Page 1

User’s Guide

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Page 2

Servicing North America:

U.S.A.: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378/1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico: En Espan˜ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807

info@omega.com.mx

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899

FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0

FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Table of contents Page

1. Function............................................................................................................................................................ 1

2. Safety instructions ............................................................................................................................................2

3. Important notes and requirements to installation and operation...................................................................... 3

4. Installation in piping.......................................................................................................................................... 3

5. Electrical connection ........................................................................................................................................3

5.1. Turbine flow sensor with pulse output.............................................................................................................. 3

6. Cleaning ........................................................................................................................................................... 4

7. Shut-down and disposal................................................................................................................................... 5

8. Materials table .................................................................................................................................................. 5

9. Technical data .................................................................................................................................................. 5

10. Dimensions....................................................................................................................................................... 6

1. Function

The turbine flow sensor of the series FTB 370 is a

transducer for volume flow recognition or for fluid dosing

use. It has an almost unlimited application through its

exceptionally compact design, its very wide measurement

range and its convincing measurement accuracy.

The liquid flowing into the meter is divided by the guiding

blades in four split beams. These hit the rotor from four

directions and put it in motion. The uniform loading of

bearing from four sides causes the forces to cancel

themselves out for the most part and wear is reduced to a

minimum.

The extremely hard bearing materials, sapphire and hard

metal, ensure in addition an extraordinary life expectancy.

The rotor speed is transmitted to an electrical pulse signal

(frequency):

- The FTB 371 is equipped with rotors which are fitted

with magnets. A Hall effect sensor recognizes the

rotation of the rotor.

In this case, a frequency signal proportional to flow (square

wave) is available.

Page 4

Safety instructions

2. Safety instructions

• Before you install the product, please read the relevant chapters of the installation instruction carefully.

• The turbine flow sensor is only suitable for measurement of fluids – never use the instrument for gas

measurements.

• Check before installation, whether the material of the turbine flow sensor is suitable for the medium to be

monitored (see Materials Table, Chapter 7)!

• You can fit the turbine flow control instrument in any position. If it is installed into vertical pipes, the flow

direction is preferably upwards. You must avoid a free outlet.

• The arrow which is placed on the flow sensor (Î) shows the only permitted flow direction.

• For precise measurement, the length of the in - and outlet tubes must be observed

(see Chap. 3: Requirements to Installation and Operation).

• The internal diameter of the in- and outlet tube must correspond with the internal diameter of the flow sensor.

• The flow medium to be monitored should preferably contain as few solid particles as possible. Present

particles must not exceed a diameter of 0.02 inch. If necessary, install a filter!

• Avoid absolutely the formation of gas bubbles or cavitation in the medium by taking proper measures.

• The material of the series FTB 371 is not suitable for monitoring oils. The strength of the used plastic parts

would be considerably reduced.

• In order to clean the flow sensor of contaminations, flush the unit with water in opposite direction to the flow

(see Chap. 7).

• A possible blowing out of the instrument must take place only in opposite direction to the flow.

• We recommend to use only shielded connection cables. Connect the shield on one side (the wire ends) on

ground.

• Attention:

The upper union nut of the instrument is sealed and must not be opened. When you loosen the union nut, the

fixation of the turbine system is disturbed and it will be damaged.

• There are special customer designs that may differ from the standard data listed in these instructions –

always consider the specifications noted on the type plate.

If you should have any problems or questions, please contact your local supplier or directly:

2

Page 5

Important notes and requirements to installation and operation

06

3. Important notes and requirements to installation and operation

Observe the following instructions in order to achieve highest-possible measurement accuracy and specified

output signal.

• Before installing the turbine flow sensor flush the pipe carefully. You avoid a blocking of the turbine caused by

particles from the pipe installation.

• The installation position of the flow control instruments is unreserved. If it is installed into vertical pipes, the

flow direction is preferably upwards. You must avoid a free outlet.

• The arrow which is placed on the flow sensor (Î) shows the only permitted flow direction.

• A straight tube in front of the flow sensor must be retained, min 10 x ID, i.e. 5,91 inch. Behind the flow sensor,

a straight outlet tube of 5 x ID, i.e. 2.95 inch, must be kept. The internal diameter of the in- and outlet tubes

must correspond with the internal diameter of the flow control instrument = 0.591 inch. Before and behind the

stabilization tubes, the line may be contracted or enlarged.

In practice these instructions often can not be observed. Then the pulse rate and the measurement accuracy

can be affected.

• The flow medium to be monitored should preferably contain as few solid particles as possible.

Present particles must not exceed a diameter of 0.02 inch. If necessary, install a filter!

• The materials of the series FTB 370 are not suitable for monitoring oils. The strength of the used plastic parts

would be considerably reduced.

• Attention:

The upper union nut of the instrument is sealed and must not be opened. When you loosen the union nut, the

fixation of the turbine system is disturbed and it will be damaged.

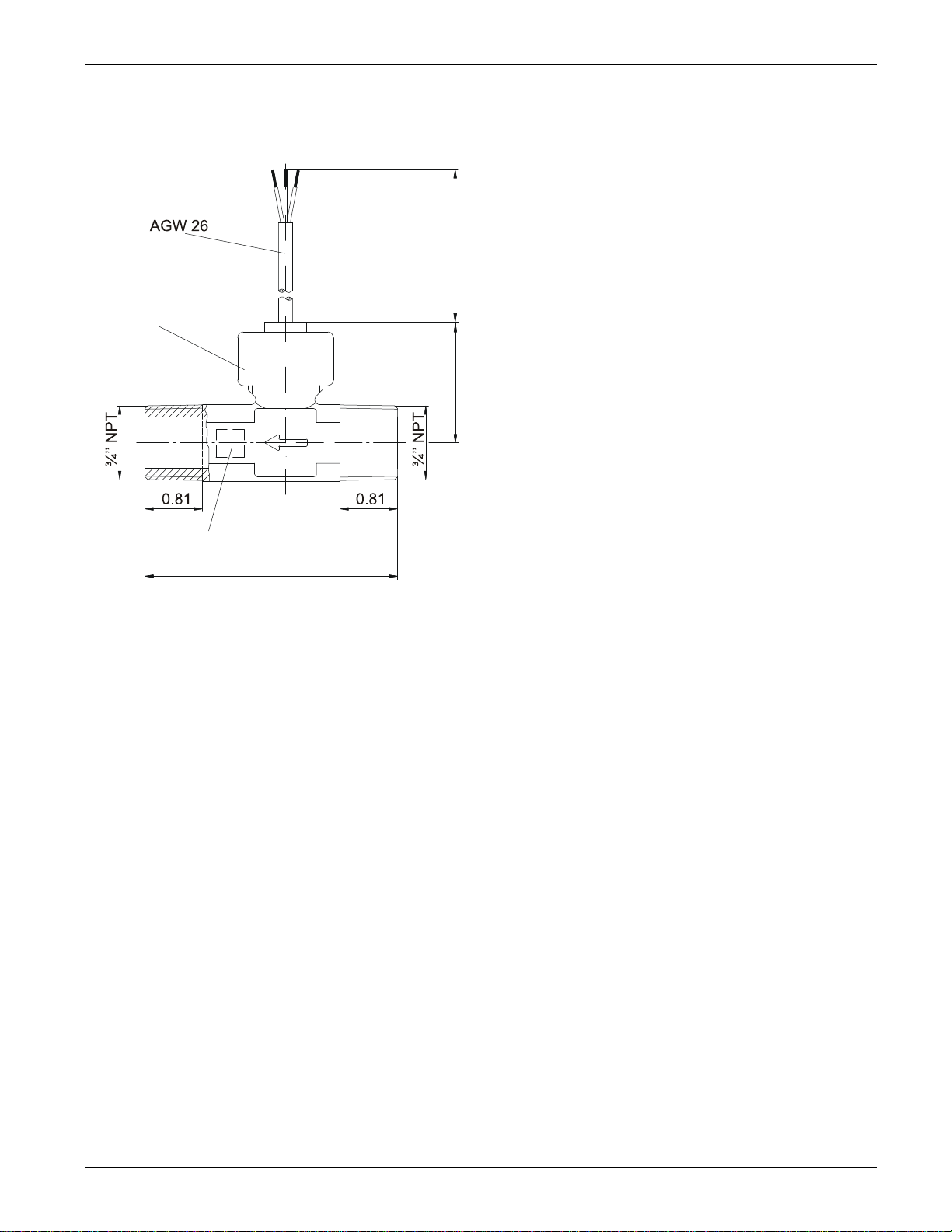

4. Installation in piping

• Now you can install the turbine in the piping

system which was prepared according to chapter

3.

The customer must not

undo the union nut,

because of the works adjustment

• The pipe section has a ¾'' NPT thread connection

male.

• Make sure that the correspondent part has a

¾'' NPT thread connection female.

Notice:

• Counterhold! When tightening the correspondent

part use only the wrench flat (a / f 1.06'') of the

turbine.

• If you seal the male thread, take care that no

fibrous sealing compounds get into the turbine

(hemp or Teflon strip).

¾’’ NPT

0.81

a / f

0.81

1.

¾’’ NPT

5. Electrical connection

Attention: We recommend to use only screened cables. Connect the shield on one side (the wire ends) on

ground.

Electrical connection with 4-pin-plug M12x1

Screw on 4-pin-plug M12x1 to sleeve and tighten plug with a starting torque of max. 0.74 ft lb.

5.1. Turbine flow sensor with pulse output

The output signal of Turbotron is a flow-proportional frequency signal. The shape of the signal is a square wave

and its amplitude corresponds approximately with the supply voltage. It is an open collector signal, NPNswitching. The connected electronic instrument should have a loading resistance (pull-up or pull-down resistor) of

5 kΩ in the inlet.

Schematic representation

A connection is made with three leads, the supply voltage must be connected between +U and GND (earth), the

output signal can be tapped between

and GND. The color assignment of the supply cables or the pin allocation

of the plug can be taken from the sketch on the type plate.

3

Page 6

Cleaning

FTB 371 connecting cable

6. Cleaning

• To remove dirt from the flow sensor, you should flush it with water always in opposite direction to the flow.

• Attention:

The union nut of the instrument is sealed and must not be opened. When you loosen the union nut, the

fixation of the turbine system is disturbed and it will be damaged. A repair in the factory becomes necessary!

Cleaning

• Warning:

A possible blowing-out the instrument with compressed air must only be carried out in opposite direction to the

flow.

Blow-out

4

Page 7

Shut-down and disposal

7. Shut-down and disposal

• Remove all electrical connections and dismantle the flow sensor.

• The turbine unit is made of different materials (see technical data). Don't dispose the turbine unit together with

household waste. The official rules of your area have to be observed at disposing of the turbine unit.

8. Materials table

Materials

Type FTB 371

Pipe section Brass, CuZn36Pb2As

Turbine system PEI Ultem

Rotor assembly Hard ferrite magnet

Bearing system / shaft shaft Arcap AP1D with hard metal pins in sapphire bearing

Union nut PA GF 30

Sensor housing PPO Noryl GFN3

O-ring NBR

Integrated temperature sensor (option) Brass or stainless steel 316 SS

Strainer (option) POM / stainless steel

9. Technical data

There are special customer designs that may differ from the standard data listed in these instructions – always

consider the specifications noted on the type plate.

Turbine flow sensor with pulse output

Type FTB 371

Material, pipe section Brass

Nominal diameter ½''

Measurement range 0.52 … 10.4 GPM

with special “bearings for low flow rates” (order code 40) with continous flow max.

5.2 GPM

Accuracy +/-1 % of range

Reproducibility +/-0.2 %

Start of output signal < 0.08 GPM

Sensor Hall sensor

Output signal

- Pulse rate / K-factor

- Resolution

- Signal shape

- Signal current

Pull-up-resistance 5 kΩ (recommendation)

Supply voltage 4.5...24 V DC

Electrical connection 5 ft PVC cable, screened

Protection class IP 54

Max. medium temperature 185 °F

Nominal pressure 145 psi

Max. particle size in the medium < 0.02''

Process connection ¾“ NPT male

The stated values refer to operation with water at 68 °F. Monitoring of fluids with higher viscosities is possible with the effect of

deviations from mentioned values.

3237 pulses / gal

3.16 fl.dr. / pulse

Square wave signal

NPN open collector

(Tmax = 158 °F)

4-pin-plug M12x1

max. 10 mA

or

5

Page 8

Dimensions

10. Dimensions

Union nut

¾’’ BSP

a/f

1.06

3.54

~ 59.1

~ 1.69

6

Page 9

WARRANTY/ DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds

an additional one (1) month grace period to the normal one (1) year product warranty to

cover handling and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be

repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting

from any action of the purchaser, including but not limited to mishandling, improper

interfacing, operation outside of design limits, improper repair, or unauthorized modification.

This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows

evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture

or vibration; improper specification; misapplication; misuse or other operating conditions

outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes

liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only

that the parts manufactured by the company will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL

IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total

liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1)

as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or

activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or

with any nuclear installation or activity, medical application, used on humans, or misused in

any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from

any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2007 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 10

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M0000/0007

Loading...

Loading...