Page 1

Scanned on 11 March 2010 by Paul Henry Golding (paul@paulgolding.id.au)

from original supplied by Windsor Davies.

This copy may be distributed freely, but must not be sold.

OLYMPUS

UNIVERSAL

MICROSCOPE

MODEL

VANOX

REPAIR

MANUAL

OLYMPUS

Page 2

TO OLYMPUS MICROSCOPE SERVICING PERSONNEL

Model

This repair manual describes repairing procedures in principle

microscope.

The

must

Therefore,

long

The

may

The

variationofinterpupillary

in this manual

tools

In

microscopist

For cleaning lenses, a

should

Requisites

1.

2. Never fail

3.

4.

5. Make repairs

VANOX

focusing mechanismofthe microscopeislargely

assure

time,

however,itwill

special

notbedisassembledorparts maybedamaged.

observation

for

adjustment are

the

diescriptions contained in this manual,

be

madeto"HowtoClean

for

Firstofall, ascertain

a)

Find

Prior

b)

efficient

After

completing

microscope

Be

careful

specified

(AH)

robbustness,

the

focusing mechanism

tools

tubeisequipped

after

sitting

repairs:

to

check

out

what

to

repair,

way.

to

not

for

purpose.

promptly

is

listed in this manual must

disassemblyofthe prism. Do

not

in the observing position through the microscope, unless other wise specified.

liquid

what

the

parts

think

the

make sure no defect should be

to

deform

designed

durability

require lubrication and repairtoprotectitfrom

distance between binocular tubes) and mustbeadjusted elaboratelyasdescribed

availableatthe

entire

are

repair, check the functionsofnot

and

as

a versatile research microscope equipped

and accuracy compatible

can

rarely

be

with

a constant tube length adjustment

site.

"right"

mixture

partsofthe microscope the userorownerofwhich wishes youtorepair.

defective and

of

repair parts during the assembly; makeitpracticetouse

accu

of

alcohol (3) and ether (7) should

the

Microscope" whichisavailable upon separate request.

functionofthe microscope before you commence its repair.

how

the best possible order

rately.

different

be

troubled in practical

employed

not

attempt

and

"left"

much they are damaged.

of

left

unremedied.

with

various accessories.

for

its standard configurationasa biological

from

thatofBHorBH2 since the

with

heavy accessoriestobe

use.

Afterithas

dust,

humidity,

for

disassembling the instrument; otherwise

(to

automatically compensate

disassemblyofthe prism when the special

are

defined in the directionasseenbythe

be

used.

For

disassembling the defective parts in a most

only

the re-assembled parts

attachedtoit.

been

etc.

details, reference

but

also the entire

tools and jigs

former

used

for

a

it

for

Page 3

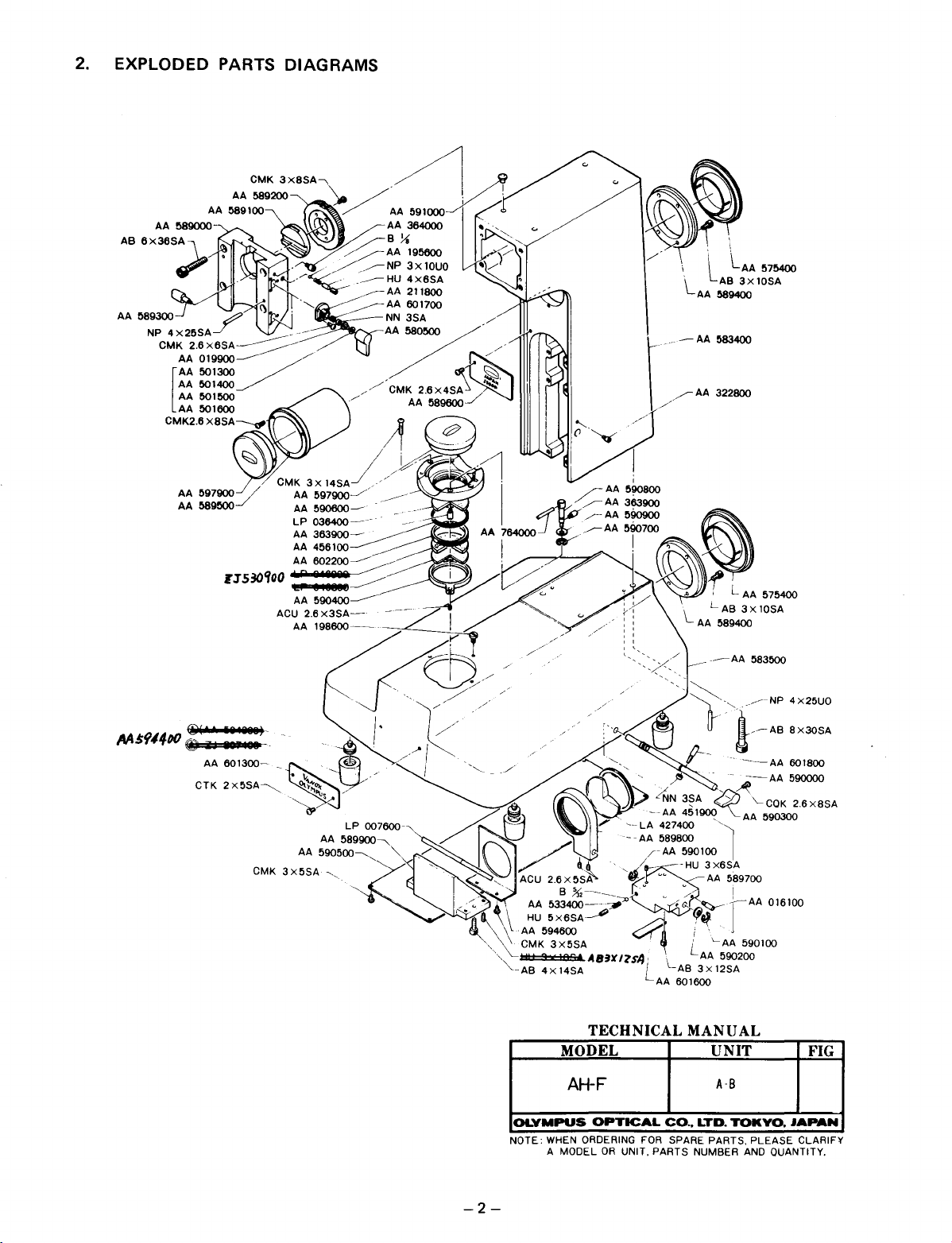

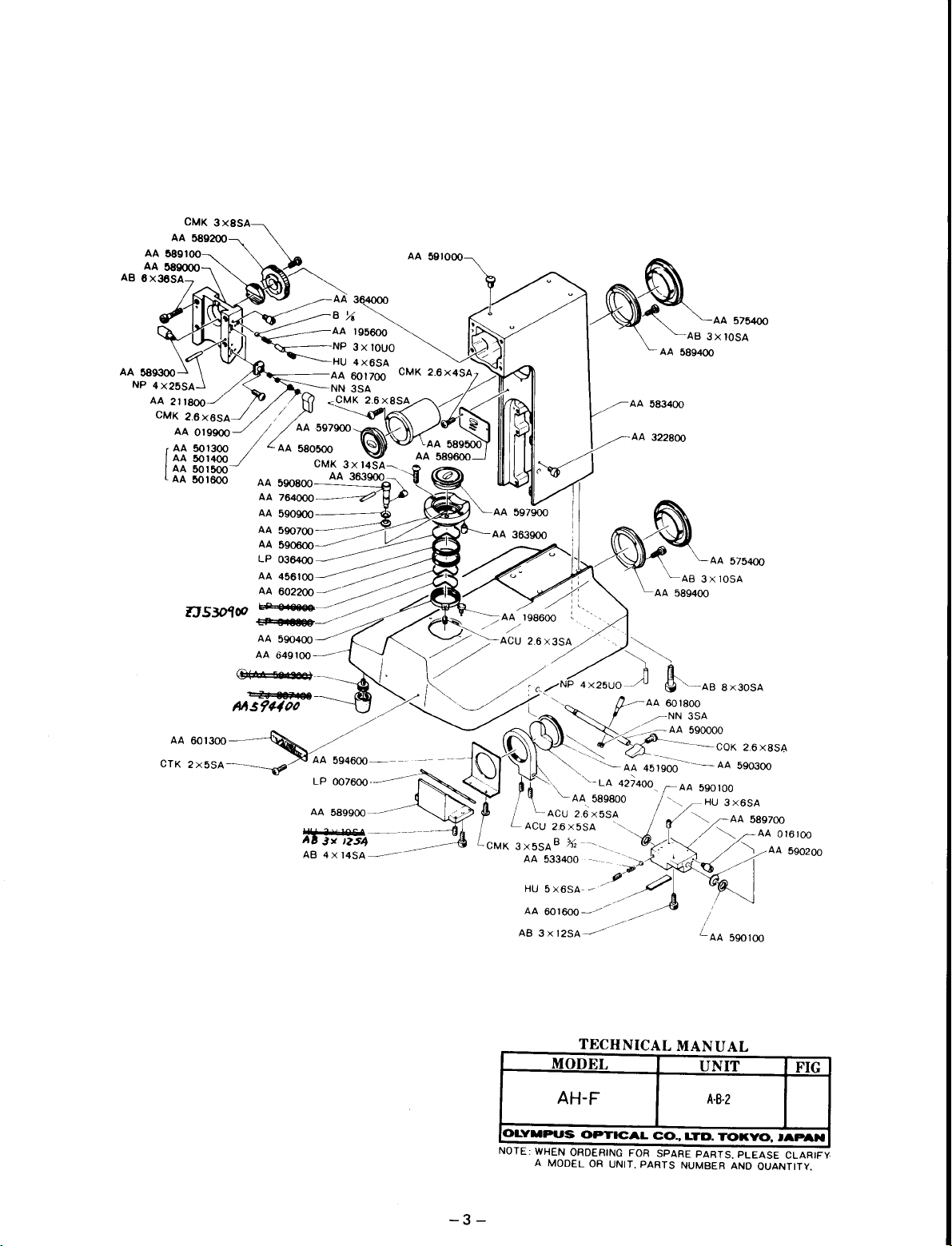

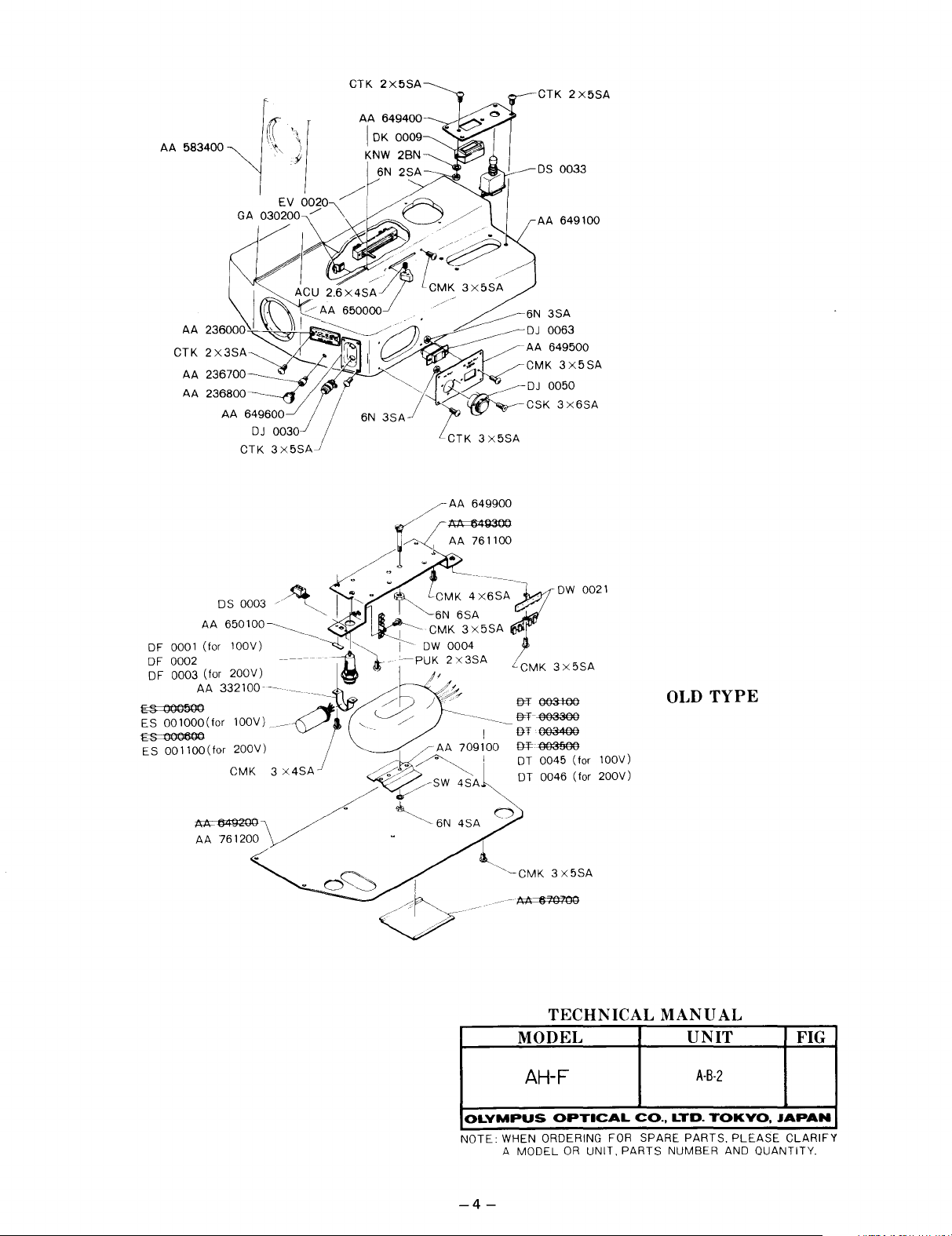

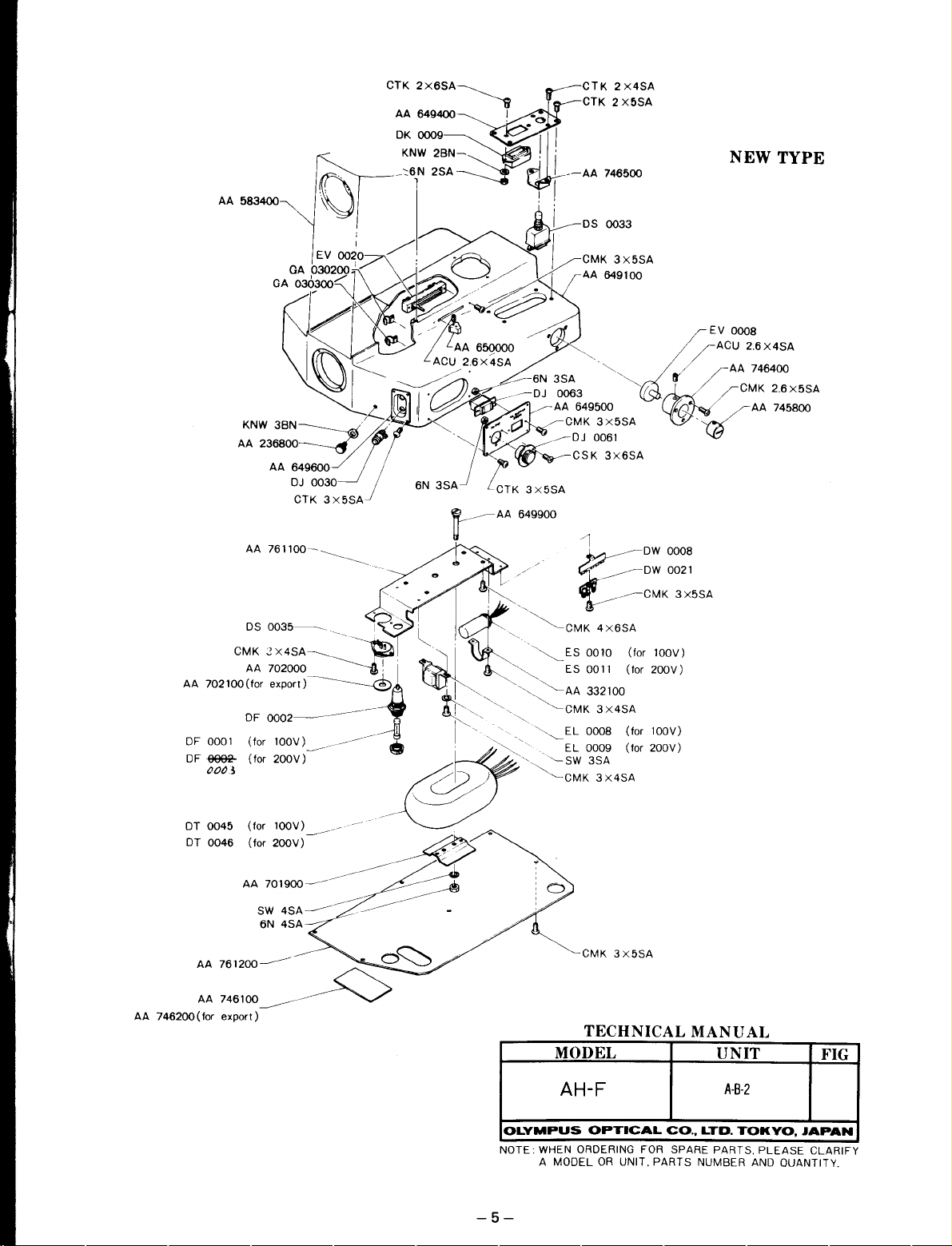

CONTENTS

1.

REPAI R TOOLS

2.

EXPLODED PARTS

3. DISASSEMBLING AND REASSEMBLING PROCEDURES

FOR A-F (AH-FRAME) 16

AND

GREASES 1

DIAGRAMS

2

4. DISASSEMBLING PROCEDURES,

OPTICAL

5. DISASSEMBLING

FOR A-SV (STAGE) 54

6. DISASSEMBLING

FOR A-CH (CONDENSER HOLDER) 70

7. DISASSEMBLING, REASSEMBLING AND ADJUSTING

PROCEDURES FOR

ALIGNMENT

AND

AND

A-AL

OF A-Bi (BINOCULAR TUBE)

REASSEMBLING PROCEDURES

REASSEMBLING PROCEDURES

(AUXI

AND

L1ARY LENS) 78

FOCUSING

AND

35

Page 4

1.

REPAI R TOOLS

1-1

Regular Tools

AND

GREASES

1-2

OT0011

OT0015

OT0016

OT0018

OT0021

OT0023

OT0035

OT0061

OT0079

OT0216

OT1028

OT1131

OT1141

OT1143

OT1144

Greases

OT2008

OT2010

OT2022

OT2024

Set

of

screwdrivers(6pes.)

Phillips screwdriver (medium

Phillips screwdriver (large size)

Screwdriver (large

size)

Adjustable spanner (rounded)

Handleofsmall

size

Phillips screwdriver, using OT1141

Tweezers (special made)

Sharp

point

pliers (size 170 mm)

Pliers (size 170 mm)

SetofAlien

Araldite

Shellac (20

Phillips screwdriver

Tension

Tension

Grease

Grease

Grease

Grease

wrenches (8 pes.)

(adhesive)

g)

(adhesive)

gauge

(200

gauge

(500

(20

g)

(20

g)

(20

g)

(20

g)

tip,

g)

g)

using

size)

OT0023

1-3

Special Tools

C-1

C-15

KKAA0044

KKAA

KKAA1466

KKAA5853

KC-2002

KC-2003

KC-2005

KC-2023

KNOO05

KN0029

SKNOO01

A-KCOO05

A-KCOO08

A-KC0010

A-KC0023

1-4

Others

FK2.5X

35WF10X

1456

10X

eyepiece

with

cross hairs

Focusing magnifier (PM-FT-36)

Pin face wrench

Pin face wrench (2

Pin face wrench (2

pes.

pes.

are

are

needed)

needed)

Pin face wrench

for

Taper reamer

Holder

Cutter

Jig

for

for

for

washerofVanox

holding

Vanox

taper reamer

pinionofVanox

Centering objective

Special eyepiece

Gauge

for

Centering plate

Jig

for

photo

Standard tube

Jig

for

prism alignment

for

checking

for

stage

checking

tube alignment

for

Vanox

checking

tilt

for

A-Si

A-AL

Photo eyepiece

Finder eyepiece

exit

pupil

-1-

Page 5

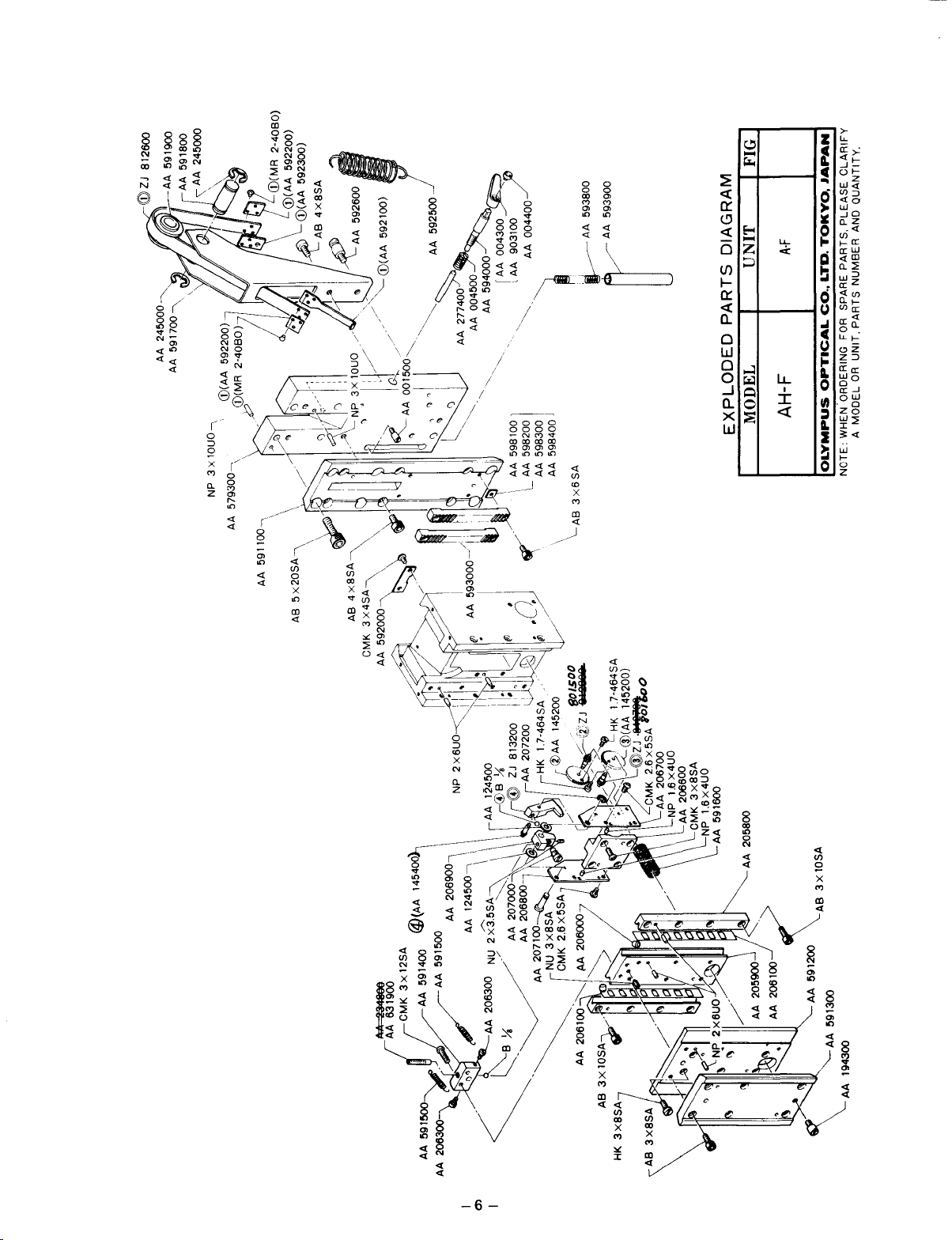

2. EXPLODED PARTS

CMK

AA

589~\.

~

'''''L..

f1'

4X25SAJ

AA 589100

.

b:?'

C\

C\

AA

AB

6x36SA

AA 589300

NP

DIAGRAMS

3x8SA,

'

'./

/'

/,/

~B

~AA

,/

~AA

/

./~~:::=~~

~

,

~"'~

'-.

.

..____AA

~Y1

AA

591000 I

364000

~

195600

~~~~~O

211800

AA 601700

NN

3SA

AA

580~'

I !

~

_,

,

-./),

/'

<-

"-"

./-

~

......

'~

111

~~

./

i l

-AA

lAA

AB

589400

583400

575400

3Xl0SA

'l

AA

CM[1:'h~E=:=~/

AA

5014OO~

AA 501500

AA

501600 .

CMK2.6X8SA~

CMK

3XI4SA//~,(l

AA~J/

AA

589500../

I':rS3(hOO

AA~~~

AA

LP

AA

AA

AA

Q

IR?'????-------

LP

AA

ACU

2.6X3SA-

..

590600~

036400-

363900-

456100 I I

602200------

818888~

590400

,.-/

/~

/'

,/

CMK

~

-

_______

--/

/d/

2.6X4SA

AA

589600

~

J::/

§'

J

I

~~AA

AA 764000 -----AA590700

I

J-~>

Ms914/JO

@(t,IS

~

ild

AA

CTK

lSU)

UTlU

.

601300-

2X5SA-----.....

~AA~

~

AA

3~900

590900

!

--AA

583500

-2-

TECHNICAL

MODEL

AH-F

OLYMPUS

NOTE:

OPTICAL

WHEN

ORDERING

A MODELORUNIT. PARTS NUMBER

FOR

MANU

CO,.

SPARE PARTS. PLEASE CLARIF'r'

LTD,

UNIT

A-S

TOKYO.

AL

AND

FIG

JAPAN

OUANTlTY.

Page 6

~~

AA 583400

AA 322800

-3-

MODEL

AH-F

OLYMPUS

WHEN ORDERING

NOTE: A MODEL

TECHNICAL

PTICAL

0

OR

OR

~

PARTS NUMBER

UNI

.

CO.,

SPARE

MA~~I~L

A·S·2

TOKYO,

LTD.

PARTSA~~

JAPAN

EASE CLARIFY.

QUANTITY.

Page 7

AA

583400

AA

236700

AA

236800

(f

GA

030200./'\

/

.

I

AA 649600

DJ

CTK

3x5SA

\~"

!

.\·~I

'f

EV

0020

/

"4t~

A~~

A~6

~

40S0;OO~

0030

- I

/

6N

~

"

3SA

CMK

3 X

5SA

• AA

.....

;;)~CMK

'~DJ

• CSK

CTK 3

x5SA

OS

AA

6N

DJ

CTK 2

0033

649100

3SA

0063

649500

3x5SA

0050

3x6SA

x5SA

OS 0003

650100~

AA

OF

0001 (for 100V) .

OF

0002

OF

0003A~or3~~~0~__

~-oooooo

ES

001000(for

ttS=000600

ES

001100(for

AA-~

AA

761200/

/~~

------

100V)_~

200V)

CMK 3

x4SA

~

_~

AJ--

/

I .

·0

~

~~

I@

.

i

~~,

.t-

~

~.AA

/

/.

~~:s:x~~~-r-'"

I CMK

I~'

DW

PUK

I

//

~~

'::'

/VSW

~6N

3x5

0004

2x3SA

7091100

~

4SA

4SA

SA

-----

DW

CMK

3x5SA

:-=

Of

•

00i5400

l)fc.~

DT

0045

DT 0046 (for

MODEL

(for 100V)

TECHNICAL

0021

200V)

OLD

MANU

UNIT

TYPE

AL

FIG

AH-F

OLYMPUS

NOTE:

WHEN ORDERING FOR SPARE

A MODELORUNIT.

-4-

OPTICAL

A·B·2

CO.,

LTD.

TOKYO,

PARTS

PARTS.

NUMBER AND QUANTITY.

PLEASE

JAPAN

CLARIFY

Page 8

AA

583400~

AA

761100-~

NEW

TYPE

6N

3SA

ft------

AA

649900

U /l

•

~

_

(I"

•

"""

~

/

,

~CMK

f~=DW

~DW

----CMK3x5SA

4x6SA

0008

0021

OF

0001

DFeee2-

0003

DT

0045

DT

0046

(for

(for

100V)

200V)

._____'-

~

I \

~

I

tl,=",'~,'~~~K33:~~~A

I "

-,'

'~

'"

""

~

ES

0010

ES 0011 (tor

",,-

EL

0008 (for 100V)

EL

0009

"'-SW

3SA

~CMK

CMK

TECHNICAL

MODEL

AH-F

3X4SA

3x5SA

(tor

(for

100V)

200V)

200V)

MANUAL

UNIT

A-B-2

FIG

-5-

OLYMPUS

NOTE:

WHEN ORDERING FOR SPARE PARTS.

A MODELORUNIT.

OPTICAL

PARTS

CO.•LTD.

TOKYO.

NUMBER AND QUANTITY.

PLEASE

JAPAN

CLARIFY

Page 9

591900

-AA

iQj)ZJ 812600

245000-"

AA

245000

591800

AA

\,AA

591700\

AA

\

lOUO~,

3x

NP

579300\

AA

\

591100,

AA

\

5X20SA\

AB

)l>

,,,,,,,,,J"

594000

004500

AA

AA

903100-/

004300

: AA

IAA

",

AA

')

AA 592500

'-

2774~'

-'~

AA

593800

~AA

• I

DIAGRAM

rAU'OW

PARTS

EXPLODED

~

I UNIT

AH-F

MODEL

CLARIFY

QUANTITY,

yO,JAPAN

PLEASE

AND

SPARE PARTS,

FOR

G

UNIT, PARTS NUMBER

OR

A MODEL

AA 205800

I

I

O'l

Page 10

145600

AA

146600

AA

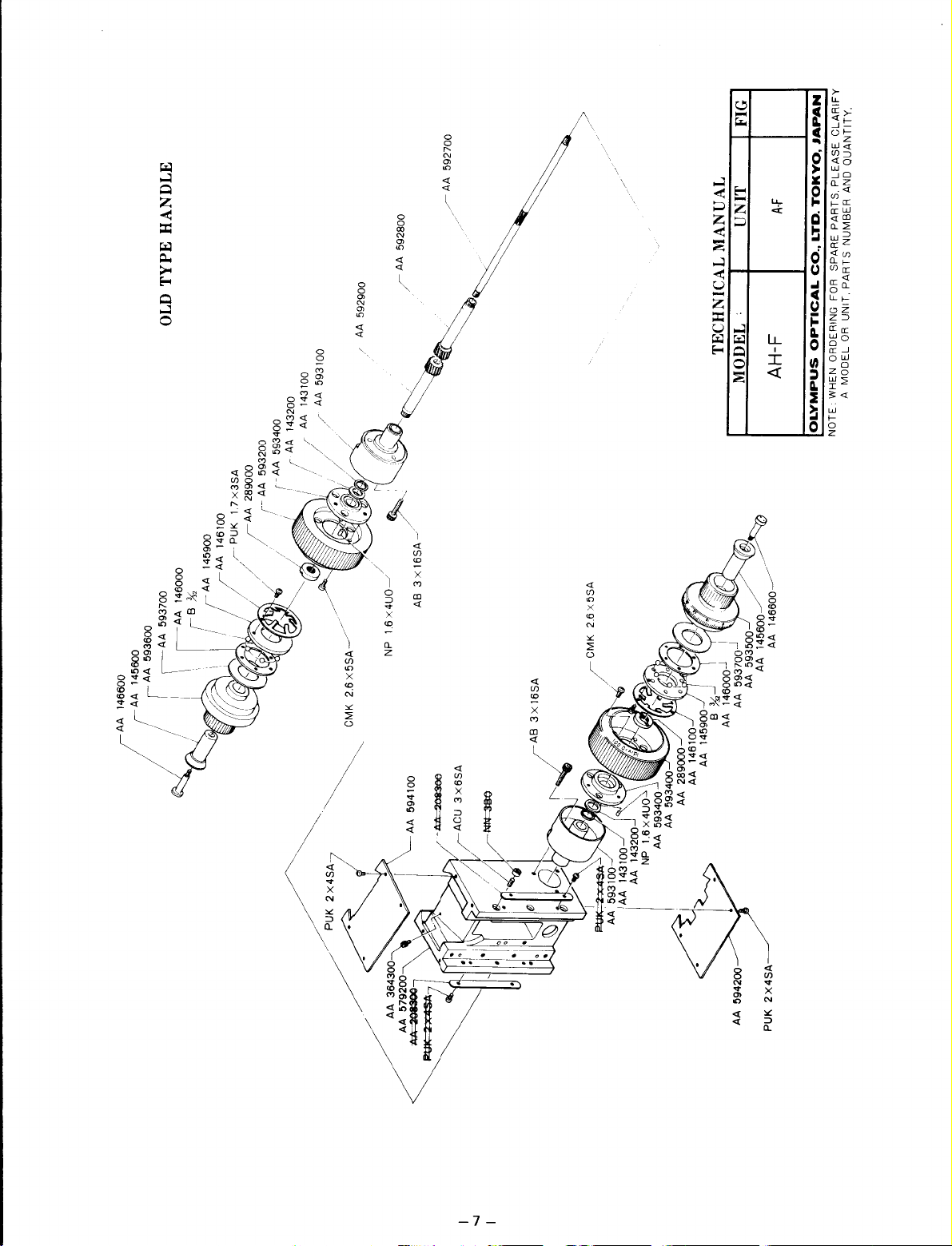

TYPE HANDLE

OLD

146000

AA

~

I AA 593600

/ I AA 593700

/ I

f

B){,

I

/ I \

x3SA

17

r PUK

! r AA 146100

I ! AA 145900

'./

"'"

".

I

~

592700

AA

592900

AA

593100

AA

143100

AA

/,'

/

'tI

/

/

,/

'/

! .

"/

"~;/

IlV

~I.

'

~

~

,,~

//

A

r A 289000

'/

593400

AA,

A 593200

r AA 143200

..

A,

_

r

' r _

..

/.

/',

~~

..! / / /

• ,

..'

-

"

~

I.

ft!r~~

T , .

2.6x5SA-/

CMK

"'/,/

'''7

~

'"

~

''-./~!~

/

x4UO---./

16

NP

594100

AA

• I

"

~

3X16SA~

AB

~~

3X16SA

f"'-.~AB

~

"',

J",I\I.'

/

143100-"

AA 143200

593100-

!AA

AA

593400

AA

1.6X4UO

AA 593400

NP

I

.\

I

145900~

AA

AA 146100

AA 289000

FIG

UNIT

TECHNICAL MANUAL

MODEL'

.

~

/

~g6~6600~/'

J

593500~

AA

AA

146000--1

){,-.J

AA 593700

B

AA

A-F

AH-F

CLARIFY

JAPAN

QUANTITY.

PLEASE

AND

TOKYO,

LTD.

SPARE PARTS.

CO.,

FOR

UNIT. PARTS NUMBER

OR

OPTICAL

ORDERING

A MODEL

WHEN

OLYMPUS

NOTE

"-

" I

//~U,

/

579200~

AA3643~0

------

AA

••

I

......

AA 594200

2X4SA

PUK

Page 11

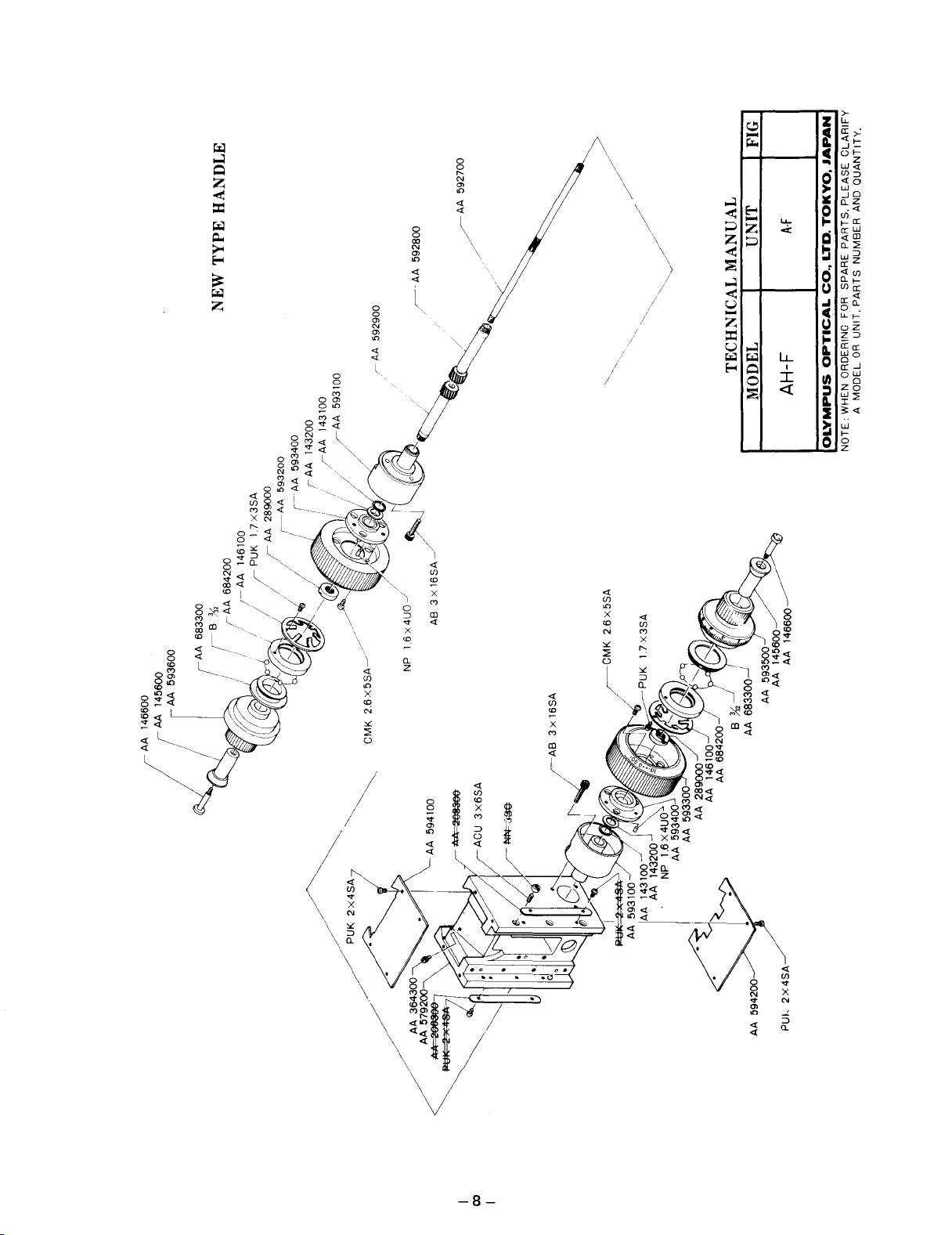

TYPE HANDLE

NEW

AA 592900

r-

AA 592800

/------

592700

FIG

A-F

UNIT

TECHNICAL MANUAL

AH-F

MODEL

CLARIFY

JAPAN

QUANTITY,

PLEASE

AND

TOKYO,

PARTS,

LTD.

NUMBER

CO.,

PARTS

UNIT,

OR

OPTICAL

A MODEL

WHEN ORDERING FOR SPARE

OLYMPUS

NOTE:

AA 145600

AA 146600

593600

,AA

(

NP

2.6X5SA~/

CMK

"~

/

2X4SA

//~

~

/PUK

AA 364300

///

5792(

~

!t)lj3OO-

//.

A'"

..

~I

( IS

:!J

f"U~:

~

3X16SA

I'~AB

2X4SA

PUk

I

I

(Xl

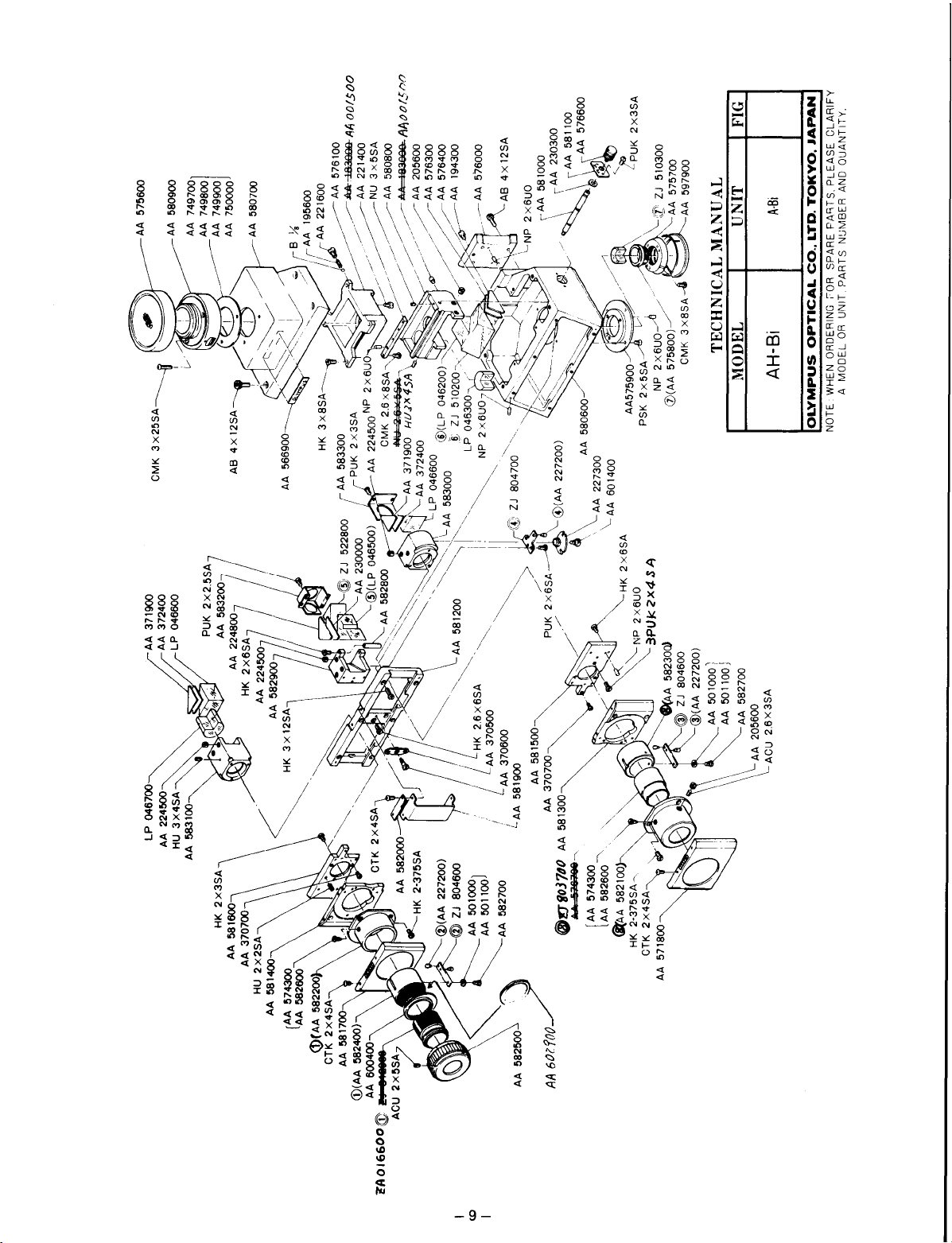

Page 12

AA 575600

3x25SA

CMK

AA 371900

AA 372400

046700

LP

580900

AA

rJ..:J

v'

~

046600

AA SA7

LP

"",-

224500

3X4SA~

583100,

AA

HU

AA

49800

749700

,

AA

AA

~

~

."

~

:

12SA • I

4X

/

PUK2x25

AA 583200

>X6SA

HK 224800

AA 224500 AB

"

"'"00

MOQ'5~

576600

~AA

''''''''

580800

"'"

..

;;d

AA 580700

..

v/

,~YJI

,~t::~

-1~':::1

AA 566900

221600

~"*

195600

//

::>::"="

£AA

rBY.

/(AA

//

~

/"

I

~

/'_

~

,'I'

"

H'

'

l'

Y!:~!JP'

~,>,,/

:'I

~"'-

U

'''"'

''''''

;~'

'"''

""""NP

3300

58 8SA

..

rAA

,,/"""'-

/,/"

~/~AA

/

~

,/

"'~"

'"

~~~

""",

HU,""A

,,,"':

""""

""""

..

..

ce

't

0%000)

ZJ 522800

i®

AA 230000 PUK

7

//~

7"17

582900

1

~

l'I.r~~;

\

@(CP

'"

:~'

,

"""00

/ ",

,"

~"~~'

"

A / ' L

>-'"l..~

3X12SAAA

HK

","

"

194300

""00

576300

576400

..

/~AA

;t:r------AA

':/

~-AA

D.

;,-'

,

~//

y,._.:>:

>/~/

' •

~'

(

q~,,--

""OOh

""'00

"

046300-

2X6U07

LP

NP

~"

""'" ')(ce

~

,,"

~~"I''''''

'''',[

, I '

A 581200

/,

A

W2SA

A 576000

'M

.,/A

'"

~,~

",'--'

I

",,_~.

804700

ZJ

!"

f~

'>

h6SA-->

PO<

"'000

A

""00

..

'''''h

fii~goJ7'O

""00

\AA

2x6UO

-

• i / LN.P

' '

ill

-/',,'

,"

--}-

/'

.~.

227200)

~@(AA

/

'

: /

~

~

/ 'IAA 230300

,@

,c.;r',

,

580600 .

AA

22

AA

~

""

,

'

~NP

"

"d

~'

, '

~

",

AA 581300

"""'"

582600'

00

..

[AA

_

582100

""""

(itAA

.,

•

~

C~'

2x3SA

581100

""

AA

~PUK

.'

\~~.

",\

.'

/'~/

AA575900

"00

""00

..

\

,

H'

"uo'

3PUI<?x4SA

~

~

I

~

J.

.

'

, ,

""

'"''

,

","'"

AA

l('C

\

,--

,

" ,

;p

.-

575800)~/

>X'uo~,~'

>SA'

x

NP

'.!J(AA

'"

PS",

"'30~

227200)

",,"00

'''''0)

A

"

@(AA

III

'-

""'"

","00

..

..

"85A->

CM'

50

"',,"":

""'"

AA

AA

..

\.

FIG

A·Si

UNIT

IINICAL MANUAL

TEe

AH-Bi

MODEL

,,'"''

AA 205600

ACU

\

CLARIFY

JAPAN

QUANTITY.

PLEASE

AND

TOKYO.

PA'iTS.

LTD.

CO.,

UNIT. PARTS NUMBER

OR

OPTICAL

ORDERING cOR SPARE

A MODEL

WHEN

OLYMPUS

NOTE

\~

1 ,

..

2X5;7

J 811

fD

~AOI6600~C~

I

I

cc

Page 13

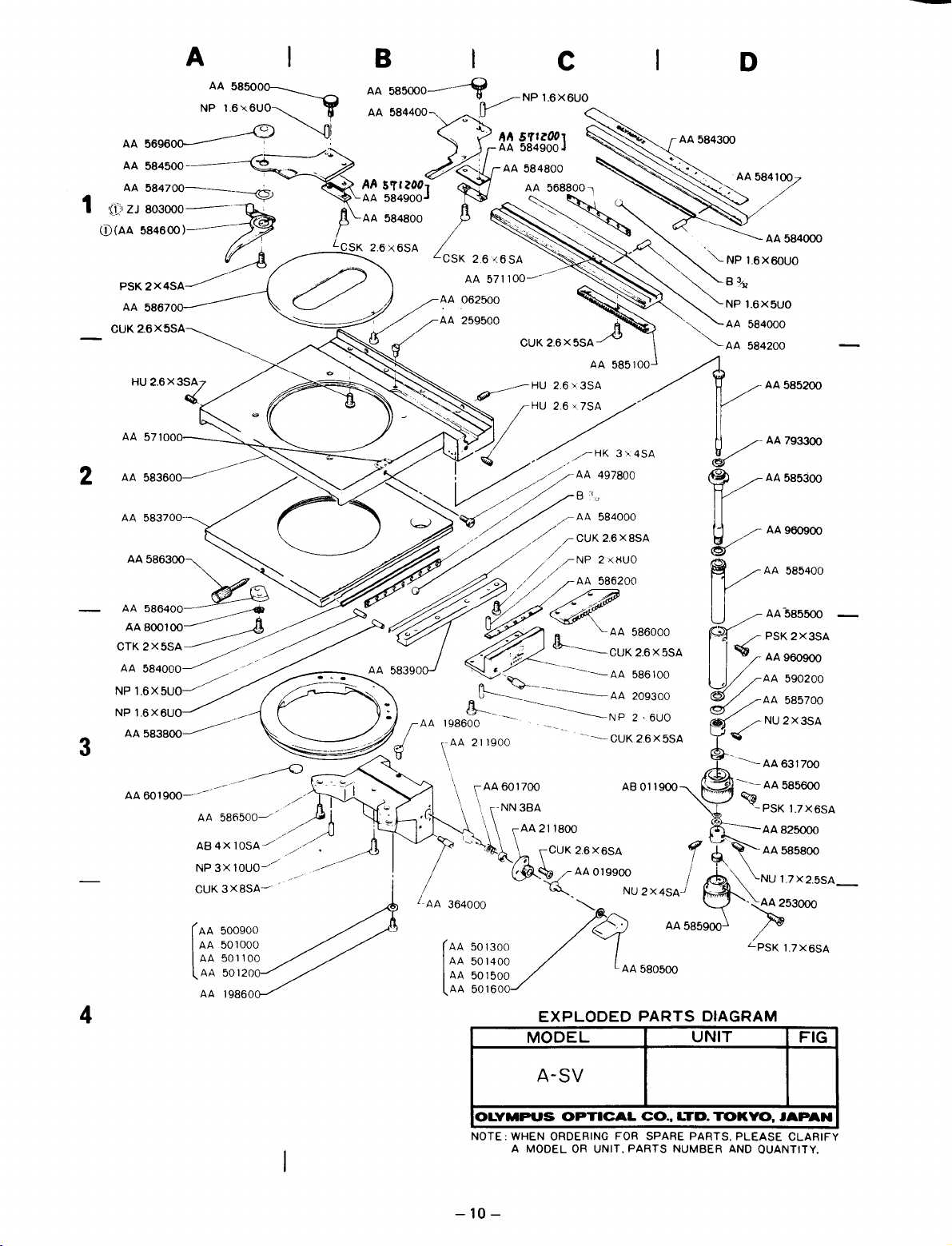

A

AA

58500~

NP 1.6 x

6UO~

AA

T AA

B

585000------"t

584400~

,V

NP

c

1.6X6UO

o

~

-r.'

.....

;

. CSK

~

1

AA

56960~

::

:::=-=~.c

'WiZJ

803000-~~

CD(AA

584600)----

...------

PSK

2X4SA--------·

AA 58670 »

CUK 2.6X

2

5SA___________

AA 571000

~

--->'~~":::::::'==--

AA 583600------

AA 583700

AA586300~

AA

",,"0

-------------

/

:-.--,!,

~

"'DI

..

~

:-:

AA

~::

r.

2.6x6SA

__

G?

.

""=---------:::: , AA 259500

0/

}JU

..

"oo]

~:::~~

~.

~AA

r

i"

CSK

AA

~A

062500 '

-~:'

----'Y"

.

~

~if

~

'.•"

•

~~:A,,"497800

(

https://manualmachine.com/

'-=-'

't1

/'

A

...:.

AA

S'rllOOJ

AA 584900 •

..

~::~o.0"~>AA5"/

~".

"~~~.

"''''''.''~.....

'.,

26~6SA

571100--

~HU

v""

~

//

/

/

~;~bA~

~

~..~:

CUK

2.6x5SA

26x3SA

""/

_~HK

/AA

/'

/'

rCUK

/ /

//NP.2XHUO

q

~~~AA584300

//

~~

/'"

'.

~.,

~.

AA 585100

3 x 4SA

584000

2.6x8SA

586200

L::<.

....

"-."

...

~AA584000

"-

""

~

"

'""

"-NP

""--B

~

'-

"--AA

V.

t..

1.6X60UO

%

NP

1.6x5UO

AA 584000

584200

AA 585200

AA 793300

AA585~00

V AA 960900

tAA.585400

AA

585500

_

CA::::~~AA":90

NP1.6X50https://manualmachine.com/

1.6x6UO

NP

AA 583800---------------

3

--

3X8SA-

CUK

AA 500900

AA 501000

AA 501100

[

AA 501200

AA 19860

4

c'·

)-

~

.""'---_.=::::::'~~

-~''-'--

0

~_~~~=~~K~~::A

~------=---------AA

AA 198600 U

I

'\AA

7

!

AA

[

-~

211900

\

\AA601700

\

NN3BA

.

~rA2~:26XOSA

https://manualmachine.com/AA019900

364000 •

AA

50130/~

AA 501400

AA

501500

AA 50160

OLYMPUS

NOTE: WHEN ORDERING FOR SPARE PARTS,

A MODELORUNIT,

----------NP2·6UO

-~CUK

~

""'-

EXPLODED

MODEL

A-SV

OPTICAL

209300

2.6 X 5SA

AB011900-V

NU2X4SA-!"

LAA580500

PARTS

CO.,

PARTS

~::=

https://manualmachine.com/AA

~

'"

~~''''''''''''AA

'"

~PSK1.>X6SA

r

~,~::=

I

~'

""

~~

AA585900

DIAGRAM

UNIT

LTD.

TOKYO,

NUMBER AND QUANTITY.

585700

/NU2X3SA

631700

~AA585600

\.NU

1.7X25SA_

•

r53000

LPSK

1.7X6SA

FIG

JAPAN

PLEASE

CLARIFY

-10

-

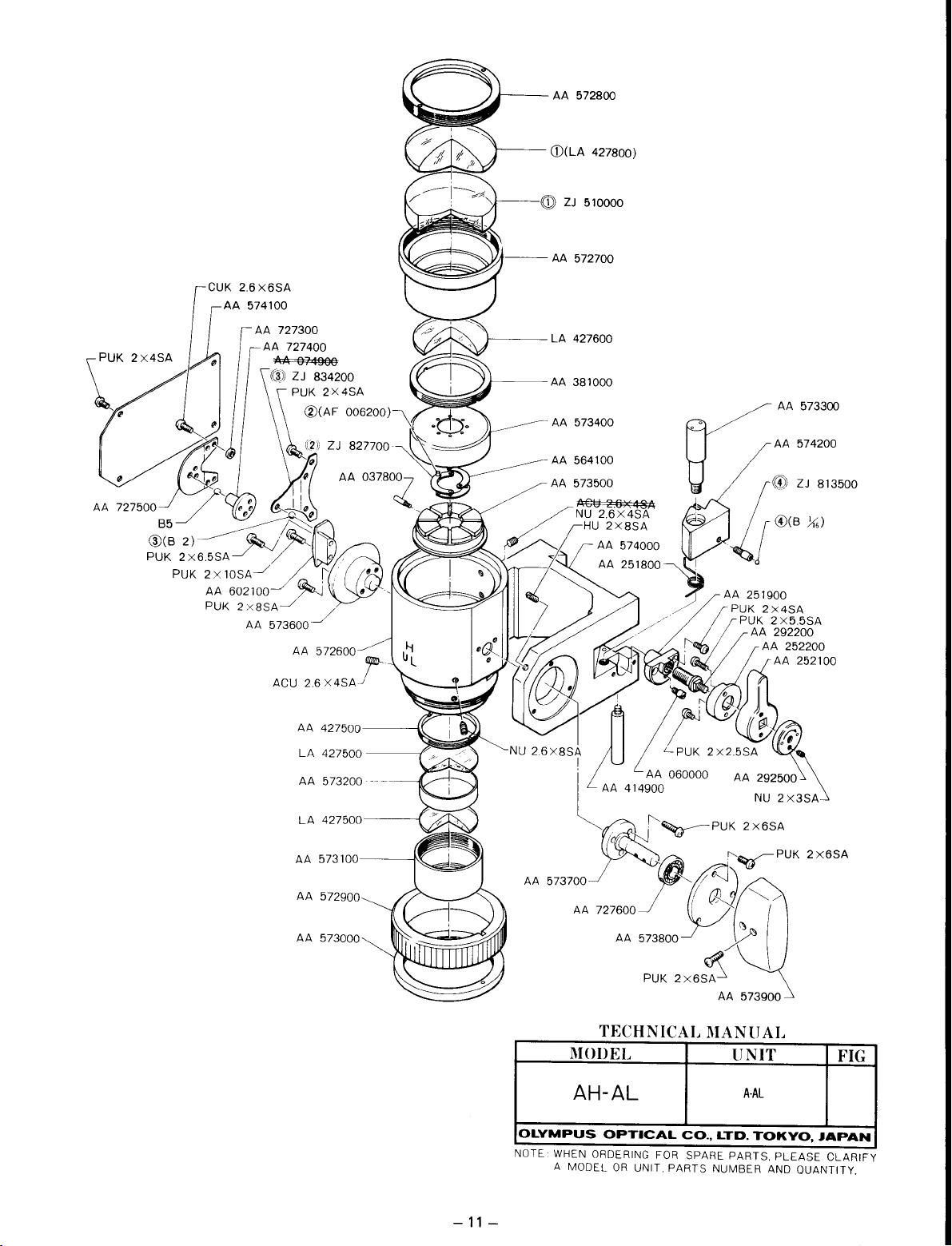

Page 14

(D(LA

@

LA

AA

AA

AA

AA

572800

ZJ

427600

381000

573400

564100

I

427800)

5100QO

PUK

2x8SA

AA

573600

AA

ACU

AA

LA

AA

LA

AA

AA

AA

~

572600

2.6

573100

572900

573000

X4SA

427500

427500

573200

427500

~

j

SA

TE

CHNICAL MANUAI.

.------;;l\~I(~)lj)")

RE

IL~

~

UNIT

--,

I

F~

AH-AL

A-AL

1 _

AL

co.,

LTD.

TOKY

0,

LYMPUS

o WHEN ORDERING

NOTE A

OPTIC

MODELORUNI .

PARE

~Op~~TS

PARTS.

NUMBER

AND

PLE

ASE

QUANTITY.

JAPANJ

CLARIFY

-11

-

I

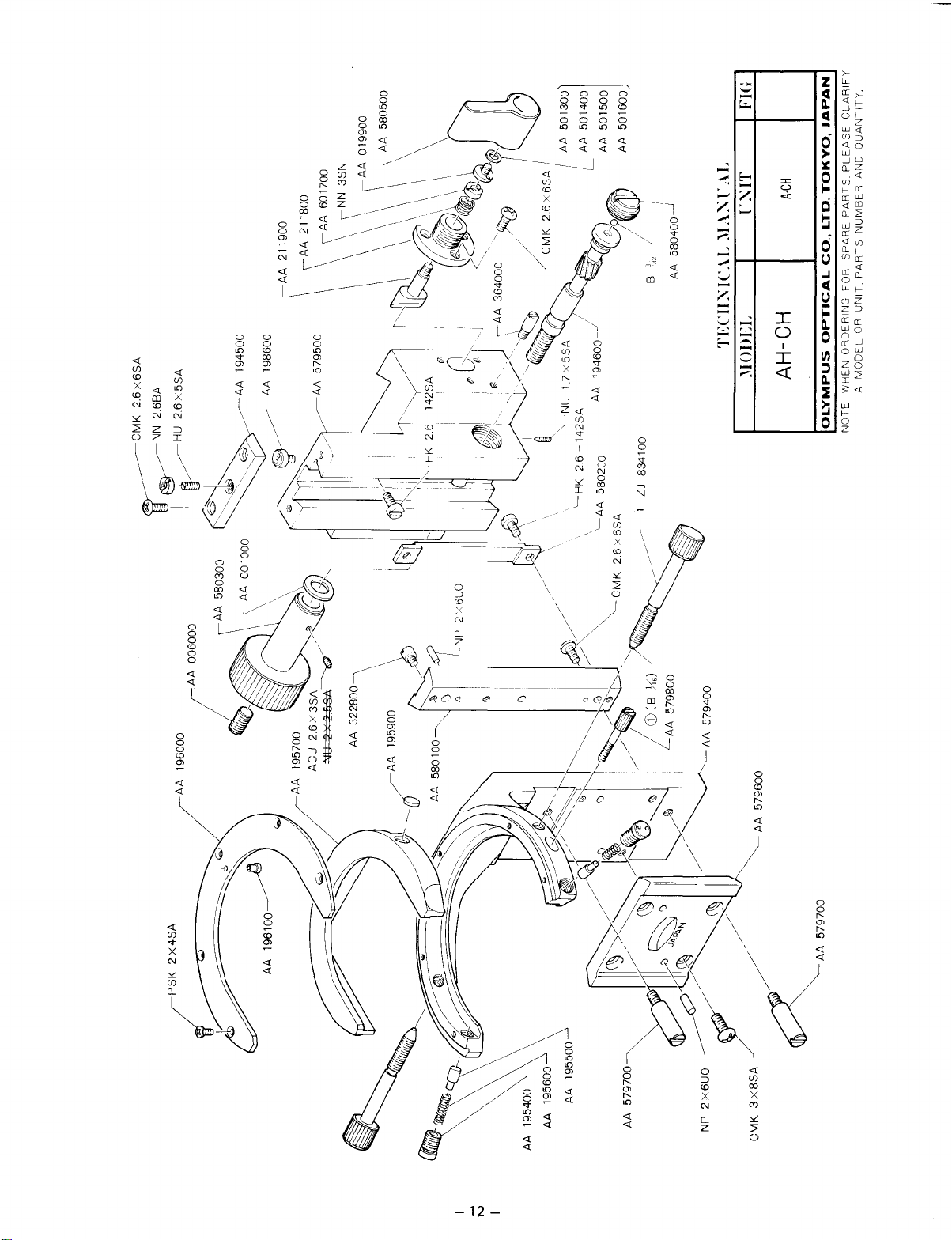

Page 15

CLARIFY

A·CH

I I

JAPAN

YO.

TOK

LTD.

..

I

CO

OPTICAL

OUANTITY.

PLEASE

AND

PARTS.

NUMBER

SPARE

PARTS

FOR

UNIT.

OR

I

C:\IT

580400.J

AA

B

J

:\L\:\L\L

I

TECII:\IL\L

AA

2x4SA

580100~,

AA

!

l)1

~'"

194600-

NU

142SA

--

2.6

f<K

L

, ''---

jJI

834100

580200 AA

ZJ

26x6S'

MK

•

~

~/

,"--C

J

I'

."

I,

....

~8

//

'

~:~-

''1'(;)

I~

)Cl

579BOO

CD<s

AA

~

/_

I Q

~~,II

/~:

\':)

"'~~

P~~

-

~"

~I~

:\IODEL

AA 579600

I '------AA 579400

/\Il

/'

AH-CH

MODEL

A

WHEN ORDERING

OLYMPUS

NOTE

AA 579700

rPSK

I

i~~

~

._

~

AA 195500

AA 195600

AA 195400

I

I'V

AA 579700

3XBSAJ

2X6UO~~

NP

CMK

~.

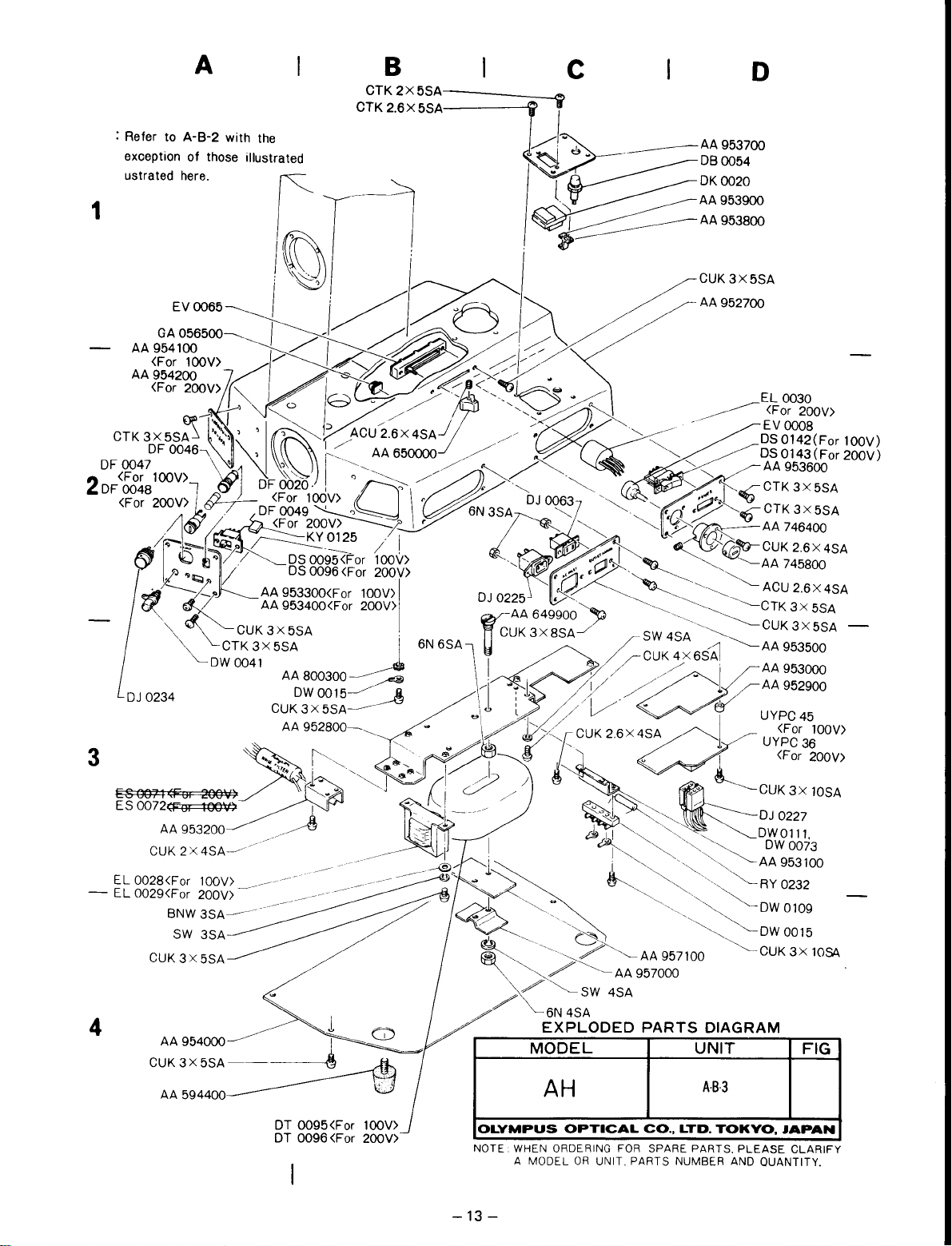

Page 16

A

B

CTK2X5SA--

2.6X

CTK

5SA i --i

c

_

D

: Refer to

exception

ustrated here.

1

AA9~:10~65OO--------~1

AA 954200

CTK

OF

0047 \

<For

2

OF

0048

<For

OJ0234

3

E80071:f€ol

ES

EL

0028<For

EL0029<For

-

A-B-2

with the

of

those illustrated

~

I~--I~:::::

EV~'

<For looV>

<For

2OOV>

~-\

3X5SA~

OF

looV>l

2OOV>

/ID'~

.

~K

.

~

0072(1"'01

AA 953200

CUK2X4SA-~'-~_~:

CUK

:"~,,,

0046,

~1

LY-~

https://manualmachine.com/

<1Y~~~For

~

JZ:?;;

I?

~It"-

/

-)!

/ AA 9534oo<For 200V>

~

~

~

CTK 3X 5SA I

DW0041

200",;~~wf

100''1')

lOOV>

200V>

BNW

3SA-----

sw

3SA

3X5SA

I~I~~II~

/~/

~I/

""

,

~

I

"",

'l1

CUK

~;)

'

~'~~

I

'\J.' I

OFdo20.

<For looV> I( \

OF0049"'---~~'

200V>~

~~5

OS

OS

AA 953300<For

3 X 5SA "

AA800300~

OW0015~

CUK3X5SA

AA

952800-

~r",~,,&,,~~,

_,,--

~

,~>

--

__

--

~

~~~~

I.Av'i'

~-

)8

~

/ACU

I,:

'~~

I

oo95<For

0096 <For 200V> <

J~"~l/

~.

//

2.6X4SA

AA650000

~a"~

/ I

lOO\;>

100V>

~

-

/!'

/

J'

/

/~'

<

6N

6SA)

• I

~

I~/i

J (I

J.

I

.....

~/,

~

-/,

1.

----/

1

~~."'-.....~

I/I~

~;;r--'

I

1:

---------=

/

X'4t61

~

w

I

«,

~

",

//.

./

~

~

6N3SA

""J~"

'-

~,'l"-

"-.

'~'~~,"'b

DJ

0225

AA

CUK

f

~

/

~;

I:

..

::e>

V"//

\~A'"

if;/

® ! t .

/

Y/

I

l~i

~

/'

_/ _ . . '

,.

~~

~~-·"~·'--AA957lO0

'"

V

~

~

~~

/i.';

:::

~

~/~

~~

~

~

OJ

0063 '

~

~

;YJ<

'

,l~

."5<

649900

"~~_,

.../

3X 8SA

I Y

~

~

/1 /

V

.CUK26X~SA

i~~

'~,:

~

.d<J

'A')

/"

~AA

SW

\

'''

~

"<'0'

~

.....

~

,I

~

~:::~~::=

,~~

SW

CUK

//~/

//

~

~.

~~,

11

~-_~~DWOlll,

~'-',,-

~

~

~"'~

'",,~DWOlO9

957000

4SA

AA 953700

OB

0054

OK

0020

CUK

3X5SA

AA 952700

EL

0030

<For 200V>

EVOOO8

OS

0142(For

OS0143(For200V)

AA 953600

~

~

~

-

"

'-.....

...

i'."c-CTK3X5SA

~'N

~'-.....~CTK3X5SA

~AA7464oo

~<&@l~CUK2.6X4SA

~

'---AA

745800

ACU2.6X4SA

~~CTK

--~

4SA

/1

_________

4X6StJ AA 953500

w 1"

y

/AA952900

3X

-CUK3X5SA-

AA953000

~

1

UYPC45

<For

UYPC36

~~cu~o~

3 lOSA

DJ

0227

DW0073

'.-~/~AA953100

RY

0232

~

DW0015

~CUK3XlO~

//~6N4SA

1

4

AA 954000

CUK3X5SA~

AA 594400

G)

I=-~

/

EXPLODED

MODEL

AH

PARTS

DIAGRAM

UNIT

A-B-3

lOOV)

5SA

lOOV>

200V>

FIG

OT

0095<For looV>

OT

0096<For

2OOV>

OLYMPUS

NOTE WHEN ORDERING FOR SPARE

A

-13

-

OPTICAL

MODELORUNIT.

CO.,

PARTS

LTD.

TOKYO,

PARTS.

NUMBER AND

PLEASE

JAPAN

CLARIFY

QUANTITY.

Page 17

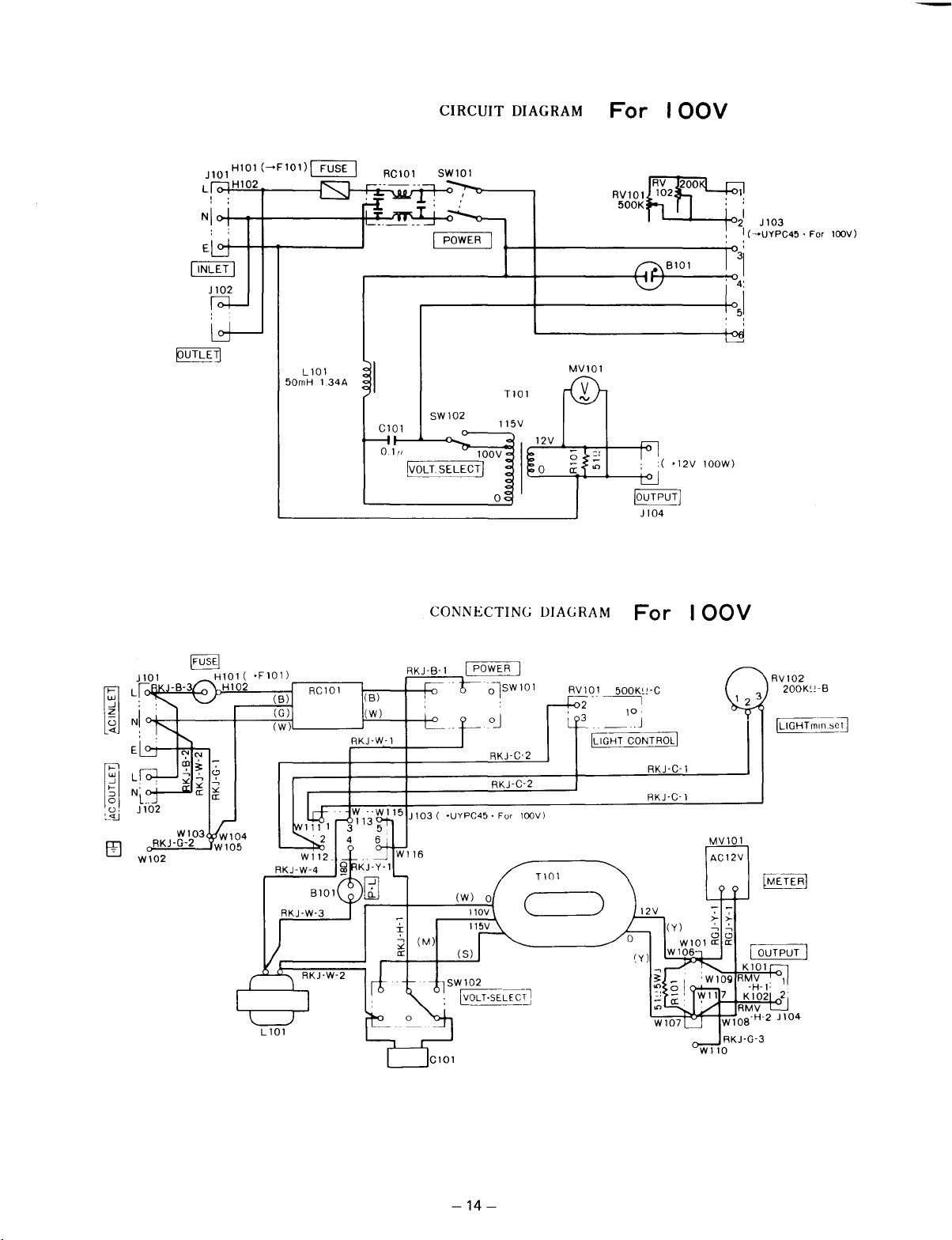

Jl0l

L

E

IINLET I

J

102

Hl0l

(~Fl01)~

Hl02

RC101

r--------

.--------+-------+0

CIRCUIT

SW101

DIAGRAM

.......

-+------+1

For

RV101

500K

IOOV

'--

.....

--+<>2

t-r----;-04:

1

J103

I

(~UYPC45'

31

1

5

For

l00V)

~

E

L

N

L

~

(J,

Jl02

~~

Wl02

.

RKJ-G-2

\FUSE-[

Wl03

Hl0l(-Fl01)

Hl02

Wl04

Wl05

(B)

(G)

(W)

50mH

L101

RC10l

134A

(B)

(W)

RKJ-W'l

C10l

01/,

§i£Sfu@

i

;;:

er:

MV101

TlOl

SW102

115V

100V

o

CONNECTING DIAGRAM

I POWER I

RV101

0J

RKJ-C'2

RKJ-C-2

·UYPC45·

(M)

(5)

For lOOV)

C

__

Tl01

For

500K~'-C

2'~

3

1°'

.. _ J

[UGHTCONTRQb]

RKJ-C-1

RKJ-C-l

)

lOOW)

IOOV

1 2 3

MV101

AC12V

RV102

200K~!'B

-14

-

Page 18

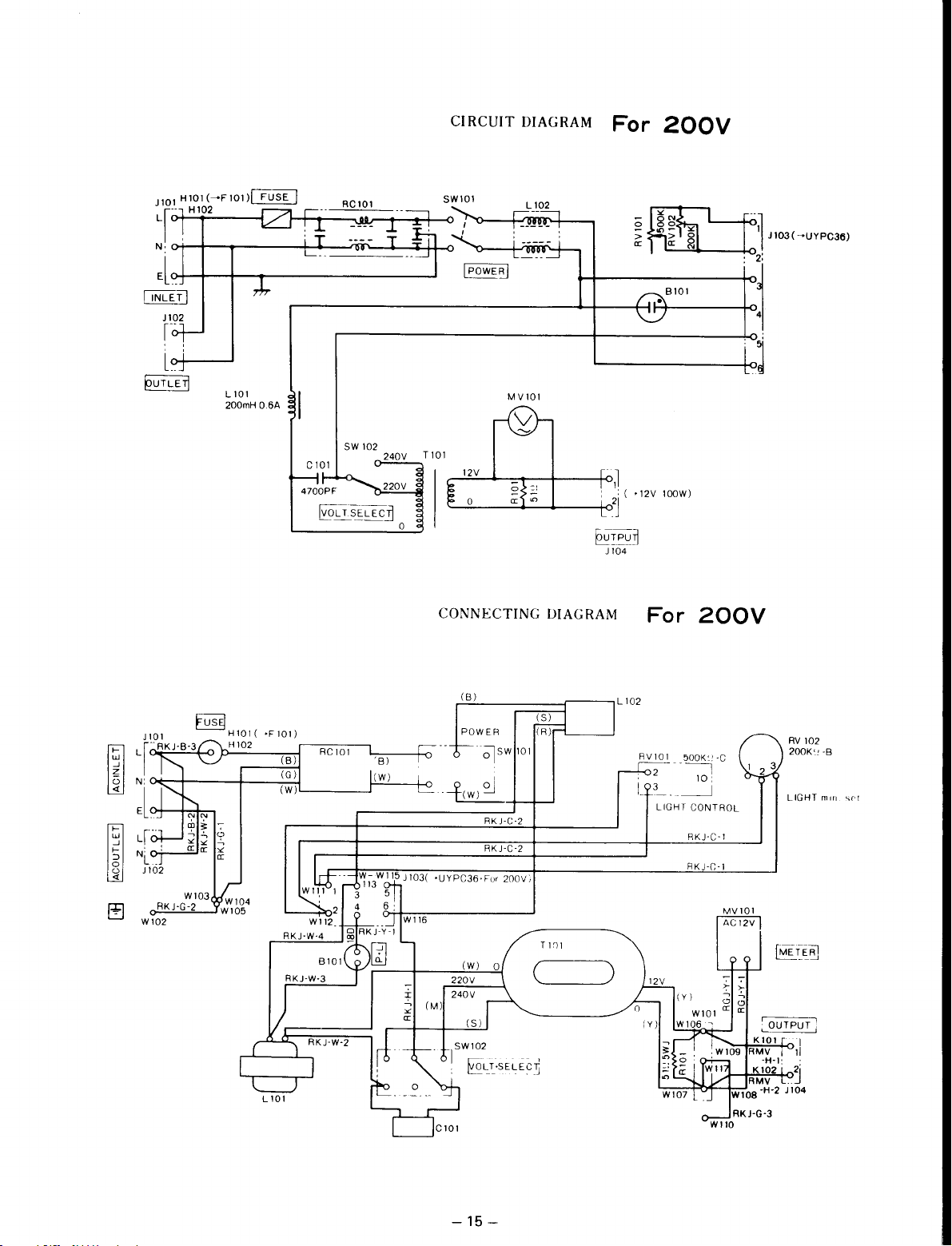

CIRCUIT DIAGRAM

For

200V

~

Jl02

,--

lo-

__

1----

L101

200mH

06A

C

101

4700PF

§""0_

5W

S

102

EC-

o

>

a:

--------+<>""

MV101

T

101

240V

~~~:-t---r----t<JJ

~

L

E

c2J

o

__

I-------t<-'2J

CONNECTING DIAGRAM

: (

-12V

100W)

~T~LJ~

Jl04

For

200V

--~

J103(~UYPC36)

~

~

W103

__

Hl01(

H 102

WI04

W105

Jl0l

O'-R_K-,"J~-G~-~2

W102

-F101)

(W)

r------;::-R:::-C"7C10::-:

(B)

(C)

:--""l,--

1

__

-r-o

'!'

><

a:

r(!.!:B~)~-----;=:::;:;::;:::r--1

POWER

--~5W

101

-t-

0 I

-(W)

'::'J

RKJ-C-2

RKJ-C-2

-UYPC36'For

220V

240V

(M)

5Wl02

I

200V)

T

I~I

(W)

(5)

(

§:LT'5EU:C~

L 102

RV

102

200K',

-B

1 2 3

LIGHT

min.

LIGHT

CONTROL

RKJ-C-'

RKJ-C-l

MV101

AC 12V

)

W110

':"

CO

a:

RKJ-G-3

0;-

':"

CO

a:

se!

-15

-

Page 19

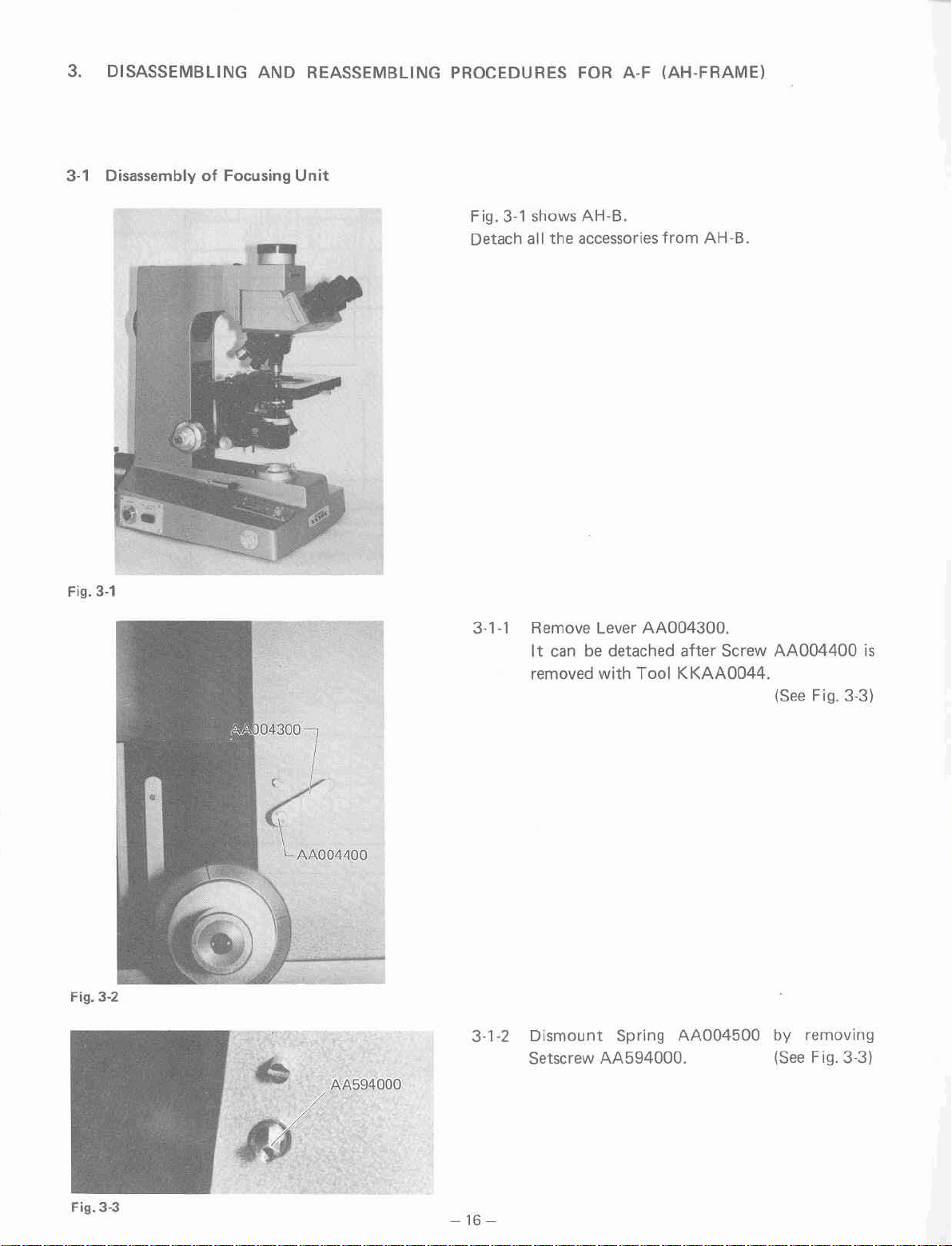

3.

DISASSEMBLING

3-1

DisassemblyofFocusing

AND

REASSEMBLING

Unit

PROCEDURES FOR

Fig.

3-1

shows AH-B.

Detach

all

the

accessories from AH-B.

A·F

(AH·FRAME)

Fig.

3·'

0430°7

(04400

AA5940QO

3-1-1 Remove Lever

It can be detached after Screw AA00440Q

3·'·2

removed

Dismount

Setscrew AA594000.

with

Spring

AA004300.

Tool

KKAA0044.

AA004500

(See Fig. 3·3)

by

removing

ISee Fig.

3-31

is

Fig.

3·3

-16-

Page 20

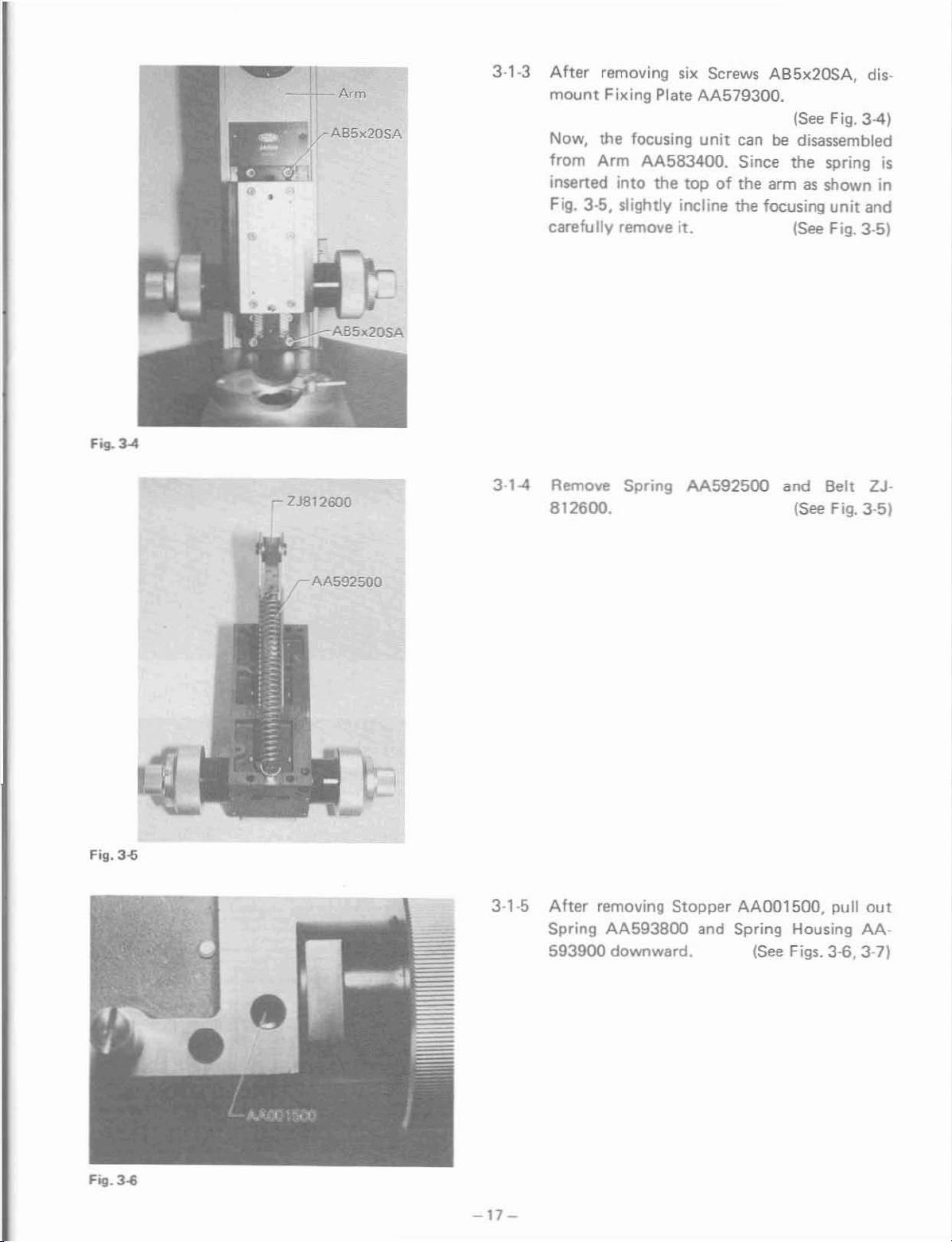

Fig. 3-4

I Arm

l.v

AB5x20SA

3-1-3 A

carefully remove

her

removing

mount

Now, the focusing

from

inserted

Fig. 3-5, slightly incline the focusing

Fixing Plate AA579300.

Arm

into

six

Screws AB5x2OSA, dis-

(See F

unit

can

be

disassembled

AA583400. Since the spring

the topofthe armasshown in

it.

(See

i9.

unit

Fig.

3-4)

is

and

3-51

Fig. 3-6

rZJ812600

AA592500

3·1-4

3-1-5

Remove Spring

812600.

After

Spring

593900 downward.

removing Stopper AAOO1500, pull

AA593800

AA592500

and

Spring Housing

(See

and Belt ZJ-

(See F

Figs.

i9.

3·51

out

AA-

3-6, 3-7)

Fig. 3-6

-17-

Page 21

\W'I'!1I'7!«1

1(j\YIfO'N'IrII

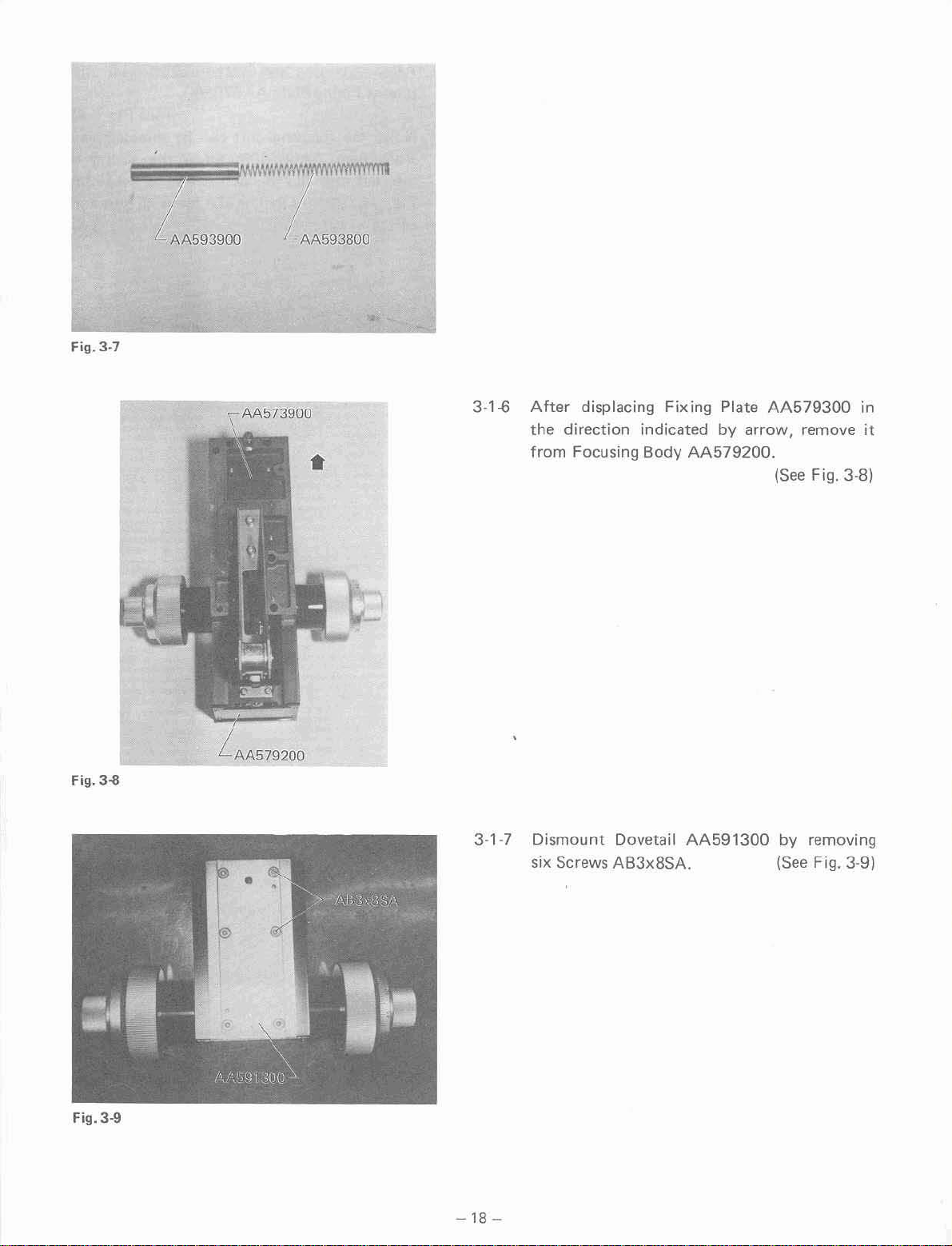

Fig. 3-7

7A59390~

,AA573900

AA593BOO

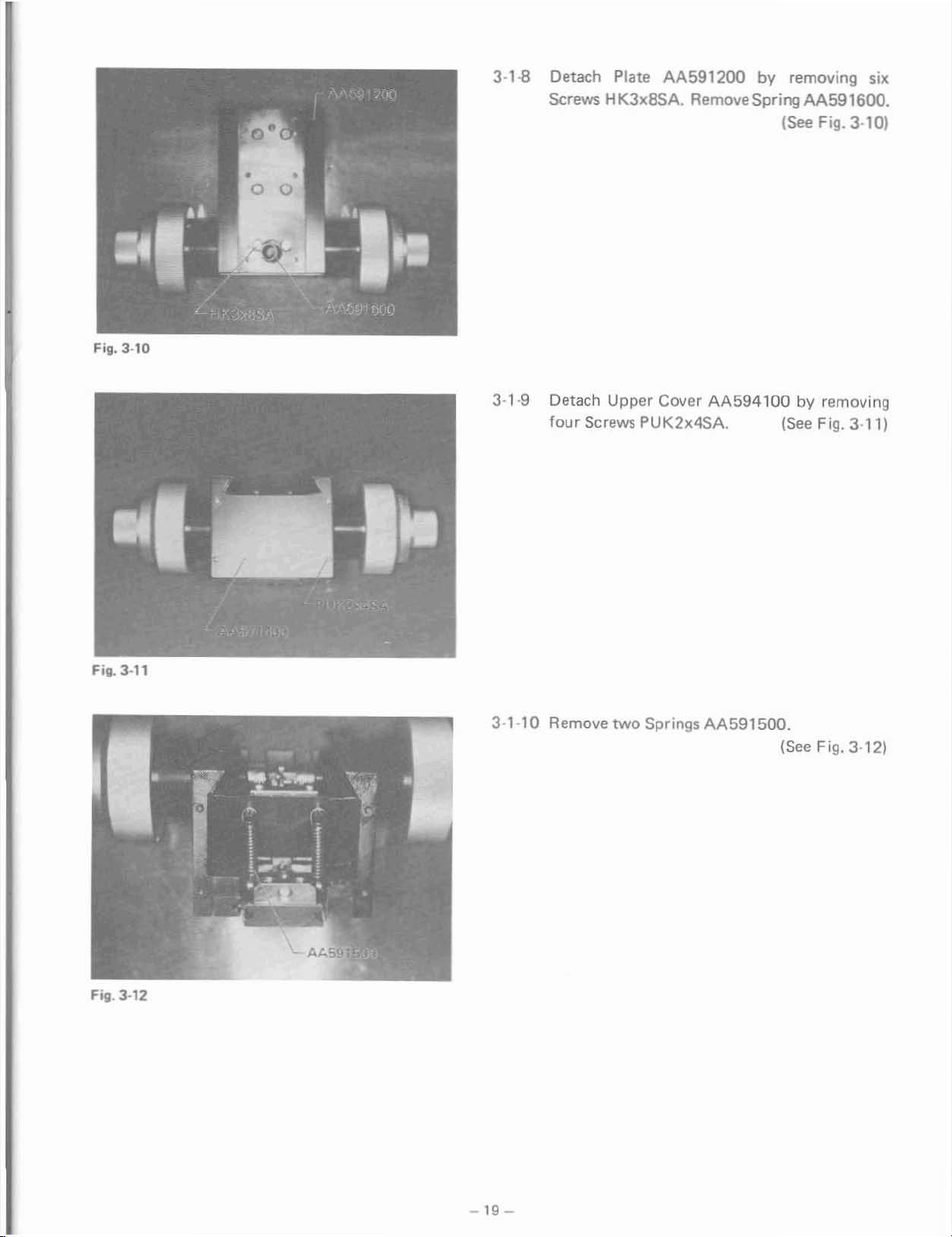

3-1.ti

After

the

from

displacing Fixing Plate

direction indicated by arrow, remove

Focusing Body

AA579200

•

AA579300

.

(See

Fig. 3-BI

in

it

Fig. 3-8

Fig.J-9

AA579200

-18

3-1-7

-

Dismount

six Screws AB3xBSA. (See Fig. 3-9)

Dovetail

AA591300

by removing

Page 22

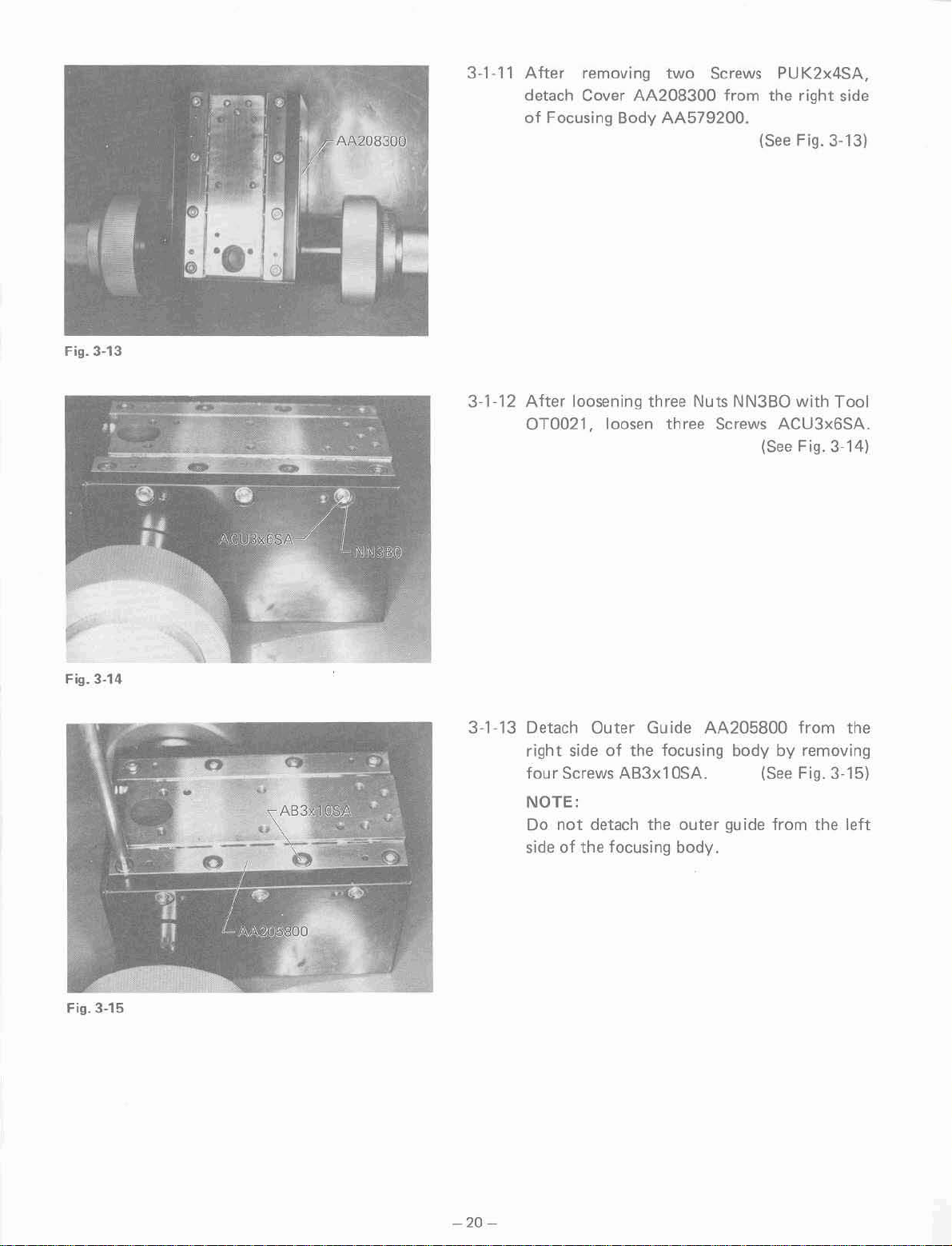

Fig. 3-10

3·1..B

Detach

Screws

Plate

AA591200 by

removing

six

HK3x8SA. RemoveSpringAA591600.

ISee Fig.3·101

Fig. 3·11

3-1-9

3-1-10

Detach

four

Screws

Remove

Upper

PUK2x4SA.

two

Springs

Cover

AA594100

AA591500.

by

removing

(See

Fig.

3·11)

ISee Fig. 3·121

Fig.

3-12

-19

-

Page 23

Fig. 3-13

3-1·11

After

removing

detach Cover

of

Focusing

two

AA208300

Body

AA579200.

Screws

from

PU

the

(See

K2x4SA,

right

side

Fig. 3-131

Fig_

3-14

3-1-12

After

OT0021,

3-1-13 Detach

right

four

Screws

NOTE:

Do

not

sideofthe focusing body.

loosening three Nuts

loosen three Screws

Outer

side

Guide

of

the focusing

AA205800

AB3x10SA.

detach the

outer

NN3BO

with

ACU3x6SA.

(See

Fig. 3-141

from

body

by

removing

(See

Fig. 3-15)

guide from the

Tool

the

left

Fig. 3-15

-

20-

Page 24

Fill. 3-16

31·14

Detach Inner Guide

mount

Casing

using

Use

subsequent

Rollers

AA206000

AA206100,

xylolorgasoline.

gasoline or

xyloltowash

stages.

AA205900.

and

wash

Then, dis·

together

off

grease

(See

Fig. 3-16)

off

greaseatthe

with

by

Fill.

3·17

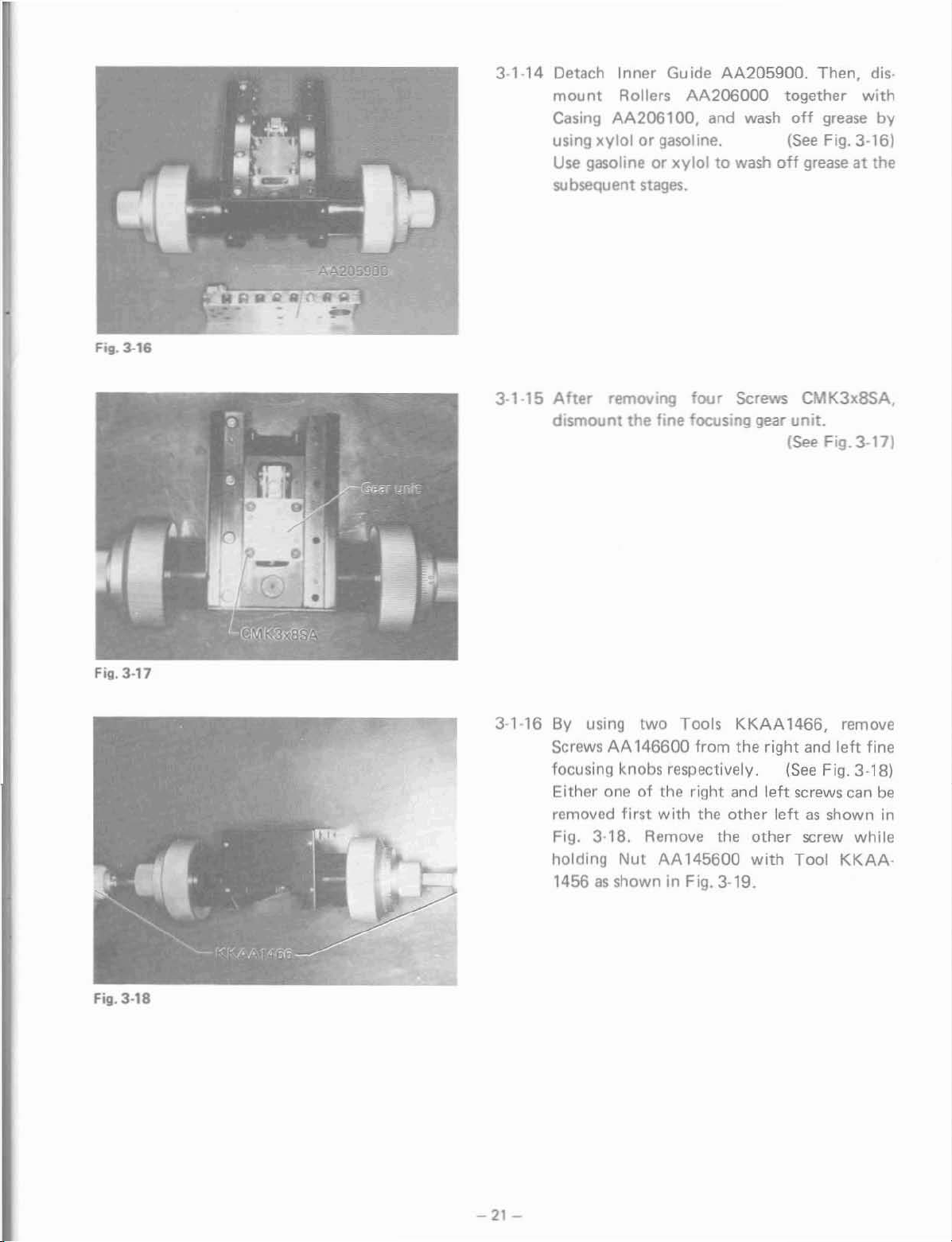

3·1-15

After

removing

four

dismount the fine focusing gear

3·1·16 By using two Tools

Screws

AA

146600 from the right and

focusing knobs respectively.

Either oneofthe right and

removed

first

with

the other

Fig. 3·18. Remove the other screw

holding

Nut

AA

145600

1456asshown in Fig. 3-19.

Screws CMK3xSSA.

unit.

(See

Fig.3·17)

KKAA1466,

(See

left

screws can

remove

left

fine

Fig. 3·18)

be

leftasshown in

while

with

Tool

KKAA-

Fig.

3·18

-21-

Page 25

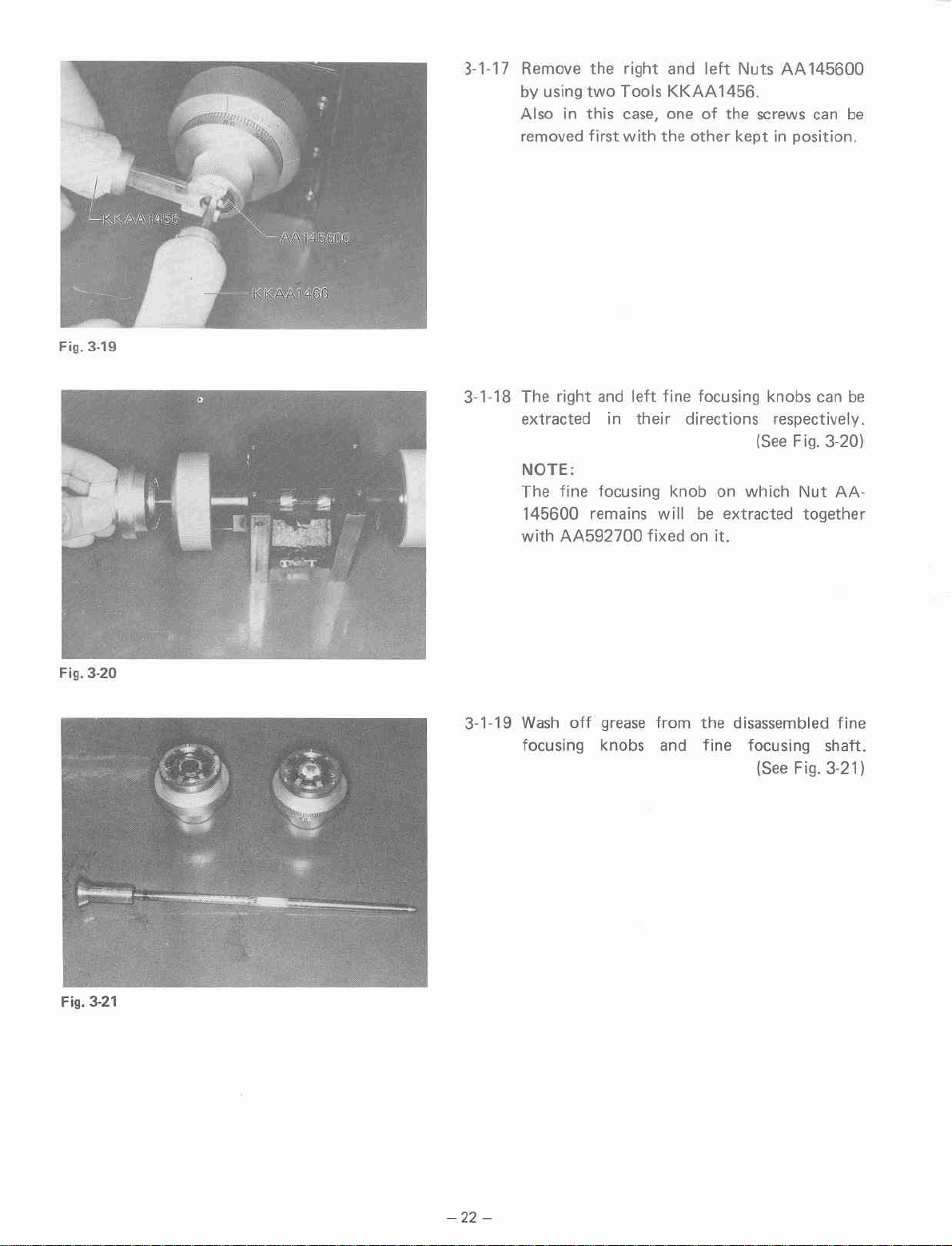

3-1-17 Remove

by

using

Also in this

removed

the

two

first

right and

Tools

KKAA

case,

one

with

the

left

Nuts

1456.

of

the screws can

other

keptinposition.

AA145600

be

Fig. 3-20

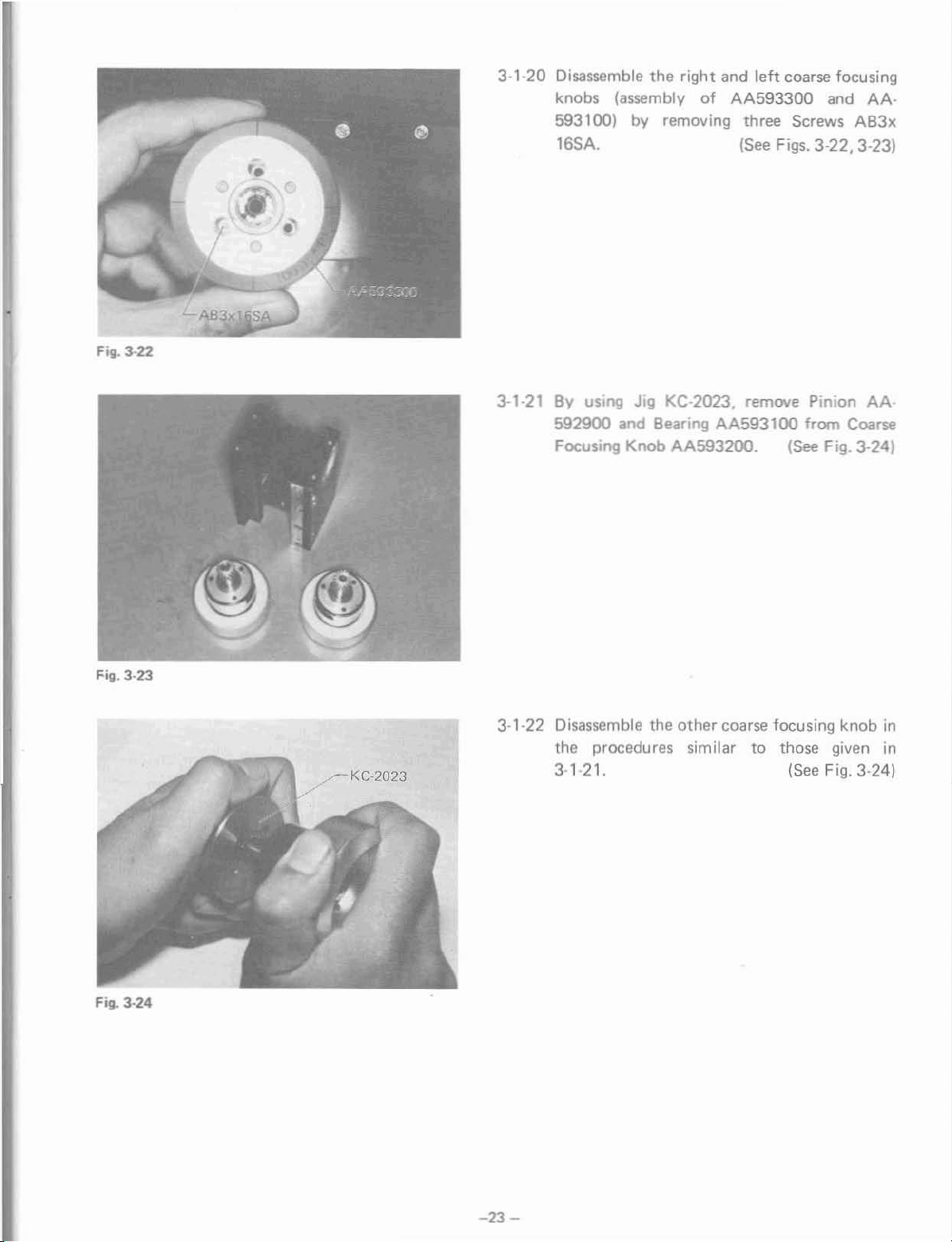

3-1-18 The

extracted in their directions respectively.

NOTE:

The

145600 remains

with

3-1-19

Wash

focusing knobs and

right

and

left

fine

focusing knob on

AA592700

off

grease

fine focusing knobs can be

ISee Fig. 3-201

will

be

fixedonit.

from

the

fine

which

extracted together

disassembled

focusing shaft.

Nut

ISee Fig. 3-211

AA-

fine

Fig. 3-21

-22

-

Page 26

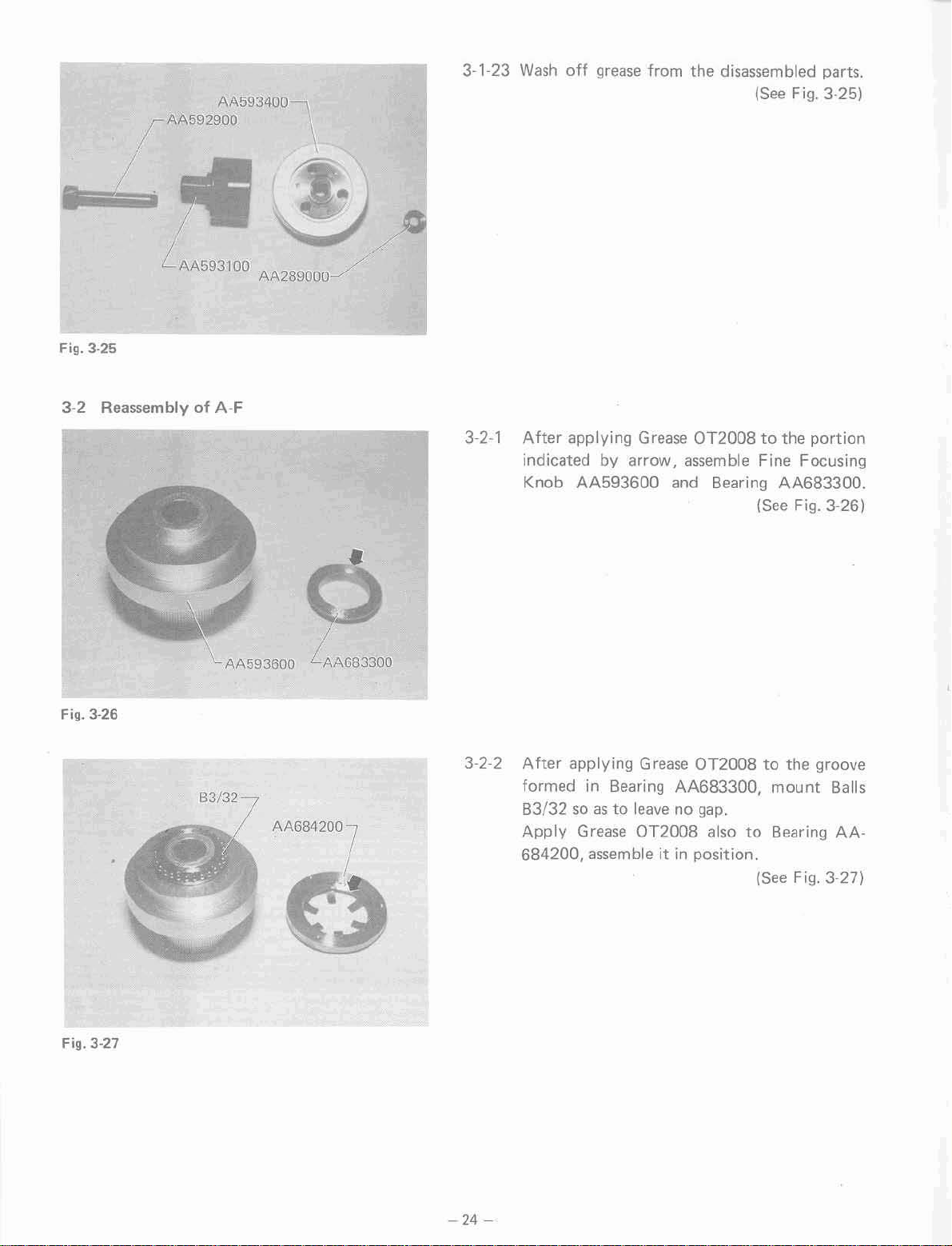

Fig. 3-22

3-1-20 Disassemble the right and

knobs (assembly

of

AA593300

593100) by removing three Screws

16SA. ISee F;gs. 3·22, 3·23)

left

coarse focusing

and

AA-

AB3x

Fig. 3-23

....---KC·2023

3-1-21

BV

using Jig KC-2023. remove Pinion

592900 and Bearing

AA593100

Focusing Knob AA5932(Xl-

from Coarse

(See

Fig.

3-241

3-1-22 Disassemble the other coarse focusing knob

the procedures similar to those given in

3·'·21.

(See

F;g.

3·241

AA·

in

Fig.

3-24

-23

-

Page 27

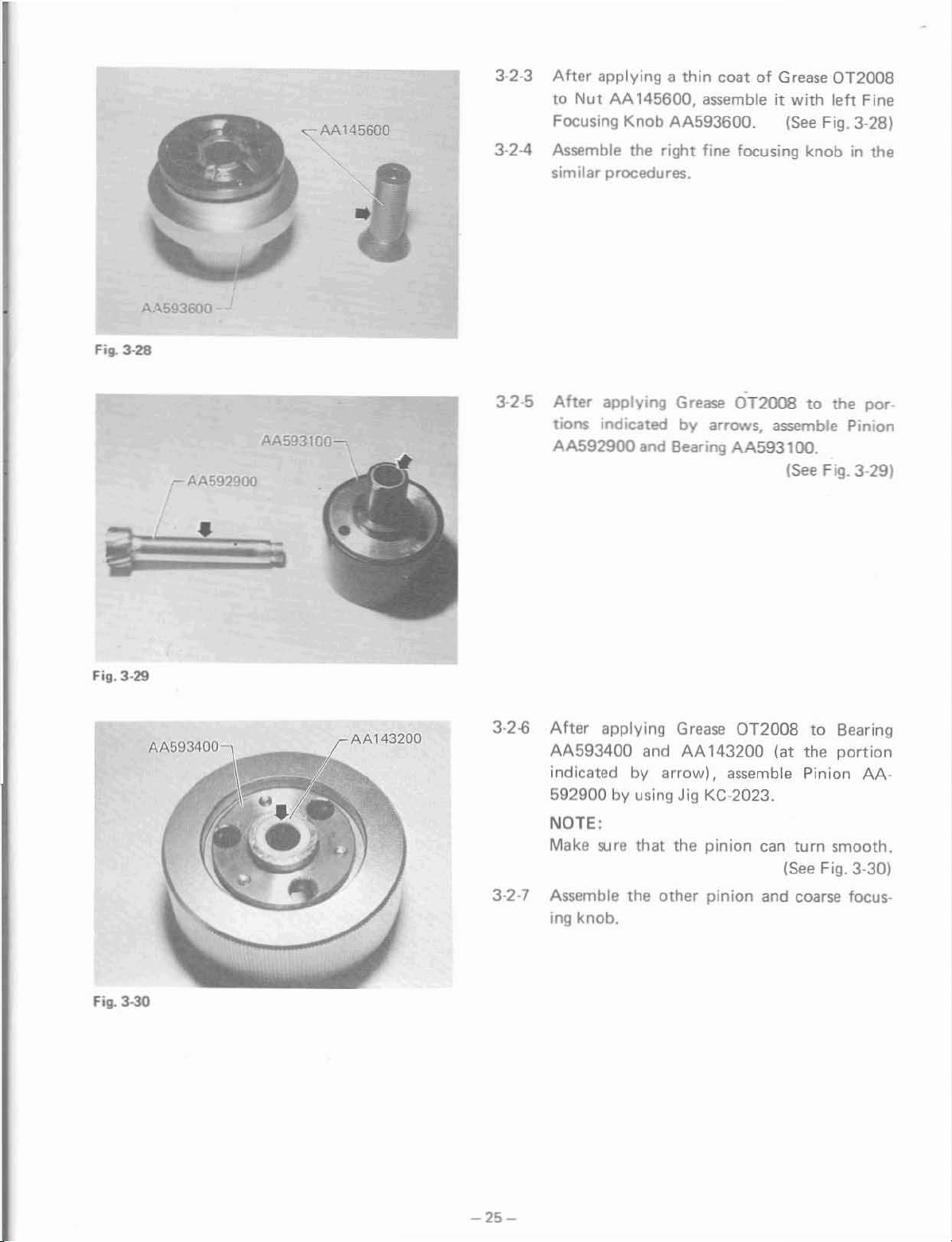

(AA592900

AA593400

3-1·23

Wash

off grease from

the

disassembled parts.

(See Fig. 3-25)

L.AA593100

Fig. 3-25

3-2 Reassembly of A-F

\...

AA593600 LAA683300

AA289000/

3-2-1 After applying Grease OT2008tothe

indicated by arrow, assemble Fine Focusing

Knob AA593600 and Bearing AA683300.

(See Fig. 3-26)

portion

Fig. 3-27

83/32

3·2-2 After applying Grease OT2008tothe groove

formed

in

Bearing AA683300,

mount

83/32soastoleave no gap.

Apply Grease OT2008 also

684200,

assemble itinposition.

to

Bearing

ISee Fig. 3·27)

-24

-

Balls

AA-

Page 28

Fig.

AA5 3600

3-28

~AA145600

3-2·3 After applying a thin

to Nut

AA

145600, assemble it with left Fine

coat

of Grease OT2008

Focusing Knob AA593600. (See Fig. 3-28)

3-2-4 Assemble the right fine focusing knob

similar procedures.

in

the

Fig. 3·29

rAA592900

AA593100

.......

AA143200

3·2·5

After applying Grease OT2008

tions indicated by arrows, assemble Pinion

AA592900

and Bearing AA593100.

ISee Fig.

3-2-6 After applying Grease OT2008

AA593400 and

143200

(at the portion

AA

indicated by arrow), assemble Pinion

592900 by using Jig KC-2023.

NOTE:

Make sure that the pinion can

ISee

to

to

turn

Fig. 3·301

the

por-

3-291

Bearing

AA-

smooth.

Fig.

3-30

3·2·7 Assemble

ing knob.

-25

-

the

other

pinion and coarse focus-

Page 29

AA593400

AA593100

AA592BOO

AA143200

AA592900 having smaller diameter

AA592800 having larger diameter

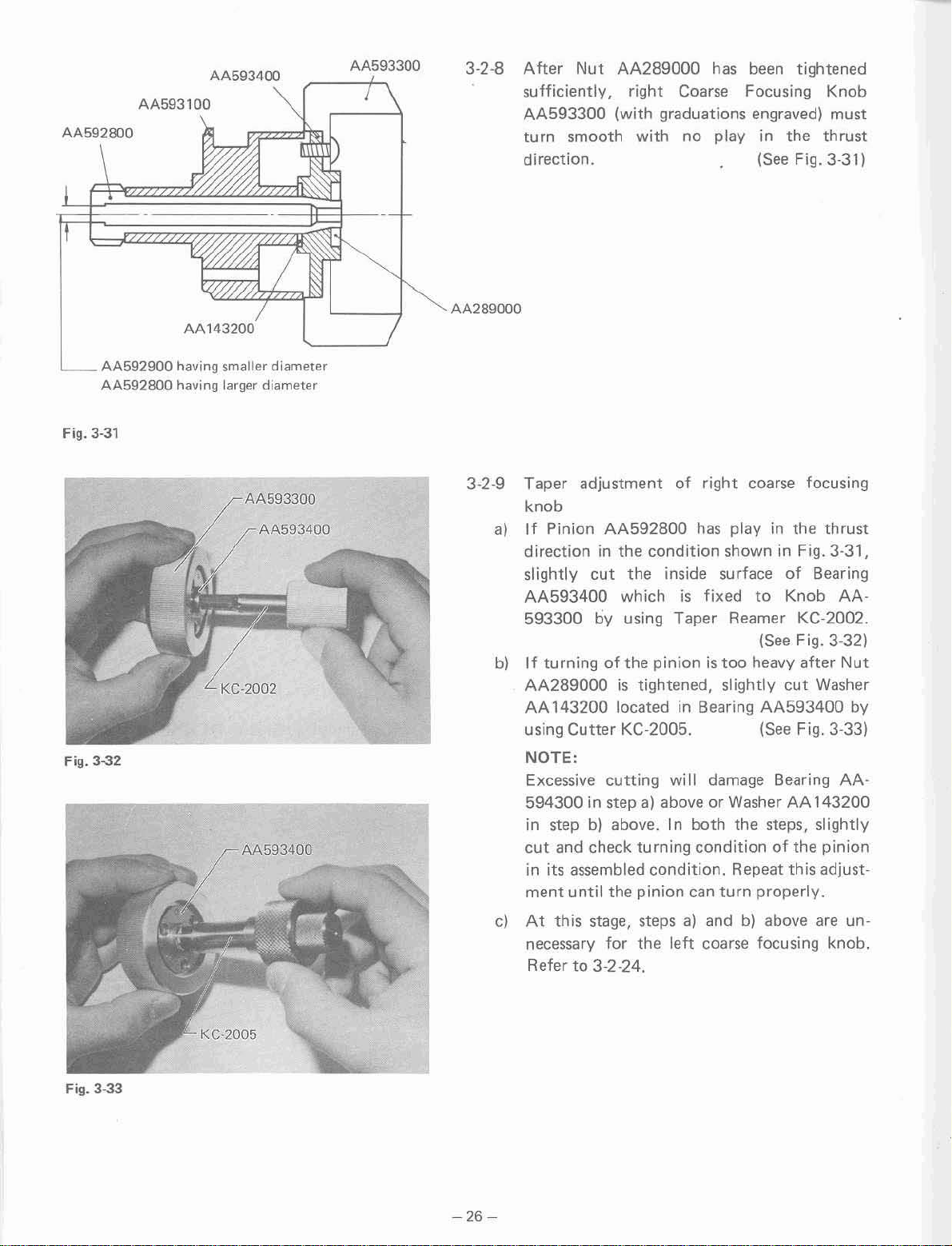

3-31

Fig.

AA593300

3-2-8 After Nut AA289000 has been tightened

sufficiently, right Coarse Focusing Knob

AA593300 (with graduations engraved) must

in

turn smooth with no play

the

direction. (See Fig. 3-31)

AA28900a

thrust

Fig.

3..:32

AA593300

AA593400

KC·2002

AA593400

3-2-9 Taper adjustment of right coarse focusing

knob

a)

If Pinion AA592800 has playinthe

direction

slightly

AA593400 which

593300

b)

If

turning of the pinionistoo

AA289000

AA

in

the

condition showninFig. 3-31,

cut

the

inside surface

is

fixed

by using Taper Reamer KC-2002.

is

tightened, slightly

143200 locatedinBearing AA593400 by

to

ISee F;9. 3·321

heavy after Nut

of

Knob

cut

thrust

Bearing

AA-

Washer

using Cutter KC-2005. (See Fig. 3-33)

NOTE:

Excessive cutting

will

damage Bearing

AA594300instepa)above or WasherAA143200

in

step

b)

cut

in

its assembled condition. Repeat this adjust-

ment

c)

At

necessary for

Refer

above.

and check turning conditionofthe

until the pinion can turn properly.

this stage, stepsa)and

to

3-2-24.

the

In

both the steps, slightly

b)

above are un-

leh

coarse focusing knob.

pinion

Fig.

3..:33

-

26-

Page 30

Fig. 3-34

3-2-10 Operation checkoffine focusing gear unit

a)

When forceisapplied from above as shown

Fig. 3-34, the sector gear should normally

or

turn smooth with no seizure

bl Apply Grease OT2008

(B

1/8) and watch oil OT 1037tothe gear

to

play.

the

operating point

bearing. (See Fig. 3-34)

cl

Attach

the

gear unit

to

Focusing Body

AA579300 with four Screws CMK3xSSA.

3-2-11 Fix the right and left coarse focusing knobs

to

Focusing Body

AB3xl6SA

AA579200

with six Screws

(three screws for each knob).

(See Fig. 3-35)

NOTE:

Figs. 3-35 through

ing knobs assembled

they are

of

not

set actuallyincorrect conditions

the reassembling steps.

3-46 show

in

position. Hovvever,

the

fine focus-

in

Fig. 3-35

Fig. 3-36

3-2-12 Apply Grease

205800.

OnOl0

to

Outer

(See Fg;g. 3-361

Guide

AA-

-27

-

Page 31

AA205900

Fig. 3-37

3-2-13

Apply

205900

Grease

(at the

OT2010

portion

to

Inner

indicated by arrow).

Guide

(SeeFi9.

AA-

3·37)

•••

• AA206100

• •

Fig. 3-38

3-2-14

3-2-15 Stand

•

•

With

the

left

Outer

downside on the focusing

AA206100

206000.

The rollers should

opposite directionsasshown in Fig. 3-38.

Fig. 3-38 and

describedin3-2-14.

NOTE,

See

toitthat

posite

manner

and arrange eight Rollers

up

Inner

the

to

each

as

shown below:

~,"-

L0

Guide

be

arranged alternately in

Guide

mount

AA205900asshown in

the casing rollers

right

other,

A_A20_5_9_0_0

A_A_2_05_9_0_0

AA205800

body,

mount

(See

Fig. 3-38)

and

left

rollers, op-

be

assembled in a

~

Q]

kept

Casing

AA-

as

L

__

A_A_2_o5_9_o_o_-!

AA579~

FiG.

3-39

D AA206000

@

AA205800 {Fixed outer guide)

@

/AA205800

__

O

__

@ @

3-2-16

---lG~oo,OO

3-2-17

~

Mount

guide on which

arranged

Fig. 3-39. Place the inner

of

Temporarily

tightening

Outer

the focusing guide.

Guide

the

to

setitin the

fix

four

Screws

Outer

AA205800

rollers have already

AB3x10SA.

on the inner

condition

gUide on the guide

Guide

shown in

(See

Fig. 3-39)

AA205800

(See

Fig. 3-39)

been

by

Page 32

Fig. 3-40

3·2-18 Adjust the

screws

and

nuts listed below

Inner Guide AA205900 drops slowly by its

own weight when Focusing Body

is

inclined atanangleof45°.

a)

Lightly tighten Screw

bl

Tighten

and

adjust Screw ACU3x6SA.

c) Tighten Screw AB3x1OSA

AB3xl0SA.

firmly.

d) Check for the item described in 3-2-16.

e)

Tighten Nuts NN3BO.

AA579200

(See

Fig. 3-40)

until

Fig. 3-41

3-2~19

Set

3-2-20

PUK2x4SA.

two

Springs

Fix

Upper Cover AA594100

AA591500

with

in position.

ISee

Fig. 3-41)

four

Screws

(See

Fig.

3-421

FiG.

3-42

-29-

Page 33

Fig.

3-43

3-2-21 Attach Plate

with

six Screws HK3x8SA. Assemble Spring

AA591600

AA591200tothe focusing body

in position.

(See

Fig. 3-43)

Fig.

344

,

~.~-l

3-2-22 Attach Dovetail

body

with

six Screws AB3x8SA.

3-2-23

Apply

of

consisting

Plate

initial conditions.

Grease

the focusing body and

of

Dovetail AA591

AA579300.

AA591300

OT2022tothe female dovetail

Assemble them in their

to the focusing

ISee Fig. 3-44)

thatofthe assembly

lOO

and

Fixing

(See

Figs. 3-45, 3·46)

•..,f1l III

.

,~-

Fig.

345

-30

-

Page 34

3-2-24 Adjustmentofcoarse focusing tension

a)

Grasp the right and left coarse focusing knobs

in

the

conditions assembledin3-2·23. While

fixing the right coarse focusing knob, turn the

left coarse focusing knob clockwise (in

tightening direction).Inthis condition, check

the coarse focusing knob for its rotation

tension (manual feeling).

Then, turn the

leh

coarse focusing knob

counterclockwise (Iooseing direction) and

check

tion tension. It should normally

the

coarse focusing knob for its

be

than felt previously.

NOTE:

For checking the coarse focusing knob for

fix

its rotation tension,

may be grasped by hand) and

the focusing body (it

tu

rn the

coarse focusing knob.

b)

If

the

turning

rotation tension

the

left coarse focusing knob clock-

cannot

be varied by

wise, disassemble the left coarse focusing

cut

the

knob and slightly

inside surface of

Bearing AA593400 by using Taper Reamer

KC-2002.

(See

cl If the coarse focusing knob turns extremely

heavily after the left coarse focusing knob

turned clockwise, disassemble the

focusing knob and slightly

cut

leh

Washer 143200

with Cutter KC-2005. (See 3·2-9-bl

the

rota~

lighter

leh

3-2-9'01

is

coarse

Fig. 3-46

3-2-25 Adjustment

pinion

Aher

be rotatable as lightly

thatitis

at

the upper, intermediate and lower positions

of

the

If it plays

below:

a)

Remove one

Check

b)

When

insert a piece

under

cl If

the

file off

-31

-

of

engagement between rack and

setting

the

coarse focusing knob so as to

as

possible, make sure

free from play (backlash)orgrating

coarse focusing range.

or

grates, adjust

of

the two Racks AA593000.

the

other rack.

the

coarse focusing knob has play,

of

tin foil (t=:0.01to0.05 mm)

the

rack.

it

as

described

coarse focusing knob grates, slightly

the

bottom surfaceofthe

rack.

Page 35

NOTE:

For

filing

off

the

bottom

surfaceofthe rack,

lay a sand paper on a flat surface (stool

similar device) and place

Then, move

top

surfaceofthe sand paper.

d) Disassemble

properly. Reassemble

out

stepsb)andc)above.

the

rack back and forth along

the

rack which has been adjusted

the

other

the

rack on it.

rack

and

or

carry

the

the

ZJS12600\

Fig.

347

,AA592500

3·2·26 Assemble

the

knobs (either

focusing shaft).

KKAA

1466isunnecessary. Screw

knobs by

firmly.

3·2·27 Apply Grease

Roller AA591900.

position and

with Screw AA592000 located on Fixing

Plate AA579300. ISee Fig.

right and left fine focusing

is

equipped with

For

this purpose, Tools

both

both

hands and tighten

OT2008

hook

to Belt

Set

Spring AA592500

the

other

ZJ812600

endofthe

the

fine

the

them

and

in

spring

3-47)

Fig. 3-48

3·2·28

3·2·29

-

32-

After applying Grease

OT2008

to

Spring

AA593800, insert it into Spring Housing

the

AA593900 and assemble it with

plate.

In

addition, attach

Stopper

ISee Figs.

Now,

the

coarse focusing

unit

fixing

AA001500.

3-48, 3-49)

has been

reassembled. Assemble it with Arm AA·

583400

and fix it with six Screws AB5x2OSA.

ISee Fig.

3-4)

Page 36

Fill. 3-49

AA0015QO

Fig. 3-50

AA277400

=

AA004500 AA594000

1 -

AA004400

AA004300

AA004300

-(

AA903100

3-2-30 Apply Grease

Screw

Assemble them with Arm AA583400.

AA594000

X

AA2174~@>

AAOO4500

Fill. 3-51

3-2-31 When

the

stopperislocked, Lever AAOO3400

is

located within

(Lock the stopper with AA004400.1

NOTE:

AA004300 and AA903100 should be used

selectively.

OT2008

AA594000

AA004300

AA9Q31

the

to

the

and Spring AA004500.

(See

Figs. 3·50, 3·511

AA583400

AA322BOO

J"~

00

AA004400

range showninFig. 3-53.

threads

.7

of

Fill. 3-52

@

AA004300

-

33-

@

AA903100

Page 37

Fig.3.s3

Lever

this

range

locked.

must

be

when

located

the

stopper

wIthin

is

3-3 AdjustmentofFine Focusing

Fig.3.Q4

Range

3-3·'

3·3·2

Make sure that the fine

movable

ing Body

within

the

AA579200

range

and Plate AA591200.

fOOJsing

engraved on

knob

Fows·

Pushing down AA591200, turn the fine

fOOJsing

Upper

Lower

When

beyond the upper and/or lower

Setscrew NU3x8SA (indicated

knob.

AA579200

limll

limit

Fig. 3·55

~AA591200

the fine focusing knob

(See

limit,

by

Fig. 3-54)

is

movable

loosen

arrow)

and

adjust vertical positionofScrew AA631900.

Aher

adjustment, tighten Setscrew NU3x8SA

(See

firmly.

Fig. 3-56)

is

Fig. 3-56

-34-

Page 38

4. DISASSEMBLING PROCEDURES AND FOCUSING AND OPTICAL

(BINOCULAR TUBE)

4-1 DisassemblyofA-Si

Fig.

4-1

shows

Fig. 4-1

A-Bi.

ALIGNMENT

OF A·Bi

Fig.

4-2

\A581800

,AA581700

4·1-1

4-1-2 Detach

By

removing three Screws ACU2x5SA.

assemble

removing four

cover.

Detach

581900 by removing four Screws CTK2x4SA.

Diopter

Covers

Scale

Ring

AA58170Q

Screws

Plate

AA582000

AA582500.

ISee

and

AA581800

CTK2x4SA from

and

Cover AA-

ISee

Figs.

dis-

Fig.

4·2)

by

each

4·3,4-41

Fig.

4-3

-35

-

Page 39

Fig. 4-4

"\---'"

"--AA581900

Fig. 4-5

-AA5822QO

- AA5812DQ

___

HK3x12SA

/

4-1-3

After

mount

Dismount

the

unit,

removing six Screws

Si-body

prism

Female Dovetail

Female Dovetail

while

unit,

lifting

etc.

AA581200.

4-1-4 Dismount Eyepiece Sleeve

Tube AA582200

and

Link AA227300 by

removing three Screws HK2-375SA and

Screw AA601600 from each part.

HK3x12SA,

(See

AA581200

up the

ZJ803700,

(See

Figs. 4-5, 4-6)

dis-

Fig. 4-5)

from

binocular

Outer

Fig.4.{j

-36

-

Page 40

Fig. 4-7

\

AA57.300·

1AA582600

4-'-5

Disassemble Eyepiece Sleeve

Helical Tube

wash

off

grease.

Eyepiece Sleeve

ed

after

AA582600.

ZA016600

ZJ803700

removing Screw AA5743DO

ZJ803700

respectively,

and

and

canbedisassembl·

or

(See

Fig.

4·7)

Fig. 4-8

ZJ8037QO

/

3PUK2x4SA-

~-""'l

!o.;'

4-1-6 Apply Grease OT2008tothe

of Eyepiece Sleeve ZJ8037DO (at the portion

by

indicated

arrow) and make sure

moves smooth. (See Fig. 4·8)

4-1-7 Disassemble the

AA583000

(by removing three Screws 3PU

AA582900

(by removing three Screws

AA583100

(by

removing three Screws

following

three prisms:

(See Figs. 4-9, 4-10)

mating portion

that

K2x4SA)

HK2.6x6SA)

3PUK2x4SA)

it

Fig. 4-9

-37

-

Page 41

Fig.4-10

AA582900

AA583:00_1

Fig.4-11

.

..

HK2x3SA

AA581600

4-'-8

4-1-9 Dismount Female Dovetail

Remove

AA581600. ISee

Dovetails

off

grease

Screw

AA581500

and

HK2x3SA from Dovetail

contaminant.

and

Fig.4·111

AA581200

AA581S00.

(See

Fig.

and

Wash

4-12)

Fig.4-12

-

38-

Page 42

Fill.

4-13

AA580700

4·1-10

By

removing

four

Cover AA580700.

Screws

AB4x12SA,

ISee

Fig. 4·13)

detach

Fill.

4-14

4-1-11 After

AA580800,

Disassemble

Body

HK3x8SA.

4-1-12

Remove

AA221600.

loosening

dismount Shaft

Female Dovetail

AA580600

Screw

Screw NU3xSSA

AA581000.

AA571600

by

removing

AA001500

and

on

Dovetail

from

four

Screws

(See

Fig. 4·14)

Spring Holder

(See

Fig. 4·15)

Fill-

4-15

-39-

Page 43

Fig. 4-16

AA221600 \....AA195600

B1/8

4-1-13

Remove

and

wash

SpringAA195600

Spring

and

Holder AA221600,

Ball B

liS.

(See

Fig.

4-16)

Fig.

4-17

r-AA516100

4-1-14

Remove

Dovetail

Dovetail AA58080Q from

AA576100

and

wash

off

(See Figs.4-17.4-1SJ

Female

grease,

etc.

Fig.

4·18

-40-

Page 44

4-2 Reassembly of

Fig.4-19

A-Bi

4-2-1 Apply Grease OT2024 to Dovetail AA580800.

Clean Prism

ZJ510200

well. (See Fig. 4-19)

Fig.

4-20

AA876100

4-2-2 Apply Grease OT2024

AA576100_

to

Female Dovetai I

(See Fig. 4-20)

4-2·3 Assemble Dovetail AA580800 with Female

that

Dovetail AA576100. Make sure

movable smooth mutually. (See Fig.

they are

4-21)

Fig. 4-21

-41

-

Page 45

Fig. 4-22

AA221600

4-2-4 Assemble Spring Holder AA221600, Spring

AA

195600

and

BallB1/8.

Apply Grease

OT200B to the ball and spring, and assemble

them

with Female Dovetail AA576100.

ISee Fig. 4-221

Fig. 4-23

LAA001500

4·2-5

4-2-6

Assemble Screw

AA580800.

Apply Grease

AA581200.

AAOO1500 with Dovetail

ISee Fig. 4-231

OT2008

Female Dovetail

to

(See Fig. 4-241

Fig. 4·24

-42

-

Page 46

4-2·7

Apply

and

Grease

OT2008toDovetail AA581500

Dovetail AA581600.

(See

Fig. 4-25)

Fig.

4·26

AA581600

AA581200

r AA581500

4·2-8 Assemble Dovetails

4·2·9

581500

Apply

and

with

Female Dovetail AA581200.

Grease

OT2008

Shaft AA370600. Assemble them

Female Dovetail AA581200.

AA581600

(See

to

Lever AA370500

(See

and

Fig_

Fig.

AA-

4-261

with

4-271

Fig.

4·27

L

AA370600

-43

-

Page 47

Fig. 4-28

HK2x6SA

4-2-10

Assemble

AA581500.

Stopper

HK2x6SA with Dovetail

ISee Fig. 4·28)

Fig. 4-29

ZA016600

ZAlJl6600

4·2·11 Apply

Grease

OT2008

to Helicoid

(See

Figs. 4-29. 4-301

ZAOl6600.

Fig.4-JO

-44

-

Page 48

Fig. 4-31

4-2-12 Apply Grease OT2024tothe mating portion

of

Outer

Tube AA582200. (See Fig. 4·31)

Fig.

4-32

ZJ804600~

r AA574300

I AA582600

4-2-13 After applying Grease OT2024

ing portion of Eyepiece Sleeve ZJ803700,

assemble

it_

Assemble Lever ZJ804600. (See Fig. 4-32)

4-2·14 Assemble Screw

AA574300

with Helical Tube ZA016600 and Eyepiece

Sleeve ZJ803700. Attach

Stopper

to the helical tube.

Screws AA573400 and AA582600 should

used selectively.

to

the

mat-

or AA582600

AA600400

be

FilJ.

4-33

-45-

NOTE,

When ZA016600 and

ZJ803700

have play

the right-left direction, the screws mentioned

above are

tobeemployed selectively.

(See

Fig. 4·331

in

Page 49

Fig.

4-34

4-3

Reassembling and

Adjusting

AA583000

Procedures

4-2·15 Assemble the prism

unit

which

Fig. 4-28.

The prism

rarily. Each prism

well.

has

been

unit

should be assembled tempo-

unit

with

the dovetail

assembledasshown in

must

have been cleaned

(See

Fig. 4-34)

Fig.

4-35

t LP046700

• P6

~P::.3

L

I

I

LP046600

,

-J-:'=oJr--'"

ZJ522800

Mount

stand BH

4-3-1

4-3-2 The optical

the

following

or

for

Jig

Centering Objective KNOO05

10X

Fix

Screws

ing manner.

illustrated in Fig. 4-36. In the

descriptions given

prisms in the forms

assemblies

asP3and (P3) respectively

omitted.

while (P3) represents a prism assembly.

prism alignment A-KNOO23

eyepiece w/cross hairs

the binocular

HK3x12SA,

NOTE,

(P3l meansanassembly consisting

Prism

Prism

(P6) meansanassembly consisting

Prism LP046700

Prism LP046600

Prism

(P7) meansanassembly consisting

Prism LP046600

Prism

checkers on the microscope

BH2asshown in Fig. 4-35:

C·1

unittoA-KN0023

layout

will

P3

means

ZJ522800

Mount

Mount

Mount

and adjust in

of

for

optical alignment, the

of

be

referred to,

an

AA582900

AA583100

AA583000

the

independent parts and

independent prism,

the

binocular

for

with

drawing nos.

of:

of:

of:

with

two

follow-

unit

following

example,

is

Fig.

4-36

LP046600

Optical

I

path

-46

-

Page 50

------

Cross hairsofC-l

CrosshairsofKNOOO5

/

"-

,

left

, t /

/,

/

4-3-3

/

,

Aligning procedures for prisms

the

When

.1

below the abscissa of the cross hairs

and the

abscissa

4-37 (or vice versal.

close

turning Prism

Fig_

4-38_

For turning Prism (P3l. slightly loosen three

Screws HK2.6x6SA located on Female

Dovetail AA581200_

right side optical axis

leh

optical axisislocated above the

of

the

cross hairs as showninFig.

the

optical axes come

to

each other and go farther away by

(P31inthe directions shown in

is

located

of

C-l

,

Fig. 4-37

BBG

Top

Fig. 4-38

Fig_

4-39

,

,

,

/

'~

/

left

/

"-

,

vIews of

"-

pmm

assemblies

,

,

,

/

Right

b)

When Prisms P3 and P4

cally moved

/

/

'/

,

,

AA582900, the right and left optical axes

come nearer the ordinate of the cross hairs of

C-'

(as

go

away fromit(or each other).

For moving Prisms

loosen

Mount AA582900 and Arm AA582800.

in

parallel with

indicated by arrowsinFig. 4·39) or

th,ee

Screws AA224500 on

ZJ522800

Prism Mount

P3

and P4. preliminarily

are verti-

Prism

•

Fig. 4-40

G

~

I

,

,

P3 '

p,

V

-47

-

Page 51

Fig.441

c}

/

/

/

/

/

Left

,

P3

,

,

,

/

/

P4

,

,

'

,

,

/

/

Right

/

/

/

/

,

,

,

,

When

the

right optical axisisaligned well

the

left optical axis

ordinate of the cross hairs of

Fig. 4-41, move Prism

direction (indicated by arrow). (See Fig. 4-42)

If the right optical

Prism

described above. For moving Prism P5 or P7,

preliminarily loosen

located on the corresponding prism mount.

P7

in

the

is

deviated from the

C-lasshown

P5

in

the right·left

axis

is

deviated, move

manner similar to

two

Screws AA224500

but

in

that

Fig.442

Fig.

443

d}

When

/

/

Right

/

/

/

/

direction shown

e)

/

/

/

Left

/

/

/

/

/

,

,

,

/

the

right optical axisisaligned well

the left side

the abscissa of the cross hairs of C-' as shown

in

Fig. 4-43, slightly turn Prism (P6)

If

the

Prism jP7)

For

moving Prism (P6)

loosen three Screws 3PUK2x4SA which are

used for fixing

By

the aligning procedures givenina)

d)

above, each

axes must

the

reticle of

oneisdeviated vertically from

in

Fig. 4-44.

right optical axis

in

either direction.

the

prism

of

the

be

adjusted within 2 divisions

the

Centering Objective

is

deviated, turn

or

(P7), slightly

mount.

right and left optical

but

in

the

through

on

KN-

0005.

Fig.

GGG

444

-48-

Page 52

Objei:tive

Fig.445

Fig.

446

pupil

HU2x2$A

Visual

fieldofKNOO29

a : b ..

within

:

within

c : d

+

-r-~I---HU2x2SA

HK2·242$A

(3PUK2x4$A)

3 : 2

3 ; 2

Adjusting pupilofobjective.

In

the condition showninFig. 4-35, remove

C-l and set Special Eyepiece

KNOO29

right eyepiece sleeve.

b)

Check

pupil from

is

If

cl

range, adjust

In

to

see

if

deviation of the objective

the

visual field centerofKNOO29

within a range of3:2. (See Fig. 4-45)

the deviationofthe pupilisnot

within the

it by turning Screw HU2x2SA.

the case illustrated

in

Fig. 4-45, pupil of

the objective is located at the position of

10 o'clock and shifted toward

of

4 o'clock by tightening Screw HU2x2SA

is

which

in

Fig. 4-46. (See Fig. 4-46)

NOTE:

arranged at the position of 4 o'clock

the

For facilitating the pupil adjustment by

tightening Screw HU2x2SA, Screw 3PUK2x

4SA

or

HK2-242SA whichever

d)

nearest

in

After

the

advance.

the

pupil adjustment of

left optical axes has

screw should

been completed, make

be

is

loosened slightly

the

sure that four Screws HU2x2SA and three

Screws 3PUK2x4SA or HK2-242SA are

tightened firmly.

into

the

position

located

right and

e)

By

using

check the right and

tion within

KNOOO5

position

C-'

instead

of

KN0029, further

left optical axes. Devia-

2 divisions on

the

can be corrected by adjusting

of

the eyepiece sleeve. Large devia·

tion must be corrected by adjusting

objective pupil

in

the

procedures given

4·3-4.

NOTE:

This adjustment

procedures given

in

4·34.

After deviationsofthe right and left

must

in

4·3·3

be done

but

not

by those given

optical axes have been adjusted within 2

divisions respectively,

the

objective pupil

must be checked by using KN0029 instead of

C-,.

These adjustments must be performed

repeated

Iy.

Model VANOX usesBiof a new type (equipped with Adjusting Screw HU2x2SA) and an

old type.

In

case of

the

old type, a piece of

tin foil should be inserted under the eyepiece

sleeve.

reticle of

the

in

by the

-

49-

Page 53

NOTE,

When

the

objective pupil cannotbeadjusted

properly by any means, adjust prism setting

once again.

4-3-5 Attach Eyepiece Sleeves AZ016600 and

ZJ803700

AA581400 respectively with

to

Mounts AA581300 and

six

Screws

HK3-375SA (three screws for each sleeve).

not

(Take care

the

left one. The helical tube mustbearrang-

to mistake

the

right sleeve for

ed on the left side.)

Before tightening the three screws, insert

C·,

into the sleeve and moveituntil KN0005

centered with

the three screws. (See Figs.

the

cross hairs. Then tighten

4-47,4-48)

Standard:

Within 2 divisions on reticle (sectioned)

KN0005.

of

is

Fig. 4-47

Fig.

4-48

4-3·6 Apply Grease OT2008 to Link AA227300

and assemble it by using Screw AA601400.

(See Fig. 4-49)

Fig.

4-49

-50-

Page 54

Fig.

4·50

4-3-7 Attach the assembly shown

Si

Body

12SA. (See Fig.

Carefully wipe

the screws with Shellac OT1131

have been tightened.

AA580600

off

with

dust from the prisms. Fix

in

Fig. 4-49

six Screws

after

to

HK3x

4·501

they

Fig. 4-51

."'-r

AA576.00

C-1

4-3-8

Mount

the microscope stand.

revolving nosepiece and Centering Objective

KNOOO5.

optical

NOTE,

A special nosepieceisusedinFig.

a)

Temporarily

prism assembly (Fig. 4-23) with four Screws

HK3x85SA.

Eyepiece

assembly in

right and left optical axes are aligned with

each

b)

Aher

aligned, check pupil by using

NOTE'

For standard, see 4-3·4-b) and e).

c)

When the pupile

repeat steps

the

path.

other.

the

Si

body (assembledin4-3-7) on

Further,

Set

the

centering objectiveinthe

(See Fig. 4·51)

fix

the optical

While observing through

C·,,

move the entire optical prism

the

right-left

right and

al

cannot

and bl

leh

optical axes have been

once

path

direction

(See Fig. 4-511

KNOO29.

meet the standard,

again.

attach the

4·51.

switching

lOX

until

the

4-3-9 After four Screws HK3x8SA have been fixed,

lock them with Shellac OT1131.

•

Fig. 4-52

4-3-10 Assemble

it with Screw NU3x5SA.

fix

4-3·11 Attach Cover AA581900

580600. Scale Plate AA582000 should

attached simultaneously. (See Fig. 4-52)

-

51-

Shaft

AA581000

in

position and

to

Bi

Body AA-

be

Page 55

Fig.

4-53

=c

4-3-12 Attach

571800

Covers

in

position.

AA581700

and

AA571800

(See

in

Fig. 4-53)

Fig.

4-54

4-4 Focusing

kKCQOOB-,..

and

Optical

__

AA580700

=c

Alignment

Low-magnification

objective

~

• !

(4

XI

7

4-3-13 Attach Cover AA5B0700

Screws

Mount

AH

Focusing

Objective

Photo

AB4x

12SA.

the

following

microscope standasshown in Fig.

magnifier

eyepiece FK2.5X

jigs and accessories on the

Finder eyepiece [3]]

Jig

for

photo

tube

alignment A-KeDG08

and tighten

(See Fig. 4-54)

4·55:

C-15

4X

Wf1OX

four

Fig.

4-55

Qi~

.".

-52

4-4-1

4-4-2

-

Mount

whichisarranged on

the

depthofthe

Further,

by

while

Focusing

mask used

focus on a specimen setonthe stage

using

the

observing

Magnifier

in

eyepiece

coarse and fine focusing knobs

through

C-15 on A-KeDG08

the

photo

A-KC0008 by adjusting

portion.

C-15.

tube.

Bring

(See Fig. 4-55)

Page 56

Fig. 4-56

4-4-3 Insert

sleeve

helicoid

of

the cross hairs (in

as those for photographing) are focused.

r:I5J

WF10X into

of

the

of

I3SI

the

right eyepiece

binocular tube and turn the

WF10X until

the

double lines

the

same procedures

Fig. 4-67

Fig. 4-68

4-4-4

4-4-5 Mount C·15 on

After

eyepiece sleeve, loosen Screw ACU2.6x3SA

arranged at the deeper location.

removing Screw AA205600 from the

I35J

WF10X. While vertically

moving Sleeve

WF10X and C-15), observe through C-15

and bring the specimen into focus.

Tighten Screw ACU2.6x3SAtofix the sleeve.

Then, set Screw AA205600 and lock it with

ZJ803700

Shellac 0T1131.

4-4-6 Insert the eyepiece WF10X into

mount

helk::oid tube

position on

to

the

of

the eyepiece with that

Correct mutual deviation by

-53-

4-4-7

piece sleeve, and

through C-15, rotate Helicoid

016600

Keeping the

align the

Ring AA582500

Sleeve AA582200. Then clamp Diopter Ring

with three Screws ACU2x5SA.

Center visual field

of

adjusting position of

taking

standard after loosening three Screws CMK3x

25SA located on Setting Mount AA580900.

bring the specimen into focus.

"0"

A·KCOOO8.

the

right observation optical axis as

ISee Fig. 4·571

(together with

ISee

Fig. 4-581

ISee

Fig. 4·581

the

C·15 on it. Looking

Tube

at

this position,

the

scaleofDiopter

index mark on Outer

the

setting

(See Fig. 4-581

I35.J

left eye·

ZA-

mount

Page 57

5.

DISASSEMBLING AND REASSEMBLING PROCEDURES

5-1 Disassembly

Fi9-

5·1

FOR

A-SV (STAGEI

A·$V

is

showninFig. 5·1.

Remove the specimen holder and stage insert.

(See

Fig.

5-11

Fig.5·2

5-1-1 After loosening Knob

5-1-2

Guide

CTK2x5SAI

Wash

AA586400

off grease

and

(by removing two Screws

Ring AA583800.

from

Ring

AA586300,

(See

AA583800.

(See

remove

Fig_

Fig.

5-21

5-3)

•

Fig. 503

-54

-

Page 58

Fig. 5-4

5~1-3

Detach Washer

Detach

Scale

AA800100.

Mount

Screw CMK2.6x5SA.

AA586100 by removing

(See

Fig. 5-4)

5-1-4 Dismount Rack AA5860QO by removing three

Screws HK2.6x5SA.

(See

Fig. 5·5)

Fig. 5-5

Fig. 5-6

AA585900

PSK

1.7x6SA

5-1-5 Dismount Vertical Handle

Horizontal Handle AA5859QQ by removing

three Screws

PSK

1.7x6SA from

AA585600

each

handle.

ISee Fig.

and

5-61

-

55-

Page 59

Fig. 5-7

5·1-6 Dismount

Screw

AA253000

Nut

AA585800

and

two

Screws NU2x4SA.

by removing

(See

Fig. 5-7)