Page 1

User’s Manual

OMB-LogBook

Stand-Alone, Intelligent Systems for

16-bit Data Acquisition and Logging

p/n

OMB-461-0901

Rev.

2.0

Page 2

OMEGAnetSM On-Line Service

http://www.omega.com

6HUYLFLQJ1RUWK$PHULFD

Internet e-mail

info@omega.com

USA:

Canada:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

e-mail: info@omega.com

976 Berger

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

e-mail: canada@omega.com

FAX: (203) 359-7700

FAX: (514) 856-6886

)RULPPHGLDWHWHFKQLFDORUDSSOLFDWLRQDVVLVWDQFH

USA and Canada:

Mexico and

Latin America:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-TC-OMEGA

En Espanol: (95) 203-359-7803

SM

SM

SM

SM

FAX: (95) 203-359-7807

e-mail: espanol@omega.com

6HUYLFLQJ(XURSH

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING:

These products are not designed for use in, and should not be used for, patient-connected applications.

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

ul. Rude armady 1868

733 01 Karvina-Hranice

Tel: 420 (69) 6311899

e-mail:czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

25 Swannington Road,

Broughton Astley, Leicestershire,

LE9 6TU, England

Tel: 44 (1455) 285520

FAX: 44 (1455) 283912

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

FAX: (31) 20 6434643

FAX: 420 (69) 6311114

FAX: (33) 130-699-120

FAX: 49 (07056) 8540

P.O. Box 7, Omega Drive,

Irlam, Manchester,

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Page 3

How To Use This Manual

This manual explains the setup and operation of the LogBook data acquisition system including LBK and

DBK options.

Quick Start, LogBook/300

powered-up, and using LogView software to collect data.

Quick Start, LogBook/360

powered-up, and using LogView software to collect data.

Chapter 1

LogBook/300 and LogBook/360. Includes system block diagrams, information regarding hardware

connections, and system testing. The chapter includes pinouts for P1, P2, and P3. Instructions on

how to stack modules are included.

System Considerations

–

Chapter 2 – System Power

Requirement Worktable and material concerning the power-related DBK30A, DBK32A, DBK33, and

DBK34.

Chapter 3

LogBook acquisition system. A How To…section provides step-by-step instructions for a variety of

acquisition tasks.

LogView

–

Chapter 4 – LBK Options

remote LogBook Terminal, four-channel Digital-to-Analog Output card, GPS support, Modem

Support, and Upload Scheduler.

Chapter 5 – DBK Expansion Options

expand your acquisition system.

Chapter 6

acquisition. Includes terminology, signal management, channel identification, and signal modes.

A troubleshooting section provides solutions to common noise, wiring, and configuration problems.

Signal Management and Troubleshooting Tips

–

– Provides instructions for getting a basic LogBook/300 system connected,

– Provides instructions for getting a basic LogBook/360 system connected,

describes system features and an operational overview for both

describes power supplies and power requirements. Includes a DBK Power

explains this windows-based application that is used to configure and run your

discusses the RS-422/485 Communications Card, memory expansion,

discusses a large number of DBK options that can be used to

explains basic concepts of data

Appendices

A – Calibrating DBK16 and DBK43A

B – Error Codes

C – Accelerometer Tutorial,

D – CE Compliance,

E – Specifications

F – PostView

G – PC-Card Compatibility

acquisition rates, as well as cards that are not compatible.

Using this equipment in ways other than described in this manual can cause

personal injury or equipment damage. Pay special attention to all cautions and

warnings.

Check the

this manual went to press.

for LogView software and LogBook hardware.

describes general requirements for complying with CE standards.

lists physical and performance specifications for LogBooks, LBKs, and DBKs.

explains how to use this program for post-acquisition data viewing.

README.TXT

primarily for the benefit of DBK4 users.

identifies PC-Cards that are 100% compatible with LogBook’s

&$87,21

file for information that may not have been available at the time

LogBook User’s Manual,

9-1-99

i

Page 4

Table of Contents

Setting Up DBK Cards……3-15

Quick Start, LogBook/300

Quick Start, LogBook/360

1 - System Considerations

LogBook Basics……1-1

Introduction ….. 1-1

Front and Rear Panels……1-2

Highlight of Features …… 1-3

LogBook/300 Block Diagram …… 1-4

LogBook/360 Block Diagram …… 1-5

System Software……1-6

4 - LBK Options

Hardware-Related Details……1-7

PC-Card Swapping……1-7

Physical/Environmental Conditions……1-7

Power Supply……1-8

Microprocessor……1-8

Field-Installation Racks and Enclosures…1-8

P1, P2, P3 Port Connectors……1-9

System Design, Setup, & Expansion…1-13

Steps to Review …… 1-13

Expansion Configurations……1-13

LBK Options……1-13

DBK Options……1-14

Mechanical Setup Options……1-16

System Power Considerations……1-17

5 - DBK Expansion Options

Operational Features……1-18

Data Acquisition, An Overview……1-18

LogBook System File……1-19

Communications……1-19

Triggering and Scan Timing……1-20

Scan Rate Limitations……1-20

Use of Outputs to Alarm and Control……1-22

Acquisition……1-22

Data Storage and Retrieval……1-22

2 - System Power

Overview……2-1

System Connections ……2-4

Installation and Configuration …… 2-4

LogView Setup …… 2-5

DBK30A Rechargeable Battery Module … 2-5

DBK32A Auxilliary Power Supply Card … 2-9

DBK33 Triple-Outlet Power Supply Card 2-10

DBK34 Vehicle UPS Module …… 2-11

3 - Using LogView

Understanding LogView……3-1

Modes of LogView Operation……3-2

LogView Features and Capabilities……3-4

Software User-Interface……3-4

File Management......3-7

How To… Procedures……3-10

Flowchart of a Simple Acquisition……3-11

Using an Attached LogBook……3-11

Using a Remote LogBook……3-13

Simple Data Logging……3-13

ii LogBook User’s Manual

Using Multiple Timebases……3-16

Using Digital 2-Point Calibration……3-17

Using Digital Outputs As Alarms……3-19

Using Exception Capturing……3-20

Menu Descriptions……3-21

File Menu……3-21

View Menu……3-25

Device Menu……3-42

Tools Menu……3-45

Indicators Menu……3-48

LBK Options, Location Reference…… 4-1

LBK/COM/422/485 …… 4-2

LBK/MEM1-U, Expanded Memory

(16 MB Upgrade) …… 4-3

LBK1, Remote LogBook Terminal……4-4

LBK2, Four Channel,

Digital-to-Analog Output ……4-8

LogBook/GPS (LogBook/360 Only)…… 4-9

LogBook/Modem…… 4-11

Overview…… 5-2

LogView Setup……5-3

DBK1 16-Connector BNC Adapter

Module……5-4

DBK4 2-Channel Dynamic Signal Input

Card……5-5

DBK7 4-Channel Frequency-To-Voltage

Input Card……5-11

DBK8 Eight-Channel High-Voltage Input

Card……5-20

DBK9 Eight-Channel RTD Card……5-22

DBK10 3-Slot Expansion Chassis……5-25

DBK11A Screw-Terminal Option Card…5-26

DBK12 and DBK13

Analog Input Multiplexer Cards……5-28

DBK15 Universal Current/Voltage Input

Card……5-31

DBK16 2-Channel Strain-Gage Card……5-34

DBK17 Simultaneous Sample and Hold

Card……5-41

DBK18 Low-Pass Filter Card……5-43

DBK19 Thermocouple Card……5-46

DBK20 & DBK21 Digital I/O Cards……5-49

DBK23 Isolated Digital Input Chassis……5-50

DBK24 Isolated Digital Output Chassis…5-53

DBK25 8-Channel Relay Card……5-57

DBK40 BNC Analog Interface……5-58

DBK41 Ten-Slot Expansion Module……5-60

Page 5

DBK42 16-Slot 5B

Signal Conditioning Module……5-63

DBK43A Eight-Channel

Strain-Gage Module……5-69

DBK44 2-Channel 5B

Signal-Conditioning Card……5-79

DBK45 4-Channel SSH

and Low-Pass Filter Card……5-83

DBK50/51 Voltage Input Modules……5-87

DBK52 Thermocouple Input Module……5-90

DBK53/54 Low/High-Gain

Analog Multiplexing Modules……5-93

6 - Signal Management & Troubleshooting

Overview……6-1

Channel Control and Expansion……6-3

Signal Acquisition……6-4

Sequencer……6-4

Scan Rate……6-5

Triggering……6-5

Counter/Timer Functions……6-5

Simultaneous Sample and Hold (SSH) ……6-6

Input Isolation……6-6

Signal Modes……6-7

References for Differential Modes……6-7

Unipolar and Bipolar Measurement……6-9

12-Bit vs 16-Bit Resolution……6-9

Signal Problems……6-10

Troubleshooting……6-12

Troubleshooting Checklist……6-12

Electrostatic Discharge (ESD) ……6-12

Radio Frequency Interference……6-12

Customer Assistance……6-13

Appendices

A – Calibrating DBK16 & DBK43A

B – Error Codes

C – Accelerometer Tutorial

D – CE Compliance

E – Specifications

F – PostView

G – PC-Card Compatibility

LogBook User’s Manual iii

Page 6

iv LogBook User’s Manual

Page 7

Quick Start, LogBook/300

Hardware Connection……1*

Hardware Configuration…… 3

Software Installation…… 3

LogBook/300 Device Configuration……3

*

Page numbers refer to QS-300 pages.

Reference Notes: You may need to refer to additional sections of this manual.

Chapter 1, for system block diagrams, operational overviews, connections, memory

upgrade procedure, or information on the RS-422/485 option.

Chapter 2, in regard to calculating system power and ensuring an adequate power

supply.

Chapter 4, if using LBK options.

Chapter 5, if using DBK options.

Electric shock hazard. Turn off power to all system-connected devices prior to connecting

or disconnecting cables, or setting hardware configurations. Failure to do so could result

in electric shock or death, and equipment damage, even under low-voltage conditions.

When using LogBook in attached mode, the PC-Card [in LogBook] must already have the

logbook.sys.

file

will appear dead.

Otherwise, LogView cannot communicate with LogBook, and LogBook

Test Hardware…… 5

Acquisition Configuration……5

Calibration…… 6

:$51,1*

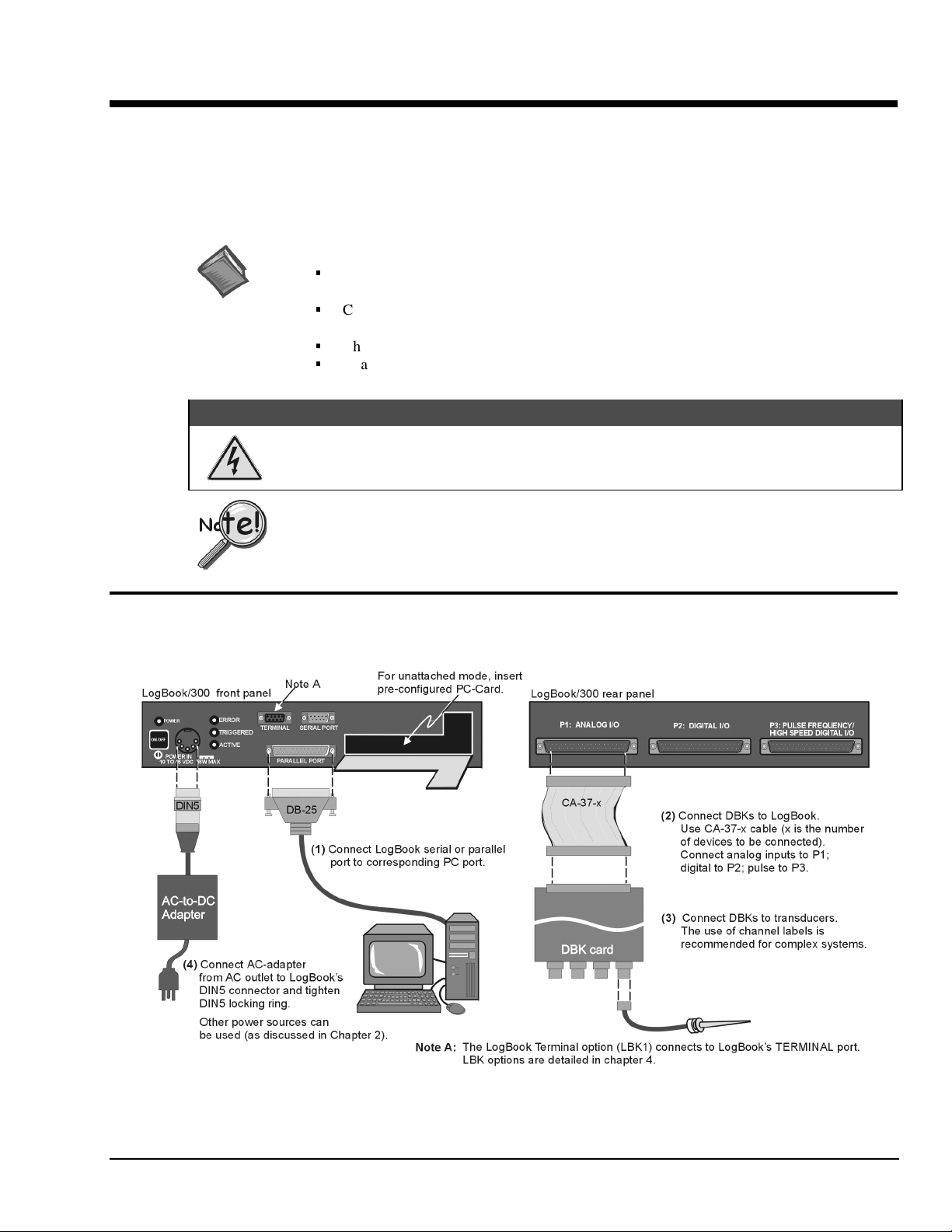

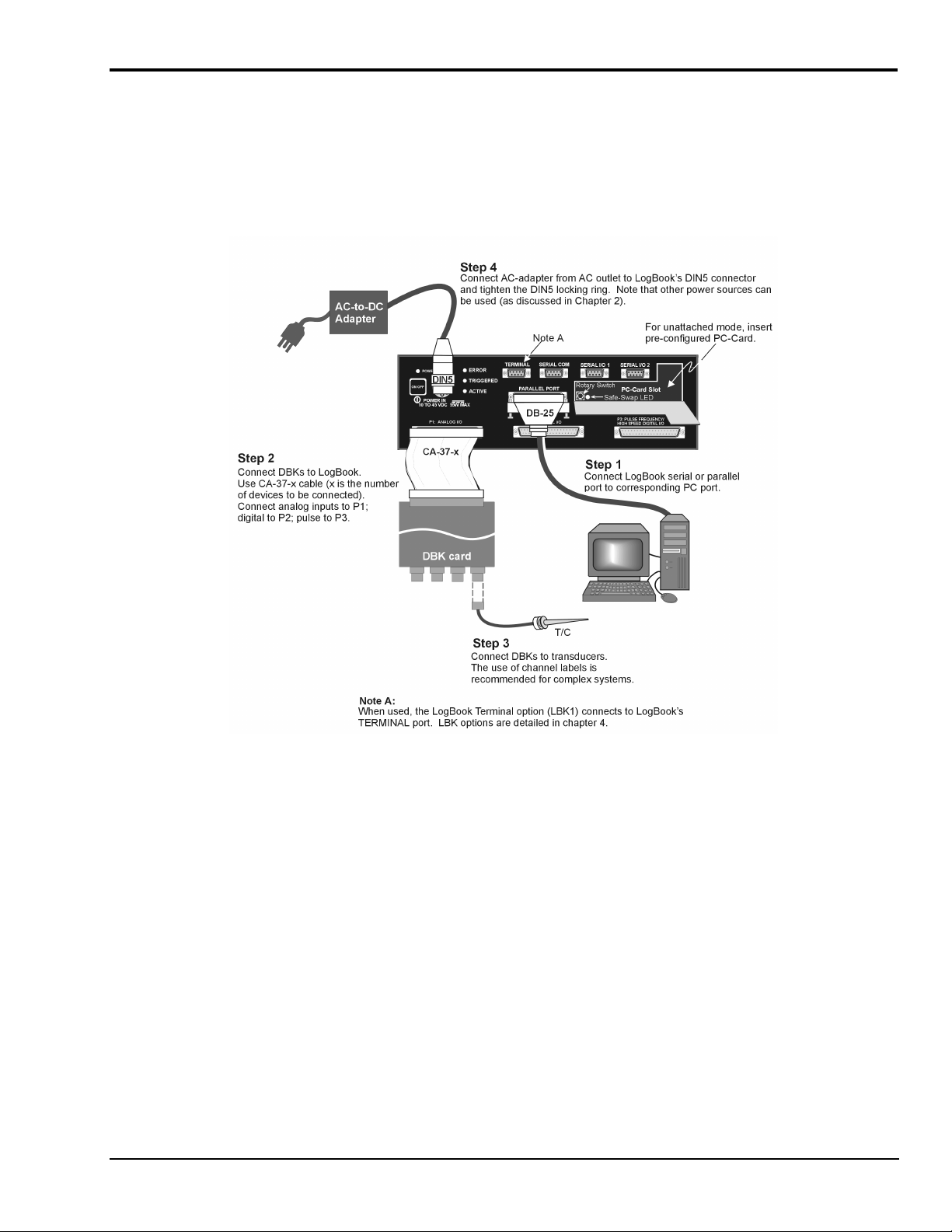

Hardware Connection

The following hardware-connection figure and procedure are generic; details vary with system complexity.

LogBook/300 System, Basic Connections

Note:

There are two styles of LogBook/300. The earlier version’s PC-Card door is hinged on the right edge. The newer model,

represented in the figure, is hinged on the lower edge.

LogBook User’s Manual,

8-17-99

Quick Start, LogBook/300 QS-300-1

Page 8

After verifying that all equipment power is off, hardware connection typically proceeds as follows.

Refer to the previous figure as needed.

1. Connect LogBook to PC. There are three ways for LogBook to communicate with the host PC.

These are: parallel port, serial port, or by physical transportation of the PC-Card. Note that the

parallel port method is represented in the previous figure.

Parallel port – If using the parallel port, connect the supplied 2-foot parallel port (DB25) cable

a)

to PARALLEL PORT on LogBook, and to the corresponding parallel port on the PC. When this

method is used, the PC must be set to the ECP mode. See ECP Parallel Port, page 4 for

additional information.

Serial port – If using the serial port, connect the supplied 6-foot serial-port (DB9) cable to

b)

SERIAL PORT on LogBook, and to the corresponding serial port on the PC.

c) PC-Card - As described chapter 1’s PC-Card Swapping section, LogBook does not require an

electrical connection to the PC. The PC-Card must be pre-configured [from LogView on the PC]

to contain the desired configuration file. Then the PC-Card is inserted into the corresponding

slot behind the door on the LogBook’s front panel.

2. Connect the LogBook to the DBK cards and modules. Most of the analog DBKs connect to P1 on

the rear panel; the digital DBKs generally connect to P2—refer to documentation for your particular

DBKs in chapter 5 and for general DBK installation details. The CA-37-x cable can daisy-chain

several DBKs including the DBK41, which has a built-in P1 bus connection for 10 DBK cards.

The x in the cable part number refers to the number of devices that can be connected (a CA-37-1

cable actually has two DB-37 connectors). The P1/P2 pinouts are included in chapter 1. Observe the

input signal strength limitation as cautioned below—especially if using a non-DBK source.

For analog signal inputs via P1, do not exceed -35 VDC or +45 VDC.

Exceeding these limits could result in equipment damage.

3. Connect DBK(s) to transducer(s). Follow instructions for particular DBK as described in chapter 5

and for the particular transducer. Some DBKs can accommodate both BNC and screw-terminal

connections.

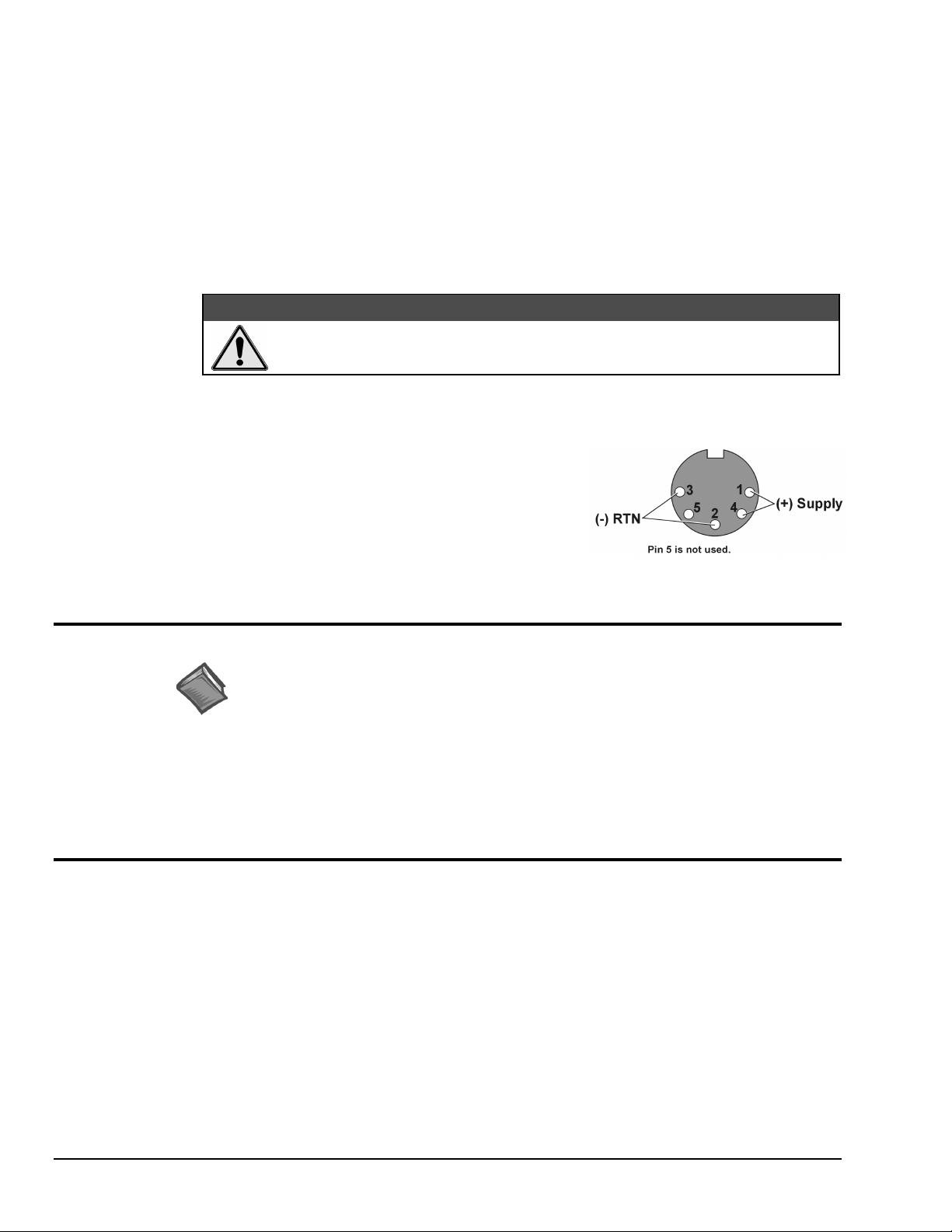

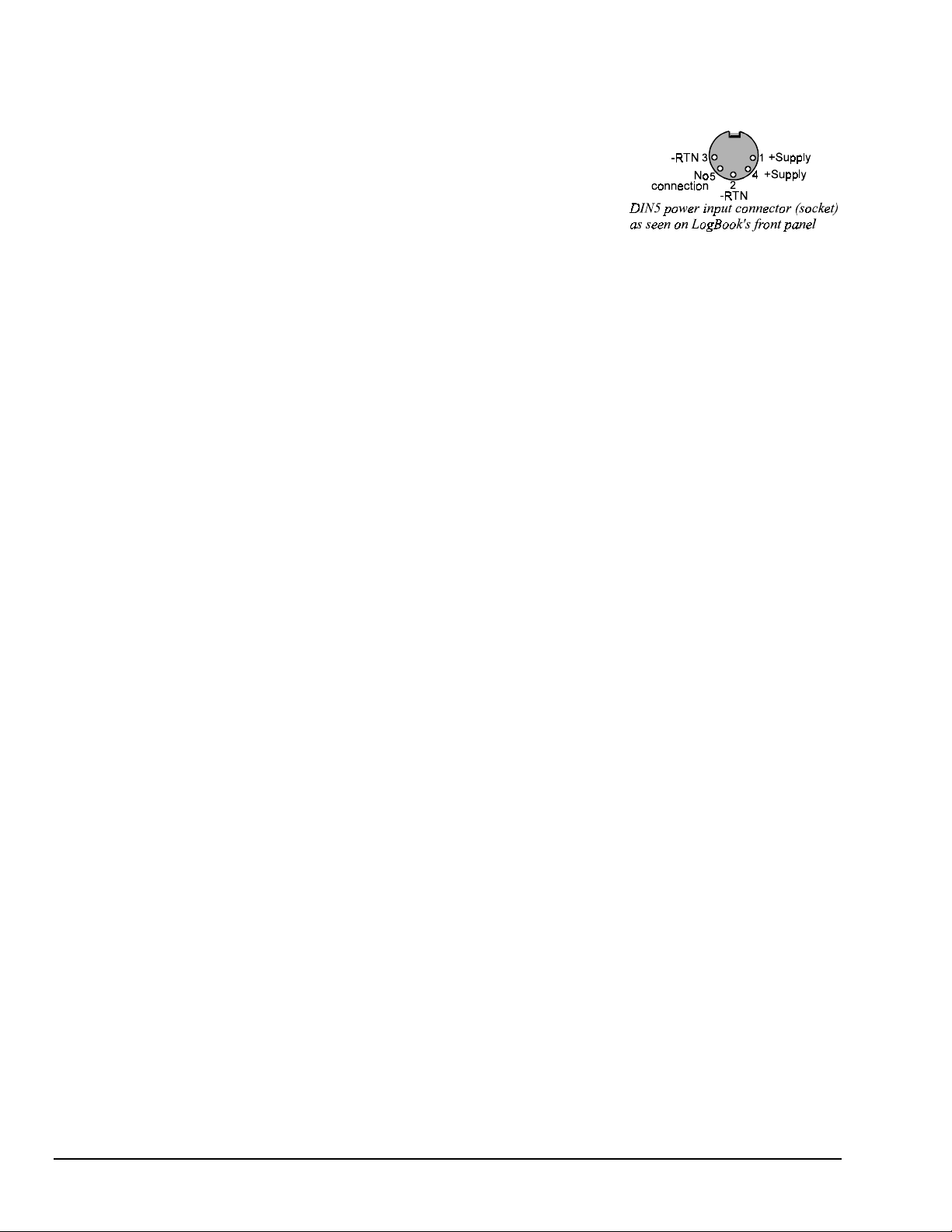

4. Connect LogBook to a suitable power source. The easiest

connection is to use the TR-43 AC-to-DC power source or the

DBK34. DC power sources such as a car batteries, etc must

supply 10 to 45 VDC and use the correct DIN5 pinout (see

figure). A locking DIN5 connector assures a secure power

connection for applications subject to vibration or thermal stress.

5. (optional) Just one cable connects between the LBK1 (via RJ-11 connector) and the LogBook (via a

DB9 connector). The standard cable is 6 ft long, and an optional cable is 25 ft long (see chapter 4 for

LBK1 installation details).

Hardware Configuration

Reference Notes:

(1) Refer to chapter 4 in regard to the various LBK options.

(2) Some DBKs require manual configuration. Refer to chapter 5 for specific DBK

information.

LogBook's top cover does not need to be removed, except to add or remove an LBK option, or to replace

the fuse.

&$87,21

Most LogBook configuration is done via software as described in section, LogBook/300 Device

Configuration. Except when using the RS-485 communication option, LogBook configuration does not

require you to set jumpers or switches.

QS-300-2 Quick Start, LogBook/300,

8-17-99

LogBook User’s Manual

Page 9

Software Installation

Note: The LogBook is supported under Windows95/98 and WindowsNT. Your computer should be a

486 or higher (Pentium

®

recommended) with at least 16 Mbytes of RAM. 32 Mbytes of RAM is

recommended.

Note: Before installing software, ensure LogBook is connected to the selected port

(serial, or ECP-parallel); and power-on the system.

Install installation CD-ROM (or installation disks, as applicable). Run the Setup.exe and follow screen

prompts.

When the software installation is complete, you will be given two options:

•

Exit running the configuration utility—if the LogBook is to be used immediately.

•

Exit and return to operating system—you can run the configuration later from the control panel.

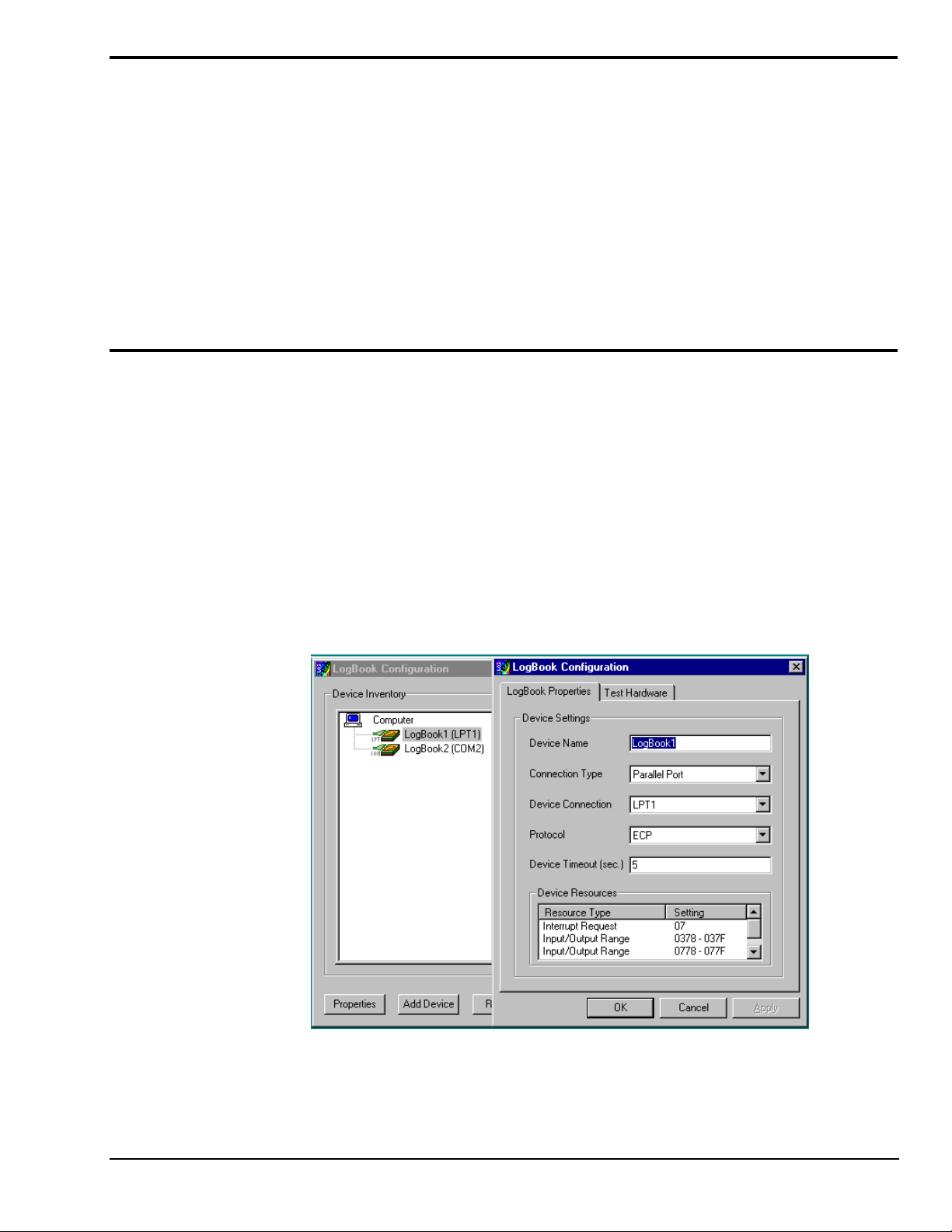

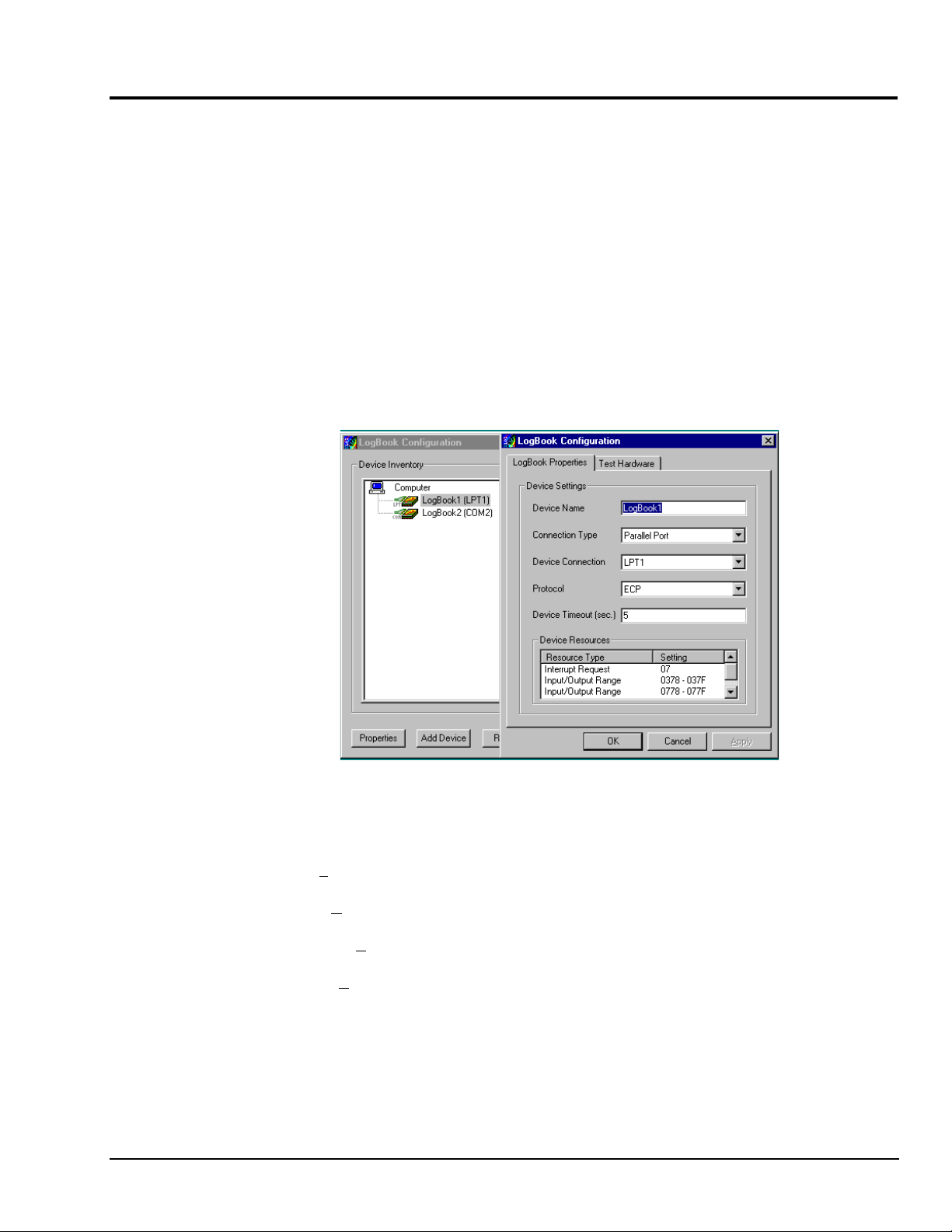

LogBook/300 Device Configuration

A configuration utility is supplied via a control panel applet. The LogBook Configuration applet allows

you to add a device, remove a device, or change existing configuration settings. From this same window,

you can also access a built-in utility to test the connected device for current setup and performance.

LogBook Configuration can be found in the Windows95/98/NT control panel. This can be navigated to

from Window’s desktop Start button:

Start ⇒ Settings ⇒ Control Panel

You can enter LogBook Configuration during driver installation or whenever you wish to add, remove or

change device configuration settings. The following description applies to either method.

st

The 1

configuration window will display configured devices in the Device Inventory field based on the

port they’re connected to. Devices are indicated by their name and icon. If no devices are currently

configured, no devices will appear in this field. (The figure shows the 1

overlapping.)

st

and 2nd configuration windows

LogBook User’s Manual,

8-17-99

LogBook Configuration Windows

Quick Start, LogBook/300 QS-300-3

Page 10

The 4 buttons across the bottom of the 1st configuration window (previous figure) are used as follows:

•

•

•

•

The 2nd configuration window displays the properties for the selected LogBook. Fields include:

•

•

•

•

•

ECP Parallel Port

Properties. Configuration settings for a device can be changed or modified from the corresponding

properties window. To do so, double-click the device icon or single-click the device and then singleclick the Properties button. The 2

nd

configuration window will appear for the selected device as

shown in the previous figure.

Add. The Add Device button is used to add a device configuration whenever a new device is added

to the system. LogView cannot recognize a device unless listed in the configuration window.

Remove. The Remove button is used to remove a device from the configuration. A device may be

removed if it is no longer installed or if the device’s configuration no longer applies.

Close. The Close button may be used at any time to exit the LogBook Configuration applet.

Device Name is displayed with the default name, numbered successively as configured. This field

can be changed to any descriptive name as desired.

Connection Type can be serial or parallel port.

Device Connection specifies the port name.

Protocol is used to set the parallel port protocol (ECP only) or serial protocol (RS-232 or RS-485).

Device Timeout specifies the number of seconds LogView will be wait for a LogBook response

before displaying an error condition.

To use parallel port communication with an attached LogBook, your PC must support

the ECP protocol AND be set in the ECP mode.

Serial Port

PCs made since 1994 probably support the Enhanced Computer Port protocol (ECP). If your parallel port

does not support ECP, you can communicate with the LogBook via the RS-232 serial port, or you can add

an ECP-compatible ISA board or PC-Card parallel port. Setting the PC to ECP mode varies with different

computers. On some computers, you can enter the BIOS Setup utility from Windows Settings or during

startup by pressing the F1 function key. The Parallel Port Mode property can be found under the Peripheral

Configuration group menu item. If necessary, consult your PC’s documentation or your PC’s manufacturer.

To ensure ECP compatibility after proper setup, use the Test Hardware utility

(described on page 5). Before testing, make sure LogBook is properly connected,

powered on, and that the Parallel Port Mode is set to ECP (in BIOS Setup).

&$87,21

Making errors in BIOS Setup can disrupt your system’s operation. If test hardware

indicates a problem and you have inadequate experience with the BIOS Setup utility,

consult your System Administrator or other qualified individual.

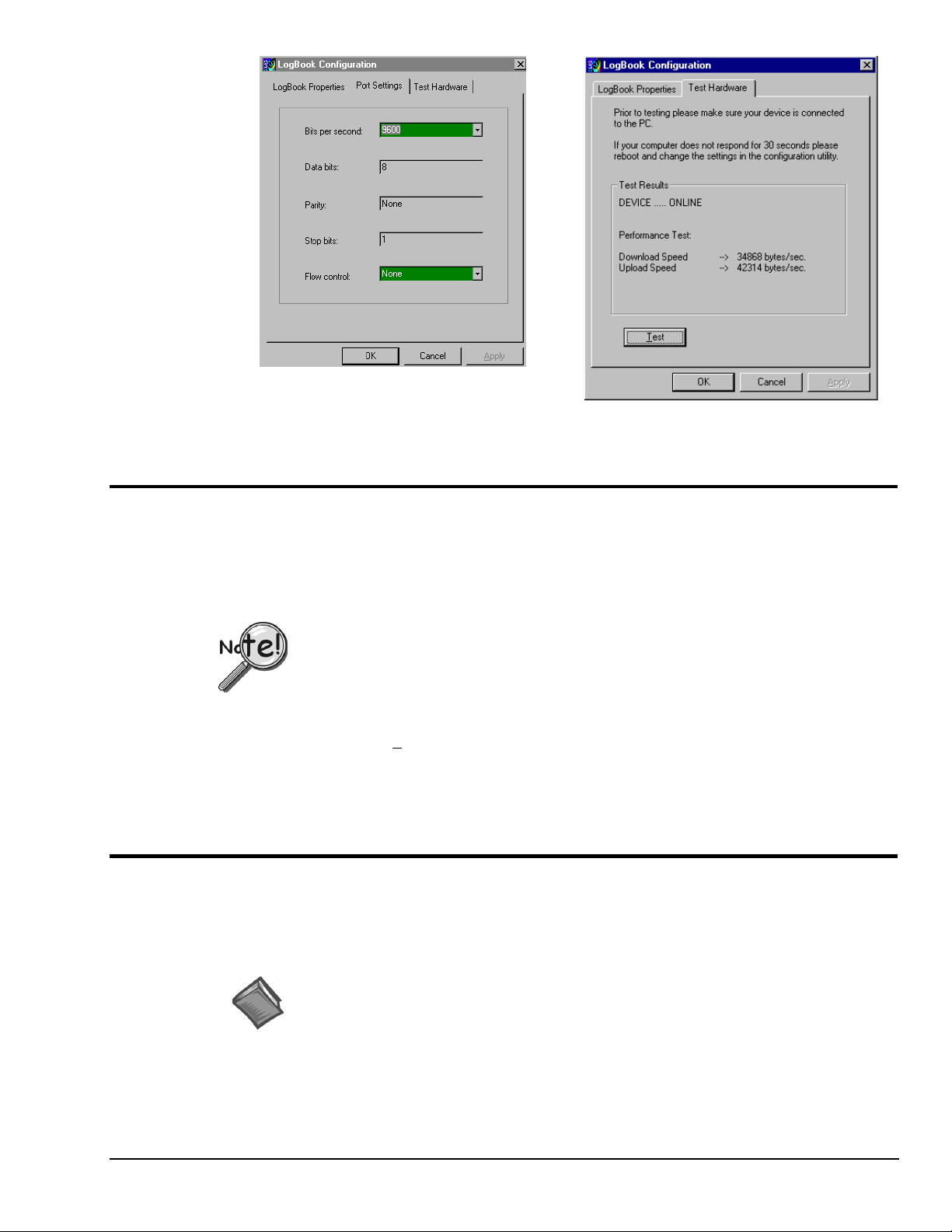

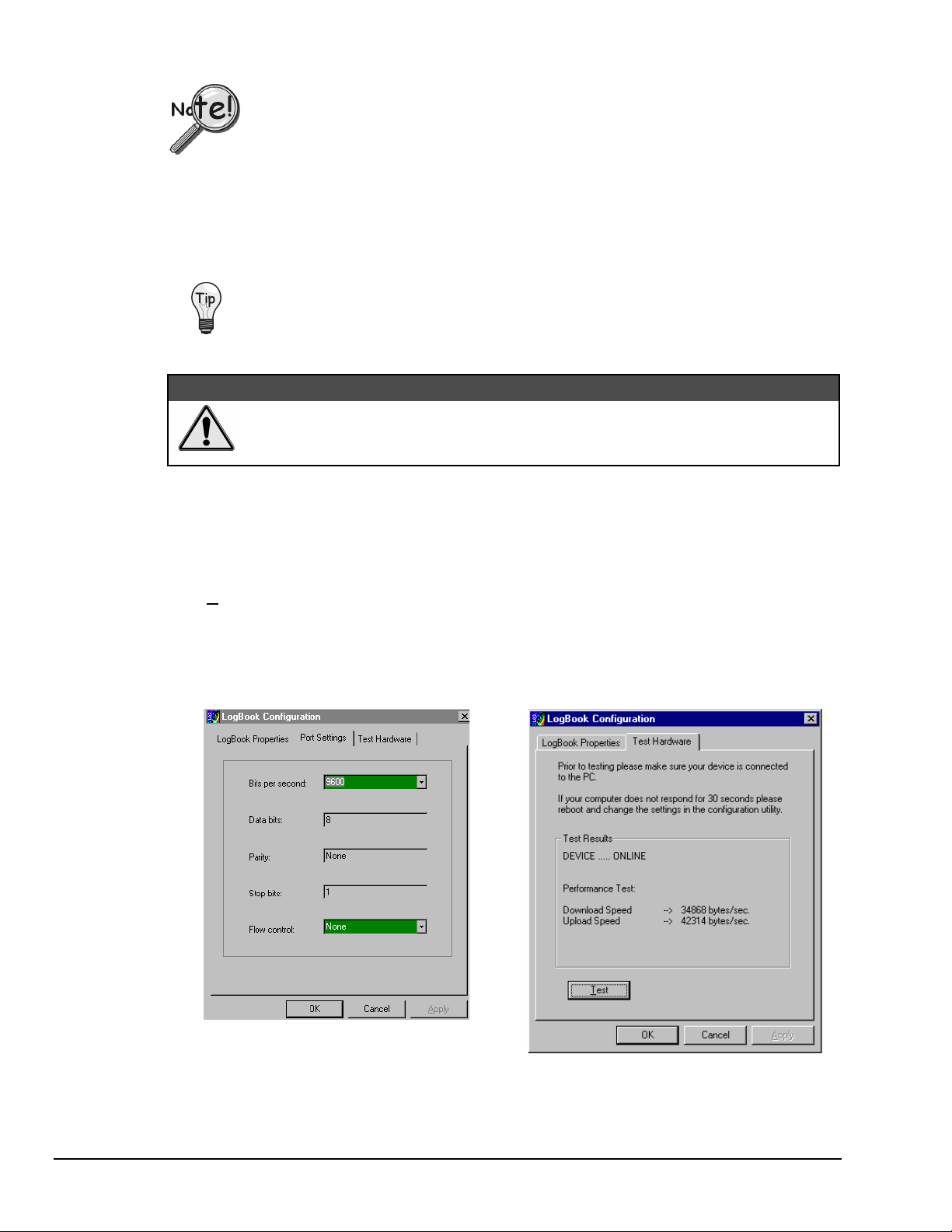

If the selected device is connected to a serial port the properties window will include the fields shown in the

figure at right. Baud rate can be set from 1200 to 115200 bits per second (default 9600). When all fields

have been changed to the desired settings, you can click on one of the following options:

•

Apply to store the device configuration. Parameters are not locked in until you click the Apply

button. If you make changes and don’t click Apply, clicking the Test button in Test Hardware will

yield unexpected errors.

•

OK to store the configuration and exit the current property screen.

•

Cancel to exit the current screen without storing any changes.

•

Test Hardware to test the current device.

QS-300-4 Quick Start, LogBook/300,

8-17-99

LogBook User’s Manual

Page 11

Test Hardware

Before testing LogBook/300:

(a) Verify the device has been properly installed

(b) Make sure the communication cable (serial or parallel) is firmly in place to the proper ports.

(c) Verify the device is powered-on.

To begin the test, click the Test button. Test results should be displayed within a few seconds.

Test results indicate if the device is online (properly connected, powered on and ready to transfer the data)

or offline. If the device is online, Performance Test will display Download and Upload speed rates. These

rates represent the maximum speed at which downloading and uploading files can be performed. Actual

transfer time will depend on channel configuration and the size of the transfer.

LogBook Properties Tab Test Hardware Tab

Testing the LogBook device might cause the system to hang. If test results are not

displayed within 30 seconds, or if the system does not respond properly: reboot the

system. Upon power-up, re-enter the LogBook Configuration and ensure the LogBook

configuration settings are correct. Change the settings as applicable.

Acquisition Configuration

An acquisition is configured using LogView on a PC and then stored as an acquisition setup file on a

PC-Card. The PC-Card may be in an attached LogBook or in the PC to be later manually transferred to an

unattached LogBook. The system’s DBK cards are listed; the scan sequence is defined; the trigger

conditions are specified, etc.

Reference Note: Configuring the acquisition is described in chapter 3, LogView.

LogBook User’s Manual,

8-17-99

Quick Start, LogBook/300 QS-300-5

Page 12

Calibration

Calibration is typically performed automatically through LogView software; however, some DBKs may

require manual calibration. LogView’s 2-point calibration fine-tunes the reading’s slope and offset error

(mx+b). DBKs working with non-linear sensors typically condition/convert the reading to a linear form.

Otherwise, a non-linear analog input signal is difficult to read accurately. Careful use of the calculated

channels may yield usable approximations in simple, limited-range conditions.

Reference Note: An example of 2-point calibration is given in the How To… section of

chapter 3, LogView.

Appendix A details the calibration methods applicable to DBK16 and DBK43.

QS-300-6 Quick Start, LogBook/300,

8-17-99

LogBook User’s Manual

Page 13

Quick Start, LogBook/360

Card Drawer Setup……2

Connect LogBook/360 to PC,

External DBKs, and Power…..5

Hardware Configuration…… 6

Software Installation…… 6

LogBook/360 Device Configuration……7

Test Hardware…… 9

Acquisition Configuration……9

Calibration…… 9

Page numbers refer to QS-360 section.

*

Reference Notes: You may need to refer to additional sections of this manual.

Chapter 1, for system block diagrams, operational overviews, connections, memory upgrade procedure,

or information on the RS-422/485 option.

Chapter 2, in regard to calculating system power and ensuring an adequate power supply.

Chapter 4, if using LBK options.

Chapter 5, if using DBK options.

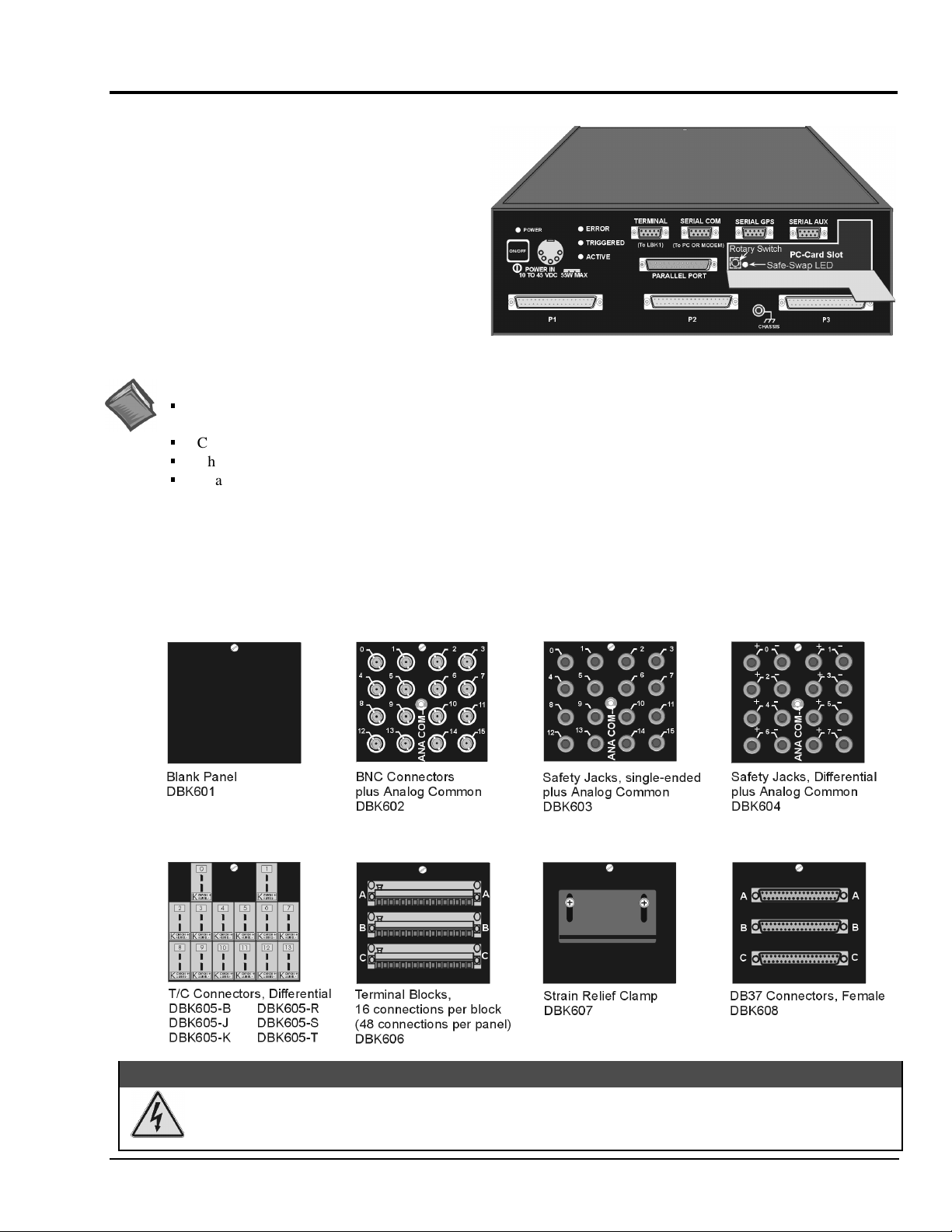

LogBook/360 combines the features and capabilities of LogBook/300 with a DBK60 expansion chassis. The lower

portion of the front panel has three male DB37 connectors (P1, P2, and P3) for system expansion, and a post for

connecting to CHASSIS ground.

The upper section is nearly identical to LogBook/300, and is detailed in chapter 1.

LogBook/360, Front Panel

The rear panel consists of three termination panels. Many different combinations of three panels are possible.

Termination panels available at the time of publication are represented in the following figure.

Electric shock hazard. Turn off power to all system-connected devices prior to connecting or

disconnecting cables, or setting hardware configurations. Failure to do so could result in electric shock

or death, and equipment damage, even under low-voltage conditions.

LogBook User’s Manual,

10-1-99

:$51,1*

Quick Start, LogBook/360 QS-360-1

Page 14

Use ESD tools, containers, and procedures during setup of DBK cards. Electrostatic

discharge can damage some components. To prevent pin damage, align DBK cards with the

backplane DB37 connectors, then gently press them together.

When using LogBook in attached mode, the PC-Card [in LogBook] must already have the file

logbook.sys.

dead.

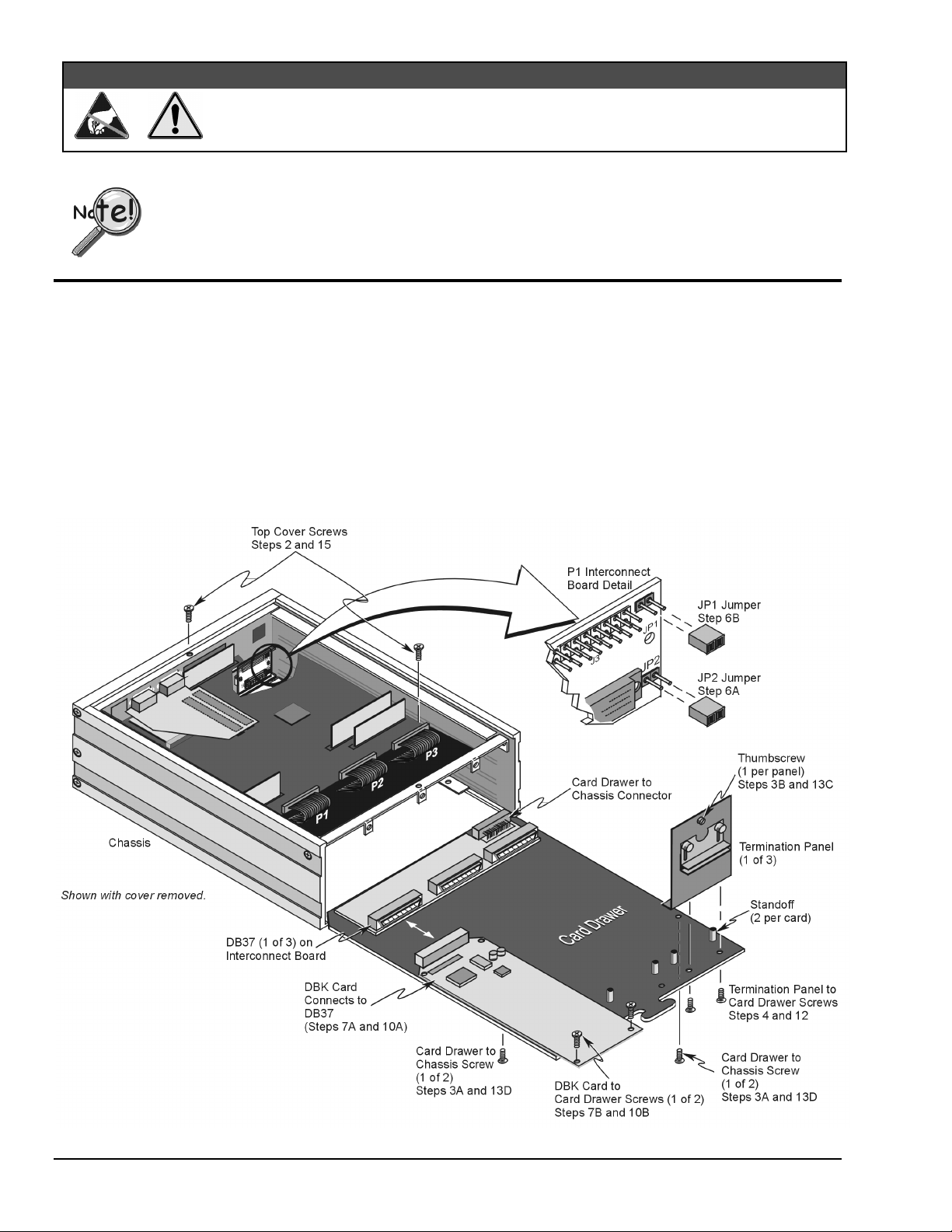

Card Drawer Setup

LogBook/360 can house three DBK cards internally, and makes use of various termination panels as depicted on

page 1 of this Quick Start. For user convenience, a card drawer can be slid free of the device. The following steps

should be used when adding, removing, or changing cards. Refer to the figure as needed.

1 – Turn off system power and disconnect LogBook/360.

Turn power off to the LogBook/360 and all connected devices. Disconnect LogBook/360 from the system.

2 – Remove top cover.

If you need to make any change on the LogBook motherboard, you will need to remove the top cover.

Otherwise, the cover can remain in place. To remove the top cover, simply remove the two top cover screws

and slide the cover free of the device.

&$87,21

Otherwise, LogView cannot communicate with LogBook, and LogBook will appear

QS-360-2 Quick Start, LogBook/360,

10-1-99

LogBook/360, Hardware Setup

LogBook User’s Manual

Page 15

3 – Remove card drawer.

A. Remove the two screws that hold the card drawer to the chassis.

B. Loosen the three termination panel thumbscrews.

C. Carefully pull the card drawer free of the chassis.

4 – Remove termination panels.

For each termination panel, remove the two screws that mount it to the card drawer, then remove the

termination panel.

5 – Determine power requirements.

Depending on the power needs of your system’s DBK cards, you may need to add a power card.

Refer to Chapter 2, System Power, in regard to calculating your power requirement.

If the required power is more than the available power (see chapter 2 for calculations), your system will

require auxiliary power. One of two power supply cards can be used with LogBook:

•

DBK32A – For use with a LogBook, DaqBook, or DaqBoard. It supplies ±15 V.

•

DBK33 – For use with Log Book, DaqBook, DaqBoard, or Daq PC-Card. It supplies +5 V and ±15 V.

6 – Configure chassis for power sources.

Proper jumper configuration limits LogBook’s P1 bus to one power source. The P1 bus should never have more

than one power source.

The JP1 and JP2 jumpers located on the P1 Interconnect Board inside chassis (see previous figure) control the

+5V distribution. Both the JP1 and JP2 jumpers are installed as factory-default.

JP2

A.

.

Only remove the JP2 jumper if cards (on the internal P1 bus) are to be powered from LogBook’s

internal PCB.

JP1

B.

.

Only remove the JP1 jumper if a DBK33 is used with the system.

7 – Install power card if necessary.

If you determined in step 5 that additional power was needed, add a DBK32A or DBK33 power card to the

chassis. Chapter 2 includes information regarding these power-related cards.

A. Carefully align the power card’s DB37 connector with a DB37 connector on the interconnect board and

gently press them together.

B. Mount the power card with two screws into the standoffs on the card drawer.

8 – Configure LogBook/360.

Refer to chapter 1. Note that if a LogBook/360 driver is not available in software, select LogBook/300.

9 – Configure DBK cards.

Configure unique channel addresses with the jumpers on the DBK cards. Some cards have other jumpers and/or

DIP switches. Refer to the particular DBK sections of Chapter 5, as needed.

10 – Install DBK cards.

You must use all analog DBK cards in the LogBook/360; unless you have a factory modification that allows the

use of all digital cards. You can not use both analog and digital cards at the same time.

A. Carefully align the DBK card’s DB37 connector with a DB37 connector on the interconnect board and

gently press them together (see figure).

B. Mount the DBK card with two screws into the standoffs on the card drawer (see figure).

C. Continue installation of any remaining DBK cards.

LogBook User’s Manual,

10-1-99

Quick Start, LogBook/360 QS-360-3

Page 16

11 – Connect internal signals.

Connect signal inputs from DBK cards to termination panels. DBK cards connect to the termination panels in

various ways (see figure and particular DBK sections in manual):

•

Single-ended connections use analog common.

•

Differential connections require the proper polarity, typically red-to-red for high (+)

and black-to-black for low (-).

•

For thermocouples, red is generally the low side. Always make sure the T/C connector and wire type match

the T/C type used.

12 – Install termination panels.

Mount the termination panels to the card drawer with two screws for each panel.

13 – Install card drawer.

The card drawer slides into the bottom track of the chassis.

A. Hold the card drawer by its handle and tilt it up slightly. Place it on the bottom track of the chassis.

B. Carefully slide the card drawer into the chassis. When it engages the bottom track, level the card drawer and

continue inserting it until it engages with the P1 interconnect board.

C. Tighten the three captive thumbscrews holding the termination panels to the chassis.

D. Install the two screws holding the card drawer to the chassis.

14 – Connect external signals.

Connect signal inputs from sensors to termination panels.

15 – Install top cover.

If the top cover was removed, slide it back into place and secure with two screws.

QS-360-4 Quick Start, LogBook/360,

10-1-99

LogBook User’s Manual

Page 17

Connect LogBook/360 to PC, External DBKs, and Power*

The following hardware-connection figure and procedure are generic; details vary with system complexity. For

“unattached mode,” a pre-configured PC-Card is inserted in the PC-Card slot, and no connection to a PC is made.

The following figure illustrates the “attached” mode.

*Note: Connecting LogBook/360 to a PC applies to the “attached mode” only. Many applications will make use of

three internal DBK cards only, having no need to attach external DBK cards or modules as discussed in the

following text.

After verifying that all equipment power is off, hardware connection typically proceeds as follows.

Refer to the above figure as needed.

1. Connect LogBook to PC. There are three ways for LogBook to communicate with the host PC.

LogBook User’s Manual,

LogBook/360 System, “Attached Mode,” Basic Connections

Note:

Rear panel connections may be made via terminal blocks, as discussed in the previous section,

Card Drawer Setup

.

These are: parallel port, serial port, or by physical transportation of the PC-Card. Note that the

parallel port method is represented in the previous figure.

a) Parallel port – If using the parallel port, connect the supplied 2-foot parallel port (DB25) cable

to PARALLEL PORT on LogBook, and to the corresponding parallel port on the PC. When this

method is used, the PC must be set to the ECP mode. See

ECP Parallel Port

, page 8 for

additional information.

b) Serial port – If using the serial port, connect the supplied 6-foot serial-port (DB9) cable to

SERIAL PORT on LogBook, and to the corresponding serial port on the PC.

c) PC-Card - As described chapter 1’s

PC-Card Swapping

section, LogBook does not require an

electrical connection to the PC. The PC-Card must be pre-configured [from LogView on the PC]

to contain the desired configuration file. Then the PC-Card is inserted into the corresponding

slot behind the door on the LogBook’s front panel.

10-1-99

Quick Start, LogBook/360 QS-360-5

Page 18

2. Connect LogBook to the DBK cards and modules. For connecting internal DBK cards, refer to the

earlier section entitled, Card Drawer Setup.

Most analog DBKs connect to P1; digital DBKs generally connect to P2. Refer to chapter 5 for your

particular DBKs and for general DBK installation details.

The CA-37-x cable can daisy-chain several DBKs including the DBK41, which has a built-in P1 bus

connection for 10 DBK cards. The x in the cable part number refers to the number of devices that

can be connected (a CA-37-1 actually has two DB-37 connectors).

Note: Chapter 1 includes LogBook P1, P2, and P3 Pinouts.

&$87,21

For analog signal inputs via P1, do not exceed -35 VDC or +45 VDC.

Exceeding these limits could result in equipment damage.

3. Connect DBK(s) to transducer(s). Follow instructions for particular DBK as described in chapter 5

and for the particular transducer. Some DBKs can accommodate both BNC and screw-terminal

connections.

4. Connect LogBook to a suitable power source, such as a

TR-43 AC-to-DC power adaptor or DBK34 vehicle UPS

module. DC power sources such as a car batteries must

supply 10 to 45 VDC and use the correct DIN5 pinout

(see figure). A locking DIN5 connector assures a secure

power connection for applications subject to vibration and

thermal stress.

DIN5 Power Input Connector

As seen on LogBook Front Panel)

(

Hardware Configuration

Reference Notes:

(1) Refer to chapter 4 in regard to the various LBK options.

(2) Some DBKs require manual configuration. Refer to chapter 5 for specific DBK

information.

LogBook's top cover does not need to be removed, except to add or remove an LBK option, or to replace

the fuse.

Most LogBook configuration is done via software as described in section, LogBook/360 Device

Configuration. Except when using the RS-485 communication option, LogBook configuration does not

require you to set jumpers or switches.

Software Installation

Note: The LogBook is supported under Windows95/98 and WindowsNT. Your computer should be a

486 or higher (Pentium

recommended.

Note: Before installing software, you should attach LogBook to the selected port (serial, or

ECP-parallel); and power-on the system.

Install installation CD-ROM (or installation disks, as applicable). Run the Setup.exe and follow screen

prompts.

When the software installation is complete, you will be given two options:

•

Exit running the configuration utility—if the LogBook is to be used immediately.

•

Exit and return to operating system—you can run the configuration later from the control panel.

®

recommended) with at least 16 Mbytes of RAM. 32 Mbytes of RAM is

QS-360-6 Quick Start, LogBook/360,

10-1-99

LogBook User’s Manual

Page 19

LogBook/360 Device Configuration

A configuration utility is supplied via a control panel applet. The LogBook Configuration applet allows

you to add a device, remove a device, or change existing configuration settings. From this same window,

you can also access a built-in utility to test the connected device for current setup and performance.

LogBook Configuration can be found in the Windows95/98/NT control panel. This can be navigated to

from Window’s desktop Start button:

Start ⇒ Settings ⇒ Control Panel

You can enter LogBook Configuration during driver installation or whenever you wish to add, remove or

change device configuration settings. The following description applies to either method.

st

The 1

configuration window will display configured devices in the Device Inventory field based on the

port they’re connected to. Devices are indicated by their name and icon. If no devices are currently

configured, no devices will appear in this field. (The figure shows the 1

overlapping.)

st

and 2nd configuration windows

The 4 buttons across the bottom of the 1st configuration window (previous figure) are used as follows:

•

•

•

•

The 2nd configuration window displays the properties for the selected LogBook. Fields include:

•

•

•

•

•

LogBook User’s Manual,

LogBook Configuration Windows

Properties. Configuration settings for a device can be changed or modified from the corresponding

properties window. To do so, double-click the device icon or single-click the device and then singleclick the Properties button. The 2

nd

configuration window will appear for the selected device as

shown in the previous figure.

Add. The Add Device button is used to add a device configuration whenever a new device is added

to the system. LogView cannot recognize a device unless listed in the configuration window.

Remove. The Remove button is used to remove a device from the configuration. A device may be

removed if it is no longer installed or if the device’s configuration no longer applies.

Close. The Close button may be used at any time to exit the LogBook Configuration applet.

Device Name is displayed with the default name, numbered successively as configured. This field

can be changed to any descriptive name as desired.

Connection Type can be serial or parallel port.

Device Connection specifies the port name.

Protocol is used to set the parallel port protocol (ECP only) or serial protocol (RS-232 or RS-485).

Device Timeout specifies the number of seconds LogView will be wait for a LogBook response

before displaying an error condition.

10-1-99

Quick Start, LogBook/360 QS-360-7

Page 20

ECP Parallel Port

PCs made since 1994 probably support the Enhanced Computer Port protocol (ECP). If your parallel port

does not support ECP, you can communicate with the LogBook via the RS-232 serial port, or you can add

an ECP-compatible ISA board or PC-Card parallel port. Setting the PC to ECP mode varies with different

computers. On some computers, you can enter the BIOS Setup utility from Windows Settings or during

startup by pressing the F1 function key. The Parallel Port Mode property can be found under the Peripheral

Configuration group menu item. If necessary, consult your PC’s documentation or your PC’s manufacturer.

Serial Port

If the selected device is connected to a serial port the properties window will include the fields shown in the

figure at right. Baud rate can be set from 1200 to 115200 bits per second (default 9600). When all fields

have been changed to the desired settings, you can click on one of the following options:

•

•

•

•

To use parallel port communication with an attached LogBook, your PC must support

the ECP protocol AND be set in the ECP mode.

To ensure ECP compatibility after proper setup, use the Test Hardware utility

(described on page 9). Before testing, make sure LogBook is properly connected,

powered on, and that the Parallel Port Mode is set to ECP (in BIOS Setup).

&$87,21

Making errors in BIOS Setup can disrupt your system’s operation. If test hardware

indicates a problem and you have inadequate experience with the BIOS Setup utility,

consult your System Administrator or other qualified individual.

Apply to store the device configuration. Parameters are not locked in until you click the Apply

button. If you make changes and don’t click Apply, clicking the Test button in Test Hardware will

yield unexpected errors.

OK to store the configuration and exit the current property screen.

Cancel to exit the current screen without storing any changes.

Test Hardware to test the current device.

LogBook Properties Tab Test Hardware Tab

QS-360-8 Quick Start, LogBook/360,

10-1-99

LogBook User’s Manual

Page 21

Test Hardware

Before testing LogBook/360:

(a) Verify the device has been properly installed

(b) Make sure the communication cable (serial or parallel) is firmly in place to the proper ports.

(c) Verify the device is powered-on.

Testing the LogBook device might cause the system to hang. If test results are not

displayed within 30 seconds, or if the system does not respond properly: reboot the

system. Upon power-up, re-enter the LogBook Configuration and ensure the LogBook

configuration settings are correct. Change the settings as applicable.

To begin the test, click the Test button. Test results should be displayed within a few seconds.

Test results indicate if the device is online (properly connected, powered on and ready to transfer the data)

or offline. If the device is online, Performance Test will display Download and Upload speed rates. These

rates represent the maximum speed at which downloading and uploading files can be performed. Actual

transfer time will depend on channel configuration and the size of the transfer.

Acquisition Configuration

An acquisition is configured using LogView on a PC and then stored as an acquisition setup file on a

PC-Card. The PC-Card may be in an attached LogBook or in the PC to be later manually transferred to an

unattached LogBook. The system’s DBK cards are listed; the scan sequence is defined; the trigger

conditions are specified, etc.

Calibration

Reference Note: Configuring the acquisition is described in chapter 3, LogView.

Calibration is typically performed automatically through LogView software; however, some DBKs may

require manual calibration. LogView’s 2-point calibration fine-tunes the reading’s slope and offset error

(mx+b). DBKs working with non-linear sensors typically condition/convert the reading to a linear form.

Otherwise, a non-linear analog input signal is difficult to read accurately. Careful use of the calculated

channels may yield usable approximations in simple, limited-range conditions.

Reference Note: An example of 2-point calibration is given in the How To… section of

chapter 3, LogView.

Appendix A details the calibration methods applicable to DBK16 and DBK43.

LogBook User’s Manual,

10-1-99

Quick Start, LogBook/360 QS-360-9

Page 22

QS-360-10 Quick Start, LogBook/360,

10-1-99

LogBook User’s Manual

Page 23

System Considerations 1

LogBook Basics……1-1

Introduction ….. 1-1

Front and Rear Panels……1-2

Highlight of Features …… 1-3

LogBook/300 Block Diagram …… 1-4

LogBook/360 Block Diagram …… 1-5

System Software……1-6

Hardware-Related Details……1-7

PC-Card Swapping……1-7

Physical/Environmental Conditions……1-7

Power Supply……1-8

Microprocessor……1-8

Field-Installation Racks and Enclosures……1-8

P1, P2, P3 Port Connectors……1-9

Reference Notes: Additional system considerations are covered in the following chapters.

Chapter 2, refers to calculating system power and ensuring an adequate power supply.

Chapter 4, details LBK options.

Chapter 5, details DBK expansion options applicable to LogBook.

LogBook Basics

System Design, Setup, and Expansion……1-13

Steps to Review …… 1-13

Expansion Configurations……1-13

LBK Options……1-13

DBK Options……1-14

Mechanical Setup Options……1-16

System Power Considerations……1-17

Operational Features……1-18

Data Acquisition, An Overview……1-18

LogBook System File……1-19

Communications……1-19

Triggering and Scan Timing……1-20

Scan Rate Limitations……1-20

Use of Outputs to Alarm and Control……1-22

Acquisition……1-22

Data Storage and Retrieval……1-22

Introduction

LogBook/300 and LogBook/360 are PC-based data acquisition systems that can work in a stand-alone

mode (no PC present), or linked to a PC. They combine onboard intelligence with a removable PC-Card

that stores the configuration file and the collected data. LogBooks have many options, most of which are

detailed in the LBK and DBK chapters. The PC link can be by serial or parallel port.

LogBook/300, Simple System Setup

The PC-Card holds the configuration file [created by LogView]. The file tells LogBook how to perform a

particular acquisition. The PC-Card also holds the acquired data files. The PC can upload to or download

from the PC-Card by cable if the PC is attached to LogBook, or by physical transport of the PC-Card from

one unit to the other. Multiple configuration files and multiple PC-Cards allow the system to handle

complex data acquisition environments with a large number of data-files.

LogBook User’s Manual,

8-30-99

System Considerations 1-1

Page 24

Front and Rear Panels

Note: Descriptions of panel items appear on the following page.

LogBook/360, Front Panel

LogBook/360, Terminal Panels (A combination of 3 make up the rear panel)

LogBook/300, Front Panel

Note

: In earlier models, the PC-Card Door has a right-edge hinge (not shown).

LogBook/300, Rear Panel

1-2 System Considerations LogBook User’s Manual,

8-30-99

Page 25

LogBook/360 panel items are listed in the following table. Not that LogBook/300 panel items are the same as those on the

360, except as called out in the following bulleted list:

Slight differences in the overlay.

•

P1, P2, and P3 appear on LogBook/300’s rear panel.

•

LogBook/300 has no SERIAL GPS connection.

•

Switches

ON/OFF Depressing the push-button switch turns the power on.

(interior rotary switch) PC-Card door provides access to a rotary switch to set device address when used in an RS-485 network.

Connectors

POWER IN This locking DIN5 input connector accepts +10 to +45 VDC.

PARALLEL PORT This DB-25 plug is a parallel port connector to a host PC (set to ECP mode)

TERMINAL PORT (TO LBK1) This DB-9 socket is a serial port connector for the LBK1 remote control panel (user-interface terminal).

SERIAL COMM

(TO PC OR MODEM)

SERIAL GPS

(LogBook/360 Only)

SERIAL AUX

(LogBook/360 Only)

P1 - ANALOG I/O Provides 16 analog input channels, 3 TTL inputs, and various signals for driving expansion cards.

P2 - DIGITAL I/O Provides 3 8-bit TTL programmable I/O ports and external interrupt input.

P3 - PULSE FREQUENCY /

HIGH-SPEED DIGITAL I/O

(PC-Card door, no label) Door provides access to PCMCIA connector—for removable PC-Card memory devices.

Indicator LEDs

POWER LED lights when power is applied to LogBook and the power switch is depressed into the ON position.

ERROR LED lights steady ON when a routine error occurs (e.g. disk full).

TRIGGERED LED lights after trigger event and during an A/D scan sequence.

ACTIVE LED lights to show that LogBook is ready to begin a scan at the next trigger event.

Safe-Swap Light

(interior green LED)

This DB-9 male serial COM port connects to a host PC or modem.

LogBook/360 only. This DB-9 male serial port option connects to a Global Positioning System.

LogBook/360 only. This DB-9 male serial port option connects to optional auxiliary devices.

Provides 4 16-bit counters, 4 analog outputs, and 16 high-speed digital I/O.

LED flashes for fatal errors; refer to

cleared.

LED lights when it is safe to swap PC-Cards.

LogBook/300 has no SERIAL AUX connection.

•

LogBook/300 has no CHASSIS grounding

•

LogBook/300 does not make use of Terminal Panels.

•

Hardware Errors

Appendix B

in

. No data can be acquired until error is

post.

Highlight of Features

LogBooks can be left unattended for long testing periods and used in environments not suitable for PCs.

With the use of PC-Cards, one PC can support several LogBooks. Other LogBook features include:

•

Onboard processor capable of real-time data reduction and system control in stand-alone mode

•

Non-volatile storage of configuration files and samples via removable, transportable PC-Cards

•

4 MB RAM onboard, expandable to 16 MB

•

100 kHz 16-bit Analog-to-Digital Conversion

•

8 differential, 16 single-ended inputs; expandable to 256 input channels via DBK cards

•

7 gain/input ranges, unipolar and bipolar

•

40 digital I/O lines, expandable to 208

•

4 pulse-counting inputs

•

Gain and unipolar/bipolar settings are programmed in real time (10 µs max)

•

Scan-sequence memory (1024 analog channels plus 128 digital channels)

for any combination of channels/gains

•

Input power: 10 to 45 VDC (AC adapter included)

•

Several LBK options (listed on page 1-13, and detailed in chapter 4)

•

Several DBK options (listed on page 1-14 detailed in chapters 2 and 5)

LogBook User’s Manual,

8-30-99

System Considerations 1-3

Page 26

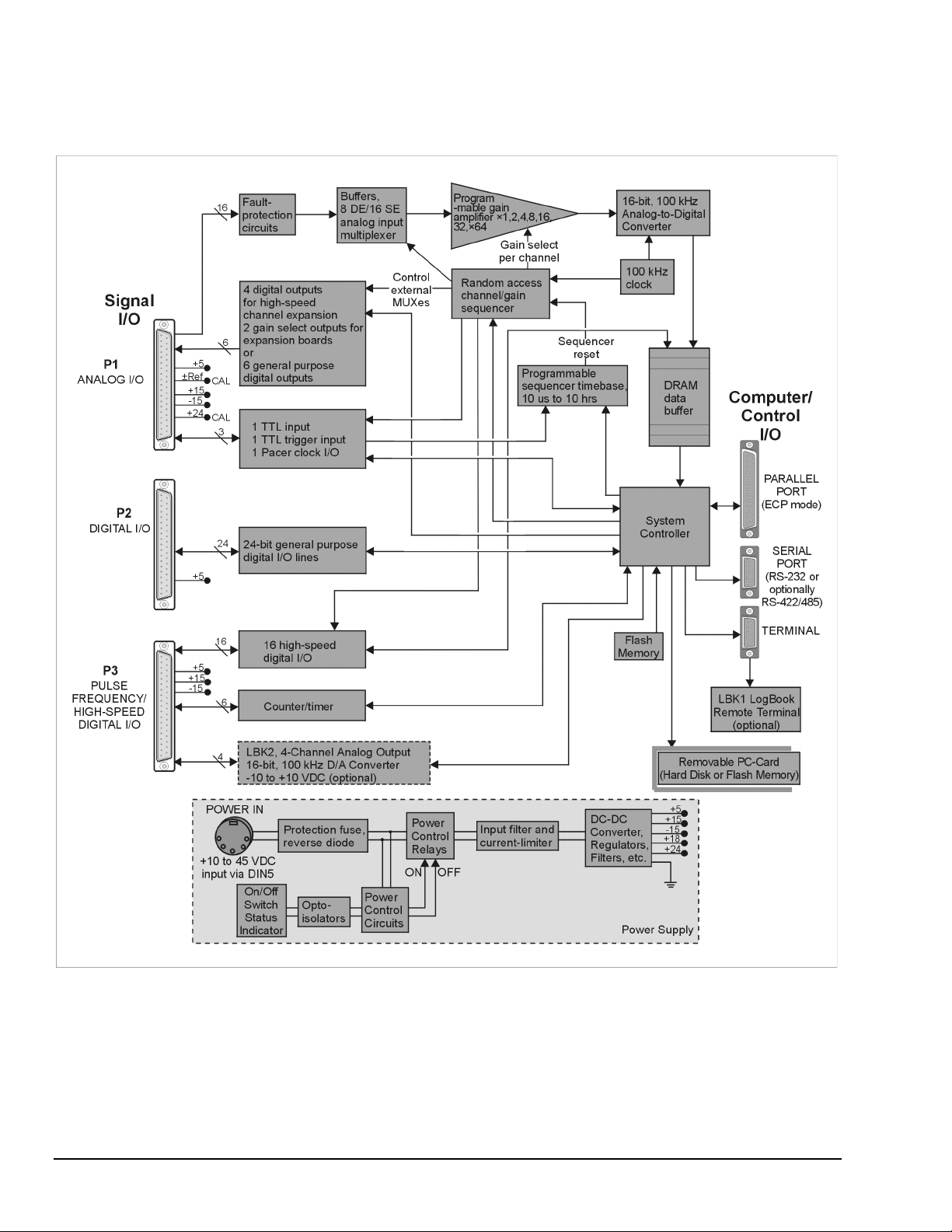

LogBook/300 Block Diagram

1-4 System Considerations LogBook User’s Manual,

8-30-99

Page 27

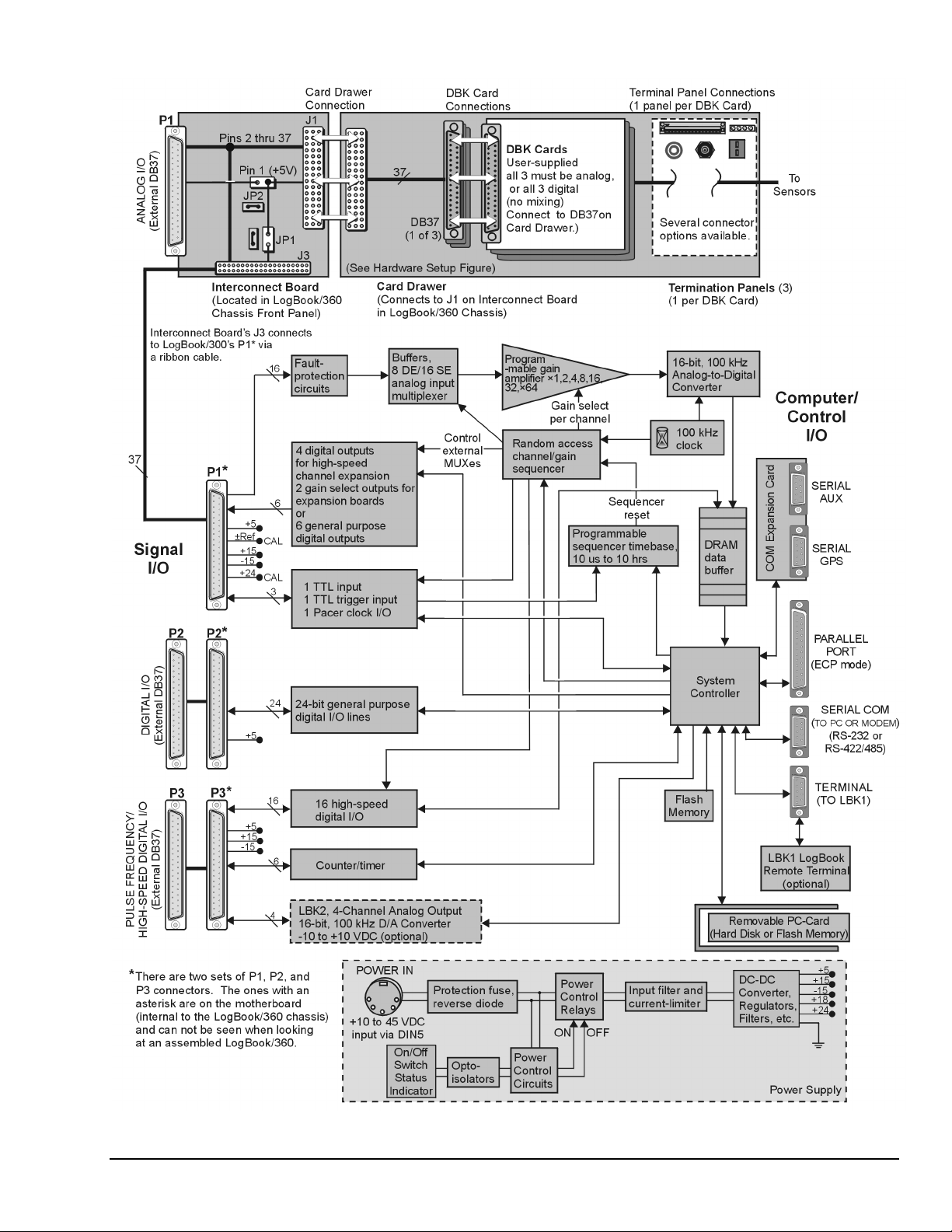

LogBook/360 Block Diagram

LogBook User’s Manual,

8-30-99

System Considerations 1-5

Page 28

The following components are represented in the previous block diagrams. Certain items apply only to

LogBook/360, as noted.

•

Removable PC-Card. A 12-520 MB capacity holds the software, operating system, user

configurations and the acquired data. The PC-Card is at the center of LogBook operations.

A PC-Card [pre-programmed by LogView] ensures an unattached LogBook comes up properly.

•

Power Supply. The internal power supply accepts an input of 10 to 45 VDC and supplies filtered

regulated voltages to its internal circuits and to accessories connected via P1/2/3. An external AC

adapter for all standard voltages is included with the system.

•

System Controller. A microprocessor chip is used within LogBook with either 4 MB (standard) of

RAM or 16 MB (optional). A field-upgradeable 512 KB Flash memory is used to store the system

startup code, self-diagnostics, and FPGA configuration.

•

Analog Input via P1. 16 main channels that can each accommodate 16 sub-channels via

multiplexing for a total of 256 analog input channels. Fault protection and buffer circuits prevent

overloads and cross-channel noise due to impedance mismatch.

•

A/D Converter. The A/D converter uses 16-bit resolution @ 100 kHz sample rate.

•

Digital I/O. 16 high-speed digital inputs via P3, three 8-bit TTL programmable I/O ports via P2,

three TTL inputs via P1. Note that LogBook/360 has P1, P2, and P3 connectors on the motherboard

that are connected [by ribbon cable] to secondary P1, P2, and P3 connectors [located on the chassis

front panel]. LogBook/300’s P1, P2, and P3 are located on the rear panel.

•

LBK2 Analog Output (optional): This option provides four channels of analog output,

16-bit @ 100 kHz @ ±10 VDC.

•

LogBook/360 only, Interconnect Board, Card Drawer (for three DBK cards), and

three Terminal Panels.

•

Computer/Control/I/O – Includes: PARALLEL PORT (ECP Mode), SERIAL PORT (for RS-232

or RS-422/485), TERMINAL PORT (for LBK1 LogBook Remote Terminal option). In addition, for

LogBook/360 only, there is a COM Expansion Card with two serial ports (SERIAL AUX and

SERIAL GPS). These two ports are for connecting auxiliary serial devices, such as a Global

Positioning System.

System Software

LogBook software includes LogView, Upload Scheduler (optional), DIAdem-View, and PostView.

LogView and the Upload Scheduler are detailed in Chapters 3 and 4, respectively. DIAdem-View is

discussed in it’s own, separate user documentation. Appendix F covers PostView, which is similar to

DIAdem-View, but much more limited. Each of these programs is discussed briefly below.

•

•

•

•

LogView is a ready-to-use Windows program for data acquisition and logging. The program

provides a means of selecting channels, gains, transducer types, and various parameters. After setting

up the configuration on the PC, you must download the configuration file to LogBook’s PC-Card.

LogBook then uses the PC-Card to start the pre-configured acquisition. During an acquisition,

LogView can display channel values in a spreadsheet, bargraph, analog meter, or digital indicator.

LogBook data can be uploaded to your PC in various data formats (Excel™, SnapMaster™,

MATLAB™, DASYLab™, Lotus

®

, Quattro, and ASCII) for compatibility with virtually all

post-acquisition analysis software. LogView is detailed in chapter 3.

DIAdem-View provides a means of viewing and analyzing data via interactive graphics. The basic

DIAdem-View can be enhanced with optional software modules. Refer to the separate DIAdem

User’s Manual and the DIAdem on-line help for detailed information.

PostView is a post-acquisition waveform-display program. The program permits the simultaneous

viewing of up to 16 pre-recorded data channels. PostView allows you to expand, contract and

auto-scale waveforms, and scroll forward or backward on the time line. PostView is detailed in

Appendix F.

Upload Scheduler is an application that exists as part of the LogBook/Modem option. Upload

Scheduler allows you to configure upload events for one or more LogBooks. A scheduled event can

be configured to execute one time, or periodically, with no post-configuration intervention by the

user.

The Upload Scheduler is detailed in chapter 4.

1-6 System Considerations LogBook User’s Manual,

8-30-99

Page 29

Hardware-Related Details

g

g

g

PC-Card Swapping

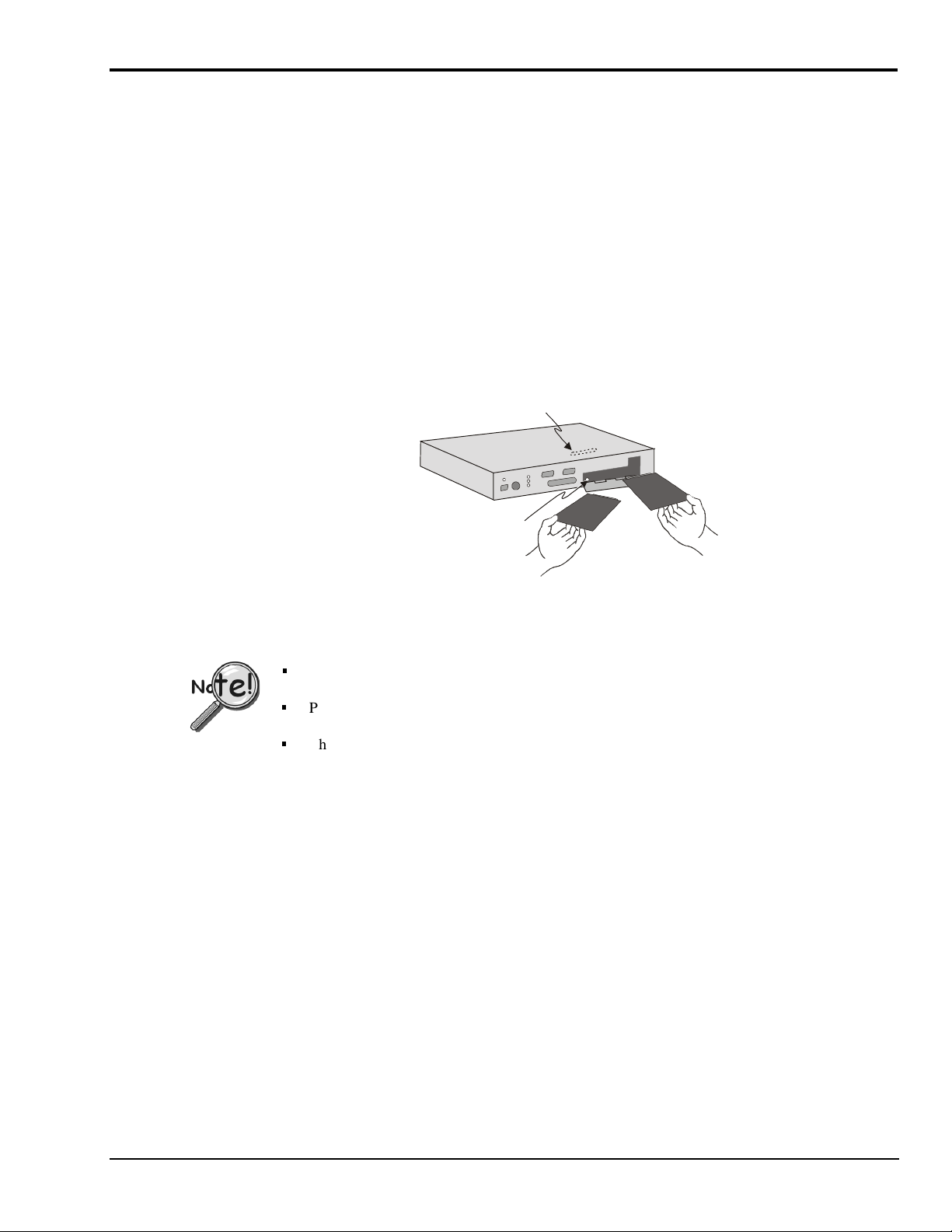

After the initial setup, you can interact with LogBook with PC-Cards. A safe-swap LED (inside the

PC-Card access door) lights when it is safe to change PC-Cards. You can also interact with LogBook using

the LBK1 Remote Terminal Panel option (discussed in chapter 4). The LBK1 option provides limited

LogBook control without use of the LogView program.

Note: during operation, LogView is the primary system interface for control and configuration.

You can change PC-Cards to load setup files, replace full cards, or transport data to an unattached PC.

When the PC-Card door is opened, a detector starts a preparatory routine to clean up files on the installed

disk. Within a few seconds, a green LED indicates it is safe to swap PC-Cards. Swapping should be done

quickly to prevent gaps in the recorded data. 4 MB RAM provides about

10 seconds at 100 kHz and 1.75 minutes at 10 kHz. 16 MB RAM provides over a minute at 100 kHz and

about 12 minutes at 10 kHz for one-channel scans.

Internal PC-Card socket (insert

card carefully to ensure

and prevent pin dama

ood connection

e)

Green LED indicates

ready for card exchan

Note

: Some models have PC-Card doors with right-edge hinges (not shown).

Swapping time is measured from when the door opens. Keep door closed unless you are in

the process of swapping cards.

PC-Cards must be pre-configured by LogView—if anticipating the need for multiple cards,

download the exact SAME ACQUISITION SETUP FILE to each PC-Card.

The PCMCIA slot accepts a Type I, II, or III hard-disk card or ATA flash-memory solid-state

card.

Physical/Environmental Conditions

LogBook/300 Dimensions: 8½ × 11 × 1-3/4 in. (216 × 279 × 44 mm). This enclosure has the same

footprint as the DBK modules for easy stacking of units.

LogBook/360 Dimensions: 14 × 11 × 3-7/16 in. (330 × 279 × 84 mm). The 11 inch width provides for

convenient stacking of DBK modules.

Operating temperature/humidity: 32° to 122°F (0° to 50°C) @ 0 to 95% RH, non-condensing.

Operation of the unit in environments exceeding these limits requires that a temperature-regulated

enclosure).

e

PC-Cards - remove

one and insert another

Swapping PC-Cards in a LogBook/300

Storage temperature: 32° to 176°F (0° to 80°C). The standard case is rugged but not designed for

immersion. Special enclosures are available for harsh environments.

All connectors, including the power connector, are locking. The D-sub connectors have thumbscrews and

the DIN5 power connector has a twist-lock ring to ensure solid connections are maintained.

LogBook User’s Manual,

8-30-99

System Considerations 1-7

Page 30

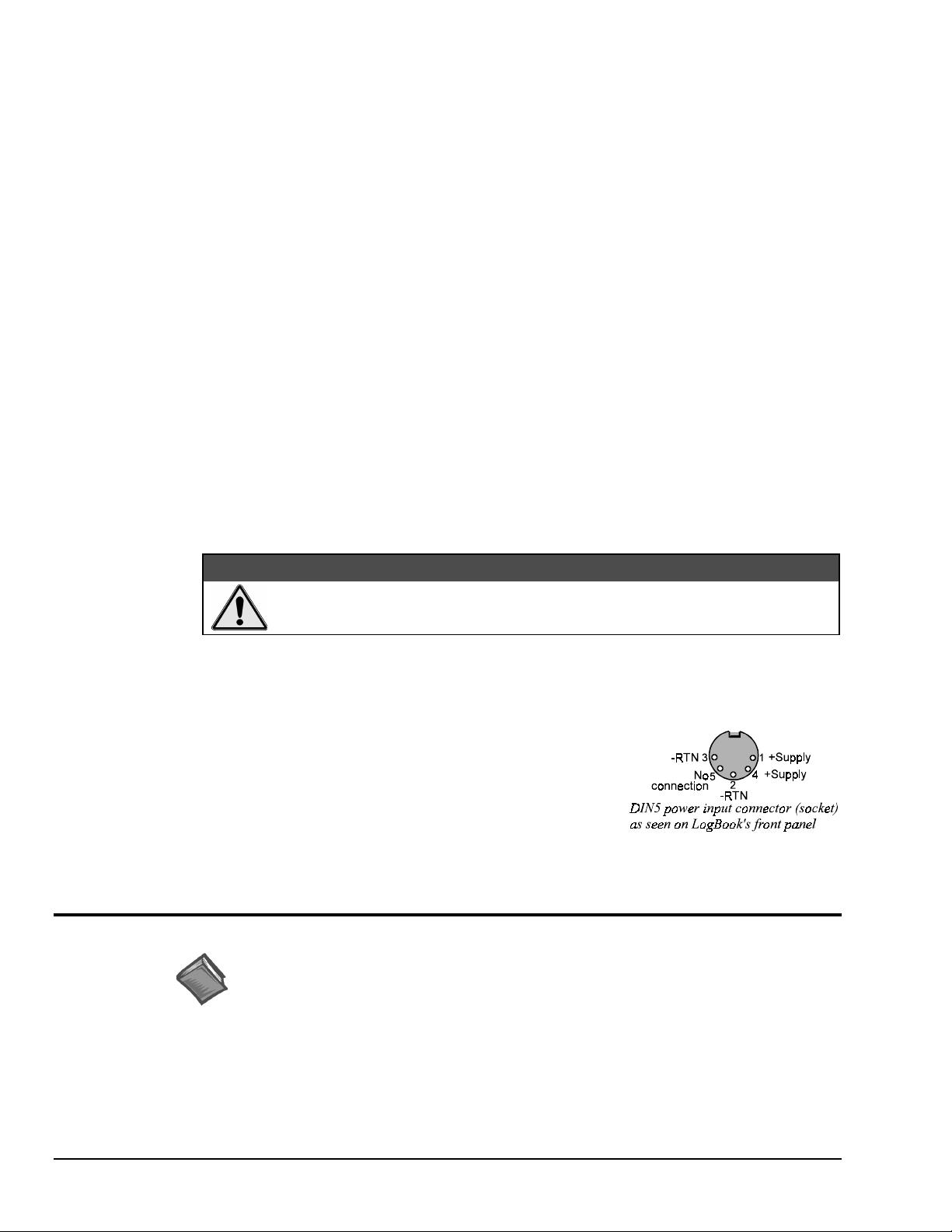

Power Supply

Power Input Connector

Internal Power Supply

AC-to-DC Adapter

UPS

LogBook’s front panel has a socket DIN5 connector to access power

(10 to 45 VDC at 0.3 to 7.0 A). The included AC-to-DC adapter

(TR-43) is recommended. However, various power supplies if properly

wired (see figure) can be used.

LogBook’s power supply is a switching design (pulse-width modulated). The input will accept 10-45 VDC

with a current range of 0.4 to 7.0 A. The input is protected by an 8 A fast-blow fuse. The fuse will open if

the input voltage is applied with the wrong polarity.

The power supply provides the necessary voltages to P1, P2, and P3 for use by DBKs. You can refer to the

P1, P2, and P3 pinouts (in this chapter) and to chapter 2, System Power, for detailed information.

An AC-to-DC adapter (TR-43) is provided with LogBook. This external, switching supply runs on

US/Europe/Japan input voltage ranges. Output voltage and power are sufficient to run the system in most

applications. Input: 90-260 V @ 50-60 Hz. Output: 15 VDC @ 2.3 A. If more power is needed, a

24 VDC, 2.2 A adapter (TR-44) is available as an option.

DBK34 is an optional uninterruptable Power Supply (UPS) that allows LogBook to operate for at least

30 minutes without any other source of power. This capability allows operation, for example, during

starting and after switch-off of an automobile. Control circuits keep the on-board batteries fully charged

when possible. For more information on the DBK34, refer to chapter 2, System Power.

Power Failure and Recovery

When power fails, LogBook preserves as much data as possible. LogBook also attempts to keep PC-Card

file formats and structures intact. Due disk drive latencies, power-supply limitations, and DOS file

structure, it may not be possible to finish the shutdown process before a complete loss of power occurs.

Note: Recovery will not occur when power is restored, unless the shutdown process was completed.

Note: The DBK34 Vehicle UPS is recommended for applications that are subject to power problems,

or are intolerant to down time. DBK34 is discussed in chapter 2, System Power.

Microprocessor

LogBook uses a high-integration microprocessor with up to 16 MB of memory (4 MB standard). The

microprocessor and a Field-Programmable Gate Array (FPGA) control all LogBook operations including

real-time control. Internal flash memory is used instead of EPROMs. This allows for field upgrades of

virtually all functions, including FPGA circuitry. Most software will be read from the disk drive.

Field-Installation Racks and Enclosures

A special rack (p/n Mount1) is available to attach the LBK1 (Remote Terminal Panel option) to the top of

LogBook. The LBK1 section of chapter 4 provides details. For applications in harsh environments, a

special enclosure can be used to shield the unit from water and thermal stress. Consult your sales rep or

factory for details.

1-8 System Considerations LogBook User’s Manual,

8-30-99

Page 31

P1, P2, P3 Port Connectors

LogBooks have three port connectors: P1, P2, and P3. For LogBook/300, these connectors are located on

the rear panel. For LogBook/360, they are on the front panel (see note). Connector pinouts begin on the

following page.

Note: LogBook/360 actually has two sets of these connectors, one set on the motherboard, and one on the

front panel. LogBook/360’s front panel P1, P2, and P3 connect to the motherboard P1, P2, and P3

via ribbon cables.

P1 (Analog Input)

LogBook’s P1 connector is compatible with all DBK options. Features and capabilities of P1 signals

include:

•

High-performance signal connection for: ±10 V and 0-20 V input ranges, gains from ×1 to ×64 (each

gain and range calibrated individually), and an input stage with low crosstalk, high dynamic

impedance, small signal injection.

•

All calibration is performed digitally; there are no pots to adjust.

•

The sequencer depth (the number of channel readings in a scan) is 1024 analog channels and 128

digital channels.

•

P1 includes an enhanced DBK-50 protocol that allows DBK cards or modules to identify themselves

and carry their own calibration data. These same connections can allow complete configuration of

DBK cards with that capability (allowing them to be jumperless).

For analog signal inputs via P1, do not exceed -35 VDC or +45 VDC or

equipment damage may result.

&$87,21

P2 (Digital I/O)

P2 is used with various kinds of digital I/O. For autonomous operation without an attached PC, the P2

outputs may be preset before the acquisition. The P2 digital outputs may be used as alarm outputs to

identify the detection of specified levels in the acquired data.

P3 (Pulse Frequency, High-Speed Digital I/O)

Features and capabilities of P3 signals include:

•

4 16-bit pulse counter channels, scanable along with analog inputs

•

Additional digital I/O control lines for high-speed digital input and output.

•

4 optional, internal, 16-bit ±10 V analog output channels (LBK2), useable for waveform or control

output, or additional control lines for external analog output expansion.

The 16 high-speed digital I/O lines, along with the additional digital I/O control lines can now be used for

real-time digital peripherals such as expanded digital input, or current or voltage DACs.

Optional, internal 4-channel 16-bit waveform/control ±10 V DACs on P3:

•

Initially setup to a static, preprogrammed voltage at the beginning of the acquisition.

•

In the future, may be used for waveform or control outputs.

The following tables give the pinout use for P1, P2, and P3.

LogBook User’s Manual,

8-30-99

System Considerations 1-9

Page 32

P1, P2, P3 Pinout Tables

You can connect signals to LogBook’s P1, P2, and P3 port connectors using a CA-37-x cable

(via a D-shell 37-pin female connector), or a DBK11 screw-terminal card with component sockets.

This page and the next two contain P1, P2, and P3 pinouts.

P1 – Analog I/O

Pin Signal Name Description for P1 Pin Use

1+5 PWR

2 -15 VDC with diode

3 CHS 3 Channel select line for expansion cards

4 CHS 1 Channel select line for expansion cards

5 GS 1 Gain select line for expansion cards

6 GS 0 Gain select line for expansion cards

7 POWER GND Digital ground

8 NEGREF (-5 V) -5.0000 VDC @ 0.005 A reference used for various DBKs

9 POSREF (+5 V) +5.0000 VDC @ 0.005 A reference used for calibration with optional 4-channel D/A board

10 N/C No Connection

11 CH 7 LO IN/CH 15 HI IN Ch 7 LO IN (differential mode)/ch 15 HI IN (single-ended mode)

12 CH 6 LO IN/CH 14 HI IN Ch 6 LO IN (differential mode)/ch 14 HI IN (single-ended mode)

13 CH 5 LO IN/CH 13 HI IN Ch 5 LO IN (differential mode)/ch 13 HI IN (single-ended mode)

14 CH 4 LO IN/CH 12 HI IN Ch 4 LO IN (differential mode)/ch 12 HI IN (single-ended mode)

15 CH 3 LO IN/CH 11 HI IN Ch 3 LO IN (differential mode)/ch 11 HI IN (single-ended mode)

16 CH 2 LO IN/CH 10 HI IN Ch 2 LO IN (differential mode)/ch 10 HI IN (single-ended mode)

17 CH 1 LO IN/CH 9 HI IN Ch 1 LO IN (differential mode)/ch 9 HI IN(single-ended mode)

18 CH 0 LO IN/CH 8 HI IN Ch 0 LO IN (differential mode)/ch 8 HI IN (single-ended mode)

19 L.L. GND Low-level ground (analog ground - use with analog inputs and outputs)

20 PCRCLK Pacer clock output/input

21 +15 VDC with diode

22 CHS 2 Channel select line for expansion cards

23 CHS 0 Channel select line for expansion cards

24 DIG IN 1 Digital input bit 1

25 DIG IN 0 External TTL trigger input

26 SSH Simultaneous Sample and Hold Output

27 CAL24 Calibration output (+24 V @ 0.010 A)

28 L.L. GND Low-level ground (analog ground - use with analog inputs and outputs)

29 L.L. GND Low-level ground (analog ground - use with analog inputs and outputs)

30 CH 7 HI IN Ch 7 HI IN (single-ended mode or differential mode)

31 CH 6 HI IN Ch 6 HI IN (single-ended mode or differential mode)

32 CH 5 HI IN Ch 5 HI IN (single-ended mode or differential mode)

33 CH 4 HI IN Ch 4 HI IN (single-ended mode or differential mode)

34 CH 3 HI IN Ch 3 HI IN (single-ended mode or differential mode)

35 CH 2 HI IN Ch 2 HI IN (single-ended mode or differential mode)

36 CH 1 HI IN Ch 1 HI IN (single-ended mode or differential mode)

37 CH 0 HI IN Ch 0 HI IN (single-ended mode or differential mode)

+5 V supply @ 0.100 A (Refer to chapter 2,

-15 V supply @ 0.150 A (Refer to chapter 2,

+15 V supply @ 0.150 A (Refer to chapter 2,

System Power

System Power

System Power

)

)

)

1-10 System Considerations LogBook User’s Manual,

8-30-99

Page 33

P2 Digital I/O

Pin Signal Name Description for P2 Pin Use

1 IR INPUT Interrupt line input (no functions to access this)

2 IR ENABLE Interrupt line enable (no functions to access this)

3 PORT B 7 Digital input/output – port B bit 7

4 PORT B 6 Digital input/output – port B bit 6

5 PORT B 5 Digital input/output – port B bit 5

6 PORT B 4 Digital input/output – port B bit 4

7 PORT B 3 Digital input/output – port B bit 3

8 PORT B 2 Digital input/output – port B bit 2

9 PORT B 1 Digital input/output – port B bit 1

10 PORT B 0 Digital input/output – port B bit 0

11 GND Digital ground

12 N/C Pin not connected/not used

13 GND Digital ground

14 N/C Pin not connected/not used

15 GND Digital ground

16 N/C Pin not connected/not used

17 GND Digital ground

18 +5 V

19 GND Digital ground

20 +5 V

21 GND Digital ground

22 PORT C 7 Digital input/output – port C bit 7

23 PORT C 6 Digital input/output – port C bit 6

24 PORT C 5 Digital input/output – port C bit 5

25 PORT C 4 Digital input/output – port C bit 4

26 PORT C 3 Digital input/output – port C bit 3

27 PORT C 2 Digital input/output – port C bit 2

28 PORT C 1 Digital input/output – port C bit 1

29 PORT C 0 Digital input/output – port C bit 0

30 PORT A 7 Digital input/output – port A bit 7

31 PORT A 6 Digital input/output – port A bit 6

32 PORT A 5 Digital input/output – port A bit 5

33 PORT A 4 Digital input/output – port A bit 4

34 PORT A 3 Digital input/output – port A bit 3

35 PORT A 2 Digital input/output – port A bit 2

36 PORT A 1 Digital input/output – port A bit 1

37 PORT A 0 Digital input/output – port A bit 0

No local lines are available if digital expansion cards are in use.

Note:

+5 V supply @ 0.100 A (Refer to chapter 2,

+5 V supply @ 0.100 A (Refer to chapter 2,

System Power

System Power

)

)

LogBook User’s Manual,

8-30-99

System Considerations 1-11

Page 34

P3 -

Pulse

Frequency/

High-Speed

Digital I/O

Pin Signal Name Description for P3 Pin Use

1 IR INPUT Interrupt line input

2 IR ENABLE Interrupt line enable

3 HSD 7 High-speed digital I/O bit 7 (low byte)

4 HSD 6 High-speed digital I/O bit 6 (low byte)

5 HSD 5 High-speed digital I/O bit 5 (low byte)

6 HSD 4 High-speed digital I/O bit 4 (low byte)

7 HSD 3 High-speed digital I/O bit 3 (low byte)

8 HSD 2 High-speed digital I/O bit 2 (low byte)

9 HSD 1 High-speed digital I/O bit 1 (low byte)

10 HSD 0 High-speed digital I/O bit 0 (low byte)

11 GND Digital ground

12 C/D13 WR14 RD15 TMR 0 OUT Timer 0 output

16 TMR 1 OUT Timer 1 output

17 CNT 2 IN Counter 2 input

18 CNT 0 IN Counter 0 input

19 +15 VDC

20 +5 V

21 N/C Pin not connected/not used

22 HSD 15 High-speed digital I/O bit 15 (high byte)

23 HSD 14 High-speed digital I/O bit 14 (high byte)

24 HSD 13 High-speed digital I/O bit 13 (high byte)

25 HSD 12 High-speed digital I/O bit 12 (high byte)

26 HSD 11 High-speed digital I/O bit 11 (high byte)

27 HSD 10 High-speed digital I/O bit 10 (high byte)

28 HSD 9 High-speed digital I/O bit 9 (high byte)

29 HSD 8 High-speed digital I/O bit 8 (high byte)

30 AGND Analog ground

31 AOUT0 / Scan Analog output 0, optional LBK2: 16-bit, 100 kHz, ±10 VDC DAC

32 AOUT1 / Trigger Analog output 1, optional LBK2: 16-bit, 100 kHz, ±10 VDC DAC

33 AOUT2 / Clock Analog output 2, optional LBK2: 16-bit, 100 kHz, ±10 VDC DAC

34 AOUT3 / DigOut Analog output 3, optional LBK2: 16-bit, 100 kHz, ±10 VDC DAC

35 CNT 3 IN Counter 3 input

36 CNT 1 IN Counter 1 input

37 -15 VDC

+15 V supply @ 0.050 A (Refer to chapter 2,

+5 V supply @ 0.100 A (Refer to chapter 2,

-15 V supply @ 0.050 A (Refer to chapter 2,

System Power

System Power

System Power

)

)

)

1-12 System Considerations LogBook User’s Manual,

8-30-99

Page 35

System Setup and Expansion Options

Steps to Review

A review of the following steps can help you decide what type of setup best suits your application.

Specifics of your actual application may alter the order and complexity of these steps. These steps should

be reviewed prior to expanding a LogBook system.

1. Determine what data you need and how data will be used and saved. What units, ranges,

sampling rates, etc are best for your needs? Will the data be charted graphically, statistically

processed, or exported to other programs? Are secondary uses envisioned for a later date? Begin by

analyzing the end use of the data and then working backwards to how you must collect it.

Determine the channel assignments, and layout the whole system plan. Typically, a hand-drawn

2.

pencil sketch can effectively note all system components and their relation to the others; however, a

computer-drawn plan can be more useful in a complex system or one that will undergo frequent

modification. Plan out the location of transducers, cable runs, DBKs, LogBook, and the computer.

Assign channel-numbers and apply labels to your transducers, cables, and connectors.

A well-documented and labeled system prevents confusion later on (especially helpful for

troubleshooting and system expansion).

3. Configure all the DBK cards and modules for your application. Some DBKs are configured by

software; however, on other DBKs, jumpers and DIP switches may need to be set manually (channel,

gain, filters, signal mode, etc). Perform all hardware configurations before connecting signal and

power lines.

4. Route and connect all signal and power cables while all power is turned OFF. To minimize

noise, route all signal lines away from any RF, high-voltage, or strong magnetic fields (motors, etc).

The IOtech Signal Conditioning Handbook (ISBN 0-9656789-0-3) contains excellent guidance in

this area.

Additional power may be required for systems that use several DBKs [or transducers].

Chapter 2 contains power supply information and includes a “DBK Power Requirement

Worktable.”

Configure LogBook (most settings are made in software). The software must recognize all the

5.

hardware in the system. Set all channels in the proper mode for the attached signal source; and

configure LogView to use measurement units and ranges that suit your purpose.

6. Energize LogBook and DBKs, and initiate a data acquisition.

7. Verify proper data acquisition and storage. Can data be acquired, stored, retrieved, and used as

needed?

Verify system accuracy; perform calibration or equipment adjustment as required.

8.

Reference Notes: You may need to refer to additional sections of this manual.

Chapter 2, for calculating system power and ensuring an adequate power supply.

The chapter contains information regarding DBK30A, DBK32A, DBK33, and DBK44.

Chapter 4, if using LBK options.

Chapter 5, if using DBK expansion options.

Expansion Configurations

LBK Options

The following LBK options are detailed in chapter 4.

•

LBK/COM/422/485, RS-232 Board with an RS-422/485 Option

•

LBKMEM1 or LBKMEM1U, 16 MB DRAM Memory Expansion

•

LBK1, a Remote Terminal with LCD screen for viewing system status,

and a keypad to control the system’s basic operation when no PC is attached.

•

LBK2, a 4-channel Digital-to-Analog Output card.

LBK2 has four 16-bit, high-speed (100 kHz) ±10 V analog outputs.

•

LogBook/GPS, Global Positioning System Support, LogBook/360 Only

•

LogBook/Modem, Modem and Upload Scheduler Software Support

LogBook User’s Manual,

8-30-99

System Considerations 1-13

Page 36

DBK Options

DBK cards and modules provide options for signal conditioning, analog output, system I/O, auxiliary

power, and expansion. Various sensor types are accommodated, including high-voltage/current, strain

gages, thermocouples, isolation, relays, accelerometers, filtering, and simultaneous sample and hold. A list

of more than 30 DBK options is provided on the following page.

Reference Notes:

Power-related DBKs are discussed in chapter 2.

Signal-conditioning related DBKs are discussed in chapter 5.

Note:

Modules attach to P1 or P2. Module footprints match that of LogBook, allowing for easy stacking.

DBK Option Cards and Modules

Product Name/Description Capacity

Analog Signal Conditioning (see chapter 5, DBK Expansion Options)

DBK4 Dynamic Signal Input Card 2 channels

DBK7 Frequency-to-Voltage Input Card 4 channels

DBK8 High-Voltage Input Card 8 channels

DBK9 RTD Measurement Card 8 channels

DBK12 Low-Gain Analog Multiplexing Card 16 channels

DBK13 High-Gain Analog Multiplexing Card 16 channels

DBK15 Universal Current/Voltage Input Card 16 channels

DBK16 Strain-Gage Measurement Card 2 channels

DBK17 Simultaneous Sample & Hold Card 4 channels

DBK18 Low-Pass Filter Card 4 channels

DBK19 High-Accuracy Thermocouple Card 14 channels

DBK42 5B Isolated Signal-Conditioning Module 16 channels

DBK43A Strain-Gage Measurement Module 8 channels

DBK44 5B Isolated Signal-Conditioning Card 2 channels

DBK45 SSH and Low-Pass Filter Card 4 channels

DBK50 Isolated High-Voltage Input Module 8 channels

DBK51 Isolated Low-Voltage Input Module 8 channels