Page 1

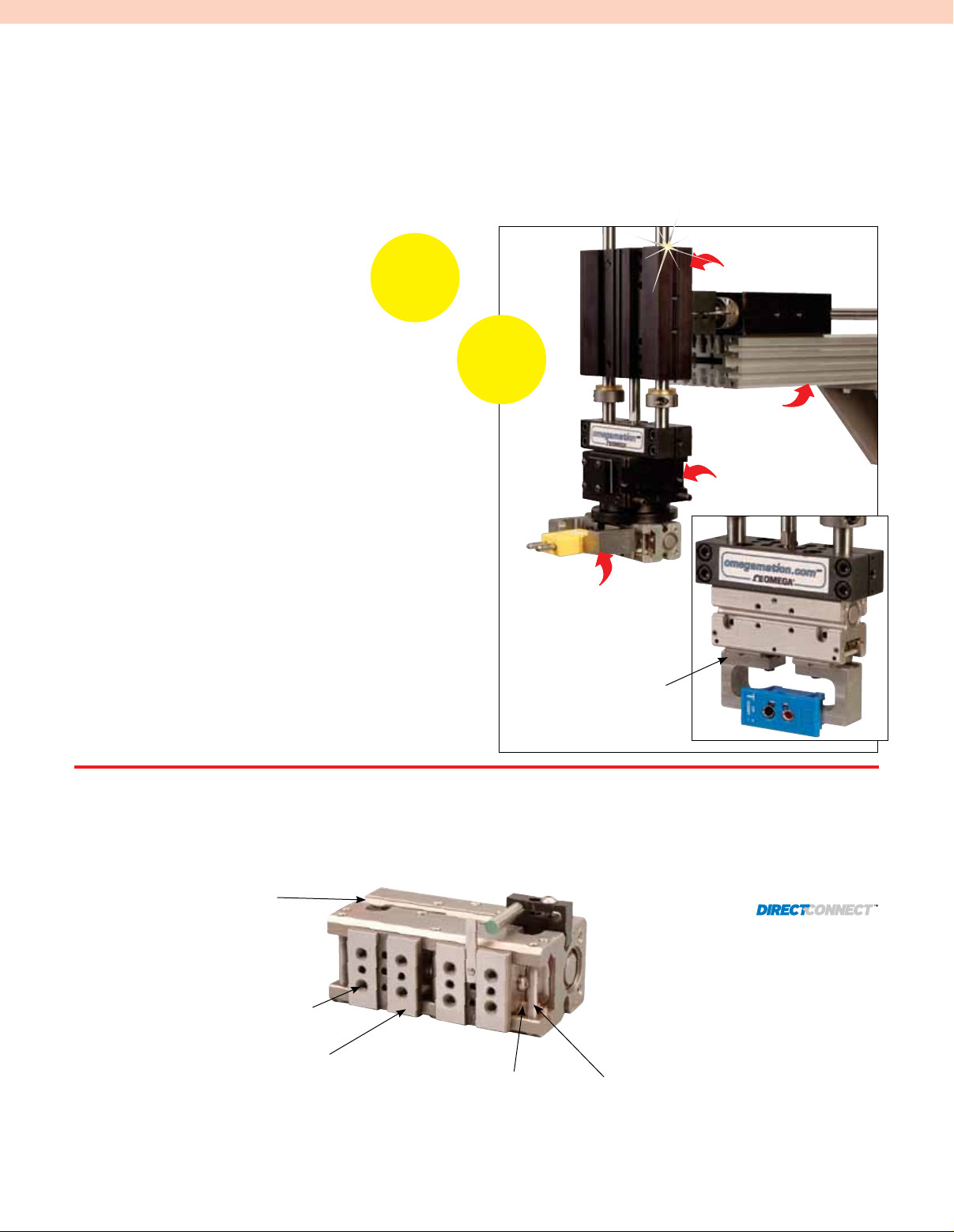

grippers pneumatic precision

parallel movement Dpp

Directconnect™ series

DPP Series

No Adaptor

Plates

Required!

l Precision Gripping—Preloaded V Roller

Bearing Eliminate Side Play Resulting in

Excellent Part Positioning

l Accuracy of ±0.03 mm (0.001") and Repeatability

of ±0.01 mm (0.0005")

l Highly Configurable Modular Automation—

Exclusive Direct Connect™ Technology Provides

Multiple Mounting Options

l Multiple Pneumatic Port Locations—Tapped Ports on

Front, Top and Both Sides are Standard

l Rigid and Low Friction Design Provides Longer Gripper

Finger Lengths and the Ability to Handle Delicate Parts

l Non Synchronous Motion Option Provides

Independent Jaw Motion

l Up to 5 Million Cycles in Typical Application—

Up to 10 Million with Maintenance

l Temperature Operating Range -35 to 80°C (-30 to 180°F)

l System Requires 0.3 to 7 bar (5 to 100 psi) Dry Filtered

(40 Micron or Better) Air Supply

l Accessory Equipment Required—4-Way, 2 Position

Pneumatic Directional Control Valve

place with

rotation

Shown

smaller than

actual size.

2-axis

pick-n-

Note: gripper fingers

are shown for reference

purposes, this tooling is the

customers responsibility.

DPP-10M-12 parallel

gripper with

SPJ-T-F snap-in panel jack

thermocouple connector

sold separately, see

omega.com

DLT-10M-E-C-50 linear

thruster slide see

omega.com

DMEX Series

mounting stanchions,

starts at see omega.com

DRF-075M-90 rotary

actuator see omega.com

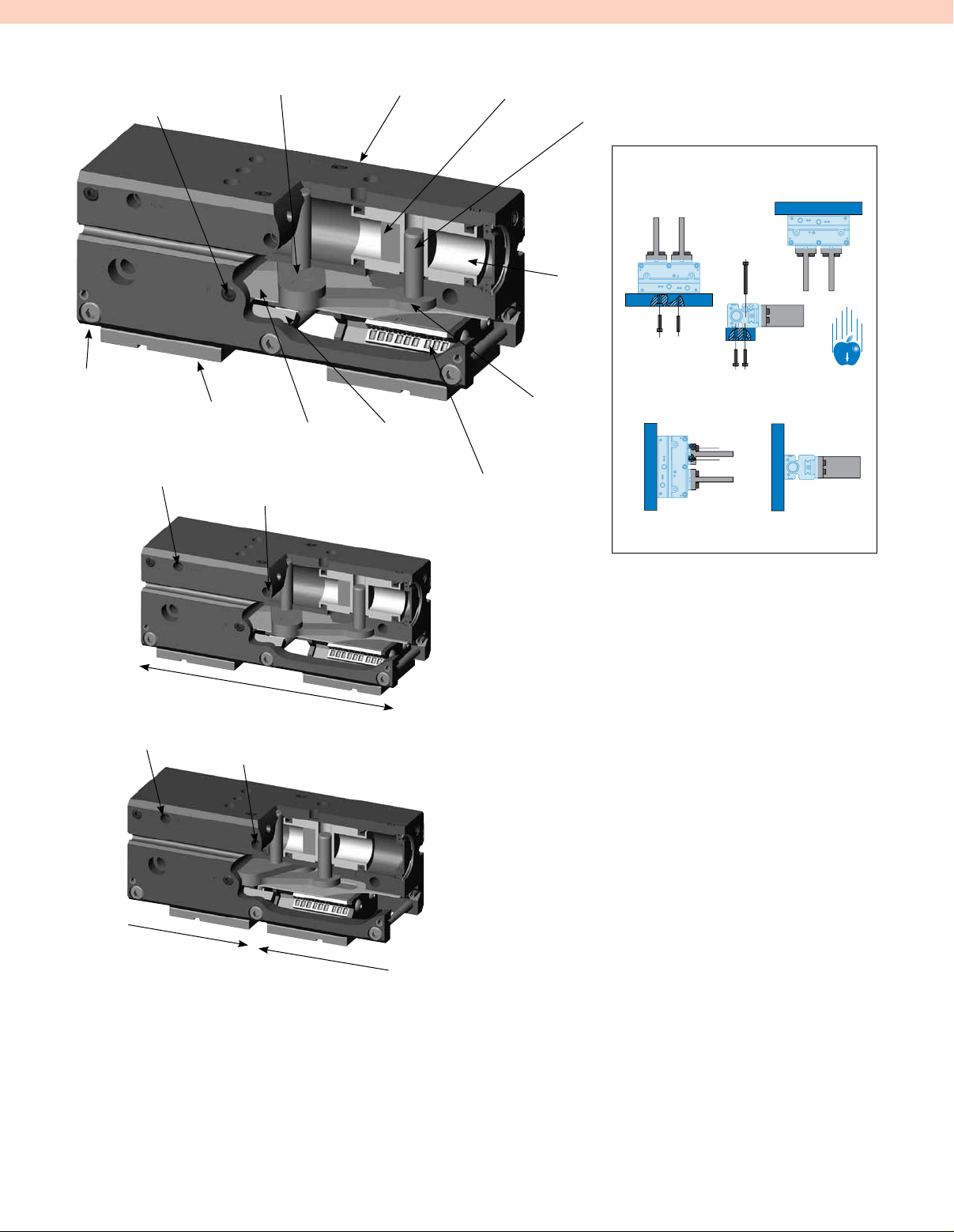

proDuct Features

Excellent Accuracy

Excellent parallelism and accuracy

between gripper mounting

surface and jaw surfaces.

Accessory Mounting Slots

For Magneto Resistive and

Inductive sensors (sensors

sold separately).

Dowel Holes

Superior Jaw

Support

Jaws are supported

using our patented

“Dual-V” roller

bearing design.

Multiple Sensor Capabilities

Capable of sensing both jaws in the open and closed positions

(up to 4 sensors can be used for multi-position sensing). Sensor

magnets on pistons come standard for Magneto Resistive Sensing.

H7 dowel pin holes in body

and jaws. Jaws also have

key slot for better finger

Hardened Plated Jaws

For wear resistance and longer life.

Top Manifold

Air Ports

Eliminates the

need for airlines.

alignment.

Provide low friction motion and are preloaded

for maximum support and zero side play.

Standard Purge/

Scavenge Port

Used with a vacuum for clean room

environments or positive pressure for

harsh environments and jaw surfaces.

“Dual-V” Roller Bearings

Available for high temperature applications.

FKM Seals

C-17a

Shielded Design

Shielded design repels contamination from

penetrating the “Dual-V” roller bearings.

Multiple Air Port Locations

Hard Coat Anodized

One piece, aircraft quality

aluminum body, has hard-

coat anodize 60 RC with

PFA impregnation.

DPP-10M-06 shown

slightly smaller

than actual size.

Adjustable

Pre-load Screws

Allows for adjustment of

preload on roller bearings.

With respect to weight due to extremely

4 standard locations; front,

top and both sides

Mounting Patterns

DIRECTCONNECT™ tapped

and dowel mounting

surfaces on top and side

of body (except DPP-28).

Optional

Spring Assist

For close stroke.

Self Lubricating

Dynamic Seals

(Buna-N only)

High Grip Force

efficient drive mechanism.

Page 2

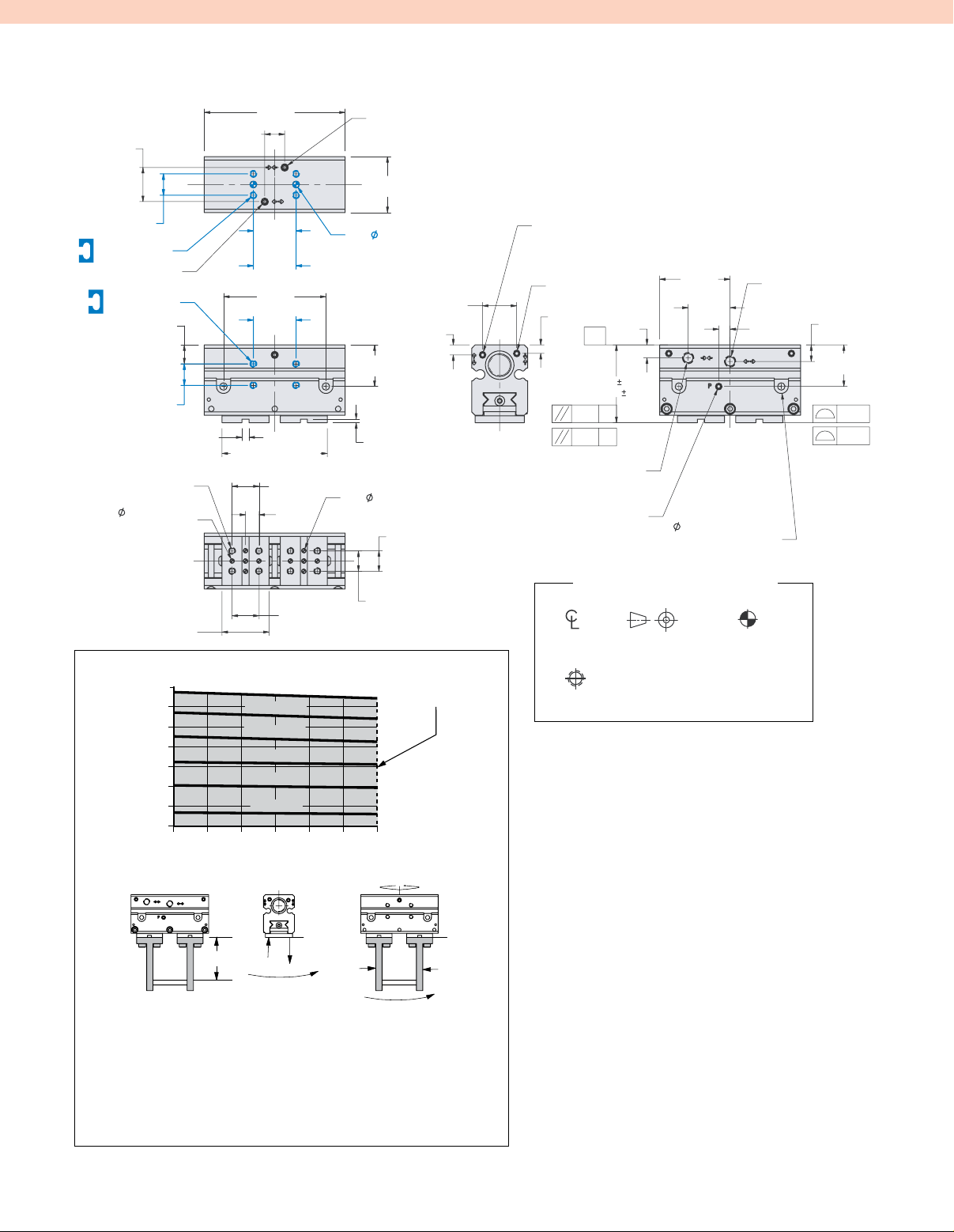

operating principle

Purge.Scavange Port

(supplied plugged)

Adjustable Pre-

Load Screws

Exhaust

Jaw

Equalizer

Pressure

Shield Cover

Body

Roller Way

Magnet

Drive Pin

mounting inFormation

Grippers can be mounted and operated in

any orientation

Piston

G

Body mounts with screws and locates

with H7 dowel pins for accuracy

Synchronizing

Bar

Roller Bearings

and Cages

Fingers attach to jaws with screws and

locate by key slot and/or H7 dowel pins

Open Position

Pressure

Closed Position

Exhaust

l Dual Double Acting Opposed Pistons, Connected

to Both a Jaw and a Synchronizing Bar by a Drive

Pin, Actuate in Opposite Directions

l The Synchronizing Bars are Connected to the

Equalizer Which Synchronizes the Motion

l Suitable for Internal and External Gripping

l The Sychronizing Elements Can be Removed for

Non-Synchronous Operation

SPECIFICATIONS

PNEUMATIC SPECIFICATIONS

Pressure Operating Range:

Standard: 5 to 100 psi (0.3 to 7 bar)

-C Spring Closed Option: 20 to 100 psi (1.5 to 7 bar)

Cylinder Type: Double acting or single acting spring

return or double acting spring assist

Dynamic Seals: Internally lubricated buna-N

Valve Required to Operate: 4-way, 2-position for double

acting or 3-way, 2-position for single acting

AIR QUALITY REQUIREMENTS

Air Filtration: 40 micron or better

Air Lubrication: Not necessary*

Air Humidity: Low moisture content (dry)

Temperature Operating Range:

Buna-N Seals (Standard): -35 to 80°C (-30 to 180°F)

FKM Seals (Optional): -30 to 120°C (-20 to 250°F)

MAINTENANCE SPECIFICATIONS

Expected Life:

Normal Application: 5 million cycles

With Preventative Maintenance: 10+ million cycles*

Field Repairable: Yes

Seal Repair Kits Available: Yes

Application Restrictions:

Dirty or gritty environments

Machine operations generating chips

Environments with loose particulate

Applications where mechanism lubricant could cause

contamination

* Addition of lubrication will greatly increase service life.

C-17b

Page 3

Dpp-10m-06 anD Dpp-10m-06-c

2X MANIFOLD AIRPORTS

SUPPLIED PLUGGED

(CLOSED PORT)

25.0

(0.984)

3 H7 X 2.5 DP]

2X [

18.5

(0.730)

2X 0.062

-0.000

[1.57 +0.02 -0.00]

4X [2 H7 X 6.4 DP]

(0.3620)

DOWELS

9.0

(0.354)

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

2.5643.0 in.

76 mm

Z

Mz

F/2

[M3 X 3 DP]

(0.600)

4.4

(0.175)

+0.001

9.19

WARNING!

My

15.2

X

F/2

15.2

(0.600)

9.5

(0.375)

4 X [M3 X 4 DP]

OPEN PORT

4X [M3 X 4 DP]

8.5

(0.333)

9.5

(0.375)

2X 0.124+0.001

-0.000

[3.15 +0.02 -0.00]

8X [M3 X 5 DP]

6X [

2 H7 X 3.6 DP]

CENTERLINE DOWELS

21.0

(0.827)

GRIP FORCE PER FINGER (with Spring Assist Option)

lbs.N

14

62

12

53

10

45

8

36

6

27

4

18

FINGER FORCE - F/2

2

9

0

0

0

0

8.9

(0.350)

C

L

47 (1.85)

53 (2.10) OPEN

C

L

100 PSI [7 bar]

80 PSI [5.5 bar]

60 PSI [4.1 bar]

40 PSI [2.7 bar]

20 PSI [1.4 bar]

1.0

0.5

25

13

EFFECTIVE FINGER LENGTH - L

L

62.9

(2.475)

C

L

19.1

(0.750)

19.05

(0.7500)

(DOWELS)

45.7

(1.800)

19.1

(0.750)

C

L

CLOSED

2X

(0.472)

6.0

(0.236)

2X

DOWELS

0 PSI [0 bar]

1.5

38

Z

C

12.0

11.99

(0.4720)

2.0

51

Y

T

Mx

Loading Capacity Static Dynamic

Maximum Tensile T 267 N (60 lb) 89 N (20 lb)

Maximum Compressive C 267 N (60 lb) 89 N (20 lb)

Maximum Moment Mx 4.0 Nm (35 in-lb) 1.4 Nm (12 in-lb)

Maximum Moment My 5.6 Nm (50 in-lb) 1.9 Nm (17 in-lb)

Maximum Moment Mz 4.0 Nm (35 in-lb) 1.4 Nm (12 in-lb)

Note: Capacities are per set of jaws and are not simultaneous.

Dimensions: mm (inch)

DIRECTCONNECTTM dimensions shown in blue

2X [M3 X 3 DP]

AUX. PORTS

SUPPLIED PLUGGED

BOTH ENDS

(OPEN PORT)

31.4

CLOSED PORT

3.8

C

L

(0.150)

[

PURGE-SCAVENGE PORT

SUPPLIED PLUGGED

[M3 X 3 DP]

5.8

(0.230)

-A-

1.3650.001

[34.67

A

0.001

A0.03

]

2X [M5 X 4 DP]

(CLOSED PORT)

0.02]

(1.238)

18.7

(0.738)

C

L

6.35 X 3 DP C'BORE

2X [

CLEARANCE FOR M3 SHCS]

BOTH SIDES

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Metric Threads

Course Pitch

Third Angle

Projection

Imperial in Metric [mm]

0.00 = ±0.01[0.] = [± 0.25]

0.000 = ±0.005 [0.0] = [± 0.13]

0.0000 = ±0.0005 [0.00] = [± 0.013]

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±0.013 mm or (±.0005")

SPECIFICATIONS

Total Rated Grip Force F @ 100 psi, 7 bar*:

120 N (27 lb)

Stroke: 6.4 mm (0.25")

Weight: 0.16 Kg (0.35 lb)

Pressure Range (Without Springs):

0.3 to 7 bar (5 to 100 psi)

Pressure Range (With Springs):

1.4 to 7 bar (20 to 100 psi)

Cylinder Bore (2X): 10.3 mm (0.406")

Displacement: 0.5 cm3 (0.032 in3)

Temperature Range:

Standard Seals: -35 to 80°C (-30 to 180°F)

FKM Seals: -30 to 150°C (-20 to 250°F)

Actuation (Without Spring/With Spring):

0.10/0.11 sec (0.10/0.11 sec)

Accuracy: ±0.03 mm (±0.001")

Repeatability: ±0.01 mm (±0.0005")

Valve Required to Actuate Single Acting:

3-way, 2-position

Valve Required to Actuate Double Acting:

4-way, 2-position

* With springs

5.1

(0.201)

OPEN

PORT

[

7.4

(0.290)

18.5

(0.730)

0.0005

0.013

]

C-17c

Page 4

10

C

L

OPEN

2X [M5 X 4 DP]

36.8

A

[34.67 0.02]

(0.950)

24.1

(0.230)

5.8

(0.290)

7.4

(0.730)

18.5

5.1

6.35 X 3 DP C'BORE

(1.450)

-A-

PURGE-SCAVENGE PORT

SUPPLIED PLUGGED

(0.200)

(CLOSED PORT)

CLEARANCE FOR M3 SHCS]

2X [

PORT

BOTH SIDES

[M3 X 3 DP]

1.3650.001

0.0010.0005

(OPEN PORT)

BOTH ENDS

3.8

(0.150)

CLOSED PORT

SUPPLIED PLUGGED

AUX. PORTS

2X [M3 X 3 DP]

A0.03

0.013

]

[

[

]

Dpp-10m-12 anD Dpp-10m-12-c

73.7

(2.900)

8.9

15.2

(0.600)

C

L

9.5

(0.375)

4 X [M3 X 4 DP]

OPEN PORT

4X [M3 X 4 DP]

8.5

(0.333)

9.5

(0.375)

2X 0.124+0.001

-0.000

[3.15 +0.02 -0.00]

8X [M3 X 5 DP]

2 H7 X 3.6 DP]

6X [

CENTERLINE DOWELS

C

L

21.0

(0.827)

Loading Capacity Static Dynamic

Maximum Tensile T 311 N (70 lb) 102 N (23 lb)

lbs.N

14

62

12

53

10

45

8

36

6

27

4

18

FINGER FORCE - F/2

2

9

0

0

0

0

(0.350)

19.1

(0.750)

19.05

(0.7500)

(DOWELS)

53.3

(2.100)

19.1

(0.750)

49 (1.93) CLOSED

62 (2.43) OPEN

GRIP FORCE PER FINGER

(with Spring Assist Option)

100 PSI [7 bar]

80 PSI [5.5 bar]

60 PSI [4.1 bar]

40 PSI [2.7 bar]

20 PSI [1.4 bar]

0 PSI [0 bar]

1.0

0.5

25

13

EFFECTIVE FINGER LENGTH - L

L

C

C

L

C

L

2X

12.0

(0.472)

6.0

(0.236)

2X

11.99

(0.4720)

DOWELS

2.0

1.5

51

38

Z

Y

T

Maximum Compressive C 311 N (70 lb) 102 N (23 lb)

Maximum Moment Mx 5.6 Nm (50 in-lb) 1.9 Nm (17 in-lb)

Maximum Moment My 7.3 Nm (65 in-lb) 2.5 Nm (22 in-lb)

Maximum Moment Mz 5.6 Nm (50 in-lb) 1.9 Nm (17 in-lb)

Note: Capacities are per set of jaws and are not simultaneous.

2X MANIFOLD AIRPORTS

2X [

18.5

(0.730)

4X [2 H7 X 6.4 DP]

2.5643.0 in.

76 mm

Mz

F/2

Mx

[M3 X 3 DP]

SUPPLIED PLUGGED

(CLOSED PORT)

25.0

(0.984)

3 H7 X 2.5 DP]

15.2

(0.600)

4.4

(0.175)

+0.001

2X 0.062

-0.000

[1.57 +0.02 -0.00]

9.20

(0.3620)

DOWELS

9.0

(0.354)

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

Z

X

F/2

My

Dimensions: mm (inch)

DIRECTCONNECTTM dimensions shown in blue

2X [M3 X 3 DP]

AUX. PORTS

SUPPLIED PLUGGED

BOTH ENDS

(OPEN PORT)

36.8

CLOSED PORT

C

L

(0.150)

[

(CLOSED PORT)

PURGE-SCAVENGE PORT

SUPPLIED PLUGGED

3.8

2X [M5 X 4 DP]

symmetrical about

symmetrical about

5.8

(0.230)

-A-

1.3650.001

[34.67 0.02]

A

0.00

A0.03

]

[M3 X 3 DP]

UNLESS OTHERWISE NOTED ALL

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

TOLERANCES ARE AS SHOWN BELOW

Dimensions are

centerline

Dimensions are

centerline

Metric Threads

Course Pitch

Metric Threads

Course Pitch

(1.450)

24.1

(0.950)

Third Angle

Projection

Imperial in Metric [mm]

0.00 = ±0.01 [0.] = [± 0.25]

0.000 = ±0.005 [0.0] = [± 0.13]

0.0000 = ±0.0005 [0.00] = [± 0.013]

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

Third Angle

0.000 = ±0.005 [0.0] = [± 0.13]

0.0000 = ±0.0005 [0.00] = [±0 .013]

±0.013 mm or (±0.0005")

Projection

Imperial in Metric [mm]

0.00 = ±0.01 [0.] = [± 0.25]

All Dowel Holes are SF (Slip Fit).

5.1

(0.200)

C

L

2X [

CLEARANCE FOR M3 SHCS]

Locational Tolerance

±0.013 mm or (±0.0005")

OPEN

PORT

7.4

(0.290)

[

6.35 X 3 DP C'BORE

BOTH SIDES

18.5

(0.730)

.0005

0.013

]

SPECIFICATIONS

Total Rated Grip Force F @ 100 psi, 7 bar*:

120 N (27 lb)

Stroke: 12.7 mm (0.50")

Weight: 0.20 Kg (0.45 lb)

Pressure Range (Without Springs):

0.3 to 7 bar (5 to 100 psi)

Pressure Range (With Springs):

1.4 to 7 bar (20 to 100 psi)

Cylinder Bore (2X): 10.3 mm (0.406")

Displacement: 1.1 cm3 (0.065 in3)

Temperature Range:

Standard Seals: -35 to 80°C (-30 to 180°F)

FKM Seals: -30 to 120°C (-20 to 250°F)

Actuation (Without Spring/With Spring):

0.11/0.12 sec (0.11/0.12 sec)

Accuracy: ±0.03 mm (±0.001")

Repeatability: ±0.01 mm (±0.0005")

Valve Required to Actuate Single Acting:

3-way, 2-position

Valve Required to Actuate Double Acting:

4-way, 2-position

* With springs

C-17d

Page 5

C

L

45.1

PORT

6.35 X 3 DP C'BORE

A

1.6620.001

(1.275)

32.4

(0.230)

5.8

(0.300)

7.6

(0.915)

23.2

(0.350)

8.9

(1.775)

-A-

2X [M5 X 5 DP]

(CLOSED PORT)

[M3 X 3 DP]

CLEARANCE FOR M3 SHCS]

OPEN

[42.21 0.02]

PURGE-SCAVENGE PORT

SUPPLIED PLUGGED

BOTH SIDES

2X [

A0.03

0.013

]

[

]

Dpp-14m-15 anD Dpp-14m-15-c

17.8

(0.700)

6X [

CENTERLINE DOWELS

Loading Capacity Static Dynamic

Maximum Tensile T 556 N (125 lb) 187 N (42 lb)

Maximum Compressive C 556 N (125 lb) 187 N (42 lb)

Maximum Moment Mx 9.0 Nm (80 in-lb) 3.1 Nm (27 in-lb)

Maximum Moment My 12 Nm (105 in-lb) 4.0 Nm (35 in-lb)

Maximum Moment Mz 9.0 Nm (80 in-lb) 3.1 Nm (27 in-lb)

Note: Capacities are per set of jaws and are not simultaneous.

C

L

9.5

(0.375)

4 X [M3 X 4 DP]

OPEN PORT

4X [M3 X 5 DP]

9.5

(0.373)

9.5

(0.375)

2X 0.124+0.001

-0.000

[3.15 +0.02 -0.00]

8X [M4 X 7 DP]

4 H7 X 3.6 DP]

C

L

28.0

(1.102)

GRIP FORCE PER FINGER (with Spring Assist Option)

lbs.N

25

111

20

89

15

67

10

45

FINGER FORCE - F/2

5

22

0

0

0

0

90.2

(3.550)

8.9

(0.350)

C

L

19.1

(0.750)

19.05

(0.7500)

(DOWELS)

19.1

(0.750)

C

L

63 (2.47) CLOSED

79 (3.10) OPEN

16.0

2X

(0.630)

8.0

(0.315)

2X

16.00

(0.6300)

DOWELS

100 PSI [7 bar]

80 PSI [5.5 bar]

60 PSI [4.1 bar]

40 PSI [2.7 bar]

20 PSI [1.4 bar]

0 PSI [0 bar]

2.0

1.0

51

25

EFFECTIVE FINGER LENGTH - L

3.0

76

Z

L

T

C

2X [3 H7 X 2.5 DP]

4X [2 H7 X 6.4 DP]

4.0

102

Mx

F/2

Y

2X MANIFOLD AIRPORTS

[M3 X 3 DP]

SUPPLIED PLUGGED

(CLOSED PORT)

34.0

(1.339)

17.8

(0.700)

5.7

(0.225)

.0622X0 +0.001

-0.000

[1.57 +0.02 -0.00]

17.98

(0.7080)

DOWELS

13.0

(0.512)

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

5.0 in.

127 mm

Z

Mz

X

F/2

My

SUPPLIED PLUGGED

C

L

[

Dimensions: mm (inch)

DIRECTCONNECTTM dimensions shown in blue

2X [M3 X 3 DP]

AUX. PORTS

BOTH ENDS

(OPEN PORT)

CLOSED PORT

3.9

(0.155)

0.001 0.0005

symmetrical about

5.8

(0.230)

-A-

1.6620.001

[42.21 0.02]

A

A0.03

]

PURGE-SCAVENGE PORT

UNLESS OTHERWISE NOTED ALL

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

Dimensions are

centerline

centerline

Metric Threads

Course Pitch

Metric Threads

Course Pitch

45.1

(1.775)

32.4

(1.275)

C

L

2X [M5 X 5 DP]

(CLOSED PORT)

SUPPLIED PLUGGED

[M3 X 3 DP]

2X [

6.35 X 3 DP C'BORE

CLEARANCE FOR M3 SHCS]

BOTH SIDES

Third Angle

Projection

Third Angle

Projection

Imperial in Metric [mm]

0.00 = ±0.01 [0.] = [± 0.25]

Imperial in Metric [mm]

0.000 = ±0.005 [0.0] = [± 0.13]

0.0000 = ±0.0005 [0.00] = [± 0.013]

0.00 = ±0.01 [0.] = [± 0.25]

0.000 = ±0.005 [0.0] = [± 0.13]

0.0000 = ±0.0005 [0.00] = [±0 .013]

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

All Dowel Holes are SF (Slip Fit).

±0.013 mm or (±0.0005")

Locational Tolerance

±0.013 mm or (±0.0005")

8.9

(0.350)

OPEN

PORT

[

SPECIFICATIONS

Total Rated Grip Force F @ 100 psi, 7 bar*:

227 N (51 lb)

Stroke: 15.9 mm (0.63")

Weight: 0.48 Kg (1.05 lb)

Pressure Range (Without Springs):

0.3 to 7 bar (5 to 100 psi)

Pressure Range (With Springs):

3.4 to 7 bar (50 to 100 psi)

Cylinder Bore (2X): 14.3 mm (0.563")

Displacement: 2.5 cm3 (0.156 in3)

Temperature Range:

Standard Seals: -35 to 80°C (-30 to 180°F)

FKM Seals: -30 to 120°C (-20 to 250°F)

Actuation (Without Spring/With Spring):

0.15/0.16 sec (0.15/0.16 sec)

Accuracy: ±0.03 mm (±0.001")

Repeatability: ±0.01 mm (±0.0005")

Valve Required to Actuate Single Acting:

3-way, 2-position

Valve Required to Actuate Double Acting:

4-way, 2-position

* With springs

7.6

(0.300)

23.2

(0.915)

0.013

]

C-17e

Page 6

C

L

59.4

PORT

6.35 X 3 DP C'BORE

A

1.6620.001

(1.838)

46.7

(0.230)

5.8

(0.300)

7.6

(0.915)

23.2

(0.351)

8.9

(2.338)

2X [M5 X 5 DP]

(CLOSED PORT)

[M3 X 3 DP]

CLEARANCE FOR M3 SHCS]

OPEN

[42.21 0.02]

PURGE-SCAVENGE PORT

SUPPLIED PLUGGED

BOTH SIDES

2X [

A0.03

0.013

]

[

]

Dpp-14m-25 anD Dpp-14m-25-c

17.8

(0.700)

4 X [M3 X 4 DP]

6X [

CENTERLINE DOWELS

Loading Capacity Static Dynamic

Maximum Tensile T 734 N (165 lb) 245 N (55 lb)

Maximum Compressive C 734 N (165 lb) 245 N (55 lb)

Maximum Moment Mx 11 Nm (100 in-lb) 3.7 Nm (33 in-lb)

Maximum Moment My 14 Nm (125 in-lb) 4.7 Nm (42 in-lb)

Maximum Moment Mz 11 Nm (100 in-lb) 3.7 Nm (33 in-lb)

Note: Capacities are per set of jaws and are not simultaneous.

C

L

9.5

(0.375)

OPEN PORT

4X [M3 X 5 DP]

9.5

(0.373)

9.5

(0.375)

2X 0.124+0.001

-0.000

[3.15 +0.02 -0.00]

12X [M4 X 7 DP]

4 H7 X 3.6 DP]

C

L

37.5

(1.476)

GRIP FORCE PER FINGER (with Spring Assist Option)

lbs.N

25

111

20

89

15

67

10

45

FINGER FORCE - F/2

5

22

0

0

0

0

118.7

(4.675)

8.9

(0.350)

C

L

19.1

(0.750)

(0.7500)

(DOWELS)

19.1

(0.750)

C

L

82 (3.23) CLOSED

107(4.23) OPEN

4X

11.0

(0.433)

5.5

(0.217)

11.00

4X

(0.4330)

DOWELS

100 PSI [7 bar]

80 PSI [5.5 bar]

60 PSI [4.1 bar]

40 PSI [2.7 bar]

20 PSI [1.4 bar]

0 PSI [0 bar]

2.0

1.0

25

EFFECTIVE FINGER LENGTH - L

3.0

51

76

Z

L

T

C

19.05

Y

4.0

102

Mx

2X [

F/2

2X MANIFOLD AIRPORTS

[M3 X 3 DP]

SUPPLIED PLUGGED

(CLOSED PORT)

34.0

(1.339)

3 H7 X 2.5 DP]

17.8

(0.700)

5.7

(0.225)

+0.0010.0622X

-0.000

[1.57 +0.02 -0.00]

4X [2 H7 X 6.4 DP]

17.98

(0.7080)

DOWELS

13.0

(0.512)

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

5.0 in.

127 mm

Z

Mz

My

SUPPLIED PLUGGED

CLOSED PORT

C

L

X

F/2

Dimensions: mm (inch)

DIRECTCONNECTTM dimensions shown in blue

2X [M3 X 3 DP]

AUX. PORTS

BOTH ENDS

(OPEN PORT)

3.9

(0.155)

[

5.8

(0.230)

-A-

1.6620.001

[42.21 0.02]

0.00 0.0005

A

A0.03

]

2X [M5 X 5 DP]

(CLOSED PORT)

PURGE-SCAVENGE PORT

SUPPLIED PLUGGED

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Dimensions are

symmetrical about

centerline

Metric Threads

Course Pitch

Metric Threads

Course Pitch

59.4

(2.338)

46.7

(1.838)

C

L

[M3 X 3 DP]

2X [

6.35 X 3 DP C'BORE

CLEARANCE FOR M3 SHCS]

BOTH SIDES

UNLESS OTHERWISE NOTED ALL

Third Angle

Projection

Third Angle

Projection

Imperial in Metric [mm]

0.00 = ±0.01 [0.] = [± 0.25]

0.000 = ±0.005 [0.0] = [± 0.13]

Imperial in Metric [mm]

0.0000 = ±0.0005 [0.00] = [± 0.013]

0.00 = ±0.01 [0.] = [± 0.25]

0.000 = ±0.005 [0.0] = [± 0.13]

0.0000 = ±0.0005 [0.00] = [±0 .013]

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±0.0005" or [±0.013 mm]

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±0.0005" or [±0.013 mm]

8.9

(0.351)

OPEN

PORT

SPECIFICATIONS

Total Rated Grip Force F @ 100 psi, 7 bar*:

214 N (48 lb)

Stroke: 25.4 mm (1.00")

Weight: 0.57 Kg (1.25 lb)

Pressure Range (Without Springs):

0.3 to 7 bar (5 to 100 psi)

Pressure Range (With Springs):

3.4 to 7 bar (50 to 100 psi)

Cylinder Bore (2X): 14.3 mm (0.563")

Displacement: 4.1 cm3 (0.249 in3)

Temperature Range:

Standard Seals: -35 to 80°C (-30 to 180°F)

FKM Seals: -30 to 120°C (-20 to 250°F)

Actuation (Without Spring/With Spring):

0.19/0.20 sec (0.19/0.20 sec)

Accuracy: ±0.03 mm (±0.001")

Repeatability: ±0.01 mm (±0.0005")

Valve Required to Actuate Single Acting:

3-way, 2-position

Valve Required to Actuate Double Acting:

4-way, 2-position

* With springs

7.6

(0.300)

23.2

(0.915)

0.013

[

]

C-17f

Page 7

OHSP-017

OSMK-119

OISP-014

OISN-014

18.3

(0.72)

3.8

(0.15)

8.6

(0.34)

OHSN-017

OHSP-011

OHSN-011

3.8

(0.15)

Multiple Air Port Locations

l Standard M5 Air Ports on Front Surface

l 3 M3 Air Port Locations (Left, Right, and

Top Surface) Are Plugged as Standard

Dimensions:

mm (inch)

18.3

(0.72)

18.5

18.5

(0.73)

(0.73)

8.6

(0.34)

Sensors

l Magneto Resistive or Inductive Proximity Available

l Capable of Sensing 4 Positions

Open and Closed on Both Jaws

l PNP and NPN Available

l Magneto Resistive Sensors Are Slot Mounted,

No Mounting Kits Required

l Threaded Quick Disconnect with Built-In LED Output

l Sensors Mount on Either Side of Gripper

l Sensors Magnets in Pistons Are Standard

OSMK-119

OISP-014

OISN-014

27.2

(1.07)

Plumbing Fittings

l Adjustable Flow Controls

l Have Thumb Screw Adjust with Locking Nut for Adjusting Actuation Time

l Available for 3 or 6 mm OD Tubing

l Failsafe Valve for Applications

l Where it is Critical That the Part Being Gripped Not be Dropped if Air

Pressure is Lost

l Can Mount Directly to Gripper or In-Line with Plumbing to Gripper

l For M5 Air Ports

l Consult Factory for Additional Plumbing Fittings

To Order Visit omega.com/dpp_10m_14m for Pricing

JAW LGTH JAW LGTH BODY BODY BODY MAX GRIP

CLOSED OPEN DEPTH LGTH HEIGHT STROKE FORCE WEIGHT

MODEL NO. mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) N (lbs) Kg (lbs)

DPP-10M-06 47 (1.85) 53 (2.10) 25 (0.98) 63 (2.47) 35 (1.36) 6.4 (0.25) 111(25) 0.16 (0.35)

DPP-10M-12 49 (1.93) 62 (2.43) 25 (0.98) 74 (2.90) 35 (1.36) 12.7 (0.50) 111(25) 0.20 (0.45)

DPP-14M-15 63 (2.47) 79 (3.10) 34 (1.34) 90 (3.55) 42 (1.66) 15.9 (0.63) 200 (45) 0.48 (1.05)

DPP-14M-25 82 (3.23) 107 (4.23) 34 (1.34) 119 (4.67) 42 (1.66) 25.4 (1.00) 200 (45) 0.57 (1.25)

DPP-10M-06-C 47 (1.85) 53 (2.10) 25 (0.98) 63 (2.47) 35 (1.36) 6.4 (0.25) 120 (27) 0.16 (0.35)

DPP-10M-12-C 49 (1.93) 62 (2.43) 25 (0.98) 74 (2.90) 35 (1.36) 12.7 (0.50) 120 (27) 0.20 (0.45)

DPP-14M-15-C 63 (2.47) 79 (3.10) 34 (1.34) 90 (3.55) 42 (1.66) 15.9 (0.63) 227 (51) 0.48 (1.05)

DPP-14M-25-C 82 (3.23) 107 (4.23) 34 (1.34) 119 (4.67) 42 (1.66) 25.4 (1.00) 214 (48) 0.57 (1.25)

Ordering Example: DPP-14M-25, pneumatically powered precision gripper with DirectConnect easy mounting technology, 25.4 mm (1") jaw

stroke and 200 N (45 lbs) of gripping force. All models have a temperature range of -35 to 80°C (-30 to 180°F). The temperature range can be

modified to -30 to 120°C (-20 to 250°F) with FKM seals. Add “V” to the end of the model number for additional cost. All models come standard

with snychornous jaws, if non snychornous is required consult sales. All models with the “-C” option have a spring assist closing mechanism

on the jaws to provide fail safe closing and additional gripping force.

Accessories

MODEL NO. DESCRIPTION

SENSOR ACCESSORIES

OISN-014 NPN inductive proximity sensor

OISP-014 PNP inductive proximity sensor

OHSN-011 NPN magneto resistive sensor 90° barrell with quick disconnect fitting

OHSP-011 PNP magneto resistive sensor 90° barrell with quick disconnect fitting

OHSN-017 NPN magneto resistive sensor short barrell with quick disconnect fitting

OHSP-017 PNP magneto resistive sensor short barrell with quick disconnect fitting

CABL-010 2 m (6.6') sensor extension cable with quick disconnect fitting

CABL-013 5 m (16') sensor extension cable with quick disconnect fitting

OSMK-119 DPP-10M-14M inductive sensor mounting kit

PNEUMATIC ACCESSORIES

Pneumatic Tubing

Pneumatic Fittings

Pneumatic Flow Controls Adjustable flow control fittings and directional control valves, see omega.com

Polyurethane tubing in multiple diameters and colors available, see omega.com

Detailed specifications and CAD drawings are available at

Poly-Tube fittings in Male or Female NPT in multiple configurations, see

omega.com

63.0

(2.48)

omega.com.

C-17g

Loading...

Loading...