Page 1

www.omega.com

e-mail: info@omega.com

User’s Guide

OME-PCI-1002

PCI Data Acquisition Board

Windows Software Manual

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

OME-PCI-1002 Software Manual for Windows

Table of Contents

1. Introduction ........................................................................................................................................4

1.1 Software Installation...................................................................................................................5

1.2 References ..................................................................................................................................7

2. Declaration Files.................................................................................................................................8

2.1 P100X.H .....................................................................................................................................9

2.2 P100Xu.C .................................................................................................................................11

2.3 P100X.BAS ..............................................................................................................................12

2.4 P100Xu.BAS ............................................................................................................................14

2.5 P100X.PAS...............................................................................................................................15

2.6 P100Xu.PAS.............................................................................................................................18

3. Demo Result .....................................................................................................................................19

3.1 Visual C++ ...............................................................................................................................19

3.2 Visual Basic..............................................................................................................................20

3.3 Delphi .......................................................................................................................................21

3.4 Borland C++ Builder ................................................................................................................22

4. Descriptions of Functions.................................................................................................................23

4.1 The Configuration Code Table.................................................................................................25

4.2 The Test Functions ...................................................................................................................26

P100X_FloatSub2.........................................................................................................................26

P100X_ShortSub2 ........................................................................................................................26

4.2.3 P100X_GetDllVersion......................................................................................................27

P100X_GetDriverVersion ............................................................................................................27

4.3 The DI/O Functions..................................................................................................................28

P100X_Di.....................................................................................................................................28

P100X_Do....................................................................................................................................28

4.4 The A/D Fixed-mode Functions...............................................................................................29

P100X_SetChannelConfig............................................................................................................29

4.4.2 P100X_Polling..................................................................................................................30

4.4.3 P100X_AdPolling.............................................................................................................31

4.4.4 P100X_AdsPolling ...........................................................................................................32

4.4.5 P100X_AdsPacer..............................................................................................................33

4.5 Driver Functions.......................................................................................................................34

P100X_DriverInit.........................................................................................................................34

P100X_DriverClose .....................................................................................................................34

4.5.3 P100X_GetConfigAddressSpace......................................................................................35

P100X_WhichBoardActive..........................................................................................................35

4.5.5 P100X_ActiveBoard.........................................................................................................36

P100X_GetIrqNo..........................................................................................................................36

4.6 The Interrupt Functions ............................................................................................................37

P100X_InstallIrq ..........................................................................................................................37

P100X_GetIntCount.....................................................................................................................37

4.6.3 P100X_INT_AdStart........................................................................................................38

P100X_INT_AdStop ....................................................................................................................38

4.6.5 P100X_GetBuffer.............................................................................................................39

P100X_GetFloatBuffer.................................................................................................................39

4.6.7 Architecture of Interrupt mode .........................................................................................40

5. Program Architecture .......................................................................................................................44

6. Reporting Problems..........................................................................................................................45

Page 3

Page 4

OME-PCI-1002 Software Manual for Windows

1. Introduction

The OME-PCI-1002 Toolkit is a collection of DLLs and device-driver for

Windows 95/98/NT/2000/XP applications. These DLLs are 32-bit and can be

called by Visual C++, BC++, Visual BASIC, Delphi and LabVIEW.

The OME-PCI-1002 Toolkit consists of the following DLLs and device

driver:

• P100X.DLL, P100X.LIB Æ for OME-PCI-1002 card

• P100X.VXD Æ OME-PCI-1002 Device driver for Windows 95/98

• P100X.SYS Æ OME-PCI-1002 Device driver for Windows

NT/2000/XP

The DLLs perform a variety of tasks including:

• Read software version

• Initialization

• Digital Input/Output

• A/D conversion

Page 4

Page 5

OME-PCI-1002 Software Manual for Windows

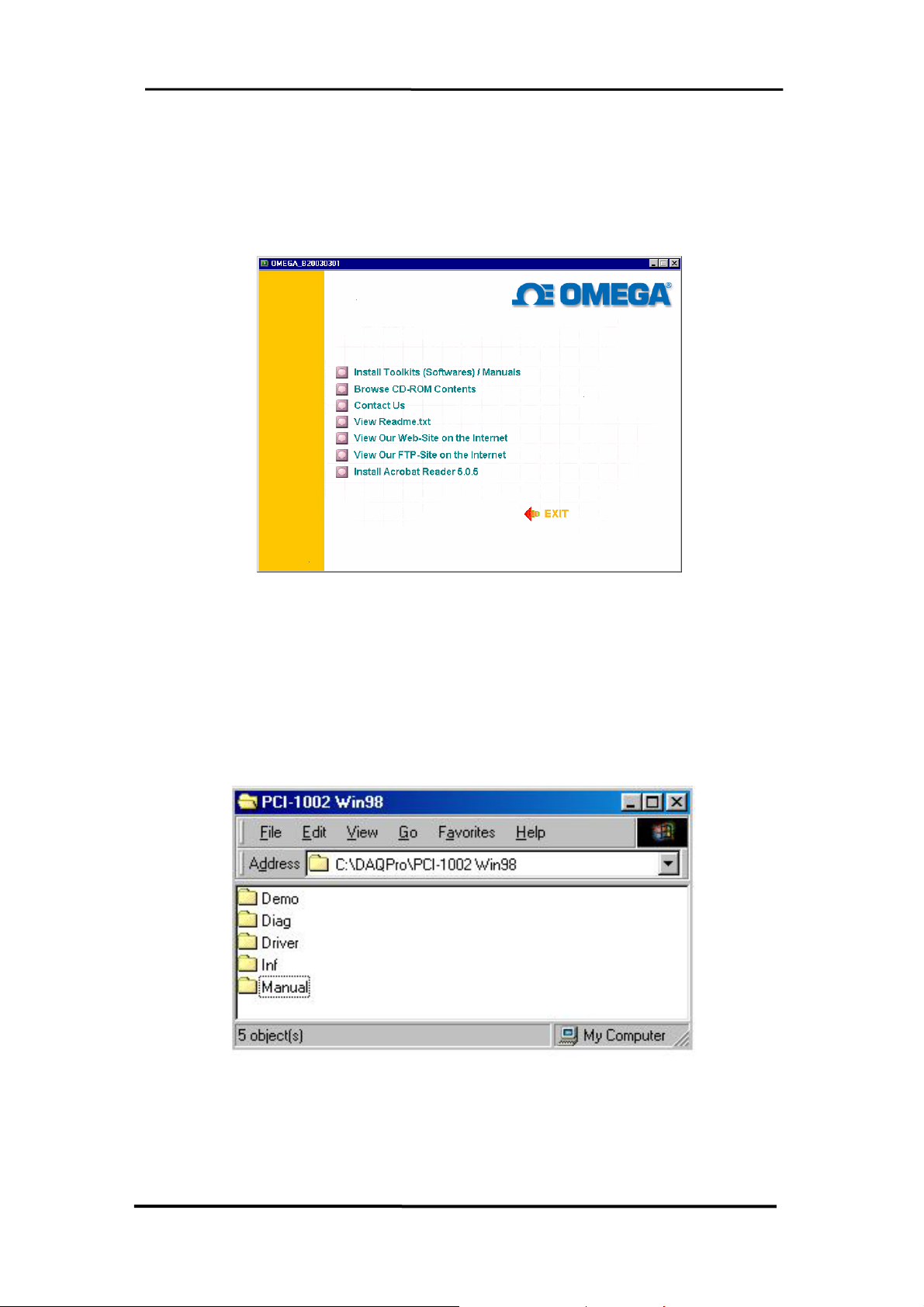

1.1 Software Installation

Insert the CD ROM included with your OME-PCI-1002 board and the following

installation screen should auto-start.

Follow the instructions on the screen to complete the software installation. The

software is designed to support the entire OME family of data acquisition

hardware, so during the installation, you will be asked to specify your particular

hardware (OME-PCI-1002 board in this case). During the installation process,

you will also be prompted to enter the operating system you will be using.

After installation the following folders will be created on your computer.

Page 5

Page 6

OME-PCI-1002 Software Manual for Windows

Demo Folder

Contains all demonstration programs including their source code. Examples

are provided for Visual C++, Borland C++, Visual Basic and Delphi.

Please note: The VC++ demos are developed with VC++ 4.0. After setting up

the environment, use the NMAKE.EXE to compiling and linking the demo code.

For Example, C:\P1002\DEMO\VC\nmake /f demo.mak

Driver Folder

Contains software drivers, include files and definition files for the programming

languages.

Manual Folder

Contains hardware user manuals, software user manuals and technical notes.

Diag Folder

Contains card diagnostic programs

Inf Folder

Contains tech notes and .INF file for the plug and play installation (only

available for operating systems that support plug and play).

Page 6

Page 7

OME-PCI-1002 Software Manual for Windows

1.2 References

Please also refer to the following user manuals:

• SoftInst.pdf:

To install the software package under Windows 95/98/NT/2000/XP.

• CallDll.pdf:

To call the DLL functions with Visual C++, Visual Basic, Delphi and

Borland C++.

• ResCheck.pdf:

To check the card resources, that is, I/O Port address, IRQ number

and DMA under Windows.

Page 7

Page 8

OME-PCI-1002 Software Manual for Windows

2. Declaration Files

Please refer to user manual "CallDLL.pdf".

|--\Driver Å some device driver

| |

| |--\VB Å for Visual Basic

| | |--\P100X.BAS Å Declaration file for Visual Basic

| | |--\P100Xu.BAS Å Functions for Visual Basic

| |

| |--\VC Å for Visual C++

| | |--\P100X.H Å Header file

| | |--\P100X.LIB Å Import library for VC only

| |

| |--\Delphi Å for Delphi

| | |--\P100X.PAS Å Declaration file

| | |--\P100Xu.PAS Å Functions for Delphi

| |

| |--\BCB Å for Borland C++ Builder 3.0

| |--\P100X.H Å Header file

| |--\P100Xu.C Å Functions for BCB

| |--\P100X.LIB Å Import library file for BCB only

Page 8

Page 9

OME-PCI-1002 Software Manual for Windows

2.1 P100X.H

#ifdef __cplusplus

#define EXPORTS extern "C" __declspec (dllimport)

#else

#define EXPORTS

#endif

// return code

#define P100X_NoError 0

#define P100X_DriverHandleError 1

#define P100X_DriverCallError 2

#define P100X_AdControllerError 3

#define P100X_ConfigCodeError 4

#define P100X_DriverNoOpen 5

#define P100X_AdPollingTimeOut 6

#define P100X_FindBoardError 7

#define P100X_AdChannelError 8

#define P100X_DaChannelError 9

#define P100X_InvalidDelay 10

#define P100X_DelayTimeOut 11

#define P100X_InvalidData 12

#define P100X_TimeoutError 13

#define P100X_ExceedBoardNumber 14

#define P100X_NotFoundBoard 15

#define P100X_OpenError 16

#define P100X_FindTwoBoardError 17

#define P100X_GetIntCountError 18

#define P100X_InstallIrqError 19

#define P100X_AllocateMemoryError 20

EXPORTS float CALLBACK P100X_FloatSub(float fA, float fB);

EXPORTS short CALLBACK P100X_ShortSub(short nA, short nB);

EXPORTS WORD CALLBACK P100X_GetDllVersion(void);

EXPORTS WORD CALLBACK P100X_DriverInit(WORD *wTotalBoards);

EXPORTS void CALLBACK P100X_DriverClose(void);

EXPORTS WORD CALLBACK P100X_GetDriverVersion

(WORD *wDriverVersion);

EXPORTS WORD CALLBACK P100X_GetIrqNo( WORD *IrqNo);

EXPORTS WORD CALLBACK P100X_GetConfigAddressSpace

(WORD wBoardNo, WORD *wAddress0,

WORD *wAddress1, WORD *wAddress2);

EXPORTS WORD CALLBACK P100X_ActiveBoard( WORD wBoardNo );

EXPORTS WORD CALLBACK P100X_WhichBoardActive(void);

Page 9

Page 10

OME-PCI-1002 Software Manual for Windows

EXPORTS void CALLBACK P100X_SetupTimer

(WORD wChannel, WORD wCoef);

EXPORTS WORD CALLBACK P100X_Delay(WORD wDownCount);

EXPORTS void CALLBACK P100X_Do(WORD wOutData);

EXPORTS WORD CALLBACK P100X_Di(WORD *wDiData);

EXPORTS WORD CALLBACK P100X_SetChannelConfig

(WORD wAdChannel, WORD wConfig);

EXPORTS WORD CALLBACK P100X_Polling(WORD *wAdVal);

EXPORTS WORD CALLBACK P100X_AdPolling(float *fAdVal);

EXPORTS WORD CALLBACK P100X_AdsPolling

(float fAdVal[], WORD wNum);

EXPORTS WORD CALLBACK P100X_AdsPacer

(float fAdVal[], WORD wNum, WORD wSamplingDiv);

EXPORTS WORD CALLBACK P100X_InstallIrq

(HANDLE *hEvent, DWORD dwCount);

EXPORTS WORD CALLBACK P100X_GetBuffer

(DWORD dwNum, WORD wBuf[]);

EXPORTS WORD CALLBACK P100X_GetFloatBuffer

(DWORD dwNum, float fAdVal[]);

EXPORTS WORD CALLBACK P100X_GetIntCount(DWORD *dwVal);

EXPORTS WORD CALLBACK P100X_INT_AdStart

(WORD Ch, WORD Gain, WORD wFreqDiv);

EXPORTS WORD CALLBACK P100X_INT_AdStop();

Page 10

Page 11

OME-PCI-1002 Software Manual for Windows

2.2 P100Xu.C

#include <math.h>

//*-----------------------------------------------------*

//* Return voltage value or -100.0 if any error occurs *

//* or parameter is out of range. *

//* HiLo : 1 --> High Gain , 0 --> Low Gain *

//* Gain : 0-3 *

//*-----------------------------------------------------*

float P100X_AD2F(Word hex, int HiLo,int Gain )

{

float ZeroBase, VoltageRange, FullRange ;

ZeroBase = 2048.0 ;

FullRange = 2048.0 ;

VoltageRange = 10.0 ;

Gain = Gain % 16 ;

if ( (Gain < 0) || (Gain > 3) )

return -100.0;

if ( HiLo == 0 ) //Low-Gain

return ((((hex - ZeroBase) / FullRange) * VoltageRange) / pow( 2 , Gain));

else

return ((((hex - ZeroBase) / FullRange) * VoltageRange) / pow( 10 ,

Gain));

}

Page 11

Page 12

OME-PCI-1002 Software Manual for Windows

2.3 P100X.BAS

Attribute VB_Name = "P100X"

' return code

Global Const P100X_NoError = 0

Global Const P100X_DriverHandleError = 1

Global Const P100X_DriverCallError = 2

Global Const P100X_AdControllerError = 3

Global Const P100X_ConfigCodeError = 4

Global Const P100X_DriverNoOpen = 5

Global Const P100X_AdPollingTimeOut = 6

Global Const P100X_FindBoardError = 7

Global Const P100X_AdChannelError = 8

Global Const P100X_DaChannelError = 9

Global Const P100X_InvalidDelay = 10

Global Const P100X_DelayTimeOut = 11

Global Const P100X_InvalidData = 12

Global Const P100X_TimeoutError = 13

Global Const P100X_ExceedBoardNumber = 14

Global Const P100X_NotFoundBoard = 15

Global Const P100X_OpenError = 16

Global Const P100X_FindTwoBoardError = 17

Global Const P100X_GetIntCountError = 18

Global Const P100X_InstallIrqError = 19

Global Const P100X_AllocateMemoryError = 20

' Function of Test

Declare Function P100X_FloatSub Lib "P100X.DLL" _

(ByVal fA As Single, ByVal fB As Single) As Single

Declare Function P100X_ShortSub Lib "P100X.DLL" _

(ByVal nA As Integer, ByVal nB As Integer) As Integer

Declare Function P100X_GetDllVersion Lib "P100X.DLL" () As Integer

' Function of Driver

Declare Function P100X_DriverInit Lib "P100X.DLL" _

(wTotalBoards As Integer) As Integer

Declare Sub P100X_DriverClose Lib "P100X.DLL" ()

Declare Function P100X_GetDriverVersion Lib "P100X.DLL" _

(wDriverVersion As Integer) As Integer

Declare Function P100X_GetIrqNo Lib "P100X.DLL" (IrqNo As Integer) _

As Integer

Declare Function P100X_GetConfigAddressSpace Lib "P100X.DLL" _

(ByVal wBoardNo As Integer, wAddrTimer As Integer, _

wAddrDio As Integer, wAddrAd As Integer) As Integer

Declare Function P100X_ActiveBoard Lib "P100X.DLL" _

(ByVal wBoardNo As Integer) As Integer

Declare Function P100X_WhichBoardActive Lib "P100X.DLL" () As Integer

Page 12

Page 13

OME-PCI-1002 Software Manual for Windows

Declare Sub P100X_SetupTimer Lib "P100X.DLL" _

(ByVal wChannel As Integer, ByVal wCoef As Integer)

Declare Function P100X_Delay Lib "P100X.DLL" _

(ByVal wDownCount As Integer) As Integer

' Function of DI/DO

Declare Sub P100X_Do Lib "P100X.DLL" (ByVal wOutData As Integer)

Declare Function P100X_Di Lib "P100X.DLL" (wDiData As Integer) As Integer

' Function of AD

Declare Function P100X_SetChannelConfig Lib "P100X.DLL" _

(ByVal wAdChannel As Integer, ByVal wConfig As Integer) As Integer

Declare Function P100X_Polling Lib "P100X.DLL" _

(wAdVal As Integer) As Integer

Declare Function P100X_AdPolling Lib "P100X.DLL" _

(fAdVal As Single) As Integer

Declare Function P100X_AdsPolling Lib "P100X.DLL" _

(fAdVal As Single, ByVal wNum As Integer) As Integer

Declare Function P100X_AdsPacer Lib "P100X.DLL" (fAdVal As Single, _

ByVal wNum As Integer, ByVal wSamplingDiv As Integer) As Integer

' Function of Interrupt

Declare Function P100X_InstallIrq Lib "P100X.DLL" _

(hEvent As Long, ByVal dwCount As Long) As Integer

Declare Function P100X_GetBuffer Lib "P100X.DLL" _

(ByVal dwNum As Long, wBuf As Integer) As Integer

Declare Function P100X_GetFloatBuffer Lib "P100X.DLL" _

(ByVal dwNum As Long, fAdVal As Single) As Integer

Declare Function P100X_INT_AdStart Lib "P100X.DLL" _

(ByVal Ch As Integer, ByVal Gain As Integer, _

ByVal wFreqDiv As Integer) As Integer

Declare Function P100X_INT_AdStop Lib "P100X.DLL" () As Integer

Declare Function P100X_GetIntCount Lib "P100X.DLL" (dwVal As Long) _

As Integer

Page 13

Page 14

OME-PCI-1002 Software Manual for Windows

2.4 P100Xu.BAS

'*-----------------------------------------------------*

'* Return voltage value or -100.0 if any error occurs *

'* or parameter is out of range. *

'* HiLo : 1 --> High Gain , 0 --> Low Gain *

'* Gain : 0-3 *

'*-----------------------------------------------------*

Function P100X_AD2F(ByVal hex, HiLo, Gain As Integer) As Single

Dim ZeroBase, BullRange, VoltageRange As Single

ZeroBase = 2048#

FullRange = 2048#

VoltageRange = 10#

Gain = Gain Mod 16

If Gain < 0 Or Gain > 3 Then

P100X_AD2F = -100#

Exit Function

End If

If HiLo = 0 Then 'Low-Gain

P100X_AD2F = ((((hex - ZeroBase) / FullRange) * VoltageRange) / (2 ^

Gain))

Else

P100X_AD2F = ((((hex - ZeroBase) / FullRange) * VoltageRange) / (10 ^

Gain))

End If

End Function

Page 14

Page 15

OME-PCI-1002 Software Manual for Windows

2.5 P100X.PAS

unit P100X;

interface

type PSingle=^Single;

type PWord=^Word;

const

// return code

P100X_NoError = 0;

P100X_DriverHandleError = 1;

P100X_DriverCallError = 2;

P100X_AdControllerError = 3;

P100X_ConfigCodeError = 4;

P100X_DriverNoOpen = 5;

P100X_AdPollingTimeOut = 6;

P100X_FindBoardError = 7;

P100X_AdChannelError = 8;

P100X_DaChannelError = 9;

P100X_InvalidDelay = 10;

P100X_DelayTimeOut = 11;

P100X_InvalidData = 12;

P100X_TimeoutError = 13;

P100X_ExceedBoardNumber = 14;

P100X_NotFoundBoard = 15;

P100X_OpenError = 16;

P100X_FindTwoBoardError = 17;

P100X_GetIntCountError = 18;

P100X_InstallIrqError = 19;

P100X_AllocateMemoryError = 20;

// Function of Test

function P100X_FloatSub(fA:Single; fB:Single):Single ; stdCall;

function P100X_ShortSub(nA:SmallInt; nB:SmallInt):SmallInt ; stdCall;

function P100X_GetDllVersion:WORD ; stdCall;

Page 15

Page 16

OME-PCI-1002 Software Manual for Windows

// Function of Driver

function P100X_DriverInit(Var wTotalBoards:Word):WORD ; stdCall;

procedure P100X_DriverClose; stdCall;

function P100X_GetDriverVersion(var wDriverVersion:Word):WORD ; stdCall;

function P100X_GetIrqNo(Var IrqNo:WORD):WORD; StdCall;

function P100X_GetConfigAddressSpace(wBoardNo:Word;

var wAddrTimer:Word; var wAddrDio:Word;

var wAddrAd:Word) :WORD ; stdCall;

function P100X_ActiveBoard(wBoardNo:Word):WORD ; stdCall;

function P100X_WhichBoardActive:WORD ; stdCall;

procedure P100X_SetupTimer(wChannel:Word; wCoef:Word); stdCall;

function P100X_Delay(wDownCount:Word):Word; StdCall;

// Function of DI/DO

procedure P100X_Do(wOutData:Word); stdCall;

function P100X_Di(var wDiData:Word):WORD ; stdCall;

// Function of AD

function P100X_SetChannelConfig

(wAdChannel:Word; wConfig:Word):WORD ; stdCall;

function P100X_Polling(var wAdVal:Word):WORD ; stdCall;

function P100X_AdPolling(var fAdVal:Single):WORD ; stdCall;

function P100X_AdsPolling(fAdVal:PSingle; wNum:Word):WORD ; stdCall;

function P100X_AdsPacer(fAdVal:PSingle; wNum:Word;

wSamplingDiv:Word ):WORD ; stdCall;

// Function of Interrupt

function P100X_InstallIrq

(Var hEvent:LongInt; dwCount: LongInt):WORD ; stdCall;

function P100X_GetBuffer(dwNum:LongInt;wBuf:PWord):WORD ; stdCall;

function P100X_GetFloatBuffer

(dwNum:LongInt; fAdVal:PSingle):Word; StdCall;

function P100X_INT_AdStart

(Ch:WORD; Gain:WORD; wFreqDiv:Word):WORD ; stdCall;

function P100X_INT_AdStop:WORD ; stdCall;

function P100X_GetIntCount(var dwVal:LongInt):WORD ; stdCall;

implementation

function 100X_FloatSub; external 'P100X.DLL' name 'P100X_FloatSub';

function 100X_ShortSub; external 'P100X.DLL' name 'P100X_ShortSub';

function 100X_GetDllVersion;

external 'P100X.DLL' name 'P100X_GetDllVersion';

function 100X_GetDriverVersion;

external 'P100X.DLL' name 'P100X_GetDriverVersion';

Page 16

Page 17

OME-PCI-1002 Software Manual for Windows

function 100X_DriverInit; external 'P100X.DLL' name 'P100X_DriverInit';

procedure 100X_DriverClose;

external 'P100X.DLL' name 'P100X_DriverClose';

function 100X_GetIrqNo; external 'P100X.DLL' name 'P100X_GetIrqNo';

function 100X_GetConfigAddressSpace;

external 'P100X.DLL' name 'P100X_GetConfigAddressSpace';

function 100X_ActiveBoard;

external 'P100X.DLL' name 'P100X_ActiveBoard';

function 100X_WhichBoardActive;

external 'P100X.DLL' name 'P100X_WhichBoardActive';

procedure 100X_SetupTimer;

external 'P100X.DLL' name 'P100X_SetupTimer';

function 100X_Delay; external 'P100X.DLL' name 'P100X_Delay';

procedure P100X_Do; external 'P100X.DLL' name 'P100X_Do';

function P100X_Di; external 'P100X.DLL' name 'P100X_Di';

function P100X_SetChannelConfig;

external 'P100X.DLL' name 'P100X_SetChannelConfig';

function P100X_Polling; external 'P100X.DLL' name 'P100X_Polling';

function P100X_AdPolling;

external 'P100X.DLL' name 'P100X_AdPolling';

function P100X_AdsPolling;

external 'P100X.DLL' name 'P100X_AdsPolling';

function P100X_AdsPacer;

external 'P100X.DLL' name 'P100X_AdsPacer';

function P100X_InstallIrq;

external 'P100X.DLL' name 'P100X_InstallIrq';

function P100X_INT_AdStart;

external 'P100X.DLL' name 'P100X_INT_AdStart';

function P100X_INT_AdStop;

external 'P100X.DLL' name 'P100X_INT_AdStop';

function P100X_GetIntCount;

external 'P100X.DLL' name 'P100X_GetIntCount';

function P100X_GetBuffer;

external 'P100X.DLL' name 'P100X_GetBuffer';

function P100X_GetFloatBuffer;

external 'P100X.DLL' name 'P100X_GetFloatBuffer';

end.

Page 17

Page 18

OME-PCI-1002 Software Manual for Windows

2.6 P100Xu.PAS

unit P100Xu;

interface

Function P100X_AD2F(hex, HiLo, Gain :Word): Single ; StdCall;

implementation

uses math;

//*-----------------------------------------------------*

//* Return voltage value or -100.0 if any error occurs *

//* or parameter is out of range. *

//* HiLo : 1 --> High Gain , 0 --> Low Gain *

//* Gain : 0-3 *

//*-----------------------------------------------------*

Function P100X_AD2F(hex, HiLo, Gain :Word): Single ;

Var

ZeroBase, VoltageRange, FullRange : Single ;

Begin

ZeroBase := 2048;

FullRange := 2048;

VoltageRange := 10;

Gain := Gain mod 16;

If (Gain < 0) Or (Gain > 3) Then

begin

P100X_AD2F := -100;

exit;

end ;

If HiLo = 0 Then //Low-Gain

Result := ((((hex - ZeroBase) / FullRange) * VoltageRange) / Power(2,

Gain))

Else

Result := ((((hex - ZeroBase) / FullRange) * VoltageRange) /

Power(10,Gain));

End;

end.

Page 18

Page 19

OME-PCI-1002 Software Manual for Windows

3. Demo Result

3.1 Visual C++

Analog Input with polling demo program

Digital I/O with MFC demo program

Page 19

Page 20

OME-PCI-1002 Software Manual for Windows

3.2 Visual Basic

Digital I/O demo program

Analog Input with pacer-trigger demo program

Page 20

Page 21

OME-PCI-1002 Software Manual for Windows

3.3 Delphi

Digital I/O demo program

Analog Input with Interrupt demo program

Page 21

Page 22

OME-PCI-1002 Software Manual for Windows

3.4 Borland C++ Builder

Digital I/O demo program

Analog input with polling demo program

Page 22

Page 23

OME-PCI-1002 Software Manual for Windows

4. Descriptions of Functions

The DLL functions are divided into the following groups:

z Test Functions

z D/I/O Functions

z A/D Fixed-mode Functions

z Driver Functions

z Interrupt Functions

Test Functions:

1. P100X_FloatSub2

2. P100X_ShortSub2

3. P100X_GetDllVersion

4. P100X_GetDriverVersion

D/I/O Functions

1. P100X_DI

2. P100X_DO

A/D Fixed-mode Functions:

1. P100X_SetChannelConfig

2. P100X_Polling

3. P100X_AdPolling

4. P100X_AdsPolling

5. P100X_AdsPacer

Driver Functions:

1. P100X_DriverInit

2. P100X_DriverClose

3. P100X_GetConfigAddressSpace

4. P100X_WhichBoardActive

5. P100X_ActiveBoard

6. P100X_GetIrqNo

Page 23

Page 24

OME-PCI-1002 Software Manual for Windows

Interrupt Functions:

1. P100X_InstallIrq

2. P100X_INT_AdStart

3. P100X_INT_AdStop

4. P100X_GetIntCount

5. P100X_GetBuffer

6. P100X_GetFloatBuffer

The following keywords are used to describe the attributes of function

parameters.

Keyword Parameter set by user

before calling function?

Data/value available from

this parameter after calling

function?

[Input] Yes No

[Output] No Yes

[Input, Output] Yes Yes

Page 24

Page 25

OME-PCI-1002 Software Manual for Windows

4.1 The Configuration Code Table

OME-PCI-1002L Configuration Code Table

Gain Bipolar Max. Switching Frequency Configuration Code

1 +/- 10V 110 K/S 0x00

2 +/- 5.0V 110 K/S 0x01

4 +/- 2.5V 110 K/S 0x02

8 +/- 1.25V 110 K/S 0x03

OME-PCI-1002H Configuration Code Table

Gain Bipolar Max. Switching Frequency Configuration Code

1 +/- 10V 44 K/S 0x10

10 +/- 1.0V 36 K/S 0x11

100 +/- 0.1V 7 K/S 0x12

1000 +/- 0.01V 0.8 K/S 0x13

Page 25

Page 26

OME-PCI-1002 Software Manual for Windows

4.2 The Test Functions

4.2.1 P100X_FloatSub2

z Description:

Calculates C = fA - fB in float format, float=4 bytes floating point

number. This function is provided to test DLL linkage.

• Syntax:

float P100X_FloatSub2(float fA, float fB);

z Parameter:

fA : [Input] 4 bytes floating point value

fB : [Input] 4 bytes floating point value

z Return:

Returns the result value (= fA - fB).

4.2.2 P100X_ShortSub2

z Description :

Calculates C = nA - nB in SHORT formats, SHORT=16 bits signed

number. This function is provided to test DLL linkage.

• Syntax :

short P100X_ShortSub2(Short nA, Short nB);

z Parameter:

nA : [Input] 16-bit value

nB : [Input] 16-bit value

z Return:

Returns the result value (= nA - nB).

Page 26

Page 27

OME-PCI-1002 Software Manual for Windows

4.2.3 P100X_GetDllVersion

z Description :

Reads the DLL version of the P100X.DLL.

z Syntax :

WORD P100X_GetDllVersion(void);

z Parameter:

None

z Return:

Returns the version of the DLL for Device-Driver.

return=0x200 Æ Version 2.0

4.2.4 P100X_GetDriverVersion

z Description :

This subroutine will read the software version of the P100X.VxD for

Windows 95 or P100X.SYS of Windows NT/2000/XP.

z Syntax :

WORD P100X_GetDriverVersion(WORD *wDriverVersion);

z Parameter:

wDriverVersion : [Output] address of wDriverVersion,

which contains the version of Device-Driver.

wDriverVersion=0x200 Æ Version 2.0

z Return:

P100X_NoError : OK

P100X_DriverHandleError : P100X.VxD open error for Windows 95

P100X.SYS open error for Windows

NT/2000/XP

P100X_DriverCallError : call P100X.VxD return error

call P100X.SYS return error

Page 27

Page 28

OME-PCI-1002 Software Manual for Windows

4.3 The DI/O Functions

4.3.1 P100X_Di

z Description :

This subroutine will read the 16 bit data from the DI(digital input)

port. This function addresses the current active OME-PCI-1002 board.

Use the P100X_ActiveBoard(….) to select the active board.

z Syntax :

WORD P100X_Di(WORD *wDi);

z Parameter:

wDi : [Output] address of wDi,

which contains the 16 bits of digital input data .

z Return:

P100X_NoError : OK

P100X_FindBoardError : cannot find the OME-PCI-100X board

P100X_ExceedBoardNumber : invalid board number

4.3.2 P100X_Do

z Description :

This subroutine will write the 16 bit data to the DO(digital output)

port. This function addresses the current active OME-PCI-1002 board. Use

the P100X_ActiveBoard(….) to select the active board.

z Syntax :

WORD P100X_Do(WORD wDo);

z Parameter:

wDo : [Input] the 16-bit data sent to the digital-output port

z Return:

P100X_NoError : OK

P100X_ExceedBoardNumber : invalid board number

P100X_FindBoardError : cannot find OME-PCI-1002 board

Page 28

Page 29

OME-PCI-1002 Software Manual for Windows

4.4 The A/D Fixed-mode Functions

4.4.1 P100X_SetChannelConfig

z Description :

This function will set the A/D channel configuration code. This

function will also set the active A/D channel for P100X_AdPolling,

P100X_AdsPolling and P100X_AdsPacer functions. The function

addresses the current active OME-PCI-1002 board. Use the

P100X_ActiveBoard(….) to select the active board.

z Syntax :

WORD P100X_SetChannelConfig(WORD wChannel, WORD wConfig);

z Parameter:

wChannel : [Input] A/D channel number

wConfig : [Input] Configuration code. Refer to Sec. 3.1 for details.

z Return:

P100X_NoError : OK

P100X_ExceedBoardNumber : invalid board number

P100X_FindBoardError : can not find the OME-PCI-1002 board

P100X_AdControllerError : MagicScan controller

hardware handshake error

Page 29

Page 30

OME-PCI-1002 Software Manual for Windows

4.4.2 P100X_Polling

z Description :

Performs a single A/D conversion on the active channel by software

polling. The P100X_SetChannelConfig subroutine can be used to

change the channel or configuration code. Use the

P100X_ActiveBoard(….) to select the active board.

z Syntax :

WORD P100X_Polling(word *wAdVal);

z Parameter:

wAdVal : [Output] address of wAdVal, which contains the A/D data

Data is returned as an integer value in the range 0-4095.

z Return:

P100X_NoError : OK

P100X_ExceedBoardNumber : invalid board number

P100X_FindBoardError : can not find the OME-PCI-1002 board

P100X_AdPollingTimeOut : hardware timeout error

Page 30

Page 31

OME-PCI-1002 Software Manual for Windows

4.4.3 P100X_AdPolling

z Description :

This subroutine will perform a single A/D conversion by polling The

P100X_SetChannelConfig function can be used to change the channel or

configuration code. This function addresses the current active OME-PCI1002 board. Use the P100X_ActiveBoard(….) function to select the active

board.

z Syntax :

WORD P100X_AdPolling(float *fAdVal);

z Parameter:

fAdVal : [Output] address of fAdVal, which contains the AD data.

The data is automatically converted to voltage based on the

settings of P100X_SetChannelConfig().

z Return:

P100X_NoError : OK

P100X_ExceedBoardNumber : invalid board number

P100X_FindBoardError : cannot find the OME-PCI-1002 board

P100X_AdPollingTimeOut : hardware timeout error

Page 31

Page 32

OME-PCI-1002 Software Manual for Windows

4.4.4 P100X_AdsPolling

• Description :

Performs multiple A/D conversions on a single channel by polling.

The P100X_SetChannelConfig subroutine can be used to change the

channel or configuration code. This function addresses the current active

OME-PCI-1002 board. Use P100X_ActiveBoard(….) to select the active

board.

Since software polling can be interrupted by the operating system,

the P100X_AdsPacer function is recommended when precisely

reconstructing the waveform is desired.

• Syntax :

WORD P100X_AdsPolling(float fAdVal[], WORD wNum);

• Parameter:

fAdVal : [Output] starting address of the A/D data buffer(Array of float)

The data is converted to voltage based on the setting of the

P100X_SetChannelConfig() function.

The user must allocate sufficient space for the buffer. The

user can access the data after calling the function.

wNum : [Input] number of A/D conversions to be performed.

• Return:

P100X_NoError : OK

P100X_ExceedBoardNumber : Invalid board number

P100X_FindBoardError : Can not find the OME-PCI-1002 board

P100X_AdPollingTimeOut : Hardware timeout error

Page 32

Page 33

OME-PCI-1002 Software Manual for Windows

4.4.5 P100X_AdsPacer

z Description :

This function performs multiple A/D conversions on a single channel

by pacer trigger. The P100X_SetChannelConfig function can be used to

change the channel or configuration code. The function addresses the

current active OME-PCI-1002 board. Use P100X_ActiveBoard(….) to

select the active board.

z Syntax :

WORD P100X_AdsPacer(float fAdVal[], WORD wNum, WORD wSample);

z Parameter:

fAdVal : [Output] Address of the A/D data buffer (Array of

WORD), data will be converted to voltage based

on the settings of P100X_SetChannelConfig().

The user must allocate sufficient space for the

buffer. The user cans access the data after calling the

function.

wNum : [Input] number of AD conversions to be performed.

wSample : [Input] AD sampling rate = 2M/wSample.

z Return:

P100X_NoError : OK

P100X_ExceedBoardNumber : invalid board number

P100X_FindBoardError : cannot find the OME-PCI-1002 board

P100X_AdPollingTimeOut : hardware timeout error

Page 33

Page 34

OME-PCI-1002 Software Manual for Windows

4.5 Driver Functions

4.5.1 P100X_DriverInit

z Description :

This function will detect all OME-PCI-1002 boards installed in the

system. This function must be called once before the other functions are

called.

z Syntax :

WORD P100X_DriverInit(WORD *wTotalBoard);

z Parameter:

wTotalBoard : [Output] Address of wTotalBoard, which will contain

the number of OME-PCI-1002 boards in the system.

wTotalBoard=0 Æ Not found.

wTotalBoard=1 Æ one OME-PCI-1002 card in the system

wTotalBoard=n Æ n OME-PCI-1002 cards in the system

z Return:

P100X_NoError : OK

P100X_NoFoundBoard : can not detect any OME-PCI-1002

P100X_FindBoardError : handshake check error

P100X_DriverHandleError : the P100X.VxD .open error for Windows 95

the P100X.SYS .open error for Windows NT

P100X_DriverCallError : call P100X.VxD return error

call P100X.SYS return error

4.5.2 P100X_DriverClose

z Description :

Releases all system resources. This function should be called

before terminating the program.

z Syntax :

void P100X_DriverClose(void);

z Parameter:

None

z Return:

None

Page 34

Page 35

OME-PCI-1002 Software Manual for Windows

4.5.3 P100X_GetConfigAddressSpace

z Description :

Get the I/O address of OME-PCI-1002 board n. This function is for

debugging purposes. It is not normally necessary to call this function.

z Syntax :

WORD P100X_GetConfigAddressSpace(WORD wBoardNo,

WORD *wAddrTimer, WORD *wAddrDio, WORD *wAddrAd);

z Parameter:

wBoardNo : [Input] OME-PCI-1002 board number

wAddrTimer, wAddrDio, wAddrAd

: [Output] Address of wAddrTimer, wAddrDio, wAddrAD

stores the address of the Timer, DI/DO and A/D.

Please refer to Hardware manual for additional details.

z Return:

P100X_NoError : OK

P100X_FindBoardError : handshake check error

P100X_ExceedBoardError : wBoardNo is invalidd

4.5.4 P100X_WhichBoardActive

z Description:

Returns the board number of the active board.

z Syntax:

WORD P100X_WhichBoardActive(void);

z Parameter:

None

z Return:

Returns the board number of the active board.

Page 35

Page 36

OME-PCI-1002 Software Manual for Windows

4.5.5 P100X_ActiveBoard

z Description:

This function makes a board active. This function must be called

once before the D/I/O, A/D or D/A functions are called.

z Syntax:

WORD P100X_ActiveBoard(WORD wBoardNo);

z Parameter:

wBoardNo [Input]The board number of the board to make active

z Return:

P100X_NoError : OK

P100X_ExceedBoardError : wBoardNo is invalid

4.5.6 P100X_GetIrqNo

z Description:

This function will get the IRQ number of the active OME-PCI-1002

board installed in the system. This function is not normally used by user

applications.

z Syntax:

WORD P100X_GetIrqNo( WORD *IrqNo);

z Parameter:

IrqNo : [Output] Address of IrqNo, which contains the IRQ No

allocated by the system.

z Return:

P100X_NoError : OK

Page 36

Page 37

OME-PCI-1002 Software Manual for Windows

4.6 The Interrupt Functions

4.6.1 P100X_InstallIrq

z Description :

This subroutine will install the interrupt handler for a specific IRQ n.

and set the maximum number of interrupts. Refer to section 3.6.7.for more

details on using interrupts

z Syntax :

WORD P100X_InstallIrq(HANDLE *hEvent, DWORD dwCount );

z Parameter:

hEvent : [Input] The user must use the CreateEvent() to create

the Event object and obtain its handle and pass the

handle to this function.

dwCount : [Input] Maximum number of counts for interrupt

transfer.

z Return:

P100X_NoError : successful

P100X_InstallIrqError : failed installing the IRQ handler.

4.6.2 P100X_GetIntCount

z Description :

This subroutine will read the interrupt transfer count.

z Syntax :

WORD P100X_GetIntCount(DWORD *dwVal )

z Parameter:

dwVal : [Output] the address of dwVal,

which contains the value of interrupt transferred count.

z Return:

P100X_NoError : successful

P100X_GetIntCountError : fail get interrupt count.

Page 37

Page 38

OME-PCI-1002 Software Manual for Windows

4.6.3 P100X_INT_AdStart

z Description :

This subroutine will start the interrupt transfer for a specific A/D

channel, set the gain code and sample rate.

z Syntax :

WORD P100X_INT_AdStart(WORD Ch, WORD Gain, WORD wFreqDiv )

z Parameter:

Ch : [Input] the A/D channel.

Gain : [Input] the Gain, refer to Section 3.1

wFreqDiv : [Input] the sampling rate is 2M/(wFreqDiv)

z Return:

P100X_NoError : successful

P100X_INTStartError : failure

4.6.4 P100X_INT_AdStop

z Description :

This subroutine will stop the interrupt transfer and remove the

installed interrupt handler.

z Syntax :

WORD P100X_ INT_AdStop(void )

z Parameter:

None

z Return:

P100X_NoError : successful

P100X_INTStopError : failure

Page 38

Page 39

OME-PCI-1002 Software Manual for Windows

4.6.5 P100X_GetBuffer

z Description :

This subroutine will copy the transferred interrupted data into the

user’s buffer (in word format).

z Syntax :

WORD P100X_GetBuffer(DWORD dwNum, WORD wBuffer[] )

z Parameter:

wNum : [Input] The total number to transfer to User’s Buffer.

wBuffer : [Output] The address of wBuffer (Array of word) that will contain

the hex A/D value.

The user must allocate sufficient space for this buffer.

This function will fill the buffer with the data. The user can access

the data after calling this function.

z Return:

P100X_NoError : successful

P100X_GetBufferError : failure

4.6.6 P100X_GetFloatBuffer

z Description :

This subroutine will copy the data into the user’s buffer (in floating-

point format).

z Syntax :

WORD P100X_GetFloatBuffer(DWORD dwNum, float fAdVal[] )

z Parameter:

wNum : [Input] The total number of data points to transfer to the

user’sbuffer.

fAdVal : [Output] Address of fAdVals (Array of float) that will

contain the data as a voltage value(floating-point).

The user must allocate sufficient space for the

buffer. This function will fill the buffer with the data. The

user cans access the data after calling this function.

z Return:

P100X_NoError : successful

P100X_GetBufferError : failure

Page 39

Page 40

OME-PCI-1002 Software Manual for Windows

4.6.7 Architecture of Interrupt mode

The flow chart below shows the steps for programming the A/D interrupt

functions:

Initialize the Device-Driver

Use Win32 API CreateEvent() to

create Event object and obtain the

handle.

Start the Interrupt Transfer

Uses Win32 API

WaitForSingleObject() to wait event.

Copy data into user's buffer

Stop the interrupt transfer and

remove the interrupt handler.

Uses Win32 API CloseHandle() to

close Event object's handle.

Close the Device-Driver

Install the IRQ

P100X_DriverInit( )

…….

CreateEvent( )

…….

P100X _InstallIrq( … )

………

P100X _INT_AdStart( … )

……

WaitForSingleObject( …. )

………..

P100X _GetBuffer( …. )

……

P100X _INT_AdStop

………

CloseHandle( )

……….

P100X _DriverClose( )

Page 40

Page 41

OME-PCI-1002 Software Manual for Windows

Next Loop

Sampling rate defined by wFreqDiv

Use P100X_InstallIrq(…) to install an

interrupt handler for IRQ level n to

transfer A/D data by interrupt.

Use P100X_INT_AdStart to specify the A/D

channel, gain and sampling rate for this

interrupt transfer, then begin the transfer.

System

Area

Application

Area

ADC

INT_Handler( )

BufferA

BufferB

A buffer(ex. BufferA) in the driver

will store the interrupt transferred

data. The buffer is in system area.

Use WaitForSingleObject( ) to wait the

event signal.

Yes

Copy the data in bufferA to a user

defined buffer(ex. BufferB) by using

P100X_GetBuffer(..) Then the users can

analyze the data in BufferB

Use P100X_INT_AdStop() to stop the

interrupt transfer and remove the

interrupt handler.

No

Page 41

Page 42

OME-PCI-1002 Software Manual for Windows

Set Event

to Signal

Thread

WaitForSingleObject( )

Device

Driver

ISR

CreateThread( )

User’s Application

Create Event

for Device Driver

CreateEvent( )

P100X_InstallIrq( )

Hardware

Interrupt Signal

Please refer to the following Windows API functions:

The following descriptions of these functions were copied from MSDN.

Refer to MSDN for complete details.

CreateEvent( )

The CreateEvent function creates or opens a named or unnamed

event object.

HANDLE CreateEvent(

// pointer to security attributes

LPSECURITY_ATTRIBUTES lpEventAttributes,

BOOL bManualReset, // flag for manual-reset event

BOOL bInitialState, // flag for initial state

LPCTSTR lpName // pointer to event-object name

);

Hardware

Device

Page 42

Page 43

OME-PCI-1002 Software Manual for Windows

CreateThread( )

The CreateThread function creates a thread to execute within the

virtual address space of the calling process.

To create a thread that runs in the virtual address space of another

process, use the CreateRemoteThread function.

HANDLE CreateThread(

// pointer to security attributes

LPSECURITY_ATTRIBUTES lpThreadAttributes,

DWORD dwStackSize, // initial thread stack size

// pointer to thread function

LPTHREAD_START_ROUTINE lpStartAddress,

LPVOID lpParameter, // argument for new thread

DWORD dwCreationFlags, // creation flags

LPDWORD lpThreadId // pointer to receive thread ID

);

WaitForSingleObject( )

The WaitForSingleObject function returns when one of the following

occurs:

• The specified object is in the signaled state.

• The time-out interval elapses.

To enter an alert-able wait state, use the WaitForSingleObjectEx

function. To wait for multiple objects, use the WaitForMultipleObjects.

DWORD WaitForSingleObject(

HANDLE hHandle, // handle to object to wait for

DWORD dwMilliseconds // time-out interval in

milliseconds

);

Page 43

Page 44

OME-PCI-1002 Software Manual for Windows

5. Program Architecture

Initialize the Device-Driver

Access/Control the Device

Access/Control the Device

Close the Device-Driver

Development

Toolkit

P100X_DriverInit( )

….

P100X_InputByte( … )

……..

……..

P100X_OutputByte(…)

…..

P100X_DriverClose( )

User's Application

Function Call into DLLs

DLLs

Services Call into Kernel-Mode

.VXDs, .SYSs (Device Driver)

Device Control

Hardware Devices

Page 44

Page 45

OME-PCI-1002 Software Manual for Windows

6. Reporting Problems

Technical support is provided at no charge you may contact us by

telephone or email at

Telephone: 1-800-872-9436

Email: das@omega.com

When reporting problems, please include the following information:

1) Is the problem reproducible? If so, how?

2) What platform and version are you using? For example, Windows 3.1,

Windows for Workgroups, Windows NT 4.0, etc.

3) Part number of the product that you are using?

4) If a dialog box with an error message was displayed, please include the full

text of the dialog box, including the text in the title bar.

5) If the problem involves other programs and/or hardware devices, please

provide a complete description of those items.

6) Other comments relative to this problem. Your suggestions are welcome.

Page 45

Page 46

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s W ARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or error s nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in suc h a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2002 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 47

M3928/0203

Where Do I Find Everything I Need for

Process Measurement and Contr ol?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERA TURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DA TA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEA TERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENT AL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...