Page 1

www.omega.com

e-mail: info@omega.com

User’s Guide

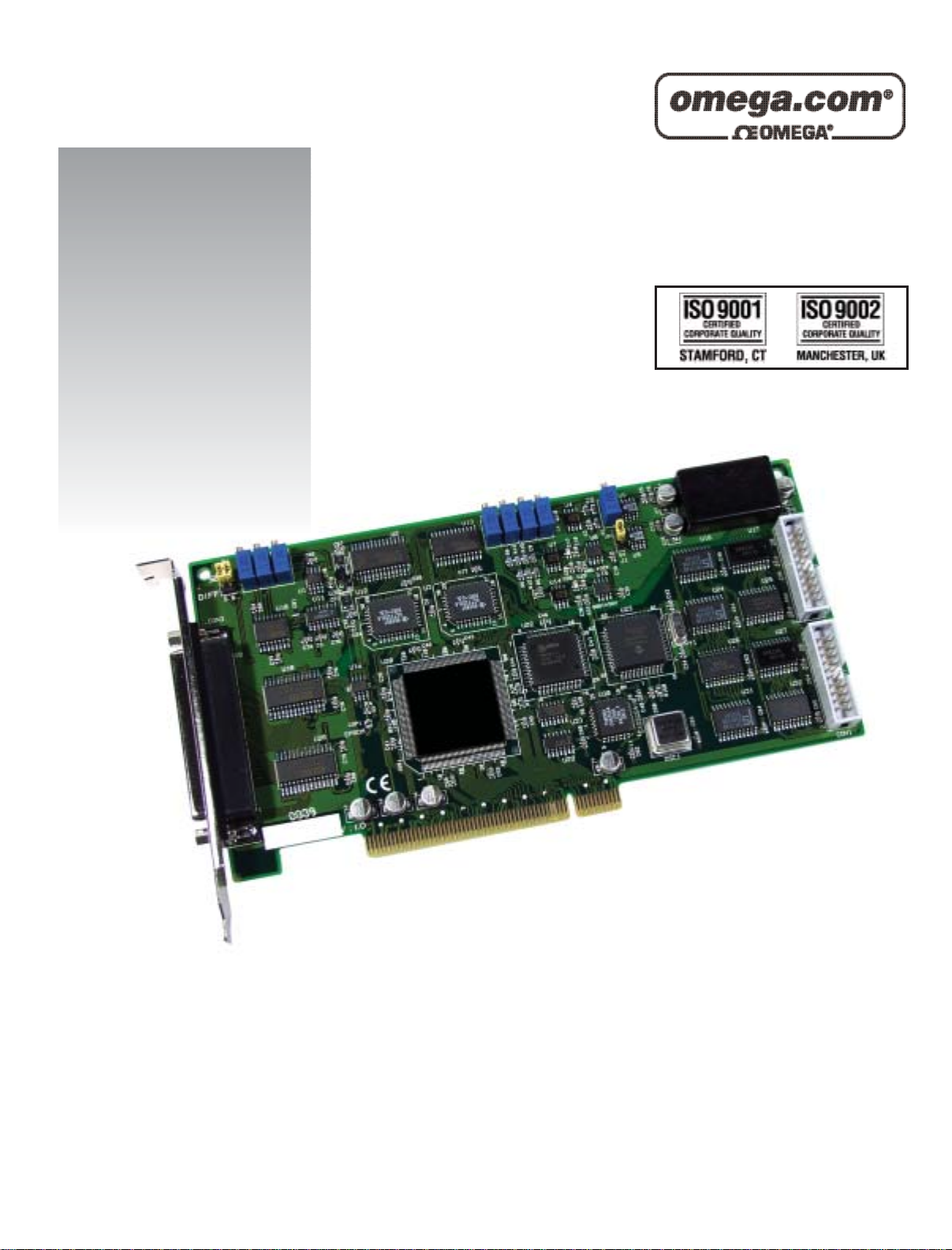

OME-PCI-1202/1602/1800/1802

PCI Data Acquisition Boards

Hardware Manual

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Table of Contents

1. INTRODUCTION ................................................................................................... 5

1.1 GENERAL DESCRIPTION .....................................................................................5

1.2 THE BLOCK DIAGRAMS ......................................................................................6

1.3 FEATURES ........................................................................................................ 7

1.4 SPECIFICATIONS ............................................................................................... 8

1.5 APPLICATIONS ................................................................................................ 14

1.6 PRODUCT CHECK LIST..................................................................................... 14

2. HARDWARE CONFIGURATION ........................................................................ 15

2.1 BOARD LAYOUT .............................................................................................. 15

2.2 JUMPER SETTING ............................................................................................ 18

2.3 DAUGHTER BOARDS ........................................................................................ 19

2.4 ANALOG INPUT SIGNAL CONNECTION................................................................23

2.5 THE CONNECTORS .......................................................................................... 27

3. I/O CONTROL REGISTER..................................................................................30

3.1 HOW TO FIND THE I/O ADDRESS....................................................................... 30

3.2 THE ASSIGNMENT OF I/O ADDRESS .................................................................. 31

3.3 THE I/O ADDRESS MAP ................................................................................... 31

3.4 SECTION 1: PCI CONTROLLER ......................................................................... 33

3.5 SECTION 2: TIMER CONTROL ........................................................................... 34

3.6 S

ECTION 3: CONTROL REGISTER ......................................................................37

3.7 SECTION 4: DI/O REGISTER.............................................................................60

3.8 SECTION 5: A/D & D/A REGISTERS .................................................................. 61

4. A/D CONVERSIONS ........................................................................................... 63

4.1 THE CONFIGURATION CODE TABLE................................................................... 63

4.2 UNIPOLAR/BIPOLAR MEASUREMENT ................................................................. 64

4.3 INPUT SIGNAL RANGE ......................................................................................64

4.4 THE SETTLING TIME ........................................................................................ 65

4.5 S

ETTLING TIME DELAY..................................................................................... 65

4.6 THE A/D CONVERSION MODE .......................................................................... 66

4.7 T

HE FIXED-CHANNEL MODE A/D CONVERSION .................................................. 68

4.8 THE MAGICSCAN MODE A/D CONVERSION ....................................................... 69

5. M_FUNCTION ..................................................................................................... 78

5.1 INTRODUCTION................................................................................................ 79

3

Page 4

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

6. CONTINUOUS AND BATCH CAPTURE FUNCTIONS ......................................83

6.1 G

ENERAL PURPOSE DRIVER ............................................................................83

6.2 HIGH SPEED BATCH CAPTURE ......................................................................... 88

7. CALIBRATION ....................................................................................................90

7.1 A/D CALIBRATION............................................................................................90

7.2 D/A CALIBRATION............................................................................................92

8. DRIVER AND DEMO PROGRAMS..................................................................... 94

9. DIAGNOSTIC PROGRAM................................................................................... 96

9.1 POWER-ON PLUG & PLAY TEST ........................................................................96

9.2 DRIVER PLUG & PLAY TEST ............................................................................. 96

9.3 D/O TEST .......................................................................................................98

9.4 D/A TEST .......................................................................................................98

9.5 A/D TEST .......................................................................................................98

10. PERFORMANCE EVALUATION ..................................................................... 99

4

Page 5

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

1. Introduction

1.1 General Description

The OME-PCI-1800(H/L) and OME-PCI-1802(H/L) are high performance, multifunction

analog and digital I/O PCI boards for PC and compatible computers. This series features a

continuous, 330K samples/second, gap-free data acquisition under DOS and Windows

95/98/NT/2000/XP. All models feature a 12-bit 330K AD converter, two 12-bit independent

DA converters, 16 channels of TTL compatible DI and 16 channels of TTL compatible DO.

The 1800H/L provides 16 single-ended or 8 differential analog input channels. The 1802H/L

provides 32 single-ended or 16 differential analog input channels. The ‘L’ in the part number

denotes low gain input range and the ‘H’ denotes high gain input range. The two DACs of this

multifunction card are independent with bipolar voltage output and jumper selectable output

range. The AD scan function of OME-PCI-1800 series is extremely versatile and is called “

MagicScan”. It uses two modes: the fix channel mode and the channel scan mode, both

modes can scan up to 330K samples per second. The boards also provide three trigger modes:

software trigger, pacer trigger and external trigger. Each trigger mode uses “MagicScan” to

perform the data acquisition. The external trigger can be programmed for one of the three

trigger types: pre-trigger, post-trigger and middle-trigger. The OME-PCI-1800/1802 fully

supports “Plug and Play” under Windows.

The OME-PCI-1202 (H/L) is very similar to OME-PCI-1802 (H/L). The differences are that

the OME-PCI-1202 boards only provide a 110K samples/second acquisition rate and a 2

Kword FIFO.

The OME-PCI-1602 features a 16 bit A/D converter. It is very similar to the OME-PCI-

1802L. The OME-PCI-1602F has a 200K sample/second acquisition rate and the OME-PCI-

1602 has a 100K acquisition rate.

5

Page 6

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

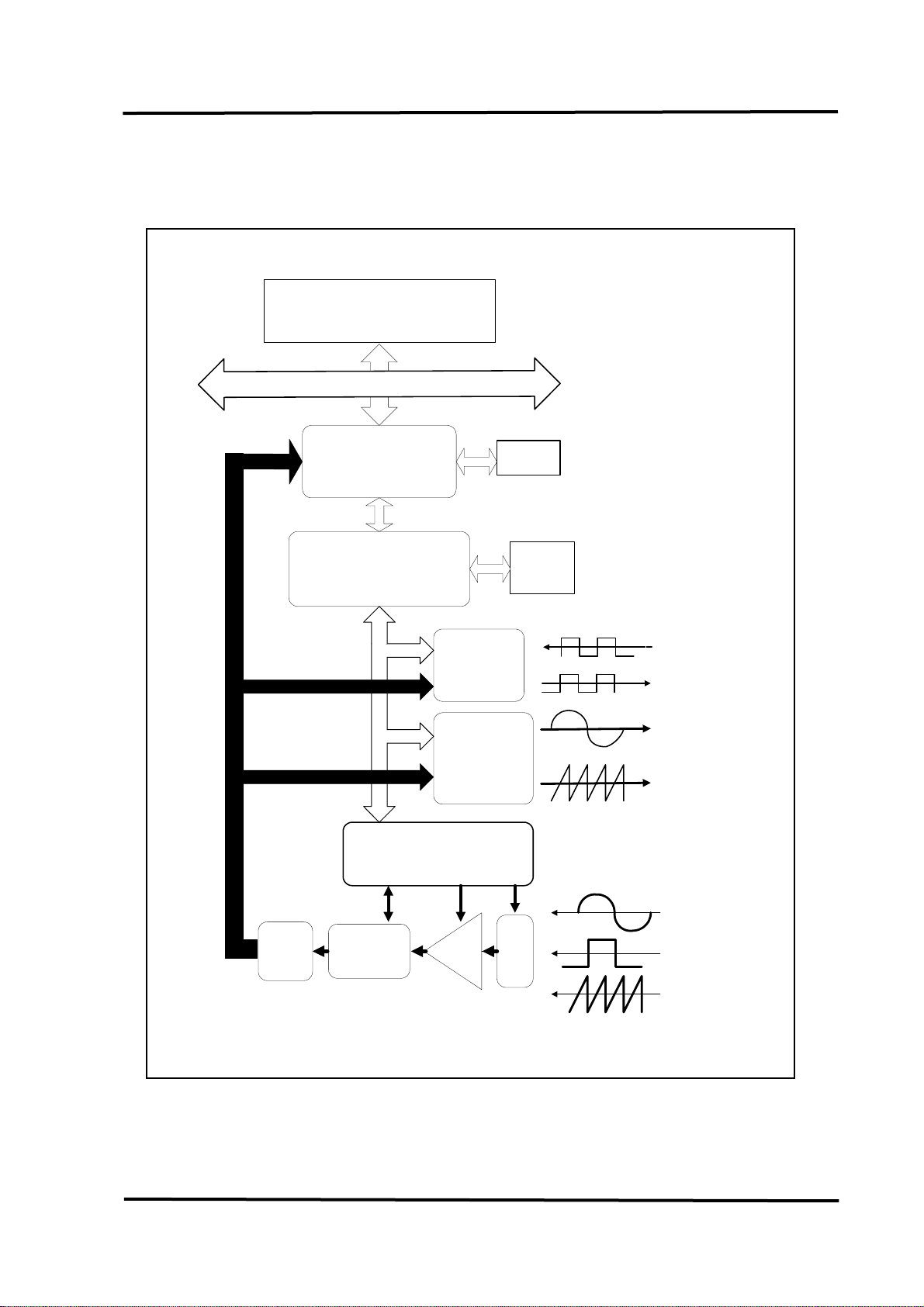

1.2 The Block Diagrams

The block diagram of OME-PCI-1202/1602/1800/1802 is given as follows:

X86 System

S

B

U

C

I

P

PCI Interface System

Local System Controller

16 bits DI

16 bits DO

2 channels

12 bit DA

Converter

Magic Scan Controller

EPROM

Status

Control

Digital Input

Digital Output

DAC OUT 0

DAC OUT 1

Analog Output

FIFO

1/2/4/8K

12/16bit A/D

Converter

MuxGain

Figure 1-1. The block diagram of OME-PCI-1202/1602/1800/1802.

6

Analog Input

Page 7

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

1.3 Features

The general features of OME-PCI-1202/1602/1800/1802 series are given as follows:

z Bus: 5V PCI (Peripherals Component Interconnect) bus.

z A/D:

1. OME-PCI-1800L/1802L: A/D converter = 330K samples/second

OME-PCI-1800H/1802H: A/D converter = 44K samples/second

OME-PCI-1602F: A/D converter = 200K samples/second

OME-PCI-1602: A/D converter = 100K samples/second

OME-PCI-1202L: A/D converter = 110K samples/second

OME-PCI-1202H: A/D converter = 44K samples/second

2. 32 single-ended / 16 differential analog inputs for OME-PCI-1202/1602/1802 H/L.

3. Three different A/D triggers: software, pacer and external trigger

. 4. Three different external triggers: pre-trigger, middle-trigger and post-trigger

5. Programmable input signal configuration.

6. “MagicScan” advanced scanning function

7. FIFO: 2K for OME-PCI-1202(H/L)/1800(H/L)

8K for OME-PCI-1602, OME-PCI-1602F and OME-PCI-1802(H/L)

z D/A:

1. Two channels independent 12 bits DACs.

2. Bipolar voltage output with +/-5V or +/- 10V jumper selectable.

3. High throughput: refer to chapter 10.

z DIO:

1. 16 channels TTL compatible DI and 16 channels TTL compatible DO .

2. High speed data transfer rate: refer to chapter 10.

z Timer:

1. Three 16-bits timer/counter (8254).

2. Timer 0 is used as the internal A/D pacer trigger timer.

3. Timer 1 is used as the external trigger timer.

4. Timer 2 is used as the machine independent timer for settling time delay.

7

Page 8

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

1.4 Specifications

1.4.1 Power Consumption:

z +5V @ 960mA maximum, OME-PCI-1202/1602/1800/1802.

z Operating temperature : 0°C to +70°C

1.4.2 Analog Inputs

z Channels: ( software programmable )

1. OME-PCI-1202/1602/1802: 32-single-ended/16-differential inputs, jumper select.

2. OME-PCI-1800: 16-single-ended/8-differential inputs, jumper select.

z Gain control: ( software programmable )

1. OME-PCI-1202/1800/1802 H: 0.5, 1, 5, 10, 50, 100, 500, 1000

2. OME-PCI-1202/1800/1802 L: 0.5, 1, 2, 4, 8

3. OME-PCI-1602/1602F: 1,2,4,8

z Bipolar input signal range :

1. OME-PCI-1202/1800/1802 L: ±10V,±5V, ±2.5V, ±1.25V, ±0.0625V

2. OME-PCI-1202/1800/1802 H: ±10V,±5V,±1V, ±0.5V, ±0.1V, ±0.05V, ±0.01V, ± 0.005V

3. OME-PCI-1602/1602F: ±10V,±5V,±2.5V,±1.25V

z Unipolar input signal range :

1. OME-PCI-1202/1800/1802 L: 0 to10V, 0 to5V, 0 to 2.5V, 0 to 1.25V

2. OME-PCI-1202/1800/1802 H: 0 to10V, 0 to1V, 0 to 0.1V, 0 to 0.01V

z Input current: 250 nA max (125 nA typical) at 25 °C.

z Over voltage : continuous single channel to 70Vp-p

z Input impedance :

OME-PCI-1202/1800/1802 H: 1010Ω // 6pF

OME-PCI-1202/1602/1800/1802 L: 1013Ω // 1pF

8

Page 9

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

1.4.3 A/D Converter

z Resolution: 12-bit for OME-PCI-1202/1800/1802 H/L

16-bit for OME-PCI-1602/1602F

z Conversion Cycle: 330K s/s for OME-PCI-1800L/1802L

44K s/s for OME-PCI-1800H/1802H

200K s/s for OME-PCI-1602F

100K s/s for OME-PCI-1602

110K s/s for OME-PCI-1202L

44K s/s for OME-PCI-1202H

z Internal sample and hold.

z 12-bit ADC Input Voltages and Output Codes for OME-PCI-1202/1800/1802 H/L

Analog Input Digital Output Binary Code Hex Code

+9.995V

0V

-4.88mv

-10V

MSB LSB

0111 1111 1111

0000 0000 0000

1111 1111 1111

1000 0000 0000

7FF

000

FFF

800

• 16-bit ADC Input Voltages and Output Codes for OME-PCI-1602/1602F

Analog Input Digital Output Binary Code Hex Code

+99.9V

+0V

-305µV

-10V

MSB LSB

0111 1111 1111 1111

0000 0000 0000 0000

1111 1111 1111 1111

1000 0000 0000 0000

7FFF

0000

FFFF

8000

9

Page 10

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

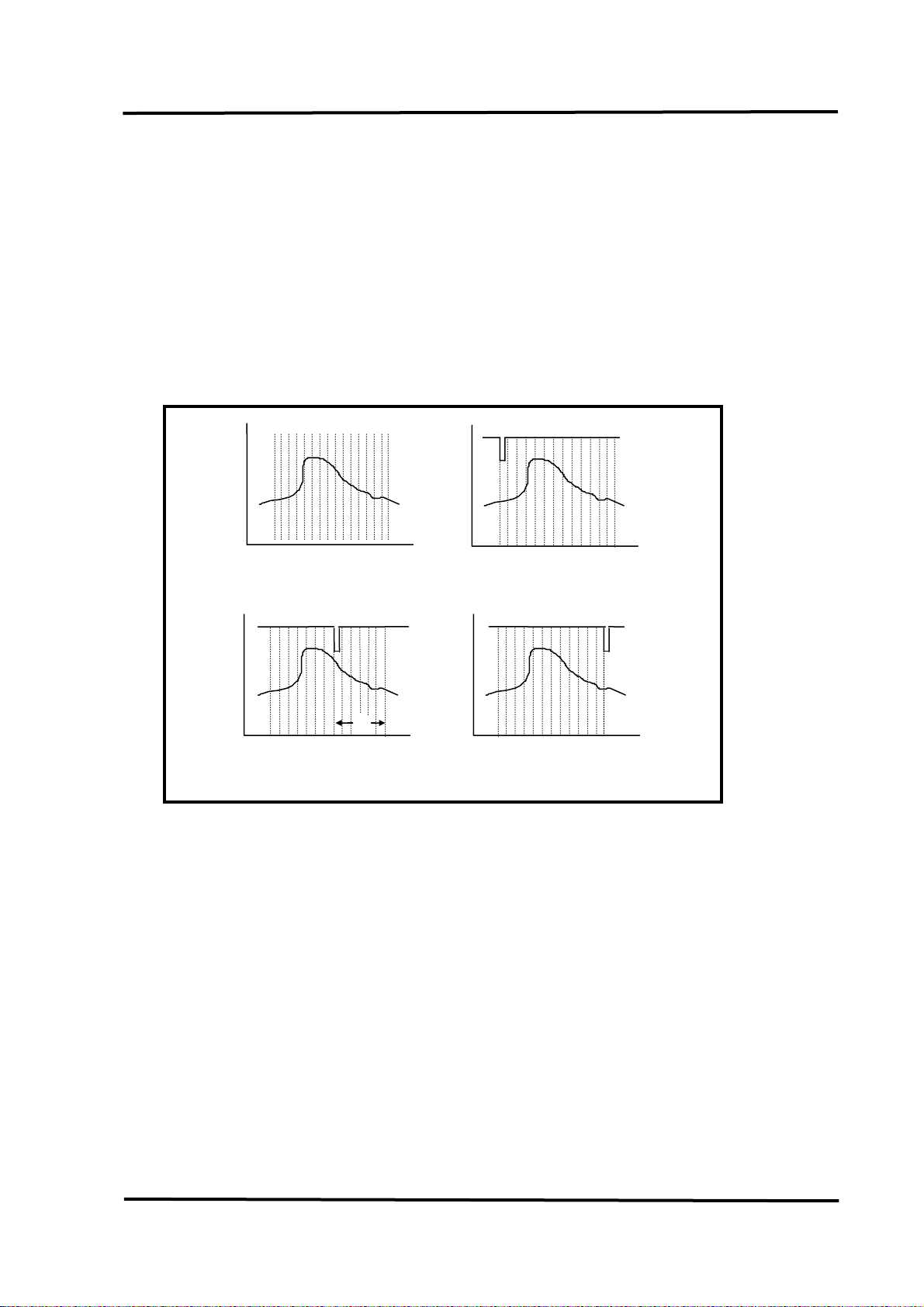

1.4.4 A/D Trigger Methods

z Trigger modes:

1. Internal software trigger

2. Internal pacer trigger

3. External trigger: pre-trigger, middle-trigger and post-trigger

CHn

CHn

External trigger

Start

Internal pacer trigger

t

Start

External post-trigger

External trigger

External trigger

CHn

CHn

External middle-trigger

N2

End

t

Start

External pre-trigger

Figure. 1-2. Trigger modes of OME-PCI-1202/1602/1800/1802.

t

t

10

Page 11

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

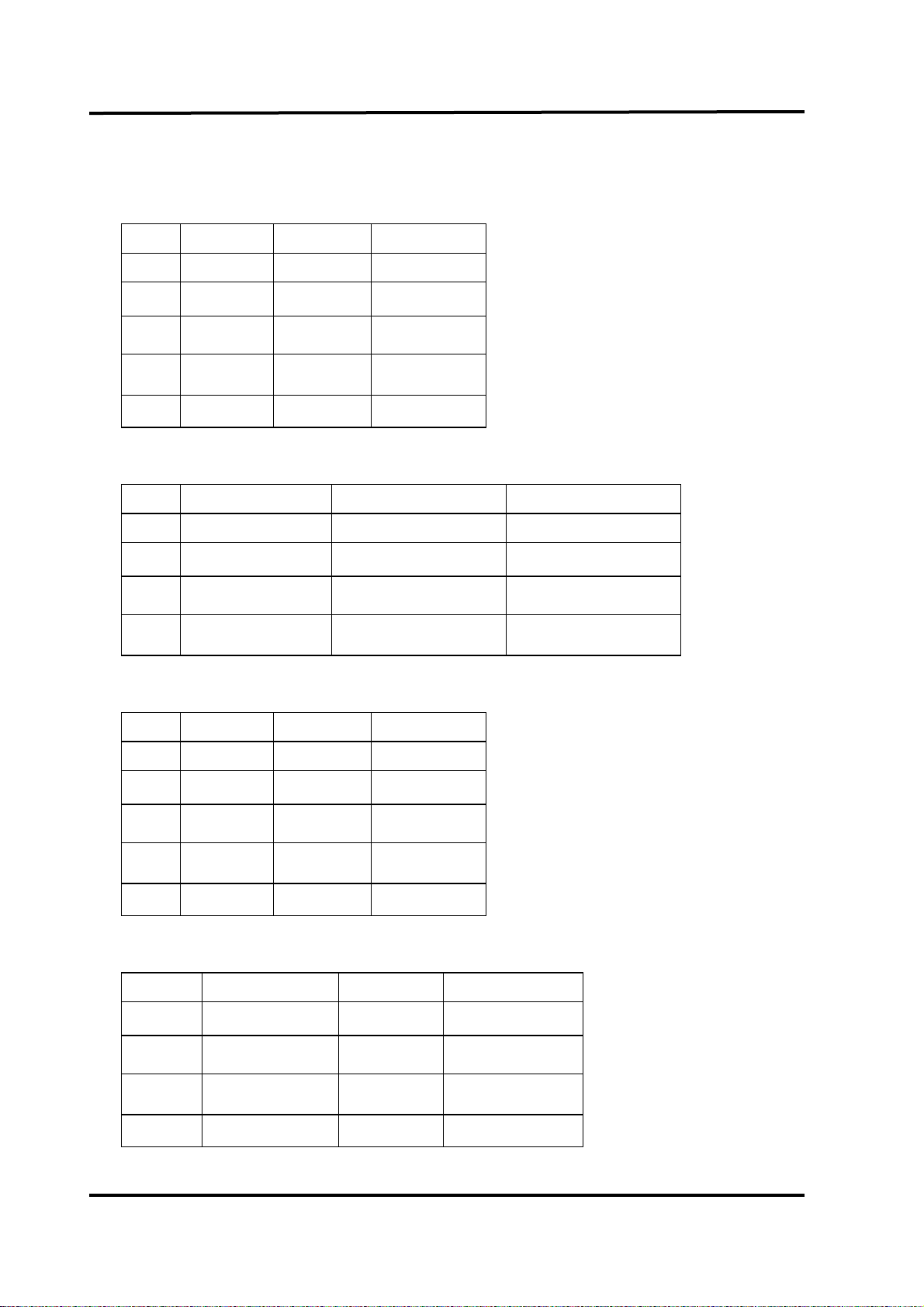

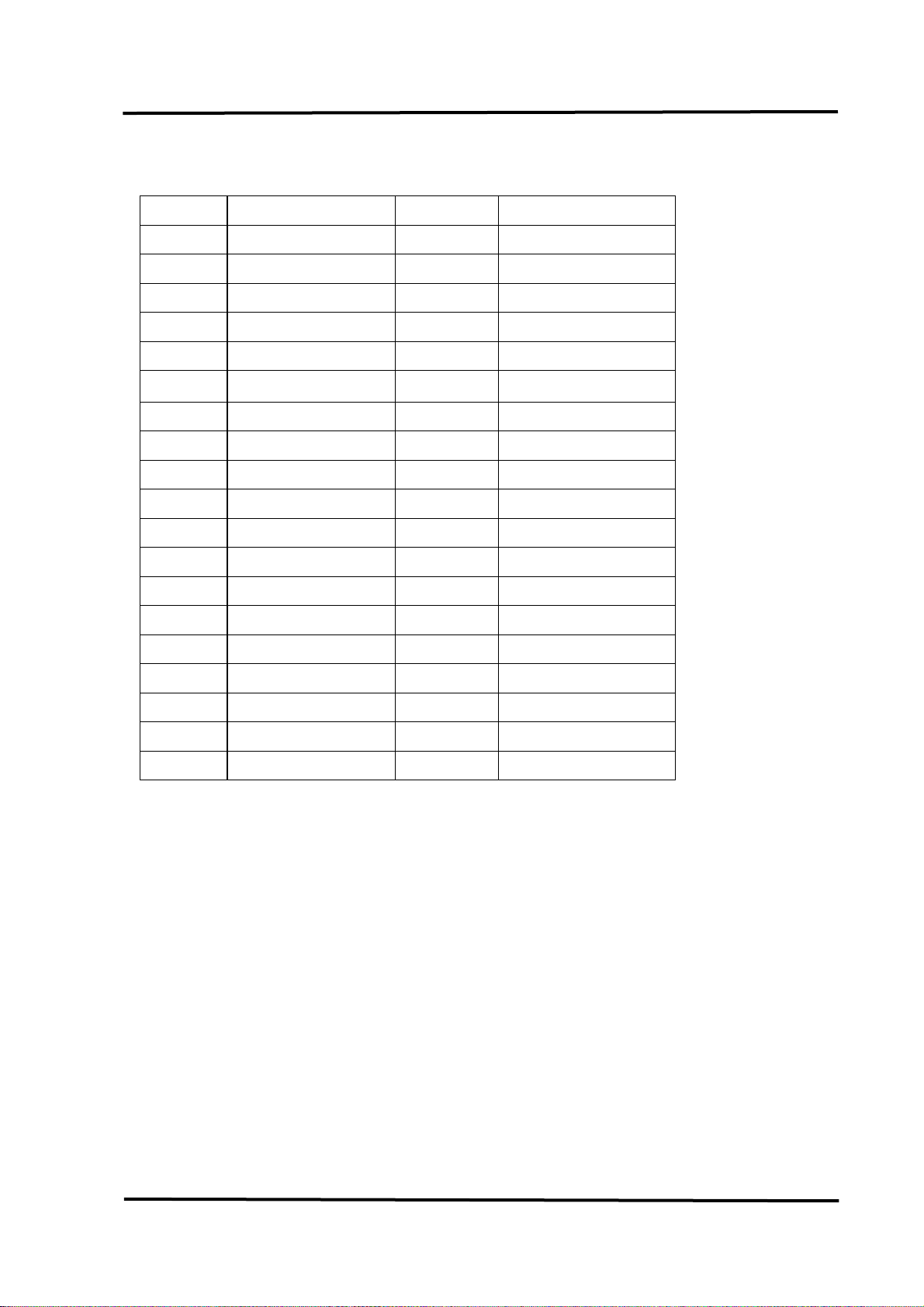

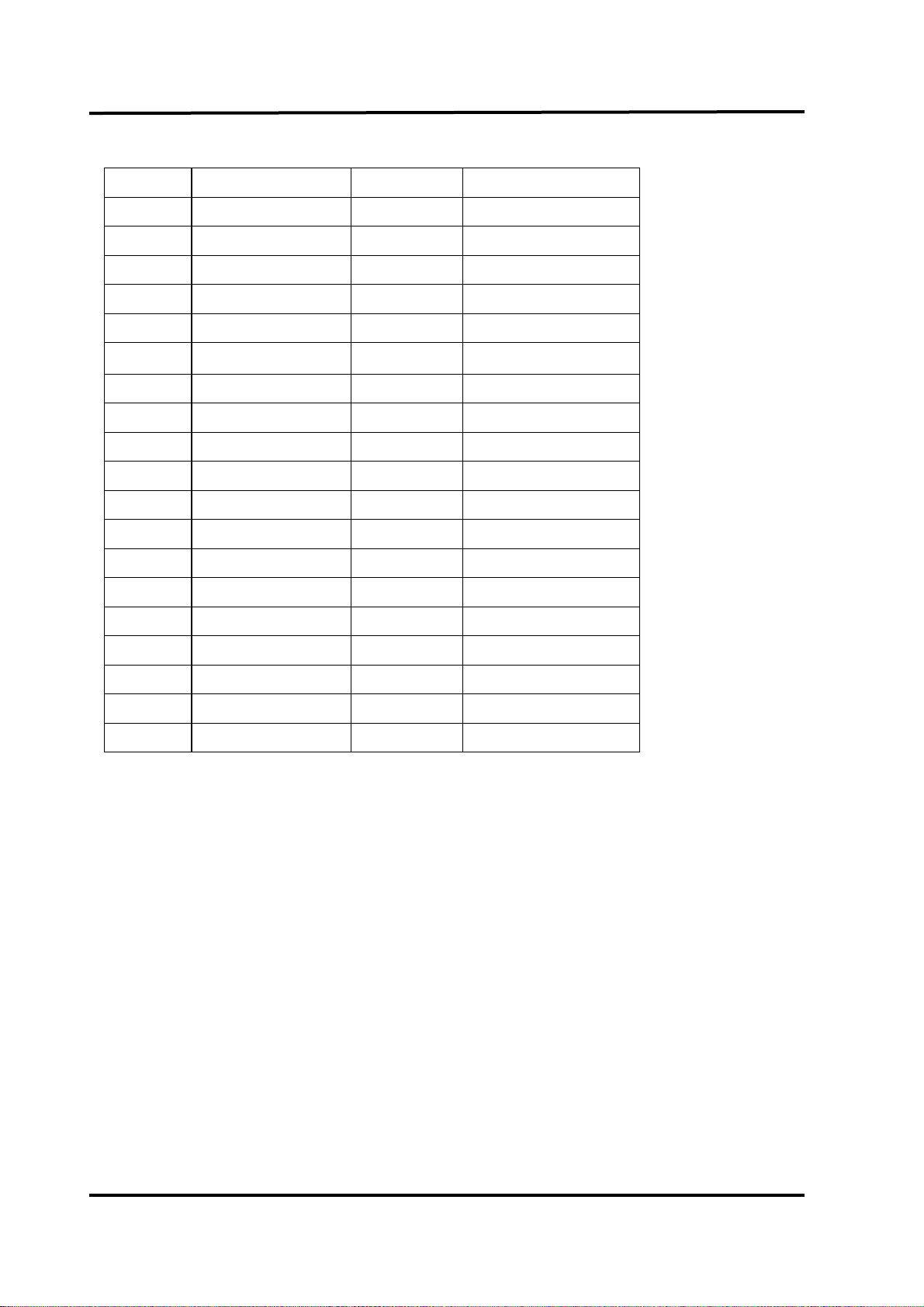

1.4.5 A/D Throughput

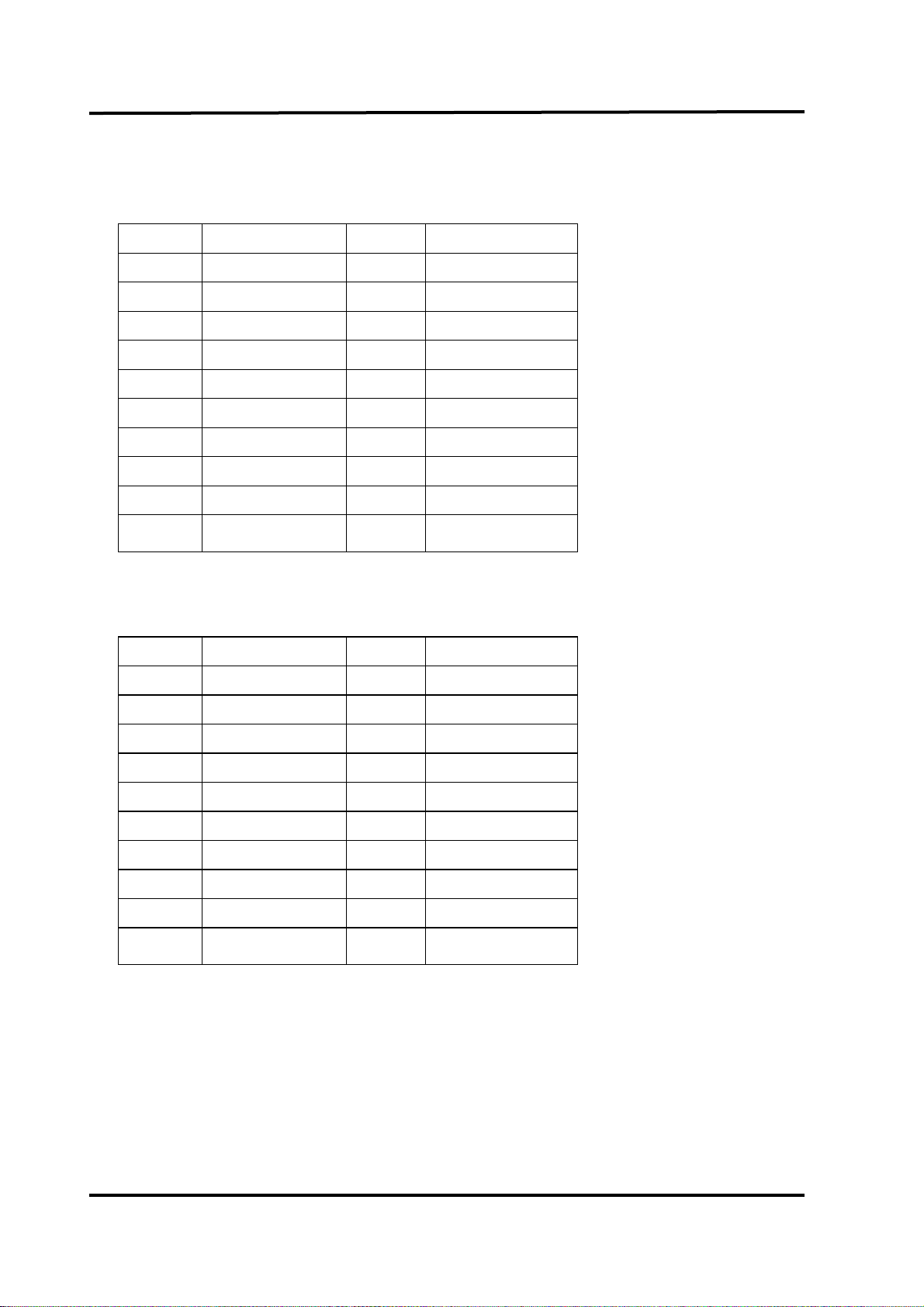

Throughput of OME-PCI-1800L/1802L

Gain Bipolar(V) Unipolar(V) Throughput

0.5 ±10V 0 to 10V 333 Ks/s

1 ±5V 0 to 10V 333 Ks/s

2 ±2.5V 0 to 5V 333 Ks/s

4 ±1.25V 0 to 2.5V 333 Ks/s

8 ±0.625V 0 to 1.25V 333 Ks/s

Throughput of OME-PCI-1602F/1602

Gain Bipolar(V) Throughput (1602F) Throughput (1602)

1 ±10V 200 Ks/s 100 Ks/s

2 ±5V 200 Ks/s 100 Ks/s

4 ±2.5V 200 Ks/s 100 Ks/s

8 ±1.25V 200 Ks/s 100 Ks/s

Throughput of OME-PCI-1202L

Gain Bipolar(V) Unipolar(V) Throughput

0.5 ±10V 0 to 10V 110 Ks/s

1 ±5V 0 to 10V 110 Ks/s

2 ±2.5V 0 to 5V 110 Ks/s

4 ±1.25V 0 to 2.5V 110 Ks/s

8 ±0.625V 0 to 1.25V 110 Ks/s

Throughput of OME-PCI-1202H/1800H/1802H

Gain Bipolar(V) Unipolar(V) Throughput

0.5/1 ±10/±5V 0 to 10V 40 Ks/s

5/10 ±1/±0.5V 0 to 1V 40 Ks/s

50/100 ±0.1/±0.05V 0 to 0.1V 10 Ks/s

500/1000 ±0.01/±0.005V 0 to 0.01V 1 Ks/s

11

Page 12

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

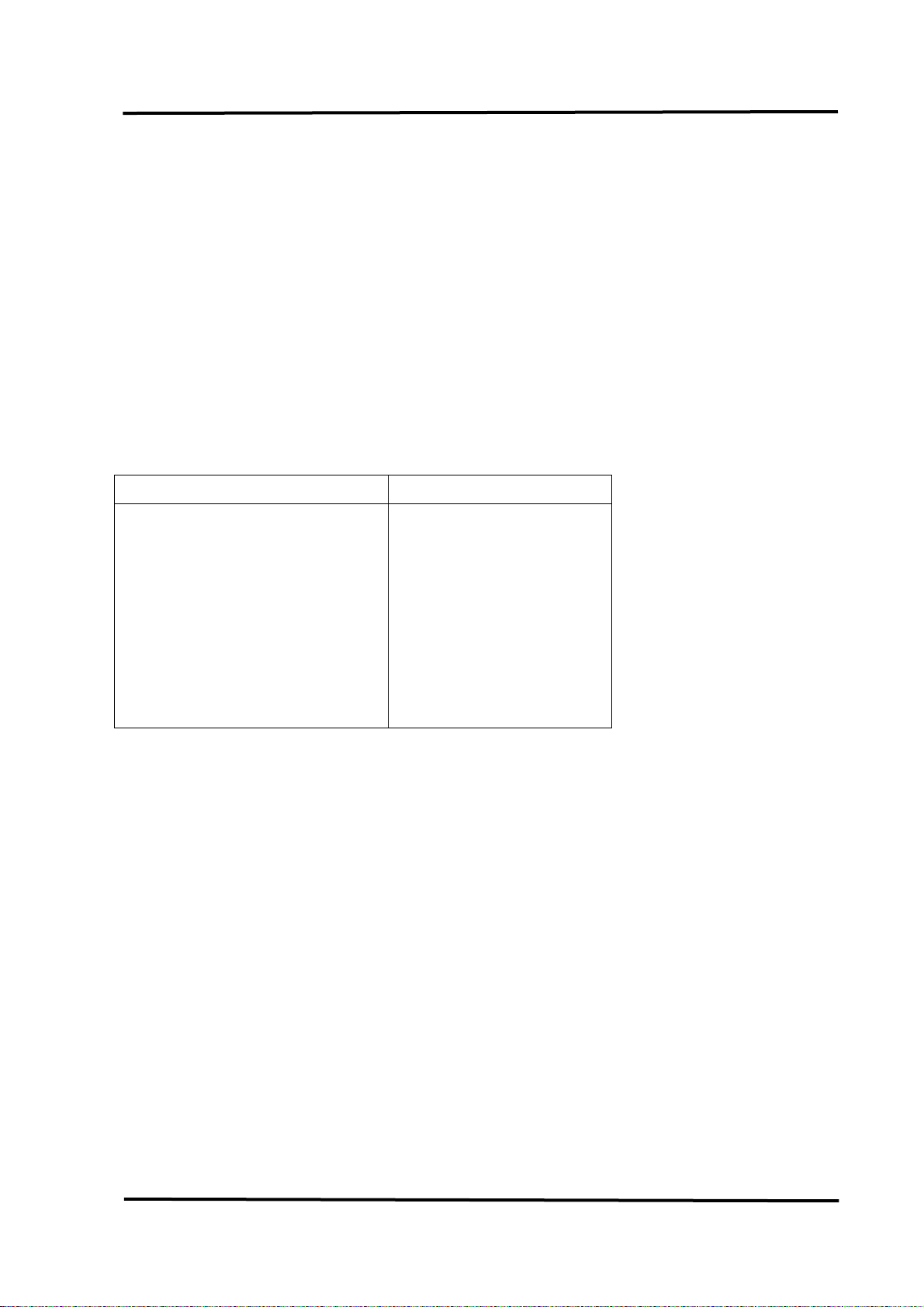

1.4.6 D/A Converter

z Channels: 2 independent.

z DAC Type: 12-bit multiplying DA converter.

z Accuracy: ±1 bit.

z Output type: 12-bit double buffered

z Output range: -5 to +5V or -10 to +10V jumper select.

z Output drive: ± 5mA

z Settling time: 0.4 µs (typical) to 0.01% for full scale step.

z Data transfer rate: 2.1 Mwords/second (non-burst mode).

12- bit DAC output code for OME-PCI-1202/1602/1800/1802 H/L

Data Input Analog Output

MSB LSB

1111 1111 1111

1000 0000 0001

1000 0000 0000

0111 1111 1111

0000 0000 0000

+Vref (2047/2048)

+Vref (1/2048)

0 Volts

-Vref (1/2048)

-Vref (2048/2048)

12

Page 13

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

1.4.7 Digital I/O

z Output port: 16-bit, TTL compatible

z Input port: 16-bit, TTL compatible

z Throughput: 2.1M word/sec (non-burst mode)

1.4.8 Interrupt Channel

z Interrupt: Automatically assigned by ROM BIOS.

z Enable/Disable: Via on-board control register.

1.4.9 Programmable Timer/Counter

z Type: 82C54 programmable timer/counter

z Timers: three 16-bit independent timer

1. Timer 0 is used as the internal A/D pacer trigger timer.

2. Timer 1 is used as the external trigger A/D pacer timer.

3. Timer 2 is used as the machine independent timer.

z Input clock: 8 MHz.

13

Page 14

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

1.5 Applications

z Signal analysis.

z FFT & frequency analysis.

z Transient analysis.

z Speech analysis.

z Temperature monitor.

z Production test.

z Process control.

z Vibration analysis.

z Energy management.

z Industrial and laboratory measurement and control.

1.6 Product Check List

In addition to this manual, the package includes the following items:

z OME-PCI-1202/1602/1800/1802 H/L multifunction card.

z NAPPCI/dos CD-ROM or diskette.

z Software User’s Manual on CD

Please read the release notes first, they contain the latest updates not found in this and the

other user manuals.

Note

If any of these items are missing or damaged, please contact OMEGA. It is

suggested that you save the shipping materials and carton in case you want to

ship or store the product in the future.

14

Page 15

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

2. Hardware Configuration

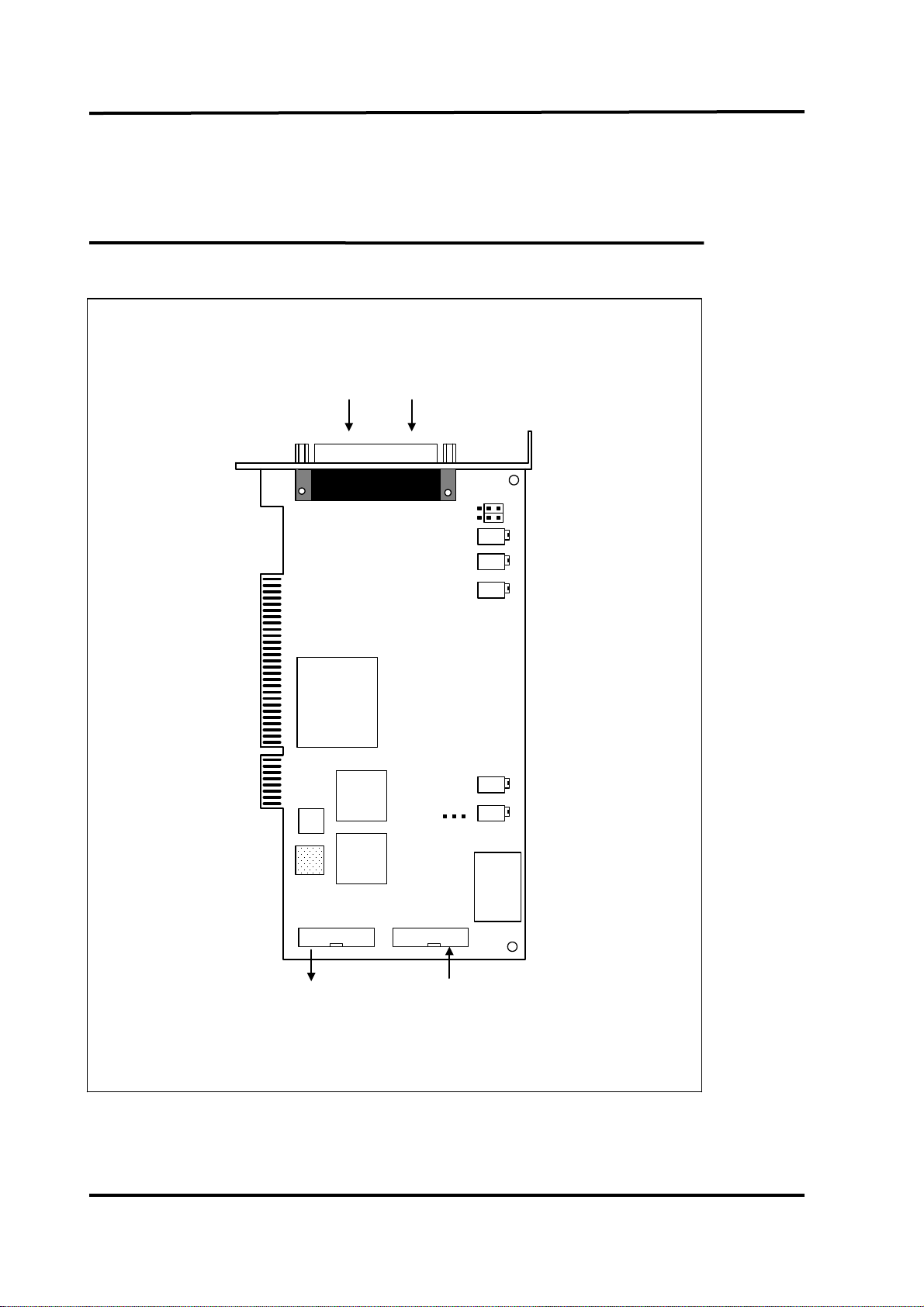

2.1 Board Layout

ADC input

16 or 32

channels

External

Trigger Input

PCI-1800/1802L/NDA REV:C

CON3

JP1

1 2

5 6

VR1 VR101 VR2 VR3VR100

J1

10V

5V

CON1

16 channels

OUT

Digital Output

CON2

IN

Digital Input

16 channels

Figure 2-1. OME-PCI-180X(H/L) /NDA board layout.

15

Page 16

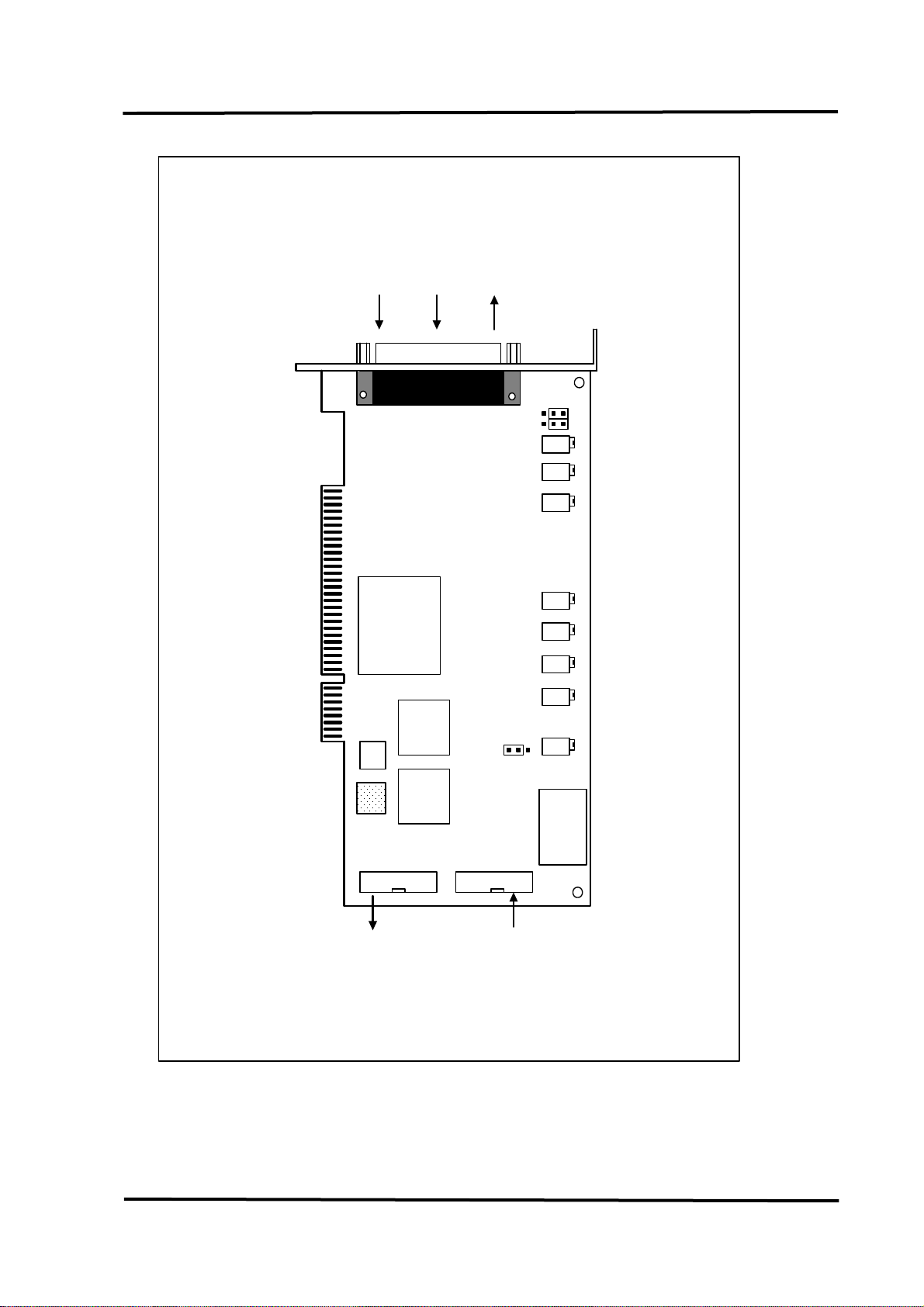

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

External

Trigger Input

16 or 32

channels

ADC input

DAC output

2 channels

PCI-1800/1802L REV:F

CON3

5 6

1 2

JP1

VR1 VR101

CON1

Digital Output

16 channels

OUT

CON2

J1

IN

5V

16 channels

VR201 VR202

VR200VR100

VR203

VR2

10V

Digital Input

Figure 2-2. OME-PCI-1202(H/L)/1800(H/L)/1802(H/L) board layout.

16

Page 17

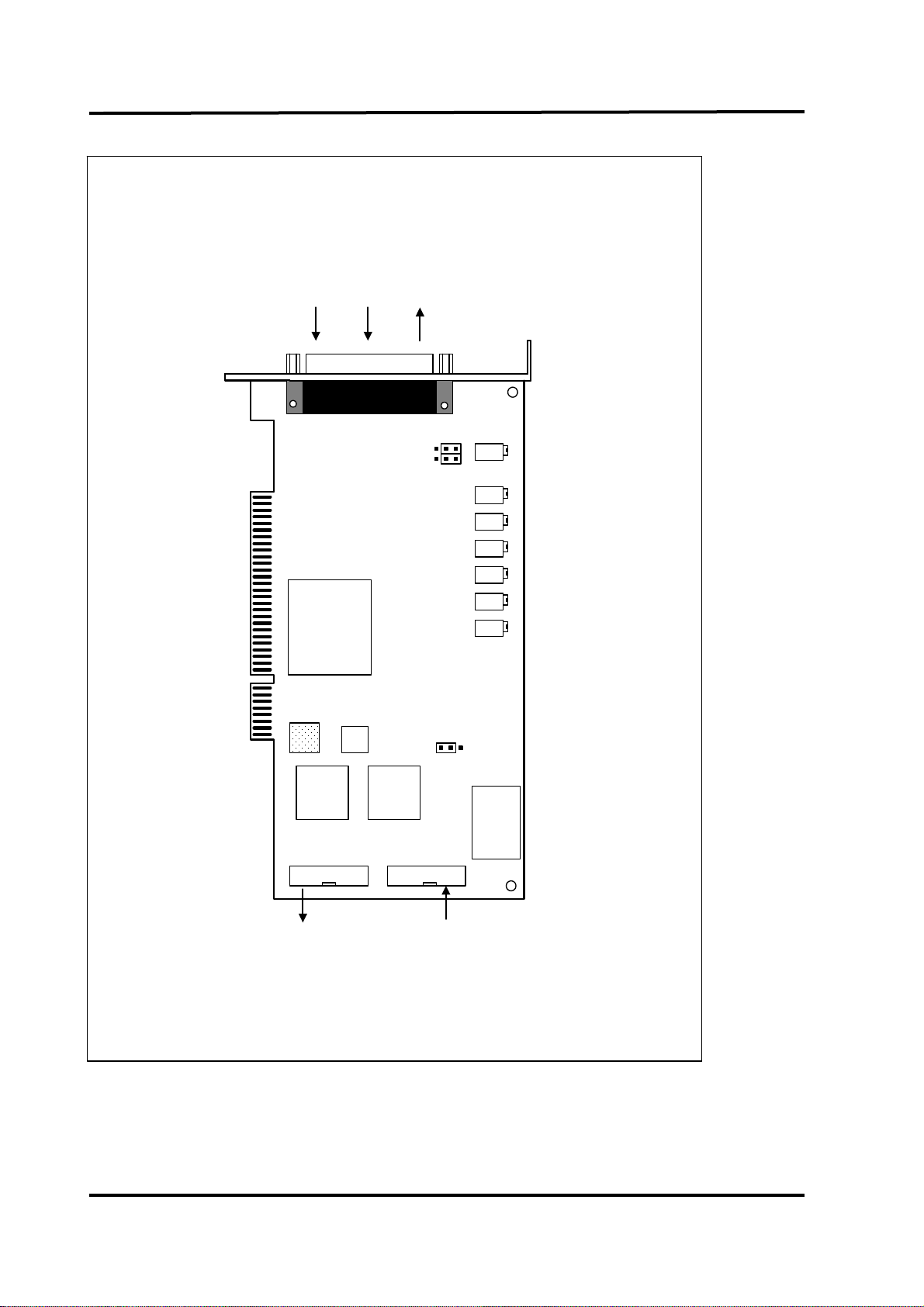

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

DAC output

2 channels

ADC input

32 channels

External

Trigger Input

PCI-1602/1602F REV:1.0

CON3

1

5

JP1

2

6

10V

5V

VR1 VR3

VR2 VR4

VR5 VR6

VR7

J1

CON1

OUT

Digital Output

16 channels

IN

16 channels

Figure 2-3. OME-PCI-1602/1602F board layout.

17

CON2

Digital Input

Page 18

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

)

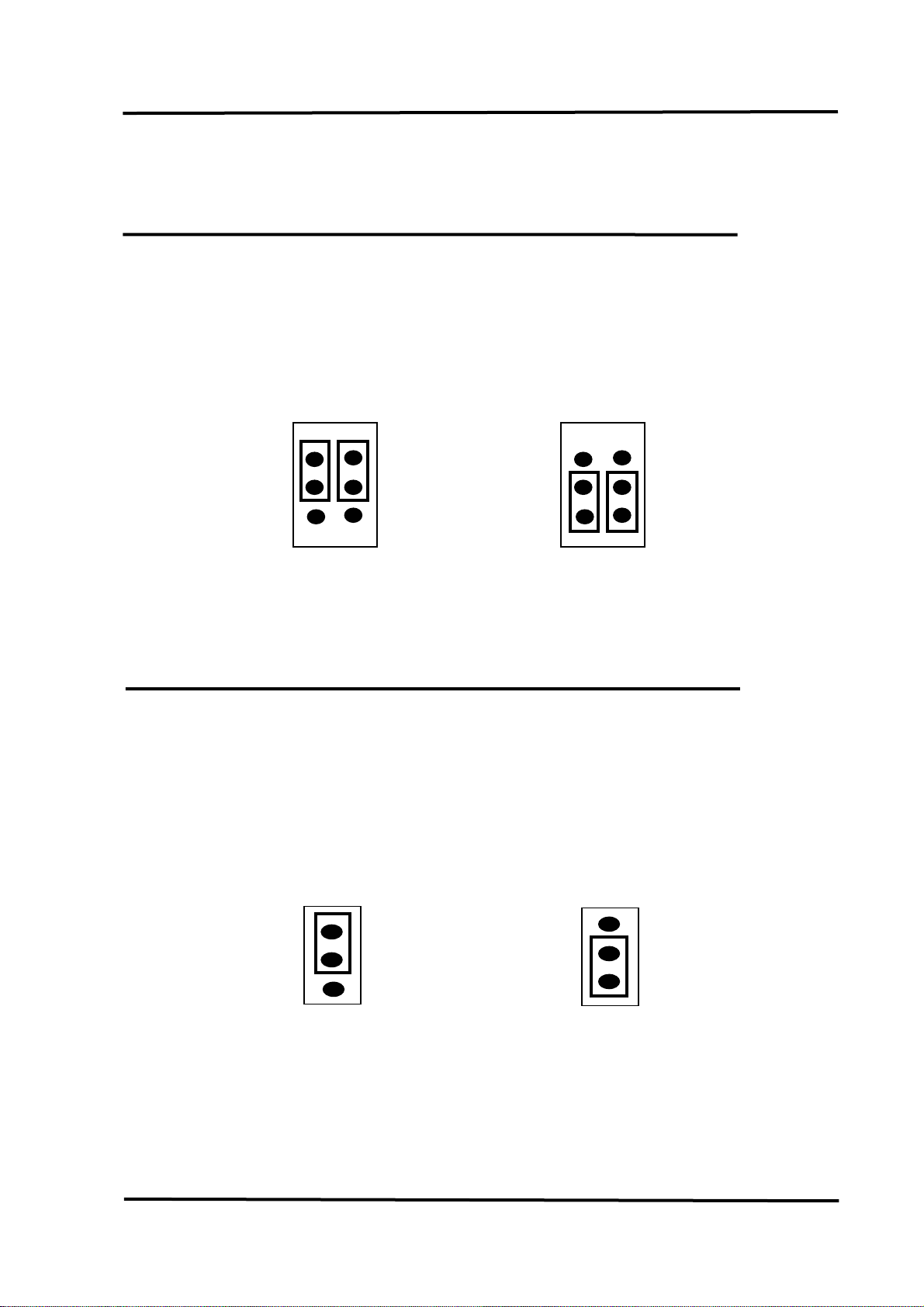

2.2 Jumper Setting

2.2.1 JP1: A/D Input Type Selection

This jumper is used to select the analog input type. For single-ended inputs, connect

pin 1,3 and pin 2,4. For differential inputs, pin 3,5 and pin 4,6 should be connected.

JP1 JP1

1

5 6

Single-Ended

Inputs (default

2

1

5

Differential

Inputs

2

6

2.2.2 J1: D/A Reference Voltage Selection

J1 is used to select the internal D/A output reference voltage. To select the ±10V

output, pin 1&2 should be connected. To select the ±5V output, pin 2&3 should be

connected.

J1 J1

1

± 10 Voltage

output (default)

18

1

± 5 Voltage

output

Page 19

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

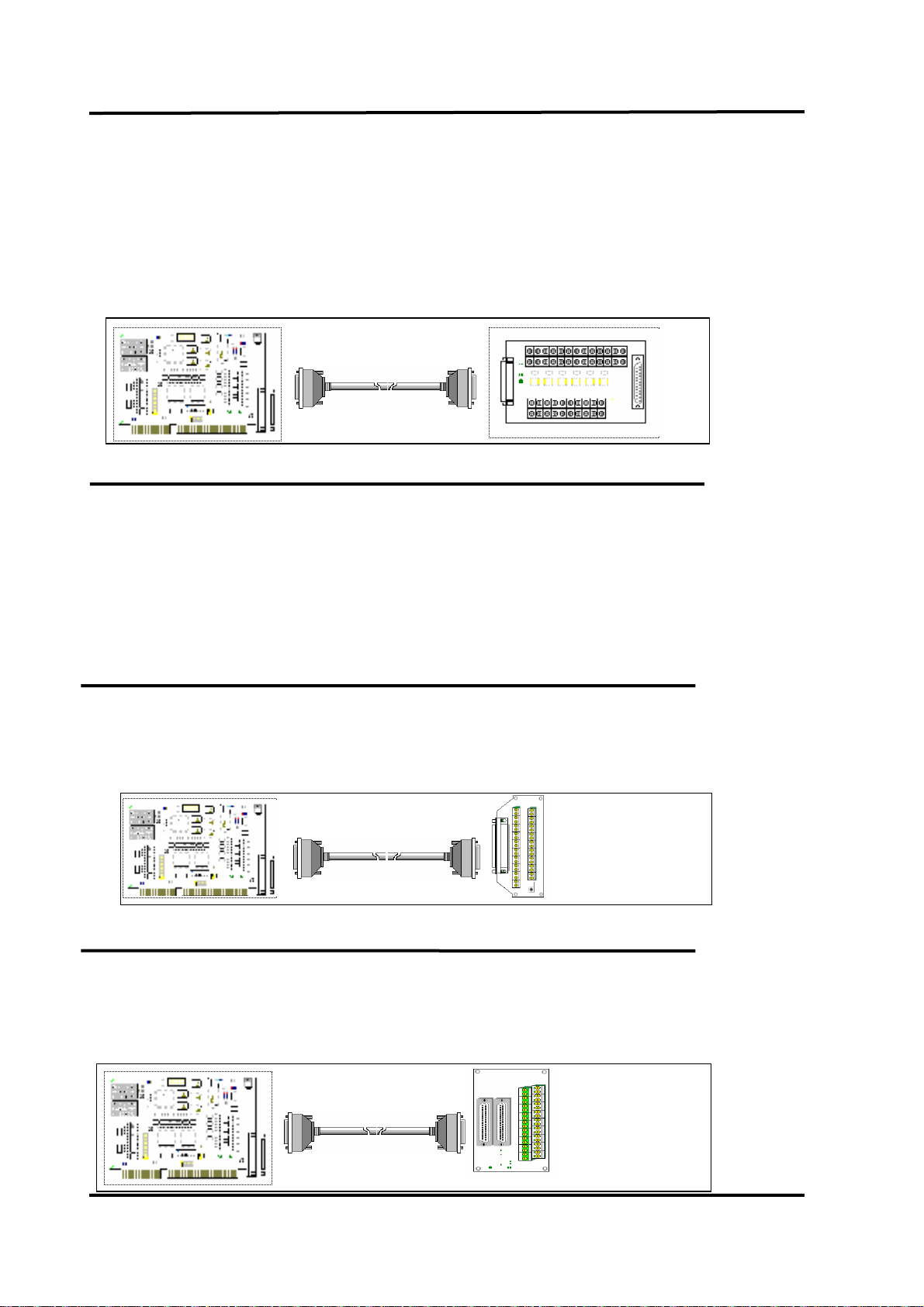

2.3 Daughter Boards

2.3.1 OME-DB-1825

The OME-DB-1825 is a daughter board designed for 32-channel AD cards such as the

OME-PCI-1202/1602/1802. Refer to Appendix A for details on the OME-DB-1825.

37pin cable

2.3.2 OME-DB-8225

The OME-DB-8225 provides a on-board CJC (Cold Junction Compensation) circuit for

thermocouple measurement and a terminal block for easy signal connection. The CJC is

connected to A/D channel_0. The OME-PCI-1800 can connect CON3 direct to an OME-DB-

8225 through a 37-pin D-sub connector. Refer to the OME-DB-8225 User Manual for details.

2.3.3 OME-DB-37

The OME-DB-37 is a general purpose daughter board for D-sub 37 pins. It is designed

for easy wire connection.

2.3.4 OME-DN-37

The OME-DN-37 is a general purpose daughter board for DIN Rail Mounting. It is

designed for easy wire connection and DIN-Rail mounting.

37pin cable

19

Page 20

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

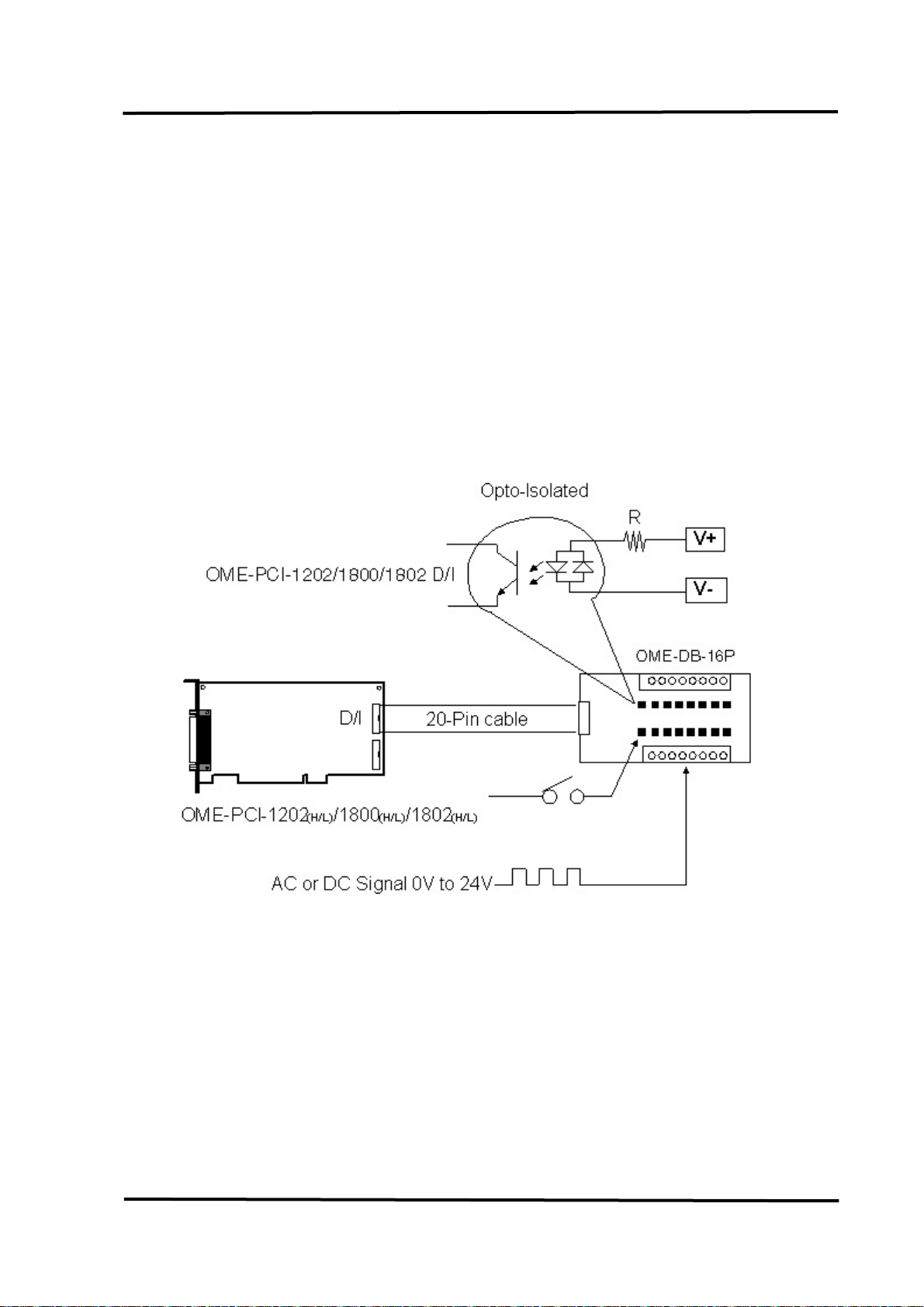

2.3.5 OME-DB-16P Isolated Input Board

The OME-DB-16P is a 16-channel isolated digital input daughter board. The optically

isolated inputs of the OME-DB-16P consist of a bi-directional optocoupler with a resistor for

current sensing. You can use the OME-DB-16P to sense DC signals from TTL levels up to 24V

or use the OME-DB-16P to sense a wide range of AC signals. You can use this board to isolate

the computer from large common-mode voltages, ground loops and transient voltage spikes

that often occur in industrial environments.

20

Page 21

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

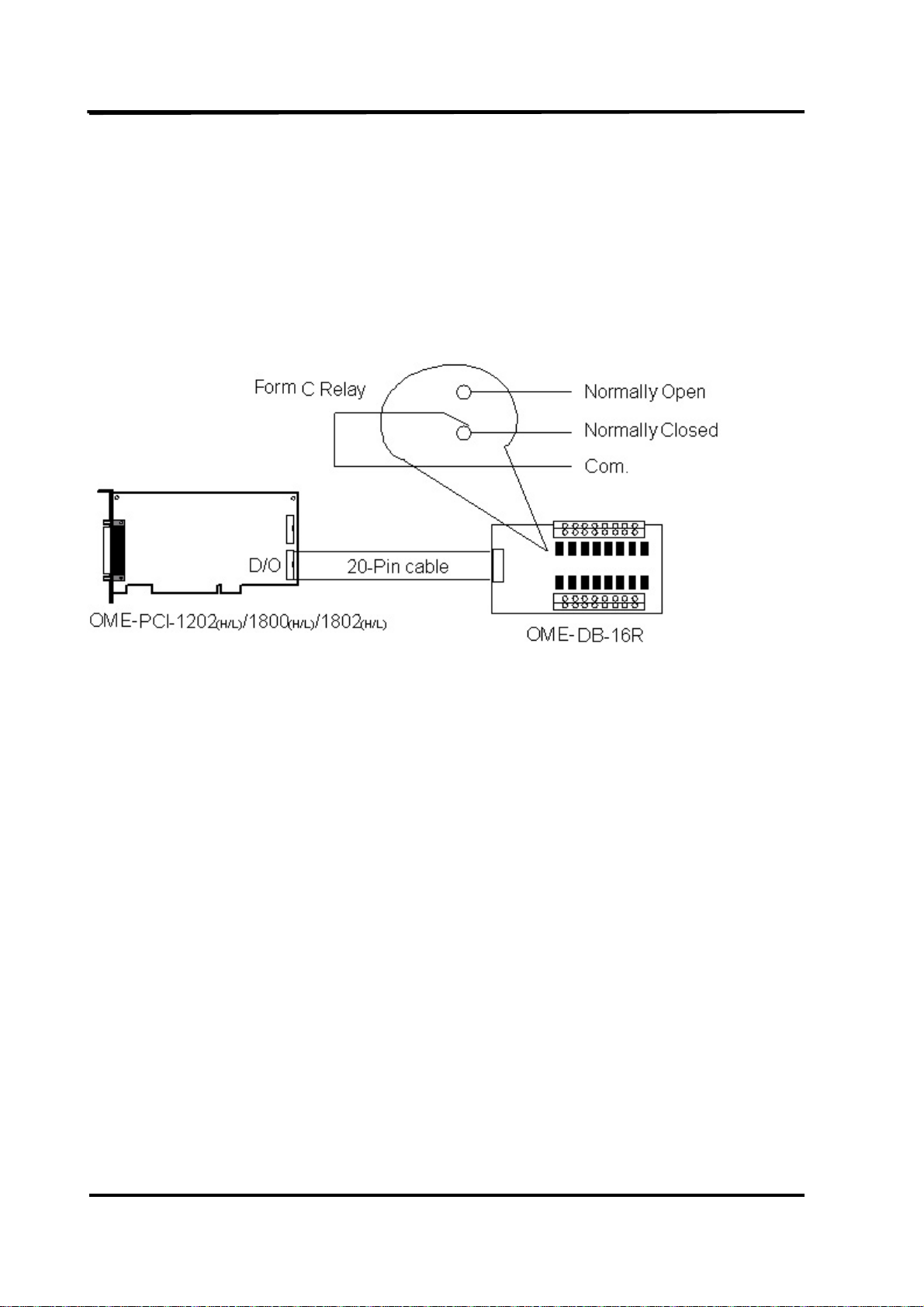

2.3.6 OME-DB-16R Relay Board

The OME-DB-16R, 16-channel relay output board consists of 16 from C relays used for

switching loads under program control. Applying 5 volts to the appropriated relay channel on

the 20-pin flat connector energizes the relays. There is 16 status LEDs for each relay, which

light when their associated relay is activated. To avoid overloading your PC’s power supply,

this board provides a screw terminal connection an for external power supply.

Note: Channel: 16 Form C Relay

Relay: Switching up to 0.5A at 110ACV or 1A at 24 DCV

21

Page 22

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

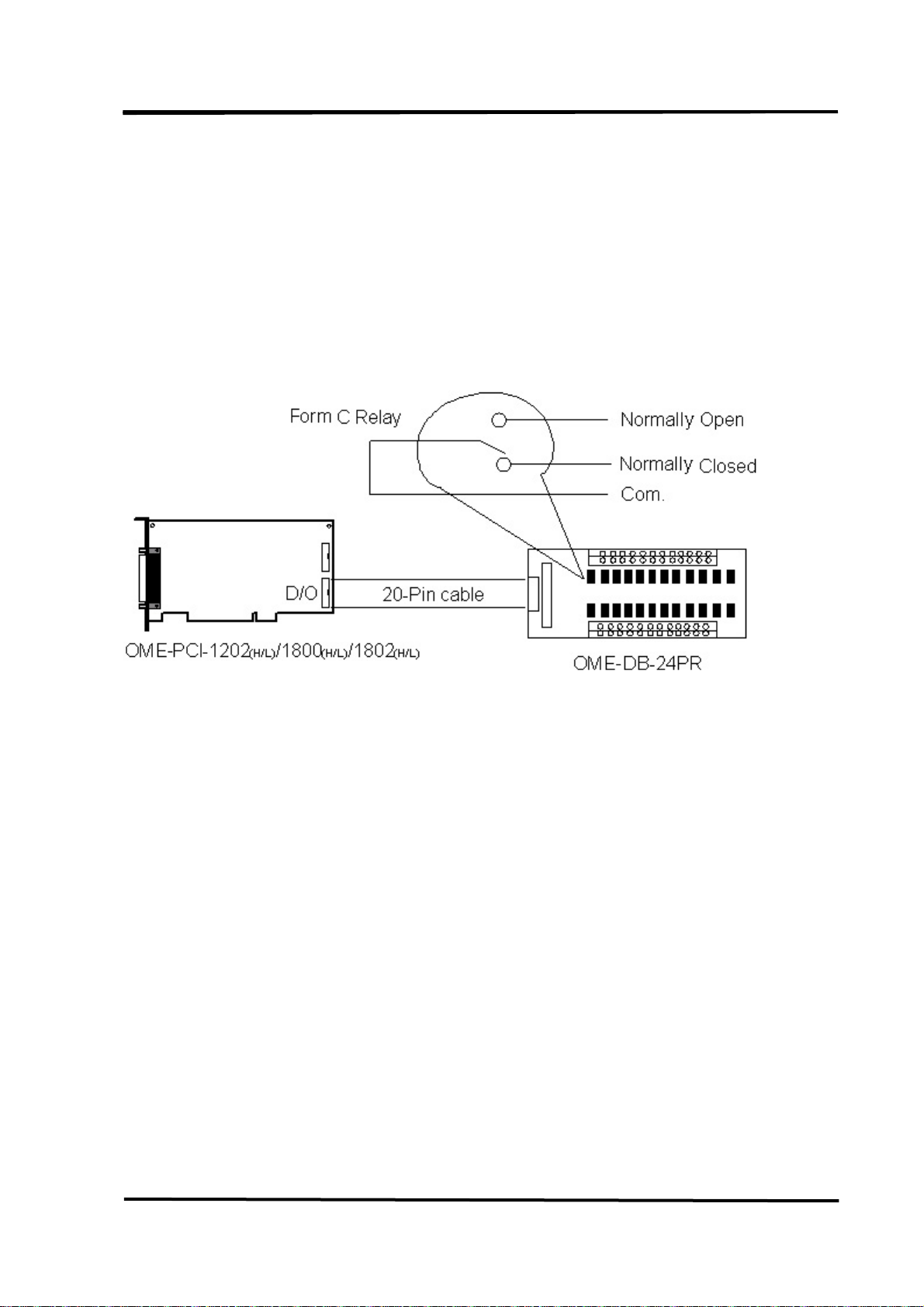

2.3.7 OME-DB-24PR Power Relay Board

The OME-DB-24PR, 24-channel power relay output board consists of 8 form C and 16

form A electromechanical relays for switching a load under program control. Each relay

contact is rated to 5A at 250ACV/30VDCV. The relay is energized by applying a 5 volt signal

to the appropriate relay channel on the 20-pin flat cable connector or 50-pin flat cable

connector. Each channel has an LED which will light when the associated relay is activated.

To avoid overloading your PC’s power supply, the board requires a +12VDC or +24VDC

external power supply.

Channel: 16 Form A Relays, 8 Form C Relays

Relay: Switching up to 5A at 110ACV / 5A at 30DCV

22

Page 23

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

2.4 Analog Input Signal Connection

The OME-PCI-1202/1602/1800/1802 can measure signals in the single-ended or

differential mode. In the differential mode each channel has a unique signal HIGH and signal

LOW connection. In the single-ended mode all channels have a unique signal HIGH

connection but share a common LOW or ground connection. Differential connections are very

useful for low level signals (millivolt), since they better reject electrical noise that can affect

the quality of the measurement. A differential connection is also necessary when a common

ground is unacceptable. The benefit of using a single-ended connection is that twice the

number of channels is available. In general, a single-ended connection is often a good choice

when working with higher level signals (5V or 10V for example), especially if the signal is

coming from an isolated device such as a signal conditioner. Several different types of wiring

diagrams are discussed below.

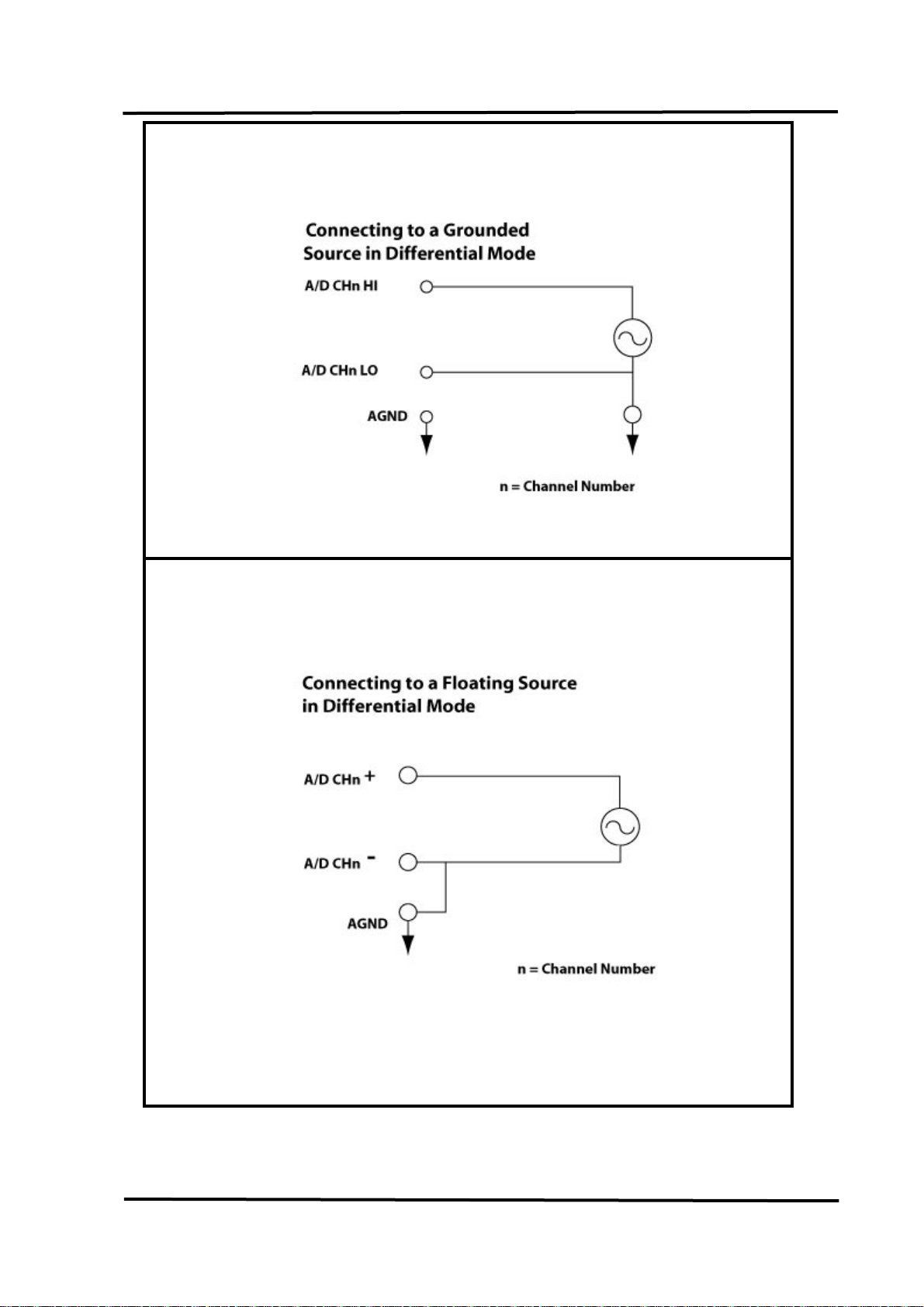

Figure 2-4A shows a differential connection to a grounded source. If the source is

grounded, making a second connection to the card’s ground could cause a ground loop

resulting in erroneous data. It is important to note that the maximum common mode

voltage between the input source and AGND is 70Vp-p. If the card is connected to a

source with a common mode voltage greater than 70Vp-p, the input multiplexer will be

permanently damaged! When measuring common mode voltage, it is best to use an

oscilloscope rather than a multi-meter.

Figure 2-4B shows a differential connection to a floating source. In such cases a

connection should be made between the low channel input and analog ground.

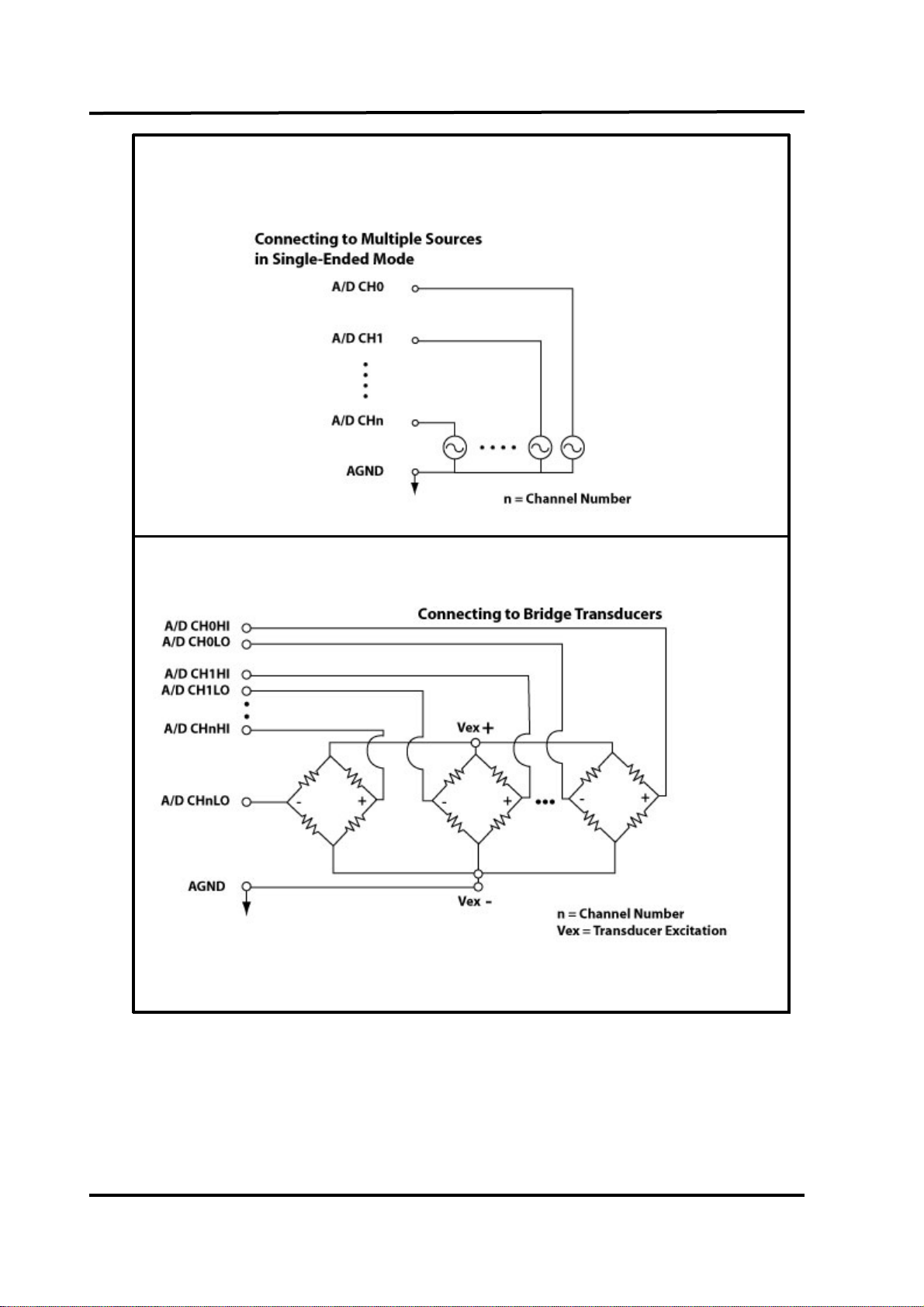

Figure 2-5 shows connection of multiple sources in single-ended mode. This connection

assumes creating one common ground will not cause a problem. This is normally the case

when connecting to devices that are isolated or floating.

Figure 2-6 demonstrates how to connect bridge transducers. Bridge transducers include

strain gauges, load cells and certain type of pressure transducers. The diagram assumes that

there is a single external power supply providing power to the bridge. Each bridge is

connected to a differential channel. No connection is made between channel low and analog

ground. A connection should be made between analog ground and the negative of the power

supply. An isolated power supply is strongly suggested.

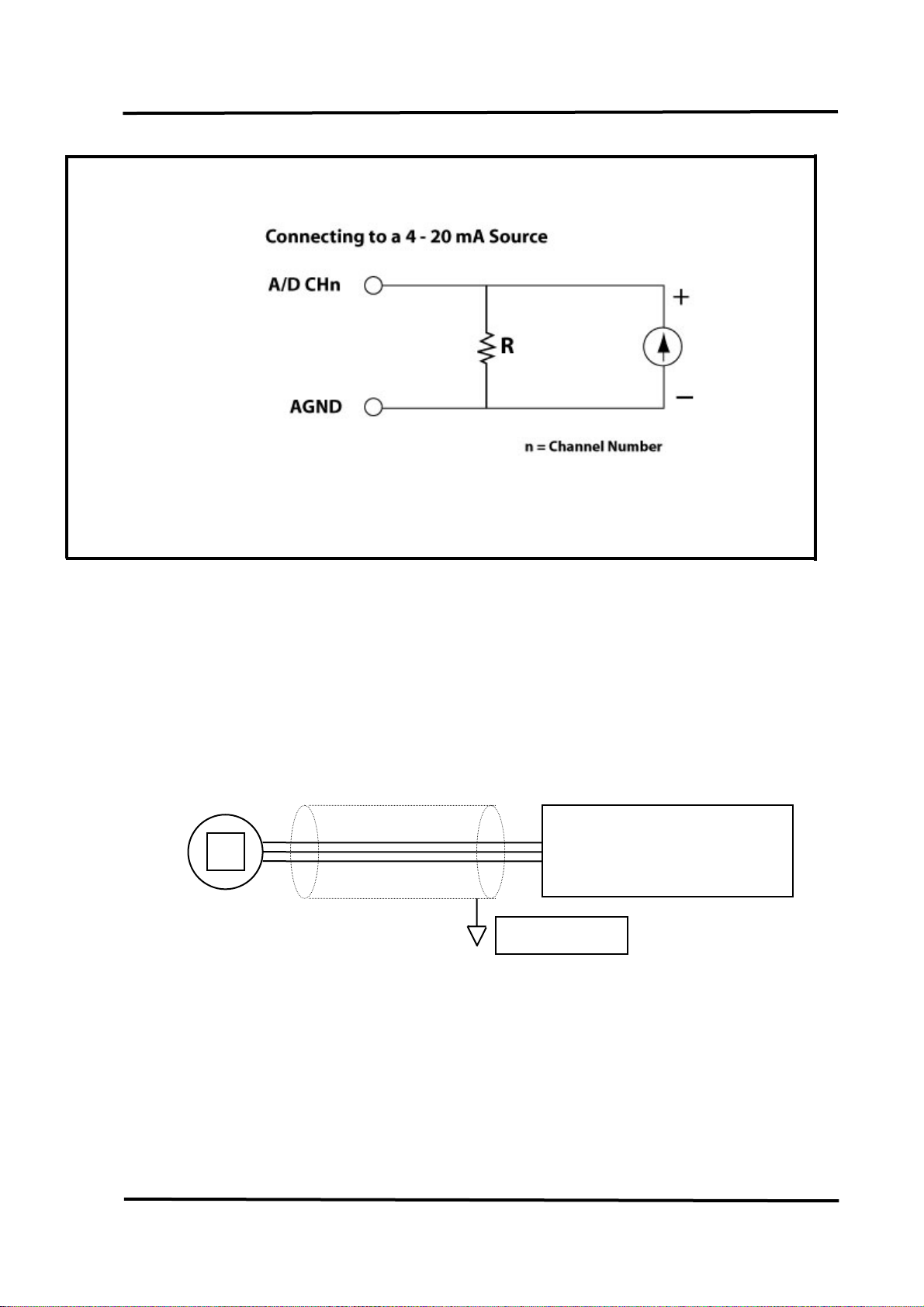

Figure 2-7 demonstrates how to connect a 4-20mA current loop. Since the card reads

voltages, the current is converted to voltage by passing it through a shunt resistor. By Ohms

law (V=IR), when using a 250Ω resistor, 4 mA will be converted to 1 volt and 20mA to 5V. If

the source is linear, the output voltage range will also be linear.

23

Page 24

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Figure 2-4A

If the source is grounded, a second ground connection

on the card could result in a ground loop.

Figure 2-4B

24

Page 25

Figure 2-5

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Figure 2-6

25

Page 26

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Figure 2-7

R is a shunt resistor. A 250Ω shunt resistor converts 4-20mA to 1-5Vdc.

Signal Shielding

z The signal shielding connections in Figure 2-4 to Figure 2-7 are all the same

z Use a single connection to frame ground (not A.GND or D.GND)

Vin

OME-PCI-1202/1602/1800/1802

A.GND

D.GND

Frame Ground

26

Page 27

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

2.5 The Connectors

CON1: Pin assignment of the digital output connector

Pin Name Pin Name

1 Digital output 0 2 Digital output 1

3 Digital output 2 4 Digital output 3

5 Digital output 4 6 Digital output 5

17 Digital output 6 8 Digital output 7

9 Digital output 8 10 Digital output 9

11 Digital output 10 12 Digital output 11

13 Digital output 12 14 Digital output 13

15 Digital output 14 16 Digital output 15

17 PCB ground 18 PCB ground

19 PCB +5V 20 PCB +12V

CON2: Pin assignment of digital input connector

Pin Name Pin Name

1 Digital input 0 2 Digital input 1

3 Digital input 2 4 Digital input 3

5 Digital input 4 6 Digital input 5

7 Digital input 6 8 Digital input 7

9 Digital input 8 10 Digital input 9

11 Digital input 10 12 Digital input 11

13 Digital input 12 14 Digital input 13

15 Digital input 14 16 Digital input 15

17 PCB ground 18 PCB ground

19 PCB +5V 20 PCB +12V

27

Page 28

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

C0N3: pin assignment of single-ended/differential inputs (for OME-PCI-

1202/1602/1802H/L)

Pin Name Pin Name

1 Analog input 0/0+ 20 Analog input 16/0-

2 Analog input 1/1+ 21 Analog input 17/1-

3 Analog input 2/2+ 22 Analog input 18/2-

4 Analog input 3/3+ 23 Analog input 19/3-

5 Analog input 4/4+ 24 Analog input 20/4-

6 Analog input 5/5+ 25 Analog input 21/5-

7 Analog input 6/6+ 26 Analog input 22/6-

8 Analog input 7/7+ 27 Analog input 23/7-

9 Analog input 8/8+ 28 Analog input 24/8-

10 Analog input 9/9+ 29 Analog input 25/9-

11 Analog input 10/10+ 30 Analog input 26/10-

12 Analog input 11/11+ 31 Analog input 27/11-

13 Analog input 12/12+ 32 Analog input 28/12-

14 Analog input 13/13+ 33 Analog input 29/13-

15 Analog input 14/14+ 34 Analog input 30/14-

16 Analog input 15/15+ 35 Analog input 31/15-

17 Analog ground 36 Analog output 1

18 Analog output 0 37 Digital ground

19 External trigger

28

Page 29

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

CON3: pin assignment of single-ended/differential input.(for OME-PCI-1800H/L)

Pin Name Pin Name

1 Analog input 0/0+ 20 Analog input 8/0-

2 Analog input 1/1+ 21 Analog input 9/1-

3 Analog input 2/2+ 22 Analog input 10/2-

4 Analog input 3/3+ 23 Analog input 11/3-

5 Analog input 4/4+ 24 Analog input 12/4-

6 Analog input 5/5+ 25 Analog input 13/5-

7 Analog input 6/6+ 26 Analog input 14/6-

8 Analog input 7/7+ 27 Analog input 15/7-

9 Analog Ground 28 Analog Ground

10 Analog Ground 29 Analog Ground

11 N.C. 30 Analog output 0

12 N.C. 31 N.C.

13 PCB +12V 32 Analog output 1

14 Analog Ground 33 N.C.

15 Digital Ground 34 N.C.

16 N.C. 35 N.C.

17 External Trigger 36 N.C.

18 N.C. 37 N.C.

19 PCB +5V

N. C.: Abbreviation of “Not Connected “.

29

Page 30

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3. I/O Control Register

3.1 How to Find the I/O Address

During the computer’s power-on stage the plug&play BIOS will assign a valid I/O address

to each OME-PCI-1800/1802 card. The P180X_DriverInit(..) can detect how many OME-

PCI-1800/1802 cards are in the system and the I/O addresses of these cards. The

P180X_DriverInit(..) is supported in both DOS and Windows driver versions. The

P180X_DriverInit(..) must be called before any other driver function. The

P180X_DriverInit(..) will:

1. Detect how many OME-PCI-1800/1802 cards in the system?

2. Detect and save the I/O control address of every OME-PCI-1800/1802 card

Sample program code is shown below:

wRetVal=P180X_DriverInit(&wBoards); /* call P180X_DriverInit(..) first */

printf("Threre are %d P180X Cards in this PC\n",wBoards);

/* dump every P180X card's configuration address space */

printf("The Configuration Space -> Timer Control DIO AD/DA \n");

for (i=0; i<wBoards; i++)

{

printf("Card %02d: %04xH %04xH %04xH %04xH\n", i,wConfigSpace[i][0],

wConfigSpace[i][1], wConfigSpace[i][2],wConfigSpace[i][3]);

}

/* The P180X_ActiveBoard() function must be used to activate a board, */

/* then all operations will apply to the active board. */

printf("Now Active First P180X Card...\n");

P180X_ActiveBoard( 0 );

z P1202_DriverInit(…) is designed for OME-PCI-1202H/L

z P1602_DriverInit(…) is designed for OME-PCI-1602 andOME-PCI-1602F

30

Page 31

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.2 The Assignment of I/O Address

The plug & play BIOS will assign a valid I/O address to OME-PCI-

1202/1602/1800/1802. If there is only one OME-PCI-1202/1602/1800/1802, the user can

easily identify board_1. If there are two OME-PCI-1202/1602/1800/1802 cards in the system,

identifying each board is a little more complicated. The software driver can support up to 16

boards. Therefore the user can install 16 boards in one PC system.

The simplest way to find the board number is to use the DEMO15.EXE program.

This demo program will send a value the digital output and read back from digital input. If

the user installs a 20-pin flat cable between CON1 & CON2, the value read from digital input

will be the same as digital output. The steps are given as follows:

1. If present, remove the 20-pin flat cable between CON1 and CON2

2. Install the OME-PCI-1202/1602/1800/1802 cards into the PC

3. Power-on and run DEMO15.EXE

4. At this time, all D/I values will be different from the D/O values

5. Install on any OME-PCI-1202/1602/1800/1802 card, a 20-pin flat cable between

CON1 & CON2

6. In the software one of the cards will have the same D/I value and D/O value. That is

the card with the cable.

7. Repeat the process to identify the remaining cards

3.3 The I/O Address Map

The I/O address of OME-PCI-1202/1602/1800/1802 is automatically assigned by

the computer’s ROM BIOS. The I/O address can also be reassigned by the user. It is

strongly recommended that the user not change the I/O address assigned by the

BIOS. There are five sections of I/O addresses used by this card and each section can

be assigned to an unused I/O space. The hardware I/O ports are described below:

31

Page 32

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Section Address Name Operation Access

1

2

3

4

Section1 + 0h PCI controller add-on

W 32-bits

mail box

Section1 + 38h PCI interrupt control

R/W 32bits

register

Section1 + 3Ch

(or 3Eh, 3Fh)

On board NV-RAM

access control register

R/W 32 bits

(8 bits)

Section2 + 00h 8254 timer1 R/W 8/16/32 bits

Section2 + 04h 8254 timer2 R/W 8/16/32 bits

Section2 + 08h 8254 timer3 R/W 8/16/32 bits

Section2 + 0Ch 8254 control W 8/16/32 bits

Section3 +00h Control register W 16/32 bits

Section3 + 00h Status register R 8/16/32 bits

Section3 + 04h A/D sofware trigger W 8/16/32 bits

Section4 + 00h DI port R 16 bits

Section4 + 00h DO port W 16 bits

Section5 + 00h A/D data port R 16 bits

5

Section5 + 00h D/A channel 1. W 16 bits

Section5 + 04h D/A channel 2. W 16 bits

The driver name of these address are given as follows:

section_2 : wAddrTimer Æ save in wConfigSpace[Board][0]

section_3 : wAddrCtrl Æ save in wConfigSpace[Board][1]

section_4 : wAddrDio Æ save in wConfigSpace[Board][2]

section_5 : wAddrAdda Æ save in wConfigSpace[Board][3]

32

Page 33

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.4 Section 1: PCI Controller

Although 64 I/O ports are used by the on-board OME-PCI-controller, only 3 registers

can be directly accessed by the user.

Address Access Functions Operation

+3C

+ 0

+38

+3F

(8bits)

Write only

(32 bit)

Write

(32bit)

Read (32bit)

Write

(8bit)

Read

Out-going mail-box Write a 0 to wait for add-on interrupt.

Enable/Re-enable/

Disable target interrupt

Read interrupt status.

Write command to

nvRAM control register

Read status from

1. Enable : Write 00010010h to this

port.

2. Re-enable: Write 00010010h to

this port.

3. Disable : Write 0 to this port.

Bit 16 : 1 Æ interrupt generated.

0 Æ no interrupt.

0x80 : load low address

0xA0: load high address

0xC0: begin write.

0xE0: begin read.

Bit 7 : 1 Æ busy

(32bit)

+3E

(8bits)

The user does not normally need to access this register. Refer to “AMCC S5933 PCI

Controllers User Manual” for all registers details.

(8bit)

Write

(8bit)

Read

(8bit)

nvRAM control register

Write nvRAM address or

nvRAM data to register. After finish writing to nvRAM control

Read nvRAM data from

this register.

33

0 Æ ready

register, write data to this port.

After finish writing to nvRAM control

register, read data from this port..

Page 34

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.5 Section 2: Timer Control

The timer-0 is used as the internal trigger A/D pacer timer. The timer-1 is used for the

external trigger pacer timer. The timer-2 is used as the machine independent timer. Timer-2 is

used for settling time delay, a critical function. Refer to Intel’s “Microsystem Components

Handbook” for 8254 programming. The block diagram of the 8254 timer is show below:

8Mhz

CLK

Timer 0

OUT0

Internal Pacer timer

Local Data Bus

D0,D1 ... D7

CLK

Timer 1

OUT1

CLK

Timer 2

OUT2

ADC

External Pacer timer

Machine indenpedent Timer

Figure 3-1: The block diagram of OME-PCI-1202/1602/1800/1802 8254 timer.

The I/O address of 8254 timer is given as follows:

z I/O address of timer/counter_0 = wAddrTimer+0*4

z I/O address of timer/counter_1 = wAddrTimer+1*4

z I/O address of timer/counter_2 = wAddrTimer+2*4

z I/O address of control register = wAddrTimer+3*4

34

Page 35

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

// timer0 Æ for pacer trigger

void enable_timer0(WORD divv) // for internal pacer trigger

{

outport((WORD)(wAddrTimer+3*4), 0x34); /* enable pacer timer_0 */

outport((WORD)(wAddrTimer+0*4), (WORD)(divv & 0xff));

outport((WORD)(wAddrTimer+0*4), (WORD)((divv>>8) & 0xff));

}

void disable_timer0(void)

{

outport((WORD)(wAddrTimer+3*4), 0x34); /* disable pacer timer_0 */

outport((WORD)(wAddrTimer+0*4), 0x01);

outport((WORD)(wAddrTimer+0*4), 0x00);

}

// timer1 Æ for external trigger

void enable_timer1(WORD divv) /* for external trigger pacer timer */

{

outport((WORD)(wAddrTimer+3*4), 0x74); /* enable pacer timer_1 */

outport((WORD)(wAddrTimer+1*4), (WORD)(divv & 0xff));

outport((WORD)(wAddrTimer+1*4), (WORD)((divv>>8) & 0xff));

}

void disable_timer1(void)

{

outport((WORD)(wAddrTimer+3*4), 0x74); /* disable timer_1 */

outport((WORD)(wAddrTimer+1*4), 0x01);

outport((WORD)(wAddrTimer+1*4), 0x00);

}

35

Page 36

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

// timer2 Æ for Machine Independent Timer

/* address of timer 2 = wAddrTimer+2*4

address of ctrl = wAddrTimer+3*4

input clock = 8M

down count 8 time = 1 us

down count 65536/8 = 8192 uS --> max 8191 uS

*/

WORD P180X_DelayUs(WORD wDelayUs)

{

WORD wDownCount,wLow,wHigh,wVal;

double fTimeOut;

if (wDelayUs>=8191) return(InvalidateDelay);

wDownCount=wDelayUs*8;

wLow=wDownCount&0xff;

wHigh=(wDownCount>>8)&0xff;

outport((wAddrTimer+3*4), 0xb0); /* timer_2 mode_0 0xb0 */

outport((wAddrTimer+2*4), wLow);

outport((wAddrTimer+2*4), wHigh);

fTimeOut=1.0; // wait 1 to stop

for (;;)

{

wVal=inport(wAddrCtrl)&0x01;

if (wVal!=0) return(NoError); /* if the timer is up, this bit will be 1 */

fTimeOut+=1.0;

if (fTimeOut>6553500.0)

return(DelayTimeOut);

}

}

z P1202_DelayUs(…) is designed forOME-PCI-1202H/L

z P1602_DelayUs(…) is designed forOME-PCI-1602 andOME-PCI-1602F

36

Page 37

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6 Section 3: Control Register

z I/O address of control register = wAddrCtrl + 0

z I/O address of status register = wAddrCtrl + 0

z I/O address of trigger register = wAddrCtrl + 1 *4

The flow path of analog input signal is given as follows:

Signals

Max=+/-10V Max=+/-5V

Single-ended

Differential

MUX

4,3,2,1,0 7,6

AMP1

Gain Rang

Figure 3-2: The flow diagram of an analog input signal.

3.6.1 The Control Register

The format of the control register is given as follows:

AMP1

9,8

ADC

0

1

0

:

:

:

:

.

1

B15 B14 B13 B12 toB10 B9, B8 B7, B6 B5 B4 to B0

z B4 - B0: A/D channel select

z B7, B6: A/D gain control.

z B9, B8: A/D input range control.

z B12 -B10: external trigger control.

z B13: handshake control to MagicScan controller.

z B15: clear FIFO.

z B5, B14: reserved

37

Page 38

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.1.1 Bit4 - Bit0: A/D channel select

A/D channel B4 B3 B2 B1 B0

0 0 0 0 0 0 1800/1202/1602/1802

15 0 1 1 1 1 1800/1202/1602/1802

16 1 0 0 0 0 1202/1602/1802

31 1 1 1 1 1 1202/1602/1802

3.6.1.2 Gain control

[B7, B6] PCI-1XXXL PCI-1XXXH

[0, 0] PGA=1 PGA=1

[0, 1] PGA=2 PGA=10

[1, 0] PGA=4 PGA=100

[1, 1] PGA=8 PGA=1000

3.6.1.3 Input Range Control

[B9, B8] Output

[0, 0] PGA

[1, 0] PGA-5

[0, 1] PGA/2

[1, 1] PGA/2 - 5

38

Page 39

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.1.4 Configuration Table

Configuration table for OME-PCI-1202L/1800L/1802L

Bipolar/Unipolar Input Signal Range Gain Settling Time [B9,B8,B7,B6]

Bipolar +/- 5V 1 3 us 0000

Bipolar +/- 2.5V 2 3 us 0001

Bipolar +/- 1.25V 4 3 us 0010

Bipolar +/- 0.625V 8 3 us 0011

Bipolar +/- 10V 0.5 3 us 0100

Bipolar +/- 5V 1 3 us 0101

Bipolar +/- 2.5V 2 3 us 0110

Bipolar +/- 1.25V 4 3 us 0111

Unipolar 0V to 10V 1 3 us 1000

Unipolar 0V to 5V 2 3 us 1001

Unipolar 0V to 2.5V 4 3 us 1010

Unipolar 0V to 1.25V 8 3 us 1011

Configuration table of OME-PCI-1202H/1800H/1802H

Bipolar/Unipolar Input Signal Range Gain Settling Time [B9,B8,B7,B6]

Bipolar +/- 5V 1 23 us 0000

Bipolar +/- 0.5V 10 28 us 0001

Bipolar +/- 0.05V 100 140 us 0010

Bipolar +/- 0.005V 1000 1300 us 0011

Bipolar +/- 10V 0.5 23 us 0100

Bipolar +/- 1V 5 28 us 0101

Bipolar +/- 0.1V 50 140 us 0110

Bipolar +/- 0.01V 500 1300 us 0111

Unipolar 0V to 10V 1 23 us 1000

Unipolar 0V to 1V 10 28 us 1001

Unipolar 0V to 0.1V 100 140 us 1010

Unipolar 0V to 0.01V 1000 1300 us 1011

39

Page 40

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.1.5 Set Channel Configuration

The SetChannelConfig command sets the channel/gain:

WORD P180X_SetChannelConfig(WORD wAdChannel, WORD wAdConfig)

{

WORD wConfig,wChannel;

wChannel = (wAdChannel&0x1f);

wSysConfig = (wAdConfig&0x1f); // store for P1802_AdPolling

wConfig = (wAdConfig&0x0f);

wConfig = wConfig << 6;

wConfig += wChannel;

/* Bit15=1 --> no reset FIFO

Bit14=?

Bit13=?

Bit12=0 --> command [001] --> set channel&Config command

Bit11=0

Bit10=1

Bit9 =B --> Range control code [BB] --> unipolar/bipolar & divided by 2

Bit8 =B

Bit7 =B --> gain control code [BB] --> 1/10/100/1000 or 1/2/4/8

Bit6 =B

Bit5 =?

Bit4-Bit0 --> channel number */

wConfig+= 0x8400; // this is set channel config command

return(pic_control(wConfig));

}

z P1202_SetChannelConfig(…) is used for OME-PCI-1202H/L

z P1602_SetChannelConfig(…) is used for OME-PCI-1602 and OME-PCI-1602F

40

Page 41

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.1.6 Calculate the A/D Value

Converting A/D value to a real number:

double ComputeRealValue(DWORD dwAdConfig, DWORD dwAdHex)

{

WORD wZERO;

double dfMAX, dfVal;

switch (dwAdConfig)

{ case 0 : wZERO=2048; dfMAX=5.0; break;

case 1 : wZERO=2048; dfMAX=2.5; break;

case 2 : wZERO=2048; dfMAX=1.25; break;

case 3 : wZERO=2048; dfMAX=0.625; break;

case 4 : wZERO=2048; dfMAX=10.0; break;

case 5 : wZERO=2048; dfMAX=5.0; break;

case 6 : wZERO=2048; dfMAX=2.5; break;

case 7 : wZERO=2048; dfMAX=1.25; break ;

case 8 : wZERO= 0; dfMAX=10.0/2.0; break;

case 9 : wZERO= 0; dfMAX=5.0/2.0; break;

case 10: wZERO= 0; dfMAX=2.5/2.0; break;

case 11: wZERO= 0; dfMAX=1.25/2.0; break;

case 0x10 : wZERO=2048; dfMAX=5.0; break;

case 0x11 : wZERO=2048; dfMAX=0.5; break;

case 0x12 : wZERO=2048; dfMAX=0.05; break;

case 0x13 : wZERO=2048; dfMAX=0.005; break;

case 0x14 : wZERO=2048; dfMAX=10.0; break;

case 0x15 : wZERO=2048; dfMAX=1.0; break ;

case 0x16 : wZERO=2048; dfMAX=0.1; break;

case 0x17 : wZERO=2048; dfMAX=0.01; break;

case 0x18 : wZERO= 0; dfMAX=10.0/2.0; break ;

case 0x19 : wZERO= 0; dfMAX=1.0/2.0; break;

case 0x1A : wZERO= 0; dfMAX=0.1/2.0; break;

For OM-EPCI-1202/1800/1802L

Note: B4=0 is used

to identify PGL

For OME-PCI-

1202/1800/1802H

Note: B4=1 is used to

identify PGH

case 0x1B : wZERO= 0; dfMAX=0.01/2.0; break;

default: return(ConfigCodeError); }

dfVal=(((double)(wAdHex)-wZERO)/2048.0)*dfMAX;

return(dfVal);

}

41

Page 42

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.1.7 MagicScan Controller Commands

Command [B12toB10] Descriptions

Reset [0 0 0] Reset the MagicScan controller. The software driver

must send this command once after power-on.

Set channel/gain [0 0 1] Set the channel/gain value of the fixed-channel mode. It

will not affect the scan queue.

Add to scan queue [1 0 0] Add the channel/gain code to the scan queue.

(At most 48 scan-channels can be stored in the

MagicScan controller.)

Start MagicScan [1 0 1] Start the MagicScan controller

Stop MagicScan [0 1 0] Stop the MagicScan controller.

Get ODM number [1 1 0] Get the ODM number of the OME-PCI-

1202/1602/1800/1802.

Resetting the MagicScan controller:

wVal=pic_control(0xC000); /* 11?0 00?? ???? ???? cmd_000=reset */

The program code to clear the MagicScan queue is shown below:

WORD P180X_ClearScan(void)

{

WORD i;

for(i=0; i<32; i++) wMagicScanSave[i]=0;

disable_timer0();

disable_timer1();

return(pic_control(0xC000)); /* 11?0 00?? ???? ???? cmd_000=reset */

}

z P1202_ClearScan(…) is designed for OME-PCI-1202H/L

z P1602_ClearScan(…) is designed for OME-PCI-1602 and OME-PCI-1602F

42

Page 43

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Sending commands to the MagicScan controller is shown below:

WORD pic_control(WORD i)

{

WORD j;

if ((inport(wAddrCtrl)&0x04)==0)

{

outport(wAddrCtrl,0xffff); /* send a recovery to PIC */

}

j=0;

while ((inport(wAddrCtrl)&0x04)==0)

{

j++;

if (j>65530) return(AdControllerError); /* time out */

}

i = i & 0xDFFF; /* set pic low !! */

outport(wAddrCtrl,i);

j=0;

while ((inport(wAddrCtrl)&0x04)!=0)

{

j++;

if (j>65530) return(AdControllerError); /* time out */

}

outport(wAddrCtrl,(WORD)(i | 0x2000)); /* set pic high !! */

j=0;

while ((inport(wAddrCtrl)&0x04)==0)

{

j++;

if (j>65530) return(AdControllerError); /* time out */

}

return(NoError);

}

43

Page 44

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

The program code to set the channel/gain is shown below:

WORD P180X_SetChannelConfig(WORD wAdChannel, WORD wAdConfig)

{

WORD wConfig,wChannel;

wChannel = (wAdChannel&0x1f);

wSysConfig = (wAdConfig&0x1f); // store for P1802_AdPolling

wConfig = (wAdConfig&0x0f);

wConfig = wConfig << 6;

wConfig += wChannel;

/* Bit15=1 --> no reset FIFO

Bit14=?

Bit13=?

Bit12=0 --> command [001] --> set channel&Config command

Bit11=0

Bit10=1

Bit9 =B --> Range control code [BB] --> unipolar/bipolar & divided by 2

Bit8 =B

Bit7 =B --> gain control code [BB] --> 1/10/100/1000 or 1/2/4/8

Bit6 =B

Bit5 =?

Bit4-Bit0 --> channel number */

wConfig+= 0x8400; // this is set channel config command

return(pic_control(wConfig));

}

z P1202_SetChannelConfig(…) is designed for OME-PCI-1202H/L

z P1602_SetChannelConfig(…) is designed for OME-PCI-1602 and OME-PCI-

1602F

44

Page 45

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

The program code to add to the MagicScan queue is shown below:

WORD P180X_AddToScan(WORD wAdChannel, WORD wAdConfig, WORD

wAverage, WORD wLowAlarm, WORD wHighAlarm, WORD wAlarmType)

{WORD wConfig,wChannel,wRetVal;

if (wAlarmType>=5) return(AlarmTypeError);

wMagicLowAlarm[wMP]=wLowAlarm;

wMagicHighAlarm[wMP]=wHighAlarm;

wMagicAlarmType[wMP]=wAlarmType;

wChannel = wAdChannel&0x1f;

wMagicChannel[wMP]=wChannel;

wSysConfig = wAdConfig&0x1f; /* Store for P180X_AdPolling */

wMagicConfig[wMP]=wSysConfig;

wMagicAve[wMP]=wAverage;

wConfig = wAdConfig&0x0f;

wConfig = wConfig << 6;

wConfig += wChannel;

/* Bit15=1 --> no reset FIFO

Bit14=1

Bit13=?

Bit12=1 --> command [100] --> add_to_scan command

Bit11=0

Bit10=0

Bit9 =B --> Range control code [BB] --> unipolar/bipolar & divided by 2

Bit8 =B

Bit7 =B --> gain control code [BB] --> 1/10/100/1000 or 1/2/4/8

Bit6 =B

Bit5 =?

Bit4-Bit0 --> channel number */

wConfig+= 0xD000; /* this is add_to_scan_queue command */

wRetVal=pic_control(wConfig);

if (wRetVal!=0) return(wRetVal);

return(NoError);

}

z P1202_AddToScan(…) is designed for OME-PCI-1202H/L

z P1602_AddToScan(…) is designed for OME-PCI-1602 and OME-PCI-1602F

45

Page 46

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

The program code to start the MagicScan operation is shown below:

WORD P180X_StartScan(WORD wSampleRate, WORD wNum)

{

WORD wVal;

WORD wRetVal;

wMagicNum=wNum;

disable_timer0(); /* Disable pacer timer first */

/* start MagicScan controller */

wRetVal=pic_control(0xD400); /* 11?1 01?? ???? ???? cmd_101=start scan */

if (wRetVal!=0) return(wVal);

/* Clear FIFO to clear all data */

outport(wAddrCtrl,0x2000); /* Bit15=0=clear FIFO, Bit13=1=not PIC cmd */

outport(wAddrCtrl,0xA000); /* Bit15=1=no reset FIFO, BIT13=1=not PIC cmd */

enable_timer0(wSampleRate); /* Enable pacer timer, sampling rate=8M/dwSample */

magic_scan(); /* Call MagicScan subroutine(DOS) or thread(Windows) */

return(NoError);

}

z P1202_StartScan(…) is designed for OME-PCI-1202H/L

z P1602_StartScan(…) is designed for OME-PCI-1602 and OME-PCI-1602F

46

Page 47

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.1.8 External Trigger Control

Setting a post-trigger

Step 1: Disable all external triggers

Step 2: Set the pacer rate of timer-1

Step 3: Clear FIFO & disable timer-1

Step4: Wait until external trigger signal

to enable timer-1

Step 5: Fetch N data(N=End-Start)

Step 6: Stop all timers

Setting a pre-trigger

Step 1: Disable all external triggers

Step 2: Set the pacer rate of timer-1

Step 3: Clear FIFO & enable timer-1

Step 4: Circular-fetch N-data until

external trigger signal to disable

timer-1 (N=End-Start)

Step 5: Stop all timers

NOTE: The circular-fetch operation is performed by software

External trigger signal

CHn

Start

External post-trigger timing

External trigger signal

CHn

Start

External pre-trigger timing diagram

t

t

Setting a middle-trigger:

Step 1: Disable all external triggers

External trigger signal

Step 2: Set the pacer rate of timer-1

Step 3: Clear FIFO & enable timer-1

CHn

Step4: Circular-fetch N-data until

external trigger signal (N=End-

Start)

External middle-trigger timing diagram

N2

End

t

Step 5:Fetch more N2-data & stop timer-1

Step 6: Stop all timers

NOTE: The circular-fetch operation is performed by software

z Note 1: The external trigger operation must use the MagicScan controller.

The software flowchart for the external trigger is given in next page.

z Note 2: The post-trigger operation can use all MagicScan functions.

z Note 3: The user should not enable the MagicScan HI/LO alarms and/or digital

filter functions when using a pre-trigger or middle-trigger.

47

Page 48

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Flowchart for External Trigger

P180X_ClearScan

Clear the MagicScan controller

P180X_AddToScan

P180X_SaveScan

P180X_AddToScan

P180X_SaveScan

P180X_AddToScan

P180X_SaveScan

Add channel 1 to circular queue

Save AD data if needed

Add channel 2 to circular queue

Save AD data if needed

Add channel ? to circular queue

Save AD data if needed

z Refer to chapter 4 for additional details

z This flowchart is valid for the OME-PCI-1202/1602/1800/1802

P180X_StartScanPostTrg

or

P180X_StartScanPreTrg

or

P180X_StartScanMiddleTrg

P180X_WaitMagicScanFinish

Perform analysis

Start the external trigger

Wait external trigger signal

48

Page 49

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Sample Program Code for Post-trigger

wRetVal=P180X_ClearScan();

wRetVal += P180X_AddToScan(0,0,1,0,0,0); // CH:0 to scan

wRetVal += P180X_SaveScan(0,wV0);

wRetVal += P180X_AddToScan(2,0,1,0,0,0); // CH:2 to scan

wRetVal += P180X_SaveScan(1,wV2); // Notice: 1 not 2

// ^ : This is an ordinal number in

// Scan Queue not a channel number.

wRetVal += P180X_StartScanPostTrg(wSampleRateDiv,DATALENGTH,nPriority);

if (wRetVal==0) sprintf(cShow,"2. External Post-Trigger Setup OK");

else sprintf(cShow,"2. External Post-Trigger Setup Error");

TextOut(hdc,x*dx,(y+iLine)*dy,cShow,strlen(cShow)); iLine++;

for (; ;)

{

P180X_ReadScanStatus(&wStatus,&dwLowAlarm,&dwHighAlarm);

if (wStatus>1) break;

Sleep(10);

}

sprintf(cShow,"3. ScanStatus=%x",wStatus);

TextOut(hdc,x*dx,(y+iLine)*dy,cShow,strlen(cShow)); iLine++;

wRetVal=P180X_StopMagicScan();

if (wRetVal!=NoError)

{

sprintf(cShow,"4. StopMagicScan Error");

TextOut(hdc,x*dx,(y+iLine)*dy,cShow,strlen(cShow)); iLine++;

for (dwI=0; dwI<100; dwI++) Beep(10,10);

}

SHOW_WAVE(hwnd,LINE1,wV0,1);

SHOW_WAVE(hwnd,LINE2,wV2,1);

z Refer to DEMO23.C for complete source code

49

Page 50

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Bit B13 must set to 1 to enable the external trigger logic. The external trigger controller commands

are given as follows:

Trigger Command sequences

[B12, B11, B10 ]

Disable external trigger

(for OME-PCI-

1800/1X02)

Post-trigger

(for OME-PCI-

1202/1602/ 1800/1802)

Pre-trigger

(for OME-PCI-

1202/1602 & OME-

PCI-1800/1802/ver-F)

[ 1, 0, X] Disable all external triggers.

[ 1, 0, X]

[ 1, 0, X ]

[ 1, 1, 1 ]

[ 1, 0, X]

[ 1, 0, X ]

[ 0, 1, X ]

[ 1, 1, 0 ]

(1) disable all external triggers

(2) set pacer time-1

(3) clear FIFO and disable timer-1

(4) wait for external signal to enable timer-1

(5) fetch N data

(6) stop all timers & disable all external triggers

(1) disable all external triggers

(2) set pacer timer-1

(3) clear FIFO and enable timer-1

(4) wait for the external signal to stop timer-1.

(5) circular-fetch the last N data

Descriptions

Middle-trigger

(for OME-PCI-

1202/1602 & OME-

PCI-1800/1802/ver-F)

Pre-trigger

(for OME-PCI-

1800/1802) (version-C)

Middle-trigger

(for OME-PCI-

1800/1802) (version-C)

[ 1, 0, X]

[ 1, 0, X ]

[ 0, 1, X ]

[ 1, 1, 1]

[ 1, 0, X]

[ 1, 0, X ]

[ 0, 1, X ]

[ 1, 1, 1]

[ 1, 0, X]

[ 1, 0, X ]

[ 0, 1, X ]

(6) stop all timers & disable all triggers

(1) disable all external triggers

(2) set pacer timer-1

(3) clear FIFO and enable timer-1

(4) wait for the external signal.

(5) fetch more N2 data (circular-fetch)

(6) stop all timers & disable all triggers

(1) disable all external triggers

(2) set pacer timer-1

(3) clear FIFO and enable timer-1

(4) wait for the external signal to stop timer-1.

(5) keep the last N data (circular-fetch)

(6) stop all timer & disable all trigger

(1) disable all external trigger

(2) set pacer timer-1

(3) clear FIFO and enable timer-1

[ 1, 1, 0]

[ 0, 1, X]

[ 1, 0, X]

(4) wait for the external signal to stop timer-1

(5) enable timer-1

(6) fetch more N2 data

(7) stop all timers & disable all triggers

50

Page 51

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

The Windows program code for a post-trigger is given as follows:

WORD CALLBACK P180X_StartScanPostTrg(WORD wSampleRateDiv, DWORD dwNum,

SHORT nPriority)

{

disable_timer0(); // disable internal pacer timer

disable_timer1(); // disable external pacer timer

wVal=pic_control(0xD400); /* 11?1 01?? ???? ???? cmd_101=start scan */

if (wVal!=0) return(wVal);

_outpw(wAddrCtrl,0xf000); // 1. disable all external trigger

enable_timer1(wSampleRateDiv); // 2. Sampling rate=8M/dwSampleRateDiv

_outpw(wAddrCtrl,0x7000); // 3. B15=0,S2=1,S1=S0=0 --> clr FIFO

_outpw(wAddrCtrl,0xf000); // 3. B15=1,S2=1,S1=S0=0 --> disable timer-1

_outpw(wAddrCtrl,0xfc00); // 4. S2=1, S1=1, S0=1 --> wait ext signal to

// enable timer-1

// create magicscan thread

InitializeCriticalSection(&MagicScan_CS);

wThreadStatus=0; wAskThreadStop=0;

hThread=CreateThread(NULL,0,(LPTHREAD_START_ROUTINE)magic_scan,

NULL, 0,&dwThreadID);// can use all MagicScan functions

SetThreadPriority(hThread,nPriority);

i=0;

for(;;)

{

EnterCriticalSection(&MagicScan_CS);

j=wThreadStatus;

LeaveCriticalSection(&MagicScan_CS);

if (j!=0) break;

i++; Sleep(1);

if (i>1000) return(ThreadCreateError);

}

return(NoError);

}

z P1202_StartScanPostTrg(…) is designed for OME-PCI-1202H/L

z P1602_StartScanPostTrg(…) is designed for OME-PCI-1602 and OME-PCI-

1602F

51

Page 52

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

The windows driver of pre-trigger is given as follows:

WORD CALLBACK P180X_StartScanPreTrg(WORD wSampleRateDiv, DWORD dwNum,

SHORT nPriority)

{

disable_timer0(); // disable internal pacer timer

disable_timer1(); // disable external pacer timer

wVal=pic_control(0xD400); /* 11?1 01?? ???? ???? cmd_101=start scan */

if (wVal!=0) return(wVal);

_outpw(wAddrCtrl,0xf000); // 1. disable all external trigger

enable_timer1(wSampleRateDiv); // 2. Sampling rate=8M/dwSampleRateDiv

_outpw(wAddrCtrl,0x6800); // 3. B15=0,S2=0,S1=1,S0=0 --> clr FIFO

_outpw(wAddrCtrl,0xE800); // 3. B15=1,S2=0,S1=1,S0=0 --> enable timer-1

_outpw(wAddrCtrl,0xF800); // 4. S2=1; S1=1; S0=0 --> wait ext signal to

// disable timer-1

// create magicscan thread

InitializeCriticalSection(&MagicScan_CS);

wThreadStatus=0; wPreMid=0; wAskThreadStop=0; // pre-trigger

hThread=CreateThread(NULL,0,(LPTHREAD_START_ROUTINE)

magic_scan_pre_mid_trg, NULL, 0,&dwThreadID);

SetThreadPriority(hThread,nPriority); // can not use HI/LO alarm & digital filter

i=0;

for(;;)

{

EnterCriticalSection(&MagicScan_CS);

j=wThreadStatus;

LeaveCriticalSection(&MagicScan_CS);

if (j!=0) break;

i++; Sleep(1);

if (i>1000) return(ThreadCreateError);

}

return(NoError);

}

z P1202_StartScanPostTrg(…) is designed for OME-PCI-1202H/L

z P1602_StartScanPostTrg(…) is designed for OME-PCI-1602 and OME-PCI-

1602F

52

Page 53

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Windows Program code for Middle-trigger:

WORD CALLBACK P180X_StartScanMiddleTrg(WORD wSampleRateDiv, DWORD

dwNum, SHORT nPriority)

{

disable_timer0(); // disable internal pacer timer

disable_timer1(); // disable external pacer timer

wVal=pic_control(0xD400); /* 11?1 01?? ???? ???? cmd_101=start scan */

if (wVal!=0) return(wVal);

_outpw(wAddrCtrl,0xf000); // 1. disable all external trigger

enable_timer1(wSampleRateDiv); // 2. Sampling rate=8M/dwSampleRateDiv

_outpw(wAddrCtrl,0x6800); // 3. B15=0,S2=0,S1=1,S0=0 --> clr FIFO

_outpw(wAddrCtrl,0xE800); // 3. B15=1,S2=0,S1=1,S0=0 --> enable timer-1

_outpw(wAddrCtrl,0xFC00); // 4. S2=1; S1=1; S0=1 --> wait for ext signal

// create magicscan thread

InitializeCriticalSection(&MagicScan_CS);

wThreadStatus=0; wPreMid=1; wAskThreadStop=0; // middle-trigger

hThread=CreateThread(NULL,0,(LPTHREAD_START_ROUTINE,

magic_scan_pre_mid_trg, NULL, 0,&dwThreadID);

SetThreadPriority(hThread,nPriority); // can not use HI/LO alarm & digital filter

i=0;

for(;;)

{

EnterCriticalSection(&MagicScan_CS);

j=wThreadStatus;

LeaveCriticalSection(&MagicScan_CS);

if (j!=0) break;

i++; Sleep(1);

if (i>1000) return(ThreadCreateError);

}

return(NoError);

}

z P1202_StartScanPostTrg(…) is designed for OME-PCI-1202H/L

z P1602_StartScanPostTrg(…) is designed for OME-PCI-1602 and OME-PCI-

1602F

53

Page 54

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Program Code for Pre-trigger for OME-PCI-1800/1802/ver-C

WORD CALLBACK P180X_StartScanPreTrgVerC(WORD wSampleRateDiv, DWORD

dwNum, SHORT nPriority)

{

disable_timer0(); // disable internal pacer timer

disable_timer1(); // disable external pacer timer

wVal=pic_control(0xD400); /* 11?1 01?? ???? ???? cmd_101=start scan */

if (wVal!=0) return(wVal);

_outpw(wAddrCtrl,0xf000); // 1. disable all external trigger

enable_timer1(wSampleRateDiv); // 2. Sampling rate=8M/dwSampleRateDiv

_outpw(wAddrCtrl,0x6800); // 3. B15=0,S2=0,S1=1,S0=0 --> clr FIFO

_outpw(wAddrCtrl,0xE800); // 3. B15=1,S2=0,S1=1,S0=0 --> enable timer-1

_outpw(wAddrCtrl,0xF800); // 4. S2=1; S1=1; S0=0 --> wait ext signal to

// disable timer-1

// create magicscan thread

InitializeCriticalSection(&MagicScan_CS);

wThreadStatus=0; wPreMid=0; wAskThreadStop=0; // pre-trigger

hThread=CreateThread(NULL,0,(LPTHREAD_START_ROUTINE,

magic_scan_pre_mid_trg_ver_c, NULL, 0,&dwThreadID);

SetThreadPriority(hThread,nPriority);

i=0;

for(;;)

{

EnterCriticalSection(&MagicScan_CS);

j=wThreadStatus;

LeaveCriticalSection(&MagicScan_CS);

if (j!=0) break;

i++; Sleep(1);

if (i>1000) return(ThreadCreateError);

}

return(NoError);

}

z This function is designed for the OME-PCI-1800/1802 version-C

54

Page 55

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Program Code for Middle-trigger for the OME-PCI-1800/1802/ver-C :

WORD CALLBACK P180X_StartScanMiddleTrgVerC(WORD wSampleRateDiv, DWORD

dwNum, SHORT nPriority)

{

disable_timer0(); // disable internal pacer timer

disable_timer1(); // disable external pacer timer

wVal=pic_control(0xD400); /* 11?1 01?? ???? ???? cmd_101=start scan */

if (wVal!=0) return(wVal);

_outpw(wAddrCtrl,0xf000); // 1. disable all external trigger

enable_timer1(wSampleRateDiv); // 2. Sampling rate=8M/dwSampleRateDiv

_outpw(wAddrCtrl,0x6800); // 3. B15=0,S2=0,S1=1,S0=0 --> clr FIFO

_outpw(wAddrCtrl,0xE800); // 3. B15=1,S2=0,S1=1,S0=0 --> enable timer-1

_outpw(wAddrCtrl,0xF800); // 4. S2=1; S1=1; S0=0 --> wait ext signal to

// disable timer-1

// create magicscan thread

InitializeCriticalSection(&MagicScan_CS);

wThreadStatus=0; wPreMid=1; wAskThreadStop=0; // middle-trigger

hThread=CreateThread(NULL,0,(LPTHREAD_START_ROUTINE,

magic_scan_pre_mid_trg_ver_c, NULL, 0,&dwThreadID);

SetThreadPriority(hThread,nPriority);

i=0;

for(;;)

{

EnterCriticalSection(&MagicScan_CS);

j=wThreadStatus;

LeaveCriticalSection(&MagicScan_CS);

if (j!=0) break;

i++; Sleep(1);

if (i>1000) return(ThreadCreateError);

}

return(NoError);

}

z This function is designed for the OME-PCI-1800/1802 version-C

55

Page 56

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

The external trigger drivers are given as follows:

Function Name Demo

program

P180X_StartScanPostTrg(…) demo23.c for OME-PCI-1800/1802 ver-C

P180X_StartScanPreTrg(…) demo24.c for OME-PCI-1800/1802 ver-F

P180X_StartScanMiddleTrg(…) demo25.c for OME-PCI-1800/1802 ver-F

P180X_StartScanPreTrgOld(…) demo26.c for OME-PCI-1800/1802 ver-C

P180X_StartScanMiddleTrgOld(…) demo27.c for OME-PCI-1800/1802 ver-C

P1202_StartScanPostTrg(…) demo23.c forOME-PCI-1202

P1202_StartScanPreTrg(…) demo24.c forOME-PCI-1202

P1202_StartScanMiddleTrg(…) demo25.c forOME-PCI-1202

P1602_StartScanPostTrg(…) demo23.c forOME-PCI-1602

P1602_StartScanPreTrg(…) demo24.c forOME-PCI-1602

P1602_StartScanMiddleTrg(…) demo25.c forOME-PCI-1602

Applications

& ver-F

3.6.1.9 Clear FIFO Bit

Bit B15 is used to reset the on-board FIFO. When set to low, the FIFO will be cleared.

The FIFO must be cleared once after power-on.

Program Code for Clearing FIFO:

// Clear FIFO to clear all data

outport(wAddrCtrl,0x2000); /* Bit15=0=clear FIFO, Bit13=1=not PIC cmd */

outport(wAddrCtrl,0xA000); /* Bit15=1=no reset FIFO, BIT13=1=not PIC cmd */

56

Page 57

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.1.10 Handshake Control Bit

Set B13 to 0 when a command is sent to the MagicScan controller, otherwise keep this bit

high.

The program code below demonstrates the use of the of handshaking control bit:

WORD pic_control(WORD i)

{

WORD j;

if ((inport(wAddrCtrl)&0x04)==0)

{

outport(wAddrCtrl,0xffff); /* send a recovery to PIC */

}

j=0;

while ((inport(wAddrCtrl)&0x04)==0)

{

j++;

if (j>65530) return(AdControllerError); /* time out */

}

i = i & 0xDFFF; /* set pic low !! */

outport(wAddrCtrl,i);

j=0;

while ((inport(wAddrCtrl)&0x04)!=0)

{

j++;

if (j>65530) return(AdControllerError); /* time out */

}

outport(wAddrCtrl,(WORD)(i | 0x2000)); /* set pic high !! */

j=0;

while ((inport(wAddrCtrl)&0x04)==0)

{

j++;

if (j>65530) return(AdControllerError); //time out

}

return(NoError);

}

57

Page 58

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.2 The Status Register

The format of the status register is shown below:

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Bit 7: FIFO half-full : 0 Æ FIFO is half-full.

Bit 6: FIFO full : 0 Æ FIFO is full.

Bit 5: FIFO empty : 0 Æ FIFO is empty.

Bit 4: ADC busy : 0 Æ ADC is busy.

Bit 3: External trigger :

For OME-PCI-180x Ver. C: 0 Æ timer-1 is disabled

For OME-PCI-180x Ver. F: 0 Æ waiting external trigger signal

Bit 2: handshake signal between host (PC) and MagicScan controller.

Bit 1: ODM indicator: non-ODM version Æ 0.

ODM version Æ ODM bit string.

Bit 0: Output of the machine independent timer. This bit will be set to 0 when the machine

MSB

1 Æ timer-1 is enabled

1 Æexternal trigger signal is active.

independent timer is started. This bit will be set to 1 when the time period has elapsed.

LSB

58

Page 59

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.6.3 The A/D software trigger register

Writing to this port will software trigger an A/D conversion. Although the PC can send

very fast trigger signals (more than 333K ), the max. sampling rate of A/D conversion can not

exceed 330K samples/second. The timing diagram is shown below:

Figure 3-3: Trigger delay time.

Sample program code for software trigger :

WORD P180X_AdPollingHex(Word *AdVal)

{

WORD wVal, wTime;

//Clear FIFO

outport(wAddrCtrl,0x2000); //B15=0=clear FIFO, B13=1=not MagicScan controller cmd

outport(wAddrCtrl,0xA000); //B15=1=no clear FIFO, B13=1= not MagicScan controller cmd

outport((WORD)(wAddrCtrl+4),0xffff); /* generate a software trigger pulse */

Software

trigger

A/D

Busy

Delay time

3µs

Conversion Time

wTime=0;

for (;;)

{

wVal=inport(wAddrCtrl)&0x20; // wait for ready signal

if (wVal!=0) break; /* If B4==1 Æ A/D data ready */

wTime++;

if (wTime>32760) return(AdPollingTimeOut);

}

AdVal=inport(wAddrAdda)&0x0fff; /* Read the available A/D data from FIFO */

return(NoError); /* 0xffff for OME-PCI-1602/1602F */

}

z P1202_AdPollingHex(…) is designed forOME-PCI-1202H/L

z P1602_AdPollingHex(…) is designed for OME-PCI-1602 and OME-PCI-1602F

59

Page 60

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.7 Section 4: DI/O Register

z I/O address of D/I = wAddrDio

z I/O address of D/O = wAddrDio

The OME-PCI-1800/1802 provides 16-channel digital input and 16-channel digital

output. All levels are TTL compatible. The connections and block diagram are given below:

I/O read

signal.

Local Data Bus

D0,D1 ... D15

DI port

I/O write

signal

DO port

CON2

CoN1

Figure 3-4: DIO block diagram.

The D/I port can be connected to the OME-DB-16P. The OME-DB-16P is a 16-channel

isolated digital input daughter board. The D/O port can be connected to the OME-DB-16R or

OME-DB-24PR. The OME-DB-16R is a 16-channel relay output board. The OME-DB-24R is

a 24-channel power relay output board.

Sample program code for the D/I/O:

WORD P180X_Di(WORD *wDi)

z P1202_Di(…) forOME-PCI-1202

{

z P1602_Di(…) forOME-PCI-1602

*wDi=inport(wAddrDio)&0xffff;

return(NoError);

}

WORD P180X_Do(WORD wDo)

{

outport(wAddrDio,wDo);

z P1202_Do(…) forOME-PCI-1202

z P1602_Do(…) forOME-PCI-1602

return(NoError);

}

60

Page 61

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

3.8 Section 5: A/D & D/A Registers

z I/O address of DA-0 = wAddrAdda

z I/O address of DA-1 = wAddrAdda + 1*4

z I/O address of FIFO = wAddrAdda

Writing data to this section will write data to the DACs and reading data from this

port will read the data from A/D FIFO. The read/write operation is given as follows:

Port Read Write

Section + 0 A/D FIFO. DAC1 write.

Section + 4 Reserved DAC2 write.

The OME-PCI-1800/1802 provides 2 independent 12-bit D/A converters with double

buffered, bipolar voltage output. The output voltage can be ±5V or ±10V selected by the J1

jumper. When the OME-PCI-1800/1802 is first powered-on, the D/A will be in the floating

state. The D/A will go to the programmed state after a D/A output command is executed. The

block diagram is given below:

5 or 10

Vref

Section5 + 0

Section5 + 4

Local Data Bus

D0,D1…D11

Select

Select

DA1

DA2

Analog Output 1

Double Buffer

Analog Output2

Figure 4-2 : D/A output diagram.

Note: The D/A output is floating after upon power-on. The D/A output will be enabled after

executing a D/A output command. This applies to all boards in the OME-PCI-

1202/1602/1800/1802 family.

61

Page 62

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

Sample program code for D/A conversion:

WORD P180X_Da(WORD wDaChannel, WORD wDaVal)

{

if (wDaChannel==0) /* channel 0 */

{

outport(wAddrAdda,wDaVal);

return(NoError);

}

else if (wDaChannel==1) /* channel_1 */

{

outport((wAddrAdda+4),wDaVal);

return(NoError);

}

else return(DaChannelError);

}

z P1202_Da(…) forOME-PCI-1202

z P1602_Da(…) forOME-PCI-1602

Sample program code for software triggered A/D conversion:

WORD P180X_AdPollingHex(Word *AdVal)

{

WORD wVal, wTime ;

//Clear FIFO

outport(wAddrCtrl,0x2000); // B15=0=clear FIFO, B13=1=not MagicScan controller cmd

outport(wAddrCtrl,0xA000); // B15=1=no clear FIFO, B13=1= not MagicScan controller cmd

outport((WORD)(wAddrCtrl+4),0xffff); /* generate a software trigger pulse */

wTime=0;

for (;;)

{

wVal=inport(wAddrCtrl)&0x20; // wait for ready signal

if (wVal!=0) break; /* if B4==1 Æ A/D data ready */

z P1202_AdPollingHex(…) for OME-PCI-1202

z P1602_AdPollingHex(…) for OME-PCI-1602

wTime++;

if (wTime>32760) return(AdPollingTimeOut);

}

AdVal=inport(wAddrAdda)&0x0fff; /* Read the available A/D data from FIFO */

return(NoError); /* 0x0fff for 12-bit ADC, 0xffff for 16-bit ADC */

}

62

Page 63

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

4. A/D Conversions

4.1 The Configuration Code Table

OME-PCI-1202L/1800L/1802L Configuration Code Table

Bipolar/Unipolar Input Signal Range Gain Settling Time Configuration Code

Bipolar +/- 5V 1 3 us 0x00

Bipolar +/- 2.5V 2 3 us 0x01

Bipolar +/- 1.25V 4 3 us 0x02

Bipolar +/- 0.625V 8 3 us 0x03

Bipolar +/- 10V 0.5 3 us 0x04

Bipolar +/- 5V 1 3 us 0x05

Bipolar +/- 2.5V 2 3 us 0x06

Bipolar +/- 1.25V 4 3 us 0x07

Unipolar 0V to 10V 1 3 us 0x08

Unipolar 0V to 5V 2 3 us 0x09

Unipolar 0V to 2.5V 4 3 us 0x0A

Unipolar 0V to 1.25V 8 3 us 0x0B

OME-PCI-1602 Configuration Code Table

Bipolar/Uniploar Input Signal Range Gain Settling Time Configuration Code

Bipolar +/-10V 1 10 us 0

Bipolar +/-5V 2 10 us 1

Bipolar +/-2.5V 4 10 us 2

Bipolar +/-1.25V 8 10 us 3

OME-PCI-1602F Configuration Code Table

Bipolar/Uniploar Input Signal Range Gain Settling Time Configuration Code

Bipolar +/-10V 1 5 us 0

Bipolar +/-5V 2 5 us 1

Bipolar +/-2.5V 4 5 us 2

Bipolar +/-1.25V 8 5 us 3

63

Page 64

OME-PCI-1202/1602/1800/1802 Hardware User’s Manual

OME-PCI-1202H/1800H/1802H Configuration Code Table

Bipolar/Unipolar Input Signal Range Gain Settling Time Configuration Code

Bipolar +/- 5V 1 23 us 0x10

Bipolar +/- 0.5V 10 28 us 0x11

Bipolar +/- 0.05V 100 140 us 0x12

Bipolar +/- 0.005V 1000 1300 us 0x13

Bipolar +/- 10V 0.5 23 us 0x14

Bipolar +/- 1V 5 28 us 0x15

Bipolar +/- 0.1V 50 140 us 0x16

Bipolar +/- 0.01V 500 1300 us 0x17

Unipolar 0V to 10V 1 23 us 0x18

Unipolar 0V to 1V 10 28 us 0x19

Unipolar 0V to 0.1V 100 140 us 0x1A

Unipolar 0V to 0.01V 1000 1300 us 0x1B

4.2 Unipolar/Bipolar Measurement

If the analog input signal is unipolar, you can measure this signal on the bipolar setting

(this will reduce resolution). If the analog input is bipolar, you must select bipolar

configuration code to measure the signal.

4.3 Input Signal Range

If the input range of the analog signal is +/- 1V, you can measure this signal with +/-10V,