Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

FTB8000A SERIES

Pulse Mete r

Shop online at

User’s Guide

Page 2

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified

Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified

Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com i n f o @ o m e g a . c o m

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

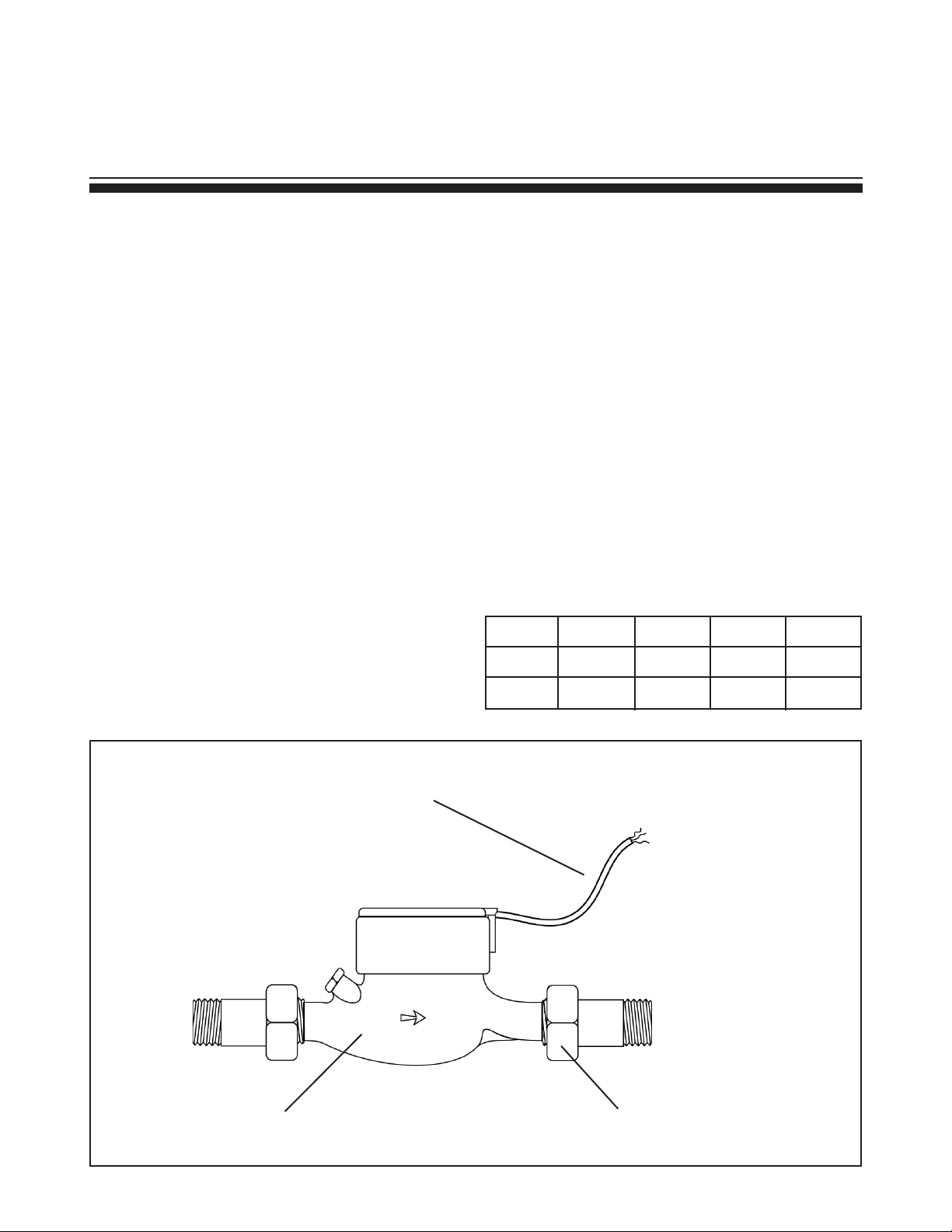

FTB8000A - SERIES

Pulse Meter Instructions

General Information

FTB8000A-Series meters use the multi-jet principle,

which has been an internationally-accepted standard

for many years. This type of meter is known for its wide

range, simplicity, and accuracy in low-quality water. The

impeller is centered in a ring of jets, with inlet jets on

one level and outlet jets on another. A gear train drives

the register totalizer dials. For pulse output, one of the

dials is replaced by a gear, which turns a magnet that

is detected by an encapsulated sensor threaded into

the outside of the lens. Pulse rate is determined by the

gear and the dial on which the gear is placed.

Mechanically, all FTB8000A-Series meters are the

same. The difference between -PR, -PT and Standard

meters is in the sensor. -PR meters use a solid-state,

long-lasting Hall-effect sensor, which requires power.

-PT meters use a two-wire reed switch. They provide a

dry contact closure and do not require power. Standard

meters totalize only and do not have a sensor.

Specications

Materials

Case Cast bronze

Internals Engineered thermoplastic

Magnet Ceramic permanent

Temperature 105° F, 40° C

Max. Pressure 150 PSI operating

Accuracy 1-1/2% of reading

Sensor

-PR Solid state

-PT Reed switch

Max. Current

-PR 20 mA

-PT 50 mA

Max. Voltage

-PR 24 VDC

-PT 24 VDC or 24 VAC

Sensor Power -PR Minimum 6 mA at 12 VDC

Cable Length 18 ft. standard, 2,000 ft. max.

Flow Rates (GPM):

3/4" 1" 1-1/2" 2"

Minimum 0.22 0.44 0.88 1.98

Features

Either -PR or -PT sensor

threads into lens without

removing top

Cast bronze body-

meets AWWA

specications

Maximum 22 52 88 132

Union end couplings for

easy service

Page 1

Page 4

(BLACK) Power (-)

(BROWN) Common

(WHITE) Signal

(WHITE) N.O.

(RED) Power (+) 6-24 VDC

sensor connection

MDR sensor connection

MDE

Installation

WARNING

DO NOT INSTALL

meter in overhead

Indoor piping or where

leakage

may cause damage

These water meters are not

recommended for installation

indoors or anywhere leakage

may cause damage.

the lens. The sensor turns on and off once each time

the magnet passes under it. Sensors are designed for

electronic control loads, and should not be used to switch

power loads or line voltages. See maximum current and

voltage ratings, under Specications.

Maintenance

All service should be performed by authorized distributor or factory to maintain the integrity of the protective

tamper-proof wire-and-seal.

Position. FTB8000A-Series meters should be installed

horizontally with the register up. Vertical mounting will

result in some degree of under-measurement and shortened life of the bearings.

Couplings. Couplings are included with each meter.

These provide male NPT threads the same nominal

size as the meter. The threads on the end of the meter

are IPS straight threads one size bigger than the meter

size. It is possible to thread a standard pipe coupling

directly onto the meter for close coupling, but the meter

couplings are much preferable because they provide a

union connection for meter service. Be sure to use the

included gasket between the end of the meter and the

coupling.

Inlet Conditions. No upstream straight pipe is required.

A strainer is built in to protect from solids, and should be

periodically cleaned.

Air Bleed. When the meter is rst installed, trapped air

should be removed. To do this, loosen the meter couplings slightly and rotate the meter to an inverted posi-

tion. Allow water to ow, then rotate the meter back

to an upright position and tighten.

Connections. -PR and -PT sensors are supplied with

a color coded output cable. See the diagram for color

codes and polarity.

Pulse Output. Both -PR and -PT sensors respond to

a magnet which rotates on the face of the meter under

Inlet Strainer. Clean the strainer yearly, or as required,

depending on water condition. Pull out the strainer or

backush the meter to loosen trapped particulates.

Calibration. Meters used for billing or billing exemption may be regulated by state or local authorities. New

meters are factory-tested to meet the AWWA C-708

Multi-Jet Meter accuracy specication. Some states

require retesting at various intervals, typically eight years

for 3/4" meters, six for 1", and four for 1-1/2" and 2". Meters used for control should be tested every 5-10 years.

Testing can be done by local meter shops authorized for

this purpose, or can be done by the factory. For tracking purposes, please obtain an Authorized Return (AR)

number before shipping to Omega.

Internal Parts Replacement. All of the internal parts

of an FTB8000A-Series meter lift out as a unit, after the

top has been unscrewed. The lens can then be removed

and the internal assembly lifted out. If necessary, turn

the meter upside down and tap one end lightly on a

countertop to loosen the internals. The three pieces of

the assembly can be separated by hand.

Breakage in a relatively-new meter is almost always due

to excessive ow. Compare maximum ow with the ow

rating table.

Changing Pulse Rates. After removing the meter top,

lift off the center magnet to expose the gears. If the only

change required is moving the drive gear (for example

from one gallon/pulse to ten gallons/pulse), gently pull

the drive gear off its shaft. Remove the pointer on the

target shaft and push the drive gear onto the target shaft

as far as it will go. Put the pointer on the vacant shaft

and push on.

Page 2

If a different gear set is required, follow the same procedure, replacing rather than moving the drive gear. To

install a drive gear on another shaft, remove the pointer

and then press the gear down until it bottoms. Use the

pulse rate chart to determine the position.

Page 5

3/4" - 10 gallons/pulse

Pulse

Rate

Drive Gear

Position

Gear Set

(X...)

20 P/G

*

2

10 P/G 1

2 P/G X0.1 2

1 P/G X0.1 1

3/4"

5 G/P X1 2

10 G/P X1 1

50 G/P X10 2

100 G/P X10 1

20 P/G

*

2

10 P/G

*

1

2 P/G X0.1 2

1"

1-1/2"

2"

1 P/G X0.1 1

5 G/P X1 2

10 G/P X1 1

50 G/P X10 2

100 G/P X10 1

2 P/G 2

1 P/G 1

5 G/P X1 2

10 G/P X1 1

50 G/P X10 2

100 G/P X10 1

500 G/P X100 2

1000 G/P X100 1

2 P/G 2

1 P/G 1

5 G/P X1 2

10 G/P X1 1

50 G/P X10 2

100 G/P X10 1

500 G/P X100 2

1000 G/P X100 1

* Unlabeled position

*

*

*

*

*

Standard

(X1) gearset

move

gear to

match

X1 Drive gear on

position

*Unlabelled position

3/4" - 50 gallons/pulse

X2 gearset

X10 Drive

gear on

position

3/4" - 1 gallon/pulse

X2 gearset

X0.1 Drive gear

on position

Page 3

Page 6

FTB8000A-Series

Parts

reed switch

w/cable

cap screw

(over)

calibration plug

(under)

strainer

slip ring

pair

lens

register

assembly

O-ring

multi-jet

assembly

FTB8000A-SERIES PARTS

Part # FOR ALL SIZES

30387 Gear Assembly, x1

30342 Gear Assembly, x2

30290 Hinge Pin

30293 Lens, Glass

30289 Lid

30296 O-ring

30300 Pickup, Reed Switch, 12' Cable

30346 Pickup, Solid State, 12' Cable, MDE

30292 Slip Ring (pair)

Part # FOR 3/4" METERS

16125 Calibration Plug

16105 Cap Screw for Calibration Plug

30381 Coupling Assembly (2 required)

30416 Coupling Gasket (2 required)

30311 Multi-jet Assembly

30308 Register Assembly

30479 Strainer

Part # FOR 1" METERS

16125 Calibration Plug

16105 Calibration Plug Cap Screw

30382 Coupling Assembly (2 required)

30417 Coupling Gasket (2 required)

30297 Drive Magnet

30323 Multi-jet Assembly

30321 Register Assembly

30480 Strainer

Part # FOR 1-1/2" METERS

30303 Calibration Plug

30305 Calibration Plug Cap Screw

30383 Coupling Assembly (2 required)

30418 Coupling Gasket (2 required)

30297 Drive Magnet

30304 Gasket

30332 Multi-jet Assembly

30330 Register Assembly

30481 Strainer

Part # FOR 2" METERS

30303 Calibration Plug

30305 Calibration Plug Cap Screw

30384 Coupling Assembly (2 required)

30419 Coupling Gasket (2 required)

30297 Drive Magnet

30304 Gasket

30326 Multi-jet Assembly

30328 Register Assembly

16240 Strainer

Page 4

Page 7

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months f rom date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be re t u rned to the factory for evaluation. O M E G A’s Customer Serv i c e

D e p a rtment will issue an Authorized Return (AR) number immediately upon phone or written re q u e s t .

Upon examination by OMEGA, if the unit is found to be defective, it will be re p a i red or replaced at no

c h a rge. O M E G A’s WARRANTY does not apply to defects resulting from any action of the purc h a s e r,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

i m p roper re p a i r, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corro s i o n ;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s c o n t rol. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

R E P R E S E N TATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTA B I L I T Y

AND FITNESS FOR A PA RTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

L I A B I L I T Y: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this ord e r, whether based on contract, warr a n t y, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon wh ich lia bility is ba sed. I n no even t s hal l O MEGA b e liab le for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

a c t i v i t y, medical application, used on humans, or misused in any way, OMEGA assumes no re s p o n s i b i l i t y

as set forth in our basic WA R R A N TY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA h a rmless from any liability or damage whatsoever arising out of the use of the

P roduct(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NU M B ER F ROM OMEGA’S CU S TO M E R S E RVICE DEPA RT M E N T ( IN ORDER TO AV O I D

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1 . P u rchase Order number under which the pro d u c t

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 8

W h e re Do I Find Eve rything I Need for

P rocess Measurement and Control?

OME GA…Of Cours e !

Shop online at omega.com

T E M P E R AT U R E

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FO RC E

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

F LOW / L E V E L

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

p H / C O N D U C T I V I TY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA AC Q U I S I T I O N

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

H E AT E R S

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

E N V I RO N M E N TA L

M O N I TORING AND CONTRO L

Metering & Control Instrumentation

R e f r a c t o m e t e r s

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

LT-12001-B

M-3958/0505

Loading...

Loading...