Omcan GR-IT-0373 Operators Manual

Cheese Cutters and Graters

Models GR-IT-0373, 0373-M, 0746, 1119, 0746-M, 1119-M, 1119-B

Items 11401, 21719, 11402, 11403, 11404, 11405, 39884

Instruction Manual

Revised - 01/29/2019

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Table of Contents

Model GR-IT-0373 / Model GR-IT-0373-M / Model GR-IT-0746 / Model GR-IT-1119 Model GR-IT-0746-M / Model GR-IT-1119-M / Model GR-IT-1119-B

Section |

Page |

|

General Information --------------------------------------------------------------------------- |

|

3 - 4 |

Safety and Warranty --------------------------------------------------------------------------- |

|

4 - 7 |

Technical Specifications -------------------------------------------------------------------------- |

|

8 |

Installation and Operation ------------------------------------------------------------------ |

8 |

- 12 |

Maintenance --------------------------------------------------------------------------------- |

12 |

- 14 |

Troubleshooting ----------------------------------------------------------------------------- |

14 |

- 15 |

Parts Breakdown --------------------------------------------------------------------------- |

16 |

- 27 |

Electrical Schematics ---------------------------------------------------------------------- |

28 |

- 32 |

Notes ------------------------------------------------------------------------------------------ |

33 |

- 34 |

Warranty Registration ---------------------------------------------------------------------------- |

|

35 |

2

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or negligent use of this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and not under the influence of any drugs or alcohol, who has been trained in the correct operation of this machine, and is wearing authorized, proper safety clothing. Any modification to the machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the external packaging, open carton to ensure all ordered items are within the box, and there is no concealed damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed), please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be filled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save these instructions for future reference. Also save the original box and packaging for shipping the equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de plus de 18 ans, saine d’esprit, et pas sous l’influence d’une drogue ou d’acohol, qui a été formé pour utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modification de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage n’est visible sur l’emballage externe, ouvrez le carton afin de s’assurer que tous les éléments commandés sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli par un tiers transporteur.

3

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona mayor de 18 años, en su sano juicio y no bajo alguna influencia de droga o alcohol, y que este ha sido entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada. Cualquier modificación a la máquina anúla la garantía y puede causar daños a las personas usando la máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

NORMAL USE, IMPROPER USE, OR NOT CORRECT USE

The machine describe in the present instructions manual for the use is foreseen to be drive from an only operator skilled and prepared on residual risks with competency and in a safe manner.

In its NORMAL USE; the machine can be used only to: 1. Grate tough cheese, bread and biscuits.

4

Safety and Warranty

The machine must not be used IN AN IMPROPER WAY; IN PARTICULAR:

1.It must not be used for domestic uses.

2.It must not be functioned with parameters different from those shown in the technical characteristics table.

3.When used with modalities different from those shown in the manual, the manufacturer declines every responsibility.

4.The user is responsible for the damages resulting from the lack of observance of the conditions described in the manual.

5.Not to tamper or damage intentionally nor remove or hide the labels.

The machine must not be used INCORRECTLY because some damages or injuries could be caused for the operator, in particular:

1.It is dangerous to move the machine when it is connected to the electric feeding.

2.It is dangerous to pull the power cable or the machine to disconnect the feeding plug.

3.It is dangerous to put weights on the machine or on the power cable.

4.It is dangerous to put the power cable on sharp or flammable objects.

5.It is dangerous to use the machine with a damaged power cable or with the control devices.

6.It is dangerous to leave the machine off with the power cable still connected.

7.It is dangerous to leave the loaded machine unsupervised.

8.It is dangerous to insert any type of object inside the motor ventilation cap.

9.It is dangerous to use flammable substances, corrosive or harmful cleaning agents.

10.It is dangerous to put the machine on top of objects.

11.It is dangerous to insert any type of object under the machine base or place clothes or other things between the machine feet and the working ground.

12.It is dangerous to plunge the machine in water or in other liquids.

13.It is dangerous that non-authorized personnel use the machine and with clothes different from that showed for the use.

14.It is dangerous to introduce the grinding neck and the grater mouth with products or objects having characteristics different from those showed in normal use, such as bones, frozen meat, non-food products and clothing.

15.It is dangerous to introduce in the grated product exit zone any object such as knives, blades, etc.

16.It is dangerous to function with the protection shelters and fixes not blocked or correctly removed.

17.It is dangerous to partially remove the protection pieces and danger signals.

18.It is dangerous to function without all the precautions about the residual risks adopted on behalf of the user.

19.It is dangerous to smoke or use free flame devices and manipulate incandescent materials, unless some suitable safety measures are adopted.

However, the user is responsible for damages resulting from not observing the specified normal use and conditions. For possible doubts you can enquire at the Authorized Assistance Center.

Failure to follow proper safety instructions can be dangerous and can cause damage or injury.

Except where differently specified, the personnel who performs the installation interventions, connection, maintenance, reassembly and reuse, damages or breakdowns, demolition and dismantling must be a skilled personnel qualified in safety matter and educated on the residual risks. The personnel must be competent and perform in a safe matter with all other maintenance employees.

5

Safety and Warranty

ENVIRONMENTS, WORKING AND PASSING PLACES

The work environment must answer to the directive 89/654/CEE requirements. In the working area no foreign objects can be present. The employer, in the directive of 89/391/CEE, must follow the measures promoting the safety and health of the workers during the work. They must eliminate or reduce the residual risks as foreseen in the manual.

WARNINGS ON THE RESIDUAL RISKS

RESIDUAL RISK DUE TO THE FIXED PROTECTIONS REMOVAL, INTERVENTIONS ON BROKEN/WORN PARTS

The operator must not try to open or remove a protection measure or tamper a safety device.

In the phase of maintenance and cleaning, and during all further manual operations that happens to introduce the hands or other body parts in the machine’s dangerous areas, a residual risk remains due above all to:

1.Hitting with machine manufacturing parts.

2.Grazing and/or abrasion with machine rough parts.

3.Injury from the sharpened parts.

4.Lacerations from a tool having sharpened parts.

The operator and maintenance personnel must be skilled for the intervention connected to the manual operations with open protections, must be trained on joined consequent risks and must be authorized from a responsible person.

PROTECTION DEVICES ON THE MACHINE

The machine protections and safety devices must not be removed. If they must be removed for extraordinary maintenance requirements, some measures will have to be immediately adopted.

To put in evidence and to reduce amount of danger. The reassembling aspect of the protection or safety devices must happen as soon as the extraordinary circumstance has completed.

The machine transmission parts are completely isolated by means of fixed protections which do not allow access improper objects. For all safety functions including the control and check systems, well-tested components and safety principles have been used.

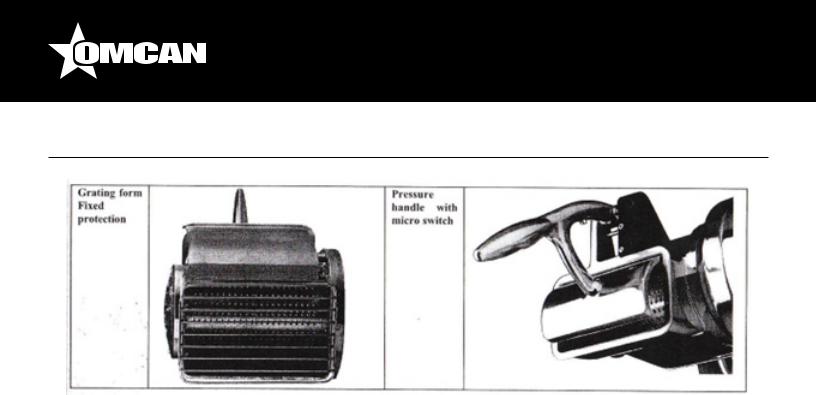

Grater group:

1.Taking into account the machine’s modality and use, the moving elements are not isolated from the protections and safety devices.

2.On the handle and pressure group, a micro switch is placed, which stops the grater roll rotation so it is possible to access the grater mouth.

3.Fingers are prevented from accessing the grater roll as there is a fixed protection piece to stop this.

6

Safety and Warranty

1 YEAR PARTS AND LABOUR BENCH WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule a drop off to either an Omcan authorized service depot in the area, or to an Omcan Service warehouse to repair the equipment.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not improper use.

Please see https://omcan.com/disclaimer for complete info.

WARNING:

The packaging components are classified as normal solid urban waste and can therefore be disposed of without difficulty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

7

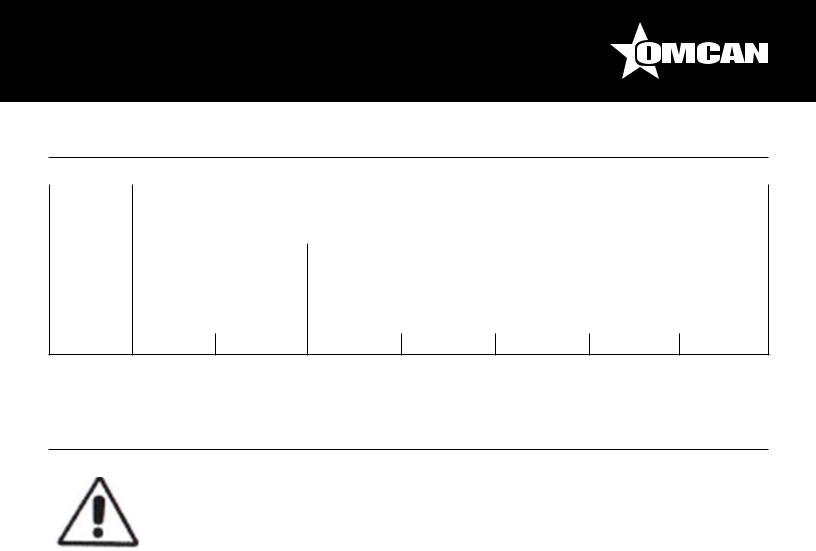

Technical Specifications

Model |

GR-IT-0373 |

GR-IT-0373-M |

GR-IT-0746 |

|

GR-IT-1119 |

|

GR-IT-0746-M |

|

GR-IT-1119-M |

GR-IT-1119-B |

||

HP |

|

0.5 |

1 |

|

1.5 |

|

1 |

|

|

1.5 |

||

Electrical |

|

|

|

|

|

110V/60/1 |

|

|

|

|

|

|

Microswitch |

No |

|

Yes |

No |

|

|

|

|

Yes |

|

|

|

Weight |

16 lbs. / 7.3 kgs. |

36 lbs. / |

|

42 lbs. / |

|

36 lbs. / |

|

44 lbs. / 20 kgs. |

||||

16 kgs. |

|

19 kgs. |

|

16 kgs. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||

Dimensions |

10.35” x 11.4” x 11.75” |

|

|

10.75” x 15.4” x 14.8” |

|

|

||||||

260 x 290 x 300mm |

|

|

|

270 x 390 x 276mm |

|

|

|

|||||

|

|

|

|

|

|

|

||||||

Item # |

11401 |

21719 |

11402 |

|

11403 |

11404 |

|

11405 |

*39884 |

|||

*Brake motor included.

Installation and Operation

The machine management is allowed only by authorized personnel and those of a sufficient technical experience.

Before switching on the machine perform the following operations:

•Read with attention the technical documentation.

•Know what protections and emergency devices are available on the machine, their location and functioning.

The non-authorized use of commercial parts and accessories altering the protections and safety devices can cause some malfunctions and danger for the operators. The operator must have received adequate training.

WORKING POSITIONS AND OPERATORS TASKS

As described in the instructions manual, the machine is designed to be drive by an operator skilled and informed on the residual risks with competency and in a safe manner.

The normal working zone of the operator is:

1.The machine’s frontal zone near the grater mouth (defined loading zone) in normal conditions of functioning is the loading operations of the food product, with the fixed covers closed and blocked.

2.The machine’s front, the product dispenser in normal conditions of functioning is the location for withdrawal operations of the food product stored in the collect container, with the fixed covers in closed and blocked position.

TRANSPORTATION, HANDLING AND STORING

All transportation and handling operations must be performed by informed and trained personnel and must have read and understood the safety instructions shown in this manual.

8

Installation and Operation

1.Perform the machine handling and transportation always when it is off.

2.Verify that lifting means are use, it is able to support the loading weight and overall dimensions in safety conditions and that are approved and subjected to a regular maintenance.

3.Adopt all necessary measures to assure the maximum stability in relation to their mass.

4.Avoid making the machine suffer shaking or accidental collisions during the moving and the loading.

5.Perform the handling with continual movements, without pulls or repeated impulses.

PACKING REMOVAL – OPENING MODALITY

PACKING DESCRIPTION – HOW TO GET RID OF THE PACKING MATERIAL

The machines are package so that the liquids inside and organic matters are not present. There is a polyethylene cover around the machine which is then inserted in a cardboard box of adequate size. The empty spaces within the box are occupied with fill material.

Do not waste the packaging, but store it for possible transportation or locate a recycling agency for disposal.

It is an employer’s obligation to be acquainted of the laws in its own country and observe these legislations. It is forbidden and liable to fines to leave the machine and electric equipment in the environment.

PREPARATION PRELIMINARY OPERATIONS

STABILITY

The machine stability is designed so that in normal functioning conditions, taking into account the climatic conditions, the machine can be used without reversal risk, fall or inopportune movement. Taking into account the conformation and the position of the machine, it will function without fastening it to the working ground.

GRATER ROLL ROTATION

The operations indicated must be performed by the maintenance person (skilled personnel in the electric maintenance field of industrial machinery). For machines fed with three phase voltage (3 PE AC 400V 50Hz), slacken lightly the blockage wheel to not have a strong pressure on the drilled plate for the cutting knife. When turning on, verify the Archimedean screw / grater roll rotates counterclockwise. If there is clockwise rotation, switch off the machine, disconnect the plug, disassemble it, disconnects the two phase conductions and invert their position.

FUNCTIONING DESCRIPTION

The control devices are designed and manufactured to handle normal service stresses and strains. The control devices are clearly visible, locatable and marked distinctly. The main control devices are shown:

9

Installation and Operation

TYPE / COLOUR |

REFERENCE / DESCRIPTION |

Button / Black |

“0” / button for the machine stop control |

Button / White |

“1” / button for the machine start control |

STARTING

The machine only starts with a voluntary action on the control device: white button “1” for the starting control.

STOP

For the stop control push the black button “0”. In case of momentary or extended stop, all food products must be removed to get the machine to function again.

FUNCTIONING SAFETY

If the machine is under stress or is exposed to long functioning times or overload, the thermal protection function will stop the machine. In this case, wait until it is completely cooled before proceeding to the starting function.

VOLTAGE LACKING

In the case of the electric feeding breaking off of the machine and being disconnected, the machine will only restarted after the electric feeding is back or there is re-connection to the power source.

STARTING

The machine only starts with a voluntary action on the control device: white button “1” for the starting control.

STOP

For the stop control push the black button “0”. In case of momentary or extended stop, all food products must be removed to get the machine to function again.

FUNCTIONING SAFETY

If the machine is under stress or is exposed to long functioning times or overload, the thermal protection function will stop the machine. In this case, wait until it is completely cooled before proceeding to the starting function.

VOLTAGE LACKING

In the case of the electric feeding breaking of if the machine is disconnected, the machine will only be restarted after the electric feeding is back or there is re-connection to the power source.

PRESSURE OPENING - ONLY FOR UNITS WITH MICRO SWITCH

Lifting the handle of the grater mouth stops the machine immediately because of the safety micro switch function. The machine can be restarted by lowering the handle and closing the mouth of the machine and pressing the on switch again.

10

Installation and Operation

CONTROLS AND VERIFICATIONS BEFORE STARTING

VERIFICATION / CONTROL |

MODALITY AND CHECKS |

Check that: |

Visually check the indicated parts, check if |

• Extraneous objects aren’t on the machine, inside the |

objects or extraneous objects around the |

grater mouth and in dispensing zone of the grated |

machine. Make sure there is not food product left |

product. |

over. In case of its presence, remove them. |

Check the cleaning: |

Visually check all parts and surfaces to verify |

• Of the grater mouth, of the pressure and grater roll. |

their cleaning. Disassemble to check internal |

• The external surface of the machine. |

parts. In case of mold or other types of dirtiness, |

|

follow the cleaning procedures indicated in |

|

chapter 5. |

Check the integrity: |

All fixed protections must perform their function. |

• Of the fixed protections. |

Verify the integrity of the external surface. The |

• Of the machine body, grater mouth, pressure and the |

parts must be replaced at first sight of erosion or |

grater roll. |

breaking. |

Check the functionality: |

All devices must perform desired function. The |

• Of control system parts / control about the safety. |

actuators and all parts must be changed at first |

• Of the control devices. |

sight of erosion or breaking. |

Check the presence: |

If there are strange noises, for example a seizing |

• Of strange noises. |

of mechanical break, stop immediately and |

• Of oil trails on the ground and on the Archimedean |

contact maintenance personnel. Check during |

screw. |

work and at the end of every use. Check if there |

|

are oil trails present. If there are any fluid drops, |

|

stop immediately and contact maintenance |

|

personnel. |

Possible changes in parts must happen with manufacturer original parts or at least of quality, safety and equivalent characteristics. For analysis, contact the Authorized Assistance Center.

PUT IN FUNCTION

The machine operator can put in function the machine if:

1.Positive check of preliminary operations.

2.Positive check of electric feeding.

3.Connection in power socket.

4.For the functioning of the GRATER GROUP.

a.Positive check of the direction of grater roll rotation.

b.Positive check result and verifications.

c.Concluded all checks and verified all safety instruments.

d.Place a gathering at the basin of the machine in correspondence of the food exit zone.

e.Activate the machine using the control device, turn to “1”.

f.Introduce manually the food product within the grater mouth and drive it towards the grater roll by lowering the pressure roll.

g.At the end of the food product introduction, or when there is no room left in the basin, stop the machine

11

Loading...

Loading...