Page 1

Made in China

DPF708, DPF808 Series

Flow Totalizers

Page 2

Page 3

CONTENTS

1. MODEL CONFIGURATION ……………...……………............................................................................................................ 3

2. TECHNICAL SPECIFICATION ……………………………………………………………………………………………………......5

3 PARAMETERS AND SETTINGS……………….….……………………………………….…………………………………………7

3.1 PARAMETER LOCK (LOC) AND FIELD PARAMETERS........................................................................................................7

3.2 THE FULL PARAMETER TABLE ...........................................................................................................................................7

4. WIRING AND REAR TERMINALS LAYOUT ………………………………………..……………………………………………. 17

5. DISPLAYS AND OPERATIONS……………………………………..………………………………………………………........... 19

5.1 FRONT PANEL DESCRIPTION …………………………………...…………………………………………………………………19

5.2 DISPLAY AND OPERATION………………………………………………………………………………………………………...20

5.2.1 DISPLAY STATUS SWITCH……………………………………………………………………………………………………….….20

5.2.2 PARAMETER SETTING………………….……………..…………………………………………………………………………….21

5.2.3 MANUALLY RESET THE ACCUMULATED VALUE…………………………………………………………………………….….21

5.2.4 POWER FAILURE MEMORY FOR ACCUMULATED VALUE………………………………………………...…………………..21

5.3 BATCH CONTROL………………………………………………………………………………………………………………..….22

Page 4

6. CONFIGURATION EXAMPLES…………………………………………..……………………………………………………..……22

7. CALCULATION PRINCIPLE OF THE INSTRUMENT……………………………………………………………………………24

7.1 CALCULATION PROCEDURE OF FLOW COMPENSATION…………………………………………………………………….24

7.2 RELEVANT COMPENSATION FORMULA AND TABLE………………………………………………………………………...25

7.2.1 TEMPERATURE-PRESSURE COMPENSATION FOR COMMON AIR……………………………………………………….25

7.2.2 TEMPERATURE COMPENSATION FOR COMMON LIQUID……………………………………………………….……………25

7.2.3 COMPENSATION FOR SATURATED STEAM AND SUPERHEATED STEAM……………………………………………….25

8. SYMBOL DESCRIPTIONS………………………………………………………………………………………………………….25

Page 5

1. MODEL CONFIGURATION

Model

DPF718(*)-(***)-(****)-(*****)

DPF728(*)-(***)-(****)-(*****)

DPF738(*)-(***)-(****)-(*****)

DPF748(*)-(***)-(****)-(*****)

DPF818(**)-(***)-(****)-(*****)

DPF828(**)-(***)-(****)-(*****)

DPF838(**)-(***)-(****)-(*****)

DPF848(**)-(***)-(****)-(*****)

* Specify input code from Flow Input Options table below

** Specify input code (For Temperature or Pressure Compensation) from Flow Input Options table below

*** Specify batch control code from Batch Output Options table below

**** Specify alarm code from Alarm Options table below

***** Low voltage power supply option (-LV)

Description

FLOW TOTALIZER 1/4 DIN

FLOW TOTALIZER 1/4 DIN, with Light Bar

FLOW TOTALIZER 1/8 DIN VERT

FLOW TOTALIZER 1/8 DIN HORIZ

FLOW TOTALIZER 1/4 DIN, with Temperature or Pressure compensation

FLOW TOTALIZER 1/4 DIN, with Light Bar, with Temperature or Pressure compensation

FLOW TOTALIZER 1/8 DIN VERT, with Temperature or Pressure compensation

FLOW TOTALIZER 1/8 DIN HORIZ, with Temperature or Pressure compensation

Page 6

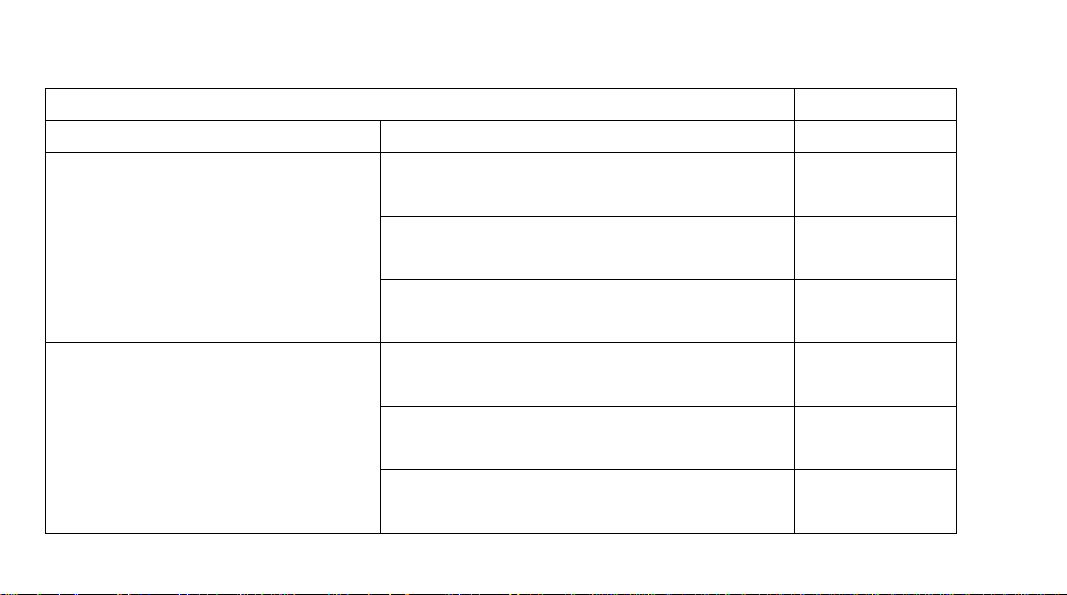

Flow Input Option (*)

Option Type

For frequency signal flow sensor, with12VDC/50mA power supply -F

For 0-5V/1-5V voltage signal flow sensor, with 12VDC/50mA power supply -V

For 4-20mA/0-20mA current signal flow sensor, with 12VDC/50mA power supply -C

Flow Input Options

Page 7

Flow Input Option (**) (For Temperature or Pressure Compensation)

Option Type (For Temperature or Pressure Compensation) Input Option

Temp. and Pressure Input: Flow Input

Dual input available, suit for two-wire

re-transmitter

Thermocouple, RTD or mV signal input; or

0-5V or 1-5V pressure sensor

For frequency signal flow sensor, with12VDC/50mA

power supply

For 0-5V/1-5V voltage signal flow sensor, with

12VDC/50mA power supply

For 4-20mA/0-20mA current signal flow sensor, with

12VDC/50mA power supply

For frequency signal flow sensor, with12VDC/50mA

power supply

For 0-5V/1-5V voltage signal flow sensor, with

12VDC/50mA power supply

For 4-20mA/0-20mA current signal flow sensor, with

12VDC/50mA power supply

-FC

-VC

-CC

-FT

-VT

-CT

Page 8

Batch Output Option (***)

Option Type Output

Relay -R1

DC SSR driver -DC1

Alarm Options (****)

Option Type Alarm Output

Relay -R2

DC SSR driver -DC2

Low voltage power supply option (*****)

Option Type

24V AC/DC, 50/60 Hz -LV

100~240VAC, 50/60Hz Blank

Page 9

2. TECHNICAL SPECIFICATION

Frequency units: Hz

Temperature units:

Pressure units: MPa

Accumulation time:

Fixed at 1 hour for flow accumulation, and the unit can be freely set for batch control.

Momentary flow unit:

Different units can be set, like M3/hour, kg/hour, ton/hour. The decimal point can be freely set.

Accumulation flow unit:

The unit and resolution is the same as momentary flow

℃

Page 10

Flow input type:

Frequency : 0-3200Hz, the low level signal is 0-1V, the high level signal is 3-24V Voltage

Voltage: 1-5V, 0-5V

Current and two wire

re-transmitter

4-20mA, 0-20mA, 0-10mA

Temperature input type:

Thermocouple

RTD

Voltage 0-20mV, 20-100mV, 0-100mV, 0-1V, 0.2-1V

Current 4-20mA, 0-20Ma

Two-wire re-transmitter Directly connect to two wire re-transmitter.

K (0-999℃), E (0-800℃), J (0-999℃)

Pt100 (-200 ~ +600℃)

Page 11

Pressure input type:

Voltage : 1-5V, 0-5V

Current 4-20mA, 4-20mA

Two-wire re-transmitter Directly connect to two wire re-transmitter.

Measurement accuracy:

±0.2% FS, for temperature 、pressure 、frequency 、momentary flow without temperature- pressure compensation.

Temperature drift:

≤0.01%FS /℃ (typical value is 50ppm/℃)

Momentary flow retransmission accuracy:

14 bit output resolution and 0.2%FS

Page 12

Temperature/pressure compensation method (For DPF818,DPF828,DPF838,DPF848 only):

General gas: Temperature- pressure compensation (Calculate by equation for ideal gases)

Saturated steam:

Saturated steam: Pressure compensation (Refer to table , absolute pressure range: 0.1-3.2Mpa)

Superheated steam:

General liquid: Only use temperature compensation, PA is compensation factor.

Temperature compensation (Refer to table , temperature range:100℃-276℃)

Temperature- pressure compensation (Refer to table , temperature range: 150℃-590℃ pressure

range: 0.1-22Mpa)

Calculation accuracy for temperature- pressure compensation:

The calculation error is less than 0.3% FS, and after compensation, the overall error is less than 0.5% FS.

Accumulation accuracy:

The error is less than 0.01%FS (just the frequency error produced by crystal oscillator).

Page 13

Electromagnetic compatibility (EMC) :

±4KV/5KHz according to IEC61000-4-4; 4KV according to IEC61000-4-5

Isolation withstanding voltage:

Between power, relay contact or signal terminal ≥2300VDC; between isolated electroweak terminals ≥600VDC

Power supply :

100 ~ 240VAC, -15%, +10% / 50-60Hz; 120 ~ 240VDC; or 24VDC/AC, 15%, +10%.

Power consumption:

≤5W

Operating Ambient :

Temperature -10~60℃; Humidity ≤90%RH

Page 14

3. PARAMETERS AND SETTINGS

3.1 Parameter Lock (Loc) and Field Parameters

In order to protect important parameters from being modified by mistake, but also offer enough flexibility for field control, parameter

lock (Loc) and field parameters are introduced.

The parameters need to be displayed and modified in the work field are called Field Parameters. The set of field parameters is a

subset of the full parameter set, and can be freely chosen by the user . User can select up to 8 filed parameters through parameter

EP1~EP8.

Loc can authorize different security privilege. For details, please read the description of parameter “Loc” in the full parameter table.

Setting Loc=808, and then pressing to confirm, can enter the full parameter table and modify all parameters.

Page 15

3.2 The Full Parameter Table

Code Name Description

FHIA

FLoA

FdF

CHIA

CLoA

High limit alarm for

momentary flow

Low limit alarm for

momentary flow

Alarm hysteresis for

momentary flow

High limit alarm for

temperature

Low limit alarm for

temperature

Alarm is triggered when momentary flow >FHIA; alarm is released when momentary flow

<FHIAF-FdF; Alarm action output can be defined by parameter ALP.

Alarm triggered when momentary flow<FLoA; alarm released when momentary

flow>FLoA+FdF

Avoid frequent alarm on-off action because of the fluctuation of PV

Alarm is triggered when temperature >CHIA; alarm is released when temperature

<CHIAF-1.0℃;

Alarm triggered when temperature <CLoA; alarm released when temperature >CLoA+1.0

℃

Setting

Range

0 ~9999

units

0 ~ 9999

units

-199.9 ~

999.9℃

Page 16

PHIA

PLoA

ALP

High limit alarm for

pressure

Low limit alarm for

pressure

Alarm output allocation

Alarm is triggered when pressure >PHIA; alarm is released when pressure

<PHIAF-0.010MPa;

Alarm triggered when pressure <PLoA; alarm released when pressure > PLoA+0.010MPa

ALP defines the alarm output allocation. Its value is calculated as below:

ALP=Ax1+Bx2+Cx4+Dx8+Ex16+Fx32

A=0, FHIA alarm triggers AL1 relay; A=1, FHIA triggers AL2.

B=0, FLoA alarm triggers AL1 relay; B=1, FLoA triggers AL2.

C=0, CHIA alarm triggers AL1 relay; C=1, CHIA triggers AL2.

D=0, CLoA alarm triggers AL1 relay; D=1, CLoA triggers AL2.

E=0, PHIA alarm triggers AL1 relay; E=1, PHIA triggers AL2.

F=0, PLoA alarm triggers AL1 relay; F=1, PLoA triggers AL2.

1.999 ~

30.00MPa

0~63

Page 17

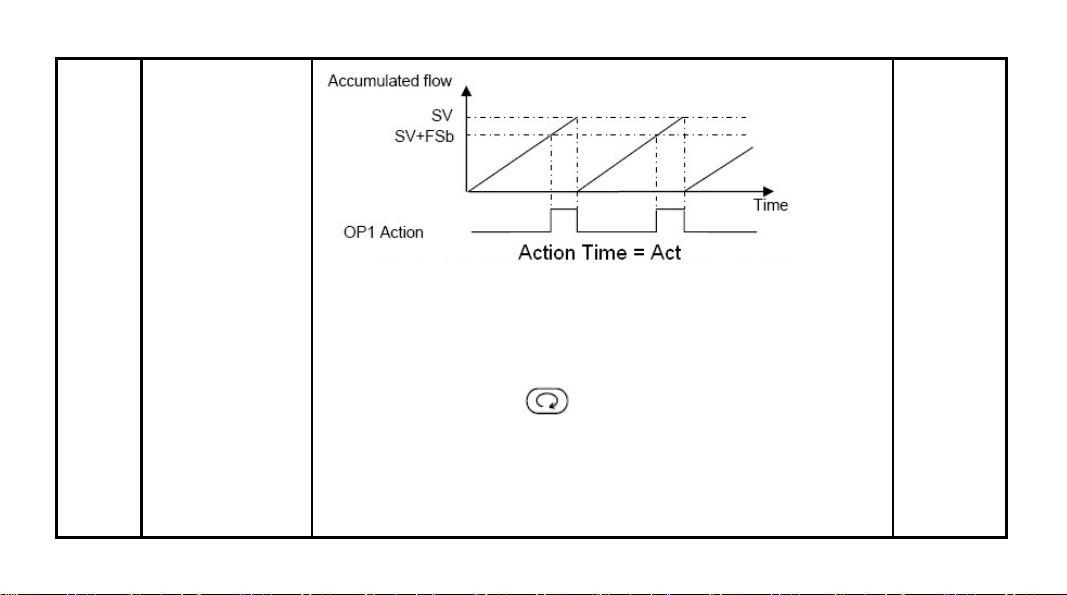

Act

Relay action time for

batch control

Act=0, batch control function is disabled, and the instrument is only used for flow

accumulation.

Act=1-254, when the flow accumulation for batch control gets to SV+FSb (setpoint+offset),

OP1 relay (the relay installed in OUTP socket) will be triggered. Parameter “Act”

determines the latching time of the relay, the unit of which is 0.48s. After the latching time

passed, OP1 relay will be released, the accumulator for batch control will be reset to zero,

and the accumulation start again.

You can set parameter FSb to make it equal to the flow accumulation value during the relay

latching time, this will make the actual flow accumulation equal to setpoint value SV.

0~255(x

0.48s)

Page 18

When Act=255, the relay latching time is infinitely long, then after the action of batch

control relay OP1 is triggered, it will not terminate or reset automatically. At this time, you

can terminate or reset the batch control action, i.e., release the OP1 relay and start the

next batch control, by pressing key or triggering an external discrete input signal.

Page 19

FSb

Batch control offset

When the instrument is used for batch control, the relay’s actual action point is “SV+FSb”.

“FSb” is usually set to be a negative value. For example, if there is a 5 units of flow during

the relay switching time, you can set FSb=-5 to make the actual control value equal to SV

value. That is to say, if SV=1000, then when the 4 digits flow accumulation value reach

995, AL2 relay is triggered immediately, and make the actual control value just equal to

1000.

-1999 ~

+9999

Page 20

SPE

Accumulation rate for

batch control

When the instrument is used for flow accumulator, the time unit in accumulation rate is

fixed, i.e., the time unit is 1 hour. When the instrument is used for batch control, you can

modify parameter “SPE” to change the accumulation rate time. The formula is as the

following:

Accumulation rate time= SPE x0.48 (seconds)

Normal setting is like the following:

SPE=7500, represents that the time unit of the accumulation rate is 1 hour. SPE=750,

represents that the time unit is 0.1 hour.

SPE=125, represents that the time unit is 1 minute. In order to get good control accuracy,

you can properly set parameter SPE according to the action period of batch control.

For example, provided that the momentary flow keep 100.0 unchanged, the flow

accumulation value will increase by 100.0 after 1 hour if you set the accumulation rate time

to be 1 hour (SPE=7500), and the flow accumulation value will increase by 100.0 after 1

minute if you set the accumulation rate time to be 1 minute (SPE=125). The smaller the

parameter SPE, the faster the flow is accumulated.

25~7500

(x0.48s)

Page 21

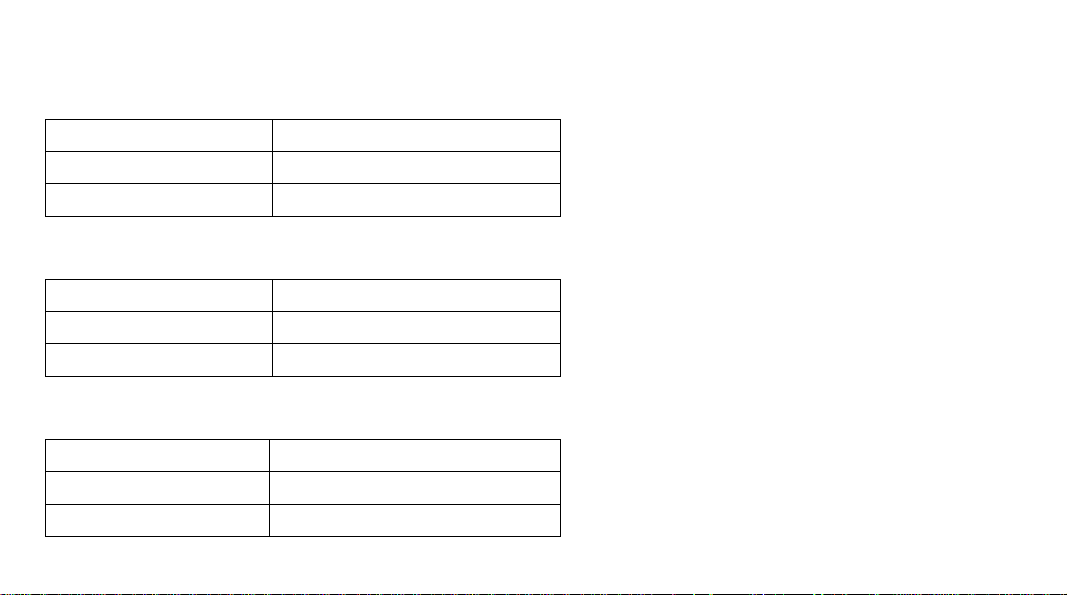

Sn

Input Specification

(temperature / pressure

/ flow)

This table is for DPF718,DP728, DPF738 and DPF748 only

Flow Input Option Code ( * )

-F (Frequency) 0

-V (0~5V / 1~5V) 1

-C (0~20mA / 4~20mA) 2

The following table is for (DPF818,DP828, DPF838 and DPF8480) only

For Temperature / Pressure Compensation type. The hundred’s place (SN_3) 、ten’s place

(SN_2) and unit’s place (SN_1) of parameter. Sn represents the signal input specification

for temperature 、pressure and flow respectively.

SN ---- [Temp.] [Pressure] [Flow]

| | |

| | |

| | Sn_1=0, Flow input signal is pulse frequency.

SN

0~999

Page 22

| | Sn_1=1, Flow input signal is 0-5V/0-20mA.

| | Sn_1=2, Flow input signal is 1-5V/4-20mA.

| |

| |

| Sn_2=0, no pressure signal input.

| Sn_2=1, Pressure signal is 0-5V, at terminals 17+, 18-.

| (For FT, VT and CT input option only).

| Sn_2=2, Pressure signal is 1-5V, at terminals 17+, 18-.

| (For FT, VT and CT input option only).

| Sn_2=3, Pressure signal is 4~20mA or two wires transmitter.

| (For FC, VC and CC input option only).

|

|

Sn_3=0, no temperature signal input.

Sn_3=1, K type thermocouple (For FT, VT and CT input option only).

Page 23

Sn_3=2, E type thermocouple (For FT, VT and CT input option only).

Sn_3=3, J type thermocouple (For FT, VT and CT input option only).

Sn_3=4, N type thermocouple (For FT, VT and CT input option only).

Sn_3=5, Cu 50 (For FT, VT and CT input option only).

Sn_3=6, Pt100 (For FT, VT and CT input option only).

Sn_3=7, Temperature signal input is 0~1V at terminals 19+, 18-

(For FT, VT and CT input option only).

Sn_3=8, Temperature signal input is 0.2~1V, at terminals 19+, 18-

(For FT, VT and CT input option only).

Sn_3=9, Temperature signal is 4~20mA or two wires transmitter.

(For FC, VC and CC input option only).

For Example: The temperature-pressure compensation is needed and the temperature

sensor type is Pt100, the pressure input signal is 1~5V, the high scale of frequency input.

Sn= 620

Page 24

CdIP

Co

CdIH

Temperature point

position

Reference working

temperature of the flow

sensor

Temperature range

It only works for customized compensation method.

CdIP=0, the temperature display format is 0000;

CdIP=1, the temperature display format is 000.0;

CdIP=2, the temperature display format is 00.00;

CdIP=3, the temperature display format is 0.000.

Parameter Co is used to set the reference working temperature of the

flow sensor. If Sn-3=0 is set, and parameter bC is set to have temperature compensation,

at this time, the system will assume that the temperature is fixed at Co for compensation

calculation.

When the temperature input is a linear voltage or current signal such as 0.2-1V 、0-1V 、

4-20mA and 0-10mA, this parameter is used to define the measurement range of

temperature transmitter (the maximum temperature minus the minimum temperature). The

low scale of temperature transmitter is defined by parameter “CSc”.

0~3

-199.9 ~

+999.9℃

0~999.9℃

Page 25

When temperature input is RTD or thermocouple, parameter CSc is used to make input

shift to compensate the error produced by sensor itself. Fox example, provided input signal

keep unchanged, if when parameter “CSc” is set to 0.0 , the temperature measurement of

the instrument is ℃ 101.0 , then when parameter “Sc” is set to ℃ -1.0℃, the temperature

CSc

Temperature input

offset / Temperature

lower limit

measurement display will be 100.0℃

When the temperature input is a linear voltage or current signal, parameter CSc is used to

define the low scale of temperature transmitter. Fox example, if the measurement range of

a temperature transmitter is 0-400℃, then you can set like the following: CSc=0.0,

CdIH=400.0; if the measurement range of a temperature transmitter is 100-400℃, then you

can set CSc=100.0 and CdIH=300.0

-199.9 ~

999.9℃

Page 26

PdIP

Po

Pressure point position

Reference working

pressure

It only works for customized compensation method.

PdIP=0, the pressure display format is XXXX;

PdIP=1, the pressure display format is XXX.X;

PdIP=2, the pressure display format is XX.XX;

PdIP=3, the pressure display format is X.XXX.

This is gauge pressure. For absolute pressure, you should add 0.1013Mpa. When the set

value is larger than 9.999Mpa, the display resolution will change from 0.001Mpa to 0.01Mpa

automatically.

0~3

0 ~

30.000MPa

Page 27

PA

Atmospheric pressure

at the instrument site /

temperature

compensation factor

If pressure compensation is needed, PA represents the atmospheric pressure at the

instrument site. The unit is Mpa. The atmospheric pressure above sea level is set to be

0.101Mpa. If the temperature transmitter has a zero shift error, you can also use this

parameter to make a input correction.

When bC=5, the instrument has temperature compensation only. This case suits for general

liquid measurement which need temperature compensation. At this time, PA represents

temperature compensation factor. The setting range is from –1.999 to +9.999, and the unit

is %/℃. The instrument compensation density formula is as the following:

ρB/ρo=1+PA×(C-Co)/100

ρB is the density after compensation, ρo is the density at reference temperature of Co, C is

the actual temperature of liquid, Co is the reference temperature.

0~1.000MPa

or %/℃

Page 28

PdIH

PSc

Cut

Frd

Range of pressure

input

Scale low limit of

pressure input

The cut off ratio for

small flow signal

Scale high limit of

frequency input

When the flow input is frequency signal, the pressure input can be 0-5V 、1-5V 、0-10mA or

4-20mA. When the set value is larger than 9.999Mpa, the display resolution will change

from 0.001Mpa to 0.01Mpa automatically.

Generally, it is set to 0. Or according to sensor measurement range to set.

For linear input: Cut=0.0~50.0%, if flow input is less than range multiply cut off ratio (FdIH x

Cut), then the flow input is ignored or set to be zero.

For frequency input: Cut=0.0~50.0Hz, if flow input is less than “Cut”, then the flow input is

ignored or set to be zero.

It represents the scale high limit of frequency input (range), and is used to calculate the flow

range for frequency input. You can set it to be a value which is a little larger than the

maximum frequency in actual use.

0 ~

30.000MPa

-1999 ~

9999MPa

0~50.0% Or

0~50Hz

5~3200Hz

Page 29

FdIP

Decimal point place for

flow display

FdIP=0, the flow display is like XXXX

FdIP=1, the flow display is like XXX.X

FdIP=2, the flow display is like XX.XX

FdIP=3, the flow display is like X.XXX

When the instrument is used for temperature-pressure compensation, the flow display value

will exceed 9999, at this time, the decimal point place will move to right by 1 digit

automatically.

When the flow display is like XXXX (FdIP=0), and if the flow display value exceeds 9999,

then the display mode will change to XX.XX because it is impossible for the decimal point

place to move to right by 1 digit. Therefore in the application where the flow display value

will exceed 9999, you had better set FdIP=3 to make the flow display be like X.XXX, and the

unit can be changed from Kg to Ton or from Ton to Kton.

0~3

Page 30

FdIH

FSc

FdL

Flow input range

Input shift for

momentary flow

Digital filter strength for

flow signal

FdIH represents the momentary flow value when the input voltage or current is at the

maximum value, or the input frequency equals to the range high limit Frd. It is the range of

flow transmitter. It is provided that the pressure and temperature equals to reference

working pressure Po and reference working temperature Co respectively. For detail

calculation of FdIH, please refer to latter description.

It is used to make input shift to compensate the error produced by sensor itself. The Input

shift value equals to FSc x 0.005%. This parameter is only used to make input shift for

analog flow input, it takes no action for frequency input.

It is used to set the digital filter strength for flow signal. When a large value is set, the flow

input is stabilized but the responsibility at the time is deteriorated. In the application where

there is a small frequency input and the retransmission output is needed, you can properly

set this parameter to make the fluctuated frequency value change into stable current

retransmission output.

When FdL=0, the filter function is disabled.

10 ~ 9999

flow units

-1000 ~

2000

(x 0.005% of

range)

0~20

Page 31

CF

Function selection

CF=A×1+C×4+D×8+E×16+F×32+G×64+Hx128

For frequency input, the instrument takes no square root extraction.

For linear voltage or current input, parameter CF.A is used to define square root extraction

like the following:

A=0, there is no square root extraction for linear input signal and temperature-pressure

compensation density ratio.

A=1, the instrument takes square root extraction for linear input signal and

temperature-pressure compensation density ratio. You should set like this for differential

transmitter. But for frequency input, this setting takes no effect.

A=2, there is no square root extraction for input signal, but the instrument takes square root

extraction for temperature-pressure compensation density ratio. No matter what types of

input, linear voltage/current or frequency, this setting takes effect.

C=0, the accumulation continues when the flow input is over range.

C=1, the accumulation stops when the flow input is over range.

D=0, the display mode 3 、4 and 5 will switch back to mode 2A and 2B automatically after 30

0~255

Page 32

seconds.

D=1, there is no automatic switching back, so the instrument can keep displaying

temperature or pressure.

E=0, For batch control, OP1 relay contact is normal open. When the flow accumulation

value is greater than the setpoint, the relay contact will be closed.

E=1, For batch control, OP1 relay contact is normal close. When the flow accumulation

value is greater than the setpoint, the relay contact will be open.

F=0, communication protocol is version V5.X.

F=1, communication protocol is version V6.0.

G=0, The flow input is linear input signal.

G=1, With flow meters the relationship between the flow rate and the output signal may

deviate from an ideal curve –linear or squared. The instrument is able to compensate for this

deviation with an additional non-linear table (see latter text for details).

H=0, display the frequency or flow before temperature-pressure compensation.

H=1, no display the frequency or flow before temperature-pressure compensation.

Page 33

bC

Temperature-

pressure

compensation mode

bC=0, no compensation.

bC=1, temperature-pressure compensation for common air (calculation with equation for

ideal gases).

bC=2, temperature compensation for saturated steam (Refer to table, temperature range:

100℃~276℃).

bC=3, pressure compensation for saturated steam (Refer to table, absolute pressure range:

0.1~3.2Mpa).

bC=4, temperature-pressure compensation for superheated steam (Refer to table, 150℃~

590℃, 0.1~22Mpa).

bC=5, temperature compensation for common liquid, PA is compensation factor.

bC=6, use temperature difference to calculate heat, it equals to the temperature difference

times the flow value.

bC=8, for common air with saturated vapor. Temperature- pressure compensation, deduct

vapor by looking up the table according to temperature. Other settings beyond 6 are used

for special compensation calculation.

0~9999

Page 34

FoH

IoL

IoH

Addr

bAud

Flow range for

retransmission

output

Low scale for

retransmission

output current

High scale for

retransmission

output current

Communication

address

Communication baud

rate

It is momentary flow range for retransmission output. For example, if you set like:

FoH=5000, IoL=40, IoH=200, then when the momentary flow value is great than or equals to

5000, the retransmission output current is 20mA, and when the momentary flow value

equals to 0, the retransmission output current is 4mA.

It is used to define the low scale for retransmission output current. If a retransmission output

of 0-10mA is needed, you can set IoL=0. If a retransmission output of 4-20mA is needed,

you can set IoL=40.

It is used to define the high scale for retransmission output current. If a retransmission

output of 0-10mA is needed, you can set IoH=100. If a retransmission output of 4-20mA is

needed, you can set IoH=200.

In the same communication line, different instrument should be set to different address.

The instrument can communicate with host computer. It is recommended to be 9600.

10~9999 flow

unit

0~60

(x 0.1mA)

0~220

(x 0.1mA)

0~100

0~19200

Page 35

CLn

FLJH

Zero reset counter

The most significant

4 digits of flow

accumulator

When the instrument is used as flow accumulator, each time you make zero reset operation

from key pad or when the 8 digits accumulator exceeds 99999999, the accumulation value

will be reset to zero, and parameter CLn will increase by 1. Parameter CLn is for display

only, modification by operator is impossible.

When the instrument is used for batch control, not matter that the 4 digits batch accumulator

is zero reset manually or automatically, parameter CLn will not change. Only when the 8

digits total acculator combined by FLJH and FLJL exceeds 99999999, parameter CLn will

increase by 1. Therefore CLn 、FLJH and FLJL can be combined together to be a 12 digits

accumulator.

When CLn exceeds 9999, it will reset to zero automatically.

It is the most significant 4 digits of the 8 digits flow accumulator. Parameter FLJH is for

display only, cannot be modified by operator.

0~9999

0~9999

Page 36

FLJL

Loc

The least significant

4 digits of flow

accumulator

Parameter lock

It is the least significant 4 digits of the 8 digits flow accumulator. Parameter FLJL is for

display only, modification by operator is impossible. When the instrument is used for batch

control, you can get total flow accumulation value by reading parameter CLn 、FLJH and

FLJL. Since this parameter is updated every 3 minutes, so the reading accumulation value

maybe less than the real accumulation value.

Loc=0, modification of field parameters is allowed, and zero reset operation for flow

accumulation from key pad is also allowed.

Loc=1, modification of field parameters is allowed, but zero reset operation for flow

accumulation from key pad is not allowed.

Loc=2, modification of field parameters is not allowed, but zero reset operation for flow

accumulation from key pad is allowed.

Loc=3, modification of field parameters is not allowed, and zero reset operation for flow

accumulation from key pad is not allowed either.

Loc=808, modification of all parameters is allowed, and zero reset operation for flow

accumulation from key pad is also allowed. If parameter set is locked, setting Loc=808 can

0~9999

0~9999

Page 37

unlock temperately. After the temperate parameter changing, Loc will reset to zero again.

Now you can set Loc to 808 again to unlock permanently.

1 to 8 field parameters can be defined by parameters EP1to EP8. If the number of the field

EP1~

EP8

Field parameter

definition

parameters is less than 8, the first idle EP parameter should be set to “nonE”.

You can define field parameters and Loc to change operation style. For example, user often

modify the parameters FHIA and CHIA, Then the EP paramters and Loc should be set as

below: Loc=0, EP1=FHIA, EP2=CHIA, EP3=none

nonE and all

parameter

codes

Compensated with an additional linearization table

With flow meters the relationship between the flow rate and the output signal may deviate from an ideal curve –linear or squared. The

instrument is able to compensate for this deviation with an additional linearization.

The linearization table enables up to 60 pairs of values to be entered.

Set parameter Loc=3698, you will enter into the configuration of the linearization table (If former setting of parameter Loc is 808, at first

you need to escape from the parameter setting status by setting Loc=0, and then enter into the parameter setting status again by setting

Loc=3698.)

Page 38

A00 function code. It is not used temporarily, and should be set to be 0.

A01 input type. For instrument, the input type is set by parameter Sn, so this parameter should be set to be 0.

A02 the low scale of input signal. The range is from –20000 to +20000.

A02= the low scale of input signal*20000/the range of amplifier. For example, if the flow input is 0-5V (the range of amplifier is 5V), and

you expect to make compensation to get 1-5V input, you can set like: A02=1 x 20000/5=4000.

A03 input signal span. For example, for 1-5V input, the span is 5-1V=4V, and you can set like: A03=4 x 20000/5=16000.

A04 the span between adjacent sample points. The number of sample points=A03/A04. If only one sample point needed, then

A04=A03.

d00 the starting point of linearization table. It is the output of linearization table when the input signal is A02. You can set it to be 0.

d01 the first output point of linearization table. It is the output of linearization table when the input signal is A02+A04.

Page 39

d02~d60: 2~60 output values of linearization table.

Sn-1 should be set according to the description in the parameter table. The instrument will process the input signal with offset,

extraction and small signal cut function. If linearization compensation is needed, set G of parameter CF to 1, and set the above

linearization compensation table.

Page 40

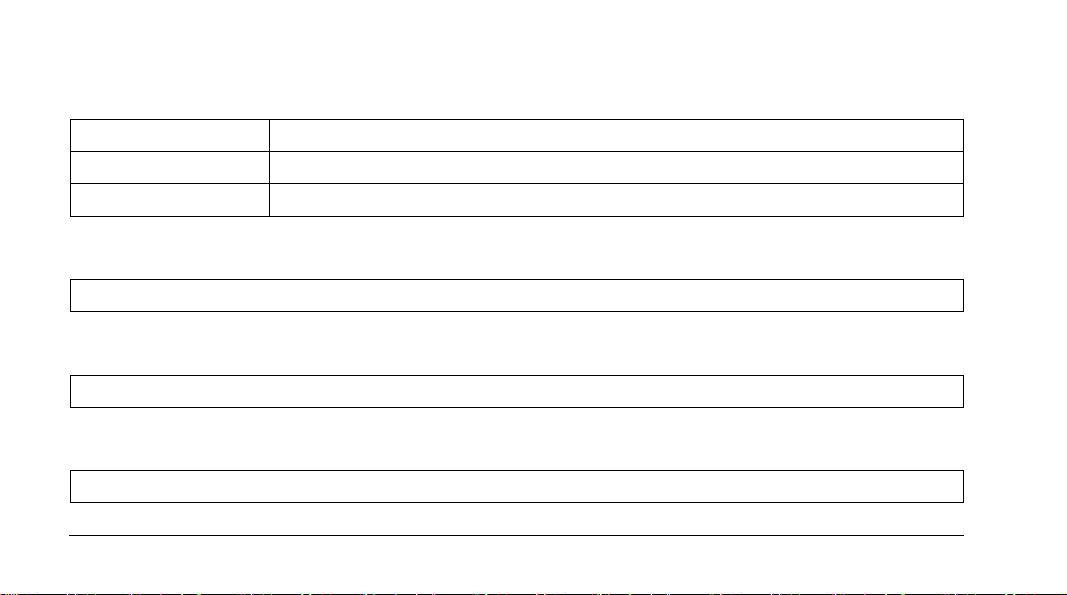

4. WIRING AND REAR TERMINALS LAYOUT

Page 41

Note:

1. Fin, Cin and Pin indicate the input interface of flow, temperature and pressure.

2. 0-5V or 1-5V signal for pressure is inputted from terminals 17+ and 18-.

3. The compensation wires for different kinds of thermocouple are different, and should be directly connect to the terminals. When

the internal auto compensation mode is used connecting the common wire between the compensation wire and the terminals will

cause measurement error.

4. Terminal 16 “V+” indicate the positive polar of internal 24V power output.

5. For 2 wires flow retransmitter, terminal 16(+), terminal 14(-)

Page 42

Select thermocouple reference junction compensation mode by using different wiring mode:

Reference junction compensation is needed junction for thermocouple input. Instrument supply good reference junction compensation

for thermocouple input through 4 different compensation modes selective using software configuration and different external wiring.

Page 43

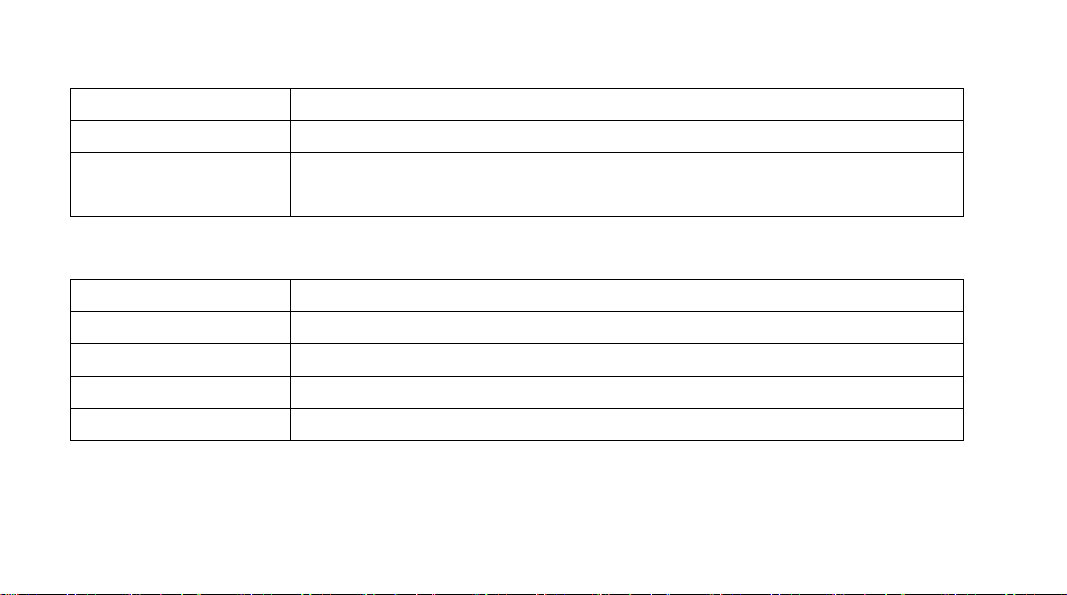

5. DISPLAYS AND OPERATIONS

5.1 Front Panel Description

1

○

Upper display window, displays PV, parameter code, etc.

○2 Lower display window, displays SV, parameter value, or alarm

message

○3 Setup key, for accessing parameter tableland conforming

parameter modification.

○4 Data shift key

○5 Data decrease key

○6 Data increase key

○7 10 LED indicators: MAN and PRG is non-applicable, MIO, OP1,

OP2, AL1, AL2, AU1, AU2 individually indicates the input/output

action of the according modules; COMM

Page 44

5.2 Display and Operation

5.2.1 Display status switch

Press key to switch between different display mode.

Mode ○1 (FL) : Displays monetary flow.

Page 45

Mode ○2 A : When the instrument works for flow accumulation (parameter Act=0), display

8 digital accumulated flow.

Mode ○2 B : When the instrument works for batch control (parameter Act=1~255), the upper window display 4 digital accumulated flow,

and the lower display window

displays ○4 digit control setpoint.

Mode ○3 (F) : When the flow input is voltage or current signal, it displays the momentary

flow before the compensation; when frequency signal, it displays the frequency.

Mode ○4 (C) : Displays temperature.

Mode ○5 (P) : Displays pressure.

If automatic display switching function is set (refer to parameter CF), the display mode ○1 , ○3 , or ○5 will automatically switch to display

mode ○2 A or ○2 B after 30 seconds. If the temperature-pressure compensation function is disabled (parameter bC=0) and the flow input

signal is not frequency, then the upper display window will not display the flow before compensation.

If the instrument has no temperature or pressure signal input, then the temperature or pressure will not be displayed.

Page 46

5.2.2 Parameter Setting

Page 47

5.2.3 Manually reset the accumulated value

When the instrument is used for flow accumulation (Act=0) and the parameter Loc=0 or 808, pressing ▲ and holding for about 2

seconds can reset the 8 digit accumulated value to zero.

After each zero reset operation, the accumulation time will be reset to zero also, and the zero reset counter Cn will increase by 1. The

zero reset counter Cn recorders total zero reset times in the instrument.

When the flow accumulation value exceed 99999999, the accumulated flow will be automatically reset to zero, and Cn increases by 1.

If the accumulated value has not been manually reset, then Cn and the 8 digit accumulated value can work together as a 12 digit

accumulator.

Cn and accumulated value can’t be manually modified. Cn will be automatically reset to zero after it is greater than 9999.

When the instrument works for batch control (Act=1 ~ 255), manually reset operation is disabled.

Page 48

5.2.4 Power failure memory for accumulated value

The accumulated value is saved in memory, and will not be lost even when power failure.

5.3 Batch control

The instruments can work for flow accumulation and batch control. (set parameter Act=1~255).

When the instrument is used as batch control, there is a 4 digit accumulator for batch control. When the accumulated value reach the

control setpoint (SV+FSb), a relay in OUTP socket will be triggered (OP1 light on). The accumulated value will be reset to zero

automatically after the relay is released. The latching time of the relay can be set to any length. If it is set to infinite long, it need to

release the relay from external operation. In batch control mode, the parameters CLn, FLJH and FLJL can work together as a 12 digital

accumulator for calculating the total accumulated value.

When the parameter Act, the latching time for batch control relay, is set to 255, it means the time is infinite long, and after the relay is

triggered, it will not be automatically released. At this situation, pressing key can release the relay, and make it available for next

control action.

In mode 2B, pressing ◄ 、▲ or ▼can modify batch control setpoint SV.

Page 49

6. CONFIGURA TION EXAMPLES

To decide the reference pressure Po or the reference temperature Co, you should select the most commonly used pressure or

temperature (or the highest pressure or temperature from re-transmissier) to avoid too big compensation factor (density ratio). If the

flow value after compensation is too small, the resolution will be low and the error will be increased. If the flow value after compensation

is greater than 25000, overflow will take place.

When the instrument is specially used for flow accumulation, the time unit for momentary flow must be “hour” to assure that the

accumulated flow and the momentary flow have the same engineering unit. When the instrument is used for batch control, you can set

parameter “SPE” to change the time unit. The numerical value of parameter “FdIH” (ignoring the decimal point) should be between 500

and 9999. You had better set it to be a four-digit number to guarantee good resolution and precision. At the same time, you should

make sure that the momentary flow after compensation be less than 25000, otherwise overflow will take place and the excess will be

ignored.

When decide on the decimal point place (parameter “FdIP”), you should keep in mind that is described as below:

When the instrument is used for temperature-pressure compensation, the flow display value maybe exceed 9999, at this time, the

decimal point place will move to right by 1 digit automatically. So, if the flow display is like XXXX (FdIP=0), and the flow value exceeds

9999, then the display mode will change to XX.XX, because it is impossible for the decimal point place to move to right by 1 digit.

Page 50

Therefore the application for flow display, you had better set FdIP=3 to make the flow display be like X.XXX, and the unit can be

changed from Kg to Ton or from Ton to Kton.

Example 1:

Use a vortex flow transmitter to measure the flow of saturated steam, temperature compensation is needed and the temperature sensor

type is Pt100, the flow factor (K) of the transmitter is 3200, and the reference temperature is 200℃ (if the flow transmitter supplier

doesn’t provide a reference temperature, you can use the most commonly used temperature as a reference temperature). By looking up

3

table, you can get that the liquid density ρo =7.864Kg/M

flow at the reference temperature is 2T/h . The time unit for the momentary flow is “hour”, and you can set like below ( t=3600):

Sn=600 (temperature input type is Pt100, no pressure, flow input signal is frequency)

Co=200.0℃

Frd=flow range x K / (ρo x t) = 2000 x 3200 / (3600 x 7.864) = 226.07 (Hz)

Since Frd should be an integer, and also some extra space should be saved to the flow range, Frd can be set to 190.

FdIH= t×Frd×ρo /K=3600×190×7.864/3200=1680.93 (Kg/h)=1.681 (T/h)

FdIP=3

bC=2 (saturated steam, temperature compensation)

when the reference temperature is 200℃. The required range of accumulated

Page 51

Example 2:

A vortex flow transmitter is used to measure the mass flow or standard volumetric flow of compressed air. The temperature-pressure

compensation is needed and the temperature sensor type is Pt100, the pressure input signal is 1~5V, the high scale of frequency input

(Frd) from the transmitter is 300Hz, the flow factor (K) of the transmitter is 2000, the reference temperature is 50 ℃, and the reference

pressure is 1Mpa (if the flow transmitter supplier doesn’t provide a reference pressure, you can use the most commonly used pressure

or the high limit scale as a reference temperature). By calculation, you can get that the liquid density ρo at the reference temperature

and pressure is 11.882Kg/ m

standard condition (0℃ and 1 standard atmosphere) the air density ρs is 1.293Kg/ m

Sn=620

Co=50.0(℃)

Po=1.000(MPa)

PA=0.101(MPa)

Frd=300(Hz)

bC=1 (temperature-pressure compensation for common air, calculation with equation for ideal gases)

If it is needed to display and accumulate mass flow, you can set FdIH and dIP like below:

3

. The absolute pressure of air equals to the reference pressure plus 0.1013Mpa, i.e., 1.1013Mpa. At

3

. You can set like below:

Page 52

FdIH= (3600×Frd×ρo) / K = 3600×300×11.882/2000=6416Kg/h=6.416(T/h)

FdIP=3

If it is needed to display and accumulate standard volumetric flow, you can set FdIH and dIP like below:

3

FdIH=6416/ρs=6416/1.293=4962(m

/h),FdIP=0

If the momentary flow after compensation may exceed 9999, it is recommended to set like below:

3

FdIH=4.962(K m

/h ),FdIP=3

Example 3:

Use orifice plate to measure flow of superheated steam, with differential pressure input, temperature-pressure compensation is needed.

When the pressure is 5Mpa and the temperature is 400℃, the maximum momentary flow is 100T/h (input voltage is 5V). You can set

like below:

Co=500(℃); Po=5.000(MPa)

PA=0.101(MPa)

FdIH=100.0(T/h)

FdIP=1(the decimal point is at ten’s place)

bC=4 (superheated steam).

Page 53

7. CALCULATION PRINCIPLE OF THE INSTRUMENT

7.1 Calculation procedure of flow compensation

Step 1:

Get the flow F before compensation at first

F=V×FdIH + FSc for voltage/current input

Or

F=f×FdIH/Frd + FSc for frequency or pulse input

Among which:

V is voltage or current signal input, the numerical value is 0-100%. Before used for calculation, V is processed by the functions of small

signal cut off and square root/no square root according to the settings of parameter Cut and CF.

f is frequency signal input. The unit is Hz. Before used for calculation, signal preprocessing like small signal cut off is done on f

according to the setting of parameter Cut.

F get from above formula is the flow at reference pressure Po and reference temperature Co.

Page 54

Step 2:

Get temperature-pressure compensation density ratio ρB/ρo according to the setting of parameter bC. If the compensation need to look

up table (for example, saturated steam and superheated steam), you can get the actual density ρB by looking up table using actual

temperature C and actual pressure P, and you can also get the reference density ρo by looking up table using reference temperature

Co and reference pressure Po. Then you can get temperature-pressure compensation density ratio ρB/ρo.

Step 3:

Get compensated flow FB

FB=F × ρB / ρo if no square root is need for temperature-pressure compensation density ratio.

FB=F× if square root is need for temperature-pressure compensation density ratio.

Page 55

7.2 Relevant compensation formula and table:

7.2.1 Temperature-pressure compensation for common air

When bC=1, the instrument make compensation for common air using the equation for ideal gases. The formula is below:

ρB / ρo =(P+PA)×(Co+273.2)/((Po+0.1013)×(C+273.2))

Among which:

ρB is the actual density after temperature-pressure compensation.

ρo is reference density at reference temperature Co and reference pressure Po.

P is actual pressure (gauge pressure).

C is actual temperature (℃).

PA is atmosphere pressure at factory site, 0.1013 MPa is one standard air pressure.

Page 56

7.2.2 Temperature compensation for common liquid

No compensation is needed for liquid. To get high precision, temperature compensation can be taken (bC=5). PA is temperature

compensation factor, the range is from –1.999 to +9.999, the unit is %/℃. The formula is below:

ρB / ρo =1+PA×(C-Co)/100

Among which:

ρB is the actual density.

ρo is reference density at reference temperature Co.

C is actual temperature (℃).

Co is reference temperature.

7.2.3 Compensation for saturated steam and superheated steam

For steam, the compensation calculation by looking up table has a higher precision. You can look up relevant material for the

relationship between steam density and temperature & pressure.

Page 57

8. SYMBOL DESCRIPTIONS

Symbol Description

Input specification setting is incorrect

Or

orAL

Input wiring is disconnected/ thermocouple problem

Or

Short circuited

EErr

8888

IC Software error

IC Software error

Page 58

Page 59

M-4547/0607

Loading...

Loading...