Page 1

Enabling Grip Switch

A4EG

Enabling Grip Switch with Distinct Feel

for Three Easily Discernible Positions

■ The difficult task of configuring safety circuits is now easily

achieved by combining the A4EG with the G9SX-GS.

■ In addition to the standard models, the lineup also includes

models with an emergency stop switch and models with a

momentary operation switch.

■ An optional Holding Key (sold separately) provides a versatile

method for selecting modes.

■ Equipped with conduit connector.

Be sure to read the “Safety Precautions” on page 12.

Ordering Information

Enabling Grip Switches

Appearance

Enabling switch Monitor switch Pushbutton switch

Two contacts

Two contacts None

Two contacts None

Contact form

1NC

(grip output)

None A4EG-C000041

Emergency stop switch

(2NC)

Momentary operation switch

(2NO)

Model

A4EG-BE2R041

A4EG-BM2B041

Accessories (Order Separately)

Appearance Item Model

Rubber Cover

(replacement part)

Mounting Bracket

(for securing the

A4EG)

Holding Key A4EG-OP3

A4EG-OP1

A4EG-OP2

33

Page 2

A4EG

Specifications

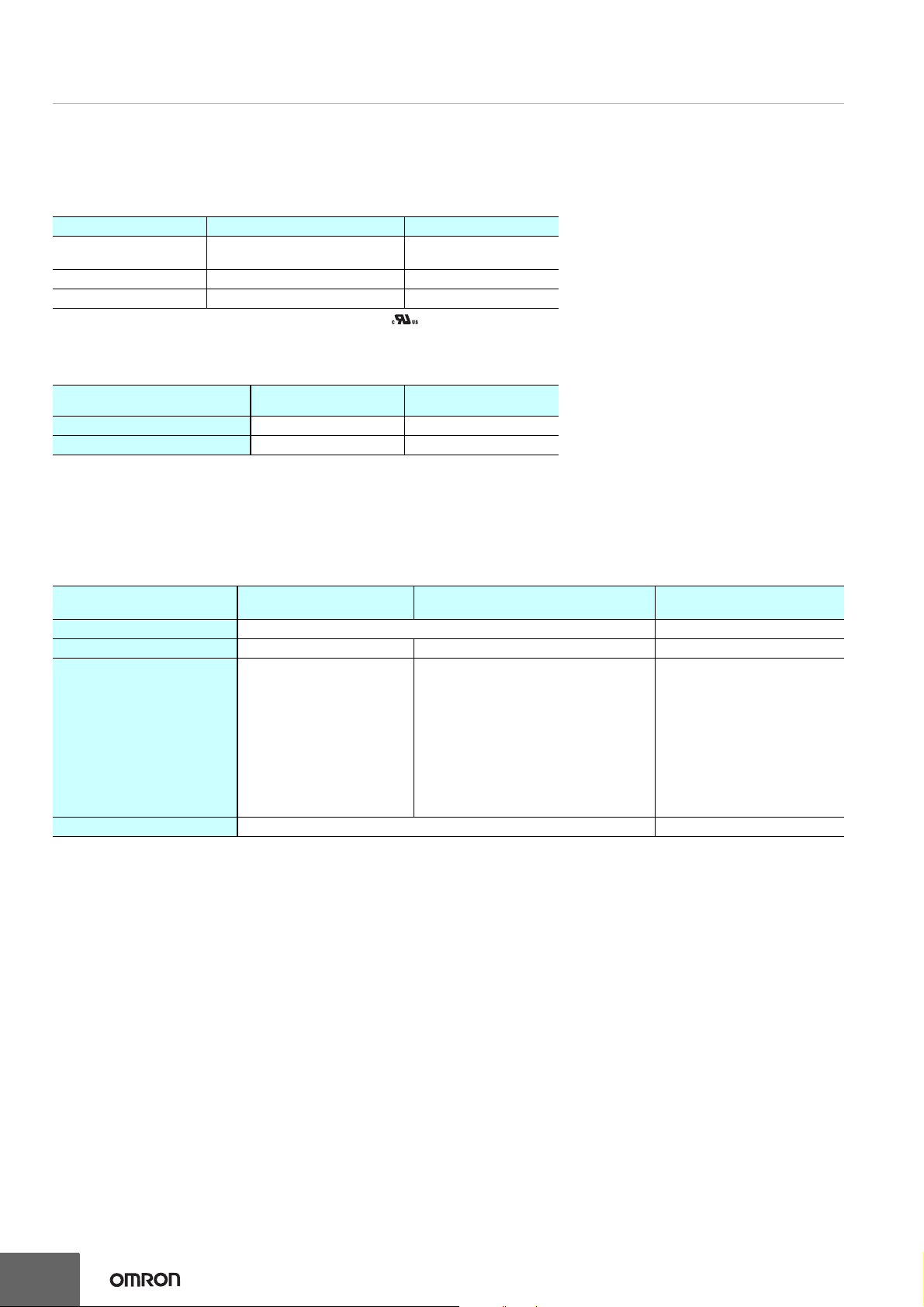

Standards and EC Directives

Compliance with EC Directives and International Standards

• Low Voltage Directive

• GS-ET-22

Certified Standards

Certifying body Standard File No.

TÜV Product Service

UL * UL 508, CSA C22.2 No.14 E76675

CQC (CCC) GB 14048.5 Pending approval

* Certification for CSA C22.2 No. 14 by UL is indicated by the .

EN 60947-5-1

(certified direct opening)

Certified Standard Ratings (Enabling Switch Section)

TÜV (EN 60947-5-1)

Item

Rated operating current (Ie) 0.75 A 0.55 A

Rated operating voltage (Ue) 240 V 125 V

Note: Use a 10-A fuse type gI or gG that conforms to IEC 60269 as the short-circuit protection device.

Utilization category

The fuse is not built into the Switch.

UL/CSA (UL 508, CSA C22.2 No.14), CCC (GB 14048.5)

• 24 VDC, 0.3 A (inductive load)

• 125 VAC, 1 A (resistive load)

AC-15 DC-13

Ask your OMRON

representative.

Ratings

Item

Section

Rated insulation voltage 250 V ---

Rated ON current 2.5 A 5 A 0.1 A

Rated load

Minimum applicable load 24 VDC, 4 mA 5 VDC, 1 mA

Enabling switch

24 VDC, 0.3 A (inductive load)

125 VAC, 1 A (resistive load)

EN certification rating:

AC-15 0.75 A/240 V

DC-13 0.55 A/125 V

General rating:

UL and cUL rating:

Emergency stop switch

(A4EG-BE2R041 only)

125 VAC, 5 A (resistive load)

250 VAC, 3 A (resistive load)

30 VDC, 3 A (resistive load)

125 VAC, 5A

(inductive load, power factor: 0.75 to 0.8)

250 VAC, 3 A

(inductive load, power factor: 0.75 to 0.8)

30 VDC, 3 A (resistive load)

Pushbutton

(A4EG-BM2B041 only)

General rating:

125 VAC, 0.1 A (resistive load)

8 VDC, 0.1 A (resistive load)

14 VDC, 0.1 A (resistive load)

30 VDC, 0.1 A (resistive load)

4

Page 3

Characteristics

Item

Degree of protection IP66 (A4EG-C000041), IP65 (A4EG-BE2R041, A4EG-BM2B041)

Operating section strength Operating direction: 200 N, 1 min

Cable pull strength 30 N, 1 min

Allowable

operating

frequency

Electrical durability

Mechanical durability

Dielectric

strength

Insulation resistance 100 MΩ min. (at 500 VDC)

Vibration

resistance

Shock

resistance

Ambient operating

temperature

Ambient operating humidity 35% to 85%

Ambient storage temperature −25 to 65°C (with no icing or condensation)

Protection against electric

shock

Pollution degree

(operating environment)

Conditional short-circuit

current

Note: The timing of contact outputs for two or more circuits is not synchronized. Confirm performance before application.

Electrical 20 operations/minute max.

Mechanical 20 operations/minute max.

Between

terminals of the

same polarity

Between

terminals of the

different polarity

Between each

terminal and

non-current

carrying

metallic parts

Malfunction 1.5 mm double amplitude, 10 to 55 Hz

Malfunction 150 m/s2 max.

Section

100,000 operations min. (rated load)

OFF-ON-OFF (direct opening):

100,000 operations min.

OFF-ON: 1,000,000 operations min.

2,500 VAC, 50/60 Hz, 1 minute

(impulse voltage)

2,500 VAC, 50/60 Hz, 1 minute

(impulse voltage)

2,500 VAC, 50/60 Hz, 1 minute

(impulse voltage)

−10 to 55°C (with no icing or condensation)

Class II (double insulation)

3 (EN 60947-5-1)

100 A (EN 60947-5-1)

Enabling switch

Emergency stop switch

(A4EG-BE2R041 only)

Operating direction: 367 N, 1 min

Rotating direction: 0.49 N·m, 1 min

10 operations/minute max.

(set/reset for one operation)

10 operations/minute max.

(set/reset for one operation)

100,000 operations min.

(set/reset for one operation)

(rated load)

100,000 operations min.

(set/reset for one operation)

1,000 VAC, 50/60 Hz, 1 minute 1,000 VAC, 50/60 Hz, 1 minute

2,000 VAC, 50/60 Hz, 1 minute 2,000 VAC, 50/60 Hz, 1 minute

2,000 VAC, 50/60 Hz, 1 minute 2,000 VAC, 50/60 Hz, 1 minute

(A4EG-BM2B041 only)

Operating direction: 50 N, 1 min

60 operations/minute max.

120 operations/minute max.

100,000 operations min. (rated load)

2,000,000 operations min.

A4EG

Pushbutton

5

Page 4

A4EG

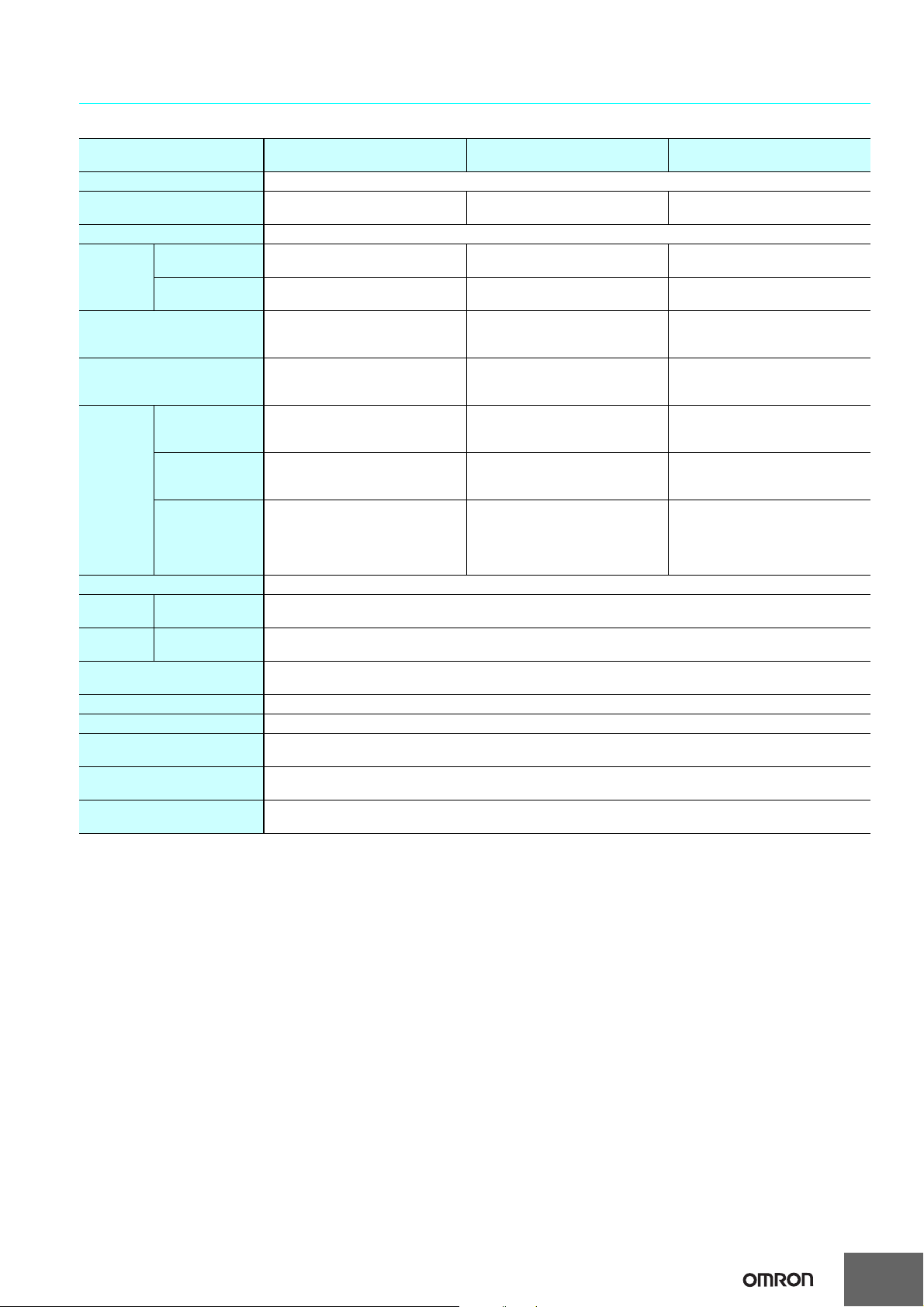

Structure and Nomenclature

Structure

A4EG-C000041

bling Switch

Ena

Section

Terminal 2

Terminal 1

Terminal 5

Terminal 6

Terminal 3

Terminal 4

A4EG-BE2R041

A4EG-BM2B041

Terminal 2

Terminal 1

Terminal 5

Terminal 6

Emergency Stop

Switch Section/

Pushbutton Switch

Section

Terminal 3

Terminal 4

Terminal 8

Terminal 7

Three Positions: OFF - ON - OFF

Position 1

Not Gripped Gripped to

Gripped lightly

OFF

Released

Middle

Position

ON

Released

Gripped Farther

Gripped past

Middle

Position

Contact Configuration

Enabling Switch Emergency Stop Switch Pushbutton Switch

Terminal No.

(2) (4) (6)

Terminal No.

(1) (3)

* Terminal No. (5), (6): A4EG-C000041 only

*

Terminal No.

(5)

(7)

*

(5)

Terminal No.

(6)

(8)

Terminal No.

(5)

(7)

Terminal No. Terminal No.

Position 3Position 2

OFF

(6)

(8)

Contact Forms

Operating Patterns

A4EG-C000041

Operation Terminal No.

Enable output

1 to 2

3 to 4

Position 1

▼

Grip output 5 to 6

A4EG-BE2R041

Operation Terminal No.

Enable output

Pushbutton

switch

Emergency

stop switch

output

1 to 2

3 to 4

Terminal No. Operation Contact

5 to 6

7 to 8

Position 1

▼

Operation (push) ON → OFF

Reset (turn reset) OFF → ON

A4EG-BM2B041

5 to 6

7 to 8

Position 1

▼

Operation Terminal No.

Enable output

Pushbutton

switch

Pushbutton

switch output

1 to 2

3 to 4

Terminal No. Operation Contact

(pushbutton switch A) *

(pushbutton switch B) *

* Refer to Dimensions on page 7 for information on the positions of

pushbutton switches A and B.

OPEN ON: CLOSED

CLOSED OFF: OPEN

Note: 1. The contact ON/OFF timing is not synchronized. Confirm

performance before application.

2. Direct opening only during grip.

Position 2

▼

Position 2

▼

Position 2

▼

Position 3

▼

Position 3

▼

Position 3

▼

Push OFF → ON

Push OFF → ON

Operating Characteristics

Chart (Enabling Switch Section)

OF2

OF1

HF

Operating force

PT1

PT2 TT1 PT3 PT4 TT2

Enable output

(1-2, 3-4)

Grip output

(5-6)

Operating Stroke (Enabling Switch Section)

Operating characteristics Specified value

Enable output (ON) PT2 max. 3.6 mm

Max. enable holding position TT1 Approx. 4.2 mm

Enable direct opening position PT3 max. 6.0 mm

Max. stroke TT2 Approx. 6.7 mm

Operating Force (Enabling Switch Section:

Reference Values)

Operating characteristics Specified value

Enable operating force OF1 max. 14 N

Enable holding force HF * Approx. 8 N

Grip operating force OF2 max. 40 N

* HF: Holding force

Operating Force (Emergency Stop Switch

Section: Reference Values)

Operating characteristics Specified value

Operating force OF max. 14.7 N

Reset force RF max. 0.1 N·m

Operating Force (Pushbutton Switch Section:

Reference Value)

Operating characteristics Specified value

Operating force OF max. 3 N

Operating stroke

6

Page 5

A4EG

Dimensions (Unit: mm)

Enabling Grip Switches

A4EG-C000041

Holding Key Mounted

Conduit connector

MG20A-P-13B Flexible Super Gland

Manufactured by AVC Corporation of Japan (included)

A4EG-BE2R041

60

(50)

38

Enabling switch

174

(262)

48

(34)

44

A4EG-OP3 Holding Key

(order separately)

60

(50)

Enabling switch

54.2

76.2

Holding Key Mounted

48

(34)

174

(277)

47.6

102.6

44

D4NS (order separately)

63

(50)

Conduit connector

MG20A-P-13B Flexible Super Gland

Manufactured by AVC Corporation of Japan (included)

38 44

Enabling switch

(191)

174

(279)

Emergency stop switch

48

(34)

A4EG-OP3 Holding Key

(order separately)

63

(50)

76.2

54.2

Emergency stop switch

Enabling switch

(191)

174

(294)

D4NS (order separately)

48

(34)

47.6

102.6

44

7

Page 6

A4EG

A4EG-BM2B041

Pushbutton

switch A

Pushbutton

switch B

48

(34)

44

Conduit connector

MG20A-P-13B Flexible Super Gland

Manufactured by AVC Corporation of Japan (included)

60

(50)

Enabling switch

(189)

174

(277)

38

48

(34)

44

A4EG-OP3 Holding Key

(order separately)

Holding Key Mounted

60

(50)

76.2

54.2

Enabling switch

(189)

174

D4NS (order separately)

48

(34)

(292)

47.6

102.6

44

Accessories (Order Separately)

Rubber Cover (Replacement Part)

A4EG-OP1

Holding Key

A4EG-OP3

Mounting Bracket (for Securing the A4EG)

A4EG-OP2

50

(44)

(88)

Two, 5.3-dia. holes

Enabling Grip Switch Mounted

83.2

43.3

235.9

(82)

t3

Mounting surface

8

Note: The screws are not included.

Page 7

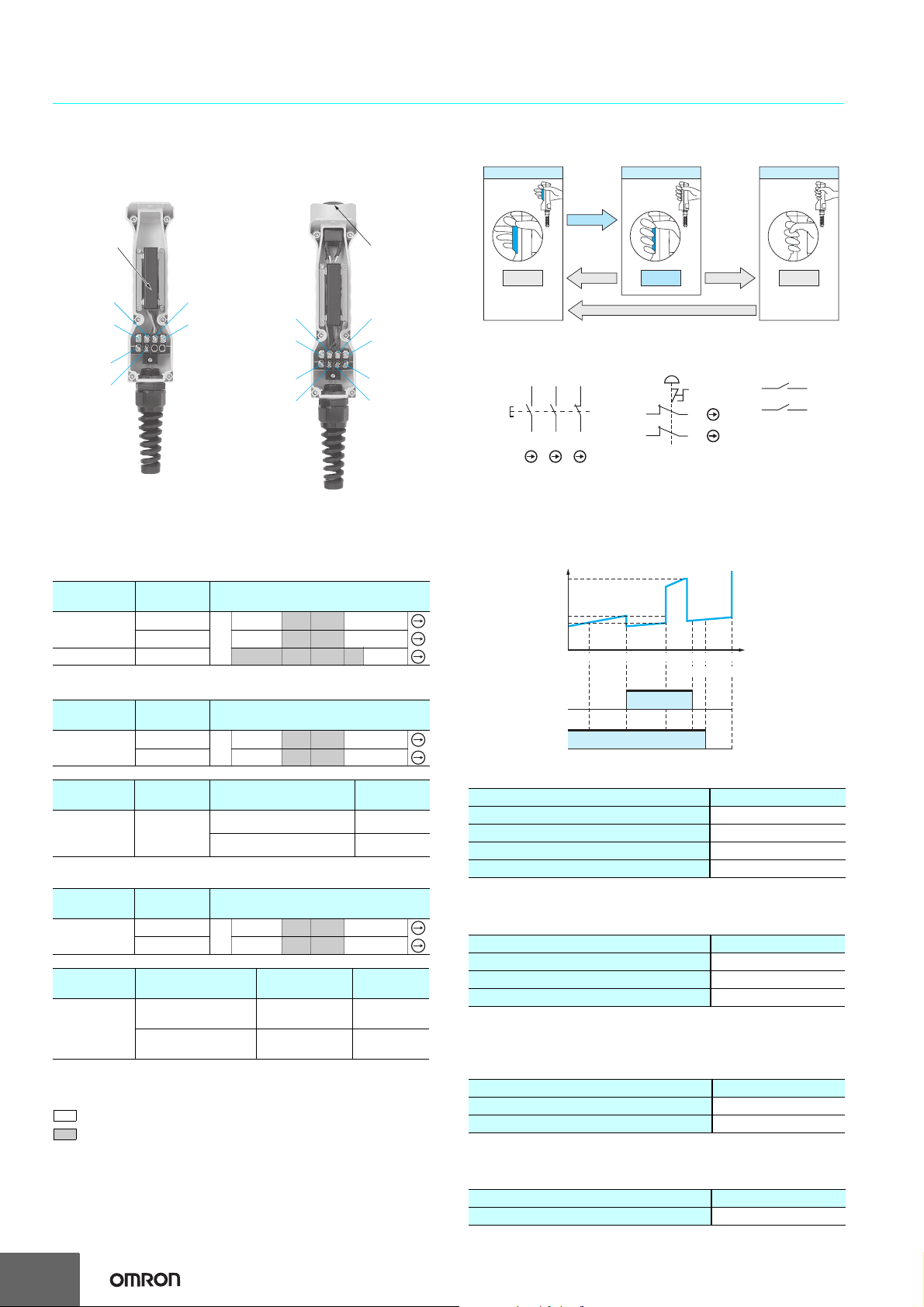

Application Examples

Application Examples

Machining Equipment Maintenance Mode

• Switching between normal operation mode and maintenance mode is performed manually.

• In normal operation mode, the Safety Door Switch is enabled, and in maintenance mode, the Enabling Grip Switch is enabled.

A4EG

Normal Operation Mode

Emergency Stop Switch

Door

1. Emergency

2. Door

1. Emergency

Stop Switch

4. Mode Selector

3. Enabling Grip

Switch

Stop Switch

Emergency

Stop Switch,

e.g., A22E

Basic Unit

G9SX-BC

Logical AND

connection

When pressed, processing will stop.

When the door is opened, processing will stop.

2.

Door

Guard Lock

Safety-door Switch,

e.g., D4NL

Safety Guard

Switching Unit

G9SX-GS

Contactor

Conveyor

3. Enabling Grip

Switch

Enabling

Grip Switch

A4EG

4. Mode

Selector

Key-type

Selector Switch

A22K

Enabling Grip Switch

The Enabling Grip Switch will be disabled.

Maintenance Mode

Emergency Stop Switch

Door

Enabling Grip Switch

When pressed, processing will stop.

The Door Switch will be disabled.

Processing will be possible only when the operator is gripping

the Enabling Grip Switch.

Note: For information on the G9SX-GS, refer to Safety Components Series Catalog (Cat. No. Y106) and G9SX User’s Guide (Cat. No. Z255).

9

Page 8

A4EG

Wiring Example

Settings (For details, refer to section 3 of the G9SX User’s Guide (Cat. No. Z255).)

G9SX-BC: Manual reset, cross fault detection: ON (category 4 wiring)

G9SX-GS: Manual reset, cross fault detection: ON (category 4 wiring), logical AND connection setting: AND

ON-delay time setting: Time is set.

Switching mode: Manual

External indicator diagnosis: Enabled

Wiring Example

Feedback loop

+24 V

GND

11 21

12

S1

T11A1T12 T21 T22 T31 T32 T33

G9SX-BC202

Control circuit

S14A2S24

KM1 KM2

KM1

22

KM2

S2

+24 V

Open

Y1

L1 L2 X1 X2

PLC etc.

Lock release signal

S5

KM3

KM4

KM1

KM2

42

41

121134

S1: Emergency Stop Switch

S2, S7: Reset switches

S3: Enabling Grip Switch

M1

S4: Guard lock Safety-door Switch

S5: Lock release switch

S6: Safety limit switch

KM1 to KM4: Contactors

M1 to M2: 3-phase motors

S4

54

53

33

+24 V

Enabling

Grip Switch

S3

G9SX-GS226-T15

GND

T11A1T12 T21

S14A2S24

KM4KM3

Mode selector

Y1

T22

Control circuit

S54

S44

Door

OPEN

Stop signal

+24 V

OpenOpen

Y3

M1 M2

L1 X3X2X1 X4

PLC etc.

(Diagnostic check enabled)

T61 T62

Indicator

To PLC

To PLC

S6

Open Open

T71

Y2

T72 T31 T32 T33 T41 T42

Y4

Feedback loop

S7

KM3

KM4

+24 V

UA UB

Indicator

(Diagnostic check enabled)

AND

OFF

Manual

Auto

KM3

KM4

M2

Note: For this circuit example, the

category is equivalent to 4.

10

Page 9

Timing Chart

A4EG

G9SX-BC202 (Upper Unit)

Emergency stop switch S1

Reset switch S2

KM1, KM2 NC contact

KM1, KM2 NO contact

Logical AND output L1

G9SX-GS226-T15 (Lower Unit)

Logical AND input T41

Guard lock safety-door switch S4

Enabling grip switch S3

Reset switch S7

Mode selection input M1

Mode selection input M2

KM3, KM4 NC contact

KM5, KM6 NC contact

KM3, KM4 NO contact

KM5, KM6 NO contact

(10)

(8)(3)

(4)

(1)

(2)

(6)

(7)(5) (9)

OFF-delay timeOFF-delay time OFF-delay time OFF-delay time

(1) The lower unit starts in operation mode.

(2) The mode switches to maintenance mode.

(3) The operator opens the door and performs maintenance work.

(4) The Enabling Grip Switch is gripped to the middle position.

(5) The lower unit starts in maintenance mode.

(6) The lower unit will stop when the Enabling Grip Switch is released or gripped.

(7) The lower unit will start again after the door is closed and the mode is switched to operation mode.

(8) The lower unit will stop when the door is open while in operation mode.

(9) The door is closed and the lower unit starts again.

(10) The upper unit and lower unit will stop if the emergency stop is pressed.

11

Page 10

A4EG

Safety Precautions

!WARNING

Always verify the operation of the safety functions before

starting the system. Not doing so may result in the safety

functions not performing as expected if the wiring or

settings are incorrect or the switches have failed.

Do not drop the switch. Doing so may damage the switch

and the system may continue to operate, possibly

causing injury or death.

Precautions for Safe Use

• This product is a switch for teaching the machine such as robot in

hazardous area. The machine is allowed to operate only when

operating the switch continuously. Configure the system so that the

machine can be operated only at position 2.

• Apply load current not to exceed the rated value.

• Do not use the switch submerged in oil or water or in locations

continuously subject to splashes of oil or water. Doing so may

result in oil or water entering the switch.

• Do not use the switch in locations where explosive or flammable

gasses may be present.

• Mount the switch securely to prevent it from falling. Otherwise,

injuries may occur.

• The durability of the switch is greatly influenced by the switching

conditions. Always test the switch under actual conditions before

application and use it in a switching circuit for which there are no

problems with performance.

• Always attach the cover after completing wiring and before using

the switch. Electric shock may occur if the switch is used without

the cover attached.

• The user must not maintain or repair equipment incorporating the

switch. Contact the manufacturer of the equipment for any

maintenance or repairs required.

• Do not disassemble or remodel the switch in any case, or the

switch will not operate normally.

• Do not override by inserting the Holding Key itself in the door

switch.

• Configure the circuit so that the machine does not operate when

operating the Enabling Switch while the Holding Key is being

inserted in the door switch.

• Do not impose excessive vibration or shock on the Door Switch

while the Holding Key is inserted. Excessive vibration or shock

may cause the Switch to fail or break.

• Do not incline and pull the switch body or do not impose shock on

the switch body in the directions shown with the arrows in Fig.1.

Otherwise, the switch may be damaged and may not operate

properly.

• Refer to the D4NS Safety-door Switch Datasheet and Instruction

Sheet about the storage, ambient conditions, the details and

handling of the Switch.

Fig. 1

No operation No operation

Insertion-pull direction

(Perpendicular direction)

No operation

A4EG

Top position

No operation

Arrow indicates

insertion-pull direction.

Precautions for Correct Use

• Do not hold the Enabling Switch Device at Position 2 by any other

methods except for handling. Otherwise, the original function of the

Enabling Switch Device is not worked.

Operating Environment

• This switch is designed for use indoors. Using the switch outdoors

may damage it.

• The switch contacts can be used with either standard loads or

microloads. Once the contact be used to switch smaller loads. The

contact surfaces will become rough once they have been used and

contact reliability for smaller loads may be reduced.

• Do not use the switch in the following locations.

• Locations where the interior of the Protective Door may into

direct contact with cutting chips, metal filings, oil chemicals

• Locations subject to detergents, thinners, or other solvents

• Locations subject to sudden temperature changes

• Locations subject to high humidity and condensation

• Locations subject to severe vibration

• Do not use the switch where corrosive gasses (e.g.,H

NH

3,HNO3, or Cl2) are present or in locations subject to high

2S, SO2,

temperature and humidity. Doing so may result in damage to the

switch as a result of contact failure or corrosion.

• Do not store the switch where corrosive gasses (e.g.,H

NH

3,HNO3, or Cl2) or dust are present or in high temperature and

2S, SO2,

humidity.

• If the switch is not turned ON and OFF for a long period of time,

contact resistance may be increased or continuity failure may

occur due to contact oxidation.

Mounting Method

Specified Tightening Torque

Loose screws may result in malfunction. Tighten the screws at the

specified torques.

Item Specified torque

Cover mounting screw 1.1 to 1.3 N·m

Terminal screw 0.4 to 0.5 N·m

Holding Key mounting screw 0.5 to 0.7 N·m

Conduit Connector mounting

(Conforming spanner 27 mm

(width across flats))

Mounting Bracket 2.4 to 2.8 N·m

Cover Mounting

• Dislocation of the seal rubber or foreign substance on the seal

rubber reduces seal performance of the switch. Mount the cover

after confirming that there is no abnormality on the seal rubber. If

the seal rubber cracks or breaks, replace the Cover with a new one

(A4EG-OP1 Rubber Cover, separately sold).

• Do not touch the rubber boot with sharp objects. Otherwise, the

rubber boot may break and the operating characteristics and the

seal performance may not be satisfied.

Seal Cover, A4EG-OP1 (sold separately)

2.0 to 2.4 N·m

12

Holding Key

A4EG-OP3

(sold separately)

D4NS (sold separately)

Magnified View

Mounting surface

Rubber boot

Seal rubber

Installing Mounting Bracket

• Securely install the Mounting Bracket using M5 screws and

washers and tighten them to a torque of 2.4 to 2.8 N·m.

Page 11

A4EG

Holding Key Type (sold separately)

• Use the A4EG-OP3 Holding Key when using the A4EG combining

with the door switch.

• Use the D4NS Safety-door Switch.

• Loose screws may result in malfunction. Tighten the screws at the

specified torques. Adhesive is recommended to prevent screws

from being loose.

The specified torque: 0.5 to 0.7 N·m (Mounting screw, 2pcs.)

• Do not impose excessive force on the tip of the Holding Key or do

not drop the switch body when the Holding Key is mounted on the

switch body. Otherwise the Holding Key may deform or break. Stop

using in case that deformation or breakage of the Holding Key

occurs.

• Use the provide Spring washers and Mounting screws when

mounting the Holding Key. Fit a tip of a slotted-screw driver on the

head of the Mounting screw as shown in the following figure when

tightening Mounting screws. The Mounting screws cannot be

released once tightened.

Holding Key

A4EG

• As shown in figure 1 in Precautions for Safe Use, install the D4NS

so that its mounting surface is above the highest part of the A4EG.

• As shown in figure 1 in the Precautions for Safe Use, use the

Holding Key inserted vertically to the insert hole.

A4EG-OP3 (sold separately)

Spring washer, 2 pcs.

(provided)

Mounting screw, 2 pcs.

(provided)

• Do not pull the cable when the Enabling

Switch Device is hung on the Bracket.

Bracket

A4EG-OP2

(sold separately)

• Use crimp terminals with insulator tube for wiring.

Recommended crimp terminal (Ring tongue terminal, Nylon-

insulated): J.S.T. Mfg Co. FN1.25-3.7 (F Type)/

N1.25-3.7 (Straight Type)

t: 0.8 mm

dz dia.: 3.7 mm

D dia.4.0 mm

B: 5.5 mm

L: 15.7 mm

F: 4.0 mm

I: 9.0 mm

D dia.

L

l F

B

dz dia.

• Cut and crimp the lead wires in length as shown in the following

table.

Otherwise, excess length may cause the cover to rise and not fit

properly.

Terminal ArrangementLead Wire Lengths

Terminal 2

Terminal 1

Terminal 3

Terminal 4

Using the A4EG-BE2R041 (Enabling Grip Switch

Equipped with an Emergency Stop Button)

If the A4EG is installed in a machine, do not use the A4EG alone as

an emergency stop switch or as an emergency shutoff switch as

specified by SEMI-S2.

SEMI-S2 specifies the installation of emergency shutoff switches at

specified intervals on equipment. The A4EG can be removed from the

equipment, and so may not satisfy the requirements of SEMI. Use the

A4EG in combination with emergency stop switches or emergency

shutoff switches that are installed at fixed positions.

Wiring

• Confirm that safety is satisfied on the operation of the equipment

to wire.

• Do not put the electric power when wiring. Otherwise electric shock

may occur.

• Use an adequate diameter of cable. The seal performance is

reduced when the diameter is smaller than the adequate diameter.

• Use the conforming sizes of lead wires to the apply voltage and

current.

Conforming cable size

Recommended multi-wire cable size: AWG20 to 18

(0.5 to 0.75 mm

Recommended cable diameter: 8.0 to 13 mm

(used with provided Conduit

Connector)

• Do not pull the lead wires with excessive force. Doing so may

disconnect them.

2

)

L2

L1

Terminal 5 Terminal 6 Terminal 7 Terminal

8

Length of lead wires Terminal No. 1-4 5-8

L1/L2

(Length to the centers of crimp terminals)

40±2 mm 25±2 mm

• Do not let particles such as small piece of lead wire in the switch

body when wiring.

Terminal No. and Circuit Configuration

Model Circuit Terminal No.

A4EG-C000041

A4EG-BE2R041

A4EG-BM2B041

• Assemble all of the parts without leaving any parts as shown in the

following figure when mounting Conduit Connector.

Mount Rubber packing, Conduit part, Cable Seal part and Spiral

Nut part in order.

Enable output 1-2, 3-4

Grip output 5-6

Enable output 1-2, 3-4

Emergency Stop

Pushbutton Switch output

5-6, 7-8

Enable output 1-2, 3-4

Pushbutton Switch output 5-6, 7-8

Rubber packing

Cable seal part

Spiral nut part

Conduit part

• Both of the switches is ON when pushing the two push buttons

simultaneously. Confirm that safety is satisfied on the operation of

the equipment to wire. (A4EG-BM2B041)

• Perform maintenance inspections periodically.

13

Page 12

OMRON Corporation

Industrial Automation Company

Safety Devices Division

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81) 75-344-7093/Fax: (81) 75-344-8197

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON SCIENTIFIC TECHNOLOGIES INC.

6550 Dumbarton Circle, Fremont

CA 94555-3605 U.S.A.

Tel: (1) 510-608-3400/Fax: (1) 510-744-1442

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

Pu Dong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Authorized Distributor:

Note: Specifications subject to change without notice.

Cat. No. C142-E1-01

Printed in Japan

1007-?M (1007) (?)

Loading...

Loading...