Page 1

www.omega.com

e-mail: info@omega.com

User ’s Guide

DPG7000

Digital Test Gauge

Shop online at

Page 2

– 2 –

Page 3

– 3 –

Congratulations on your purchase of the Omega®DPG 7000 digital

test gauge with total error band full-scale accuracy and the largest

display readout in the industry of .66˝ high. Other industry-leading

features include twelve selectable engineering units, seven languages,

and password-protected disable and calibration functions. With the

range printed on the keypad, the Omega DPG 7000 digital gauge

meets the ASME B40.7 digital gauge specification. See a complete

listing of product features and specifications on pages 14 & 15.

TABLE OF CONTENTS

Page

Quick Reference Guide 4-5

Keypad Functions 6-7

• ON/OFF KEY

• BACKLITE KEY

• MIN/MAX KEY

• ZERO/CLEAR KEY

• ENTER KEY

• CONFIG KEY

Configurable Functions (CONFIG Mode) 7-12

• Units (Engineering) 7

• Update Rate 7-8

• Auto Off 8

• Backlite 8-9

• Languages 9

• Damping 9-10

• Contrast 10

• Calibrate (Gauge Calibration) 10-11

• Disable 12

Available Ranges 13

Specifications 14-15

Installation & Battery Replacement 16

• Mounting

• Battery Replacement & Installation

Page 4

– 4 –

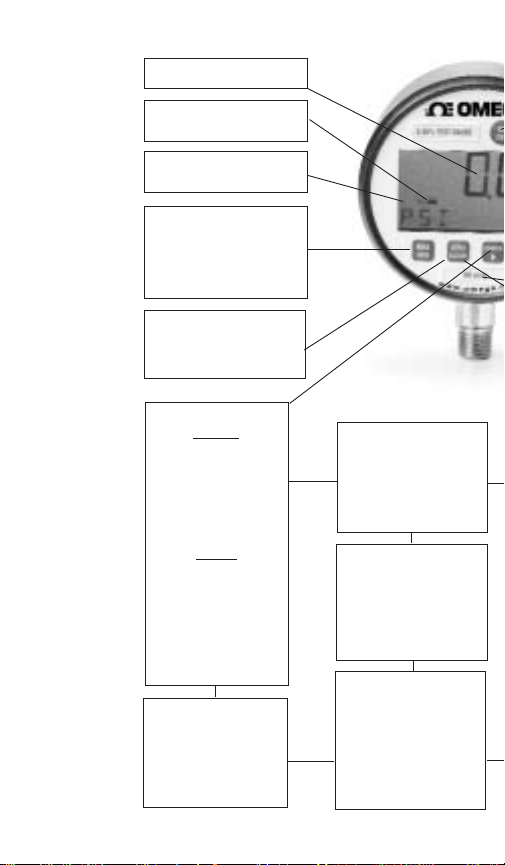

Bar graph

% of full scale

Flashing display when unit

pressured below zero

Press to indicate minimum

or maximum pressure

gauge has measured

Press again to return to

pressure units

While in max or min mode,

press to clear minimum or

maximum displayed values

UNITS (Pressure)

ENGLISH

PSI

INHG

INH2O

with Temperature

(Options: 60°F,

4°C, 20°C)

FTSW

METRIC

BAR

MBAR

KPA

MPA

mmHG

CMH2O

mmH2O

KG/CM2

UPDATE RATE

(Pressure measurement

per second)

10x*

5x

2x

1x

BACKLITE

(Off options)

ON/OFF*

10 SEC

30 SEC

1 MIN

5 MIN

LANGUAGE(s)

English*

French

Spanish

German

Italian

Portuguese

Dutch

DAMPING

(averages gauge reading

None*

AVG 2

AVG 4

AVG 6

AVG 8

.66˝ high display

QUICK REFE

Page 5

– 5 –

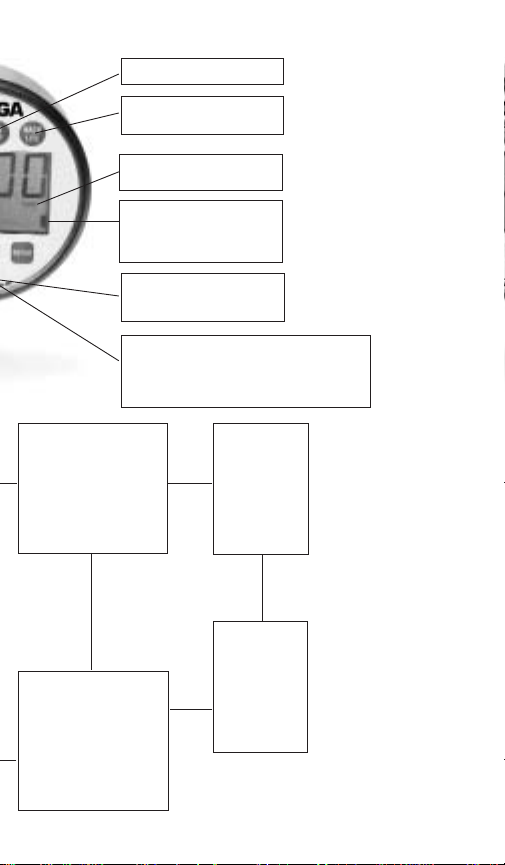

While in unit of measurement mode (eg: psi),

press the ZERO CLEAR button to rezero the

gauge. This feature functions when displayed

pressure is within ±5% of zero value

This bar graph indicates

battery level; the more

segments, the closer the

battery is to full charge

Flashing display when unit

pressured beyond full-scale

Press to turn backlite

on or off

Range on keypad;

complies with ASME B40.7

Press to turn unit on or off

AUTO OFF

(Turns unit off after

option selected)

Never*

2 minutes

5 minutes

15 minutes

30 minutes

CALIBRATE

Zero and span

adjustments,

password

protected

DISABLE

Allows for

“lockout” of

CONFIG

options

CONTRAST

(Customizes

display

readout)

7 available

Selection 4 is

Default*

*Indicates Default

Page 6

– 6 –

Turns the gauge on and off. When pressing the

ON/OFF key while in the off position, gauge startup display first indicates the software version

followed by the model number and gauge pressure range. The gauge will then display indicated

pressure and be ready for use.

Manually turns backlite on and off. (See

CONFIG

mode for options).

Press this key prior to gauge usage to rezero

any initial offset less than ±5% of the rated

gauge range. If indicated pressure is greater

than 5% of range, the rezero feature becomes

inoperable. This prevents accidental tare of a

pressurized gauge.

To clear minimum and maximum values, press

ZERO/CLR button (when min/max values are

indicated.

KEYPAD FUNCTIONS

ON/OFF

BACK

LITE

MAX

MIN

ZERO

CLR

ENTER

Allows review of minimum and maximum pressure values since unit start-up or last push of the

clear button. Press key to:

1) Indicate maximum pressure.

2) Indicate minimum pressure.

3) Exit MAX/MIN mode and return to unit of pressure measurement mode. To clear minimum

and maximum values press ZERO/CLR button.

Must be in MAX/MIN mode.

Note: MIN/MAX data is lost when unit is

turned off.

Used in conjunction with CONFIG key, see

next page.

Page 7

– 7 –

This key allows for customization of the gauge.

Pressing the CONFIG key allows cycling through

the main menu items; UNITS, UPDATE, AUTO

OFF, BACKLITE, LANGUAGE, DAMPING,

CONTRAST & CALIBRAT.

KEYPAD FUNCTIONS

UNITS: 12 units of measurement are available,

both English and metric, by cycling through the

UNITS key; psi, ˝Hg, ˝H

2

O (with three temperature

options, 60°F, 4°C and 20°C), ftSw, Bar, mBar,

kPa, mPa, mmHg, cmH

2

O, mmH2O, kg/cm2.

Step 1: Press the CONFIG key until the word

UNITS appears.

Step 2: Press the ENTER key.

Step 3: Press the CONFIG key once to select

ENGLISH or again to select METRIC.

Step 4: Press the ENTER key with selection of

ENGLISH or METRIC.

Step 5: Press CONFIG key to select unit of

measurement.

Step 6: Press ENTER key to finalize unit of

measurement.

UPDATE: this option allows for changing the rate

at which pressure is updated on the display

screen. The default rate measures pressure at

the maximum rate of

10* updates per second or

100 milli-seconds. Optional rates of measurement are measured in updates per second. The

options are

10*, 5, 2 or 1 update of pressure

measurement per second.

*Indicates default.

CONFIG

Page 8

– 8 –

Since customer processes vary, update rates

should be selected based on the application.

To use the UPDATE option:

Step 1:

Press the CONFIG key until the word

UPDATE appears.

Step 2: Press the ENTER key.

Step 3: Press the CONFIG key to select the

desired update rate.

Step 4: Press ENTER key to finalize UPDATE rate.

AUTO OFF: this option sets the amount of time

before the gauge will turn itself off after no activity.

Offerings are

Never*, 2, 5, 15, or 30 minutes.

To use the AUTO OFF option:

Step 1:

Press the CONFIG key until the word

AUTO OFF appears.

Step 2: Press the ENTER key.

Step 3: Press the CONFIG key to select the

desired AUTO OFF rate.

Step 4 Press the ENTER key to finalize the AUTO

OFF rate.

BACKLITE: 5 options are available. They include

ON/OFF*, 10 seconds, 30 seconds 1 or 5 min-

utes. With the ON option pressed, the gauge

backlite will remain lit whenever the gauge is in

the ON mode or until the backlite button is

pushed again. Options allow the backlite to automatically turn-off after a selected period of time.

Note: leaving backlite button on will decrease

battery life.

KEYPAD FUNCTIONS

*Indicates default.

Page 9

– 9 –

To use the BACKLITE option:

Step 1:

Press the CONFIG key until the word

BACKLITE appears.

Step 2: Press the ENTER key.

Step 3: Press the CONFIG key to select one of

the available time options.

Step 4: Press the ENTER key to finalize your

choice of BACKLITE options.

LANGUAGE: available in seven different languages, this option allows the user to change

the default language in the CONFIG mode. The

languages include

English*, French, Spanish,

German, Italian, Portuguese and Dutch.

Step 1: Press the CONFIG key until the word

LANGUAGE appears.

Step 2: Press the Enter key.

Step 3: Press the CONFIG key to select one of

the available LANGUAGE options.

Step 4: Press the ENTER key to finalize your

LANGUAGE option.

DAMPING: with six different options, this mode

allows for taking process pressure readings and

averaging them. This option is particularly useful when there is pulsation in the process. The

options are

NONE*, AVG 2, 4, 6 or 8.

Step 1: Press the CONFIG key until the word

DAMPING appears.

Step 2: Press the ENTER key.

Step 3: Press the CONFIG key to select one of

the available DAMPING options.

KEYPAD FUNCTIONS

*Indicates default.

Page 10

– 10 –

Step 4: Press the ENTER key to finalize your

DAMPING option.

CONTRAST: this mode allows for BACKLITE

contrast level. Seven options are available, 1, 2,

3,

4*, 5, 6 and 7.

Step 1: Press the CONFIG key until the word

CONTRAST appears.

Step 2: Press the ENTER key.

Step 3: Press the CONFIG key to select one of

the available CONTRAST options.

Step 4: Press the ENTER key to finalize your

CONTRAST selection.

Note: setting high contrast levels will decrease

battery life.

CALIBRAT.:

Gauge Calibration:

Both zero and span adjustments are available. This gauge has been configured with a default password of ШШШШШ. This

factory password does not allow access to calibration. To access the calibration mode, it is

necessary to configure a

user password. Once

the user password is configured, it will become

the default password that allows access to

gauge calibration

.

To access the factory default password:

Step 1:

Press the CONFIG key until the word

CALIBRAT appears.

Step 2: Press the ENTER key.

Step 3: The letters/asterisks… PW***** appear.

KEYPAD FUNCTIONS

*Indicates default.

Page 11

– 11 –

KEYPAD FUNCTIONS

Step 4:

Press the CONFIG key. An Ø appears in

the first position.

Step 5: Press the ENTER key once.

Step 6: Press the CONFIG key until Ø appears.

Ø will appear in the second position.

Step 7: Press ENTER.

Step 8: Use this format until all the asterisks are

replaced with Ø.

There now should be a total of five Ø’s on the

keyboard display. The zero in the fifth position

should be blinking.

Step 9: Press the ENTER key. You are now

prompted to SET PW (or set password).

Step 10: Press the ENTER key.

Step 11: Decide on a five number user pass-

word, then follow the procedure above inserting

a number in the flashing display until all five

numbers are inserted.

Step 12: A SAVE prompt will then appear. If the

selected user password is acceptable, press

ENTER. If the selected user password is not

acceptable press ZERO CLEAR to refigure the

user password.

After the password is configured, the default

factory password will be replaced with the user

password. Once configured, the factory password is no longer accessible.

If an incorrect password is entered, the system

will display WRONG. Press the CONFIG key to

reenter the correct password.

Step 13: Press ENTER again to begin calibration.

Note: Calibration feature allows recalibration of

zero and span.

*Indicates default.

Page 12

Step 14: Once the correct password is entered,

the user will be prompted to set the pressure to

zero followed by setting maximum gauge pressure (must be within 5% of the range).

If the user password is lost or stolen,

contact Omega customer service at (203)

359-1660 for a new factory password that

will allow the user to establish a new user

password.

DISABLE: allows “lockout” of individual

CONFIG options. The default is ENABLE for

all options in the CONFIG mode.

Step 1: Press the CONFIG key until the

word DISABLE appears.

Step 2: Press the ENTER key.

Step 3: Insert the user password following

the procedure as described in steps 3

through 13 above.

Note: This is the same user password as in

the CALIBRAT mode.

Step 4: Press the ENTER key.

Step 5: the first option in the CONFIG menu

will now be displayed (UNITS).

Step 6: To DISABLE the UNITS option press

the ENTER key until the word DISABLE

appears.

Step 7: Press the CONFIG key. The UNITS

option is now DISABLED.

Step 8: Proceed through the balance of the

CONFIG menu options by pressing the

CONFIG key. Follow steps 6-8.

– 12 –

Page 13

– 13 –

DIGITAL TEST GAUGE RANGES:

Compound Bar/ Compound

psi (psi) kPa KSC (bar)

vac.

15# & vac.

25 1 –1 to 30

5

30# & vac.

40 1.6 –1 to 30

10

30# & vac.

40 1.6 –1 to 30

15 60 2.5

30 100 4

60 160 6

100 250 10

160 400 16

200 600 25

300 1000 40

500 60

600 100

800 160

1000 250

1500 400

2000 500

2500

3000

5000

7000

mBar/ Absolute

mmH2O MPa cmH2O (psia)

3000 1 250 15

5000 1.6 300 25

10,000 2.5 400 50

6 500

100 600

160 1000

250 1600

400 2000

500 2500

4000

5000

6000

10,000

Page 14

– 14 –

Type DPG 7000 (0.05% accuracy)

Accuracy 0.05% Full Scale Terminal Point Total Error Band (TEB)

Accuracy Including Hysteresis, Linearity, Repeatablilty &

Temperature (–18/65°C) (0/150°F)

Dial Size 3"

Case Material

300 Series SS

Case FinishElectropolished

Case Enclosure Rating

Weatherproof, IP65

Socket Material

316 SS

Socket Size1⁄

4 NPT Male (others on application)

Connection Location

Lower, 3:00, 9:00

Ranges Vac thru 7000 psi (see engineering units below for other

units of measurement)

Operating Temperature

0/150°F

Storage Temperature

–40/180°F

DISPLAY :

Type LCD

Display Digits 41⁄

2

Character Height .66˝

Backlit Off By Default

Bar Graph Yes

Battery Life 1000 Hrs.

Agency Approvals

CE, FM (CSA, Cenelec pending)

KEYPAD FUNCTIONS:

On/Off

Manually Turns Unit On & Off

(auto off options in config menu)

Backlit Manually Turns Backlit On & Off

(auto off options in config menu)

Min/Max Stores Min & Max Values

Zero/Clear Zeros Display or Clears Min/Max Values When

Displayed

Enter Selects Items In CONFIG Menu

SPECIFICATIONS

Page 15

– 15 –

Config Mode

Allows Scrolling Through CONFIG Menus

Engineering Units

Psi, ˝Hg, ˝H2O (with three temperature options, 60°F, 4°C

and 20°C), ft.SW, bar, mbar, kPa, mPa, mmHg, cmH

2

O,

mmH2O, kg/cm

2

Update Rate

4 Options: 10x/sec, 5x/sec, 2x/sec, 1x/sec

Auto Off 6 Options: Never, 2 Min., 5 Min., 15 Min., 30 Min.,

Dampening 6 Options: None, Average 2, 4, 6, 8 x update rate

Languages 7 Languages: English, Spanish, French, Italian, German,

Portuguese, Dutch

Backlite 5 Options: On/Off, 10 Sec., 30 Sec., 5 Min., 15 Min.

Field Recalibration

Zero & Span (password protected)

Contrast 7 Available Options

Disable Config Options

Allows disabling of Config Options (password protected)

Calibration Chart

10 Point Individual NIST Traceable Calibration Chart,

Standard

Standard Accessories

300 Series SS Protective Cover

Nylon Protective Carrying Pouch

Display Description

Flashing Gauge over/underpressured

0% or 100% beyond 105% of range

LOW BAT Low battery, replace

ERROR

Internal error, call customer

service (203) 359-1660

Pressure unit conversion exceeds

RES ERROR display resolution or gauge

pressured beyond resolution

SPECIFICATIONS

WARNING AND ERROR MESSAGES

Page 16

– 16 –

Gauge Installation:

Pipe Mount – The

Omega

digital test gauge comes standard with a1⁄4NPT

connection. Good piping practices recommend using teflon tape or a pipe

sealant on the gauge threads. Utilize a

7

⁄16˝ wrench on the wrench flat of the

gauge to tighten the gauge to the process.

NEVER TIGHTEN GAUGE THREADS BY HOLDING THE BODY OF THE GAUGE.

DOING SO MAY DAMAGE THE GAUGE AND MAKE THE GAUGE INOPERABLE.

Panel Mount – The lower connected

Omega

digital test gauge is available

with an optional flange for panel mounting. Please refer to illustration and

dimensions below.

!

Pipe to which gauge is attached must be properly grounded.

Battery Installation and Replacement:

The gauge comes standard with a quantity of three AAA alkaline batteries

(installed). Use either Duracell MN2400, MX2400 or Energizer E92BP,

X92RP AAA alkaline, non-rechargeable batteries.

Batteries have a life of approximately 1000 hours. Battery life is dependent

on gauge usage, backlite settings and power off settings. When the display

flashes LOW BAT, batteries should be replaced.

To replace the batteries:

1) Remove the single screw on the back of the gauge case.

2) Hold the keypad in the palm of hand.

3) Carefully remove the three batteries from the holder and replace the

batteries. Use only AAA alkaline non-rechargeable batteries.

HOLE

CUTOUT

DIAMETER

3.406

(313⁄32±1⁄32)

.17

1.860

4.00

Page 17

– 17 –

Page 18

– 18 –

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s

WARRANTY adds an additional one (1) month grace period to the normal one (1)

year product warranty to cover handling and shipping time. This ensures that

OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number

immediately upon phone or written request. Upon examination by OMEGA, if the unit

is found to be defective, it will be repaired or replaced at no charge. OMEGA’s

WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of

design limits, improper repair, or unauthorized modification. This WARRANTY is VOID

if the unit shows evidence of having been tampered with or shows evidence of

having been damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted,

including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products.

However, OMEGA neither assumes responsibility for any omissions or errors

nor assumes liability for any damages that result from the use of its products

in accordance with information provided by OMEGA, either verbal or written.

OMEGA warrants only that the parts manufactured by it will be as specified

and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED,

EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE HEREB Y DISCLAIMED. LIMITATION OF LIABILITY: The remedies

of purchaser set forth herein are exclusive, and the total liability of OMEGA

with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase

price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be

used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear

installation or activity; or (2) in medical applications or used on humans. Should any

Product(s) be used in or with any nuclear installation or activity, medical application,

used on humans, or misused in any way, OMEGA assumes no responsibility as set

forth in our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser

will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the P roduct(s) in suc h a manner .

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service

Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER

MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S

CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS).

The assigned AR number should then be marked on the outside of the return package

and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper

packaging to prevent breakage in transit.

FOR

WARRANTY RETURNS, please

have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number under

which the product was

PURCHASED,

2. Model and serial number of the

product under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product,

and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA ’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may

not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of

OMEGA ENGINEERING, INC.

Page 19

– 19 –

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Stamford CT 06907-0047

Certified Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Canada: Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Frystatska 184, 733 01 Karviná, Czech Republic

Republic: Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Austria:

Tel:+ 49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United One Omega Drive, River Bend Technology Centre

Kingdom: Northbank, Irlam, Manchester

ISO 9002 M44 5BD United Kingdom

Certified Te l: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®On-Line Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its

products to the European New Approach Directives. OMEGA will add the CE

mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but

OMEGA Engineering, Inc. accepts no liability for any errors it contains, and

reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be

used for, human applications.

Page 20

M4025/1203

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes,

Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...