Page 1

Meter with

Computer Display

Digital Pulse Meter

FTB691A through FTB695A

Electronic Water Meters

Page 2

Page 3

TABLE OF CONTENTS

English ...........................................................1

Español ..........................................................7

Deutsch .......................................................12

Italiano .........................................................18

Français .......................................................23

E N G L I S H

IMPORTANT NOTICE

Use FTB690 Series meters with water and other

chemicals compatible with wetted components

(see Specifications Section). Do not use to

meter fuel or incompatible chemicals. FTB690

Series meters are available with either a local

electronic display, or a conditioned signal

output module to provide a digital signal to

customer interfacing equipment. FTB690

Series meters with computer display measure

in gallons or liters. Refer to the Calibration

Section for details.

These meters are not legal for trade applications.

FTB690 Series meters are very sensitive to

electric noise if operated within one to two

inches of some electric motors or other sources

of electronic noise.

INSTALLATION

Install your meter in-line either horizontally or

vertically or at the end of the hose adjacent to

the nozzle. Installation to metal connections is

not recommended. Install as follows:

1. Plan to install turbine with a minimum

straight pipe length as follows:

– Upstream from the turbine, allow a mini-

mum straight pipe length of 10 times

the internal diameter of the turbine.

– Downstream from the turbine, allow a

minimum straight pipe length of 5 times

the internal diameter of the turbine.

2. For NPT Fittings wrap all connections with

3 to 4 wraps of thread tape. Make sure the

tape does not intrude into the flow path.

3. Attach meter with arrow pointed in the

direction of flow.

4. For NPT Fittings - Hand tighten the meter

at the housing ends. Do not use a wrench

or similar tool to tighten. This can damage

the housing.

Conditioned Signal Output

Module Wiring

This conditioned signal output module can be

wired to provide an open collector signal output

or 6-volt square wave output.

When installing an FTB690 Series meter, the

correct K-factor must be entered into the readout

device. You can find the K-factor printed on the

turbine body. All K-factors on Omega flowmeters

are calculated in pulses per gallon (PPG).

Open Collector Signal Output

To achieve an open collector signal output,

reference Wiring Diagram 1. The terminal block

is located on the back side of the module. The

module is factory assembled for open collector signal output. Please provide the (820 ohm

minimum) resistor, if not supplied by receiving

equipment.

Ten feet (3 m) of cable is provided with the

module. Trim it to desired length or extend it as

necessary. Distances up to 5,000 feet (1,524 m)

can be achieved for open collector signal output.

Square Wave Output

To achieve square wave output, reference Wiring Diagram 2 and use an FLSC790-BATT (sold

separately) for battery power. The terminal block

and battery location are located on the back

side of the module. Access as follows:

1. Remove the four Phillips-head screws from

the front of the module and lift the module

from the turbine.

2. To change terminal block connections,

loosen the appropriate screws. Reconnect

the wires in the proper positions and tighten

the screws.

1

Page 4

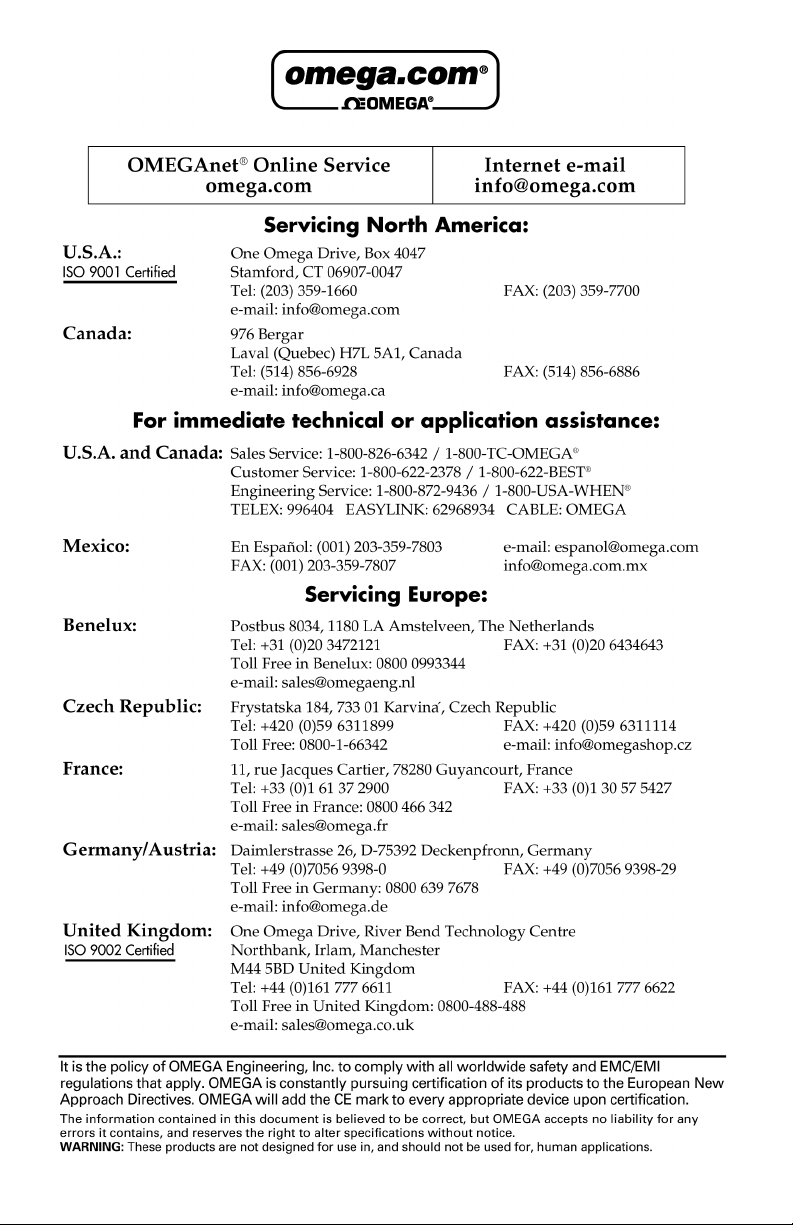

Wiring Diagram 1

+9 to 35 volt DC

Open Collector

Signal

3

2

1

4

Red

White

Black

Common

(Ground)

Terminal

Block

Customer

Interfacing

Equipment

The terminal block is identified as follows:

Pin #1 6 volt square wave (not used)

Pin #2 +9 to 35 volt DC Input

Pin #3 Common Ground

Pin #4 Open Collector signal Output

3

2

1

4

White

Black

Common

(Ground)

Terminal

Block

Customer

Interfacing

Equipment

6 volt Square

Wave Signal

The terminal block is identified as follows:

Pin #1 6 volt square wave

Pin #2 +9 to 35 volt DC Input (not used)

Pin #3 Common Ground

Pin #4 Open Collector signal Output (not used)

OPEN COLLECTOR SIGNAL OUTPUT

Resistor

(820 ohm min.)

Wiring Diagram 2

2

SQUARE WAVE OUTPUT

Page 5

3. Install the batteries. Make sure the positive

post is in the correct position.

4. Position the module on the turbine housing.

To avoid moisture damage, make sure the

seal is fully seated. Tighten the four screws

on the front of the module.

Ten feet (3 m) of cable is provided with the

module. Trim the cable to desired length or

extend it as necessary.

Verify Meter Accuracy

Before using, check the meter’s accuracy and

verify calibration.

1. Make sure there is no air in the system

by starting the flow until it runs steadily.

Then, stop or divert the flow using a valve

or nozzle.

2. Hold down DISPLAY for 3 seconds to zero

the meter’s Batch Total. When zeros appear,

release the button.

3. Meter an exact known volume into an

accurate container. For best results, meter

with one continuous full stream.

4. Check the volume against the display

or recording equipment. If the amount

metered is accurate, field calibration is not

necessary. If not, refer to the Calibration

Section for further instructions.

Batch and Cumulative Totals

The computer maintains two totals. The Cumulative Total provides continuous measurement

and cannot be manually reset. The Batch Total

can be reset to measure flow during a single

use. The Cumulative Total is labeled TOTAL 1,

Batch Total is labeled TOTAL 2 BATCH.

When the Cumulative Total reaches a display

reading of 999,999 the computer will highlight

an X10 icon. This indicates to the operator that

a zero must be added to the 6 digits shown.

When the next rollover occurs, the computer

will highlight an X100 icon. This indicates to

the operator that two zeros must be added to

the 6 digits shown.

Press the DISPLAY button briefly to switch

between the TOTAL 1, TOTAL 2 BATCH and

FLOWRATE. Press DISPLAY briefly to display

the TOTAL 2 BATCH. Hold the DISPLAY button

for 3 seconds to reset the Batch Total to zero.

When fluid is flowing through the meter, a small

propeller icon is highlighted.

Flowrate Feature

To use this feature, press and release DISPLAY

button until FLOWRATE icon appears. The

factory set time base will be highlighted to the

right of FLOWRATE (M = minutes, H = hours,

D = days). When FLOWRATE is invoked, the

display will be indicating rate of flow.

OPERATION

Computer Display

All operations are reflected in the LCD readout.

The large center digits indicate amounts, where

smaller words or “icons” located above and

below indicate specific information regarding

totals, flow, calibration and units of measure.

Activate the Meter

Computer is on continuously and always ready

to perform. The computer is powered by field

replaceable batteries. When display becomes

dim, faded or the low battery message appears

(see below), the batteries need to be replaced.

Reference the Maintenance Section for details.

Factory and Field Calibration

All calibration information is visible to the user

as icons on the top line of the display, above

the numeric digits.

All units are configured with a “factory” calibration. Both gallons and liters are available (“GL” or

“LT” will be displayed). While holding the CALIBRATE button, briefly press DISPLAY to toggle

between gallons and litres. This factory calibration (indicated with FAC) is permanently programmed into the computer and is not user adjustable.

NOTE: Your computer may have other units of

measure programmed into it. If so, holding

the CALIBRATE button and momentarily

pressing the DISPLAY button will toggle

through all factory set units. Other possible units are: IGL (imperial gallon), QT

(quart), CF (cubic feet), CM (cubic meter),

BL (42 gal. barrel), CC (cubic centimeter)

or OZ (ounce).

3

Page 6

Switching between different units will not corrupt

the Total’s contents. For example, in GL mode,

the computer totalizes 10.00 gallons, if the user

switches to LT mode, the display will read 37.85

litres (the same volume, different unit).

The “field” calibration may be set by the user,

and can be changed or modified at any time

using the calibration procedure described below

in the Calibration Section. Totals or flowrate

derived from the field calibration are invoked

when the FAC icon is no longer visible on the

top line of the display.

CALIBRATION

Verify Accuracy Before

Beginning Field Calibration

For the most accurate results, dispense at

a flowrate which best simulates your actual

operating conditions. Avoid “dribbling” more

fluid or repeatedly starting and stopping the

flow. This can result in less accurate calibrations.

Make sure you meet the meter’s minimum

flowrate requirements:

FTB690A Series Meters

1/2 inch meter 1 GPM (3.8 LPM)

3/4 inch meter 2 GPM (7.5 LPM)

1 inch meter 5 GPM (18.9 LPM)

1-1/2 inch meter 10 GPM (37.9 LPM)

2 inch meter 20 GPM (75 LPM)

The use of a uniformly dependable, accurate

calibration container is recommended for the

most accurate results. Due to high flowrate, it

is strongly recommended that calibration be

completed with a combination of volume and

weight using fine resolution scales. For best

results, the meter should be installed and purged

of air before field calibration.

Field Calibration Procedures

(Dispense/Display Method)

1. To field calibrate, press and hold CALIBRATE and DISPLAY buttons for about 3

seconds until you see FLdCAL. Release

both buttons and you will see dd000.0.

You are now in the field calibration mode.

2. Dispense a known amount of fluid at a

flowrate representative of the application.

Any amount between .1 and 999.9 units

can be used. Display will count up while

fluid is flowing through the meter.

3. The DISPLAY button can then be pushed

to select the digit location and the CALIBRATE button can be pushed to scroll the

desired value at the blinking position. Edit

the amount shown with the value that was

dispensed above. Values from 000.1 to

999.9 can be entered.

4. When satisfied with the value, press both

CALIBRATE and DISPLAY buttons simultaneously. CALEnd will be displayed and

unit will go back to normal operation, less

the FAC (factory calibration) icon.

5. The meter will now be operating with a custom calibration number unique to the above

dispense procedure. No unit of measure

(gallon, litre, etc.) icon will be highlighted.

NOTE: To return to factory calibration (FAC),

press and hold both CALIBRATION and

DISPLAY buttons for about 3 seconds, until

FAcCAL is displayed. Then release buttons.

Unit should return to normal operation and

FAC icon visible.

NOTE: If the field calibration mode is entered

and NO fluid is dispensed, then upon leaving, the computer will use data from the last

successful field calibration.

Field Calibration with

Computer Display

Field Calibration and Factory Calibration are

defined in the Operation Section. Factory

calibration settings are programmed into each

computer during manufacturing, using water

at 70° F (21° C). Readings using the Factory

Calibration (FAC) may not be accurate in some

situations, for example, under extreme temperature conditions, non-standard plumbing

configurations or with fluids other than water.

4

Page 7

MAINTENANCE

SPECIFICATIONS

Proper handling and care will extend the life

and service of the meter.

Turbine Rotor

The meter is virtually maintenance-free.

However, it is important the rotor moves freely.

Keep the meter clean and free of contaminants.

If the rotor does not turn freely, apply a penetrating lubricant on the rotor, shaft, and bearings.

Remove any debris or deposits from the rotor

using a soft brush or small probe. Be careful not

to damage the turbine rotor or supports.

CAUTION

Blowing compressed air through the turbine

assembly could damage the rotor.

Battery Replacement

The computer display is powered by two 3-volt

lithium batteries which may be replaced while

the meter is installed. When batteries are

removed or lose power, the batch and cumulative totals and the field and factory calibrations

are re tained.

If the display becomes dim, blank or the low

battery message appears (see below), replace

the batteries as follows:

1. Remove the four Phillips-head screws from

the face of the meter and lift the faceplate

from the turbine.

2. Remove the old batteries and clean any

corrosion from the terminals.

3. Install new batteries. Make sure the positive

post is in the correct position.

4. When the batteries are replaced, the faceplate will power ON. Check the display to

ensure normal functions have resumed

before assembling again.

5. Reseat batteries, if necessary, and position

the faceplate on the turbine housing.

To avoid moisture damage, make sure the

seal is fully seated. Tighten the four screws

on the faceplate.

Inlet and Outlet:

For NPT Models:

FTB691A-NPT/FTB691A-NPT-P 1/2" NPT

FTB692A-NPT/FTB692A-NPT-P 3/4" NPT

FTB693A-NPT/FTB693A-NPT-P 1" NPT

FTB694A-NPT/FTB694A-NPT-P 1-1/2" NPT

FTB695A-NPT/FTB695A-NPT-P 2" NPT

Design Type: Turbine

Wetted Components:

Housing: PVC

Journal Bearings: Ceramic

Shaft: Tungsten Carbide

Rotor and Supports: PVDF

Retaining Washer: Stainless Steel

Fitting Types: Schedule 80 NPT

Max. Working Pressure: 225 PSIG @ 73° F

U.S. Measurement

Unit of Measure: Gallon

Flow Range:

1/2 inch 1 - 10 GPM

3/4 inch 2 - 20 GPM

1 inch 5 - 50 GPM

1-1/2 inch 10 - 100 GPM

2 inch 20 - 200 GPM

Accuracy: ± 3.0% of reading (Accuracy can

be improved with field calibration)

Operating Temperature: +32° to +140° F

NOTE: Do not allow fluid to freeze inside

meter.

Storage Temperature: –40° to +158° F

Weight: (Includes Computer Display. Conditioned

Signal Module adds .30 lbs.)

1/2 inch .55 lbs.

3/4 inch .67 lbs.

1 inch .84 lbs.

1-1/2 inch 1.38 lbs.

2 inch 1.78 lbs.

Dimensions - inches (W x H x L):

(Includes Computer Display. Conditioned Signal

Module adds 1.1 inch to height)

1/2 inch 2.0 x 2.8 x 5.5

3/4 inch 2.0 x 2.9 x 5.5

1 inch 2.0 x 3.3 x 6.2

1-1/2 inch 2.3 x 3.9 x 7.6

2 inch 3.5 x 4.5 x 7.9

5

Page 8

Metric Measurement

Unit of Measure: Liter

Flow Range:

1/2 inch 3.8 - 38 LPM

3/4 inch 7.6 - 76 LPM

1 inch 19 - 190 LPM

1-1/2 inch 38 - 380 LPM

2 inch 76 - 760 LPM

Accuracy: ± 3.0% of reading (Accuracy can

be improved with field calibration)

Operating Temperature: 0° to +60° C

NOTE: Do not allow fluid to freeze inside

meter.

Storage Temperature: –40° to +70° C

Weight: (Includes Computer Display. Conditioned

Signal Module adds .14 kg)

1/2 inch .249 kg

3/4 inch .304 kg

1 inch .381 kg

1-1/2 inch .626 kg

2 inch .807 kg

Dimensions - cm (W x H x L): (Includes Com-

puter Display. Conditioned Signal Module adds

2.8 cm to height)

1/2 inch 5.0 x 7.1 x 13.9

3/4 inch 5.0 x 7.3 x 13.9

1 inch 5.0 x 8.3 x 15.7

1-1/2 inch 5.8 x 9.9 x 19.3

2 inch 8.8 x 11.4 x 20.0

PARTS

The following parts and accessories are available for the FTB690 Series meters:

Part No. Description

FLSC790-BATT Battery Replacement Kit

FTB890 O-ring O-Ring

FTB691A-NPT-RK 1/2 in., NPT, PVC, Turbine

Assembly Kit

FTB692A-NPT-RK 3/4 in., NPT, PVC Turbine

Assembly Kit

FTB693A-NPT-RK 1 in., NPT, PVC Turbine

Assembly Kit

FTB694A-NPT-RK 1-1/2 in., NPT, PVC,

Turbine Assembly Kit

FTB695A-NPT-RK 2 in., NPT, PVC Turbine

Assembly Kit

Computer Kits:

FTB691-CK 1/2 in., Computer Assy Kit

FTB692-CK 3/4 in., Computer Assy Kit

FTB693-CK 1 in., Computer Assy Kit

FTB694-CK 1-1/2 in., Computer

Assy Kit

FTB695-CK 2 in., Computer Assy Kit

6

Page 9

E S P A Ñ O L

AVISO IMPORTANTE

Utilizar los metros de los Series del FTB690

con agua y otros productos químicos que son

compatibles con les componentes que se exponen

al líquido (véase la sección de especificaciones). No utilizar para medir el incompatible

combustible o los productos químicos. Los

metros de la serie del FTB690 están disponibles

con una visualización electrónica local, o un

módulo de salida condicionado de la señal

para proporcionar una señal numérica al

equipo de interconexión del cliente. Los

medidores Series FTB690 miden en galones

o litros. Referirse a la sección de la calibración

para mayores pantalla de ordenador detalles.

Estos medidores no son legales para las

aplicaciones comerciales.

Los medidores de las Series FTB690 son muy

sensibles a interferencia electrónica si funcionan

a 1 o 2 pulgadas de algunos motores eléctricos

o de otras fuentes del uso electrónico.

Instalar su medidor en línea, u horizontalmente,

o verticalmente, o en el extremo de la manguera

adyacente al inyector. No se recomienda la

instalación a las conexiones de metal. Siga

estos pasos para instalar:

1. Planee instalar la turbina con una longitud

mínima de la pipa recta de esta manera:

– Contra la corriente de la turbina,

permita a una longitud mínima de la

– Con la corriente de la turbina, permita

una longitud mínima de la pipa recta de 5

veces el diámetro interno de la turbina.

2. Para las Conexiones del NPT cubrir las con

exiones de pipa con la vueltas de cinta del

3 a 4 veces. Cerciorarse de que la cinta no

imponga en la trayectoria del flujo.

3. Unir el metro con la flecha señalada en la

dirección del flujo.

INSTALACIÓN

pipa recta de 10 veces el diámetro

interno de la turbina.

4. Para las Conexiones del NPT utilizar

solamente sus manos para apretar las

conexiones del metro. No utilizar una llave

inglesa o una herramienta similar para

apretar. Esto puede dañar la cubierta.

Señal de Salida Condicionada

Cableado de Módulo

Este módulo de Señal de salida condicionada

se puede conectar para proporcionar una

salida de colector abierta o de señal de onda

cuadra da de 6-voltios.

Al instalar un flujómetro de la turbina de la serie

del FTB690, el factor K correcto se debe incorporar en el dispositivo de la lectura. Usted puede

encontrar el factor K impreso en el cuerpo de la

turbina. Todos los factores K en flujómetros del

Omega se calculan en pulsos por galón (PPG).

Señal de Salida de Colector Abierto

Para alcanzar una señal de salida de colector

abierto, refierase por favor al digrama eléctrico

1. El bloque de terminales está situado en

el lado trasero del módulo. El módulo viene

montado de fábrica para señal de colector

abierta. Por favor proporcionar (el resistor de

un minimo de 820 ohmios), si no es provisto

por el equipo de recepción.

Diez pies (3 m) de cable se proporcionan con el

módulo. Ajustar el cable a la longitud deseada

o extender el cable cuanto le sea necesario.

Se puede alcanzar una señal de salida de

colector abierto hasta distancias de 5.000

pies (1,524 m).

Salida de corrente de

Onda Cuadrada

Para lograr una salida de corriente de onda

cuadrada, refierase por favor al digrama eléctrico 2 y utilize un FLSC790-BATT (vendido

por separado) para la fuente de energia de la

bateria. El bloque de terminales y la localización

de la bateria están situados en el lado trasero

del modulo. Acceda al módulo de la siguiente

manera:

1. Quitar los cuatro tornillos de cabeza

Phillips del frente del módulo. Levantar el

módulo de la turbina.

7

Page 10

2. Para cambiar las conexiones del bloque

de terminales, aflojar los tornillos apropiados. Volver a conectar los alambres

en las posiciones apropiadas y apretar

los tornillos.

3. Instalar las baterias. Cerciorarse de que el

poste positivo esté en la posición correcta.

4. Colocar el módulo en la cubierta de la

turbina. Para evitar daños causados por

la humedad, cerciorarse de que el anillo

esté asentado completamente. Apretar los

cuatro tornillos en el frente del módulo.

Diez pies (3 m) de cable se proporcionan con el

módulo. Ajustar el cable a la longitud deseada

o extender el cable cuanto le sea necesario.

Verificar la Exactitud del Metro

Antes de usar, comprobar la exactitud del metro

y verificar la calibración.

1. Cerciorarse de que no haya aire en el sistema

comenzando el flujo hasta que funciona

constantemente. Entonces, detener o des-

viar el flujo mediante una válvula o la boquilla.

2. Mantenga el botón de la DISPLAY durante

3 segundos para llevar a cero el total de

medidor. Cuando aparezcan los ceros,

suelte el botón.

3. Con el medidor, mida un volumen exacto en

un envase exacto. Para mejores resultados,

medir con una corriente complete y continua.

4. Comprobar el volumen contra la pantalla o

el equipo de grabacion. Si la cantidad medi-

da es exacta, la calibración de campo no

es necesaria. Si no, refeierase a la sección

de la calibración.

OPERACIÓN

Ordenador de Pantalla

Todas las operaciones se reflejan en la lectura

del LCD. Los dígitos grandes del centro indican

cantidades, donde las palabras más pequeñas

o “iconos” que se encuentran por encima y por

debajo indican la información específica sobre

los totales, el flujo, la calibración y unidades de

medida.

Para Activar el Contador

El ordenador está encendido continuamente

y siempre dispuesto a operar. El equipo es alimentado por baterías reemplazables de campo.

Cuando la pantalla se vuelve opaco, desteñido

o el mensaje de batería baja (vea más abajo),

las baterías necesitan ser reemplazadas. Referencia de la sección de mantenimiento para

más detalles.

Lote y los Totales Acumulados

El computadora mantiene dos totales. El total

acumulativo proporciona la medida continua y

no puede ser reajustado manualmente. El total

de hornada se puede reajustar para medir el

flujo durante una sola vez. El total acumulativo

se etiqueta con el TOTAL 1 LOCKED. Esto indica que el total esta bloqueado y no puede ser

puesto a cero manualmente. l total acumulado

es etiquetado con TOTAL 1, lote total se etiqueta

TOTAL 2 BATCH.

Cuando el total acumulado llega a una lectura de

la pantalla de la computadora 999.999 resaltar

un icono de X10. Esto indica al operador que

un cero se debe agregar a los 6 dígitos que se

muestran. Cuando el traspaso se produzca la

próxima vez, el equipo se hará hincapié en un

icono X100. Esto indica al operador que dos

ceros se debe agregar a los 6 dígitos que se

muestran.

Pulse brevemente el botón DISPLAY para

cambiar entre el TOTAL 1, TOTAL 2 BATCH y la

configuración FLOWRATE. Pulse brevemente

DISPLAY para mostrar un total de TOTAL 2

BATCH. Mantenga pulsado el botón DISPLAY

durante 3 segundos para restablecer el lote

total a cero.

Cuando el líquido fluye a través del medidor, un

icono de hélice está resaltado.

Atributo del Indice de Flujo

Para utilizar esta función, pulse el botón DISPLAY y la FLOWRATE hasta que el icono aparece. La fábrica del conjunto de base de tiempo

se pondrá de relieve a la derecha del caudal de

agua (M = minutos, h = horas, D = días). Cuando

el cuadal de agua fluye, en la pantalla se indica

la velocidad de flujo.

8

Page 11

Calibración de Campo de Fábrica

Toda la información de calibración es visible

para el usuario como iconos en la línea superior de la pantalla, por encima de los dígitos

numéricos.

Todas las unidades están configurados con una

calibración de fabrica. Ambos galones y litros

están disponibles (“GL” o “LT” se mostrará).

Mientras mantiene el botón CALIBRATE, pulse

DISPLAY para cambiar entre galones y litros.

Esta calibración de fábrica (se indica con FAC)

está programada permanentemente en la computadora y no es ajustable por el usuario.

NOTA: El equipo puede tener otras unidades

de medida programada en ella. Si es así,

manteniendo pulsado el botón CALIBRATE

y momentáneamente pulsando el botón

DISPLAY, se activará a través de todas las

unidades de conjunto de la fábrica. Otras

unidades posibles son: IGL (galón imperial),

QT (cuarto), CF (pies cúbicos), CM (metros

cúbicos), BL (42 gal. Barril), CC (centímetros

cúbicos) o OZ (onzas).

El cambiar entre diferentes unidades no dañará

el Total. Por ejemplo, en el modo de GL, el equipo totaliza 10,00 galones, si el usuario cambia

a modo de LT, la pantalla se leerá 37,85 litros

(el mismo volumen, las diferentes unidades).

Los “campos” de calibración pueden ser configurados por el usuario, y puede ser cambiado

o modificado en cualquier momento mediante

el procedimiento de calibración se describe a

continuación en la sección de calibración. De

los totales o caudal de agua derivada de la

calibración de campo se invoca cuando el icono

de la FAC ya no es visible en la línea superior

de la pantalla.

Cerciorese de reunir todos los requisitos mínimos del índice de flujo del medidor:

Medidores de las Series del FTB690A

Medidor de 1/2 pulgada de

1 GPM (3,8 LPM)

Medidor de 3/4 pulgada de

2 GPM (7,5 LPM)

Medidor de 1 pulgada de

5 GPM (18,8 LPM)

Medidor de 1-1/2 pulgadas de

10 GPM (37,85 LPM)

Medidor de 2 pulgadas de

20 GPM (75 LPM)

Se recomienda para resultados más exactos

de la calibración el uso de un envase uniforme,

confiable, y exacto. Debido al alto indice de flujo,

se recomienda que la calibración esté terminada

con una combinación de volumen y de peso

usando escalas de alta resolución. Para mejores

resultados, el medidor se debe instalar y purgar

del aire antes de la calibración de campo.

Calibración de Campo con

Ordenador de Pantalla

La calibración de campo y de fábrica se definen

en la Sección de Operaciones. Parámetros de

calibración de fábrica son personalizados programado en cada equipo durante la fabricación,

el uso de agua a 70° F (21° C). Lecturas utilizando la calibración de fábrica (FAC), puede no

ser exacta en algunas situaciones, por ejemplo,

bajo condiciones de temperatura extrema, las

configuraciones de plomería estándar o con

otros líquidos distintos del agua.

CALIBRACIÓN

Favor de Verificar la Precisión

Antes de Iniciar la Calibración de

Campo

Para resultados más exactos, dispense un

índice de flujo que simule lo mejor posible sus

condiciones de funcionamiento reales. Evite “de

gotear” más líquido o en varias ocasiones, o el

comenzar y de parar el flujo. Estas acciones

darán lcomo resultado calibraciones menos

exactas.

9

Page 12

Procedimientos de Calibración

de Campo (Método de Dispensar/

Visualización)

1. Para calibración de campo, presione y

mantenga los botones de CALIBRATE y

DISPLAY durante unos 3 segundos hasta

que aparezca FLdCAL. Suelte los botones

y podrás ver dd000.0. Ahora está en el

modo de calibración de campo.

2. Prescindir de una cantidad conocida de

fluido a un caudal representativo del de la

aplicación. Cualquier cantidad entre .1 y

999,9 unidades pueden ser utilizados. La

pantalla se encargará de contar mientras

el líquido fluye a través del medidor.

3. El botón DISPLAY puede ser presionado

para seleccionar la ubicación de dos dígitos y el botón CALIBRATE se puede presionar para desplazar el valor deseado

en la posición que parpadea. Modificar

el importe que figura con el valor que se

dispensó anteriormente. Se pueden utlizar

valores de 000.1 a 999.9.

4. Cuando esté satisfecho con el valor, pulse

dos botones CALIBRATE y DISPLAY simultáneamente. CALEnd se mostrará y la

unidad volverá al funcionamiento normal,

menos el icono de la FAC (calibración de

fábrica).

5. El medidor estará operando con un núme-

ro de calibración personalizada única

al anterior procedimiento. No resaltará

ningún icono de unidad de medida (galón,

litro, etc).

NOTA: Para volver a la calibración de fábrica

(FAC), presione y mantenga los botones

de pantalla de CALIBRATION y DISPLAY

durante unos 3 segundos, hasta que

se muestre FAcCAL. Inmediatamente

después suelte los botones. La Unidad

debe volver al funcionamiento normal y el

icono de FAC debe estar visible de nuevo.

NOTA: Si durante el modo de calibración de

campo NO se introduce ni se dispensa

líquido alguno, al concluir el equipo utilizará los datos de calibración, de la última

calibración de campo exitosa.

MANTENIMIENTO

La utilización y el cuidado apropiados ampliarán

la vida y el servicio del medidor.

Rotor de Turbina

El medidor practicamente no tiene necesidad

de mantenimiento. Sin embargo, es importante

que los movimientos del rotor ocurran libremente. Mantener el medidor limpio y libre de

contaminantes.

Si el rotor no da vuelta libremente, aplicar

un lubricante penetrante en el rotor, el eje, y

los rodamientos. Quitar cualquier desecho o

depósito del rotor usando un cepillo suave o una

punta de prueba pequeña. Tenga cuidado de

no dañar el rotor de turbina o los soportes.

PRECAUCIÓN

El aire comprimido a través del montaje de

la turbina podría dañar el rotor.

Reemplazo de la Batería

La pantalla del ordenador se alimenta de

dos pilas de litio de 3-voltios, que podrá ser

sustituido mientras se instala el medidor.

Cuando las baterías se quitan o pierden la

potencia, la hornada y los totales acumulativos

seran reajustados a cero, pero las calibraciones

de campo y de la fábrica se conservan.

Si la pantalla se vuelve oscura, en blanco o

el mensaje de batería baja (vea más abajo),

reemplazar las baterías de la siguiente manera:

1. Quitar los cuatro tornillos de la cara del

metro y levantar la placa frontal de la

turbina.

2. Quitar las viejas baterías y limpiar cualquier

corrosión de los terminales.

3. Instalar las baterías nuevas. Cerciorarse de

que el poste positivo esté en la posición

correcta.

4. Cuando se substituyen las baterías, la

placa frontal estará encendida. Comprobar

la exhibición para asegurarse de que las

funciones normales han resumido antes

de montar otra vez.

10

Page 13

5. Volver a sentar las baterías, en caso

necesario, colocar la placa frontal en la

cubierta de la turbina. Evite el daño

causado por la humedad, cerciorarse de

que el anillo esté asentado completamente.

Apretar los cuatro tornillos en la placa

frontal.

ESPECIFICACIONES

Entrada y Enchufe:

Por NPT Modelos:

FTB691A-NPT/FTB691A-NPT-P 1/2" de NPT

FTB692A-NPT/FTB692A-NPT-P 3/4" de NPT

FTB693A-NPT/FTB693A-NPT-P 1" de NPT

FTB694A-NPT/FTB694A-NPT-P 1-1/2" de NPT

FTB695A-NPT/FTB695A-NPT-P 2" de NPT

Tipo del Diseño: Turbina

Componentes Mojados:

Cubierta: PVC

Rodamientos: De Cerámica

Eje: Carburo de Tungsteno

Rotory Soportes: PVDF

Arandela De Retención: Stainless Steel

Tipo de las Guarnicione: Resbalón de 80 NPT

Máxima Presión de Funcionamiento:

225 PSIG a los 73°F

Medida de Estados Unidos

Unidad de la Medida: Galón

Gama del Flujo:

1/2" 1 - 10 GPM

3/4" 2 - 20 GPM

1" 5 - 50 GPM

1-1/2" 10 - 100 GPM

2" 20 - 200 GPM

Exactitud: ±3.0% de la lectura (la exactitud se

puede mejorar con la calibración del

campo)

Temperatura de Funcionamiento:

+32° a +140° F

NOTA: No permitir que el líquido

congele dentro del metro.

Temperatura del Almacenaje:

-40° a +158° F

Peso: (Incluye pantalla de ordenader. Módulo de

Señal de salida condicionada añade .30 libras.)

1/2" ,55 libras

3/4" ,67 libras

1" ,84 libras

1-1/2" 1,38 libras

2" 1,78 libras

Dimensiones - Pulgadas (Grosor x Altura x

Longitud):

(Incluye pantalla de ordenader. Módulo de

Señal de salida condicionada añade 1.1 altura.)

1/2" 2,0 x 2,8 x 5,5

3/4" 2,0 x 2,9 x 5,5

1" 2,0 x 3,3 x 6,2

1-1/2" 2,3 x 3,9 x ,67

2" 3,5 x 4,5 x 7,9

Medida Métrica

Unidad de la Medida: Litro

Gama del Flujo:

1/2" 3,8 - 38 LPM

3/4" 7,6 - 76 LPM

1" 19 - 190 LPM

1-1/2" 38 - 380 LPM

2" 76 - 760 LPM

Exactitud: ±3.0% de la lectura (la exactitud se

puede mejorar con la calibración del

campo)

Temperatura de Funcionamiento:

0° a +60° C

NOTA: No permitir que el líquido

congele dentro del metro.

Temperatura del Almacenaje:

-40° a +70° C

Peso: (Incluye pantalla de ordenader. Módulo

de Señal de salida condicionada añade .14 kg.)

1/2" .249 kilogramo

3/4" .304 kilogramo

1" .381 kilogramo

1-1/2" .626 kilogramo

2" .807 kilogramo

Dimensiones - Centímetro

(Grosor x Altura x Longitud):

(Incluye pantalla de ordenader. Módulo de

Señal de salida condicionada añade 2.8 cm.)

1/2" 5,0 x 7,1 x 13,9

3/4" 5,0 x 7,3 x 13,9

1" 5,0 x 8,3 x 15,7

1-1/2" 5,8 x 9,9 x 19,3

2" 8,8 x 11,4 x 20,0

11

Page 14

PIEZAS

Las piezas y los accesorios siguientes de

recambio están disponibles para los medidores

de los Series del FTB690A:

Parte No. Descripción

FLSC790-BATT Systema de reemplazo de

la batería

FTB890 O-Ring Anillo-O

FTB691A-NPT-RK 1/2" NPT, PVC - kit de la

assamblea de la turbina

FTB692A-NPT-RK 3/4" NPT, PVC - kit de la

assamblea de la turbina

FTB693A-NPT-RK 1" NPT, PVC - kit de la

assamblea de la turbina

FTB694A-NPT-RK 1-1/2" NPT, PVC - kit de la

assamblea de la turbina

FTB695A-NPT-RK 2" NPT, PVC - kit de la

assamblea de la turbina

Kits de la Computadora:

FTB691-CK 1/2" - kit de la asamblea

de la computadora

FTB692-CK 3/4" - kit de la asamblea

de la computadora

FTB693-CK 1" - kit de la asamblea de

la computadora

FTB694-CK 1-1/2" - kit de la asamblea

de la computadora

FTB695-CK 2" - kit de la asamblea de

la computadora

D E U T S C H

WICHTIGE NACHRICHT

Die FTB690 Series Meßinstrumente mit

Wasser und anderen Chemikalien benutzen,

die mit Bestandteilen kompatibel sind, die

Flüssigkeit (Spezifikationen Abschnitt sehen).

Verwenden Sie nicht zu Meter von Kraftstoff

ofer chemikalien unvereinbar. Die FTB690 Reihe

Meßinstruments sind vorhanden entweder mit

einer lokalen elektronischen Anzeige oder einer

konditionierten Signalausgabebaugruppe, ein

digitales Signal zum Kunde Schnittstellenmodul

zur Verfügung zu stellen. FTB690 Series mißt

in Gallonen oder Litern. Auf den Kalibrierungsabschnitt Computer mit Anzeige für Beiwek

beziehen.

Diese Meßinstrumente sind nicht für den

Handel zulässig.

FTB690 Series Meßinstrumente sind gegen

elektronische Störung sehr empfindlich, wenn

sie innerhalb 2,5 bis 5 cm einiger Elektromotoren oder anderer Quellen des elektronischen Gebrauches bedient werden.

INSTALLATION

Ihr Meßinstrument inline entweder am Ende des

Schlauches neben der Düse horizontal oder

vertikal anbringen. Installation zu Metallanschlüssen wird nicht empfohlen. Diesen

Schritten folgen, um anzubringen:

1. Planen, die Turbine mit einer minimalen

Länge geraden Rohres anzubringen:

– Gegen den Strom von der Turbine, einer

minimalen Länge des geraden Rohres

von 10mal dem internen Durchmesser

der Turbine erlauben.

– Stromabwärts von der Turbine, eine

minimale Länge des geraden Rohres

von 5mal dem inneren Durchmesser

der Turbine erlauben.

2. Für NPT Befestigungen spule Klebeband

3 bis 4 mal um die Pipe-Verbindungen.

Sicherstellen, daß das Klebeband nicht

das Innere des Rohres berührt.

12

Page 15

3. Das Meßinstrument mit dem Pfeil anbringen,

der in die Richtung des Flusses zeigt.

4. Für NPT Befestigungen nur Ihre Hände

benutzen um die Pipe-Verbindun. Wenn Sie

die Anschlüsse festziehen, sich erinnern,

keine Werkzeuge zu benutzen.

Konditioniertes Signal Ausgeben

Baugruppenverdrahtung

Diese konditionierte Signalausgabebaugruppe

kann verdrahtet werden, um einen geöffneten

Kollektorsignal-Ausgang oder Welle des Quadrats 6-volt Ausgang zur Verfügung zu stellen.

Wenn man ein FTB690 Reihe Turbineströmungsmesser anbringt, muß der korrekte KFaktor in die Auslesenvorrichtung eingetragen

werden. Sie Können den K-Faktor finden

gedruckt auf dem Turbinekörper. Alle K-Faktoren

auf Omega Strömungsmessern werden in den

impulsen pro Gallone (PPG).

Öffnen Kollektor-Signal-Ausgang

Um einen geöffneten Kollektor Ausgang zu

erzielen, Bezugsbauschaltplan 1 signalisieren.

Der Klemmenblock ist auf der Rückseite des

Moduls. Das Modul ist die Fabrik, die für geöffneten Kollektorsignalausgang. Bitte geben sie

die (820-Ohm-Minimum) Widerstand, wenn

nicht durch den Empfang Ausrüstung geliefert.

10 Fuß (3 m) Kabel wird mit dem Modul.

Versehen Das Kabel zur gewünschten Länge

trimmen oder das Kabel wie benötigt verlängern. Abstände bis 5.000 Fuß (1,524 m) könne

für geöffneten Kollektorsignalausgang erzielt

werden.

Quadratischer Welle Ausgang

Um Quadratischen Welle Ausgang zu erzielen,

Bezugsbauschaltplan 2 signalisieren und einen

FLSC790-BATT (separat verkauft) für die Batterieleistung benutzen. Der Klemmenblock und

die Batterieposition sind auf der Rückseite des

Moduls. Zugang wie folgt:

1. Die vier Kreuzkopfschrauven von der Frontseite des Moduls entfernen. Das Modul von

der Turbine anheben.

2. Um die Klemmenblockanschlüsse zu

ändern, die passenden Schrauben lösen.

Die Leitungen in den korrekten Positionen

wieder anschließen und die Schrauben

festziehen.

3. Die Batterien anbringen. Sicherstellen,

daß der positive Pfosten in der richtigen

Position ist.

4. Das Modul auf das Turbinegehäuse in Position bringen. Um Feuchtigkeit Beschädigung zu vermeiden, sicherstellen daß der

Dichtung völlig setzt. Die vier Schrauben

an der Frontseite des Moduls festziehen.

10 Fuß (3 m) Kabel wird mit dem Modul versehen. Das Kabel zur gewünschten Länge trimmen

oder das Kabel wie benötigt verlängern.

Meßinstrument Genauigkeit

Überprüfen

Bevor Sie verwenden, die Genauigkeit des

Meßinstruments überprüfen und die Kalibrierung überprüfen.

1. Stellen Sie sicher, dass keine Luft in

das System, indem Sie die Flüssigkeit

durch den Zähler, bis die Flüssigkeit läuft

kontinuierlich. Dann, zu stoppen oder

umzuleiten den Fluss mit einem Ventil oder

eine Düse.

2. Ha lten Sie die DISPLAY-Tast e für 3

Sekunden, damit die Messgeräts Batch

Insgesamt werden auf Null gesetzt

werden. Wenn null erscheint, die Taste

freigeben.

3. Das Meßinstrument ein genau bekanntes

Volumen in einen genauen Behälter abgeben lassen. Für beste Resultate mit einem

ununterbrochenen vollen Strom messen.

4 Das Vojumen gegan die Anzeige order

die Aufnahmeausrüstung überprüfen.

Wenn die Menge, die gemessen wird,

genau ist, ist Nacheichung nicht notwendig.

Wenn nicht, auf den Kalibrierungsabschnitt

für weitere Anweisungen beziehen.

13

Page 16

BETRIEB

Computer-Display

Alle Operationen werden in der LCD-Anzeige

wieder. Das große Zentrum Ziffern geben

Mengen, in denen kleinere Wörter oder

“Ikonen” befindet sich oben und unten zeigen,

spezifische Informationen über die Summen,

Durchfluss-, Kalibrier-und Maßeinheiten.

Aktivieren Sie die Meter

Computer wird weiterhin kontinuierlich und

immer bereit zu erfüllen. Der Computer ist

durch Feld-powered austauschbaren Batterien.

Wenn die Anzeige schwach, schwach oder die

Batterie-Meldung angezeigt wird (siehe unten),

müssen die Batterien ausgetauscht werden.

Verweisen Sie auf die Wartung Abschnitt für

Details.

Batch-und Gesamtsummen

Der Computer verwaltet zwei Summen. Der

kumulierte Betrag stellt die kontinuierliche

Messung und kann nicht manuell zurückgesetzt

werden. Der Batch Insgesamt kann zurückgesetzt werden, fließen in einer einzigen Anwendung zu messen. Der kumulierte Betrag ist mit

TOTAL 1 bezeichnet, ist Batch Total beschriftet

TOTAL 2 BATCH.

Wenn der kumulierte Betrag erreicht eine Anzeige Lesung 999.999 der Computer wird ein

X10-Symbol zu markieren. Dies deutet darauf

hin, dass dem Betreiber eine Null an die 6

gezeigten Ziffern hinzugefügt werden. Wenn

die nächste Rollover auftritt, wird der Computer

ein Highlight X100-Symbol. Diese zeigt dem

Bediener, dass zwei Nullen an die 6 gezeigten

Ziffern hinzugefügt werden.

Drücken Sie die DISPLAY-Taste kurz, um

zwischen den insgesamt 1, TOTAL 2 BATCH

und FLOWRATE. Drücken Sie DISPLAY, um

die kurz TOTAL 2 BATCH. Halten Sie die

DISPLAY-Taste für 3 Sekunden wieder auf die

Batch-Total auf Null.

Wenn die Flüssigkeit fließt durch das Messgerät,

ein kleiner Propeller-Symbol markiert ist.

Durchfluss Funktion

Um diese Funktion, drücken Sie DISPLAY

verwenden, bis FLOWRATE-Symbol erscheint.

Die Fabrik eingestellten Zeit wird auf Basis des

Rechts der FLOWRATE hervorgehoben werden

(M = Minuten, H = Stunden, D = Tage). Wenn

FLOWRATE aufgerufen wird, wird das Display

um darauf hinzuweisen, Fließgeschwindigkeit.

Betriebs-und Kalibriersoftware

Alle Kalibrier-Informationen für den Benutzer

sichtbar als Symbole in der oberen Zeile des

Displays, über die Ziffern.

Alle Einheiten sind mit einer “Fabrik” Kalibrierung konfiguriert werden. Beide Gallonen und

Liter stehen zur Verfügung ( “GL” oder “LT”

wird angezeigt). Halten Sie die Schaltfläche

CALIBRATE, drücken Sie kurz DISPLAY, um

zwischen Gallonen und Liter zu wechseln.

Diese Fabrik-Kalibrierung (mit FAC angegeben)

ist fest in den Computer programmiert und

kann nicht vom Benutzer einstellbar.

HINWEIS: Ihr Computer ist möglicherweise

auch andere Maßeinheiten in sie programmiert. Wenn ja, hält die Schaltfläche

CALIBRATE und momentan Drücken der

DISPLAY-Taste wird durch alle werkseitig

eingestellt Einheiten zu wechseln. Andere

mögliche Einheiten sind: IGL (Imperial Gallonen), QT (Quart), CF (Kubikmeter), CM

(Kubikmeter), BL (42 gal. Barrel), CC (Kubikzentimeter) oder OZ (Unzen).

Wechseln zwischen verschiedenen Einheiten

werden nicht beschädigt die Total-Inhalten.

Zum Beispiel, im OpenGL-Modus, den Computer summiert 10,00 Gallone, wenn der

Benutzer schaltet in den LT, erscheint auf dem

Display 37,85 Liter (das gleiche Volumen, verschiedene Einheit) zu lesen.

Das “Feld” Kalibrierung kann vom Anwender

eingestellt werden und kann geändert werden,

oder jederzeit über das Kalibrierverfahren um

nachstehend beschriebenen Abschnitt der

Kalibrierung. Summen bzw. aus dem Bereich

Kalibrierung Durchfluss abgeleitet werden

aufgerufen, wenn der FAC-Symbol nicht mehr

sichtbar in der oberen Zeile des Displays wird.

14

Page 17

CALIBRATION

Vor Dem Beginn Der Nacheichung

Für die genauesten Resultate an einer Fließgesc h w i n digkeit zufüh ren, di e gut Ihre

tatsächlichen Betriebsbedingungen simuliert.

Vermeiden, mehr Flüssigkeit “zu tröpfeln”

oder wiederholt den Fluß zu beginnen und zu

stoppen. Diese Vorgänge ergeben weniger

genaue Kalibrierungen.

Versichern Sie sich, dass Sie die minimalen

Fließgeschwindigkeiten des Meßinstruments

erreichen:

FTB690A Series Meßinstrumente

1/2 Zoll 1 GPM (3,8 LPM)

3/4 Zoll 2 GPM (7,5 LPM)

1 Zoll 5 GPM (18,8 LPM)

1-1/2 Zoll 10 GPM (37,85 LPM)

2 Zoll 20 GPM (75 LPM)

Der Gebrauch eines gleichmäßig zuverlässigen,

genauen Kalibrierung Behälters wird in hohem

Grade für die genauesten Resultate empfohlen.

Wegen der hohen Fließgeschwindigkeit, wird

es stark empfohlen, daß Kalibrierung mit einer

Kombination des Volumens und des Gewichts

mit feine Auflösung Skalen durchgeführt wird.

Für beste Resultate sollte das Meßinstrument

angebracht werden und bereinigt worden von

der Luft vor Kalibrierung auffangen.

Feld Kalibrierung mit

Computer-Display

Field Kalibrierung und Kalibrierung sind an der

Operation Abschnitt definiert. Werkskalibrierung

Einstellungen sind in jedem Computer während

der Herstellung programmiert, unter Verwendung von Wasser bei 70° C (21° C). Messwerte mit

Hilfe der Factory Calibration (FAC) ist möglicherweise nicht in einigen Situationen richtig, zum

Beispiel unter extremen Temperaturbedingungen, Nicht-Standard-Sanitär-Konfigurationen

oder mit anderen Medien als Wasser.

2. Dispense eine bekannte Menge von Flüssigkeit bei einem Durchfluß, Vertreter der

Anwendung. Jeder Betrag zwischen .1

und 999,9 Einheiten verwendet werden

kann. Anzeige zählt, solange Flüssigkeit

fließt durch den Zähler.

3. Die DISPLAY-Taste können dann geschoben werden, um die Position der Ziffer

auswählen und die Schaltfläche Kalibrieren geschoben werden können, um den

gewünschten Wert an der blinkenden Position zu blättern. Bearbeiten Sie den Betrag mit dem Wert, der oben gezeigt wurde

verzichtet. Werte von 000,1 bis 999,9

eingegeben werden können.

4. Wenn Sie zufrieden sind mit dem Wert,

drücken Sie beide CALIBRATE und

DISPLAY Tasten gleichzeitig. CALEnd

wird angezeigt und Gerät zurück zum

normalen Betrieb, abzüglich der FAC

(Werkskalibrierung)-Symbol.

5. Das Gerät ist nun in Betrieb sein mit einer benutzerdefinierten Kalibrierung eine

einmalige Nummer, die oben genannten

Verfahren zu verzichten. Nr. Maßeinheit

(Gallonen, Liter usw.) Symbol wird hervorgehoben.

Hinweis: Um wieder auf die werkseitigen Ka-

librierung (FAC), drücken und halten Sie

beide CALIBRATE und DISPLAY-Taste

etwa 3 Sekunden, bis FAcCAL angezeigt

wird. Dann Entriegelungstasten. Einheit

sollte Rückkehr zum normalen Betrieb und

die FAC-Symbol sichtbar.

HINWEIS: Wenn das Feld der Betriebsart

Kalibrierung eingetragen ist, und keine

Flüssigkeit verzichtet wird, dann beim

Verlassen, wird der Computer Daten aus der

letzten erfolgreichen Kalibrierung vor Ort.

WARTUNG

Field Calibration Procedures

(Dispense / Display-Methode)

1. So kalibrieren, drücken Sie bei gedrückter

CALIBRATE und DISPLAY-Taste etwa 3

Sekunden, bis Sie FLdCAL sehen können.

Lassen Sie beide Tasten, und Sie werden

dd000.0 sehen. Sie befinden sich nun im

Bereich der Betriebsart Kalibrierung.

Die korrekte Behandlung und die Wartung

verlängern das Leben und den Service des

Meßinstruments.

15

Page 18

Turbinenrotor

Das Meßinstrument ist praktisch wartungsfrei.

Jedoch ist es wichtig, dass sich der Rotor frei

bewegen kann. Das Meßinstrument sauber

halten und von Verunreinigung freihalten.

Wenn der Läufer sich nicht frei dreht, ein

Durchdringungsschmiermittel auf dem Läufer,

der Welle und den Wellenlagern anwenden.

Allen möglichen Rückstand oder Ablagerungen

vom Läufer mit einer weichen Bürste oder

einem kleinen Fühler entfernen. Achtgeben, daß

Sie nicht den Turbinenrotor oder die Stützen

beschädigen.

VORSICHT

Pressluft durch die Turbine blasen kann den

Rotor beschädigen.

BatterieAustausch

Das Computer-Display wird durch zwei 3-Volt

Lithium-Batterien, die ersetzt werden kann,

während das Gerät installiert ist. Die Zwischensummen und kumulativen Gesamtmengen

stellen sich auf Null zurück, wenn die Batterien

schwach werden oder entfernt worden sind.

Die Fabrik- und Nacheichung bleibt erhalten.

Wenn die Anzeige schwächer wird, leer oder

die Batterie-Meldung (siehe unten), ersetzen

Sie die Batterien wie folgt:

1. Die vier Kreuzschlitzschrauben von der

Vorderseite des Meßinstruments entfernen

und die Frontplatte von der Turbine

anheben.

2. Die alten Batterien entfernen und jede

mögliche Korrosion von den Klemmen

säubern.

3. Neue Batterien anbringen. Überprüfen, daß

der positive Pfosten in der richtigen Posi-

tion ist.

4. Wenn die Batterien ausgetauscht sind,zeigt

die Frontplatte “POWER ON”. Die Anzeige

überprüfen, um normale Funktionen sicherzustellen, bevor Sie wieder zusammenbauen.

16

5. Falls nötig, Batterieeinsetzung berichtigen,

und die Frontplatte auf das Turbinegehäuse

in Position bringen. Um Feuchtigkeit-

sbeschädigung zu vermeiden, überprüfen,

daß der Dichtung völlig sitzt. Die vier

Schrauben an der Frontplatte festziehen.

SPEZIFIKATIONEN

Eingang und Anschluß:

Für NPT-Modelle:

FTB691A-NPT/FTB691A-NPT-P 1/2" NPT

FTB692A-NPT/FTB692A-NPT-P 3/4" NPT

FTB693A-NPT/FTB693A-NPT-P 1" NPT

FTB694A-NPT/FTB694A-NPT-P 1-1/2" NPT

FTB695A-NPT/FTB695A-NPT-P 2" NPT

DesignBaumuster: Turbine

Naßgemachte Bauteile:

Gehäuse: PVC

Achslager: Keramisch

Welle: Hartmetall

Läufer und Halterungen: PVDF

Haltering: Rostfreier Stahl

Verbindungstyp: Zeitplan 80 NPT

Max. FunktionsDruck: 225 PSIG @ 73° F

U.S. Maß

Maßeinheit der Maßnahme: Gallone

FlußStrecke:

1/2" 1 - 10 GPM

3/4" 2 - 20 GPM

1" 5 - 50 GPM

1-1/2" 10 - 100 GPM

2" 20 - 200 GPM

Genaui g k e i t : ± 3.0% lesegenauigkeit

(Genauigkeit kann mit verbessert werden

auffangen Kalibrierung)

Betriebstemperatur: +32° zu +140° F

ANMERKUNG: Flüssigkeit nicht innerhalf

des Meßinstruments einfrieren lassen

SpeicherTemperatur: -40° zu +158° F

Gewicht:

(Eingeschlossen sind Computer-Display.

Korditioniertes Signal Ausgeben modul fügt .30

Pfund.)

1/2" ,55 Pfund

3/4" ,67 Pfund

1" ,84 Pfund

1-1/2" 1,38 Pfund

2" 1,78 Pfund

Page 19

Abmessungen - Zoll (W x H x L):

(Eingeschlossen sind Computer-Display.

Korditioniertes Signal Ausgeben modul fügt 1,1

Zoll bis Höhe.)

1/2" 2,0 x 2,8 x 5,5

3/4" 2,0 x 2,9 x 5,5

1" 2,0 x 3,3 x 6,2

1-1/2" 2,3 x 3,9 x 7,6

2" 3,5 x 4,5 x 7,9

Metrisches Maß

Maßeinheit: Liter

FlußStrecke:

1/2" 3,8 - 38 LPM

3/4" 7,6 - 76 LPM

1" 19 - 190 LPM

1-1/2" 38 - 380 LPM

2" 76 - 760 LPM

Genaui g k e i t : ± 3.0% lesegenauigkeit

(Genauigkeit kann mit verbessert werden

auffangen Kalibrierung)

Betriebstemperatur: 0° zu +60° C

ANMERKUNG: Flüssigkeit nicht innerhalf

des Meßinstruments einfrieren lassen

SpeicherTemperatur: -40° zu +70° C

Gewicht:

(Eingeschlossen sind Computer-Display.

Korditioniertes Signal Ausgeben modul fügt

.14 kg)

1/2" .249 Kilogramm

3/4" .304 Kilogramm

1" .381 Kilogramm

1-1/2" .626 Kilogramm

2" .807 Kilogramm

Abmessungen - Zentimeter (W x H x L):

(Eingeschlossen sind Computer-Display.

Korditioniertes Signal Ausgeben modul fügt

2.8 cm bis Höhe.)

1/2" 5,0 x 7,1 x 13,9

3/4" 5,0 x 7,3 x 13,9

1" 5,0 x 8,3 x 15,7

1-1/2" 5,8 x 9,9 x 19,3

2" 8,8 x 11,4 x 20,0

TEILE

Die folgenden Ersatzteile und die Zusatzgeräte

sind für die FTB690 Series Meßinstrumente

vorhanden:

Teil Nr. Beschreibung

FLSC790-BATT Batterie Austausch lnstallationssatz

FTB890 O-Ring O-Ring

FTB691A-NPT-RK 1/2 Zoll, NPT, PVC, Turbine einheitsinstallationssatz

FTB692A-NPT-RK 3/4 Zoll, NPT, PVC, Turbine einheitsinstallationssatz

FTB693A-NPT-RK 1 Zoll, NPT, PVC, Turbine einheitsinstallationssatz

FTB694A-NPT-RK 1-1/2 Zoll, NPT, PVC,

Turbineeinheitsinstalla tionssatz

FTB695A-NPT-RK 2 Zoll, NPT, PVC, Turbine einheitsinstallationssatz

Computereinheitsinstallationssatz:

FTB691-CK 1-/2 Zoll, Computereinheit sinstallationssatz

FTB692-CK 3/4 Zoll, Computereinheit sinstallationssatz

FTB693-CK 1 Zoll, Computereinheit sinstallationssatz

FTB694-CK 1-1/2 Zoll, Computerein heitsinstallationssatz

FTB695-CK 2 Zoll, Computereinheit sinstallationssatz

17

Page 20

I T A L I A N O

AVVISO IMPORTANTE

Usare i tester dei Series del FTB690 con acqua

ed altri prodotti chimici che sono compatibili

con le parti che sono esposti a liquido (vedere

la sezione di specifiche). Non usare misurare il

combustibile o incompatibili o i prodotti chimici.

I contametri di serie FTB690 sono a disposizione

con una Visualizzazione elettronica locale, o un

modulo di uscita condizionato del segnale per

fornire un segnale numerico all’apparecchiatura

di collegamento del cliente. I Series di FTB690

misura la misura con un contatore nei galloni

o nei litri. Riferirsi alla taratura con display del

computer di sezione per i particolari.

Questi tester non sono per le applicazioni

commerciali.

I tester dei Series del FTB690 sono molto

sensibili ad interferenza elettronica se sono

funzionati all’interno di 1 - 2 pollici di alcuni

motori elettrici o di altre fonti di uso elettronico.

Installare il vostro tester in linea orizzontalmente

o verticalmente o all’estremità del tubo flessibile

adiacente all’ugello. L’installazione ai collegamenti del metallo non è suggerita. Seguire questi

punti per installare:

1. Progettare installare la turbina con una

– A monte dalla turbina, concedere ad

– A valle dalla turbina, concedere ad una

2. Per i Montaggi del NPT circondare i

3. Fissare il tester con la freccia indicata nel

4. Per i Montaggi del NPT utilizzare soltanto

INSTALLAZIONE

lunghezza minima del tubo diritto:

una lunghezza minima di un tubo diritto

di 10 volte il diametro interno della

turbina.

lunghezza minima di un tubo diritto di 5

volte il diametro interno della turbina.

collegamenti di tubo con giri di nastri

adesivi del 3-4 volte.

senso del flusso.

le vostre mani per stringere i collegamenti.

Non utilizzare gli attrezzi per stringere. Ciò

può causare danni.

Segnale Condizionato Produrre

Cablaggio di Modulo

Questo modulo di segnale condizionato del

può essere legato per fornire del collettore

dell’ segnale aperta o dell’onda del quadrato

di 6-volti.

Nell’installare un flussometro della turbina

di serie di FTB690, il fattore K corretto deve

essere inserito nel dispositivo della lettura.

Potete trovare il fattore K stampato sul corpo

della turbina. Tutti i fattore K sui fludssometri

del Omega sono calcolati negli impulsi per il

gallone (PPG).

Collettore dell’Segnale Aperta

Per raggiungere Collettore dell’ Segnale Aperta,

Riferiscasi allo schema elettrico di riferimento

1. Il blocchetto terminali è situato dal lato pos-

teriore del modulo. Il modulo è fabbrica montata per collettore dell’ segnale aperta. Fornire

prego il resistore di minimo di 820 Ohm, se non

è fornito dall’apparecchiatura di ricezione.

Dieci piedi (3 m) di cavo è fornito del modulo.

Assettare il cavo alla lunghezza voluta o estendere il cavo come necessario. Le distanze fino a

5,000 piedi (1,524 m) possono essere realizzate

per l’collettore dell’ segnale aperta.

Segnale dell’Onda Quadrata

Per raggiungere segnale dell’Onda Quadrata,

Riferiscasi allo schema elettrico di riferimento

2 ed usare FLSC790-BATT (venduto esclusivamente) per la potenza della batteria. Il blocchetto terminali e la posizione della batteria

sono situati dal modulo. Accesso come segue:

1. Rimuovere le quattro viti Phillips dalla parte

anteriore del modulo. Alzare il modulo dalla

turbina.

2. Per cambiare i collegamenti del blocchetto

terminali, allentare le viti adatte. Ricollegare

i legare nelle posizioni adequate e stringere

le viti.

3. Installare le batterie. Assicurarsi che l’alberino positivo è nella posizione corretta.

4. Posizionare il modulo sull’alloggiamento

della turbina. Evitare danni dell’umidità,

assicurarsi che l’anello completamente è

messo. Stringere le quattro viti sulla parte

anteriore del modulo.

18

Page 21

Dieci piedi (3 m) di cavo è fornito del modulo.

Assettare il cavo alla lunghezza voluta o estendere il cavo come necessario.

Verificare L’Esattezza del Tester

Prima di utilizzare, controllare l’esattezza del

tester e verificare la taratura.

1. Assicurarsi che non ci è aria nel sistema

iniziando la quantità di fluido fino a che

non funzioni costantemente. Poi, fermare

o deviare il flusso con una valvola o ugelli.

2. Mantenere il tasto dell’ DISPLAY per 3

secondi – zero totali in lotti del tester. Quando

gli zeri compaiono, liberare il tasto.

3. Per mezzo del tester, misurare un volume

conosciuto esatto in un contenitore esatto.

Per i risultati migliori, misurare con un

flusso pieno continuo.

4. Controllare il volume contro l’esposizione

o l’apparecchiatura di registrazione. Se

l’importo misurato è esatto, la taratura

del campo non è necessaria. Se non,

riferirsi alla sezione di taratura per ulteriori

istruzioni.

FUNZIONAMENTO

Computer Display

Tutte le operazioni sono riflessi nel display LCD.

Le cifre di grandi dimensioni indicano importi,

dove le parole più piccole o “icone” che si trova

sopra e sotto indica informazioni specifiche sui

totali, il flusso, la calibratura e unità di misura.

Per Attivare il Misuratore

Computer è sempre acceso e sempre pronto

a eseguire. Il computer è alimentato da batterie sostituibili campo. Quando il display diventa

debole, sbiadite o il messaggio di batteria

scarica viene visualizzato (vedi sotto), le batterie devono essere sostituite. Riferimento alla

sezione Manutenzione per ulteriori dettagli.

Batch e Cumulativo Totali

Il computer effettua due totali. Il totale cumulativo fornisce la misura continua e non può essere

ripristinato manualmente. Il totale in lotti può

essere ripristinato per misurare il flusso durante

il monouso. Il totale cumulato è etichettato con

TOTAL 1, Batch totale è etichettato TOTAL 2

BATCH.

Quando il totale cumulato raggiunge una lettura del display di 999.999 computer metterà in

evidenza l’icona X10. Ciò indica l’operatore che

uno zero deve essere aggiunto il 6 cifre indicate.

Quando il cambio di data successiva verifica,

il computer metterà in evidenza l’icona X100.

Ciò indica l’operatore che due zeri deve essere

aggiunto il 6 cifre indicate.

Premere brevemente il tasto DISPLAY per

passare tra il TOTAL 1, TOTAL 2 BATCH e

FLOWRATE impostazioni. Premere brevemente

DISPLAY per visualizzare la TOTAL 2 BATCH Tenere premuto il pulsante DISPLAY per 3 secondi

per ripristinare il Batch totale a zero.

Quando è fluido che scorre attraverso il contatore, una piccola icona elica viene evidenziata.

Caratteristica Indice di Flusso

Per utilizzare questa funzione, premere e rilasciare DISPLAY fino FLOWRATE appare l’icona.

La fabbrica di base di tempo sarà evidenziato

al diritto della FLOWRATE (M = minuti, H = ore,

D = giorno). Quando FLOWRATE è richiamato,

il display sarà che indica la velocità di flusso.

Calibratura del Campo

e della Fabbrica

Tutte le informazioni di calibrazione è visibile

all’utente come icone sulla linea superiore del

display, sopra le cifre numeriche.

Tutte le unità sono configurati con una taratura di “fabbrica”. Entrambi i litri e litri sono

disponibili (“GL” o “LT” verrà visualizzato). Tenendo premuto il pulsante CALIBRATE, premere

brevemente DISPLAY per passare tra litri e litri.

Questa calibrazione di fabbrica (indicato con

FAC) è programmato in modo permanente nel

computer e non è regolabile dall’utente.

19

Page 22

NOTA: Il computer può avere altre unità di misura

programmato in esso. In tal caso, tenendo

premuto il pulsante CALIBRATE e per un

momento premendo il pulsante DISPLAY

sarà scorrere tutte le unità di fabbrica. Altre

unità possibili sono: IGL (gallone imperiale),

QT (Quart), CF (metri cubi), CM (metro

cubo), BL (42 gal. Barile), CC (centimetro

cubo) o OZ (once).

I contenuti di commutazione tra diverse unità

non rovinerà la Total. Ad esempio, in modalità

GL, il computer totalizza 10,00 litri, se l’utente

passa alla modalità di LT, il display leggerà 37,85

litri (lo stesso volume, differenti unità).

Il “campo” di taratura può essere impostato

dall’utente, e può essere cambiato o modificato

in qualsiasi momento, utilizzando la procedura di

taratura descritta di seguito nella sezione di calibrazione. Totali o portata derivata dalla taratura

campo vengono richiamati quando l’icona FAC

non è più visibile sulla riga superiore del display.

CALIBRAZIONE

Prima di Cominciare Taratura

del Campo

Per i risultati più esatti, erogare ad un debito

che simula il più bene le vostre condizioni di

gestione reali. Evitare di “gocciolare” più liquido

o ripetutamente iniziare ed arrestare il flusso.

Queste azioni provocheranno le calibrature

meno esatte.

Vi assicurate raduno i requisiti minimi di debito

del tester:

Tester dei Series del FTB690A

Tester di 1/2 Pollice 1 GPM (3,8 LPM)

Tester da 3/4 di Pollice 2 GPM (7,5 LPM)

Tester da 1 Pollice 5 GPM (18,8 LPM)

Tester di 1-1/2 Pollice 10 GPM (37,85 LPM)

Tester da 2 Pollici 20 GPM (75 LPM)

Usando un contenitore credibile e ed esatto di

taratura altamente è suggerito per i risultati più

esatti. Dovuto l’ alto debito, è suggerito vivamente che la calibratura è completata con una

combinazione di volume e di peso usando le

scale di alta risoluzione. Per i risultati migliori,

il tester dovrebbe essere installato ed eliminato

l’inceppo di aria prima della taratura del campo.

20

Taratura di Campo con

Visualizzatore del Computer

Taratura di Campo e di calibrazione di fabbrica sono definite nella sezione operativa.

Impostazioni di calibrazione di fabbrica sono

programmati in ogni computer durante la produzione, utilizzando l’acqua a 70° F (21° C). Letture utilizzando la taratura di fabbrica (FAC), non

possono essere precisi in alcune situazioni, per

esempio, in condizioni di temperatura estreme,

configurazioni non standard o idraulico con

liquidi diversi dall’acqua.

Procedimento di Taratura di

Campo (Metodo di Campo

Dispense/Visualization)

1. Per la taratura di campo, pulsanti e tenere

premuto i tasti CALIBRATE e DISPLAY per

circa 3 secondi fino a visualizzare FLdCAL. Rilasciare entrambi i tasti e vedrete

dd000.0. Ora siete in modalità di taratura

di campo.

2. Erogare una quantità nota di liquido a un

rappresentante portata della domanda.

Qualunque importo tra .1 e 999.9 unità può

essere utilizzata. Il monitor contare mentre

fluido che scorre attraverso il contatore.

3. Il tasto DISPLAY può essere spinto a

selezionare la posizione di una cifra e il pulsante CALIBRATE può essere spinto per

far scorrere il valore desiderato nella posizione lampeggiante. Modifica l’importo

indicato con il valore che è stato dispensato sopra. Valori da 000.1 a 999.9 possono

essere inseriti.

4. Quando siete soddisfatti con il valore, premere entrambi i CALIBRATE e DISPLAY i

pulsanti contemporaneamente. Agenda

verrà visualizzata e l’unità tornerà al funzionamento normale, meno il icona di FAC

(taratura di fabbrica).

5. Il contatore sarà ora di funzionamento con

un numero di taratura personalizzata unica

per la procedura di cui sopra dispensa.

Nessuna icona d l’unità di misura (litri, galloni, ecc), sarà evidenziata.

NOTA: Per tornare alla taratura di fabbrica

(FAC), premere e tenere premuti i tasti

CALIBRATION e DISPLAY per circa 3

secondi, fino a quando FAcCAL viene visualizzato. L’unità dovrebbe tornare al normale funzionamento e l’icona FAC visibili.

Page 23

NOTA: Se la modalità di calibrazione campo

è inserito e NO fluido è erogata, poi al

momento di partire, il computer utilizzerà

i dati dal campo di taratura d’ultimo

successo.

MANUTENZIONE

Il maneggiamento e la cura adeguati estenderanno la durata ed il servizio del tester.

4. Quando le batterie sono sostituite, la piastra

frontale alimenterà SOPRA. Controllare

l’esposizione per accertare le funzioni nor

hanno ripreso prima del montaggio ancora.

5. Riposizionare le batterie, se necessario e

posizionare la piastra frontale sull’alloggiamento della turbina. Evitare danni dell’

umidità, assicurarsi che l’ anello completamente è messo. Stringere le quattro

viti sulla piastra frontale.

mali

Rotore di Turbina

Il tester è virtualmente manutenzione-free.

Tuttavia, è liberamente importante i movimenti

del rotore. Mantenere il tester pulito ed esente

dagli agenti inquinanti.

Se il rotore non gira liberamente, applicare un

lubrificante penetrante sul rotore, sull’albero

e sui cuscinetti. Rimuovere tutti i residui o

depositi dal rotore usando una spazzola molle

o una piccola sonda. Fare attenzione non

danneggiare il rotore di turbina o i supporti.

ATTENZIONE

Appiattito fornisc tramite il complessivo

della turbina ha potuto danneggiare il

rotore.

Rimontaggio della Batteria

Il computer display è alimentato da due batterie

del litio 3-volt che possono essere sostituite

mentre il tester è installato. Quando le batterie

sono rimosse o perdono l’alimentazione, il

batch ed i totali cumulativi ripristinati a zero

ma le calibrature della fabbrica e del campo

sono mantenuti.

Se il Visualizzatore diventa debole, vuoto o il

messaggio di batteria scarica viene visualizzato (vedi sotto), sostituire le batterie nel modo

seguente:

1. Rimuovere le quattro viti della Phillips-testa

dalla faccia del tester ed alzare la piastra

frontale dalla turbina.

2. Rimuovere le vecchie batterie e liberare

tutta la corrosione dai terminali.

3. Installare le nuove batterie. Assicurarsi che

l’alberino positivo è nella posizione corretta.

SPECIFICHE

Ingresso e Presa:

Per NPT Modelli:

FTB691A-NPT/FTB691A-NPT-P 1/2" NPT

FTB692A-NPT/FTB692A-NPT-P 3/4" NPT

FTB69A3-NPT/FTB693A-NPT-P 1" NPT

FTB694A-NPT/FTB694A-NPT-P 1-1/2" NPT

FTB695A-NPT/FTB695A-NPT-P 2" NPT

Tipo di Disegno: Turbina

Componenti Bagnati:

Alloggiamento: PVC

Cuscinetti: Di Ceramica

Albero: Carburo Di Tungsteno

Rotore e Supporti: PVDF

Fermo: Acciaio Inossidabile

Tipo dei Collegamento: Programma 80,

NPT

Massimo Pressione di Esercizio:

225 PSIG @ 73° F

Misura Degli Stati Uniti

Unità della Disura: Gallone

Gamma di Flusso:

1/2" 1 - 10 GPM

3/4" 2 - 20 GPM

1" 5 - 50 GPM

1-1/2" 10 - 100 GPM

2 20 - 200 GPM

Esattezza: ±3.0% di lettura (esattezza può

essere migliorata con la calibratura del

campo)

Temperatura di Funzionamento:

+32° a +140° F

NOTA: Non lasciare che il liquido congeli

all’inerno del tester.

21

Page 24

Temperatura di Immagazzinaggio:

-40° a +158° F

Peso:

(Include il schermo del computer. Segnale

Condizionato Modulo aggiunge .30 libbre.)

1/2" ,55 libbre

3/4" ,67 libbre

1" ,84 libbre

1-1/2" 1,38 libbre

2" 1,78 libbre

Dimensioni - Pollici (Larghezza, Altezza,

Lunghezza):

(Include il schermo del computer. Segnale

Condizionato Modulo aggiunge 1,1 pollici di

altezza.)

1/2" 2,0 x 2,8 x 5,5

3/4" 2,0 x 2,9 x 5,5

1" 2,0 x 3,3 x 6,2

1-1/2" 2,3 x 3,9 x 7,6

2" 3,5 x 4,5 x 7,9

Misura Metrica

Unità della Misura: Litro

Gamma di Flusso:

1/2" 3,8 - 38 LPM

3/4" 7,6 - 76 LPM

1" 19 - 190 LPM

1-1/2" 38 - 380 LPM

2" 76 - 760 LPM

Esattezza: ±3.0% di lettura (esattezza può

essere migliorata con la calibratura del

campo)

Temperatura di Funzionamento:

0° a +60° C

NOTA: Non lasciare che il liquido congeli

all’inerno del tester.

Temperatura di Immagazzinaggio:

-40° a +70° C

Peso:

(Include il schermo del computer. Segnale

Condizionato Modulo aggiunge .14 kg.)

1/2" .249 kg

3/4" .304 kg

1" .381 kg

1-1/2" .626 kg

2" .807 kg

Dimensioni - Centimetro (Larghezza,

Altezza, Lunghezza):

(Include il schermo del computer. Segnale Condizionato Modulo aggiunge 2.8 cm di altezza.)

1/2" 5,0 x 7,1 x 13,9

3/4" 5,0 x 7,3 x 13,9

1" 5,0 x 8,3 x 15,9

1-1/2" 5,8 x 9,9 x 19,3

2" 8,8 x 11,4 x 20,0

PARTI

Le seguenti parti ed accessori di ricambio sono

disponibili per i tester dei Series del FTB690A:

Parte No. Descrizione

FLSC790-BATT Corredo del Rimontaggio

della Batteria

FTB890 O-Ring Anello a “cso”

FTB691A-NPT-RK 1/2 Pollice, NPT, PVC,

Corredo dell’Assemblea

della Turbina

FTB692A-NPT-RK 3/4 Pollice, NPT, PVC,

Corredo dell’Assemblea

della Turbina

FTB693A-NPT-RK 1 Pollice, NPT, PVC,

Corredo dell’Assemblea

della Turbina

FTB694A-NPT-RK 1-1/2 Pollice, NPT, PVC,

Corredo dell’Assemblea

della Turbina

FTB695A-NPT-RK 2 Pollice, NPT, PVC,

Corredo dell’Assemblea

della Turbina

Corredo Del Calcolatore:

FTB691-CK 1/2 Pollice, Corredo dell’

Assemblea del Calcolatore

FTB692-CK 3/4 di Pollice, Corredo dell’

Assemblea del Calcolatore

FTB693-CK 1 Pollice, Corredo dell’

Assemblea del Calcolatore

FTB694-CK 1-1/2 Pollice, Corredo dell’

Assemblea del Calcolatore

FTB695-CK 2 Pollici, Corredo dell’

Assemblea del Calcolatore

22

Page 25

F R A N Ç A I S

NOTIFICATION IMPORTANTE

Utilisez les mètres de Series de FTB690 avec

l’eau et d’autres produits chimiques qui sont

compatibles avec les composants qui sont

exposés au fluide (voir la section de caractéristiques). N’employez pas pour mesurer le

carburant ou des produits chimiques incompatibles. Les Series de FTB690 sont disponibles

avec une visualisation électronique locale, ou

un module de rendement conditionné de signal

pour fournir un signal numérique à l’équipement

d’interface de client. Les Series de FTB690 dose

la mesure en gallons ou litres. Référez-vous à

la section de calibrage avec écran d’ordinateur

pour des détails.

Ces compteurs ne sont pas légaux pour les

applications commerciales.

Les compteurs de Series de FTB690 sont très

sensibles à l’interférence électronique s’ils sont

actionnés à moins de 1 à 2 pouces de quelques

moteurs électriques ou d’autres sources de

bruit électronique.

INSTALLATION

Installez votre compteur en ligne horizontalement

ou verticalement ou à l’extrémité du tuyau à

côté du bec. L’installation aux raccordements

en métal n’est pas recommandée. Suivez ces

étapes pour installer:

1. Projetez installer la turbine avec une

longueur minimum de pipe droite :

– En amont de la turbine, permettez à

une longueur minimum de la pipe droite

de 10 fois le diacompteur interne de la

turbine.

– En aval de la turbine, permettez à une

longueur minimum de la pipe droite

de 5 fois le diacompteur interne de la

turbine.

2. Pour des Raccord e m en t s de NPT

enveloppez tous les raccordements de pipe

avec la bande adhésive de 3 ou 4 fois pour

cachet. Ne laissez pas le glisser à l’intérieur

de la pipe.

3. Attachez le compteur avec la flèche dirigée

dans la direction de l’écoulement.

4. Pour des Raccordements de NPT utilisez

vos mains pour serrer le mètre aux

extrémités des raccordements. N’utili-sez

aucun outil pour serrer. Ceci peut endommager le logement.

Le Signal de Sortie Conditionné le

Câblage de Module

Ce module du signal de sortie conditionné peut

être installer pour fournir un signal ouvert collecteur de sortie ou un signal carré de sortie

de 6-V.

En installant un débitmètre de turbine de série

FTB690, le K-facteur qui est correct doit être

écrit dans le dispositif d’afficheur. Vous pouvez

trovez le K-facteur imprimé sur le corps de turbine. Tous les K-facteurs sur des débitmetres

d’Omega sont calculés dans les signaux par

gallon (PPG).

Le Signal Ouvert Collecteur

de Sortie

Pour obtenir un signal ouvert collecteur de

sortie, référez le diagramme de câblage 1. Le

bloc terminal est situé de l’arrière du module.

Le module est usine assemblée pour le signal

ouvert collecteur de sortie. Fournissez la résistance (de minimum de 820 ohms), si elle n’est

pas fournie par l’équipement de réception.

Dix pieds (3 m) de câble est fourni avec le

module. Coupez le câble à la longueur désirée ou prolongez le câble selon les besoins.

Les distances jusqu’a 5.000 pieds (1,524 m)

peuvent être obtenues pour le signal ouvert

collecteur de sortie.

Le Signal Carré de Sortie

Pour obtenir le signal carré de sortie, référez le

diagramme de câblage 2 et utilisez FLSC790BATT (vendu séparément) pour la puissance

de batterie. Le bloc terminal et l’endroit de

batterie sont situés de’arière du module. Accès

comme suit:

1. Enlevez les quatre vis Phillips de’avant

du module. Soulevez le module de la

turbine.

23

Page 26

2. Pour changer les raccordements du block

terminal, desserrez les vis appropriées.

Rebranchez les fils en les positions appropriées et serrez les vis.