Links

Displaying Network and Node Status

of words to be received from a particular areas at remote nodes.

Controller Link

Support Software

Starting and stopping

Data link status monitor

Data link area monitor

Network monitor

Node status display

Controller Link

Support Software

Connection

information

IBM PC/AT or compatible

PC (startup node)

Controller Link Network

IBM PC/AT or compatible

Controller Link Network

Controller Link

Support Software

Optical Ring

Controller Link

Network

4

Page 14

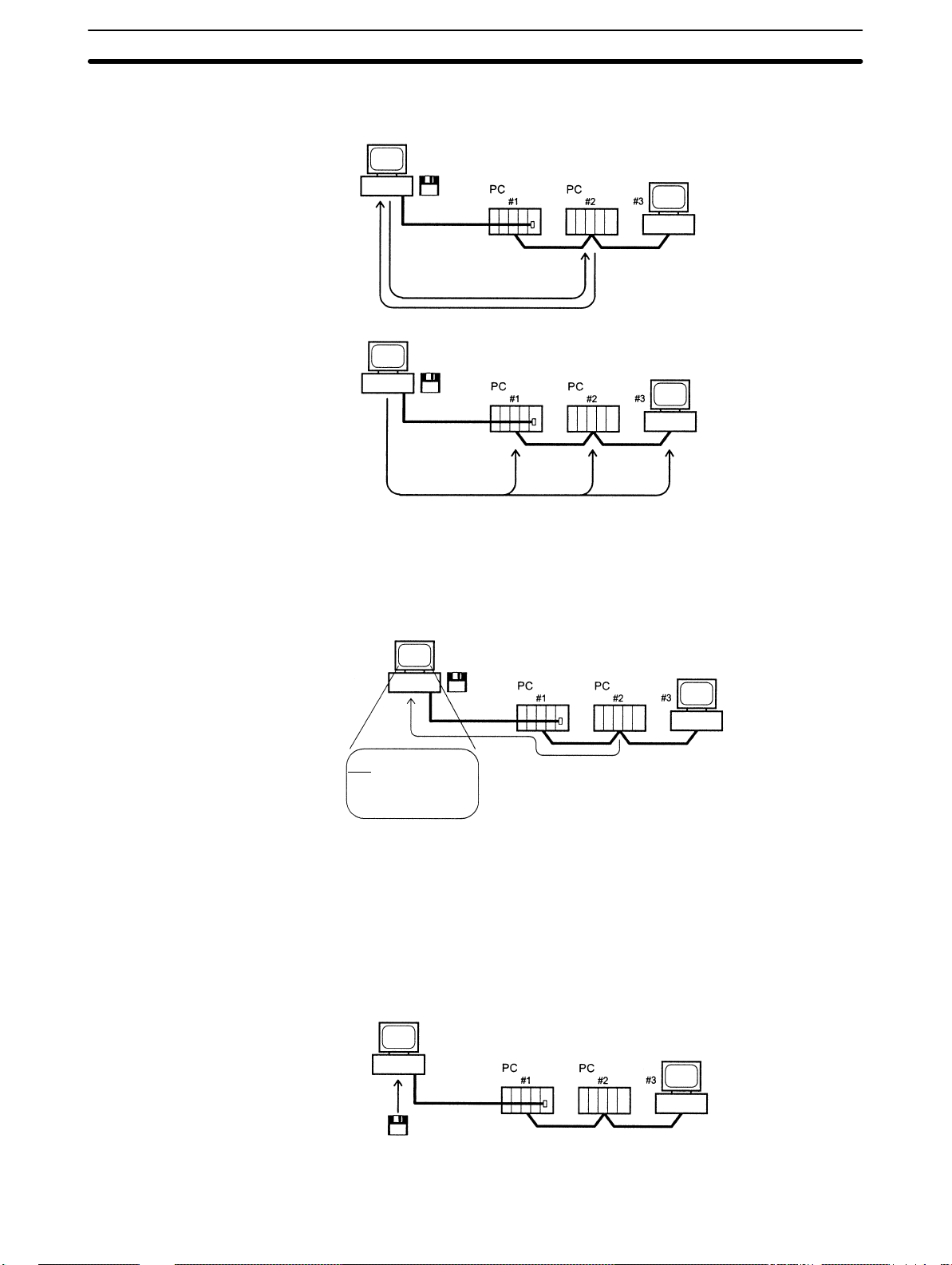

Testing

Controller Link

Support Software

1-1SectionAbout the Controller Link Support Software

IBM PC/AT or compatible

Displaying Error Logs

Echoback test between the local

node and the specified node

Returns the test data unchanged.

Controller Link

Support Software

Test data is broadcasted to all nodes the specified number of times and

the success count is examined (broadcast test.)

Controller Link

Support Software

Controller Link Network

IBM PC/AT or compatible

Controller Link Network

IBM PC/AT or compatible

Node#2Error code

020C

96/09/10 10:00

1-1-5 Connecting to the Network

Connecting to a PC

The Controller Link Support Software can be run from a computer that is connected to a Network PC as a dedicated programming device, i.e., one that is not

a node on the Network.

Controller Link

Support Software

Date Time

IBM PC/AT or

compatible

Controller Link Network

Reading error log

IBM PC/AT or compatible

Controller Link Network

5

Page 15

1-1SectionAbout the Controller Link Support Software

The Controller Link Support Software can also be used simultaneously with the

SYSMAC Support Software, i.e., it can be registered in the Option Menu of the

SYSMAC Support Software.

IBM PC/AT or

compatible

Installing in a Computer

Node

The Controller Link Support Software can also be run directly from a Network

computer.

Supplemental Connection Information

The Controller Link Support Software can be connected to PCs via modems.

Option

Menu

SYSMAC Support

Software

Controller Link

Support Software

Controller Link

Support Software

Controller Link Network

IBM PC/AT or compatible

Controller Link Network

IBM PC/AT or compatible

Controller Link

Support Software

Modem

Controller Link

Support Software

IBM PC/AT or compatible

Modem

Controller Link Network

6

Page 16

1-3SectionOperating Environment

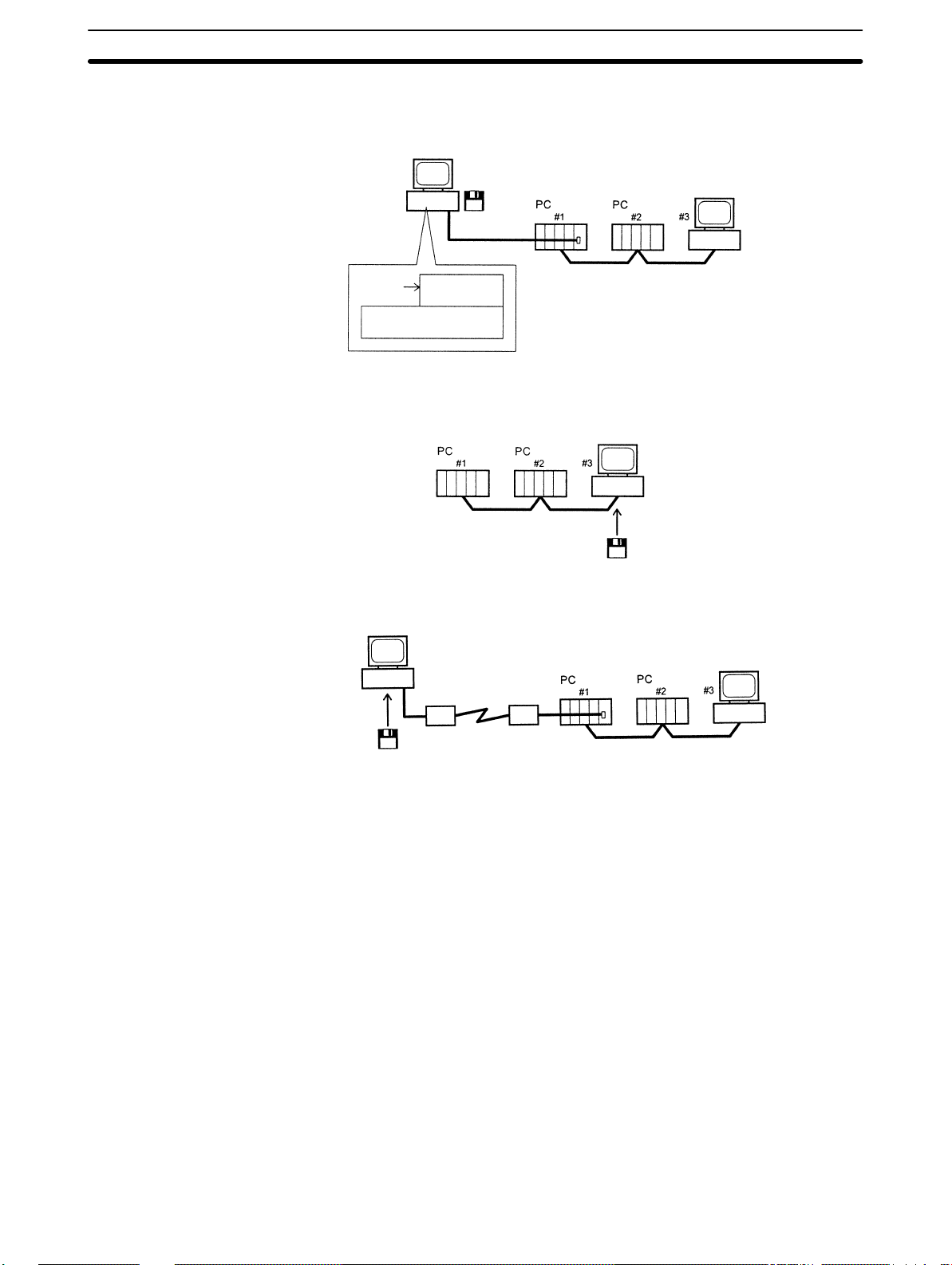

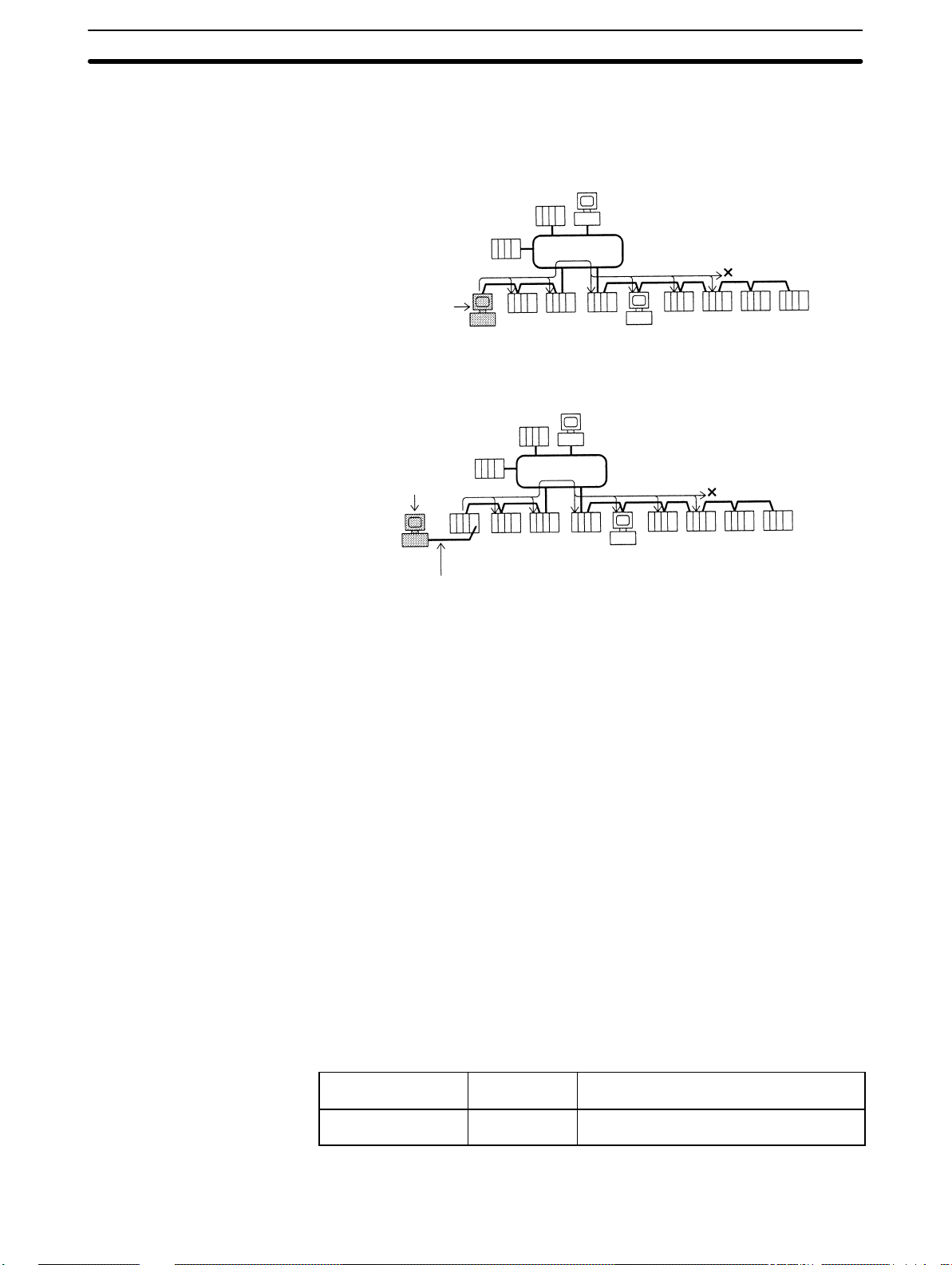

When multiple FA networks are inter-connected, the Controller Link Support

Software can be used to set up and monitor up to three levels of Controller Link

Networks, including the local network. In this case, set routing tables at each

node.

Running from a Computer Node

SYSMAC NET Network (2nd network)

Computer running the

Controller Link Support

Software

Controller Link Network

(1st network: local)

Running from a Programming Device

Controller Link Network (3rd network)

4 Network levels

are not possible

Controller Link Network (4th network)

Computer running the

Controller Link Support

Software

Controller Link Network

(1st network: local)

The connection to the

PC is not counted as

a network level.

SYSMAC NET Network (2nd network)

Controller Link Network (3rd network)

4 Network levels

are not possible

Controller Link Network (4th network)

1-2 Checking Components

When you first open the container, check the contents to be sure you have the

product you ordered and that all items are present.

1-2-1 C200HW-ZW3AT2-E-V2 Controller Link Support Software

The C200HW-ZW3AT2-E-V2 Controller Link Support Software is used when

connecting to a PC from a computer that is not a node on the Network.

• Installation disk (3.5”): 1

• Operation manual (this manual): 1

• User registration card: 1

1-3 Operating Environment

1-3-1 Compatible Computers

The Controller Link Support Software must be run on an IBM PC/A T or compatible computer.

Controller Link

Support Software

C200HW-ZW3AT2-E

-V2

The computer must provide the following.

Manufacturer Model

Various IBM PC/AT or compatible computer

7

Page 17

1-3-2 Printers

1-3SectionOperating Environment

Item Specifications

Processor 80386/80486 or higher

Main memory 450K bytes min.

Floppy disk 3 1/2” 2HD

Hard disk 1M bytes min. empty disk space

Display 640 × 480 dots (i.e., a 640 × 480 dot display with Windows

95/98)

Keyboard The following keys are required: Home, Escape, Control,

Page Up, Page Down, Backspace, F1 through F10, End,

Insert, Delete, Tab.

OS IBM PC-DOS 7.0 or later

Microsoft MS-DOS 6.2 or later

Windows 95/98

To print data from the Controller Link Support Software, use a printer that can

execute the following emulation:

Printer specifications

PCL2 specifications

IBM

ESC/P

The following printers are recommended:

Printers

HP Laser Jet 4P

IBM 4202-003

EPSON MJ-500

8

Page 18

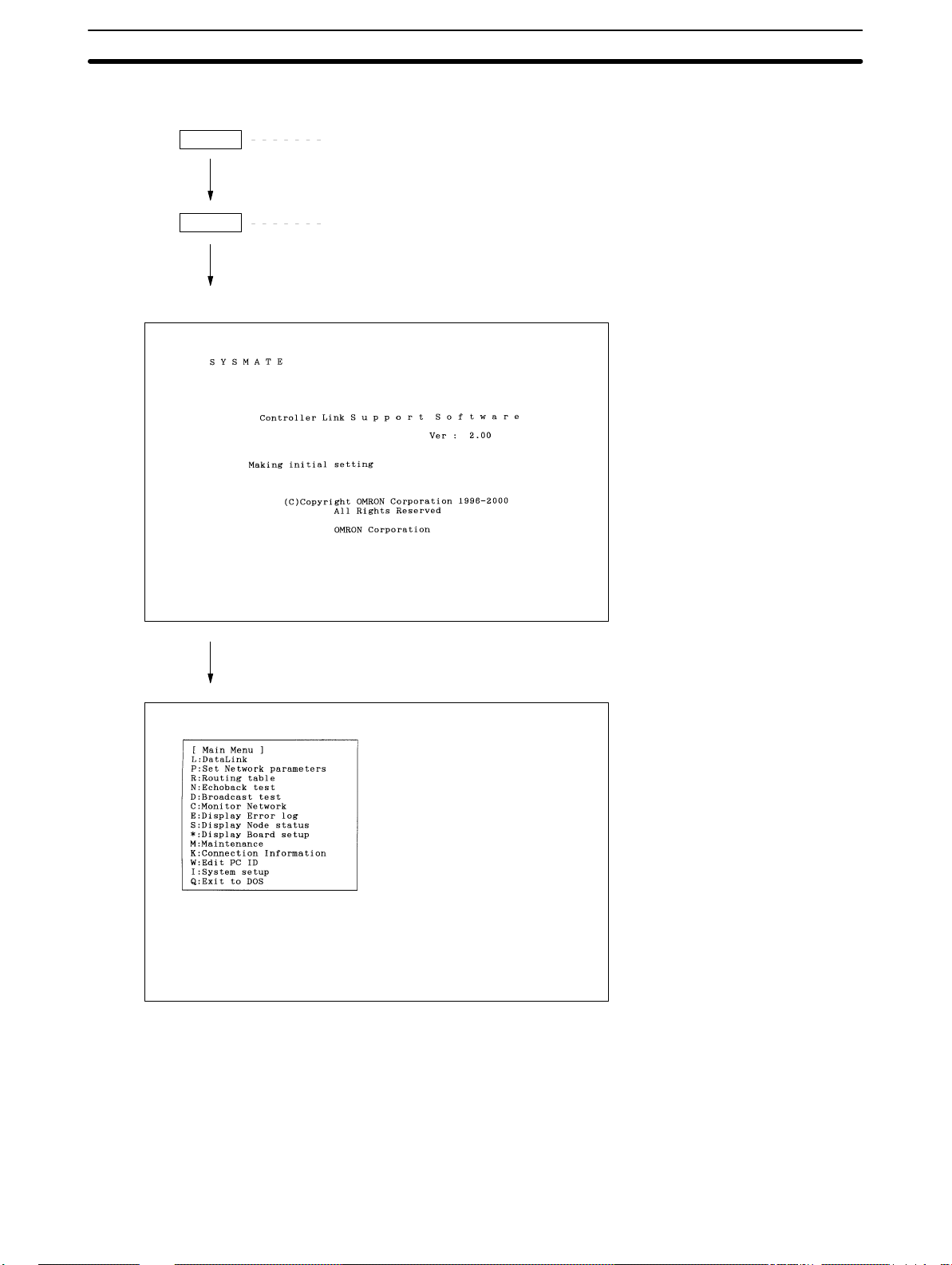

1-4 Overall Flow of Operation

1-4SectionOverall Flow of Operation

Install

Start

Type A:\>INSTALL then press the Enter Key.

Follow the instructions displayed on the screen. The path to

C:\CLK must be specified in AUTOEXEC.BAT.)

Type C:\CLK>CLKSS then press the Enter Key.

This screen is displayed for a

few seconds.

Select the desired item from the

menus to perform setting or

monitoring operations.

9

Page 19

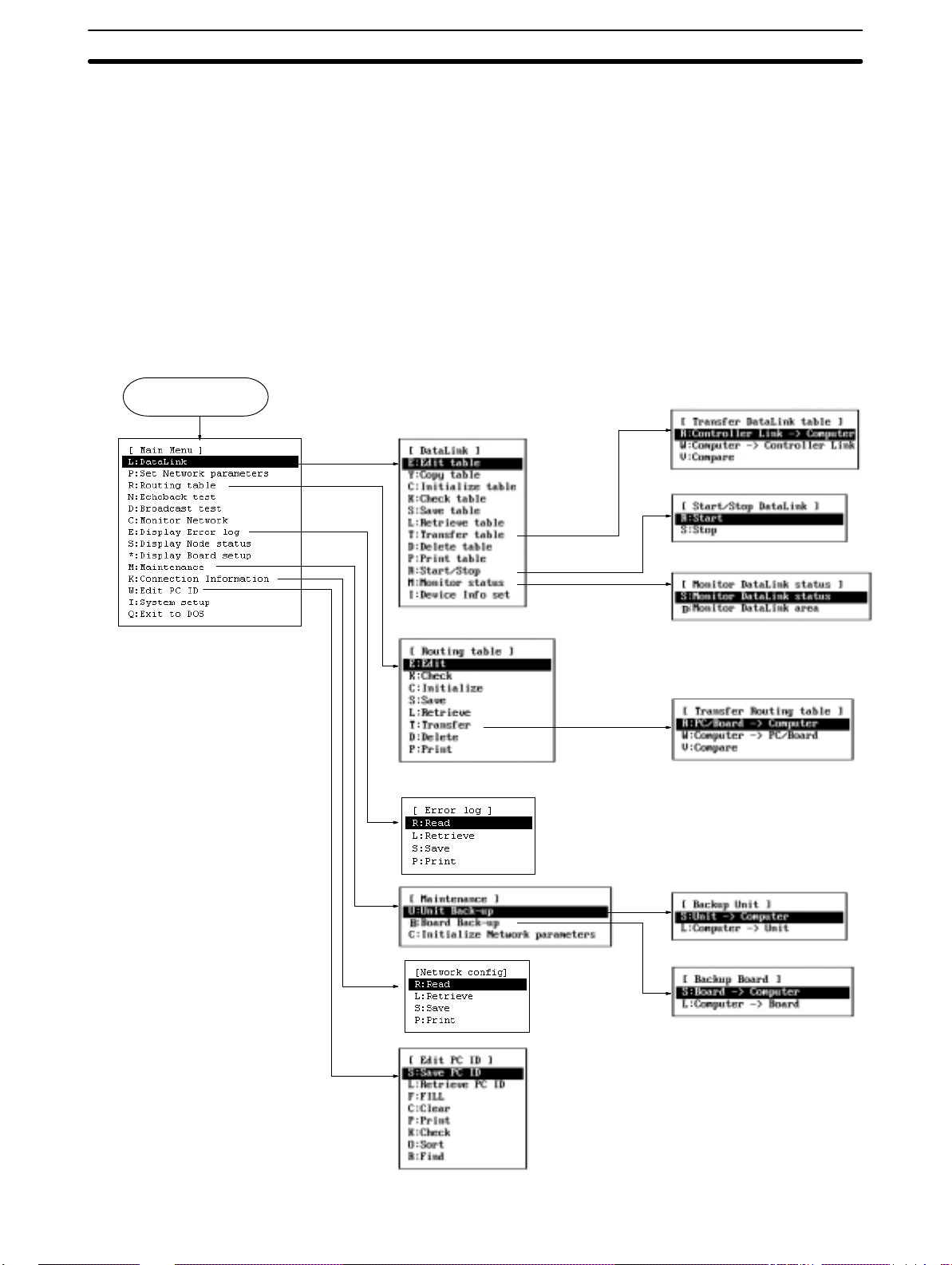

1-5 Menu Hierarchy

This section shows the menu hierarchy of the Controller Link Support Software.

The following illustration shows the overall flow of the menus; it does not show all

the steps necessary to display individual menus.

The menu items marked with asterisks (*) are valid only when a Controller Link

Support Board is installed in the computer. If a Controller Link Support Board i s

not installed in the computer , these menu items cannot be selected.

Note Use Controller LInk Support Software Ver. 1.10 when creating a Controller Link

Network with a Controller Link Support Board. This version is included with the

Support Board. Also, use the SYSMAC C200HW-ZW3AT2-E

3G8F5-CLK11-E/CLK21-E Controller Link Support Software Operation Manual

instead of this manual.

Start Controller Link

Support Software

L

R

1-5SectionMenu Hierarchy

E

*

M

K

W

*

T

R

W

*

T

U

10

B

Page 20

SECTION 2

Installation

This section describes how to install the C200HW-ZW3AT2-E-V2 Controller Link Support Software.

2-1 Preparations for Installation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Check Items 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Backing Up the Installation Disk 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Installation Procedure 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Page 21

2-1 Preparations for Installation

This section describes the knowledge required and tasks to be performed before installation.

2-1-1 Check Items

Item Contents

Product Installation disk: 1

Operating environment See 1-3 Operating Environment (page 7.)

2-1-2 Backing Up the Installation Disk

Files may be erased or data may be corrupted by operation errors during installation. Create a copy of the floppy disk of the Controller Link Support Software

and use the disk containing the copy for installation. This will protect the master

installation disk should any problem occur. Creation of a disk copy is called backing up the disk.

Prepare one new floppy disk for the backup. After completing the backup, store

the master disk (the original floppy disk) carefully. It will be necessary for future

version upgrades. Use the copied disk for subsequent operation. If the copy is

ever damaged, make a backup copy again. If the master disk is damaged,

please return it to OMRON. OMRON will fix or replace the disk for a small

charge.

This section describes the backup procedure using the following drive structure

as the example. If the drive structure is different, replace the drive name.

Floppy disk drive:Drive A (for 3.5” 2HD floppy disks)

Hard disk drive: Drive C (contains the DOS system)

Note 1) Write protect the Controller Link Support Software disk to ensure that files

are not accidentally erased.

2) Always create a backup copy for the Controller Link Support Software in order to provide protection against data corruption.

3) Use the DISKCOPY command of DOS for backing up the disk. The disk to

which data is to be copied need not be formatted since DISKCOPY command formats the disk before copying.

4) The operating system (MS-DOS) is not provided with the Controller Link

Support Software.

2-1SectionPreparations for Installation

Operation manual (this manual): 1

Required Items

Backup Procedure

12

New floppy disk (3.5” 2HD): 1

1, 2, 3... 1. Turn on the power of the computer. In this example, the computer is started

from the hard disk and command input is prompted as shown below.

C:\>

Note If other applications are running, terminate them and display the DOS

command input prompt. Refer to the related manuals for your computer and application software.

2. Write protect the floppy disk containing the Controller Link Support Board.

3. Enter the following command (underlined section).

C:\>DISKCOPY A: A:

The following messages will be displayed.

Insert SOURCE disk in Drive A:

and press ENTER when ready...

Page 22

4. Insert a disk of the Controller Link Support Software in Drive A.

5. Press the Enter Key. The data on the disk will be read and the following messages will be displayed after a short time.

Insert TARGET disk in drive A:

and press ENTER when ready...

6. Remove the master disk of the Controller Link Support Software from drive

A and insert a new floppy disk.

7. Press the Enter Key. The data will be written to the new disk.

8. If a message prompts replacing the disk, replace the disk in drive A according to the message.

9. When copying is completed, the following message will be displayed.

Create another copy (Y/N)?

10. Press the N key. The following message will be displayed immediately.

Copy another disk (Y/N)?

11. Press the N key.

Note Store the master installation disk carefully.

2-2SectionInstallation Procedure

2-2 Installation Procedure

This section describes how to install the C200HW-ZW3AT2-E-V2 Controller

Link Support Software to the hard disk of a DOS computer connected to a PC.

In this example, the system environment is as follows:

• Floppy disk drive: Drive A

• Destination drive in hard disk: Drive C

• Destination directory: C:\CLK

If the drives to be used are different from those shown in this example, replace

drives A and C in the following descriptions with the actual drives to be used. Any

directory name (up to 8 characters long) can be specified as the destination directory.

Always follow the procedure described in this section. Otherwise, the software

may not be installed properly.

1, 2, 3... 1. Turn on the power to the computer. The computer is started from the hard

disk and command input is prompted as shown below.

C:\>

Note If another applications is started, terminate it and display a DOS com-

mand input prompt. Refer to the related manuals for your computer

and the application software.

2. Insert the Controller Link Support Software disk into drive A.

Note Be sure to use the backup disk previously created when installing the

software.

3. Change the current drive to drive A by entering the following command.

C:\>A:

4. Execute the insta l l a t i o n p rogram by entering the following command. Specify in the underlined section the directory in which the Controller Link Support

Software is to be installed. If a nonexistent directory is specified, it will be

automatically created.

A:\>INSTALL C:\CLK

13

Page 23

2-2SectionInstallation Procedure

When the installation program file is activated, the Controller Link Support

Software files will be copied from the floppy disk to the hard disk. Follow the

instructions displayed on the screen.

Note If the destination directory is omitted, the files will be copied to

C:\CLK.

5. When the installation processing is complete, the following message will be

displayed.

Add ”path=%PATH%;C:\CLK” to AUTOEXEC.BAT.

Command Usage : CLKSS

6. Use a text editor to add the following line anywhere in the AUTOEXEC.BAT

file as indicated by the message in step 5.

path=%PATH%;C:\CLK

This completes the installation procedure.

Note If the Controller Link Support Software is registered in the SYSMAC Support

Software, it can be started from the SYSMAC Support Software’s Option Menu.

See Appendix C Registering the Controller Link Support Software in the SYS-

MAC Support Software (page 163) for the registration procedure. We recommend that the Controller Link Support Software be registered in this way if the

SYSMAC Support Software is already installed.

14

Page 24

SECTION 3

Basic Operations and Connections

This section describes the Controller Link Support Software menu structure and basic operations, such as starting and exiting

the software. It also describes how to connect the computer running the Controller Link Support Software to the Network.

3-1 Starting and Exiting the Controller Link Support Software 16. . . . . . . . . . . . . . . . . . . . . . . .

3-1-1 Starting the Software 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-2 Exiting the Software 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Basic Operations 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Screen Displays 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 Selecting Menu Items 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-3 Entering Word Addresses 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-4 Selecting a File from the File List Screen 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-5 Printing Screens 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Connecting to a Node 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Connection Method 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-2 PC Settings 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

Page 25

3-1SectionStarting and Exiting the Controller Link Support Software

3-1 Starting and Exiting the Controller Link Support Software

This section describes how to start and exit the Controller Link Support Software.

Note 1) In the following examples, all command strings are shown in uppercase.

They can also be entered in lowercase.

2) If the Controller Link Support Software is registered in the SYSMAC Support

Software, it can be started from the SYSMAC Support Software’s Option

Menu. See Appendix C Registering the Controller Link Support Software in

the SYSMAC Support Software (page 163) for the registration procedure.

3) The Controller Link Support Software can be run from Windows. See Ap-

pendix D Running the Controller Link Support Software under Windows

95/98 (page 165) for the procedure.

3-1-1 Starting the Software

This section describes how to start the Controller Link Support Software.

In this example, the system environment is as follows:

• Hard disk: Drive C

• Directory for Controller Link Support Software: C:\CLK

If the drive and directory to be used are different from those shown in this example, replace drive C and directory C:\CLK in the following descriptions with the

actual drive and directory being used.

Basic Procedure

1, 2, 3... Turn on the power of the computer. The computer will be started from the

hard disk and command input will be prompted as shown below.

C:\>

Note If another application is started, terminate it and display a DOS com-

mand input prompt. Refer to the related manuals for your computer

and the application software.

Make sure that the current drive is the drive in which the Controller Link Support Software has been installed.

Note a) The current drive is the default drive that files are read from or writ-

ten to. If a file name is specified without a drive name, the file will

be searched or written in the current drive.

b) When C:\> is displayed as shown in step , drive C is the current

drive.

If the current drive is not the drive in which the Controller Link Support Software has been installed, enter the drive name as below to change the current drive.

Example: When changing the current drive from drive A to drive C

A:\>C:

Enter the command shown below to change the current directory to the directory in which the Controller Link Support Software has been installed.

Specify in the underlined section the directory in which the Controller Link

Support Software has been installed.

Example: Controller Link Support Software is in directory CLK

C:\>CD \CLK

16

Note a) The current directory is the default directory that files are read

from or written to. If a file is specified without a directory name, the

file will be searched or written in the current directory.

Page 26

Startup Options

3-1SectionStarting and Exiting the Controller Link Support Software

b) If the path to the Controller Link Support Software directory is spe-

cified in the AUTOEXEC.BAT file, this step need not be performed.

Enter the following command string to start the Controller Link Support Software.

C:\CLK>CLKSS

Note a) Options can be specified in the start command. See Start Options

(on page 17) for details.

b) If the Controller Link Support Software is started normally, the

logo screen and the Main Menu will be displayed in order. The version number of the Controller Link Support Software appears on

the logo screen.

The operation mode can be specified using options when starting the Controller

Link Support Software. The option entry format is as follows:

CLKSS /B [/OSSS path]

/U

Portions in brackets [ ] may

be omitted. The brackets

themselves are not input.

Option Meaning

/B The Controller Link Support Software is started for use with a

/U The Controller Link Support Software is started for use with a

Both /B and

/U omitted

/OSSS path The Controller Link Support Software is started with the same

Controller Link Support Board (as a node.) This option is valid

only when a Controller Link Support Board is installed in the

computer. If a Controller Link Support Board is not installed or

does not operate normally, an error message will be displayed.

Controller Link Unit (for connecting to a PC.) Even if the

Controller Link Unit is not connected to a PC, no error will occur.

The Controller Link Unit may be connected to PC only when

data needs to be transferred between them.

The Controller Link Support Software is started in either of the

following modes, depending on the presence or absence of the

driver for the Controller Link Support Board.

When the driver exists: The Controller Link Support Software is

started for use with the Controller Link Support Board (as a

node.)

When the driver does not exist: The Controller Link Support

Software is started for use with the Controller Link Unit (for

connecting to a PC.)

conditions as the SYSMAC Support Software by reading the

information specified in the System Setup of the SYSMAC

Support Software.

In the SSS path, specify the directory in which the SYSMAC

Support Software is installed (e.g., C:\SYSMATE.) The following

system setup information is read.

Communications parameters

Printer model

Data drive

This option is invalid when the SYSMAC Support Software is not

installed or does not operate normally.

17

Page 27

3-1-2 Exiting the Software

1, 2, 3... Press the F1 (Menu) Key to display the Main Menu.

If the Main Menu does not appear when the F1 Key is pressed, press the

Escape Key or F10 (End) Key to terminate the active function, and then

press the F1 Key.

3-1SectionStarting and Exiting the Controller Link Support Software

Select “Q: Exit to DOS” from the Main Menu.

T o select “Q: Exit to DOS,” press “Q,” or use the Up and Down Cursor Keys

to highlight “Q: Exit to DOS” and then press the Enter Key.

The Controller Link Support Software will terminate and the system will be

ready to receive the next command as shown below.

C:\>

Note a) If the Controller Link Support Software is started from the SYS-

MAC Support Software or Windows, it will return to the original

state when terminated.

b) If the Controller Link Support Software is started for use with the

Controller Link Support Board, the Controller Link Support Board

will be disconnected from the network when the software terminates. Then, an error indicating that the number of nodes participating in the network has decreased (error code 0206 Hex) will be

recorded in the error log in the other nodes connected to the network.

18

Page 28

3-2 Basic Operations

3-2-1 Screen Displays

A sample screen for the Controller Link Support Software is shown below.

Error message display area

An error message is displayed if an error occurs

during Controller Link Support Software operation.

3-2SectionBasic Operations

Subfunction name

The submenu item corresponding to the current

function is displayed. Nothing is displayed when the

current function (main menu item) has no submenu.

Function name

The main menu item corresponding

to the current function is displayed.

Cursor

The cursor indicates the

selection or input object. On the

menu, move the cursor to a

desired item, then press the

Enter Key. For setting, enter a

character string or numerical

value at the cursor position.

Function Keys

The Function Keys labels are arranged from left to right and correspond to the F1 to

F10 Keys, respectively. Pressing a Function Key executes the displayed function.

For example, pressing the F1 (Menu) Key displays the Main Menu. The functions of

Function Keys differ according to the screen displayed.

Note The display color of the function and subfunction name fields indicates the de-

vice to which the Controller Link Support Software is connected.

Blue: The Controller Link Support Software is running for connecting to a

Controller Link Unit (for connecting to a PC.)

Yellow: The Controller Link Support Software is running for use with the

Controller Link Support Board (as a node.)

The destination to which the Controller Link Support Software is to be connected

can be selected by specifying an option when starting the software (see page

17.)

19

Page 29

3-2-2 Selecting Menu Items

Menu items can be selected in either of the following two ways.

3-2SectionBasic Operations

Using Shortcut Keys

Using the Cursor

As shown in the figure below, a letter is displayed on the left of each main menu

item or submenu item. This key for this letter on the keyboard is called a shortcut

key. You can select a menu item by simply pressing the corresponding shortcut

key.

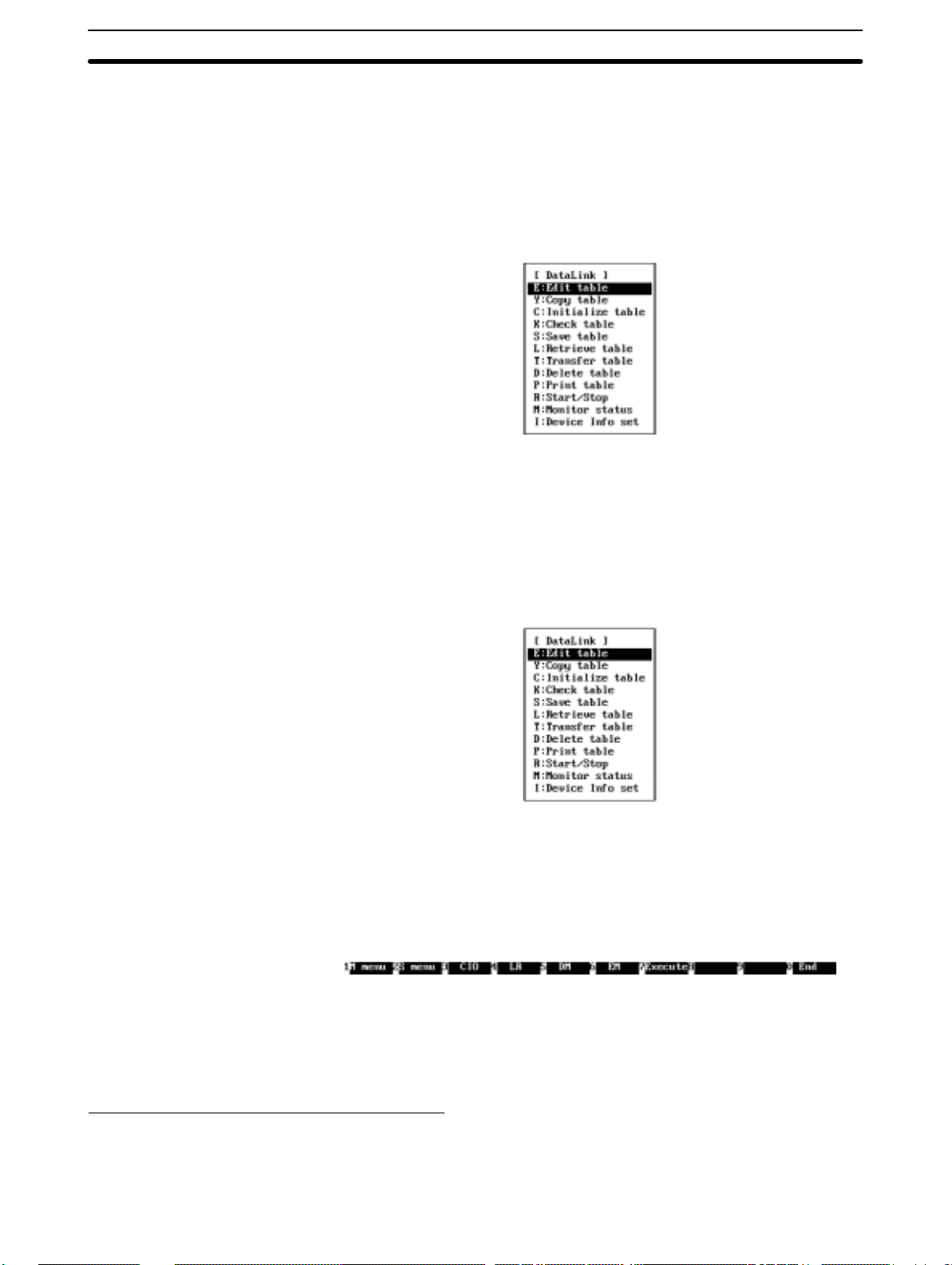

Example: Data Link Submenu

In this example, pressing “K” at the Data Link Submenu selects “K: Check

table.”

Part of each Controller Link Support Software menu is always highlighted. This

highlighted portion is called the cursor. The cursor indicates a selected object.

To move the cursor, use the Up and Down Cursor Keys.

Press the Enter Key to select the item at the cursor position.

Example: Data Link Submenu

In this example, pressing the Enter Key selects “E:Edit table.”

3-2-3 Entering Word Addresses

The Controller Link Support Software displays the Function Keys at the bottom

of the screen as shown below when the cursor moves to the word address entry

field.

The word address entry methods for CIO (IR), LR, and DM Areas are slightly

different from that for the EM Area.

Note When entering data in the first status word field, you can also use the “–” Key

and the Delete Key to set the first status word to its default value.

Specifying CIO, LR, and DM Addresses

1, 2, 3... Specify the data area by pressing the corresponding Function Key.

In the following example, the DM Area is specified by pressing the F5 (DM)

Key.

20

Page 30

3-2SectionBasic Operations

Example:

[D00000 ]

Specify a word address by pressing the numeric keys.

Each time a numeric key is pressed, the corresponding number appears on

the right end of the highlighted portion and the other digits shift to the left.

Example: When pressing “1”, “2”, and “5” in this order

[D00001 ] [D00012 ] [D00125 ]→→

Press the Enter Key to register the entered data.

The entered data will be automatically checked according to the node model

specified as described in 5-3-15 Specifying Node Models (page 81.)

Example:

[D00125 ]

Note You cannot use the Backspace Key or the Delete Key when entering a word ad-

dress. If an incorrect digit is entered, continue to enter digits until the correct fivedigit number is entered. Each time a digit is entered, the incorrect digit shifts to

the left and eventually disappears from the field.

The Function Keys for data area selection (F3 to F6) are valid while a word address is being entered. If an incorrect digit is entered, the word address entry

procedure can be canceled and restarted by pressing one of the F3 to F6 Keys.

Specifying EM Addresses

1, 2, 3... Press the F6 (EM) Key.

Note 1) You cannot use the Backspace Key or the Delete Key when entering a word

The display will wait for input of the bank.

Example:

[E0_00000 ]

Enter a bank number by pressing one of the numeric keys or A” to “F.”

The bank number must be a single-digit hexadecimal number. The bank

number must be followed by a word address.

Example: Pressing “1” (bank number 1)

[E1_00000 ]

Specify a word address by pressing the numeric keys.

Each time a numeric key is pressed, the corresponding number appears on

the right end of the highlighted portion and the other digits shift to the left.

Example: When pressing “4”, “1”, and “9” in this order

[E1_00004] [E1_00041 ] [E1_00419 ]→→

Press the Enter Key to register the entered data.

The entered data will be automatically checked according to the node model

specified as described in 5-3-15 Specifying Node Models (page 81.)

Example:

[E1_00419 ]

address. If an incorrect digit is entered, continue to enter digits until the correct five-digit number is entered. Each time a digit is entered, the incorrect

digit shifts to the left and eventually disappears from the field.

The Function Keys for area selection (F3 to F6) are valid while a word address is being entered. If an incorrect digit is entered, the word address entry

procedure can be canceled and restarted by pressing one of the F3 to F6

Keys.

2) If an incorrect bank number is entered, it cannot be corrected. Press the F6

(EM) Key to restart the entry procedure.

21

Page 31

3-2-4 Selecting a File from the File List Screen

The Controller Link Support Software allows you to display a list of files in a directory and select one of the files. This will save you the trouble of entering file

names and also prevent entry mistakes.

Displaying a File List

The F8 Key serves as the “Files” Function Key as shown below and allows you

to select a file from the file list. File lists can be displayed in any window where the

F8 Key has “Files” displayed for it.

Selecting from a File List

1, 2, 3... Specify in the file name entry field the directory for which the file list is to be

displayed. Enter a file name with Alphanumeric Keys, the Insert Ke y, the D elete Key, and the Backspace Key.

The character string before the last backslash (\) is treated as a directory

name. When the window is first displayed, the directory specified in “Data

disk drive” of the “System setup” Menu is displayed.

Example:

3-2SectionBasic Operations

In this example, C:\CLK\DATA is treated as the directory name.

Press the F8 (Files) Key.

A list of files in the specified directory will be displayed.

Example:

Select a file.

Use the Cursor Keys to move the cursor to a desired file, then press the Enter Key. Subdirectories are displayed as <DIR> in the “Size” column. Selecting a subdirectory displays a list of files in the subdirectory.

Selecting a file will return you to the original screen. The specified file name

will appear in the file name entry field.

Example: Selecting LINE3.CLK

22

Page 32

Note In the file list screen, you can switch to the file list of a subdirectory but cannot

return to the parent directory. Press the Escape Key to return to the file name

entry screen, then specify the directory again.

3-2-5 Printing Screens

The Controller Link Support Software allows you to print the screen from the

connected printer.

1, 2, 3... Make sure that the correct printer model is specified in “Printer model” of the

3-3SectionConnecting to a Node

If necessary, you can press the F8 (Files) Key and select a file again from the

file list.

Press the Enter Key.

The file will be selected.

“System setup” Menu.

Make sure that the printer is connected to the computer in which the Control-

ler Link Support Software is running and that the printer is ready to operate.

Press the Print Screen Key.

The current screen images will be printed.

Note The Controller Link Support Software cannot be operated while printing.

3-3 Connecting to a Node

3-3-1 Connection Method

Running from a Computer Node

If the Controller Link Support Software is being used in a computer in which a

Controller Link Support Board is installed and the computer is connected as a

Network node, you need not bother to connect the Controller Link Support Software.

If the Support Board is activated normally , the Controller Link Support Software

will be automatically connected to nodes when started.

Connecting to a PC

If the computer in which the Controller Link Support Software is installed is to be

connected to a PC, use the SYSMAC Support Software connection cable to connect the computer to the PC.

Note The Controller Link Support Software communicates with a PC only when data

is transferred between them. Therefore, you may connect the computer to a PC

only when necessary to transfer data or monitor status.

Peripheral Port on CS1-series PCs

Computer Cable PC PC

PC/AT CS1W-CN226/626 (D-Sub 9-pin ↔ dedicated connector)

RS-232C Peripheral port

Peripheral port on

CS1-series PC

communications

Peripheral Bus or

Host Link

23

Page 33

Peripheral Port on C200HX/HG/HE PCs

3-3SectionConnecting to a Node

Computer Cable PC PC

PC/AT CQM1-CIF02 (D-Sub 9-pin ↔ dedicated connector)

RS-232C Peripheral port

Peripheral port on

C200HX/HG/HE

PC

communications

Peripheral Bus or

Host Link

Peripheral Port on CVM1 and CV-series PCs

Computer Cable PC PC com-

PC/AT

If the RS-232C

connector on the

computer is a 9-pin

connector, use a

commercially available

9-to-25-pin conversion

adapter to connect the

cable to the computer.

CV500-CIF01 (D-Sub 25-pin ↔ dedicated connector) Peripheral

Peripheral device bus connectorRS-232C

device

connector

on CVM1 or

CV-series

PC

munica-

tions

Peripheral

Bus

Peripheral Port on CQM1H PCs

Computer Cable PC PC com-

PC/AT

CQM1-CIF02 and CS1W-CN114

RS-232C Host Link Port on PC’s CPU Unit

Computer Cable PC PC com-

PC/AT

If the RS-232C

connector on the

computer is a 9-pin

connector, use a

commercially available

9-to-25-pin conversion

adapter to connect the

cable to the computer.

XW2Z-200S (D-Sub 25-pin ↔ D-Sub 9-pin)

XW2Z-500S (D-Sub 25-pin ↔ D-Sub 9-pin)

munica-

tions

Peripheral

port on

CQM1H PC

RS-232C

port on

CS1-series

PC

RS-232C

RS-232C portRS-232C

port on

C200HX/H

G/HE (see

note),

CVM1,

CV-series,

or CQM1H

PC

Peripheral

Bus or Host

Link

munica-

tions

Peripheral

Bus or Host

Link

Host Link

24

Note Connection is only possible to a C200HX/HG/HE CPU Unit with an

RS-232C port.

Page 34

RS-232C Port on Host Link Unit

Computer Cable PC (Host

PC/AT

CV500-LK201 port 1, in full-duplex mode:

XW2Z-200S (D-Sub 25-pin ↔ D-Sub 9-pin)

XW2Z-500S (D-Sub 25-pin ↔ D-Sub 9-pin)

CV500-LK201 port 2, in full-duplex mode:

XW2Z-200P (D-Sub 25-pin ↔ D-Sub 25-pin)

XW2Z-500P (D-Sub 25-pin ↔ D-Sub 25-pin)

Select an appropriate cable according to the shape of the RS-232C connector

on the Host Link Unit.

RS-232C Port on Serial Communications Board/Unit

Computer Cable PC(Serial

PC/AT

XW2Z-200S (D-Sub 25-pin ↔ D-Sub 9-pin)

XW2Z-500S (D-Sub 25-pin ↔ D-Sub 9-pin)

3-3SectionConnecting to a Node

Link Unit)

RS-232C

port on

Host LInk

Unit for

CVM1 or

CV-series

PC

(CV500-LK

201)

RS-232C portRS-232C

Communic

ations

Board/Unit)

RS-232C

port on

Serial Communications

Board

(CS1W-SC

B21/41) or

RS-232C portRS-232C

Serial Communications

Unit

(CS1W-SC

U21) for

CS1-series

PC

PC com-

munica-

tions

Host Link

PC com-

munica-

tions

Host Link

3-3-2 PC Settings

Peripheral Bus

CS1-series PCs

If the Controller Link Support Software is to communicate with a PC via the peripheral bus, the PC must be set to the same baud rate as the Controller Link

Support Software.

Note See 5-14-3 Setting PC Communications (on page 137) in 5-14 System Setup to

set the baud rate for the Controller Link Support Software.

Connecting to Peripheral Port

When connecting to the peripheral port on the CPU Unit, set DIP switch pin 4 to

OFF, and set the baud rate for the Controller Link Support Software to the maximum value (19,200 bps). Alternatively, set DIP switch pin 4 to ON and make the

PC Setup settings for the CPU Unit using CX-Programmer. Select the peripheral

port and set the serial communications mode to peripheral bus, and make the

same communications settings as the Controller Link Support Software.

Connecting to RS-232C Port

When connecting to the RS-232C port on the CPU Unit, set DIP switch pin 5 to

ON, and set the baud rate for the Controller Link Support Software to the maximum value (19,200 bps). Alternatively, set DIP switch pin 5 to OFF and make the

PC Setup settings for the CPU Unit using CX-Programmer. Select the RS-232C

port and set the serial communications mode to peripheral bus, and make the

same communications settings as the Controller Link Support Software.

25

Page 35

3-3SectionConnecting to a Node

C200HX/HG/HE PCs

Set the same baud rate as the Controller Link Support Software in PC Setup

words DM 6650 and DM 6651 of the CPU Unit.

Setting the Standard Communications Parameters

Peripheral port: DM 6650

Communications parameters

0: Standard communications parameters (9600 bps)

1: According to DM6651

Initial status: 0000 (Standard communications parameters at 9,600 bps.)

Setting the Baud Rate

Peripheral port: DM 6651 bits 0 to 7

Baud rate

00: 1200 bps (see note)

01: 2400 bps

02: 4800 bps

03: 9600 bps

04: 19200 bps

Initial status: 0000 (1200 bps)

Note The baud rate cannot be set to 1,200 bps for the Controller Link Support Soft-

ware.

26

Page 36

3-3SectionConnecting to a Node

CVM1 and CV-series PCs

DIP switch

CQM1H PCs

Use DIP switch pins 1 and 2 on the CPU Unit to set the same baud rate as the

Controller Link Support Software.

DIP switch pins

1 2

OFF OFF 50 Kbps (see note)

ON OFF 19,200 bps

OFF ON 9,600 bps

ON ON 4,800 bps

Baud rate

Note The baud rate cannot be set to 50 kbps for the Controller Link Support

Software.

Connecting to Peripheral Port

Use one of the following methods when connecting to the peripheral port on the

CPU Unit.

a) Set DIP switch pins 5 and 7 to ON, and set the baud rate for the Controller

Link Support Software to 9,600 bps.

b) Set DIP switch pin 5 to OFF and pin 7 to ON, and set the PC Setup word

DM 6650 (peripheral port settings) to 0000 Hex (standard setting). Set

the baud rate for the Controller Link Support Software to 9,600 bps.

c) Set DIP switch pin 5 to OFF and pin 7 to ON, and set the PC Setup word

DM 6650 (peripheral port settings) to 0001 Hex (settings according to

DM 6651). Set the communications settings (DM 6651: peripheral port

settings) to the same settings as the Controller Link Support Software.

Set the baud rate for the Controller Link Support Software to a value in

the range 2,400 to 19,200 bps.

Connecting to RS-232C Port

Peripheral bus connection to the RS-232C port is not possible.

Host Link

CS1-series PCs

If the Controller Link Support Software is to communicate with a PC via a Host

Link, the PC must be set to the same communications parameters as the Controller Link Support Software.

Note See 5-14-3 Setting PC Communications (on page 137) in 5-14 System Setup to

set the communications parameters for the Controller Link Support Software.

Connecting to Peripheral Port

When connecting to the peripheral port on the CPU Unit, set DIP switch pin 5 to

ON and make the PC Setup settings for the CPU Unit using CX-Programmer.

Select the peripheral port and set the serial communications mode to Host Link,

and make the same communications settings as the Controller Link Support

Software.

Connecting to RS-232C Port

When connecting to the RS-232C port on the CPU Unit, set DIP switch pin 5 to

OFF and make the PC Setup settings for the CPU Unit using CX-Programmer.

27

Page 37

3-3SectionConnecting to a Node

Select the RS-232C port and set the serial communications mode to Host Link,

and make the same communications settings as the Controller Link Support

Software.

CS1-series Serial

Communications

Board/Unit

In the software switch settings of the Serial Communications Board/Unit registered in the CX-Programmer’s I/O table, select the serial port for connection, set

the serial communications mode to Host Link, and make the same communications settings as the Controller Link Support Software.

28

Page 38

3-3SectionConnecting to a Node

C200HX/HG/HE PCs

Use the PC Setup (DM Area) of the PC to set the communications parameters

for the port to be used (peripheral port or RS-232C port.)

Note When DIP switch pin 5 on the CPU Unit is set to ON, the communications param-

eters are set as follows, regardless of the PC Setup:

Communications: Host Link mode

Node No.: 00

Start bits: 1 bit

Data bits: 7 bits

Stop bits: 2 bits

Parity: Even

Baud rate: 9,600 bps

Transmission delay: None

Setting Standard Communications Parameters

RS-232C port: DM6645

Communications mode

Set to (0: Host Link)

Not related when Host Link is set

CTS control (Yes/No)

Communications parameters

0: Standard communications parameters

1: According to DM 6646

Initial status: 0000 (Standard communications at 9,600 bps.)

Bits 8 to 11 are valid for only the master node with 1:1 link.

Bits 0 t o 7 and 12 to 15 are valid only when DIP switch pin 5 on the CPU Unit is set

to OFF.

The standard communications parameters are as follows:

Start bits: 1 bit

Data bits: 7 bits

Stop bits: 2 bits

Parity: Even

Baud rate: 9,600 bps

Always set the mode to be used.

If the above communications parameters are acceptable, specify 00 in the lower

two digits.

Setting Communications Parameters

The Controller Link Support Software can communicate with PC only when DIP

switch pin 5 on the CPU Unit is set to OFF and DM 6645 is set to use DM 6646

settings.

RS-232C port: DM 6646

Transmission frame format (see table)

Baud rate (see table)

Initial status: 0000 (Start bits: 1, Data length: 7, Stop bits: 1, Even parity, 1,200 bps.)

29

Page 39

Transmission Frame Format

3-3SectionConnecting to a Node

Setting Start

bits

00 1 7 1 Even 06 1 8 1 Even

01 1 7 1 Odd 07 1 8 1 Odd

02 1 7 1 None 08 1 8 1 None

03 1 7 2 Even 09 1 8 2 Even

04 1 7 2 Odd 10 1 8 2 Odd

05 1 7 2 None 11 1 8 2 None

Data

length

Stop

bits

Parity Setting Start

bits

Data

length

Stop

bits

Parity

Baud Rate

Setting Baud rate

00 1,200 bps

01 2,400 bps

02 4,800 bps

03 9,600 bps

04 19,200 bps

The baud rate cannot be set to 1,200 bps for the Controller Link Support Software.

Set the communications parameters for the PC according to the communications parameters for the Controller Link Support Software.

Setting the Node Number

CVM1 and CV-series PCs

Communications

port

RS-232C

RS-422

RS-232C port: DM 6648

Node no. (2 digit BCD) 00 to 31

Initial status: 00 (node no. 00.)

When multiple PCs are connected to the host computer, a node number is assigned to each PC for identification purposes. Assign the PC the same node

number as that specified in the Controller Link Support Software.

Use the DIP switch on the PC and the PC Setup to set the communications parameters for the Host Link connection.

Note Use the SYSMAC Support Software to set up the PC Setup.

I/O port setting (selector switch)

Set the selector switch to RS-232C.

System setup (DIP switch pin 4)

To set to the values specified by the DIP switch: Set DIP switch pin 4 to ON.

To set to the values specified in the PC Setup: Set DIP switch pin 4 to OFF.

Note For CPU Units manufactured before June 1995 (lot No.

jj65), the default values specified by the DIP switch differ

from those specified in PC Setup as follows:

The default values specified by the DIP switch are 2,400 bps,

one stop bit, even parity, and 7-bit data length.

The default values specified in the PC Setup are 9,600 bps, two

stop bits, even parity, and 7-bit data length.

For CPU Units manufactured after July 1995 (lot No. jj75), the

values specified in the DIP switch have been changed to 9,600 bps

and two stop bits to make them identical with those of the PC

Setup.

30

Page 40

3-3SectionConnecting to a Node

CVM1/CV-series Host

Link Unit

Set the communications parameters for the port to be used (port 1 or 2) with the

rotary switches, DIP switch, and CPU Bus Unit System Setup of the CVM1/CV series Host Link Unit (CV500-LK201).

Setting the Node Number for Communications Port 2

When multiple PCs are connected to the host computer, a node number is assigned to each PC for identification purposes. Decimal numbers 0 to 31 can be

assigned as the node number of communications port 2. Set the tens digit with

the left switch and the ones digit with the right switch.

Setting Example

Node No.

x 10

1

0

Node No.29x 10

Note 1) Do not specify a node number higher than 31. Doing so results in a error and

lights the ERC2 indicator on the display panel.

2) Since the Controller Link Support Software and the Host Link Unit are always connected on the one-to-one basis, the node number can normally be

0.

3) The node number of communications port 1 is fixed at 0.

DIP Switch Settings of CVM1/CV-series Host Link Units

Communications port 1

(RS-232C)

Communications port 2

(RS-232C/RS-422A)

Communications port switch

(RS-232C/RS-422A)

DIP switch

31

Page 41

For each DIP switch pin, ON is on the left side and OFF is on the right side.

No. Function Setting Meaning

1 Communications

parameter settings (for

communications ports 1

and 2) (see note)

2 CTS switch

(communications port 1)

3 CTS switch

(communications port 2)

4 Reserved for system use

5 Loopback test

6 Test port selection

ON The communications parameters

for communications ports 1 and 2

are as follows:

Baud rate: 9,600 bps

Stop bits: 2 bits

Parity: Even

Data bits: 7 bits

Xon/Xoff control: No

Communications method: Full

duplex

OFF The values specified for the CPU

Bus Unit System in the PC are

used as communications

parameters. The initial values are

as follows:

Baud rate: 9,600 bps

Stop bits: 2 bits

Parity: Even

Data bits: 7 bits

Xon/Xoff control: Not

Communications method: Full

duplex

ON The CTS signal (ready to receive)

is always set to ON (0 V fixed.)

Always set this switch pin to ON

when connecting the Controller

Link Support Software.

OFF Cannot be set.

ON The CTS signal (ready to receive)

is always set to ON (0 V fixed.)

Always set this switch pin to ON

when connecting the Controller

Link Support Software.

OFF Cannot be set.

ON Cannot be set.

OFF Always set this bit to OFF.

ON Cannot be set when the

Controller Link Support Software

is connected.

OFF Always set this switch pin to OFF

when connecting the Controller

Link Support Software.

ON Cannot be set when the

Controller Link Support Software

is connected.

OFF Always set this switch pin to OFF

when connecting the Controller

Link Support Software.

3-3SectionConnecting to a Node

32

Page 42

3-3SectionConnecting to a Node

Note For Host Link Units manufactured after July 1995 (lot No.**75), the communica-

tions parameter settings when DIP switch pin 1 is ON are as shown in the table

above.

For Host Link Units manufactured before June 1995 (lot No.**65), the communications parameter settings are different from the above (baud rate = 2,400

bps, stop bits = 1 bit.)