Page 1

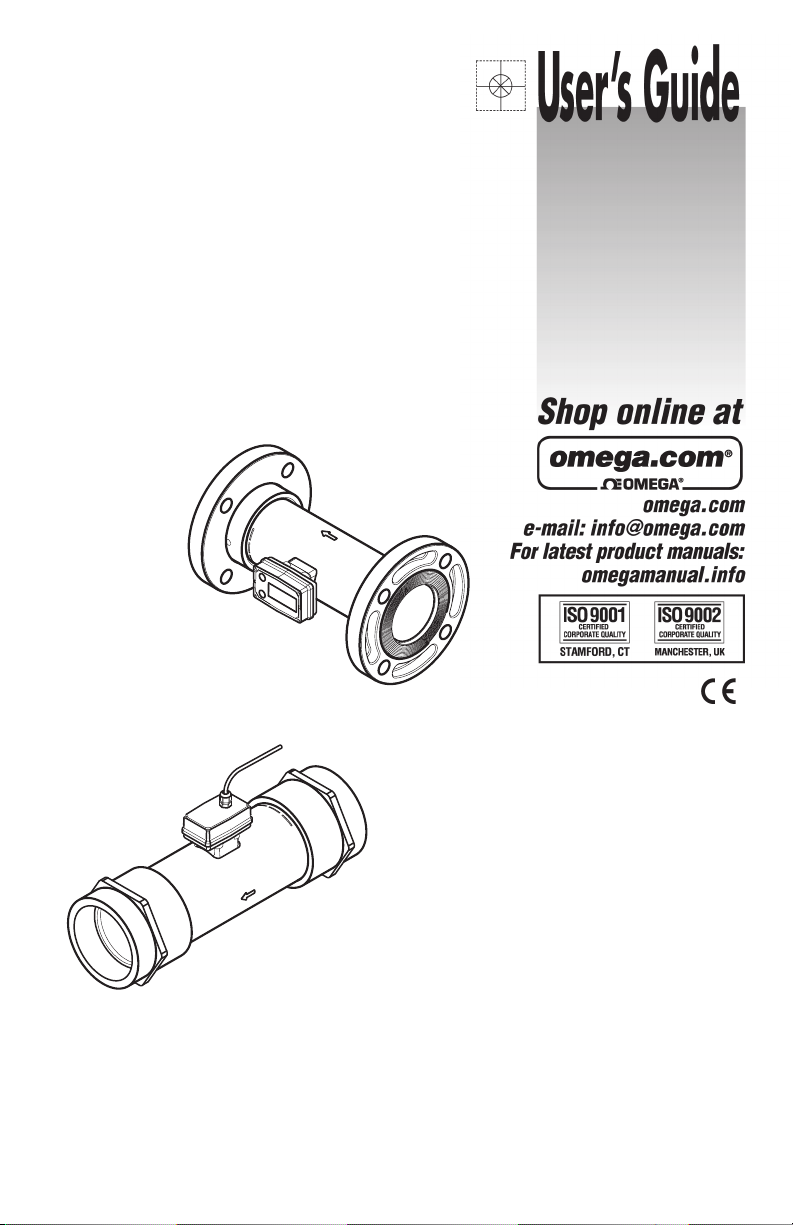

Meter with

Computer Display

FTB696A through FTB697A

Digital Pulse Meter

Electronic Water Meters

Page 2

Page 3

TABLE OF CONTENTS

English ...........................................................1

Español ..........................................................7

Deutsch .......................................................13

Italiano .........................................................20

Français .......................................................26

E N G L I S H

IMPORTANT NOTICE

Use these meters with water and other chemicals compatible with wetted components (see

Specifications Section). Do not use to meter

fuel or incompatible chemicals. Omega meters

are available with either a computer for local

electronic display, or a conditioned signal output

module to provide a digital signal to customer

interfacing equipment. Omega meters with

computer display measure in gallons or litres.

Refer to the Calibration Section for details.

These meters are not legal for trade applications.

Omega meters are very sensitive to electric

noise if operated within 1 to 2 inches of some

electric motors or other sources of electronic

noise.

INSTALLATION

Connections

Install your meter in-line either horizontally or

vertically or at the end of the hose adjacent to

the nozzle. Installation to metal connections is

not recommended. Install as follows:

1. Plan to install turbine with a minimum

straight pipe length as follows:

• Upstream from the turbine, allow a mini-

mum straight pipe length of 10 times the

internal diameter of the turbine.

• Downstream from the turbine, allow a

minimum straight pipe length of 5 times

the internal diameter of the turbine.

2. For NPT Fittings wrap all connections with

3 to 4 wraps of thread tape. Make sure the

tape does not intrude into the flow path.

3. Attach meter with arrow pointed in the

direction of flow.

4. For NPT Fittings - Hand tighten the meter

at the housing ends. Do not use a wrench

or similar tool to tighten. This can damage

the housing.

5. For Flange Fittings - Customer to provide:

• Ring Gaskets or Full-Face Gaskets ap-

proved for use with ANSI flanges and the

fluid being monitored (2 required).

• 5/8" bolts and nuts: 4 per side for 3-inch

meters; 8 per side for 4-inch meters.

Torque bolts using a star pattern to 25 ft-lbs.

Supplied flanges are two-piece and allow

the meter to be oriented regardless of the

mating flanges position.

Conditioned Signal Output

Module Wiring

This conditioned signal output module can be

wired to provide an open collector signal output

or 6-volt square wave output.

Open Collector Signal Output

To achieve an open collector signal output,

reference Wiring Diagram 1. The terminal block

is located on the back side of the module. The

module is factory assembled for open collector signal output. Please provide the (820 ohm

minimum) resistor.

Ten feet (3 m) of cable is provided with the

module. Trim it to desired length or extend it as

necessary. Distances up to 5,000 feet (1,524 m)

can be achieved for open collector signal output.

Square Wave Output

To achieve square wave output, reference

Wiring Diagram 2 and use an Electronic Digital

Meter Battery Kit (sold separately) for battery

power. The terminal block and battery location

are located on the back side of the module.

Access as follows:

1. Remove the four Phillips-head screws from

the front of the module and lift the module

from the turbine.

1

Page 4

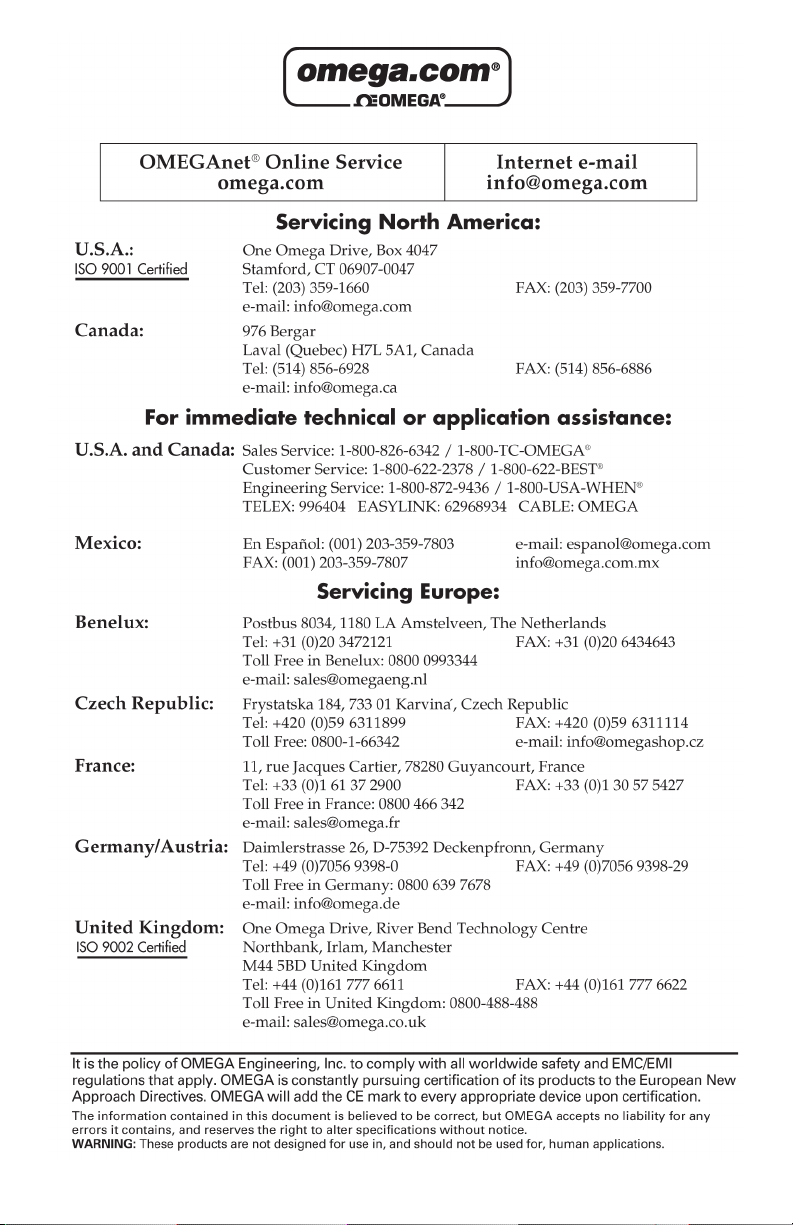

Wiring Diagram 1

+9 to 35 volt DC

Open Collector

Signal

3

2

1

4

Red

White

Black

Common

(Ground)

Terminal

Block

Customer

Interfacing

Equipment

The terminal block is identified as follows:

Pin #1 6 volt square wave (not used)

Pin #2 +9 to 35 volt DC Input

Pin #3 Common Ground

Pin #4 Open Collector signal Output

Resistor

3

2

1

4

White

Black

Common

(Ground)

Terminal

Block

Customer

Interfacing

Equipment

6 volt Square

Wave Signal

The terminal block is identified as follows:

Pin #1 6 volt square wave

Pin #2 +9 to 35 volt DC Input (not used)

Pin #3 Common Ground

Pin #4 Open Collector signal Output (not used)

OPEN COLLECTOR SIGNAL OUTPUT

Wiring Diagram 2

2

SQUARE WAVE OUTPUT

Page 5

2. To change terminal block connections,

loosen the appropriate screws. Reconnect

the wires in the proper positions and tighten

the screws.

3. Install the batteries. Make sure the positive

post is in the correct position.

4. Position the module on the turbine housing.

To avoid moisture damage, make sure the

seal is fully seated. Tighten the four screws

on the front of the module.

Ten feet (3 m) of cable is provided with the

module. Trim the cable to desired length or

extend it as necessary.

Verify Meter Accuracy

Before using, check the meter’s accuracy and

verify calibration.

1. Make sure there is no air in the system

by starting the flow until it runs steadily.

Then, stop or divert the flow using a valve

or nozzle.

2. Meter an exact known volume into an accurate container. For best results, meter

with one continuous full stream.

3. Check the volume against the display or

recording equipment. If the amount metered

is accurate, further calibration is not necessary. If not, refer to the Calibration Section

for further instructions.

OPERATION

Computer Display –

Batch and Cumulative Totals

The computer maintains two totals. The Cumulative Total provides continuous measurement and

cannot be manually reset. The Batch Total can

be reset to measure flow during a single use.

The Cumulative Total is labeled with TOTAL 1,

Batch Total is labeled TOTAL 2 BATCH.

When the Cumulative Total reaches a display

reading of 999,999 the computer will highlight

an X10 icon. This indicates to the operator that

a zero must be added to the 6 digits shown.

When the next rollover occurs, the computer

will highlight an X100 icon. This indicates to the

operator that two zeroes must be added to the

6 digits shown.

Press the DISPLAY button briefly to switch

between the TOTAL 1, TOTAL 2 BATCH and

FLOWRATE. Press DISPLAY briefly to display

the TOTAL 2 BATCH. Hold the DISPLAY button

for 3 seconds to reset the Batch Total to zero.

When fluid is flowing through the meter, a small

propeller icon is highlighted.

NOTE: Totalization counts total units without

differentiating between gallons, litres or

field calibrated units.

Flowrate Feature

To use this feature, press and release DISPLAY

until FLOWRATE icon appears. The factory

set time base will be highlighted to the right of

FLOWRATE (M = minutes, H = hours, D = days).

When FLOWRATE is invoked, the display will

be indicating rate of flow.

Activate the Meter

Computer is on continuously and always ready

to perform. The computer is powered by field

replaceable batteries. When display becomes

dim, faded or the low battery message appears

(see below), the batteries need to be replaced.

Reference the Maintenance Section for details.

Factory and Field Calibration

All calibration information is visible to the user

as icons on the top line of the display, above

the numeric digits.

All units are configured with a “factory” calibration. Both gallons and litres are available (“GL”

or “LT” will be displayed). While holding the

CALIBRATE button, briefly press DISPLAY to

toggle between gallons and litres. This factory

calibration (indicated with FAC) is permanently

programmed into the computer and is not user

adjustable.

NOTE: Your computer may have other units of

measure programmed into it. If so, holding

the CALIBRATE button and momentarily

pressing the DISPLAY button will toggle

through all factory set units. Other possible units are: IGL (imperial gallon), QT

(quart), CF (cubic feet), CM (cubic meter),

BL (42 gal. barrel), CC (cubic centimeter)

or OZ (ounce).

3

Page 6

Switching between different units will not corrupt

the Total’s contents. For example, in GL mode,

the computer totalizes 10.00 gallons, if the user

switches to LT mode, the display will read 37.85

litres (the same volume, different unit).

The “field” calibration may be set by the user,

and can be changed or modified at any time

using the calibration procedure described below

in the Calibration Section. Totals or flowrate

derived from the field calibration are invoked

when the FAC icon is no longer visible on the

top line of the display.

CALIBRATION

Verify Accuracy Before

Beginning Field Calibration

For the most accurate results, dispense at a

flowrate which best simulates your actual operating conditions. Avoid “dribbling” more fluid or

repeatedly starting and stopping the flow. This

can result in less accurate calibrations.

Make sure you meet the meter’s minimum

flowrate requirements:

Omega Meters

3 inch meter 30 GPM (113.6 LPM)

4 inch meter 40 GPM (151.4 LPM)

The use of a uniformly dependable, accurate

calibration container is recommended for the

most accurate results. Due to high flowrate, it

is strongly recommended that calibration be

completed with a combination of volume and

weight using fine resolution scales.

For best results, the meter should be installed

and purged of air before field calibration.

Field Calibration with

Computer Display

Field Calibration and Factory Calibration are

defined in the Operation Section. Factory

calibration settings are programmed into each

computer during manufacturing, using water

at 70° F (21° C). Readings using the Factory

Calibration (FAC) may not be accurate in some

situations, for example, under extreme temperature conditions, non-standard plumbing

configurations or with fluids other than water.

Field Calibration Procedures

(Correction Factor Method)

1. To calibrate, press and hold the CALIBRATE

and DISPLAY buttons for about 3 seconds

until you see FLdCAL. Release both buttons

and you will see CF - 00.0. You are now in

the field calibration mode and values from

-99.9% to +99.9% can be entered.

+

2. The

3. The DISPLAY button can then be pushed

4. All enabled units-of-measure remain visible

5. To return to factory calibration (FAC), press

/– position appears either as an

“underscore” character for plus, or as a

“hyphen” character for minus. The DISPLAY button selects the position and the

CALIBRATE button toggles this character.

to select the numeric positions. Press the

CALIBRATE button to scroll from 0 to 9.

Enter the percentage of change you want

the display to correct. When satisfied with

the value, press both CALIBRATE and

DISPLAY buttons simultaneously. CALEnd

will be displayed and unit will go back to

normal operation, less the FAC (factory

calibration) icon.

and selectable – the entered correction will

be applied to all enabled units.

and hold both CALIBRATE and DISPLAY

buttons for about 3 seconds until FAcCAL

is displayed. Then release buttons. Unit

should return to normal operation and FAC

icon is visible.

Calibration with Conditioned

Signal Output Module

The K-factor of your meter appears on the

calibration report as the number of pulses per

gallon. The factor is determined during production using water at 70° F (21° C). This K-factor

may be used for “single point” calibration

and provide acceptable accuracy. However,

readings may not be accurate when using this

calibration method in some situations. For

example, extreme temperature conditions,

non-standard plumbing configurations or with

fluids other than water.

4

Page 7

MAINTENANCE

Proper handling and care will extend the life

and service of the meter.

Turbine Rotor

The meter is virtually maintenance-free. However, it is important the rotor moves freely. Keep

the meter clean and free of contaminants.

The rotor can be removed for cleaning and

inspection. Begin by unscrewing the nose cone

from the outlet end of the meter. A 1/4" square

socket extension can be used. Remove the

lock and flat thrust washers. Rotor can then be

removed from shaft. Note orientation because

rotor is not bi-directional. Remove debris or

deposits using soft brush or small probe. Reassemble in reverse order.

CAUTION

Blowing compressed air through the turbine

assembly could damage the rotor.

Battery Replacement

The computer display is powered by two

3-volt lithium batteries which may be replaced

while the meter is installed. When batteries are

removed or lose power, the batch and cumulative totals and the field and factory calibrations

are re tained.

If the display becomes dim, blank or the low

battery message appears (see below), replace

the batteries as follows:

1. Remove the four Phillips-head screws from

the face of the meter and lift the faceplate

from the turbine.

2. Remove the old batteries and clean any

corrosion from the terminals.

3. Install new batteries. Make sure the positive

post is in the correct position.

4. When the batteries are replaced, the faceplate will power ON. Check the display to

ensure normal functions have resumed

before assembling again.

5. Reseat batteries, if necessary, and position the faceplate on the turbine housing.

To avoid moisture damage, make sure the

seal is fully seated. Tighten the four screws

on the faceplate.

SPECIFICATIONS

Inlet and Outlet:

NPT Models:

FTB696A-NPT/

FTB696A-NPT-P 3 inch NPT

FTB697A-NPT/

FTB697A-NPT-P 4 inch NPT

Flange Models:

FTB696A-F/

FTB696A-F-P 3 inch 150# ANSI

Flange

FTB697A-F/

FTB697A-F-P 4 inch 150# ANSI

Flange

Design Type: Turbine

Wetted Components:

Housing: PVC

Journal Bearings: PEEK

Shaft: Stainless Steel

Rotor and Nose Cone: Acetal

Washers: Stainless Steel

Max. Working Pressure:

FTB696A (All Models): 225 PSIG @ 73° F

FTB697A (All Models): 225 PSIG @ 73° F

(Non CE), 135 PSIG @ 73° F

(CE applications)

U.S. Measurement

Unit of Measure: Gallon

Flow Range:

3 inch: 40-400 GPM (Linearity: ±3.0%

of Reading)

30-600 GPM (Accuracy: ±2.0%

Full Scale)

4 inch: 60-600 GPM (Linearity: ±3.0

of Reading)

40-800 GPM (Accuracy ±2.0%

Full Scale)

Accuracy with Computer: ± 3.0% of reading

(Accuracy can be improved with field cal ibration)

Operating Temperature: +32° to +140° F

(Do not allow fluid to freeze inside meter.)

Battery Life: 5 years

5

Page 8

Storage Temperature: –40° to +158° F

Product Weight - lbs.:

NPT Flange

3 inch: 3.9 5.8

4 inch: 6.1 9.2

Dimensions - Inches (L x H x W):

NPT:

3 inch: 14.7 x 5.78 x 4.37

4 inch: 17.0 x 6.76 x 5.34

*

**

Flange:

3 inch: 12.0 x 7.5 x 7.5

4 inch: 14.0 x 9.0 x 9.0

PARTS

The following replacement parts and accessories are available for the FTB690A Series meters:

Part No. Description

FLSC790-P-ND Conditioned Signal Output Module

FLSC790-BATT Battery Replacement Kit

12517601 Gasket

12519001 Computer Mount Assembly

FTB899-ORING Seal

* Add .3 lbs. for Conditioned Signal Module.

** Add 1.1 inches to height for Conditioned Signal

module.

Metric Measurement

Unit of Measure: Litre

Flow Range:

3 inch: 151-1514 LPM (Linearity: ±3.0%

of Reading)

113-2271 LPM (Accuracy: ±2.0%

Full Scale)

4 inch: 227-2271 LPM (Linearity: ±3.0

of Reading)

151-3028 LPM (Accuracy ±2.0%

Full Scale)

Accuracy with Computer: ± 3.0% of reading

(Accuracy can be improved with field cal ibration)

Operating Temperature: 0° to +60° C

(Do not allow fluid to freeze inside meter.)

Battery Life: 5 years

Storage Temperature: –40° to +70° C

Product Weight - kgs:

NPT Flange

3 inch: 1.77 2.63

4 inch: 2.77 4.17

Dimensions - cm (L x H x W):

NPT:

3 inch: 37.3 x 14.7 x 11.1

4 inch: 43.2 x 17.3 x 13.6

*

**

Flange:

3 inch: 30.5 x 19.1 x 19.1

4 inch: 35.6 x 22.9 x 22.9

SERVICE

For warranty consideration, contact your local

distributor. If you need further assistance, contact the Omega Customer Service Department.

You will need to:

• Provide information from the decal on your

meter.

• Receive a Return Authorization number.

• Flush any fluid from the meter before shipping to the factory.

If possible leave customer installed fittings or

ample length of bare pipe for reinstallation.

CAUTION

Do not return the meter without specific

authority from the Omega Customer Service Department. Due to strict regulations

governing transportation, handling, and

disposal of hazardous or flammable liquids,

Omega will not accept meters for rework

unless they are completely free of liquid

residue.

* Add .14 kg to weight for Conditioned Signal

Module.

** Add 2.8 cm to height for Conditioned Signal

module.

6

Page 9

WEEE DIRECTIVE

E S P A Ñ O L

The Waste Electrical and Electronic

Eq uip men t (WEEE) directiv e

(2002/96/EC) was approved by the

European Parliament and the Council

of the European Union in 2003. This

symbol indicates that this product

contains electrical and electronic

equipment that may include bat-

teries, printed circuit boards, liquid

crystal displays or other components that may be subject

to local disposal regulations at your location. Please

understand those regulations and dispose of this product

in a responsible manner.

AVISO IMPORTANTE

Utilizar los medidores con agua y otros productos químicos que son compatibles con los

componentes que se exponen al líquido (véase

la sección de especificaciones). No utilizar este

medidor con combustible u otros productos

qulmicos incompatibles. Los medidores Omega

están disponibles con una computadora para la

visualización electrónica local, o un módulo de

salida condicionado de la señal que proporcione

una señal numérica al equipo de interconexión

del cliente. Los medidores Omega miden en

galones o litros. Referirse a la sección de la

calibración para mayores detalles.

Estos medidores no son legales para las aplicaciones comerciales.

Los medidores Omega son muy sensibles a

interferencia electrónica si funcionan a 1 o 2

pulgadas de algunos motores eléctricos o de

otras fuentes del uso electrónico.

INSTALACIÓN

Conexiones

Instalar su medidor en línea, u horizontalmente,

o verticalmente, o en el extremo de la manguera

adyacente al inyector. No se recomienda la instalación a las conexiones de metal. Siga estos

pasos para instalar:

1. Planee instalar la turbina con una longitud

mínima de la pipa recta de esta manera:

• Contra la corriente de la turbina, permita

a una longitud mínima de la pipa recta

de 10 veces el diámetro interno de la

turbina.

• Con la corriente de la turbina, permita

una longitud mínima de la pipa recta de

5 veces el diámetro interno de la turbina.

2. Para Accesorios NPT envolver todas las

conexiones de 3 a 4 vueltas de cinta de

hilo. Asegúrese de que la cinta no inmiscuirse en la trayectoria del flujo.

3. Unir el medidore con la flecha señalada en

la dirección del flujo.

7

Page 10

4. Para las Conexiones del NPT utilizar

solamente sus manos para apretar las

conexiones del medidor. No utilizar una

llave inglesa o una herramienta similar para

apretar. Esto puede dañar la cubierta.

5. Para las Guarniciones de Brida - Atención

al cliente que debe proporcionar:

• Anillo de juntas o juntas de Cara-Com-

pleta aprobados para su uso con bridas

ANSI y se debe estar supervisando el

fluido (2 requeridos).

• pernos y tuercas de 5/8’’: 4 por parte de

los metros 3 pulgadas, 8 por cada lado

de metros de 4 pulgadas.

Pernos de par utilizando un patrón de es-

trellas a 25 libraspie. Bridas suministrados

son de dos piezas, y permiten que el contador este orientado, independientemente de

la posición de las bridas de acoplamiento.

Señal de Salida Condicionada

Cableado De Módulo

Este módulo de Señal de salida condicionada

se puede conectar para proporcionar una salida

de colector abierta o de señal de onda cuadrada

de 6-voltios.

Señal de Salida de Colector Abierto

Para alcanzar una señal de salida de colector

abierto, refierase por favor al digrama eléctrico

1. El bloque de terminales está situado en el lado

trasero del módulo. El módulo viene montado

de fábrica para señal de colector abierta. Por

favor proporcionar el resistor de un minimo de

820 ohmios.

Diez pies (3 m) de cable se proporcionan con el

módulo. Ajustar el cable a la longitud deseada

o extender el cable cuanto le sea necesario. Se

puede alcanzar una señal de salida de colector

abierto hasta distancias de 5.000 pies (1,524 m).

Salida de Corrente de

Onda Cuadrada

Para lograr una salida de corriente de onda

cuadrada, refierase por favor al digrama eléctrico 2 y utilize un kit electrónico de bateria del

medidor digital (vendido por separado) para la

fuente de energia de la bateria. El bloque de

terminales y la localización de la bateria están

situados en el lado trasero del modulo. Acceda

al módulo de la siguiente manera:

1. Quitar los cuatro tornillos de cabeza Phillips

del frente del módulo. Levantar el módulo

de la turbina.

2. Para cambiar las conexiones del bloque de

terminales, aflojar los tornillos apropiados.

Volver a conectar los alambres en las posiciones apropiadas y apretar los tornillos.

3. Instalar las baterias. Cerciorarse de que

el poste positivo esté en la posición correcta.

4. Colocar el módulo en la cubierta de la

turbina. Para evitar daños causados por

la humedad, cerciorarse de que el anillo

esté asentado completamente. Apretar los

cuatro tornillos en el frente del módulo.

Diez pies (3 m) de cable se proporcionan con el

módulo. Ajustar el cable a la longitud deseada

o extender el cable cuanto le sea necesario.

Verificar la Exactitud del Metro

Antes de usar, comprobar la exactitud del metro

y verificar la calibración.

1. Cerciorarse de que no haya aire en el sistema comenzando el flujo hasta que funciona constantemente. Entonces, detener o

desviar el flujo mediante una válvula o la

boquilla.

2. Con el medidor, mida un volumen exacto

en un envase exacto. Para mejores resultados, medir con una corriente complete

y continua.

3. Comprobar el volumen con lo indicado

en la pantalla o el equipo de grabación.

Si la cantidad medida es exacta, no es

necesario mayor calibración. Si no, referir

a la sección de la calibración.

8

Page 11

OPERACIÓN

Pantalla de la Computadora –

Lotes y Totales Acumulativos

El computadora mantiene dos totales. El total

acumulativo proporciona la medida continua y

no puede ser reajustado manualmente. El total

de hornada se puede reajustar para medir el

flujo durante una sola vez. El total acumulativo

se etiqueta con el TOTAL 1 LOCKED. Esto indica que el total esta bloqueado y no puede ser

puesto a cero manualmente. l total acumulado

es etiquetado con TOTAL 1, lote total se etiqueta

TOTAL 2 BATCH.

Cuando el total acumulado llega a una lectura de

la pantalla de la computadora 999.999 resaltar

un icono de X10. Esto indica al operador que

un cero se debe agregar a los 6 dígitos que se

muestran. Cuando el traspaso se produzca la

próxima vez, el equipo se hará hincapié en un

icono X100. Esto indica al operador que dos

ceros se debe agregar a los 6 dígitos que se

muestran.

Pulse brevemente el botón DISPLAY para

cambiar entre el TOTAL 1, TOTAL 2 BATCH y la

configuración FLOWRATE. Pulse brevemente

DISPLAY para mostrar un total de TOTAL 2

BATCH. Mantenga pulsado el botón DISPLAY

durante 3 segundos para restablecer el lote

total a cero.

Cuando el líquido fluye a través del medidor, un

icono de hélice está resaltado.

NOTA: Totalization cuenta las unidades totales

sin distinguir entre los galones, los litros o

las unidades calibradas de campo.

Atributo del Indice de Flujo

Para utilizar esta función, pulse el botón DISPLAY y la FLOWRATE hasta que el icono aparece. La fábrica del conjunto de base de tiempo

se pondrá de relieve a la derecha del caudal de

agua (M = minutos, h = horas, D = días). Cuando

el cuadal de agua fluye, en la pantalla se indica

la velocidad de flujo.

Para Activar el Contador

El ordenador está encendido continuamente

y siempre dispuesto a operar. El equipo es alimentado por baterías reemplazables de campo.

Cuando la pantalla se vuelve opaco, desteñido

o el mensaje de batería baja (vea más abajo),

las baterías necesitan ser reemplazadas. Referencia de la sección de mantenimiento para

más detalles.

Calibración de Campo de Fábrica

Toda la información de calibración es visible

para el usuario como iconos en la línea superior de la pantalla, por encima de los dígitos

numéricos.

Todas las unidades están configurados con una

calibración de fabrica. Ambos galones y litros

están disponibles (“GL” o “LT” se mostrará).

Mientras mantiene el botón CALIBRATE, pulse

DISPLAY para cambiar entre galones y litros.

Esta calibración de fábrica (se indica con FAC)

está programada permanentemente en la computadora y no es ajustable por el usuario.

NOTA: El equipo puede tener otras unidades

de medida programada en ella. Si es así,

manteniendo pulsado el botón CALIBRATE

y momentáneamente pulsando el botón

DISPLAY, se activará a través de todas las

unidades de conjunto de la fábrica. Otras

unidades posibles son: IGL (galón imperial),

QT (cuarto), CF (pies cúbicos), CM (metros

cúbicos), BL (42 gal. Barril), CC (centímetros

cúbicos) o OZ (onzas).

El cambiar entre diferentes unidades no dañará

el Total. Por ejemplo, en el modo de GL, el equipo totaliza 10,00 galones, si el usuario cambia

a modo de LT, la pantalla se leerá 37,85 litros

(el mismo volumen, las diferentes unidades).

Los “campos” de calibración pueden ser configurados por el usuario, y puede ser cambiado

o modificado en cualquier momento mediante

el procedimiento de calibración se describe a

continuación en la sección de calibración. De

los totales o caudal de agua derivada de la

calibración de campo se invoca cuando el icono

de la FAC ya no es visible en la línea superior

de la pantalla.

9

Page 12

CALIBRACIÓN

Favor de Verificar la Precisión

Antes de Iniciar la Calibración de

Campo

Para resultados más exactos, dispense un

índice de flujo que simule lo mejor posible sus

condiciones de funcionamiento reales. Evite “de

gotear” más líquido o en varias ocasiones, o el

comenzar y de parar el flujo. Estas acciones

darán lcomo resultado calibraciones menos

exactas.

Cerciorese de reunir todos los requisitos mínimos del índice de flujo del medidor:

Medidores Omega

3 metros pulgadas 1 GPM (3,8 LPM)

4 metros pulgadas 40 GPM (151,4 LPM)

Se recomienda para resultados más exactos

de la calibración el uso de un envase uniforme,

confiable, y exacto. Debido al alto indice de flujo,

se recomienda que la calibración esté terminada

con una combinación de volumen y de peso

usando escalas de alta resolución.

Para mejores resultados, el medidor se debe

instalar y purgar del aire antes de la calibración

de campo.

Calibración de Campo con

Ordenador de Pantalla

La calibración de campo y de fábrica se definen

en la Sección de Operaciones. Parámetros de

calibración de fábrica son personalizados programado en cada equipo durante la fabricación,

el uso de agua a 70° F (21° C). Lecturas utilizando la calibración de fábrica (FAC), puede no

ser exacta en algunas situaciones, por ejemplo,

bajo condiciones de temperatura extrema, las

configuraciones de plomería estándar o con

otros líquidos distintos del agua.

Procedimientos de Calibración

de Campo (Método de Factor de

Corrección)

1. Para calibrar, presione y mantenga los bo-

tones de CALIBRATE y DISPLAY durante

unos 3 segundos hasta que aparezca FLdCAL. Suelte los botones y podrás ver CF -

00.0. Ahora está en el modo de calibración

de campo y los valores de -99,9% a 99,9%

pueden ser introducidos.

2. El + / - posición aparece como subrayan

un “carácter” de más, o como un carácter

“hyphen” para menos. El botón DISPLAY selecciona la posición y el botón CALABRATE

cambia este personaje.

3. El botón DISPLAY puede ser empujado a

seleccionar las posiciones numéricas. Pulse

el botón CALIBRATE para desplazarse desde

0 hasta 9. Introduzca el porcentaje de cambio

que desea que la pantalla correcta. Cuando

esté satisfecho con el valor, pulse dos CALIBRATE y DISPLAY botones simultáneamente.

CALEnd se mostrará y la unidad volverá al

funcionamiento normal, menos el icono de

la FAC (calibración de fábrica).

4. Todas las unidades habilitadas de medida

siguen siendo visibles y seleccionables dentro en la corrección se aplicará a todas

las unidades habilitadas.

5. Para volver a la calibración de fábrica (FAC),

presione y mantenga CALIBRATE y DISPLAY

de botonoes de la pantalla durante unos 3 se-

gundos hasta que aparezca FAcCAL. Luego

sulete botones. La unidad debe volver al funcionamiento normal y el icono de FAC visible.

Calibración Con el Módulo de

Señal de Salida Condicionada

El factor K de su medidor aparece en el informe

de la calibración como el número de pulsos por

galón. El factor se determina durante la producción usando el agua a 70° F (21° C). Este factor K

se puede utilizar para la calibración de “un solo

punto” y proporcionará una exactitud aceptable. Sin embargo, las lecturas pueden no ser

exactas cuando usted utiliza este método de la

calibración en algunas situaciones. Por ejemplo,

las condiciones extremas de temperatura, las

configuraciones de plomería estándar o con

otros líquidos distintos del agua.

10

Page 13

MANTENIMIENTO

La utilización y el cuidado apropiados ampliarán la vida y el servicio del medidor.

Rotor de Turbina

El medidor practicamente no tiene necesidad

de mantenimiento. Sin embargo, es importante

que los movimientos del rotor ocurran libremente. Mantener el medidor limpio y libre de

contaminantes.

El rotor se puede quitar para la limpieza y la

inspección. Comience por desenroscar la ojiva

del extremo de salida del medidor. Un enrosque

de 1/4” cuadrado de extensión se pueden

utilizar. Quitar el bloqueo y las arandelas de

empuje plana. El rotor puede ser removido del

eje. Fíjese en la orientación porque el rotor no

es bi-direccional. Retirar los escombros o los

depósitos con un cepillo suave o una pequeña

sonda. Vuelva a montar en orden inverso.

PRECAUCIÓN

El aire comprimido a través del montaje de

la turbina podría dañar el rotor.

Reemplazo de la Batería

La pantalla de la computadora funciona a través

de dos baterías del litio de 3-voltios que puedan ser substituidas mientras que el medidor

está instalado. Cuando las baterías se retiran

o pierden fuerza, el lote, y el total acumulado

y el de campo, y la calibración de fábrica se

conservan.

Si la pantalla se vuelve oscura, en blanco o

el mensaje de batería baja (vea más abajo),

reemplazar las baterías de la siguiente manera:

1. Quitar los cuatro tornillos de la cara del

metro y levantar la placa frontal de la turbina.

2. Quitar las viejas baterías y limpiar cualquier corrosión de los terminales.

3. Instalar las baterías nuevas. Cerciorarse de

que el poste positivo esté en la posición

correcta.

4. Cuando se substituyen las baterías, la

placa frontal estará encendida. Comprobar la exhibición para asegurarse de que

las funciones normales han resumido antes

de montar otra vez.

5. Volver a sentar las baterías, en caso necesario, colocar la placa frontal en la cubierta

de la turbina. Evite el daño causado por

la humedad, cerciorarse de que el anillo

esté asentado completamente. Apretar los

cuatro tornillos en la placa frontal.

ESPECIFICACIONES

Entrada y Enchufe:

Modelos NPT:

FTB696A-NPT/

FTB696A-NPT-P 3 pulgadas NPT

FTB697A-NPT/

FTB697A-NPT-P 4 pulgadas NPT

Modelos de Brida:

FTB696A-F/

FTB696A-F-P 3 pulgadas, 150#

ANSI Brida

FTB697A-F/

FTB697A-F-P 4 pulgadas, 150#

ANSI Brida

Tipo del Diseño: Turbina

Componentes Humedos:

Vivienda: PVC

Cojinetes: PEEK

Eje: Acero Inoxidable

Del Rotor y la Nariz de Cono: Acetal

Arandelas: Acero Inoxidable

Máxima Presión de Trabajo:

FTB696A (Todos los modelos):

225 PSIG @ 73° F

FTB697A (Todos los modelos):

225 PSIG @ 73° F

(Non CE), 135 PSIG @ 73° F

(CE aplicaciones)

Medidas de Estados Unidos

Unidad de la Medida: Galón

Rango de Flujo:

3 pulgadas 40-400 GPM (Linealidad:

±3,0% de la lectura)

30-600 GPM (Linealidad:

±2,0% a escala completa)

11

Page 14

4 pulgadas 60-600 GPM (Linealidad:

±3,0% de la lectura)

40-800 GPM (Linealidad:

±2,0% a escala completa)

Exactitud con la Computadora: ±3.0% de la

lectura (la exactitud se puede mejorar con

la calibración del campo)

Temperatura de Funcionamiento:

+32° a +140° F (No permitir que el líquido

se congele dentro del metro.)

Duración de la Batería: 5 años

Temperatura del Almacenaje:

-40° a +158° F

Peso del Producto - lbs.:

NPT Brida

3 pulgadas 3,9 5,8

4 pulgadas 6,1 9,2

Dimensiones - Pulgadas (L x H x W):**

NPT:

3 pulgadas: 14,7 x 5,78 x 4,37

4 pulgadas: 17,0 x 6,76 x 5,34

Brida:

3 pulgadas: 12,0 x 7,5 x 7,5

4 pulgadas: 14,0 x 9,0 x 9,0

*

Añadir £ .3. acondicionado para la señal

del módulo.

**

Añadir 1,1 pulgadas a la altura del módulo

de la señal acondicionado.

*

Medida Métrica

Unidad de la Medida: Litro

Rango de flujo:

3 pulgadas 151-1514 LPM (Linealidad:

±3,0% de la lectura)

113-2271 LPM (Exactitud:

±2,0% a escala completa)

4 pulgadas 227-2271 LPM (Linealidad:

±3,0% de la lectura)

151-3028 LPM (Precisión:

±2,0% a escala completa)

Exactitud con la Computadora: ±3.0% de la

lectura (la exactitud se puede mejorar con

la calibración del campo)

Temperatura de Funcionamiento:

0° a +60° C (No permitir que el líquido

se congele dentro del metro.)

Duración de la Batería: 5 años

Temperatura del Almacenaje:

-40° a +70° C

Peso del Producto - kgs:

NPT Brida

3 pulgadas 1,77 2,63

4 pulgadas 2,77 4,17

Dimensiones - cm (L x H x W):**

NPT:

3 pulgadas: 37,3 x 14,7 x 11,1

4 pulgadas: 43,2 x 17,3 x 13,6

Brida:

3 pulgadas: 30,5 x 19,1 x 19,1

4 pulgadas: 35,6 x 22,9 x 22,9

*

Añadir .14 kg de peso, para acondicionado

de señal del módulo.

**

Añadir 2,8 cm a la altura del módulo de la

señal acondicionado.

*

PIEZAS

Las piezas y los accesorios siguientes de recambio están disponibles para los medidores

de los Series del FTB690A:

Parte No. Descripción

FLSC790-P-ND Señal de salida del módulo

acondicionado

FLSC790-BATT Kit de sustitución de baterías

12517601 Junta

12519001 Monte de la Asamblea PC

FTB899-ORING Sello

12

Page 15

SERVICIO

Para la consideración de la garantía, contacte

con su distribuidor local. Si usted necesita ayuda

adicional, contacte con el departamento de

servicios al cliente de Omega.

Usted necesitará:

• Proporcionar la información de la etiqueta

en su medidor.

• Recibir un número de la autorización de

devolución.

• Limpiar cualquier líquido con un chorro

de agua del medidor antes de enviar a la

fábrica.

Si es posible, dejar las guarniciones instaladas

por el cliente o una longitud amplia de la pipa

pelada para la reinstalación.

PRECAUCIÓN

No devolver el metro sin la autoridad específica del departamento de servicios al

cliente de Omega. Debido a las regulaciones

terminantes gubernamentales Omega no

aceptará los medidores para la reanudación

a menos que estén totalmente libres de residuos líquidos peligrosos o inflamables, o

líquidos de todos tipos durante el transporte,

la dirección, y la disposición.

WEEE DIRECTIVA

La Directiva 2002/96/CE del

Parlamento Europeo y del Consejo

de la Unión Europea sobre Residuos

de Aparatos Eléctricos y Electrónicos

(RAEE) fue aprobada por el Parlamento Europeo y el Consejo de la

Union Europea en 2003. Este símbolo indica que este producto contiene

equipo eléctrico y electrónico que

puede incluir baterías, tableros de circuito impresos,

indicadores de crystal líquido u otros componentes que

pueden estar sujetos a regulaciones locales de desecho.

Por favor info rmese ace rca de estas reglas y

deseche de este producto de manera responasble.

D E U T S C H

WICHTIGE HINWEISS

Verwenden sie diese Meßinstrumente mit

Wasser und anderen Chemikalien benetzt

kompatibel mit Komponenten (Spezifikationen

Abschnitt sehen). Dieses Meßinstrument mit

Kraftstoff oder anderen inkompatiblen Chemikalien nicht benutzen. Die Omega Meßinstrumente sind entweder mit einem Computer

für lokale elektronische Anzeige oder einer

konditionierten Signalaus-gabebaugruppe

vorhanden, die ein digitales Signal zu Kunde

Schnittstellenmodul. Die Omega mißt in Gallonen oder Litern. Auf den Kalibrierungsabschnitt für Einzelheit beziehen.

Diese Meßinstrumente sind nicht für den Handel zulässig.

Die Omega Meßinstrumente sind gegen elektronische Störung sehr empfindlich, wenn sie

innerhalb 2,5 bis 5 cm einiger Elektromotoren

oder anderer Quellen des elektronischen Gebrauches bedient werden.

AUFSTELLUNG

Anschlüsse

Ihr Meßinstrument inline entweder am Ende

des Schlauches neben der Düse horizontal

oder vertikal anbringen. Installation zu Metallan-schlüssen wird nicht empfohlen. Diesen

Schritten folgen, um anzubringen:

1. Planen, die Turbine mit einer minimalen

Länge geraden Rohres anzubringen:

• Gegen den Strom von der Turbine, einer

minimalen Länge des geraden Rohres

von 10mal dem internen Durchmesser

der Turbine erlauben.

• Stromabwärts von der Turbine, eine

minimale Länge des geraden Rohres

von 5mal dem inneren Durchmesser der

Turbine erlauben.

2. Bei NPT Fittings alle Verbindungen Wrap

mit 3 bis 4 Packungen der Befestigungsgewinde. Vergewissern Sie sich, die Kassette nicht einmischen in die Fließweg.

3. Das Meßinstrument mit dem Pfeil anbringen, der in die Richtung des Flusses zeigt.

13

Page 16

4. Für NPT Befestigungen nur Ihre Hände

benutzen um die Pipe-Verbindun. Wenn Sie

die Anschlüsse festziehen, sich erinnern,

keine Werkzeuge zu benutzen.

5. Für Flansch-Fittings - Kunden zu bieten:

• Ring-Dichtungen oder Full-Face-Dich-

tungen zugelassen für die Verwendung

mit ANSI-Flansche und die Flüssigkeit

überwacht (2 erforderlich).

• 5/8" Schrauben und Muttern: 4 pro

Seite für 3-Zoll-Meter; 8 pro Seite für

4-Zoll-Meter.

Drehmoment Schrauben mit einem stern-

förmig bis 25 ft-lbs. Im Lieferumfang sind

zwei Flansche-Stück und damit das Messgerät unabhängig von der Paarung werden

orientierte Flansche Position.

Konditioniertes Signal Ausgeben

Baugruppenverdrahtung

Diese konditionierte Signalausgabebaugruppe

kann verdrahtet werden, um einen geöffneten

Kollektorsignal-Ausgang oder Welle des Quadrats 6-volt Ausgang zur Verfügung zu stellen.

Öffnen Kollektor-Signal-Ausgang

Um einen geöffneten Kollektor Ausgang zu

erzielen, Bezugsbauschaltplan 1 signalisieren.

Der Klemmenblock ist auf der Rückseite des

Moduls. Das Modul ist die Fabrik, die für geöffneten Kollektorsignalausgang. Zusammengebaut wird Den (820-Ohm-Minimum) Widerstand

bitte zur Verfügung stellen.

10 Fuß (3 m) Kabel wird mit dem Modul.

Versehen Das Kabel zur gewünschten Länge

trimmen oder das Kabel wie benötigt verlängern. Abstände bis 5.000 Fuß (1,524 m) könne

für geöffneten Kollektorsignalausgang erzielt

werden.

Quadratischer Welle Ausgang

Um Quadratischen Welle Ausgang zu erzielen,

Bezugsbauschaltplan 2 signalisieren und einen

elektronischen Digital Meßinstrument-Batterie-Installationssatz (separat verkauft) für die

Batterieleistung benutzen. Der Klemmenblock

und die Batterieposition sind auf der Rückseite

des Moduls. Zugang wie folgt:

1. Die vier Kreuzkopfschrauven von der Frontseite des Moduls entfernen. Das Modul von

der Turbine anheben.

2. Um die Klemmenblockanschlüsse zu

ändern, die passenden Schrauben lösen.

Die Leitungen in den korrekten Positionen

wieder anschließen und die Schrauben

festziehen.

3. Die Batterien anbringen. Sicherstellen,

daß der positive Pfosten in der richtigen

Position ist.

4. Das Modul auf das Turbinegehäuse in Position bringen. Um Feuchtigkeit Beschädigung zu vermeiden, sicherstellen daß der

dichtung völlig setzt. Die vier Schrauben

an der Frontseite des Moduls festziehen.

10 Fuß (3 m) Kabel wird mit dem Modul versehen. Das Kabel zur gewünschten Länge trimmen

oder das Kabel wie benötigt verlängern.

Meßinstrument Genauigkeit

Überprüfen

Bevor Sie verwenden, die Genauigkeit des

Meßinstruments überprüfen und die Kalibrierung überprüfen.

1. Überprüfen, daß es keine Luft in der Anlage

gibt, indem Sie den Fluß beginnen, bis er

ständig läuft. Dann, zu stoppen oder umzuleiten den Fluss mit einem Ventil oder

eine Düse.

2. Das Meßinstrument ein genau bekanntes

Volumen in einen genauen Behälter abgeben lassen. Für beste Resultate mit einem

ununterbrochenen vollen Strom messen.

3. Das Volumen gegen die Anzeige Oder die

Aufnahmeausrüstung überprüfen. Wenn

die Menge, die gemessen wird, genau ist,

ist weitere Kalibrierung nicht notwendig.

Wenn nicht, auf den Kalibrierungsabschnitt

für weitere Anweisungen beziehen.

14

Page 17

BETRIEB

Computer-Display –

Batch-und Gesamtsummen

Der Computer verwaltet zwei Summen. Der

kumulierte Betrag stellt die kontinuierliche

Messung und kann nicht manuell zurückgesetzt

werden. Der Batch Insgesamt kann zurückgesetzt werden, fließen in einer einzigen Anwendung zu messen. Der kumulierte Betrag ist mit

TOTAL 1 bezeichnet, ist Batch Total beschriftet

TOTAL 2 BATCH.

Wenn der kumulierte Betrag erreicht eine Anzeige Lesung 999.999 der Computer wird ein

X10-Symbol zu markieren. Dies deutet darauf

hin, dass dem Betreiber eine Null an die 6

gezeigten Ziffern hinzugefügt werden. Wenn

die nächste Rollover auftritt, wird der Computer

ein Highlight X100-Symbol. Diese zeigt dem

Bediener, dass zwei Nullen an die 6 gezeigten

Ziffern hinzugefügt werden.

Drücken Sie die DISPLAY-Taste kurz, um

zwischen den insgesamt 1, TOTAL 2 BATCH

und FLOWRATE. Drücken Sie DISPLAY, um

die kurz TOTAL 2 BATCH. Halten Sie die

DISPLAY-Taste für 3 Sekunden wieder auf die

Batch-Total auf Null.

Wenn die Flüssigkeit fließt durch das Messgerät,

ein kleiner Propeller-Symbol markiert ist.

Hinweis: Summierung zählt Einheiten in-

sgesamt, ohne Unterscheidung zwischen

Gallonen, Liter oder das Feld kalibriert

Einheiten.

Durchfluss Funktion

Um diese Funktion, drücken Sie DISPLAY

verwenden, bis FLOWRATE-Symbol erscheint.

Die Fabrik eingestellten Zeit wird auf Basis des

Rechts der FLOWRATE hervorgehoben werden

(M = Minuten, H = Stunden, d = Tage). Wenn

FLOWRATE aufgerufen wird, wird das Display

um darauf hinzuweisen, Fließgeschwindigkeit.

Aktivieren Sie die Meter

Computer wird weiterhin kontinuierlich und

immer bereit zu erfüllen. Der Computer ist

durch Feld-powered austauschbaren Batterien.

Wenn die Anzeige schwach, schwach oder die

Batterie-Meldung angezeigt wird (siehe unten),

müssen die Batterien ausgetauscht werden.

Verweisen Sie auf die Wartung Abschnitt für

Details.

Betriebs-und Kalibriersoftware

Alle Kalibrier-Informationen für den Benutzer

sichtbar als Symbole in der oberen Zeile des

Displays, über die Ziffern.

Alle Einheiten sind mit einer “Fabrik” Kalibrierung konfiguriert werden. Beide Gallonen und

Liter stehen zur Verfügung ( “GL” oder “LT”

wird angezeigt). Halten Sie die Schaltfläche

CALIBRATE, drücken Sie kurz DISPLAY, um

zwischen Gallonen und Liter zu wechseln.

Diese Fabrik-Kalibrierung (mit FAC angegeben)

ist fest in den Computer programmiert und

kann nicht vom Benutzer einstellbar.

HINWEIS: Ihr Computer ist möglicherweise

auch andere Maßeinheiten in sie programmiert. Wenn ja, hält die Schaltfläche

CALIBRATE und momentan Drücken der

DISPLAY-Taste wird durch alle werkseitig

eingestellt Einheiten zu wechseln. Andere

mögliche Einheiten sind: IGL (Imperial Gallonen), QT (Quart), CF (Kubikmeter), CM

(Kubikmeter), BL (42 gal. Barrel), CC (Kubikzentimeter) oder OZ (Unzen).

Wechseln zwischen verschiedenen Einheiten

werden nicht beschädigt die Total-Inhalten.

Zum Beispiel, im OpenGL-Modus, den Computer summiert 10,00 Gallone, wenn der

Benutzer schaltet in den LT, erscheint auf dem

Display 37,85 Liter (das gleiche Volumen, verschiedene Einheit) zu lesen.

Das “Feld” Kalibrierung kann vom Anwender

eingestellt werden und kann geändert werden,

oder jederzeit über das Kalibrierverfahren um

nachstehend beschriebenen Abschnitt der

Kalibrierung. Summen bzw. aus dem Bereich

Kalibrierung Durchfluss abgeleitet werden

aufgerufen, wenn der FAC-Symbol nicht mehr

sichtbar in der oberen Zeile des Displays wird.

15

Page 18

KALIBRIERUNG

Stellen Sie Sicher, Genauigekeit

vor Anfang Feld Kalibrierung

Für die genauesten Resultate an einer Fließgeschwindigkeit zuführen, die gut lhre tatsächlichen Betriebsbedingungen. Simuliert Vermeiden, mehr Flüssigkeit “zu tröpfein” oder wiederholt den Fluß zu beginnen und zu stoppen.

Dieses kann weniger genaue Kalibrierungen

ergeban.

Stellen Sie Treffen die minimalen Fließgeschwindigkeitanforderungen des Meßinstruments

sicher:

Omega Meßinstrumente

3-Zoll-Meter 30 GPM (113,61 LPM)

4-Zoll-Meter 40 GPM (151,41 LPM)

Der Gebrauch eines gleichmäßig zuverlässigen,

genauen Kalibrierung Behälters wird in hohem

Grade für die genauesten Resultate empfohlen.

Wegen der hohen Fließgeschwindigkeit, wird

es stark empfohlen, daß Kalibrierung mit einer

Kombination des Volumens und des Gewichts

mit feine Auflösung Skalen durchgeführt wird.

Für beste Resultate sollte das Meßinstrument

angebracht werden und bereinigt worden von

der Luft vor Kalibrierung auffangen.

Feld Kalibrierung mit

Computer-Display

Field Kalibrierung und Kalibrierung sind an der

Operation Abschnitt definiert. Werkskalibrierung

Einstellungen sind in jedem Computer während

der Herstellung programmiert, unter Verwendung von Wasser bei 70° C (21° C). Messwerte mit

Hilfe der Factory Calibration (FAC) ist möglicherweise nicht in einigen Situationen richtig, zum

Beispiel unter extremen Temperaturbedingungen, Nicht-Standard-Sanitär-Konfigurationen

oder mit anderen Medien als Wasser.

Feld Kalibrierung Handlungsweisen

(Korrektur-Faktor-Methode)

1. So kalibrieren, drücken und halten Sie die

CALIBRATE und DISPLAY-Taste etwa 3

Sekunden, bis Sie FLdCAL. Lassen Sie

beide Tasten, und Sie werden sehen, CF

- 00,0. Sie befinden sich nun im Bereich

der Betriebsart Kalibrierung und Werte von

-99,9% auf 99,9% eingegeben werden.

2. Die +/- Position wird entweder als ein

“Unterstrich”-Zeichen für Plus, oder als

ein Zeichen “hyphen” für Minus. Die

DISPLAY-Taste wählt die Position und die

CALIBRATE-Taste schaltet diesen Charakter.

3. Die DISPLAY-Taste können dann geschoben werden, um den numerischen

Positionen zu wählen. Drücken Sie die

Taste, um CALIBRATE 0 bis 9 zu blättern.

Geben Sie den Prozentsatz der Änderung,

die Sie wollen, dass die Anzeige zu korrigieren. Wenn Sie zufrieden sind mit dem

Wert, drücken Sie beide CALIBRATE und

DISPLAY Tasten gleichzeitig. CALEnd

wird angezeigt und Gerät zurück zum

normalen Betrieb, abzüglich der FAC

(Werkskalibrierung)-Symbol.

4. Alle aktiven Einheiten-of-Maßnahme bleiben sichtbar und wählbar - die eingegebenen Korrektur wird auf alle aktivierten

Einheiten angewendet werden.

5. Um wieder auf die werkseitigen Kalibrierung (FAC), drücken und halten Sie beide

CALIBRATE und DISPLAY-Taste etwa 3

Sekunden, bis FAcCAL angezeigt wird.

Dann Entriegelungstasten. Einheit sollte

Rückkehr zum normalen Betrieb und die

FAC-Symbol sichtbar.

16

Page 19

Kalibrierung mit konditionierter

Signal-Ausgabebaugruppe

Der K-Faktor lhres Meßinstruments erscheint

auf dem Kalibrierung Report als die Zahl Impulsen pro Gallone. Der Faktor wird während

der Produktion mit Wasser an 70° F (21° C) festgestellt. Dieser K-Faktor kann für Kalibrierung

“des einzelnen Punktes” verwendet werden

und wird eine annehmbare Genauigkeit liefern.

Jedoch können die Messwerte möglicherweise

nicht genau sein, wenn Sie diese Kalibrierung

Methode in einigen Situationen verwenden.

Zum Beispiel, extreme Temperaturen, NichtStandard-Sanitär-Konfigurationen oder mit

anderen Medien als Wasser.

WARTUNG

Die korrekte Behandlung und die Wartung

verlängern das Leben und den Service des

Meßinstruments.

Turbinenrotor

Das Meßinstrument ist praktisch wartungsfrei.

Jedoch ist es wichtig, dass sich der Rotor frei

bewegen kann. Das Meßinstrument sauber

halten und von Verunreinigung freihalten.

Der Rotor kann für die Reinigung und Inspektion entfernt werden. Beginnen Sie mit dem

Abschrauben der Nase Kegel aus der Steckdose Ende des Zählers. A 1/4” Vierkant SocketErweiterung verwendet werden kann. Entfernen

Sie die Sperre und flach Anlaufscheiben. Der

Rotor kann dann von der Welle entfernt werden.

Notieren Sie sich die Orientierung, weil der

Rotor ist nicht bidirektional. Entfernen Sie

den Schmutz oder Ablagerungen mit einem

weichen Pinsel oder kleine Sonde. Der Zusammenbau erfolgt in umgekehrter Reihenfolge.

VORSICHT

Pressluft durch die Turbine blasen kann den

Rotor beschädigen.

BatterieAustausch

Das Computeranzeige wird durch zwei 3-Volt

Lithium Batterien angetrieben, die ausgetauscht werden können, während das Meßinstrument installiert ist. Wenn die Batterien entfernt

werden oder verlieren Macht, die Batch-und

Gesamtsummen und das Feld und Werkskalibrierungen beibehalten werden.

Wenn die Anzeige schwächer wird, leer oder

die Batterie-Meldung (siehe unten), ersetzen

Sie die Batterien wie folgt:

1. Die vier Kreuzschlitzschrauben von der

Vorderseite des Meßinstruments entfernen

und die Frontplatte von der Turbine anheben.

2. Die alten Batterien entfernen und jede

mögliche Korrosion von den Klemmen

säubern.

3. Neue Batterien anbringen. Überprüfen,

daß der positive Pfosten in der richtigen

Position ist.

4. Wenn die Batterien ausgetauscht sind,zeigt

die Frontplatte “POWER ON”. Die Anzeige

überprüfen, um normale Funktionen sicherzustellen, bevor Sie wieder zusammenbauen.

5. Falls nötig, Batterieeinsetzung berichtigen,

und die Frontplatte auf das Turbinegehäuse

in Position bringen. Um Feuchtigkeitsbeschädigung zu vermeiden, überprüfen, daß

der dichtung völlig sitzt. Die vier Schrauben

an der Frontplatte festziehen.

Einlass-und Auslass:

NPT-Modelle:

FTB696A-NPT/

FTB696A-NPT-P 3 Zoll NPT

FTB697A-NPT/

FTB697A-NPT-P 4 Zoll NPT

Flansch-Modelle:

FTB696A-F/

FTB696A-F-P 3 Zoll 150# ANSI

Flansch

FTB697A-F/

FTB697A-F-P 4 Zoll 150# ANSI

Flansch

SPEZIFIKATIONEN

17

Page 20

DesignBaumuster: Turbine

Benetzte Komponenten:

Gehäuse: PVC

Journal Bearings: PEEK

Welle: Edelstahl

Rotor-und Nose Cone: Acetal

Unterlegscheiben: Edelstahl

Max. Betriebsdruck:

FTB696A (alle Modelle): 225 psig @ 73° F

FTB697A (alle Modelle): 225 psig @ 73° F

(Non CE), 135 psig

@ 73° F

(CE Anwendungen)

U.S. Maß

Maßeinheit der Maßnahme: Gallone

FlußStrecke:

3 Zoll: 40-400 GPM (Linearität: ± 3,0%

vom Messwert)

30-600 GPM (Genauigkeit: ± 2,0%

Komplett)

4 Zoll: 60-600 GPM (Linearität: ± 3,0

vom Messwert)

40-800 GPM (Genauigkeit ± 2,0%

Komplett)

Genauigkeit mit Computer: ± 3.0% des

Lesens (Genauig-keit kann mit verbessert

werden auffangen Kalibrierung)

Betriebstemperatur: +32° zu +140° F

(Flüssigkeit nicht innerhalf des Meßinstru ments einfrieren lassen.)

Lebensdauer der Batterie: 5 Jahre

SpeicherTemperatur: -40° zu +158° F

Größe und Gewicht - lbs.:

NPT Flansch

3 Zoll 3,9 5,8

4 Zoll 6,1 9,2

Abmessungen - Zoll (W x H x L):**

NPT:

3 cm: 14,7 x 5,78 x 4,37

4 cm: 17,0 x 6,76 x 5,34

Flansch:

3 cm: 12,0 x 7,5 x 7,5

4 cm: 14,0 x 9,0 x 9,0

*

Metrisches Maß

Maßeinheit: Liter

FlußStrecke:

3 Zoll: 151-1514 LPM (Linearität: ±3,0%

vom Messwert)

113-2271 LPM (Genauigkeit:

±2,0% Komplett)

4 Zoll: 227-2271 LPM (Linearität: ±3,0%

vom Messwert)

151-3028 LPM (Genauigkeit ±2,0%

Komplett)

Genauigkeit mit Computer: ±3.0% des

Lesens (Genauig-keit kann mit verbessert

werden auffangen Kalibrierung)

Betriebstemperatur: 0° zu +60° C

(Flüssigkeit nicht innerhalf des Meßinstru ments einfrieren lassen.)

Lebensdauer der Batterie: 5 Jahre

SpeicherTemperatur: -40° zu +70° C

Größe und Gewicht - kgs.:

NPT Flansch

3 Zoll 1,77 2,63

4 Zoll 2,77 4,17

Abmessungen - cm (L x B x H):**

NPT:

3 cm: 37,3 x 14,7 x 11,1

4 cm: 43,2 x 17,3 x 13,6

Flansch:

3 cm: 30,5 x 19,1 x 19,1

4 cm: 35,6 x 22,9 x 22,9

* .14 kg hinzufügen zu Gewicht für Condi-

tioned Signal-Modul.

** 2,8 cm Höhe für die aufbereitete Signal-

Modul.

*

* In ,3 lbs. für konditionierte Signal-Modul.

** 1,1 Zoll Zu Höhe für aufbereitete Signal-

Modul.

18

Page 21

TEILE

Die folgenden Ersatzteile und die Zusatzgeräte

sind für die FTB690A Series Meßinstrumente

vorhanden:

Teilenummer Beschreibung

FLSC790-P-ND Aufbereitete Signal ausgabebaugruppe

FLSC790-BATT Batterie-Wiedereinbau Installationssatz

12517601 Dichtung

12519001 Versammlung

FTB899-ORING Dichtung

SERVICE

Für Garantiansprüche mit Ihrem lokalen Verteiler in Verbindung treten. Wenn Sie weitere

Unterstützung benötigen, mit der OmegaKunden-dienstabteilung in Verbindung treten.

Sie benötigen:

• Informationen vom Abziehbild auf Ihrem

Meßinstrument zur Verfügung stellen.

• Eine Rückholermächtigungszahl empfangen.

• Jede mögliche Flüssigkeit vom Meßinstrument spülen, bevor Sie zur Fabrik versenden.

Wenn möglich, Abnehmer-angebrachte Befestigungen oder eine reichliche Länge des Rohres

für Wiedereinbau belassen.

WEEE RICHTLINIE

Der Richtlinie 2002/96/EG über

Elektro- und Elektronik-Altgeräte

(WEEE) des Europäischen Parlaments

bzw. des EU-Ministerrats. Dieses

simbol zeigt an, daß dieses Produkt

elektrische und elektronische Ausrüstung, die Batterien mit einschließen

ka nn, Pri ntpla tte versc hal t,

Flüssigkristall-Sichtanzeigen oder

andere Bestandteile enthält, die abhängig von Einheimischvergeudung Regelungen sein können. Bitte verstehen

Sie jene Regelungen wenn Sie dieses Produkt sich

entledigen.

VORSICHT

Das Meßinstrument nicht ohne die spezifische Berechtigung der Omega-Kundendienstabteilung zurückbringen. Wegen

der strengen Regelungen des Transportes,

der Behandlung und der Beseitigung der

gefährlichen oder feuergefährlichen Flüssigkeiten, nimmt Omega nicht Meßinstrumente für Überarbeitung an, es sei denn,

class sie vom flüssigen Überrest vollständig

frei sind.

19

Page 22

I T A L I A N O

AVVISO IMPORTANTE

Usare i tester con acqua ed altri prodotti chimici

che sono compatibili con le parti che sono esposti a liquido (vedere la sezione di specifiche).

Non utilizzare questo tester con combustibile

o altri prodotti chimici incompatibili. I tester

di Omega sono con un calcolatore per visualizzazione elettronica locale, o un modulo di

uscita condizionato del segnale che fornisce un

segnale numerico all’apparecchiatura di collegamento del cliente. Omega testers con display

del computer le misura nei galloni o nei litri.

Riferirsi alla sezione di taratura per i particolari.

Questi tester non sono per le applicazioni commerciali.

I tester dei Omega sono molto sensibili ad interferenza elettronica se sono funzionati all’interno

di 1 - 2 pollici di alcuni motori elettrici o di altre

fonti di uso elettronico

Collegamenti

Installare il vostro tester in linea orizzontalmente

o verticalmente o all’estremità del tubo flessibile

adiacente all’ugello. L’installazione ai collegamenti del metallo non è suggerita. Seguire questi

punti per installare:

1. Progettare installare la turbina con una

• A monte dalla turbina, concedere ad una

• A valle dalla turbina, concedere ad una

2. Per NPT Raccordi a capo tutte le connes-

3. Fissare il tester con la freccia indicata nel

INSTALLAZIONE

lunghezza minima del tubo diritto:

lunghezza minima di un tubo diritto di 10

volte il diametro interno della turbina.

lunghezza minima di un tubo diritto di 5

volte il diametro interno della turbina.

sioni da 3 a 4 involucri di nastro thread.

Assicurarsi che il nastro non intromettersi

nel percorso del flusso.

senso del flusso.

4. Per i Montaggi del NPT utilizzare soltanto

le vostre mani per stringere i collegamenti.

Non utilizzare gli attrezzi per stringere. Ciò

può causare danni.

5. Per i Raccordi a Flangia - Cliente di fornire:

• Ring o Full-Face Guarnizioni approvato

per l’uso con flange ANSI e il fluido monitorate (2 richieste).

• bulloni e dadi di 5/8": 4 per lato per 3

metri pollici, 8 per lato per 4 metri pollici.

Bulloni di coppia con un modello di stella

a 25 ft-lbs. Flange forniti sono due pezzi e

consentire il contatore di essere orientato

a prescindere dalla posizione di accoppiamento flange.

Segnale Condizionato Produrre

Cablaggio di Modulo

Questo modulo di segnale condizionato del può

essere legato per fornire del collettore dell’ segnale aperta o dell’onda del quadrato di 6-volti.

Collettore dell’Segnale Aperta

Per raggiungere Collettore dell’ Segnale Aperta,

Riferiscasi allo schema elettrico di riferimento 1.

Il blocchetto terminali è situato dal lato posteriore del modulo. Il modulo è fabbrica montata

per collettore dell’ segnale aperta. Fornire prego

il resistore di minimo di 820 Ohm.

Dieci piedi (3 m) di cavo è fornito del modulo.

Assettare il cavo alla lunghezza voluta o estendere il cavo come necessario. Le distanze fino a

5.000 piedi (1,524 m) possono essere realizzate

per l’collettore dell’ segnale aperta.

Segnale Dell’Onda Quadrata

Per raggiungere segnale Dell’Onda Quadrata,

Riferiscasi allo schema elettrico di riferimento 2

ed usare un corredo elettronico della batteria del

tester di Digital (venduto esclusivamente) per la

potenza della batteria. Il blocchetto terminali e la

posizione della batteria sono situati dal modulo.

Accesso come segue:

1. Rimuovere le quattro viti Phillips dalla parte

anteriore del modulo. Alzare il modulo dalla

turbina.

2. Per cambiare i collegamenti del blocchetto

terminali, allentare le viti adatte. Ricollegare

i legare nelle posizioni adequate e stringere

le viti.

20

Page 23

3. Installare le batterie. Assicurarsi che l’alberino positivo è nella posizione corretta.

4. Posizionare il modulo sull’alloggiamento

della turbina. Evitare danni dell’umidità,

assicurarsi che l’anello completamente è

messo. Stringere le quattro viti sulla parte

anteriore del modulo.

Dieci piedi (3 m) di cavo è fornito del modulo. Assettare il cavo alla lunghezza voluta o estendere

il cavo come necessario.

Verificare L’Esattezza Del Tester

Prima di utilizzare, controllare l’esattezza del

tester e verificare la taratura.

1. Assicurarsi che non ci è aria nel sistema

iniziando la quantità di fluido fino a che

non funzioni costantemente. Poi, fermare

o deviare il flusso con una valvola o ugelli.

2. Per mezzo del tester, misurare un volume

conosciuto esatto in un contenitore esatto.

Per i risultati migliori, misurare con un flusso

pieno continuo.

3. Controllare il volume contro l’esposizione o

l’apparecchiatura di registrazione. Se l’importo misurato è esatto, ulteriore calibratura

non è necessaria. Se non, riferirsi alla sezione di taratura per ulteriori istruzioni.

FUNZIONAMENTO

Visualizzatore del Computer Partita e Totali Comulativi

Il computer effettua due totali. Il totale cumulativo fornisce la misura continua e non può essere

ripristinato manualmente. Il totale in lotti può

essere ripristinato per misurare il flusso durante

il monouso. Il totale cumulato è etichettato con

TOTAL 1, Batch totale è etichettato TOTAL 2

BATCH.

Quando il totale cumulato raggiunge una lettura del display di 999.999 computer metterà in

evidenza l’icona X10. Ciò indica l’operatore che

uno zero deve essere aggiunto il 6 cifre indicate.

Quando il cambio di data successiva verifica,

il computer metterà in evidenza l’icona X100.

Ciò indica l’operatore che due zeri deve essere

aggiunto il 6 cifre indicate.

Premere brevemente il tasto DISPLAY per

passare tra il TOTAL 1, TOTAL 2 BATCH e

FLOWRATE impostazioni. Premere brevemente

DISPLAY per visualizzare la TOTAL 2 BATCH Tenere premuto il pulsante DISPLAY per 3 secondi

per ripristinare il Batch totale a zero.

Quando è fluido che scorre attraverso il contatore, una piccola icona elica viene evidenziata.

NOTA: Totalization conta le unità totali senza

differenziare fra i galloni, i litri o le unità

campotaratura.

Caratteristica Indice di Flusso

Per utilizzare questa funzione, premere e rilasciare DISPLAY fino FLOWRATE appare l’icona.

La fabbrica di base di tempo sarà evidenziato

al diritto della FLOWRATE (M = minuti, H = ore,

D = giorno). Quando FLOWRATE è richiamato,

il display sarà che indica la velocità di flusso.

Per Attivare il Misuratore

Computer è sempre acceso e sempre pronto a

eseguire. Il computer è alimentato da batterie

sostituibili campo. Quando il display diventa debole, sbiadite o il messaggio di batteria scarica

viene visualizzato (vedi sotto), le batterie devono

essere sostituite. Riferimento alla sezione Manutenzione per ulteriori dettagli.

Calibratura del Campo

e Della Fabbrica

Tutte le informazioni di calibrazione è visibile

all’utente come icone sulla linea superiore del

display, sopra le cifre numeriche.

Tutte le unità sono configurati con una taratura di “fabbrica”. Entrambi i litri e litri sono

disponibili (“GL” o “LT” verrà visualizzato). Tenendo premuto il pulsante CALIBRATE, premere

brevemente DISPLAY per passare tra litri e litri.

Questa calibrazione di fabbrica (indicato con

FAC) è programmato in modo permanente nel

computer e non è regolabile dall’utente.

21

Page 24

NOTA: Il computer può avere altre unità di misura

programmato in esso. In tal caso, tenendo

premuto il pulsante CALIBRATE e per un

momento premendo il pulsante DISPLAY

sarà scorrere tutte le unità di fabbrica. Altre

unità possibili sono: IGL (gallone imperiale),

QT (Quart), CF (metri cubi), CM (metro

cubo), BL (42 gal. Barile), CC (centimetro

cubo) o OZ (once).

I contenuti di commutazione tra diverse unità

non rovinerà la Total. Ad esempio, in modalità

GL, il computer totalizza 10,00 litri, se l’utente

passa alla modalità di LT, il display leggerà 37,85

litri (lo stesso volume, differenti unità).

Il “campo” di taratura può essere impostato

dall’utente, e può essere cambiato o modificato

in qualsiasi momento, utilizzando la procedura di

taratura descritta di seguito nella sezione di calibrazione. Totali o portata derivata dalla taratura

campo vengono richiamati quando l’icona FAC

non è più visibile sulla riga superiore del display.

CALIBRATURA

Prima di Verificare l’Accuratezza

All’inizio del Taratura di Campo

Per i risultati più esatti, erogare ad un debito

che simula il più bene le vostre condizioni di

gestione reali. Evitare di “gocciolare” più liquido

o ripetutamente iniziare ed arrestare il flusso.

Queste azioni provocheranno le calibrature

meno esatte.

Vi assicurate raduno i requisiti minimi di debito

del tester:

Tester Di Omega

3 metro pollici 30 GPM (113,6 LPM)

4 metro pollici 40 GPM (151,4 LPM)

Usando un contenitore credibile e ed esatto di

taratura altamente è suggerito per i risultati più

esatti. Dovuto l’ alto debito, è suggerito vivamente che la calibratura è completata con una

combinazione di volume e di peso usando le

scale di alta risoluzione.

Per i risultati migliori, il tester dovrebbe essere

installato ed eliminato l’inceppo di aria prima

della taratura del campo.

Taratura di Campo con

Visualizzatore del Computer

Taratura di Campo e di calibrazione di fabbrica sono definite nella sezione operativa.

Impostazioni di calibrazione di fabbrica sono

programmati in ogni computer durante la produzione, utilizzando l’acqua a 70° F (21° C). Letture utilizzando la taratura di fabbrica (FAC), non

possono essere precisi in alcune situazioni, per

esempio, in condizioni di temperatura estreme,

configurazioni non standard o idraulico con

liquidi diversi dall’acqua.

Procedura di Taratura di Campo

(Metodo di Fattore di Correzione)

1. Per calibrare, tenere premuto il pulsante

CALIBRATE e DISPLAY per circa 3 secondi

fino a visualizzare FLdCAL. Rilasciare entrambi i tasti e vedrete CF - 00.0. Ora siete

in modalità di calibrazione in campo e di

valori da -99,9% a 99,9% possono essere

inseriti.

2. Il +/- posizione appare sia come un segno

di sottolineatura “carattere” di più, o come

un carattere “hyphen” per meno. Il tasto

DISPLAY sceglie la posizione e il pulsante

CALIBRATE commuta questo personaggio.

3. Il tasto DISPLAY può essere spinto a

selezionare le posizioni numerico. Premere

il pulsante CALIBRATE per passare da 0 a

9. Inserisci la percentuale di cambiamento

che si desidera la visualizzazione da correggere. Quando siete soddisfatti con il

valore, premere entrambi i CALIBRATE e

DISPLAY i pulsanti contemporaneamente.

CALEnd verrà visualizzata e l’unità tornerà

al funzionamento normale, meno il icona

FAC (taratura di fabbrica).

4. Tutte le unità permesso-di-misura rimangono visibili e selezionabili – la correzione è

entrato sarà applicato a tutti i abilitati unità.

5. Per tornare alla taratura di fabbrica (FAC),

premere e tenere premuti i pulsanti di CALIBRATE e DISPLAY per circa 3 secondi fino

a quando FAcCAL viene visualizzato. Quindi

rilasciare i pulsanti. Unità dovrebbe tornare

al normale funzionamento e l’icona FAC

visibili.

22

Page 25

Calibratura con il Modulo di

Segnale Condizionato Produrre

Il fattore K del vostro tester compare sul rapporto di calibratura come il numero di impulsi

per il gallone. Il fattore è determinato durante

la produzione usanto l’acqua a 70° F (21° C).

Questo fattore K può essere usato per “la calibratura del singolo punto” e fornirà un’esattezza

accettabile. Tuttavia, le letture non possono

essere esatte quando usate questo metodo di

calibrature in alcune situazioni. Ad esempio, le

condizioni di temperatura estreme, configurazioni non standard o idraulico con liquidi diversi

dall’acqua.

MANUTENZIONE

Il maneggiamento e la cura adeguati estenderanno la durata ed il servizio del tester.

Rotore di Turbina

Il tester è virtualmente manutenzione-free. Tuttavia, è liberamente importante i movimenti del

rotore. Mantenere il tester pulito ed esente dagli

agenti inquinanti.

Il rotore può essere rimosso per la pulizia e

l’ispezione. Iniziate svitando l’ogiva dal terminale

di uscita del contatore. A 1/4” estensione dei

zoccolo quadrati può essere utilizzato. Rimuovere il blocco e le rondelle di spinta piatto. Il

rotore può essere rimosso dal pozzo. Nota:

l’orientamento, perché il rotore non è bi-direzionale. Rimuovere i detriti e depositi utilizzando

una spazzola morbida o piccola sonda. Rimontare in ordine inverso.

ATTENZIONE

Appiattito fornisc tramite il complessivo della turbina ha potuto danneggiare il rotore.

Rimontaggio Della Batteria

Il visualizzatore del computer è alimentato da

due batterie del litio 3-volt che possono essere

sostituite mentre il tester è installato. Quando le

batterie vengono rimosse o di perdere il potere,

la partita e totali cumulativi e il tarature di campo

e di fabbrica vengono conservati.

Se il Visualizzatore diventa debole, vuoto o il

messaggio di batteria scarica viene visualizzato (vedi sotto), sostituire le batterie nel modo

seguente:

1. Rimuovere le quattro viti della Phillips-testa

dalla faccia del tester ed alzare la piastra

frontale dalla turbina.

2. Rimuovere le vecchie batterie e liberare tutta

la corrosione dai terminali.

3. Installare le nuove batterie. Assicurarsi che

l’alberino positivo è nella posizione corretta.

4. Quando le batterie sono sostituite, la piastra frontale alimenterà SOPRA. Controllare

l’esposizione per accertare le funzioni nor

hanno ripreso prima del montaggio ancora.

5. Riposizionare le batterie, se necessario e

posizionare la piastra frontale sull’alloggiamento della turbina. Evitare danni dell’

umidità, assicurarsi che l’anello completamente è messo. Stringere le quattro viti sulla

piastra frontale.

mali

SPECIFICHE

Entrata ed Uscita:

NPT Modelli:

FTB696A-NPT/

FTB696A-NPT-P 3 pollici NPT

FTB697A-NPT/

FTB697A-NPT-P 4 inch NPT

Flangia Modelli:

FTB696A-F/

FTB696A-F-P 3 pollici 150#

ANSI Flange

FTB697A-F/

FTB697A-F-P 4 pollici 150#

ANSI Flange

Tipo di Disegno: Turbina

Componenti Umidi:

Corpo: PVC

Journal Bearings: PEEK

Albero: Acciaio Inox

Rotore e Nose Cone: Acetal

Rondelle: Acciaio Inossidabile

23

Page 26

Max. Pressione di Lavoro:

FTB696A (Tutti i modelli): 225 psig @ 73° F

FTB697A (Tutti i modelli): 225 psig @ 73° F

(Non CE),

135 psig @ 73° F

(applicazioni CE)

Misura Degli Stati Uniti

Unità Della Disura: Gallone

Range di Flusso:

3 pollici: 40-400 GPM (Linearità: ± 3.0%

della lettura)

30-600 GPM (Precisione: ± 2.0%

Completo)

4 pollici: 60-600 GPM (Linearità: ± 3,0%

of Lettura)

40-800 GPM (Precisione ± 2.0%

Completo)

Esattezza Con il Computer: ±3.0% di lettura

(esattezza può essere migliorata con la

calibratura del campo)

Temperatura di Funzionamento:

+32° a +140° F (Non lasciare che il liquido

congeli all’inerno del tester.)

Durata Della Batteria: 5 anni

Temperatura di Immagazzinaggio:

-40° a +158° F

Peso del Prodotto - lbs.:

NPT Flangia

3 pollici: 3,9 5,8

4 pollici: 6,1 9,2

Dimensioni - Pollici (L x H x W): **

NPT:

3 pollici: 14,7 x 5,78 x 4,37

4 pollici: 17,0 x 6,76 x 5,34

Flangia:

3 pollici: 12,0 x 7,5 x 7,5

4 pollici: 14,0 x 9,0 x 9,0

*

Misura Metrica

Unità Della Misura: Litro

Range di Flusso:

3 pollici: 151-1514 LPM (Linearità: ± 3.0%

della Lettura)

113-2271 LPM (Precisione: ± 2.0%

Completo)

4 pollici: 227-2271 LPM (Linearità: ± 3,0%

della Lettura)

151-3028 LPM (Precisione ± 2.0%

Completo)

Esattezza con il Computer: ± 3.0% di lettura

(esattezza può essere migliorata con la

calibratura del campo)

Temperatura di Funzionamento:

0° a +60° C (Non lasciare che il liquido

congeli all’inerno del tester.)

Durata Della Batteria: 5 anni

Temperatura di Immagazzinaggio:

-40° a +70° C

Peso del Prodotto - kgs:

NPT Flangia

3 pollici: 1,77 2,63

4 pollici: 2,77 4,17

Dimensioni - cm (L x H x W): **

NPT:

3 pollici: 37,3 x 14,7 x 11,1

4 pollici: 43,2 x 17,3 x 13,6

Flangia:

3 pollici: 30,5 x 19,1 x 19,1

4 pollici: 35,6 x 22,9 x 22,9

* Aggiungi ,14 kg di peso per Condizionata

Signal Module.

** Aggiungere 2,8 centimetri di altezza per il

modulo del segnale condizionata.

*

* Aggiungi ,3 £. per Condizionata Signal

Module.

** Aggiungere 1,1 pollici di altezza per il

modulo del segnale condizionata.

24

Page 27

PARTI

La direttiva 2002/96/EC del Parlamento europeo e del Consiglio

dell'Unione europea sui rifiuti di

apparecchiature elettriche ed

elettroniche (RAEE) e stato aprovatto del Parlamento europeo e del