Page 1

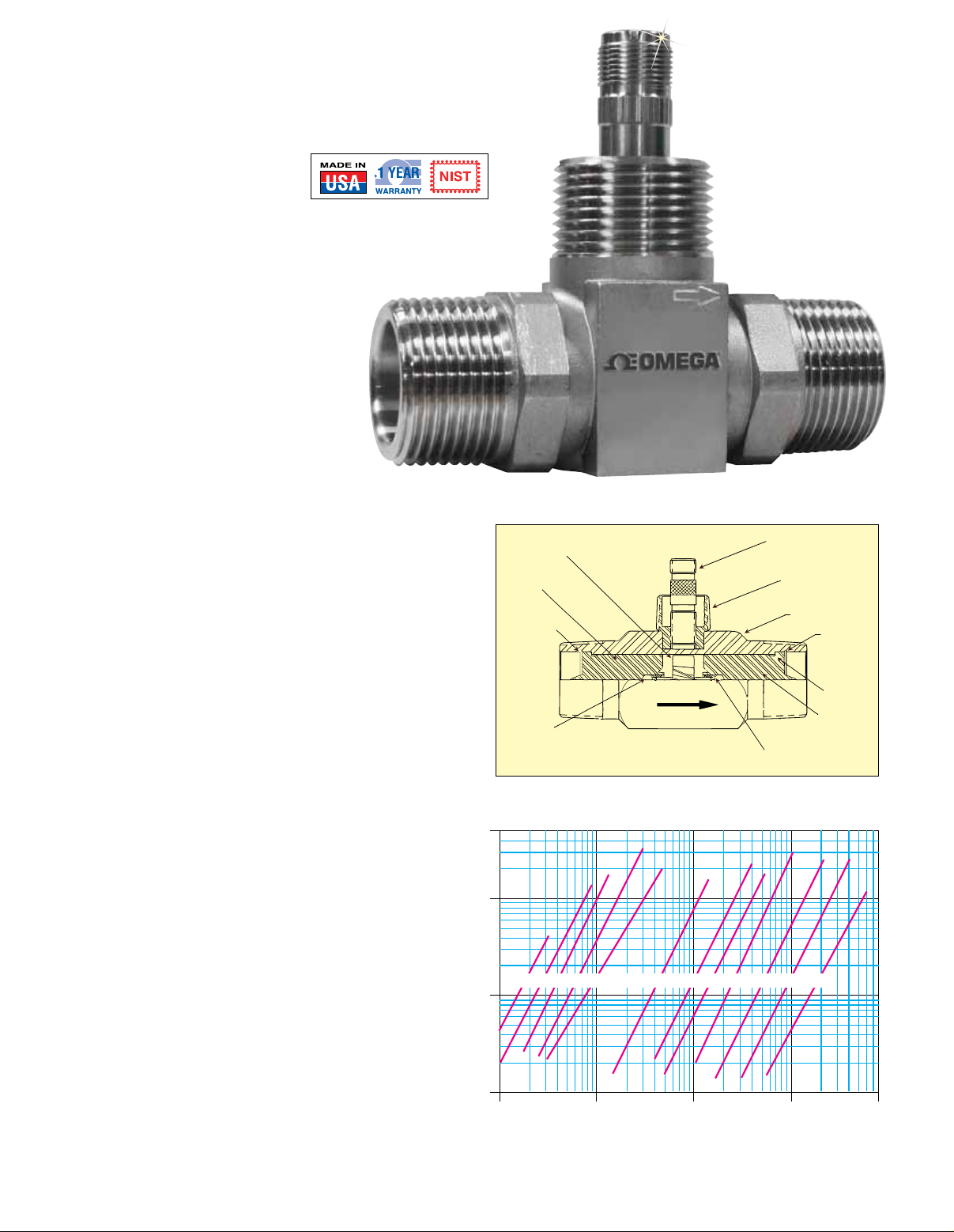

Magnetic

Pick-Up

Meter Body

Retaining Ring

Inlet Flow

Straightener

Conduit

Adapter

Retaining

Ring

Outlet Flow

Straightener

Turbine Assembly

ECONOMICAL LIQUID

TURBINE FLOWMETERS

FTB-1400 Series

Standard

U Cost-Effective Solution

for Turbine Flowmeter

Applications

U Rugged 316 Stainless Steel

Construction Offers Long

Service Life in Severe

Operating Environments

U Accurate and Repeatable

Flow Measurement

U Installation in Pipe Sizes

U NIST Calibration

The OMEGA® FTB-1400 turbine flowmeter is

designed to meet the demands of the most rigorous

flow measurement applications. Originally developed

for the secondary oil recovery market, the FTB-1400

is an ideal meter for liquid flow measurement on or

off the oilfield. The meter features a 316 Stainless

Steel housing and rotor support, CD4MCU Stainless

Steel rotor, and abrasion-resistant tungsten carbide

rotor shaft and journal bearings. These materials help

the meter to maintain accuracy and mechanical

integrity when measuring the corrosive and abrasive

fluids found in many industries.

Fluid entering the meter first passes through an inlet

flow straightener that reduces its turbulent flow

pattern. Fluid then passes through the turbine,

causing the turbine to rotate at a speed proportional

to fluid velocity. As each turbine blade passes through

the magnetic field generated by the meters magnetic

pick-up, an AC voltage pulse is generated. These

pulses provide an output frequency that is proportional

to volumetric flow.

from

1

⁄2 to 2"

Rotor and

Rotor Shaft

*Upstream

Rotor Support

*Retaining

Ring

*Thrust

Ball

Note: * Indicates Parts Contained in Repair Kits

50

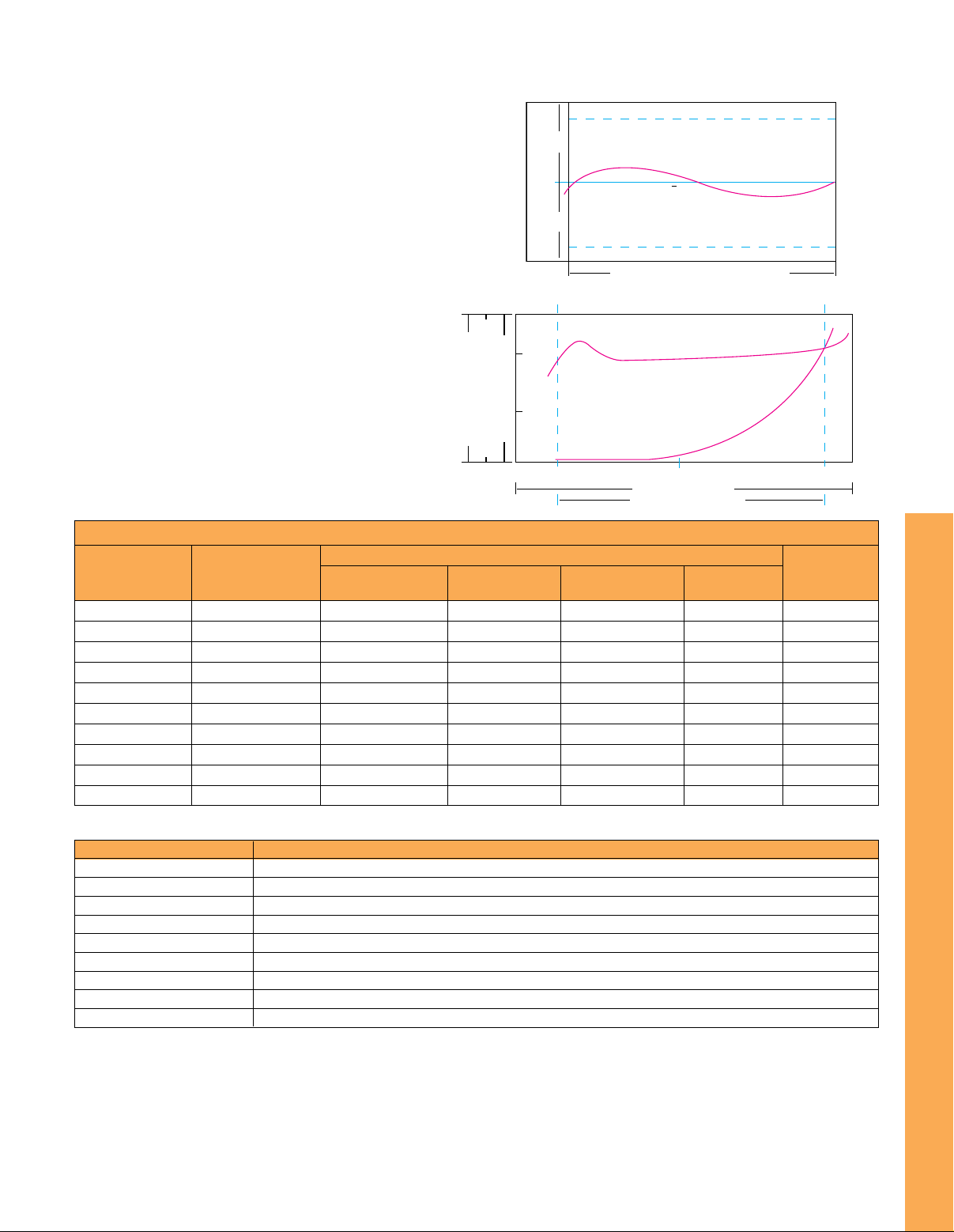

Pressure Drop vs. Flow Rate

FTB-1425, shown

smaller than actual size.

Magnetic

Pick-up

Conduit

Adaptor

Meter Body

Retaining

Ring

Groove

Retainer

Pins

*Downstream

Rotor Support

*Bearing

SPECIFICATIONS

Accuracy: ±1% of reading for 1" and larger, ±1% of

reading over the upper 70% of the measuring range

1

⁄2" meters

for

Repeatability: ±0.1%

Magnetic Pickup: 30 mV/P-P

Materials of Construction

Body: 316 Stainless Steel

Rotor: CD4MCU Stainless Steel

Rotor Support: 316 Stainless Steel

Rotor Shaft: Tungsten carbide

Turndown Ratio: 10:1

Calibration: Water (NIST traceable calibration)

Pressure Rating: 5000 psi (maximum)

Turbine Temperature: -101 to 177°C (-150 to 350°F);

-101 to 232°C (-150 to 450°F) (with “-HT” option)

End Connections: NPT, BSPP optional

10

3/4"

3/8"

1/2"

7/8"

1"

1-1/2"

2"

3"

4"

6"

10"

8"

1

PSID Pressure Drop

.1

1 10 100 1,000 8,000

(34) (343) (3429) (34,286) (274,286)

Flow Rate GPM (BPD)

F-49

Page 2

Typical K-Factor Curve (Pulses per Gallon)

K-Factor

The K-Factor represents the number of output pulses

transmitted per gallon of fluid passing through the

turbine meter. Each turbine has a unique K-Factor.

Typical K-Factor Curve (Pulses Per Gallon)

+1%

+%

However, turbine meters are not functionally consistent

throughout the full flow range of the meter.

There are several forms of “friction” inherent in turbine

meters that retard the rotational movement of the turbine

rotor. These frictional forces include: magnetic drag,

created by electromagnetic force of pickup transducers;

mechanical drag, due to bearing friction; and viscous

drag, produced by flowing fluid. See charts on right.

LINEARITY (DESIGN DEVIATION)

-1%

-%

K

AVG. K-FACTOR (K)

1" AND LARGER TURNDOWN APPROX. 10:1

½" TURNDOWN APPROX. 3:1

-

F

A

C

T

O

)

R

(

P

U

L

S

N

O

L

L

A

G

/

E

S

As flow increases, the frictional forces are minimized

and the free-wheeling motion of the turbine rotor

becomes more linear (proportional to flow). The

K-Factor becomes relatively constant and linear

100%

K-FACTOR (PULSES/GALLON)

throughout the balance of the linear flow range.

This is approximately a 10:1 turndown ratio from the

maximum flow rate down to the minimum flow rate.

K-FACTOR (CYCLES/GALLON)

50%

P

O

% OF VALUE AT FLOW RATE

OUTPUT FREQUENCY (CYCLES/SEC)

0% 10% 50% 100%

R

P

FULL FLOW RANGE

LINEAR FLOW RANGE

R

D

E

R

U

S

S

E

To Order Visit omega.com/ftb1400_series for Pricing and Details

Range

Connection K-Factor Lay Length

Model No. MNPT LPM GPM Barrels/Day Pul/Gal mm (inch)

FTB-1411 ¹⁄₂ 2.3 to 11.3 0.6 to 3 20 to 100 18,000 76 (3)

FTB-1412 ¹⁄₂ 2.8 to 28 0.75 to 7.5 25 to 250 13,000 76 (3)

FTB-1413 ¹⁄₂ 7.6 to 56.7 2 to 15 68 to 515 3300 76 (3)

FTB-1421 1 2.3 to 11.3 0.6 to 3 20 to 100 18,000 76 (3)

FTB-1422 1 2.8 to 28 0.75 to 7.5 25 to 250 13,000 76 (3)

FTB-1423 1 7.6 to 56.7 2 to 15 68 to 515 3300 76 (3)

FTB-1424 1 11.3 to 113 3 to 30 100 to 1000 3100 101 (4)

FTB-1425 1 18.9 to 189 5 to 50 170 to 1700 870 101 (4)

FTB-1431 1¹⁄₂ 56.8 to 681 15 to 180 515 to 6000 330 152 (6)

FTB-1441 2 56.8 to 681 15 to 180 515 to 6000 330 152 (6)

F

Accessories

Model No. Description

FTB-1400-CABLE 3 m (10') cable assembly with 2-pin connector (required for remote display)

FTB-1400-90CABLE 3 m (10') cable assembly with 2-pin 90º connector (required for remote display)

FTB-1400-MP Replacement standard magnetic pick-up

FTB-1400-MD Battery powered basic meter mount display

FTB-1400-MD-A Battery powered advanced meter mount display

FTB-1400-RD Battery powered basic remote mount display

FTB-1400-RD-A Battery powered advanced remote mount display

FTB-1400-SD Battery powered basic swivel mount display

FTB-1400-SD-A Battery powered advanced swivel mount display

Comes complete with operator’s manual and 5 point NIST calibration certificate for water. Cable with connector sold separately.

Cable/connector are required for operation.

For units with high temp magnetic pulse output, add suffix “-HT” to model number, consult Flow Engineering for price

(not available on “-AMP” models).

For units with amplified pulse output, add suffix “-AMP” to model number consult Flow Engineering for price (not available on “-HT” models).

For units with BSPP threads, add suffix “BSP” to model number for additional cost.

Ordering Examples: FTB-1424, 1 NPT stainless turbine and FTB-1400-MD, battery powered basic meter mount.

FTB-1411, ½ NPT stainless turbine and DPF701, digital panel meter for rate of total display, FTB-1400-CABLE, 3 m (10') cable assembly with

2-pin connector. For details on DPF701 meter, visit omega.com/dpf700 for details.

F-50

Loading...

Loading...