Page 1

FULL-FEA TURED POWER MODULE FOR HIGH-VOLT AGE

205 Crawford Street, Leominster, MA 01 453 USA (978) 534-5776 FAX (978) 537-4246

Visit Our Web Site at www.omnirel.com

DIRECT DRIVE OF 3-PHASE BRUSHLESS DC MOTORS

25 Amp. Push-Pull 3-Phase Brushless

DC Motor Controller/Driver Module

in a Power Flatpack

FEATURES

• Fully integrated 3-Phase Brushless DC Motor Control Subsystem

includes power stage, non-isolated driver stage, and controller stage

• Rugged IGBT Power Output Stage with Soft Recovery Diode

• 25AAverage Phase Current with 300V Maximum Bus Voltage

• Internal Precision Current Sense Resistor (6W max. dissipation)

• Speed and Direction Control of Motor

• Brake Input for Dynamic Braking of Motor

• Overvoltage/Coast Input for Shutdown of All Power Switches

• Soft Start for Safe Motor Starting

• Unique Hermetic or Plastic Ring Frame Power Flatpacks

• Hermetic (3.10" x 2.10" x 0.385")

• Plastic Ring Frame (4.13" x 2.00" x 0.49")

OM9369

APPLICATIONS

• Fans and Pumps

• Hoists

• Actuator Systems

DESCRIPTION

The OM9369 is one of a series of versatile, integrated three-phase brushless DC motor

controller/driver subsystems housed in a 43 pin power flatpack. The OM9369 is best used as a two

quadrant speed controller for controlling/driving fans, pumps, and motors in applications which require

small size. Typical size brushless DC motors that the OM9369 can effectively control range from

fractional HP up to several HP. The OM9369 is ideal for use on DC distribution busses up to and

including 270Vdc. Many integral control features provide the user much flexibility in adapting the

OM9369 to specific system requirements.

The small size of the complete subsystem is ideal for aerospace, military, and high-end industrial

applications. Two package types provide a broad range of cost and screening options to fit any

application.

8 10 R2

Supersedes 6 11 R1

Page 2

OM9369

SIMPLIFIED BLOCK DIAGRAM

COMMUTATION TRUTH TABLE

This table shows the Phase Output state versus

the state of the Hall-Effect and Direction Inputs.

Please note that the OM9369 Hall-Effect Inputs

are Grey-encoded; that is, only one input is

allowed to change from one input state to

another at a time.

The commutation coding shown reflects HallEffect sensors that are spaced at 120°

mechanical increments. Also, internal

protection logic disables all three Phase

Outputs when the Hall-Effect Inputs are set to

an illegal condition (i.e. all logic low or all logic

high).

DIGITAL INPUTS PHASE OUTPUTS

Dir H1 H2 H3 A B C

1 0 0 1 Hi-Z Sink Source

1 0 1 1 Sink Hi-Z Source

1 0 1 0 Sink Source Hi-Z

1 1 1 0 Hi-Z Source Sink

1 1 0 0 Source Hi-Z Sink

1 1 0 1 Source Sink Hi-Z

0 1 0 1 Sink Source Hi-Z

0 1 0 0 Sink Hi-Z Source

0 1 1 0 Hi-Z Sink Source

0 0 1 0 Source Sink Hi-Z

0 0 1 1 Source Hi-Z Sink

0 0 0 1 Hi-Z Source Sink

X 0 0 0 Hi-Z Hi-Z Hi-Z

X 1 1 1 Hi-Z Hi-Z Hi-Z

2.1 - 2

Page 3

OM9369

ABSOLUTE MAXIMUM RATINGS

Motor Supply Voltage, Vm.................................................. 300 Vdc

Peak Motor Supply Voltage V

Average Phase Output Current, Io ................................... 25 Amperes DC*

Peak Phase Output Current, Iom................................... 50 Amperes Peak**

Control Supply Voltage, V

cc

Logic Input Voltage (Note 1) ............................................ -0.3 V to +8 V

Reference Source Current ................................................ -30 mAdc

Error Amplifier Input Voltage Range, (EA1+/EA1-) ....................-0.3 Vdc to 10 Vdc

Error Amplifier Output Current .............................................. ±8 mAdc

Spare Amplifier Input Voltage (EA2+/EA2-) ...........................-0.3 Vdc to 10 Vdc

Spare Amplifier Output Current ............................................. ±8 mAdc

Current Sense Amplifier Input Voltage (ISH/ISL) ....................... -0.3 V to +6 Vdc

Current Sense Amplifier Output Current.....................................±10 mAdc

Tachometer Output Current................................................±10 mAdc

PWM Input Voltage ..............................................-0.3 Vdc to +6 Vdc

Operating Junction Temperature .....................................-55°C to +150° C

Storage Temperature Range........................................-65° C to +150° C

Power Switch Junction-to-Case Thermal Resistance, Rθ

Package Isolation Voltage .................................................600 Vrms

Lead Soldering Temperature .............300°C, 10 seconds maximum, 0.125” from case

* Tcase = 25° C

** Tcase = 25° C, Maximum pulse width = 10mSec

........................................... 500 Vdc

m pK

................................................... +18 V

jc......................0.48°C/W

RECOMMENDED OPERATING CONDITIONS (Tcase = 25° C)

Motor Power Supply Voltage, Vm ......................................... +270Vdc

Average Phase Output Current, I

With Internal Current Sense Resistor (Note 2)

Each Power Switch .............................................25 A

Control Supply Voltage, V

cc

Logic Low Input Voltage, Vil........................................... 0.8 Vdc (max)

Logic High Input Voltage, Vih........................................... 2.0 Vdc (min)

Note 1: Logic Inputs: Direction, Hall Inputs (H1...H3) Overvoltage - Coast, Speed, and Quad Select.

Note 2: The internal 5mΩ current sense resistor is limited to 6 Wdc power dissipation. Other values are available.

Please contact the factory for more information.

O

............................................ 15Vdc ±10%

2.1 - 3

Page 4

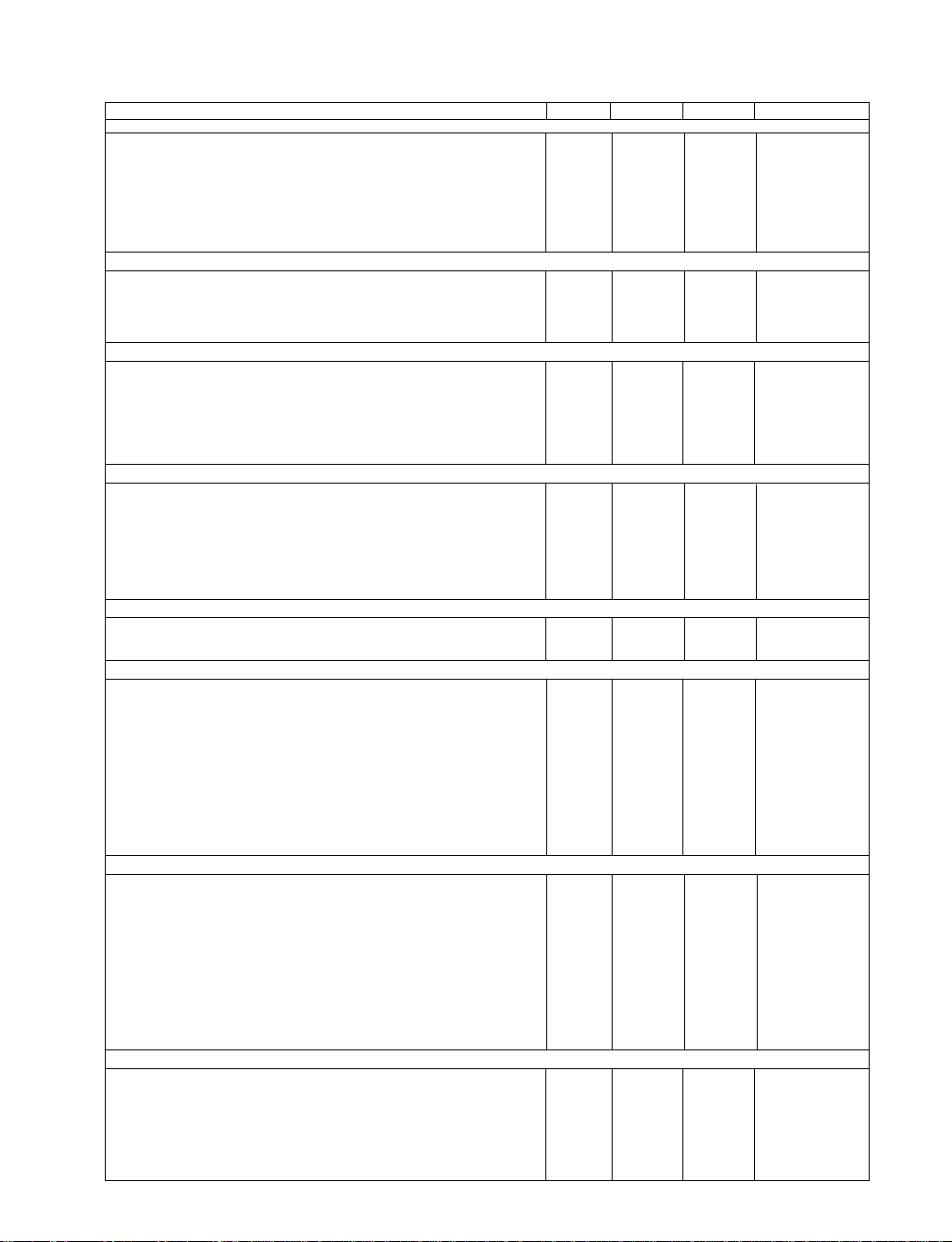

ELECTRICAL CHARACTERISTICS

PARAMETER SYMBOL CONDITIONS (NOTE 1) MIN. TYP. MAX. UNITS

Power Output Section

IGBT Leakage Current I

IGBT c-e Saturation Voltage Vce(sat) Ic = 50Adc 3.2 V

Diode Leakage Current I

Diode Forward Voltage V

Diode Reverse Recovery Time trr Io= 1A, di/dt = -100A/usec, 50 ns

Control Section

Control Supply Current Icc Vcc over operating range 100 mA

Control Turn-On Threshold Vcc(+) Tc over operating range 9.45 V

Driver Turn-On Threshold Vcc(+) Tc over operating range 13.0 V

Reference Section

Output Voltage Vr

Output Voltage Vr

Output Current Io --- --- 30 mA

Load Regulation Iload = 0mA to -20mA -40 -5 mV

Short Circuit Current Isc Tc over operating range 50 100 150 mA

Error Amplifier / Spare Amplifier Sections

EA1 / EA2 Input Offset Current Ios V(pin 2) = V(pin 4) = 0V -30 -3 0 nA

EA1 / EA2 Input Bias Current Iin V(pin 2) = V(pin 4) = 0V -50 -45 0 nA

Input Offset Voltage Vos 0V < Vcommon-mode < 3V 7 mV

Amplifier Output Voltage Range -- 0 6 V

PWM Comparator Section

PWM Input Current Iin V(pin 9) = 2.5V 0 3.0 30 uA

Current-Sense Amplifier Section

ISH / ISL Input Current Iin V(pin 12) = V(pin 13) = 0V -850 -320 0 uA

Input Offset Current Ios V(pin 12) = V(pin 13) = 0V +/-2 +/-12 uA

Peak Current Threshold Voltage Vpk V(pin 12) = 0V, V(pin 13) 0.14 0.20 0.26 V

Over Current Threshold Voltage Voc V(pin 12) = 0V, V(pin 13) 0.26 0.30 0.36 V

ISH / ISL Input Voltage Range -- (Note 2) -1 2 V

Amplifier Voltage Gain Av V(pin 12) = 0.3V, V(pin 13) 1.75 1.95 2.15 V/V

Amplifier Level Shift -- V(pin 12) = V(pin13) = 0.3V 2.4 2.5 2.65 V

Logic Input Section

H1, H2, H3 Low Voltage Threshold Vil Tc over operating range 0.8 1.0 1.2 V

H1, H2, H3 High Voltage Threshold Vih Tc over operating range 1.6 1.9 2.0 V

H1, H2, H3 Input Current Iin Tc over operating range, -400 -250 -120 uA

Quad Select / Direction

Threshold Voltage Vth Tc over operating range 0.8 1.4 2.0 V

Quad Select Voltage Hysteresis Vh 70 mV

Direction Voltage Hysteresis Vh 0.6 V

Quad Select Input Current Iin -30 50 150 uA

Direction Input Current Iin -30 -1 30 uA

Overvoltage / Coast Input Section

Overvoltage / Coast Inhibit

Threshold Voltage Vth Tc over operating range 1.65 1.75 1.85 V

Overvoltage / Coast Restart

Threshold Voltage Vth Tc over operating range 1.55 1.65 1.75 V

Overvoltage / Coast Hysteresis Voltage Vh 0.05 0.10 0.15 V

Overvoltage / Coast Input Current Iin -10 -1 0 uA

ces

r

ef

ef

Vce = 600Vdc 300 uA

V

= 0V

ge

V

= 15V

ge

Vr= 600Vdc 100 uA

If= 37A 1.7 V

f

Vr = 30V

Tc over operating range 4.7 5.0 5.3 V

V(pin 3) = V(pin 6) = 0V

V(pin 3) = V(pin 6) = 0V

Varied to Threshold

Varied to Threshold

= 0.5V to 0.7V

V(pin 20, 21 or 22) = 0Vdc

4.9 5.0 5.1 V

2.1 - 4

OM9369

Page 5

OM9369

Parameter Symbol Conditions (Note 1) MIN. TYP. MAX. Units

Soft-Start Section

Soft-Start Pull-Up Current Ip V(pin) 18) = 0V -16 -10 -5 uA

Soft-Start Discharge Current Id V(pin 18) = 2.5V 0.1 0.4 3.0 mA

Soft-Start Reset Threshold Voltage Vth 0.1 0.2 0.3 V

Tachometer/Brake Section

Tachometer Output High Level Voh

Tachometer Output Low Level Vol

Tachometer On-Time ton 85 100 140 us

Tachometer On-Time Variation -Brake/Tach Timing Input Current Iin V (pin 16) = 0V -4.0 -1.9 mA

Brake/Tach Timing

Threshold Voltage Vth

Brake/Tach Timing

Voltage Hysteresis Vh 0.09 V

Speed Input Threshold Voltage Vth Tc over operating range 220 257 290 mV

Speed Input Current Iin -30 -5 30 uA

Oscillator Section

Oscillator Frequency fo Measured at pin 10 13.5 14.8 20.0 kHz

Tc over operating range 4.7 5.0 5.3 V

(Pin 15) 10kΩ to 2.5 V

Tc over operating range

(Pin 15) 10kΩ to 2.5 V 0.2 V

Tc over operating range 0.1 %

Tc over operating range 0.8 1.0 1.2 V

SPECIFICATION NOTES:

1. All parameters specified for Ta = 25°C, Vcc = 15Vdc, Rosc = 75K

are sourced by (flow from) the pin under test.

2. Either ISH or ISL may be driven over the range shown.

3. Bold parameters tested at -55°C, 25°C, 125°C for SFB.

PINOUT

PIN# NAME PIN# NAME

1 VCC 23 Speed Input

2 EA1 “-” Input 24 Direction Input

3 EA2 “+” Input 25 CSH

4 EA1 “+” Input 26 CSL

5 +5V Reference Output 27 Motor Return

6 EA2 “-” Input 28 Motor Return

7 EA2 Output 29 Source C

8 EA1 Output 30 Source C

9 PWM Input 31 Phase C Output

10 Oscillator Timing Input 32 Phase C Output

11 Isense 33 Vmotor

12 ISH 34 Source B

13 ISL 35 Source B

14 Quad Select Input 36 Phase B Output

15 Tachometer Output 37 Phase B Output

16 Brake/Tach Timing Input 38 Vmotor

17 Overvoltage/Coast Input 39 Source A

18 Soft-Start Input 40 Source A

19 Ground 41 Phase A Output

20 H3 Input 42 Phase A Output

21 H2 Input 43 Vmotor

22 H1 Input (Case) (No Connection)

Ω (to Vref), Cosc = 1800 pF, and all Phase Outputs unloaded (Ta ~ Tj). All negative currents shown

2.1 - 5

Page 6

PIN DESCRIPTIONS / FUNCTIONALITY

VCC (Pin 1) -- The Vcc Supply input provides bias

voltage to all of the internal control electronics within

the OM9369, and should be connected to a nominal

+15Vdc power source. High frequency bypass

capacitors (10uF polarized in parallel with 0.1uF

ceramic are recommended) should be connected as

close as possible to pin 1 and Ground (pin 19).

ERROR AMPLIFIER (EA1- Input, Pin 2; EA1+

Input, Pin 4; EA1 Output, Pin 8) -- The Error

Amplifier is an uncommitted LM158-type operational

amplifier, providing the user with many external

control loop compensation options. This amplifier is

compensated for unity gain stability, so it can be

used as a unity gain input buffer to the internal PWM

comparator when pin 2 is connected to pin 8. The

output of the Error Amplifier is internally connected

to the PWM comparator's "-" input, simplifying

external layout connections.

+5V REFERENCE OUTPUT (Pin 5) -- This output

provides a temperature-compensated, regulated

voltage reference for critical external loads. It is

recommended that this pin be used to power the

external Hall-effect motor position sensors. By

design, the +5V reference must be in regulation

before the remainder of the control circuitry is

activated. This feature allows the Hall-effect sensors

to become powered and enabled before any Phase

Output is enabled in the OM9369, preventing

damage at turn-on. High-frequency bypass

capacitors (10uF polarized in parallel with 0.1uF

ceramic are recommended) should be connected as

close as possible to pin 5 and Ground (pin 19).

SPARE AMPLIFIER (EA2- Input, Pin 6; EA2+

Input, Pin 3; EA2 Output, Pin 7) -- The Spare

Amplifier is an uncommitted LM158-type operational

amplifier, and in addition to the internal error

amplifier, provides the user with additional external

control loop compensation options. This amplifier is

also compensated for unity gain stability and it can

be used as a unity gain input buffer when pin 6 is

connected to pin 7. If the Spare Amplifier is unused,

pin 3 should be connected to Ground, and pin 6

should be connected to pin 7.

PWM INPUT (Pin 9) -- This pin is connected to the

"+" input of the internal PWM comparator. The PWM

output clears the internal PWM latch, which in turn

commands the Phase Outputs to chop. For voltagemode control systems, pin 9 may be connected to

the Oscillator Timing Input, pin 10.

OSCILLATOR TIMING INPUT (Pin 10) -- The Oscillator

OM9369

Timing Input sets a fixed PWM chopping frequency by

means of an internal resistor (Rosc), whose value is set

to 75kΩ, connected from pin 10 to the +5V Reference

Output, and an internal capacitor (Cosc), whose value

is 1800pF, connected from pin 10 to Ground. In custom

applications, the recommended range of values for

Rosc is 10kΩ to 100kΩ, and for Cosc is 0.001uF to

0.01uF, and the maximum operating frequency should

be kept below 20kHz. The approximate oscillator

frequency is:

2

fo = (Rosc x Cosc)

The voltage waveform on pin 10 is a ramp whose

magnitude is approximately 1.2Vp-p, centered at

approximately 1.6Vdc. In addition to the voltage-mode

PWM control, pin 10 may be used for slope

compensation in current-mode control applications.

ISENSE (Pin 11) -- This pin is connected to the output

of the internal current-sense amplifier. It drives a peakcurrent (cycle-by-cycle) comparator which controls

Phase Output chopping, and a fail-safe current

comparator which, in the event of an output overcurrent

condition, activates the soft-start feature and disables

the Phase Outputs until the overcurrent condition is

removed. The magnitude of the voltage appearing at pin

11 is dependent upon the voltages present at the

current-sense amplifier inputs, ISH and ISL:

V(Isense) = 2.5V + [2 x ABS (ISH - ISL)] [Volts]

CURRENT SENSE INPUTS (ISH, Pin 12; ISL, pin 13)

-- These inputs to the current-sense amplifier are

interchangeable and they can be used as differential

inputs. The differential voltage applied between pins 12

and 13 should be kept below +/-0.5Vdc to avoid

saturation.

QUAD SELECT INPUT (Pin 14) -- This input is used to

set the OM9369 in a half control or full control chopping

regime. When driven with a logic low level, the OM9369

is in the half control mode, whereby only the three lower

(pull-down) power switches associated with the Phase

Outputs are allowed to chop. Alternately, when driven

with a logic high level, the OM9369 is in the full control

mode, where all six power switches (pull-up and pulldown) associated with the Phase Outputs are chopped

by the PWM. During motor braking, changing the logic

state of the Quad Select Input has no effect on the

operation of the OM9369.

[Hz]

2.1 - 6

Page 7

OM9369

TACHOMETER OUTPUT (Pin 15) -- This output

provides a fixed width 5V pulse when any Hall-effect

Input (1, 2 or 3) changes state. The pulse width of the

Tachometer Output is set internally in the OM9369 to

113µs (nominal). The average value of the output

voltage on pin 15 is directly proportional to the motor's

speed, so this output may be used (with an external

averaging filter) as a true tachometer output, and fed

back to the Speed Input (pin 23) to sense the actual

motor speed.

Note: Whenever pin 15 is high, the internal Hall-effect

position latches are inhibited (i.e. "latched"), to reject

noise during the chopping portion of the commutation

cycle, and this makes additional commutations

impossible. This means that in order to prevent false

commutation at a speed less than the desired

maximum speed, the highest speed as observed at

the Tachometer Output should be set above the

expected maximum value.

BRAKE / TACH TIMING INPUT (Pin 16) -- The

Brake/Tach Timing Input is a dual-purpose input.

Internal to the OM9369 are timing components tied

from pin 16 to Ground (a 51kΩ resistor and a 3300pF

capacitor). These components set the minimum pulse

width of the Tachometer Output to 113µs, and this

time may be adjusted using external components,

according to the equation:

T(tach) = 0.67 x (Ct+ 3300pf) x

The recommended range of external resistance (to

Ground) is 15kΩ to ∞, and the range of external

capacitance (to Ground) is 0pF to 0.01uF. With each

Tachometer Output pulse, the capacitor tied to pin 16

is discharged from approximately 3.33V to

approximately 1.67V by an internal timing resistor.

The Brake / Tach Timing Input has another function. If

this pin is pulled below the brake threshold voltage,

the OM9369 will enter the brake mode. The brake

mode is defined as the disabling of all three high-side

(pull-up) drivers associated with the Phase Outputs,

and the enabling of all three low-side (pull-down)

drivers.

OVERVOLTAGE / COAST INPUT (Pin 17) -- This

input may be used as a shutdown or an

enable/disable input to the OM9369. Also, since the

switching inhibit threshold is so tightly defined, this

input can be directly interfaced with a resistive divider

which senses the voltage of the motor supply, Vm, for

overvoltage conditions. A high level (greater than the

inhibit threshold) on pin 17 causes the coast condition

to occur, whereby all Phase Outputs revert to a Hi-Z

state and any motor current which flowed prior to the

Overvoltage / Coast command is commutated via the

power "catch" rectifiers associated with each Phase

Output.

Rt x 51kΩ )(µs)

(

Rt + 51kΩ

SOFT-START INPUT (Pin 18) -- The Soft-Start input is

internally connected to a 10µA (nominal) current source,

the collector of an NPN clamp/discharge transistor, and

a voltage comparator whose soft-start/restart threshold

is 0.2Vdc (nominal). An external capacitor is connected

from this pin to Ground (pin 19). Whenever the Vcc

supply input drops below the turn-on threshold,

approximately 9Vdc, or the sensed current exceeds the

over-current threshold, approximately 0.3V at the current

sense amplifier, the soft-start latch is set. This drives the

NPN clamp transistor which discharges the external softstart capacitor. When the capacitor voltage drops below

the soft-start/restart threshold and a fault condition does

not exist, the soft-start latch is cleared; the soft-start

capacitor charges via the internal current source.

In addition to discharging the soft-start capacitor, the

clamp transistor also clamps the output of the error

amplifier internal to the controller IC, not allowing the

voltage at the output of the error amplifier to exceed the

voltage at pin 18, regardless of the inputs to the amplifier.

This action provides for an orderly motor start-up either

at start-up or when recovering from a fault condition.

GROUND (Pin 19) -- The voltages that control the

OM9369 are referenced with respect to this pin. All

bypass capacitors, timing resistors and capacitors, loop

compensation components, and the Hall-effect filter

capacitors must be referenced as close as possible to

pin 19 for proper circuit operation. Additionally, pin 19

must be connected as close as physically possible to the

Motor Return, pins 27 and 28.

HALL-EFFECT INPUTS (H1, Pin 22; H2, Pin 21; H3,

Pin 20) -- Each input has an internal pull-up resistor to

the +5V Reference. Each input also has an internal

180pF noise filter capacitor to Ground. In order to

minimize the noise which may be coupled from the motor

commutation action to these inputs, it is strongly

recommended that additional external filter capacitors,

whose value is in the range of 2200pF, be connected

from each Hall-Effect Input pin to Ground. Whatever

capacitor value is used, the rise/fall times of each input

must be guaranteed to be less than 20us for proper

tachometer action to occur. Motors with 60 degree

position sensing may be used if one or two of the Halleffect sensor signals is inverted prior to connection to the

Hall-Effect Inputs.

2.1 - 7

Page 8

SPEED INPUT (Pin 23) - This pin is connected to the

“+” input of a voltage comparator, whose threshold is

0.25Vdc. As long as the Speed Input is less than

0.25V, the direction latch is transparent. When the

Speed Input is greater than 0.25V, then the direction

latch inhibits all changes in direction. It is

recommended, especially while operating in the half

control mode, that the Tachometer Output is

connected to the Speed Input via a low-pass filter,

such that the direction latch is transparent only

when the motor is spinning very slowly. In this

case, the motor has too little stored energy to damage

the power devices during direction reversal.

DIRECTION INPUT (Pin 24) - This input is used to

select the motor direction. This input has an internal

protection feature: the logic-level present on the

Direction Input is first loaded into a direction latch, then

shifted through a two-bit shift register before

interfacing with the internal output phase driver logic

decoder. Also, protection circuitry detects when the

input and the output of the direction latch or the 2-bit

shift register are different, and inhibits the Phase

Outputs (i.e. Hi-Z) during those times. This feature

may be used to allow the motor to coast to a safe

speed before a direction reversal takes place. Power

stage cross-conduction (current "shoot-through" from

Vmotor to Ground through simultaneously enabled

pull-up and pull-down drivers) is prevented by the shift

register as it is clocked by the PWM oscillator, so that

a fixed delay of between one and two PWM oscillator

clock cycles occurs. This delay or "dead-time"

guarantees that power-stage cross-conduction will not

occur.

CURRENT SENSE OUTPUTS (CSH, Pin 25; CSL,

Pin 26) - The Current Sense Outputs produce a

differential voltage equal to the motor current times the

sense resistance value (5mΩ nominal). There is an

internal 1000pF filter capacitor across pins 25 and 26,

and two 100Ω series resistors, one between each pin

and each end of the current sense resistor. To

configure the current sense amplifier for cycle-by-cycle

current limiting and/or overcurrent protection, connect

pin 25 to pin 12 (ISH) and pin 26 to pin 13 (ISL).

OM9369

SOURCE (Pins 29, 30, 34, 35, 39 and 40) -- The

source pins form the low-side connection of the pulldown switches associated with each Phase Output.

Because of the switching current capability of the

OM9369, all 6 pins should be externally connected

together with a low impedance bus to minimize losses

and voltage differentials. Also, due to layout design

considerations, pins 29 and 30 are internally

connected to the "top" of the internal current-sense

resistor.

PHASE OUTPUTS (Phase A, Pins 41 and 42; Phase

B, Pins 36 and 37; Phase C, Pins 31 and 32) --

These outputs are connected to either Vmotor via the

pull-up driver or Source via the pull-down driver,

depending upon the Hall-Effect and Direction Inputs

(see Commutation Truth Table). The two pins

associated with each Phase Output must be

connected to one of the three phases of the motor

driven by the OM9369.

V

MOTOR

connected to the most positive terminal of the motor

supply (Vm+). For proper operation, all three pins

must be connected together externally with a low

impedance power bus. The V

be bypassed with an adequately voltage-rated

ceramic capacitor, 0.1µF (typical), and a low-ESR

electrolytic capacitor, whose capacitance value can be

selected by the following: 10µF-per-Ampere of

average motor current from V

Note: All connections, including the power bus

capacitor connections, must be made as close as

possible to the V

minimize parasitic effects.

PACKAGE AND SCREENING OPTIONS

The OM9369 is offered in a hermetic flatpack package

as well as a plastic ring frame, low profile flatpack

package. The hermetic package, F-43, is shown in

Figure 1. The plastic ring frame, low profile package,

MP3-43L, has slightly larger dimensions and is shown

in Figure 2.

(Pins 33, 38, and 43) - These pins are

power bus should

motor

to Motor Return.

motor

and Motor Return pins to

motor

MOTOR RETURN (Pins 27 and 28) - These pins are

connected to the most negative terminal of the motor

supply (Vm-). This connection is electrically isolated

from the logic Ground internal to the OM9369 package

to minimize, if not eliminate, noise on the logic ground.

The connection to the logic ground is made by the user

external to the package (refer to Ground (pin 19)). In

order to minimize packaging losses and parasitic

effects, it is essential that both of these pins be firmly

connected to the motor supply Ground, with as short a

connection as physically possible.

The hermetic version is offered in two standard

screening levels: a full military temperature range of 55°C to +125°C with limited screening and with MILSTD-883 screening. The plastic ring frame version is

offered in an industrial temperature range of -40°C to

+85°C with limited screening.

The screening levels for the SFB, SF and SPP

versions are listed in the table below. All tests and

inspections are in accordance with those listed in MILSTD-883.

2.1 - 8

Page 9

OM9369

Test/Inspection SFB SF SPP

Precap Visual Inspection 100% 100% 100%

Temperature Cycle 100% N.A. N.A.

Mechanical Shock 100% N.A. N.A.

Hermeticity (Fine and Gross Leak) 100% 100% N.A.

Pre Burn-In Electrical 100% N.A. N.A.

Burn-In (160 hours) 100% N.A. N.A.

Final Electrical Test -55°C, +25°C, +25°C +25°C

+125°C

Group A Testing 100% N.A. N.A.

Final Visual Inspection 100% 100% 100%

APPLICATIONS

Start-Up Conditions

The OM9369 3-phase brushless DC motor

controller/driver is designed to drive fractional to

integral horsepower motors. To ensure proper

operation, it is necessary to ensure that the high-side

bootstrap capacitors are charged during initial startup. However, the method(s) used to ensure this may

be dependent upon the application. For example,

some applications may only require that OV_COAST

(pin 17) be connected to ground, either via a hardwire

connection or via a switch (Enable/Disable), before

applying Vcc. When Vcc is applied, the

controller/driver is forced into brake mode for

approximately 200µsec (all high-side drivers are

disabled and all low-side drivers are enabled).

This may not be adequate for other applications;

RC_BRAKE (pin 16) may have to be momentarily

connected to ground via a switch, either manually or

electronically (ref. Figure 3). Note that with the

component values shown in Figure 3, RC_BRAKE is

pulled low for approximately 300 mSec after applying

Vcc at pin1.

Modes of Operation

Figures 4 and 5, shown on the following pages,

provide schematic representations of typical voltagemode and current-mode applications for the OM9369

controller/driver.

Figure 4 represents the implementation of a typical

voltage-mode controller for velocity control. Avoltage

or speed command is applied to the noninverting input

of the error amplifier which is configured as a voltage

follower. The output of the error amplifier is compared

to a pulse width modulated ramp, and since motor

speed is nearly proportional to the average phase

output voltage, the speed is controlled via duty cycle

control. If a speed feedback loop is required, the

tachometer output can be connected to the inverting

input of the error amplifier via a loop compensation

network.

Figure 4 also shows the implementation of the cycleby-cycle current limit/overcurrent protection feature of

the OM9369. The load current is monitored via the

controller’s internal sense resistor. The current sense

signal is filtered and fed into the current sense amplifier

where the absolute value of ISH-ISLis multiplied by two

and biased up by 2.5 volts. The output of the current

sense amplifier is compared to a fixed reference, thus

providing cycle-by-cycle current limiting and/or

overcurrent protection as necessary. The typical peak

current threshold (ISH-ISL) is 0.20 volts; the typical

over current threshold (ISH-ISL) is 0.30 volts.

Figure 5 represents the implementation of a typical

current-mode controller for torque control. The load

current is monitored via the controller’s internal sense

resistor. The current sense signal is filtered and fed

into the current sense amplifier where the absolute

value of ISH-ISL is multiplied by two and biased up by

2.5 volts. Besides the implementation of the cycle-bycycle current limit/overcurrent protection feature of the

OM9369 discussed in the preceding paragraph, the

output of the current sense amplifier is fed into the error

amplifier which is configured as a differential amplifier.

An error signal representing the difference between the

current command input and the value of the amplified

current sense signal is produced. Then it is compared

to a pulse width modulated ramp and since torque is

nearly proportional to the average phase output

current, the torque is controlled via duty cycle control.

2.1 - 9

Page 10

MECHANICAL OUTLINE

3.100

2.850

.30

25 x .100

Tol. Non-Cumulative

.125 .250

2.50

TYP.

•Pin1

.130

REF.

2.100

1.860

1.600

.128 DIA.

4 HOLES

.250

TYP.

16 x .150

Tol. Non-Cumulative

OM9369

2.40

.350

.385

MAX.

.125

TYP.

.020

DIA.

.500

.750

.050

.040

DIA.

Fig 1: Mechanical Outline F-43 Hermetic Package

Fig 2: Mechanical Outline MP3-43L Plastic Ring Frame Package

2.1 - 10

Page 11

Fig 3: Optional Start-Up Circuit

OM9369

+15V

3.24k

COMMAND

1k

1.50k

FROM MOTOR HALL SENSORS

H3

H2

H1

10uF

4700pF

.1uF

+

1

Vcc

2

EA1-

3

EA2+

4

EA1+

5

VREF

6

EA2-

7

EA2_OUT

8

EA1_OUT

9

PWM_IN

10

OSCILLATOR

11

I_SENSE

12

ISH

13

ISL

14

.1uF

10k

.1uF

232

232

15

16

17

18

19

20

21

22

23

24

25

26

QUAD_SEL

TACH_OUT

BRAKE

OV_COAST

SOFT_START

GROUND

H3_HALL_INPUT

H2_HALL_INPUT

H1_HALL_INPUT

SPEED_IN

DIRECTION

CSH

CSL

PHASE_A_OUT

PHASE_A_OUT

PHASE_B_OUT

PHASE_B_OUT

PHASE_C_OUT

PHASE_C_OUT

MOTOR_RETURN

MOTOR_RETURN

V_MOTOR

SOURCE_A

SOURCE_A

V_MOTOR

SOURCE_B

SOURCE_B

V_MOTOR

SOURCE_C

SOURCE_C

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

C_BUS

Fig 4: Implementation of a Voltage-Mode Controller

C_FILT

+

HALL SENSORS

V_MOTOR

H1

H2

H3

MOTOR

2.1 - 11

Page 12

CURRENT_COMMAND

205 Crawford Street, Leominster, MA 01 453 USA (978) 534-5776 FAX (978) 537-4246

Visit Our Web Site at www.omnirel.com

+15V

3.24k

OM9369

.1uF10uF

+

1k

OFFSET

3.24k

MOTOR HALL SENSORS

H3

H2

H1

35.6k

.26uF

1800pF

43k

4700pF

2k

10k.1uF

.1uF

232

232

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Vcc

EA1EA2+

EA1+

VREF

EA2EA2_OUT

EA1_OUT

PWM_IN

OSCILLATOR

I_SENSE

ISH

ISL

QUAD_SEL

TACH_OUT

BRAKE

OV_COAST

SOFT_START

GROUND

H3_HALL_INPUT

H2_HALL_INPUT

H1_HALL_INPUT

SPEED_IN

DIRECTION

CSH

CSL

V_MOTOR

PHASE_A_OUT

PHASE_A_OUT

SOURCE_A

SOURCE_A

V_MOTOR

PHASE_B_OUT

PHASE_B_OUT

SOURCE_B

SOURCE_B

V_MOTOR

PHASE_C_OUT

PHASE_C_OUT

SOURCE_C

SOURCE_C

MOTOR_RETURN

MOTOR_RETURN

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

C_BUS

Fig 5: Implementation of a Current-Mode Controller

C_FILT

+

HALL SENSORS

V_MOTOR

H1

H2

H3

MOTOR

2.1 - 12

Loading...

Loading...