Page 1

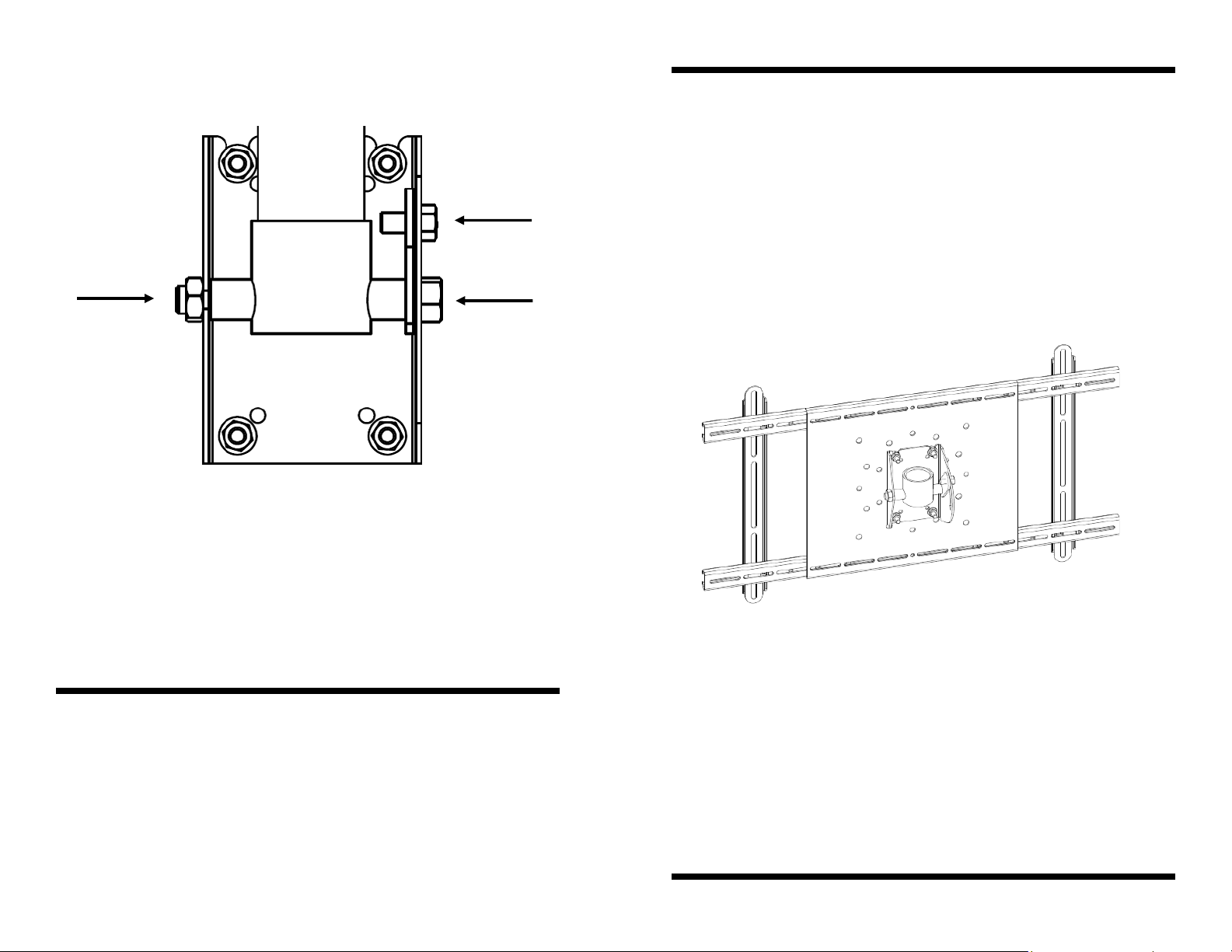

Step 10 — Adjusting Tilt

Installation Instructions

C.

B. A.

To adjust tilt

1. Hold A with 3/4” Socket

2. Loosen B with 3/4” Socket

3. Loosen C with 9/16” Socket

4. Position Display

5. Tighten A,B, & C

TPUM-1: Tilting Pipe Adapter

Specifications are subject to change without prior notice.

Every effort has been made to provide accurate and error-free assembly and installation. OmniMount Systems disclaims liability for any difficulties arising from the interpretation of information

contained in these instructions. If OmniMount products are used for purposes other than their

original intent, OmniMount, its distributors and retailers shall not be held responsible or liable for

injuries or property damage, direct, indirect, or consequential, which may arise from the inability

to use this product safely, properly, and in the manner for which it has been designed and manufactured. Warranty does not apply to products which have been lost, damaged by misuse, abuse, or

accident.

PN —9/05

12

• Designed for 26” - 55” Flat Panel TV’s

• Maximum Weight Capacity: 175 lbs. (79.4 Kg)

• Connects to 1.5” NPT Pipe

Page 2

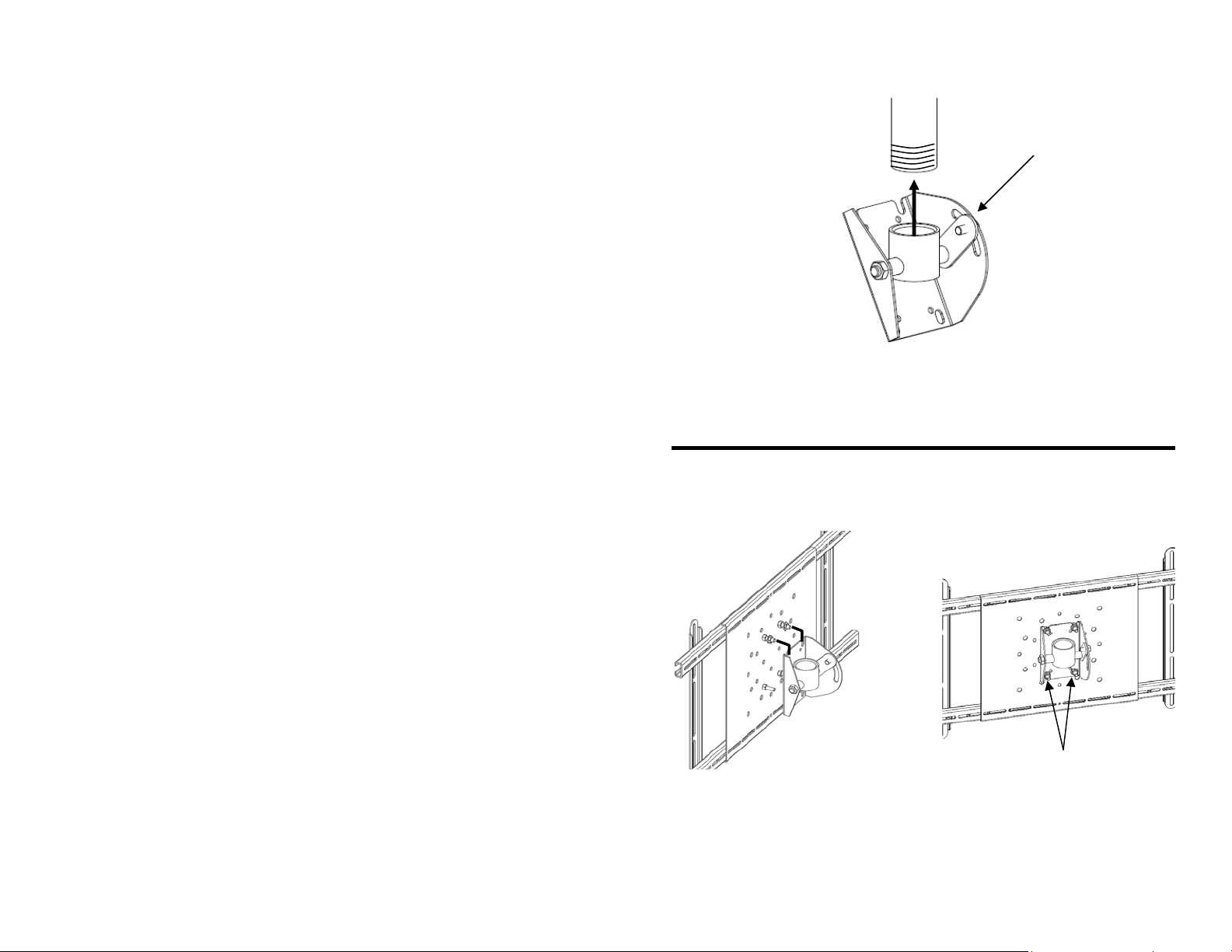

Step 8 — Attaching the Tilt-PA to the Pipe

Tighten Here

1. Thread and tighten Tilting Pipe Adapter onto 1.5” NPT Pipe (not included).

2. Tighten Tilt Tension Nut before attaching Adapter.

Step 9 — Attaching the Adapter and Display to the Pipe Adapter

Note: Pipe removed for clarity

4.

3. Align the space between the

top Nuts with the grooves in the

Tilting Pipe Adapter and gently

lower the Adapter.

4. Thread the last Nylock Nuts (2)

onto the bottom two Stud Screws.

5. Securely tighten all Nylock Nuts

2 11

Page 3

Step 7 — Attaching the UM1 to the Display

Spacer

(if needed)

Mounting

Screw

Display

Back

Plate

Required Tools:

Ratchet and 5/16” Deep Socket

or

5/16” Open Wrench

or

Adjustable Spanner Wrench

Square

Washer

Large Universal Adapter Component Guide

Extended Rails

1. Thread Mounting Screw through Square Washer, Rail, Spacer (if needed),

and into the Display’s Mounting Holes.

NOTE: Ensure Retaining Screws are loose enough to allow for adjustment

2. Center the Back Plate on the Display and securely tighten the Retaining

Screws and Mounting Screws

Important

DO NOT over tighten the mounting screws, or the display may be damaged.

NEVER use a power driver to tighten the mounting screws.

10

Channel

Back Plate

Standard Rails

3

Page 4

Parts List

Step 5 — Secure Sliders and Back Plate (continued)

ID Description Qty

A Philips Screws M4 x 16mm 4

B Philips Screws M4 x 36mm 4

C Philips Screws M4 x 45mm 4

D Philips Screws M5 x 16mm 4

E Philips Screws M5 x 36mm 4

F Philips Screws M5 x 46mm 4

G Philips Screws M6 x 16mm 4

H Philips Screws M6 x 36mm 4

I Philips Screws M6 x 46mm 4

J Philips Screws M8 x 16mm 4

K Philips Screws M8 x 36mm 4

L Philips Screws M8 x 46mm 4

M 5/8" Urethane Spacer 4

N 3/4" Urethane Spacer 4

Description Qty

NOTE: The outer corners

of the Back Plate must always be secured. Some

wide Displays will require

the installation of a 6mm

Screw and 6mm Lock Nut

(not included) to secure the

Back Plate.

Step 6 — Hardware Selection

Consult the supplied Hardware Cross Reference list, and locate the appropriate

mounting screws (A-L) for your display

Spacers

Some displays will require the use of a spacer.

There are two spacers provided:

5/8” (16 mm) round nose spacer (M)

3/4” (19 mm) block spacer (N)

6mm x 12mm Screws 8

Square Washer 4

Small Hex Wrench 1

Stud Screws 4

5/16" Flange Nuts 4

5/16" Nylock Jam Nuts 4

Large Hex Wrench 1

4

Flange Nut

The spacers may be used individually, or may be snapped together to create

one large stacked spacer. The spacers have been designed to snap directly into

the mounting rail for ease in handling, and also include two different mounting

holes to manage the various screw sizes.

Nylock Jam Nut

Generally, the 5/8” Spacer (M) is used on displays with slightly curved backs

and/or recessed mounting lands. The 3/4” Spacer (N) is used on displays with

curved backs, and Stacked Spacers (M&N) will be used on displays with

deeply curved backs and/or protruding accessories.

9

Page 5

Step 4 — Rail Installation

Step 1 — Set Studs in UM-1

Standard Configuration

Step 5 — Secure Sliders and Back Plate

1. Set Rails to horizontal distance between Mounting Holes on Display.

Narrow Configuration

Insert Stud

Screws Here

1. Insert Stud Screws (4) into front of Adapter.

2. Loosely thread Slider Retaining Screws through Channels into Sliders

8

2. Thread Flange Nuts (4)

onto Stud Screws and tighten

using a 5/16” Socket.

3. Thread Nylock Nut (2) onto the

two top Stud Screws leaving space

between Nylock and Flange Nuts.

5

Page 6

Step 2 — Determine Rail Selection

Step 3 — Determine Width Configuration

Measure the vertical distance between

Mounting Holes on Display.

If distance is greater than 19” (48cm)

use the supplied Extended Rails.

Extended Rail Installation

(only if required)

1. Using the Small Hex Wrench

unscrew the Slider Retaining

Screws (8).

2. Pull to remove the Standard

Rail and attached Sliders.

Measure the horizontal distance between

Mounting Holes on Display.

See below for Width Configuration details.

Prior to adjustment, loosen Slider Retaining Screws.

Standard Configuration

Slider

Retaining

Screws

Range: 15 ¾” (40cm) to 38 ½” (98cm)

3. Using the Small Hex Wrench unscrew the Rail Retaining Screws (4)

and remove the Standard Rail.

4. Replace with the Extended Rail,

insert the Rail Retaining Screws and

tighten.

6

Rail

Retaining

Screws

Slider

Rail Retaining

Screw Holes

Rail

Narrow Configuration

Range: 3 ½” (9cm) to 15 ½” (39cm)

7

Loading...

Loading...