Page 1

DIGITAL TACHOMETER

AND PROCESS METER

OMDC-DM8000

Starts at

$

335

l Four Devices in One:

Tachometer, Counter, Totalizer,

and Zero Speed Switch

l Selectable Alarm Relay Output

l Control Modes are Selectable

Between Rate, Time, and Counter

l User Inputs Allow for Special

Functions: Counter Reset,

Counter Gate, and Alarm Display

l Non-Volatile Memory for Storage

of Custom Settings

l Universal AC Input Voltage from

85 to 265 Vac

l NEMA 4X Rating

OMDC-DM8000, $335.

The OMDC-DM8000 is an economical

microprocessor-based digital tachometer

system capable of measuring shaft speeds

lower than 1 RPM. With an on-board

microcomputer coupled with sophisticated

internal software and a quartz crystal

controlled reference frequency, the

OMDC-DM8000 is able to maintain accuracy

of ±0.04%, even if the shaft is uneven. The

OMDC-DM8000 is field programmable

through the easy-to-use frontpanel interface

and can be configured to display any desired

unit of measure. Large 13 mm (

LED display numbers allow viewing under

the most adverse conditions.

The isolated 5 amp form C relay output can

be configured for many different alarming

conditions. Designed to use a variety of

inputs, including the hall-effect solid state

OMDC-PU-E Series pick-up, the system

delivers trouble free operation at an

economical cost. The OMDC-DM8000 offers

the same enhanced display options and

capabilities featured inour other digital

control products, as well as the universal

power supply and rugged european-style

terminal strip.

1

⁄

2") 4-digit

The OMDC-DM8000 can be used in process

applications for monitoring speeds and

rates, or counting discrete input signals.

Process applications using counting may be

batching, filling, mixing, punching, cutting,

drilling, diverting, or alarming. While

process applications using speed or rate

monitoring may be conveyors, conveyor

ovens, material flow, rotational rpm,

and testing.

SPECIFICATIONS

ELECTRICAL

Line Input

Voltage: Any voltage from

85 to 265 Vac

Frequency: Any freq from 48 to 62 Hz

Signal Input Frequency Range:

0 to 100,000 pulses per minute

(higher frequencies are possible when

using internal frequency divisor)

Resolution: From 0.01 RPM

Accuracy: ±0.04% display update

every pulse or 0.5 seconds, whichever

is longer

Isolated High/Low Alarm Output:

5 A, 230 Vac

Settable Alarm Range: 0 to 9999

D-1

Transducer Signal Input: 0 to 5 to

0 to 24 Vdc

Display Range: 0.001 to 99,990

Units of Operation: User

programmable, any unit sensor/pickup

Power Supply: 5V @ 50 mA

Isolated Alarm Relay Output Ratings:

240 Vac @ 5A

MECHANICAL

Display Type: LED, red, 4 digit,

13 mm (½") H

Housing Type (With Supplied Gasket in

NEMA 4X Panel): NEMA 4X

Connector Style (Pluggable Connector

Optional): 12-position 5 mm

european-style

Terminal Block Torque Setting:

4.4 in-lb max or 0.5 N-M

Faceplate Material: Polycarbonate with

polycarbonate overlay

Housing Material: Aluminum

Dimensions:

Length (Panel Depth):

117.5 mm (4.6")

Width: 115.3 mm (4.5")

Weight: 382 g (13.5 oz)

ENVIRONMENTAL

Operating Temperature Range:

-10 to 45ºC (15 to 115ºF)

Operating Humidity Range: 95%,

non-condensing

Page 2

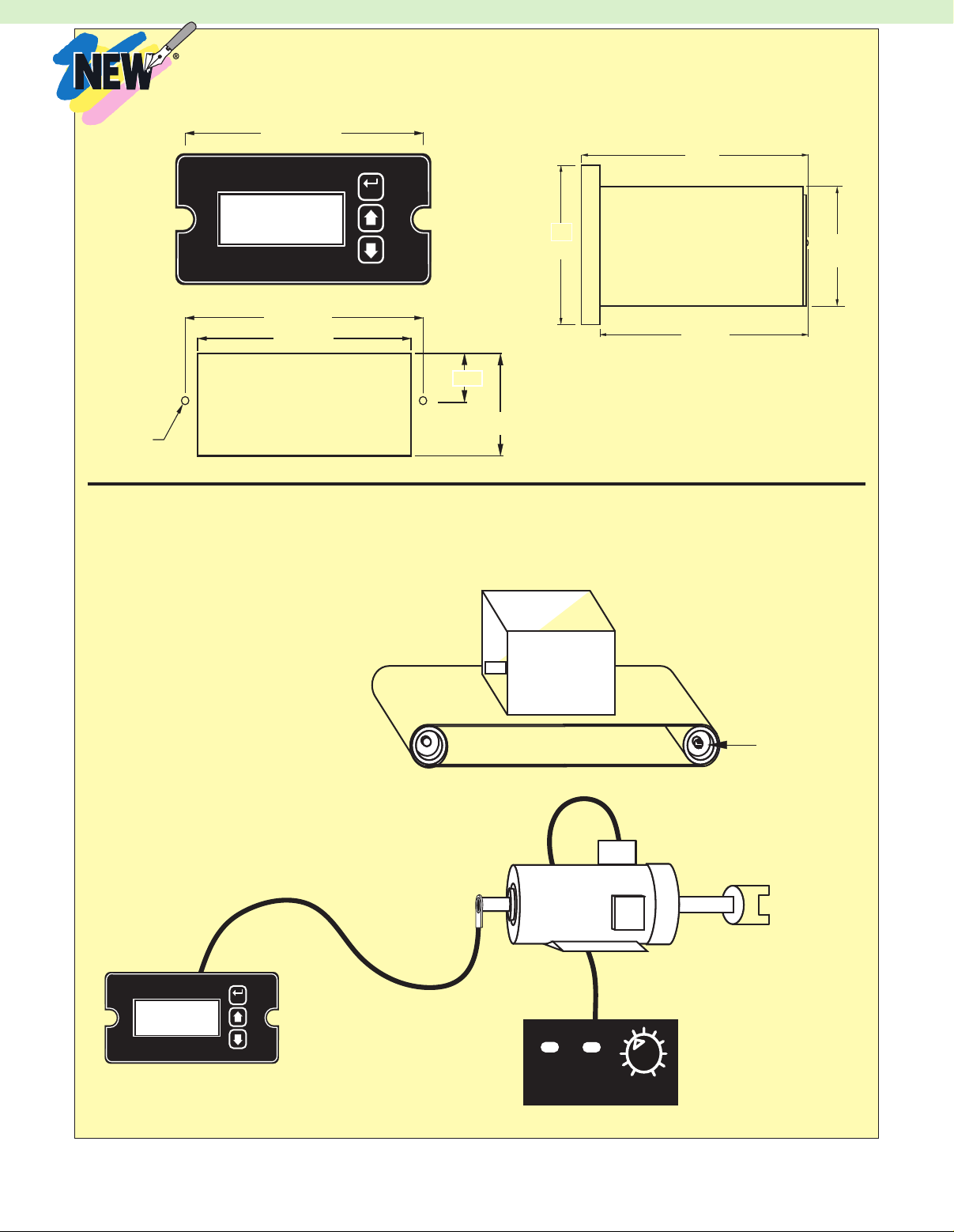

Cut-Out and Mounting Dimensions: mm (in)

127

(5)

117.4

(4.6)

58.2

(2.3)

41.9

(1.7)

Tach

Ite

m

ValuPage

TAC HOM ETE R

ENTER

101.6 (4)

101.6 (4)

HOUSING DEPTH

117.6 (4.6)

PANEL CUT- OU T

OMDC-DM8000

92 (3.6)

3.6

(0.1) x2

22.4 (0.9)

45 (1.8)

Bi-directional Incremental Position Display

Coupling to

Chain Drive

Tach

Ite

m

ValuPage

TAC H O ME T ER

ENTER

263.4

Drive Train Specs:

40 revolutions = 3.5"

of platform motion

OMDC-PU-20EQUAD

or equivalent

OMDC-DM8000 Meter

530BRE-36M Control

ON

OFF

FWD

REV

Connect to

Coupling

Linear-Motion System

Platform

Description:

A system is needed which will track the position of a bi-directional linear-motion platform

and allow the user to select a home or zero position. The display should read in inches

and indicate the position of the platform at all times.

APPLICATIONS

D-2

Page 3

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

OMDC-DM8000

P1-9

P1-10

P1-11

P1-12

Not Used

Not Used

Not Used

}

AC Line Input 85 to 265 Vac, 50 to 60 Hz

2 Amp

OMDC-PU-20EQUAD

black

white

red

NC1

C1

NO1

N

L

COM

+5V

S1

S2

NC2

C2

NO2

Not Used

Not Used

Not Used

brown

or equivalent

Conveyor Oven Time Monitor with Over-Heating Alarm

Heat Source

Tach

Ite

m

ValuPage

TAC HO M ET ER

ENTER

18:40

ON

OFF

0

10

4

6

8

2

253G or other Motor Control

Tunnel Oven

OMDC-PU-20E

or equivalent

Non-Reduced

Shaft

Gear Motor

Coupling to

Chain Drive

Connect to

Coupling

OMDC-DM8000 Meter

Description:

An oven monitor displaying the “tunnel” time in minutes and seconds. The tunnel time is defined as the time it takes

for the heated object on the conveyor to travel from point A to piont B in the application diagram below. A visual indicator

should activate if the tunnel time rises above a preset imit of 22 minutes and 30 seconds which could cause overheating of

the processed material. The indicator should automatically reset when the tunnel time returns to the normal operating range.

For ease of use, the display should be averaged over a period of 1 second.

A B

Drive Train Specs:

1250 RPM at non-reduced motor shaft equates

to 9 minutes and 15 seconds of tunnel time

WIRING DIAGRAM

PARAMETER CONFIGURATION

PARAMETER VALUE NOTES

10 5 Up/down counter mode

20 35 Because the initial values were 40 revolutions per 3.5" of platform motion, each is

21 400 In count mode, the reference RPM is set in revolutions. 400 has been entered here

22 10 Pulses per revolution of shaft encoder or pick-up is 10 PPM

25 3 Decimal point position set to XXX.X on display

multiplied by 10 to give an even number to increase accuracy since the displays

can be programmed in whole numbers. Additionally, because of the decimal point

position, the display reference is multiplied by 10 to generate the proper display

format. Without the second multiplication by 10, the display would only read 3.5"

when the driver motor turned 400 revolutions.

to represent 40 revolutions and the disply reference has also been multiplied by

10 to yeild the whole numbers.

APPLICATIONS

D-3

Page 4

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

OMDC-DM8000

P1-9

P1-10

P1-11

P1-12

Not Used

Not Used

Not Used

}

AC Line Input 85 to 265 Vac, 50 to 60 Hz

2 Amp

OMDC-PU-20E or

black

white

red

NC1

C1

NO1

N

L

COM

+5V

S1

S2

NC2

C2

NO2

Not Used

Not Used

Not Used

equivalent encoder

WIRING DIAGRAM

PARAMETER CONFIGURATION

PARAMETER VALUE NOTES

10 2 Time mode setting

20 555 Display should indicate 9:15 (555) when motor at reference RPM, parameter 21.

In time mode, all display values are entered in total number of seconds.

For example, 555 = (9minutes *60 seconds-per-minute) + 15 seconds

21 1250 This is the RPM at which the display reference, parameter 20, should be displayed

22 1 Pulses per revolution of shaft encoder or pick-up is 1 PPM

24 1 Display filtering/averaging set to 1 second

40 4 Alarm active when display value is above upper limit

41 1 Constant alarm output with automatic reset

43 1 Flash display when alarm output is active

48 1350 Upper limit setting for 22 minutes and 30 seconds. In time mode, all limits are

entered in total number of seconds.

For example, 1350 = (22 minutes *60 seconds-per-minute) + 30 seconds

To Order (Specify Model Number)

MODEL NO. PRICE DESCRIPTION

OMDC-DM8000 $335 Digital tachometer with alarm relay output

OMDC-DM8000-R 355 Digital tachometer with 2 alarm relay outputs

OPTIONAL SPEED SENSORS

MODEL NO. PRICE DESCRIPTION

OMDC-PU-20E $114 Shaft-mounted NPN pickup sensor, 10 pulses per revolution

OMDC-PU-40E 114 Shaft-mounted NPN pickup sensor, 20 pulses per revolution

OMDC-PU-20EQUAD 175 Shaft-mounted NPN quadrature pickup sensor, 10 pulses per revolution

Comes complete with panel-mount hardware and operator’s manual.

Ordering Example: OMDC-DM800, digital tachometer with alarm relay output, $335.

D-4

AVAILABLE FOR FAST DELIVERY!

Page 5

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...