Page 1

C200H-CT021

High-speed Counter Unit

Operation Manual

Revised December 2000

Page 2

iv

Page 3

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to the product.

!DANGER

Indicates information that, if not heeded, is likely to result in loss of life or serious injury.

!WARNING

Indicates information that, if not heeded, could possibly result in loss of life or serious

injury.

!Caution

Indicates information that, if not heeded, could result in relatively serious or minor injury,

damage to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for any-

thing else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 1996

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

r

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

f

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 4

vi

Page 5

vii

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xv

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION 2

Specifications and Components. . . . . . . . . . . . . . . . . . . . . . . 5

2-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2 High-speed Counter Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION 3

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-1 External Connector Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-2 Connector Wiring Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-3 I/O Circuit Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3-4 Wiring Examples of Encoder Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-5 Wiring Example of External Control Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-6 Example of External Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 4

Functions and Operating Modes. . . . . . . . . . . . . . . . . . . . . . 25

4-1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-2 DM and IR Bit Allocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4-3 Linear Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-4 Circular Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-5 Preset Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-6 Gate Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-7 Cumulative Gate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4-8 Sampling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4-9 Input Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-10 Counter Reset Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4-11 Data Processing with PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Page 6

viii

TABLE OF CONTENTS

SECTION 5

DM Area Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5-1 DM Area Allocation in Simple Counter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5-2 DM Area Allocation in Linear and Circular Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5-3 DM Area Allocation in Preset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5-4 DM Area Allocation in Gate, Cumulative Gate, and Sampling Modes . . . . . . . . . . . . . . . . 60

SECTION 6

Guidance for Program Development . . . . . . . . . . . . . . . . . . 63

6-1 Operating Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6-2 Unit Number Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

SECTION 7

Program Development with Drum Function . . . . . . . . . . . . 67

7-1 Performance Specifications of Drum Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7-2 DM Area Settings and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7-3 IR Area Settings and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7-4 I/O Signal Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7-5 Data Transfer Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7-6 Program Example for Linear Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7-7 Program Example for Circular Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

SECTION 8

Program Development with Preset Function . . . . . . . . . . . . 85

8-1 Performance Specifications of Preset Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8-2 DM Area Settings and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8-3 IR Area Settings and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8-4 I/O Signal Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8-5 Data Transfer Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8-6 Program Example for Preset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

SECTION 9

Program Development with Counting Function . . . . . . . . . 101

9-1 Performance Specifications of Counting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9-2 DM Area Settings and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9-3 IR Area Settings and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

9-4 I/O Signal Timing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9-5 Program Example for Gate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9-6 Program Example for Cumulative Gate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9-7 Program Example 1 for Sampling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

9-8 Program Example 2 for Sampling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Page 7

ix

TABLE OF CONTENTS

SECTION 10

Using IORD and IOWR Instructions . . . . . . . . . . . . . . . . . . 115

10-1 IORD and IOWR Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10-2 Control Codes of IORD and IOWR Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10-3 Types of Data Written with IOWR Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10-4 Program Examples with IORD Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

10-5 Program Examples with IOWR Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

10-6 Flags Used for IOWR Instruction and Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

SECTION 11

Error Processing and Troubleshooting . . . . . . . . . . . . . . . . 127

11-1 Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11-2 Errors Monitored with CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Appendices

A Comparison with C200H-CT001-V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

B Data Area Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

C DM Coding Sheet Unit Number

@

: DM

@@

00 to DM @@99 . . . . . . . . . . . . . . . . . . . . . . 145

D Using with CS1-series PCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Page 8

xi

About this Manual:

This manual describes the installation and operation of the C200H-CT021 High-speed Counter Unit

and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the C200H-CT021 High-speed Counter Unit. Be sure to read the

precautions in the next section.

Section 1 provides a list of features and a system configuration example.

Section 2 provides the Unit’s basic specifications and describes its major components.

Section 3 explains how to connect various input and output devices to the High-speed Counter Unit.

Section 4 describes the High-speed Counter Unit functions and their operating modes.

Section 5 provides information on the DM and IR bit allocation in each mode.

Section 6 describes the steps required to operate the High-speed Counter Unit in each mode, the DM

required for unit number settings, and IR bit allocation.

Section 7 describes program development using the drum function in linear and circular modes.

Section 8 describes program development using the preset function.

Section 9 describes program development using the counting function in gate, latch, and sampling

modes.

Section 10 provide information on using the IORD and IOWR instructions.

Section 11 provides information on error processing and troubleshooting procedures.

The Appendices provide a comparison with the C200H-CT001-V1, information on data area allocation, and a DM coding sheet.

!WARNING

Failure to read and understand the information provided in this manual may result in personal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

Page 9

xiii

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and the High-speed Counter

Unit.

The information contained in this section is important for the safe and reliable application of the PC and the

High-speed Counter Unit. You must read this section and understand the information contained before

attempting to set up or operate a PC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Page 10

xiv

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating OMRON

PCs and the High-speed Counter Unit. Be sure to read this manual before

attempting to use the High-speed Counter Unit and keep this manual close at

hand for reference during operation.

!WARNING

It is extremely important that a PC and all PC Units be used for the specified

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the abovementioned applications.

3 Safety Precautions

!WARNING

Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING

Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING

Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING

Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, in order to ensure safety in the system if an abnormality occurs due to malfunction of the PC or another external

factor affecting the PC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

Page 11

xv

Operating Environment Precautions 4

• The PC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

4 Operating Environment Precautions

!Caution

Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution

Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution

The operating environment of the PC system can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PC

system. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the PC system.

!WARNING

Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always ground the system to 100 Ω or less when installing the Units. Not

connecting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the

following. Not turning OFF the power supply may result in malfunction or

electric shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Units, or any

other Units.

• Assembling the Units.

Page 12

xvi

Application Precautions 5

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution

Failure to abide by the following precautions could lead to faulty operation of

the PC or the system, or could damage the PC or PC Units. Always heed

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Always use the power supply voltages specified in this manual. An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in this manual. Incorrect

tightening torque may result in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Wire correctly. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors com-

pletely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

Page 13

xvii

Application Precautions 5

• Resume operation only after transferring to the new CPU Unit the contents of the DM Area, HR Area, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so

may break the cables.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static built-up. Not doing so may result in malfunction or damage.

Page 14

1

SECTION 1

Features and System Configuration

This section provides a list of features and a system configuration example.

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Page 15

2

Fe at ur es Section 1-1

1-1 Features

The C200H-CT021 High-speed Counter is a Special I/O Unit for the C200H,

C200HS, C200HX, C200HG, and C200HE PCs.

The High-speed Counter Unit has the following features.

Two Built-in Counters The High-speed Counter Unit has two high-speed increment/decrement

counters, each of which can be connected to an incremental encoder with

open collector output to count line driver input pulses at a rate of 75,000 cps

max.

Built-in Line Driver Input

Circuit

An encoder with RS-422 line driver output can be directly connected to the

High-speed Counter Unit. Line driver input resists noise, thus making it possible to connect the encoder to the High-speed Counter Unit through a long

cable or to wire the cable in places where noise may be generated.

An open collector output from an encoder can be connected as a line driver

input to the High-speed Counter Unit through the C500-AE001 Encoder Conversion Adapter.

Counts in BCD or

Hexadecimal

The High-speed Counter Unit can count BCD or hexadecimal values.

The following are the available counting ranges.

BCD: –8,388,608 to 8,388,607

Hexadecimal: 800000 to FFFFFF (–8,388,608 to –1) and 000000 to

7FFFFF (0 to 8,388,607)

Refer to page 10 for the data configuration of the count value in hexadecimal.

Seven Operating Modes The High-speed Counter Unit has the following three functions and seven

operating modes. None of the three functions are available to the High-speed

Counter Unit in simple counter mode, which is the basic operating mode of

the High-speed Counter Unit.

Simple Counter Mode: Counts the number of input pulses.

Drum Function

Linear Mode: Controls outputs when the count value is in a preset range.

The High-speed Counter Unit counts the number of pulses

within the available counting ranges.

Circular Mode: Controls outputs when the count value is within a preset

range. The High-speed Counter Unit counts the number of

pulses from zero to the maximum countable value preset with

the High-speed Counter Unit. The count value is reset to zero

after it reaches the maximum countable value.

Preset Counter Function

Preset Mode: Controls outputs after counting a preset value.

Counting Function

Gate Mode: Counts the number of pulses only while the control

input signal is turned ON.

Cumulative Gate Mode: Accumulates the number of pulses whenever the

control input signal is turned ON.

Sampling Mode: Counts the number of pulses for a preset interval

from the rising edge of the control signal.

Eight Types of External

Outputs

The High-speed Counter Unit has eight external outputs, either NPN or PNP.

Three Types of Pulse

Inputs

The following three types of pulse inputs are available.

• Offset phase inputs

Page 16

3

System Configuration Section 1-2

• Up and down pulse inputs

• Pulse and direction inputs

The High-speed Counter Unit has a function to multiply offset phase inputs by

two or four. The resolution of the High-speed Counter Unit can be increased in

proportion to the number of pulses input from encoders.

Change Present and Set

Values During High-speed

Counter Unit Operation

The High-speed Counter Unit in normal operation uses settings that are read

when the High-speed Counter Unit is turned ON. The settings, which include

the present counter values of the High-speed Counter Unit, can be changed

anytime.

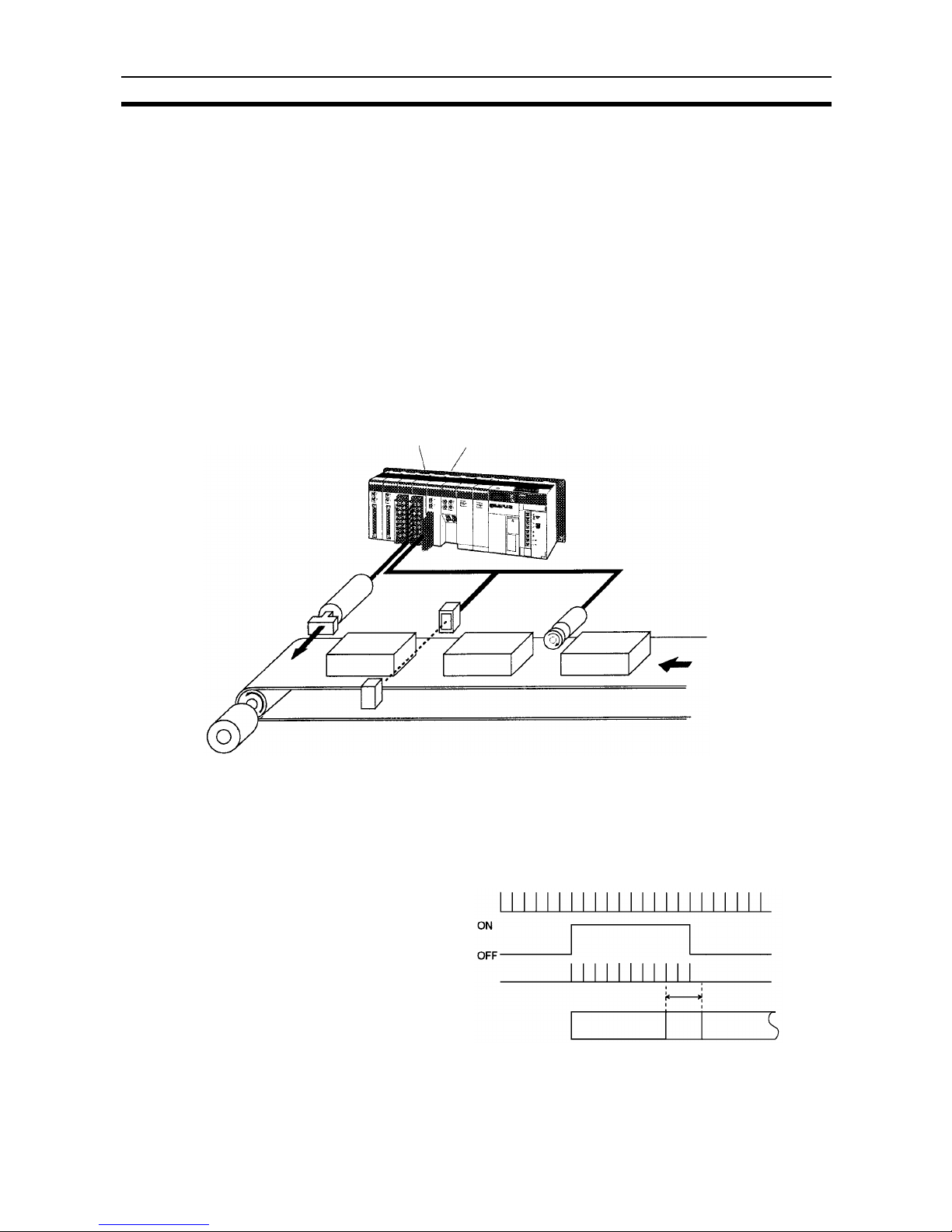

1-2 System Configuration

Discriminating Product

Sizes

In the following example, the size of each product on the belt conveyor is measured and improper-sized products are removed from the line using the solenoid.

The High-speed Counter Unit counts the number of pulses that is input from

the encoder while each product is passing between the emitter and receiver of

the through-beam photoelectric sensor.

When the count value of a product is not within the range preset with the

High-speed Counter Unit, the solenoid will be activated and the product will be

removed from the line.

C200H-OA221

AC Output Unit

C200H-CT021

High-speed Counter Unit

Solenoid:

Used to remove

improper-sized

products.

Through-beam

Photoelectric Sensor:

Used to sense the

products.

Incremental Encoder:

Used to sense the speed

of the belt conveyor.

Motor

Belt conveyor

C200HX

Incremental

encoder output

Photoelectric

sensor output

Count value

Discrimination

criteria

Reject OK Reject

Page 17

4

System Configuration Section 1-2

Number of Mounted Units The maximum number of High-speed Counter Units and other Special I/O

Units that can be mounted to the C200HX, C200HG, or C200HE CPU Rack,

Expansion I/O Rack, or Slave Rack is 16 and the maximum number of those

mounted to any other PC is 10.

Note 1. A maximum of four High-speed Counter Units can be mounted to the Slave

Rack.

2. Do not mount the High-speed Counter Unit to the two slots on the right of

the CPU.

3. Do not mount the High-speed Counter Unit to the Slave Rack if the IORD

or IOWR instruction is to be used with the C200HX, C200HG, or C200HE.

Page 18

5

SECTION 2

Specifications and Components

This section provides the Unit’s basic specifications and describes its major components.

2-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-2 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-3 I/O Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-1-4 Counting Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-1-5 BCD or Hexadecimal Count Values. . . . . . . . . . . . . . . . . . . . . . . . . 10

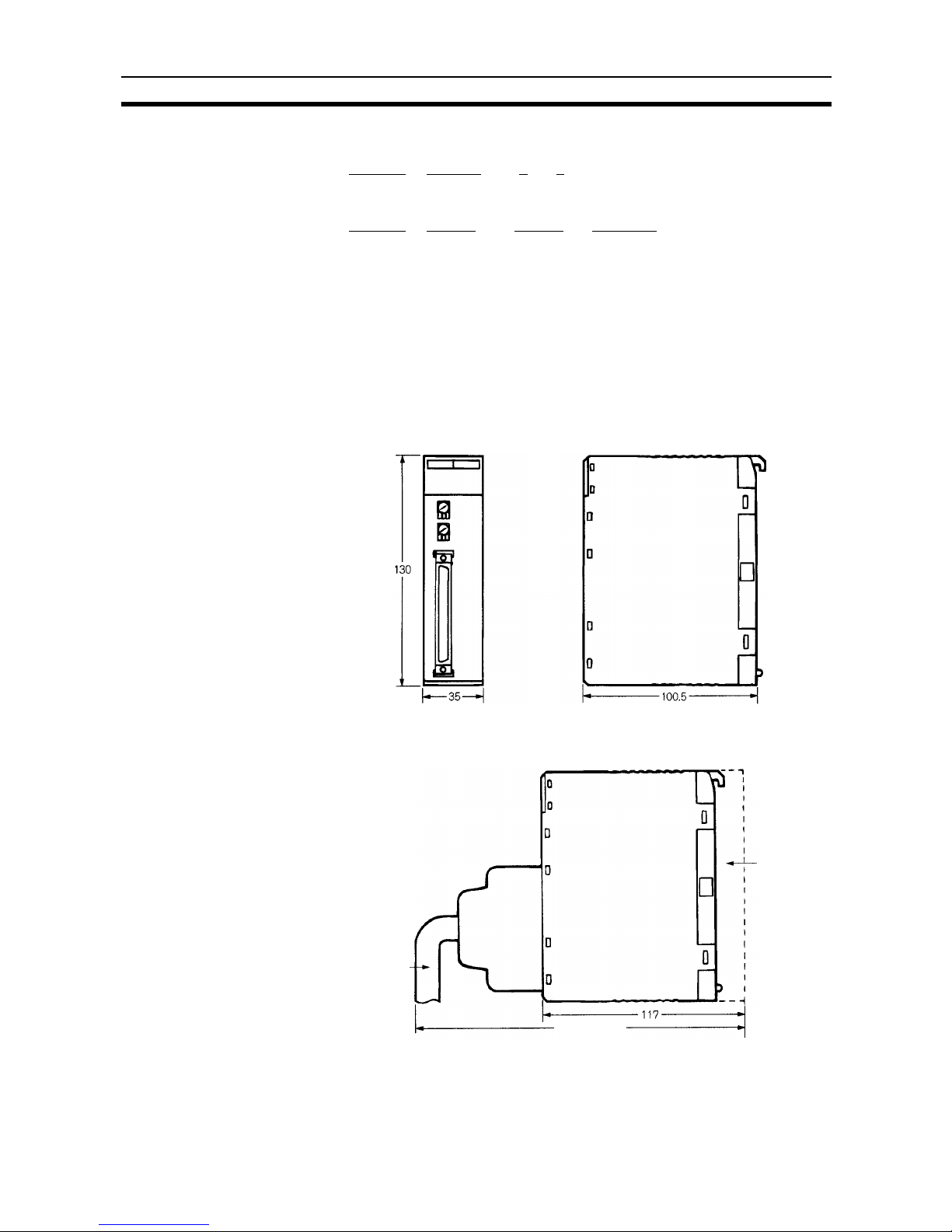

2-1-6 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1-7 Dimensions with High-speed Counter Unit Mounted . . . . . . . . . . . 11

2-2 High-speed Counter Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2-2 Indicator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2-3 Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-2-4 Rear Setting Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Page 19

6

Specifications Section 2-1

2-1 Specifications

2-1-1 General Specifications

The general specifications conform to the C-series specifications.

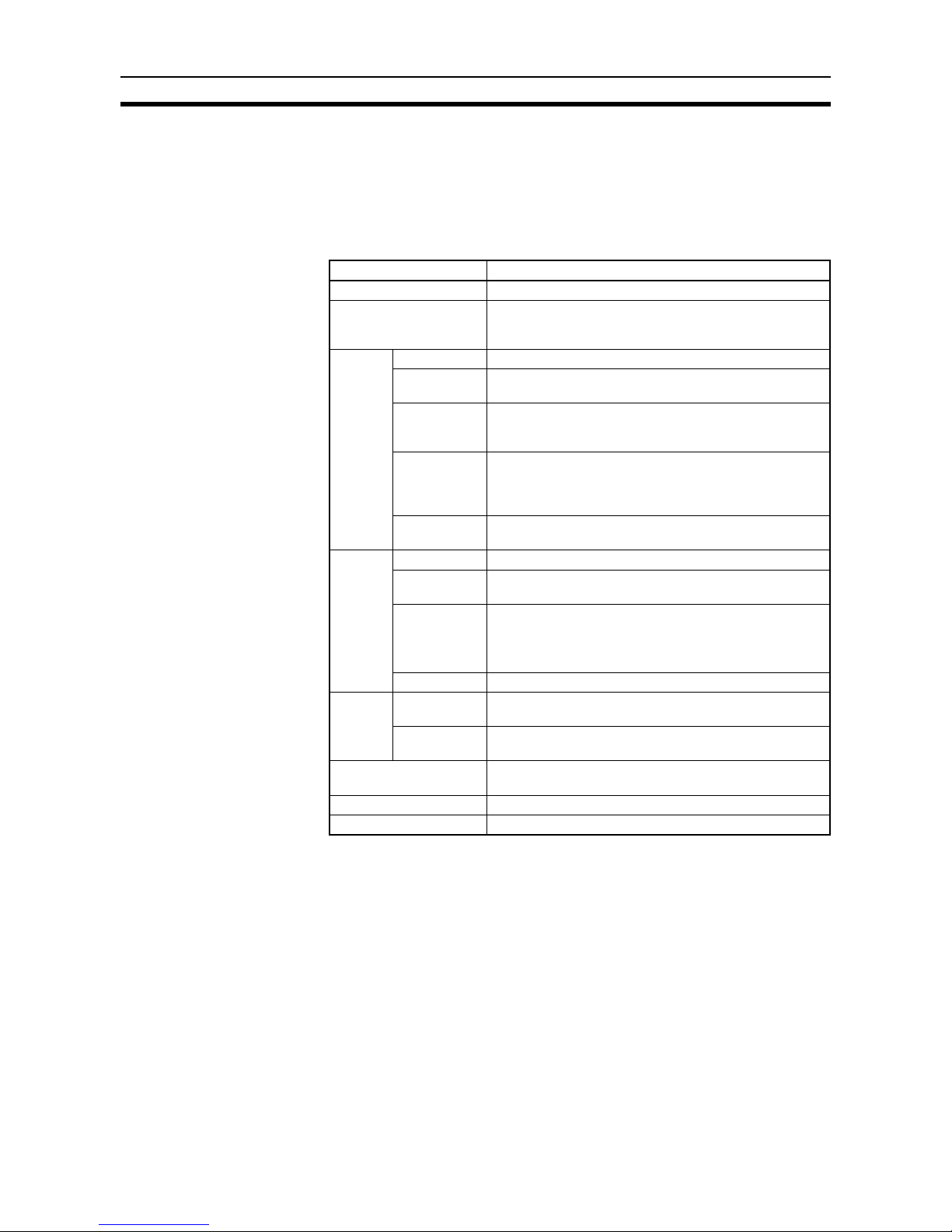

2-1-2 Characteristics

Item Specification

Number of counters 2

Operating modes Simple counter, linear counter, circular counter, preset

counter, gate counter, cumulative gate counter, and sampling modes.

Count

inputs

Input signals Counter 1 inputs A and B and counter 2 inputs A and B

Signal levels RS-422 line driver signal (equivalent to Am26LSS31), 12

or 24 VDC (selectable)

Ty p e s o f

inputs

Offset phase inputs

Up and down pulse inputs

Pulse+direction inputs

Counting rate Voltage input: 50,000 cps max. at a line driver input rate

of 75,000 cps max.

The counting speed of the number of offset phase input

pulses varies with the encoder. Refer to page 9 for details.

Others The multiple function (x 1, x 2, or x 4) can be selected for

offset phase input

External

inputs

Input signal Counter 1 input Z, Counter 2 input Z

Signal levels RS-422 line driver signal (equivalent to Am26LSS31), 12

or 24 VDC (selectable)

Input signal Counter 1 external control input IN1

Counter 1 external control input IN2

Counter 2 external control input IN1

Counter 2 external control input IN2

Signal levels 12 VDC and 24 VDC

External

outputs

Outputs External outputs 0 to 7, 8 points

NPN or PNP output (selectable)

Switching

capacity

Output power supply: 16 to 80 mA at 5 to 24 VDC

Internal current consumption

400 mA max. at 5 VDC (Supplied from Backplane.)

Dimensions (mm) 130 × 35 × 100.5 (H × W × D)

Weight 305 g (excluding connectors)

Page 20

7

Specifications Section 2-1

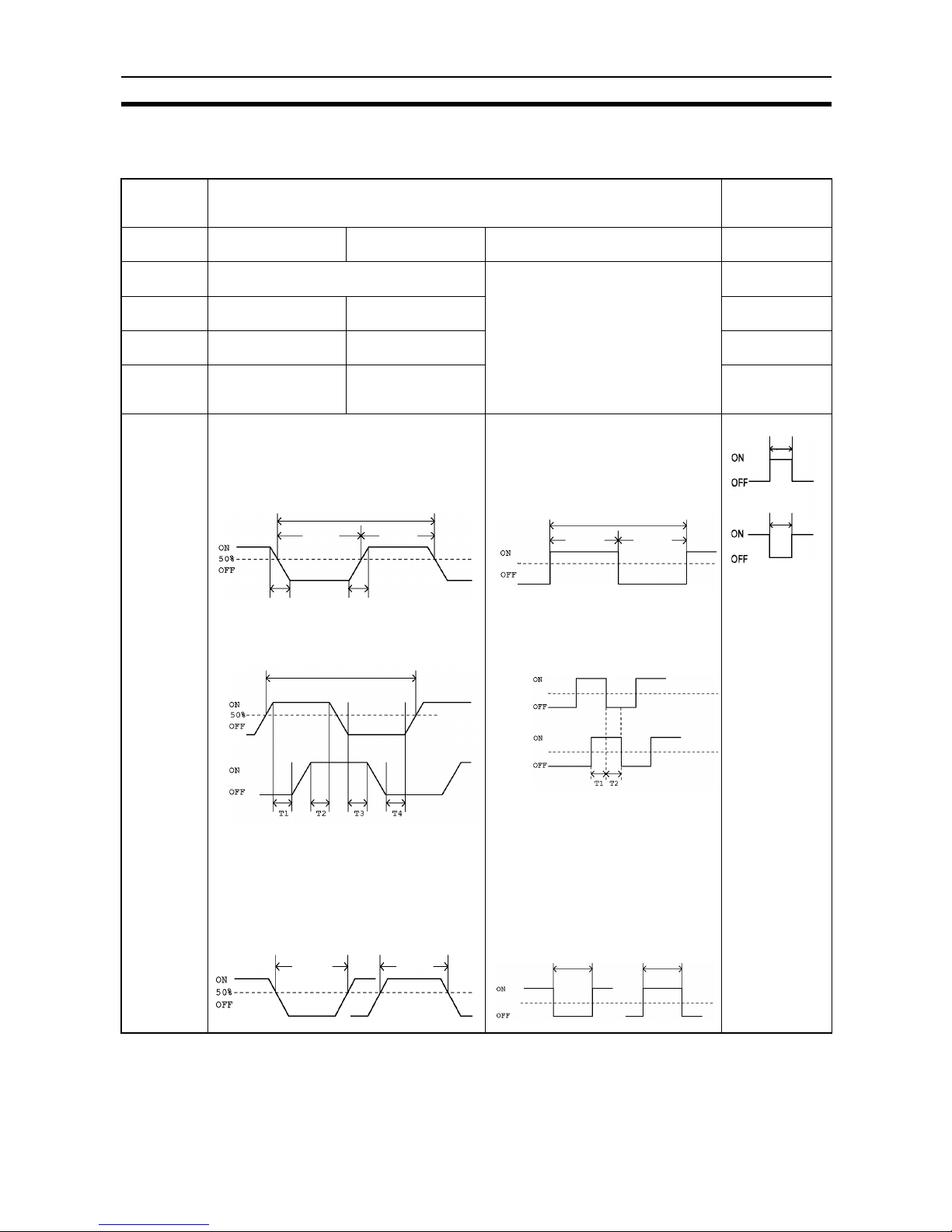

2-1-3 I/O Electrical Specifications

Input Characteristics

Item Counter inputs A, B, and Z External

control inputs

IN1 and IN2

Input voltage 12 VDC ±10% 24 VDC ±10% RS-422 line driver 12 to 24 VDC

±10%

Input current 14 mA (typical) at each voltage (12.9 to

17.1 mA)

Conform to RS-422 line driver

(Am26LS31) specifications.

4 to 11 mA

ON voltage

(min.)

5.6 VDC 15.2 VDC 10.2 VDC

OFF voltage

(max.)

2.4 VDC 4.8 VDC 3.0 VDC

ON/OFF

response

time (max.)

--- --- 0.1 ms

Minimum

response

pulse

Counter Inputs A and B

Waveform

Input rising time/calling time: 3 µs max. at

50 kHz with pulses with a duty factor of

50%

10 µs

min.

3 µs max.3 µs max.

Relationship between A and B phases with

offset phase input

20 µs min.

Phase B

T1, T2, T3, and T4: 4.5 µs min.

The switching time between A and B

phases must be 4.5 µs min.

Counter Input Z

A pulse width of 100 µs min. is required.

100 µs

min.

100 µs

min.

20 µs min.

min.

10 µs

Phase A

Counter Inputs A and B

Waveform

At 75 kHz with pulses with a duty

factor of 50%

13.3 µs min.

6.7 µs

min.

6.7 µs

min.

0 V

Relationship between A and B

phases with offset phase input

Phase A

Phase B 0 V

0 V

T1 and T2: 3.2 µs min.

The switching time between A and B

phases must be 3.2 µs min.

Counter Input Z

A pulse width of 100 µs min. is

required.

100 µs min. 100 µs min.

0 V

When

accessing

these signals

from the PC,

the signals

must be ON

longer than the

PC's c

ycle time.

0.1 ms min.

0.1 ms min.

Page 21

8

Specifications Section 2-1

Output Characteristics

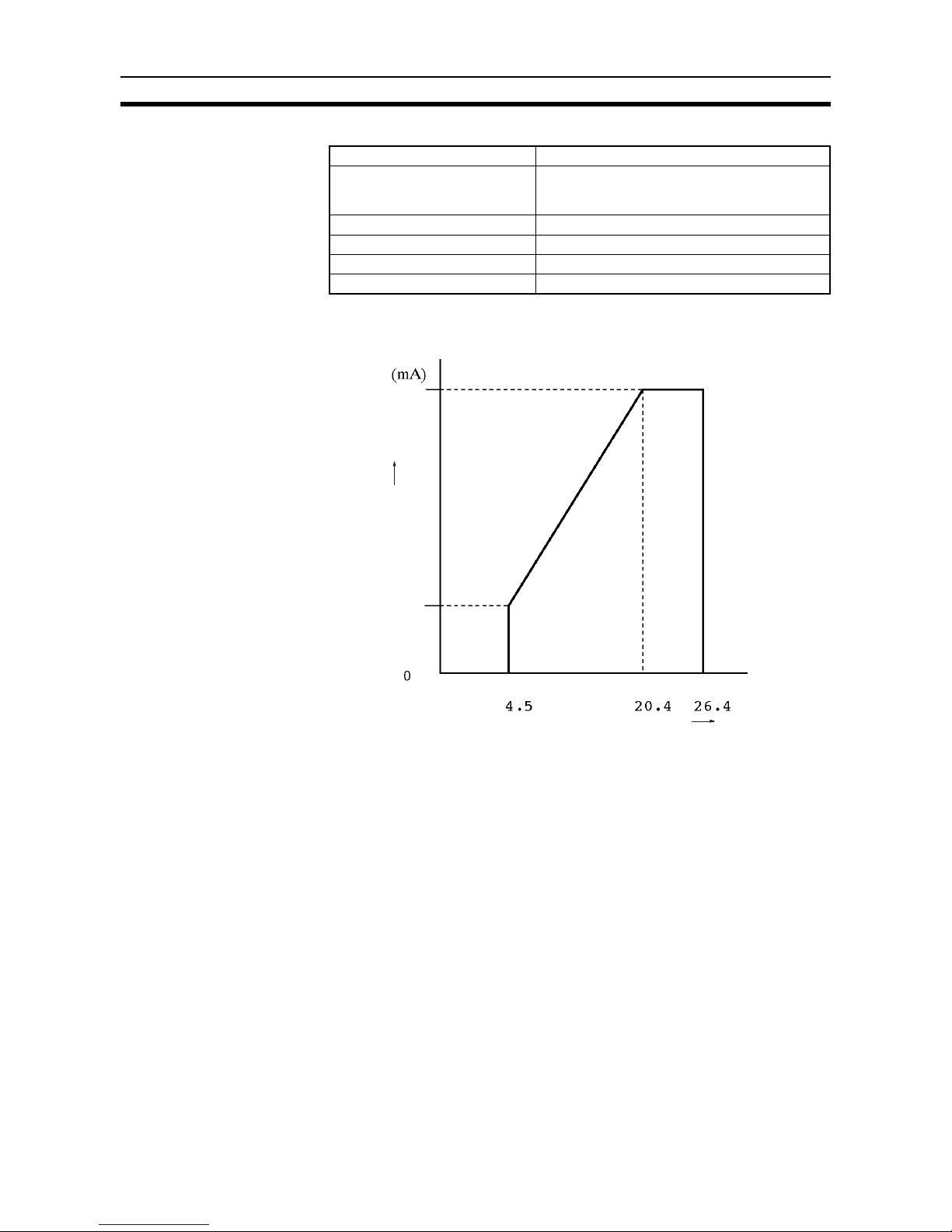

The maximum switching current depends upon the power supply voltage, as

shown below.

Note The output current must not exceed 0.5 A per common (i.e., eight points), oth-

erwise the built-in fuse will blow out. The built-in fuse cannot be replaced by

the user.

Item External Outputs 0 to 7

Max. switching capacity 16 mA at 4.5 VDC to 80 mA at 26.4 VDC

(See the following graph.)

320 mA max./common

Leakage current 0.1 A max.

Residual voltage 0.8 V max.

ON/OFF response time 0.2 ms max.

External power supply 5 to 24 VDC ±10% (50 mA max. at 26.4 VDC)

(VDC)

80

50

16

External power supply voltage

Maximum switching capacity

Page 22

9

Specifications Section 2-1

2-1-4 Counting Speed

The maximum response pulse frequency of the High-speed Counter for offset

phase inputs is determined with the type of increment encoder connected to

the High-speed Counter. In this following example, OMRON’s E6B-CWZ3C

Encoder is connected to the High-speed Counter.

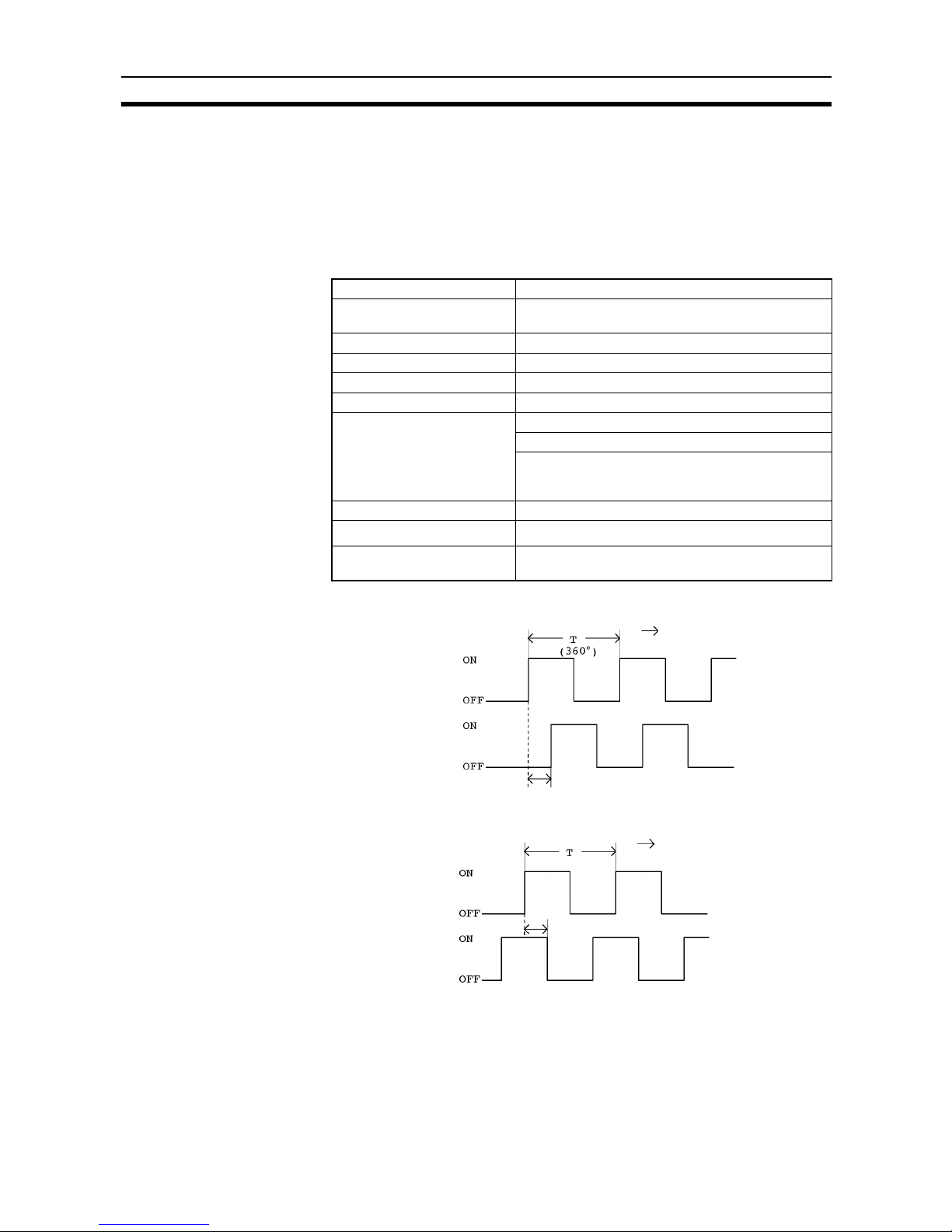

Example:E6B-CWZ3C (500 pulses/time)

Ratings

Clockwise (CW) Rotation Phase A is advanced

1

⁄4±1⁄8T phase ahead of phase B.

Counterclockwise (CCW)

Rotation

Phase A is delayed

1

⁄4±1⁄8T phase behind phase B.

Item Specification

Power supply voltage 5 VDC (–5%) to 12 V (+10%) with a peak-to-peak rip-

ple rate of 5% max.

Current consumption 50 mA max.

Resolution (P/R) 500

Output phases Phase A, phase B, phase Z

Output type Open collector output

Output capacity Applied voltage: 30 VDC max.

Sink current: 80 mA max.

Residual voltage:

1 V max (when the sink current is 80 mA)

0.4 V max (when the sink current is 20 mA)

Max. response frequency 30 KHz

Output phase difference

A/B phase difference 90°±45° (

1

⁄4±1⁄8T)

Output rise/fall time 1.0 µs max. (Control output voltage 5 V, load resis-

tance 1 KΩ, cord length 50 cm)

Phase A

Phase B

CW direction

1

⁄4T±1⁄8T (90°±45°)

1

⁄4T±1⁄8T (90°±45°)

(360°)

CCW direction

Phase A

Phase B

Page 23

10

Specifications Section 2-1

The output offset phase is 90°±45°. Therefore, the greatest offset phase of the

encoder is 45° (i.e., 90° – 45°).

The Unit requires a minimum offset phase of 3.2 µs.

Thus:

Inverting the period yields the maximum frequency of 27.7K cps.

From the above, use the High-speed Counter at a maximum counting speed

of 27,000 cps if the High-speed Counter is connected to an encoder with a

maximum response frequency of 27,000 cps.

Note The pulse width of counter input Z must be 100 µs min. if the counter is reset

with a Z-phase input from the encoder at a repetition frequency of 2000 cps

max.

The repetition frequency of line driver input must be 1,000 cps when considering the software processing time.

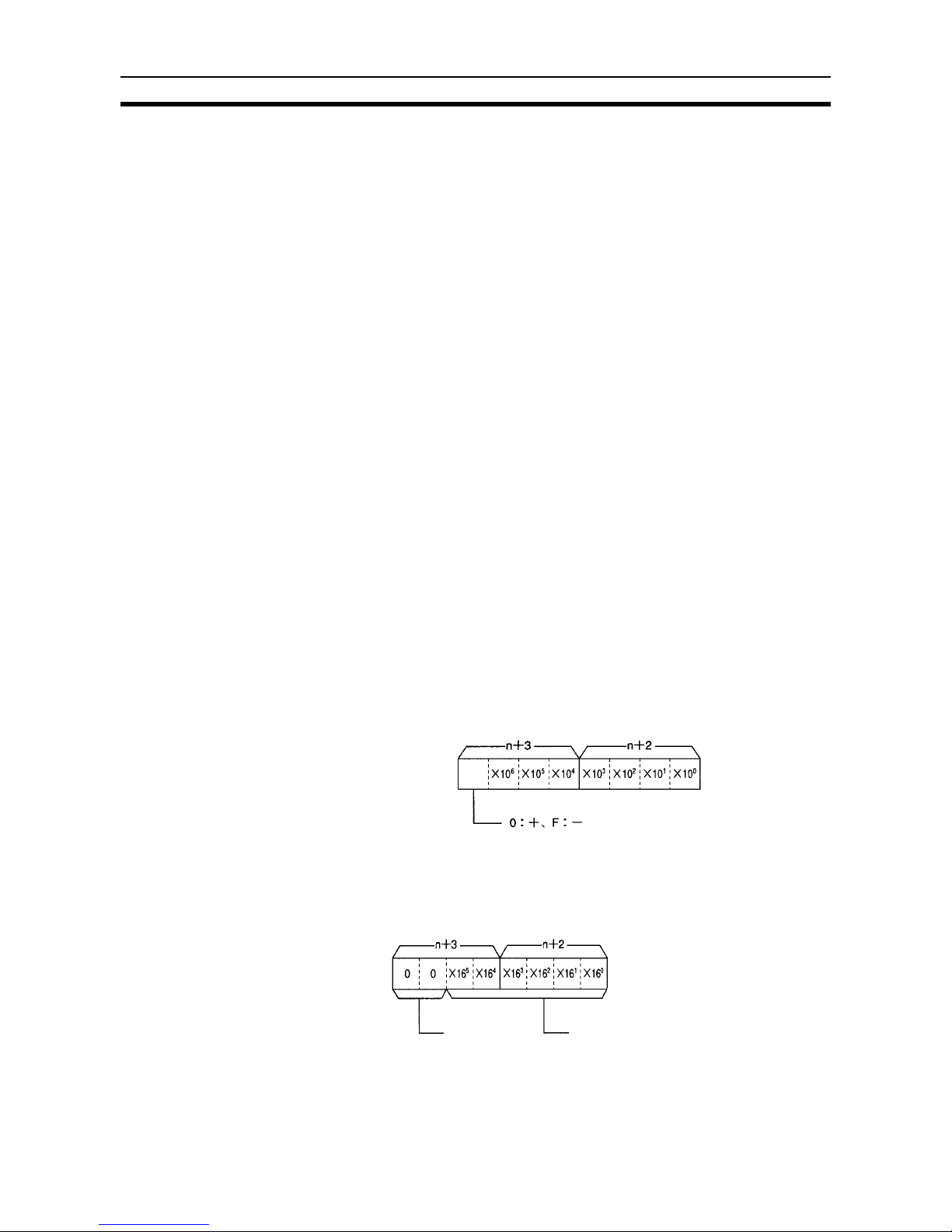

2-1-5 BCD or Hexadecimal Count Values

The High-speed Counter Unit can set the present counter value and the upper

and lower limit count values in BCD or hexadecimal.

The High-speed Counter Unit can process hexadecimal values faster than

BCD values because it need not convert the hexadecimal values into BCD

values.

Refer to the following for the data configuration’s BCD and hexadecimal count

values.

BCD Example:Present counter value

The above is the data configuration of the present counter value stored in

words n+2 and n+3 of the data area.

Counting range: –8,388,608 to 8,388,607

Hexadecimal

The sign of the hexadecimal value is determined with 2’s complement of the

leftmost bit.

4.5 µ s

T

--------------

45°

360°

-----------<

(When the rise and fall of the Encoder's

output are equivalent.)

T36µs<

(T is the minimum pulse period that for

responses.)

1

T

---

1

36 µ s

------------- 27.7K cps=<

(78 revolutions/s when there are

500 pulses/revolution)

Sign

Set to 0.

Data within a range of 000000 to

FFFFFF is stored. Refer to the

following for the actual count values.

Page 24

11

Specifications Section 2-1

Example:

In the following example, the count value is FFFFFF.

– {1000000

– (FFFFFF)} = – 1 = – 1

Hex. Hex. Hex. BCD

In the following example, the count value is 800000.

– {1000000

– (800000)} = – 800000 = – 8,388,608

Hex. Hex. Hex. BCD

Therefore the following counting range can be obtained.

Hexadecimal BCD

800000 (–8,388,608)

to to

FFFFFF (–1)

00

to to

7FFFFF (8,388607)

2-1-6 Dimensions

2-1-7 Dimensions with High-speed Counter Unit Mounted

Connecting

cable

Backplane

Approx. 200

Page 25

12

High-speed Counter Unit Components Section 2-2

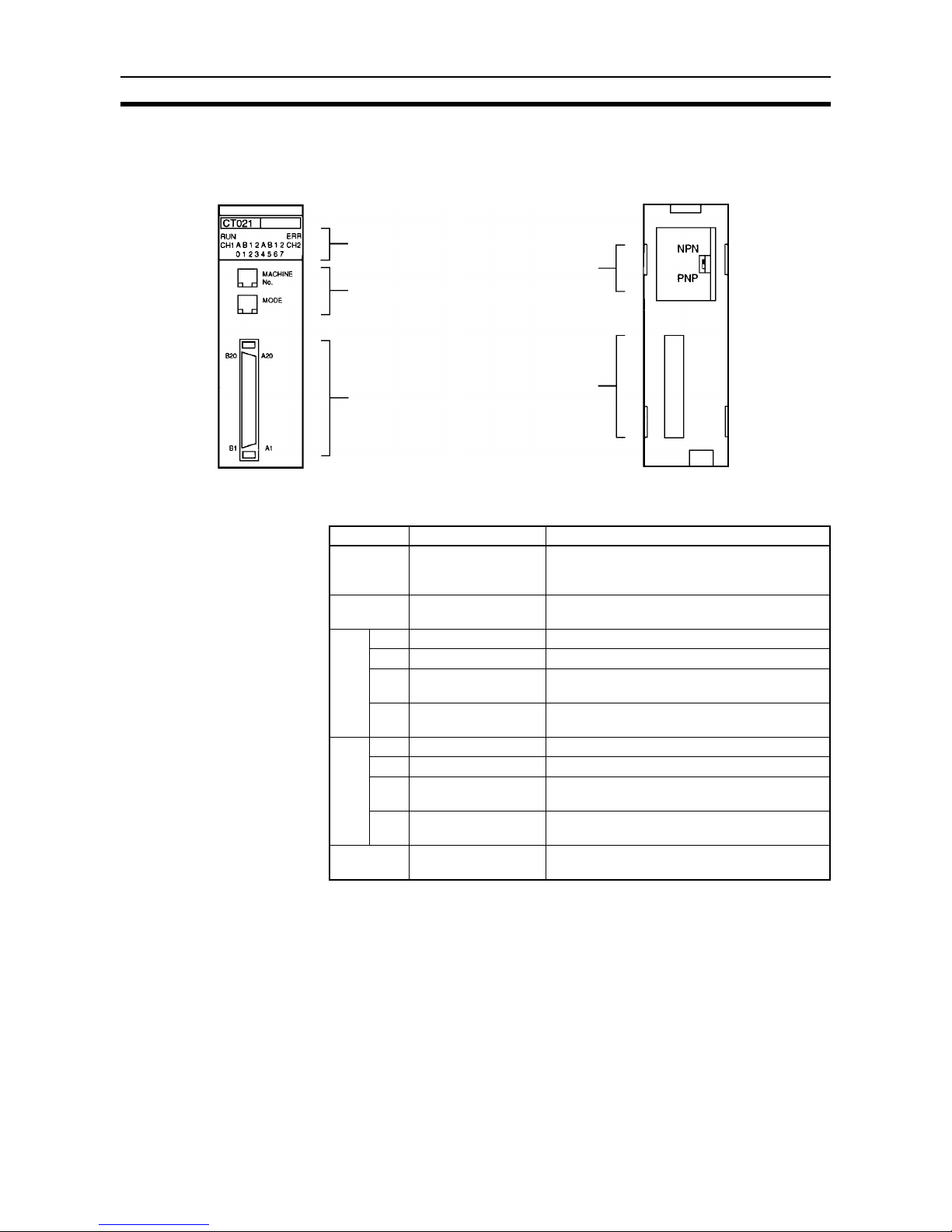

2-2 High-speed Counter Unit Components

2-2-1 Nomenclature

2-2-2 Indicator Functions

Indicator Name Function

RUN Operation Lit when the High-speed Counter is in normal

counting operation. Not lit when the High-speed

Counter stops counting pulses.

ERR Error Lit when an error, counter overflow, or counter

underflow results.

CH1 A Counter 1 input A Lit when counter 1 input A is ON.

B Counter 1 input B Lit when counter 1 input B is ON.

1 Counter 1 external

control input IN1

Lit when external control input IN1 is ON.

2 Counter 1 external

control input IN2

Lit when external control input IN2 is ON.

CH2 A Counter 2 input A Lit when counter 2 input A is ON.

B Counter 2 input B Lit when counter 2 input B is ON.

1 Counter 2 external

control input IN1

Lit when external control input IN1 is ON.

2 Counter 2 external

control input IN2

Lit when external control input IN2 is ON.

01234567 External output These indicators light when the corresponding

external output (0 through 7) is ON.

Indicators

Rotary switches

External connector

Rear setting

switch

Backplane

connector

Page 26

13

High-speed Counter Unit Components Section 2-2

2-2-3 Switch Settings

There are two rotary switches on the front panel of the High-speed Counter

Unit, which can be used for unit number and operating mode settings.

Note 1. Be sure to turn OFF the High-speed Counter Unit before setting the unit

number and operating mode.

2. Use a flat-blade screwdriver for rotary switch settings.

3. Be sure not to damage the grooves of the rotary switches with the flat-

blade screwdriver. Do not leave either of the rotary switches set midway

between numbers. Otherwise a setting error may occur.

Note The unit number must not be same as the unit number of any other Special I/

O Unit or Position Control Unit in the same system, otherwise a setting error

will result. Each unit number in the system must be unique.

The unit number can be set within a range of 0 to 9 if the C200H, C200HS,

C200HE-CPU11/32/42(-Z), C200HG-CPU33/43(-Z), or C200HX-CPU34/44(Z) is used with the High-speed Counter Unit.

The operating mode must be set within a range of 0 to 6. Do not set the operating mode to 7, 8, or 9, otherwise the High-speed Counter Unit will not operate.

2-2-4 Rear Setting Switch

The rear setting switch of the High-speed Counter Unit is used to select the

output mode.

Switch Setting Function

MACHINE No. Unit number setting Set the switch within a range of 0 to F.

MODE Operating mode set-

ting

Set the switch within a range of 0 to 6.

0: Simple counter mode

1: Linear mode

2: Circular mode

3: Preset mode

4: Gate mode

5: Cumulative gate mode

6: Sampling mode

7 to 9: Not used

Switch Function

NPN Outputs 0 to 7 will be NPN outputs.

PNP Outputs 0 to 7 will be PNP outputs.

Page 27

15

SECTION 3

Wiring

This section explains how to connect various input and output devices to the High-speed Counter Unit.

!WARNING

Do not touch the terminals while the power is being supplied. Otherwise

an electric shock may occur.

3-1 External Connector Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-2 Connector Wiring Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-3 I/O Circuit Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-4 Wiring Examples of Encoder Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-5 Wiring Example of External Control Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-6 Example of External Output Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page 28

16

External Connector Pins Section 3-1

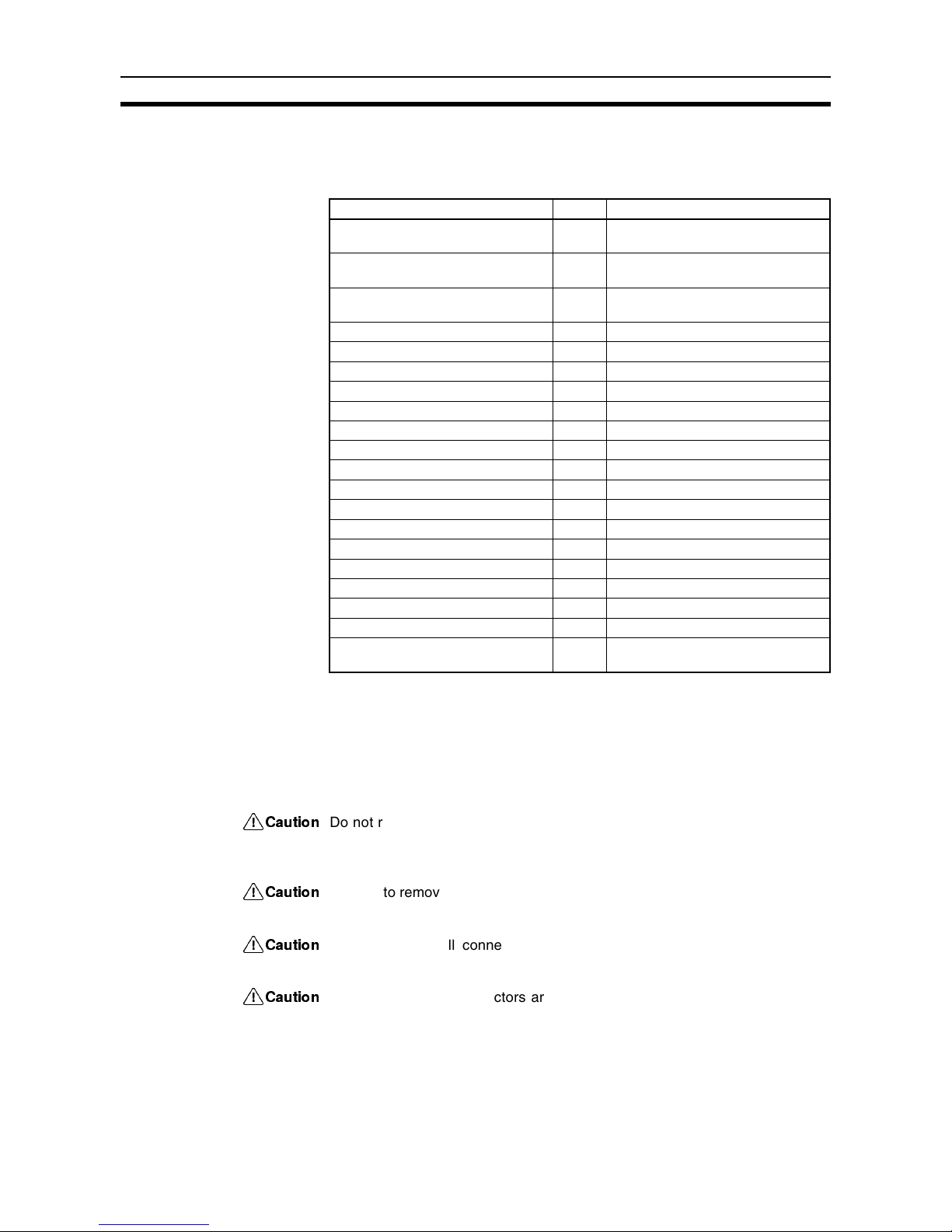

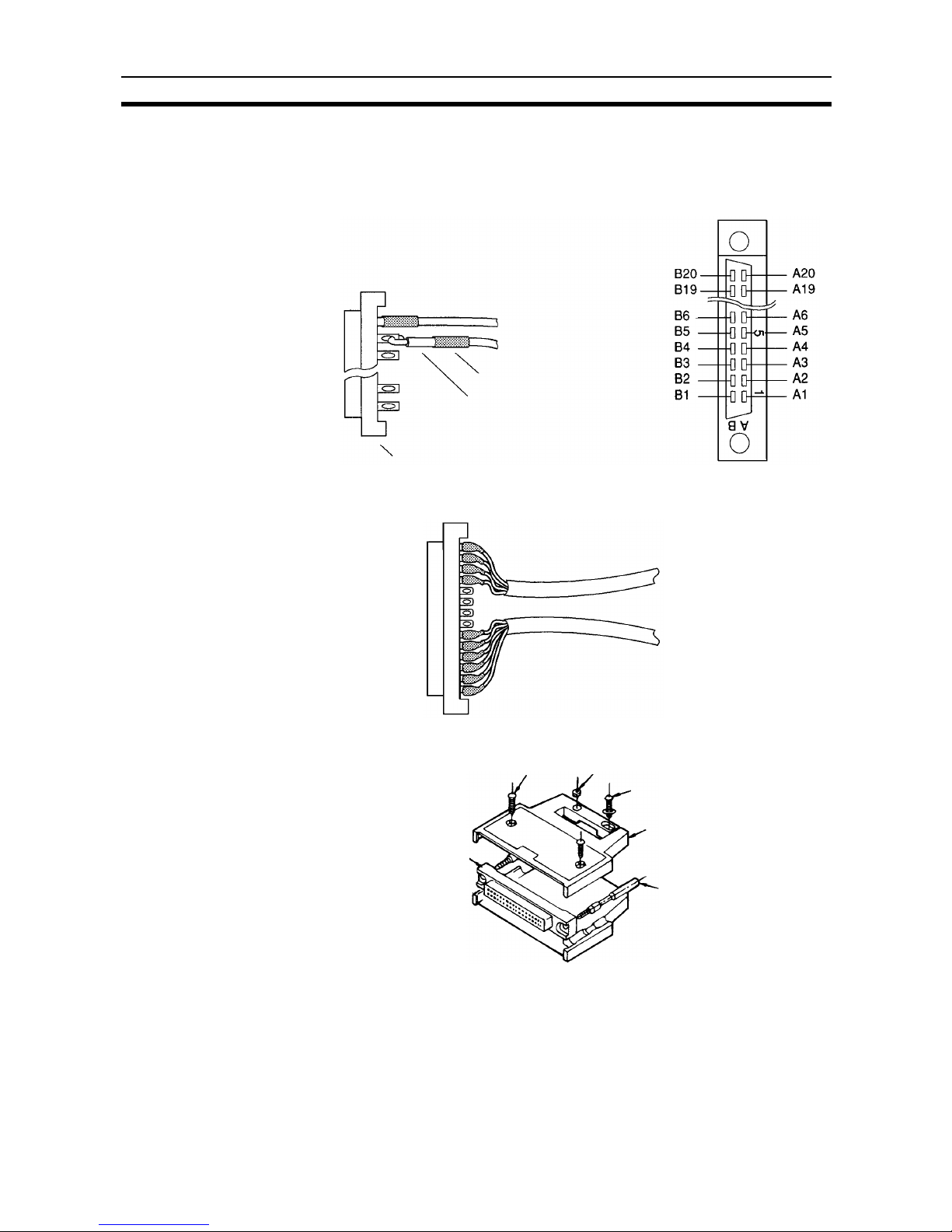

3-1 External Connector Pins

The following table lists the allocation of the external connector pins on front

side of the High-speed Counter Unit.

Each external connector is attached with a soldering terminal (Fujitsu FCN361J040).

3-2 Connector Wiring Method

The connectors of the High-speed Counter Unit must be soldered.

!Caution

Do not remove the label on top of the High-speed Counter Unit before wiring

the connectors, otherwise wire cuttings may fall into the High-speed Counter

Unit and short-circuit the internal circuitry causing the Unit to malfunction.

!Caution

Be sure to remove the label on top of the High-speed Counter Unit after wiring

the connectors, otherwise the Unit in operation may overheat and malfunction.

!Caution

Make sure that all connectors are correctly connected to the High-speed

Counter Unit, otherwise the Unit may burn.

!Caution

Make sure that all connectors are wired correctly, otherwise the High-speed

Counter Unit may burn.

Note 1. The thickness of each wire connected to the High-speed Counter Unit

must be 0.3 mm

2

max.

Row B Pin no. Row A

Counter 1 external control input IN2:

12 or 24 VDC

20 Counter 2 external control input IN2:

12 or 24 VDC

Counter 1 external control input IN1:

12 or 24 VDC

19 Counter 2 external control input IN1:

12 or 24 VDC

Counter 1 external control input IN1/

IN2: COM

18 Counter 2 external control input IN1/

IN2: COM

Counter 1 input Z: 24 VDC 17 Counter 2 input Z: 24 VDC

Counter 1 input Z: 12 VDC 16 Counter 2 input Z: 12 VDC

Counter 1 input Z: + (Line driver) 15 Counter 2 input Z: + (Line driver)

Counter 1 input Z: – (Line driver) 0 V 14 Counter 2 input Z: – (Line driver) 0 V

Counter 1 input B: 24 VDC 13 Counter 2 input B: 24 VDC

Counter 1 input B: 12 VDC 12 Counter 2 input B: 12 VDC

Counter 1 input B: + (Line driver) 11 Counter 2 input B: + (Line driver)

Counter 1 input B: – (Line driver) 0 V 10 Counter 2 input B: – (Line driver) 0 V

Counter 1 input A: 24 VDC 9 Counter 2 input A: 24 VDC

Counter 1 input A: 12 VDC 8 Counter 2 input A: 12 VDC

Counter 1 input A: + (Line driver) 7 Counter 2 input A: + (Line driver)

Counter 1 input A: – (Line driver) 0 V 6 Counter 2 input A: – (Line driver) 0 V

External output 0 5 External output 4

External output 1 4 External output 5

External output 2 3 External output 6

External output 3 2 External output 7

External output 0 to 7 COM: 0 V 1 Power supply for external outputs 0

to 7: 5 to 24 VDC

Page 29

17

Connector Wiring Method Section 3-2

2. Do not short-circuit any terminals when wiring. Covering each soldered

portion with an insulating tube is recommended.

3. When using multi-conductor cables, separate the input and output cables.

Wires

Cable Separation

Assembling Connectors

The following Fujitsu 360-series parts are available.

1. FCN-361J040-AU (solder terminal)

FCN-360C040-B (cover)

2. FCN-363J040 (solderless terminal housing)

FCN-363J-AU (contact)

3. FCN-367J040-AU/F (solderless terminal)

Insulating tube

Wire (Thickness: 0.3 mm

2

max.)

Connector

Connector terminal side

Input cable

Output cable

Two, M2 pan-head screws

(8 mm long)

Connector jack

Four, M2 nuts

Two, M2 pan-head screws

(10 mm long)

Case

Screw

Page 30

18

I/O Circuit Configurations Section 3-3

Wiring Precautions Refer to the following for noise prevention when wiring counter inputs A, B,

and Z.

1,2,3... 1. Use shielded, twisted-pair cable and ground the shield to a resistance of

100 Ω max.

2. Make the wiring as short as possible and do not run the wires parallel to

lines that produce a lot of noise, such as high-power lines.

3. Try to use a separate stabilized power supply for the High-speed Counter

Unit and another power supply for other I/O.

4. Be sure not to reverse the polarity when wiring a line driver input.

5. Be sure to connect wires to a 5- to 24-VDC output power supply terminal

and COM (0 V) terminal correctly. If the wires are connected to these terminals reversely, the built-in fuse will blow out. The built-in fuse cannot be

replaced by the user.

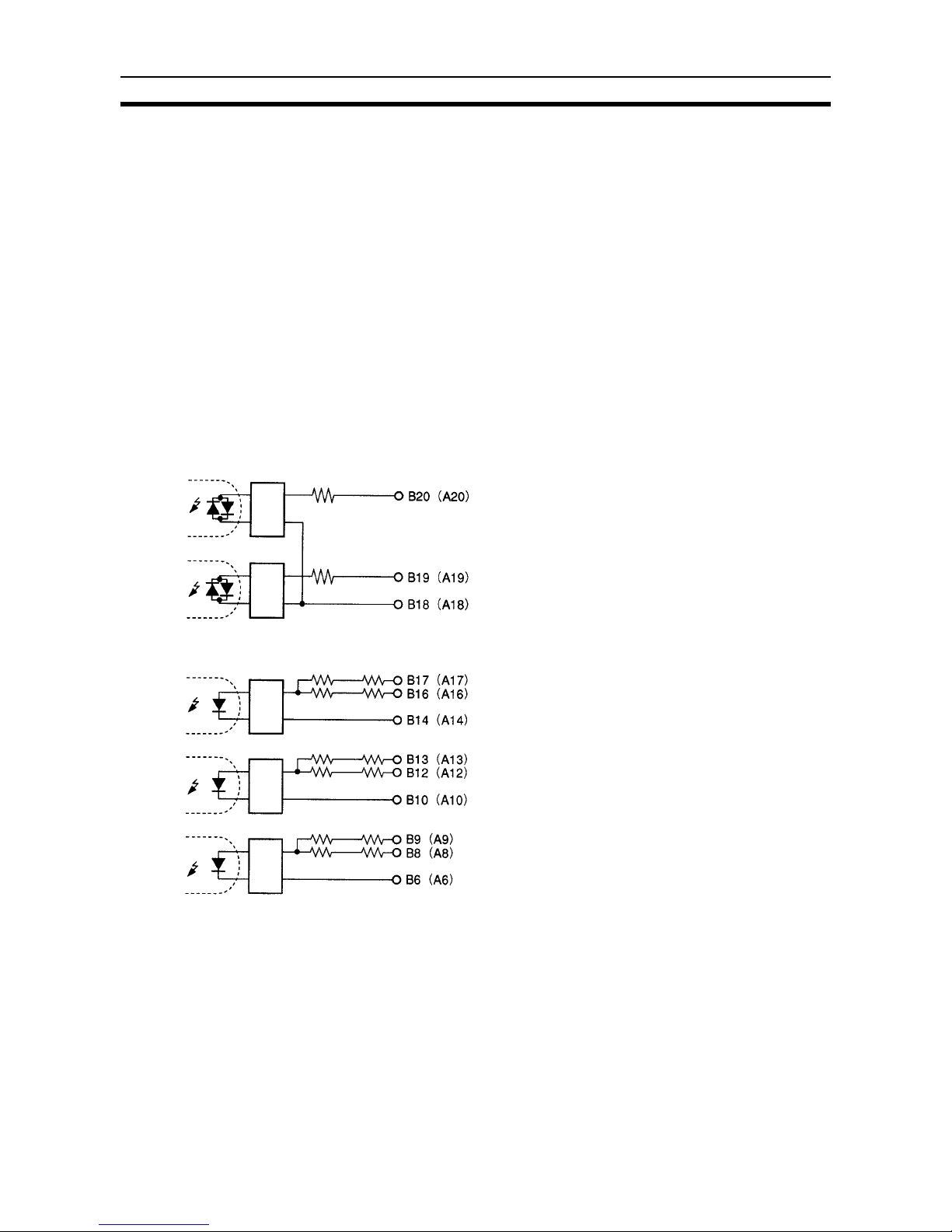

3-3 I/O Circuit Configurations

Input Configuration Terminals numbers in parentheses are used with counter 2.

filterfilterfilter

Rectifier

Rectifier

Terminal number Name

Counter 1 external control IN2: 12 or 24 VDC

Counter 1 external control IN1/IN2: Input common

Counter 1 input Z: 24 VDC

Counter 1 external control IN1: 12 or 24 VDC

Counter 1 input Z: 12 VDC

Counter 1 input Z: 0 V

Counter 1 input B: 24 VDC

Counter 1 input B: 12 VDC

Counter 1 input B: 0 V

Counter 1 input A: 24 VDC

Counter 1 input A: 12 VDC

Counter 1 input A: 0 V

Page 31

19

I/O Circuit Configurations Section 3-3

Line Driver Input

Configuration

Terminals numbers in parentheses are used with counter 2.

External Output Configuration

Counter 1 input Z: (+)

Counter 1 input Z: (−)

Counter 1 input B: (+)

Counter 1 input B: (−)

Counter 1 input A: (+)

Counter 1 input A: (−)

Terminal number Name

Internal circuitry

Fuse (1 A)

(NPN/PNP output)

Fuse (1 A)

A1: 5- to 24 VDC-power

supply for external

outputs 0 to 7

B5: External output 0

B4: External output 1

B3: External output 2

B2: External output 3

A5: External output 4

A4: External output 5

A3: External output 6

A2: External output 7

B1: External output 0 to 7

COM : 0 V

Page 32

20

Wiring Examples of Encoder Inputs Section 3-4

3-4 Wiring Examples of Encoder Inputs

The following are wiring examples of an encoder with A, B, and Z-phase outputs.

Wiring Example 1: 12-VDC Open-collector Encoder

Wiring Example 2: 12-VDC

Voltage-output (Sink

Load) Encoder

In the following example, an input to the High-speed Counter Unit will be

turned OFF when an output from the encoder is H and an input to the Unit will

be turned ON when an output from the encoder is L.

C200H-CT021 High-speed Counter Unit

Counter input A

Rectifierfilter

Counter input B

Counter input Z

24 V

12 V

0 V

24 V

12 V

0 V

24 V

12 V

0 V

12-VDC 12 VDC

power

supply

0 V

Shielded, twisted-pair cable

Encoder

Powe r

A phase

Encoder

output

B phase

Z phase

Rectifier

Rectifierfilter Rectifier

Counter input A

Counter input B

Counter input Z

C200H-CT021 High-speed Counter Unit

Shielded, twisted-pair cable

24 V

12 V

0 V

24 V

12 V

0 V

24 V

12 V

0 V

12-VDC 12 VDC

power

supply

0 V

Encoder

Powe r

A phase

B phase

Z phase

Encoder

output

Page 33

21

Wiring Examples of Encoder Inputs Section 3-4

Wiring Example 3: 12-VDC Voltage-output (Source load) Encoder

Wiring Example 4: Line-driver Output (Am26LS31 or Equivalent) Encoder

Rectifierfilter Rectifier

Counter input A

Counter input B

Counter input Z

C200H-CT021 High-speed Counter Unit

Shielded, twisted-pair cable

24 V

12 V

0 V

24 V

12 V

0 V

24 V

12 V

0 V

12-VDC 12 VDC

power

supply

0 V

Encoder

A phase

B phase

Z phase

C200H-CT021 High-speed Counter Unit

Counter input A

Counter input B

Counter input Z

Shielded, twisted-pair cable

Encoder

Power

Page 34

22

Wiring Example of External Control Inputs Section 3-5

Example 5: With Encoder

Conversion Adapter

In the following example, open collector outputs from an encoder is connected

as line driver inputs through the C500-AE001 Encoder Conversion Adapter.

Note Connect the wires so that a counter input to the High-speed Counter Unit will

be turned ON when an output from the encoder is turned ON.

The C500-AE001 Encoder Conversion Adapter uses an Am26LS31-compatible line driver. H will be output to the positive terminal and L will be output to

the negative terminal of the C500-AE001 when an input to the C500-AE001 is

H.

3-5 Wiring Example of External Control Inputs

In order to prevent chatter at the input, use solid-state as much as possible.

Counter input A

Counter input B

Counter input Z

Shielded, twisted-pair cable

Encoder

Shielded, twisted-pair cable

12-VDC12 VDC

power

supply

0 V

0 V 0 V

0 V

C500-AE001 Encoder

Conversion Adapter

Voltage

regulator

C200H-CT021 High-speed Counter Unit

External control input IN1

filterfilter

Sensor

Sensor output

Twisted-pair cable

Sensor

Sensor output

External control input IN2

12 or 24 V

12 or 24 V

12- to 24-VDC

power

supply

0 V

12 to 24 VDC

Page 35

23

Example of External Output Wiring Section 3-6

3-6 Example of External Output Wiring

In the following example, relays are connected to external outputs 0 to 3 and

TTLs are connected to external outputs 4 to 7.

Note In the above connection example, the output power supply voltage must be

higher than the load supply voltage, and if the external power supply is different from the load power supply, make sure that the external power supply voltage is the same as or higher than the load supply voltage.

C200H-CT021 High-speed Counter Unit

Fuse (1 A)

Driving circuirtry

Output 0

Relay

Pull-up resistor

(4.7 kΩ)

Fuse (1 A)

Output 1

Output 7

Output 0

Output 1

Relay

5 to 24 VDC

0 V

Power supply

5 VDC

power

supply

0 V

Output 7

Page 36

25

SECTION 4

Functions and Operating Modes

This section describes the High-speed Counter Unit functions and their operating modes.

4-1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4-2 DM and IR Bit Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-3 Linear Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-3-1 Operation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-3-2 Configuration of Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-4 Circular Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-4-1 Configuration of Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-5 Preset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-5-1 External Output Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-5-2 Count Range for Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-5-3 Configuration of Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-6 Gate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-7 Cumulative Gate Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4-8 Sampling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4-8-1 Configuration of Sampling Time . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-9 Input Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-10 Counter Reset Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-11 Data Processing with PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Page 37

26

Operating Modes Section 4-1

4-1 Operating Modes

The High-speed Counter Unit can operate in any of the following seven

modes selected with the rotary switch on the front panel of the High-speed

Counter Unit. The modes other than the simple counter modes are classified

according to the function.

Drum Function Linear mode

Circular mode

Preset Function Preset mode

Counting Function Gate mode

Cumulative gate mode

Sampling mode

The following pages provide information on data area allocation for value settings and functions of set values.

Note The High-speed Counter Unit in simple counter mode does not use any set

value. For the data area allocation of the High-speed Counter Unit in simple

counter mode, refer to 5-1 DM Area Allocation in Simple Counter Mode.

MODE Operating mode Function Page

0 Simple Counter

Mode

Counts the number of input pulses within a range of –8,388,608 to 8,388,607. ---

1 Linear Mode A total of 16 ranges with upper and lower limits between –8,388,608 and

8,388,607 can be set and when the count value is within one of the ranges, 8point signals can be output.

29

2 Circular Mode A total of 16 ranges with upper and lower limits between 0 and 65,535 can be

set and when the count value is within one of the ranges, 8-point signals can

be output. The number of pulses from 0 to 65,535 is counted. The count value

is reset to 0 after it reaches the maximum countable value set and the Highspeed Counter Unit continues counting the number of pulses.

31

3 Preset Mode Counter value is decremented beginning with a preset value whenever a

counter input is turned ON. Both counters 1 and 2 have three external outputs

that will be turned ON and OFF while the count is decremented and an external

output that will be turned ON when the High-speed Counter Unit finishes counting down the number of pulses. A total of 20 values can be preset within a

range of 1 to 8,388,607, any of which can be used with the High-speed

Counter Unit in this mode.

33

4 Gate Mode Counts the number of pulses within a range of –8,388,608 to 8,388,607 while

control input IN1 is turned ON. The High-speed Counter Unit resets the count

value at the rising edge of control input IN1. An external control input or an IR

bit can be used as the control input.

36

5 Cumulative Gate

Mode

Counts the number of pulses within a range of –8388,608 to 8,388,607 while

control input IN2 is turned ON to accumulate the count value. The High-speed

Counter Unit resets the count value at the rising edge of control input IN1. An

external control input or an IR bit can be used as the control input.

37

6 Sampling Mode Counts the number of pulses from the rising edge of control input IN1 within a

range of –8,388,608 to 8,388,607 for a preset interval. An external control input

or an IR bit can be used as the control input.

37

Page 38

27

DM and IR Bit Allocation Section 4-2

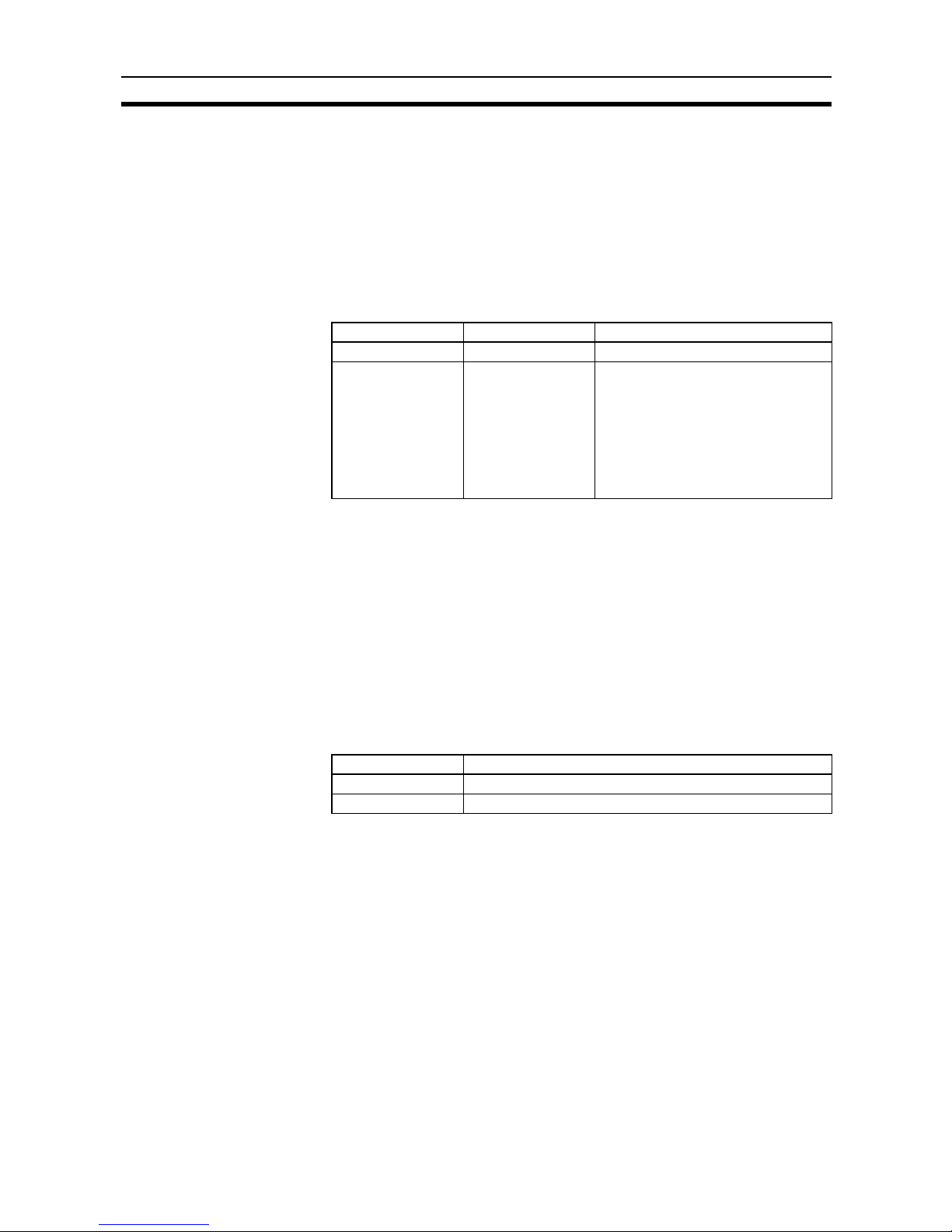

4-2 DM and IR Bit Allocation

The following DM and IR bits are allocated to the Special I/O Unit for the

C200H, C200HS, C200HX, C200HG, or C200HE PC.

DM Area A block of 100 words between DM 1000 to DM 2599 is allocated to the Spe-

cial I/O Unit.

The words allocated to the Special I/O Unit are within the following range.

Words m to m+99 (m = 1000 + 100 × Unit No. 0 to 15)

Upper and lower limits, output pattern, and other settings for each mode are

stored in these words.

Note Unit numbers 10 to 15 (A to F) are available only when the C200HX, C200HG,

or C200HE PC is used with the C200H-CT021.

IR Area A block of 10 words between IR 100 to IR 199 or IR 400 to IR 459 is allocated

to the Special I/O Unit.

The words allocated to the Special I/O Unit are within the following range.

Words n to n+9 (n = (100 + 10 × Unit No. 0 to 9) or (400 + 10 × (Unit No. – 10)

(Unit No. 10 to 15))

Note Unit numbers 10 to 15 (A to F) are available only when the C200HX, C200HG,

or C200HE is used with the C200H-CT021.

IR words n and n+1 are used for outputs from the PC to the Special I/O Unit

and IR words n+2 to n+9 are used for inputs from the Special I/O Unit to the

PC.

IR output words includes information to control the Special I/O Unit, such as

Start, Stop, and Data Transfer commands.

The status data blocks of the Special I/O Unit, such as present counter value

and operation data, are input to the PC from the input data area.

Data of 100 DM words is transferred to the Special I/O Unit when the Special

I/O Unit is turned ON or restarted.

Page 39

28

DM and IR Bit Allocation Section 4-2

Data of 10 IR words and data from the Special I/O Unit are transferred at the

time of the PC’s I/O refresh.

Note Refer to 4-11 Data Processing with PC for I/O refresh and data transfer tim-

ing.

[DM]

Unit 0

Unit 1

Unit 2

Unit 3

Unit 4

Unit 5

Unit 6

Unit 7

Unit 8

Unit 9

Unit A

Unit B

Unit C

Unit D

Unit E

Unit F

Unit 0

Unit 1

Unit 2

Unit 3

Unit 4

Unit 5

Unit 6

Unit 7

Unit 8

Unit 9

Unit A

Unit B

Unit C

Unit D

Unit E

Unit F

DM 1000 to 1099

DM 1100 to 1199

DM 1200 to 1299

DM 1300 to 1399

DM 1400 to 1499

DM 1500 to 1599

DM 1600 to 1699

DM 1700 to 1799

DM 1800 to 1899

DM 1900 to 1999

DM 2000 to 2099

DM 2100 to 2199

DM 2200 to 2299

DM 2300 to 2399

DM 2400 to 2499

DM 2500 to 2599

IR 100 to 109

IR 110 to 119

IR 120 to 129

IR 130 to 139

IR 140 to 149

IR 150 to 159

IR 160 to 169

IR 170 to 179

IR 180 to 189

IR 190 to 199

IR 400 to 409

IR 410 to 419

IR 420 to 429

IR 430 to 439

IR 440 to 449

IR 450 to 459

Optional bit areas

(DM, fixed DM, EM,

IR, LR, HR, and AR)

[IR area]

Initial data transfer

Executed when the

CT021 is turned

ON or restarts.

Data area,

READ DATA and

WRITE DATA

By e xe cuting IORD and

IOWR instructions, data can

be written to and read from

the data area of the

High-speed Counter Unit.

Set the assigned area to

data and set the data

transfer IR bit to 1 to

transfer the data.

Scanned and refreshed

At the time of the PC's I/O

refresh, the PC to the

High-speed Counter Unit (OUT)

and the High-speed Counter Unit

to the PC (IN) are refreshed.

The EM area is available with the C200HX and C200HG.

Example: C200HX High-speed Counter Unit

Data area of the

High-speed Counter Unit

Up to 100 words are used.

m = 1000 + 100 × Unit No.

OUT data area

I/O data area

IN data area

Up to 10 words are used

n = 100 + 10 × Unit No. (0 to 9)

n = 400 x 10 × (Unit No. − 10)

(A to F)

New data and preset

value transfer

Word m

to

Word (m+99)

Word n

to

Word (n+99)

to

Page 40

29

Linear Mode Section 4-3

4-3 Linear Mode

A total of 16 ranges with upper and lower limits between –8,388,608 and

8,388,607 can be set in this mode and when the count value is within the

ranges, the High-speed Counter Unit will turn an output ON.

4-3-1 Operation Example

This example uses the following lower and upper limits with the outputs to be

turned ON.

If the present counter value is 3,000, outputs 7, 6, and 5 will be turned ON

because the present counter value will be within ranges 1 and 2, in which

case the OR of the outputs will be turned ON.

If the present counter value is –5,000, outputs 3, 2, and 1 will be turned ON

because the present counter value will be within ranges 0 and 3.

In the case where ranges of counters 1 and 2 are different from each other, if

the present counter value is within a range of counter 1 or 2, the OR of outputs corresponding to the range will be turned ON.

4-3-2 Configuration of Range

Note The configuration of the range in linear mode is briefly described in the follow-

ing to explain the functions of the High-speed Counter Unit. Besides the settings described in this section, a variety of settings, such as operating mode,

input type, and counter reset condition settings, are required. Refer to 5-2 DM

Area Allocation in Linear and Circular Modes for data area allocation in detail.

Range 0

Present

counter

value

(800000 to FFFFFF) (000000 to 7FFFFF)

Range 1

Range 2

Range 3

Count value

Range Lower limit Upper limit Output (ON)

Range 0 –7,000 –5,000 3, 1

Range 1 –1,000 4,500 7, 6

Range 2 –4,000 3,000 6, 5

Range 3 –6,000 2,000 2, 1

Page 41

30

Linear Mode Section 4-3

A range consists of lower and upper limits and output pattern, and uses five

words. The lower limit uses two words, the upper limit uses two words, and

the output pattern uses one word. Up to 16 ranges are available.

The upper and lower limits can be set within a range of –8,388,608 and

8,388,607.

The following is an example of range 0.

Lower Limit BCD

Range: –8,388,608 to 8,388,607

Hexadecimal

Range: 800000 to FFFFFF (–8,388,608 to –1) and 000000 to 7FFFFF (0 to

8,388,607)

Upper Limit The configuration of the upper limit is the same as that of the lower limit.

Replace word m+16 with m+18 and word m+15 with m+17.

Lower limit

Upper limit

Output pattern

Range 0

to

to

to

Range 1

Range 15

to

Lower limit

Upper limit

Output pattern

Lower limit

Upper limit

Output pattern

Sign

Set to 0.

Page 42

31

Circular Mode Section 4-4

Output Pattern External outputs 7 to 0 correspond to the rightmost 8 bits (07 to 00) for the

output pattern.

Both internal and external outputs or only eight internal outputs can be specified. The results of the outputs will be transferred to word n+9.

It is possible to preset 16 ranges, any of which can be chosen.

Ranges and external outputs can be enabled or disabled.

A maximum of three ranges and a present counter value can be changed by

transferring data even when the High-speed Counter Unit is in operation.

Both upper and lower limits cannot be set to 8,388,607.

4-4 Circular Mode

The High-speed Counter Units in this mode counts the number of pulses

within a range of 0 to 65,535. The count value is reset to 0 after it reaches the

maximum countable value set and the High-speed Counter Unit continues

counting the number of pulses. A total of 16 ranges with upper and lower limits can be set and when the count value is within the ranges, the High-speed

Counter Unit will turn an output ON.

The example below uses the following lower and upper limits with the outputs

to be turned ON.

External outputs

Internal outputs

To output pins 0 to 7 of the external connector.

Range Lower limit Upper limit Output (ON)

Range 0 4,000 4,500 3, 1

Range 1 200 3,000 7, 6

Range 2 9,000 1,000 6, 5

Range 3 4,300 7,000 2, 1

Range 2

Present counter value

Range 1

Range 0

Range 3

Maximum

value (9,999)

Count value

Page 43

32

Circular Mode Section 4-4

If the present counter value is 600, outputs 7, 6, and 5 will be turned ON

because the present counter value is within ranges 1 and 2, in which case the

OR of the outputs will be turned ON.

If the present counter value is 4,500, outputs 3, 2, and 1 will be turned ON

because the present counter value is within ranges 0 and 3.

In the case the ranges of counters 1 and 2 are different from each other, if the

present counter value is within a range of counter 1 or 2, the OR of outputs

corresponding to the range will be turned ON.

4-4-1 Configuration of Range

Note The configuration of the range of the High-speed Counter Unit in circular

mode is briefly described below to explain the functions of the High-speed

Counter Unit. Besides the settings described in this section, a variety of settings, such as operating mode, input type, and counter reset condition settings, are required. Refer to 5-2 DM Area Allocation in Linear and Circular

Modes for data area allocation in detail.

Circular mode requires settings for the maximum count value of the Highspeed Counter Unit. Except for the maximum count value, the configuration of

the High-speed Counter Unit in circular mode is the same as that of the Highspeed Counter Unit in linear mode.

The lower and upper limits use two words each and the output pattern uses

one word. Up to 16 ranges are available.

Maximum Count Value The maximum count value can be set to 1 to 65,535.

BCD

Set value: 1 to 65,535

Hexadecimal

Set value: 0001 to FFFF

The above is an example of the maximum count value of counter 1.

Counter 2 uses words m+10 and m+9.

Note If the maximum count value is changed with the IOWR instruction, reset the

count value to 0, otherwise the count value will not be reset to 0 after the

count value reaches the new maximum count value.

Set to 0.

Set to 0.

Page 44

33

Preset Mode Section 4-5

Upper and Lower Limits

and Output Pattern

Upper and lower limits can be within a range of 0 to the maximum count value

set.

Outputs 7 to 0 correspond to the rightmost 8 bits (07 to 00) for the output pattern.

For the data configuration of the output pattern, refer to the output pattern in

linear mode.

Both internal and external outputs or only eight internal outputs can be specified.

It is possible to preset 16 ranges, any of which can be enabled or disabled.

External outputs can be enabled or disabled.

A maximum of three ranges and a present counter value can be changed by

transferring data even when the High-speed Counter Unit is in operation.

4-5 Preset Mode

Note The High-speed Counter Unit is in decrement counting operation in this mode.

Therefore, sensor inputs such as encoder inputs to the High-speed Counter

Unit must be in decrement mode.

The High-speed Counter Unit in this mode counts down the number of pulses

whenever a counter input is turned ON beginning with a preset value. Both

counters 1 and 2 have three external outputs that will be turned ON and OFF

while the count is being decremented and an external output that will be

turned ON when the High-speed Counter Unit finishes counting the number of

pulses.

External outputs 0 to 3 are for counter 1 and external outputs 4 to 7 are for

counter 2.

Bit 01 is a flag of counter 2.

In the above chart, horizontal lines express count values for external outputs

0, 1, 2, 4, 5, and 6 and timing for external outputs 3 and 7.

Pulse input

Counter preset value

Count value

External output 0/4

Start

Word n bit 00 (01)

External output 1/5

External output 2/6

External output 3/7

*

*

*

Page 45

34

Preset Mode Section 4-5

Note An interval of 2 ms min. is required between the preset count values marked

with asterisks in the above chart, otherwise no external output can be

obtained normally.

4-5-1 External Output Pattern

External outputs 0 to 3 are for counter 1 and external outputs 4 to 7 are for

counter 2.

4-5-2 Count Range for Output Control

4-5-3 Configuration of Range

Note The configuration of the range in preset mode is briefly described below to

explain the functions of the High-speed Counter Unit. In addition to the settings described in this section, a variety of settings, such as operating mode,

input type, and counter reset condition settings, are required. Refer to 5-3 DM

Area Allocation in Preset Mode Mode for data area allocation in detail.

Count Values for Output

Control

Words m+10 to m+20 are for counter 1 and words m+30 to m+40 are for

counter 2. Count values can be set within a range of 0 to 8,388,607.

Values in parentheses are for counter 2 in the following diagram.

Output Output pattern

0/4 Turned ON when the counter starts and turned OFF at count value 0+A.

1, 2/5, 6 Turned ON at the counter preset value + B and the counter preset value

+ D and turned OFF at count values 0+C and 0+E.

3/7 Turned ON for a preset interval after the counter finishes operating.

Always turned ON if the time is set to FFFF.

Mark Meaning Range

A A count value turning external outputs 0 and 4 OFF. 0 to 8,388,607

(0 to 8,388,606 for

count value A)

B, D A count value turning external output 1 and 5 or 2

and 6 ON.

C, E A count value turning external output 1 and 5 or 2

and 6 OFF.

T Time to keep external outputs 3 and 7 turning ON. 0 to 99.99 s or

always ON

External output 0 (4)

OFF count value

External output 1 (5)

ON count value

External output 1 (5)

OFF count value

External output 2 (6)

ON count value

External output 2 (6)

OFF count value

Time to keep external output

3 (7) from turning ON

to

m+10 (m+30)

m+11 (m+31)

m+18 (m+38)

m+19 (m+39)

m+20 (m+40)

Page 46

35

Preset Mode Section 4-5

Example 1: OFF Count

Value of External Output 1

BCD

Set value: 0 to 8,388,607

(0 to 8,388,606 for external output 0 (4))

Hexadecimal

Set value: 000000 to 7FFFFF

(0 to 7FFFFE for external output 0 (4))

There is no difference in configuration among count values for external outputs 0, 2, 4, 5, and 6.

Example 2: ON Time of

External Output 3

External output 3 will be kept ON until the counter starts again if the time is

set to FFFF.

Set value: 0 to 9999 (0 to 99.99 s)

Unit: 0.01 s

Counter Preset Values The maximum number of counter preset values is 20 within a range of 1 to

8,388,607, any of which can be chosen.

Set to 0.

Counter preset

value 0

Counter preset

value 1

Counter preset

value 18

Counter preset

value 19

Page 47

36

Gate Mode Section 4-6

Example: Counter Preset

Val ue 0

BCD

Set value: 1 to 8,388,607

Hexadecimal

Set value: 000001 to 7FFFFF

A maximum of six counter preset values can be changed by transferring data

from the PC, in which case data blocks A to E and T for turning the outputs