Page 1

www.omega.com

e-mail: info@omega.com

User’s Guide

OME-PCI-1602

PCI Data Acquisition Board

Windows Software Manual

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

Table of Contents

1. INTRODUCTION ..........................................................................................................................5

1.1 SOFTWARE INSTALLATION ......................................................................................................6

1.2 REFERENCE: ............................................................................................................................7

2. DECLARATION FILES................................................................................................................8

2.1 THE P1602.H ...........................................................................................................................8

2.2 THE P1602.BAS....................................................................................................................12

2.3 THE P1602.PAS ....................................................................................................................16

2.4 LABVIEW CALL DLLS.........................................................................................................22

2.5 DEMO PROGRAM ...................................................................................................................24

3. DESCRIPTION OF FUNCTIONS..............................................................................................29

3.1 THE CONFIGURATION CODE TABLE ......................................................................................31

3.2 THE TEST FUNCTIONS ...........................................................................................................32

3.2.1 P1602_FloatSub2.........................................................................................................32

3.2.2 P1602_ShortSub2.........................................................................................................32

3.2.3 P1602_GetDllVersion...................................................................................................33

3.2.4 P1602_GetDriverVersion.............................................................................................33

3.3 THE M_FUNCTIONS ............................................................................................................34

3.3.1 P1602_M_FUN_1 .........................................................................................................34

3.3.2 P1602_M_FUN_2..........................................................................................................35

3.3.3 P1602_M_FUN_3 .........................................................................................................36

3.4 THE DIO FUNCTIONS ..........................................................................................................38

3.4.1 P1602_Di........................................................................................................................38

3.4.2 P1602_Do.......................................................................................................................38

3.5 THE D/A FUNCTIONS ..........................................................................................................39

3.5.1 P1602_Da.....................................................................................................................39

3.6 THE A/D FIXED-MODE FUNCTIONS.......................................................................................40

3.6.1 P1602_SetChannelConfig ............................................................................................40

3.6.2 P1602_AdPolling .........................................................................................................40

3.6.3 P1602_AdsPolling........................................................................................................41

3.6.4 P1602_AdsPacer..........................................................................................................42

3.7 THE MAGICSCAN FUNCTIONS .............................................................................................43

3.7.1 P1602_ClearScan.........................................................................................................43

3.7.2 P1602_StartScan..........................................................................................................44

3.7.3 P1602_ReadScanStatus................................................................................................45

3

Page 4

3.7.4 P1602_AddToScan...........................................................................................................46

3.7.5 P1602_SaveScan ..........................................................................................................47

3.7.6 P1602_WaitMagicScanFinish ......................................................................................48

3.8 THE PULG&PLAY FUNCTIONS.............................................................................................49

3.8.1 P1602_DriverInit..........................................................................................................49

3.8.2 P1602_DriverClose......................................................................................................49

3.8.3 P1602_GetConfigAddressSpace...................................................................................50

3.8.4 P1602_WhichBoardActive............................................................................................50

3.8.5 P1602_ActiveBoard......................................................................................................51

3.9 MULTIBOARD BATCH CAPTURE ............................................................................................52

3.9.1 P1602_FunA_Start.......................................................................................................52

3.9.2 P1602_FunA_ReadStatus.............................................................................................54

3.9.3 P1602_FunA_Stop........................................................................................................55

3.9.4 P1602_FunA_Get.........................................................................................................55

3.10 THE SINGLE BOARD BATCH CAPTURE ...................................................................................56

3.10.1 P1602_FunB_Start......................................................................................................56

3.10.2 P1602_FunB_ReadStatus............................................................................................57

3.10.3 P1602_FunB_Stop.......................................................................................................58

3.10.4 P1602_FunB_Get........................................................................................................58

THE CONTINUOUS CAPTURE FUNCTIONS..............................................................................................59

3.10.5 P1602_Card0_StartScan...........................................................................................59

3.10.6 P1602_Card0_ReadStatus.........................................................................................60

3.10.7 P1602_Card0_Stop....................................................................................................60

3.10.8 P1602_Card1_StartScan...........................................................................................61

3.10.9 P1602_Card1_ReadStatus.........................................................................................62

3.10.10 P1602_Card1_Stop....................................................................................................62

3.11 OTHER FUNCTIONS................................................................................................................63

3.11.1 P1602_DelayUs.........................................................................................................63

4. DEMO PROGRAMS....................................................................................................................64

4

Page 5

1. Introduction

The driver is a collection of DLLs for Windows 95/98/NT/2000/XP applications.

These DLLs are standard Win32 DLLs (32 bits) and can be called from Visual C/C++,

BC++, Visual BASIC, Delphi, BCB and LabVIEW.

These DLLs can perform a variety of data acquisition operations including:

z Get software version

z Initialization

z Digital Input/Output

z A/D conversion

z D/A conversion

5

Page 6

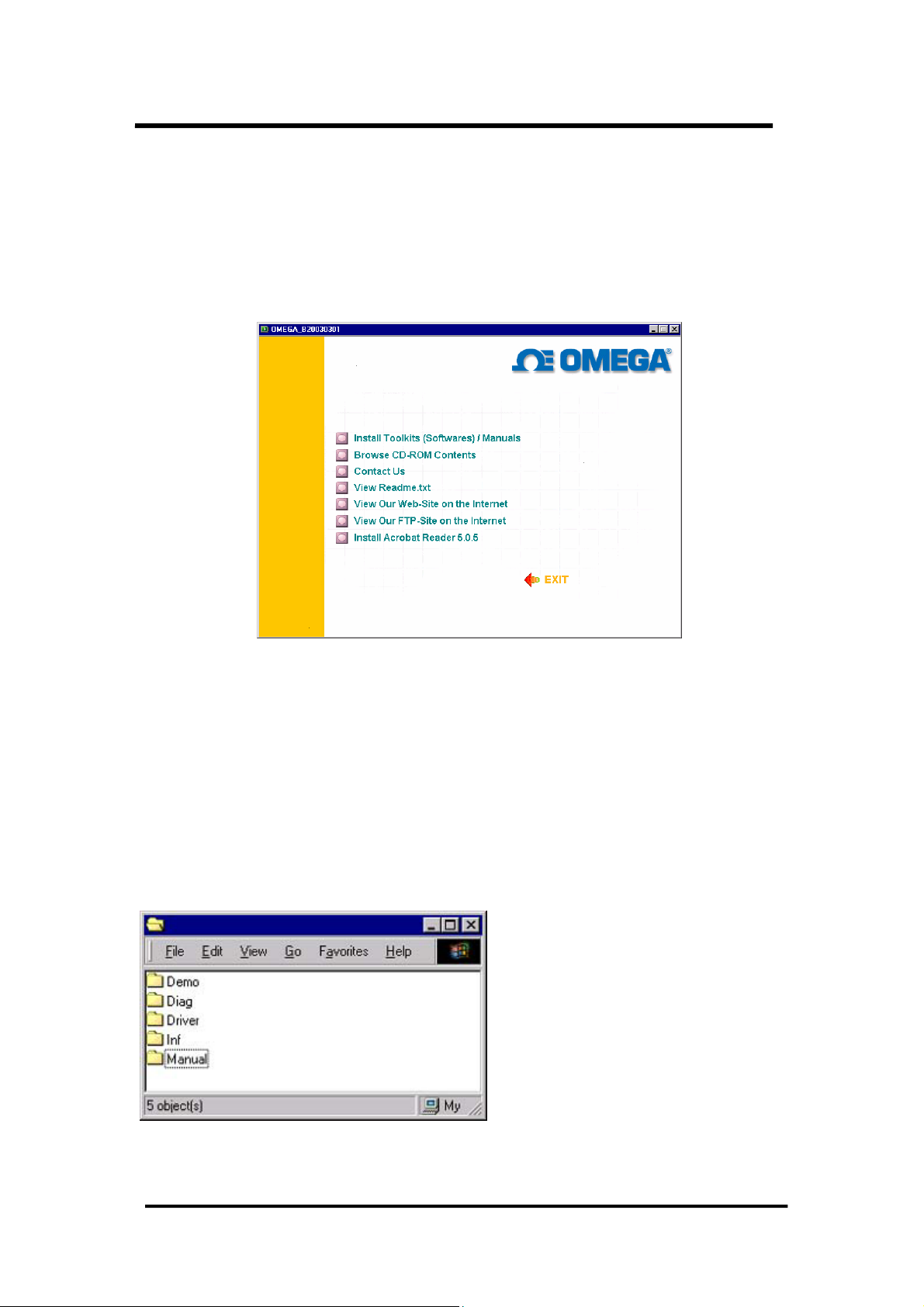

1.1 Software Installation

Insert the CD ROM included with your OME-PCI-1602 board and the following

installation screen should auto-start.

Follow the instructions on the screen to complete the software installation. The

software is designed to support the entire OME family of data acquisition hardware, so

during the installation, you will be asked to specify your particular hardware (OME-

PCI-1602 board in this case). During the installation process, you will also be

prompted to enter the operating system you will be using.

After installation the following folders will be created on your computer.

6

Page 7

Demo Folder

Contains all demonstration programs including their source codes. Examples are

provided for Visual C++, Borland C++, Visual Basic and Delphi.

Please note: The VC++ demos are developed with VC++ 4.0. After setting up the

environment, use NMAKE.EXE to compiling and link the demo code. For example,

C:\P1602\DEMO\VC\nmake /f demo1.mak

Driver Folder

Contains software drivers, include files and definition files for the programming

languages.

Manual Folder

Contains hardware user manuals, software user manuals and technical notes.

Diag Folder

Contains card diagnostic programs

Inf Folder

Contains tech notes and .INF file for the plug and play installation (only available for

operating systems that support plug and play).

1.2 Reference:

Please refer to the following user manuals for more information.

CallDll.pdf:

Calling the DLL with VB5, VC5, Delphi3, and BCB3.

ResCheck.pdf:

How to check the system resources.(IRQ, IO Port, and DMA)

PnPInstall.pdf:

Installing the information file (.inf ) under Windows 95/98/2000/XP with Plug & Play.

SoftInst.pdf:

Installing the software driver (package).

7

Page 8

2. Declaration files

2.1 The P1602.h

#define EXPORTS extern "C" __declspec (dllimport)

//#define EXPORTS

// return code

#define NoError 0

#define DriverHandleError 1

#define DriverCallError 2

#define AdControllerError 3

#define M_FunExecError 4

#define ConfigCodeError 5

#define FrequencyComputeError 6

#define HighAlarm 7

#define LowAlarm 8

#define AdPollingTimeOut 9

#define AlarmTypeError 10

#define FindBoardError 11

#define AdChannelError 12

#define DaChannelError 13

#define InvalidDelay 14

#define DelayTimeOut 15

#define InvalidData 16

#define FifoOverflow 17

#define TimeOut 18

#define ExceedBoardNumber 19

#define NotFoundBoard 20

#define OpenError 21

#define FindTwoBoardError 22

#define ThreadCreateError 23

#define StopError 24

#define AllocateMemoryError 25

8

Page 9

EXPORTS float CALLBACK P1602_FloatSub2(float fA, float fB);

EXPORTS short CALLBACK P1602_ShortSub2(short nA, short nB);

EXPORTS WORD CALLBACK P1602_GetDllVersion(void);

EXPORTS WORD CALLBACK P1602_DriverInit(WORD *wTotalBoards);

EXPORTS void CALLBACK P1602_DriverClose(void);

EXPORTS WORD CALLBACK P1602_GetDriverVersion(WORD *wVxdVersion);

EXPORTS WORD CALLBACK P1602_GetConfigAddressSpace(WORD

wBoardNo, WORD *wAddrTimer,WORD *wAddrCtrl, WORD *wAddrDio, WORD

*wAddrAdda);

EXPORTS WORD CALLBACK P1602_ActiveBoard( WORD wBoardNo );

EXPORTS WORD CALLBACK P1602_WhichBoardActive(void);

EXPORTS WORD CALLBACK P1602_M_FUN_1(WORD wDaFrequency, WORD

wDaWave, float fDaAmplitude, WORD wAdClock, WORD wAdNumber, WORD

wAdConfig, float fAdBuf[], float fLowAlarm, float fHighAlarm);

EXPORTS WORD CALLBACK P1602_M_FUN_2(WORD wDaNumber, WORD

wDaWave, WORD wDaBuf[], WORD wAdClock, WORD wAdNumber, WORD

wAdConfig, WORD wAdBuf[]);

EXPORTS WORD CALLBACK P1602_M_FUN_3(WORD wDaFrequency, WORD

wDaWave, float fDaAmplitude, WORD wAdClock, WORD wAdNumber, WORD

wChannelStatus[], WORD wAdConfig[], float fAdBuf[], float fLowAlarm, float

fHighAlarm);

EXPORTS WORD CALLBACK P1602_M_FUN_4(WORD wType, WORD

wDaFrequency, WORD wDaWave, float fDaAmplitude, WORD wAdClock, WORD

wAdNumber, WORD wChannelStatus[], WORD wAdConfig[], float fAdBuf[], float

fLowAlarm, float fHighAlarm);

EXPORTS WORD CALLBACK P1602_Di(WORD *wDi);

EXPORTS WORD CALLBACK P1602_Do(WORD wDo);

EXPORTS WORD CALLBACK P1602_Da(WORD wDaChannel, WORD wDaVal);

EXPORTS WORD CALLBACK P1602_SetChannelConfig(WORD wAdChannel,

9

Page 10

WORD wConfig);

EXPORTS WORD CALLBACK P1602_AdPolling(float *fAdVal);

EXPORTS WORD CALLBACK P1602_AdsPolling(float fAdVal[], WORD wNum);

EXPORTS WORD CALLBACK P1602_AdsPacer(float fAdVal[], WORD wNum,

WORD wSample);

EXPORTS WORD CALLBACK P1602_ClearScan(void);

EXPORTS WORD CALLBACK P1602_StartScan(WORD wSampleRateDiv,

DWORD dwNum, SHORT nPriority);

EXPORTS void CALLBACK P1602_ReadScanStatus(WORD *wStatus,

DWORD *dwLowAlarm, DWORD *dwHighAlarm);

EXPORTS WORD CALLBACK P1602_AddToScan(WORD wAdChannel, WORD

wConfig, WORD wAverage, WORD wLowAlarm, WORD wHighAlarm, WORD

wAlarmType);

EXPORTS WORD CALLBACK P1602_SaveScan(WORD wAdChannel, WORD

wBuf[]);

EXPORTS void CALLBACK P1602_WaitMagicScanFinish(WORD *wStatus,

DWORD *dwLowAlarm, DWORD *dwHighAlarm);

EXPORTS WORD CALLBACK P1602_StopMagicScan();

EXPORTS WORD CALLBACK P1602_DelayUs(WORD wDelayUs);

EXPORTS WORD CALLBACK P1602_Card0_StartScan(WORD wSampleRate,

WORD wChannelStatus[], WORD wChannelConfig[],WORD wCount);

EXPORTS WORD CALLBACK P1602_Card0_ReadStatus(WORD wBuf[], WORD

wBuf2[], DWORD *dwP1, DWORD *dwP2, WORD *wStatus);

EXPORTS void CALLBACK P1602_Card0_Stop(void);

EXPORTS WORD CALLBACK P1602_Card1_StartScan(WORD wSampleRate,

WORD wChannelStatus[], WORD wChannelConfig[],WORD wCount);

EXPORTS WORD CALLBACK P1602_Card1_ReadStatus(WORD wBuf[], WORD

wBuf2[], DWORD *dwP1, DWORD *dwP2, WORD *wStatus);

EXPORTS void CALLBACK P1602_Card1_Stop(void);

EXPORTS WORD CALLBACK P1602_FunA_Start(WORD wClock0Div, WORD

wChannel0[], WORD wConfig0[], WORD *Buffer0, DWORD dwMaxCount0,

WORD wClock1Div, WORD wChannel1[],WORD wConfig1[], WORD *Buffer1,

10

Page 11

DWORD dwMaxCount1, SHORT nPriority);

EXPORTS WORD CALLBACK P1602_FunA_ReadStatus(void);

EXPORTS WORD CALLBACK P1602_FunA_Stop(void);

EXPORTS WORD CALLBACK P1602_FunA_Get(DWORD *P0, DWORD *P1);

EXPORTS WORD CALLBACK P1602_FunB_Start(WORD wClock0Div, WORD

wChannel0[], WORD wConfig0[], WORD *Buffer0, DWORD dwMaxCount0,

SHORT nPriority);

EXPORTS WORD CALLBACK P1602_FunB_ReadStatus(void);

EXPORTS WORD CALLBACK P1602_FunB_Stop(void);

EXPORTS WORD CALLBACK P1602_FunB_Get(DWORD *P0);

EXPORTS WORD CALLBACK P1602_MemoryStatus(DWORD *dwTotalPhys,

DWORD *dwAvailPhys, DWORD *dwTotalPageFile, DWORD *dwAvailPageFile,

DWORD *dwTotalVirtual, DWORD *dwAvailVirtual);

EXPORTS WORD CALLBACK P1602_AllocateMemory(HGLOBAL *hMem,

WORD *Buffer, DWORD dwSize);

EXPORTS WORD CALLBACK P1602_FreeMemory(HGLOBAL hMem);

EXPORTS WORD CALLBACK P1602_StartScanPostTrg(WORD wSampleRateDiv,

DWORD dwNum, SHORT nPriority);

EXPORTS WORD CALLBACK P1602_StartScanPreTrg(WORD wSampleRateDiv,

DWORD dwNum, SHORT nPriority);

EXPORTS WORD CALLBACK P1602_StartScanMiddleTrg(WORD

wSampleRateDiv, DWORD dwN1, DWORD dwN2, SHORT nPriority);

EXPORTS WORD CALLBACK P1602_StartScanPreTrgVerC(WORD

wSampleRateDiv, DWORD dwNum, SHORT nPriority);

EXPORTS WORD CALLBACK P1602_StartScanMiddleTrgVerC(WORD

wSampleRateDiv, DWORD dwN1, DWORD dwN2, SHORT nPriority);

11

Page 12

2.2 The P1602.BAS

Attribute VB_Name = "P1602"

Option Explicit

Global Const NoError = 0

Global Const DriverHandleError = 1

Global Const DriverCallError = 2

Global Const AdControllerError = 3

Global Const M_FunExecError = 4

Global Const ConfigCodeError = 5

Global Const FrequencyComputeError = 6

Global Const HighAlarm = 7

Global Const LowAlarm = 8

Global Const AdPollingTimeOut = 9

Global Const AlarmTypeError = 10

Global Const FindBoardError = 11

Global Const AdChannelError = 12

Global Const DaChannelError = 13

Global Const InvalidDelay = 14

Global Const DelayTimeOut = 15

Global Const InvalidData = 16

Global Const FifoOverflow = 17

Global Const TimeOut = 18

Global Const ExceedBoardNumber = 19

Global Const NotFoundBoard = 20

Global Const OpenError = 21

Global Const FindTwoBoardError = 22

Global Const ThreadCreateError = 23

Global Const StopError = 24

Global Const AllocateMemoryError = 25

12

Page 13

Declare Function P1602_DriverInit Lib "P1602.dll" (wTotalBoards As Integer) As

Integer

Declare Sub P1602_DriverClose Lib "P1602.dll" ()

Declare Function P1602_GetDriverVersion Lib "P1602.dll" (wVxdVersion As

Integer) As Integer

Declare Function P1602_GetConfigAddressSpace Lib "P1602.dll" (ByVal wBoardNo

As Integer, wAddrTimer As Integer, wAddrCtrl As Integer, wAddrDio As Integer,

wAddrAdda As Integer) As Integer

Declare Function P1602_ActiveBoard Lib "P1602.dll" (ByVal wBoardNo As Integer)

As Integer

Declare Function P1602_WhichBoardActive Lib "P1602.dll" () As Integer

Declare Function P1602_M_FUN_1 Lib "P1602.dll" (ByVal wDaFrequency As

Integer, ByVal wDaWave As Integer, ByVal fDaAmplitude As Single, ByVal

wAdClock As Integer, ByVal wAdNumber As Integer, ByVal wAdConfig As Integer,

fAdBuf As Single, ByVal fLowAlarm As Single, ByVal fHighAlarm As Single) As

Integer

Declare Function P1602_M_FUN_2 Lib "P1602.dll" (ByVal wDaNumber As Integer,

ByVal wDaWave As Integer, wDaBuf As Integer, ByVal wAdClock As Integer,

ByVal wAdNumber As Integer, ByVal wAdConfig As Integer, wAdBuf As Integer)

As Integer

Declare Function P1602_M_FUN_3 Lib "P1602.dll" (ByVal wDaFrequency As

Integer, ByVal wDaWave As Integer, ByVal fDaAmplitude As Single, ByVal

wAdClock As Integer, ByVal wAdNumber As Integer, wChannelStatus As Integer,

wAdConfig As Integer, fAdBuf As Single, ByVal fLowAlarm As Single, ByVal

fHighAlarm As Single) As Integer

Declare Function P1602_M_FUN_4 Lib "P1602.dll" (ByVal wType As Integer,

ByVal wDaFrequency As Integer, ByVal wDaWave As Integer, ByVal fDaAmplitude

As Single, ByVal wAdClock As Integer, ByVal wAdNumber As Integer,

wChannelStatus As Integer, wAdConfig As Integer, fAdBuf As Single, ByVal

fLowAlarm As Single, ByVal fHighAlarm As Single) As Integer

Declare Function P1602_Di Lib "P1602.dll" (wDi As Integer) As Integer

Declare Function P1602_Do Lib "P1602.dll" (ByVal wDo As Integer) As Integer

Declare Function P1602_Da Lib "P1602.dll" (ByVal wDaChannel As Integer, ByVal

wDaVal As Integer) As Integer

Declare Function P1602_SetChannelConfig Lib "P1602.dll" (ByVal wAdChannel As

Integer, ByVal wConfig As Integer) As Integer

Declare Function P1602_AdPolling Lib "P1602.dll" (fAdVal As Single) As Integer

Declare Function P1602_AdsPolling Lib "P1602.dll" (fAdVal As Single, ByVal

13

Page 14

wNum As Integer) As Integer

Declare Function P1602_AdsPacer Lib "P1602.dll" (fAdVal As Single, ByVal wNum

As Integer, ByVal wSample As Integer) As Integer

Declare Function P1602_ClearScan Lib "P1602.dll" () As Integer

Declare Function P1602_StartScan Lib "P1602.dll" (ByVal wSampleRate As Integer,

ByVal dwNum As Long, ByVal nPriority As Integer) As Integer

Declare Sub P1602_ReadScanStatus Lib "P1602.dll" (wStatus As Integer,

dwLowAlarm As Long, dwHighAlarm As Long)

Declare Function P1602_AddToScan Lib "P1602.dll" (ByVal wAdChannel As Integer,

ByVal wConfig As Integer, ByVal wAverage As Integer, ByVal wLowAlarm As

Integer, ByVal wHighAlarm As Integer, ByVal wAlarmType As Integer) As Integer

Declare Function P1602_SaveScan Lib "P1602.dll" (ByVal wOridinalOrder As

Integer, wBuf As Integer) As Integer

Declare Sub P1602_WaitMagicScanFinish Lib "P1602.dll" (wStatus

As Integer, wLowAlarm As Integer, _ wHighAlarm As Integer)

Declare Function P1602_StopMagicScan Lib "P1602.dll" () As Integer

Declare Function P1602_DelayUs Lib "P1602.dll" (ByVal wDelayUs As Integer) As

Integer

'------------------------ FunB series ---------------------------Declare Function P1602_FunB_Start Lib "P1602.dll" (ByVal wClockDiv As Integer,

wChannel As Integer, wConfig As Integer, Buffer As Integer,

ByVal dwMaxCount As Long, ByVal nPriority As Integer) As Integer

Declare Function P1602_FunB_ReadStatus Lib "P1602.dll" () As Integer

Declare Function P1602_FunB_Stop Lib "P1602.dll" () As Integer

Declare Function P1602_FunB_Get Lib "P1602.dll" (P0 As Long) As Integer

Declare Function P1602_Card0_StartScan Lib "P1602.dll" (ByVal wSampleRate As

Integer, wChannelStatus As Integer, wChannelConfig As Integer, ByVal wCount As

Integer) As Integer

Declare Function P1602_Card0_ReadStatus Lib "P1602.dll" (wBuf As Integer, wBuf2

As Integer, dwP1 As Long, dwP2 As Long, wStatus As Integer) As Integer

Declare Sub P1602_Card0_Stop Lib "P1602.dll" ()

Declare Function P1602_Card1_StartScan Lib "P1602.dll" (ByVal wSampleRate As

Integer, wChannelStatus As Integer, wChannelConfig As Integer, ByVal wCount As

Integer) As Integer

Declare Function P1602_Card1_ReadStatus Lib "P1602.dll" (wBuf As Integer, wBuf2

As Integer, dwP1 As Long, dwP2 As Long, wStatus As Integer) As Integer

Declare Sub P1602_Card1_Stop Lib "P1602.dll" ()

Declare Function GetTickCount Lib "kernel32" () As Long

Declare Sub Sleep Lib "kernel32" (ByVal dwMilliseconds As Long)

Global AdBuf(10000) As Single

Global Channel(32) As Integer

Global ConfigCode(32) As Integer

14

Page 15

Global Buf(10000) As Integer

Global Buf1(10000) As Integer

Global Buf2(10000) As Integer

Global Card0Buf0(10000) As Integer

Global Card0Buf1(10000) As Integer

Global Card1Buf0(10000) As Integer

Global Card1Buf1(10000) As Integer

Global AdNumber As Integer

Global CR

Global LF

15

Page 16

2.3 The P1602.PAS

unit P1602;

interface

type PSingle=^Single;

type PWord=^Word;

const

// return code

NoError = 0;

DriverHandleError = 1;

DriverCallError = 2;

AdControllerError = 3;

M_FunExecError = 4;

ConfigCodeError = 5;

FrequencyComputeError = 6;

HighAlarm = 7;

LowAlarm = 8;

AdPollingTimeOut = 9;

AlarmTypeError = 10;

FindBoardError = 11;

AdChannelError = 12;

DaChannelError = 13;

InvalidDelay = 14;

DelayTimeOut = 15;

InvalidData = 16;

FifoOverflow = 17;

TimeOut = 18;

ExceedBoardNumber = 19;

NotFoundBoard = 20;

OpenError = 21;

FindTwoBoardError = 22;

ThreadCreateError = 23;

StopError = 24;

16

Page 17

AllocateMemoryError = 25;

// Function of Test

function P1602_FloatSub2(fA:Single; fB:Single):Single ; stdCall;

function P1602_ShortSub2(nA:SmallInt; nB:SmallInt):SmallInt ; stdCall;

function P1602_GetDllVersion:WORD ; stdCall;

// Function of Driver

function P1602_DriverInit(Var wTotalBoards:Word):WORD ; stdCall;

procedure P1602_DriverClose; stdCall;

function P1602_GetDriverVersion(var wDriverVersion:Word):WORD ; stdCall;

function P1602_GetConfigAddressSpace(wBoardNo:Word;var wAddrTimer:Word;

var wAddrCtrl:Word; var wAddrDio:Word;

var wAddrAdda:Word):WORD ; stdCall;

function P1602_ActiveBoard(wBoardNo:Word):WORD ; stdCall;

function P1602_WhichBoardActive:WORD ; stdCall;

// Function of M_Fun series

function P1602_M_FUN_1(wDaFrequency:WORD; wDaWave:WORD;

fDaAmplitude:Single; wAdClock:WORD; wAdNumber:WORD; wAdConfig:WORD;

fAdBuf:PSingle; fLowAlarm:Single; fHighAlarm:Single):WORD ; stdCall;

function P1602_M_FUN_2(wDaNumber:WORD; wDaWave:WORD;

wDaBuf:PWord; wAdClock:WORD; wAdNumber:WORD; wAdConfig:WORD;

wAdBuf:PWord):WORD ; stdCall;

function P1602_M_FUN_3(wDaFrequency:WORD; wDaWave:WORD;

fDaAmplitude:Single; wAdClock:WORD; wAdNumber:WORD;

wChannelStatus:PWord; wAdConfig:PWord; fAdBuf:PSingle;

fLowAlarm:Single; fHighAlarm:Single):WORD ; stdCall;

function P1602_M_FUN_4(wType:WORD; wDaFrequency:WORD;

wDaWave:WORD; fDaAmplitude:Single; wAdClock:WORD; wAdNumber:WORD;

wChannelStatus:PWord; wAdConfig:PWord; fAdBuf:PSingle; fLowAlarm:Single;

fHighAlarm:Single):WORD ; stdCall;

// Function of DI/DO

17

Page 18

function P1602_Do(wOutData:Word):Word; stdCall;

function P1602_Di(var wDiData:Word):WORD ; stdCall;

// Function of AD/DA

function P1602_Da(wDaChannel:Word; wDaVal:Word):WORD ; stdCall;

function P1602_SetChannelConfig(wAdChannel:Word; wConfig:Word):WORD ;

stdCall;

function P1602_AdPolling(var fAdVal:Single):WORD ; stdCall;

function P1602_AdsPolling(fAdVal:PSingle; wNum:Word):WORD ; stdCall;

function P1602_AdsPacer(fAdVal:PSingle; wNum:Word;

wSamplingDiv:Word ):WORD ; stdCall;

//*******************

function P1602_ClearScan:WORD ; stdCall;

function P1602_StartScan(wSampleRateDiv:WORD; dwNum:LongInt;

nPriority:SmallInt):WORD ; stdCall;

procedure P1602_ReadScanStatus(var wStatus:WORD; var dwLowAlarm:LongInt;

var dwHighAlarm:LongInt); stdCall;

function P1602_AddToScan(wAdChannel:WORD; wConfig:WORD;

wAverage:WORD; wLowAlarm:WORD; wHighAlarm:WORD;

wAlarmType:WORD):WORD ; stdCall;

function P1602_SaveScan(wAdChannel:WORD; wBuf:PWord):WORD ; stdCall;

procedure P1602_WaitMagicScanFinish(var wStatus:WORD; var

dwLowAlarm:LongInt; var dwHighAlarm:LongInt); stdCall;

function P1602_StopMagicScan:WORD ; stdCall;

//*******************

function P1602_DelayUs(wDelayUs:WORD):WORD ; stdCall;

//*******************

//function P1602_Card0_StartScan( wSampleRate:WORD; wChannelStatus:PWORD;

// wChannelConfig:PWORD; wCount:WORD):WORD ; stdCall;

function P1602_Card0_StartScan( wSampleRate:WORD; wChannelStatus:PWORD;

wChannelConfig:PWORD; wCount:WORD):WORD ; stdCall;

function P1602_Card0_ReadStatus(wBuf:PWORD; wBuf2:PWORD;

var dwP1:LongInt; var dwP2:LongInt;

var wStatus:WORD):WORD ; stdCall;

procedure P1602_Card0_Stop; stdCall;

18

Page 19

function P1602_Card1_StartScan(wSampleRate:WORD; wChannelStatus:PWORD;

wChannelConfig:PWORD; wCount:WORD):WORD ; stdCall;

function P1602_Card1_ReadStatus(wBuf:PWORD; wBuf2:PWORD; var

dwP1:LongInt; var dwP2:LongInt; var wStatus:WORD):WORD ; stdCall;

procedure P1602_Card1_Stop; stdCall;

//*******************

function P1602_FunA_Start( wClock0Div:WORD; wChannel0:PWord;

wConfig0:PWord; Buffer0:PWord; dwMaxCount0:LongInt; wClock1Div:WORD;

wChannel1:PWord; wConfig1:PWord; Buffer1:PWord; dwMaxCount1:LongInt;

nPriority:SmallInt):WORD ; stdCall;

function P1602_FunA_ReadStatus:WORD ; stdCall;

function P1602_FunA_Stop:WORD ; stdCall;

function P1602_FunA_Get(var P0:LongInt; var P1:LongInt):WORD ; stdCall;

//*******************

function P1602_FunB_Start( wClock0Div:WORD; wChannel0:PWord;

wConfig0:PWord; Buffer0:PWord; dwMaxCount0:LongInt;

nPriority:SmallInt):WORD ; stdCall;

function P1602_FunB_ReadStatus:WORD ; stdCall;

function P1602_FunB_Stop:WORD ; stdCall;

function P1602_FunB_Get(var P0:LongInt):WORD ; stdCall;

//********************************************************************/

/*********************************************************************

implementation

function P1602_FloatSub2; external 'P1602.DLL' name 'P1602_FloatSub2';

function P1602_ShortSub2; external 'P1602.DLL' name 'P1602_ShortSub2';

function P1602_GetDllVersion; external 'P1602.DLL' name 'P1602_GetDllVersion';

function P1602_GetDriverVersion; external 'P1602.DLL' name

'P1602_GetDriverVersion';

19

Page 20

function P1602_DriverInit; external 'P1602.DLL' name 'P1602_DriverInit';

procedure P1602_DriverClose; external 'P1602.DLL' name 'P1602_DriverClose';

function P1602_GetConfigAddressSpace;

external 'P1602.DLL' name 'P1602_GetConfigAddressSpace';

function P1602_ActiveBoard; external 'P1602.DLL' name 'P1602_ActiveBoard';

function P1602_WhichBoardActive;

external 'P1602.DLL' name 'P1602_WhichBoardActive';

// Function of M_Fun series

function P1602_M_FUN_1; external 'P1602.DLL' name 'P1602_M_FUN_1';

function P1602_M_FUN_2; external 'P1602.DLL' name 'P1602_M_FUN_2';

function P1602_M_FUN_3; external 'P1602.DLL' name 'P1602_M_FUN_3';

function P1602_M_FUN_4; external 'P1602.DLL' name 'P1602_M_FUN_4';

function P1602_Do; external 'P1602.DLL' name 'P1602_Do';

function P1602_Di; external 'P1602.DLL' name 'P1602_Di';

function P1602_Da; external 'P1602.DLL' name 'P1602_Da';

function P1602_SetChannelConfig;

external 'P1602.DLL' name 'P1602_SetChannelConfig';

function P1602_AdPolling; external 'P1602.DLL' name 'P1602_AdPolling';

function P1602_AdsPolling; external 'P1602.DLL' name 'P1602_AdsPolling';

function P1602_AdsPacer; external 'P1602.DLL' name 'P1602_AdsPacer';

//*********************

function P1602_ClearScan; external 'P1602.DLL' name 'P1602_ClearScan';

function P1602_StartScan; external 'P1602.DLL' name 'P1602_StartScan';

procedure P1602_ReadScanStatus; external 'P1602.DLL' name

'P1602_ReadScanStatus';

function P1602_AddToScan; external 'P1602.DLL' name 'P1602_AddToScan';

function P1602_SaveScan; external 'P1602.DLL' name 'P1602_SaveScan';

procedure P1602_WaitMagicScanFinish; external 'P1602.DLL' name

'P1602_WaitMagicScanFinish';

function P1602_StopMagicScan; external 'P1602.DLL' name

'P1602_StopMagicScan';

//*********************

20

Page 21

function P1602_DelayUs; external 'P1602.DLL' name 'P1602_DelayUs';

//*******************

function P1602_Card0_StartScan; external 'P1602.DLL' name

'P1602_Card0_StartScan';

function P1602_Card0_ReadStatus; external 'P1602.DLL' name

'P1602_Card0_ReadStatus';

procedure P1602_Card0_Stop; external 'P1602.DLL' name 'P1602_Card0_Stop';

function P1602_Card1_StartScan; external 'P1602.DLL' name

'P1602_Card1_StartScan';

function P1602_Card1_ReadStatus; external 'P1602.DLL' name

'P1602_Card1_ReadStatus';

procedure P1602_Card1_Stop; external 'P1602.DLL' name 'P1602_Card1_Stop';

//*******************

function P1602_FunA_Start; external 'P1602.DLL' name 'P1602_FunA_Start';

function P1602_FunA_ReadStatus; external 'P1602.DLL' name

'P1602_FunA_ReadStatus';

function P1602_FunA_Stop; external 'P1602.DLL' name 'P1602_FunA_Stop';

function P1602_FunA_Get; external 'P1602.DLL' name 'P1602_FunA_Get';

//*******************

function P1602_FunB_Start; external 'P1602.DLL' name 'P1602_FunB_Start';

function P1602_FunB_ReadStatus; external 'P1602.DLL' name

'P1602_FunB_ReadStatus';

function P1602_FunB_Stop; external 'P1602.DLL' name 'P1602_FunB_Stop';

function P1602_FunB_Get; external 'P1602.DLL' name 'P1602_FunB_Get';

end.

21

Page 22

2.4 LabVIEW Call DLLs

LabVIEW is an industrial graphical programming system developed by National

Instruments. With LabVIEW, the user can quickly design a user interface and

application program as a block diagram.

NAPPCI\Win\VIEW\P1602.Dll Æ DLLs

NAPPCI\Win\VIEW\DEMO1.VI Æ Demo VI

NAPPCI\Win\VIEW\MFUN1.VI Æ Driver VI

NOTE:

1. Tested under Windows 95/98/NT and LabVIEW 4.0

2. The demo1.VI will call MFUN1.VI to perform M_Functions. The M_Functions

can send out an arbitrary waveform to the D/A output port and perform A/D input

at the same time. If you connect D/A channel_0 to A/D channel_0, the

M_Functions can measure the D/A output back. The output response is shown in

Fig 8 and the connecting diagram of demo1.VI is given in Fig. 9.

Fig 8. The output of DEMO1.VI. (call M_FUN_1)

22

Page 23

Fig 9. The connection diagram for DEMO1.VI (call MFUN1.VI)

Fig 10. The connection diagram for MFUN1.VI (call DLL M_FUN_1)

23

Page 24

2.5 Demo Program

A common demo program is used for all P1602.dll examples. The demo program

will accept wDaFreq and wAdClk and call the different driver functions for

demonstration purposes.

#include <windows.h>

#include <stdlib.h>

#include <stdio.h>

#include <conio.h>

#include "P1602.H"

/********************************************************************/

/* DEMO1 program for one P1602 cards in the PC system. */

/* Please set the resolution of your monitor to at least 1024*768 */

/********************************************************************/

/* First Card: some P1602 function call demo. */

/* For the proper operation the P1602, the following functions */

/* must be used. */

/* P1602_DriverInit(); <-- initial the driver */

/* P1602_DriverClose(); <-- close the driver */

/********************************************************************/

short nDMA=-1, nIRQ=-1; // not used

WORD wBase=0x220,wAdBuf[510],wFlag=0,wAddrCtrl;

int iLine;

DWORD dwDaNum=90,dwAdClk=24;

WORD wTotalBoard,wInitialCode;

void READ_CMD(char *);

short ASCII_TO_HEX(char);

void TEST_CMD(HWND, int, int, int, int);

LRESULT CALLBACK WndProc(HWND, UINT, WPARAM, LPARAM);

void SHOW_WAVE(HWND hwnd);

/* ---------------------------------------------------------------- */

int WINAPI WinMain (HINSTANCE hInstance, HINSTANCE hPrevInstance,

PSTR szCmdLine, int iCmdShow)

{

static char szAppName[] = "P1602 Demo1";

HWND hwnd ;

MSG msg ;

WNDCLASSEX wndclass ;

wndclass.cbSize = sizeof(wndclass);

wndclass.style = CS_HREDRAW|CS_VREDRAW;

wndclass.lpfnWndProc = WndProc;

wndclass.cbClsExtra = 0;

wndclass.cbWndExtra = 0;

wndclass.hInstance = hInstance;

wndclass.hIcon = LoadIcon(NULL, IDI_APPLICATION);

wndclass.hCursor = LoadCursor(NULL, IDC_ARROW);

wndclass.hbrBackground = (HBRUSH)GetStockObject(WHITE_BRUSH);

wndclass.lpszMenuName = NULL;

wndclass.lpszClassName = szAppName;

wndclass.hIconSm = LoadIcon(NULL, IDI_APPLICATION);

24

Page 25

RegisterClassEx(&wndclass) ;

hwnd=CreateWindow(szAppName,"P1602 Demo1 Program",

WS_OVERLAPPEDWINDOW,

CW_USEDEFAULT, CW_USEDEFAULT,

CW_USEDEFAULT, CW_USEDEFAULT,

NULL, NULL, hInstance, NULL) ;

ShowWindow(hwnd,SW_SHOWMAXIMIZED);

UpdateWindow(hwnd);

while (GetMessage(&msg, NULL, 0, 0))

{

TranslateMessage(&msg);

DispatchMessage(&msg);

}

return msg.wParam;

}

/* ---------------------------------------------------------------- */

LRESULT CALLBACK WndProc(HWND hwnd, UINT iMsg, WPARAM wParam, LPARAM

lParam)

{

static int cxChar, cyChar, cxClient, cyClient,cxBuffer;

static int cyBuffer, xCaret, yCaret;

static char cBuf[80];

HDC hdc;

TEXTMETRIC tm;

PAINTSTRUCT ps;

int i;

switch (iMsg)

{

case WM_CREATE : // window initial

/**************************************************************/

/* NOTICE: call P1602_DriverInit() to initialize the driver. */

/**************************************************************/

// Initialize the device driver, and return the board number in the PC

wInitialCode=P1602_DriverInit(&wTotalBoard);

if( wInitialCode!=NoError )

{

MessageBox(hwnd,"No P1602 card in this system !!!",

"P1602 Card Error",MB_OK);

}

hdc=GetDC(hwnd);

SelectObject(hdc,GetStockObject(SYSTEM_FIXED_FONT));

GetTextMetrics(hdc, &tm);

cxChar=tm.tmAveCharWidth;

cyChar=tm.tmHeight;

ReleaseDC(hwnd, hdc);

return 0;

case WM_SIZE :

cxClient=LOWORD(lParam); // window size in pixels

cyClient=HIWORD(lParam);

cxBuffer=max(1,cxClient/cxChar); // window size in characters

cyBuffer=max(1,cyClient/cyChar);

return 0;

case WM_SETFOCUS :

CreateCaret(hwnd, NULL, cxChar, cyChar);

SetCaretPos(xCaret * cxChar, yCaret * cyChar);

25

Page 26

ShowCaret(hwnd);

return 0;

case WM_KILLFOCUS :

HideCaret(hwnd);

DestroyCaret();

return 0;

case WM_CHAR : // user press KEYBOARD

for (i = 0 ; i < (int) LOWORD(lParam) ; i++)

{

switch (wParam)

{

case '\b' : // backspace pressed

if (xCaret > 0)

{

xCaret-- ;

cBuf[xCaret]=' ';

HideCaret(hwnd);

hdc=GetDC(hwnd);

SelectObject(hdc,GetStockObject(SYSTEM_FIXED_FONT));

TextOut(hdc, xCaret * cxChar, yCaret *

cyChar,cBuf+xCaret,1);

ShowCaret(hwnd);

ReleaseDC(hwnd, hdc);

}

break;

case '\r' : // carriage return pressed

if (wFlag==1)

{

InvalidRect(hwnd, NULL, TRUE);

wFlag=0;

break;

}

wFlag=1;

cBuf[xCaret]=0;

if (xCaret!=0) {xCaret=0; yCaret++;}

READ_CMD(cBuf);

TEST_CMD(hwnd,xCaret, cxChar, yCaret,cyChar);

xCaret=0; yCaret+=iLine;

if (yCaret >= cyBuffer) InvalidRect(hwnd, NULL, TRUE);

break ;

case '\x1B' : // escape pressed

InvalidRect (hwnd, NULL, TRUE) ;

xCaret=yCaret=0;

break;

default : // other KEY pressed

cBuf[xCaret]=(char) wParam;

HideCaret(hwnd);

hdc=GetDC (hwnd);

SelectObject(hdc,GetStockObject(SYSTEM_FIXED_FONT));

TextOut(hdc,xCaret*cxChar,yCaret*cyChar,cBuf+xCaret,1);

ShowCaret(hwnd);

ReleaseDC(hwnd, hdc);

xCaret++;

break ;

}

}

SetCaretPos(xCaret*cxChar, yCaret*cyChar);

return 0;

case WM_PAINT : // clr and show HELP

InvalidRect(hwnd, NULL, TRUE);

hdc=BeginPaint(hwnd, &ps);

26

Page 27

SelectObject(hdc,GetStockObject(SYSTEM_FIXED_FONT));

sprintf(cBuf,"Press any key to continue");

TextOut(hdc,0,0,cBuf,strlen(cBuf));

xCaret = 0 ; yCaret=1;

SetCaretPos(0,yCaret*cyChar);

EndPaint(hwnd, &ps);

return 0;

case WM_DESTROY :

/**************************************************************/

/* NOTICE: call P1602_DriverClose() to close the driver. */

/**************************************************************/

P1602_DriverClose(); // close the driver

PostQuitMessage(0);

return 0 ;

}

return DefWindowProc(hwnd, iMsg, wParam, lParam);

}

/* -------------------------------------------------------------------

- */

/* [0][1][2][3][4]=wII, [6][7][8][9]=dwAdClk */

void READ_CMD(char szCmd[])

{

DWORD nT1,nT2,nT3,nT4,nT5;

if(szCmd[0]==0) return; // only press [Enter]

nT1=ASCII_TO_HEX(szCmd[0]); // HEX format

nT2=ASCII_TO_HEX(szCmd[1]);

nT3=ASCII_TO_HEX(szCmd[2]);

nT4=ASCII_TO_HEX(szCmd[3]);

nT5=ASCII_TO_HEX(szCmd[4]);

dwDaNum=nT1*10000+nT2*1000+nT3*100+nT4*10+nT5;

nT1=ASCII_TO_HEX(szCmd[6]); // HEX format

nT2=ASCII_TO_HEX(szCmd[7]);

nT3=ASCII_TO_HEX(szCmd[8]);

nT4=ASCII_TO_HEX(szCmd[9]);

dwAdClk=(DWORD)(nT1*1000+nT2*100+nT3*10+nT4);

}

short ASCII_TO_HEX(char cChar)

{

if(cChar<='9') return(cChar-'0');

else if (cChar<='F') return(cChar-'A'+10);

else return(cChar-'a'+10);

}

/* -------------------------------------------------------------------- */

void TEST_CMD(HWND hwnd, int x, int dx, int y, int dy)

{

Test subroutine placed here

27

Page 28

}

The READ_COM only accepts fix format command. The command

format is given as below:

space key

Enter key

0

z if = Æ accept current setting of wDaFreq and wAdClk

demo programs share similar setup code as above. The separate testing functions are

placed in “

placed in TEST_CMD is shown in subsequent listings in this manual.

1 2 3 4 5

wDaFreq

0

The steps to compile and link the demo program are described in Sec. 1.3. All

Enter key

6 7 8 9

wAdClk

10

TEST_CMD(….) { ……….}”. Only the code that would be

28

Page 29

3. Description of Functions

The DLL functions are divided the following groups:

z The Test functions

z The M_Functions function

z The D/I/O functions

z The D/A function

z The A/D fixed-mode functions

z The A/D MagicScan mode functions

z The A/D continuous capture functions

z The A/D batch capture functions

z The Plug & Play functions

z Other functions

•

The functions of the fixed-channel mode are as follows:

1. P1602_SetChannelConfig

2. P1602_AdPoling

3. P1602_AdsPolling

4. P1602_AdsPacer

•

The functions of the MagicScan mode are as follows:

1. P1602_ClearScan

2. P1602_StartScan

3. P1602_AddToScan

4. P1602_SaveScan

5. P1602_ReadMagicScanResult

•

The functions of the M_functions are as follows:

1. P1602_M_FUN_1

data in float format

data in 16 bits HEX format

2. P1602_M_FUN_2

3. P1602_M_FUN_3

29

Page 30

•

The multiboard batch capture functions are as follows:

1. P1602_FunA_Start

2. P1602_FunA_ReadStatus

3. P1602_FunA_Stop

4. P1602_FunA_Get

•

The single board batch capture functions are as follows:

1. P1602_FunB_Start

2. P1602_FunB_ReadStatus

3. P1602_FunB_Stop

4. P1602_FunB_Get

•

The continuous capture functions are as following:

1. P1602_Card0_StartScan

2. P1602_Card0_ReadStatus

3. P1602_Card0_StopScan

4. P1602_Card1_StartScan

5. P1602_Card1_ReadStatus

6. P1602_Card1_StopScan

Group-0: for card_0 continuous capture function

Group-1: for card_1 continuous capture function

30

Page 31

3.1 The Configuration Code Table

OME-PCI-1602 Configuration Code Table

Bipolar/Unipolar Input Signal Range Gain Settling Time Configuration Code

Bipolar +/- 10V 1 10 us 0

Bipolar +/- 5V 2 10 us 1

Bipolar +/- 2.5V 4 10 us 2

Bipolar +/- 1.25V 8 10 us 3

OME-PCI-1602F Configuration Code Table

Bipolar/Unipolar Input Signal Range Gain Settling Time Configuration Code

Bipolar +/- 10V 1 5 us 0

Bipolar +/- 5V 2 5 us 1

Bipolar +/- 2.5V 4 5 us 2

Bipolar +/- 1.25V 8 5 us 3

31

Page 32

3.2 The Test Functions

3.2.1 P1602_FloatSub2

z Description:

Calculates C=A-B in float format, float=4 bytes floating point number. This function is

provided to test DLL linkage.

• Syntax: float P1602_FloatSub2(float fA, float fB);

z Input Parameter :

fA : 4 bytes floating point value

fB : 4 bytes floating point value

z Return Value : return=fA-fB

z Demo Program : DEMO1.C

3.2.2 P1602_ShortSub2

Description :

z

Calculates C=A-B in SHORT formats, SHORT=16 bits signed number.

is provided to test DLL linkage.

• Syntax : short P1602_ShortSub2(Short nA, Short nB);

z Input Parameter :

nA : 16 bits value

This function

nB : 16 bits value

z Return Value : return=nA-nB

z Demo Program : DEMO1.C

32

Page 33

3.2.3 P1602_GetDllVersion

z Description :

Reads the version of the P1602.DLL.

z Syntax : WORD P1602_GetDllVersion(void);

z Input Parameter : void

z Return Value :

return=0x200 Æ Version 2.0

z Demo Program : DEMO1.C

3.2.4 P1602_GetDriverVersion

z Description : This function will read the software version number of

Nappci.VxD for Windows 95/98 or Napwnt.SYS for Windows NT.

z Syntax : WORD P1602_GetDriverVersion(WORD *wDriverVersion);

Input Parameter : *wDriverVersion : address of wDriverVersion

z

wDriverVersion=0x200 Æ Version 2.0

z Return Value :

NoError : OK

DriverHandleError : the NAPPCI.VxD open error for Windows 95/98

the Napwnt.SYS open error for Windows NT

DriverCallError : call NAPPCI.VxD return error

call Napwnt.SYS return error

z Demo Program : DEMO1.C

33

Page 34

3.3 The M_Functions

3.3.1 P1602_M_FUN_1

z Description :

The P1602_M_FUN_1 will calculate the waveform image automatically. (Refer to the

“OME-PCI-1602 Hardware Manual” chapter-5 for details) (input=A/D channel_0,

output=D/A channel_0)

• Syntax :

WORD P1602_M_FUN_1(WORD wDaFrequency, WORD wDaWave, float

fDaAmplitude, WORD wAdClock, WORD wAdNumber, WORD wAdConfig,

float fAdBuf[], float fLowAlarm, float fHighAlarm)

z Input Parameter :

wDaFrequency : D/A output frequency = 1.8M/wDaFrequency (Pentium 120)

wDaWave : Number of D/A waveform to be output

fDaAmplitude : Amplitude of D/A output. NOTE : the hardware J1 must select +/-10V

wAdClock : A/D sampling clock = 8000000/wAdClock samples/sec

wAdNumber: Number of A/D data to be read

wAdConfig : A/D input range configuration code

Refer to "Section 3.1 Configuration Table"

fAdBuf[] : the starting address of fAdBuf which store the A/D data

fLowAlarm : low alarm limit. if fAdBuf[?]< fLowAlarm Æ LowAlarm

fHighAlarm : high alarm limit. if fAdBuf[?]>fHighAlarm Æ HighAlarm

Return Value :

z

NoError : OK

DriverHandleError : Invalid VxD/SYS handle

DriverCallError : VxD/SYS function call error

ExceedBoardNumber: invalid board number

FindBoardError: no OME-PCI-1602 board

AdControllerError : embedded controller handshake error

M_FunExecError : M_Functions return code error

ConfigCodeError : wAdConfig

Refer to "Section 3.1 Configuration Table"

HighAlarm : fAdBuf[?]>fHighAlarm

configuration code error

LowAlarm : fAdBuf[?]< fLowAlarm

z Demo Program : DEMO5.C

34

Page 35

3.3.2 P1602_M_FUN_2

z Description :

The P1602_M_FUN_2 will

“OME-PCI-1602 Hardware Manual” chapter-5 for details) (input=A/D channel_0,

output=D/A channel_0)

not compute the waveform image automatically. (Refer to

• Syntax :

WORD P1602_M_FUN_2(WORD wDaNumber, WORD wDaWave, WORD wDaBuf[],

WORD wAdClock, WORD wAdNumber, WORD wAdConfig, WORD

wAdBuf[]);

z Input Parameter :

wDaNumber: number of D/A samples in one waveform

wDaWave : Number of D/A waveform to be output

wDaBuf[] : The array stores the D/A waveform image

wAdClock : A/D sampling clock = 8000000/wAdClock samples/sec

wAdNumber: Number of A/D data to be read

wAdConfig : A/D input range configuration code.

Refer to "Section 3.1 Configuration Table"

wAdBuf[] : the starting address of fAdBuf which store the A/D data

z Return Value :

NoError : OK

DriverHandleError : Invalid VxD/SYS handle

DriverCallError : VxD/SYS function call error

ExceedBoardNumber: invalid board number

FindBoardError: no OME-PCI-1602 board

AdControllererror : embedded controller handshake error

M_FunExecError : M_Functions return code error

ConfigCodeError : wAdConfig configuration code error, Refer to "Section 3.1"

z Demo Program : DEMO7.C

The D/A output waveform generator is a

output frequency = 1.8M/wDaNumber is machine dependent. Some benchmarks

are shown below:

D/A output frequency = 1.8M/dwDaNumber for Pentium 120

D/A output frequency = 2.0M/dwDaNumber for Pentium 133

machine dependent function. The D/A

The user should benchmark their system before using M_FUN_1,

M_FUN_2 and M_FUN_3.

35

Page 36

3.3.3 P1602_M_FUN_3

z Description :

The P1602_M_FUN_3 will calculate the waveform image automatically. (Refer to

“OME-PCI-1602 Hardware Manual” chapter-5 for details) (input=programable channels,

output=D/A channel_0) This function will refer to the current active OME-PCI-1602 board.

Use the P1602_ActiveBoard(….) to select the active board. Refer to Sec. 2.4.2 for more

information.

z Syntax :

WORD P1602_M_FUN_3(WORD wDaFrequency, WORD wDaWave, float

fDaAmplitude, WORD wAdClock, WORD wAdNumber, WORD

wChannelStatus[], WORD wAdConfig[], float fAdBuf[], float fLowAlarm, float

fHighAlarm)

z Input Parameter :

wDaFrequency : D/A output frequency = 1.8M/wDaFrequency (Pentium 120)

wDaWave : Number of D/A waveform to be output

fDaAmplitude : Amplitude of D/A output. NOTE : the hardware jumper J1 must be set

to +/-10V

wAdClock : A/D sampling clock = 8000000/wAdClock samples/sec

wAdNumber: Number of A/D samples to be read

wAdChannel[]: 1=scan, 0=no scan

wAdConfig[]: configuration code

Refer to "Section 3.1 Configuration Table"

fAdBuf[] : the starting address of fAdBuf which store the A/D data

fLowAlarm : low alarm limit. if fAdBuf[?]< fLowAlarm Æ LowAlarm

fHighAlarm : high alarm limit. if fAdBuf[?]>fHighAlarm Æ HighAlarm

Return Value :

z

NoError : OK

DriverHandleError : Invalid VxD/SYS handle

DriverCallError : VxD/SYS function call error

ExceedBoardNumber: invalid board number

FindBoardError: no OME-PCI-1602 board

AdControllerError : embedded controller handshake error

M_FunExecError : M_Functions return code error

ConfigCodeError : wAdConfig

HighAlarm : fAdBuf[?]>fHighAlarm

LowAlarm : fAdBuf[?]< fLowAlarm

configuration code error, Refer to "Section 3.1"

36

Page 37

• Demo Program : DEMO9.C

37

Page 38

3.4 The DIO Functions

3.4.1 P1602_Di

z Description : This function will read the 16 bit data from the digital input (D/I) port.

This function will refer to the current active OME-PCI-1602. Use the

P1602_ActiveBoard(….) to select the active board.

z Syntax : WORD P1602_Di(WORD *wDi);

z Input Parameter :

*wDi : address of wDi which contains the 16 bits of D/I data

z Return Value :

NoError : OK

FindBoardError : cannot find the OME-PCI-1602 board

ExceedBoardNumber: invalid board number

Demo Program : DEMO1.C

z

3.4.2 P1602_Do

Description : This function will write the 16 bit data to the digital output(D/O) port.

z

This function will refer to the current active OME-PCI-1602 board. Use the

P1602_ActiveBoard(….) to select the active board.

z

Syntax : WORD P1602_Do(WORD wDo);

z Input Parameter :

wDo : the 16 bits of data sent to the D/O port

z Return Value :

NoError : OK

ExceedBoardNumber: invalid board number

FindBoardError : cannot find the OME-PCI-1602 board

z Demo Program : DEMO1.C

38

Page 39

3.5 The D/A Functions

3.5.1 P1602_Da

Description: This function will write the 12 bit data to D/A port. This function will

refer to the current active OME-PCI-1602 board. Use the P1602_ActiveBoard(….) to select

the active board.

z Syntax : WORD P1602_Da(WORD wChannel, WORD wDaVal);

z Input Parameter :

wChannel : 0 for channel_0 D/A, 1 for channel_1 D/A

wDaVal : 12 bit data sent to D/A port. 0=minimum and 4095=maximum. The D/A

output can be +/- 5V or +/- 10V depending on the setting hardware jumper JP1.

The software cannot detect the state of JP1, the user must be aware of its state.

z Return Value :

NoError : OK

FindBoardError : cannot find the OME-PCI-1602 board

ExceedBoardNumber: invalid board number

DaChannelError : channel number must be 0 or 1

Demo Program : DEMO1.C

z

39

Page 40

3.6 The A/D Fixed-mode Functions

3.6.1 P1602_SetChannelConfig

z Description : This function will set the A/D channel’s configuration code. This

function will set the active A/D channel for P1602_AdPolling, P1602_AdsPolling and

P1602_AdsPacer functions. This function will refer to the current active OME-PCI-1602

board. Use the P1602_ActiveBoard(….) to select the active board.

z Syntax : WORD P1602_SetChannelConfig(WORD wChannel, WORD wConfig);

z Input Parameter :

wChannel : A/D channel number

wConfig : Configuration code. Refer to "Section 3.1 Configuration Table"

z Return Value :

NoError : OK

ExceedBoardNumber: invalid board number

FindBoardError : cannot find the OME-PCI-1602 board

AdControllerError : MagicScan controller hardware handshake error

Demo Program : DEMO1.C

z

3.6.2 P1602_AdPolling

z Description : This function will perform a single A/D conversion by software

polling. The P1602_SetChannelConfig function can be used to change channel or

configuration code used by the P1602_AdPolling function. This function will refer to the

current active OME-PCI-1602 board. Use the P1602_ActiveBoard(….) to select the

active board.

z Syntax : WORD P1602_AdPolling(float *fAdVal);

z Input Parameter :

*fAdVal : address of fAdVal which will contain the A/D data (16 bits), this data

is automatically converted to volts based on the setting

P1602_SetChannelConfig.

z Return Value :

NoError : OK

ExceedBoardNumber: invalid board number

FindBoardError : cannot find the OME-PCI-1602 board

AdPollingTimeOut : hardware timeout error

z Demo Program : DEMO1.C

40

Page 41

3.6.3 P1602_AdsPolling

z Description : This function will perform multiple A/D conversions by polling. The

P1602_SetChannelConfig function can be used to change the channel or configuration

code used by the P1602_AdsPolling function. This function will refer to the current

active OME-PCI-1602 board. Use the P1602_ActiveBoard(….) to select the active board.

z Syntax : WORD P1602_AdsPolling(float fAdVal[], WORD wNum);

z Input Parameter :

fAdVal[]: starting address of A/D data buffer (16 bit), the data will be

automatically converted to volts based on the setting of the

P1602_SetChannelConfig function.

wNum: number of A/D conversions to be performed.

• Return Value :

NoError: OK

ExceedBoardNumber: invalid board number

FindBoardError: cannot find the OME-PCI-1602 board

AdPollingTimeOut: hardware timeout error

z Demo Program : DEMO1.C

41

Page 42

3.6.4 P1602_AdsPacer

z Description : This function will perform multiple A/D conversions by pacer trigger.

The P1602_SetChannelConfig function can be used to change channel or configuration

code. The hardware pacer will generate a periodic trigger signal to the A/D converter.

Software polling is used by the P1602_AdsPolling function, so the A/D conversion

process could be interrupted by the computer’s operating system. Since the

P1602_AdsPacer function uses the hardware pacer, operating system interrupts will not

affect it. For this reason the P1602_AdsPacer function should be used if a waveform

must be precisely reconstructed. This function will refer to the current active OME-

PCI-1602 board. Use the P1602_ActiveBoard(….) to select the active board.

z Syntax : WORD P1602_AdsPacer(float fAdVal[], WORD wNum, WORD wSample);

z Input Parameter :

fAdVal[] : starting address of the A/D data buffer (16 bit), the data will be

automatically converted to volts based on the setting of the

P1602_SetChannelConfig function.

wNum : number of A/D conversions to be performed.

wSample : A/D sample rate = 8M/wSample.

for example: wSample=24 Æ sample rate=8M/24=330K

z Return Value :

NoError : OK

ExceedBoardNumber: invalid board number

FindBoardError : cannot find the OME-PCI-1602 board

AdPollingTimeOut : hardware timeout error

z Demo Program : DEMO1.C

P1602_SetChannelConfig

P1602_AdPolling

P1602_AdsPollng

Fix channel A/D conversion mode

P1602_AdsPacer

42

Page 43

3.7 The MagicScan Functions

3.7.1 P1602_ClearScan

z Description : This function will initialize the MagicScan controller. This function

will refer to the current active OME-PCI-1602 board. Use the P1602_ActiveBoard(….) to

select the active board.

z Syntax : WORD P1602_ClearScan();

z Input Parameter : void

z Return Value :

NoError : OK

ExceedBoardNumber: invalid board number

FindBoardError : cannot find the OME-PCI-1602 board

AdControllerError : MagicScan controller hardware handshake error

z Demo Program : DEMO11.C

43

Page 44

3.7.2 P1602_StartScan

z Description : This function will start the MagicScan operation. This

function will return to the caller before the MagicScan operation finishes. The

user can use the P1602_WaitMagicScanFinish(…) function or the

P1602_ReadScanStatus(…) function to check the state of MagicScan operation.

This function will refer to the current active OME-PCI-1602 board. Use the

P1602_ActiveBoard(….) to select the active board.

z Syntax : WORD P1602_StartScan(WORD wSampleRate, WORD wNum);

z Input Parameter :

wSampleRate : A/D sample rate = 8M/wSampleRate.

wSampleRate=24 Æ sample rate=8M/24=330K

wNum : Number of MagicScan cycles to perform

z Return Value :

NoError : OK

ExceedBoardNumber: invalid board number

FindBoardError : cannot find the OME-PCI-1602 board

AdControllerError : MagicScan controller hardware handshake error

z Demo Program : DEMO11.C

44

Page 45

3.7.3 P1602_ReadScanStatus

z Description : This function will read the status of the MagicScan operation. This

function will refer to the current active OME-PCI-1602 board. Use the

P1602_ActiveBoard(….) to select the active board.

z Syntax : void P1602_ReadScanStatus(WORD *wStatus, WORD

*wLowAlarm, WORD *wHighAlarm);

z Input Parameter :

*wStatus : address of wStatus which will contain the MagicScan status

*wLowAlarm : address of wLowAlarm which will contain the MagicScan alarm

status

*wHighAlarm : address of wHighAlarm which will contain the MagicScan alarm

status

z Return Value : void

Demo Program : DEMO11.C

z

wStatus = 0x00 Æ MagicScan initial condition (idle state)

= 0x01 Æ MagicScan operation started

= 0x02 Æ MagicScan stage 1 controller timeout

= 0x04 Æ MagicScan stage 2 controller timeout

= 0x08 Æ MagicScan FIFO overflow

= 0x80 Æ MagicScan function OK

wLowAlarm Æ 32 bits corresponding to 32 channels

Æ 0 = no low alarm

Æ 1 = is low alarm

wLowAlarm=0 Æ all channels OK, no low alarm

wLowAlarm=1 Æ channel_0 is low alarm, others are OK

wLowAlarm=3 Æ channel_0 and channel_1 are low alarm, others are OK

wHighAlarm Æ 32 bits corresponding to 32 channels

Æ 0 = no high alarm

Æ 1 = is high alarm

wHighAlarm=0 Æ all channels OK, no high alarm

wHighAlarm=1 Æ channel_0 is high alarm, others are OK

wHighAlarm=3 Æ channel_0 and channel_1 are high alarm, others are

OK

45

Page 46

3.7.4 P1602_AddToScan

z Description : This function will add one channel to the MagicScan circular queue.

This function will refer to the current active OME-PCI-1602 board. Use the

P1602_ActiveBoard(….) function to select the active board.

z Syntax : word P1602_AddToScan(WORD wAdChannel, WORD wConfig, WORD

wAverage, WORD wLowAlarm, WORD wHighAlarm, WORD wAlarmType);

z Input Parameter :

wAdChannel : A/D channel number

wConfig : the configuration code

Refer to "Section 3.1 Configuration Table"

wAverage : the digital average filter factor

wLowAlarm : 16 bit low alarm data

wHighAlarm : 16 bit high alarm data

wAlarmType : 0=no alarm, 1=high alarm, 2=low alarm, 3=in-alarm, 4=out-alarm

z Return Value :

NoError : Ok

ExceedBoardNumber: invalid board number

FindBoardError : cannot find the OME-PCI-1602 board

AdChannelError : invalid A/D channel

AlarmTypeError : only 0/1/2/3/4 are valid

AdControllerError : MagicScan controller hardware handshake error

Demo Program : DEMO11.C

z

46

Page 47

3.7.5 P1602_SaveScan

z Description : This function will specify the starting address of A/D data buffer for

MagicScan.

z Syntax : void P1602_SaveScan(WORD wAdChannel, WORD wBuf[]);

z Input Parameter :

wAdChannel : Scan number in the scan queue.

(Note: not the A/D channel number.)

wBuf : starting address of the A/D data buffer for the channel specified in

wAdChannel

z Return Value :

NoError : Ok

ExceedBoardNumber: invalid board number

FindBoardError : cannot find the OME-PCI-1602 board

AdChannelError : invalid A/D channel

Demo Program :.DEMO11.C

z

• Code Fragment

WORD wV0[100000]; // A/D ch:0 buffer

WORD wV2[100000]; // A/D ch:2 buffer

:

:

wRetVal=P1602_ClearScan();

//**** For OME-PCI-1602L

wRetVal += P1602_AddToScan(0,0,1,0,0,0); // CH:0 to scan

wRetVal += P1602_SaveScan(0,wV0);

wRetVal += P1602_AddToScan(2,0,1,0,0,0); // CH:2 to scan

wRetVal += P1602_SaveScan(1,wV2); // Notice: 1 not 2

// ^ Notice: This is a ordinal number in

// Scan Queue not a channel number.

wSampleRateDiv=80; // sample rate=8M/wSampleRateDiv

P1602_StartScan(wSampleRateDiv,DATALENGTH,nPriority);

47

Page 48

3.7.6 P1602_WaitMagicScanFinish

z Description : This function will delay until the MagicScan operation is finished.

This function will refer to the current active OME-PCI-1602 board. Use the

P1602_ActiveBoard(….) to select the active board.

z Syntax : void P1602_WaitMagicScanFinish(WORD *wStatus, WORD

*wLowAlarm, WORD *wHighAlarm);

z Input Parameter :

*wStatus : address of wStatus which will contain the MagicScan status

*wLowAlarm : address of wLowAlarm which will contain the MagicScan alarm

status

*dwHighAlarm : address of wHighAlarm which will contain the MagicScan

alarm status

z Return Value : void

Demo Program : DEMO11.C

z

wStatus = 0x00 Æ MagicScan initial condition (idle state)

= 0x01 Æ MagicScan operation started

= 0x02 Æ MagicScan stage 1 controller timeout

= 0x04 Æ MagicScan stage 2 controller timeout

= 0x08 Æ MagicScan FIFO overflow

= 0x80 Æ MagicScan function OK

wLowAlarm Æ 32 bits corresponding to 32 channels

Æ 0 = no low alarm

Æ 1 = is low alarm

wLowAlarm=0 Æ all channels OK, no low alarm

wLowAlarm=1 Æ channel_0 is low alarm, others are OK

wLowAlarm=3 Æ channel_0 and channel_1 are low alarm, others are OK

wHighAlarm Æ 32 bits corresponding to 32 channels

Æ 0 = no high alarm

Æ 1 = is high alarm

wHighAlarm=0 Æ all channels OK, no high alarm

wHighAlarm=1 Æ channel_0 is high alarm, others are OK

wHighAlarm=3 Æ channel_0 and channel_1 are high alarm, others are OK

48

Page 49

3.8 The Pulg&Play Functions

3.8.1 P1602_DriverInit

z Description: This function will detect all of the OME-PCI-1602 boards installed in

the system. This function must be called once before any other function is called.

z Syntax : WORD P1602_DriverInit(WORD *wTotalBoard);

z Input Parameter : *wTotalBoard: address of wTotalBoard

wTotalBoard=1 Æ one OME-PCI-1602 card in the system

wTotalBoard=n Æ n*OME-PCI-1602 cards in the system

z Return Value :

NoError : OK

NoFoundBoard: can not detect any OME-PCI-1602

FindBoardError: handshake check error

DriverHandleError : the NAPPCI.VxD .open error for Windows 95

the Napwnt.SYS .open error for Windows NT

DriverCallError : call NAPPCI.VxD return error

Call Napwnt.SYS return error

z Demo Program: All DEMO programs.

3.8.2 P1602_DriverClose

z Description: Returns all resources to the system. This function should be called

before the program is terminated.

z Syntax : void P1602_DriverClose(void);

Input Parameter : void

z

z

Return Value : void

Demo Program: All DEMO programs.

z

49

Page 50

3.8.3 P1602_GetConfigAddressSpace

z Description: Gets the I/O address of OME-PCI-1602 board n. This function

is for debugging purposes only. It is not necessary to call this function.

z Syntax : WORD P1602_GetConfigAddressSpace(WORD wBoardNo, WORD

*wAddrTimer,WORD *wAddrCtrl, WORD *wAddrDio, WORD *wAddrAdda);

z Input Parameter :

wBoardNo: OME-PCI-1602 board number

wAddrTimer, wAddrCtrl, wAddrDio, wAddrAdda: refer to the “OME-PCI-1602

Hardware manual” chapter-3 for details.

z Return Value :

NoError : OK

FindBoardError: handshake check error

ExceedBoardError: wBoardNo is invalid

Demo Program : DEMO1.C

z

3.8.4 P1602_WhichBoardActive

z Description: Returns the board number of the active board.

z Syntax: WORD P1602_WhichBoardActive(void);

z Input Parameter: void

z Return Value: board number of the active board.

z Demo Program: DEMO1.C

50

Page 51

3.8.5 P1602_ActiveBoard

z Description: This function will make active one of the OME-PCI-1602 boards

installed in the system. This function must call once before the D/I/O, A/D, D/A functions

are called.

z Syntax: WORD P1602_ActiveBoard(WORD wBoardNo);

z Input Parameter:

wBoardNo: board number

Return Value :

z

NoError : OK

ExceedBoardError: wBoardNo is invalid

z Demo Program : All DEMO programd.

The P1602_ActiveBoard(…) function will effect all functions except the following:

1. P1602_FloatSub2

2. P1602_ShortSub2

3. P1602_GetDriverVersion

4. P1602_DriveInit

5. P1602_DriveClose

6. P1602_GetConfigAddressSpace

7. P1602_Card0_StartScan

8. P1602_Card0_ReadData

9. P1602_Card0_Stop

10. P1602_Card1_StartScan

11. P1602_Card1_ReadData

12. P1602_Card1_Stop

51

Page 52

3.9 Multiboard Batch Capture

(Two boards operating simultaneously)

3.9.1 P1602_FunA_Start

Description: This function will start the batch capture process for two boards

z

operating simultaneously.

z

Syntax :

WORD P1602_FunA_Start(WORD wClockDiv0, WORD wChannel0[],

WORD wConfig0[], WORD *Buffer0, DWORD dwMaxCount0,

WORD wClockDiv1, WORD wChannel1[],

WORD wConfig1[], WORD *Buffer1, DWORD dwMaxCount1

Short nPriority);

Input Parameter :

z

wClockDiv0: the A/D sample rate divisor for first board.

the sample rate is 8M/wClockDiv0.

wChannel0[]: (0=no scan, 1=scan) for each channel of the first board

wConfig0[]: configuration code for each channel of the first board

Refer to "Section 3.1 Configuration Table"

*Buffer0: buffer to store the A/D data of the first board

dwMaxCount0: sample count for the first board

wClockDiv1: the A/D sample rate divisor for the second board.

the sample rate is 8M/wClockDiv1.

WChannel1[]: (0=no scan, 1=scan) for each channel of the second board

WConfig1[]: configuration code for each channel of the second board

Refer to "Section 3.1 Configuration Table"

*Buffer1: buffer to store the A/D data of the second board

dwMaxCount1: sample count for the second board

52

Page 53

nPriority: A/D thread priority. The value of nPriority range from:

-2: THREAD_PRIORITY_LOWEST

-1: THREAD_PRIORITY_BELOW_NORMAL

0: THREAD_PRIORITY_NORMAL

1: THREAD_PRIORITY_ABOVE_NORMAL

2: THREAD_PRIORITY_HIGHEST

Other: THREAD_PRIORITY_NORMAL

z Return Value :

NoError : OK

FindTwoBoardError : cannot find out two OME-PCI-1602 boards

z Demo Program : DEMO20.C

53

Page 54

3.9.2 P1602_FunA_ReadStatus

z Description : This function will read the status of the batch capture process.

z Syntax :

WORD P1602_FunA_ReadStatus( void );

z Input Parameter :

void;

Return Value :

z

0: data is ready

1: data not ready

z Demo Program : DEMO20.C

54

Page 55

3.9.3 P1602_FunA_Stop

z Description: This function will stop the batch capture function.

z Syntax:

word P1602_FunA_Stop(void);

z Input Parameter:

void

z Return Value :

NoError : OK

StopError : Stop Error

Demo Program : DEMO20.C

z

3.9.4 P1602_FunA_Get

z Description: This function will retrieve the number A/D samples acquired.

z Syntax:

word P1602_FunA_Get(DWORD *P0, DWORD *P1);

Input Parameter:

z

*P0: [output] the number of A/D samples that have been acquired for the first board.

*P1: [output] the number of A/D samples that have been acquired for the second board.

z

Return Value :

NoError : OK

z Demo Program : DEMO20.C

55

Page 56

3.10 The Single Board Batch Capture

3.10.1 P1602_FunB_Start

z

Description : This function will start the batch capture process.

z Syntax :

WORD P1602_FunB_Start(WORD wClockDiv0, WORD wChannel0[],

WORD wConfig0[], WORD *Buffer0, DWORD dwMaxCount0,

SHORT nPriority);

Input Parameter :

z

wClockDiv0: the A/D sample rate divisor for this board.

the sample rate is 8M/wClockDiv0.

wChannel0[]: (0=no scan, 1=scan) for each channel of this board

wConfig0[]: configuration code for each channel of this board

Refer to "Section 3.1 Configuration Table"

*Buffer0: buffer to store the A/D data of this board

dwMaxCount0: to specify the data length of this board

nPriority: Thread priority. The value of nPriority ranges from:

-2: THREAD_PRIORITY_LOWEST

-1: THREAD_PRIORITY_BELOW_NORMAL

0: THREAD_PRIORITY_NORMAL

1: THREAD_PRIORITY_ABOVE_NORMAL

2: THREAD_PRIORITY_HIGHEST

Other: THREAD_PRIORITY_NORMAL

z Return Value :

NoError : OK

FindBoardError : cannot find the OME-PCI-1602 board

AdControllerError : MagicScan controller hardware handshake error

z Demo Program : DEMO21.C

56

Page 57

3.10.2 P1602_FunB_ReadStatus

z Description : This function provides the status of the batch capture.

z Syntax :

WORD P1602_FunB_ReadStatus( void );

z Input Parameter :

void;

z Return Value :

0: data is ready

1: data not ready

Demo Program : DEMO21.C

z

57

Page 58

3.10.3 P1602_FunB_Stop

z Description: This function will stop the batch capture function.

z Syntax:

word P1602_FunB_Stop(void);

z Input Parameter:

void

Return Value :

z

NoError : OK

StopError : Stop Error

z Demo Program : DEMO21.C

3.10.4 P1602_FunB_Get

z Description: This function will retrieve the number of A/D samples that have

been acquired.

Syntax:

z

word P1602_FunB_Get(DWORD *P0);

z

Input Parameter:

*P0: [output] the number of A/D samples that have been acquired.

z Return Value :

NoError : OK

Demo Program : DEMO21.C

z

58

Page 59

The Continuous Capture Functions

3.10.5 P1602_Card0_StartScan

z Description : This function will start the continuous capture function for card

0. The continuous capture functions are best suited for low speed, long duration

collection. Although computer dependent, sample rates should generally be kept

under 40kHz. Refer to the OME-PCI-1602 Hardware User Manual, for additional

details on this function.

z Syntax : WORD P1602_Card0_StartScan(WORD wSampleRate, WORD

wChannelStatus[], WORD wChanelConfig[], WORD wCount);

z Input Parameter :

wSampleRate : A/D sample rate = 8M/wSampleRate.

wSampleRate=240 Æ sample rate=8M/240=33KHz

wChannelStatus[]: (0=no scan, 1=scan) for each channel

wChannelConfig[]: configuration code for each channel

Refer to "Section 3.1 Configuration Table"

wCount: number of A/D data for each scan channel

z Return Value :

NoError : OK

FindBoardError : cannot find the OME-PCI-1602 board

AdControllerError : MagicScan controller hardware handshake error

Demo Program : DEMO13.C

z

59

Page 60

3.10.6 P1602_Card0_ReadStatus

z Description : This function will read the data collected by the continuous

capture function.

z Syntax : P1602_Card0_ReadStatus(WORD wBuf[], WORD wBuf2[],

DWORD *dwP1, DWORD *dwP2, WORD *wStatus);

z Input Parameter :

wBuf[]: in scan sequence order(012…N012…N……012…N)

wBuf2[]: in channel sequence order(00000…..11111……22222….NNNNN….)

dwP1: reserved

dwP2: reserved

wStatus: 1=thread start, 2=TimeOut, 8=FIFO overflow, 0x80=thread finish

z Return Value :

0: data is ready

1: data not ready

Demo Program : DEMO13.C

z

3.10.7 P1602_Card0_Stop

Description : This function will stop the continuous capture function.

z

z

Syntax : void P1602_Card0_Stop(void);

z Input Parameter :void

Return Value :void

z

z

Demo Program : DEMO13.C

60

Page 61

3.10.8 P1602_Card1_StartScan

z Description: This function will start the continuous capture function for card