Page 1

1

⁄8 DIN VERSATILE PROCESS MONITORS

CONFIGURABLE

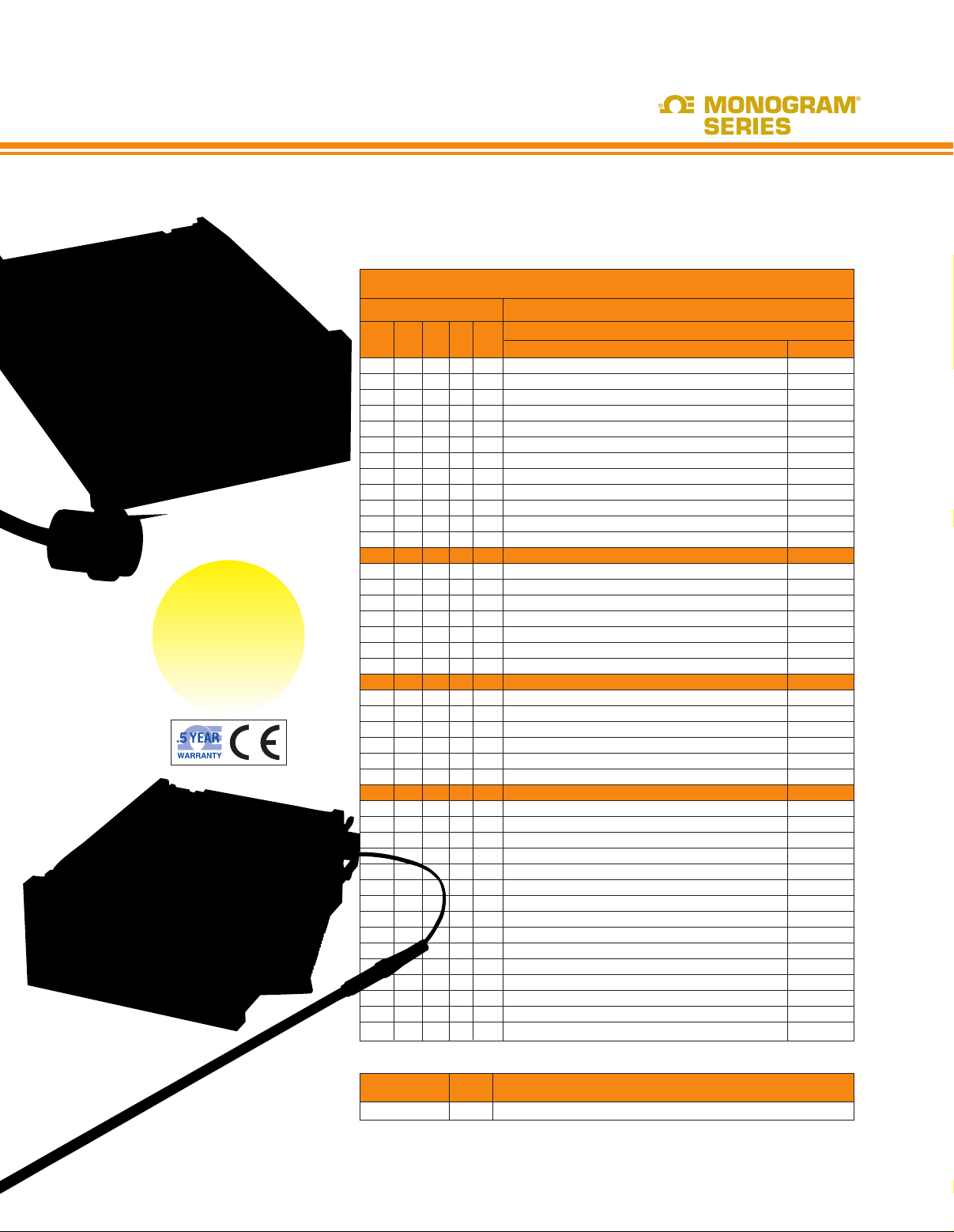

OMEGA®DP2000 digital indicator/controllers introduce a new world

DP2000 Series

DP2000-S, 1⁄8 DIN meter, $360,

shown smaller than actual size.

Starts at

$

265

Complete with

Input Board

of versatility. A universal 1⁄8 DIN case houses each meter. Choose any

combination of display type (LED or LCD), operating power, input type

and range, analog output, and digital or control outputs. OMEGA will

supply a fully burned-in and tested DP2000.

DP2000 ORDERING GUIDE

To Order (Specify Model Number)

MODEL NO.

DESCRIPTION

DP2

000XA. Motherboards

0 LED; 120 Vac (50/60 Hz) $225

1 LCD; 120 Vac (50/60 Hz) 275

2 LED; 240 Vac (50/60 Hz) 225

3 LCD; 240 Vac (50/60 Hz) 275

4 LED; 9 to 32 Vdc, isolated 370

5 LCD; 9 to 32 Vdc, isolated 420

6 LED; 5 Vdc 355

7 LCD; 5 Vdc 405

8 LED; 24 Vac 255

9 LCD; 24 Vac 305

A LED; 26 to 56 Vdc, isolated 365

B LCD; 26 to 56 Vdc, isolated 415

0 1 mV/count (supplied on all units) N/C

1 0 to 5 Vdc $70

2 0 to 10 Vdc 70

3 0 to 1 mA (internally driven) 70

4 4 to 20 mA (internally driven) 70

5 4 to 20 mA (externally driven) 115

6 4 to 20 mA (isolated) 135

0 None N/C

1 Dual setpoint, 10 A relay (SPDT) $165

2 Proportional 4 to 20 mA 225

3 Proportional/time proportioning, 2 A relay 295

4 Parallel BCD, isolated 155

5 Single setpoint, 10 A relay (SPDT) 125

Accessory

B. Analog Outputs

C. Control Outputs

D. Signal Conditioner Inputs

A(*)

DC voltage $40

B(*)

DC current 40

C(*)

AC AVG voltage 65

D(*)

AC AVG current 65

E(*)

Process signal with 15 Vdc excitation 80

F(*)

AC RMS voltage 100

G(*)

AC RMS current 100

H(*)

Frequency/rate 85

J(*)

Type J thermocouple 80

K(*)

Type K thermocouple 80

T(*)

Type T thermocouple 100

P(*)

Process signal 60

M(*)

RTD, 1° resolution 90

R(*)

RTD, 0.1° resolution 100

S(*)

Strain gage 135

Refer to the specification pages D-82 and D-83 for information about

*

PRICE

signal conditioners.

DP2000-J1, $305, with

TJ36-ICSS-116G-12,

transition joint probe, $28,

shown smaller than actual size,

visit omega.com/tj36-icin

Model No. Price Description

DPP-5 $5251⁄8 DIN panel punch

Comes complete with operator’s manual.

Ordering Example: DP2000-A2, LED 120 Vac, 1 mV/count, DC voltage between

-1.999 and 1.999 V, $225 + 40 = $265.

D-79

Page 2

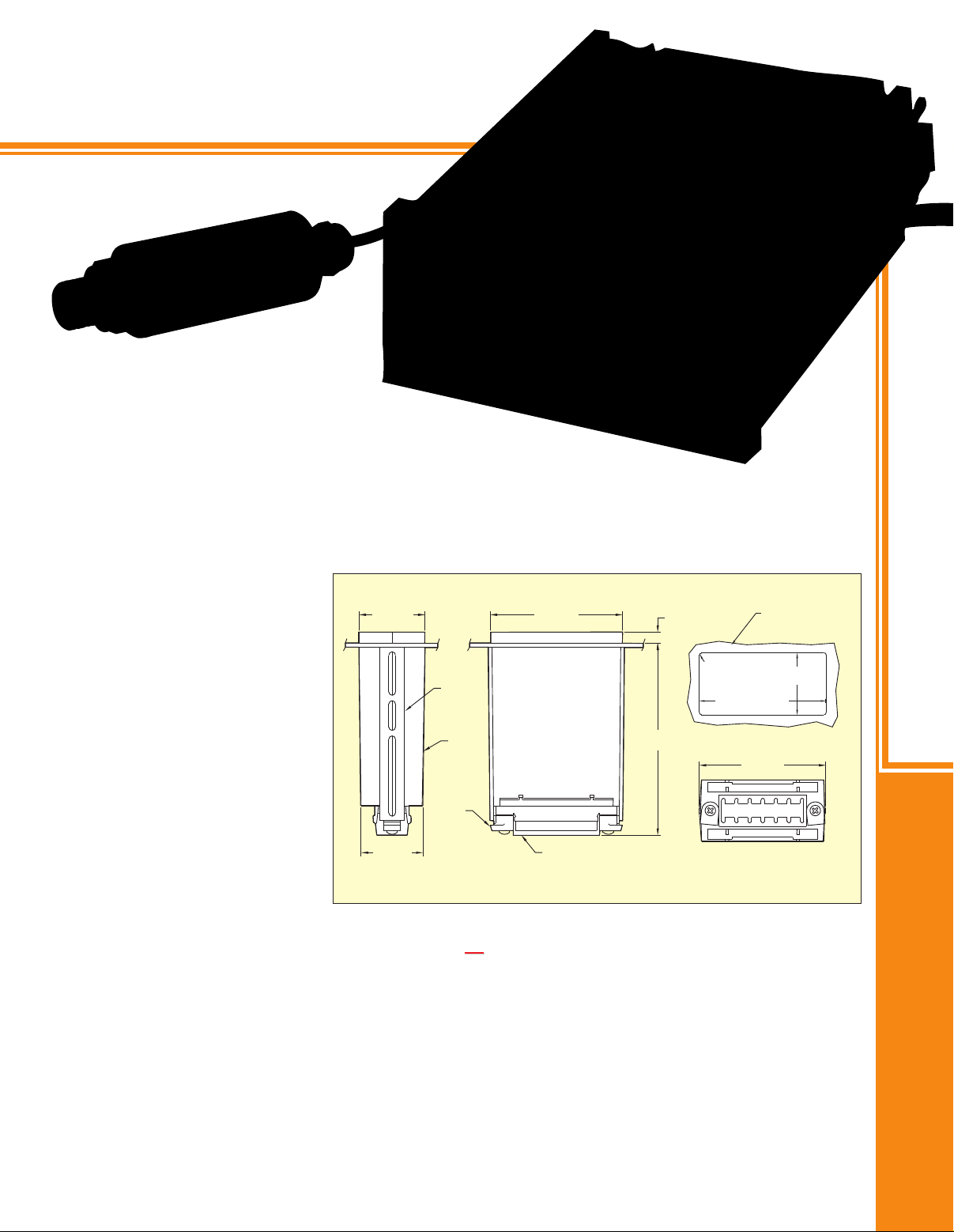

48.0

(1.89)

SLIDE

RETAINER

CASE

CLAMP

RING

45.0

(1.77)

TERMINAL BLOCK COVER

Terminal block cover and bezel

not shown for clarity. Clamp rings

rotated and slide retainers removed

as shown for installation.

91.9

(3.62)

139.6 (5.50)

MAX

92.00 +0.81/-0.00

(3.622 +0.032/0.000)

45.00 +0.61/-0.00

(1.772 +0.024/-0.000)

R

1.5

(0.06)

4 PLCS

PANEL THICKNESS:

6.4 (0.25) MAX

0.8 (0.03) MIN

7.9

(0.31)

MAX

96.0

(3.78)

VERSATILE PROCESS MONITORS

DP2401-P, $595, shown smaller

than actual size, with PX209, $195,

pressure transducer, sold separately,

see page B-90.

SPECIFICATIONS

Conversion

Technique: Auto-zero,

dual slope, average value

Signal Integration Period:

100 ms, nominal

Reading Rate: 2.5/s, nominal

Display

LED: Red, 14.2 mm (0.56"), 7-segment

LCD: 12.7 mm (0.50"), 7-segment

Range: 0 to ±1999

Overload Indication: 3 least-significant

digits blanked, “1” or “-1” displayed

Power

AC Models: 120/240 Vac

(10 to 15%), 49 to 440 Hz or

24 Vac (10 to 15%)

DC Models: 5 Vdc ±5%, 9 to 32 Vdc

or 26 to 56 Vdc

Common Mode

Voltage: 1500 Vp test

(354 Vp per IEC spacing).

Rejection (DC to 60 Hz): 120 dB

Environmental

Operating Temperature: 0 to 60°C

(32 to 140°F)

Storage Temperature: -40 to 85°C (-40 to 185°F)

Humidity: To 95% RH, non-condensing @ 0 to 40°C

(32 to 104°F)

Mechanical

Case Material: 94 V-0 UL-rated, polycarbonate

Weight: 0.57 kg (1.26 lb) with controller

Dimensions: mm (in)

Visit omega.com/panelpunches for panel punches.

INSTRUMENTATION

D

A. Motherboards DP20000-x, base price from

(Power and display preferences refer to the DP2000 ordering guide.)

Choose the appropriate OMEGA®motherboard. The motherboard constitutes the complete DPM electronics and

power supply for any combination of inputs and outputs.

All power supplies provide cool operation, resulting in extended component life. The AC-powered versions use a

high-efficiency power transformer, and the isolated 9 to 32 Vdc versions maintain display brightness over the entire

voltage range. A non-isolated 5 Vdc version is also available.

Signal input and power connections are made via a rear barrier terminal strip. The motherboard rear edge

connector provides access to hold and display test, polarity, clock, and the standard 1 mV/count analog output

and optional analog outputs. Decimal point position can be selected by jumpers on the edge connector or

by placement of gas-tight jumpers behind the front lens.

Ordering Example: DP2100-J1, LCD, 120 Vac motherboard with J thermocouple signal conditioner input, $275 + 80 = $355.

D-80

$

225

Page 3

VERSATILE PROCESS MONITORS

B. Analog Outputs DP20000-x

In addition to the standard OMEGA® analog output

of 1 mV/count, 6 optional outputs are available:

1. 0 to 5 Vdc $70

2. 0 to 10 Vdc 70

3. 0 to 1 mA (Internally Driven) 70

4. 4 to 20 mA (Internally Driven) 70

5. 4 to 20 mA (Externally Driven) 115

6. 4 to 20 mA (Isolated) 135

Both DC voltage outputs drive up to 2 mA. The internally

driven 4 to 20 mA output drives up to 600 Ω (12V

compliance), while the externally sourced 4 to 20 mA

output can be driven by 5 to 40 Vdc. The user has access

to the analog output at the motherboard edge connector.

Ordering Example: DP2010-A1, LED, 120 Vac motherboard, 0 to 5 Vdc

analog output with ±0.1999 Vdc input, $225 + 70 + 40 = $335.

Add to Base Price:

C. Control Outputs DP20000-x

For capabilities beyond simple indicating, choose from 5 OMEGA®control outputs: a dual-setpoint on/off controller,

a proportional 4 to 20 mA controller, a proportional plus time-proportioning controller, a parallel

BCD output, or a single-setpoint on/off controller. Controllers feature convenient quick-connect terminals with

mating connectors supplied. The parallel BCD outputs to a 50-pin edge connector.

1. Dual-Setpoint Controller, add

The OMEGA®dual-setpoint controller features 2 internal relays controlled by high/low setpoint adjustments

accessible through the front lens. These screwdriver-adjustable setpoints can be used for limit alarm functions,

on/off control, 2-position differential control, 3-position control, and limit-cycle control.

The low setpoint is adjustable over the entire -1999 to 1999 display range. The high setpoint is adjustable in the

range between the selected low setpoint and 1999. Either setpoint can be displayed by pressing the low or high

setpoint pushbutton on the front panel.

Both relays are de-energized when the input value (measured variable) is between the low and high setpoints.

When the input value falls below the low setpoint, the low relay energizes. When the input rises above the high

setpoint, the high relay energizes.

Red “LO” and “HI” lamps on the front panel light when their respective relays are energized. All relays are rated

10 A @ 120 Vac and 240 Vac.

Ordering Example: DP2001-A2, LED motherboard, dual-setpoint controller with ±1.999 Vdc input, $225 + 165 + 40 = $430.

2. Proportional 4 to 20 mA Controller, add

The OMEGA®proportional controller provides a 4 to 20 mA output in proportion to the difference between the input

and the selected setpoint value. The screwdriver-adjustable setpoint, accessible through the front lens, can be set

for any value within the -1999 to 1999 display range. The setpoint or the deviation of input from setpoint may be

displayed by pressing front-panel pushbuttons.

The controller features adjustable proportional band (1 to 10%) and a front-panel LED that lights

when the input (process) is within this band.

The 4 to 20 mA output provides 12V compliance, or it can be connected to use an external source

for up to 35V compliance.

Ordering Example: DP2002-P9, LED motherboard, proportional 4 to 20 mA controller with 4 to 20 mA input, $225 + 225 + 60 = $510.

3. Proportional Plus Time-Proportioning Controller, add

This controller provides all the features of a proportional controller, plus a time-proportioning solid state relay

output for on/off cycling control.

Two red LEDs on the front panel indicate when the relay is energized and when the process is within the

proportional band. A screwdriver adjustment, accessible through the front lens, lets the user adjust the manual

reset over 100% of the proportioning band. A front-panel pushbutton switch allows display of the input parameter or

the amount of deviation from setpoint. Logic inputs allows reversing of the sense of the relay or the relay LED.

All relays are rated 2 A @ 240 Vac.

Ordering Example: DP2003-P9, LED motherboard, proportional/time proportioning control with 4 to 20 mA input, $225 + 295 + 60 = $580.

$

165 to base price

$

225 to base price

$

295to base price

D-81

Page 4

VERSATILE PROCESS MONITORS

4. Parallel BCD Output*, add

For users with digital data acquisition needs, this option provides

buffered, isolated (350V), gated, and stored BCD outputs on 14 parallel lines

plus 2 lines for polarity and data-ready. All buffers have 3 stateoutputs for easy parallel

bussing in data acquisition systems. Inputs and outputs are 5 Vdc TTL logic, positive true logic only. A BCD HOLD

input holds the BCD data stored in the latches, but allows the instrument to continue making updated conversions.

Along with broadside parallel outputs, this option allows the transmission of 8 bits of data at a time for devices with

8-bit data paths such as computers. A 5V @ 100 mA power supply is necessary to use the BCD output.

POWER SUPPLY FOR BCD PARALLEL OUTPUT*

To Order

MODEL NO. PRICE DESCRIPTION

PSP-5 $125

PST-5 165

(Specify Model Number)

5V @ 250 mA output (pin terminal style)

5V @ 500 mA output (screw terminal style)

5. Single-Setpoint Controller, add

The single-setpoint controller board features one internal form “C” relay, rated to 10 A @ 30 Vdc or 240 Vac,

resistive load. The setpoint is front-panel adjustable over the entire display range. The setpoint provides adjustable

deadband to limit relay cycling or chatter. Pushbuttons are conveniently mounted on the front panel, and the LED

lamp provides on/off status of the relay.

$

155 to base price

$

125 to base price

* Note: A power supply is required when ordering a parallel

BCD output card.

Ordering Example: DP2004-K2, LED motherboard, BCD

output with Type K thermocouple input, PST-5, power supply,

$225 + 155 + 80 + 165 = $625.

Fail-Safe Control Mode:

In this mode, the relay is energized when the meter input is below the setpoint. When the input rises above

the setpoint, the relay is de-energized. In the event of a power failure, the relay is de-energized, signaling an

alarm condition.

Latched or Non-Latched Operation:

The controller can be configured so that the relay is latching. In latched operation, the relay remains energized

until the alarm condition is acknowledged either by pressing both front-panel pushbuttons simultaneously

or by momentarily closing an external switch tied to a RESET input.

Add the OMEGA®signal conditioner that matches the sensor and process variables. OMEGA®will configure the

range the user selects, which can be changed later via a “pin-forest” of gas-tight, movable internal jumpers.

Fine calibration is effected with zero and full scale adjustments on the left side of the display behind the lens. All

signal input connections are made via barrier screw-terminal strips.

Ordering Example: DP2005-P9, LED motherboard, single-setpoint controller with 4 to 20 mA input, $225 + 125 + 60 = $410.

INSTRUMENTATION

D

D. Signal Conditioners DP2000-xx

A Series DC Voltage Inputs, add $40 to base price

ORDERING INPUT NMR@

CODE

A1 ±0.1999V 1 GΩ 0.1 mV

A2 ±1.999V 1 MΩ 1 mV

A3 ±19.99V 1 MΩ 10 mV

A4 ±199.9V 1 MΩ 100 mV

B Series DC Current Inputs, add $40 to base price

ORDERING INPUT IMPEDANCE NMR@

CODE RANGE (200 mV SHUNT) RESOLUTION 50/60 Hz ACCURACY

B1 ±19.99 µA 10 kΩ 0.01 µA

B2 ±199.9 µA 1 kΩ 0.1 µA

B3 ±1.999 mA 100 Ω 1 µA

B4 ±19.99 mA 10 Ω 10 µA

B5 ±199.9 mA 1 Ω 100 µA

B6 ±1.999 A 0.1 Ω 1 mA

Ordering Example: DP2000-B3, LED 120 Vac, 1 µA/count, DC current between -1.999 mA and 1.999 mA, $225 + 40 = $265.

RANGE

IMPEDANCE

RESOLUTION

D-82

50/60 HZ

50 dB

50 dB

ACCURACY

±0.05% of reading

±1 count

±0.05% of reading

±1 count

Page 5

VERSATILE PROCESS MONITORS

C Series AC AVG Voltage Inputs, add $65 to base price

ORDERING FREQUENCY

CODE RANGE INPUT IMPEDANCE RESOLUTION RANGE ACCURACY

C2 0.1999V 0.1 mV

C3 1.999V 1 mV

C4 19.99V 10 mV

C5 199.9V 100 mV

C6 650V 10MΩ 1V

Full-wave rectified average AC signal, calibrated for sinusoidal input.

Ordering Example: DP2000-C5, LED 120 Vac, 100 mV/count, 199.9V range for AC AVG voltage input, $225 + 65 = $290.

D Series AC AVG Current Inputs, add $65 to base price

ORDERING INPUT IMPEDANCE FREQUENCY

CODE RANGE (200 mV SHUNT) RESOLUTION RANGE ACCURACY

D1 19.99 µA 10 kΩ 0.01 µA

D2 199.9 µA 1 kΩ 0.1 µA

D3 1.999 mA 100 Ω 1 µA

D4 19.99 mA 10 Ω 10 µA

D5 199.9 mA 1 Ω 100 µA

D6 1.999 A 0.1 Ω 1 mA

D7 5.00 A* 0.01 Ω 2.5 mA

50 mV shunt for 5 A current transformer input. Full-wave rectified average AC signal, calibrated for sinusoidal input.

*

Ordering Example: DP2000-D4, LED 120 Vac, 10 µA/count, 19.99 mA range for AC AVG current input, $225 + 65 = $290.

E Series

Note: The “E” Series can be factory-set to any one of 11 ranges.

Field range change is not recommended.

Gain = full span display (counts) (see Part A of example)

*

Accuracy: ±0.05% of reading, ±1 count

Notes: 1

input span (mV, V or mA)

. Built-in zero offset ±2.25 mV @ 10V excitation

(225 µV per V of excitation), see example B.

Greater zero offsets, such as may be required by load

cells, may be achieved with an external resistor.

The value of the resistor (in kΩ) is calculated as follows:

dead load = (250)(LCR)(LCC)

resistor (LCV)(DL)

2. Zero and span adjustments made by user,

via accessible potentiometers.

LCR = load cell resistance (Ω)

LCC = cell capacity (lb)

LCV = load cell voltage (mV/V)

DL = dead load (lb)

1.1 MΩ

47 to 1000 Hz

10 MΩ

47 to 1000 Hz

Strain Gage, Pressure Transducer, and Load

Cell Signal Input with 15 Vdc Power Supply,

ORDERING MAXIMUM MINIMUM MAXIMUM

CODE INPUT SPAN GAIN GAIN

E1 0.5V 0.08 counts/mV 2.85 counts/mV

E2 0.5V 2.84 counts/mV 5.55 counts/mV

E3 0.5V 5.49 counts/mV 8.17 counts/mV

E4 5.0V 8.0 counts/mV 231.0 counts/mV

E5 5.0V 230.0 counts/mV 449.0 counts/mV

E6 10.0V 4.0 counts/mV 114.5 counts/mV

E7 10.0V 114.0 counts/mV 223.0 counts/mV

E8 4 to 20 mA 2.5 counts/mA 70.4 counts/mA

E9 4 to 20 mA 70.5 counts/mA 137.0 counts/mA

E10 10 to 50 mA 1.0 counts/mA 28.2 counts/mA

E11 10 to 50 mA 28.1 counts/mA 55.0 counts/mA

3. Decimal point location by jumper behind front lens.

4. Maximum display is ±1999 counts.

To Determine Ordering Code:

1: Determine full scale span required (max reading – min reading).

2: Determine gain = full scale span

3: Find ordering code for which desired gain lies between minimum

and maximum values listed.

4: Use ordering code to complete part number.

Ordering Example:

Signal range 0.5 to 5.5V (5 Volt span)

Full scale display: 100.0 psi (1000 counts)

Gain = 1000 counts

Choose E4 because 8 < 200 < 231

To order, specify DP2000-E4, $285.

Model E is designed for use with OMEGA

cells and strain gage devices.

5V

signal span

= 200 counts/V

±0.1% of reading

±0.1% of reading

$

add

80 to base price

®

pressure transducers, load

D-83

±1 count

±1 count

Page 6

VERSATILE PROCESS MONITORS

F Series AC RMS Voltage Inputs, add $100 to base price

ORDERING FREQUENCY

CODE RANGE INPUT IMPEDANCE RESOLUTION RANGE ACCURACY

F2 0.1999V 0.1 mV

F3 1.999V 1 mV

F4 19.99V 10 mV

F5 199.9V 100 mV

F6 650V 10MΩ 1V

Provides true RMS accuracy for non-sinusoidal inputs with a crest factor of 3:1 or less.

Ordering Example: DP2000-F3, LED 120 Vac, 1 mV/count, 1.999V for AC RMS voltage input, $225 + 100 = $325.

G Series AC RMS Current Inputs, add $100 to base price

ORDERING INPUT IMPEDANCE FREQUENCY

CODE RANGE (200 mV SHUNT) RESOLUTION RANGE ACCURACY

G1 19.99 µA 10 kΩ 0.01 µA

G2 199.9 µA 1 kΩ 0.1 µA

G3 1.999 mA 100 Ω 1 µA

G4 19.99 mA 10 Ω 10 µA

G5 199.9 mA 1 Ω 100 µA

G6 1.999 A 0.1 Ω 1 mA

G7 5.00 A* 0.01 Ω 2.5 mA

50 mV shunt for 5 A current transformer input. Provides true RMS accuracy

*

for non-sinusoidal inputs with a crest factor of 3:1 or less.

Ordering Example: DP2000-G2, LED 120 Vac, 0.1 µA/count, 19.99 mA

for AC AVG current input, $225 + 100 = $325.

1.1 MΩ

1 MΩ

47 Hz to 5 kHz

47 Hz to 5 kHz

±0.1% of reading

±1 count

±0.1% of

reading

±1 count

INSTRUMENTATION

H Series Frequency/Rate Inputs, add $85 to base price

MINIMUM

ORDERING FOR 1999 COUNT HIGH LOW MINIMUM MAXIMUM

CODE (MAX DISPLAY) SENSITIVITY* SENSITIVITY* GAIN GAIN

H1 100 to 200 Hz 10 counts/Hz 20 counts/Hz

H2 200 to 400 Hz 5 counts/Hz 10 counts/Hz

H3 400 to 800 Hz 2.5 counts/Hz 5 counts/Hz

H4 500 to 1000 Hz 2 counts/Hz 4 counts/Hz

H5 1000 to 2000 Hz 1 counts/Hz 2 counts/Hz

H6 2000 to 4000 Hz 0.5 counts/Hz 1 counts/Hz

H7 2500 to 5000 Hz 0.4 counts/Hz 0.8 counts/Hz

H8 5000 to 10,000 Hz 0.2 counts/Hz 0.4 counts/Hz

H9 10,000 to 20,000 Hz 0.1 counts/Hz 0.2 counts/Hz

Note: The “H” Series can be factory-set to any one of 9 ranges.

Field range change is not recommended.

Sensitivity is rear-connector selectable; units are shipped with

*

low sensitivity.

Accuracy: ±0.1% of reading, ±1 count

Maximum Input: 130 Vrms

Input Impedance: 150 kΩ

Notes: 1

. Zero offset adjustable from +100 to -1000 counts.

2. Zero and span adjustments made by user,

via accessible potentiometers.

3. Decimal point location by jumper behind front lens.

4. Inputs may be sinusoidal or square wave,

symmetric or asymmetric.

5. Minimum frequency is 5% of selected full span.

6. Maximum display is ±1999 counts.

FREQUENCY

MINIMUM SIGNAL

PEAK TO PEAK WITH

15 mV p-p

30 mV p-p

90 mV p-p

125 mV p-p

175 mV p-p

To Determine Ordering Code:

1: Determine max input frequency (Hz).

2: Determine full scale span required (max reading – min reading)

3: Determine gain = display

maximum frequency

4: Find ordering code for which desired gain lies between minimum

and maximum values listed.

5: Use ordering code to complete part number.

Input frequency: 400 Hz; signal level: 200 mV; full scale display:

500 psi; gain = 500/400 = 1.25.

Choose H5 because 1 < 1.25 < 2.

Ordering Example: DP2000-H5, LED 120 Vac and

1000 to 2000 Hz frequency, $225 + 85 = $310.

Model H is designed for use with OMEGA®frequency output

transducers, including flowmeters and pressure transducers.

D-84

DISPLAY GAIN

D

Page 7

TEMPERATURE

INPUT MODELS

DP2000 Series

DP2000-K1,

$305, shown

smaller than

actual size.

J, K, T Series Thermocouple Inputs, add $80 to base price

ORDERING CALIBRATION TEMPERATURE LEAD RESISTANCE SENSE

CODE TYPE RANGE ACCURACY (±1⁄2 COUNT) (MAXIMUM) CURRENT

J1

J2

K1

K2

T1

T2

ANSI code. All types: 1° resolution with polylog III linearization calibrated to NBS tables (IPTS-68).

*

Ordering Example: DP2101-K1, LCD, 120 Vac, 1°C/count, dual setpoint (10 A relay), Type K 0 to 1260°C (32 to 1999°F) range,

$275 + 165 + 80 = $520.

J*

Iron- 277 to 760°C: ±0.5% rdg

constantan

K*

CHROMEGA

ALOMEGA

T* -59 to 93°C: ±1°C

copper- 93 to 371°C: ±0.6% rdg

constantan

0 to 760°C

32 to 1400°F

0 to 1260°C

®

- 277 to 1260°C: ±0.6% rdg

®

32 to 1999°F

-184 to 371°C

-300 to 700°F

0 to 277°C: ±1.2°C

32 to 530°F: ±2.4°F

530 to 1400°F: ±0.5% rdg

0 to 277°C: ±1.8°C

32 to 530°F: ±3.0°F 0.5 µA

530 to 1999°F: ±0.6% rdg

-184 to -59°C: ±1.5% rdg

-300 to -75°F: ±1.5% rdg

-75 to 200°F: ±1.5°F

200 to 700°F: ±0.5% rdg

500 Ω

395 Ω

200 Ω

BURNOUT

M, R Series RTD Inputs (Pt 100 Ω), M Series add $90, R Series add $100, to base price

ORDERING ACCURACY

CODE ALPHA RESOLUTION RANGE (±1⁄2 COUNT) ZERO TEMPCO

M1

M2

R1

R2

Temperature Coefficient, Span: ±0.006% rdg/°C

Excitation Current: 0.42 mA for M, 4.2 mA for R models

Lead Resistance: 20 Ω max for 3- or 4-wire input, within specified error; for 2-wire input, add 2.6°C or 4.7°F per Ω

change to specified error

Curve: Alpha = 0.00385, DIN 43760

Ordering Example: DP2101-M1, LCD, 120 Vac, 1°C/count, dual setpoint (10 A relay), RTD Input, 1.0°C resolution, -200 to 830°C

(-328 to 1526°F), $275 + 165 + 90 = $530.

0.00385

0.00385

1°

0.1°

-200 to 830°C ±0.3°C ±0.2% rdg

-328 to 1526°F ±0.5°F ±0.2% rdg

-199.9 to 199.9°C ±0.1°C ±0.05% rdg

-199.9 to 199.9°F ±0.2°F ±0.05% rdg

D-85

0.05 °/°

0.005 °/°

Page 8

P Series Process Signal Inputs, add $60 to base price

ORDERING MAXIMUM MINIMUM MAXIMUM

CODE INPUT SPAN GAIN GAIN

P1 0.5V 0.08 counts/mV 2.85 counts/mV

P2 0.5V 2.84 counts/mV 5.55 counts/mV

P3 0.5V 5.49 counts/mV 8.17 counts/mV

P4 5.0V 8.0 counts/V 231.0 counts/V

P5 5.0V 230.0 counts/V 449.0 counts/V

P6 10.0V 4.0 counts/V 114.5 counts/V

P7 10.0V 114.0 counts/V 223.0 counts/V

P8 4 to 20 mA 2.5 counts/mA 70.4 counts/mA

P9 4 to 20 mA 70.5 counts/mA 137.0 counts/mA

P10 10 to 50 mA 1.0 counts/mA 28.2 counts/mA

P11 10 to 50 mA 28.1 counts/mA 55.0 counts/mA

Note: The “P” Series can be factory-set to any one of 11 ranges.

Field range change is not recommended.

Gain = full span display (counts)

*

Accuracy: ±0.05% of reading, ±1 count

Input Impedance:

Notes: 1

To Determine Ordering Code:

1: Determine full scale span required (max display – min display)

S Series

input span (mV, V or mA)

Voltage ranges: greater than 100 kΩ

Current ranges: greater than 250 Ω

. Zero offset adjustable from -605 to 870 counts.

2. Zero and span adjustments made by user,

via accessible potentiometers.

3. Decimal point location by jumper behind front lens.

4. Maximum display is ±1999 counts.

Strain Gage, Pressure Transducer, and Load Cell Signal Input,

ORDERING MAXIMUM MINIMUM MAXIMUM

CODE INPUT SPAN GAIN GAIN

S1 499 mV 4.01 counts/mV 9.9 counts/mV

S2 249 mV 8.02 counts/mV 19.8 counts/mV

S3 124 mV 16.10 counts/mV 39.7 counts/mV

S4 62.5 mV 32.00 counts/mV 79.0 counts/mV

S5 31.2 mV 64.20 counts/mV 158.0 counts/mV

S6 15.6 mV 128.00 counts/mV 315.0 counts/mV

S7 7.8 mV 258.00 counts/mV 637.0 counts/mV

Note: The “S” Series can be factory-set to any one

of 7 ranges.

Field range change is not recommended.

Gain = full span display (counts) (see Part A of example)

*

Accuracy: ±0.05% of reading, ±1 count

Note: 1

input span (mV, V or mA)

. Built-in zero offset ±2.25 mV @ 10V excitation

(225 µV per V of excitation):

see example B.

Greater zero offsets, such as may be required by

load cells, can be achieved with an external resistor.

The value of the resistor (in kΩ)

is calculated as follows:

2. Zero and span adjustments made by user,

3. Decimal point location by jumper behind front lens.

4. Maximum display is ±1999 counts.

5. Excitation factory adjustable from 1 to 10V.

dead load = (250)(LCR)(LCC)

resistor (LCV)(DL)

LCR = load cell resistance (Ω)

LCC = cell capacity (lb)

LCV = load cell voltage (mV/V)

DL = dead load (lb)

via accessible potentiometers.

2: Determine gain = full scale span

3: Find ordering code for which desired gain lies

between minimum and maximum values listed.

4: Use ordering code to complete part number.

Ordering Example:

Signal Range: 0.5 to 5.5V (5V span)

Full scale display: 100.0 psi (1000 counts)

Gain = 1000 counts

Choose P4 because 8 < 200 < 231

To Order, specify DP2000-P4, $285.

Model P is designed for use with OMEGA

cells and strain gage devices.

input span

= 200 counts/V

5V

add

To Determine Ordering Code:

1: Determine full scale span

required (max reading – min reading)

2: Determine gain = full scale span

3: Find ordering code for which

desired gain lies between

minimum and maximum

values listed.

4: Use ordering code to complete

part number.

Ordering Example:

(Part A—Gain Determination)

Input signal range: 0 to 100 mV

Full scale display: 500 psi (500 counts)

Gain = 500 counts

Choose S1 because 4.01 < 5 < 9.9

Ordering Example: DP2000-S4, $360

(Part B—Zero Offset Determination with

10 V Excitation, for Pressure Transducer)

Zero offset = [ ±2.25 mV (from note 1)]

Zero offset = ±11.25 counts

Model S is designed for use with OMEGA

transducers, load cells and strain gage devices.

100 mV

signal span

= 5 counts/mV

x [gain (from part A)]

= [(±2.25 mV) (5 counts/mV)]

®

pressure

D-86

®

pressure transducers, load

$

135 to base price

Field-Scalable

Display!

INSTRUMENTATION

D

Page 9

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...