Page 1

PROFIBUS-DP Master Unit

OPERATION MANUAL

Cat. No. W349-E2-2

C200HW-PRM21

Page 2

Page 3

Page 4

Page 5

C200HW-PRM21

PROFIBUS-DP Master Unit

Operation Manual

Produced May 2000

Page 6

iv

Page 7

Notice:

!

Caution

!

DANGER!

!

WARNING

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to the product.

Indicates information that, if not heeded, is likely to result in loss of life or serious injury.

Indicates information that, if not heeded, could possibly result in loss of life or serious injury.

Indicates information that, if not heeded, could result in relatively serious or minor injury,

damage to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalised in this manual. The word “Unit” is also capitalised when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Logic Controller and is not used as an abbreviation for

anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3…Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 8

vi

Page 9

TABLE OF CONTENTS

PRECAUTIONS .........................................................................................xi

1 Intended Audience........................................................................................................................................................xii

2 General Precautions......................................................................................................................................................xii

3 Safety Precautions ........................................................................................................................................................xii

4 Operating Environment Precautions.............................................................................................................................xii

5 Application Precautions...............................................................................................................................................xiii

6 EC Directives ..............................................................................................................................................................xiv

1 PROFIBUS-DP......................................................................................1

1-1 Introduction..............................................................................................................................................................2

1-2 Protocol architecture ................................................................................................................................................2

1-3 Device types.............................................................................................................................................................4

1-4 PROFIBUS-DP characteristics.................................................................................................................................4

1-5 Device Data Base files .............................................................................................................................................8

1-6 Profiles.....................................................................................................................................................................8

2 INSTALLATION.................................................................................. 9

2-1 Physical layout of the unit......................................................................................................................................10

2-2 Mounting the C200HW-PRM21 ............................................................................................................................13

2-3 Setting up a network...............................................................................................................................................14

3 SPECIFICATIONS AND PERFORMANCE..................................17

3-1 Overall Specifications............................................................................................................................................18

3-2 Performance ...........................................................................................................................................................20

4 CONFIGURATOR.............................................................................29

4-1 General...................................................................................................................................................................30

4-2 Setup ......................................................................................................................................................................31

4-3 Operation................................................................................................................................................................32

4-4 Debug mode...........................................................................................................................................................46

5 PLC INTERFACE..............................................................................51

5-1 Unit Settings...........................................................................................................................................................52

5-2 Input / Output Mailbox...........................................................................................................................................59

5-3 Control and status area...........................................................................................................................................60

5-4 LEDs ......................................................................................................................................................................70

6 MESSAGE COMMUNICATION, IOWR / IORD .........................73

6-1 Message communication........................................................................................................................................74

6-2 IOWR.....................................................................................................................................................................74

6-3 IORD......................................................................................................................................................................76

6-4 Messages................................................................................................................................................................77

7 TROUBLESHOOTING AND MAINTENANCE ...........................83

7-1 Error Indicators ......................................................................................................................................................84

7-2 Troubleshooting .....................................................................................................................................................84

7-3 Maintenance...........................................................................................................................................................90

vii

Page 10

Appendices ..................................................................................................93

Appendix A Tips and sample programs....................................................................................................93

Appendix B GSD file for C200HW-PRM21 ..........................................................................................101

Appendix C CS1 PLC series compatibility.............................................................................................103

Index ..........................................................................................................105

Revision History .......................................................................................107

viii

Page 11

About this Manual:

!

WARNING

This manual describes the installation and operation of the PROFIBUS-DP Master Unit and includes the

sections described below.

Please read this manual carefully and be sure you understand the information provided before attempting to install and operate the PROFIBUS-DP Master Unit. Be sure to read the precautions provided

in the following section.

Section 1 gives a brief description of PROFIBUS-DP.

Section 2 describes the installation of the C200HW-PRM21.

Section 3 describes the overall specifications and the communication performance of the Unit.

Section 4 describes the software for configuring the PROFIBUS-DP network.

Section 5 describes the interface with the user.

Section 6 describes the message communication.

Section 7 describes the troubleshooting procedures and maintenance operations.

Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read

each section in its entirety and be sure you understand the information provided in

the section and related sections before attempting any of the procedures or

operations given.

ix

Page 12

x

Page 13

PRECAUTIONS

This section provides general precautions for using the PROFIBUS-DP Master Units, Programmable Controllers, and

related devices.

The information contained in this section is important for the safe and reliable application of the PROFIBUS-DP

Master Units. You must read this section and understand the information contained before attempting to set up or

operate a PROFIBUS-DP Master Unit and PLC system.

1 Intended Audience........................................................................................................................................................xii

2 General Precautions......................................................................................................................................................xii

3 Safety Precautions ........................................................................................................................................................xii

4 Operating Environment Precautions.............................................................................................................................xii

5 Application Precautions...............................................................................................................................................xiii

6 EC Directives ..............................................................................................................................................................xiv

xi

Page 14

Operating Environment Precautions

!

WARNING

!

WARNING

!

WARNING

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance

specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment,

amusement machines, safety equipment, and other systems, machines, and

equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating OMRON

PROFIBUS-DP Master Units. Be sure to read this manual before operation

and keep this manual close at hand for reference during operation.

It is extremely important that a PLC and all PLC Units be used for the

specified purpose and under the specified conditions, especially in

applications that can directly or indirectly affect human life. You must consult

with your OMRON representative before applying a PLC system to the above

mentioned applications.

3 Safety Precautions

Never attempt to disassemble any Units while power is being supplied. Doing

so may result in serious electrical shock or electrocution.

Never touch any of the terminals while power is being supplied. Doing so may

result in serious electrical shock or electrocution.

4 Operating Environment Precautions

Do not operate the control system in the following places.

• Where the PLC is exposed to direct sunlight.

• Where the ambient temperature is below 0°C or over 55°C.

• Where the PLC may be affected by condensation due to radical

temperature changes.

• Where the ambient humidity is below 10% or over 90%.

• Where there is any corrosive or inflammable gas.

• Where there is excessive dust, saline air, or metal powder.

• Where the PLC is affected by vibration or shock.

• Where any water, oil, or chemical may splash on the PLC.

xii

Page 15

Application Precautions

The operating environment of the PLC System can have a large effect on the

!

Caution

!

Caution

!

Caution

!

WARNING

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified

conditions at installation and remains within the specified conditions during

the life of the system.

5 Application Precautions

Observe the following precautions when using the PROFIBUS-DP Master

Units or the PLC.

Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to

protect against electrical shock.

• Always turn OFF the power supply to the PLC before attempting any of the

following. Performing any of the following with the power supply turned ON

may lead to electrical shock:

• Mounting or removing any Units (e.g., I/O Units, CPU Unit, etc.) or

memory cassettes.

• Assembling any devices or racks.

• Connecting or disconnecting any cables or wiring.

Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Use the Units only with the power supplies and voltages specified in the

operation manuals. Other power supplies and voltages may damage the

Units.

• Take measures to stabilise the power supply to conform to the rated supply

if it is not stable.

• Provide circuit breakers and other safety measures to provide protection

against shorts in external wiring.

• Do not apply voltages exceeding the rated input voltage to Input Units. The

Input Units may be destroyed.

• Do not apply voltages exceeding the maximum switching capacity to Output

Units. The Output Units may be destroyed.

• Always disconnect the LG terminal when performing withstand voltage

tests.

• Install all Units according to instructions in the operation manuals. Improper

installation may cause faulty operation.

• Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near power supply lines.

• Be sure to tighten Backplane screws, terminal screws, and cable connector

screws securely.

• Do not attempt to take any Units apart, to repair any Units, or to modify any

Units in any way.

The following precautions are necessary to ensure the general safety of the

system. Always heed these precautions.

• Provide double safety mechanisms to handle incorrect signals that can be

xiii

Page 16

6 EC Directives

generated by broken signal lines or momentary power interruptions.

• Provide external interlock circuits, limit circuits, and other safety circuits in

addition to any provided within the PLC to ensure safety.

PROFIBUS-DP Master Units that meet EC directives also meet the common

emission standard (EN50081-2). When PROFIBUS-DP Master Units are built

into equipment, however, the measures necessary to ensure that the

standard is met will vary with the overall configuration, the other devices

connected, and other conditions. You must therefore confirm that EC

directives are met for the overall machine or device.

xiv

xiv

Page 17

1 PROFIBUS-DP

This section gives a brief description of PROFIBUS-DP.

1-1 Introduction................................................................................................................................................................2

1-2 Protocol architecture ..................................................................................................................................................2

1-3 Device types...............................................................................................................................................................4

1-4 PROFIBUS-DP characteristics ..................................................................................................................................4

1-4-1 Bus Access Protocol .........................................................................................................................................4

1-4-2 Data throughput...............................................................................................................................................5

1-4-3 Diagnostics functions .......................................................................................................................................6

1-4-4 Protection mechanisms.....................................................................................................................................6

1-4-5 Network states ..................................................................................................................................................7

1-5 Device Data Base files ...............................................................................................................................................8

1-6 Profiles.......................................................................................................................................................................8

1

Page 18

Introduction

!

Caution

1-1 Introduction

Multi-vendor

Standard

EN 50170

High speed

Process Automation

Section 1-1

PROFIBUS is a vendor-independent, open fieldbus standard for a wide range

of applications in manufacturing, process and building automation. Vendor

independence and openness are guaranteed by the PROFIBUS standard

EN 50170. With PROFIBUS, devices of different manufacturers can

communicate without special interface adjustments.

The PROFIBUS family consists of three compatible versions:

PROFIBUS-DP

DP stands for Decentralised Periphery. It is optimised for high speed and low-

cost interfacing, especially designed for communication between automation

control systems and distributed I/O at the device level.

PROFIBUS-PA

PA stands for Process Automation. It permits sensors and actuators to be

connected on one common bus line even in intrinsically-safe areas. It permits

data communication and power supply over the bus using 2-wire technology

according the international standard IEC 1158-2.

Higher level

Uniform bus access protocol

PROFIBUS-FMS

FMS stands for Fieldbus Message Specification. This version is the general-

purpose solution for communication tasks at a higher level. Powerful services

open up a wide range of applications and provide great flexibility. It can also

be used for extensive and complex communications tasks.

PROFIBUS-DP and PROFIBUS-FMS use the same transmission technology

and a uniform bus access protocol. Thus, both versions can be operated

simultaneously on the same cable. However, FMS field devices cannot be

controlled by DP masters or vice versa.

It is not possible to exchange one of these family members by another family

member. This will cause faulty operation.

The rest of this section only describes PROFIBUS-DP.

1-2 Protocol architecture

OSI

The PROFIBUS protocol architecture is oriented on the OSI (Open System

Interconnection) reference model in accordance with the international

standard ISO 7498. Layer 1 (physical layer) of this model defines the physical

transmission characteristics. Layer 2 (data link layer) defines the bus access

protocol. Layer 7 (application layer) defines the application functions.

2

Page 19

Protocol architecture

Section 1-2

DP-Profiles

DP-Extensions

User Interface Layer DP Basic Functions

(7) Application Layer

(6) Presentation Layer

(5) Session Layer NOT DEFINED

(4) Transport Layer

(3) Network Layer

(2) Data Link Layer Fieldbus Data Link (FDL)

(1) Physical Layer RS-485 / Fibre Optics

Layer 1, 2 and user interface

Transmission medium

High-speed, inexpensive

Easy installation

Cable length

PROFIBUS-DP uses layers 1 and 2, and the user interface. Layers 3 to 7 are

not defined. This streamlined architecture ensures fast and efficient data

transmission. The application functions which are available to the user, as

well as the system and device behaviour of the various PROFIBUS-DP device

types, are specified in the user interface. RS-485 transmission technology or

fibre optics are available for transmission. RS-485 transmission is the most

frequently used transmission technology. Its application area includes all

areas in which high transmission speed and simple inexpensive installation

are required. Twisted pair shielded copper cable with one conductor pair is

used.

The RS-485 transmission technology is very easy to handle. Installation of the

twisted pair cable does not require expert knowledge. The bus structure

permits addition and removal of stations or step-by-step commissioning of the

system without influencing the other stations. Later expansions have no effect

on stations which are already in operation.

Transmission speeds between 9.6 kbit/s and 12 Mbit/s can be selected. One

unique transmission speed is selected for all devices on the bus when the

system is commissioned.

The maximum cable length depends on the transmission speed (see table

below). The specified cable lengths are based on type-A cable (see

section 2-3-1). The length can be increased by the use of repeaters. The use

of more than 3 repeaters in series is not recommended.

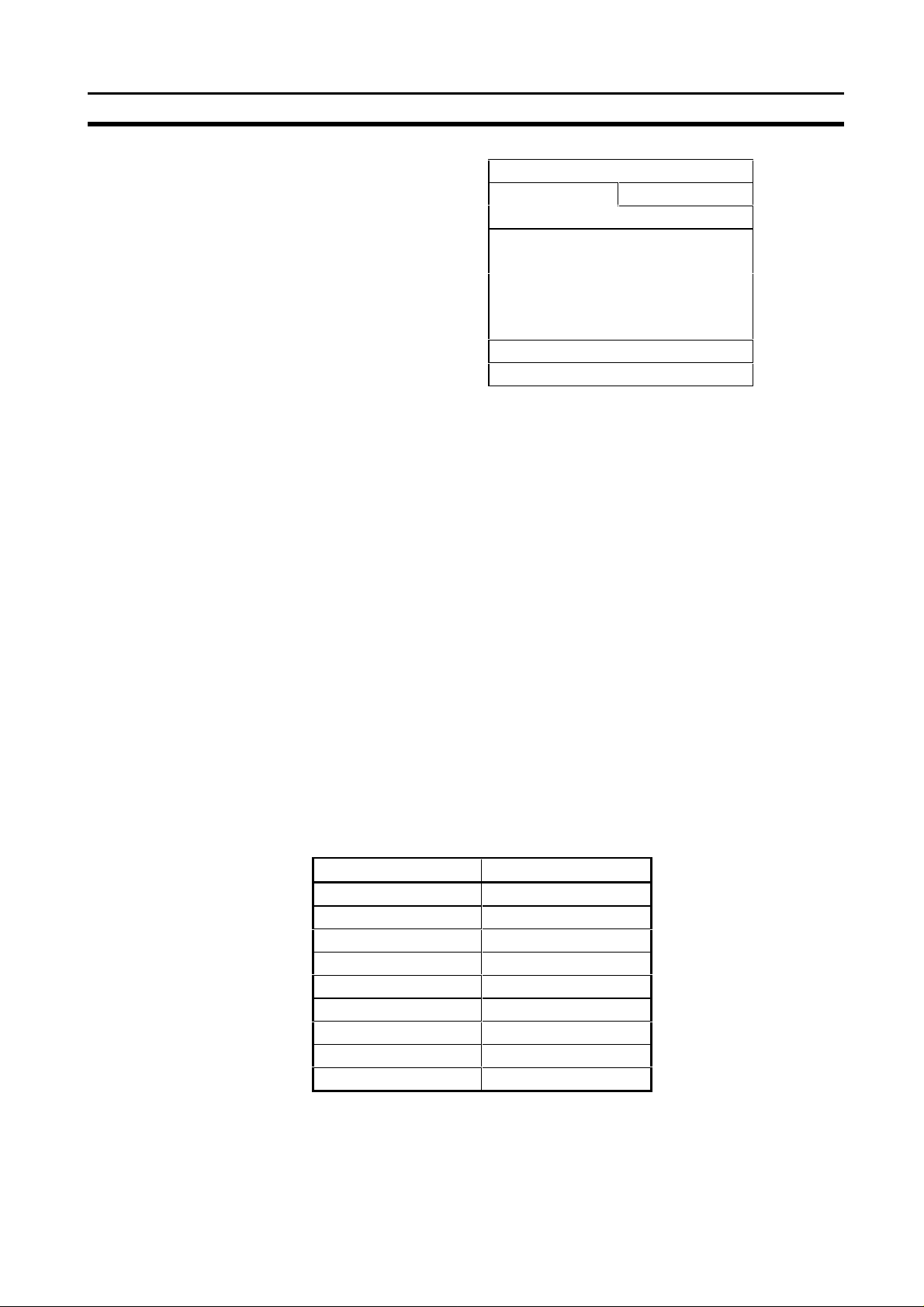

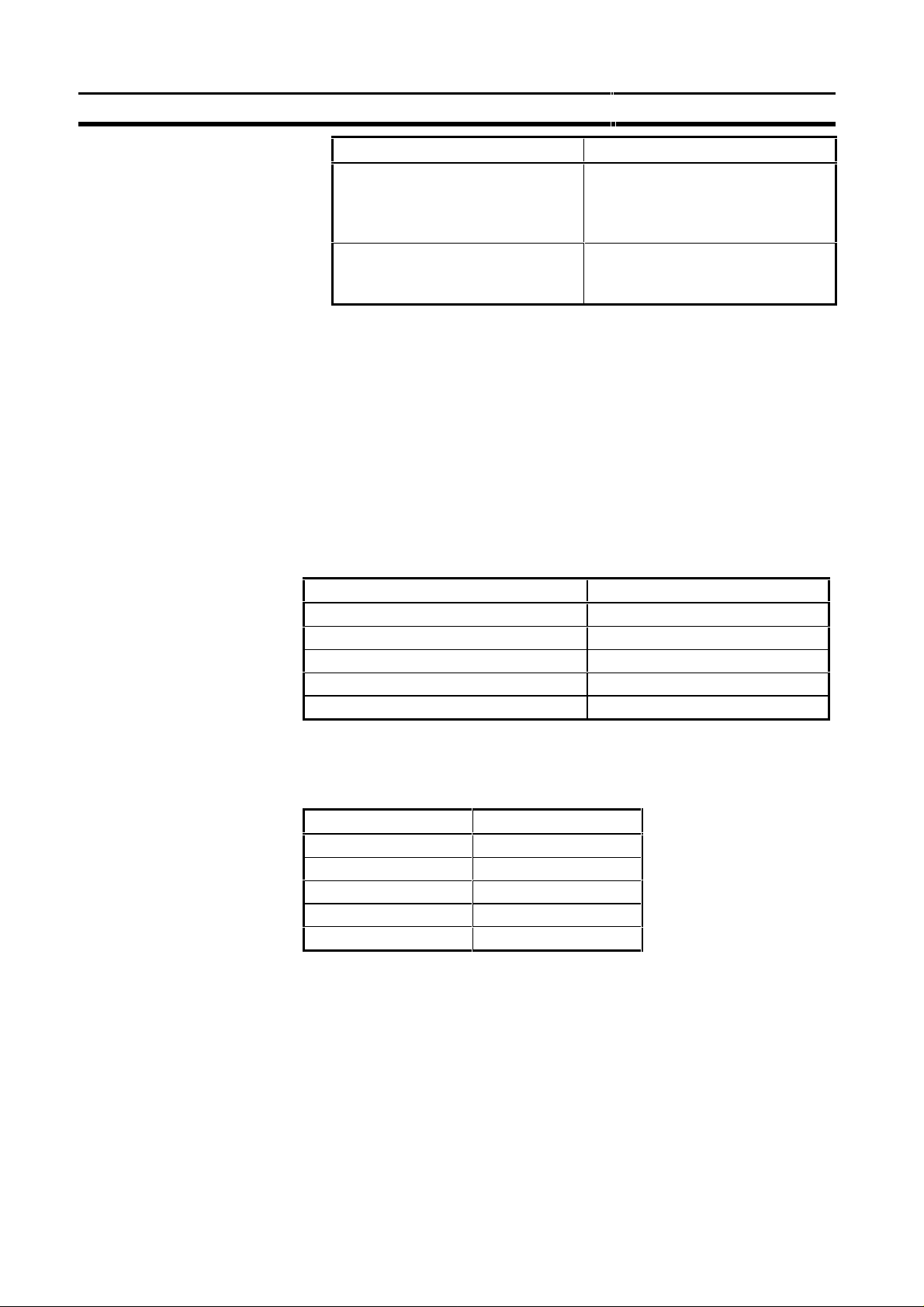

Baud rate (kbit/s) Distance/segment (m)

9.6 1200

19.2 1200

93.75 1200

187.5 1000

500 400

1500 200

3000 100

6000 100

12000 100

3

Page 20

Device types

1-3 Device types

Master devices

Active stations

DPM1, DPM2

Slave devices

Passive stations

Section 1-3

PROFIBUS distinguishes between master devices and slave devices.

Master devices determine the data communication on the bus. A master can

send messages without an external request when it holds the bus access

rights (the token). Masters are also called active stations in the PROFIBUS

protocol.

There are two types of master devices: DP master class 1 (DPM1) and DP

master class 2 (DPM2). A DPM1 is a central controller which exchanges

information with the decentralised stations (i.e. DP slaves) within a specified

message cycle. DPM2 devices are programmers, configuration devices or

operator panels. They are used during commissioning for configuration of the

DP system or for operation and monitoring purposes.

Slave devices are peripheral devices. Typical slave devices include

input/output devices, valves, drives and measuring transmitters. They do not

have bus access rights and they can only acknowledge received messages or

send messages to the master when requested to do so. Slaves are also

called passive stations.

The C200HW-PRM21 is a DPM1 device.

1-4 PROFIBUS-DP characteristics

1-4-1 Bus Access Protocol

Layer 2

Medium Access Control

Token passing

Polling procedure

The bus access protocol is implemented by layer 2. This protocol also

includes data security and the handling of the transmission protocols and

telegrams.

The Medium Access Control (MAC) specifies the procedure when a station is

permitted to transmit data. The token passing procedure is used to handle the

bus access between master devices and the polling procedure is used to

handle the communication between a master device and its assigned slave

device(s).

The token passing procedure guarantees that the bus access right (the token)

is assigned to each master within a precisely defined time frame. The token

message, a special telegram for passing access rights from one master to the

next master must be passed around the logical token ring - once to each

master - within a specified target rotation time.

The polling or master-slave procedure permits the master, which currently

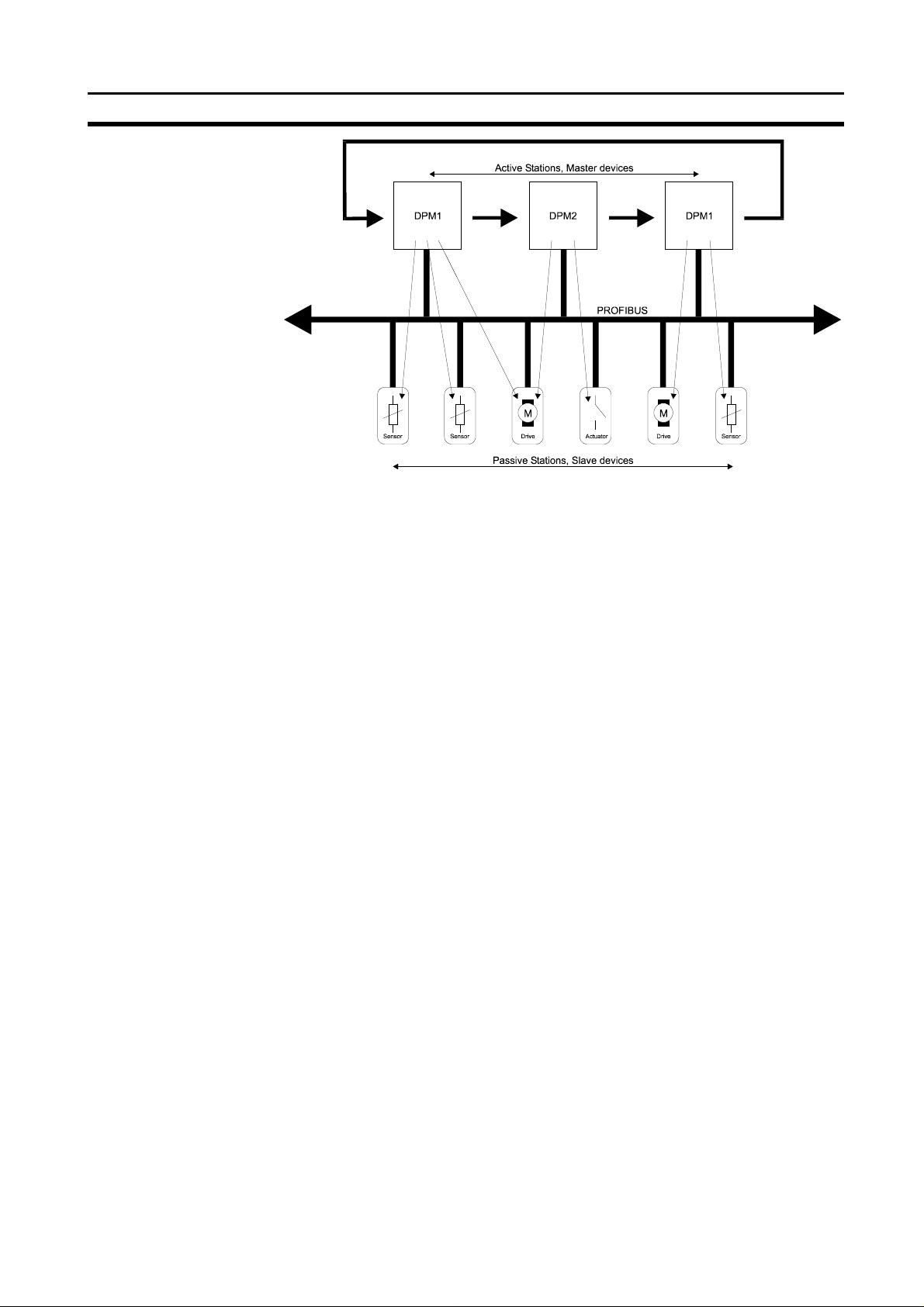

owns the token, to access the assigned slaves. The picture below shows a

possible configuration.

4

Page 21

PROFIBUS-DP characteristics

The configuration shows three active stations (masters) and six passive

stations (slaves). The three masters form a logical token ring. When an active

station receives the token telegram, it can perform its master role for a certain

period of time. During this time it can communicate with all assigned slave

stations in a master-slave communication relationship and a DPM2 master

can communicate with DPM1 master stations in a master-master

communication relationship.

Multi-peer communication

In addition to logical peer-to-peer data transmission, PROFIBUS-DP provides

multi-peer communication (broadcast and multicast).

Broadcast communication: an active station sends an unacknowledged

Multicast communication: an active station sends an unacknowledged

Section 1-4

message to all other stations (master and

slaves).

message to a predetermined group of stations

(master and slaves).

1-4-2 Data throughput

Transmission time

At 12 Mbit/s PROFIBUS-DP requires only about 1 ms for the transmission of

512 bits of input data and 512 bits of output data distributed over 32 stations.

The figure below shows the typical PROFIBUS-DP transmission time

depending on number of stations and transmission speed. The data

throughput will decrease when more than one master is used.

5

Page 22

PROFIBUS-DP characteristics

Bus cycle time vs number of slaves

Section 1-4

25.0

Bus cycle time [ms]

Conditions: Each slave has 2 bytes of input data and 2 bytes of output data.

1-4-3 Diagnostics functions

Extensive diagnostics

Device related diagnostics

Module related diagnostics

Channel related diagnostics

The extensive diagnostic functions of PROFIBUS-DP enable fast location of

faults. The diagnostic messages are transmitted over the bus and collected at

the master. These messages are divided into three levels:

• Device related diagnostics

These messages concern the general operational status of the whole

device (i.e. overtemperature or low voltage).

• Module related diagnostics

These messages indicate that a fault is present in a specific I/O range

(e.g. an 8-bit output module) of a station.

• Channel related diagnostics

These messages indicate an error at an individual input or output (e.g.

short circuit on output 5).

20.0

15.0

10.0

5.0

0.0

0 4 8 12 16 20 24 28 32

500

1500

3000

12000

Slaves

1-4-4 Protection mechanisms

Time monitoring

At the master

At the slave

6

PROFIBUS-DP provides effective protection functions against parameterisation errors or failure of the transmission equipment. Time monitoring is

provided at the DP master and at the DP slaves. The monitoring interval is

specified during the configuration.

• Protection mechanism at the master.

The DPM1 monitors data transmission of the slaves with the

Data_Control_Timer. A separate control timer is used for each slave. This

timer expires when correct data transmission does not occur within the

monitoring interval. The user is informed when this happens. If the

automatic error reaction (Auto_clear = TRUE) has been enabled, the

DPM1 exits its Operate state, switches the outputs of all assigned slaves

to fail-safe status and changes to its Clear status (see also next section).

• Protection mechanism at the slave.

The slave uses the watchdog control to detect failures of the master or the

transmission line. If no data communication with the master occurs within

the watchdog control interval, the slave automatically switches its outputs

to the fail-safe status.

Also, access protection is required for the inputs and outputs of the DP

slaves operating in multi-master systems. This ensures that direct access

Page 23

PROFIBUS-DP characteristics

1-4-5 Network states

PROFIBUS-DP distinguishes four different states.

Offline

Stop

Clear

Operate

Auto_clear

Fail-safe state

• Offline

• Stop

• Clear

• Operate

When an error occurs during the data transfer phase of the DPM1, the

‘Auto_clear’ configuration parameter determines the subsequent actions. If

this parameter is set to false, the DPM1 remains in the Operate state. If set to

true, the DPM1 switches the outputs of all assigned DP slaves to the fail-safe

state and the network state changes to the Clear state.

Section 1-4

can only be performed by the authorised master. For all other masters, the

slaves offer an image of their inputs and outputs which can be read from

any master, even without access rights.

Communication with all DP participants is stopped.

Communication between DPM1 and DP slaves is stopped. Only communication between DPM1 and DPM2 is possible.

DPM1 master tries to set parameters, check the configuration, and

perform data exchange with its associated DP-slaves. The data exchange

comprises reading the inputs of the DP-slaves and writing zero’s to the

outputs of the DP-slaves.

DPM1 master exchanges data with its assigned slaves, inputs are read

and outputs are written. Beside this, the DPM1 cyclically sends its local

status to all assigned DP slaves (with a multicast) at a configurable time

interval.

7

Page 24

Device Data Base files

1-5 Device Data Base files

Section 1-5

Plug-and-play

DDB-file, GSD-file

General section

DP-master section

DP-slave section

Configurator

To achieve simple plug-and-play configuration of the PROFIBUS-DP network,

the characteristic features of a device are specified in a file. This file is called

a DDB-file (Device Data Base file) or a GSD-file (Gerätestammdaten file). The

GSD files are prepared individually by the vendor for each type of device

according a fixed format. Some parameters are mandatory, some have a

default value and some are optional.

The device data base file is divided into three parts:

• General specifications

This section contains vendor and device names, hardware and software

release states, station type and identification number, protocol specification and which baud rates are supported.

• DP master-related specifications

This section contains all parameters which only apply to DP master

devices (i.e. maximum memory size for master parameter set, maximum

number of entries in the list of active stations or the maximum number of

slaves the master can handle).

• DP slave-related specifications

This section contains all specification related to slaves (i.e. minimum time

between two slave poll cycles, specification of the inputs and outputs and

about consistency of the I/O data).

The device data base file of each device is loaded in the configurator and

downloaded to the master device. The device data base file for the C200HWPRM21, named OC_1656.GSD, is provided with the configuration software.

Section 4 will describe the configurator package SyCon, which is used for

configuration of the C200HW-PRM21, in more detail.

1-6 Profiles

Exchanging devices

To enable the exchange of devices from different vendors, the user data has

to have the same format. The PROFIBUS-DP protocol does not define user

data, it is only responsible for the transmission of this data. The format of user

data is defined in so called profiles. Profiles may reduce engineering costs

since the meaning of application-related parameters is specified precisely.

Profiles have for instance been defined for drive technology, encoders, and

for sensors / actuators.

8

Page 25

2 Installation

This section describes the installation of the C200HW-PRM21

2-1 Physical layout of the unit........................................................................................................................................10

2-1-1 LEDs...............................................................................................................................................................10

2-1-2 Rotary Switch .................................................................................................................................................10

2-1-3 BUS Connector...............................................................................................................................................11

2-1-4 Configurator Connector.................................................................................................................................12

2-1-5 Termination Switch.........................................................................................................................................13

2-2 Mounting the C200HW-PRM21 ..............................................................................................................................13

2-3 Setting up a network.................................................................................................................................................14

2-3-1 Fieldbus cabling.............................................................................................................................................14

2-3-2 Configuring the fieldbus.................................................................................................................................16

9

Page 26

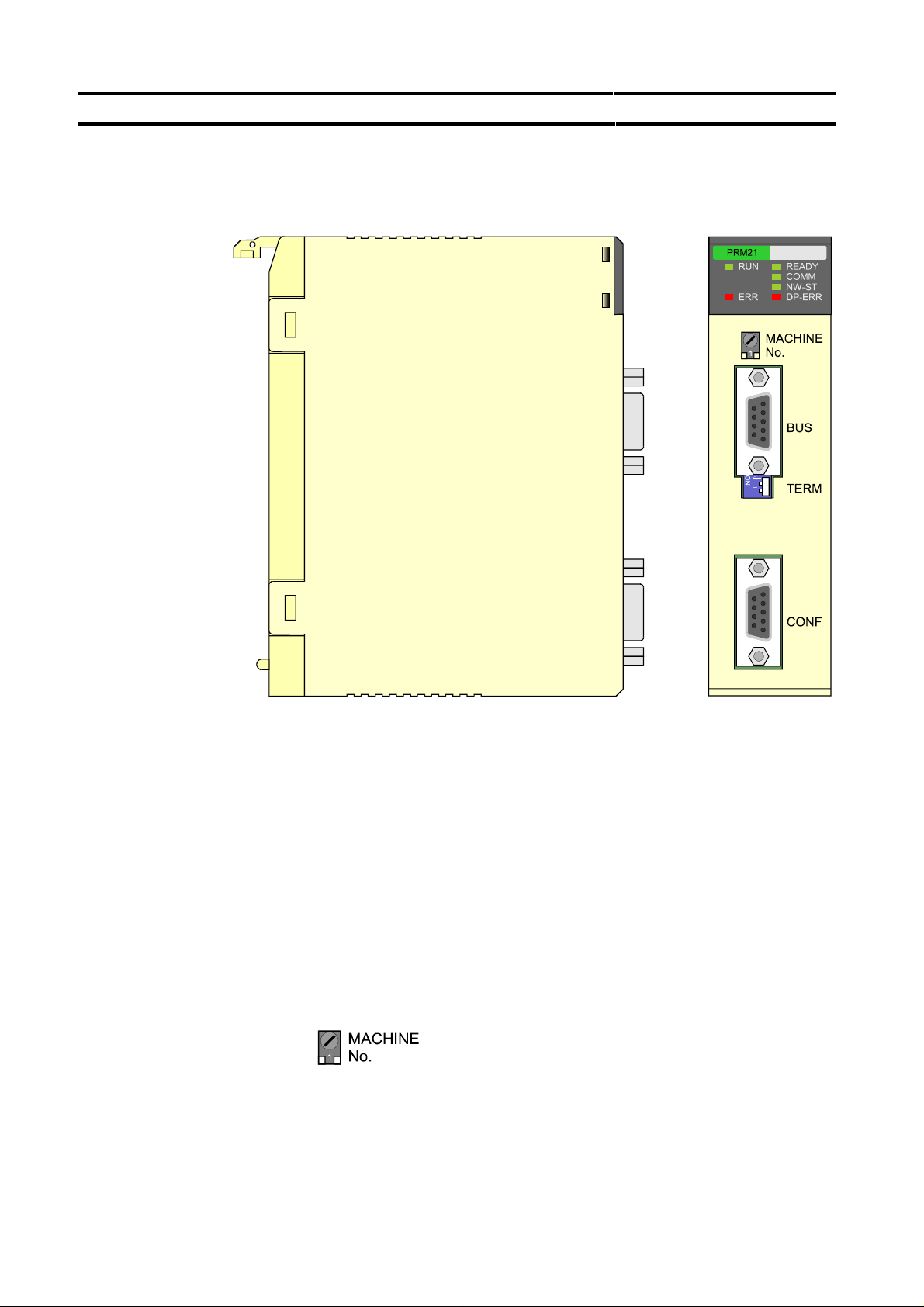

Physical layout of the unit

2-1 Physical layout of the unit

The figure below shows the side and front views of the C200HW-PRM21.

Section 2-1

2-1-1 LEDs

2-1-2 Rotary Switch

The front view shows the indicator LEDs, the ‘Machine No.’ rotary switch, two

9-pin female sub-D connectors, and the bus termination switch.

The C200HW-PRM21 has 6 indicator LEDs. The two LEDs on the left side

give a status indication of the unit in general. The four LEDs on the right side

are related to the status of the PROFIBUS-DP network Refer to section 5-4

for a detailed (functional) description of the LEDs.

The rotary switch is used to set the unit number (or so called “Machine No.”).

The unit number setting determines which words in the Internal Relay and

Data Memory Areas are allocated to the Master Unit.

The allowed unit number setting range depends on the PLC CPU Unit being

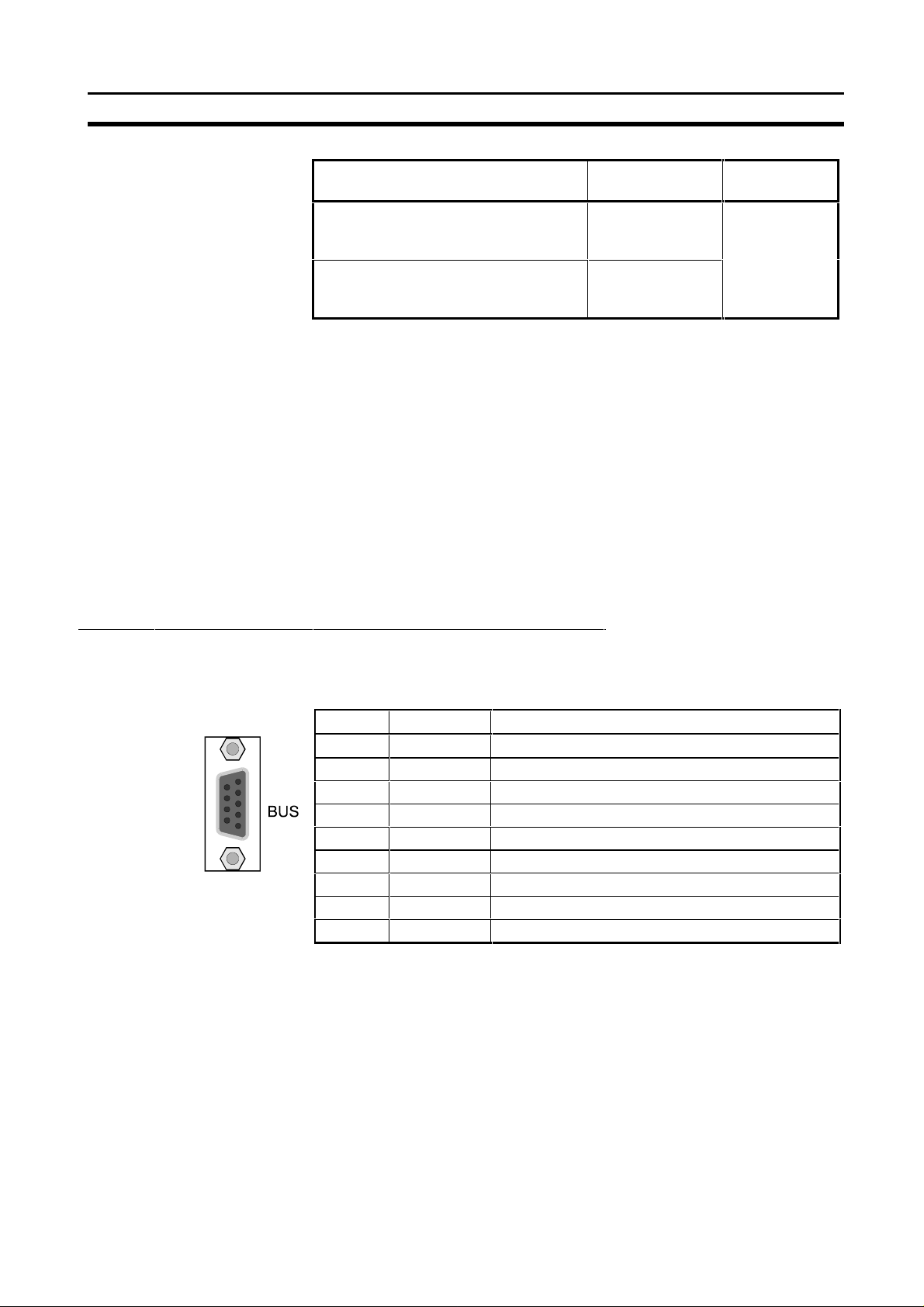

used, as shown in the following table.

10

Page 27

Physical layout of the unit

Section 2-1

Note

2-1-3 BUS Connector

CPU Unit models Unit number

C200HS, C200HE,

C200HG-CPU3[ ]-E/CPU4[ ]-E,

C200HX-CPU3[ ]-E/CPU4[ ]-E

C200HG-CPU5[ ]-E/CPU6[ ]-E,

C200HX-CPU5[ ] -E/CPU6[ ]-E

Cs1-series

setting range

0 to 9 Single-digit

0 to F

Setting

method

hexadecimal

Any unit number in the setting range is allowed as long as it has not been set

on another Special I/O Unit connected to the PLC. If the same unit number is

used for the C200HW-PRM21 and another Special I/O Unit, an I/O Unit Over

error will occur in the PLC and it will not be possible to start up the

PROFIBUS-DP Network.

Always turn OFF the power to the PLC before changing the unit number

setting. The Unit only reads the unit number setting during the initialisation

after power-up, so not after a software reset.

Use a small flat-blade screwdriver to turn the rotary switch; be careful not to

damage the switch.

The fieldbus connector is a 9-pin female sub-D connector, as recommended

by the PROFIBUS standard EN 50170.

Pin No. Signal Description

1 Shield Shield / protective ground

2 - 3 B-line Data signal

4 RTS Control signal for repeaters (direction control) (TTL)

5 DGND Data ground

6 VP Supply voltage of the terminator resistance (5V)

7 - 8 A-line Data signal

9 - -

The signals DGND and VP are used internally to power the bus terminator

(see section 2-1-5).

The signal RTS (TTL signal) is meant for the direction control of repeaters if

repeaters without self control capability are used.

The PROFIBUS standard defines 24 V remote powering signals for pin 2 and

pin 7. These signals are optional and have not been implemented in this Unit.

11

Page 28

Physical layout of the unit

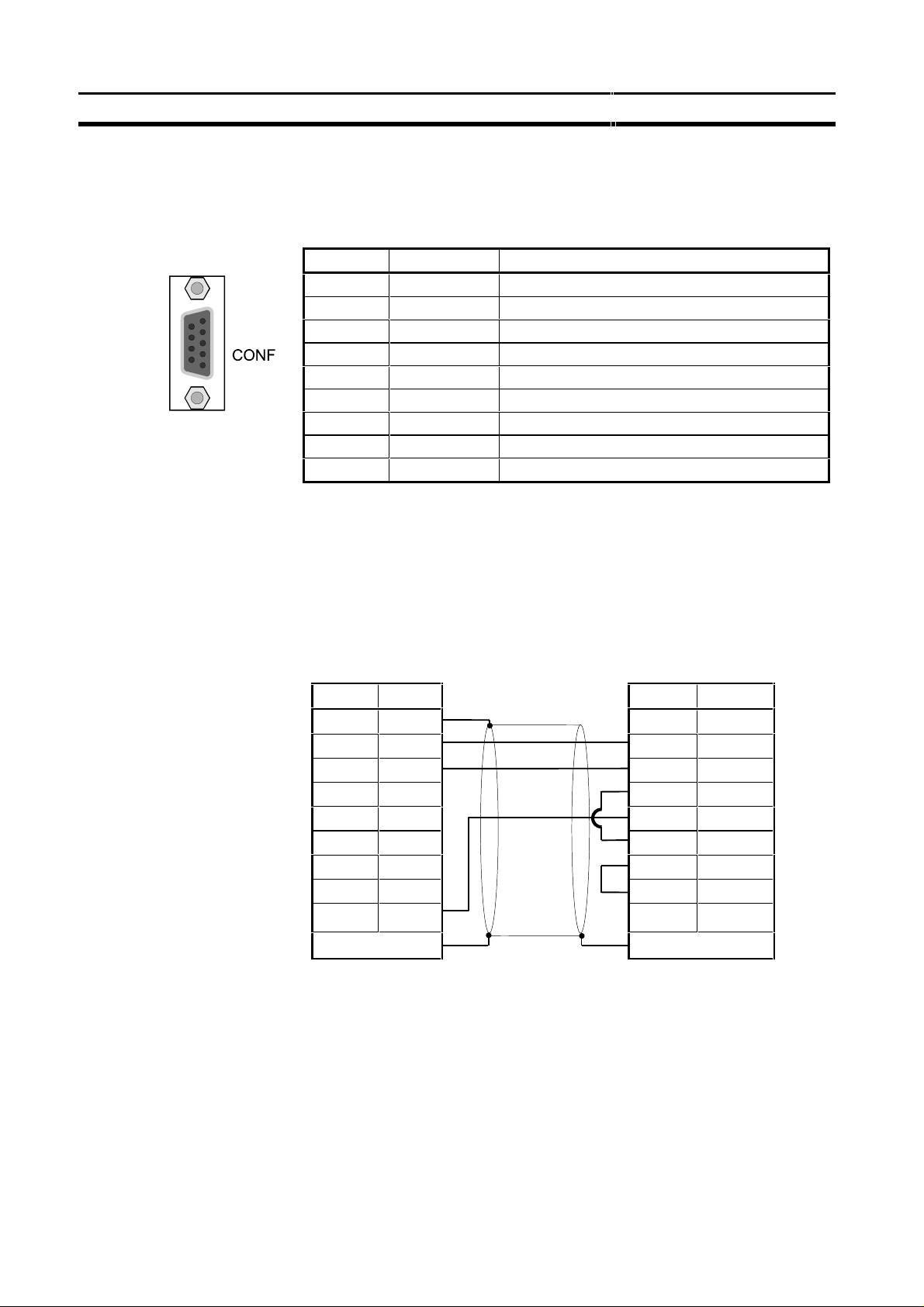

2-1-4 Configurator Connector

The configurator connector is a 9-pin female sub-D connector.

Pin No. Signal Description

1 FG Frame Ground (shield)

2 SD Send Data

3 RD Receive Data

4 RS Request to Send

5 CS Clear to Send

6 - 7 - 8 - 9 SG Signal Ground

The pin assignment of this connector is the same as the that of the RS-232C

port provided on most C200H-series CPUs. This enables the use of the same

serial communication cable for both the CPU and the C200HW-PRM21.

Section 2-1

The wiring of the RS-232C cable is shown in the picture below.

PRM21

Personal computer

Configurator port

Signal Pin No. Pin No. Signal

FG 1

shielded cable

1 SD 2 2 RD

RD 3 3 SD

RS 4 4 DTR

CS 5 5 SG

- 6 6 DSR

- 7 7 RS

- 8 8 CS

SG 9 9 -

Case Case

12

Page 29

Mounting the C200HW-PRM21

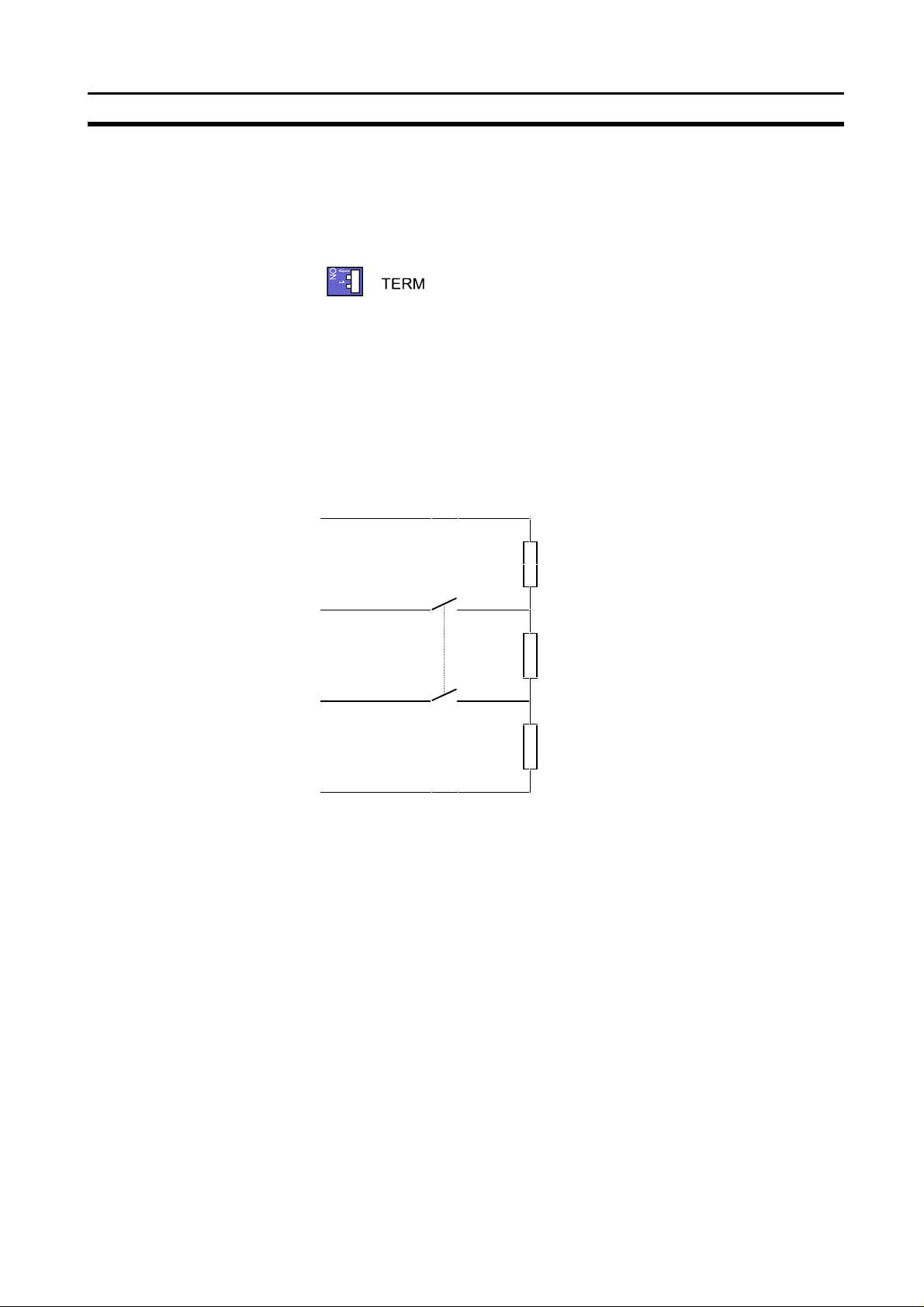

2-1-5 Termination Switch

The termination switch has two positions. When the switch is set to the right

(as shown below), the termination is disabled. By setting the switch to the left,

the termination is enabled.

Enabling the termination connects the two data lines using a 220 Ω resistor

which is connected to VP and DGND via two 390 Ω resistors (see figure

below). The powering of the terminator resistor ensures a defined idle state

potential on the data lines.

To ensure proper functioning up to the highest baud rate, the bus cable has to

be terminated on both ends of the cable.

VP

Section 2-2

390 Ω

B-line

220 Ω

A-line

390 Ω

DGND

2-2 Mounting the C200HW-PRM21

The PROFIBUS-DP Master Unit (C200HW-PRM21) can be mounted to the

CPU Rack or Expansion I/O Rack of any CS1, C200HX, -HG, -HE, or -HS

PLC. Refer to the PLC’s Installation Guide for details on mounting Units.

Limitations

There are some limitations on mounting the Master Unit.

• The Master Unit is a Special I/O Unit. It can be mounted in any slot in the

Backplane of a CPU Rack or Expansion I/O Rack as long as its unit

number is not the same as the unit number of another Special I/O Unit

within the system.

• The current consumption all of units mounted on one backplane should not

exceed the maximum output of the power supply. The C200HW-PRM21

consumes up to 600 mA from the 5V supply. Verify the characteristics of

all other units on their respective Instruction Sheets.

• The maximum number of Master Units that can be mounted depends on

the PLC CPU type.

13

Page 30

Setting up a network

C200HS-CPU[ ] (all models)

C200HE-CPU11/32/42

C200HG-CPU33/43

C200HX-CPU34/44

C200HG-CPU53/63

C200HX-CPU54/64

CS1-series

2-3 Setting up a network

2-3-1 Fieldbus cabling

Section 2-3

CPU Unit models Max. No. of Master Units

10

16

Bus structure

Cable type

Maximum length

All devices are connected in a bus structure (i.e. line). Up to 32 stations

(master or slaves) can be connected in one segment. The bus must be

terminated at the beginning and at the end of each segment. When more than

32 stations are used, repeaters must be used to link the individual bus

segments. The maximum number of stations that can be connected to a

C200HW-PRM21 is 124.

The standard EN 50170 specifies to use line type A of shielded twisted pair

cables with the following parameters:

Parameter Value

Impedance 135 to 165 Ω

Capacitance per unit length < 30 pF/m

Loop resistance 110 Ω/km

Core diameter 0.64 mm

Core cross section > 0.34 mm

2

The maximum length of the cable depends on the transmission speed. The

cable lengths specified in the table below are based on line type A.

Baud rate (kbit/s) Distance/segment (m)

9.6, 19.2, 93.75 1200

187.5 1000

500 400

1500 200

3000, 6000, 12000 100

Repeaters

Stub lines

14

The communication distance can be increased by the use of repeaters. It is

not recommended to use more than 3 repeaters in series. A repeater also

must be included in the count of the number of stations per segment to

determine the bus load (so only 31 ‘normal’ devices are possible per segment

if a repeater is used)

Stub lines should be avoided for data transmission speeds of more than

500 kbit/s. Plug connectors available on the market permit the incoming data

cable and the outgoing data cable to be connected directly in the plug

connector. This means that stub lines do not have to be used, and the bus

plug connector can be connected and disconnected at all times without

interrupting data communication with the other stations.

Page 31

Setting up a network

AAB

B

3

8

indu

c

tors

Section 2-3

Fieldbus connector

to next

station

The connector plug to be used on the C200HW-PRM21 is a 9-pin male subD, preferably with a metal case, and a facility to connect the shield of the

cable to the case. The cable should at least be connected to pin 3 (B-line) and

pin 8 (A-line) of the connector.

At baud rates of 1.5 Mbit/s or higher, always use special PROFIBUS-DP

plugs with built-in series inductances, to ensure that cable reflections caused

by the capacitive the load of each unit are minimised.

Connector plugs with built-in inductors, as shown here schematically, are

available from various manufacturers.

A standard 9-pin sub-D plug can only be used if the C200HW-PRM21 is at

the start or at the end of a bus segment, or on a stub line at baud rates of 500

kbit/s or less.

To ensure electro-magnetic compatibility (EMC), the shield of the cable

should be connected to the metal case of the connector. If this is impossible,

use pin 1.

If the Unit is installed within a control cabinet, the cable shield of the bus cable

should be electrically connected to a grounding rail as close as possible to the

cable lead-through using a shield grounding clamp or similar. The cable shield

should continue within the cabinet to the fieldbus device.

Ensure that the PLC and the control cabinet in which the device is mounted

have the same ground potential by providing a large-area metallic contact to

ground (use e.g. galvanised steel to ensure a good connection). Grounding

rails should not be attached to painted surfaces.

outside

cabinet

ground rail

You may find further information about

• Commissioning of PROFIBUS equipment

• Testing the PROFIBUS cable and bus connectors

• Determining the loop resistance

• Testing for correct bus termination

• Determining the segment length and cable route

• Other test methods

• Example of an equipment report

in the PROFIBUS guideline "Installation Guideline for PROFIBUS-DP/FMS"

(PNO Order No- 2.112), which is available at every regional PROFIBUS user

organisation.

15

Page 32

Setting up a network

2-3-2 Configuring the fieldbus

After making the physical connections of the network, the network needs to

be configured. For each master and its assigned slaves, a configuration has

Configurator

to be defined using SyCon, a dedicated PC-based configuration program.

The configurator provides the master with information about:

• The slaves that are connected to the master.

• The assignment of slaves to groups for broadcast / multicast messages.

• The mapping of the slaves into the memory of the master.

• The bus parameters (e.g. baud rate, target rotation time etc.).

For more details about the configurator refer to section 4.

Section 2-3

Downloading configuration

After entering the configuration, it must be downloaded to the master unit. A

serial COM-port of the PC is to be connected to the C200HW-PRM21 via the

prescribed RS-232C cable.

16

Page 33

3 Specifications and Performance

This section describes the overall specifications and the communication performance of the Unit

3-1 Overall Specifications..............................................................................................................................................18

3-2 Performance.............................................................................................................................................................20

3-2-1 Fieldbus cycle time.........................................................................................................................................20

3-2-2 PLC cycle time................................................................................................................................................24

3-2-3 I/O response time in asynchronous mode.......................................................................................................25

3-2-4 I/O response time in synchronous mode.........................................................................................................27

17

Page 34

Overall Specifications

3-1 Overall Specifications

Model code

Maximum. number of Master

Units

(with user defined I/O mapping)

Master Unit mounting position

Settings

Displays

External connectors

No. of IR words

No. of DM settings

No. of slave status words

Remote I/O

communications

Message communications

PROFIBUS-DP Baud rate

Network configuration

Current consumption

Storage temperature

Operating temperature

Operating humidity

Conformance to EMC- and

environmental standards

Weight

Max. No. of

Slaves per

Master Unit

Max. No. of I/O

words per

Master Unit

Supported

functions

CPU Rack or Expansion I/O Rack (classified as Special I/O Unit)

Unit cannot be mounted to SYSMAC BUS Slave Racks.

Unit cannot be used on a C200H PLC system.

Rotary switch : Unit number

Toggle switch : Bus termination

Unit status : RUN (green LED), ERR (red LED)

Network status : READY (green LED), COMM (green LED),

9-pin female sub-D connector (fieldbus connector, RS-485)

9-pin female sub-D connector (configurator connector, RS-232C)

2 words of control data out + 3 words of unit status in

18 words of unit setup information

16 words of status + diagnostic bits (location is user definable)

With default DM settings:

32 words in, 32 words out

With user defined DM settings:

80 words, in up to 4 areas

Not supported via IOWR / IORD instructions

as client : Data_Exchange, Slave_Diag, Set_Prm, Chk_Cfg, Global_Control

as server : Get_Master_Diag

Configurator program (SyCon V.1.5x) for WIN 3.x, WIN 95 and WIN NT

Section 3-1

C200HS C200HE/HG/HX, CS1

C200HW-PRM21

C200HE-CPU11/32/42

10

NW-ST (green LED), DP-ERR (red LED)

9.6 / 19.2 / 93.75 / 187.5 / 500 kbit/s,

1.5 / 3 / 6 / 12 Mbit/s

600 mA at 5 V DC (from PLC power supply)

-20 to +75°C

10% to 90% (non-condensing)

EN 50081-2

EN 61131-2

C200HG-CPU33/43

C200HX-CPU34/44

C200HG-CPU53/63

C200HX-CPU54/64

CS1-series

124

With default DM settings:

50 words in, 50 words out

With user defined DM settings:

300 words in up to 4 areas;

maximum 100 words per area

0 to +55°C

250 g

10

16

18

Page 35

Overall Specifications

Section 3-1

Dimensions

The following diagram shows the dimensions of the Master Unit. Refer to the

PLC’s Installation Guide for the dimensions of the Unit when it is mounted to

the Backplane. (All dimensions are in mm.)

19

Page 36

Performance

3-2 Performance

3-2-1 Fieldbus cycle time

This section gives a simplified method of fieldbus cycle time calculations.

Refer to EN 50170 for a more detailed calculation of the fieldbus cycle time.

The fieldbus cycle time with only one master is approximately:

Section 3-2

tBC = (ns + nr) x tMC + t

GAP_REQ

+ t

TC

where: ns = number of slave stations

nr = number of message retry cycles

tMC = message cycle time

t

= live list check time

GAP_REQ

tTC = token cycle time

The calculation of the fieldbus cycle time for multiple master networks is more

complex. For simplicity, extra time needed by each additional master can be

said to equal the time it holds the token and passes the token to the next

station, plus the time to check for live stations. In this case the fieldbus cycle

is approximately:

tBC = (ns + nr) x tMC + nm x (t

GAP_REQ

+ tTC)

where: ns = number of slave stations

nr = number of message retry cycles

tMC = message cycle time

nm = number of master stations

t

= live list check time

GAP_REQ

t

TC

= token cycle time

20

For each master station it is possible to specify the target rotation time using

the configurator software. If the actual fieldbus cycle time is less than the

target rotation time, all messages will be transmitted. If not, the master

stations will retain the low priority messages and transmit them at the next or

the following token receptions.

Note The fieldbus cycle time depends on many variables, not only those

mentioned in the formulas above. Therefore the formulas above only

give an approximation of the fieldbus cycle time.

The minimum possible fieldbus cycle time equals approximately 1 ms

(even if the formula gives a lower value).

The message cycle time, the live list check time, and the token cycle time are

explained below.

Page 37

Performance

Section 3-2

Message cycle time

A message consists of an action frame (request or send/request frame) and a

reply frame (acknowledge or response frame). The message cycle time is

composed of the frame transmission times, the transmission delay times, the

station delay time and the bus idle time.

TMC = t

ACTION-FRAME

+ t

REPLY-FRAME

+ 2 x t

TRANSMIT_DELAY

+ t

STATION-DELAY

+ t

IDLE

The station delay time is the time the slave needs for decoding the request

and generating an acknowledge or response frame.

The bus idle time is the time between an acknowledgement or response of

the slave and a new request from the master. Part of this time is used for

synchronisation (t

SYN

= 33 t

).

BIT

PROFIBUS has different formats for the action frame and the reply frame.

The frames can have a fixed format (with no data field or with a data field of 8

octets) or a variable format (with a variable data field length).

A general formula for the message cycle time:

tMC = (9+n1) x 11 + (9+n2) x 11 + 2 x 0 + 30 + 37 t

= (265 + 11n) t

BIT

BIT

where: n1 = number of action data bytes

n2 = number of reply data bytes

n = n1 + n2

The formula is based upon the following assumptions:

• The action frame and response frame have a variable format.

• The transmission delay times are negligible.

• t

• t

STATION-DELAY

IDLE

= 37 t

= 30 t

BIT

(typical value for the ASIC SPC3)

BIT

Live list check time

Each bus cycle the master requests the FDL (Fieldbus Data Link) status of

one of the stations connected to the network, except for the master stations

that have been entered in the LAS (List of Active Stations). The stations are

checked in sequence.

Each master is designated a certain range of slaves that it has to check. This

range is determined by the station addresses of the masters connected to the

network and the value for the parameter HSA (Highest Station Address).

A master checks the station addresses one higher than his own address up to

the next master address. If there is no master with a higher address, the

master checks until the value of HSA and starts again with checking from

station address 0.

If the station that is being checked is present and functions correctly, the

check time is approximately:

t

GAP_REQ

= t

REQ_FRAME

= 6 x 11 + 6 x 11 + 2 x 0 + 30 + 37 t

= 200 t

+ t

RES_FRAME

BIT

+ 2 x t

TRANSMIT_DELAY

BIT

+ t

STATION-DELAY

+ t

IDLE

21

Page 38

Performance

Section 3-2

If the station is not present, the master stops waiting for an answer after the

slot-time (one of the bus parameters). The check time in this case is:

t

= t

GAP_REQ

REQ_FRAME

= 6 x 11 + 100 + 37 t

= 203 t

The formulas are based upon the following assumptions:

• The transmission delay times are negligible.

• t

• t

• t

STATION-DELAY

IDLE

SLOT

= 37 t

= 100 t

= 30 t

BIT

BIT

(configurable)

BIT

Token cycle time

The token cycle time is the time each master station requires to process and

transfer the token. It is composed of the token frame time, the transmission

delay time and the bus idle time.

+ t

+ t

SLOT

IDLE

BIT

BIT

(typical value for the ASIC SPC3)

tTC = t

TOKEN-FRAME

+ t

TRANSMIT_DELAY

+ t

IDLE

The bus idle time contains the station delay time of the receiver and the

synchronisation time.

A general formula for the token cycle time:

tTC = 3 x 11 + 0 + 37 t

= 70 t

BIT

BIT

The formula is based upon the following assumptions:

• The transmission delay time is negligible.

• t

= 37 t

IDLE

BIT

Examples

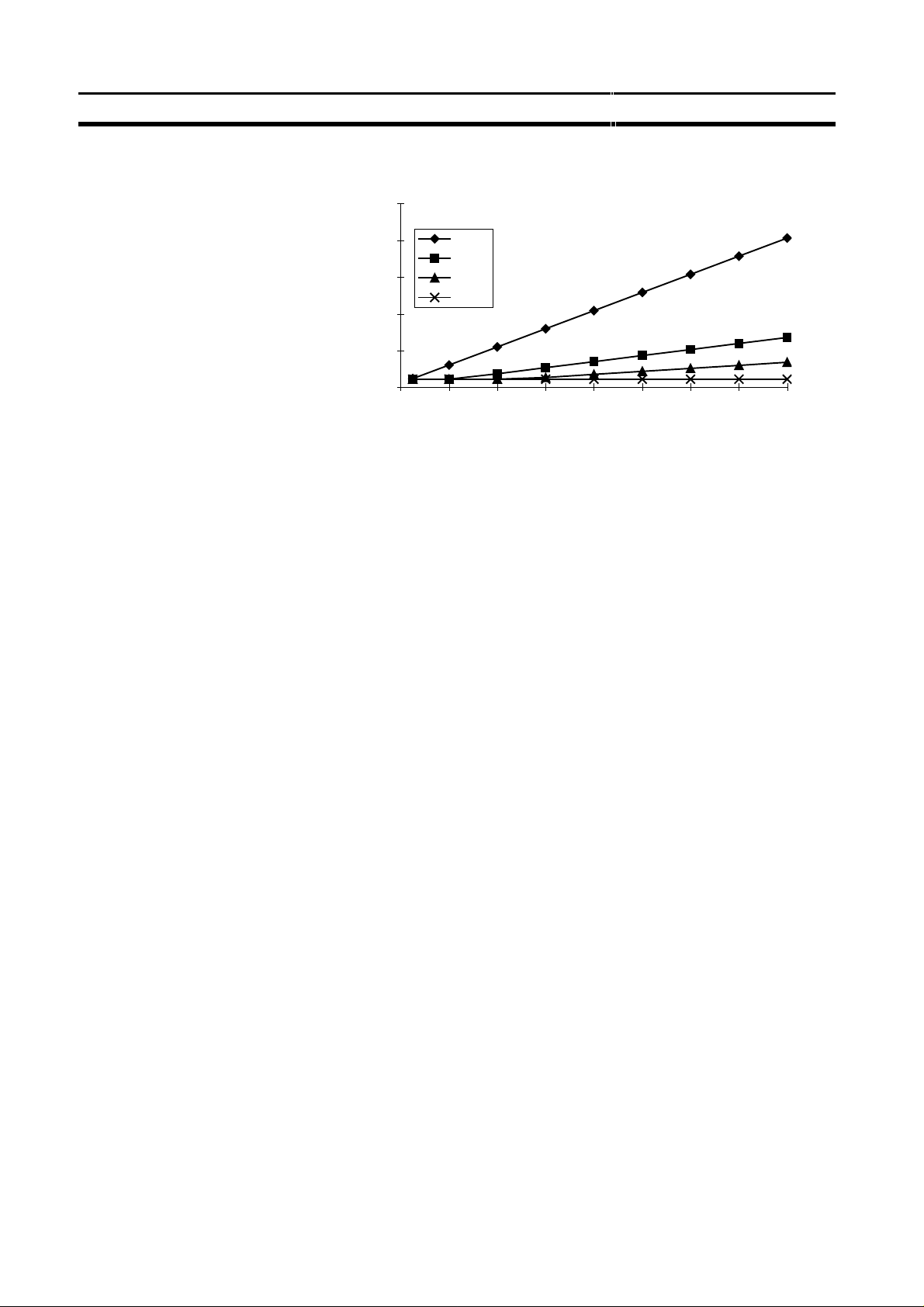

The two figures below give an indication of the fieldbus cycle time. In each

figure the bus cycle time is calculated for four different baud rates (500 kbit/s,

1500 kbit/s, 3000 kbit/s, and 12000 kbit/s).

The first figure shows the effect of the number of slaves on the bus cycle time.

The values of the parameters are:

n = 4 (number of data bytes per slave)

ns = variable on the x-axis

nr = 0

Baud rate = variable per curve

The fieldbus cycle time is calculated with the formula for a single master

system.

The bus cycle time increases when the number of slaves increases due to the

fact that the total number of data bytes that needs to be transferred increases.

22

Page 39

Performance

Bus cycle time vs number of slaves

Baud rate

kbit/s

Section 3-2

25.0

20.0

15.0

10.0

Bus cycle time [ms]

5.0

0.0

0 4 8 12 16 20 24 28 32

500

1500

3000

12000

Slaves

The second figure shows the effect of the number of masters on the bus cycle

time. The values of the parameters are:

n = 4

ns = nm (each master has one slave)

nm = variable on the x-axis

nr = 0

Baud rate = variable per curve

Bus cycle time vs number of masters

40.0

35.0

30.0

25.0

20.0

15.0

10.0

Bus cycle time [ms]

5.0

0.0

0 4 8 12 16 20 24 28 32

500

1500

3000

12000

Masters

This figure is resembles the first figure. An increase of the number of masters

also increases the number of slaves and thus increases the number of data

bytes that needs to be transferred. The only difference is the addition of the

time to pass the token from one master to the other master and the total time

on checking the stations is increased. This is an addition of about 270 t

per

additional master.

23

Page 40

Performance

3-2-2 PLC cycle time

Section 3-2

The PLC cycle time mainly depends on the size of the PLC program and the

I/O refresh time of the units.

The size of the PLC program is application specific. Besides optimising the

PLC program, the program execution time can only be decreased by using a

faster CPU.

The total I/O refresh time depends on the types of units that are mounted on

the Backplane(s). Not all units refresh the same amount of data.

The I/O refresh time of the C200HW-PRM21 depends on the number of data

areas and the number of I/O data words that have been mapped.

The I/O refresh time of the C200HW-PRM21 Unit can be calculated with the

following formulas.

C200HS:

t

= 1.6 + 0.4 x na + 0.067 x nw [ms]

IORF

C200HE, C200HG, C200HX, CS1:

t

= 1.0 + 0.4 x na + 0.018 x nw [ms]

IORF

where: na = number of mapped data areas

nw = number of mapped I/O words (na ≥ 1)

Note

Using the default mapping mode, the I/O refresh time is:

C200HS : 6.7 ms (2 areas: 32 words out, 32 words in)

C200HE,

C200HG,

C200HX,

CS1-series : 3.6 ms (2 areas: 50 words out, 50 words in)

Refer to the Operation Manual of the CPU for more detailed calculations of

the PLC cycle time.

The I/O refresh time is not constant over all PLC cycles. During an I/O

refresh, the unit can transfer I/O data, slave status information, and IR words

(control & status). IR data is always transferred. I/O data and slave status

data are only transferred under certain conditions:

Input data: Only when there is new input data available. The

situation that there is no new input data occurs when the

fieldbus cycle time is greater than the PLC cycle time or

when the communication is inhibited.

Output data: Always transferred after the Unit is initialised, except

during a download and in the synchronous mode when

the fieldbus cycle time is greater than the PLC cycle time.

Slave Status: Always transferred after the Unit is initialised.

24

Page 41

Performance

3-2-3 I/O response time in asynchronous mode

In asynchronous data transfer mode, the fieldbus cycle is not synchronised

with the PLC cycle; fieldbus cycles are triggered continuously, independent of

the PLC cycle.

Minimum I/O response time

The figure below shows the minimum I/O response time in asynchronous

mode. The figure shows the timing at the PLC, the timing at the Master Unit,

the timing at the slave input and the timing at the slave output.

Section 3-2

Conditions

tIN : The Input Slave’s ON (OFF) delay

t

: The Output Slave’s ON (OFF) delay

OUT

t

BC

t

RF

t

PE

: The fieldbus cycle time

: The I/O refresh time

: Program Execution time

The minimum response time can be achieved under the following conditions:

1. No other master is connected to the network. More masters will increase

the fieldbus cycle time due to the token rotation between masters.

2. User defined I/O data mapping. Only map the input and output data of the

configured slaves. This will minimise the number of words that needs to be

transferred per PLC cycle and therefore the I/O refresh time.

3. The fieldbus baud rate is set to the highest value allowed for the attached

slaves and the used cable length.

4. The IORF instruction can be used to further decrease processing time in

the PLC program.

The minimum I/O response time that can be achieved with C200HE, -HG or HX and the CS1-series is approximately

9 ms + tIN + t

OUT

25

Page 42

Performance

Section 3-2

Maximum I/O response time

The figure below shows the maximum I/O response time in asynchronous

mode. The figure shows the timing at the PLC, the timing at the Master Unit,

the timing at the slave input and the timing at the slave output.

tIN : The Input Slave’s ON (OFF) delay

t

: The Output Slave’s ON (OFF) delay

OUT

t

BC

t

PC

t

RF

t

PE

: The Fieldbus cycle time

: The Poll cycle time of the respective master

: The I/O refresh time

: The Program Execution time

The maximum response time can occur under the following conditions.

1. The slave in question is polled by the respective master at the beginning

of the poll cycle.

2. The Input data is available just after the master polled the respective

slave.

3. The Master Unit finished processing just after the I/O refresh. The Input

data is not transferred to the PLC until the next PLC cycle.

4. A fieldbus cycle just started before the end of the I/O refresh, the output

data is not transferred until the next fieldbus cycle.

The I/O response time in the case above is:

t

RESPONSE

= tIN + 2 x tBC + tPC + 2 x tRF + 2 x tPE + t

OUT

Note: With tPC is meant the time the master of the respective slave needs

to poll all slaves that have been assigned to this master.

26

Page 43

Performance

3-2-4 I/O response time in synchronous mode

In synchronous data transfer mode, the fieldbus cycle is triggered immediately

following the I/O refresh of the PLC. If the fieldbus cycle has not finished

before the start of the I/O refresh, the fieldbus cycle is not triggered until after

the next I/O refresh.

Minimum I/O response time

The figure below shows the minimum I/O response time in synchronous

mode. The figure shows the timing at the PLC, the timing at the Master Unit,

the timing at the slave input and the timing at the slave output.

Section 3-2

tIN : The Input Slave’s ON (OFF) delay

t

: The Output Slave’s ON (OFF) delay

OUT

t

BC

t

RF

t

PE

: The fieldbus cycle time

: The I/O refresh time

: Program Execution time

The minimum response time can be achieved under the following conditions:

1. No other master is connected to the network. More masters will increase

the fieldbus cycle time due to the token rotation between masters.

2. User defined I/O data mapping. Only map the input and output data of the

slave. This will minimise the number of words that needs to be transferred

per I/O refresh and therefore minimise the I/O refresh time.

3. PLC cycle time is greater than the fieldbus cycle time. In this case it is

guaranteed that one fieldbus can be triggered per PLC cycle.

4. The fieldbus baud rate is set to the highest value allowed for the attached

slaves and used cable length.

5. The IORF instruction can be used to further decrease processing time in

the PLC program.

The minimum I/O response time that can be achieved with C200HE, -HG or HX and the CS1-series is approximately

8 ms + tIN + t

OUT

27

Page 44

Performance

Section 3-2

Maximum I/O response time

The figure below shows the maximum I/O response time in synchronous

mode. The figure shows the timing at the PLC, the timing at the Master Unit,

the timing at the slave input and the timing at the slave output.

tIN : The Input Slave’s ON (OFF) delay

t

: The Output Slave’s ON (OFF) delay

OUT

t

PC

t

RF

t

PE

: The Poll cycle time of the respective master

: The I/O refresh time

: The Program Execution time

The maximum response time can occur under the following conditions.

1. The slave in question is polled by the respective master at the beginning of

the poll cycle.

2. The poll cycle time of the respective master is less than the program

execution time of the PLC program.

3. The Input data is available just after the master polled the respective

slave.

The I/O response time in the case above is:

t

RESPONSE

= tIN + 3 x tPE + 3 x tRF + t

OUT

Note: With tPC is meant the time that the master of the respective slave

needs to poll all slaves that have been assigned to this master.

28

Page 45

4 Configurator

This section describes the configuration software package, required to set up a PROFIBUS-DP network

4-1 General...................................................................................................................................................................30

4-1-1Introduction ....................................................................................................................................................30

4-1-2System Requirements ......................................................................................................................................30

4-2 Setup ......................................................................................................................................................................31

4-2-1Installation......................................................................................................................................................31

4-2-2Uninstall .........................................................................................................................................................31

4-3 Operation................................................................................................................................................................32

4-3-1PROFIBUS-DP configuration ........................................................................................................................33

4-3-2Device database..............................................................................................................................................33

4-3-3Bus configuration............................................................................................................................................34

4-3-4Device configuration.......................................................................................................................................36

4-3-5Group membership .........................................................................................................................................39

4-3-6Check I/O assignments....................................................................................................................................40

4-3-7Bus parameters ...............................................................................................................................................42

4-3-8Download........................................................................................................................................................44

4-4 Debug mode...........................................................................................................................................................46

4-4-1Master Diagnostics .........................................................................................................................................47

4-4-2Slave Diagnostics............................................................................................................................................48

4-4-3Extended diagnostics ......................................................................................................................................49

29

Page 46

General

rd

4-1 General

SyCon

4-1-1 Introduction

Section 4-1

To define the network topology and PROFIBUS-DP system characteristics,

the C200HW-PRM21 needs to be provided with information about the slave

units connected to the network, and basic communication parameters.

This information is entered in the Unit by means of the configuration software

package SyCon (V.1.5 or higher). It is not possible to use other (generalpurpose) PROFIBUS-DP configuration software packages available from 3

parties.

The configuration software package for the C200HW-PRM21 PROFIBUS-DP

master is used to define:

• The configuration of the bus system connected to the C200HW-PRM21.

• Configuration- and parameter data of all connected slave stations.

• Overall bus communication settings.

All configuration data can be prepared offline. A serial communication link

with the C200HW-PRM21 is only necessary to download the configuration file

to the Unit, and for debugging purposes.

After the initial configuration has been downloaded, the software package can

be used for:

• Addition / deletion of slave units or -modules.

• Monitoring the PROFIBUS system status.

• Troubleshooting communication problems.

It is not possible to set up the C200HW-PRM21 without this configuration

software. Once the configuration data has been downloaded into the Unit, the

software package is no longer required during normal operation.

4-1-2 System Requirements

The following are the minimum requirements for a PC to install the

PROFIBUS-DP configurator SyCon V2.620.

Processor: 486DX50 or higher

Operating System: Windows 95/98

RAM: 16 MB or more

Hard disk space: 10 MB minimum

Graphics: 800x600x256 minimum

Serial port: RS-232C; COM1 to COM4 supported

Communication cable see 2-3-1 Fieldbus cabling

Windows NT 3.51

Windows NT 4.0

30

Page 47

Setup

4-2 Setup

4-2-1 Installation

Section 4-2

The PROFIBUS-DP configurator SyCon V2.620 is supplied on CD-ROM.

For installation instructions, see the file README.TXT on the CD-ROM.

For installation under Windows NT, administrator rights are required.

Since SyCon V2.620 serves as PROFIBUS-DP configurator for Master

devices of several manufacturers, it is necessary to make the correct choices

during installation to provide the correct settings for the C200HW-PRM21:

4-2-2 Uninstall

The license code is will be provided on the next installation screen.

When prompted, select to install the PROFIBUS component as well as the

CIF device driver.

SyCon V2.620 can be removed from your system by:

• selecting ‘SyCon Uninstall’ from the start menu, or

• through ‘Add/remove Programs’ in Control Panel.

31

Page 48

Operation

4-3 Operation

Section 4-3

Menu

File

Edit

View

Insert

Online

Settings

The operation of the configurator is menu-driven.

The functions located under the main menu items are:

• Create, load and save PROFIBUS-DP configuration files.

• Print configuration data.

• Copy GSD files to the device database folder.

• Exit the configurator.

• Delete items from the configuration.

• List all configured devices, sorted by address or by memory allocation.

• Add Masters and Slaves to the configuration

• Download the configuration to the Unit.

• Enter the online debug mode.

• Monitor the status of the network.

• Select serial communication port.

• Set overall bus system and communication parameters.

• Define group assignments for global control commands.

• Enter general project information.

• Select the display language (English, French, German)

Tools

Window

Help

• View the main data of PROFIBUS-DP GSD files.

• Arrange and select all open configuration windows.

• Access the help files

• Display version information.

32

Page 49

Operation

!

Caution

4-3-1 PROFIBUS-DP configuration

To build a PROFIBUS-DP configuration in a reliable and efficient way, adhere

to the following sequence of actions:

1, 2, 3...

1. Copy the GSD files of all stations into the assigned folder.

2. Define the master unit, and assign a bus address to it.