Page 1

OMB-TempBook/66

Thermocouple & Voltage Measurement

Data Acquisition System

User’s Manual

p/n

GE285-0920,

Rev.

4.0

Page 2

OMEGAnetSM On-Line Service

http://www.omega.com

Servicing North America:

Internet e-mail

info@omega.com

USA:

Canada:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

e-mail: info@omega.com

976 Berger

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

e-mail: canada@omega.com

FAX: (203) 359-7700

FAX: (514) 856-6886

For immediate technical or appli cation assistance:

USA and Canada:

Mexico and

Latin America:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-TC-OMEGA

En Espanol: (95) 203-359-7803

SM

FAX: (95) 203-359-7807

e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained i n t hi s document is believed t o be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves t he right to alter specifications without notic e.

WARNING: These products are not desi gned f or use in, and should not be used for, pat i ent-connected applications.

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

ul. Rude armady 1868

733 01 Karvina-Hranice

Tel: 420 (69) 6311899

e-mail:czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

25 Swannington Road,

Broughton Astl ey, Leicestershire,

LE9 6TU, England

Tel: 44 (1455) 285520

FAX: 44 (1455) 283912

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

FAX: (31) 20 6434643

FAX: 420 (69) 6311114

FAX: (33) 130-699-120

FAX: 49 (07056) 8540

P.O. Box 7, Omega Drive,

Irlam, Manchester,

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Page 3

About This Manual

This manual explains the setup and operation of the TempBook data acquisition system. This manual

consists of chapters and document modules. The later are like chapters, but as they are shared by other

manuals and are sometimes used as “stand-alone” documents. For these reasons the document modules

do not contain chapter headings, nor do they contain footers that associate them with a specific manual.

Chapter 1 - Introduction and Quick Start includes an overview, specifications, and a Quick Start that

explains how to hook up a simple system.

Chapter 2 - Installation, Configuration, and Calibration discusses switches, indicators, connectors,

hardware hookups, software installation, configuration, and calibration.

Document Module

– DaqView [32-Bit Support]. DaqView is out-of-the-box data acquisition software

that is installed during 32-Bit Product Support Installation. Pull-down menus, toolbars, charts,

and parameter fields are discussed. The program does not apply to 16-Bit TempBook Support.

Document Module

- DaqViewXL [32-Bit Support]. DaqViewXL is an optional out-of-the-box

Microsoft-based add-on for data-acquisition and spreadsheet display. The program does not

apply to 16-Bit TempBook Support.

Document Module

– PostView [16-Bit and 32-Bit Support]. PostView is a post-data acquisition

viewing program that allows you to view waveforms that were previously acquired by

TempView.

Document Module

- TempView [16-Bit Support]. This document module explains the use and features

of the out-of-the-box data acquisition software that is installed during the 16-Bit Product Support

Installation. Pull-down menus, charts, and parameter fields are discussed. Note that this

document module does not apply to 32-Bit TempBook Support.

Chapter’s 3 and 4 – These two chapter’s have been replaced with document modules. Your user’s

manual continues at this point with chapter 5.

Chapter 5 - Programmer’s Guide explains how to custom-program for your application. Various

concerns are discussed; e.g., a comparison of standard and enhanced APIs and language support.

Chapter 6 – 16-Bit API Programming of the TempBook With C describes several example programs

using the standard API with the C language.

Chapter 7 - Software Calibration and Zero Compensation describes the commands and parameters

related to calibration and zero compensation. This chapter organizes and supplements related

sections of the tbkCommand Reference chapter.

Chapter 8 - Thermocouple Measurement describes the commands and parameters related to

thermocouple measurement. This chapter organizes and supplements related sections of the

tbkCommand Reference chapter.

Chapter 9 - tbkCommand Reference (16-Bit API) describes the commands and parameters of the

16-Bit API including useful reference tables.

Chapter 10 - Programming Models for 32-Bit API describes the fundamental building blocks for

TempBook data acquisition software. These programming blocks can then be arranged and

filled with your parameters to make your system do as you please. Program excerpts illustrate

the basic concepts and can often (with modifications) be used in your code.

Chapter 11 - daqCommand Reference (32-Bit API) describes the commands and parameters of the

32-Bit API including useful reference tables.

Using this equipment in ways other than described in this manual can cause

personal injury or equipment damage. Before setting up and using your

equipment, you should read all documentation that covers your system. Pay

special attention to cautions and warnings formatted like this one.

TempBook User’s Manual

04-26-01

CAUTION

CAUTION

CAUTIONCAUTION

i

Page 4

Software Reference Note for Users of 16-Bit TempBook Support:

16-bit PC users can use TempView out-of-the-box software (see the TempView

document module), or may choose to program their own application.

Programmers using 16-bit API should refer to chapters 5 through 9. Chapters 6, 7, and 8

provide examples and explain how to perform common tasks with the 16-bit API

detailed in chapter 9.

Software Reference Note for Users of 32-Bit TempBook Support:

32-bit PC users can use the DaqView and DaqViewXL out-of-the-box software

programs (refer to the related document modules); or program their own application.

Programmers using 32-bit API should refer to chapters 5, 10, and 11. Chapter 10

explains programming models for the enhanced API, detailed in chapter 11.

Note: 16-Bit and 32-bit refer to software support, not to A/D resolution.

ii

04-26-01

TempBook User’s Manual

Page 5

Table of Contents

1 Introduction and Quick Start

Overview …… 1-1

Description …… 1-1

Available Accessories ……1-2

Specifications …… 1-2

Quick Start …… 1-4

Signal Connection ……1-4

PC Connection …… 1-4

Power Connection ……1-5

Software Installation ……1-5

Parallel Port Capabilities …… 1-6

TempBook Configuration Under Windows 95/98/ME/NT and 2000 …… 1-6

2 Installation, Configuration, and Calibration

Inspection …… 2-1

Panel Connectors and Indicators …… 2-1

Termination Card and I/O Connectors …… 2-2

Internal Configuration …… 2-3

Watchdog Timer Enable/Disable (JP8)….. 2-4

Time Base Selection (JP9)……2-4

Hardware Installation …… 2-4

Rechargeable Battery Module (DBK30A)…… 2-4

Charging the Battery Modules …… 2-5

Battery Module Connection ……2-5

Connection Troubleshooting …… 2-6

Calibration of TempBook …… 2-7

Calibration Constants File Installation …… 2-7

Hardware Calibration …… 2-7

Differential Measurement Configurations …… 2-8

Floating Differential …… 2-8

Referenced Differential …… 2-8

Document Module

[32-Bit Support]

Overview……

Starting DaqView……

A Tour of DaqView……

Acquisition Setup ……

Data Destination ……

Pull-Down Menus ……

Toolbar Items ……

Document Module

[32-Bit Support]

Overview……

Program Requirements……

Installation of DaqViewXL Software……

Basic Function of DaqViewXL ……

Hints and Tips for using DaqViewXL ……

– DaqView

DaqView_pv, pg.

DaqView_pv, pg.

– DaqViewXL

DaqViewXL, pg.

2

DaqView_pv, pg.

DaqView_pv, pg.

DaqView_pv, pg.

DaqView_pv, pg.

DaqView_pv, pg.

19

1

DaqViewXL, pg.

2

2

13

15

16

DaqViewXL, pg.

1

DaqViewXL, pg.

DaqViewXL, pg.

2

2

4

TempBook User’s Manual

04-26-01

iii

Page 6

Document Module

– PostView

[16-Bit and 32-Bit Support]

Introduction ……

Starting PostView ……

Toolbar ……

Channel Information Region ……

Menu Items ……

Understanding Groups, Charts, and Channels ……

Chart Setup Wizard ……

Display Configuration ……

PostView Timebase ……

PostView, pg.

PostView, pg.

PostView, pg.

PostView, pg.

4

6

PostView, pg.

PostView, pg.

2

PostView, pg.

3

PostView, pg.

7

9

15

5

PostView, pg.

7

Document Module

- TempView

[16-Bit Support]

Application Startup……

TempView, pg.

TempView Components……

1

TempView, pg.

2

Charts and the Spreadsheet's "Reading" Column……

TempView Menu Items ……

Chapters 3 and 4 have been replaced by the preceding Document Modules.

3 – 4

TempView, pg.

8

5 Programmer’s Guide

A Programmer’s View of TempBook Operations ……5-1

Driver Options …… 5-3

16-Bit API (tbk…) …… 5-3

32-Bit API (daq…) ……5-3

Language Support …… 5-3

6 16-Bit API Programming of the TempBook With C

Accessing TempBook from a Windows Program …… 6-1

Accessing TempBook from a C-for-Windows Program …… 6-1

High-Level Analog Input …… 6-1

Low-Level Analog Input …… 6-2

Analog Input in the Background …… 6-2

General Purpose Digital I/O Functions ……6-4

High-Speed Digital Input …… 6-4

Counter/Timer Functions …… 6-5

High-Level Thermocouple Data Acquisition …… 6-6

Thermocouple Linearization …… 6-7

Sample Programs …… 6-8

High-Level Analog Input …… 6-8

Low-Level Analog Input …… 6-9

Analog Input in the Background …… 6-10

General Purpose Digital I/O …… 6-11

High-Speed Digital Input …… 6-12

Counter Timer Functions ……6-13

High-Level Thermocouple Measurement …… 6-14

Low-Level Thermocouple Linearization …… 6-15

16-Bit API Command Summary, for C Language …… 6-17

TempView, pg.

7

iv

04-26-01

TempBook User’s Manual

Page 7

7 Software Calibration and Zero Compensation

Software Calibration …… 7-1

Initializing the Calibration Constants ……7-1

Calibration Setup and Conversion …… 7-2

Calibration Example ……7-2

Zero Compensation ……7-3

Zero Compensation Example ……7-4

Automatic Zero Compensation …… 7-5

8 Thermocouple Measurement

Low-Level Thermocouple Data Conversion Functions …… 8-1

High-Level Thermocouple Measurement Functions …… 8-3

Single-Channel Measurement (tbkRdTemp) …… 8-3

Multiple Measurements from a Single Channel (tbkRdTempN) …… 8-4

Multiple Channel Measurement (tbkRdTempScan) …… 8-4

Multiple Measurements from Multiple Channels (tbkRdTempScanN) …… 8-4

9 tbkCommand Reference (16-Bit API)

Overview…… 9-1

Commands in Alphabetical Order …… 9-2

API Reference Tables …… 9-32

A/D Channel Descriptions ……9-32

A/D Gain Definitions ……9-32

A/D Trigger Source Definitions …… 9-32

Pretrigger Functions Trigger Source Definitions …… 9-33

Thermocouple Types …… 9-33

API Error Codes - C Languages …… 9-33

API Error Codes – QuickBASIC …… 9-34

API Error Codes - Turbo Pascal …… 9-35

API Error Codes - Visual Basic …… 9-36

10 32-Bit API Programming Models for TempBook

Overview …… 10-1

Data Acquisition Environment …… 10-1

Application Programming Interface (API) …… 10-1

32-Bit vs 16-Bit API ……10-1

Hardware Capabilities and Constraints ……10-1

Signal Environment ……10-2

Basic Models …… 10-2

Initialization and Error Handling ……10-3

Foreground Acquisition with One-Step Commands ……10-4

Temperature Acquisition Using One-Step Commands ……10-6

Counted Acquisition Using Linear Buffers ……10-8

Indefinite Acquisition, Direct-To-Disk Using Circular Buffers ……10-10

Multiple Hardware Scans, Software Triggering ……10-13

Background Acquisition……10-15

Temperature Acquisition Using TC Conversion Functions……10-17

Double Buffering……10-20

Direct-To-Disk Transfers……10-22

Transfers With Driver-Allocated Buffers……10-25

Summary Guide of Selected 32-Bit API Functions……10-27

TempBook User’s Manual

04-26-01

v

Page 8

11 daqCommand Reference, 32-Bit

Overview……11-1

Commands in Alphabetical Order……11-2

API Reference Tables……11-35

Daq Device Property Definitions……11-36

Event-Handling Definitions……11-36

Hardware Information Definitions……11-36

ADC Trigger Source Definitions……11-37

ADC Miscellaneous Definitions……11-37

TempBook Definitions……11-38

General I/O Definitions……11-38

DaqTest Command Definitions……11-38

Calibration Input Signal Sources……11-38

API Error Codes……11-39

vi

04-26-01

TempBook User’s Manual

Page 9

Introduction and Quick Start

Overview

This chapter describes the TempBook in general terms including specifications. A Quick Start is included

in the chapter to help you get a simple system up and running in a short amount of time. Chapter 2 has

more detailed instructions.

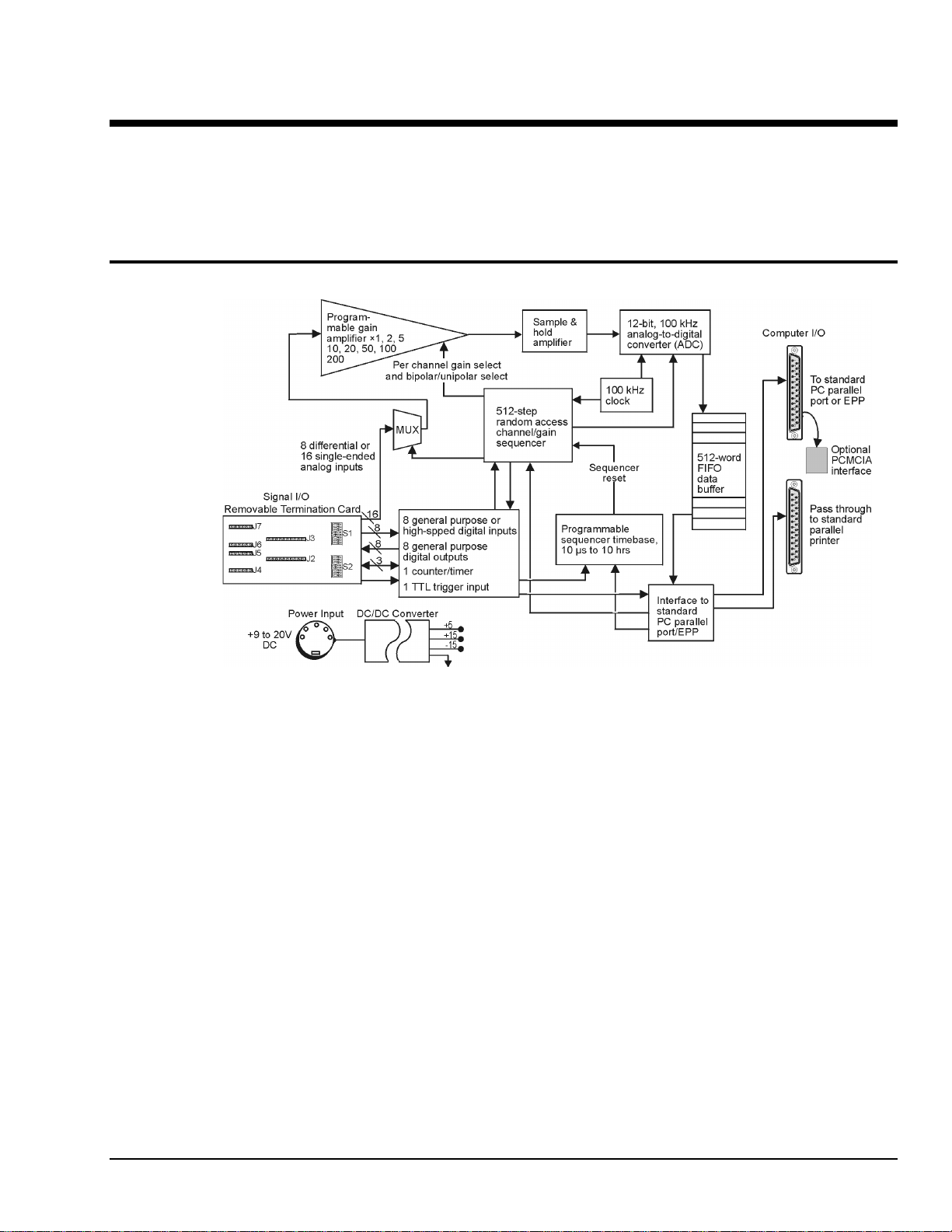

Description

1

TempBook/66 Block Diagram

The TempBook/66 adds voltage and thermocouple measurement capability to notebook PCs for portable

test applications. The TempBook also provides an effective alternative to plug-in boards for desktop PCs.

The TempBook provides 12-bit, 100 kHz data acquisition and can support up to 800 Kbyte/s data transfer

to a PC via an enhanced parallel port interface or PCMCIA link. The unit can also connect to a standard

parallel port and transfer readings [directly to disk] at up to 100K readings/s. As an external module with

the same footprint as a typical notebook PC, the TempBook can be attached directly under a notebook PC

for portability.

The TempBook has a built-in analog capability that permits it to measure 8 channels in a differential mode

or 16 channels in single-ended mode. Its on-board programmable-gain instrumentation amplifier can be set

to gains of ×1, 2, 5, 10, 20, 50, 100 or 200 on a per channel basis. Its A/D converter scans selected

channels at a constant 10 us/channel rate, minimizing the time skew between consecutive channels. The

time between the start of each scan sequence can be programmed to start immediately or at intervals of up

to 10 hours. The TempBook features a hardware-based digital/TTL trigger that minimizes trigger latency to

less than 10 us. The TempBook can also be triggered from a command from the PC.

The TempBook/66 can be powered by an included AC adapter, a standard 12V car battery, any

+9 to 20 VDC source, or an optional rechargeable nickel-cadmium battery module (DBK30A). This makes

it ideal for field and remote data acquisition applications.

TempBook User’s Manual

04-20-01_o

Introduction and Quick Start 1-1

Page 10

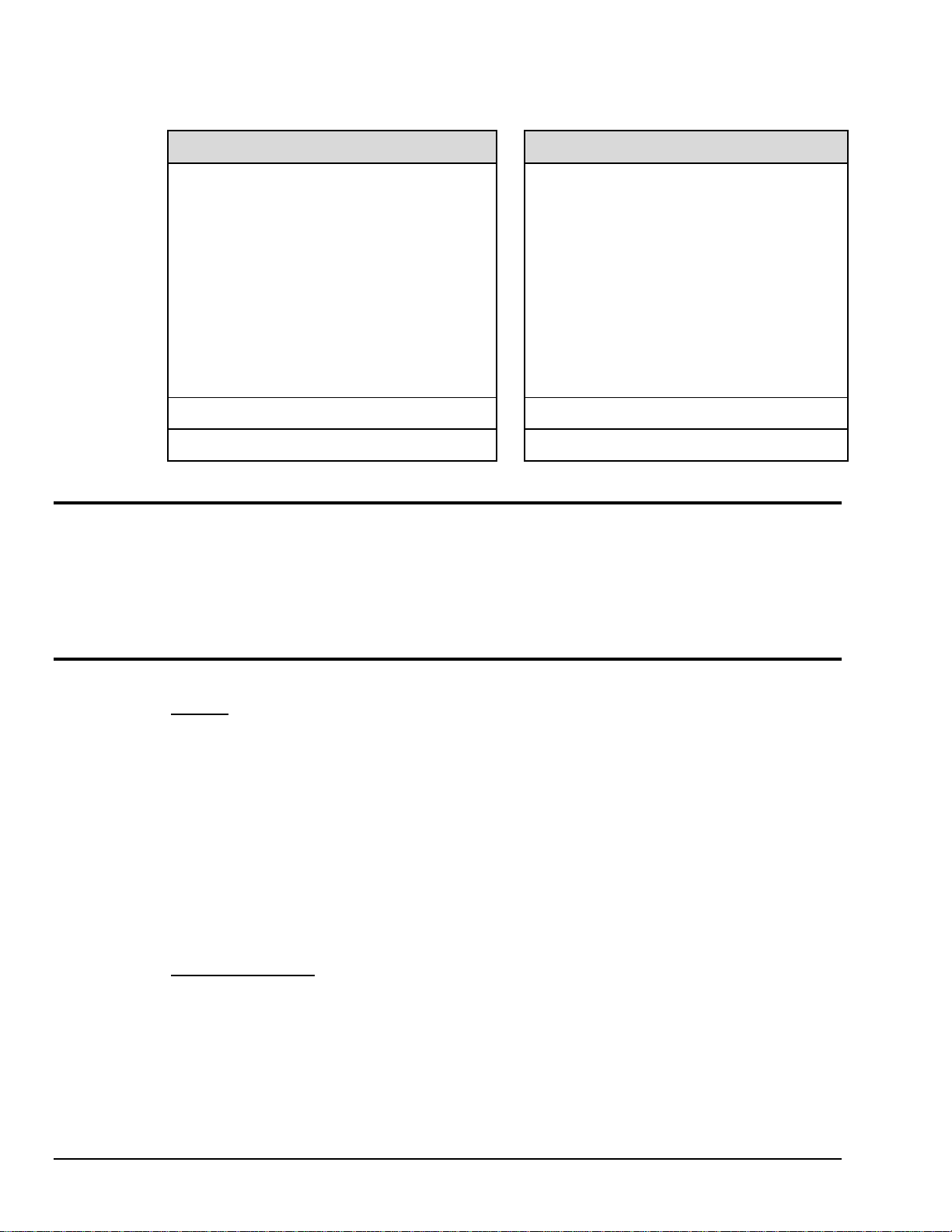

TempBook related Software – What you should install from the Data Acquisition CD

For 32-Bit Support* For 16-Bit Support*

32-bit TempBook Support

•

is used with Windows 9x, ME, NT, and

Windows 2000 Operating Systems and

installs the following:

DaqView (32-bit)

DaqViewXL (32-bit)

File Converter (32-bit)

DaqCal (32-bit)

32-bit drivers for VB, C, and Delphi

PDF version of Programmer’s Manual

PostView, Post-data viewing program

•

Acrobat Reader

•

*32-bit refers to support, not to A/D resolution. *16-bit refers to support, not to A/D resolution.

Available Accessories

Additional accessories that can be ordered for the TempBook/66 include:

• WBK20A PCMCIA interface card and cable

• DBK30A Rechargeable battery module

• WBK21 ISA Interface Card

16-bit TempBook Support

•

is used with Windows 3.x Operating

Systems and installs:

TempView (16-bit)

TempCal (16-bit)

16-bit drivers for VB, C, PASCAL, and

DOS

PostView, Post-data viewing program

•

Acrobat Reader

•

Specifications

General

Connector

removable screw-terminal card.

Thermocouple Types

Input Ranges

Unipolar

Bipolar

Analog Inputs

Analog-to-Digital Converter

Cold Junction Sensor Output

Input Impedance

Input RC Filter -3dB Frequency

Gain Accuracy

Maximum Input Voltage

CMRR (Input Stage)

Offset

Offset Drift

Channel Sequencer

Depth

Speed

Interval Between Scans

Gains

Unipolar/Bipolar

Single-Ended/Differential: Software programmable for all channels

: Connects to a PC via an included parallel port cable; user signals are connected via screw terminals on a

: J, K, S, T, E, B, R & N

:

: .05, 0.1, 0.2, 0.5, 1, 2, 5, 10V

: ±0.025, .05, 0.1, 0.25, 0.5, 1, 2.5, 5 V

: 8 differential or 16 single-ended voltage or 8 differential thermocouple inputs

: 12-bit with no missing codes, unsigned binary output format.

: 100 mV/°C

: 100K/100M Ohm, Switch-selectable on a per-channel basis in parallel with switched 100 pF

: 15.9 kHz switch-selectable on a per channel basis

: 0.1%

: ±15 V

: 90 dB typ, DC to 60 Hz

: Software-compensated

: Software-compensated

: 512 locations

: 10 µs per channel, fixed

: 10 µs to 10 hours, software-programmable

: Sequencer programmable on a per-channel basis.

: Sequencer programmable on a per channel basis.

1-2 Introduction and Quick Start

04-26-01_o

TempBook User’s Manual

Page 11

Digital I/O

Inputs

Number

Usage

Outputs

Trigger Input

: 8 fixed as inputs

: General-purpose register addressable or high-speed scanned via channel sequencer

Type

: TTL-compatible

High Voltage

Low Voltage

Number

Usage

Type

: TTL-compatible

High Voltage

Low

Voltage: 0.4V @ 2.5 mA sink

Type

: TTL-compatible

High Voltage

Low Voltage

: 2.0 V min

: 0.8 V max

: 8 fixed as outputs

: General-purpose register addressable

: 3.0 V @ 2.5 mA source

: 2.0 V min

: 0.8 V max

Counter/Timer Port

Device

: 8254 (P0 only)

Number

Clock

Usage

Type

Input High Voltage

Input Low Voltage

Output High Voltage

Output Low Voltage

Temperature Specifications

: 1 gate input, 1 clock input & 1 output

: Internal 100 kHz or external up to 10 MHz

: Register addressable

: TTL compatible

: 2.0 V min

: 0.8 V max

: 3.0 V @ 2.5 mA source

: 0.4 V @ 2.5 mA sink

Thermocouple Accuracy

(TempBook/66 @ 0 to 50°C)

Type Min Max Accuracy

(°C ) (°C ) (<°C ) (>°C ) Type <0°C >0°C

J -200 760 ±0.9 ±0.9 J 1.2 0.5

K -200 1260 ±2.4 ±1.5 K 1.1 0.8

T -200 400 ±2.1 ±1.2 T 0.8 0.3

E -270 1000 ±2.1 ±1.3 E 1.9 0.9

N28 -270 400 ±1.2 ±1.2 N28 0.9 0.9

N14 - 1300 - ±1.5 N14 - 5.0

S - 1780 - ±2.4 S - 1.6

R - 1780 - ±2.4 R - 1.5

B +900 1820 - ±2.7 B - 1.8

Thermocouple Resolution (°C)

TempBook User’s Manual

04-26-01_o

Introduction and Quick Start 1-3

Page 12

Quick Start

For those users who wish to get their TempBook up and running as quickly as possible, this section

provides a brief explanation of the steps required.

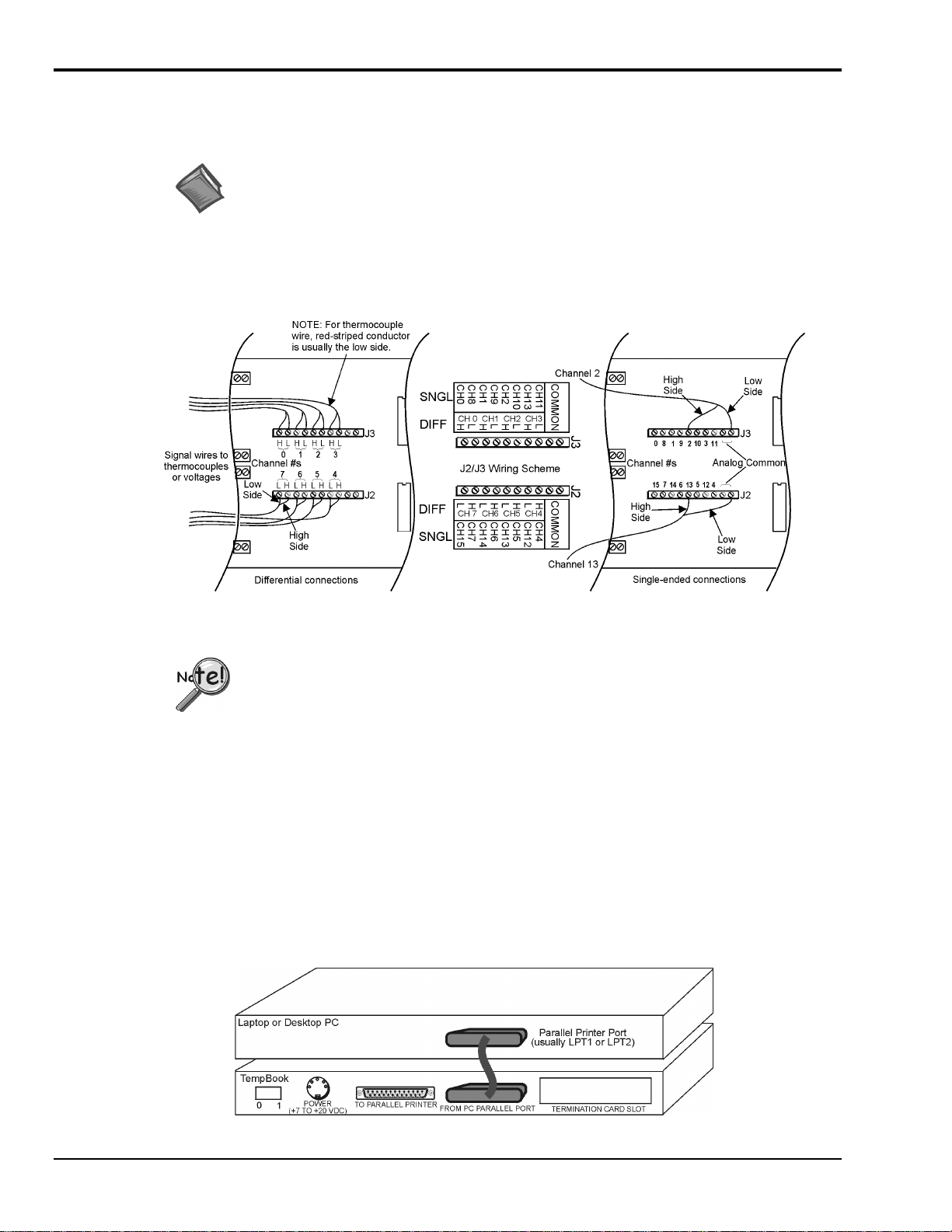

Signal Connection

The thermocouple and voltage input signals are fed to the TempBook through a removable termination

card. To remove this card, rotate the ejector handle with your thumb or finger. Once removed, the

thermocouple or voltage connections should be made as shown in the figure.

Reference Note: Refer to chapter 2, Installation and Configuration, if you are not

already familiar with TempBook systems, or if you need information that goes beyond

the scope of this Quick Start.

The DIP switches located on the termination card connect optional biasing resistors as well as input filters.

For further details, refer to section Termination Card and I/O Connectors in chapter 2.

PC Connection

The TempBook communicates with a laptop or desktop computer through the parallel printer port. Connect

the supplied cable to the computer’s parallel port and the TempBook's parallel port.

Signal Connections, Differential and Single-Ended

When connecting both low and high level signals, the low-level signals should be

connected to the lowest numbered channels with connections following in ascending

order of signal magnitude.

•

For thermocouple or other differential inputs, these switches should be closed to provide the required

bias current path.

•

For single-ended inputs these switches can be optionally opened or closed.

1-4 Introduction and Quick Start

PC-to-TempBook Connection

04-26-01_o

TempBook User’s Manual

Page 13

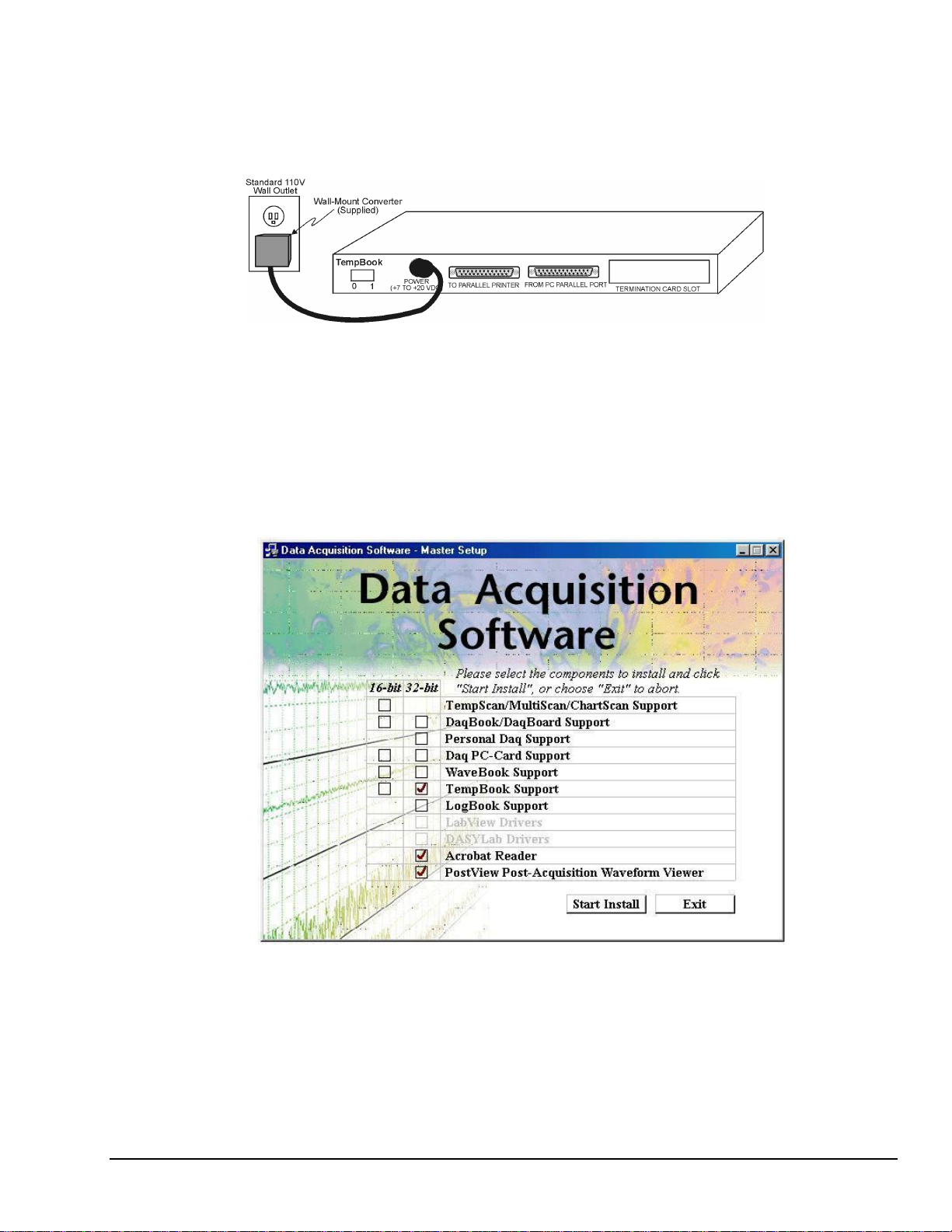

Power Connection

The TempBook is typically powered from the supplied wall-mount converter or from an optional DBK30A

battery module. The wall-mount converter plugs into any standard 110 VAC wall outlet and its other end

plugs into the circular DIN5 receptacle on the TempBook's rear panel. If using the battery module, please

refer to the section Rechargeable Battery Module in chapter 2.

Software Installation

The TempBook/66 comes with a Microsoft Windows-based application (32-bit DaqView) that provides the

easiest means to collect data from the TempBook. To install the software insert the installation CD into

your PC’s CD drive. After agreeing with the legal statement a master setup screen will appear (see

following figure).

If you are using Windows 3.x, select 16-bit TempBook Support from the Data Acquisition Software Master

Setup screen, otherwise select 32-bit (see following figure).

TempBook Power Connection

Selecting TempBook Support (32-Bit), Acrobat Reader, and PostView from the Master Setup Screen

After selecting TempBook Support [also, Acrobat Reader and PostView, if desired], click

Start Install and follow the on-screen prompts.

Once the setup program has installed the software, a TempBook program group will appear within

Windows. To start DaqView, click on its program icon. The main window will soon display a spreadsheet

of channels in rows and channel parameters in columns.

TempBook User’s Manual

04-26-01_o

Introduction and Quick Start 1-5

Page 14

Reference Note:

Users of 32-bit TempBook Support should refer to the DaqView, DaqViewXL, and

PostView document modules.

Users of 16-bit TempBook Support should refer to the TempView and PostView

document modules.

Parallel Port Capabilities

The TempBook includes a test program that verifies your computer's parallel port, testing its standard and

enhanced capabilities.

•

Standard LPT ports on IBM compatible computers have two modes to read data from the printer port:

4-bit and 8-bit. The 8-bit mode is somewhat faster than the 4-bit, but not all printer ports support this

mode.

• Enhanced parallel ports (EPP) are parallel ports that include additional hardware that allows the

TempBook to communicate with the PC at 3 to 10 times the speed possible with standard parallel

ports. This greatly improves data acquisition performance.

Enhanced parallel ports require special hardware, and only certain computers are EPP capable. Most laptop

computers that use the Intel 386SL or 486SL chip set (which includes the 82360 I/O Controller) are EPP

capable. For those computers which have plug-in card slots, EPP adapter cards are available. You may

wish to contact your computer's manufacturer for details about your machine and possible adapter cards.

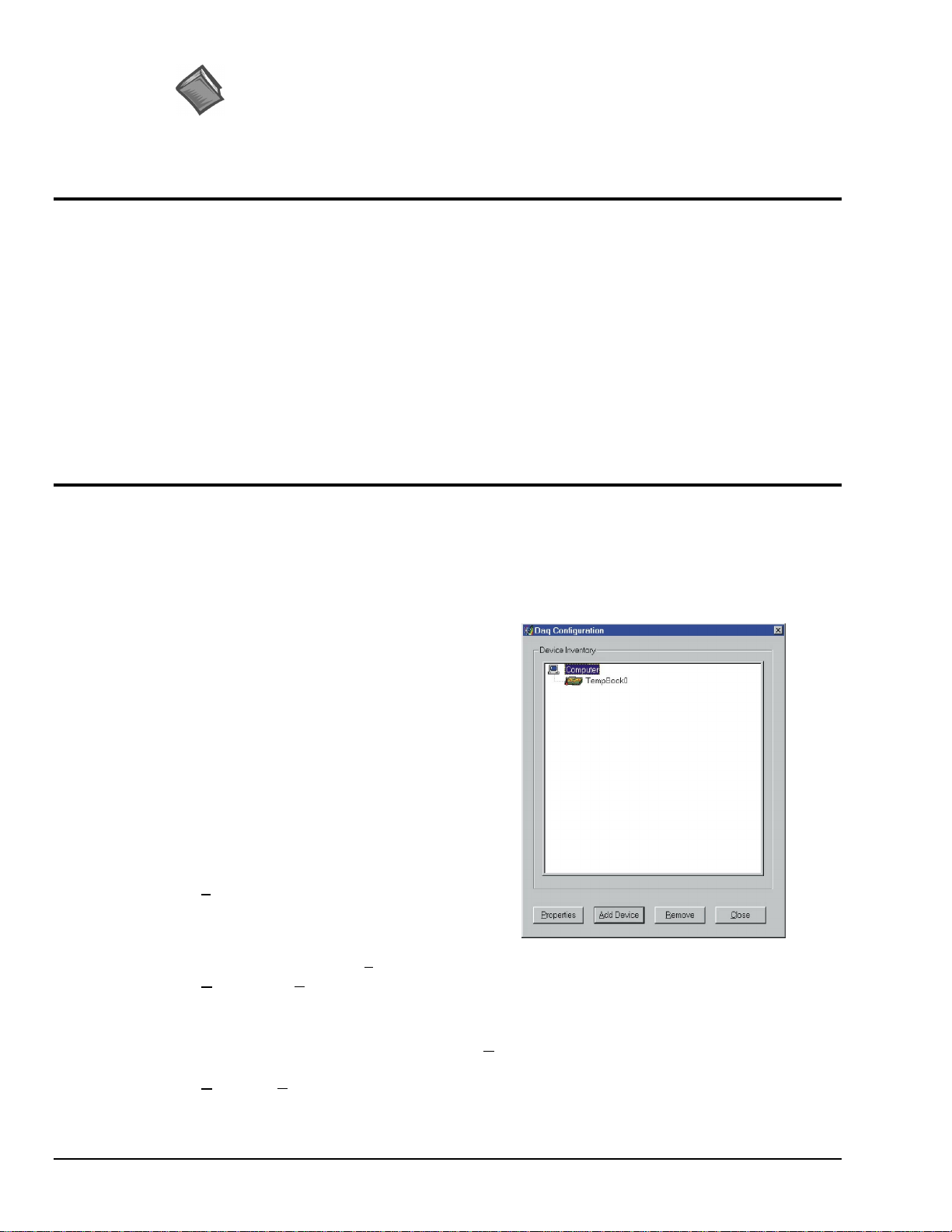

TempBook Configuration Under Windows 95/98/ME/NT/ and 2000

This section describes the configuration of TempBook devices under the Windows 95/98/ME/NT and 2000

operating systems. A configuration utility is supplied via a control panel applet. The Daq Configuration

applet allows you to add a device, remove a device, or change existing configuration settings. Daq

Configuration also has a built-in test utility to test the device. The test utility provides feedback on the

validity of the current configuration settings as well as providing relevant performance summaries.

Daq Configuration can be found in the Windows

control panels and can be executed any time that it is

desirable to add, remove or change device

configuration settings. Daq Configuration may also

be entered during driver installation. The following

description applies to either method.

The Daq Configuration/Device Inventory screen at

right will display all currently configured devices.

Devices are identified by their name, and by an icon

that indicates the device type. If no device is currently

configured, no device will appear in this field.

The 4 buttons across the bottom of the Daq

Configuration screen are used as follows:

• Properties. Current configuration settings for a

device can be changed by bringing up the

corresponding properties screen. To do so,

double-click the device icon or single-click the

device and then select the Properties button.

• Remove. The R

removed if it is no longer installed or if the device’s configuration no longer applies.

Note: If a device is removed, applications may no longer access the device. However, the device can

be re-configured at any time using the Add Device function described below.

emove button is used to remove a device from the configuration. A device may be

• Close. The C

1-6 Introduction and Quick Start

lose button may be used at any time to exit the Daq Configuration applet.

04-26-01_o

TempBook User’s Manual

Page 15

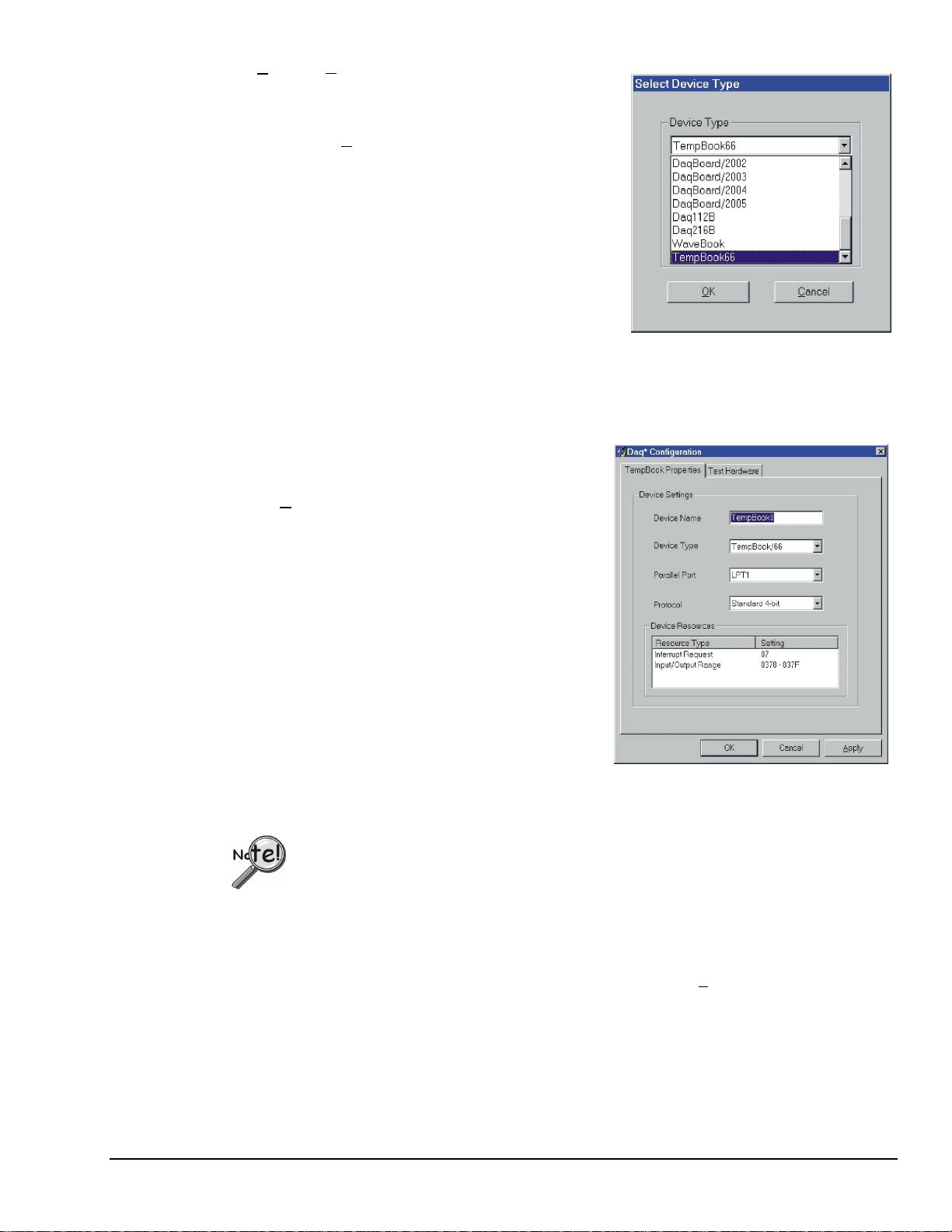

• Add. The A

dd Device button is used to add a device

configuration whenever a new device is added to the

system. Failure to perform this step will prevent

applications from properly accessing the device.

Selecting the Add Device button will display a window as

shown in the figure.

Use the scroll bar to find the TempBook device type to be

configured. Once found, click the device type (the type should

then appear in the main edit box). Now select the OK button.

The next screen displays the properties for the TempBook

device with the default configuration settings. Fields include:

• The Device Name field is displayed with the default

device name. However, this field can be changed to any

descriptive name as desired.

• The Device Type field should indicate the device type which was initially selected. However, it can

be changed here if necessary.

• The Protocol field is used to set the parallel port protocol for communicating with the TempBook.

Depending on your system, not all protocols may be available.

When all fields have been changed to the desired settings,

you can click:

• the Apply button to store the configuration.

• the OK button to store the configuration and exit the

current property screen.

•

the Cancel button to exit the current device

configuration property screen without storing any

changes.

• the Test Hardware tab to test the current stored

configuration for the device. This selection will bring

up the Test property screen.

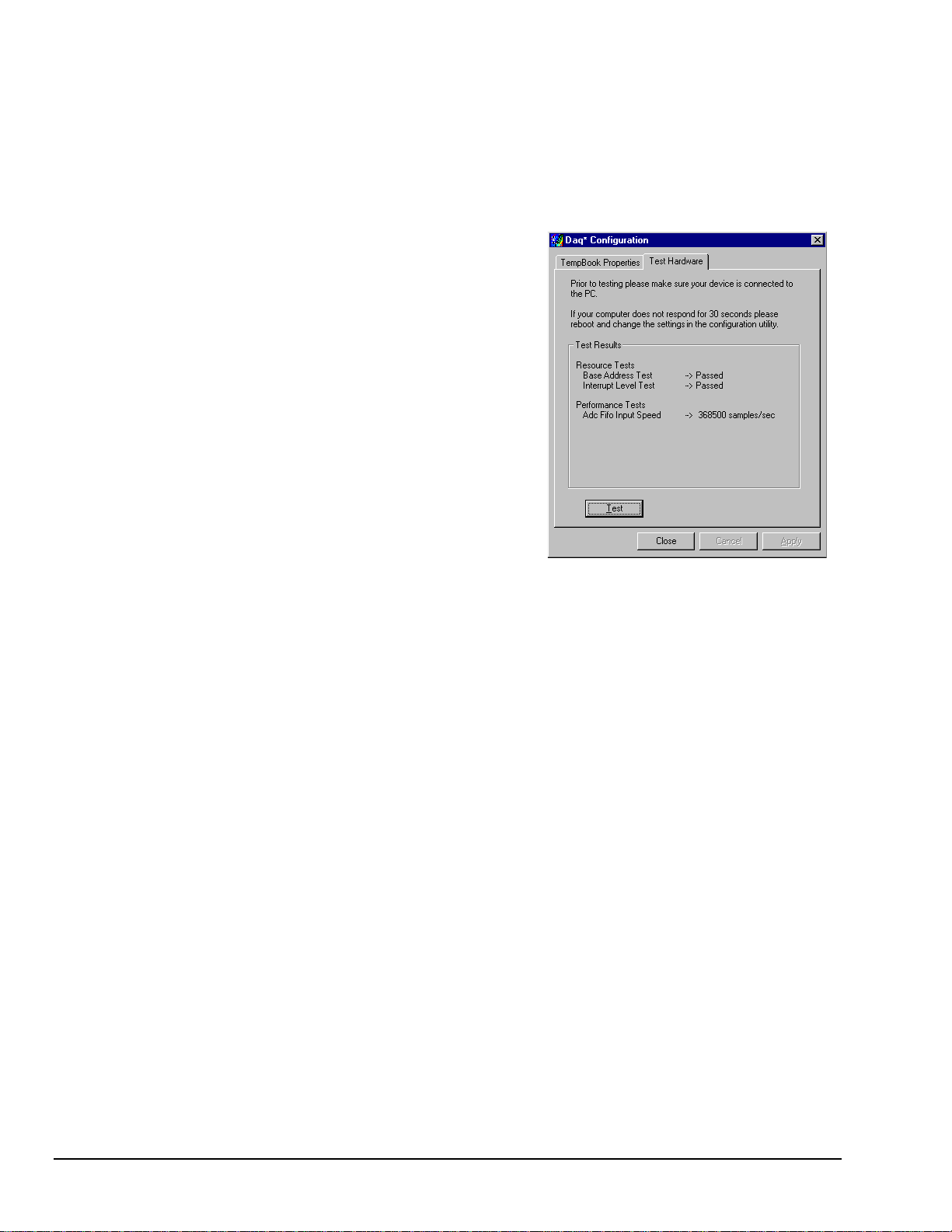

Before testing the TempBook, make sure the device has

been properly installed and powered-on. Make sure the

parallel port cable is firmly in place on both the TempBook

and the proper LPT port in the computer.

Testing the TempBook device may, in some cases, cause the system to hang.

If test results are not displayed in 30 seconds or if the system does not seem to be

responding …

(1) reboot the system.

(2) upon power-up, re-enter the Daq Configuration, and

(3) change the configuration settings to those that work properly.

To test the current stored configuration for the device, click the Test button. Test results

should be displayed within a few seconds. The test results have 2 components:

Resource Tests and Performance Tests.

TempBook User’s Manual

04-26-01_o

Introduction and Quick Start 1-7

Page 16

Resource Tests

The resource tests are intended to test system capability for the current device configuration. These tests

are pass/fail. Resource test failure may indicate a lack of availability of the resource or a possible resource

conflict.

• Base Address Test - This test will test the base address for the selected parallel port. Failure of this

test may indicate that the parallel port is not properly configured within the system. See relevant

operating system and computer manufacturer’s documentation to correct the problem.

Performance Tests

The performance tests are intended to test various

TempBook functions with the current device

configuration. These tests give quantitative results for

each supported functional group. The results represent

maximum rates at which the various operations can be

performed. These rates depend on the selected parallel

port protocol and will vary according to port hardware

capabilities.

• ADC FIFO Input Speed - This test will test the

maximum rate at which data can be transferred from

the TempBook’s internal ADC FIFO to computer

memory through the parallel port. Results are given

in samples/second (sample is 2 bytes in length

representing a single A/D count).

1-8 Introduction and Quick Start

04-26-01_o

TempBook User’s Manual

Page 17

Installation, Configuration, and Calibration 2

Inspection

The TempBook components were carefully inspected prior to shipment. When you receive your data

acquisition system, carefully unpack all items from the shipping carton and check for any obvious signs of

physical damage that may have occurred during shipment. Immediately report any damage to the shipping

agent. Retain all shipping materials in case you must return the unit to the factory.

Every TempBook is shipped with the following items:

•

TempBook Data Acquisition System

•

User's Manual

• Installation CD

• Calibration Constants Disk

• Accessory Kit, including: CA-35-2 (2 ft parallel port cable) and an AC Adapter

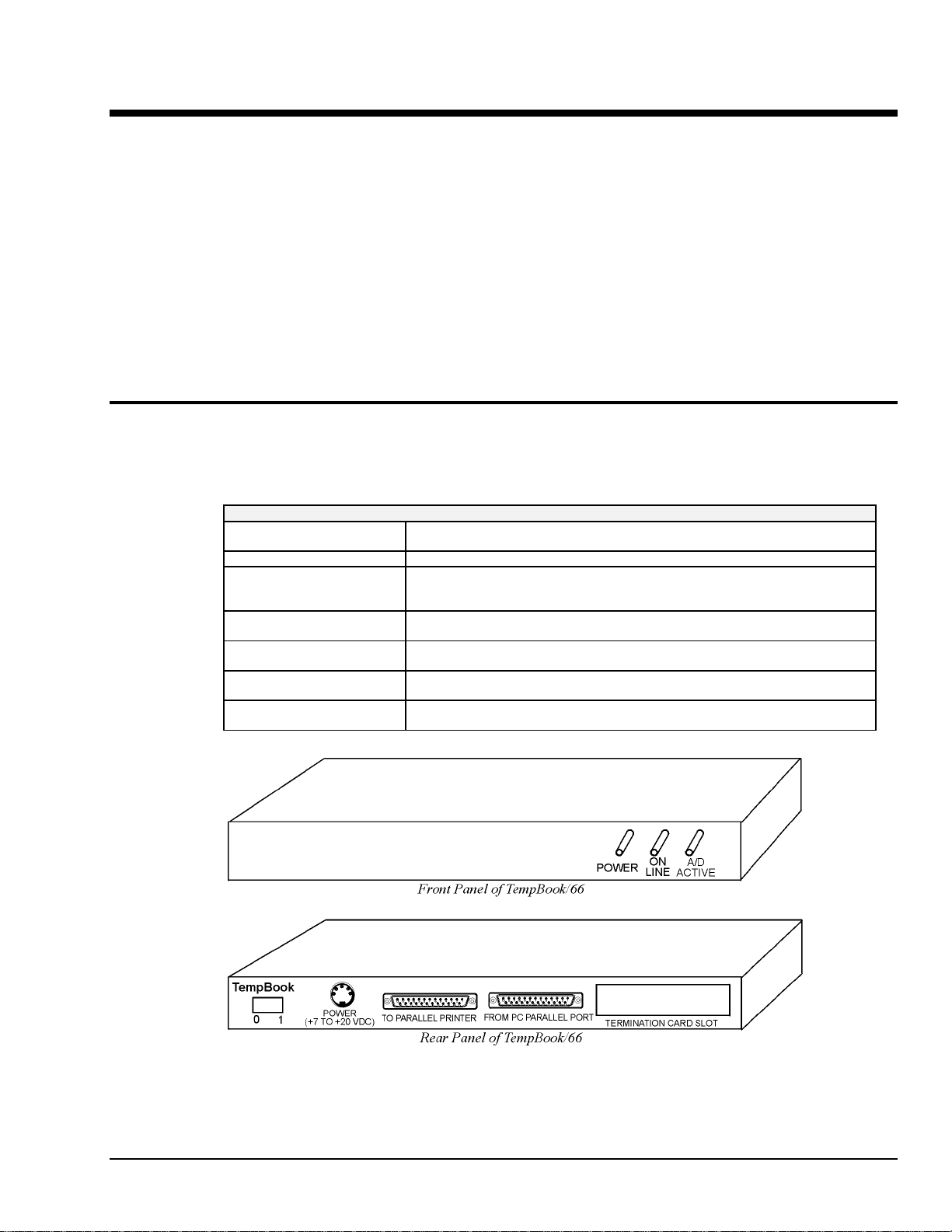

Panel Connectors and Indicators

The TempBook front panel consists of 3 status-indicator LEDs. The rear panel consists of the power

switch, power input, two DB25s for parallel port connection and pass-thru, and a slot to accept the input

termination card. The function of each of these components is described below.

TempBook Panel Connectors and Indicators

POWER SW ITCH This rocker arm switch turns on the DC power to the TempBook when the "1" side

POWER INPUT This input connector accepts +7 VDC to +20 VDC.

TO PARALLEL PRINTER This parallel port can connect to any standard parallel printer. This allows the

FROM PC PARALLEL PORT This parallel port connects directly to the PC's parallel printer port. This allows

POWER This LED is ON when power is applied to the TempBook (and the power switch is

ON-LINE This LED is ON when the TempBook is in an Active state. OFF, when the

A/D ACTIVE ON during an A/D scan sequence. If the sequence has a small number of steps

of the switch is depressed.

user to attach both the TempBook and a parallel printer to the system

simultaneously.

the host system to communicate with the TempBook.

in the ON position). OFF, if power is not present.

TempBook is not enabled or in the printer pass through mode.

and occurs infrequently, this indicator will only flash briefly.

TempBook User’s Manual

TempBook Front and Rear Panels

04-25-01

Installation, Configuration, and Calibration 2-1

Page 18

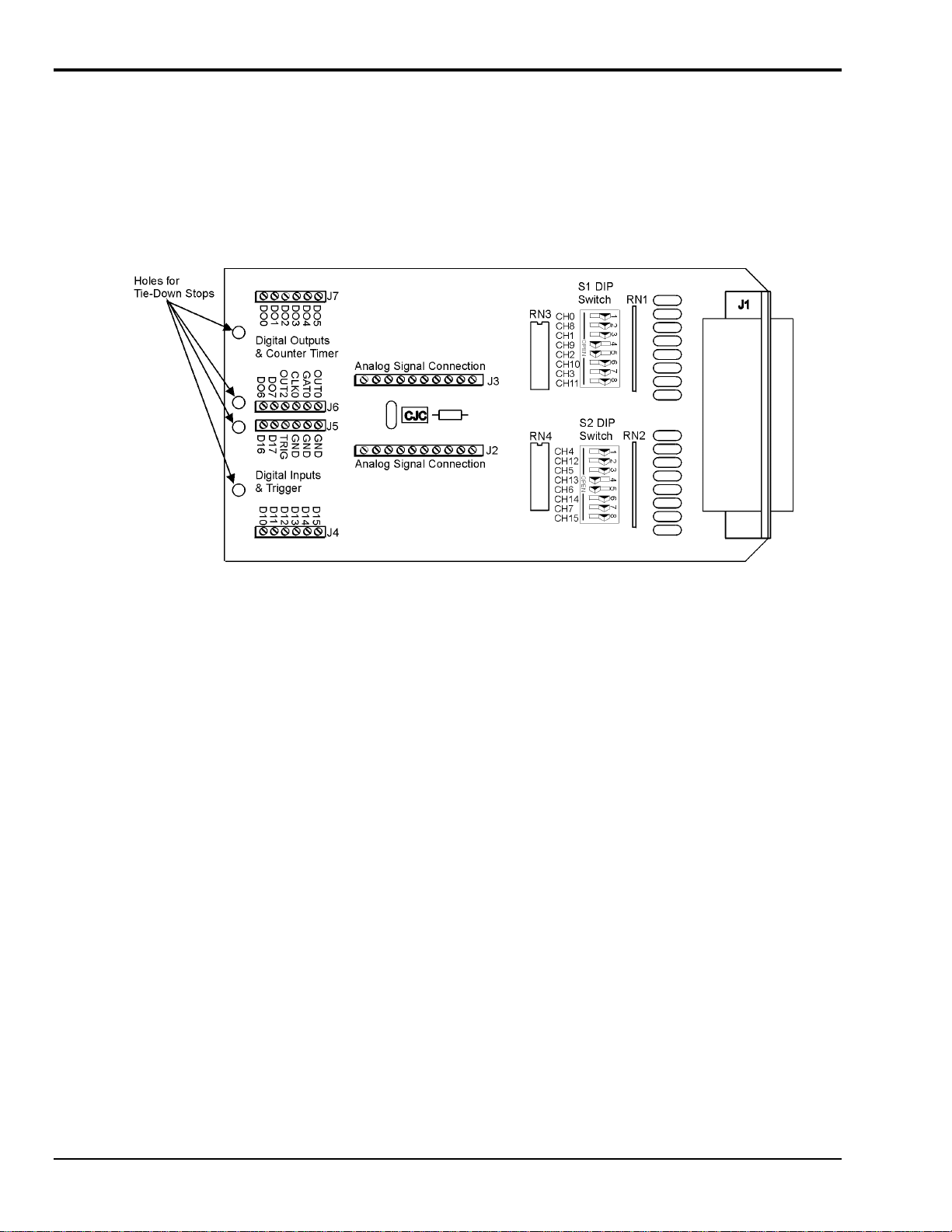

Termination Card and I/O Connectors

The TempBook/66 accepts all analog and digital I/O signals via a removable termination card (see figure).

This termination card has six screw terminal strips, a CJC temperature sensor, and input R/C filters which

also provide a bias current return path for the TempBook's instrumentation amplifier. The filters/bias

resistors are switch-selectable on a per channel basis.

TempBook Termination Card

Terminal strips J2 and J3 provide analog input signal connection. Note that the terminals are arranged in

differential pairs for easy thermocouple connection. These terminal strips also provide analog signal

common connections for convenient referencing of single-ended input signals.

Terminal strips J4 and J5 provide connections for the eight digital outputs and the TTL trigger input. These

terminal strips also provide ground connections for referencing digital signals. Terminal strips J6 and J7

provide connections for the eight digital inputs, the pacer clock output (OUT2), and the three counter/timer

(8254 P0) I/O signals.

2-2 Installation, Configuration, and Calibration

04-25-01

TempBook User’s Manual

Page 19

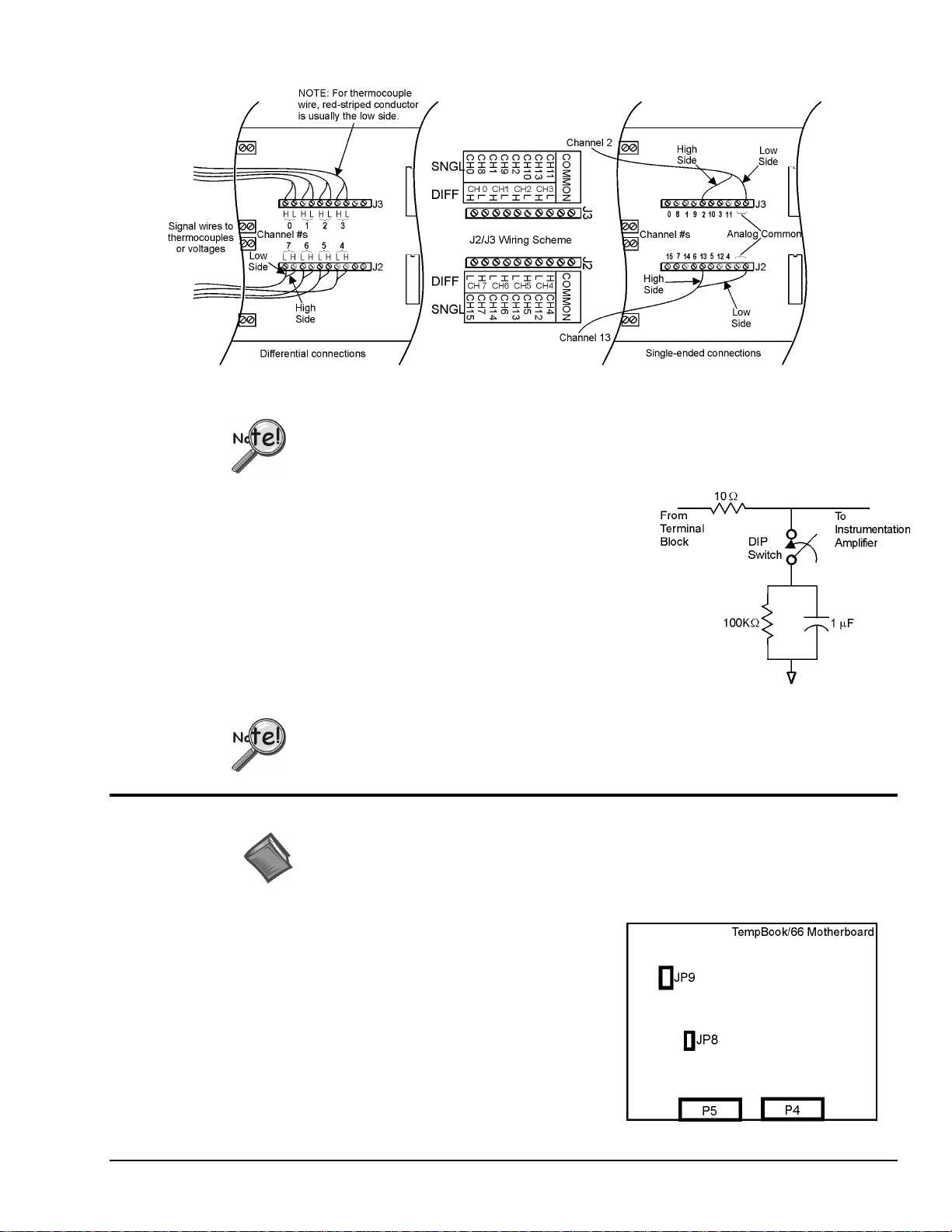

The thermocouple or voltage connections should be made as shown in the following figure.

Analog Signal Connection

When connecting both low and high level signals, the low-level signals should be

connected to the lowest numbered channels with connections following in ascending

order of signal magnitude.

Each of the 16 analog input channels is configured as shown in the

figure (also, refer to page 2-10 for more information on wiring

differential inputs).

The series resistance and shunt capacitance form a single-pole lowpass filter with a corner frequency of 15.9 kHz. The shunt

resistance provides the bias current path for the instrumentation

amplifier.

When reading thermocouples, these filters should be switched in.

If the filters are not used with thermocouples or any other

differential input, then the user must provide a bias current return

path to signal common.

Two DIP switches need to be set for each differential channel.

Internal Configuration

Reference Note:

This section pertains to TempBook/66 hardware configuration. Software installation and

software configuration under Windows 95/98/Me/NT and 2000 is discussed in chapter 1.

To open the unit, place the TempBook on a flat surface.

Remove the screw on the top rear of the case, and slide out the

top cover. Reverse this procedure to assemble the unit.

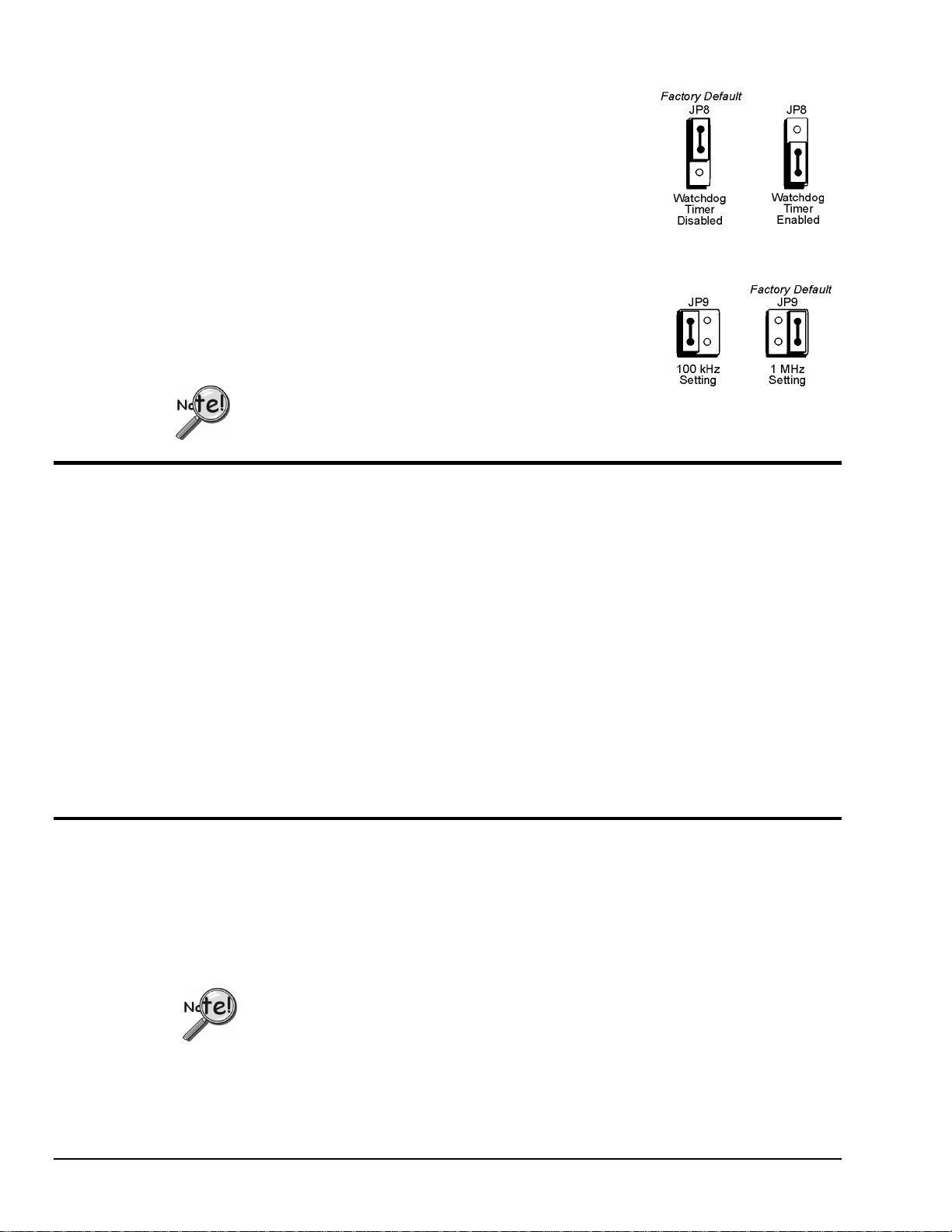

The internal configuration of a TempBook/66 consists of

setting the following jumpers to reflect the desired mode of

operation:

•

Time Base (JP9)

• Watchdog Timer Enable (JP8)

The location of each jumper is shown in the figure.

TempBook User’s Manual

04-25-01

Installation, Configuration, and Calibration 2-3

Page 20

Watchdog Timer Enable/Disable (JP8)

This 3-pin header allows the elective use of the TempBook watchdog timer

function. If using a printer with the TempBook, the watchdog timer should

be enabled to allow the TempBook to be most reliably reset by the host

computer. Note that enabling the watchdog timer might impede background

measurements. If the user is not going to attach a printer, the timer is

optional. The default setting is Watchdog Timer Disabled. To enable, place

the shunt jumper in the enabled position as shown in the figure. To disable,

place the jumper in the disabled position, as shown.

Time Base Selection (JP9)

This 2×2 header allows the user to select one of two oscillator derived

frequencies to be applied to the pacer clock (8254 P1 & P2). The pacer clock

sets the interval between scans in continuous trigger mode. The two

frequencies are 1 MHz and 100 kHz. The most useful range of clock output

frequencies [for the typical user] is provided by the default, 1 MHz setting.

DaqView only supports a setting of 1 MHz, which is the factory default.

Hardware Installation

Connect the TempBook to any PC parallel printer port (female DB25) by unplugging the printer cable and

plugging the male end of the supplied cable (CA-35) into the computer and the female end into the mating

connector on the TempBook. Any printer port (LPT1, LPT2, or LPT3) may be used but should be noted

for use in software installation.

TempBook allows for LPT pass-through for simultaneous data acquisition and printer operation. When

using a printer in the system, attach the original printer cable male DB25 into the mating connector on the

TempBook.

The TempBook may be powered by the supplied AC adapter that plugs into any standard wall outlet or

from an isolated 9-20 VDC source of 1-2 A.

If using the power adapter, plug it into a 120 VAC outlet, and attach the low voltage end to the jack on the

TempBook. Turn ON the power switch, and the POWER LED should be on.

At power-on, the printer should behave normally and can be checked by issuing a PRINT SCREEN

command (or any other convenient method of checking the printer). (Installation of the software will be

necessary before the TempBook can perform any functions.)

Rechargeable Battery Module (DBK30A)

For portable applications where external AC or DC power is not available, the DBK30A rechargeable

nickel cadmium battery module can be used with the TempBook/66. This module is housed in a rugged

metal package that is the same size as the TempBook. It also comes with high-strength Velcro tabs that

allow convenient mounting underneath the TempBook/66.

The DBK30A has two modes, the 14 VDC default and the 28 VDC mode. An internal slide-switch

determines the mode.

Only the 14VDC mode of the DBK30A is to be used with the TempBook/66.

The 14VDC operating mode provides 14.4 VDC at 3.4 A-Hr. This setup can power the TempBook for 3 to

6 hours depending on the application. The battery module has built-in automatic battery-charging circuits,

which quickly and safely recharge the internal batteries when connected to the supplied AC adapters. The

only requirement for trouble-free operation is for the user to fully charge the battery module before

attempting to use it.

2-4 Installation, Configuration, and Calibration

04-25-01

TempBook User’s Manual

Page 21

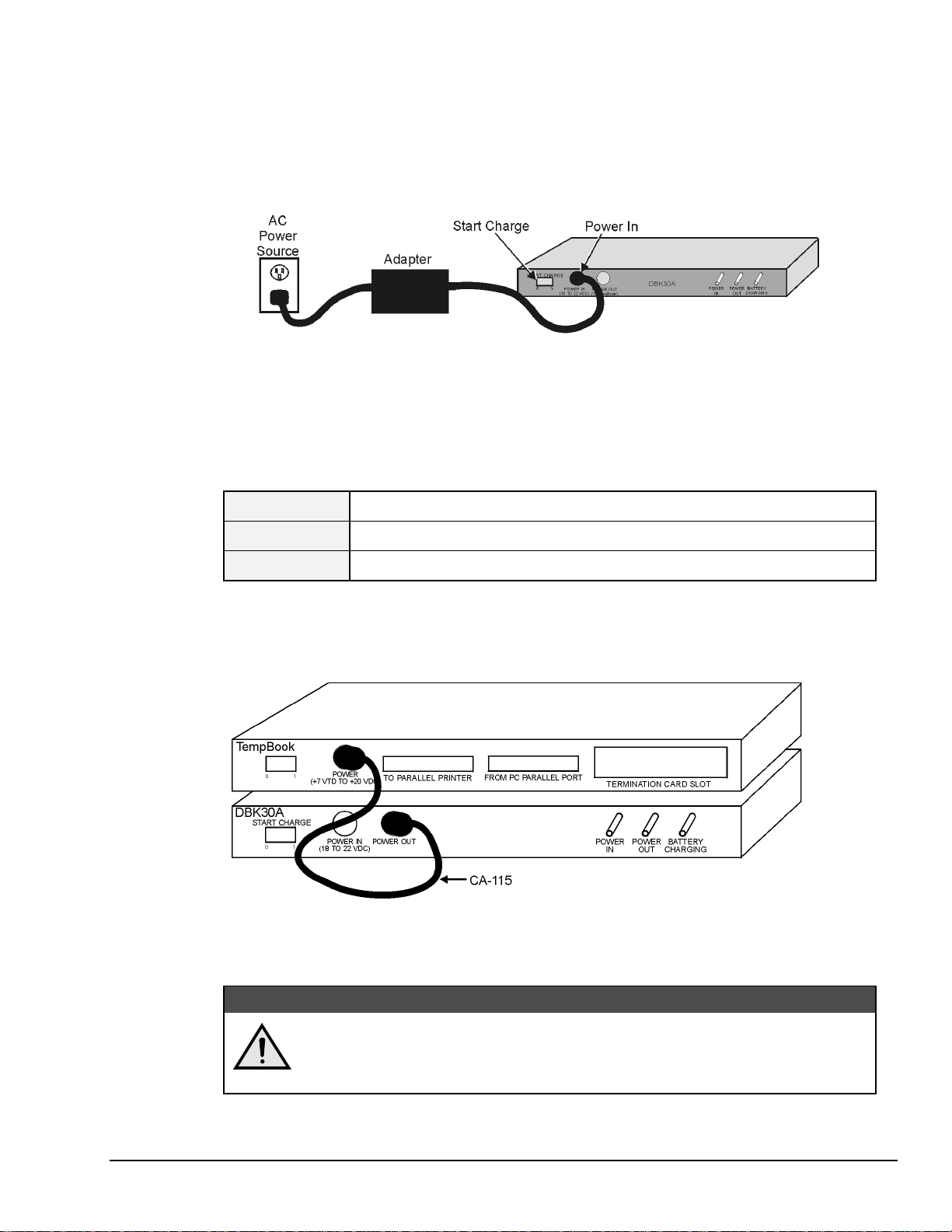

Charging the Battery Modules

The DBK30A package includes a charger for the intended line voltage (either 120 VAC or 230 VAC). To

charge the battery module, plug the output cable from the charger into the POWER IN connector on the

DBK30A, and plug the charger into an appropriate source of AC power (see figure). The charge cycle will

be initiated automatically, and the batteries will be fully charged after the charging cycle terminates.

To initiate another charge cycle, depress the START CHARGE momentary rocker-arm switch. Subsequent

charge cycles applied to a fully charged DBK30A will have no ill effect because the DBK30A will sense

the fully-charged status of the batteries and revert to the trickle-charge state within a few minutes.

Three LED status indicators on the DBK30A provide information on the charge process or external load as

noted in the table.

Power In

Battery Charging

Power Out

Illuminated when the charger is connected to a source of AC power and to the battery

Illuminated steadily while battery is in the high current (2-amp) charge mode.

Flashing briefly, one or two flashes at a time, when the internal batteries are fully charged.

Illuminated steadily when an external TempBook product is connected and drawing current

Connecting the Charger

module.

from the battery modules.

Battery Module Connection

The DBK30A package includes a short connecting cable (CA-115) to connect to the TempBook. This

cable connects the Power Out connector on the DBK30A to the Power In connector on the TempBook (see

figure).

The run time available from a DBK30A operating a TempBook will depend on what the TempBook is

doing. This time can be as little as 3 hours or as much as 6 hours.

The DBK30A must periodically be fully discharged or the cells may develop "lazy

chemistry" that may limit storage capacity. (This “memory” is characteristic for

nickel-cadmium batteries.) To manually discharge a battery pack, connect a

TempBook, and leave it turned on until the indicator lights go dark.

Connecting the TempBook to the Battery Module

CAUTION

CAUTION

CAUTIONCAUTION

TempBook User’s Manual

04-25-01

Installation, Configuration, and Calibration 2-5

Page 22

Connection Troubleshooting

If communications cannot be established with the TempBook or if trying to connect causes the system to

hang or crash, then you should:

• Check that TempBook’s power LED is ON. If not ON, verify power connection between the

TempBook and the power source.

• Make sure the LPT cable is firmly attached to the computer’s proper LPT port and to the TempBook

port labeled “TO COMPUTER”.

•

Check that the desired LPT port has the proper resource configurations. The base address and IRQ

level must be properly configured and recognized by the operating system. The parallel port must be

capable of generating interrupts for proper operation. (This information may be obtained in the

Device Manager in the Control Panel of the operating system). More information on this subject can

be found in the readme.txt file in the current software release.

•

Check the BIOS settings for the LPT port. If ECP, change to normal or bi-directional.

• Make sure the BIOS LPT protocol settings are compatible with the settings selected for the LPT port

with the Control Panel applet.

• Make sure the Daq Configuration Applet has been run and the proper LPT port and protocol have

been selected for the device. The Daq Configuration applet can be found in the Control Panel of the

operating system. The Test Hardware function in the control panel applet can be used to confirm

proper communication with the device.

2-6 Installation, Configuration, and Calibration

04-25-01

TempBook User’s Manual

Page 23

Calibration of TempBook

The TempBook/66 is factory calibrated for gain and offset. After calibration, gain and offset errors, and

software correction constants are calculated.

Calibration Constants File Installation

Each TempBook is shipped with a calibration constants file. The file is named serial_no.cal where

serial_no is the serial number of the TempBook for which the constants were generated.

The default calibration constants filename is tempbook.cal. Use Windows Explorer to copy serial_no.cal

from the disk to the following directory.

C:\PROGRAM FILES\DAQX\APPLICATIONS\TEMPBOOK.CAL\

Within DaqView, the user must go to Window/P

TEMPBOOK.CAL file.

Next one should enable “Perform zero-offset adjustment” by checking the check box.

Hardware Calibration

Since the TempBook is factory calibrated, user recalibration is not recommended. One exception to this

recommendation is the calibration of the TempBook's internal 5V reference. This 5V reference is used to

level-shift the amplified analog input signal for unipolar measurements. Reference-voltage drift is not

compensated for with zero compensation; and therefore, periodic recalibration can improve unipolar

measurement accuracy.

The following characteristics can be calibrated through potentiometer adjustments on the TempBook main

board:

• 5V Reference Voltage

•

Instrumentation Amplifier Offset

• Level Shift Amplifier Offset

• ADC Offset

• ADC Span

The TempBook includes a simple calibration program that can be used to perform these adjustments. If the

user is only performing the reference voltage adjustment, then only a 4-1/2 digit DMM is required. If the

user is performing the full TempBook calibration, then an adjustable voltage calibrator is also required.

references. Specify “Use Cal File” and browse to pick the

Reference Note:

Refer to the DaqView document module for more information.

A Microsoft Windows program, DAQCAL.EXE, is provided to perform calibration of the TempBook. To

use this program, install the TempBook Windows support and launch the DAQCAL program; follow the

on-screen instructions.

TempBook User’s Manual

04-25-01

Installation, Configuration, and Calibration 2-7

Page 24

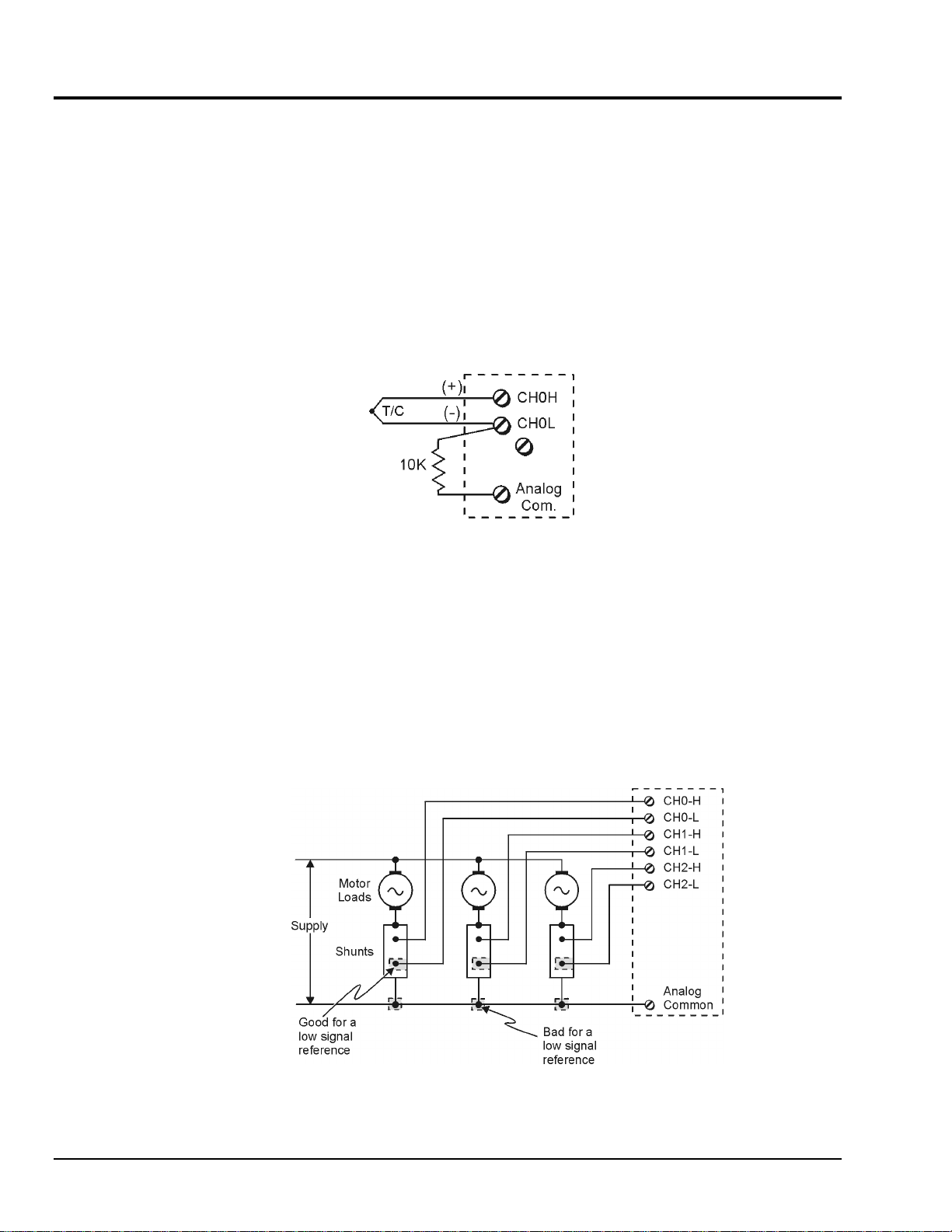

Differential Measurement Configurations

Floating Differential

Floating differential measurements are generally made when low-level signals must be measured in the

presence of relatively high levels of common mode noise. The most common example would be a nongrounded thermocouple. When the signal source has no direct connection to the system analog common,

one must be provided. The easiest way to do this on the TempBook is to use the built-in biasing resistors

by closing the corresponding input channel DIP switches (S1 and S2) on the termination card. Discussion

of the card begins on page 2-2. As an alternative, a resistor can be connected between one of the two signal

lines (usually the lower in potential) and common. A resistor of 10 KΩ to 100 KΩ is satisfactory (less

noise with the lower values).

Floating Differential Configuration

Referenced Differential

Referenced differential measurement is used when measuring several voltages. However, the voltages

cannot share the same common node as a group of single-ended measurements might. An example is to

measure several currents via shunts that happen to share a common supply terminal along a bus. The

weakness in a single-ended hookup is that current flow through the common bus can introduce substantial

errors that can be indistinguishable from the real values measured. The need for the system common to be

connected to the common supply terminal is shown in the figure.

2-8 Installation, Configuration, and Calibration

Referenced Differential Configuration

04-25-01

TempBook User’s Manual

Page 25

DaqView

Overview……2

Starting DaqView……2

A Tour of DaqView……2

A Look at the Main Window…..3

Functionality Differences……4

A DaqView Walk-Through…… 7

Channel Setup……11

Acquisition Setup……13

Data Destination……15

Pull-Down Menus……16

Toolbar Items……19

All Users:

DaqView can only be used with one device at a time.

For multiple DaqBoard/2000 Series board use (via custom programming)

refer to the Programmer’s Manual (1008-0901), chapter 3, Using Multiple

Devices.

TempBook Users:

TempBook devices do not make use of DBK cards or DBK modules, nor do

they make use of certain DaqView functions. TempBook users should skip

over material that is identified as “not applicable to TempBook.”

Document Module

04-24-01

DaqView

_pv

, pg. 1

Page 26

Overview

DaqView is a 32-bit Windows-based data acquisition program that can be used to operate DaqBoard/2000

Series boards, ISA-type DaqBoards, DaqBooks, Daq PC-Cards, and TempBooks.

Daq devices typically make use of optional DBK cards and modules. TempBooks are never used with

DBK cards or modules.

Note: TempBook does not make use of optional DBK cards or DBK modules.

DaqView was designed for ease-of-use; programming expertise is not required. DaqView allows you to:

•

Set up system parameters (selecting channels, gains, transducer types, etc) to acquire data.

• Save data to disk and transmit data to spreadsheets and databases.

•

Automatically re-arm the trigger function and save data in new files as needed.

•

Configure and operate the DBK option modules. Does not apply to TempBook.

• Configure the counter/timer into one of three modes for measuring frequency, totalizing, or

generating pulse trains. Does not apply to TempBook.

• Use the two analog outputs, including waveform generation for DaqBoards.

Does not apply to TempBook.

• Use digital I/O (for Daq devicess with digital I/O). Does not apply to TempBook.

PostView can be launched from DaqView to view, measure, and edit data. PostView is discussed in

a separate document module that is included as part of this manual.

DaqViewXL is a Microsoft Excel-based “add-in.” The application is discussed in a separate document

module that is included as part of this manual.

Starting DaqView

Minimum computer requirements include:

• Intel

• 32 Mbytes of RAM

• Windows 95/98, Windows NT 3.51, or Windows NT 4.0

•

Data acquisition hardware

To run DaqView, double-click the DaqView icon or use your Windows desktop Start button to navigate to

the program file.

Note: If acquisition hardware is not available, or you just want to explore the software, you can select

Simulated Instrument; the main window will open (see following figure).

When DaqView detects hardware, or a simulated instrument has been selected, DaqView’s main window

will open.

Note: In event of a Daq device communication problem, exit DaqView and perform a hardware test from

the Daq Configuration applet control panel.

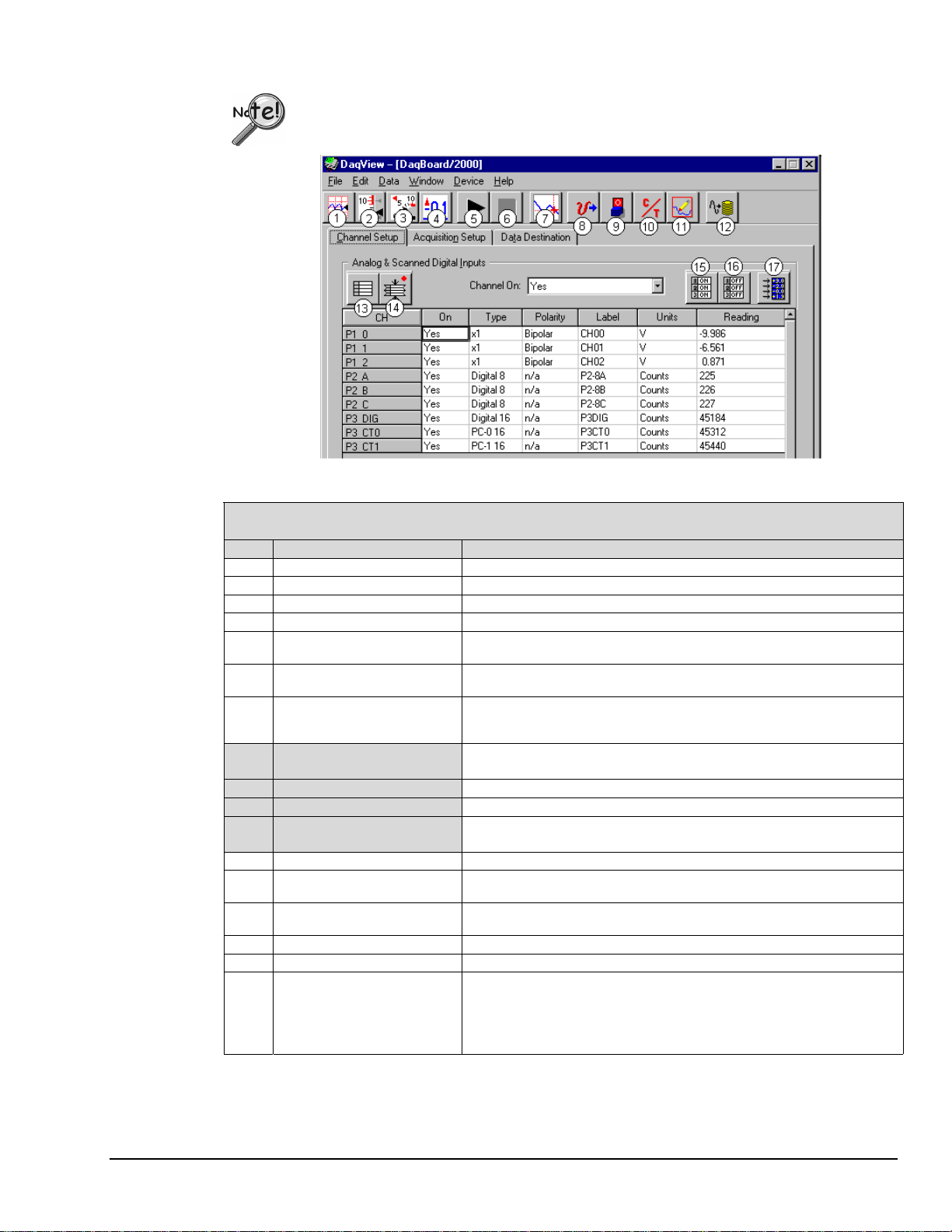

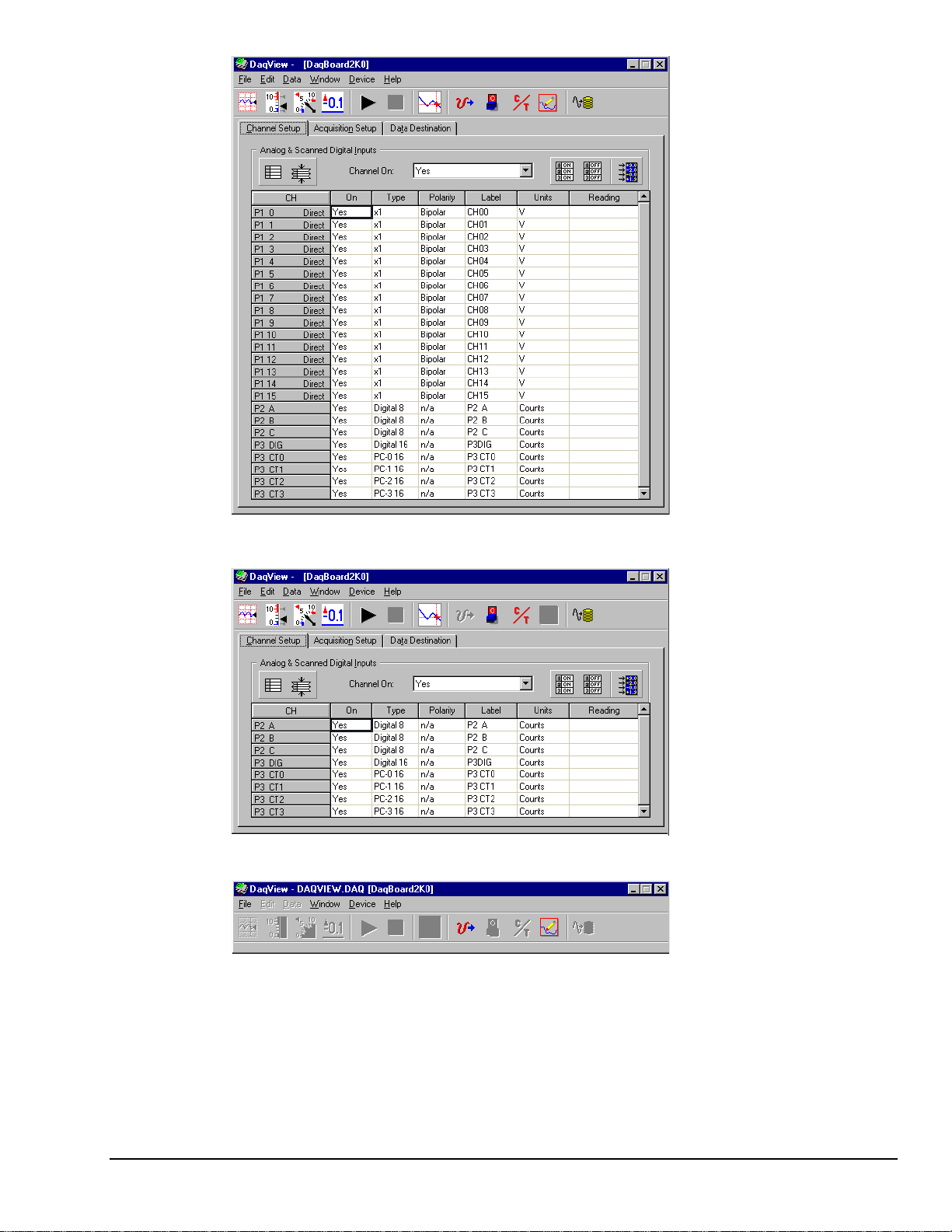

The following figure shows DaqView’s main window for a DaqBoard/2000 and a TempBook. The table

identifies the toolbar buttons, and other buttons that are visible when the Channel Setup Tab is selected [as

in the following figure].

A Tour of DaqView

This section includes a look at DaqView’s main window, a discussion of DaqBoard series 2000 and

TempBook functionality, and steps for completing a self-tour of DaqView. The tour will acquaint you with

several of DaqView’s basic features.

TM

Pentium® P100, or equivalent

DaqView

, pg. 2

_pv

04-24-01

Document Module

Page 27

A Look at the Main Window

Daq devices differ from one another in regard to functionality. Functions that are not

supported by a particular board [or device] will be grayed-out.

Main Window, a Brief Description of Button Control Functions

Note: Functions 8, 9, 10, and 11 are not used by TempBook.

#

Item Description

1 Charts Displays the DaqView Channel Display window.

2 Bar Graph Meters Displays a bar graph meter.

3 Analog Meters Displays an analog dial meter.

4 Digital Meters Displays a digital meter.

5 Start All Indicators Starts displaying data in the Reading column and any open Chart or Meters

6 Stop All Indicators Stops displaying data in the Reading column and any open Chart or Meters

7 View File Data Launches PostView, an independent post-data acquisition program.

8 Analog Output Displays the Analog Output window of the two DAC channels.

9 Digital I/O Displays the Digital I/O window. This feature is not used by TempBook.

10 Counter/Timer Displays the Counter/Timer window. This feature is not used by TempBook.

11 Waveform & Pattern Output Displays the Arbitrary Waveform and Streamed Output windows.

12 Acquire Activates an acquisition of data to a file.

13 Show ALL Channels Expands Analog & Scanned Digital Inputs spreadsheet to show all channels,

14 Hide INACTIVE Channels Condenses the Analog & Scanned Digital Inputs spreadsheet, to hide

15 Turn All Visible Channels ON Turns all visible channels ON. Hidden channels will remain off.

16 Turn All Channels OFF Turns all the channels OFF.

17 Channel Reading A toggle button that enables [or disables] the Channel Reading column of

DaqView Main Window in a DaqBoard/2000 Application

Channel Setup Tab Selected

window.

window.

PostView allows you to manage and view data acquired by DaqView. Refer

to separate PostView documentation for details.

This feature is not used by TempBook.

This feature is not used by TempBook.

whether active or not.

channels that are inactive.

the Analog and Scanned Digital Input spreadsheet. Some windows require

the Channel Reading column to be disabled when changing channels or

other parameters. This command is also available from the Data pull-down

menu.

Document Module

04-24-01

DaqView

_pv

, pg. 3

Page 28

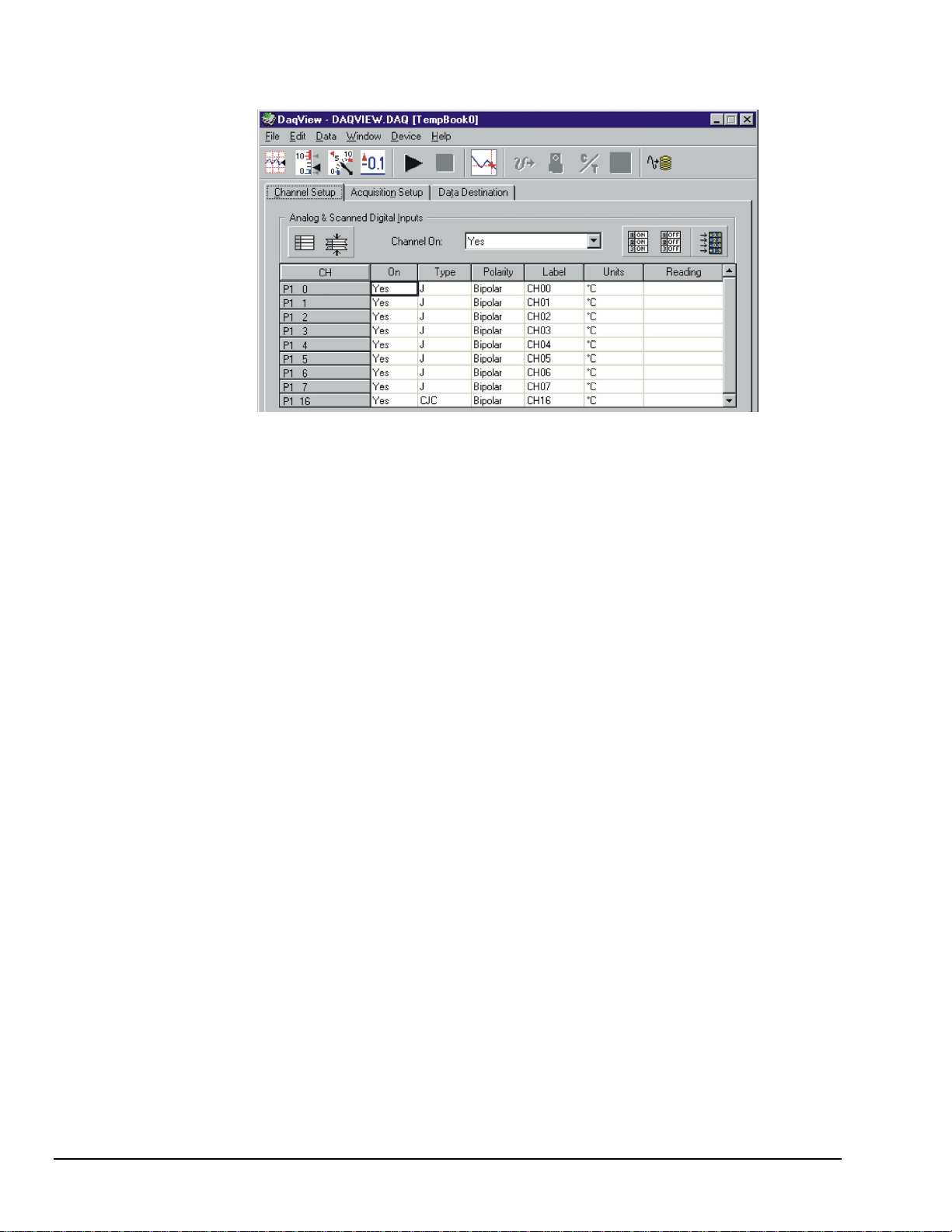

DaqView Main Window in a TempBook Application

Channel Setup Tab Selected

As noted in the previous table, and as can be seen in the above figure, when DaqView functions do not

apply to a device the non-applicable buttons are grayed-out. TempBook, for example, does not make

use of DaqView’s Analog Output, Digital I/O, Counter/Timer, or Waveform & Pattern Output

functions.

Functionality Differences amongst the DaqBoard/2000 Series Boards

Each of the DaqBoard/2000 Series Boards has a different I/O count. DaqBoard/2001 has more I/O than

any of the other boards [in the 2000 series]. All other 2000 series boards are essentially derivations of

DaqBoard/2001.

The differences in the boards are paralleled in the DaqView software. Basically, if a board does not support

a particular function, the related software feature will be disabled (grayed-out). When using any of the

information presented in this chapter, always take time to note whether or not it applies to your specific

board.

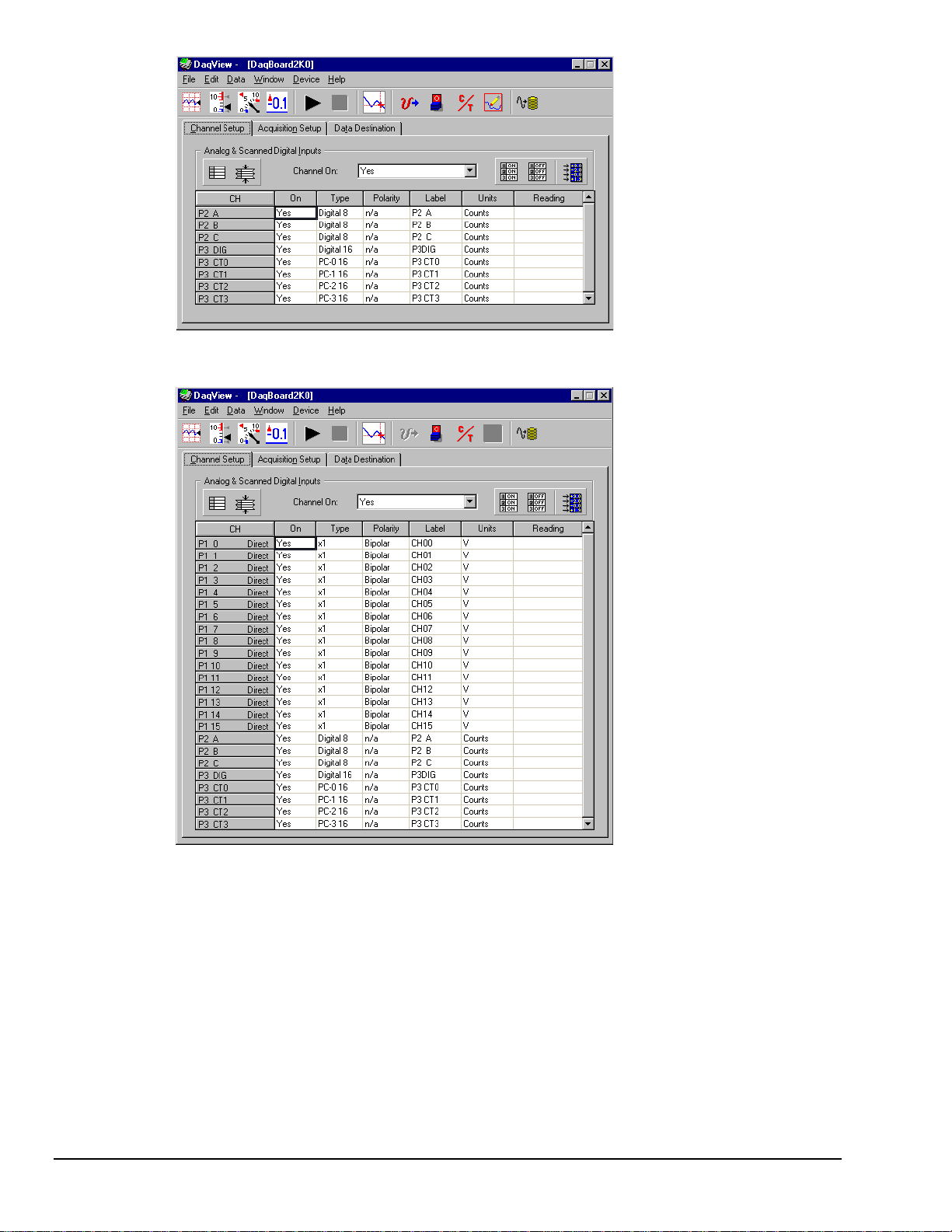

The following screen images represent DaqView Main Windows as they appear for the various boards.

A board synopsis is provided just to the right of each screen.

DaqView

, pg. 4

_pv

04-24-01

Document Module

Page 29

DaqBoard/2000 and

DaqBoard/2001 Boards

These boards have 16 Analog

Input Channels, 40 Digital I/O

Channels, and 6 Counter/

Timers.

In addition:

DaqBoard/2000 boards have 2

Analog Output Channels.

DaqBoard/2001 boards have 4

Analog Output Channels.

DaqBoard/2000 and DaqBoard/2001 Main Window

DaqBoard/2002 Main Window – Channel Setup Tab Selected

DaqBoard/2003 Main Window

DaqBoard/2002 Boards

These boards have 40 Digital

I/O Channels and 6 Counter/

Timers.

These boards have no Analog

Channels. Analog-related

buttons are grayed-out and P1

(Analog Input) Channels do not

appear in the spreadsheet.

DaqBoard/2003 Boards

DaqBoard/2003 has 4 Analog

Output Channels. The main

window allows use of four pulldown menus and two toolbar

buttons: Analog Output, and

Waveform and Pattern Output.

Remaining toolbar buttons

serve no purpose with this

board and are grayed-out.

DaqBoard/2003’s Main

Window has no spreadsheet.

Document Module

04-24-01

DaqView

_pv

, pg. 5

Page 30

DaqBoard/2004 Main Window

DaqBoard/2004 Boards

DaqBoard/2004 has 4 Analog

Output Channels, 40 Digital I/O

Channels, and 6 Counter/

Timers.

The board has no Analog Input

Channels, and for that reason no

P1 designated channels appear

on the spreadsheet portion of

the window.

DaqBoard/2005 Boards

DaqBoard/2005 has 16 Analog

Input Channels, 40 Digital I/O

Channels, 6 Counter/Timers.

The board has no Analog

Output Channels, and for that

reason the Waveform and

Pattern Output button is grayedout.

DaqView

, pg. 6

_pv

DaqBoard/2005 Main Window

04-24-01

Document Module

Page 31

A DaqView Walk-Through

The following walk-through is intended to familiarize you quickly with the DaqView data acquisition

program. The walk-through does not apply to DaqBoard/2003, as that board makes minimal use of

DaqView. DaqBoard/2003 users can, however, go through the following steps with the simulated

instrument.

(1) Open DaqView. If your Daq device or DBK signal conditioning units are not connected you can

select Simulated Instrument as your device.

(2) From DaqView’s File menu, select

Authorization.

(3) If you ordered DaqView, enter the

Authorization Code found on a separate sheet and

click the Apply Code button.

If you have no Authorization Code you can click

the Start 30-Day Trial button to enable a

temporary version of DaqView. Note that you can

also order DaqView upgrades “online.”

Since each DaqBoard/2000 Series board has

different enabled functions, your board’s actual

screen shots may appear slightly different than

shown in the following example screens.

(4) To familiarize yourself with the three windows

available from DaqView’s main window, click the

tabs Channel Setup, Acquisition Setup,

and Data Destination. These are not available for

DaqBoard/2003.

Channel Setup displays a spreadsheet for viewing

and changing the configuration of analog and

scanned digital input channels. Each row is

dedicated to a single channel.

Document Module

04-24-01

DaqView

_pv

, pg. 7

Page 32

Acquisition Setup displays a window that includes

parameters for triggering and configuring the scan.

These settings are used when an acquisition to disk

is started with the toolbar’s Acquire button. When

the trigger is satisfied, scans are collected at the

selected scan frequency and stored to disk in the

designated file. Note that these parameters cannot

be altered while an acquisition is in progress.

Data Destination provides a means of designating

the desired file formats and directories for acquired

data.

From DaqView’s Device menu, select Configure

Hardware Settings.

The window Configure System Hardware will appear. Whenever expansion cards are added, you must

update this window.

On the left side of the window, select any channel’s pull-down box to reveal the external connection

options. Besides the default, direct signal connection, you can choose among the DBK option cards and

modules. The right side of the screen sets up digital connections if your Daq device is so equipped.

User’s of certain DBK cards will need to select an internal clock speed of 100 kHz as discussed in the

following section.

Click OK to return to DaqView’s main window.

DaqView

, pg. 8

_pv

04-24-01

Document Module

Page 33

Configure System Hardware Screen Sample

for DaqBoard/2000, /2001, and /2005)

Configure System Hardware Screen Sample

for DaqBoard/2002 and /2004

DaqBoard/2002 and DaqBoard 2004 have no

Analog Input, thus the Analog I/O Option Cards

sections of the screen are grayed-out.

Document Module

04-24-01

DaqView

_pv

, pg. 9

Page 34

The information in this block only applies to DaqBoard/2000, /2001, and /2005.

Selecting 100 kHz Internal Clock Speed

User’s of DBK12, DBK13, DBK15, DBK19, DBK52, DBK53, or DBK54 need to select

100 kHz internal clock speed as discussed below.

In the Configure Systems

Hardware window, after

selecting DBK12, DBK13,

DBK15, DBK19, DBK52,

DBK53, or DBK54 you will

need to select an internal

clock speed of

100 kHz.

To select an “Internal Clock Speed” of 100 kHz:

(1) Select the Acquisition Setup tab on DaqView’s main window.

(2) On the lower left corner of the window, under Scan Configuration,

click the Preferences button.

The Advanced Options window will appear (following figure).

Note: The Advanced Options box can also be accessed from the

Windows pull-down menu.

Continuing with the “Tour of DaqView”…

Select the Channel Readings button. If in the Simulated Instrument mode, the Reading

column of the Analog & Scanned Digital Inputs spreadsheet will display simulated data.

Selecting the Channel Readings button again will freeze the Reading column’s display.

If working hardware is connected, the readings will quantify actual signals.

To acquire data to a file, press the Acquire button. For simulated hardware, you will be

prompted to enable a manual trigger. Binary data is acquired to a file (with default name

of daqv.bin).

To view the PostView data, click the View File Data button.

Refer to the PostView module for detailed information regarding PostView.

(3) Under “Internal Clock Speed,”

select 100 kHz.

(4) Click the OK button to return to

DaqView’s main window.

This completes the clock setting

procedure.

DaqView

, pg. 10

_pv

04-24-01

Document Module

Page 35

Channel Setup

The Channel Setup window (first tab on lower portion of main window) displays the analog and scanned

digital input channels and allows you to configure them. Each row shows a single channel and its

configuration. The number of rows may vary, but each row has seven columns. Some columns allow blocks

of cells to be altered at the same time (clicking a column header can select the entire column). Other

columns allow only a single cell to change. The table summarizes the function of each column.

Channel Setup Tab Selected

Document Module

04-24-01

DaqView

_pv

, pg. 11

Page 36

Channel Setup Window

Column Description

CH

The channel number (cannot be changed from this window). This number includes the main channel

number and the expansion board number and channel (if used). Expansion channels are configured

using the Hardware Configuration window described later in this module.

On

Type

Polarity

Label

Units

This column allows you to select whether data will be collected from that channel. When a cell or

block of cells in this column is selected, a selection box will appear that allows “Yes” to enable or

“No” to disable the channel. Double-clicking a cell in this column will toggle the channel status. The

Edit menu allows you to Make All Channels Active or Make All Channels Inactive.

This column allows you to set the gain or input type for each channel. The gains and types will vary

among the option cards. A block of cells in this column can be selected for multiple channels with

the same type of option card. Double-clicking a cell will select the next available gain or type.

Note: If one of the P3 counters is active in the scan, and Type is selected for frequency

measurement, low frequency input signals will require a slow scan rate setting for accurate

measurement. For example, for a frequency of 200 Hz, set the Scan Rate (in the Acquisition Setup

window) for 1 scan per second or 6 scans per minute.

This column shows the channel polarity (unipolar or bipolar) for each channel. The polarity can be

programmed here on a per channel basis when using a DaqBook/200, /216, /260 and any DaqBoard

[ISA or PCI type], or a DBK15 Universal Current/Voltage expansion card. When using any other

Daq*s, this column is set in the Hardware Setup window. For selected cells that can be changed, a

selection box will display “Unipolar” or “Bipolar”. Double-clicking in a cell will toggle the polarity. If

the hardware cannot program the polarity, no selection box will be displayed.

This column contains a descriptive name for the input channel. The default label is the channel

number, but it can be changed to any 8 characters and must be unique. This label is used when

selecting a channel in the analog trigger and chart selection lists.

This column allows you to change the engineering units of each channel and apply a linear equation

to the Daq data. When a cell or block of cells in this column is selected, the analog input box

displays entry options in a pull-down box. Selecting “mx+b” allows you to define m and b and the

engineering units label. The engineering units will then be displayed in the “Units” column and the

“mx+b” equation will be applied to the reading from the Daq before the reading is displayed or written

to disk. The X in this equation is the voltage read back from the Daq (or degrees Celsius for a

DBK19). For example, if a Daq channel is configured as bipolar and unity (×1) gain, the default

voltage would be ±5 V. This corresponds to an m of 1, a b of 0, and a unit of V. V can be changed

to millivolts by setting m to 1000 and units to mV. The Units column can also be used to perform a

software calibration of the Daq. This is done by reading known inputs at two different points of the

input voltage range (usually at 0 and full-scale) and solving the equation y = mx + b. The full-scale

voltage, which changes according to the gain of the channel, is 5 V/gain for bipolar channels and 10

V/gain for unipolar channels.

DaqView

, pg. 12

_pv

Reading

This column displays the device’s analog or scanned digital input readings. This column cannot be

altered by the user and is enabled by selecting Enable Input Reading Column under the Data menu

or by selecting “Start/Stop All Indicators” under the window menu. This column will update the

readings as fast as the computer will allow. The spreadsheet cannot be altered while the input

reading column is enabled.

04-24-01

Document Module

Page 37

Acquisition Setup

Selecting the second tab of the main window displays the Acquisition Setup window. The four main parts of

this window include setup parameters for triggering and configuring the scan. These settings will be used

when an acquisition to disk is started by selecting “Acquire” (last item on the toolbar). When the trigger is

satisfied, the scans are collected at the selected scan frequency and stored to disk in the designated file.

Acquisition Tab Selected

Acquisition Setup Window

Parameter Description

Pre-Trigger

Trigger Event

These 6 triggers

apply only to

DaqBoard/2000

Series Boards

The number of scans to acquire before the trigger event.

Selects the trigger source, depending on the device. Possible trigger sources include:

Immediately – arms and executes the trigger immediately.

Key Hit – arms the acquisition and waits for the user to press a key.

External TTL Rising/Falling – waits for a rising or falling edge slope on P1-25.

Hardware Rising/Falling Edge – monitors value with hysteresis on selected channel; triggers

when parameter is satisfied.

External TTL High/Low – waits for a TTL high or low level on pin 25 of connector P1.

Hardware Above/Below Level – monitors value on selected channel; triggers when parameter is

satisfied.

Above/Below Level – monitors value on selected channel; triggers when parameter is satisfied.

Rising/Falling Edge – monitors value with hysteresis on selected channel; triggers when

parameter is satisfied.

Inside/Outside Window – monitors upper and lower values on selected channel; triggers when

parameters are satisfied.

Digital Pattern – monitors 8-bit pattern on selected digital input channel; triggers when

parameters (less/greater than or equal to/not equal to) are satisfied.

Document Module

04-24-01

DaqView

_pv

, pg. 13

Page 38

Stop Event

These 4 Stop

Events apply

only to

DaqBoard/2000

Series Boards

Scan Configuration

Selects the event that stops the scanning, depending on the device connected. Possible

sources include:

Number of Scans - can range from 1 to 100,000,000. A scan includes all of the channels that

are marked as “On” in the Analog & Scanned Digital Inputs spreadsheet.

Key Hit – stops acquisition when the user presses a key.

Above/Below Level – monitors value on selected channel; stops scan when parameter is

satisfied.

Rising/Falling Edge – monitors value with hysteresis on the selected channel; stops the scan

when the parameter is satisfied.

Inside/Outside Window – monitors upper and lower values on selected channel; stops scan

when parameters are satisfied.

Digital Pattern – monitors 8-bit pattern on selected digital input channel; stops scan when

parameters (less/greater than or equal to/not equal to) are satisfied.

Clock Source Selects the device’s internal clock or an external, user-supplied clock. The Preferences button

brings up a Preferences box the following options:

Internal Clock Speed - For DaqBoard/2000 series boards, the default setting is 200 kHz. Note

that the use of certain DBK cards requires a setting of 100 kHz, as discussed elsewhere in this

manual. (For DaqBoard/2000 Series Only).

Pacer Clock – Enable or disable a pacer clock. (For DaqBoard/2000 Series Only).

File Conversion – Enable or disable a “delete Raw Binary files” notice.

Calibration Table – Select Factory or User calibration table. (For DaqBoard/2000 Series Only).

Calibration File – Included on a separate disk, the calibration file fine tunes the accuracy of the

device. Read the readme.txt file on the disk for more information.

Zero Offset Adjustment –Protects against drift

Channel Display –Enables the expansion option type in the channel list.

The following sections

of the “Preferences” box

apply only to the

DaqBoard/2000 Series

Boards:

• Internal Clock Speed

• Pacer Clock

• Calibration Table

Zero Offset Adjustment

applies only to DBK19,

DBK52, and TempBook

Preferences Box

Scan Rate

The scan frequency can be set in units of seconds, milliseconds, minutes, or hours via a pulldown box. Typing into the numeric field changes the rate. The maximum scan frequency is

dependent on the number of channels that are enabled and whether or not averaging is

enabled. Enabling more channels or averaging will lower the maximum scan frequency.

DaqView

, pg. 14

_pv

Averaging

The checkbox allows averaging of the analog input data to be enabled or disabled. Averaging

can be used to increase the effective accuracy of a noisy signal. Averaging will increase the

actual scan frequency and number of scans, but the perceived scan frequency and number of

scans (which is set by DaqView) does not change.

Note: These parameters cannot be altered during an acquisition.

04-24-01

Document Module

Page 39

Data Destination

Selecting the third tab of the main window displays the Data Destination window. The two parts of this

window let you designate the directory for acquired data and the desired file formats.

Data Destination Tab Selected

Data Destination Window

Parameter Description

Data Destination

Data File Name Acquired data is saved to this file name. This file always has a “.bin” file extension.

Base Directory This is the directory from which other directories are created to store the converted and

Auto Re-Arm

Binary Data and Selected Format File List

File Conversion

Preferences

acquired data. You can type in changes or use the Browse button to direct files elsewhere,

including other disk drives.

With the Enable Auto Re-Arm box checked, you can specify when file conversions are

performed and the sequence range of incrementing file names.

This button lets you select the format of saved data. Selections include: DIAdem, ASCII text,

DADiSP, DASYLab, MATLAB, PostView Binary, and Snap-Master Binary. The tree shows

where the various formatted files will be saved on disk.

The graphic display shows the directories and files created during acquisition. Double-clicking

a directory brings up Windows Explorer. Double-clicking a file brings up any program

associated with the file type.

Document Module

04-24-01

DaqView

_pv

, pg. 15

Page 40

Pull-Down Menus

Some (but not all) items in the pull-down menu can also be enabled from the toolbar. Their description in

the toolbar section is more detailed than presented in this section.

File

New Set all parameters to their startup, default setting.

Open Set all parameters as directed by a specified setup file.

Save Save the existing configuration for later recall (overwrites the existing version).

Save As Saves the existing configuration for later recall; asks whether to overwrite the original

Authorization Displays the Authorization window for entering the Authorization Code.

Exit

Edit

Hide Inactive

Channels

Show All Channels This command shows all channels, whether turned on or off.

Make All Channels

Inactive

Make All Channels

Active

Fill Down

F8

File Menu Items and Descriptions

version or save under a new filename.

Leave the DaqView program.

Edit Menu Items and Descriptions

This command collapses the spreadsheet to show only those channels that are turned on.

It can be selected repeatedly as needed.

This command places a “No” in the On field of all channels. To scan only a few channels it

may be easier to make all channels inactive, then turn on the desired channels.

This command places a “Yes” in the On field of all of the channels.

For multiple cells selected within a column, this command copies the value in the top cell to

all the cells below.

Data

Data Menu Items and Descriptions

Acquire This command arms the hardware for an acquisition to disk. When the trigger is satisfied,

Convert Existing

Files

Enable Input

Reading Column

the acquisition begins. All of the interactive I/O controls are disabled while the system is

armed. No acquisition parameters can be altered at this time.

During an acquisition, a raw binary file is created and updated as data is read. This

command lets you convert raw binary files to the selected formats. This allows you to

convert files that may not have been converted when the data was acquired.

This command reads the analog inputs and scanned digital inputs and puts the numeric

values in the spreadsheet in the “Reading” column. If the Reading column is already

enabled, this command disables it.

DaqView

, pg. 16

_pv

04-24-01

Document Module

Page 41

Window

Window Menu Items and Descriptions

Charts Displays the charts window.

Bar Graph Meters Displays a bar graph meter.

Analog Meters Displays an analog dial meter.

Digital Meters Displays a digital meter.

Start All Indicators Starts displaying data in the Reading column and any open Chart or meters window.

Stop All Indicators Stops displaying data in the Reading column and any open Chart or meters window.