Page 1

FTB6100

and

FTB6200

Series

ldustrial

Ir

old Water Meters

C

Positive Displacement

m

b

An OMEGA

FTB6205

OMEGA”

TechnologJes

Company

d

shown

Operator’s Manual

Page 2

TABLE OF CONTENT S

SECTION 1

SECTION 2

SECTION 3

INTRODUCTION

AVAILABLE MODELS

INSTALLATION

3.1 Unpacking

3.2 Installation

SECTION 4

SECTION 5

START-UP PROCEDURE

SPECIFICATIONS

SECTION 6 OPTIONS

FTB6100

/ 6200

COLD WATER METER

2”

l/2”

THROUGH

POSITIVE DISPLACEMENT

.................................................................

........................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..................................................................

..................................................................

..................................................

...............................................................

................................................................................

PAGE

1

1

2

3

3

-PT

6.1

6.2 -PS

Option

Option

..................................................................

..................................................................

SECTION 7 DIMENSIONAL DRAWINGS

.................................................

4

4

5

Page 3

SECTION 1 INTRODUCTION

The OMEGA@

FTB6100/6200 Cold Water Meter is a volumetric type operating on the

oscillating piston principle. This utilizes a piston which the water rotates in a working chamber,

with each piston revolution being equivalent to a known volume of water. The highly accurate

FTB6100/6200 is specifically designed for cold water applications.

3”,

rotatable

for extra long life and assured accuracy. Its

magnetically-driven, permanently hermetically sealed and nitrogen-filled register

l/4”

thickglassface is tempered to resist breakage,

It features giant fully

scratching, and abrasion. A flow detector located on the top of the center spindle, provides

visual proof of plumbing leaks.

The

FTB6100/6200 has a self-lubricating positive displacement design. The

precision-

machined internal parts are manufactured from graphite impregnated thermoplastic in

combination with a longer life, more trouble-free service. Its internal 40 mesh strainer

minimizes stoppages due to foreign matter in the pipe.

Because of its unique oscillating piston

design and low oscillation rate, wear is reduced to a minimum.

The piston movement is transferred by appropriate reduction gearing and a magnetic drive to

m3

a straight reading sealed register calibrated in U.S. Gallons,

ft.”

(cubic feet) or

(cubic

meters).

WARNING

THESE WATER FLOWMETERS HAVE PLASTIC INTERNAL PARTS THAT ARE RAPIDLY ATTACKED BY

HYDROCARBON FLUIDS, SUCH AS GASOLINE, DIESEL FUEL, KEROSENE, AND SIMILAR MATERIALS.

EVEN TRACE AMOUNTS OF THESE MATERIALS IN WATER WILL TEND TO ACCUMULATE IN THE

PLASTIC PARTS, LEADING TO COMPLETE FAILURE OF THE FLOWMETER.

SECTION 2 AVAILABLE MODELS

Port

Size Range

Water

Water Meter

Meter

Water Meter

Water Meter

Water Meter

l/2”

314”

314”

”

1

l-l

12”

Water Meter 2”

Port

Size

Water Meter

Water Meter

Water Meter

l/2”

314”

314”

DESCRIPTION (BRONZE BODY)

Normal Operating

Part

Number

1to20

1 to 25 GPM

GPM

2 to 30 GPM

3to50 GPM

5to100GP M

8 to 160 GPM

FTBGI

FTB6107

FTBGI

FTBGI

FTB6115

FTB6120

DESCRIPTION (POLYMER BODY)

Normal Operating

Range

1 to 25 GPM

to

25 GPM

1

2 to 30 GPM

Part

Number

FTB6205

FTB6207

FTB6207X

05

07X

10

-l-

Page 4

SECTION 3 INSTALLATION

3.1 UNPACKING

Remove the Packing list and verify that you have received all equipment, including the

following (quantities in parentheses):

FTB6100 or FTB6200 Series Cold Water Meter (1)

Operator’s Manual (1)

If you have any questions about the shipment, please call the OMEGA Customer Service

Department. When you receive the shipment, inspect the container and equipment for signs

of damage. Note any evidence of rough handling in transit. Immediately report any damage

to the shipping agent,

NOTE

The carrier will not honor any claims unless all shipping material

is saved for inspection. After examining and removing contents, save

packing material and carton in the event reshipment is necessary.

3.2 INSTALLATION

The meter must be installed in a clean pipeline, free from any foreign materials. The dial must

be mounted face upwards, no more than

45” from the horizontal.

The meter must be inserted with the flow in the direction of the arrow molded, or cast, into the

meter body.

112”

Couplings are provided, which allow for connection with NPT threads in sizes

12”

The l-l

and 2” meters have NPT screwed ends or oval flanged ends.

through I”.

SECTION 4 START-UP PROCEDURE

The meter piston can be damaged if the meter

is

subjected to full flow conditions prior to

expelling all the air from the piping. Therefore, turn on the flow gradually.

-2-

Page 5

SECTION 5 SPECIFICATIONS

ACCURACY:

FLUID TEMPERATURE RANGE:

WETTED PARTS:

MAXIMUM PRESSURE DROP:

MAXIMUM PRESSURE:

MAXIMUM TOTAL

(MILLIONS OF GALLONS)

MODEL

FTB6105

FTBGI

07 1-25

FTBGI 07X

FTBGI

FTBGI

FTBGI

10

15

20

NORMAL

OPERATING

RANGE

I-20 GPM

GPM

2-30 GPM

3-50

GPM

5-100

GPM

8-160

GPM

MIN.

TEST

FLOW

GPM

0.25

0.25

0.50

0.75

1.5

2

+ 1-l 12% of reading at normal operating range

120”

to +

bronze or polyacetal body;

impregnated polystyrene,

F.

graphite-

molybdenum-

loaded and glass-filled nylon, barium

ferrite magnet and polyacetal internal

wetted parts, neoprene gaskets, polymer

strainer (stainless steel for 2” unit).

PSID

15

150

10 up to 1

LENGTH

OVERALL

(<____________

7.5

7.5

9

10.75

12.63

15.25

at 1 CSTK

PSIG

DIA.

INCHES

4.75

4.75

4.75

7.06

7.5

8.75

‘I;

100 for l-1

HEIGHT SHIPPING

OVERALL

____________>)

5.5

6.94

8.5

10.5

/2” and 2”

5

5

WEIGHT (PULSE/

LBS. GAL)

6

6

15

24

26

42

“-PS”

STDlOPT

100/200

100/200

66.6/l

33.2

24.6149.2

11.3122.6

5.6111

.I

FTB6205 0.25-25

FTB6207 0.25-25

FTB6207X

0.5-30

GPM

GPM

GPM

*minimum measurable with

0.25

0.25

0.50

7.5

7.5

9

4.82

4.82

5.03

+ 5% of reading accuracy

5

5

5.5

4

4

5

SECTION 6 OPTIONS

“-PS”

Add suffix

“-PT”

or

for pulse output. Register is no longer hermetically sealed with

pulse output, but is weatherproof. Pulse option adds 0.63 lb. to weight, and

for PS. Pulse option adds 2 Ibs. to weight and 2 ” height for PT.

Pulse Output Options:

12”

1”

1

6.1

“-PT”:

pulse/gallon for

pulser is a limit switch rated at 3A

“-PS”: Solid State requires 6-24 VDC, 3

6.2

or smaller:

@125

above.

VAC.

l

puise/lO gallon for

wire.

For pulse rate, see

l-1

and 2”. PT

PS

100/200

100/200

66.61133.2

2-314”

height

(pulse/gallon)

-3-

Page 6

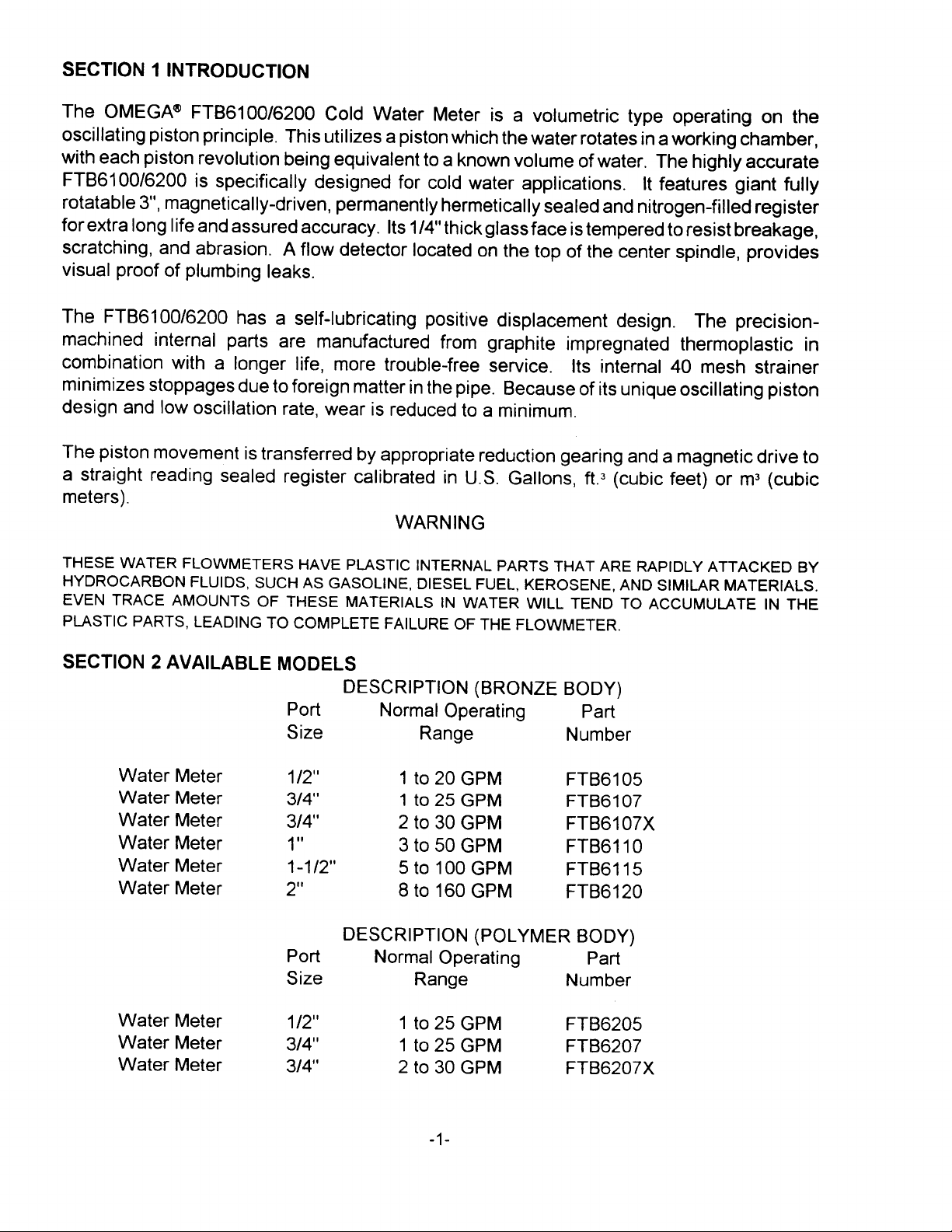

SECTION 6 OPTIONS

6.1

To be wired in series. Refer to Figure

-PT OPTION

1.

This unit requires power from an external source.

WIRING DIAGRAM

N/O = Normally Open

N/C = Normally Closed

SOUKCE

-

PT Option

Figure 1.

PWEK

Wiring Diagram for

The transmitting element is a 3A limit switch, giving a closure rate as follows:

98”

314”

1”

l-1/2”

2”

6.2

-PS OPTION (SOLID STATE)*

1 Contact Per Gallon

1 Contact Per Gallon

1 Contact Per Gallon

1

Contact

1

Contact

Per10Gallons

Per10Gallons

3-wire system. Refer to Figure 2. The unit requires power from an external source, 6-24

VDC, NEMA 4.

Red -------

Black

White ------- Output

Figure 2. Wiring Diagram for New Solid State Pulser -PS Option

The transmitting element is

actuated to provide a

mA

(max) (3 wire).

50150

Contact Closures are:

SIZE

112”

5/8”

5/8”

5/8”

518”

314”

I”

Bronze

l-l

2” Bronze

Improved Brz

x

3/4”

Improved Brz

x

IQ”

Polymer

x

314”

Polymer

x

314”

x

/2” Bronze

BtzIPoly

_______

an open collector current sink

open/closed ratio. Supply Voltage: 6-24 VDC; Supply Current: 13.5

+ Positive Power Supply, 6-24 VDC

-

Negative Ground

(NPN)(20V

STANDARD

(Contacts/gallon) (Contacts/gallon)

115.2

115.2

100.0

100.0

66.6

24.6

11.3

5.6

mA

OPTIONAL

230.4

230.4

200.0

200.0

133.2

49.2

22.6

11.1

max.) magnetically

??

All previous hi-resolution pulsers (PS-type) were dry contact reed switches

-4-

(3W)

and were wired in series.

Page 7

BRONZE

BODY

POLYMER BODY

[

Meter

Size

Dimensions and Net Weights

;

A

‘12.x Q’

V.’ x s/a-

j

j

Dmenslons

)

C 0 i

1

1

SEE

When used with couplings, add to dimension (inches) A:

lW62,qhr

-I

/)

(Ibs

1

I

I

1

Meter

52%

/

‘I,- x 5,; 1

Bronze Body Polymer Body

7/a

4

Ata

5

i/a

5

3/a

5

PAGEj

PAGEj

Size

5/a

518

314

(tnches)

)

D E

SEti

112

x

x

314

314

x

1

7

7

When used with pulser, add to dimension B:

Pulsers model PT

Pulsers model PS

??

3/16

.

2

. . . .

314

.

2

. . .

*Dotted line shows position of PT

Dlmenslons

/‘BBC

-s+TjT

;‘,_I

4

pulsers

and Net Weights

(Inches)--Dmenslons

D---zy-

B

,

314

5

5

DiE

9’11)

Wegri7

(Ibs

3’1,

!

:

:

Cover is deleted when meter is provided with a pulser.

NOTE:

All above dimensions are inch measurements.

DIMENSIONS

COLD WATER METERS

FTB 6105

FTB 6107

FTB 6107X

FTB 6110

-5-

FTB 6205

FTB 6207

6207X

f=TB

Page 8

- 0

View on direction of arrow

“A” showing flow arrow and

body markings.

Connections are oval flanged o

CENTER

NPT Female.

LINE TO BOTTOM DIAMETER HEIGHT

(C) (D)

l/8”

2

1

314”

8

8

112”

314”

Meters are designed for Cold Water Service up to 120°F.

At 150 PSIG. Strainers with a 40 Mesh Screen should be used if foreign matter is

present.

NOTE:

Dotted line shows position of PT or PS Pulser.

Cover is deleted when meter is provided with a pulser.

12

14

(E)

l/4”

l/4”

10

12

PT

7/16”

5116”

WlPULSER SHIPPINGW/LID UP HEIGHT

PS

l/4”

11

13”

Loading...

Loading...