Page 1

DPG9045

DPG9145

DPG9245

DPG9030

DPG9130

DPG9230

Digital Industrial Gauge

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 1

Page 2

– 3 –– 2 –

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, r ue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 2

Page 3

– 5 –– 4 –

Congratulations on your purchase of the Omega

®

digital industrial gauge. This feature-packed gauge

offers a menu-driven display for easy customization.

User selectable features include 12 units of measure-

ment, password protected calibration and disable

functions, adjustable bar graph and update rate. A

five digit display for maximum resolution is standard.

Optional 4-20mA output, switching and line- power

add to the versatility of the gauge. With the range

printed on the keypad, Omega digital gauges meet

ASME B40.7 specification. See a complete listing of

product features and specifications on pages 18.

TABLE OF CONTENTS

Quick Reference ............................................6-7

Keypad Functions..........................................8-10

• ON/OFF KEY

• ZERO/CLEAR KEY

• MIN/MAX KEY

(down arrow key)

• MENU KEY

• BACKLITE KEY

(up arrow key)

• ENTER KEY

MENU Functions (MENU Mode) ..............................11-17

• Engineering Units

• CONFIG Mode

• Set Password

• Recalibration of Gauge

• Zero Key Adjustment

• Disabling Menu Options

• Bar Graph Options

• Auto Off Options

• Update Options for Displayed Pressure

• Dampening Options

• Backlite Options (Backlite Optional)

• Set Switch(es) Option(s) (Switches Optional)

Specifications ................................................18

Ranges ........................................................19

Display Messages ..........................................19

Wiring Diagrams ........................................20-23

Gauge Installation & Maintenance....................24-25

• Mounting

• Battery Replacement & Installation

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 4

Page 4

– 7 –– 6 –

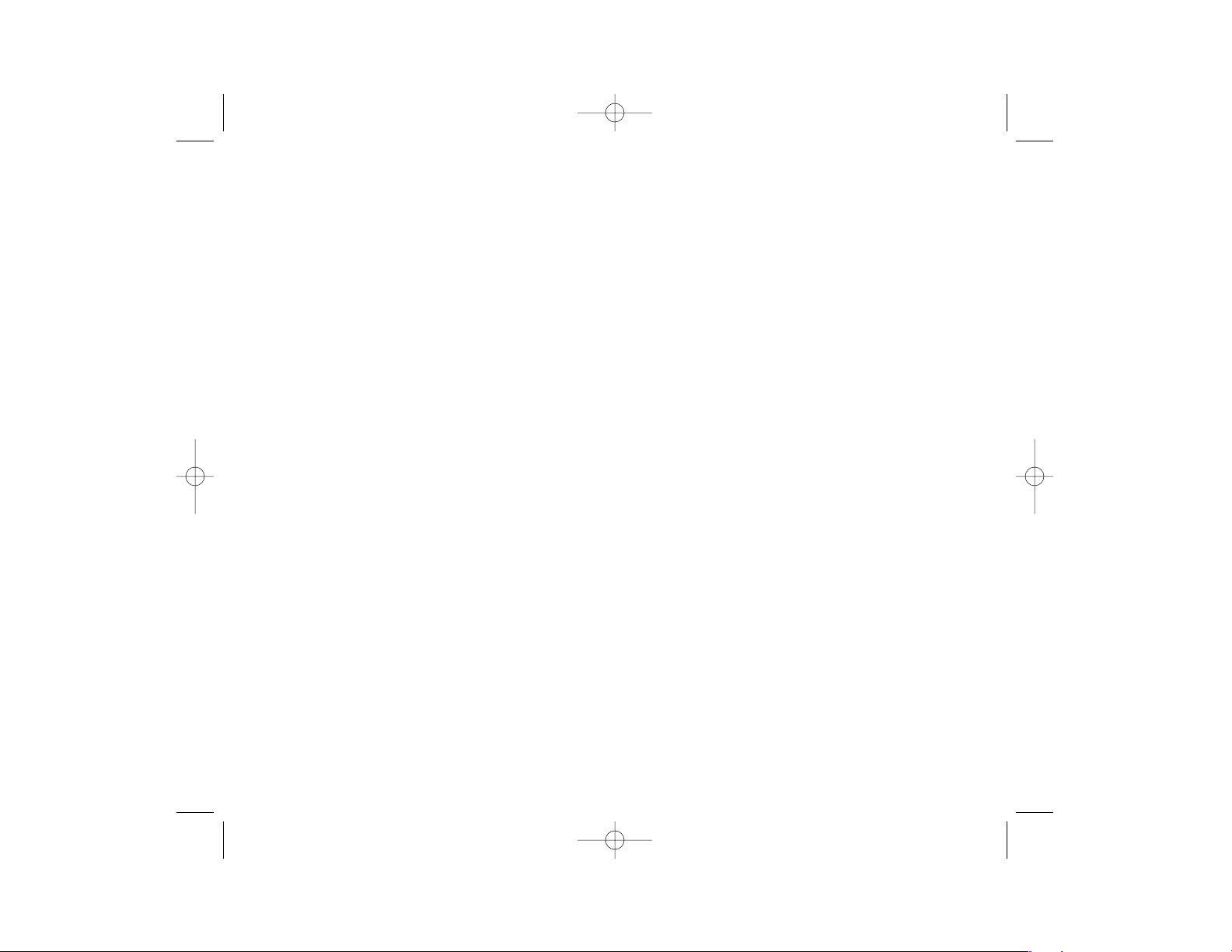

Bar graph

% of full scale

Flashing display when unit

pressured below zero

Press to indicate minimum

or maximum pressure

gauge has measured

Press again to return to

pressure units

Press to read menu

While in unit of measurement mode (eg: psi),

press the ZERO CLEAR button to rezero the

gauge. This feature functions when displayed

pressure is within ±5% or 10% of zero value

This bar graph indicates battery level;

the more segments, the closer the

battery is to full charge (only dis-

played on units with battery

Flashing display when unit

pressurized beyond full-scale

UNITS (Pressure)

ENGLISH

INHG

PSI*

INH2O

@ 4°C, 20°C, 60°F

FTW

FTSW

METRIC

BAR

MBAR

KPA

CMH2O

KG/CM2

Press to turn backlite on or off

(backlite optional)

Range on keypad;

complies with ASME B40.7

Press to turn unit on or off

UPDATE RATE

(Pressure measurement

per second)

10x (100 MS)*

5x (200 MS)

2x (500 MS)

1x (1 Sec)

AUTO OFF

(Turns unit off after

option selected)

Never*

2 minutes

5 minutes

15 minutes

30 minutes

CALIBRATE

Zero and span

adjustments,

password

protected

DISABLE

Allows for

“lockout” of

MENU

options

BACKLITE

(Off options)

Never

2 SEC

5 SEC*

15 MIN

30 MIN

DAMPENING

(Takes pressure reading

and averages

process pressure

None*

Avg 2

Avg 4

Avg 6

Avg 8

.88˝ high digital display (41⁄2˝ case)

.60 high digital display(3˝ case)

*Indicates Default

QUICK REFERENCE

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 6

Page 5

– 9 –– 8 –

Turns the gauge on and off. When pressing the

ON/OFF key while in the off position, gauge startup display first indicates the software version

followed by the model number and gauge pressure range. The gauge will then display indicated

pressure and be ready for use.

Press this key for one second prior to gauge

usage to rezero any initial zero shift. If zero shift

is greater than programmed zero allowance, the

gauge will display OFSET (blinking) for 1 second, then return to the measure mode. To clear

minimum and maximum values, press

ZERO/CLR button (when min/max values are

indicated). Gauge will auto advance once zeroed.

This key allows for customization of the gauge.

Pressing the MENU key allows cycling through

the main MENU items; UNITS, CONFIG, GRAPH,

OFF, UPDAT & DAMP. Any item changed in the

Menu become the new default setting(s).

Revised settings are saved in the event of power

loss.

The

(up arrow key) or (down arrow key)

on the keypad allows for scrolling through the

MENU options to increase or decrease numeric

values as required. If in the menu mode, gauge

will automatically advance to measure mode

once selected MENU item has been set.

This key manually turns the backlite on or off.

five options are available. They include NEVER,

10 sec, 30, sec, 1 min, 5 min*. With the NEVER

option, the gauge BACKLITE will remain lit

whenever the gauge is in the ON mode or until

the BACKLITE button is pushed again. Options,

10 sec, 30 sec, 1 min, 5 min*. allow the BACKLITE to automatically turn-off after a selected

period of time.

To use the BACKLITE option:

Step 1: Press the MENU key.

Step 2: Press the

(up arrow key) or (down

arrow key) until the word LITE appears.

Step 3: Press ENTER.

Step 4: Press the

(up arrow key) or (down

arrow key) to select the BACKLITE option.

Step 5: Press the ENTER key to finalize your

choice of LITE options.

KEYPAD FUNCTIONS

KEYPAD FUNCTIONS

ON/OFF

ZERO

CLR

MAX/MIN

MENU

The Max/Min key allows review of minimum and

maximum pressure values since unit start-up or

last push of the clear key. Press key to:

1) Indicate maximum pressure.

2) Indicate minimum pressure.

3) Exit MAX/MIN mode and return the unit to

pressure measurement mode. To clear minimum and maximum values press ZERO/CLR

key (must be in MAX/MIN mode).

The

(down arrow key) is used in the MENU

mode, see following MENU key section.

Key for gauge

with Backlite

Key for gauge

without Backlite

displayed with

(up arrow

icon only)

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 8

Page 6

– 11 –

MENU FUNCTIONS

How to Use Your Menu Functions

To set a user password (SETPW):

Step 1: Press the Menu key on the keypad

Step 2: Press the

(up arrow key) or (down arrow

key) until the word CONFIG appears.

Step 3: Press Enter. The word SETPW appears on the

gauge display

Step 4: Press Enter. A five digit numeric password is now

required.

Step 5: Press the

(up arrow key) or (down arrow

key) on the keypad to select the first digit of the password.

Step 6: Press ENTER.

Step 7: Repeat until the five-digit password is shown on

the gauge display.

Step 8: Press ENTER.

Note: to erase password at any time while in the SETPW

(set password) mode, press the ZERO/CLEAR key. The

user will be prompted to reprogram the password once the

five-digit password is entered. The gauge will display SAVE.

Step 9: Press Enter to save the password setting.

ENTPW: Once a user password has been established and

entry into the CONFIG mode is required, the user will be

prompted to ENTPW or enter password.

Follow setup steps 4-8 above.

RECAL: or recalibrate allows for zero, mid-scale, full-scale

and factory default calibration of the gauge. The RECAL

feature also allows for recalibration of gauges with

4-20mA output.

*Indicates default.

– 10 –

KEYPAD FUNCTIONS

MENU OPTIONS

UNITS: 12 units of measurement are available: psi, mmHG,

inH

2

O with three temperature options: 20°C, 60°F, 4°C*,

mBar, inHg, ftH

2

O, mPa, kPa, kg/cm2and bar.

Step 1: Press the MENU key until the word UNITS appears.

Step 2: Press Enter.

Step 3: Press the

(up arrow key) or (down arrow

key) to select the required unit of measure.

Step 4: Press ENTER to finalize the UNIT selection.

Note: For inH

2

0 range with three temperature options,

press the

(up arrow key) and (down arrow key) to

select the desired temperature, then press ENTER to finalize the UNIT selection.

CONFIG: This option allows access to additional Menu

options. Options include:

• ENTPW or enter password (this appears as a sub-menu

in the CONFIG mode if a user password has been set).

• RECAL (allows for zero, span and mid-scale calibra-

tion of the gauge).

• 0bUTN or zero key (allows for adjustment of % of

range that can be zeroed),

• dISAb, allows for disabling MENU options.

• SETPW: This feature allows for a user defined numer-

ic password. If a user password is not set, all features

in the CONFIG mode will be accessible without a

password. If a user password is set, all items in the

CONFIG menu options are accessible with or without

a user password. If a user password is programmed,

it will be required to access the CONFIG menu options.

*Indicates default.

ENTER

This key allows for selecting gauge features in the

menu finalizing selection. Use of the enter key is

described throughout operating instructions.

KEYPAD FUNCTIONS

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 10

Page 7

– 13 –

Note: Calibration of Zero, mid-scale or span can be set independently of each other. For instance, if only full-scale calibration is required, press the

(down arrow key) until the

gauge display indicates full-scale pressure. Press Enter and

proceed as indicated above. Calibration of zero, midscale and

full-scale is recommended when recalibrating the gauge.

ZERO KEY (0bUTN): This feature allows the user to select

percent of full-scale at which the gauge can be rezeroed

using the Zero/Clear key on the keypad. Options include 5%

full-scale*, 10% full-scale or DISAB (disable of the zero key).

To use ZERO option:

Step 1: Press the Menu key on the keypad.

Step 2: Press the

(up arrow key) or (down arrow

key) until the word CONFIG appears.

Step 3: Press Enter.

Step 4: Enter user password, if it has been programmed.

Step 5: Press the

(up arrow key) or (down arrow

key) until the word 0bUTN (zero key) appears.

Step 6: Press Enter.

Step 7: Press the

(up arrow key) or (down arrow

key) to select 5PCT (5% full-scale), dISAb (disable zero

key) or 10PCT (10% full-scale).

Step 8: Press Enter to finalize the selection.

DISAB: or disable: This feature allows the user to dISAb

(or disable) or ENAb (enable) items in the MENU. Some

keypad keys can also be enabled or disabled. Any or all

MENU items can be enabled or disabled.

To use DISAB option:

Step 1: Press the Menu key on the keypad.

Step 2: Press the

(up arrow key) or (down arrow

key) until the word dISAb appears.

MENU FUNCTIONS

*Indicates default.

– 12 –

To use RECAL option:

Step 1: Press the Menu key on the keypad

Step 2: Press the

(up arrow key) or (down arrow

key) on the keypad until the word CONFIG appears.

Step 3: Press Enter.

Step 4: Enter user password if it has been programmed.

Step 5: Press

(up arrow key) or (down arrow key)

until the word RECAL appears.

Step 6: Press Enter.

Step 7: The gauge will now flash between INPUT and unit

of measure on the lower line and .00 on the top line. Apply

zero pressure to the gauge.

Step 8: Press Enter. Zero pressure is now set.

Step 9: The gauge will display full-scale pressure. Apply

full-scale pressure to the gauge.

Step 10: Press Enter. Full-scale pressure is now set.

Step 11: The gauge will now display mid-scale pressure.

Apply mid-scale pressure to the gauge.

Step 12: Press Enter. Mid-scale pressure is now set.

(Note: For compound ranges this recalibration is zero,

full-scale, mid-scale and full-vac.)

FOR FACTORY CALIBRATED SETTINGS:

Step 13: To reinstate factory calibrated settings for zero,

full-scale and mid-scale press the

(down arrow key)

Menu key until the word FACT appears.

Step 14: Press Enter. Factory calibration settings are now

reinstated.

Step 15: After zero, full-scale and/or mid-scale or factory

default calibration have been set, the word SAVE appears

on the gauge display.

Step 16: Press Enter to finalize calibration.

MENU FUNCTIONS

*Indicates default.

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 12

Page 8

Step 5: Press the ENTER key to finalize your choice. The

gauge display will now display SET. After two seconds the

screen will display the pressure value for 0% on the top

line. The middle line indicates the bar graph at 100% of

fullscale. The bottom line will display SET 0.

Step 6: Press the

(up arrow key) or (down arrow

key) on the keypad to increase or decrease gauge value at

0% of range.

Step 7: Press the ENTER key to finalize your choice. The

new values for the bar graph and 4/20mA settings have

now been saved.

OFF: This option sets the amount of time before the gauge will

turn itself off. Offerings are Never*, 30MIN,10MIN, 5MIN, 2

MIN.

To use the OFF option:

Step 1: Press the MENU key.

Step 2: Press the

(up arrow key) or (down arrow

key) until the word OFF appears.

Step 3: Press ENTER.

Step 4: Press the

(up arrow key) or (down arrow

key) to select the desired OFF time.

Step 5: Press the Enter key to finalize the OFF setting.

UPDATE: This option allows for changing the rate at which

pressure is updated on the display screen. This feature is

useful with rapid changes in process pressure that may

cause flutter of the display. Options are 100ms*, 1 sec,

500ms and 200ms, updates per second or 100ms*.

Since customer processes vary, update rates should be

selected based on the application.

To use the UPDATE option:

Step 1: Press the MENU key.

– 15 –

– 14 –

MENU FUNCTIONS

MENU FUNCTIONS

Step 3: press ENTER. The current setting (ENAB or dISAB)

will be displayed.

Step 4: Press the

(up arrow key) or (down arrow

key) on the keypad to select a setting.

Step 5: Press ENTER To finalize the setting.

GRAPH: This option allows the user to change the BAR

graph on the gauge display to correspond to any desired

pressure within the pressure limits of the gauge. This

option is useful when identifying a select portion of the

full-scale range of the gauge. The default setting for the

GRAPH is zero and full-scale pressure. For compound

gauges, the default setting for zero is set at full-scale vacuum. Full-scale pressure is set at the positive pressure as

displayed on the gauge keypad.

For gauges supplied with the 4-20mA output option, the

default is 4mA equals 0% of the bar graph and 20 mA

equals 100% of the bar graph.

Changing the bar graph to a pressure other than 0 and

100% of range will also change the 4-20mA output to correspond with the new bar graph pressures for 0 and 100%.

To use GRAPH option:

Step 1: Press the MENU key.

Step 2: Press the

(up arrow key) or (down arrow key)

on the keypad until the word until the word GRAPH appears.

Step 3: Press ENTER . The gauge display will indicate the

set full scale pressure range setting on the top line. The

middle line indicates the bar graph at 100% of full-scale.

The bottom line of the display will indicate SETFS to set

the full-scale range as displayed by the bar graph and 420mA.

Step 4: Press the

(up arrow key) or (down arrow key)

on the keypad to increase or decrease gauge value at

100% of range.

*Indicates default.

*Indicates default.

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 14

Page 9

– 17 –– 16 –

Step 2: Press the (up arrow key) or (down arrow

key) until the word UPDATE appears.

Step 3: Press Enter.

Step 4: Press the

(up arrow key) or (down arrow

key) to select an update rate.

Step 5: Press ENTER to finalize the selection.

DAMP or dampening: with five different options, this mode

allows for taking process pressure readings and averaging

them. This option is particularly useful to stabilize minor

process fluctuations. The options are NONE*, AVG 8, AVG

6, AVG 4, AVG 2.

Step 1: Press the MENU key until the word dAMP appears.

Step 2: Press Enter

Step 3: Press the

(up arrow key) or (down arrow

key) to select a dampening option.

Step 4: Press the ENTER key to finalize your Damp option.

(This Menu item is only seen on units with the switch option)

SWSET: Allows for setting switch setpoints. The gauge is

offered with one or two SPDT switches. If (one) SPDT

switch is ordered the menu option is SW1. If (two) SPDT

switches are ordered, the MENU options are SW1 and SW2.

Step 1: Press the MENU key.

Step 2: Press the

(up arrow key) or (down arrow

key) on the keypad to select the switch to be set. (If two

switches are present.)

Step 3: Press ENTER. The top line of the gauge display will

indicate pressure at 60% of the full-scale gauge range* or

the most recent switch setpoint. The middle line of the display will indicate a bar graph that displays the pressure

position within the pressure range. The bottom line will

display SETPT (blinking).

*Indicates default.

Note: Setpoints are limited to the full-scale pressure range

of the gauge.

Step 4: Press the

(up arrow key) or (down arrow key)

on the keypad to increase or decrease switch set-point

Step 5: Press the ENTER key to finalize switch setpoint. The

gauge will display SET. After two seconds, the top line will

indicate RETRP pressure. The bottom line will read SET.

Step 6: Repeat above to set RETRP (retrip value) If the

gauge is supplied with (one) setpoint, the screen will

advance to the measurement mode. If (two) switches are

supplied the display will advance to SW2.

Repeat the aforementioned if the gauge is supplied with

two switches.

Notes: The bar graph will increase or decrease as any

setpoint pressure is adjusted. The bar graph indicates

switch setpoint position within the full-scale pressure

range of the gauge.

The switch setpoint unit of pressure measurement corresponds with the current set unit of measure of the gauge.

If gauge unit of measurement is changed after switch(es)

is set, switch setpoint(s) will automatically be updated to

correspond with revised unit of measurement. Switch

deadband is the difference between the SETPT (setpoint)

and the RETRP (retrip) pressure.

MENU FUNCTIONS

MENU FUNCTIONS

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 16

Page 10

– 19 –

Comp. mmHg in.Hg In. mm ft. Bar/

psi (psi) (press.) (press.) H2OH2O mBar H2O mPa kPa ksc

-15/0/15

1500 60 800 60 250 30 6 200 2

-15/0/30

2000 100 1000 100 300 60 10 300 4

-15/0/60

3000 160 160 400 160 50 400 6

30

-15/0/100

200 200 500 200 600 10

60 300 300 600 300 800 16

100 400 400 1000 400 1000 25

160 600 600 1500 600 1600 40

200 800 800 2000 1000 2500 60

300 1000 1000 2500 4000 100

600 1600 4000 6000 160

800 2000 5000 8000 250

1000 3000 400

1500 6000 500

2000 800

3000 1000

5000

8000

10,000

15,000

20,000

DIGITAL INDUSTRIAL GAUGE RANGES:

DIGITAL INDUSTRIAL GAUGE SPECIFICATIONS:

DISPLAY MESSAGES:

Display/Problem Description Action

No Battery Icon

Display (applicable to

gauges with batteries

Gauge has <10%

battery life left

Replace batteries

OFSET (blinking)

Zero/Clear button

pushed when pressure

displayed is beyond set

rezero pressure limit

Only rezero the gauge within

limits of setting in Menu

Menu button disabled

Gauge is in

Max/Min mode

Push Max/Min button until

unit of measure is displayed

on keypad

Unit of measure

selected in Menu

displays N/A

Resolution at full scale

pressure range

exceeds 50,000 counts

Choose another unit of

measure

I can’t access items in

the main Menu

Items that cannot be

accessed have been

disabled

Enable item(s) in the Menu.

See Menu/CONFIG and

diSAb or DISABLE

I can’t set the

password I want

00000 is not a valid

password

Select a different password

– 18 –

Type: 2074 (battery), 2174 (loop), 2274 (line)

Accuracy: .25% Full Scale, terminal point

Case Size: 3˝, 41⁄2˝

Case Material: 3˝ SS, 4

1

⁄2˝ fiberglass reinforced thermoplastic or

black epoxy coated aluminum

Case Encl. Rating: Weatherproof, IP65

Wetted Materials: 17-4 SS (sensor), 316SS (socket)

Socket Size:

1

⁄4

or

1

⁄2

NPT, JIS, DIN, SAE, (

1

⁄2

NPT only with 4

1

⁄2

˝ case,

others on application)

Socket Location: Lower, 3, 9 and 12 o’clock

Ranges: Vac. thru 20,000 psi (see engineering units below for other

units)

Operating Temp.: 14/140°F (10/60°C)

Storage Temp.: –4/158°F (-20/70°C)

DISPLAY

Type: LCD

Display Digits: Five (5)

Character Height: 3˝ .60˝, 41⁄2˝ .88˝

Backlite: Optional

Bar Graph: Yes

Battery Life: 3˝ >1000 hrs., 41⁄2˝ >3600 hrs.

Agency Approvals: CE, FM* (Intrinsically Safe Class1, Div 1), CSA and CENELEC

*FM is not available with the following: 4

1

⁄2˝ polypropylene

case, SPDT switch option(s) (XU1, U2) or Backlite (XBL)

option)

KEYPAD FUNCTIONS

On/Off: Manually turns unit on and off (auto off options in menu)

Zero/Clear: Zeros display or clears min. and max. values when displayed

Min/Max

(down) Stores min and max values, arrow key allows for

Arrow Key: scrolling thru menu items

Menu Key: Provides access to menu options

Backlite

(up) Manually turns backlite on and off (auto off options in

Arrow Key: menu), arrow key allows for five menu options.

(up)

(Backlite optional) arrow key allows for scrolling thru menu options

Enter: Selects items in the menu

MENU MODE

Engineering Units: 10 units of measurement are available; psi, In. H

2

O (with

three temp. options: 20°C, 60°F, 4°C*), Ft. H

2

O, mPa, mBar,

kPa, kg/cm2, Bar, inHg and mmHg

Configuration Mode Allows for changes to default settings of gauge

(Config): Including zero disable feature

Bar Graph (Graph): Allows for adjustment of bargraph and 4-20

(optional feature)

Auto Off (Off): Allows for changes to auto off of gauge, five options:

Never, 2 min., 5 min., 15 min., 30 min.

Update Rate

(Update): Four options: 100 ms, 200 ms, 500 ms, 1 sec

Dampening (Damp): Six options: None, average, 2, 4, 6, 8 times per 100ms

Backlite: Five options: Never, 10 sec., 30 sec., 1 min., 5 min.

Field Recalibration: Allows for recalibration of zero, midscale and span

(password protected)

OPTIONS

4-20mA Display: 12-36 Vdc, mA with unlimited turndown (within gauge range)

Line Powered: 12-36 Vdc, 2VA max.

Switching*: (1) or (2) SPDT switches,(max. contact 30Vdc, 1 amp,

125Vac .5 Amp, Switches adjustable to 100% of range

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 18

Page 11

– 21 –

L

T

9

Y1

0

9

C3

C7R2J

2

7

C15

8

D5

D

D12

0

2

+24V

GND

GN

FID3

DRESSER

321CO

8

J5

J3

C4

Q

C10

C9

R6

C5

1

U4

O7

8

R1

R5

C

T

3

V6

T8

D

FID6

R19

ed

c

k

O

09

S

d

G

Whi

e

t

ypad Input

S

t

WIRING DIAGRAM

Line Powered/Loop Powered 4-20mA (Type DPG9245_-A)

4 conductor, 20 AWG shielded

Line Powered with (1) SPDT switch (Type DPG9245_-S1)

5 conductor, 22 AWG shielded

L

T

9

Y1

0

9

C3

J

2

7

C15

D6

5

D

D12

0

2

+24V

GND

EGN

FID3

DRESSER

321CO

J5

3

C4

Q

C10

C9

R6

C5

1

U4

O7

8

R1

R5

C

4

C6

DQ/TB 2003

V6

T8

D

FID6

R19

ed

c

k

O

09

t

yp p

S

t

C

C7

J1

J6

C2

0

C17

7

C15

8

3

0

1

GND

EGN

D

3

1

8

Q2

J5

J

4

Q1

C10

C

6

C5

U4

5

C1

C6

C8

2

J2

6

06

S

l

d

ac

ed

t

ypad Input

t

– 20 –

WIRING DIAGRAM

Line Powered (DPG9245)

2 conductor, 20 AWG shielded

Loop Powered 4-20mA (Type DPG9145)

2 conductor, 20 AWG shielded

(– exc.)

(+ exc.)

(– exc.)

(+ exc.)

(– exc.)

(+ exc.)

(+ exc.)

(– exc.)

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 20

3

Battery Inpu

R2

D

T1

7

R

D

9

R

3

FID

T1

C

321CO2

DQ/TB 2003

hie

Bl

R

LOOP+

OOP

ECN

T

D1

C14

7

D

R

Y

a

Sensor Inpu

Wieco 92

LOOP+

OOP

ECN

T

D1

C14

7

D

F1D1

1

Battery Inpu

C

C17

U

R1

9

D

3

T1

T1

21–

E

R

a

1

R

F

1

Q2

L

B 200

hiel

reen

J2

ensor Inpu

-

Wieco 92

t

1

Battery Inpu

C

21–

1

R

F

1

Q2

J2

L

J

R

ensor Inpu

Wieco 92

-

C17

U

D1

3

T1

T1

Page 12

– 23 –

LOOP+

LOOP–

T7

D9

D7

Y1

D10

C14

T9

U5

V1

F1D1

C3

C7

R7

R2

J1

1

1

J6

C2

R22

R20 C17

D11

U7

D14

D1

C15

R18

D5

R23

R24

D13

R14R16

J3

J7

1

Q4

D16

D6

D15

D3

D12

T10

T12

T11

+24V

GND

EGND

FID3

DRESSER

321CO21–

D8

Q2

J5

J3

C4

R9

R10

R11

R12

R13

Q1

C10

C9

R6

C5

L1

U4

FO7

R8

FID4

V2

R1

R5

C12

C13

C1

R4

C6

C8

DQ/TB 2003

Y2

J2

T4

T6

T5

FID2

C11

K1

K2

K2

D2

T3T2T1

V6

R21

ISO1

R15

ISO2

Q3

T8

ECND

FID6

FID5

R17

R19

Red

Black

(N.O.) Blu e

(N.C.) Or ange

(COM) Brown

(N.C.) Violet

(N.O.) Yel lo w

(COM) Grey

227X-XAO-XU2

Belden 9946

Shield

Green

White

Battery Input

Keypad Input

Sensor Input

Switch 1

Switch 2

WIRING DIAGRAM

Line Powered/Loop Powered 4-20mA with (2) SPDT switches

(Type DPG9245_-AS2) 10 conductor, 22 AWG shielded

– 22 –

T

9

Y1

U

1

C3

C2

U7

C15

D16

D6

5

D3

D12

0

2

+24V

EGN

FID3

DRESSER

321CO

J5

3

C4

C10

C9

R6

C5

1

U4

O7

8

R1

R5

C

4

C6

DQ/TB 2003

1

K1

K

R1

SO

Q3

FID6

R19

ed

c

k

(N.O

.)

ue

(N.C.)

g

e

(

)

ow

O-XU1

3

S

d

G

Whi

e

t

ypad Input

S

t

WIRING DIAGRAM

Line Powered/Loop Powered 4-20mA with (1) SPDT switch

(Type DPG9245_-AS1) 7 conductor, 22 AWG shielded

Line Powered with (2) SPDT switches (DPG9245_-S2)

8 conductor, 22 AWG shielded

(– exc.)

(+ exc.)

(– exc.)

(+ exc.)

(– exc.)

(+ exc.)

(– exc.)

(+ exc.)

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 22

LOOP+

7

D

F1D

5

5

C1

I

R17

2

1

R

F

L

J

21–

R

hiel

reen

Battery Inpu

C17

D1

T1

T1

GND

T3T2T1

D2

Y1

F1D1

C3

J1

1

R2

C7

1

R7

J6

R22

R20 C17

D14

D1

R14R16

R24

J3

R23

1

D13

J7

Q4

D16

D15

Battery Input

D12

D3

T10

+24V

ISO1

R15

V1

C2

D11

U7

C15

R18

D5

D8

D6

T12

T11

GND

EGND

FID5

R9

R10

FID3

DRESSER

321CO21–

C11

ISO2

R17

FID4

V2

R11

K1

K2

K2

FID6

C13

C1

C12

R8

R5

FO7

R1

L1

C10

Q1

R12

R13

C9

R6

Q2

C5

J5

J3

C4

C8

DQ/TB 2003

C6

R4

Keypad Input

Shield

Black

Red

R

a

l

Oran

COM

ID

J2

ensor Inpu

-

Belden 994

t

(N.O.) White

(N.C.) Green

(COM) Brown

FID2

T5

(N.O.)

T6

(N.C.) Bl ue

(COM) Orange

T4

J2

U4

Y2

Sensor Input

227X-XU2

Belden 9944

Switch 1

Switch 2

Page 13

– 25 –

GAUGE INSTALLATION:

The Omega

®

digital industrial gauge comes standard with either

1

⁄4or1⁄2NPT connection.

Good piping practices recommend using teflon tape or a pipe sealant on the gauge

threads. Utilize a

9

⁄

16

˝ (3˝ case),

5

⁄

8

˝ (4

1

⁄

2

˝ case) wrench on the wrench flat of the gauge to

tighten the gauge to the process.

NEVER TIGHTEN GAUGE THREADS BY HOLDING THE BODY OF THE GAUGE. DOING SO

MAY DAMAGE THE GAUGE AND MAKE THE GAUGE INOPERABLE.

!

Pipe to which gauge is attached

must be properly grounded.

CLAMPING RING (1278G ONLY)

WASHER

SPACER POST

(3 REQ’D)

“B” (3 REQ’D)

PANEL

MOUNTING

RING

6˝ RING

DIA.

5.65˝

PANEL

OPENING

5/16˝ MAX PANEL

THICKNESS

Battery Installation and Replacement:

The Types DPG9030 and DPG9045 come standard with batteries installed. The 3˝ case

uses qty (2) AA alkaline batteries, the 4

1

⁄2˝ case uses qty (2) C alkaline batteries. Use

either Duracell MN2400, MX2400 or Energizer E92BP, X92RP AAA alkaline, nonrechargeable batteries.

Batteries have a life of approximately 1500 hours (3˝ case). 3600 hours (4

1

⁄

2

˝ case).

Battery life is dependent on gauge usage, backlite settings and power off settings.

When the lower bar of the battery icon of the gauge display flashes, the gauge has

approximately 7 hours of life remaining.

HOLE

CUTOUT

DIAMETER

3.406

(3

13

⁄32±1⁄32)

To replace the batteries (3˝ case):

1) Remove the single screw on the back of

the gauge case.

2) Hold the keypad in the palm of hand.

3) Carefully remove the two batteries from

the holder and replace batteries. Use only

AA alkaline non-rechargeable batteries.

To provide maximum battery life, replace

both batteries.

To replace the batteries (4

1

⁄

2

˝ case):

1) Remove the ring on the front of the

gauge case.

2) Looking at the gauge case, carefully

pull the front face out of the case.

3) Lay the gauge, face down on a flat surface.

4) Carefully remove the two batteries from

the holder and replace the batteries.

Use only C alkaline non-rechargeable

batteries. To provide maximum battery

life, replace both batteries.

Notes:

1) Do not mix ages or brands of batteries.

2) Do not replace batteries in hazardous

areas.

3˝ CASE

4

1

⁄2˝ CASE

PANEL MOUNTING DIMENSIONS

WIRING DIAGRAM

Vdc MIN = 12V + [0.022A* X (RL) ]

R

L

= RS+ R

W

RL= Loop Resistance (ohms)

R

S

= Sense Resistance (ohms)

R

w

= Wiring Resistance (ohms)

*Includes a 10% safety factor.

– 24 –

(seperate power supply required when switch(s) is/are ordered)

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 24

POWER

SUPPLY

+

–

PIN A

(+)

V+

GAUGE

(–)

V–

–

PIN B

+

METER

4-20mA

Load Limitations 4-20mA Output Only

1000

750

500

OPERATING

250

RL-Loop Resistance in Ohms

0

0362010

Loop Supply Voltage (Vdc)

REGION

30

.17

1.860

4.00

Page 14

– 27 –– 26 –

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 26

Page 15

– 29 –– 28 –

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 28

Page 16

– 31 –

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s Warranty

adds an additional one (1) month grace period to the normal one (1) year product

warranty to cover handling and shipping time. This ensures that OMEGA’s customers

receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to

be defective, it will be repaired or replaced at no charge. OMEGA’sWARRANTY does not

apply to defects resulting from any action of the purchaser, including but not limited to

mishandling, improper interfacing, operation outside of design limits, improper repair, or

unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having

been tampered with or shows evidence of having been damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication;

misuse or other operating conditions outside of OMEGA’s control. Components which

wear are not warranted, including but not limited tocontact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only

that the parts manufactured by it will be as specified and free of defects. OMEGA

MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY:

The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase

price of the component upon which liability is based. In no event shall OMEGA be

liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be

used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear

installation or activity; or (2) in medical applications or used on humans. Should any

Product(s) be used in or with any nuclear installation or activity, medical application,

used on humans, or misused in any way, OMEGA assumes no responsibility as set forth

in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will

indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service

Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST

OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER

SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper

packaging to prevent breakage in transit.

FOR WARRANTY RETURNS, please have

the following information available

BEFORE contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for current repair charges.

Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the prod-

uct, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, pho-

tocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole

or in part, without the prior written consent of OMEGA ENGINEERING, INC.

– 30 –

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 30

Page 17

– 32 –

M-4226/0705

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

OMEGA DIG 9045 3-06 3/30/06 4:29 PM Page 32

Loading...

Loading...