Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User ’s Guide

M-4934/0710

DPG4000-SW Data Logging Software

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0) 5 9 6 3 1111 4

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

1. Introduction

This Manual describes the data logging capability and operation of the

pressure gauge, plus the operation of the related DPG4000-SW

Microsoft Windows application. All DPG4000's with firmware with

revision 3.0 or higher are capable of data logging when used with the

DPG4000-SW software. This manual complements and extends the

user manual received with the pressure gauge. Please refer to the

gauge manual for additional information on its operation.

The DPG4000-SW Data Logging Software application is used to

configure logging parameters in the gauge, and to retrieve logged data

from the gauge for storage and analysis on a personal computer.

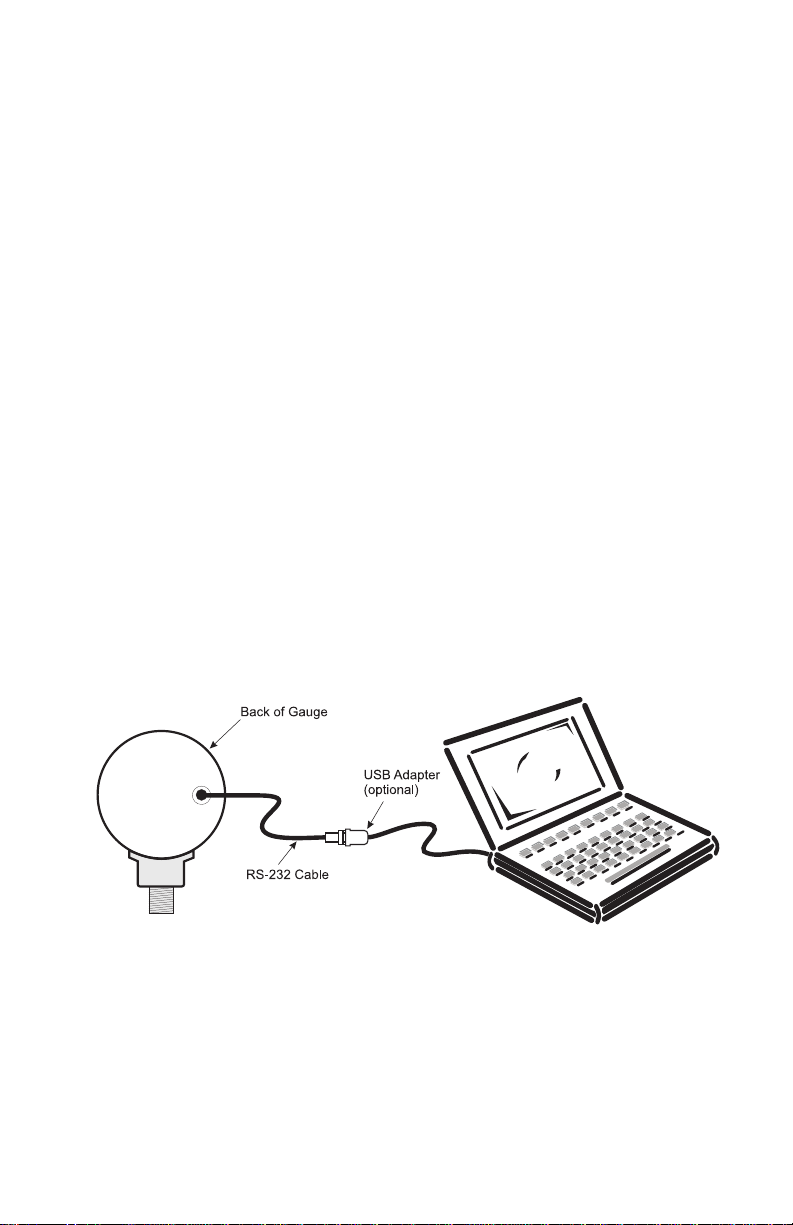

Before you start check to make sure your data logging kit came with

the following items:

1) DPG4000-SW CD

2) RS -232 Cable with stereo style jack (this end plugs into the gauge)

3) RS -232 to USB adapter (with mini-CD) for newer computers that

only have USB ports. Refer to the instructions packaged with the

USB adapter to load the driver and operate the adapter.

4) Users manual

Refer to figure 1 to see how to connect the RS-232 cable to the Gauge.

Figure 1

2. Description

The gauge can log multiple sets of data, each of which is identified by

a sequential run number. Data logging runs are started and stopped

using new items inserted into the gauge's CONFIG menu sequence.

Logging parameters can be changed from one data logging run to the

next, and data logging runs may be as short as a single sample or as

1

Page 4

long as desired subject to the maximum storage capacity of the gauge.

The gauge can log pressure only for each sample, or it can log

pressure and temperature for each sample. This selection applies to

all runs and must be made prior to starting the first run.

When logging pressure only, the gauge has a capacity of 8500 data

records for storing run identification data and log sample data. Each

new data logging run requires 7 records for run identification overhead.

One record is required to log each sample, except for the triple value

case (average, minimum, maximum) where 3 records are required to

log each sample set.

Assuming a single run, the maximum capacity for all but the triple

value case is 8493 samples, and the maximum capacity for the triple

value case is 2831 sample sets.

When logging pressure and temperature, the gauge has a capacity of

5100 data records for storing run identification data and log sample

data. Each new data logging run requires 7 records for run

identification overhead. One record is required to log each sample,

except for the triple value case (average, minimum, maximum) where 3

records are required to log each sample set.

Assuming a single run, the maximum capacity for all but the triple

value case is 5093 samples, and the maximum capacity for the triple

value case is 1697 sample sets.

The interval time setting determines the frequency of sample

calculation and storage. Eleven discrete interval times are available,

ranging from 1 second to 1 hour.

A sample value is calculated at the end of each interval based on all of

the pressure measurements made during that interval. The sample

value may be the last measurement made in the interval, or it may be

the average, minimum, maximum, or median of all of the

measurements made during that interval.

A sample value may be stored for every interval during the run, only for

those intervals where the sample value exceeds a specified high or low

limit, or only for those intervals where the pressure differential during

the interval exceeds a maximum span.

The data logging function is disabled by default in all new gauges.

The DPG4000-SW application is used to enable and disable the data

log function in a gauge.

Two data logging modes are available, Download and Demand.

Multiple log runs are allowed in either mode, with the potential number

of runs dependent on the number of samples logged in each run and

the capacity of the gauge.

When the data logging mode is set to Download, the DPG4000-SW

application is used to enter or change the data logging parameters and

2

Page 5

send them to the gauge. The gauge remains in this mode until either

the DPG4000-SW application or the gauge 'CLEAr DATA' function is

used clear the logged data in the gauge, at which time the mode is set

to Demand. In Download mode none of the parameters may be

changed using the gauge menus and the downloaded values are

always used for each new log run. The DPG4000-SW application may

be used to change the logging parameters between runs without

affecting previously logged data stored in memory. The Download

mode data logging parameters are:

• Interval time selection:

- 1, 2, 5, 10, 30 seconds

- 1, 2, 5, 10, 30 minutes

- 1 hour

• Maximum number of samples to store per run. This may range from

1 to the full capacity of the gauge.

• Log type selection:

- Continuous. This is the most commonly used log type where a

sample is stored at every interval during the run. The sample

value stored is defined by the sample type selection below. The

run can be stopped manually, or stops automatically when the

log memory is full or the maximum number of samples per run is

logged.

- Trip high, where interval samples are stored during the run only

when the sample values exceed a high limit. Sample storage

starts when an interval's sample value becomes greater than the

trip setpoint, and continues at every interval until a subsequent

interval's sample value becomes less than the trip reset. Sample

storage then stops until a sample value again becomes greater

than the trip setpoint. The sample value stored, and used for

comparison, is defined by the sample type selection below. The

run can be stopped manually, or stops automatically when the

log memory is full or the maximum number of samples per run is

logged.

- Trip low, where interval samples are stored during the run only

when the sample values exceed a low limit. Sample storage

starts when an interval's sample value becomes less than the trip

setpoint, and continues at every interval until a subsequent

interval's sample value becomes greater than the trip reset.

Sample storage then stops until a sample value again becomes

less than the trip setpoint. The sample value stored, and used for

comparison, is defined by the sample type selection below. The

run can be stopped manually, or stops automatically when the

log memory is full or the maximum number of samples per run is

logged.

3

Page 6

- Trip Range, where interval samples are stored during the run

only when the pressure differential during the interval exceeds a

maximum span or range of values. Sample storage starts when

the difference between an interval's maximum and minimum

measurements becomes greater than the trip setpoint, and

continues at every interval until a subsequent interval's difference

becomes less than the trip reset. Sample storage then stops until

an interval's difference again becomes greater than the trip

setpoint. The run can be stopped manually, or stops

automatically when the log memory is full or the maximum

number of samples per run is logged.

• Sample type selection:

- Last measurement made in the sample interval.

- Average of all measurements made in the sample interval.

- Minimum of all measurements made in the sample interval.

- Maximum of all measurements made in the sample interval.

- Median of all the measurements made in the sample interval, the

midpoint between minimum to maximum measurements.

- Average, minimum, and maximum of all measurements made in

the sample interval. This requires 3 records of storage per

logged sample set and reduces capacity by a factor of 3.

• Log pressure unit selection. All supported pressure units including

custom.

• Trip setpoint expressed in log unit selection.

• Trip reset expressed in log unit selection.

• Log custom pressure unit factor.

When the data logging mode is set to the Demand mode the user can

set the gauge up to data log without the need to first connect it to the

computer. The gauge menus are used to enter and change some data

logging parameters, while the remaining parameters default to fixed

values. The gauge menus may be used to change the logging

parameters between runs without affecting previously logged data

stored in memory. The demand mode data logging parameters are:

• Interval time selection:

- 1, 2, 5, 10, 30 seconds

- 1, 2, 5, 10, 30 minutes

- 1 hour

• Maximum number of samples to log. This may range from 1 to the

full capacity of the gauge.

• Log type selection fixed at 'Continuous'.

4

Page 7

• Sample type selection fixed at 'Last measurement made in the

sample interval'.

• Log pressure unit selection. The unit is selected with the existing

configuration function before the log run is started.

• Trip setpoint not used.

• Trip reset not used.

• Log custom pressure unit factor. The factor is selected with the

existing configuration function before the log run is started

The gauge does not have real time clock capability, so the time stamp

on all samples in a run is elapsed days, hours, minutes and seconds

from run start. The DPG4000-SW application provides a feature for

relating each uploaded run start point to a real time base date and

time. When this feature is used, all uploaded elapsed time stamps in

the run are recalculated accordingly to get true time stamps of the form

year, month, day, hour, minute, second.

3. Gauge Operation

3.1 Data Logging Disabled

Until data logging functionality is enabled using the DPG4000-SW

application, the gauge operates as described in the user manual

received with the gauge. You must connect the gauge to the

DPG4000-SW software to enable the logging function. This is

true for both Demand and Download modes.

3.2 Download Mode

Once data logging functionality is enabled, a new item is inserted at

the start of the gauge configuration menu tree to direct the user to a

completely separate branch which contains all data logging functions.

This new menu item shows 'LOG' in the main display and 'DATA' in the

secondary display. Press the CONFIG key to proceed to the existing

configuration functions, or press the ENTER key to proceed to the new

data logging branch. The data logging configuration menu sequence

(new branch) is as follows:

1) Start or stop data logging

• Main display: LOG

• Secondary display: FULL if the log memory is full, OFF if not

logging data, else ON if logging data.

• the ▼ and ▲ keys are ignored if the log memory is FULL,

otherwise press either key to toggle between OFF and START if

5

Page 8

not logging data, or to toggle between ON and STOP if logging

data.

• press the CONFIG key to step to the next menu item.

• press the ENTER key to exit configuration if the display is FULL,

ON, or OFF, to stop logging and exit configuration if the display

is STOP, or to start logging and exit configuration if the display is

START.

2) Display number of free log records

• Main display: number of free records

• Secondary display: FREE

• the ▼ and ▲ keys are ignored.

• press the CONFIG key to step to the next menu item if not

logging, otherwise it exits configuration.

• press the ENTER key to exit configuration.

3) Erase all logged data and set to Demand mode

• Main display: CLEAr

• Secondary display: DATA

• the ▼ and ▲ keys are ignored.

• press the ENTER key to step to the next menu item and confirm

erasure.

• press the CONFIG to exit configuration without erasing the data.

4) Confirm erasure of all logged data and set to Demand

mode

• Main display: CLEAr

• Secondary display: CNFRM

• the ▼ and ▲ keys are ignored.

• press the ENTER key to erase the data, set Demand mode, and

exit configuration after briefly displaying CLr to confirm erasure.

• press the CONFIG key to exit configuration without erasing the

data.

While not logging data, the gauge operates as described in the user

manual received with the gauge.

When a log run is started, the pressure unit and custom factor are

forced to the downloaded selections. They are restored to their

original values at the end of the run.

While logging data, the following operating changes occur:

• Pressing the power button causes the log run to be stopped

before power is turned off.

6

Page 9

• Forced power off on low battery detection causes the log run to

be stopped before power is turned off.

• The zero key is active and an event record (including the change

in the zero offset value) is placed in the log.

• Auto off is disabled. It is restored to its original value at the end

of the run.

• The engineering units, damp, sample rate, tare, and custom

factor items on the existing configuration menu are disabled.

• The units field on the display cycles between the units, the text

LOG, and the text RUN at a rate of once per second. This

provides visual feedback that data logging is active, and the

number after the text RUN identifies the run number for later

reference.

3.3 Demand Mode

The Demand mode allows the user to conduct an impromptu data

measurement/log without the need of a computer to configure all of the

logging parameters.

Once data logging functionality is enabled, a new item is inserted at

the start of the configuration menu tree to direct the user to a

completely separate branch which contains all data logging functions.

This new menu item shows 'LOG' in the main display and 'DATA' in the

secondary display. Press the CONFIG key to proceed to the existing

configuration functions, or press the ENTER key to proceed to the new

data logging branch. The data logging configuration menu sequence

(new branch) is as follows:

1) Start or stop data logging

• Main display: LOG

• Secondary display: FULL if the log memory is full, OFF if not

logging data, else ON if logging data.

• the ▼ and ▲ keys are ignored if the log memory is FULL,

otherwise press either key to toggle between OFF and START if

not logging data, or to toggle between ON and STOP if logging

data.

• press the CONFIG key to step to the next menu item.

• press the ENTER key to exit configuration if the display is FULL,

ON, or OFF, to stop logging and exit configuration if the display

is STOP, or to start logging and exit configuration if the display is

START.

7

Page 10

2) Display number of free log records

• Main display: number of free records

• Secondary display: FREE

• the ▼ and ▲ keys are ignored.

• press the CONFIG key to step to the next menu item if not

logging, otherwise it exits configuration.

• press the ENTER key to exit configuration.

3) Select logging interval

• Main display: interval choice presently selected, one of 1, 2, 5,

10, 30 for seconds, or 1, 2, 5, 10, 30 for minutes, or 1 for hours.

• Secondary display: time unit SEC, MIN, or HOUR as appropriate

for the choice presently selected

• press the ▼ key to decrease the interval selection, stopping at 1

second.

• press the ▲ key to increase the interval selection, stopping at 1

hour.

• press the CONFIG key to step to the next menu item.

• press the ENTER key to exit configuration.

4) Select maximum number of samples

• Main display: number of samples presently selected

• Secondary display: SAMPL

• press the ▼ key to decrease the number, stopping at 1.

• press the ▲ key to increase the number, stopping at the

maximum number of records 8500.

• press the CONFIG key to step to the next menu item.

• press the ENTER key to exit configuration.

5) Erase all logged data and set to Demand mode

• Main display: CLEAr

• Secondary display: DATA

• the ▼ and ▲ keys are ignored.

• press the ENTER key to step to the next menu item and confirm

erasure.

• press the CONFIG to exit configuration without erasing the data.

8

Page 11

6) Confirm erasure of all logged data and set to Demand mode

• Main display: CLEAr

• Secondary display: CNFRM

• the ▼ and ▲ keys are ignored.

• press the ENTER key to erase the data, set Demand mode, and

exit configuration after briefly displaying CLr to confirm erasure.

• press the CONFIG key to exit configuration without erasing the

data.

While not logging data, the gauge operates as described in the user

manual received with the gauge.

When a log run is started, the pressure unit and custom factor are left

at the values set by the existing configuration functions.

While logging data, the following changes occur:

• Pressing the power button causes the log run to be stopped

before power is turned off.

• Forced power off on low battery detection causes the log run to

be stopped before power is turned off.

• The zero key is active and an event record (including the change

in the zero offset value) is recorded in the log.

• Auto off is disabled. It is restored to its original value at the end

of the run.

• The engineering units, damp, sample rate, tare, and custom

factor items on the existing configuration menu are disabled.

• The units field on the display cycles between the units, the text

LOG, and the text RUN at a rate of once per second. This

provides visual feedback that data logging is active, and the

number after the text RUN identifies the run number for later

reference.

4. DPG4000-SW Microsoft Windows

Application

This application provides the following features:

• set up data logging configuration in a gauge

• upload logged data from the gauge, including export of run data to

text, CSV, and Excel format files

• clear logged data from the gauge

The application requires Microsoft Windows 2000 (SP4), XP (SP2), or

Vista. Exporting data to Excel files requires Microsoft Excel version

2002 or later.

9

Page 12

4.1 Installation and Registration

Insert the distribution CD into the drive on your computer. The install

should start automatically. If it does not, navigate to the drive

containing the CD and run the program "setup.exe". Follow the

prompts on the screen to install the application.

DPG4000-SW must be registered and activated within seven days of

installation. Full operation is available for seven days, but is then

restricted until activation is completed. A registration screen is

displayed at startup until activation is completed. Click Cancel to

proceed directly to the application. Fill in the requested information

and click REGISTER to save it to a text file on disk. Email this file to

OMEGA as an attachment, or print and fax it, per the contact

information on the support screen. When OMEGA returns the

activation key, enter it at the bottom of the registration screen and click

ACTIVATE to complete the process.

DPG4000-SW must be registered and activated separately on each

computer on which it is installed.

4.2 Menus

The control buttons on the Main Display are intended to be the primary

method used to operate the application. The menu items duplicate the

functions of these buttons for those users who are more comfortable

with menu style operation.

The terms of the software license permit the installation of the

DPG4000-SW application on a single computer. Please contact

technical support for re-installation or to move the application to

another computer.

4.2.1 File Menu

The File Menu contains the application exit function:

Exit Exit the Data Log Utility.

4.2.2 Gauge Menu

The Gauge Menu contains the functions required to interact with the

gauge:

Connect Connect to the gauge and retrieve the gauge

description and data logging setup. The

communications port to which the gauge is

connected must be selected on the Main Display

before using this item. See the Connecting to a

Gauge description in the Main Display section 4.3.

Disconnect Disconnect from the gauge. See the Disconnecting

from a Gauge description in the Main Display

10

Page 13

section 4.3.

Upload Data Upload all data logging runs from the gauge and

show them on the Log Upload Display described in

section 4.4. The data may be exported from that

display. See the Uploading Logged Data description

in the Main Display section 4.3.

Clear Data Erase all data logging runs from the gauge. See the

Clearing Logged Data description in the Main

Display section 4.3.

Send Setup Send the setup data to the gauge. See the Sending

Setup Configuration description in the Main Display

section 4.3.

Retrieve Setup Retrieve the setup data from the gauge. See the

Retrieving Setup Configuration description in the

Main Display section 4.3.

4.2.3 Options Menu

The Options Menu contains functions for specifying the default display

and export options. These functions are described in detail in sections

4.5 and 4.6 below.

4.2.4 Help Menu

The Help Menu contains the functions required to obtain help and

support information:

Help Display online help

Support Display customer support information.

Registration Register DPG4000-SW and display registration

information

About Display application description and version

information.

11

Page 14

4.3 Main Display

The top portion of the display contains controls to connect to a gauge,

disconnect from a gauge, upload logged data, clear logged data, and

exit the application. Once connected to a gauge, it shows the model,

serial number, and firmware version of the gauge, plus the number of

data logging records presently used and free.

The lower portion of the display contains controls to configure data

logging parameters in a gauge, send the configuration to a gauge, and

retrieve the present configuration from a gauge.

Connecting to a Gauge

Select the communications port to which the gauge is connected and

click the Connect button. The gauge description, present capacity,

and present setup are retrieved from the gauge and displayed in the

appropriate fields. The button description and function changes to

Disconnect. A connection must be established before any other

actions may be performed. To change to another gauge, first

disconnect from the present gauge and reconnect.

Disconnecting from a Gauge

Click the Disconnect button. The button description and function

changes to Connect and all displayed data is cleared.

Uploading Logged Data

Click the Upload button. The logged data is uploaded and shown on

the Log Upload Display described in section 4.4. A progress display

shows percent complete and an estimate of the time remaining in the

upload.

12

Page 15

Clearing Logged Data

Click the Clear button. After confirmation of the action, all logged data

is cleared from the gauge, the data logging mode is set to Enabled,

Demand, and all data on the display is refreshed.

Sending Setup Configuration

After making the desired selections, click the Send button. The

configuration is sent to the gauge and all data on the display is

refreshed. The data logging mode must be set to Enabled, Download

to change anything more than the mode.

Retrieving Setup Configuration

Click the Retrieve button. The gauge description, present capacity,

and present setup are retrieved from the gauge and displayed in the

appropriate fields.

Setup Configuration Fields

Data Logging

Disabled Disable data logging in the gauge. All data

logging functions are removed from the

gauge's CONFIG menu sequence.

Enabled, Download Enable data logging in the gauge with all

logging parameters downloaded from this

application. All data logging functions

associated with parameter changes are

removed from the gauge's CONFIG menu

sequence. The only gauge functions

available are starting and stopping data

logging, displaying the number of free

records, and clearing all logged data.

Enabled, Demand Enable data logging in the gauge with all

logging parameters set in the gauge. This

application may only be used to upload

logged data, clear all logged data, retrieve

data logging parameters, and change the

data logging mode. The data logging

functions available in the gauge's CONFIG

menu sequence are starting and stopping

data logging, displaying the number of free

records, changing the logging interval,

changing the samples per run, and clearing

all logged data. The log type is fixed at

Continuous and the sample type is fixed at

Interval End.

13

Page 16

Interval

One of the following sampling intervals:

1, 2, 5, 10, or 30 seconds

1, 2, 5, 10, or 30 minutes

1 hour

Samples/Run

The maximum number of samples to log per run. This may range

from 1 to 8500.

Log Temperature

– Yes

– No

Log Type

Continuous A sample is stored at every interval during

the run. The sample value stored is defined

by the sample type selection below. This is

most common type of logging.

Trip high Interval samples are stored during the run

only when the sample values exceed a high

limit. Sample storage starts when an

interval's sample value becomes greater

than the trip setpoint, and continues at every

interval until a subsequent interval's sample

value becomes less than the trip reset.

Sample storage then stops until a sample

value again becomes greater than the trip

setpoint. The sample value stored, and

used for comparison, is defined by the

sample type selection below.

Trip low Interval samples are stored during the run

only when the sample values exceed a low

limit. Sample storage starts when an

interval's sample value becomes less than

the trip setpoint, and continues at every

interval until a subsequent interval's sample

value becomes greater than the trip reset.

Sample storage then stops until a sample

value again becomes less than the trip

setpoint. The sample value stored, and

used for comparison, is defined by the

sample type selection below.

14

Page 17

Trip range Interval samples are stored during the run

only when the pressure differential during

the interval exceeds a maximum span or

range. Sample storage starts when the

difference between an interval's maximum

and minimum measurements becomes

greater than the trip setpoint, and continues

at every interval until a subsequent interval's

difference becomes less than the trip reset.

Sample storage then stops until an interval's

difference again becomes greater than the

trip setpoint.

Sample Type

One of the following:

- Interval end, the last measurement made in the sample

interval

- Average of all measurements made in the sample interval

- Minimum of all measurements made in the sample interval

- Maximum of all measurements made in the sample interval

- Median of all measurements made in the sample interval,

the midpoint between minimum and maximum

- Average, minimum, and maximum of all measurements

made in the sample interval. This requires 3 records of

storage per logged sample set and reduces capacity by a

factor of 3.

Unit

Any pressure unit supported by the present gauge configuration,

including custom.

Custom Factor

Custom unit conversion factor expressed as units per psi.

Trip Setpoint

Trip setpoint as defined for the Log Type selected above,

expressed in the log unit selected above.

Trip Reset

Trip reset as defined for the Log Type selected above, expressed in

the log unit selected above.

15

Page 18

4.4 Log Upload Display

The top portion of the display lists the individual data logging runs

found in the uploaded data. To display a run's data in the lower portion

of the display, highlight it by clicking on it.

Use the Display Mode box to select the subset of run data displayed:

All Data, Selected Data, or Readings Only. When the Display Mode is

set to Selected Data, click the Change Selection button to modify the

display options. This is described further under Display Options in

section 4.5.

The gauge has no realtime clock so the uploaded data samples are

initially tagged by elapsed day and time from run start. Also the runs

are described simply by numeric position within the uploaded data. To

enter a more descriptive label and a true calendar base date and time

for a run, highlight the run and click the Set Date/Label button. The

base date and time are added to the elapsed day and time for each

sample to provide a true calendar date and time for each sample.

To export an individual run, highlight the run and click the Save Run

button. The Export Options screen is shown to allow the options to be

customized for exporting this run. Next, a standard Save As screen is

shown for selecting the file name and the folder where the file is to be

placed. Click the Cancel button of either screen to skip the export.

16

Page 19

The Export Options screen is described further under Export Options in

section 4.6.

To export all runs, click the Save All button. The Export Options screen

is shown to allow the options to be customized for exporting these

runs; the same options are used for all runs. For each run, a standard

Save As screen is shown for selecting the file name and the folder

where the file is to be placed. Click the Cancel button of the Save As

screen for an individual run to skip the export of that run. Click the

Cancel button of the Export Options screen to skip the export of all

runs. The Export Options screen is described further under Export

Options in section 4.6.

Export to an Excel file requires Excel 2002 or later to be installed on

your computer.

The default location for files is the folder "OMEGA DPG4000-SW" in "My

Documents".

4.5 Display Options

This screen is used to modify the default selections for the run

description fields shown on the Log Upload Display when the display

mode is set to Selected Data. When data is initially uploaded the

selections are set to these default values. After the initial data display,

the selections may be temporarily changed for the duration of the data

display. Place a checkmark next to each field that is to be shown on

the display when the display mode is set to Selected Data. Logged

pressure readings are always displayed.

17

Page 20

4.6 Export Options

This screen is used to it to modify the default selections for the file type

and run description fields to be exported from the Log Upload Display.

When data is initially uploaded the selections are set to these default

values. After the initial data display, the selections may be temporarily

changed for each export operation, and remain changed for the

duration of the data display. Logged pressure readings are always

exported.

18

Page 21

The selections are as follows:

File Type

TXT File A formatted text file that may be printed

directly or opened in a text editor. The run

description fields are placed on separate

lines at the beginning of the file, followed by

a line for each logged data sample and zero

change.

CSV File An Excel Comma Separated Variable file

where each data item on a line is enclosed

in quotation marks and all items are

separated by commas. The run description

fields are placed on separate lines at the

beginning of the file, followed by a line for

each logged data sample and zero change.

New Excel File A new Excel spreadsheet (xls) file. The

locations of the run description fields,

logged data samples, and zero changes

within the spreadsheet are specified in the

Excel Cell column below. This option

requires Excel 2002 or later to be installed

on your computer.

Excel Template An Excel spreadsheet (xls) file based on a

predefined Excel template (xlt) file. The

locations of the run description fields,

logged data samples, and zero changes

within the spreadsheet are specified in the

Excel Cell column below. These locations

must be coordinated with the fixed data in

the template. This option requires Excel

2002 or later to be installed on your

computer.

Multiple runs in

Single File When the upload contains multiple data

logging runs, export all runs to a single file.

Separate Files When the upload contains multiple data

logging runs, export each individual run to a

separate file.

Excel Template

When the file type is set to Excel Template, the template to

be used is selected here. Click on the Browse button and

navigate to the desired template file. See section 5 for more

information on Excel templates.

19

Page 22

Include Field

Place a checkmark next to each field that is to be exported.

Logged pressure readings are always exported.

Insert Description

An optional field description may be included for each field

being exported. Place a checkmark on each field

description that is to be included.

Excel Cell

Enter the cell location where the data is to be placed. Cell

columns may range from A to YZ. Cell rows may range from

1 to 99999. The data fields are placed as follows:

Run description fields

If the field description is included, the field

description is placed in the specified cell and the

field value is placed in the next cell to the right. If

the field description is not included, the field value is

placed in the specified cell. The Gauge Description

has 4 values (manufacturer, model, serial number,

and firmware version) all in one cell separated by

commas. The Log and Data Type, Trip Setpoint and

Reset, and Initial Zero and Tare fields each consist of

two data items which occupy two rows, each with its

own description and field value, with the second row

immediately below the first.

Zero Changes

Zero changes are listed one per row starting at the

specified cell row. There are four field values for

each zero change: the date, the time, the new zero

setting, and the pressure unit. The second, third,

and fourth values are placed in the immediately

adjacent cells to the right of the first. If the field

description is included, the field description is

placed in the specified cell column and the field

values are placed in the next cell columns to the

right. If the field description is not included, the field

values are placed in the specified cell columns.

Pressure Readings

Pressure readings are listed one per row starting at

the specified cell row. There are four field values for

each single value pressure reading: the date, the

time, the reading, and the pressure unit. The

second, third, and fourth values are placed in the

immediately adjacent cells to the right of the first.

20

Page 23

There are six field values for each triple value

pressure reading: the date, the time, the average

reading, the minimum reading, the maximum

reading, and the pressure unit. The second, third,

etc. values are placed in the immediately adjacent

cells to the right of the first. If the field description is

included, the field description is placed in the

specified cell column and the field values are placed

in the next cell columns to the right. If the field

description is not included, the field values are

placed in the specified cell columns.

Temperature Readings

If temperature readings are available in the uploaded

data, they are listed one per row starting at the

specified cell row. There are two field values for

each single value sample: the temperature, and the

temperature unit. The second value is placed in the

immediately adjacent cell to the right of the first.

There are four field values for each triple value

sample: the average temperature, the temperature at

the time of the minimum pressure, the temperature

at the time of the maximum pressure, and the the

first. If the field description is included, the field

description is placed in the specified cell column

and the field values are placed in the next cell

columns to the right. If the field description is not

included, the field values are placed in the specified

cell columns.

5. Excel Templates

An Excel template contains predefined text, titles, graphs, and

calculations which are merged with uploaded pressure data to form a

more complete spreadsheet presentation. A template may be reused

many times, thus avoiding unnecessary work reformatting raw data.

Templates are created with Excel in the same manner as normal

spreadsheets and they support all Excel features. They are stored with

the special ".xlt" suffix to differentiate them from normal spreadsheets,

and to avoid overwriting them when saving merged data.

The field options and Excel cell locations specified on the Export

options screen must be coordinated with the predefined data in the

template to ensure a correct merging of the data.

The sample templates provided with DPG4000-SW are described

below. They are provided in a separate folder on the distribution

media and must be manually copied to your hard drive.

21

Page 24

5.1 Single Run Graph

This template provides custom titles and a graph of the merged data.

The graph vertical axis is scaled to the range of the uploaded pressure

values and the horizontal axis is scaled to the number of samples

uploaded.

The template file name is:

DPG4000-SW-template-single-run-pressure-graph.xlt

The Export options corresponding to this template are as follows:

Field Include Field Insert Description Excel Cell

Run # or Label Yes No B3

Gauge Description Yes No B5

Log and Sample Type Yes No B10

Interval Time Yes No B12

Pressure Unit Yes No B8

Custom factor Yes Yes B18

Trip Setpoint and Reset Yes Yes B16

Initial Zero and Tare Yes Yes B14

Zero Changes Yes No J24

Temperature Readings No No any

Pressure Readings Yes No B24

5.2 Single Run Pressure and Temperature Graph

This template provides custom titles and a graph of the merged data.

The pressure graph vertical axis is scaled to the range of the uploaded

pressure values and the horizontal axis is scaled to the number of

samples uploaded. The temperature graph vertical axis is scaled to

the range of the uploaded temperature values and the horizontal axis is

scaled to the number of samples uploaded.

The template file name is:

DPG4000-SW-template-single-run-pressure-temperature-graph.xlt

The Export options corresponding to this template are as follows:

22

Page 25

Field Include Field Insert Description Excel Cell

Run # or Label Yes No B3

Gauge Description Yes No B5

Log and Sample Type Yes No B10

Interval Time Yes No B12

Pressure Unit Yes No B8

Custom factor Yes Yes B18

Trip Setpoint and Reset Yes Yes B16

Initial Zero and Tare Yes Yes B14

Zero Changes Yes No N44

Temperature Readings Yes No I44

Pressure Readings Yes No B44

Note: Additional templates may be available on the software CD-ROM

or by download from our website. Detailed descriptions for each are in

the template file.

23

Page 26

TRADEMARKS

Trademarks or trade names are subject to state and federal laws

concerning their unauthorized use or other infringements. The fact that

the product marks or names in this software, and related

documentation, do not bear a trademark symbol does not mean that

the product mark or name is not registered as a trademark or trade

name. Any queries concerning ownership or existence of any

trademarks or trade names mentioned in this software, and related

documentation, should be independently confirmed with the

manufacturer or distributor of the product.

24

Page 27

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s Wa rranty adds an

additional one (1) month grace period to the normal one (1) year product warranty to cover

handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage

on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized R eturn (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired

or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any

action of the purchaser, including but not limited to mishandling, improper interfacing, operation

outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence

of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration;

improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s

control. Components which wear are not warranted, including but not limited to

contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for

any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENT ATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED,

EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not ex ceed the purchase price of the component upon which liability is based. In no event shall OMEGA be

liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as

a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity;

or (2) in medical applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language,

and, additionally, purchaser will indemnify OMEGA and hold OM EGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked

on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR W

ARRANTY RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 28

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gages

MU

Load Cells & Pressure Gages

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

MU

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Datalogging Systems

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

MU

pH, Conductivity & Dissolved Oxygen Instruments

M-4934/0710

Loading...

Loading...