Omega Products CN9-SW-95 Installation Manual

®

User ’s Guide

http://www.omega.com

e-mail: info@omega.com

CN9-SW-95

CN9-SW-NT

Software Communications Manual

INDEX

Index

KEY TO PROGRAM ICONS

OVERVIEW (inside front cover)

INSTALLATION/CABLING

RS232 1

RS485 2

Termination resistors 3

Bias resistors 4

RS232/RS485 features 5

INSTRUMENT COMMS SETTINGS 6

CONFIGURING INSTRUMENT COMMS SETTINGS 7-8

INSTALLING CN9-SW SOFTWARE 9-10

GETTING STARTED 11

CN9-SWINSTRUMENT SCREENS 12

PC COM PORT SETTINGS 13-14

INSTRUMENT PARAMETER CONFIGURATION

SOFTWARE ALARMS 15

SETPOINT ADJUSTMENT 16

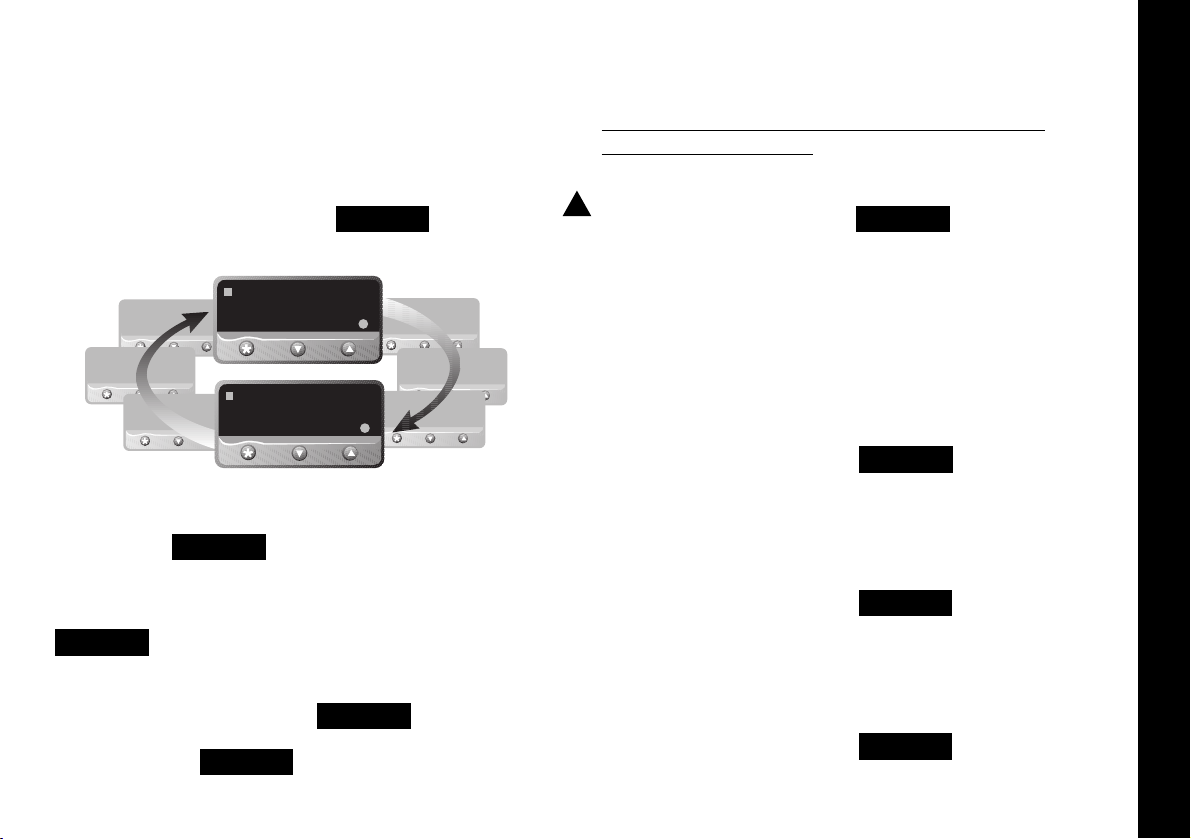

INSTRUMENT CLONING 17

SAVING SETTINGS TO FILE 18

SECURITY LOCKOUTS 19-20

LOGGING AND CHARTING 21-24

LOG ON CHANGE 25-26

EXPORTING LOG FILES 27

TROUBLE SHOOTING 28

GLOSSARY OF TERMS 29-30

WARRANTY 31

Change comms settings &

start monitoring

Create new file

Print chart recorder

Toggle Modbus comms

de-bug window

Add new instrument CN 9500

Add new instrument CN 9300

Arrange instruments in grid

Make instruments larger

Make instruments smaller

Set security locks

Add new chart recorder

Open existing file

Export file in text format

Select units to record

Toggle grid density

Select background colour

Select primary grid colour

Select grid colour

Make chart bigger

Key to Program Icons

Close program

Make chart smaller

Scroll chart up 100%

Scroll chart up 10%

Find chart zero

Scroll chart down 10%

Scroll chart down 100%

Expand verticle scaling range

Decrease verticle scaling range

Increase time/division

Decrease time/division

OVERVIEWKey to Program Icons

CN9-SW is a graphic WINDOWSTMbased software

package designed for PC supervision of Omega Model

CN9500 / CN9400 and Model CN9300 controllers. It offers

the capability of remote adjustment, instrument

configuration, cloning, saving and retrieving instrument

settings to files together with logging and charting in real

time.

Communication uses the MODBUS

fully isolated RS232 or RS485 link depending on the number

of instruments and the transmission distances involved in the

®

protocol via either a

Overview

application.

PC Requirements

To gain the full benefit of CN9-SW software, it is recommend

that the PC is fitted with a Pentium processor and is running

WINDOWS 95 or Windows NT programs. A minimum of 16

Mb RAM is recommended to run the program, together with

enough free hard disc space to meet logging requirements.

This manual assumes that a mouse or other pointing device

will be employed, but alternatively or in an emergency the

standard WINDOWS key convention can be used to operate

or close the program.

Because the controllers are “stand alone” they do not need

PC supervision for their normal function, and will continue to

control the process unaffected by failure of any part of the

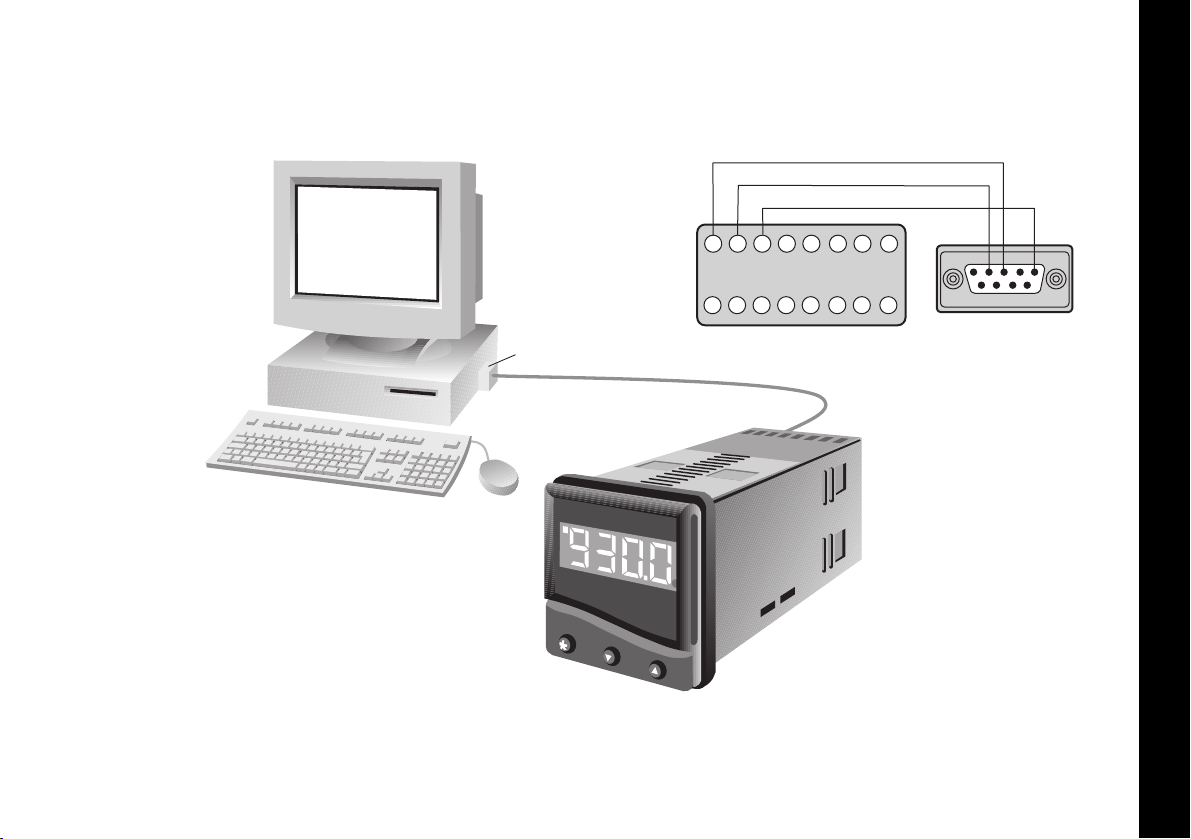

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

CN 9500 / CN 9300

rear terminal

1

5

69

PC Com 1

DB-9 Pin

Tx

Rx

Gnd

COM port

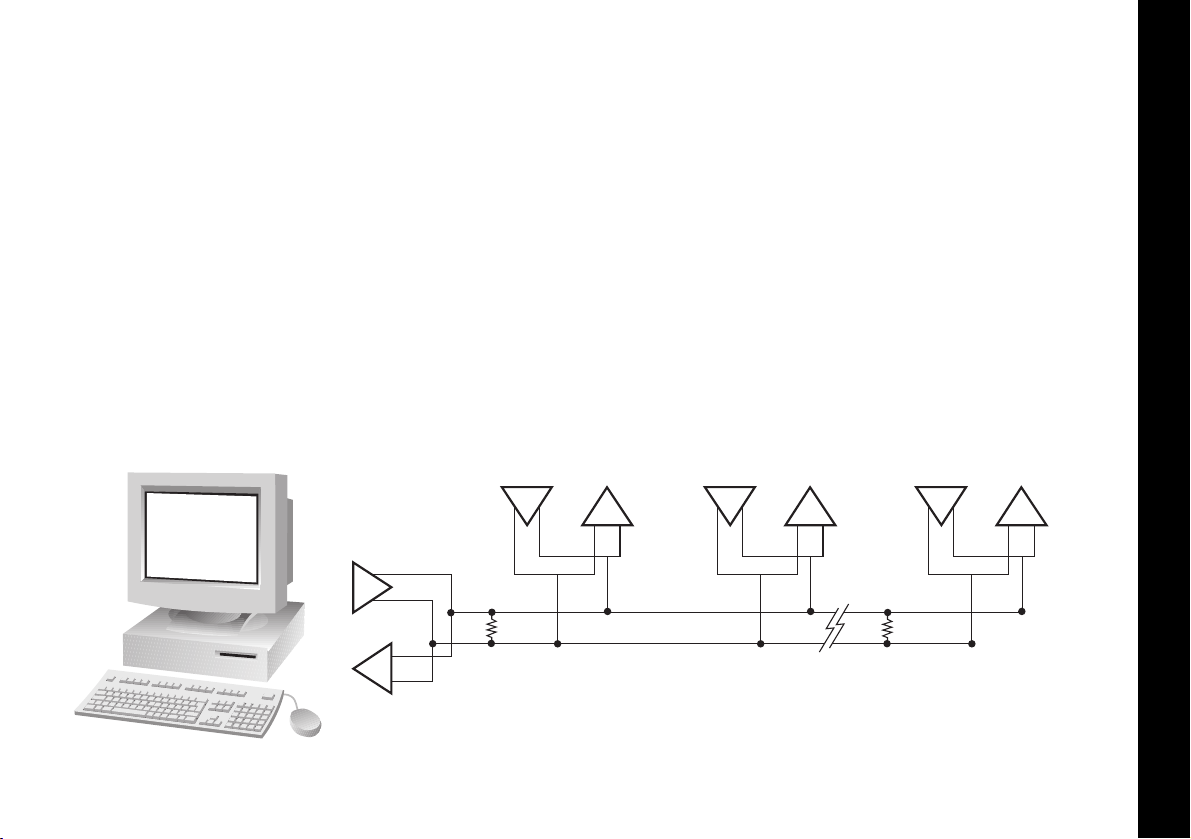

Installation/Cabling

Installation/Cabling

1

RS-232 Is the standard most widely used for interfacing

peripherals to PC's and is designed for serial

communications with single instrument up to a distances

of 15 metres, in a low electrical noise environment.

Connection is via a screened two core cable where the

voltage signal on each line is referenced to the screen

which is grounded. Most PC's have one or two RS-232

compatible ports fitted as standard.

RS232 Connections

PortCN9500 / CN9400 / CN9300

Installation/Cabling

Installation/Cabling

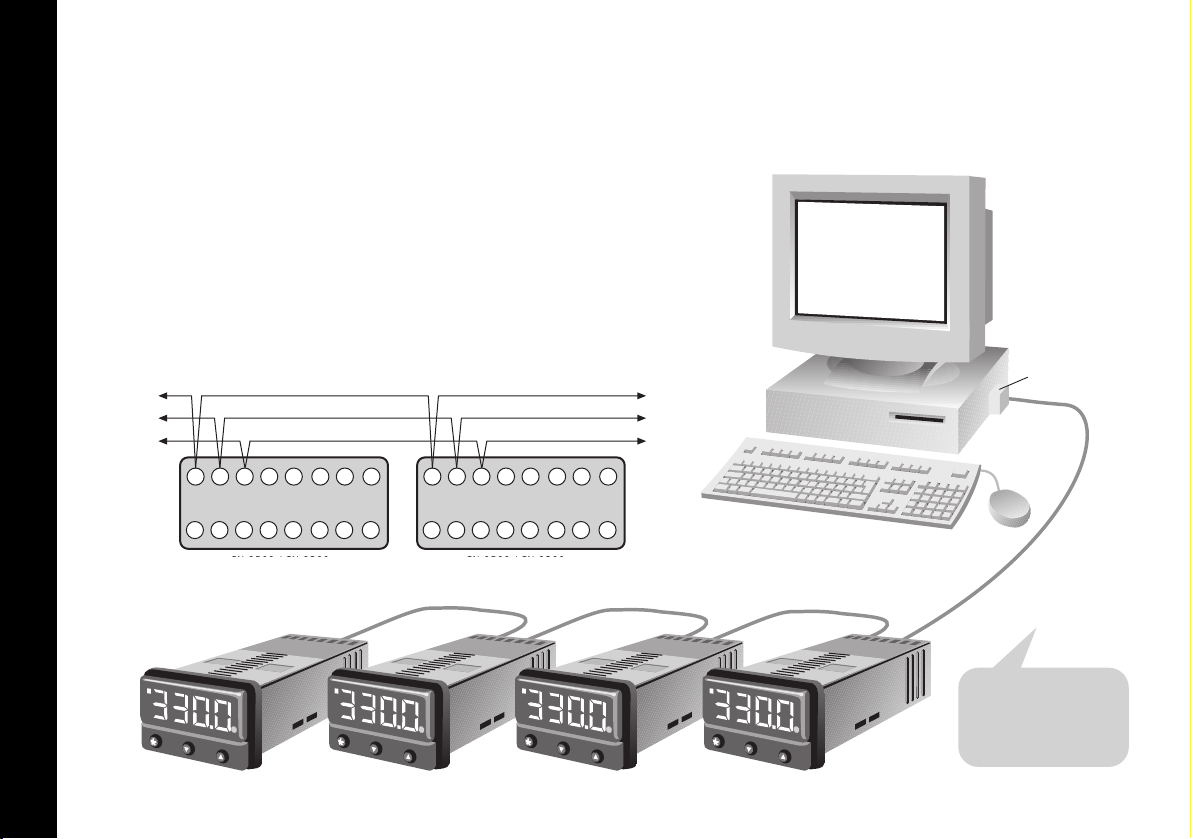

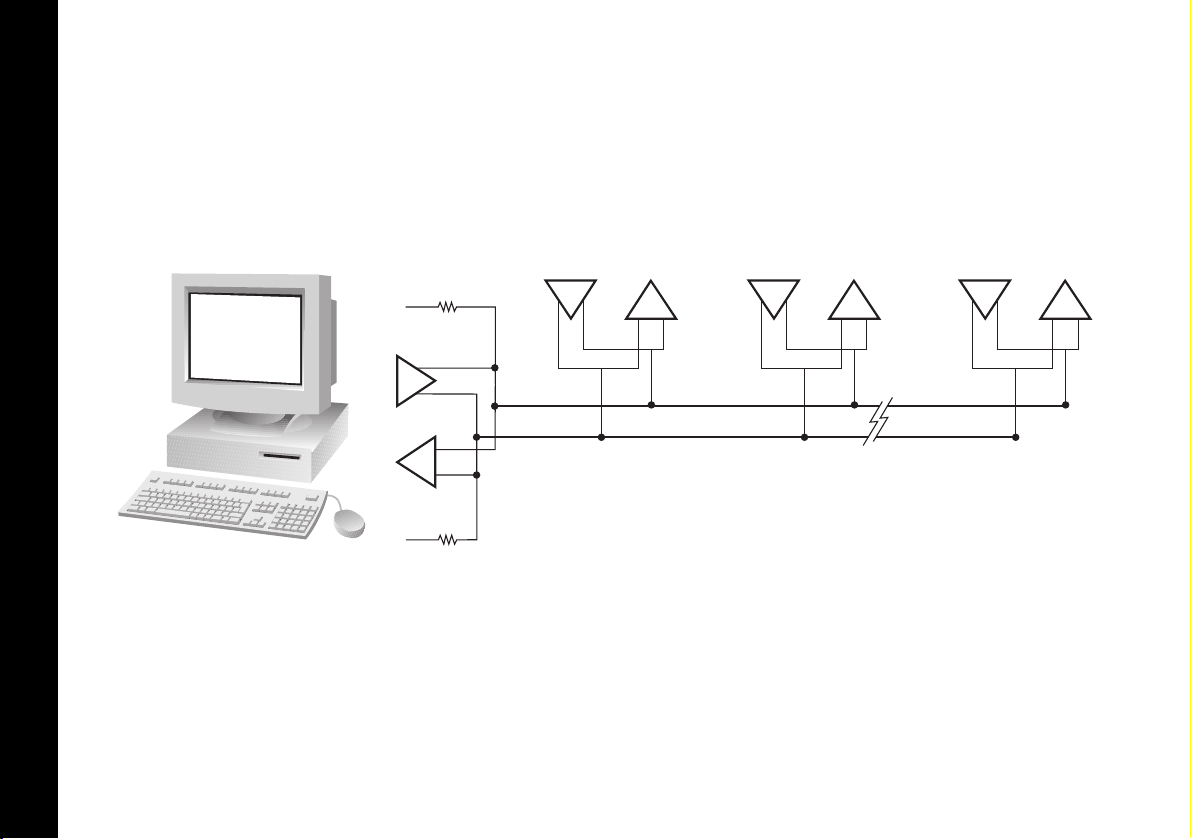

2

Tx Rx (+)

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

To

additional

units

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

CN 9500 / CN 9300

unit 2

Tx Rx (-)

CN 9500 / CN 9300

unit 1

Gnd

Tx Rx (+)

Tx Rx (-)

Gnd

Daisy chained connections

Connections if PC 485 card used

To RS 485 Interface

Either plug in board or

separate converter

Note:

Where separate RS 485

interface is used, refer to

manufacturers instructions for

connection details

To

RS 485

interface

COM port

RS485 Connections

RS-485 Is a half duplex serial communications link and is the

standard most commonly used for industrial applications due

to it's high noise immunity and multi-drop capability. It

enables a PC to communicate with up to 32 instruments

over distances up to 1200 metres, and requires the addition

of an RS-485 interface card, or a separate RS-232/485

converter.

CN9500 / CN9400 / CN9300

unit 2

CN9500 / CN9400 / CN9300

unit 1

Installation/Cabling

Installation/Cabling

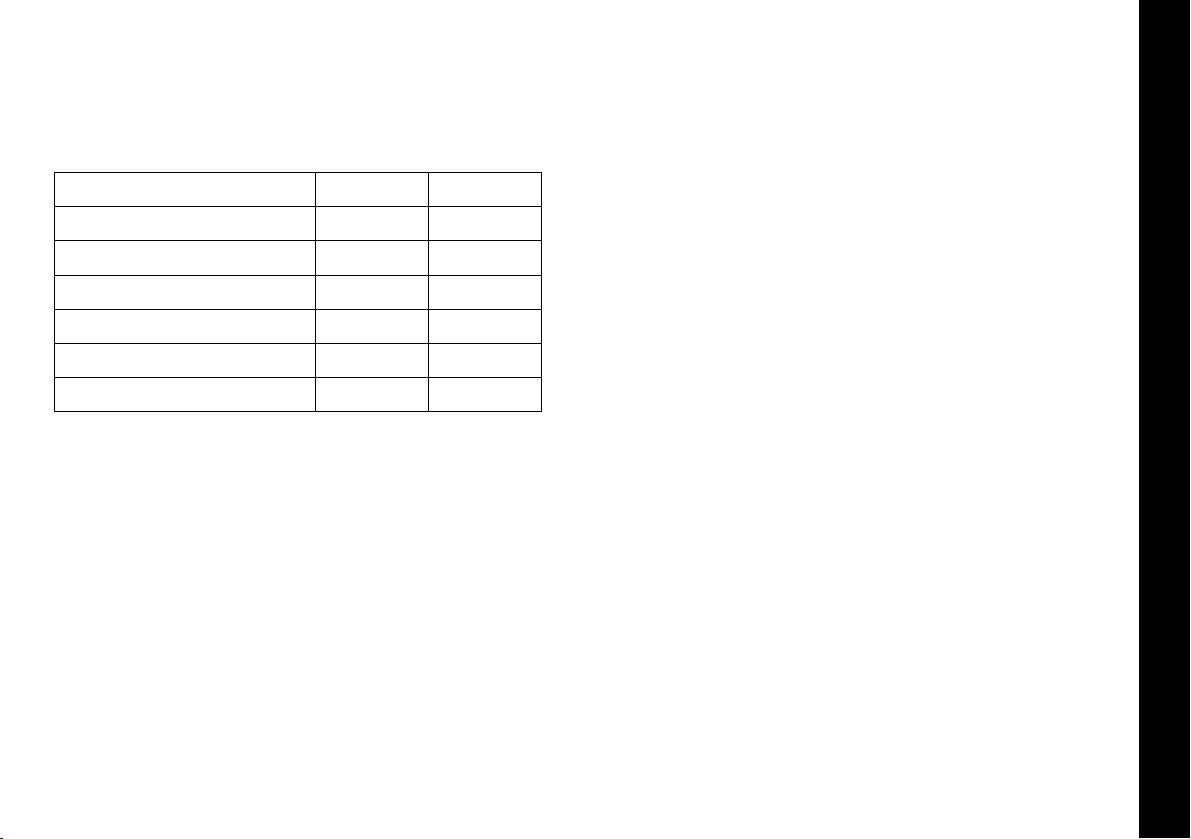

3

Termination resistors

–

120Ω

Tx

Rx

+

+

–

+

–

+

–

Tx

Rx

+

–

+

–

Tx

Rx

+

–

+

–

Tx

Rx

120Ω

Instrument 1 Instrument 2 Instrument ‘N’

Each RS485 interface has specific connection and

termination biasing requirements which will be detailed in

their installation instructions. The general principles are as

follows.

Terminations Because each wire is a transmission line, it

must be properly terminated to prevent reflections. Where

multiple instruments are daisy-chained together, a 120 ohm

terminating resistor should be fitted at the connection to

the PC and to the last instrument in the chain.

Installation/Cabling

Installation/Cabling

4

Bias resistors

–

Tx

Rx

+

+

–

+

–

+

–

Tx

Rx

+

–

+

–

Tx

Rx

+

–

+

–

Tx

Rx

Instrument 1 Instrument 2 Instrument ‘N’

+5V

620Ω

-5V

620Ω

Bias resistors When transmission lines are not transmitting,

they remain in an indeterminate state which can allow

receivers to receive invalid data bits due to electrical noise

on the cable. To prevent this, the the lines should be forced

into a known state by fitting two 620 ohm bias resistors to

one point (node).

If an RS-485 interface card is being fitted to the PC,

separate bias resistors may not be needed because they

may already be fitted to the card. Check the manufacturers

specification.

Installation/Cabling

Installation/Cabling

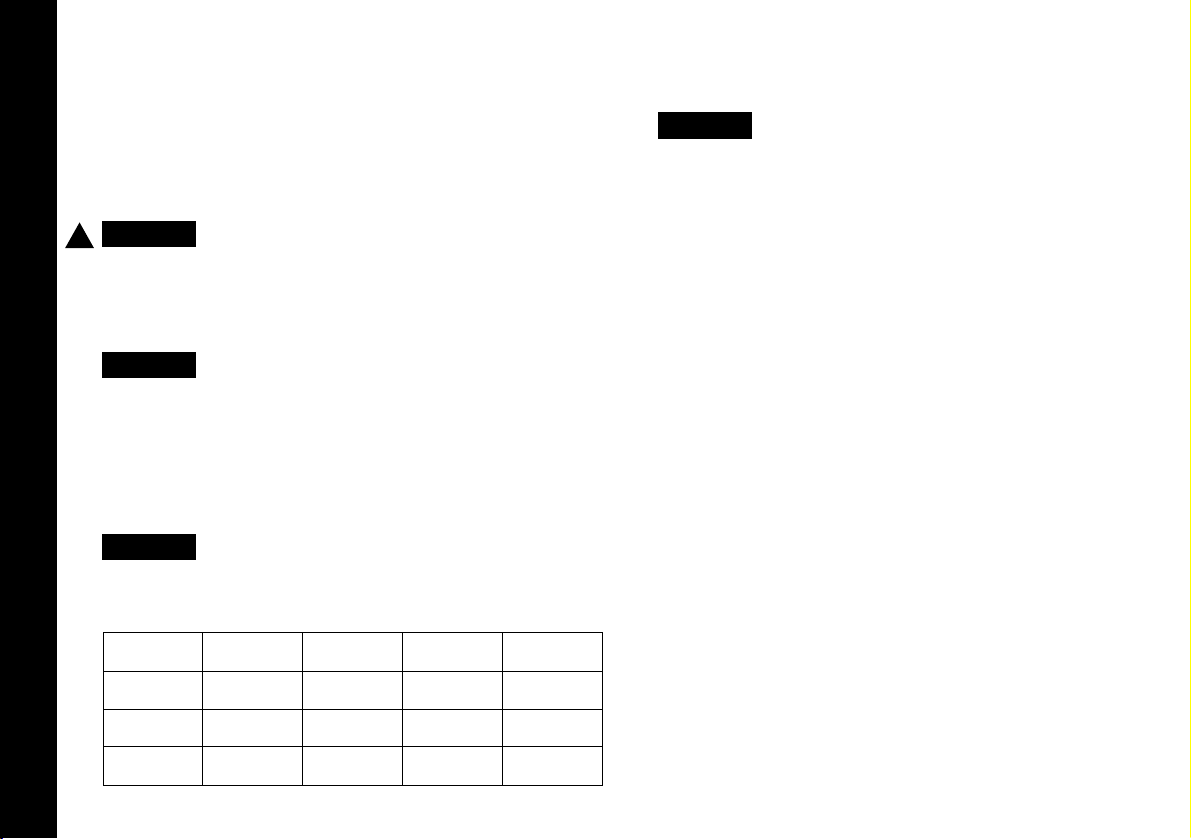

5

For a continually updated list of recommended RS-485

interface cards, contact Omega.

Feature

Type of transmission lines Unbalanced

132

321

15M

19.2Kb/sec 19.2Kb/sec

+/- 25V + 12 to - 7V

1200M

Differential

Maximum number of drivers

Maximum number of receivers

Maximum cable length

Maximum data rate

Maximum CMV

RS232 RS485

Table lists the features of both RS-232 and RS-485

standards.

Cable To ensure data integrity over long transmission

distances, it is recommended that good quality RS-485 cable

is used.

Instrument Comms Settings

Instrument Comms Settings

6

Immediately after power-up, both instrument, and PC comms

settings need to be made compatible before communication

between them is possible. Instrument defaults are shown

below together with the available options.

ADDR (Address) This is a unique

identification number that must be

allocated to each instrument

connected to the network.

Default =0. Options;

1 to 247

BAUD (Baud rate) The setting determines

the serial communication data

transmission rate in bits/sec, and must

match the PC settings

Default =

9600

.

Options;

1200;2400;4800;9600 and 19200

DATA (Data) Sets the transmission format, and

must match the PC settings.

Data Format Table

Settings Start bits

1

1

1

Data bits

8

8

8

Parity

n (none)

e (even)

o (odd)

Stop bits

1

1

1

Default

Option 1

Option 2

DBUG (Debug). Commissioning and

troubleshooting aid. Display shows

when the instrument is transmitting or

receiving data by rapidly flashing the

three horizontal segments of the first

and last digit of the display.

First digit = Tx; last digit = Rx

Default = Off. Options

off; on

Only use dbuG during commissioning or trouble-shooting

because it shares display segments and therefore

corrupts the normal display.

!

Instrument Comms Address

Configuring Instrument Comms Settings

7

This should also be done immediately after power-up, and

is only possible from the instrument front panel.

On power-up the controller will display the self test

sequence followed by Alternating INPT and

nonE

INPT

INPT

INPT

NONE

NONE

NONE

CAL 3300

INPT

NONE

Note: During the following procedure the display will revert

to alternating INPT and

nonE

after 60 seconds of

keying inactivity, but will retain any settings already

completed. Should this occur, or in the event of becoming

"lost" in the program, please start again from the alternating

INPT and

nonE

display

To select Level C (communications settings)

Press ▼ once display alternates LEVL and

5

Press and hold ✱ and press ▼ five times to reach level C

display alternates LEVL and

C

!

Note: Level C is only visible when the comms interface

board is fitted to the unit

To set up Instrument comms address

Press ▲ once display alternates ADDR and

0

Press and hold ✱ and press ▲ to index to chosen address

number

(1 to 247)

Note: In the absence of any conflicting information the

following comms settings should be left as the default

values. (see details on page 6).

To read or adjust comms settings

Baud rate

Press ▲ once display alternates BAUD and

9600

(Default setting)

Press and hold ✱ and use ▲ or ▼ keys to select preferred

value

Data format

Press ▲ once display alternates DATA and

18n1

(Default setting)

Press and hold ✱ and use ▲ or ▼ keys to select preferred

setting (see table page 6)

Debug setting

Press ▲ once display alternates DBUG and

oFF

(Default setting)

Press and hold ✱ and use ▲ key to select

on

Loading...

Loading...